Patents

Literature

329results about How to "Suitable for manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

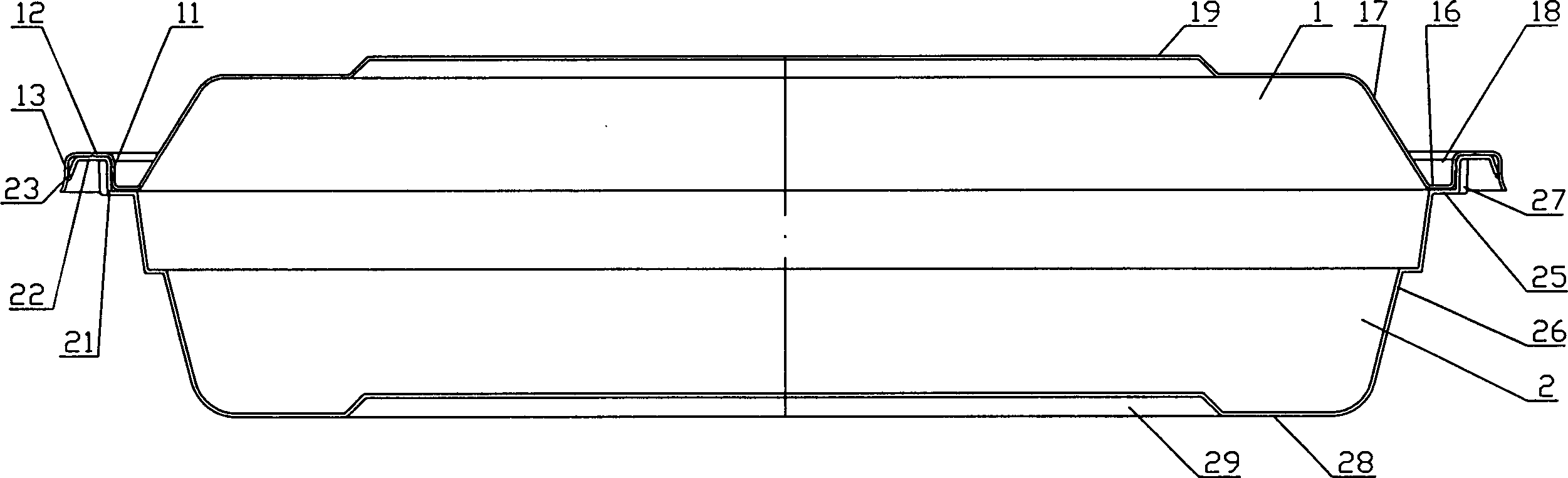

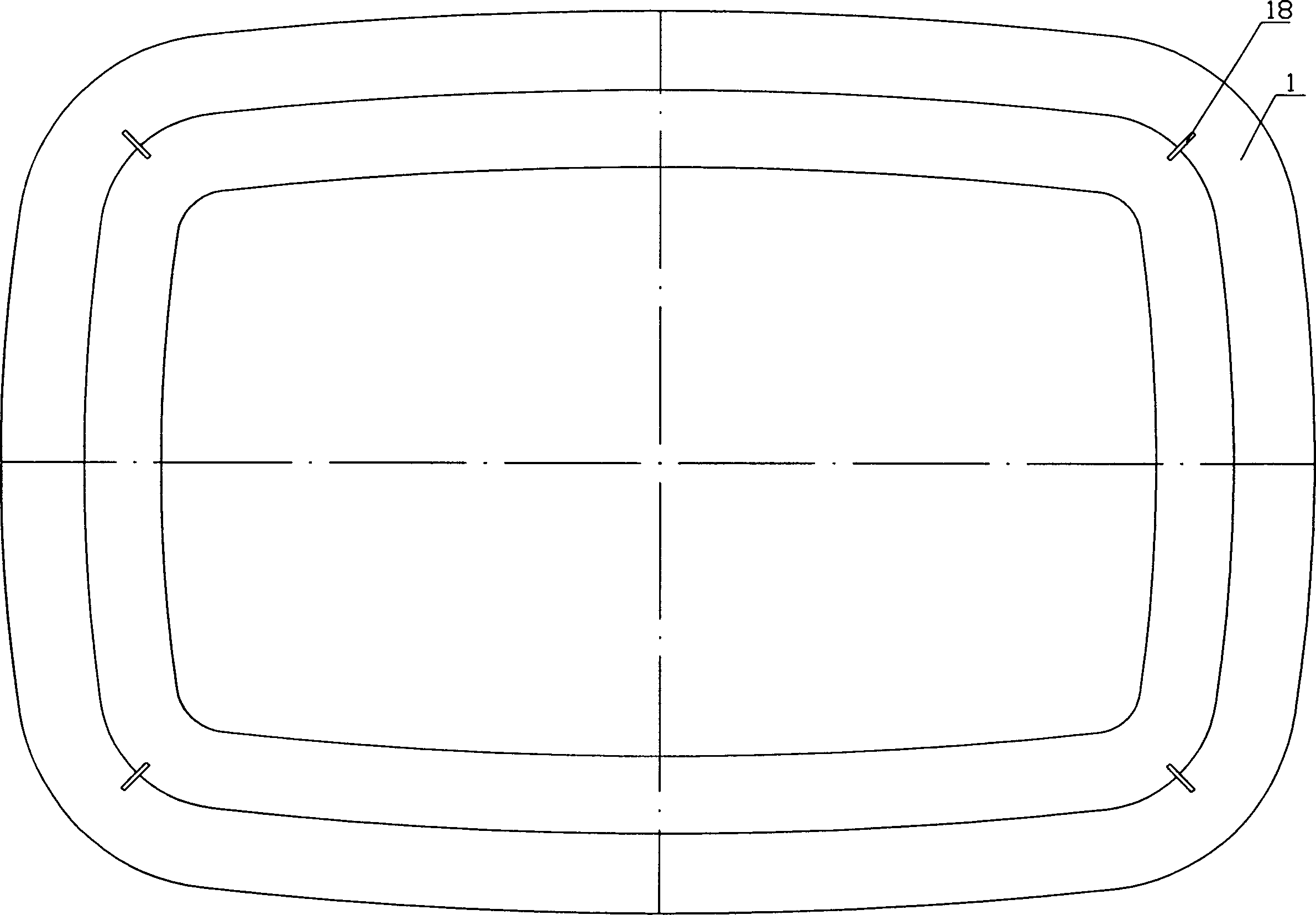

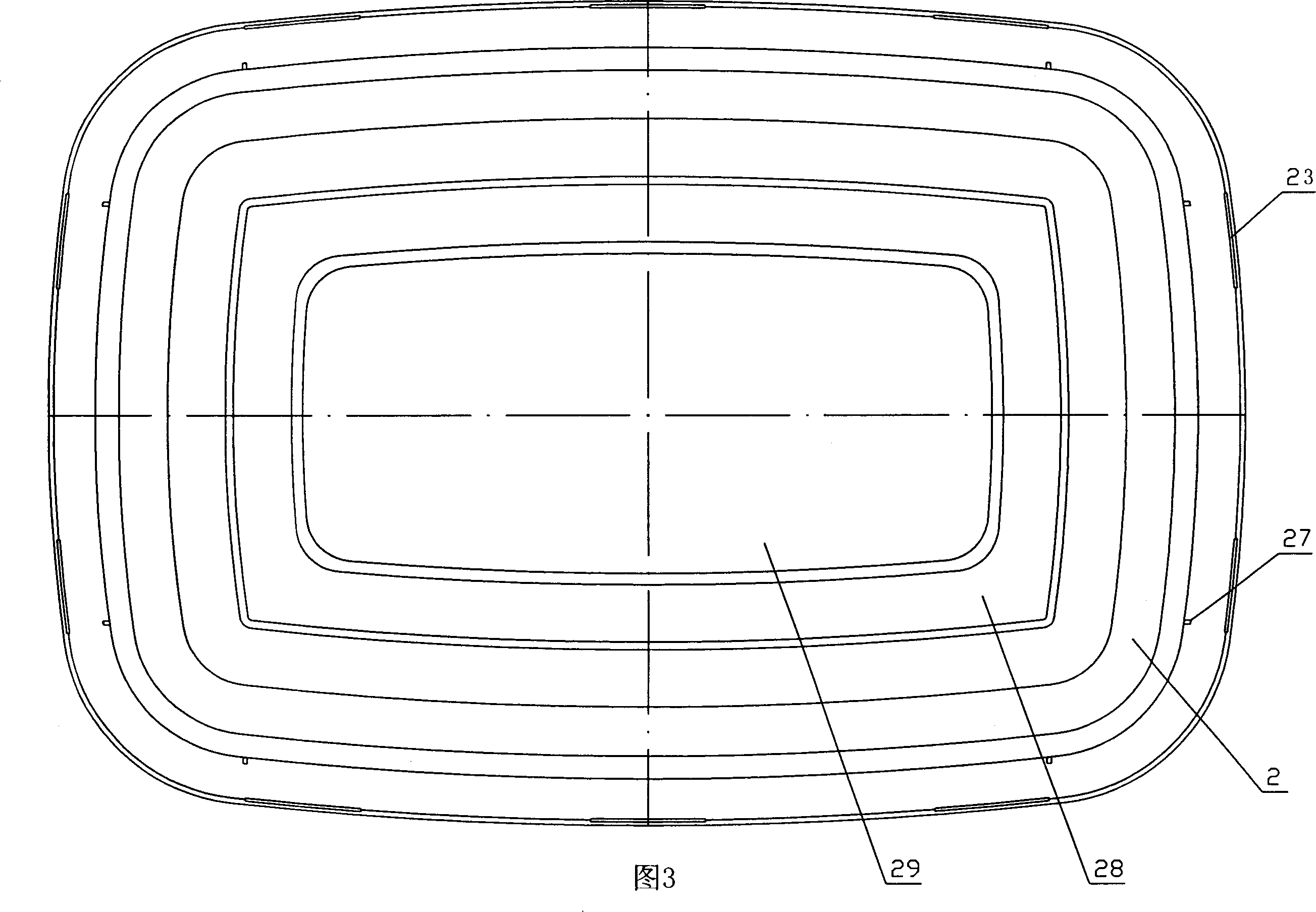

Full closed superthin food container

ActiveCN1820679AReasonable structureEasy to open and closeOther accessoriesLidsEngineeringCompressive strength

Owner:MEIYANG PLASTIC METALS PRODS QUANZHOU

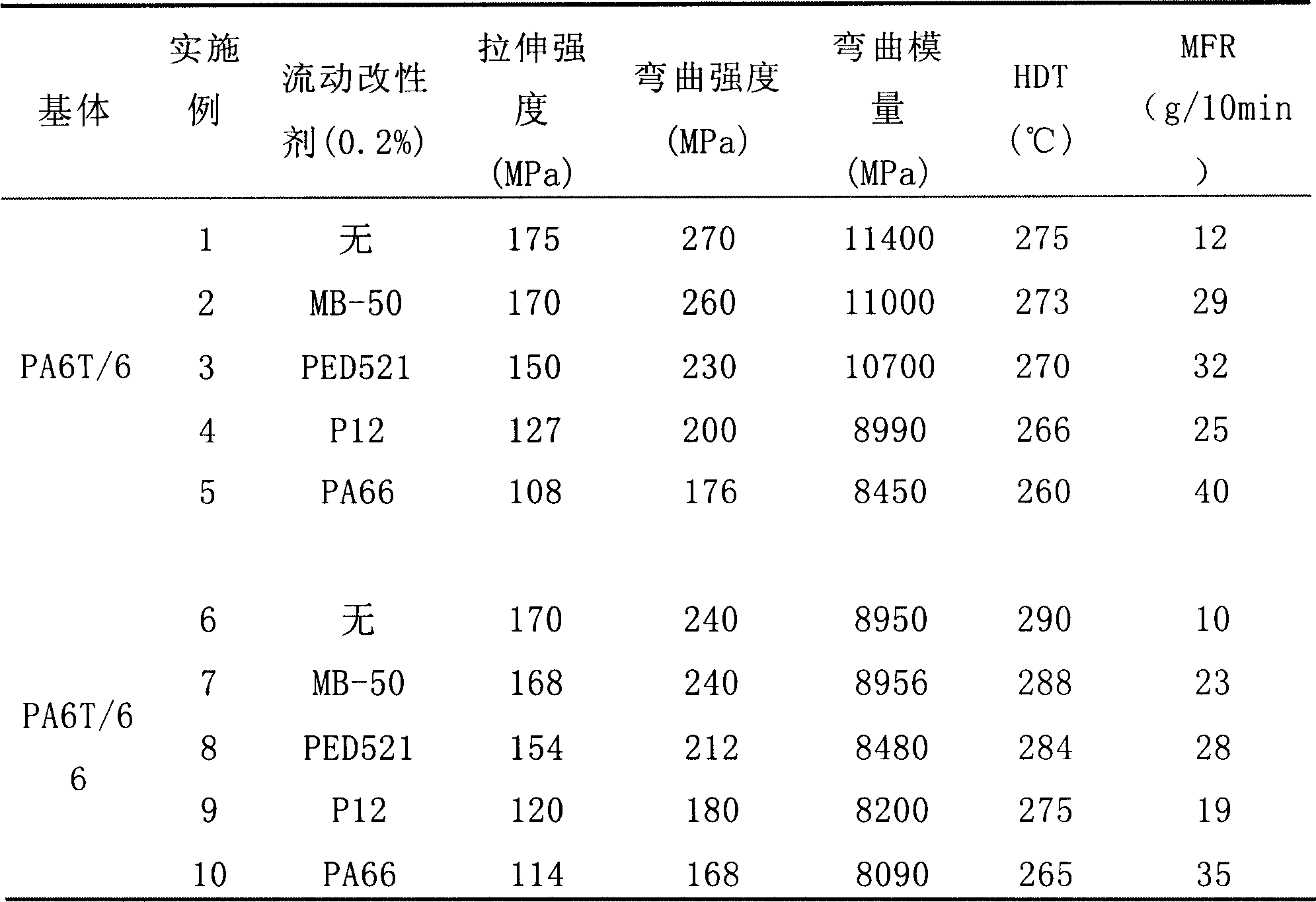

Fast-flow high temperature resistant nylon composite material

ActiveCN101200591AImprove mechanical propertiesImprove heat resistanceHeat resistanceMechanical property

The present invention provides composite material used for preparing fast flowing high-temperature resistant nylon, which comprises the following components: 20 to 84.9 weight portions of high-temperature resistant nylon resin and 0.1 to 10 weight portions of flowing modifier, wherein, the high-temperature resistant nylon resin is selected from the semi-aromatic nylon with the self melting point between 290 DEG C to 330 DEG C; the semi-aromatic nylon is obtained by the copolymerization of terephthalic acid or isophthalic acid, the diamine with 4 to 12 carbon atoms and the aliphatic nylon with 6 to 24 carbon atoms. The fast flowing high-temperature resistant nylon of the present invention has good heat resistance and fluidity and good chemical performance, exact formability and size stability and is mainly used for the production of thin-wall product in the electronic appliance field.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Environment-friendly high-temperature-resistant durable flame retardant fibers and preparation method thereof

ActiveCN103789858ASimple processSubtraction of alkali washing desulfurization processArtificial filaments from viscoseWoven fabricFlame resistance

The invention discloses environment-friendly high-temperature-resistant durable flame retardant fibers and a preparation method of the environment-friendly high-temperature-resistant durable flame retardant fibers. The environment-friendly high-temperature-resistant durable flame retardant fibers comprise the following raw materials: cellulose, a flame retardant and a cationic crosslinking agent, wherein the flame retardant is a carbon-nitrogen flame retardant which meets relevant national requirements in environment-friendliness and flame retardance. By adopting the preparation method disclosed by the invention, spinning pause easily caused by aged and gelatinized glue of previous silicon flame retardant, downstream spinning and spinning difficulty caused by low strength and loss of the flame retardant components as well as a lasting flame retardant effect in the using process are overcome. Long and short filaments produced by the process can be used for manufacturing clothes, as well as knitwear and textiles for home furnishing, army protection and public decoration.

Owner:SOL FLAME RETARDANT FIBER

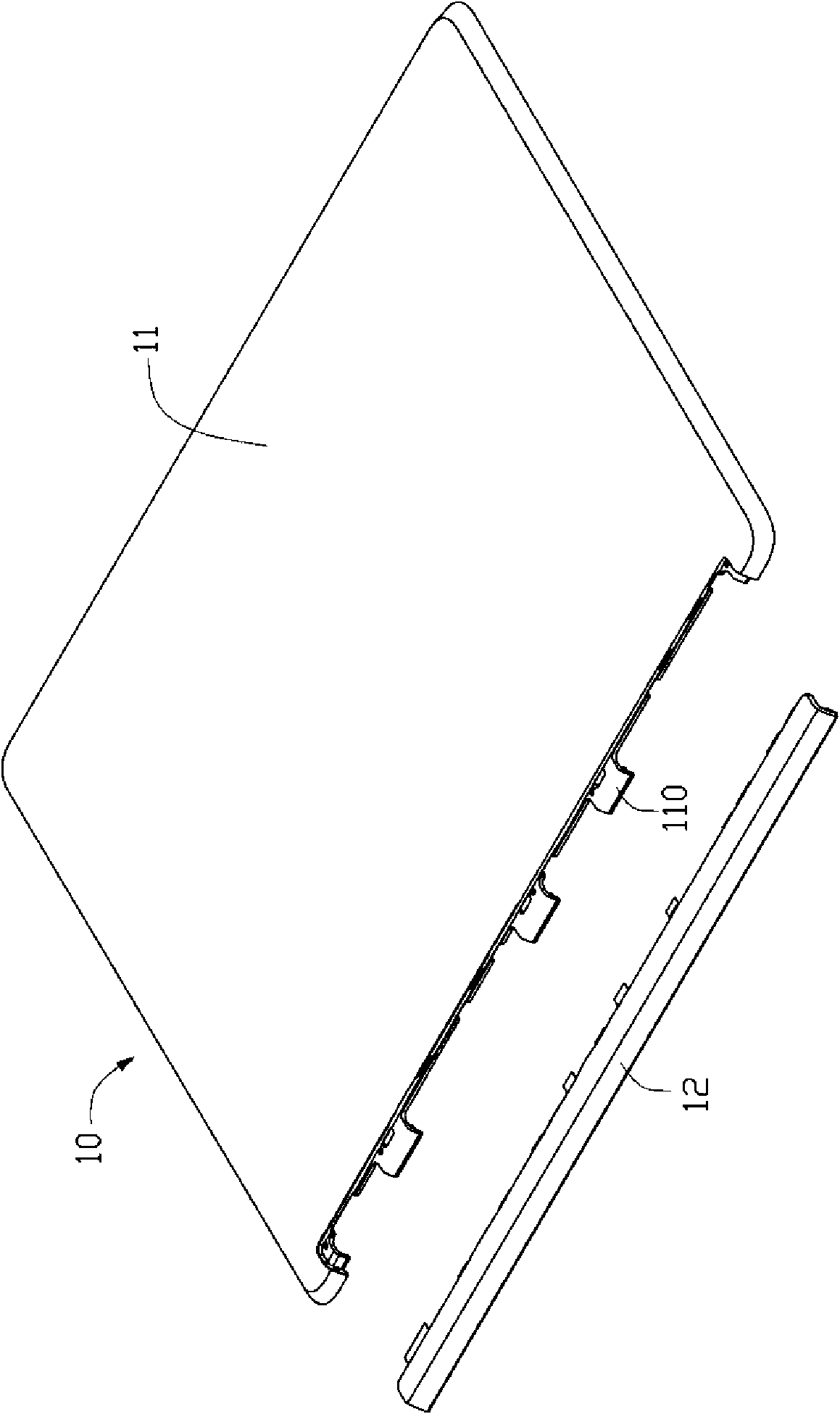

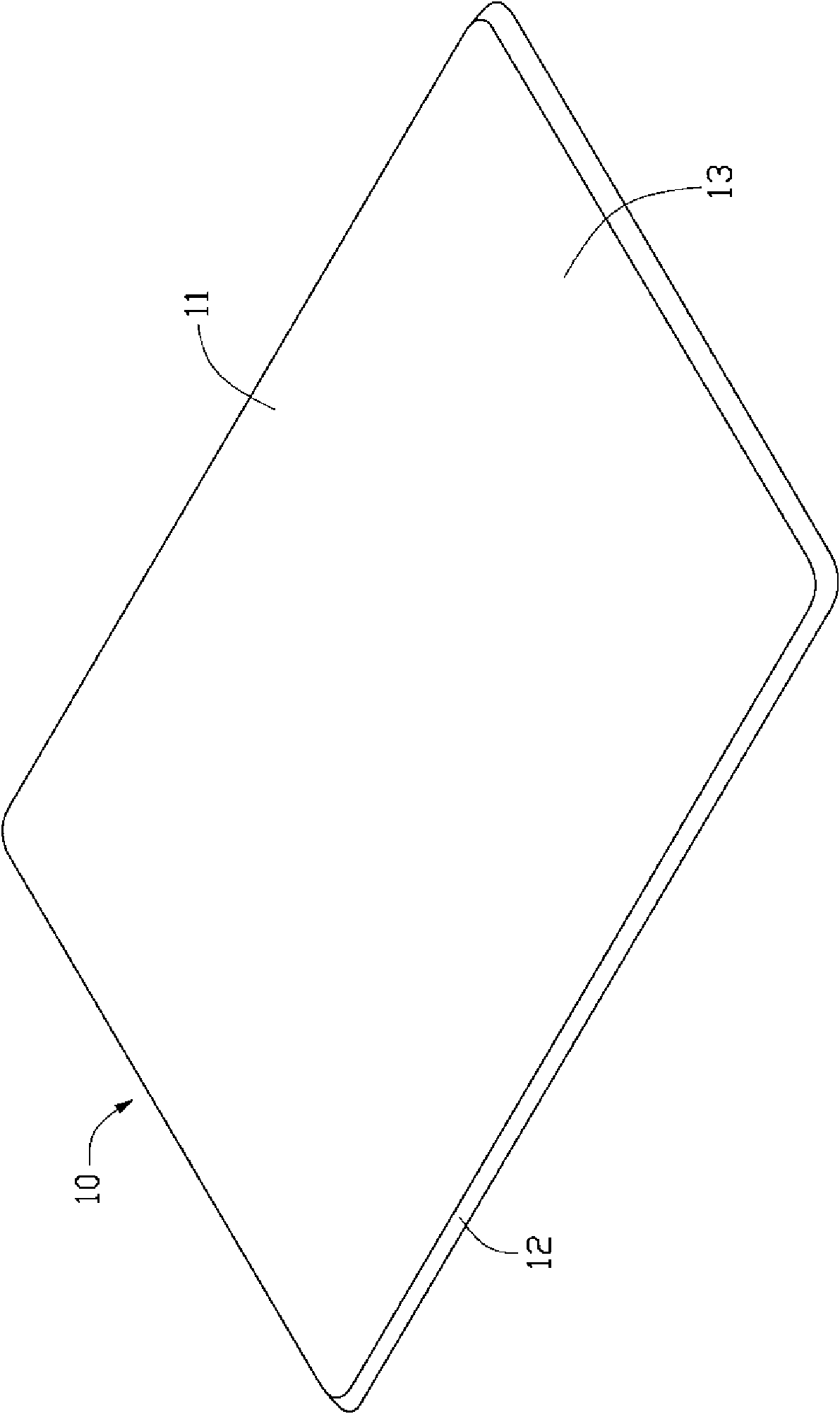

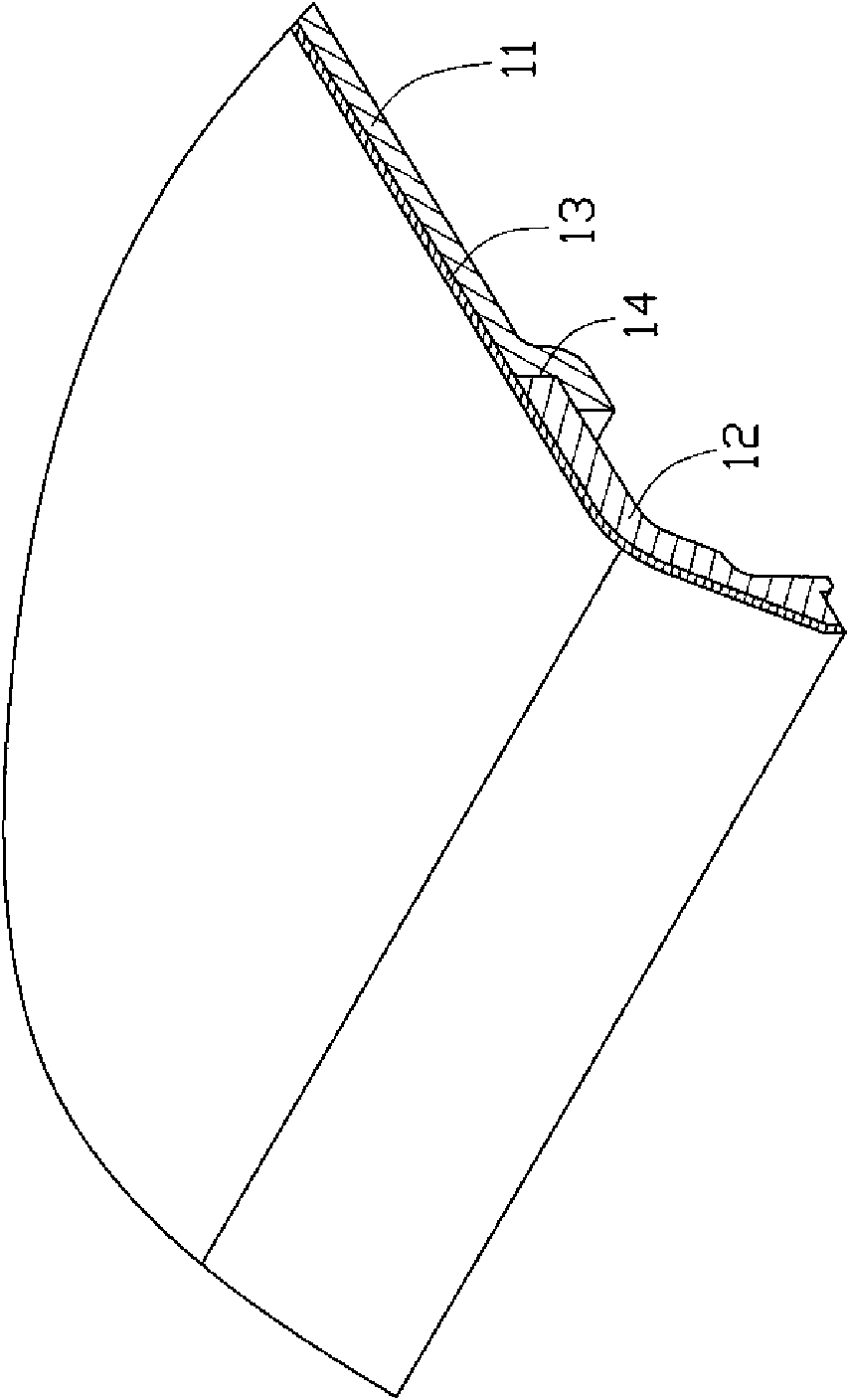

Electronic device shell and manufacturing method thereof

InactiveCN101573009APlay a protective effectSuitable for manufacturingLiquid surface applicatorsCasings/cabinets/drawers detailsEngineeringMechanical engineering

Owner:FU ZHUN PRECISION IND SHENZHEN +1

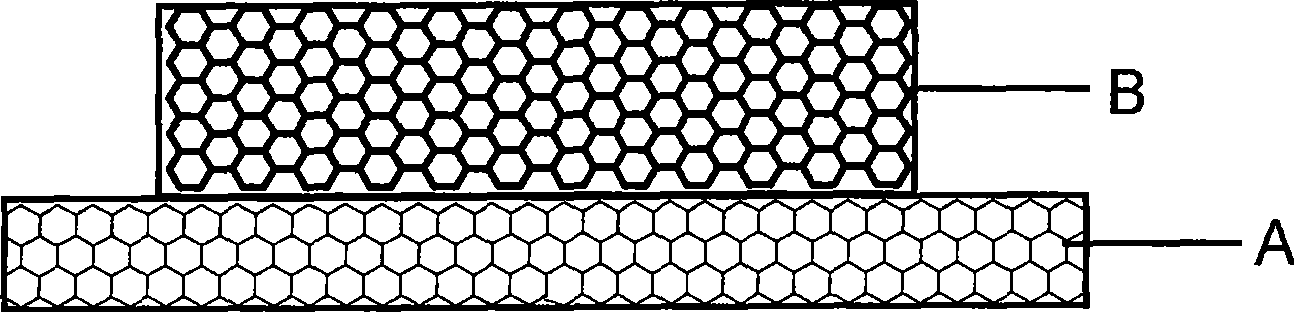

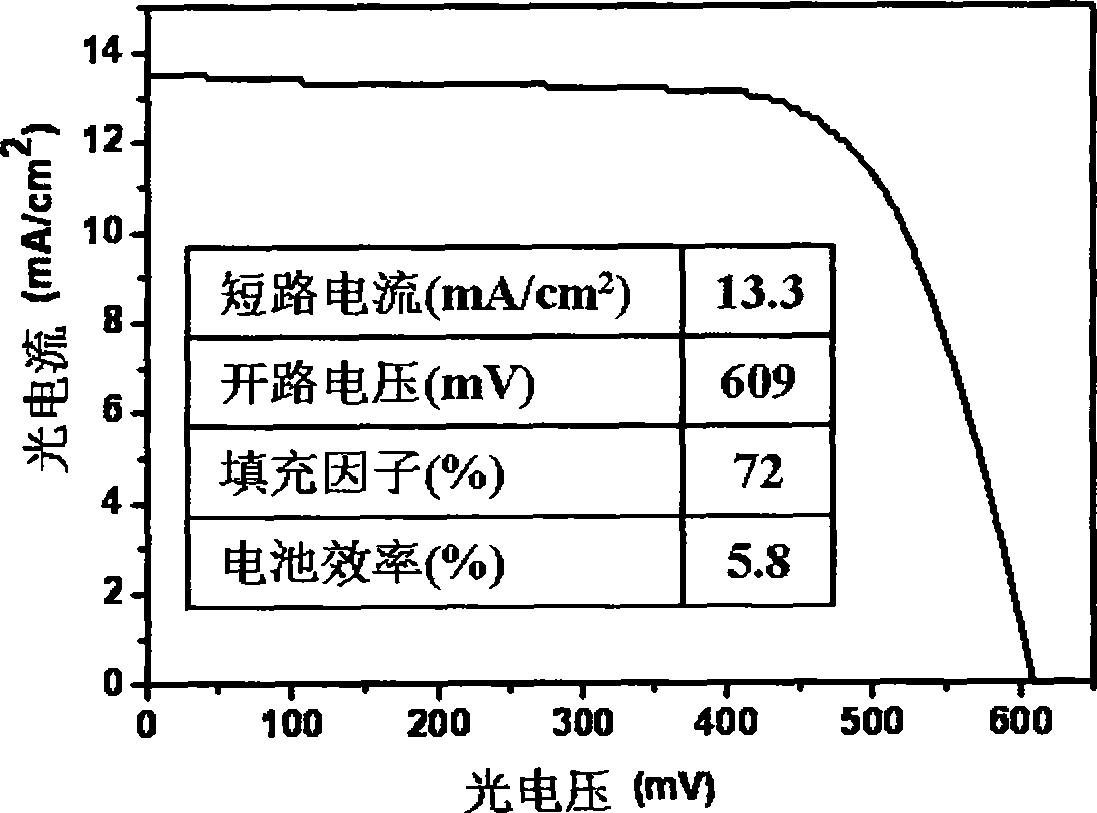

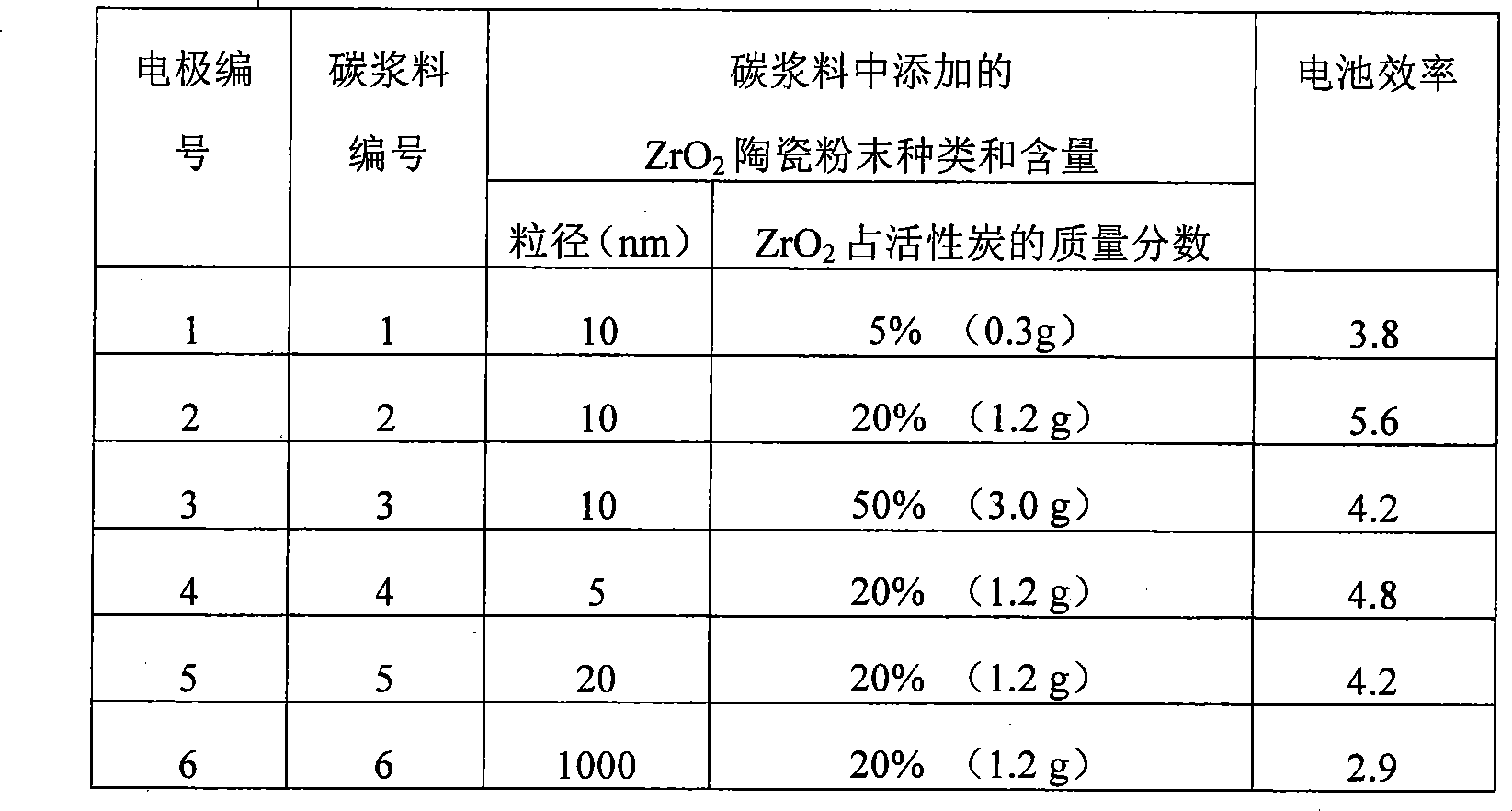

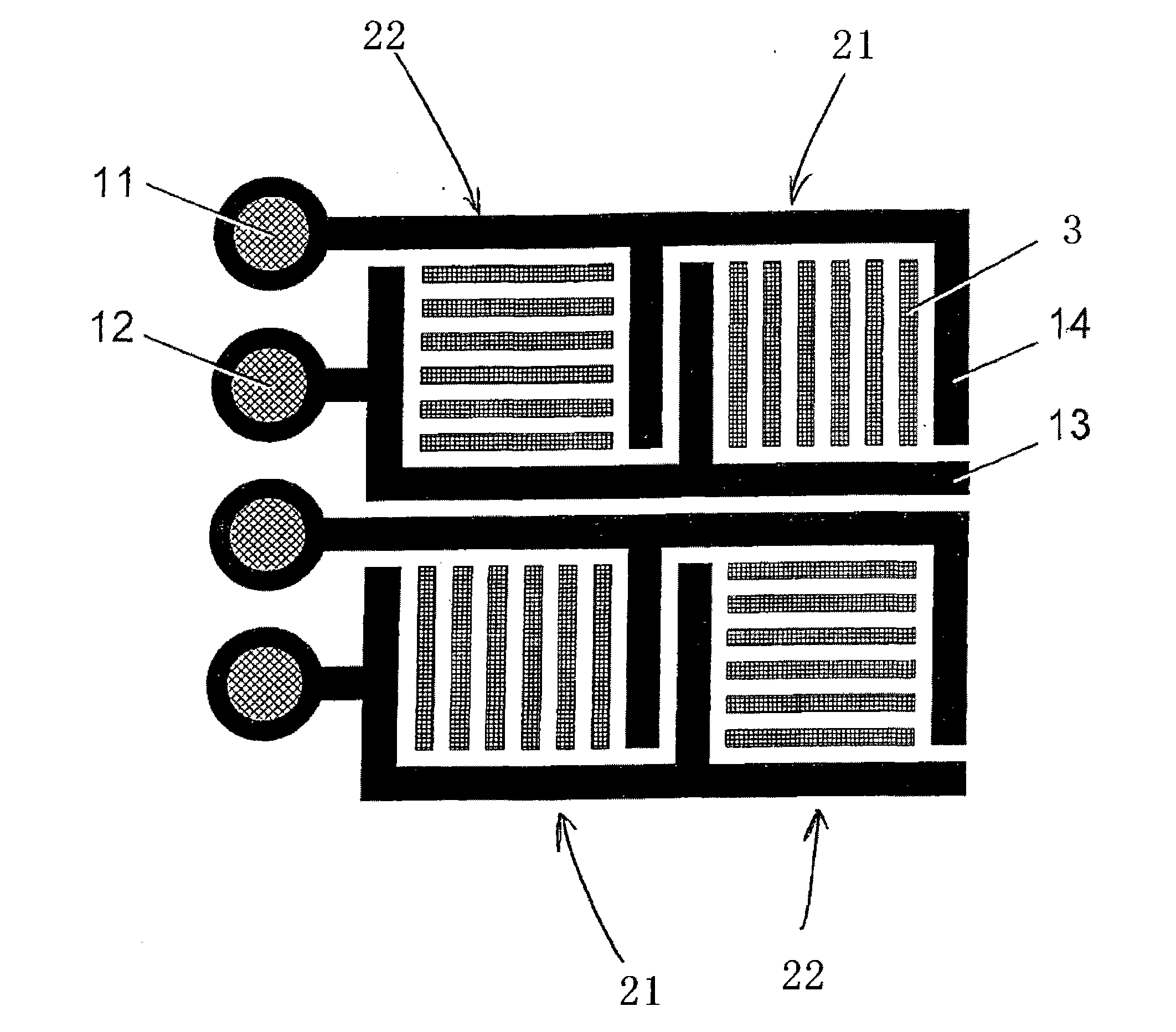

Full carbon counter electrode dye-sensitized solar cell and preparing method

ActiveCN101388294AGood mechanical properties such as friction resistanceImprove mechanical propertiesLight-sensitive devicesElectrode manufacturing processesElectrical batteryFilm coating

The invention relates to an all carbon counter electrode for a dye-sensitized solar cell and a process for preparation, wherein the all carbon counter electrode is formed by a carbon substrate A and a carbon catalytic active layer B which is coated on the carbon substrate. The process for preparing the all carbon counter electrode comprises firstly dispersing carbon catalytic active material and making into carbon paste according to the process of preparing carbon paste disclosed by the patient closure number CN101188257A, then transferring to the clean carbon substrate A through the methods of screen painting, spread coating, rotary film coating, film dropping or Czochralski method, and finally preparing the all carbon counter electrode through drying or kilning. The all carbon electrode of the invention can reduce series resistance and interface resistance, thereby increasing the short-circuit current (Jsc), filling factor (FF) and photoelectric transformation efficiency of the dye-sensitized solar cell. The substrate material adopted by the all carbon counter electrode of the invention has smaller resistance, can reduce using or avoid using metal flow concentration leads, and simplifies preparation technology.

Owner:深圳市华物光能技术有限公司

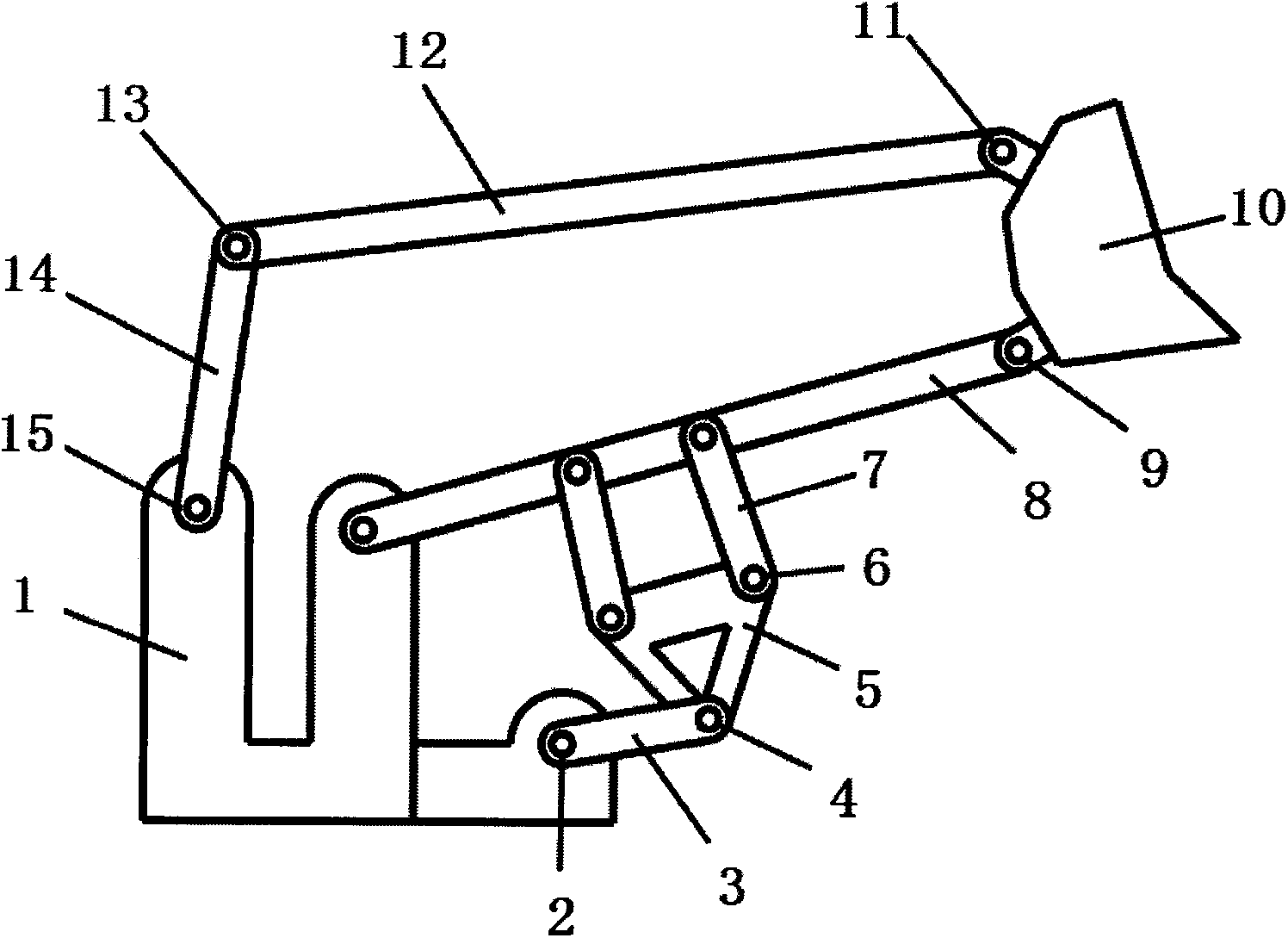

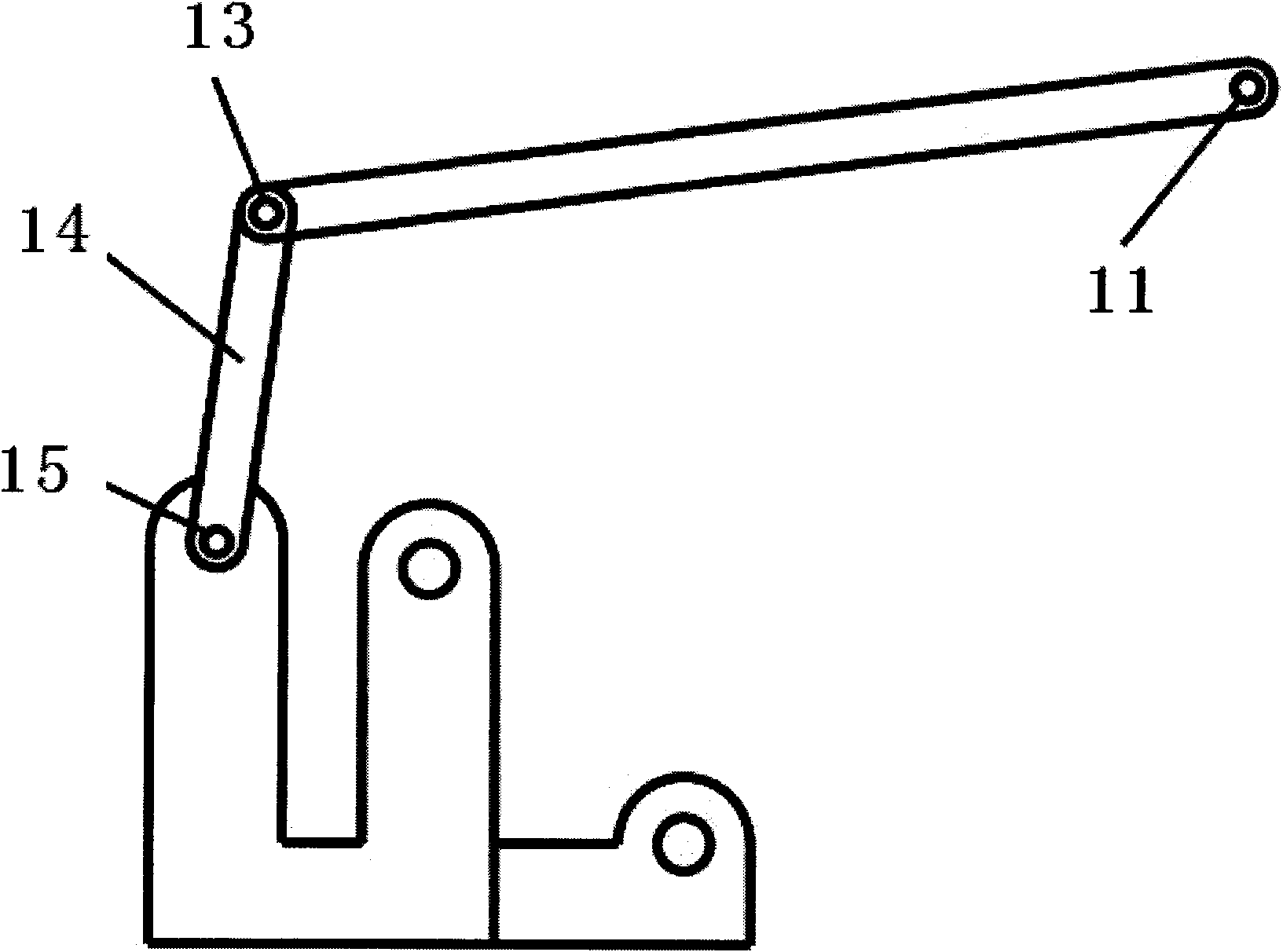

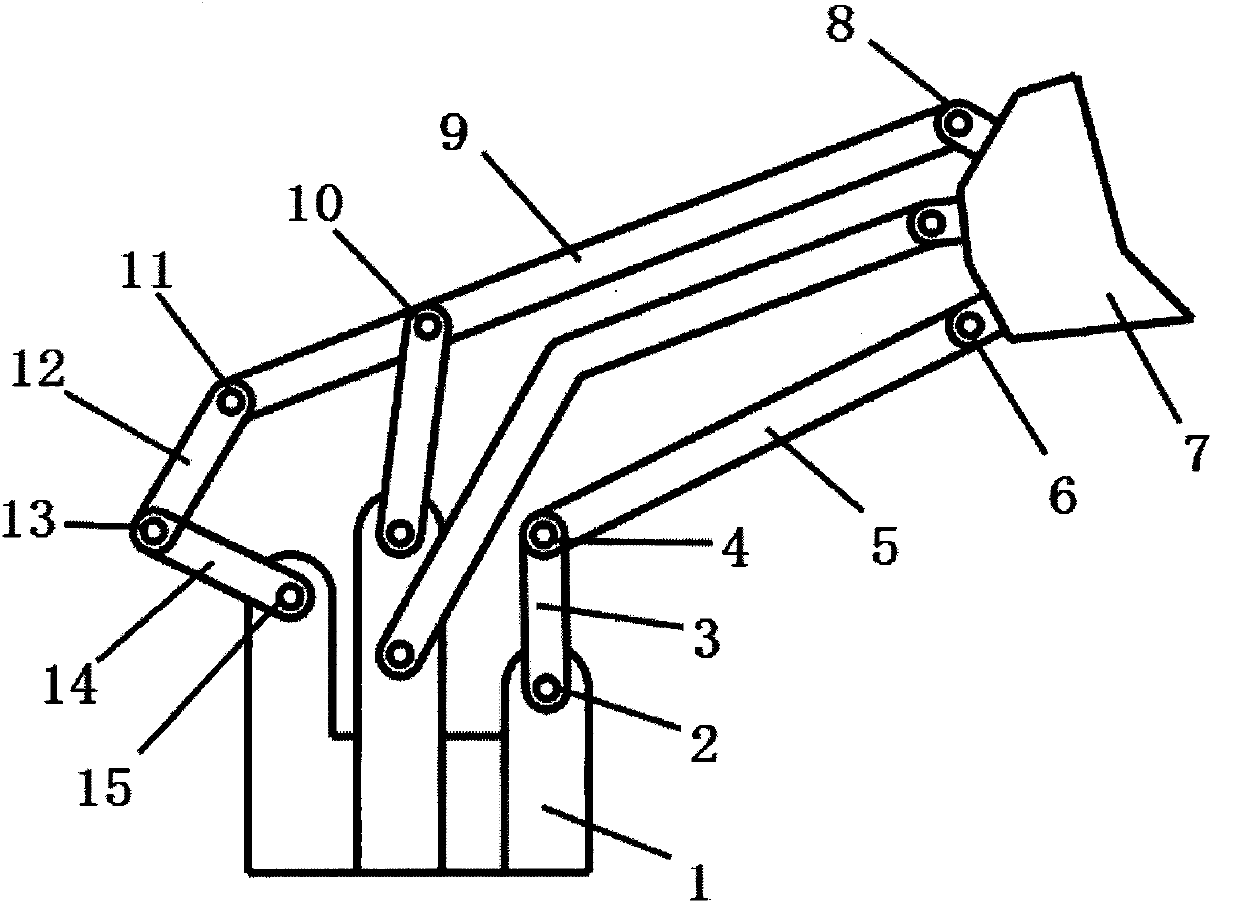

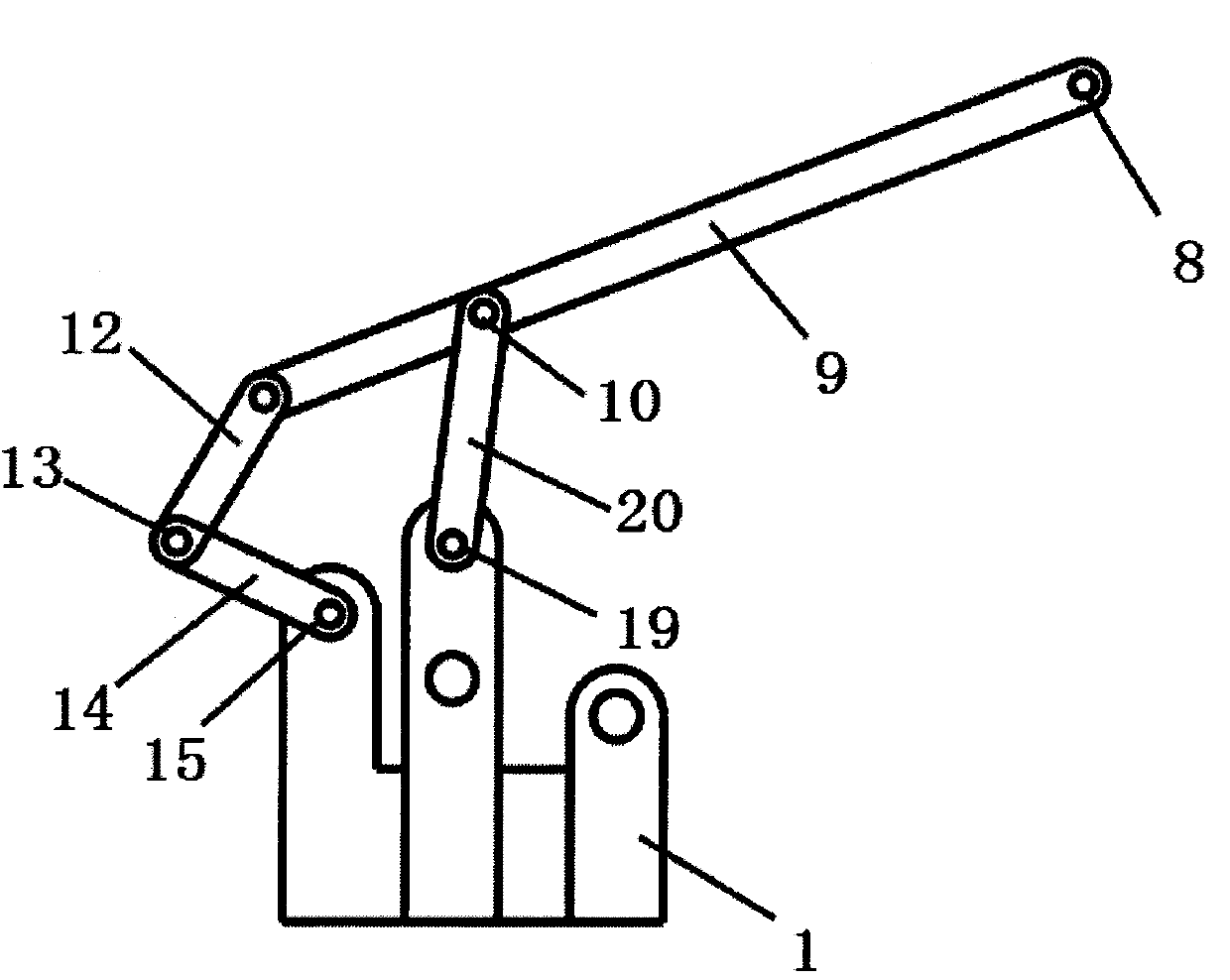

High-rigidity nine-lever and two-freedom degree controllable mechanical loading mechanism

InactiveCN103711157AImprove mechanical propertiesSuitable designMechanical machines/dredgersKinematicsEngineering

The invention relates to a high-rigidity nine-lever and two-freedom degree controllable mechanical loading mechanism, which comprises a machine frame, a movable arm control branched chain and a bucket control branched chain, wherein the movable arm control branched chain is controlled by a first driving lever and is used for elevating a movable arm; the bucket control branched chain is controlled by a second driving lever and is used for turning a bucket. The mechanical loading mechanism can complete loading and unloading operation by means of the interaction of the movable arm elevating branched chain and the bucket control branched chain. According to the mechanical loading mechanism, all the levers are connected through revolute pairs, and thereby the defects of high cost, low reliability, high maintenance cost and the like of the conventional full hydraulic loading mechanism with sliding pairs are overcome. Moreover, compared with other controllable loading mechanisms, the mechanical loading mechanism has the advantages of compact structure, high rigidity, and novel structure with superior kinematic and dynamic performance, and thereby the loading mechanism is higher in reliability and dynamic stability.

Owner:GUANGXI UNIV

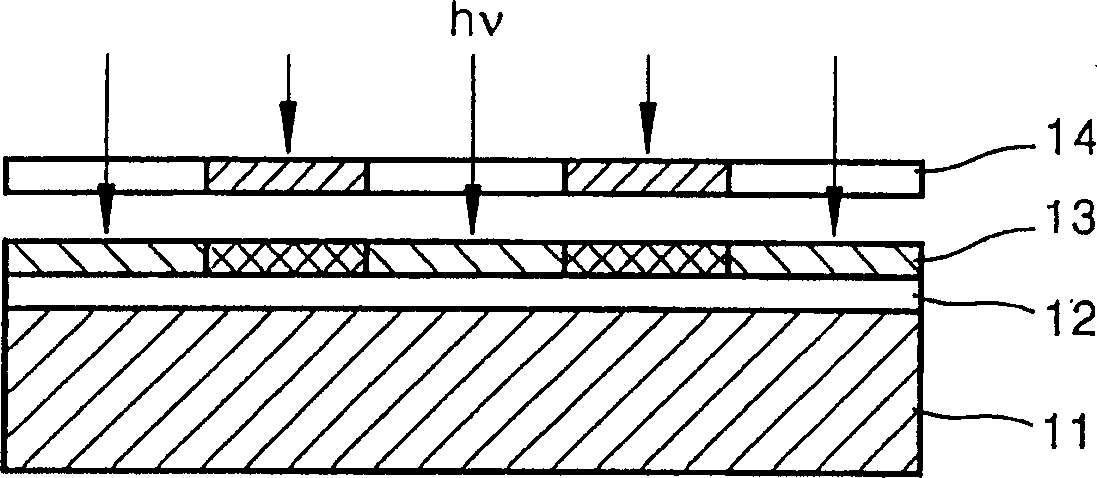

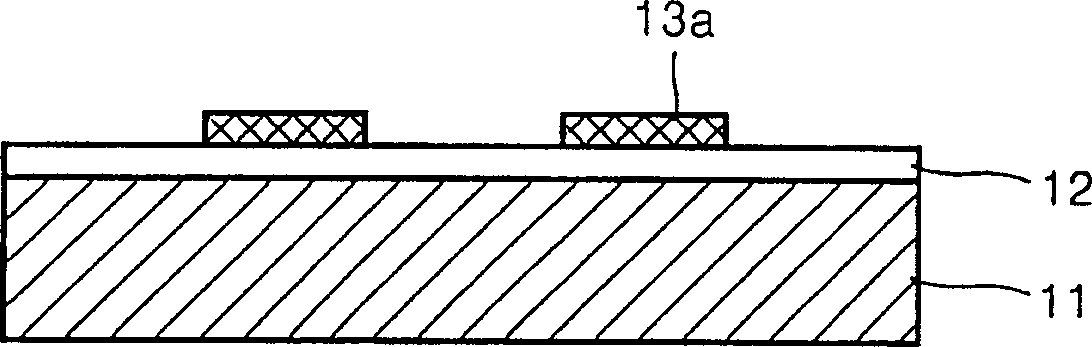

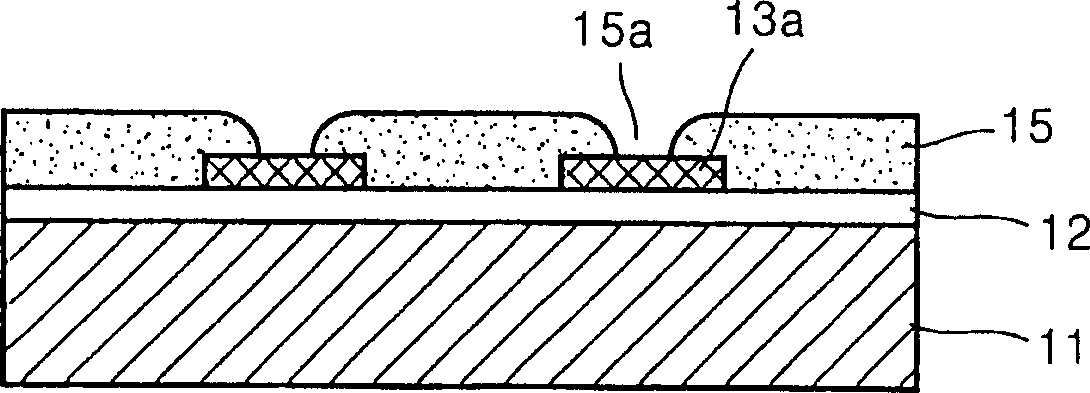

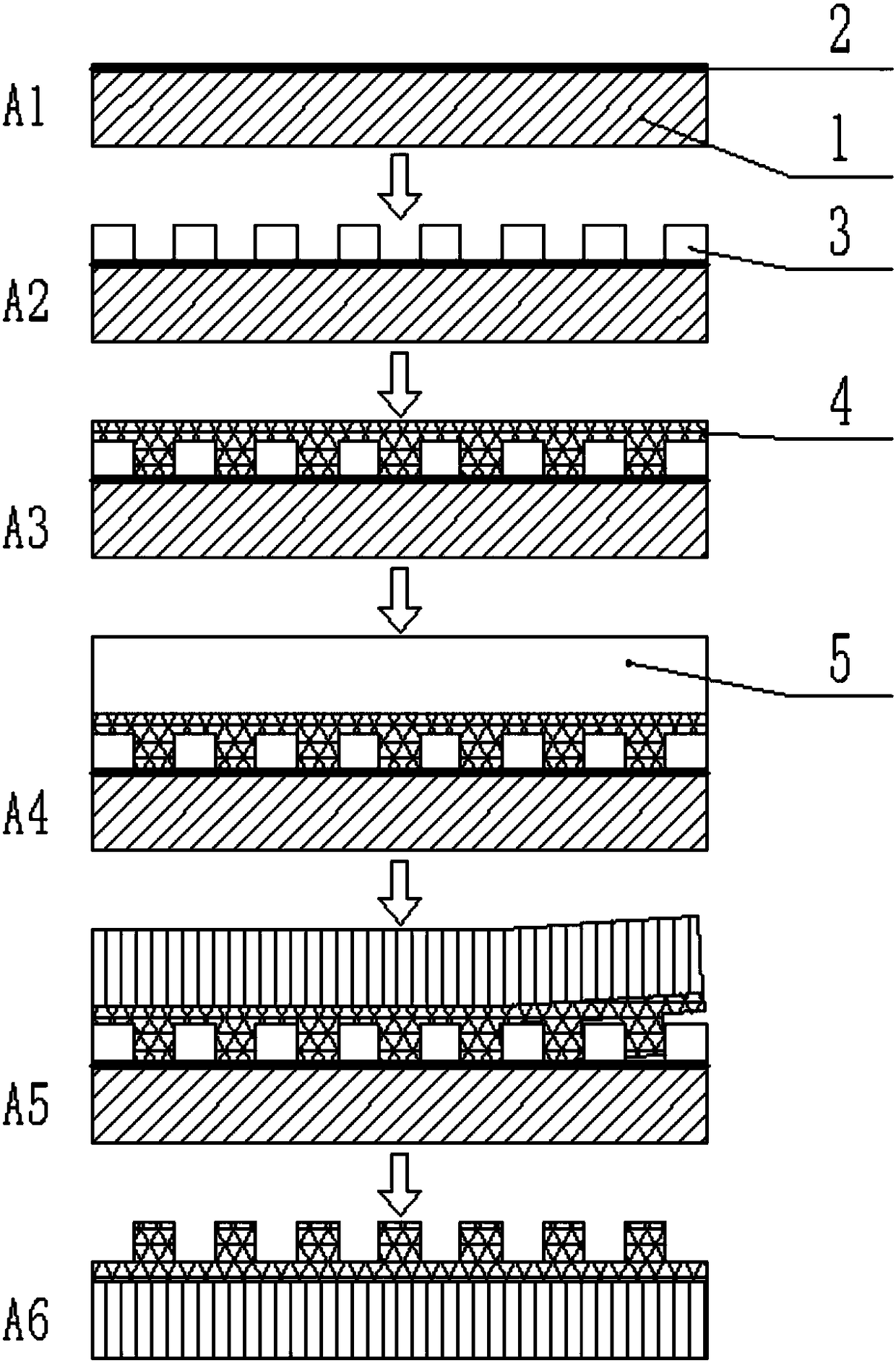

Manufacture process of single ink jet head

InactiveCN1417033ASuitable for manufacturingSimple processPhotomechanical apparatusPrintingResistEngineering

The present invention discloses a method of manufacturing a monolithic ink-jet printhead which includes a heating element which generates bubbles by heating ink is formed on a surface of the substrate, and a negative photoresist which is coated to a predetermined thickness on the substrate on which the heating element is formed. Next, a portion, which forms a sidewall of an ink passage forming wall surrounding an ink chamber and a restrictor, of the negative photoresist is flush exposed to light and cured using a first photomask in which patterns of the ink chamber and the restrictor of the ink passage are formed. Subsequently, a second portion which forms an upper wall of the ink passage forming wall of the negative photoresist is exposed to the light using a second photomask in which the pattern of a nozzle is formed, and the second portion is exposed to the light by only a predetermined thickness. Last, an uncured portion of the negative photoresist is dissolved and removed using solvent. An ink-jet printhead whose elements are monolithically formed by a simplified process using a single negative photoresist can be manufactured.

Owner:SAMSUNG ELECTRONICS CO LTD

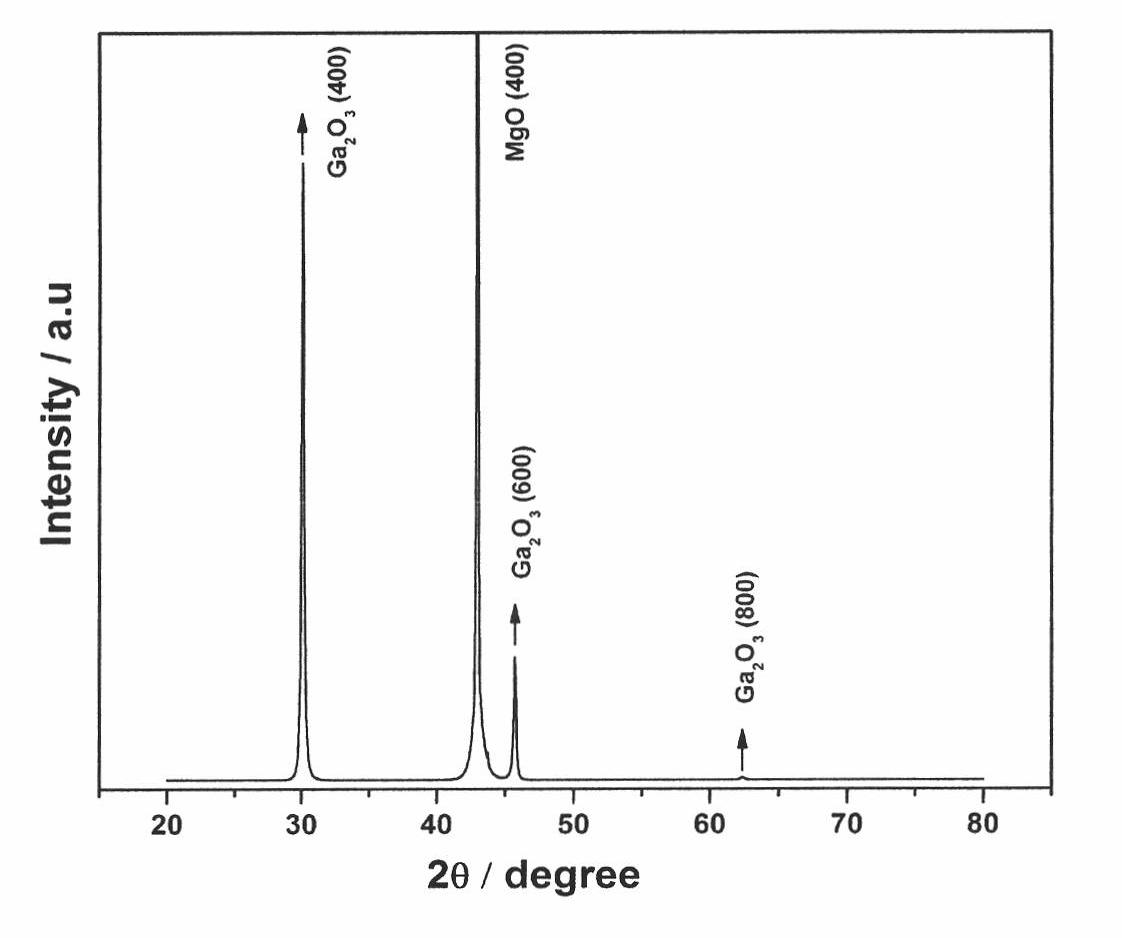

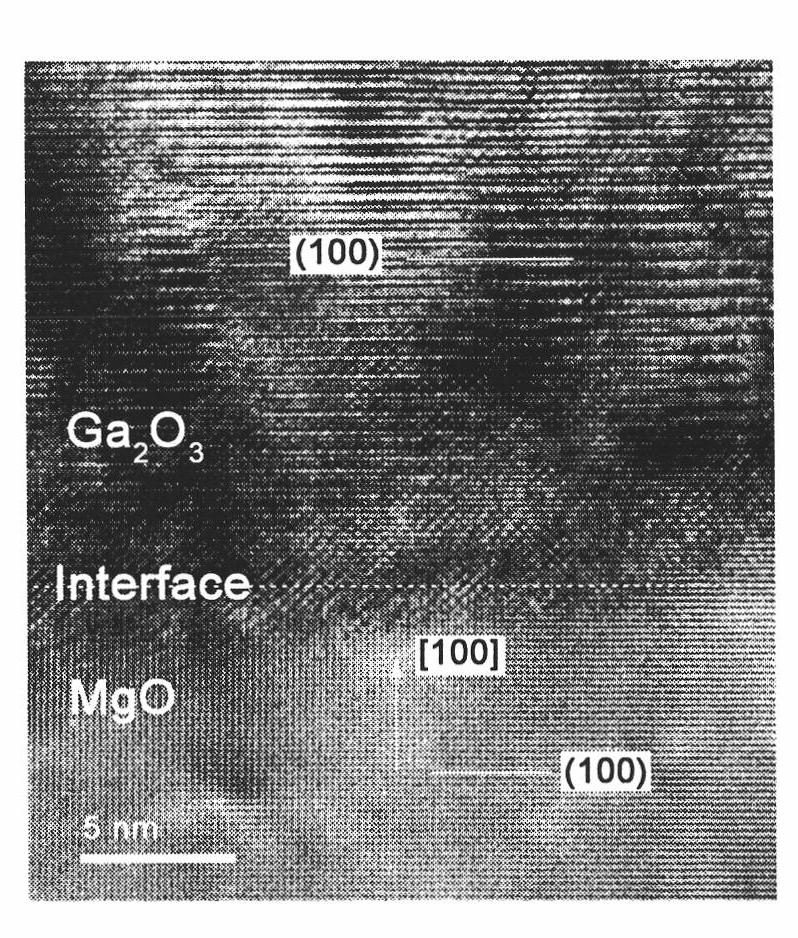

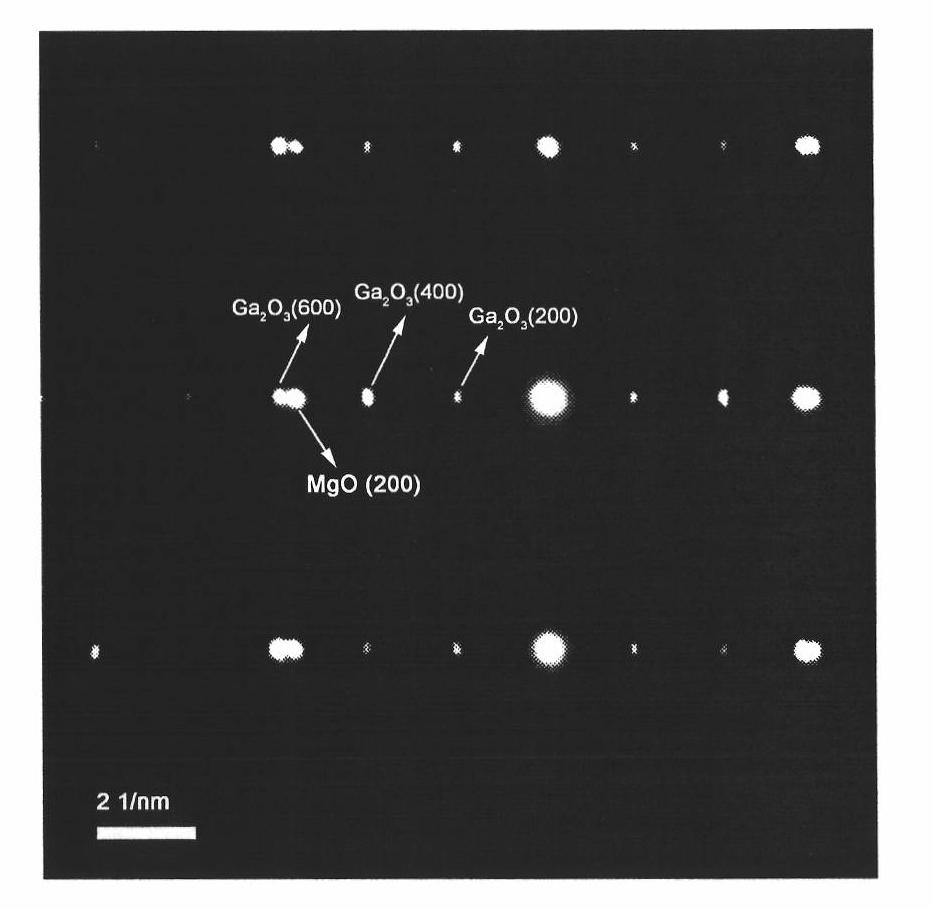

Method for preparing monoclinic gallium oxide single-crystal film on magnesium oxide substrate

InactiveCN101967680AGood crystal qualitySimple process conditionsPolycrystalline material growthSemiconductor/solid-state device manufacturingFilm materialMagnesium

The invention relates to a method for preparing a monoclinic gallium oxide single-crystal film on a magnesium oxide substrate. The monoclinic gallium oxide single-crystal film is epitaxially grown on the magnesium oxide substrate with a cubic structure under a vacuum condition by organic metal chemical vapor deposition equipment through an organic metal chemical vapor deposition process, wherein trimethylgallium serves as an organic metal source; nitrogen serves as a carrier gas; and oxygen serves as an oxidizing gas. The film is an epitaxial material with a single-crystal structure; the forbidden bandwidth of the film material is 4.86eV; and the film is applicable to the manufacturing of ultraviolet transparent and short-wavelength photoelectronic devices.

Owner:SHANDONG UNIV

A method for making IV-VI sector semiconductor single crystal film on CdZnTe underlay

InactiveCN101236905AQuality improvementClear interfaceSemiconductor/solid-state device manufacturingFrom condensed vaporsBridgman methodGas phase

The invention provides a method for preparing an IV-VI semiconductor single crystal thin film on a CdZnTe substrate, wherein, in a molecular beam epitaxy(MBE) device, by adopting an MBE growth method and utilizing molecular beam sources of different IV-VI compounds and under different growth temperatures(200 to 425DEG C), the single crystal thin film is epitaxially grown on the CdZnTe single crystal substrate materials; the CdZnTe substrate has a general formula of Cd1-xZnxTe, wherein X is equal to 0 to 0.3; the single crystal thin film grows by the vertical Bridgman method or vapor transport method, is cut along the (111) crystal orientation or (100) crystal orientation, is mechanically polished by Al2O3 powder and then is chemically polished by the bromine-methanol, the concentration of which is 1 percent. The method for preparing an IV-VI semiconductor single crystal thin film on a CdZnTe substrate has the advantages of being capable of realizing the controllable growth of device structures such as hetero junction, quantum well and superlattice, etc.

Owner:ZHEJIANG UNIV

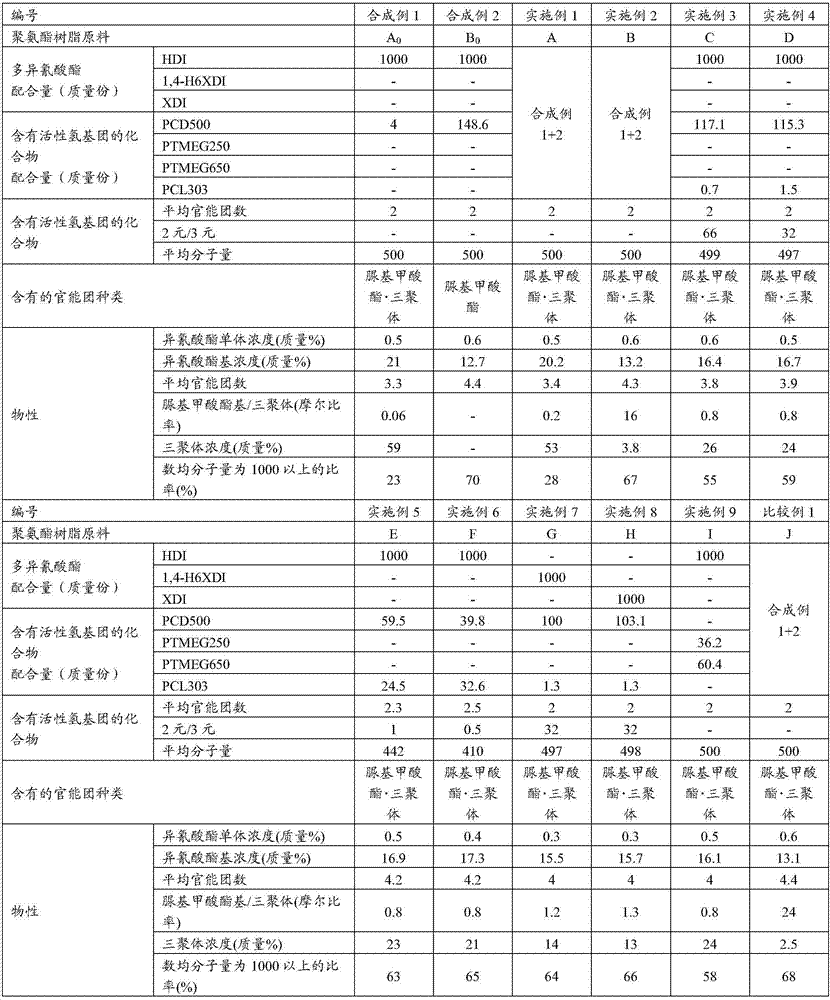

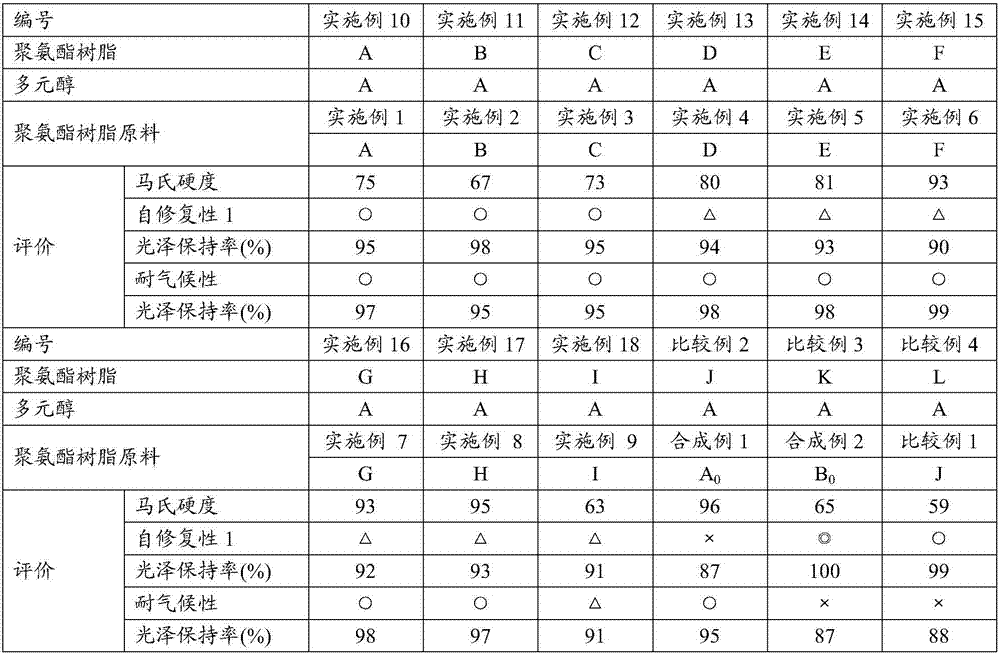

Self-repairing polyurethane resin raw material, self-repairing polyurethane resin, self-repairing coating material, self-repairing elastomeric material, self-repairing polyurethane resin raw material production method and self-repairing polyurethane resin production method

InactiveCN107001558AImprove balanceExcellent self-healing performancePolyurea/polyurethane coatingsElastomerPolymer science

This self-repairing polyurethane resin raw material is obtained by reacting a polyisocyanate compound having an aliphatic polyisocyanate and / or an araliphatic polyisocyanate and an active hydrogen containing compound, is used in the production of a polyurethane resin having self-repairing properties, and has an isocyanate group at the molecular terminal. The self-repairing polyurethane resin raw material contains an allophanate group and an isocyanate trimer, and has a 0.1-20 molar ratio of allophanate groups to isocyanate trimers.

Owner:MITSUI CHEM INC

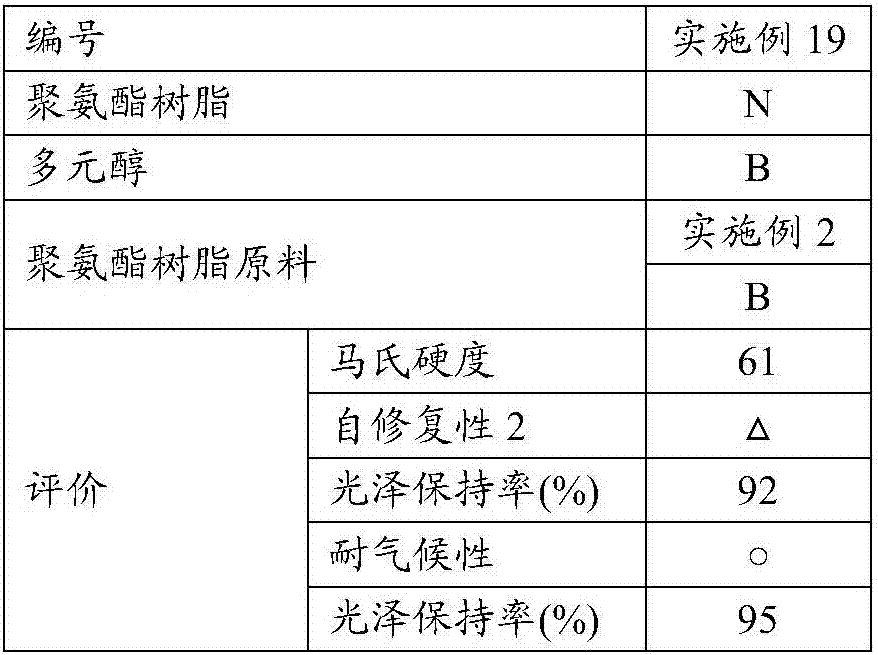

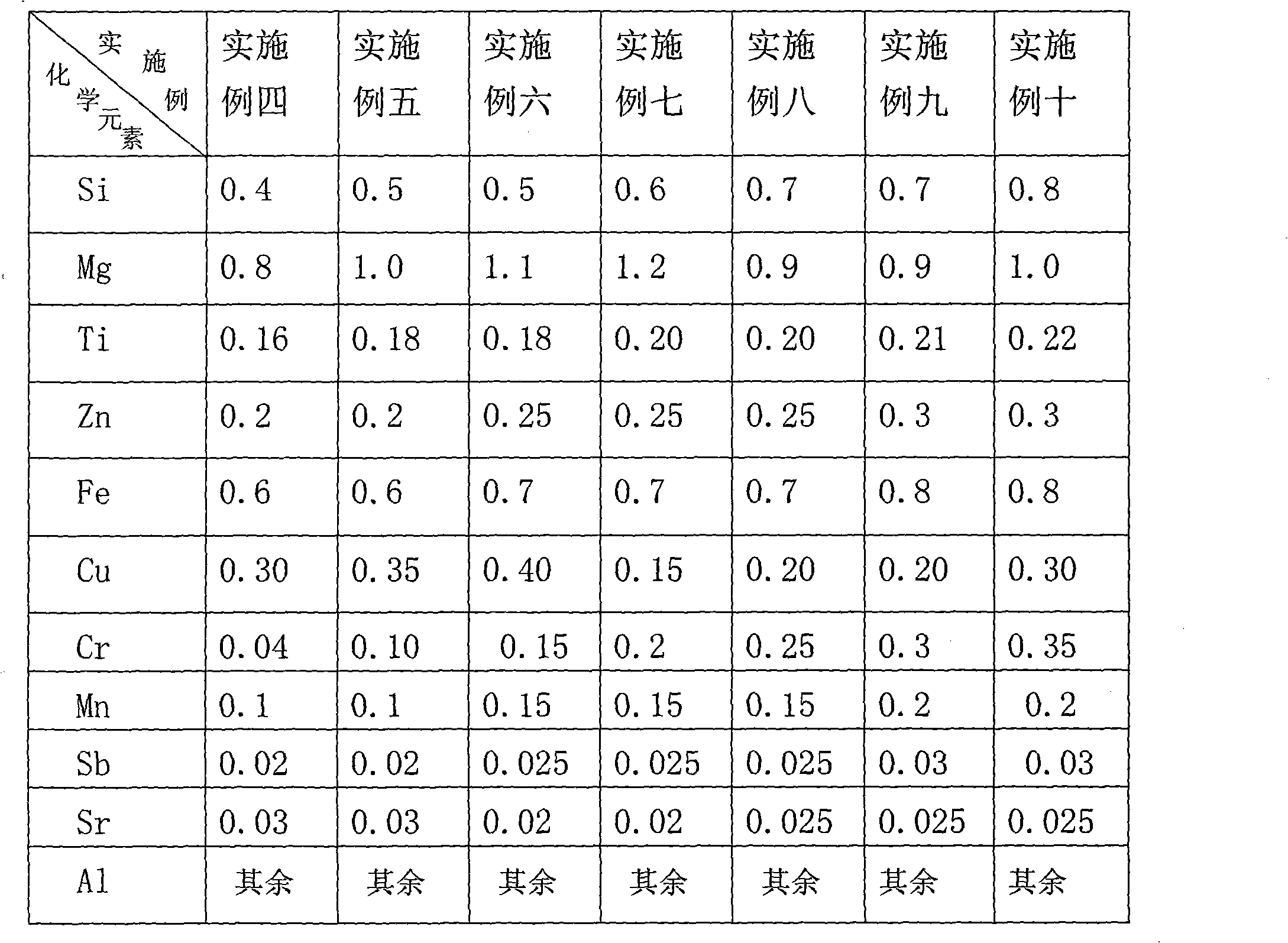

High strength automobile aluminium alloy wheel rim

The invention relates to a high strength automobile aluminium alloy wheel rim, in particular to an automobile wheel rim matched with oversize vehicles. The high strength automobile aluminium alloy wheel rim is made of high strength aluminium alloy material which comprises main chemical elements with the mass percent: 0.4-0.8% of Si, 0.8-1.2% of Mg, 0.16-0.22% of Ti, 0.2-0.3% of Zn, 0.6-0.8% of Fe,0.15-0.4% of Cu, 0.04-0.35% of Cr, 0.1-0.2% of Mn, 0.02-0.03% of Sb, 0.02-0.03% of Sr and the rest of Al. The automobile aluminium alloy wheel rim has high tensile strength which is 10% higher than that of the existing aluminium alloy wheel rim produced by 6061-T6, is good in mechanical property, enhances the rotatable performance of alloy when the structure is refined, and has the advantages ofwide application scope, low production cost and easy popularization and use.

Owner:HECHI UNIV

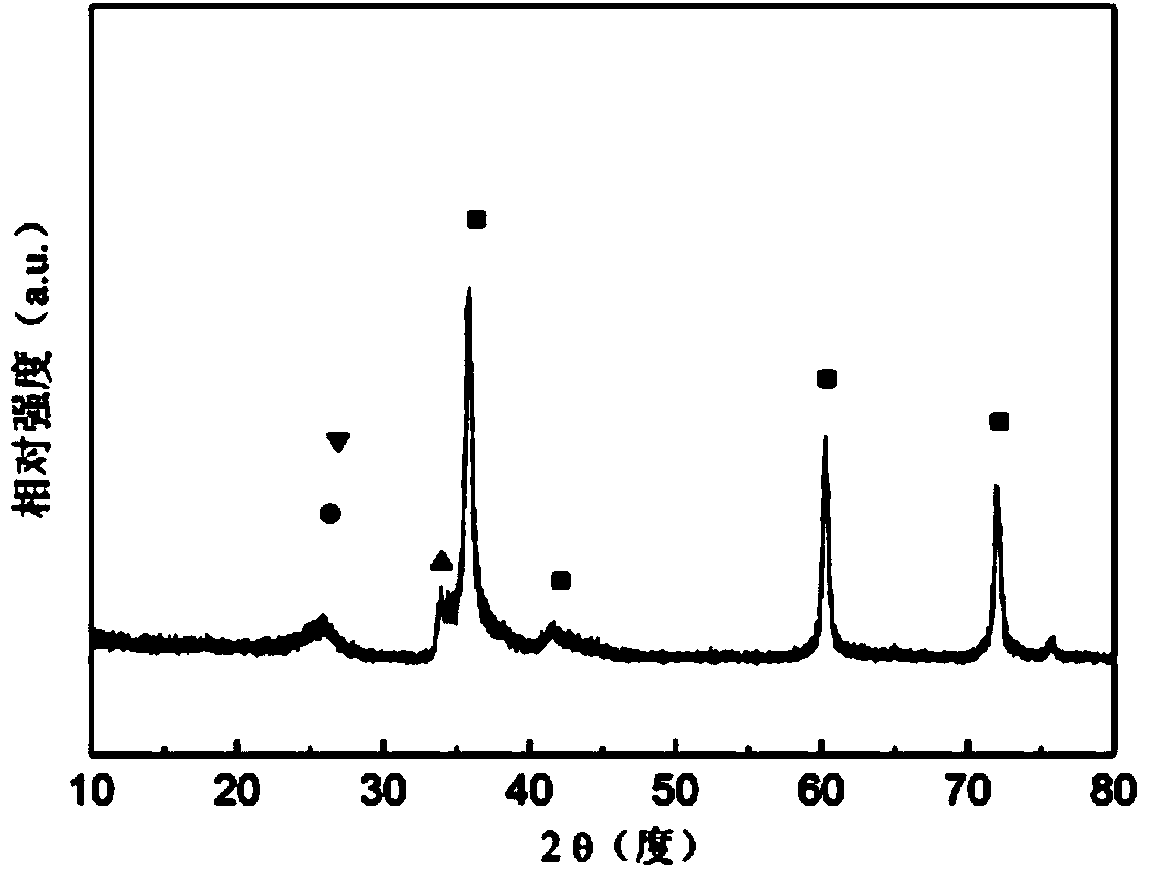

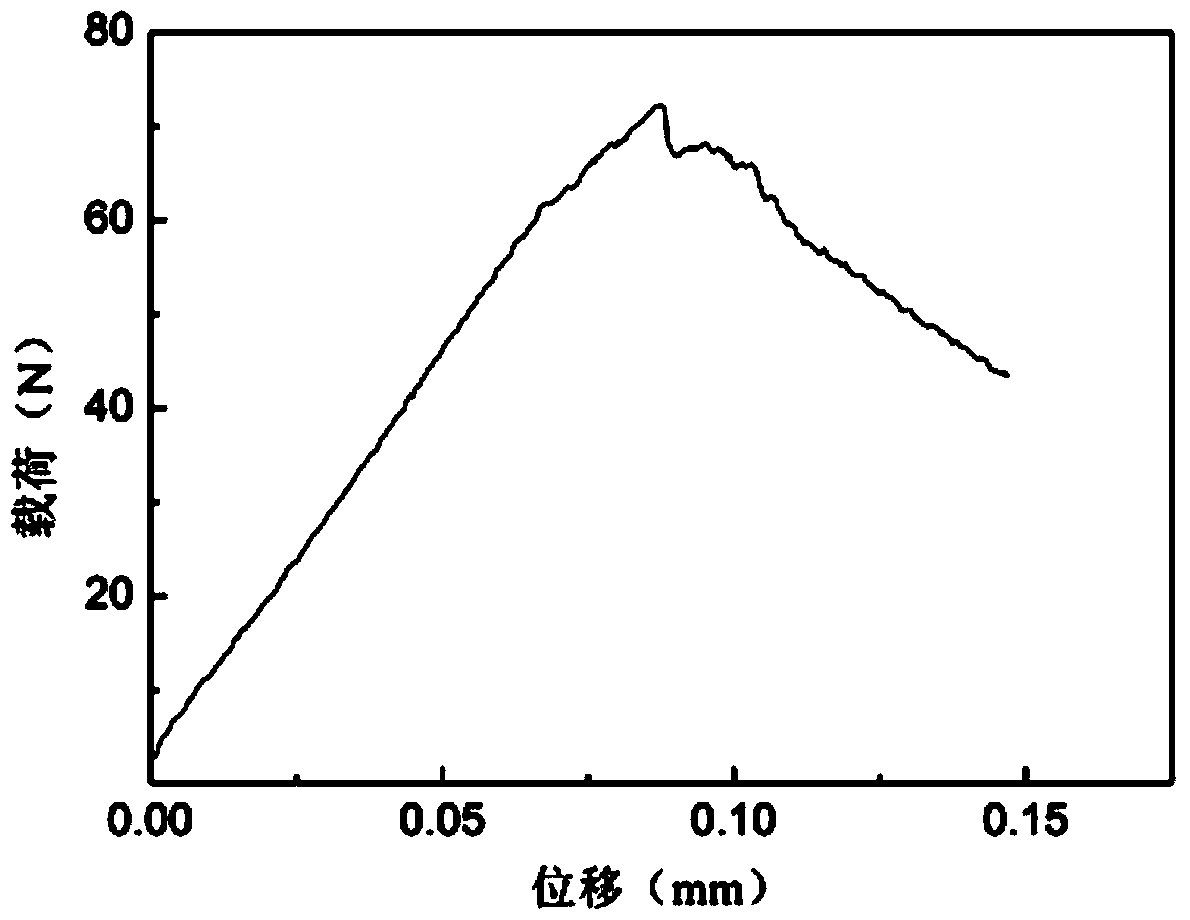

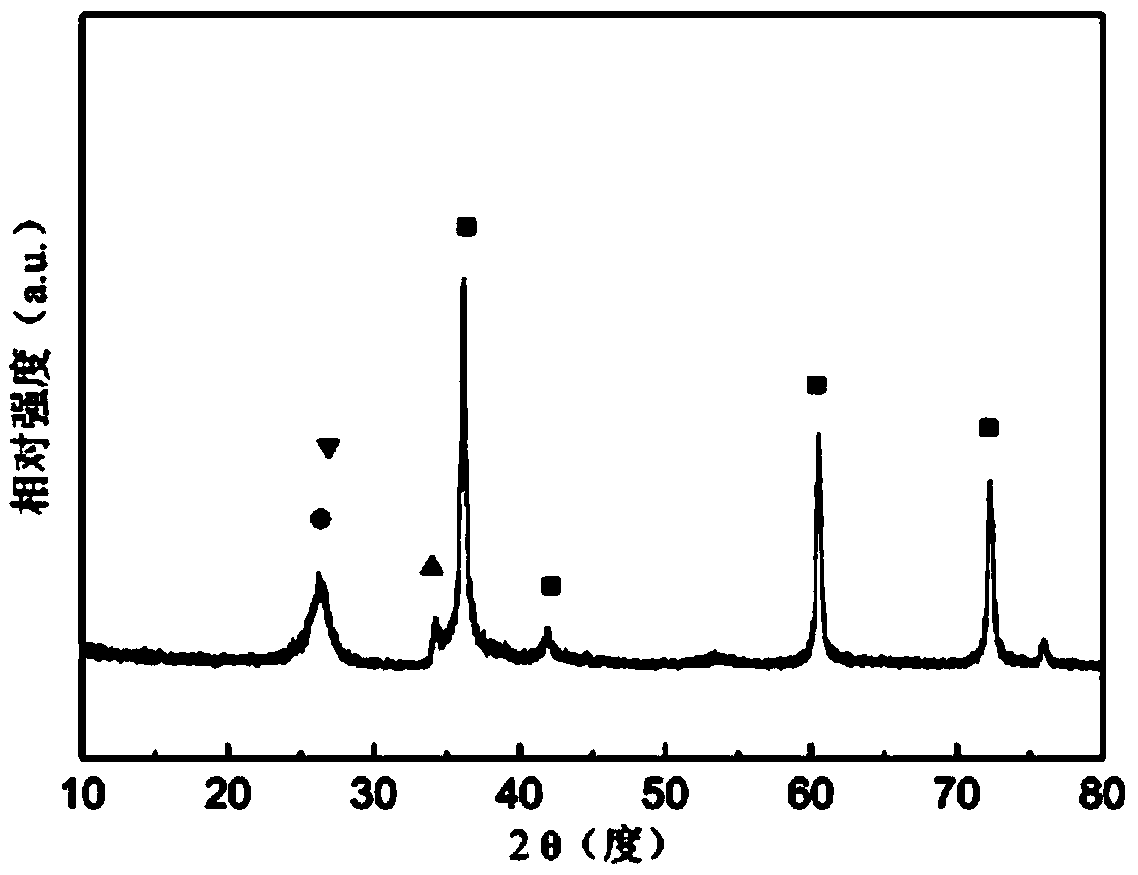

Carbon/carbon fiber-silicon, boron, carbon and nitrogen ceramic composite material and preparation method thereof

The invention relates to a carbon / carbon fiber-silicon, boron, carbon and nitrogen ceramic composite material and a preparation method thereof. The invention relates to a short carbon fiber reinforced silicon, boron, carbon and nitrogen ceramic composite material and a preparation method thereof. The invention aims to solve the problem that the existing fiber reinforced silicon, boron, carbon and nitrogen ceramic composite material is complex in preparation process and high in cost, and the strengthening and toughening effect of the fibers is not remarkable due to over-strong interfacial adhesion. The product is prepared from short carbon fibers, phenolic resin, acetone and silicon, boron, carbon and nitrogen ceramic composite powder. The preparation method comprises the following steps: I, dissolving phenolic resin in acetone to prepare dipping liquor; II, putting the short carbon fibers in the dipping liquor to dip, and then splitting in an argon atmosphere to obtain carbon coating-coated short carbon fibers; III, putting silicon powder, graphite and hexagonal boron nitride in a ball mill to ball-mill and mix to obtain composite powder; and IV, after mixing the carbon coating-coated short carbon fibers with the composite powder, carrying out hot pressed sintering to obtain the carbon / carbon fiber-silicon, boron, carbon and nitrogen ceramic composite material.

Owner:HARBIN INST OF TECH

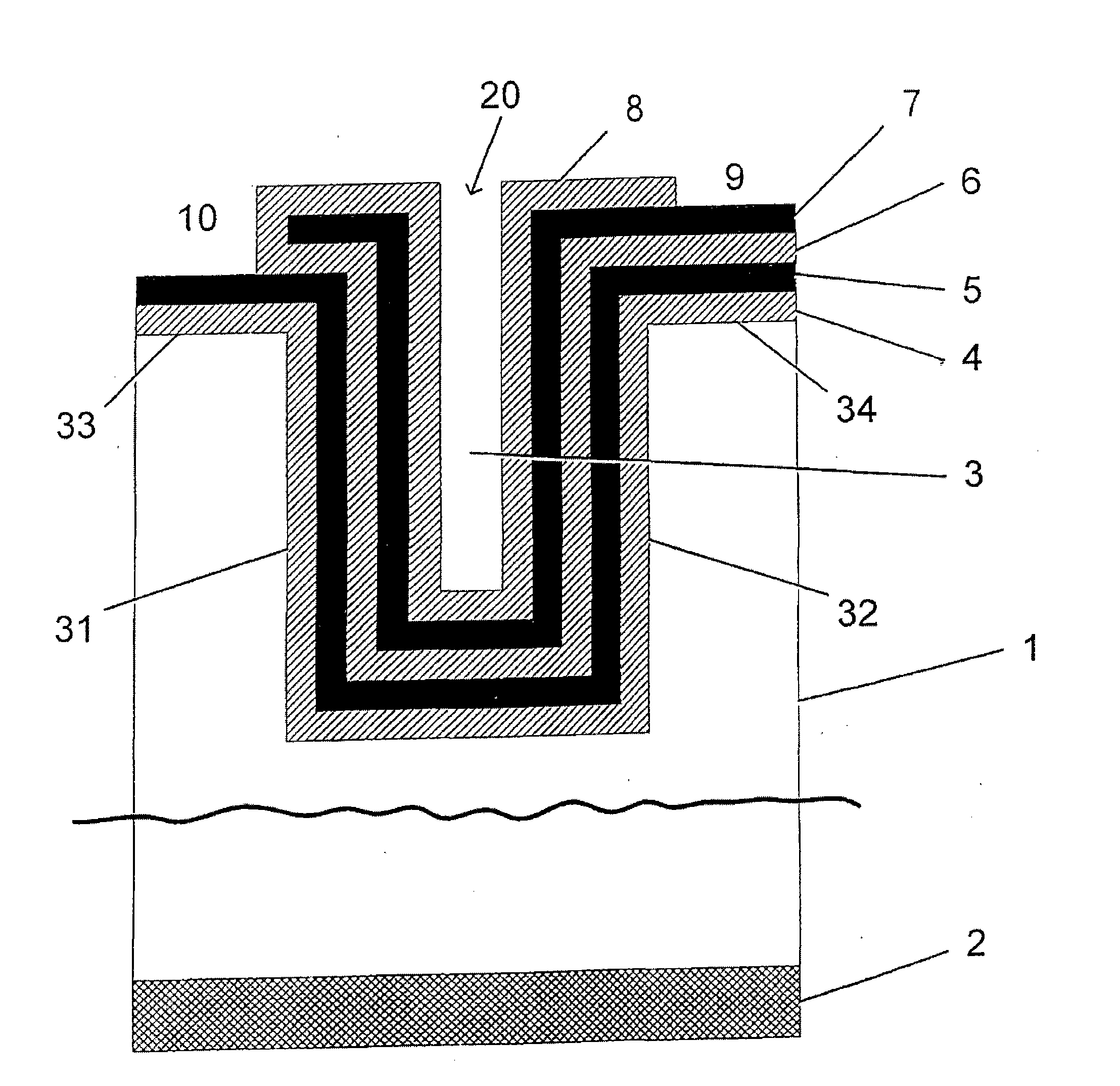

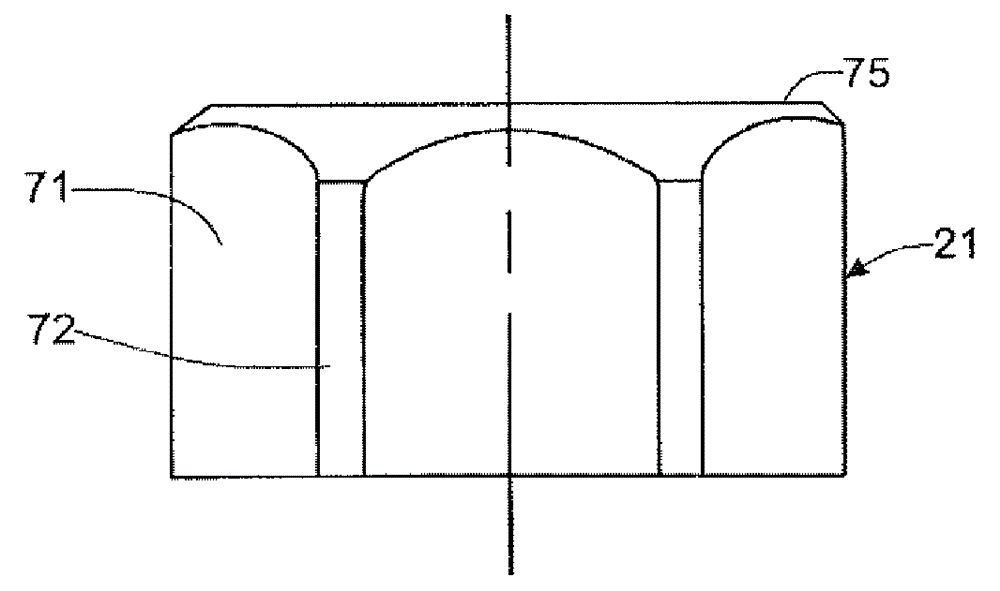

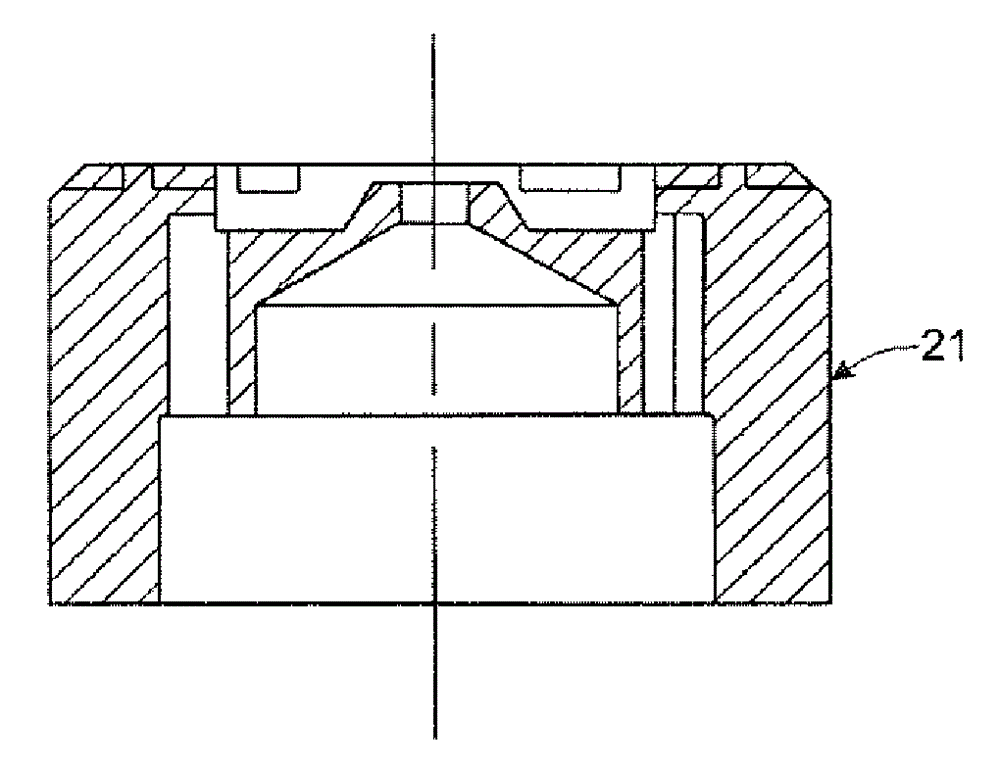

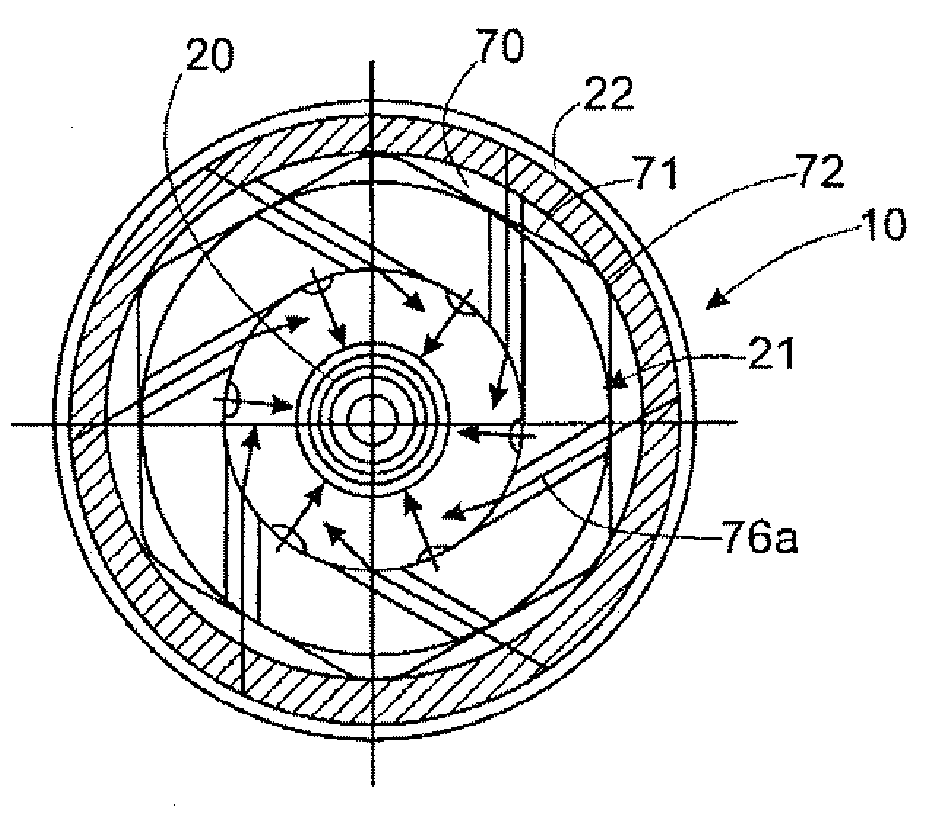

Semiconductor arrangement with trench capacitor and method for production thereof

ActiveCN101636826ASmall sizeImprove buffering effectSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention relates to a semiconductor arrangement and method for production thereof, wherein the semiconductor arrangement is provided with an integrated circuit (2) arranged on a substrate (1). The integrated circuit (2) is structured on the front face of the substrate and at least one capacitor (20) is connected to the integrated circuit, characterised in that the at least one capacitor is designed as a monolithic deep structure in trenches (3). The trenches are arranged in at least one first group and at least one second group, the trenches of a group running essentially parallel to each other and the first and second group are at an angle to each other, essentially at right angles to each other.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

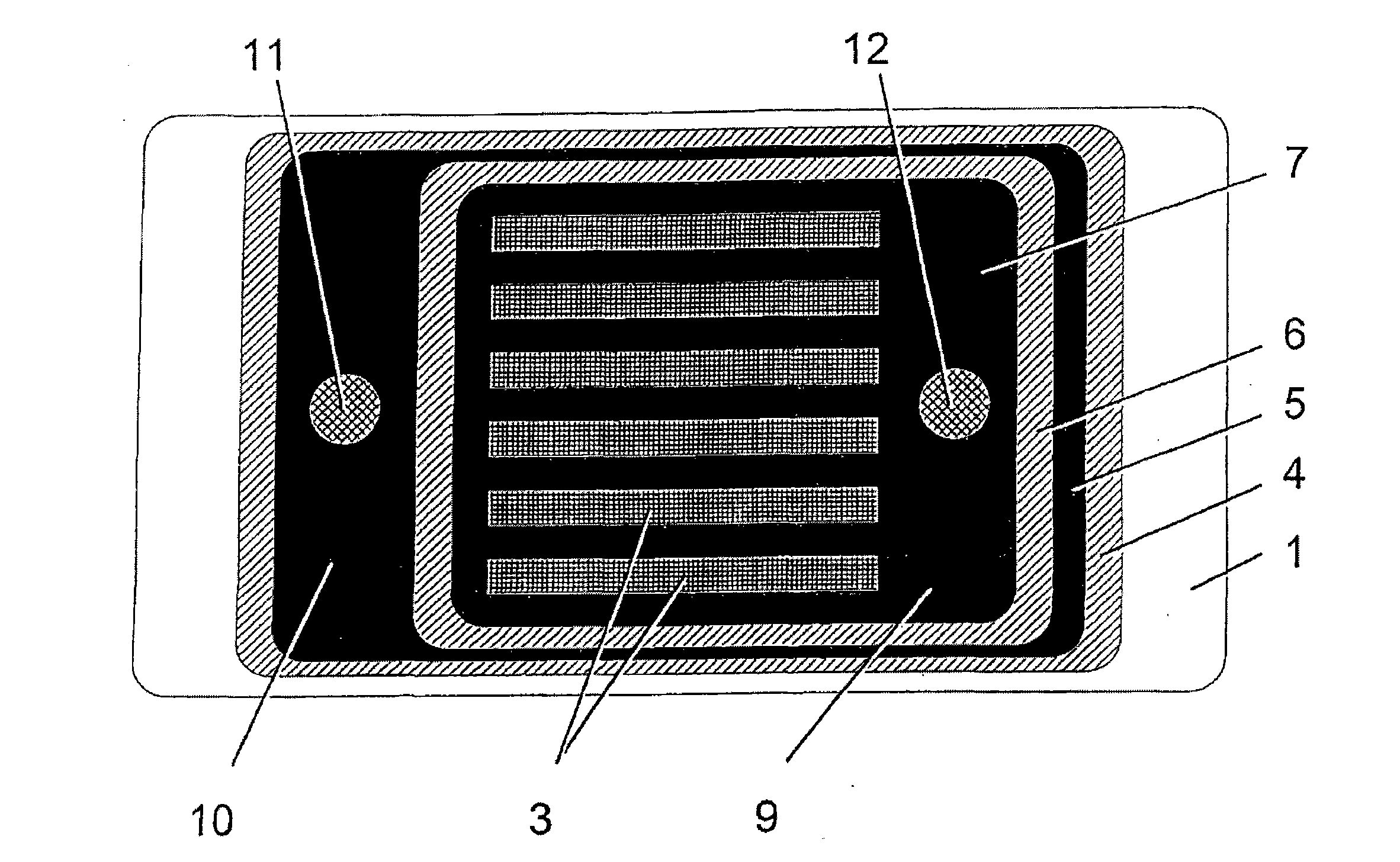

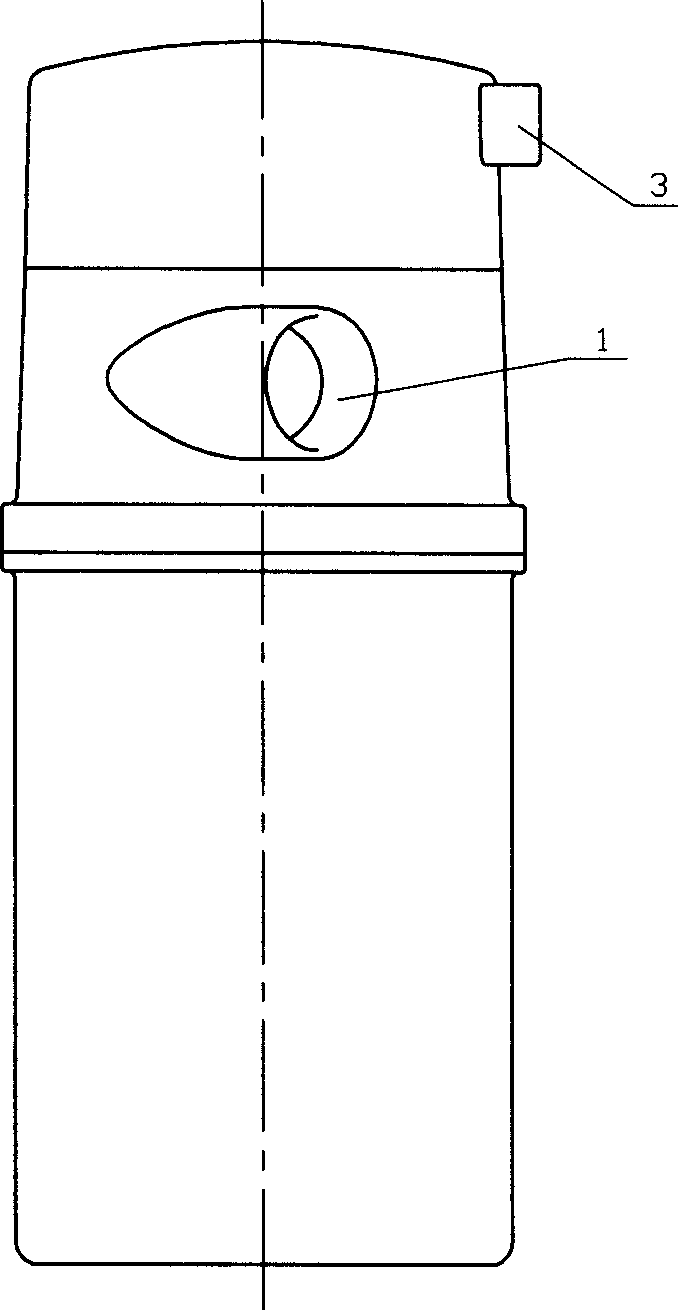

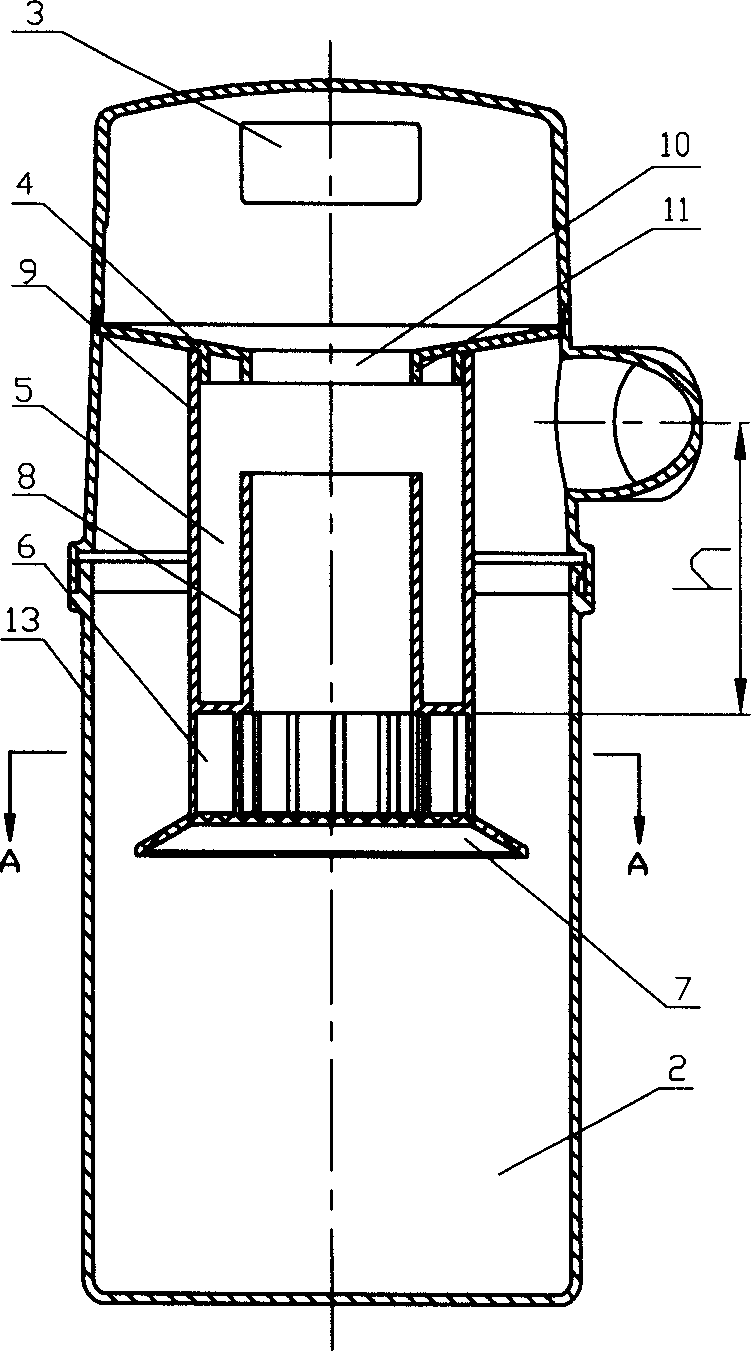

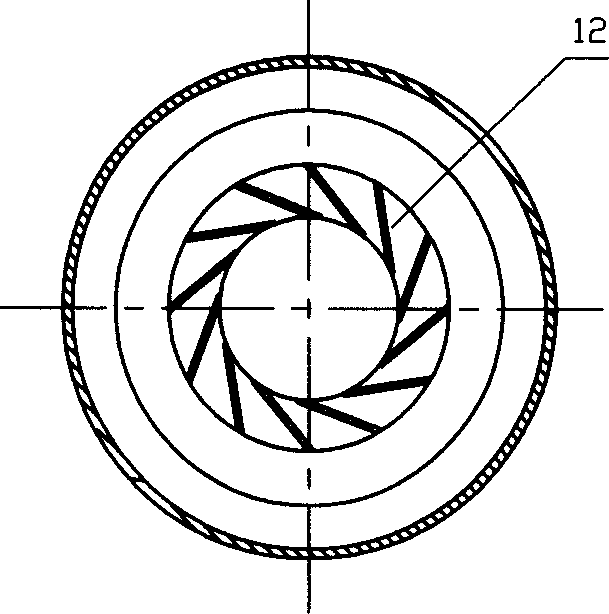

Integral twice separation dust cup of dust collector

InactiveCN1701747ACompact structureEasy to cleanSuction filtersDust collectorElectrical and Electronics engineering

The invention relates to an twice-separation dust cup of dust collector, which comprises a casing, an air outlet arranged on the casing, an air intake port in tangency with the casing circumferential wall and a segregator arranged in the casing, the segregator is provided with an air intake port with a shielding hood arranged below, the segregator is also provided with two inside and outside pipes arranged coaxially, the air intake port of the segregator is in communication with the air outlet port of the dust cup through the inner tube, the air intake port of the separator is formed by blades by ring form array, the horizontal position of the segregator's air intake port is lower than the dust cup air intake port. The outer volume of the product is substantially reduced.

Owner:王跃旦

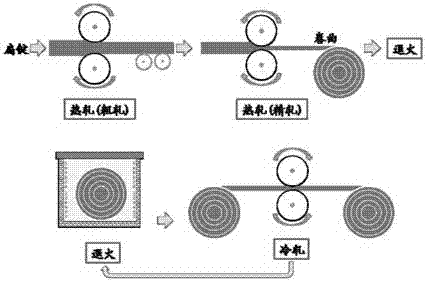

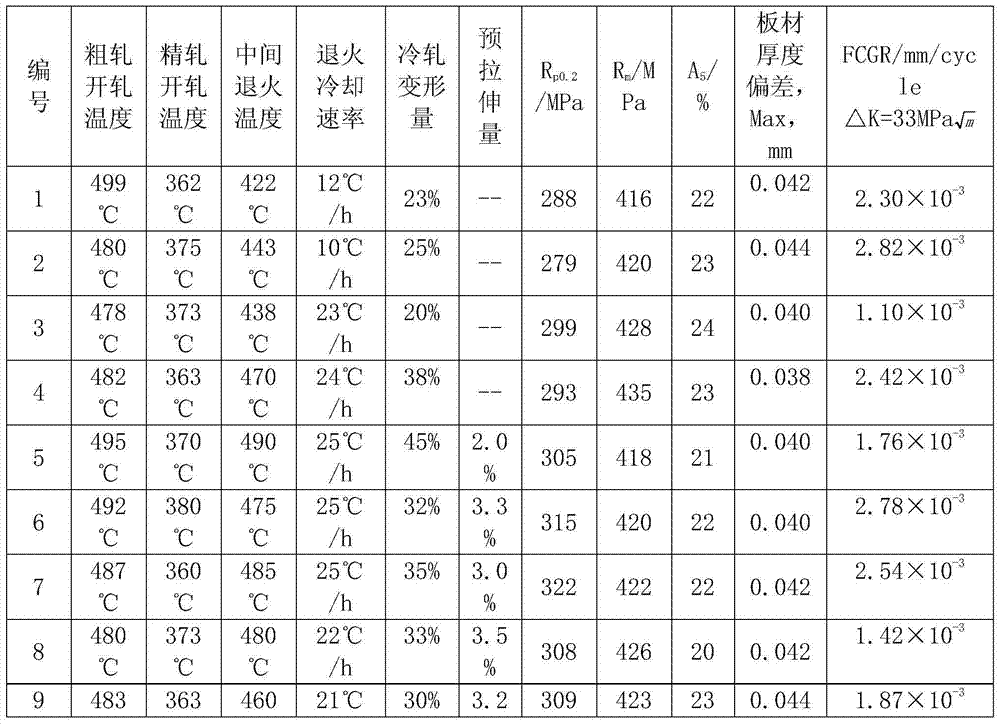

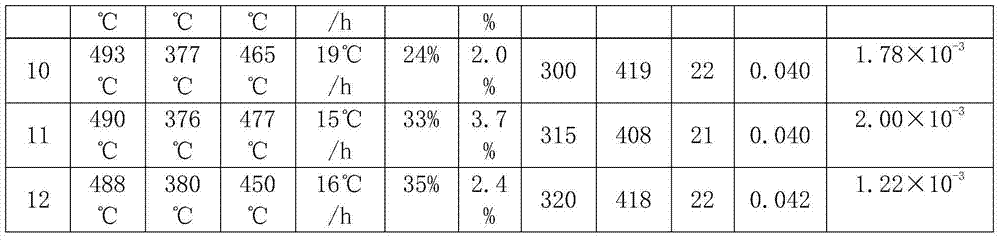

Preparation method of Al-Cu-Li-X series aluminum lithium alloy sheet

The invention discloses a preparation method of an Al-Cu-Li-X series aluminum lithium alloy sheet. The sheet prepared by the method is 0.8mm-8.0mm in thickness. The method comprises the following steps: cogging and hot-rolling homogenized slab ingots to a specified thickness and coiling; carrying out annealing treatment, uncoiling and carrying out band-type cold-rolling; carrying out intermediate annealing according to deformation during cold-rolling, thus obtaining the sheets with uniform thicknesses. The sheets can be in different states after being subjected to solution treatment, prestretching and aging treatment, so as to meet different usage requirements. Compared with the prior art, the aluminum lithium alloy sheet with high surface quality, uniform sheet size and smooth sheet shape is prepared by the method through band-type cold-rolling. The sheets can be in different states by different heat-treating processes, so as to meet usage requirements under different application conditions.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

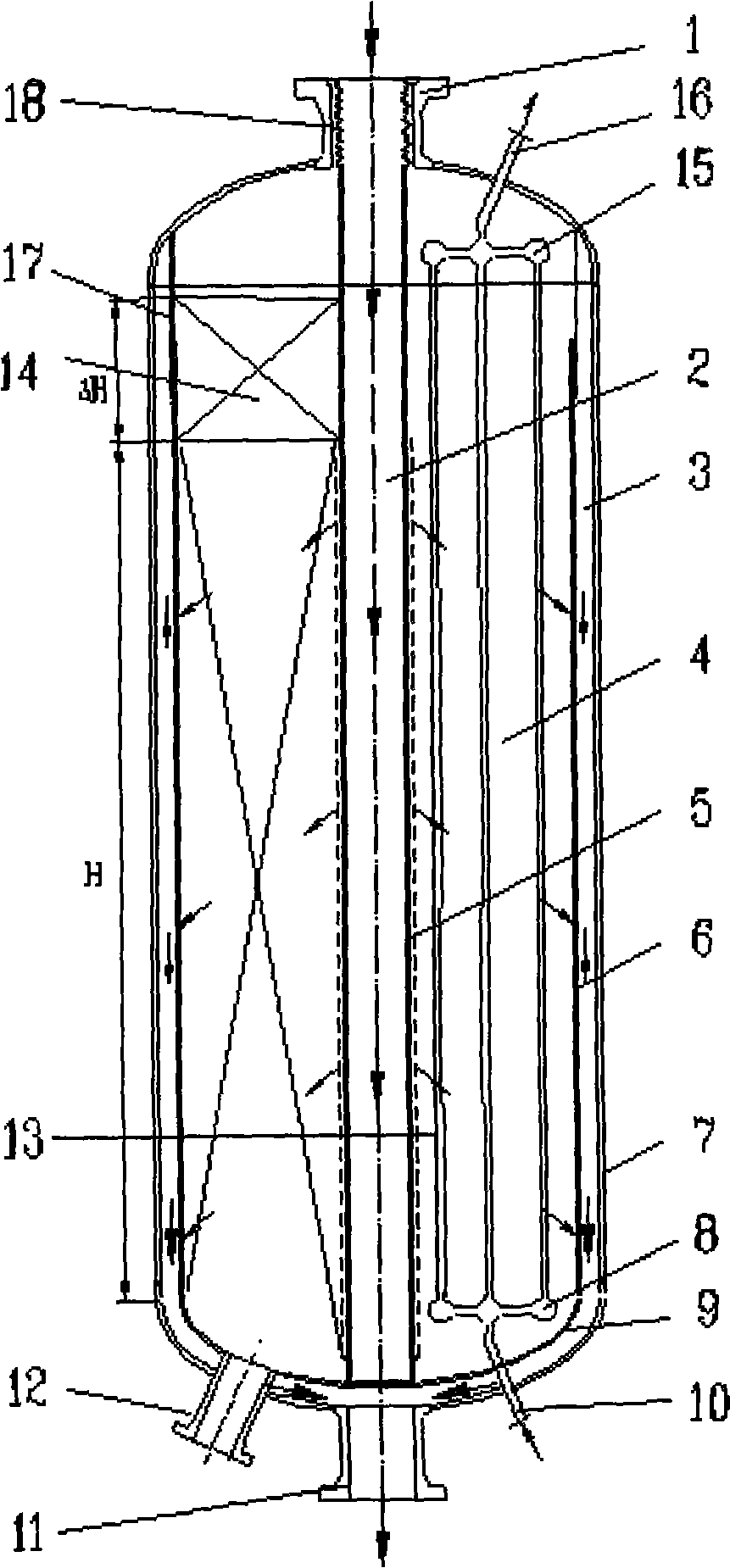

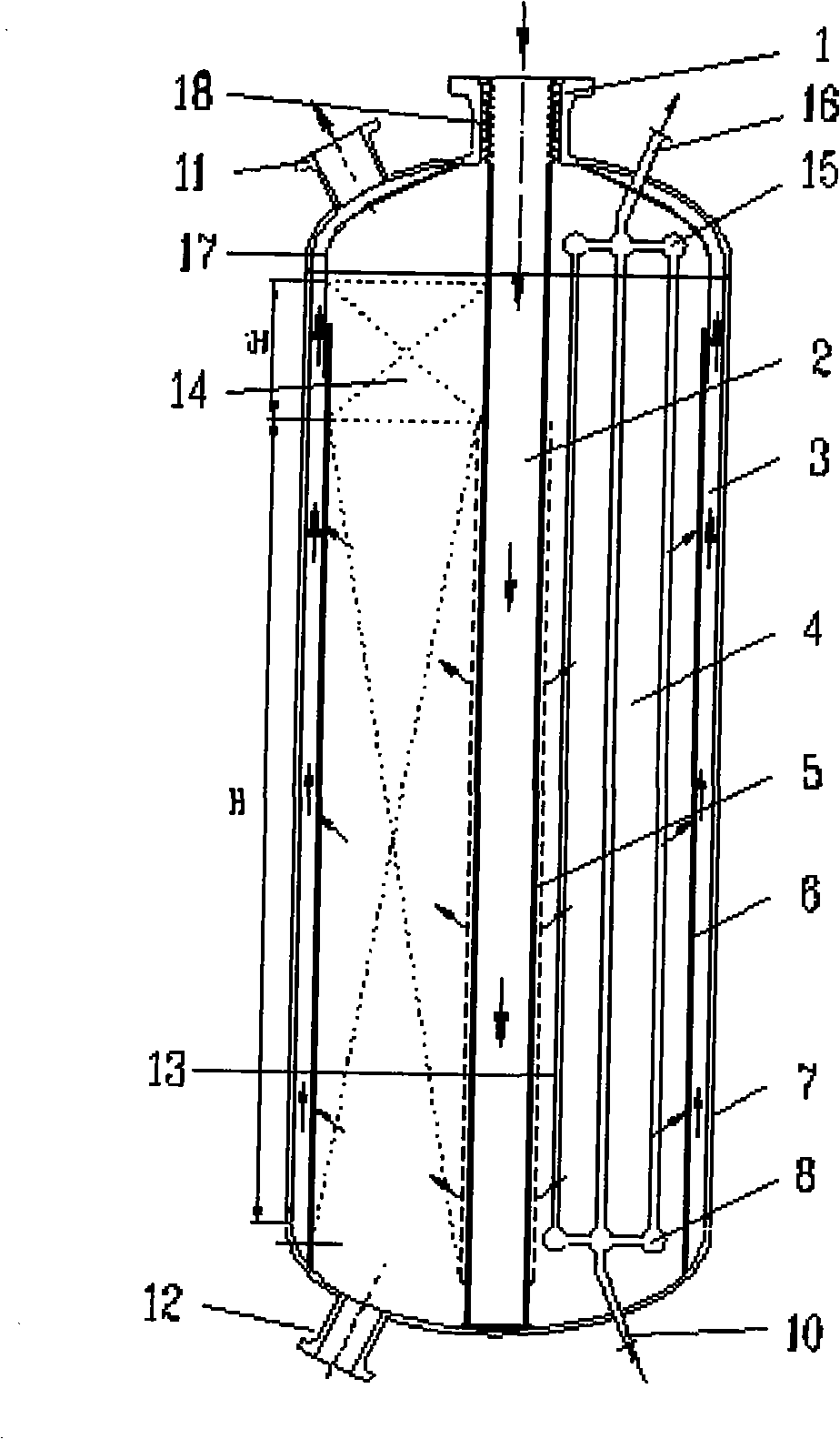

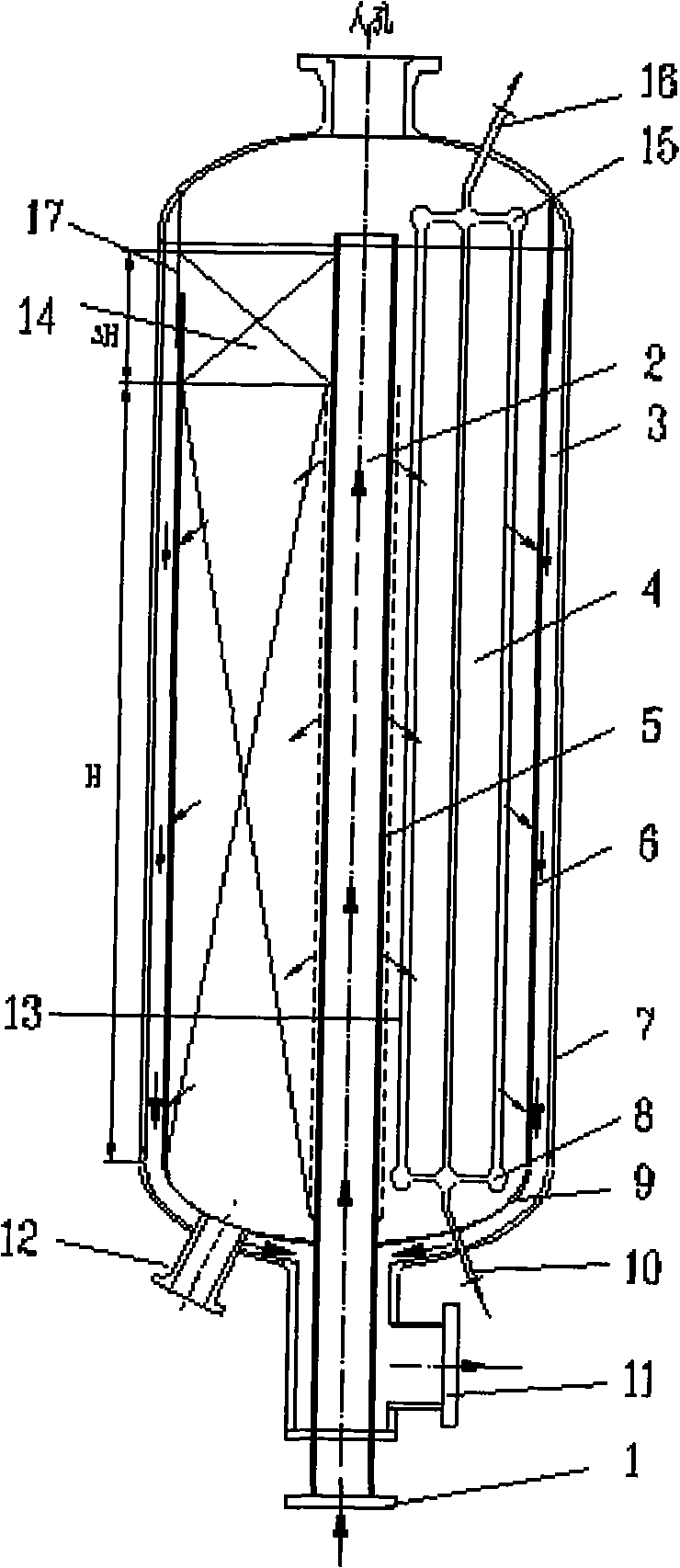

Method used for heat liberation pressurization catalytic reaction

InactiveCN101254442AImprove fill factorSuitable for large-scale processingStationary tubular conduit assembliesChemical/physical processesGas solidNuclear engineering

The invention provides a method for exothermic catalytic reaction under increased pressure and a reactor thereof. The method and the reactor are characterized in that: a round pressure vessel (7) with a catalytic bed (4) is used; a gas inlet (1) is positioned on an end cover of the vessel (7) and connected with an internal distribution drum (5) to form a shunt passage (2) for reacting gases; a gas outlet (11) is communicated with a space that is formed between the wall of the vessel (7) and an external distribution drum (6), to form a concentration passage (3) for the reacting gases, the catalytic bed (4) is defined between the external distribution drum (6) and the internal distribution drum (5) and is filled with catalysts; the reacting gases flow axially in a centrifugal manner from the internal distribution drum (5) to the external distribution drum (6). The method and the reactor have the advantages of axial and uniform distribution of the reaction gases, optimum distribution of bed temperature, high utilization rate of catalysts, and low pressure drop of fluids passing through the reactor. The invention is suitable for catalytic reactions in methanol, ammonia and dimethyl ether synthesis, as well as other exothermic gas-solid catalytic reactions under increased pressure.

Owner:EAST CHINA UNIV OF SCI & TECH

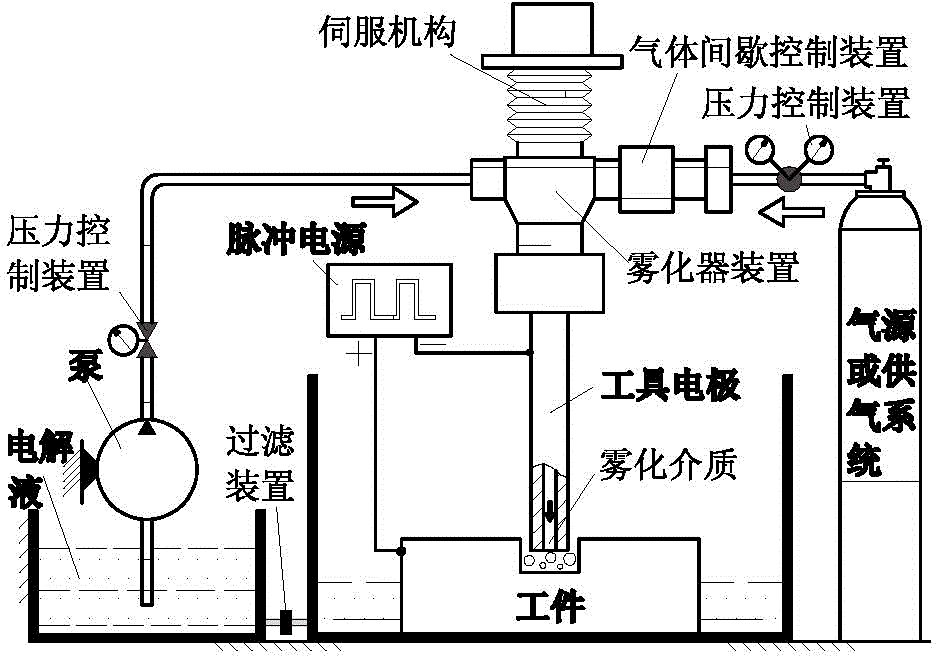

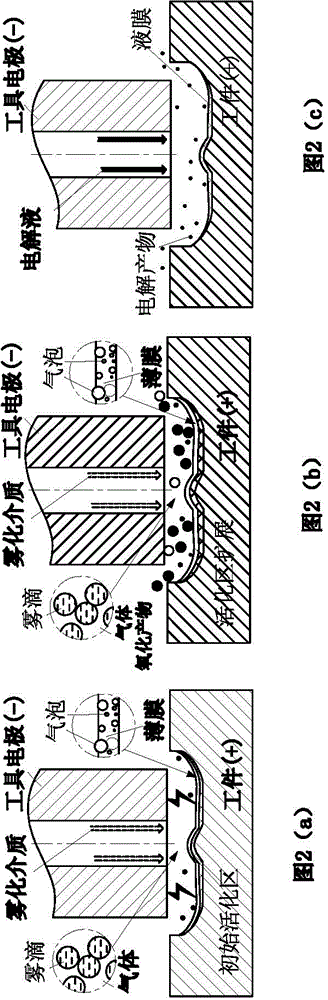

Conductivity adjustable atomizing medium electric spark discharge ablation and electrolytic combined machining method

The invention provides a conductivity adjustable atomizing medium electric spark discharge ablation and electrolytic combined machining method which is characterized in that during the electric spark induced ablation machining, an insulated working medium used by electric spark discharge is replaced by electrolyte and forms an atomizing medium with an inflammable (combustion-supporting) gas such as oxygen to be sprayed into the machining area, the aim of controlling the conductivity of the atomizing medium is achieved by adjusting the proportion of the gas and the electrolyte during the machining, and a machining manner of mainly taking discharge induced ablation machining, or discharge induced ablation and electrolytic machining, or electrolytic machining can be realized at different stages of the whole machining process based on the machining needs or stage requirements, and the machining improves the machining efficiency through ablation, or takes the machining efficiency and surface quality into account, or removes a surface degenerating layer. The aims of initial high efficiency machining based on machining needs during the whole machining process and degenerating layer reduction or removal at the end are achieved. The machining manner can be applied to milling of conductive materials and machining of deep blind holes.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

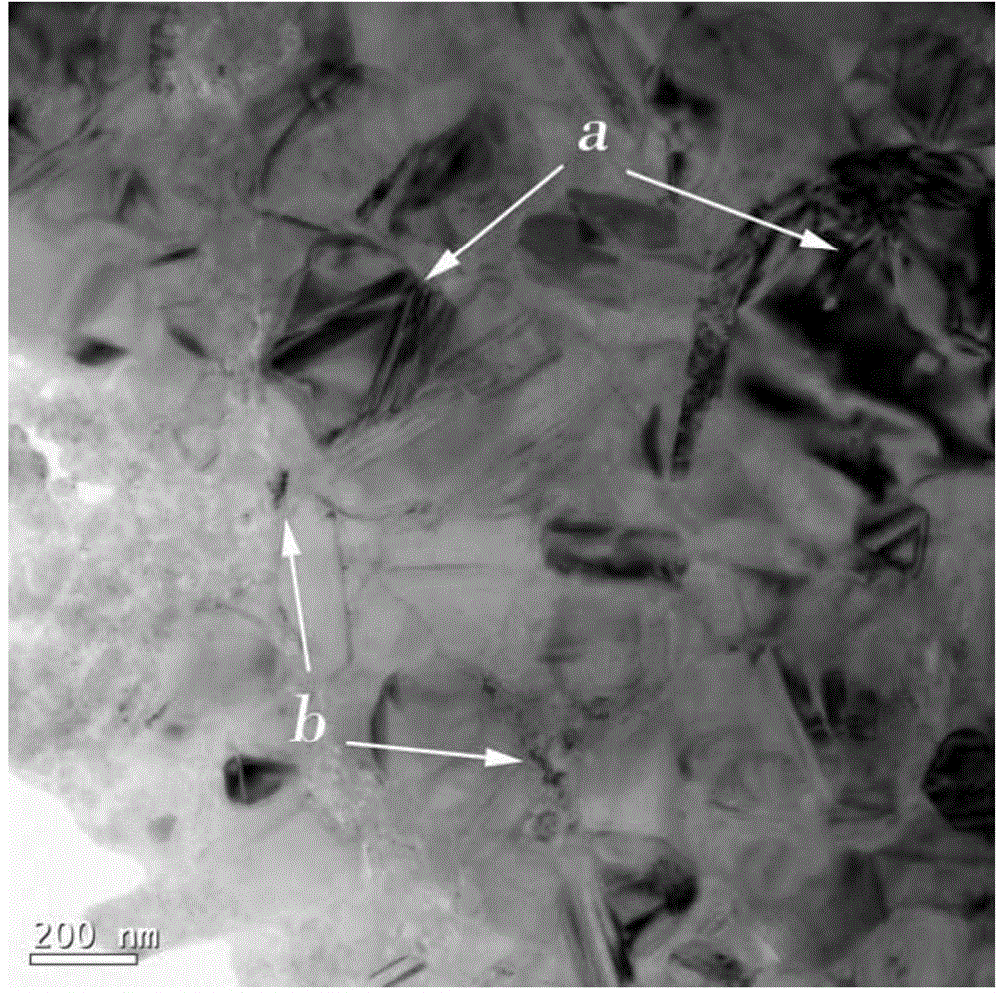

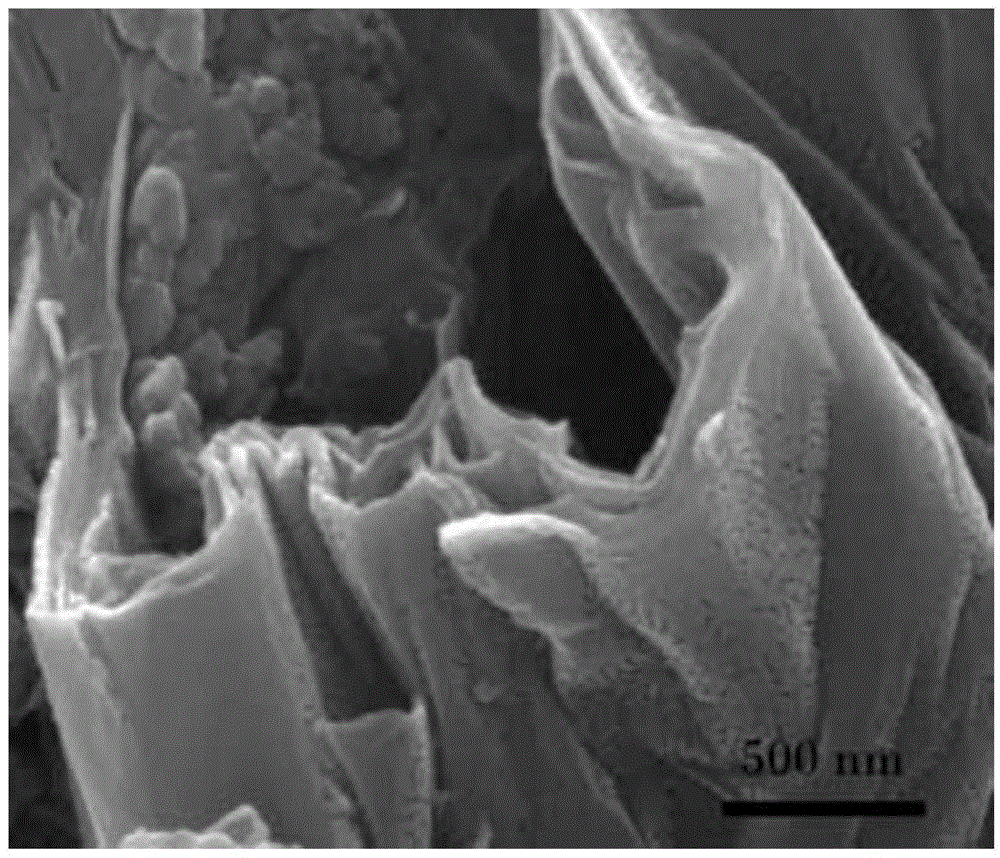

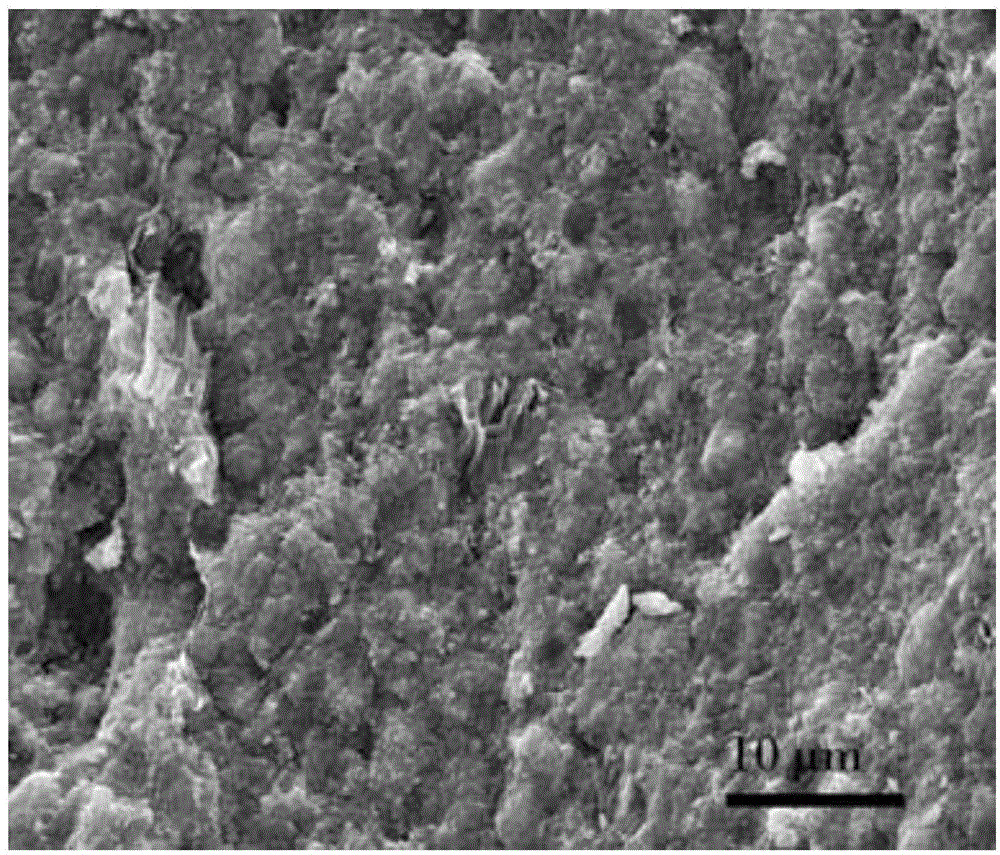

Graphene-reinforced silicon-boron-carbon-nitrogen ceramic composite material and preparation method thereof

InactiveCN104529468AImprove antioxidant capacityImprove high temperature resistanceCeramic compositeHexagonal boron nitride

The invention relates to a graphene-reinforced silicon-boron-carbon-nitrogen ceramic composite material and a preparation method thereof. The invention aims to solve the problems of low strength, poor ductility and uncertain thermal shock and ablation mechanisms in the existing silicon-boron-carbon-nitrogen ceramic composite material. The product is prepared from 90-99 parts by volume of SiBCN amorphous powder and 1-10 parts by volume of graphene. The method comprises the following steps: 1. adding silicon powder, graphite and hexagonal boron nitride into a ball mill, and carrying out ball milling in an argon protective atmosphere to obtain SiBCN amorphous powder; 2. uniformly mixing the SiBCN amorphous powder and graphene by ball milling to obtain mixed powder; and 3 carrying out discharge plasma sintering on the mixed power to obtain the graphene-reinforced silicon-boron-carbon-nitrogen ceramic composite material.

Owner:HARBIN INST OF TECH

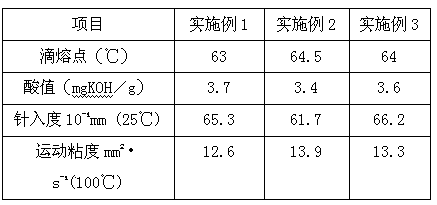

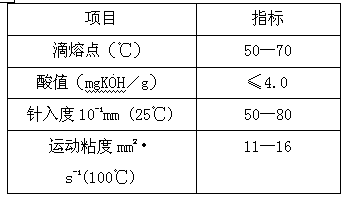

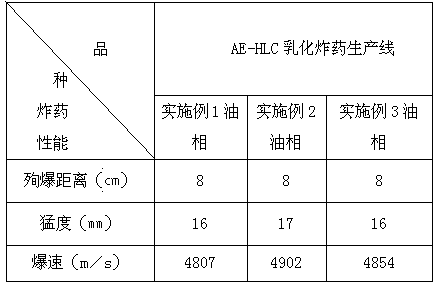

Plant type compound oil phase for emulsion explosive

ActiveCN103694068ASimple production processProduct quality is easy to controlNon-explosive/non-thermic compositionsWaxVegetable oil

The invention discloses a plant type compound oil phase for an emulsion explosive. The compound oil phase comprises main components of plant wax and plant oil, and is characterized by comprising the following materials by mass: 20%-50% of the plant wax, 10%-25% of the plant oil, 10%-25% of light dewaxing paste, 20%-35% of an emulsifier and 5%-15% of additives, wherein the total mass percentage of the materials is 100%. The compound oil phase prepared from the plant wax and the plant oil is applied to the industrial explosive production, so that a production process is simplified, and the production process quality is conveniently controlled; the compound oil phase is proper in drop melting point, acid value, needle penetration degree and kinematic viscosity, and is an ideal emulsion explosive oil phase material; the produced emulsion explosive is good in explosion performance; the plant oil phase material is clean, environment-friendly, low in price and highly available, and can effectively reduce the production cost; the compound oil phase used for producing the emulsion explosive has good economic and social benefits and is convenient for industrialization production and application.

Owner:FUZHOU GUOTAI COMPOSITE MATERIAL CO LTD

Method for producing formaldehyde-free low-density crop straw grain board

ActiveCN101037000ALow densityHave mechanical strengthClimate change adaptationDomestic articlesVolumetric Mass DensityParticle board

A making method of crop straw particle board of low density without formaldehyde includes crushing, taking materials and weighting by balance, paving, stirring of spray glue, prepressing and hot-pressing of the crop straw, characterized in that: the crop straw should crush to particle state of less than or equal to 4.75mm, after calculating weight of straw particle with density of 250-400kg / m3 based on thickness of board and once machining area of apparatus, taking materials by weight of following components, the hot-pressing temperature is 130-180 DEG C, through two times of increasing and reducing press hot set from high to low, at first time the press is increased to 90-110 bar during 10 seconds, keeping for 25 seconds, then the press is reduced to 40-60 bar, then second increasing press to 80-100 bar, keeping for 30 seconds, then three times of reducing press by speed of 1-3 bar / second, at last stabilizing the press in 10-20 bar, keeping for 10 seconds. The invention settles technological problem of hot-pressing mode and material compositions of artificial plate with production density less than 400kg / m3, secondly settles technological problem of spray glue.

Owner:SHANGHAI COMPAK ENVIRONMENTAL PROTECTION EQUIP CO LTD

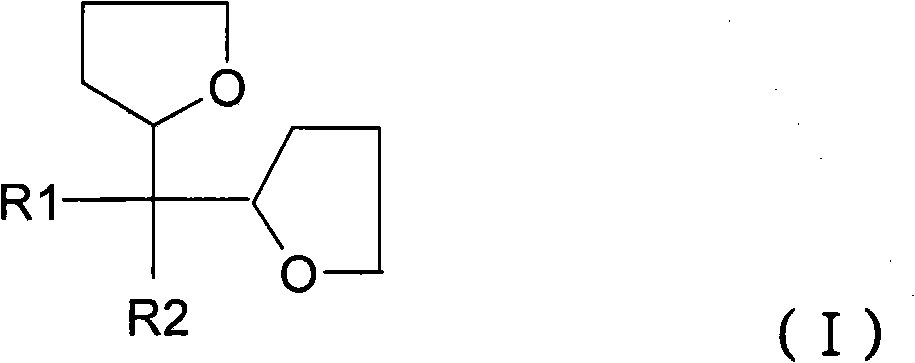

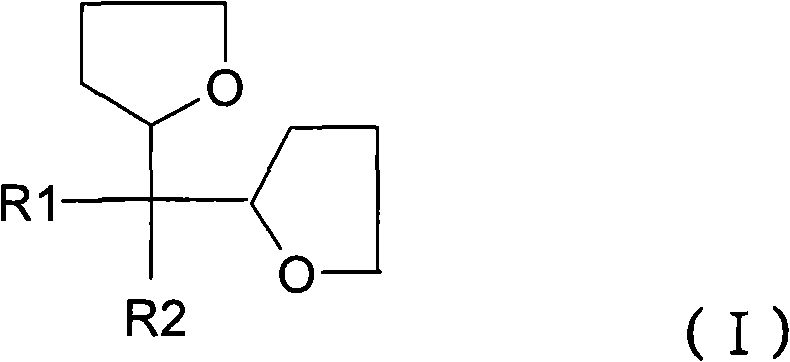

Terpolymer rubber with medium/high side group content and preparation method and applications thereof

ActiveCN102372823AImprove wet skid resistanceReduce rolling resistanceSpecial tyresRolling resistance optimizationPolymer scienceRolling resistance

The invention discloses terpolymer rubber with medium / high side group content and a preparation method and applications thereof. The invention relates to a method which uses a bistetrahydrofuran compound as the structural modifier to synthesize monovinylarene / conjugated diene 1 / conjugated diene 2 terpolymer rubber through solution polymerization, the monovinylarene / conjugated diene 1 / conjugated diene 2 terpolymer rubber synthesized by the method and products based on the copolymer rubber, such as tires. The copolymer rubber synthesized by the method has good wet-skid resistance and low rolling resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacturing method for large-size seamless micro-nano soft mold

ActiveCN108162425ALow cost manufacturingReduce manufacturing costAdditive manufacturing apparatusPhotomechanical apparatusMicro nanoHot melt

The invention discloses manufacturing method for a large-size seamless micro-nano soft mold. The manufacturing method comprises the following steps that 1, a base plate is pretreated; 2, power jet printing on a hot melt electric fluid to manufacture a sacrificial structure, and according to pattern structure of the micro-nano mold to be manufactured, the sacrificial structure which is opposite tothe mold is manufactured; 3, graph replication and transfer are carried out, wherein a spin coating or pouring process is adopted, liquid soft mold material uniformly coats on the sacrificial structure, and the liquid soft mold material is pre-cured; 4, demolding is carried out, wherein a combination body of a soft mold and the printed sacrificial structure is completed separated from the base plate so as to obtain the composite soft die; and 5, post-treatment is carried out on the composite soft mold. According to the manufacturing method, the technical advantages of power jet printing on thehot melt electric fluid and a casting replication transfer process are combined, so that manufacturing of the large-size seamless micro-nano soft mold is realized, and the manufacturing method particularly has the unique advantage that the rapid and low-cost manufacturing of the meter-scale seamless micro-nano composite soft mold can be achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

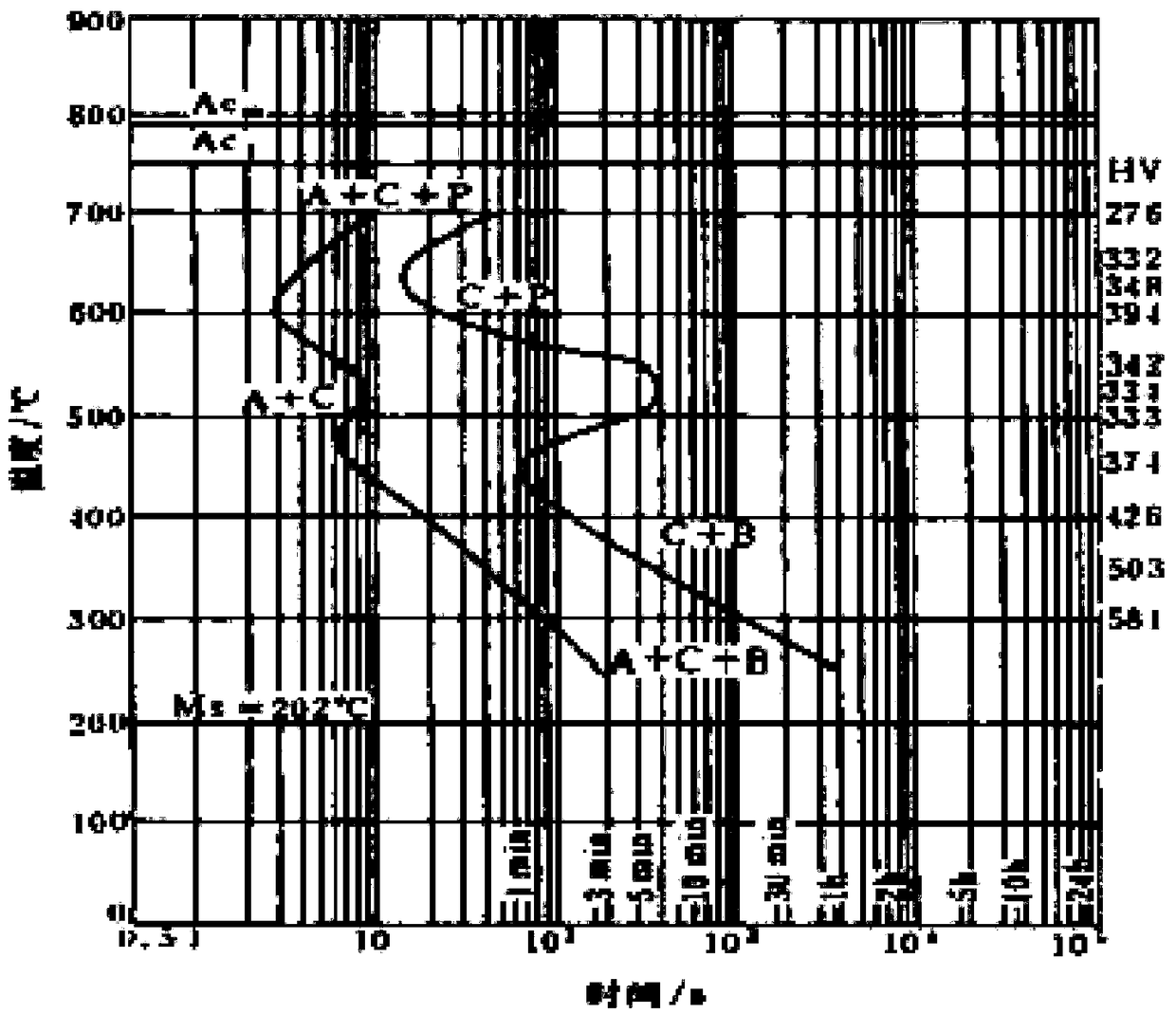

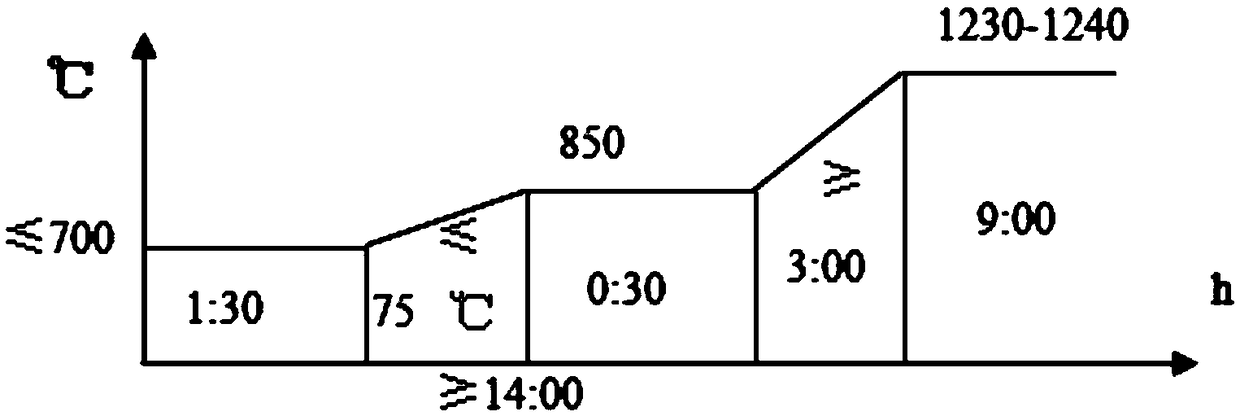

Rare earth microalloying bearing steel and preparation method thereof

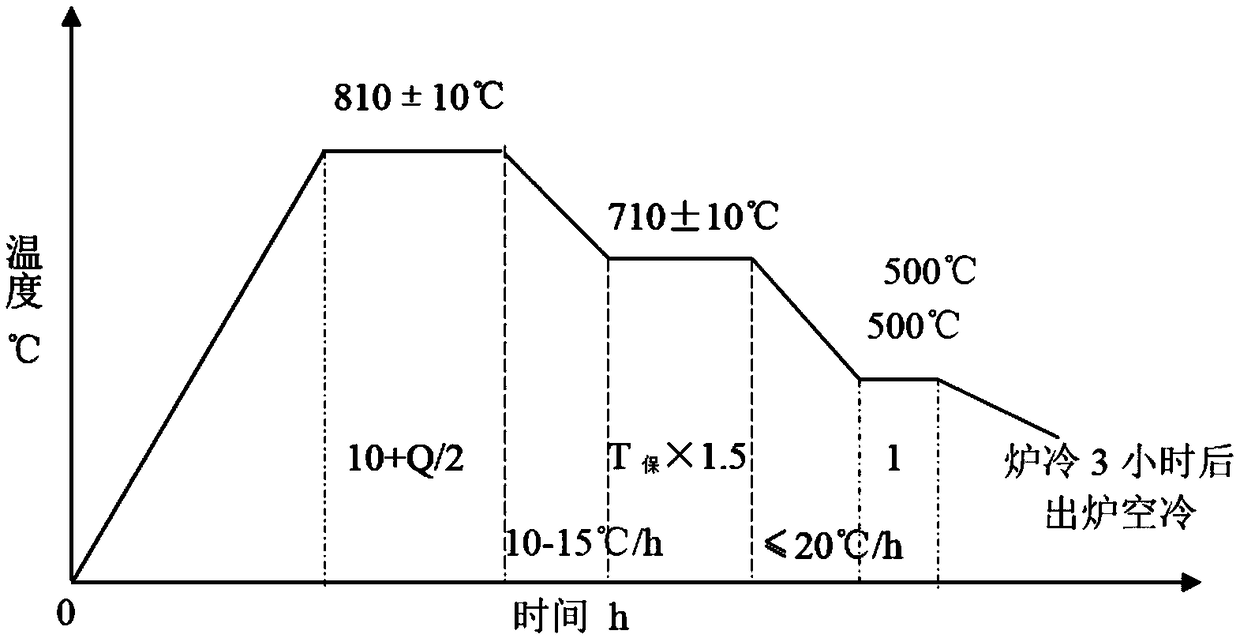

ActiveCN109457081AHigh elastic limitImprove hardenabilityFurnace typesHeat treatment furnacesSlow coolingMaterials science

The invention discloses rare earth microalloying bearing steel and a preparation method thereof and belongs to the technical field of bearing steel manufacturing. According to the technical aim, the performance of the bearing steel is improved. According to the rare earth microalloying bearing steel, converter, LF-RH refining and square billet continuous casting are carried out, electroslag remelting is carried out after scaling of a prepared continuous casting billet, then cover cooling and pit cooling are carried out, and then primary heating rolling cogging is carried out; after annealing or slow cooling is carried out, checking and cleaning are carried out, and a primary rolled steel billet is prepared and subjected to secondary heating rolling; and after stack cooling or slow coolingis carried out, a secondary rolled steel billet is prepared and subjected to spheroidizing annealing, straightening, polishing or scaling, flaw detection, cleaning and checking are carried out, and then the rare earth microalloying bearing steel is prepared. The content design ingredient of Nb ranges from 0.010% to 0.45%, and the rare earth microalloying bearing steel is suitable for being used for manufacturing various bearing rings and rolling elements and roller pins within a wide size range.

Owner:建龙北满特殊钢有限责任公司

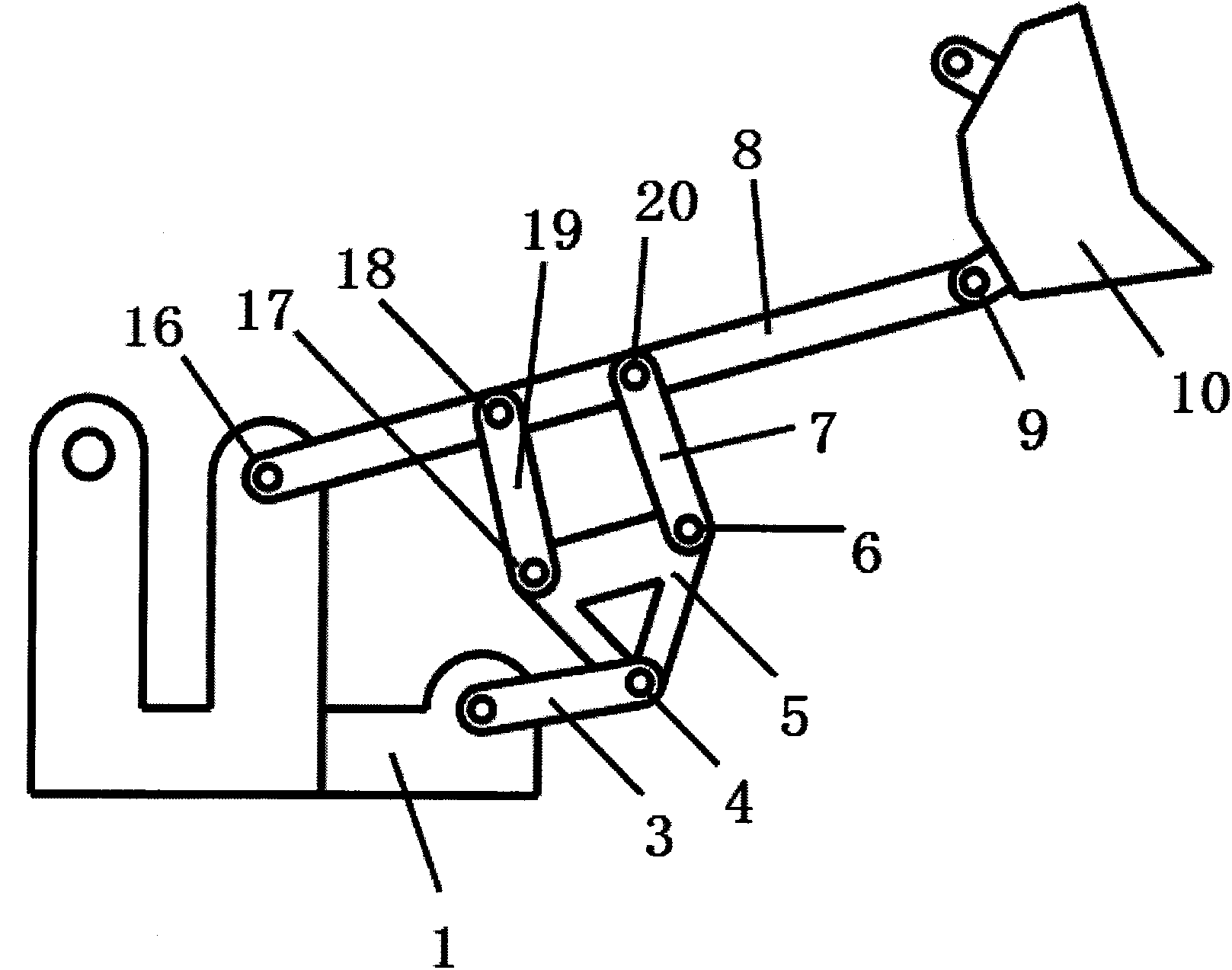

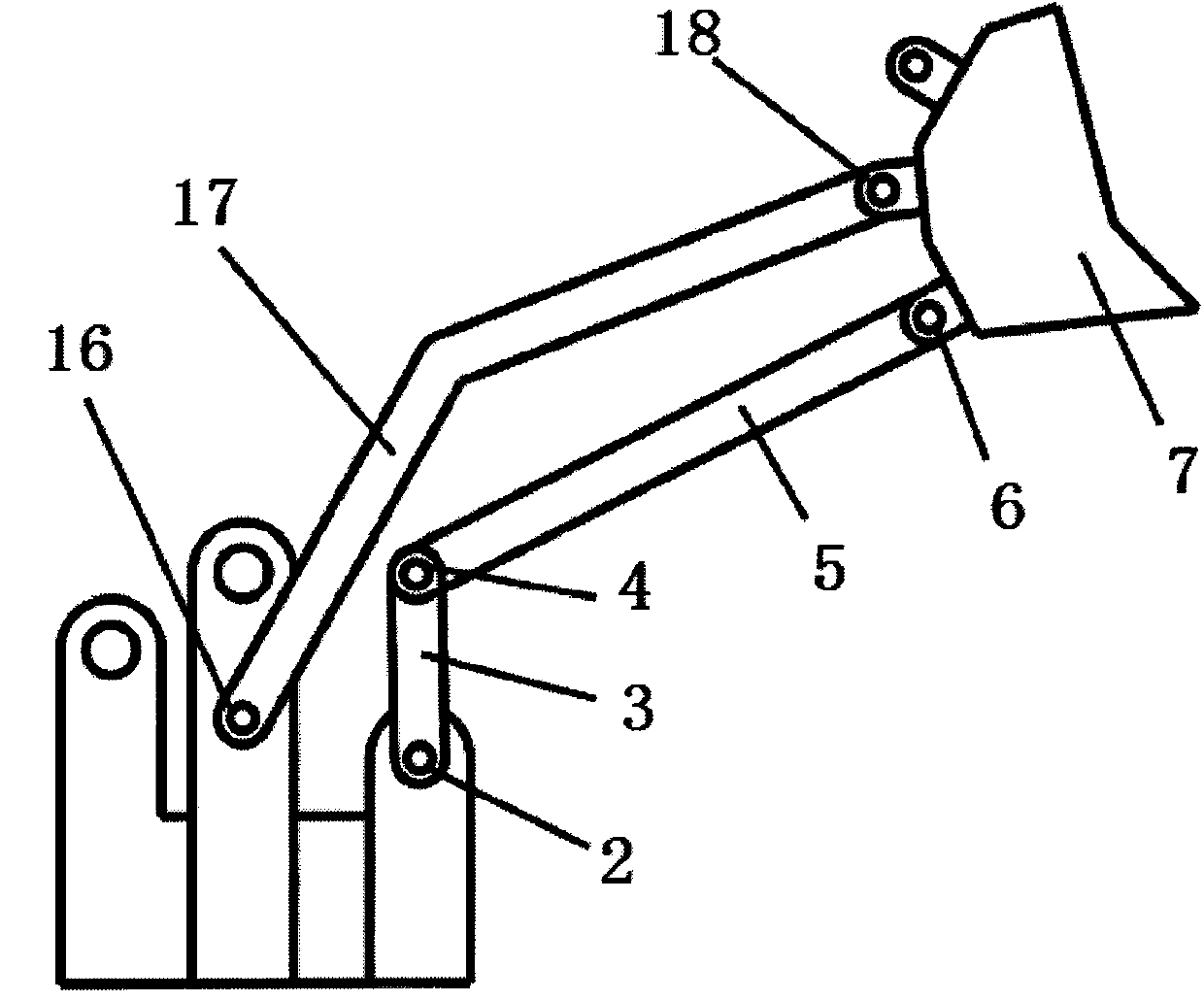

Large-rigidity multi-connecting-rod controllable mechanical loading mechanism

InactiveCN103726524AImprove mechanical propertiesSuitable designMechanical machines/dredgersEngineeringMechanical engineering

A large-rigidity multi-connecting-rod controllable mechanical loading mechanism comprises a frame, a movable arm control branch chain and a bucket control branch chain. The movable arm control branch chain is controlled by a first drive rod to perform movable arm ascending or descending. The bucket control branch chain is controlled by a second drive rod to control turning of a bucket. By cooperation of the movable arm control branch chain and the bucket control branch chain, loading operation can be completed. Rods of the mechanical loading mechanism are connected through rotating pairs, and the defects that traditional total-hydraulic loading mechanisms containing moving pairs are high in manufacturing cost, poor in reliability, high in maintenance cost and the like are overcome. Compared with other controllable mechanical loading mechanisms, the loading mechanism is compact in structure, high in rigidity, and good in reliability and dynamic stability by using the novel structure with excellent kinematic and dynamic performance.

Owner:GUANGXI UNIV

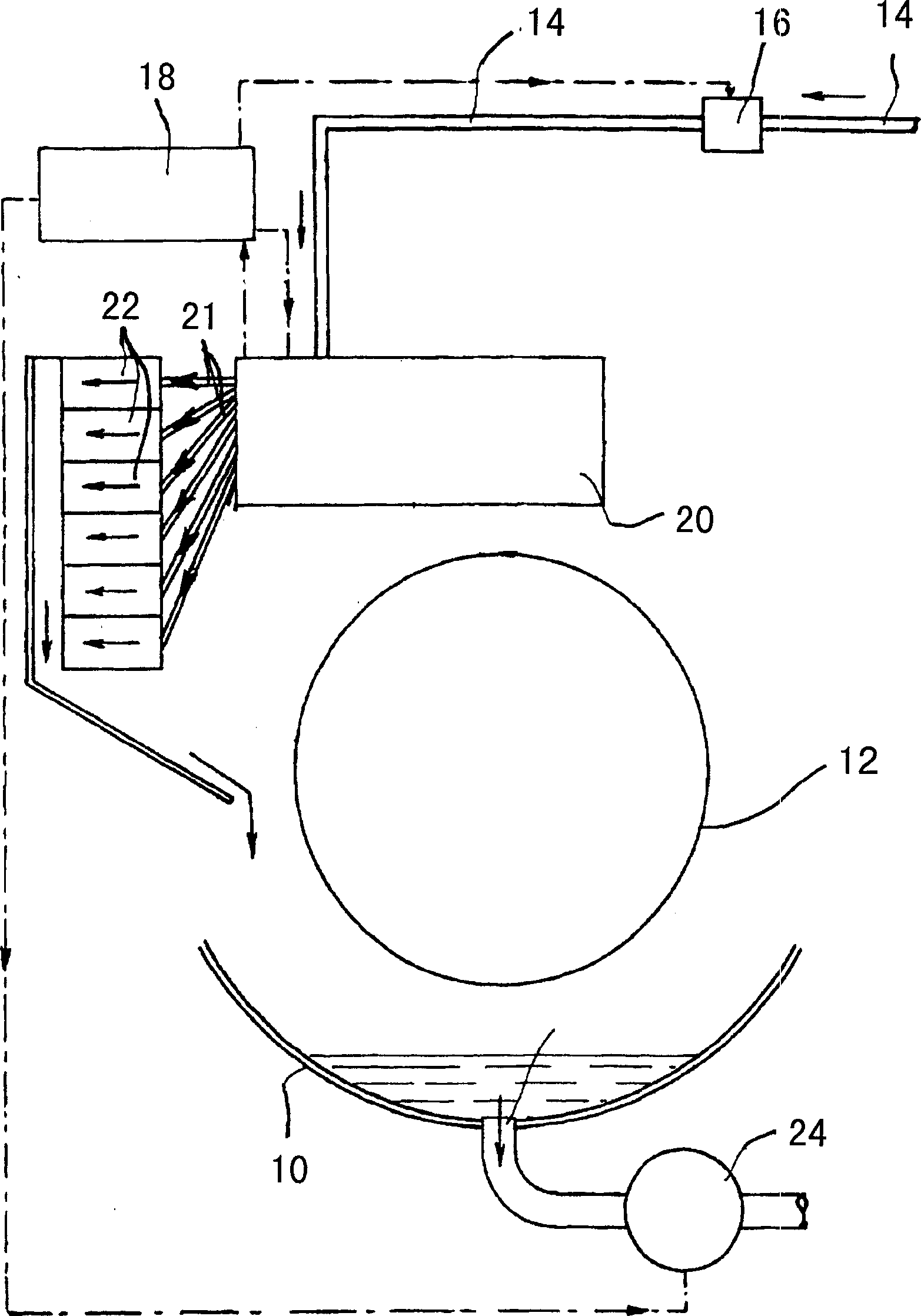

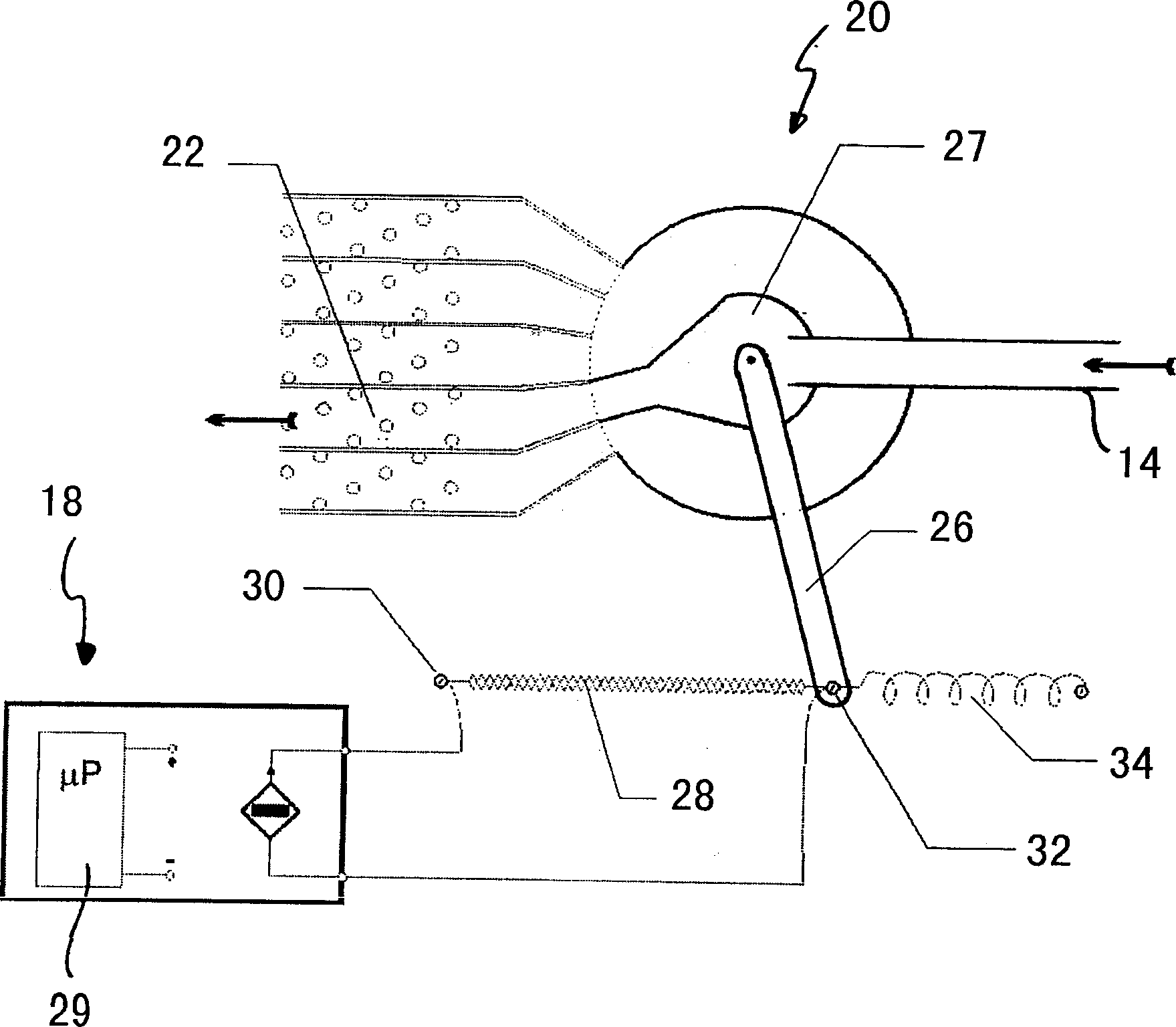

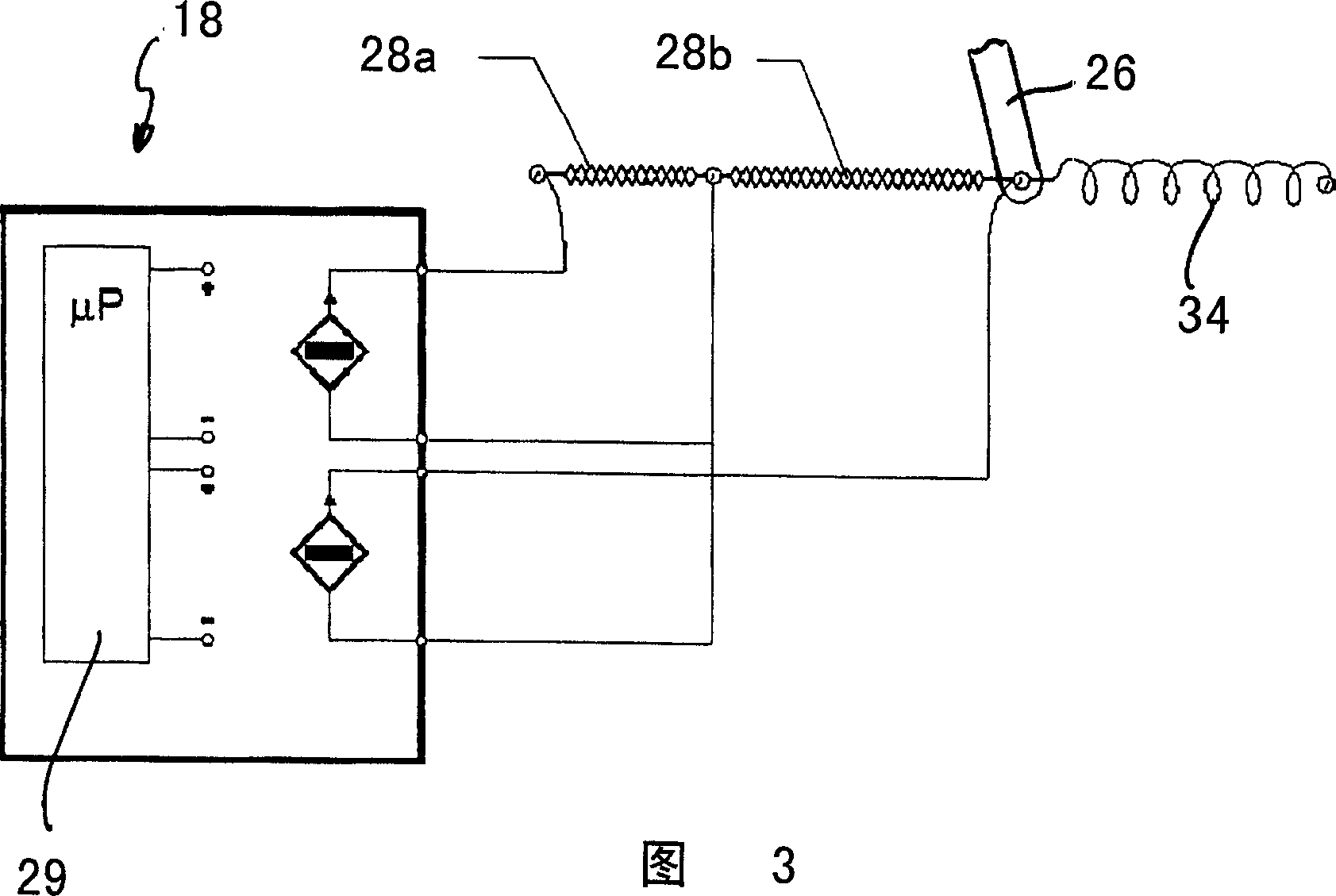

Water supply device for automatic washing machine or dish washing machine

InactiveCN1408935AWork reliablyNo noiseOther washing machinesTextiles and paperShape-memory alloyEngineering

A water distributor (20) for an automatic laundry or dishwashing machine, comprises a water inlet (14, 21) that is controllable by a programming device (18) of the machine and a movable element (26, 27) controllable by said programming device (18) which serves for supplying water to a predetermined detergent dispenser (22) for carrying a selected detergent towards the washing tub (10) according to the washing programme of the machine. The movable element (26, 27) is driven through a shape memory alloy wire (28, 28a, 28b, 28c) electrically connected to a drive circuit that is part of the programming device.

Owner:WHIRLPOOL CORP

PCB (Polychlorinated Biphenyl) acidic etching solution

The invention discloses a PCB (Polychlorinated Biphenyl) acidic etching solution which comprises the following components: 130-180 g / L of etching mother liquid copper, 120-200 g / L of hydrochloric acid (the concentration of the hydrochloric acid is 30%-38%), 150-250 g / L of oxidizing agents, 120-250 g / L of industrial salt, 0.5-15 g / L of stabilizing agents, 5-30 g / L of accelerating agents, 0.05-0.2 g / L of buffering agents and the balance of water. According to the PCB acidic etching solution, the acid value of the hydrochloric acid can be controlled to be less than 1.8 N and is greatly lower than the acid value less than 2.5 N in the prior art; the etching uniformity can reach more than 90%; and the etching factor is more than 3.5, so that the accuracy of an etching route figure and the stability of the etching solution are effectively ensured.

Owner:长沙牧泰莱电路技术有限公司

Bamboo powder composite material and preparation method and application thereof

The invention provides a bamboo powder composite material, which is characterized by comprising the following components in part by weight: 30 to 60 parts of bamboo powder, 40 to 70 parts of melamine resin powder and 3 to 12 parts of hot melt adhesive powder, wherein the ratio of the bamboo powder to the hot melt adhesive powder is 10:1-2. The invention also provides a method for preparing the composite material, which comprises the following steps of: (1) preparing raw materials; (2) pretreating the raw materials; and (3) mixing the pretreated materials. The invention also provides a method for preparing a product of the composite material, which comprises the following steps of: (4) prefabricating a mold; (5) filling the composite material into the mold; (6) performing die casting on the composite material; (7) cooling the die-cast material; and (8) demolding the cooled material. The invention also provides application of the product in the field of manufacturing of sound boxes and the like. The bamboo powder composite material provided by the invention has high bamboo powder content and reasonable preparation process. The product can be particularly applied in specific fields and is in accordance with the concept of waste utilization, environmental friendliness, energy conservation and green production.

Owner:陈俊珂

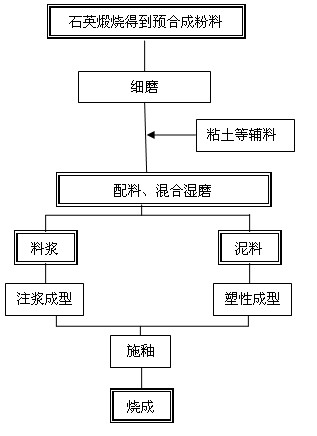

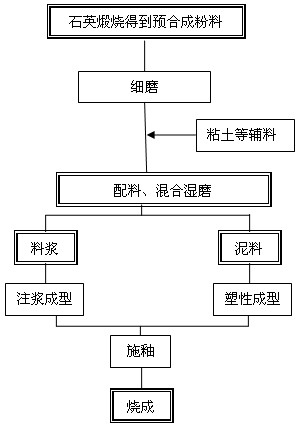

Ceramic manufacturing method using quartz as matrix material and product

The invention discloses a ceramic manufacturing method using quartz as a matrix material and a product. Silicon dioxide is used as the matrix material; aluminum oxide, basic oxide and magnesium oxide are used as auxiliary materials; and the ceramic comprises the following materials in part by weight: 90 to 94 percent of silicon dioxide, 3 to 6 percent of aluminum oxide, 0.5 to 1.5 percent of basic oxide, 0.2 to 1 percent of magnesium oxide and the balance of impurities. The method comprises the following steps of: calcining the silicon dioxide serving as the matrix material to obtain pre-synthesized powder, wherein the beta-quartz is converted into alpha-quartz by crystal transfer in the calcining process; grinding the obtained pre-synthesized powder, wherein the granularity distribution of the ground pre-synthesized powder meets certain requirements; weighing and proportioning the ground pre-synthesized powder and auxiliary materials in a ratio, performing wet milling in a ball mill to obtain slurry, and molding the slurry to obtain a daily ceramic blank; and preparing a ceramic product by the processes of drying, glazing, temperature controlled sintering and the like.

Owner:HUNAN HUALIAN CHINA IND

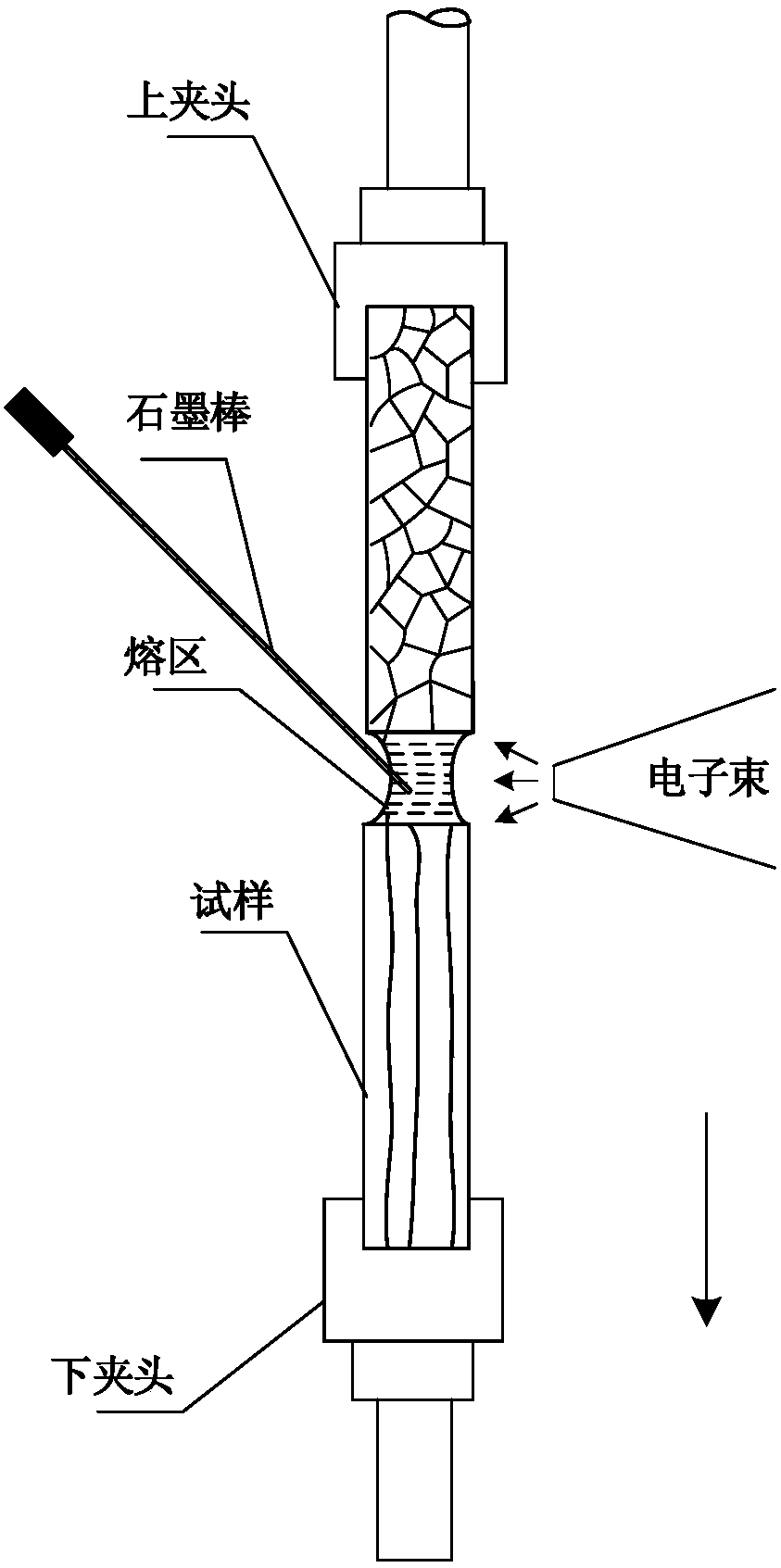

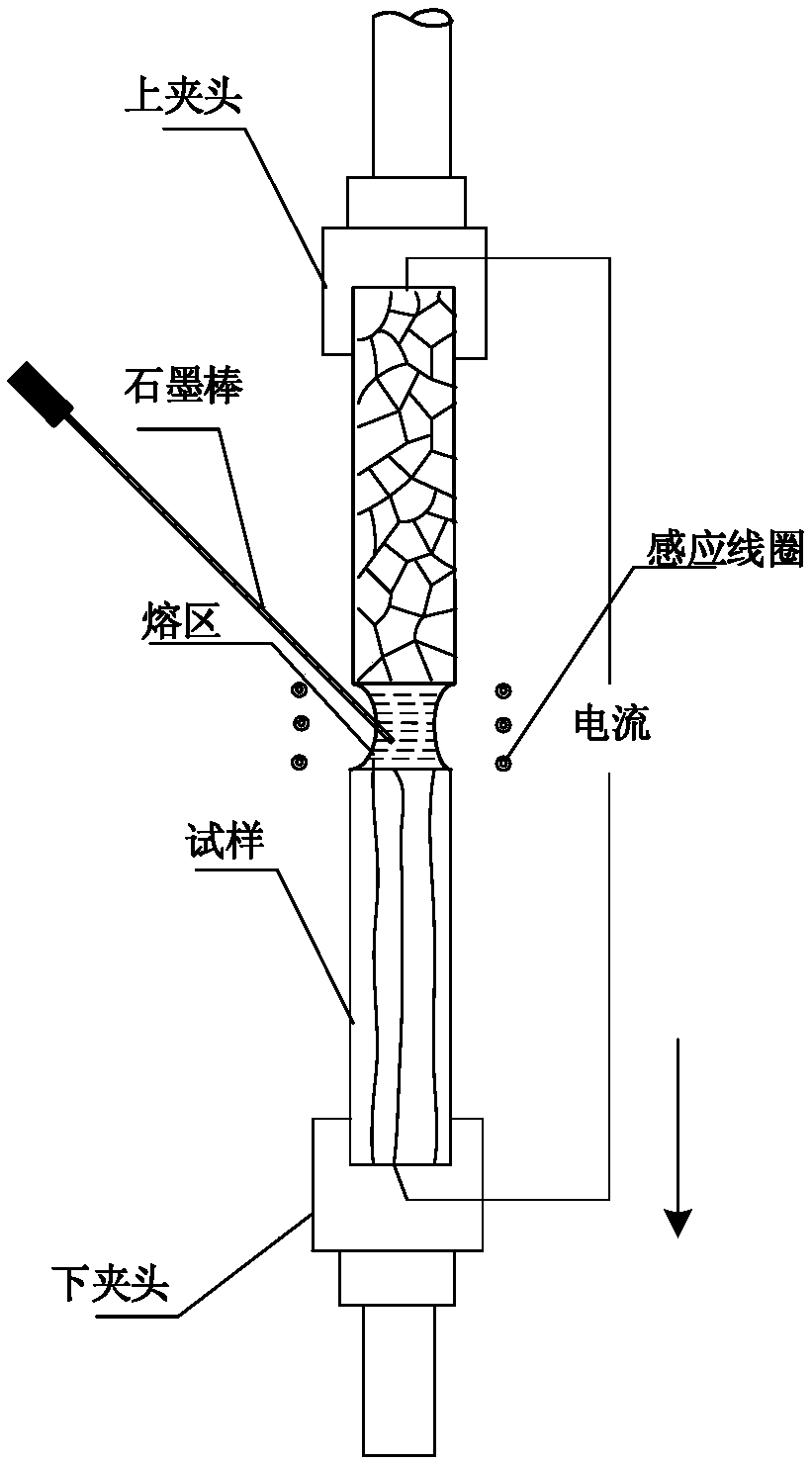

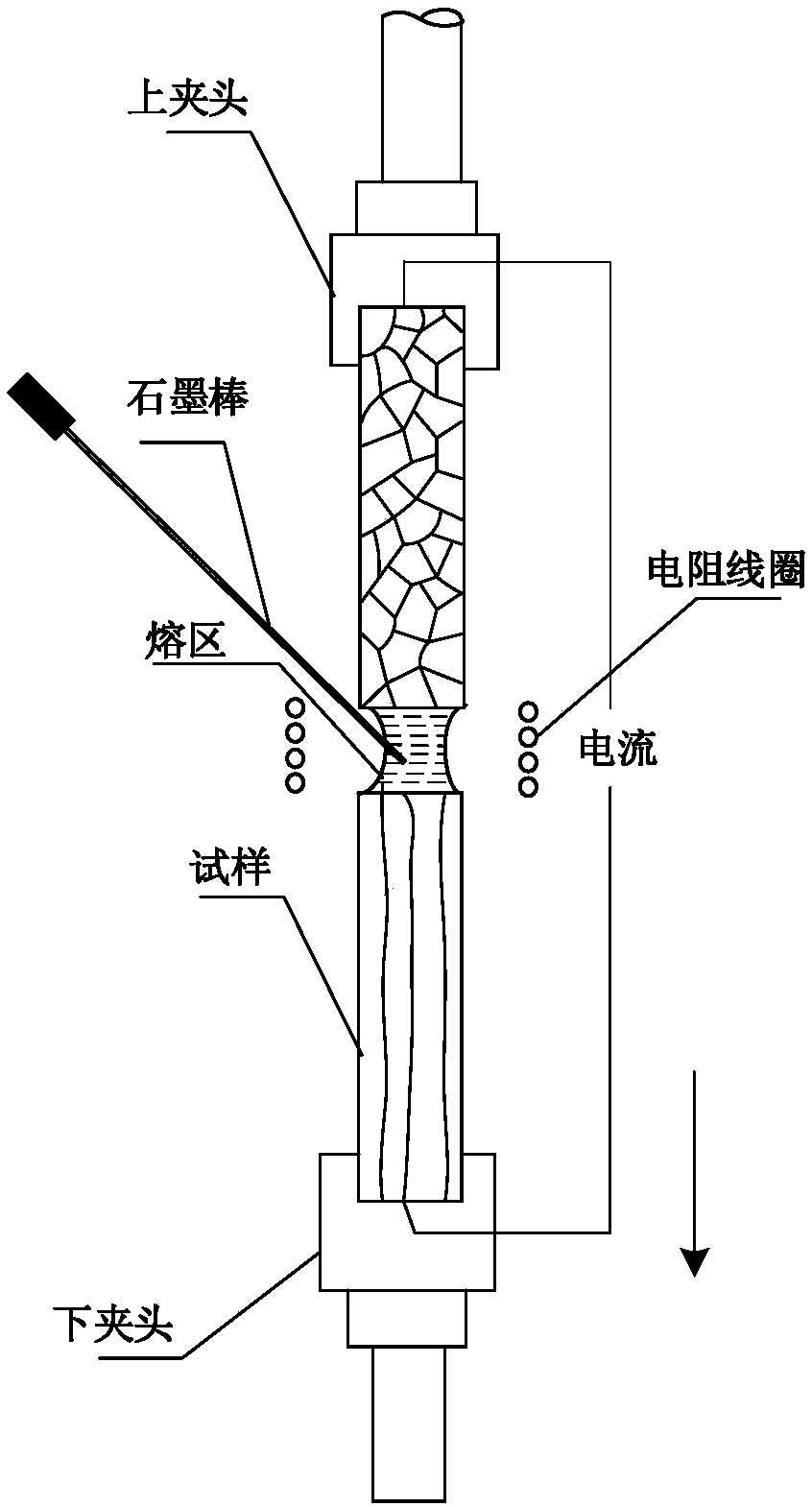

Graphene/metal composite material and preparation method thereof

The invention discloses a graphene / metal composite material and a preparation method thereof. The method comprises the following steps of: (1) weighing a metal rod and a high-purity carbon rod in percentage by mass, wherein the high-purity carbon rod accounts for 1%-30%; (2) clamping the cleaned metal rod on an upper chuck and a lower chuck of a withdrawing system of a directional solidification furnace adopting a floating zone method, clamping the high-purity carbon rod on a clamp beside the withdrawing system, and enabling the bottom end of the high-purity carbon rod to be in contact with amelting zone of the metal rod; and (3) performing vacuum-pumping on the directional solidification furnace adopting the floating zone method, performing directional solidification on the metal rod, controlling length of a melting zone to be 1-50 mm, moving the metal rod from top to bottom at a rate of 1-5000 [mu]m / s, and rotating along the axis of the withdrawing system; and enabling the bottom end of the high-purity carbon rod to be within the melting zone of the metal rod all the time. According to the graphene / metal composite material obtained by the method disclosed by the invention, carbon exists in a metal lattice in the form of graphene, and the two-phase interface is good in combination, so that conductivity of the material is favorably improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Full cone air-assisted spray nozzle assembly

ActiveCN104540597AEfficient injectionSimple structureSpray nozzlesLiquid spraying apparatusWaste managementNozzle

A pressurized air assisted liquid spray nozzle assembly having a liquid spray nozzle having a downstream discharge orifice for discharging a solid stream of liquid, an air guide mounted in surrounding relation to a downstream end of said liquid spray nozzle, and an outer nozzle body disposed in surrounding relation to said air guide. The air guide defines a first plurality of air passages for directing pressurized atomizing air transversely to liquid discharging from said liquid spray nozzle for atomizing the discharging liquid and a second plurality of air passages for directing shaping air tangentially to liquid discharging from said liquid spray nozzle for shaping the atomized liquid particles into a predetermined conical spray pattern.

Owner:SPRAYING SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com