Peel-able ultra-thin copper foil using copper foil as carrier and preparation method thereof

A technology of ultra-thin copper foil and copper foil carrier, applied in electrolysis process, electroforming and other directions, can solve the problems of increased adhesive strength, highly toxic chromium, inability to mass-produce, etc., and achieves less defects and surface roughness. Low, glossy and clean finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

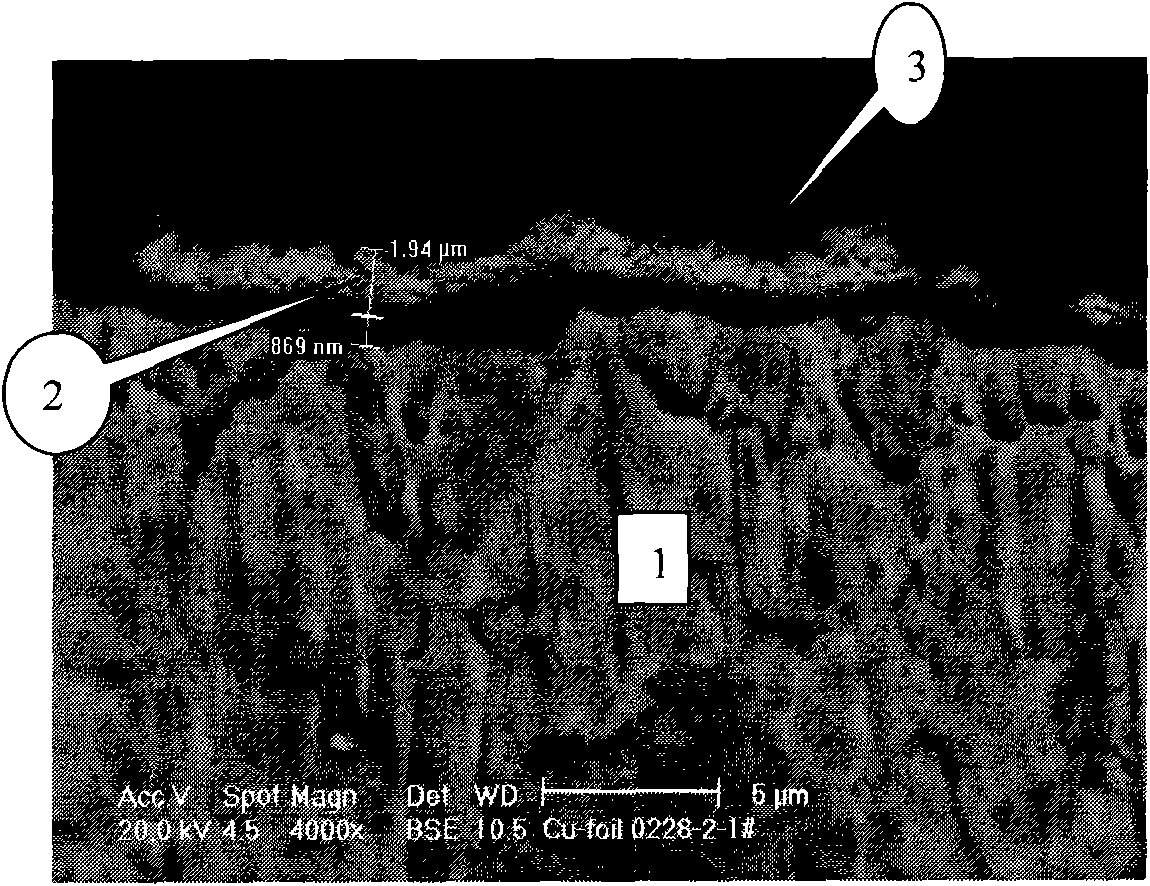

[0060] An electrodeposited copper foil having a thickness of 35 µm was prepared as a metal carrier foil. These copper foils generally have a rough side (ie, a matte side) and a smooth side (ie, a shiny side). Then, an organic layer is formed on the bright side of the carrier foil, and then an alloy layer is electroplated on the organic layer, followed by the first electrodeposition of copper, the second electrodeposition of copper, the third electrodeposition of copper and passivation treatment , the stirring method used in the experiment was magnetic particle stirring. Proceed using the following procedure:

[0061] A. Forming an organic layer

[0062] A 35 micron thick copper foil was immersed in an aqueous solution containing 6 g / L benzotriazole (BTA) at room temperature for 30 seconds to form an organic layer of BTA, which was taken out and rinsed in deionized water for 6S.

[0063] B. Formation of alloy layer

[0064] Immerse the rinsed carrier foil with the BTA organ...

Embodiment 2

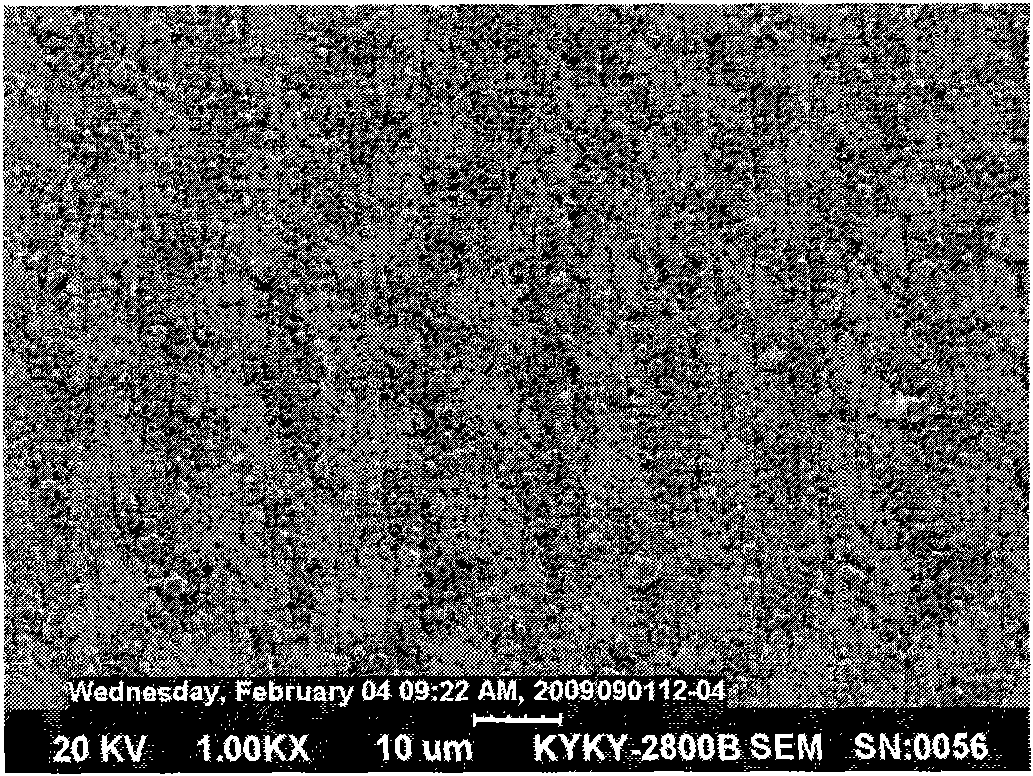

[0077] The carrier-supported ultra-thin copper foil was prepared in the same manner as in Example 1, except that nickel sulfate was 25 g / L and sodium tungstate 70 g / L in the tungsten-nickel alloy solution used. The results show that the carrier and the ultra-thin copper foil can be peeled off, and the peel strength reaches 0.11 kgf / cm. The surface of the thin copper foil is bright and clean, and the thickness of the ultra-thin copper foil is 3 microns.

Embodiment 3

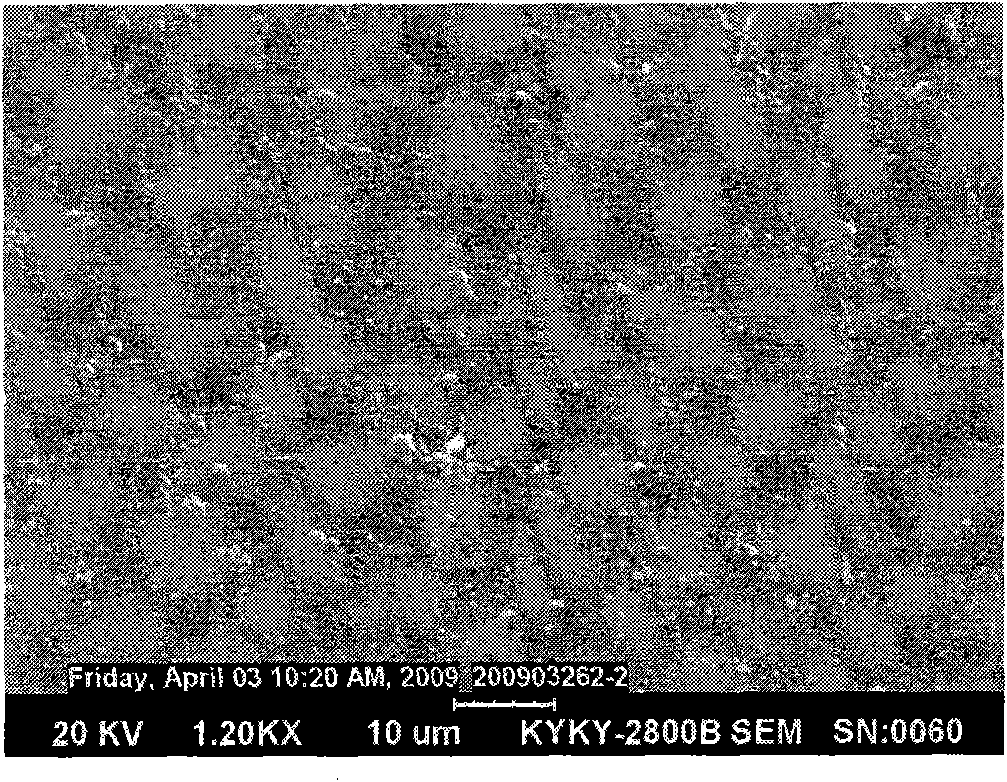

[0079] The carrier supporting ultra-thin copper foil was prepared in the same manner as in Example 1, except that nickel sulfate was 40 g / L and sodium tungstate 80 g / L in the tungsten-nickel alloy solution used. The results show that the carrier and the ultra-thin copper foil can be peeled off, and the peel strength reaches 0.13 kgf / cm. The surface of the thin copper foil is bright and clean, and the thickness of the ultra-thin copper foil is 3 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com