Carbon/carbon fiber-silicon, boron, carbon and nitrogen ceramic composite material and preparation method thereof

A ceramic composite material and a silicon-boron-carbon-nitrogen technology are applied in the field of silicon-boron-carbon-nitrogen ceramic composite materials and their preparation, which can solve the problems of high cost, insignificant fiber strengthening and toughening effect, complicated preparation process, and the like, and achieve a short preparation period. , the effect of good comprehensive performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

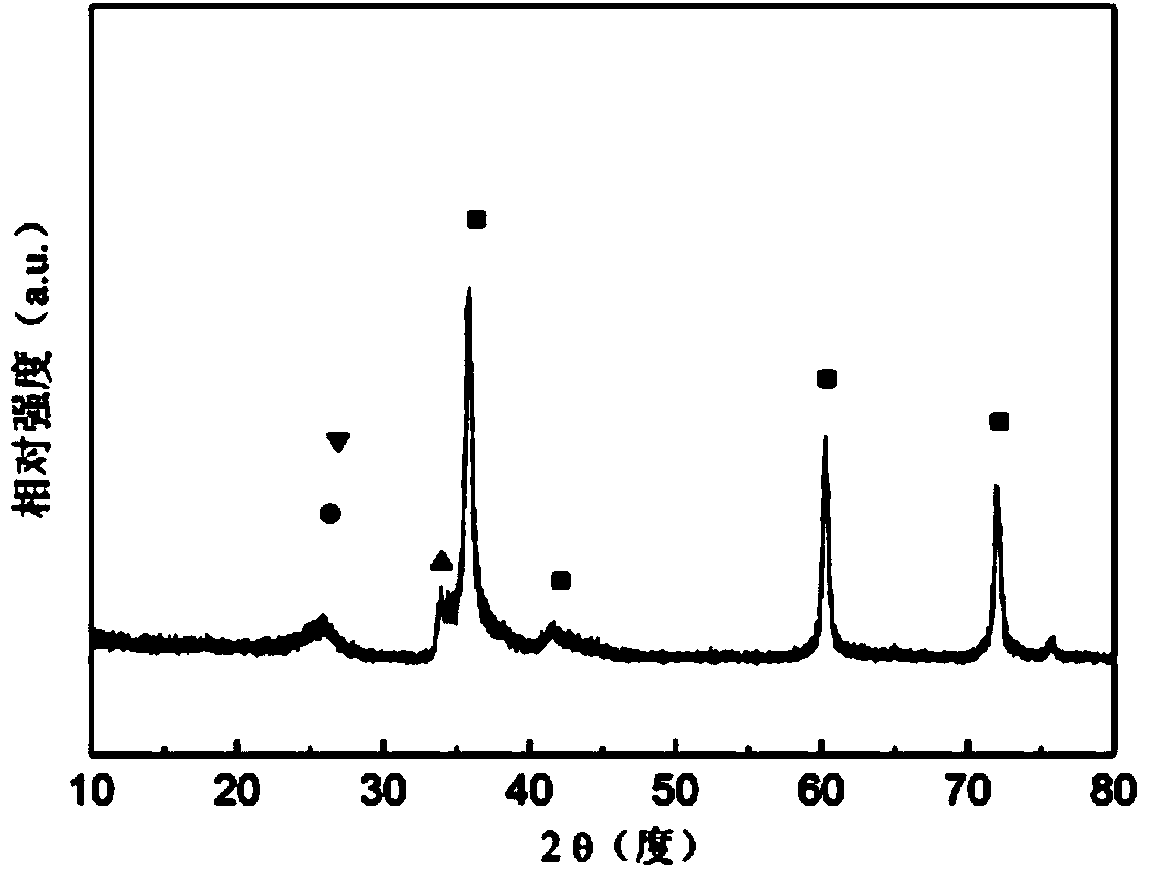

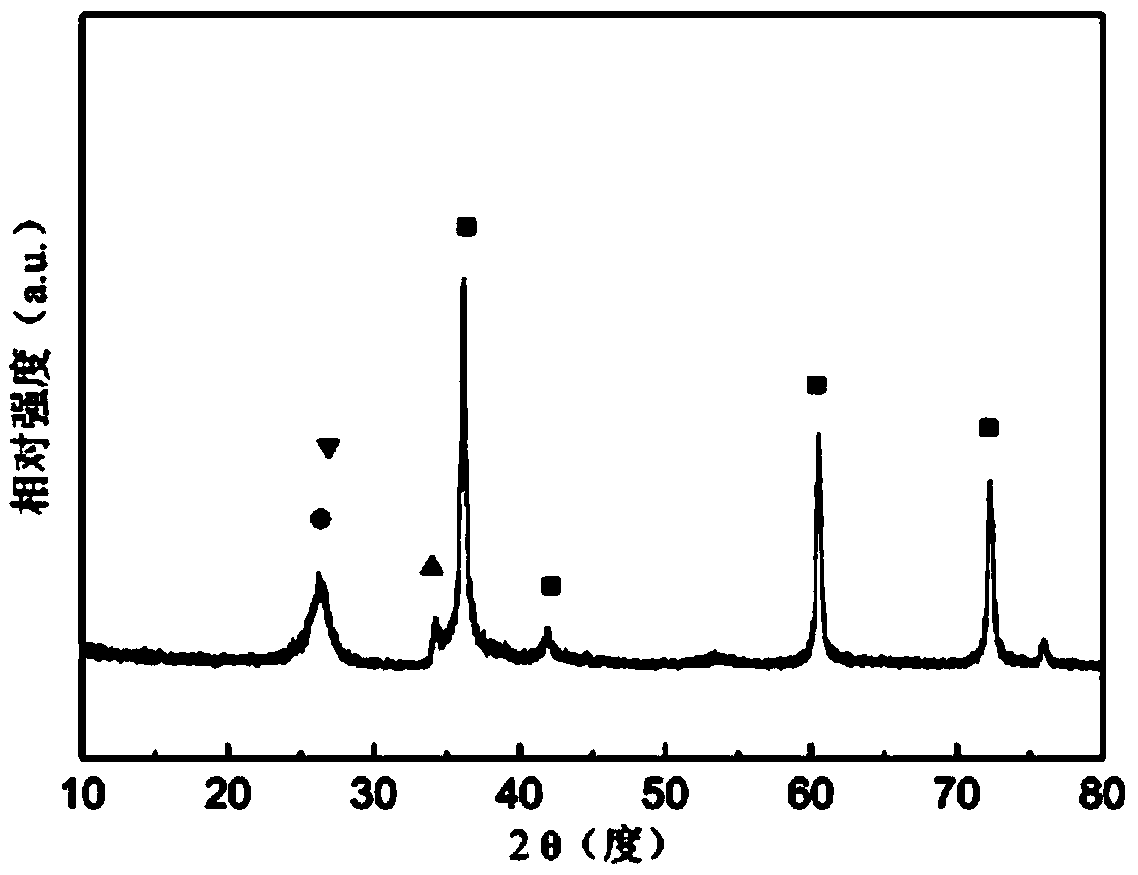

[0018] Embodiment 1: The carbon / carbon fiber-silicon-boron-carbon-nitrogen ceramic composite material of this embodiment is prepared from short carbon fibers, phenolic resin, acetone and silicon-boron-carbon-nitrogen ceramic composite powder; the silicon-boron-carbon-nitrogen ceramic composite powder It is formed by ball milling silicon powder, graphite and hexagonal boron nitride powder; the mass ratio of the short carbon fiber to the phenolic resin is 1: (1-12); the mass ratio of the phenolic resin to the volume of acetone (10-60) g: 1L; the volume ratio of the short carbon fiber to the silicon-boron-carbon-nitrogen ceramic composite powder is (5-35): 100; the mass ratio of the silicon powder to graphite is 1: (0.1 ~1.5); the mass ratio of silicon powder to hexagonal boron nitride powder is 1: (0.1~1.2); the length of short carbon fiber is 1mm~2mm, and the diameter of single filament is 6μm~7μm; The purity of the silicon powder is 99% to 99.9%, and the particle size is 1 μm ...

specific Embodiment approach 2

[0020]Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio of the short carbon fiber to the phenolic resin is 1: (2-10); the ratio of the mass of the phenolic resin to the volume of acetone (20-50) g: 1L; the volume ratio of the short carbon fiber to the silicon-boron-carbon-nitrogen ceramic composite powder is (8-32): 100; the mass ratio of the silicon powder to graphite is 1: (0.1 ~1.2); the mass ratio of the silicon powder to the hexagonal boron nitride powder is 1: (0.1~1.0). Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of the short carbon fiber to the phenolic resin is 1: (3-9); the mass of the phenolic resin to the volume of acetone The ratio is (25-48) g: 1L; the volume ratio of the short carbon fiber to the silicon boron carbonitride ceramic composite powder is (16-24): 100; the mass ratio of the silicon powder to graphite is 1: (0.15-0.75); the mass ratio of the silicon powder to the hexagonal boron nitride powder is 1: (0.15-0.85). Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com