Patents

Literature

49 results about "Boron carbonitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

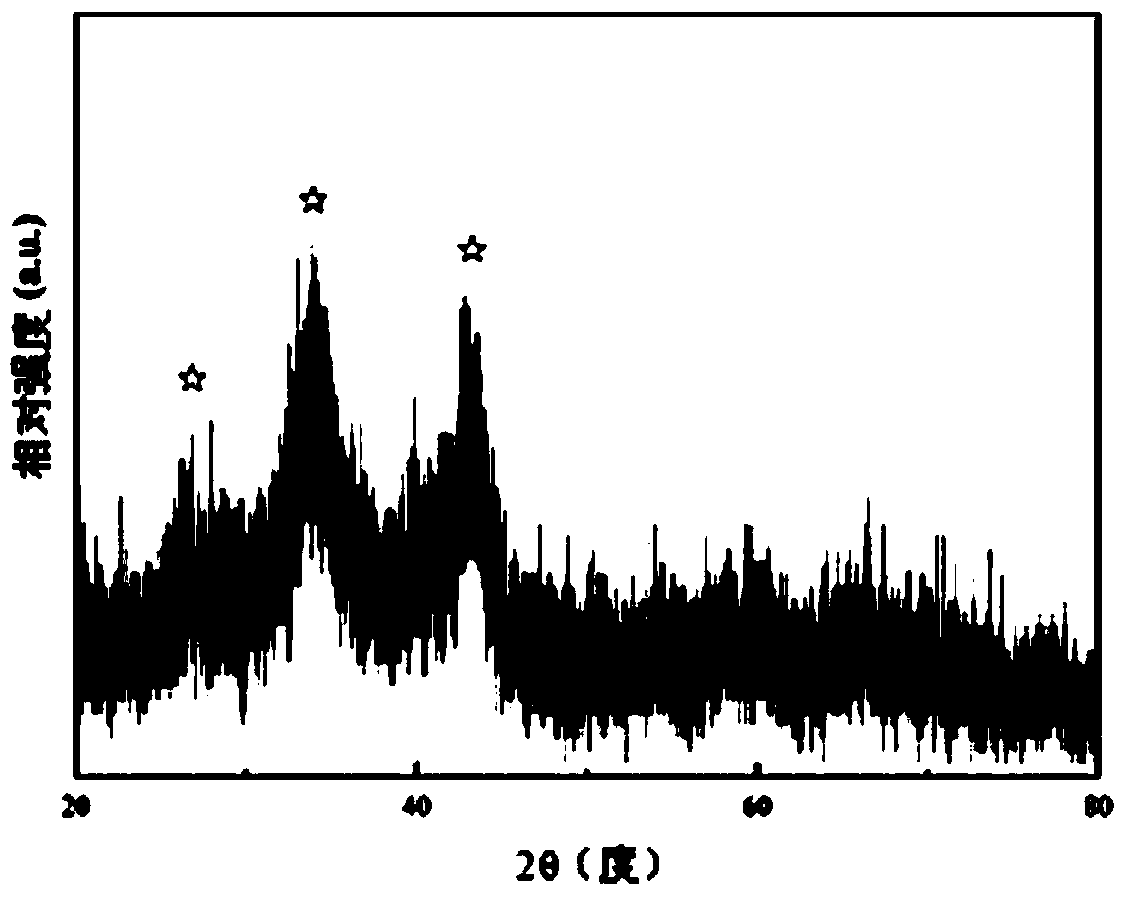

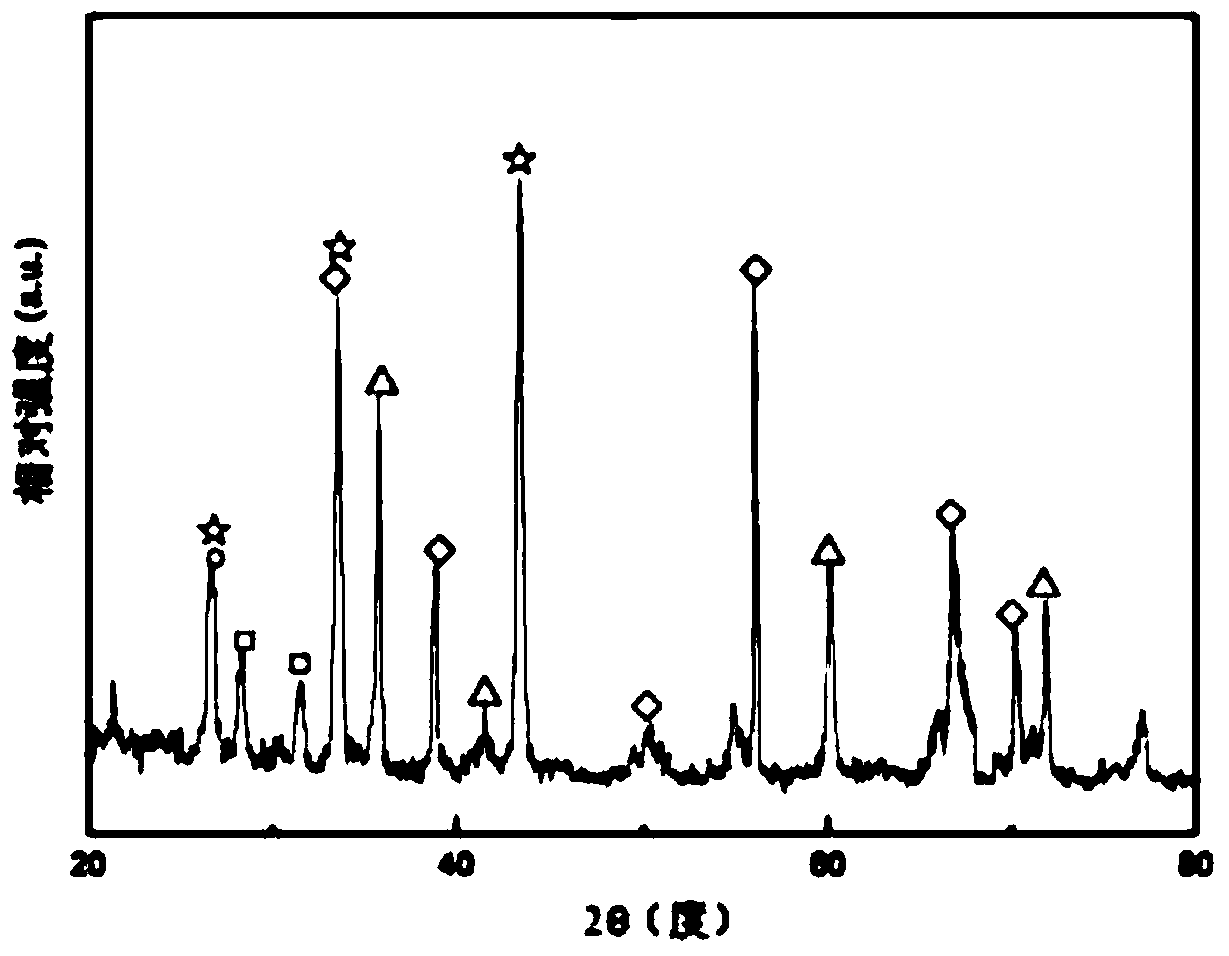

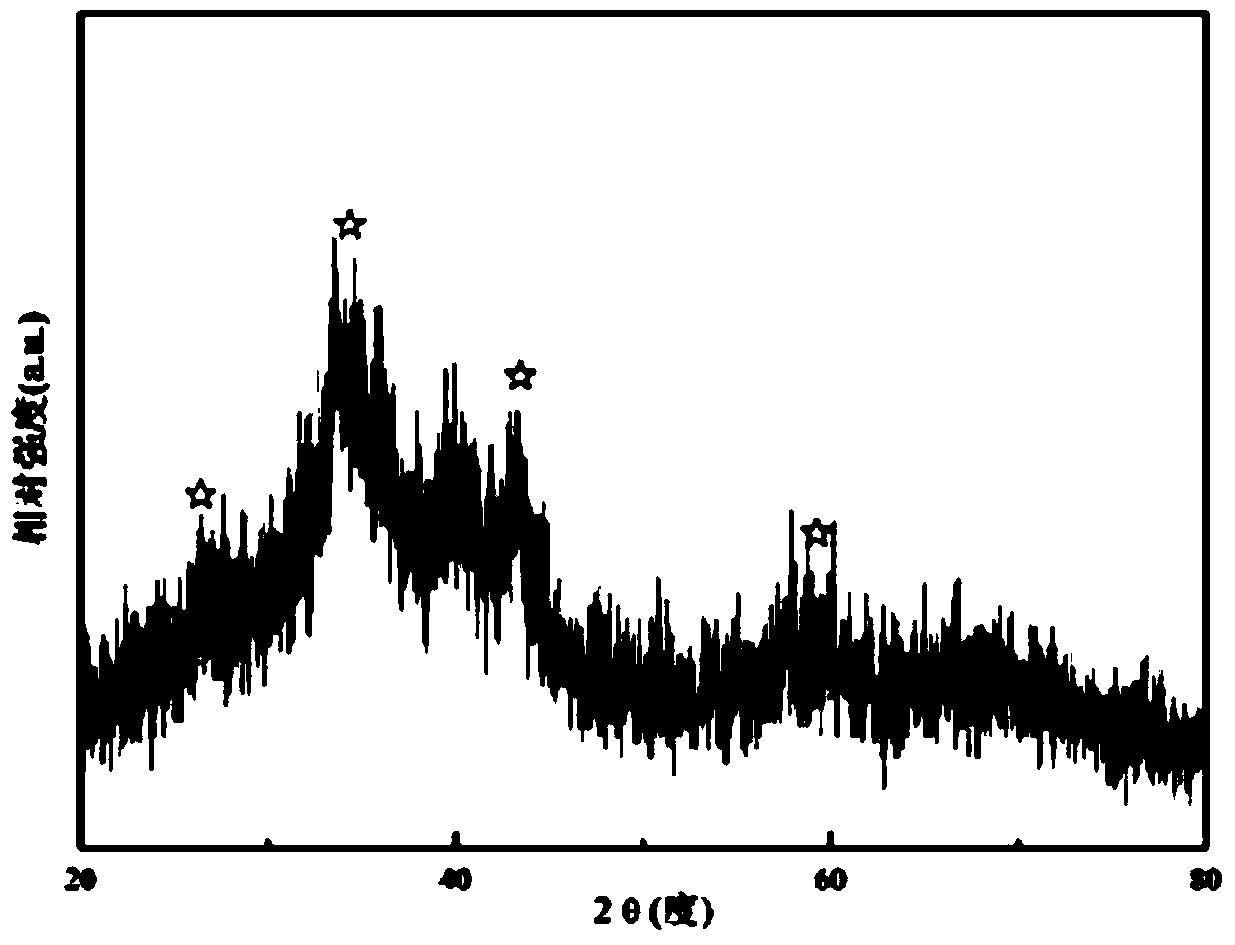

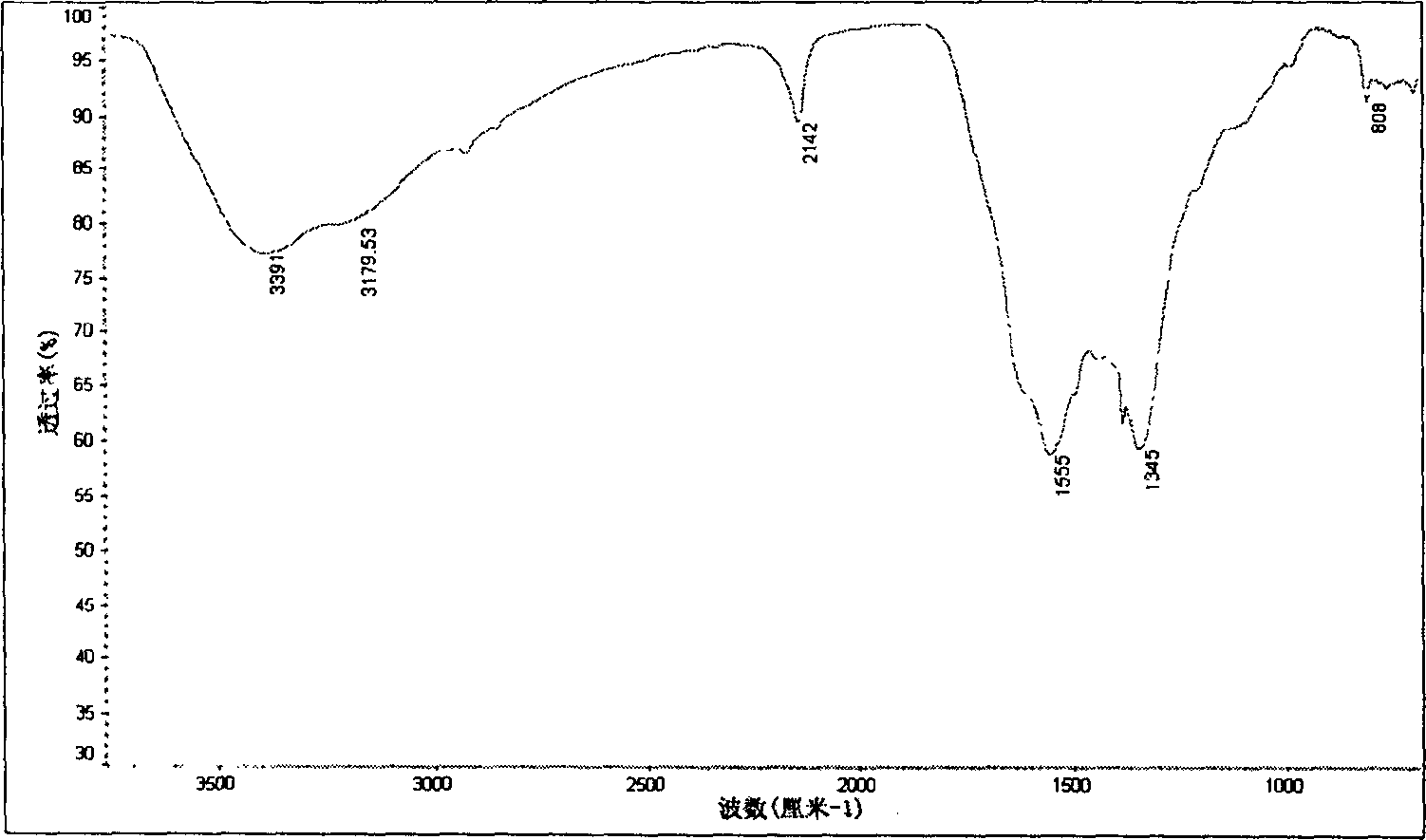

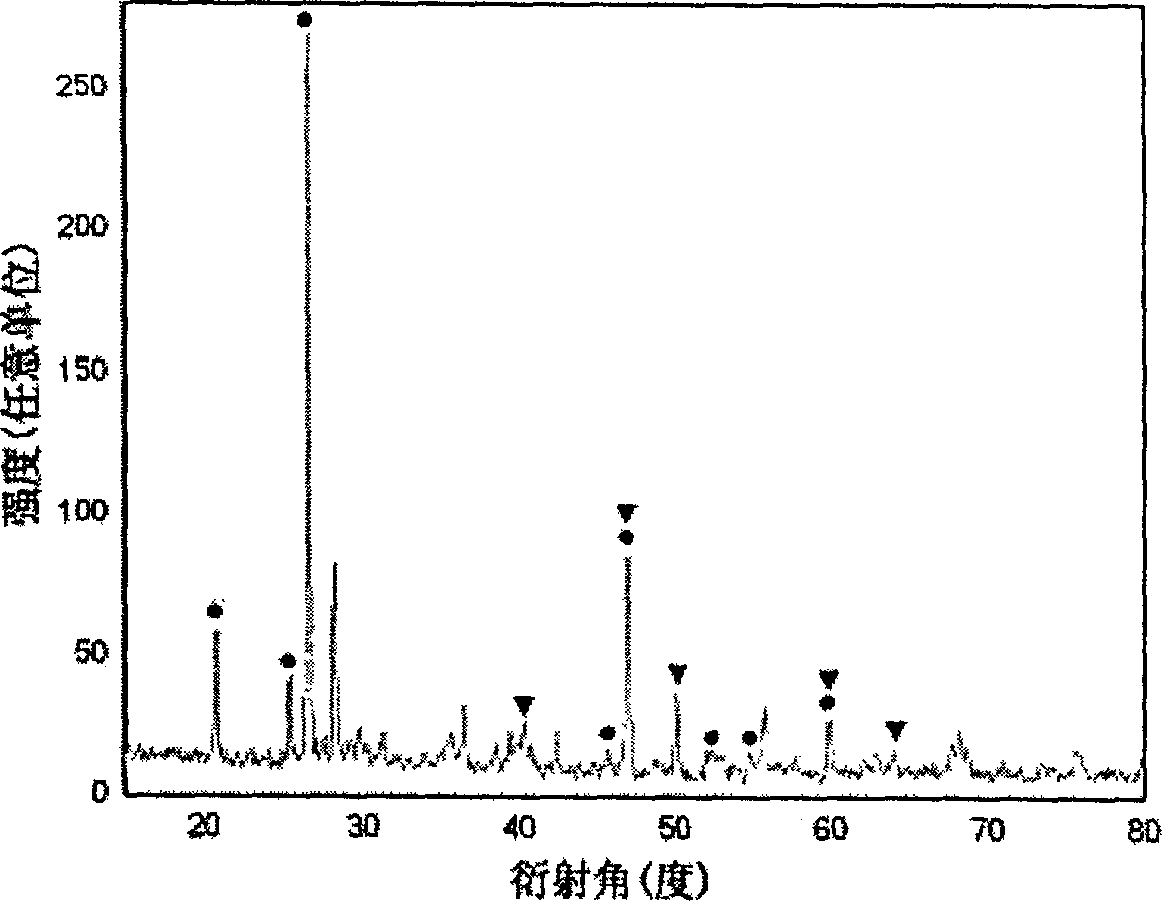

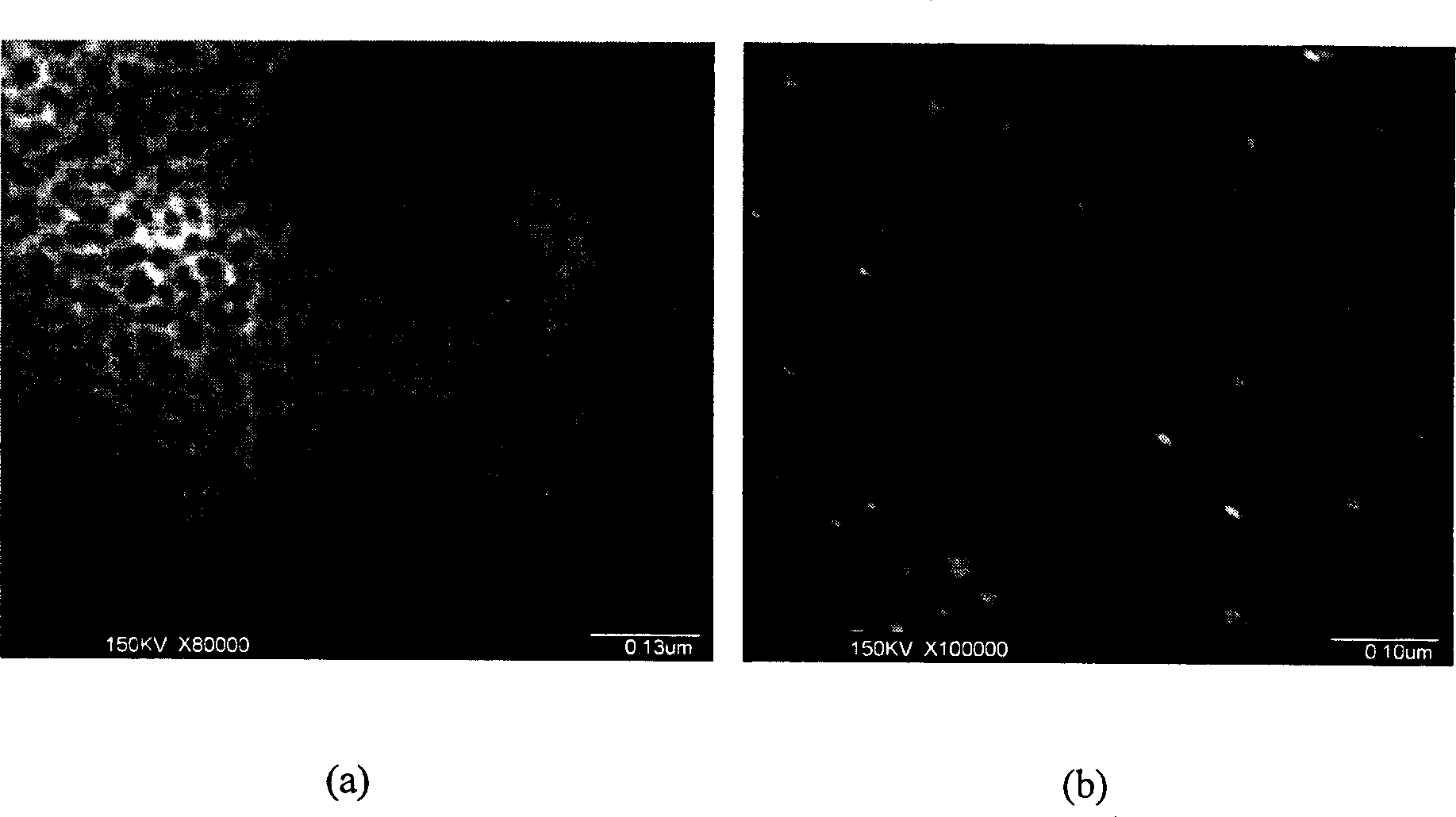

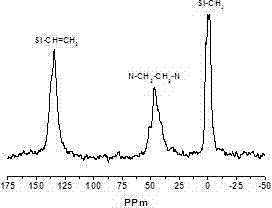

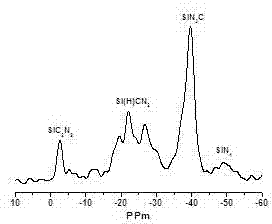

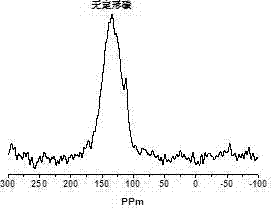

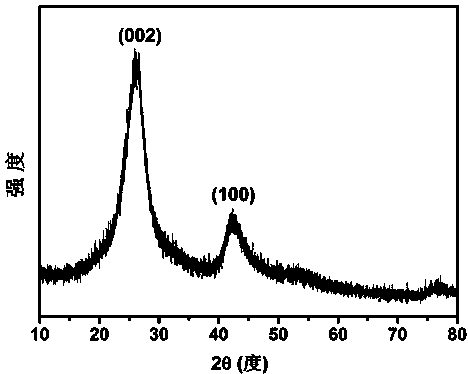

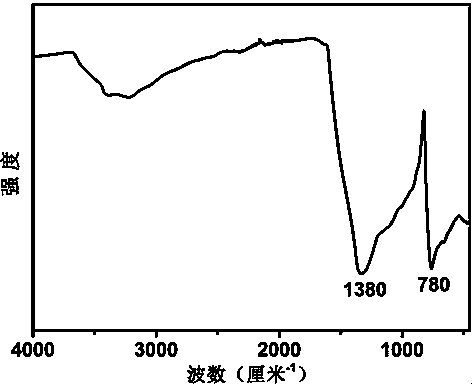

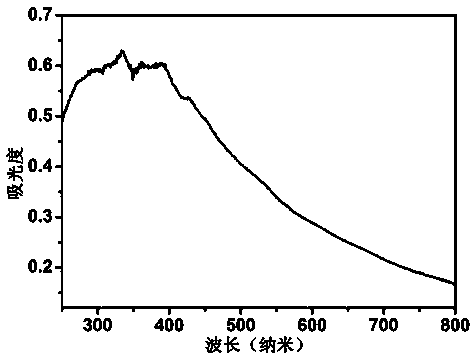

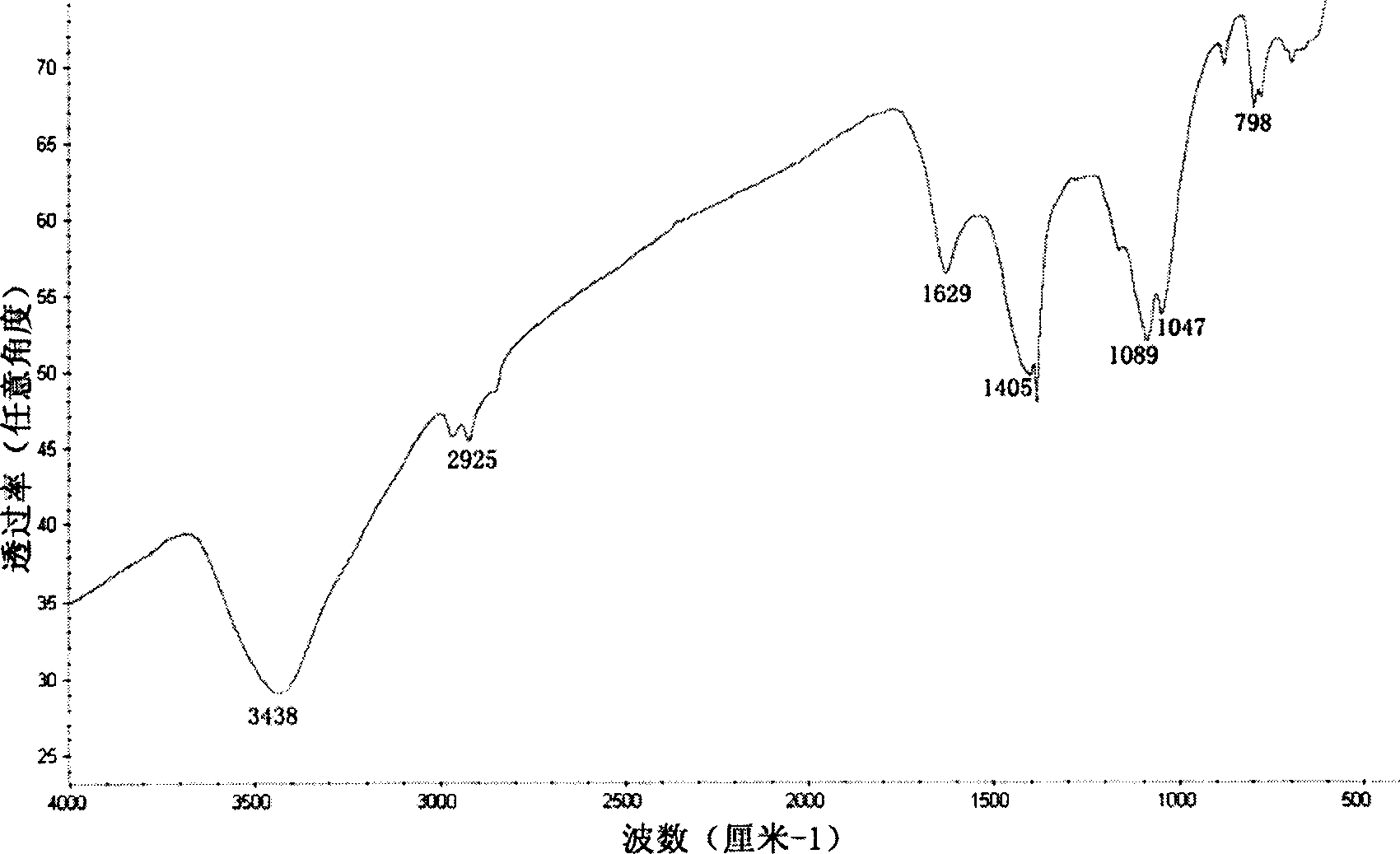

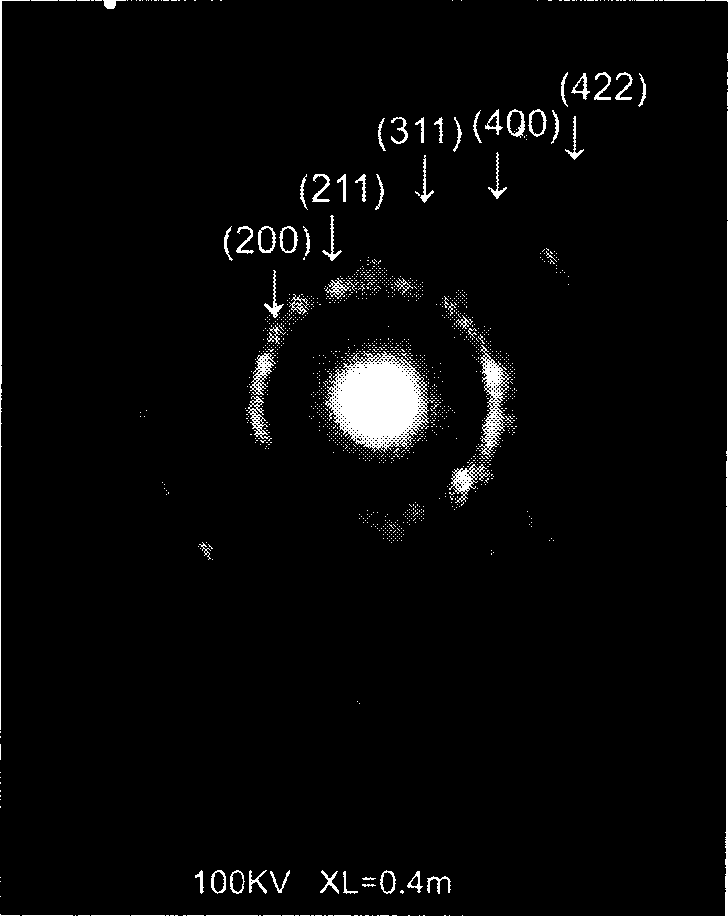

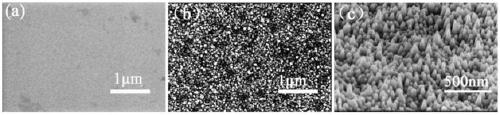

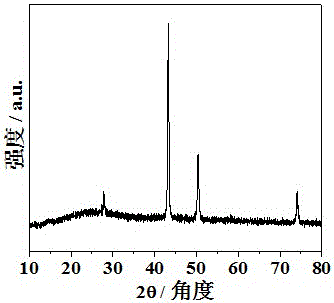

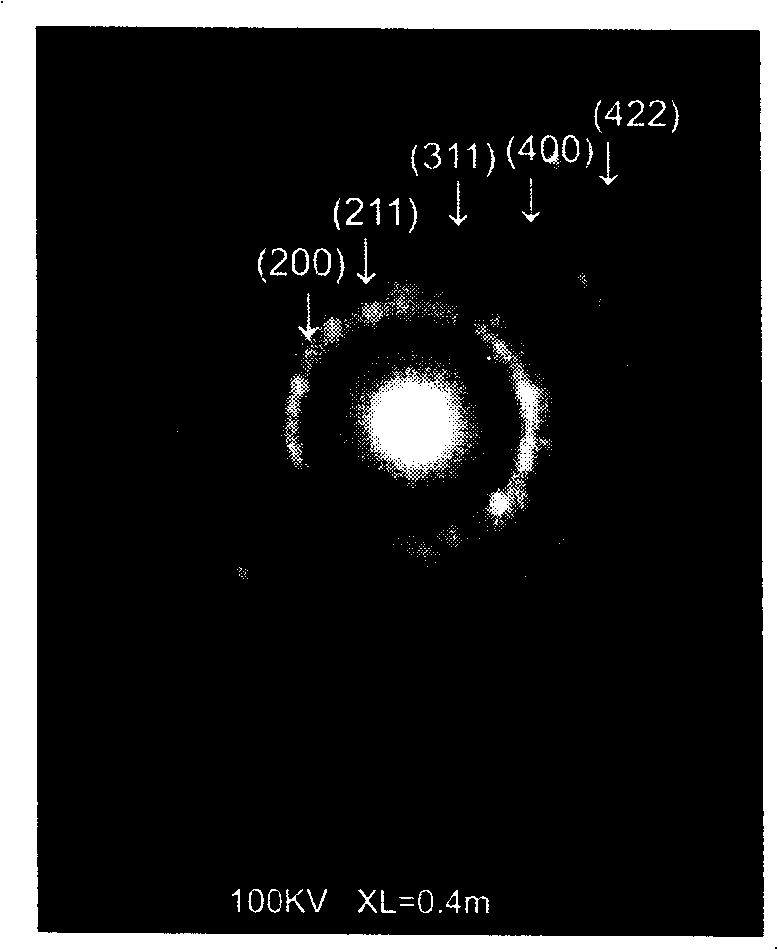

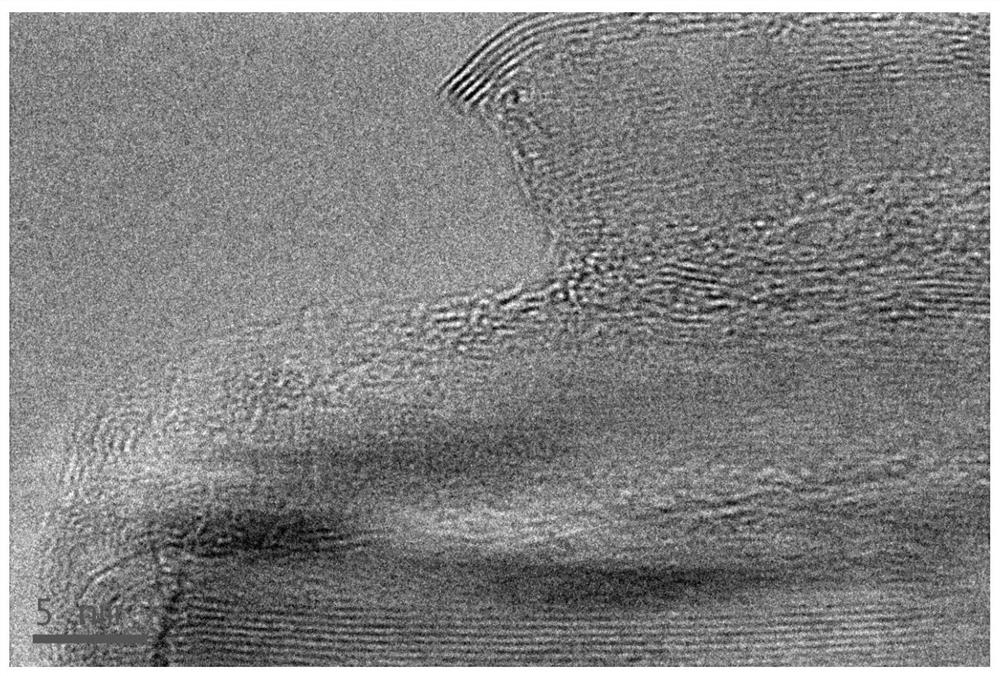

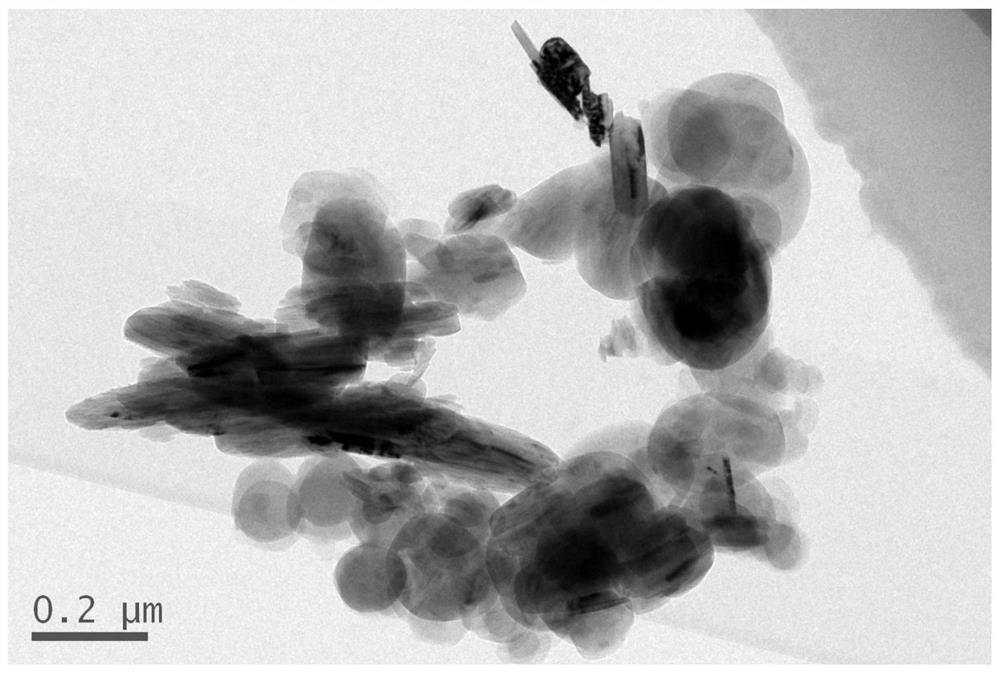

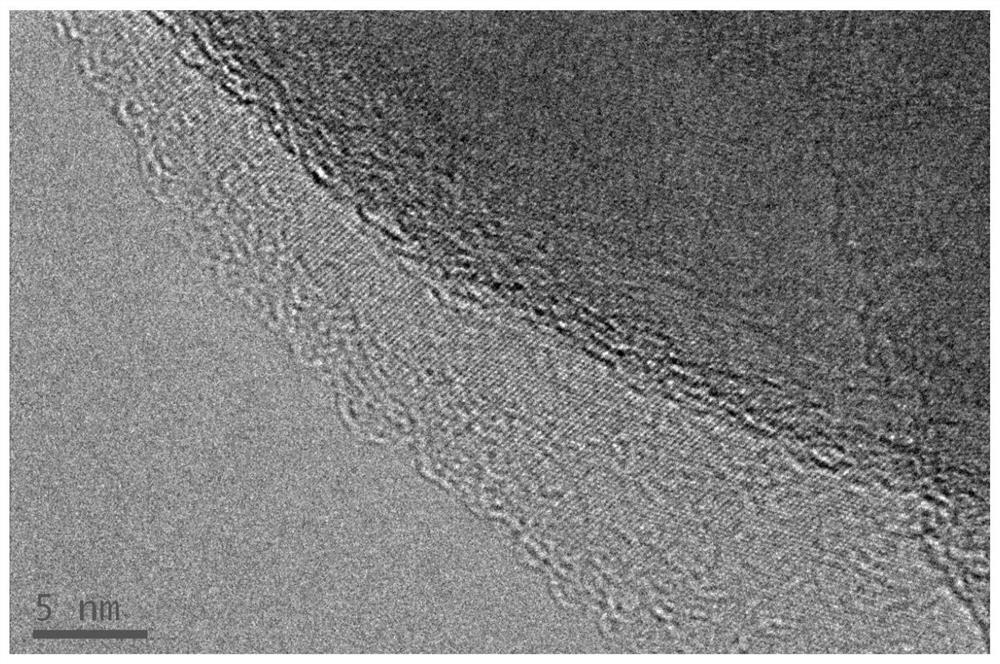

Synthesis of hexagonal boron carbonitride phase by solvothermal method. ... (c-BCN) are expected to combine the properties of diamond and cubic boron nitride (c-BN), whereas hexagonal structures ... The novel synthetic route may provide a new means of preparing boron carbonitride, which holds some promise for synthesizing metastable bulk boron ...

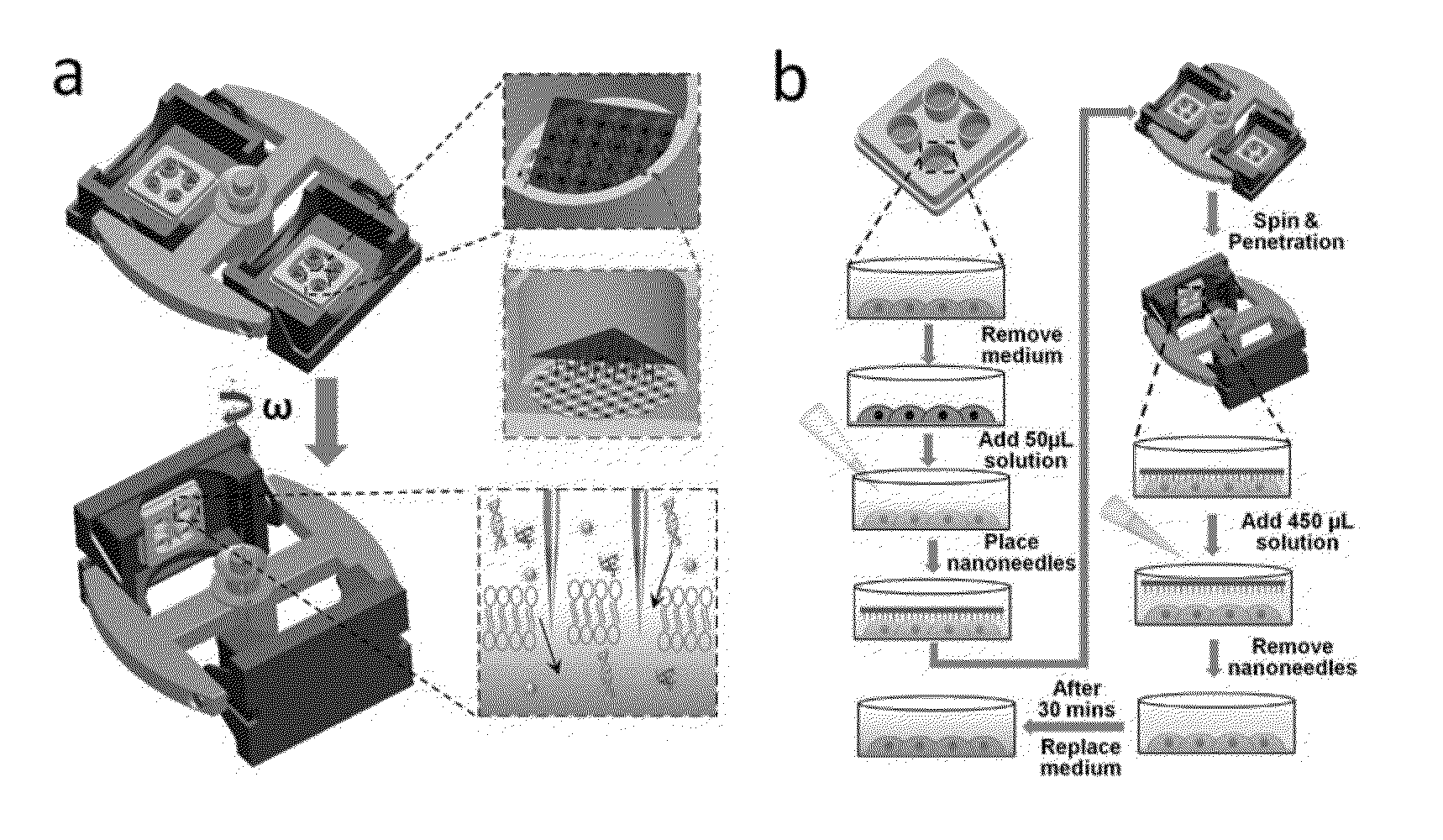

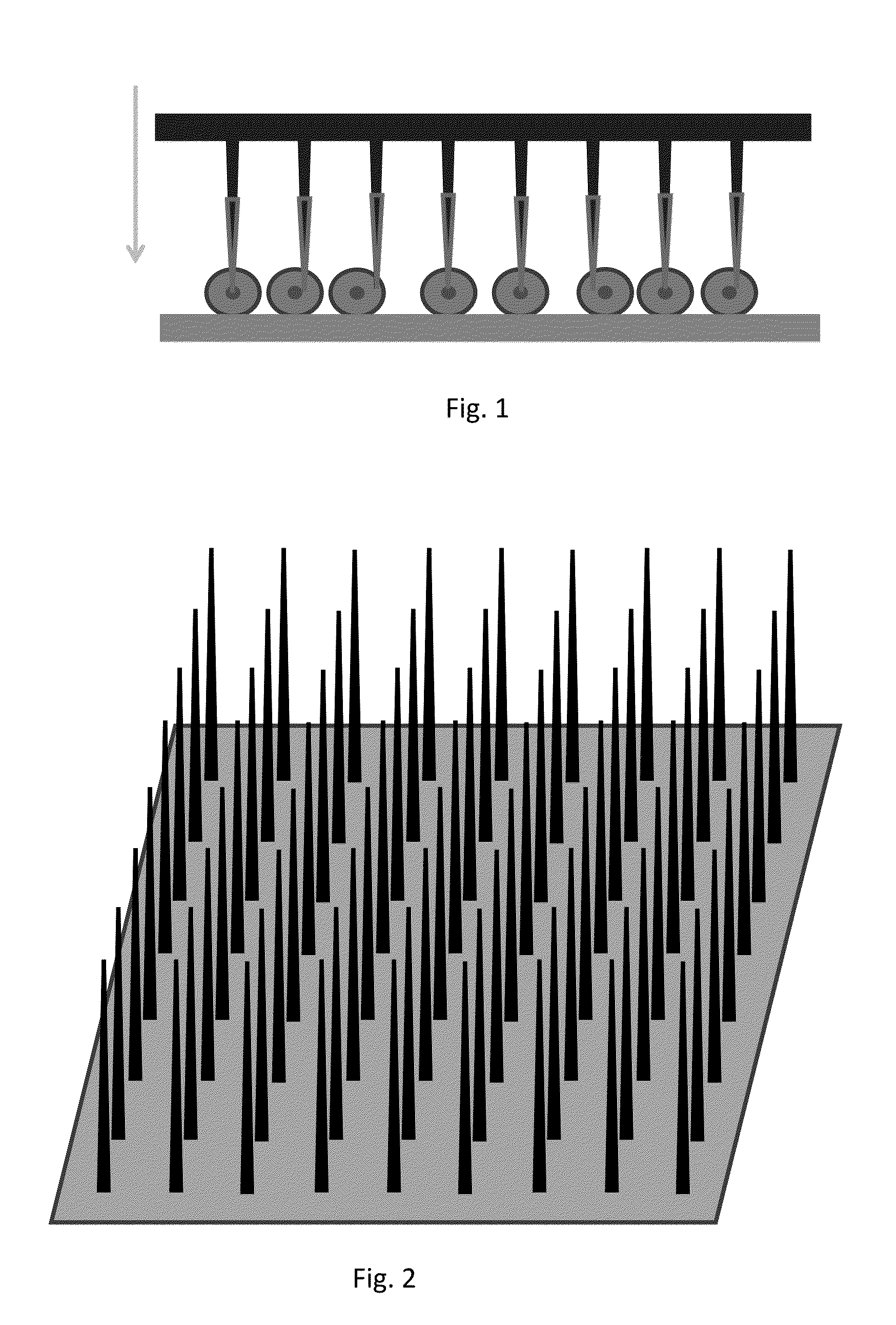

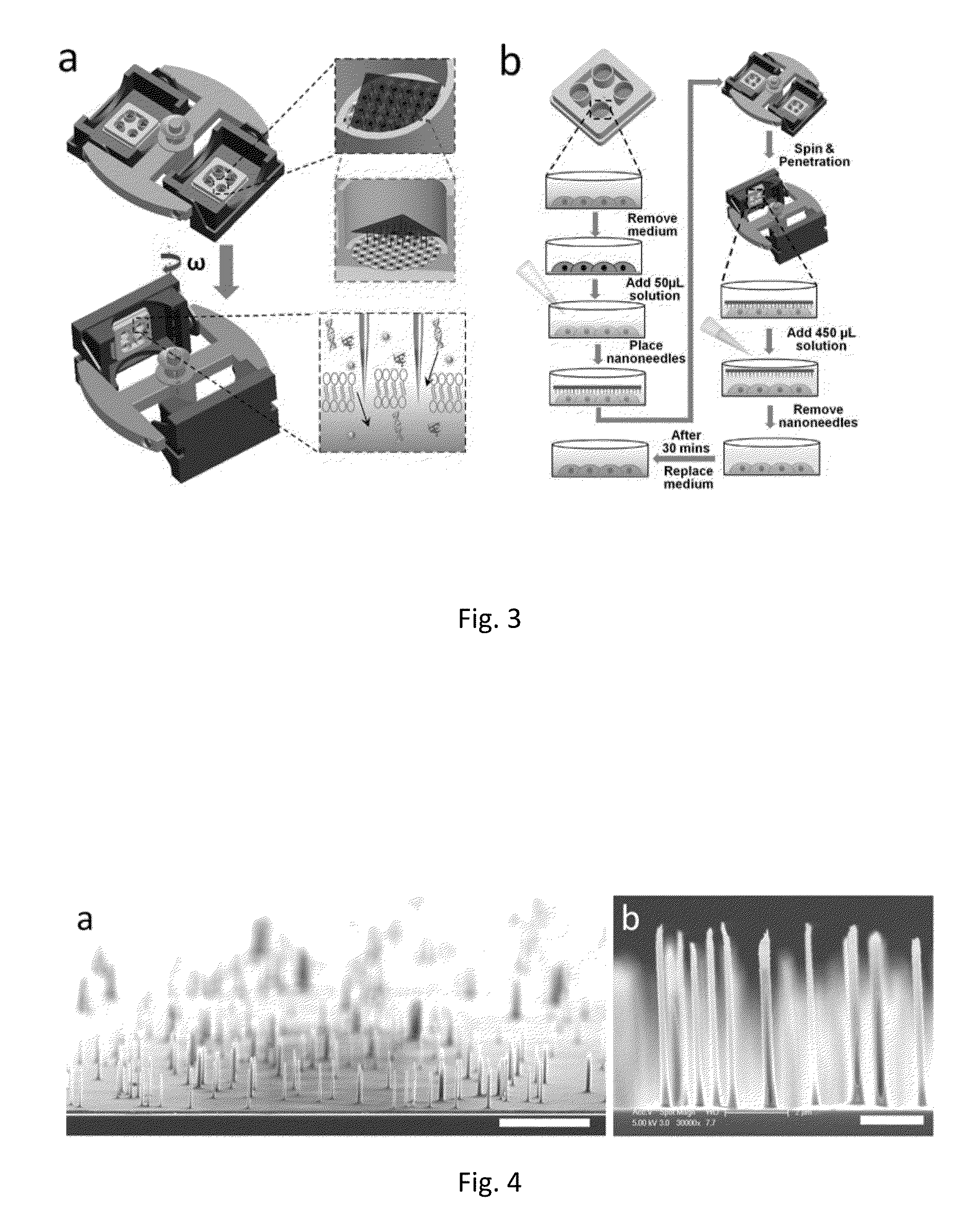

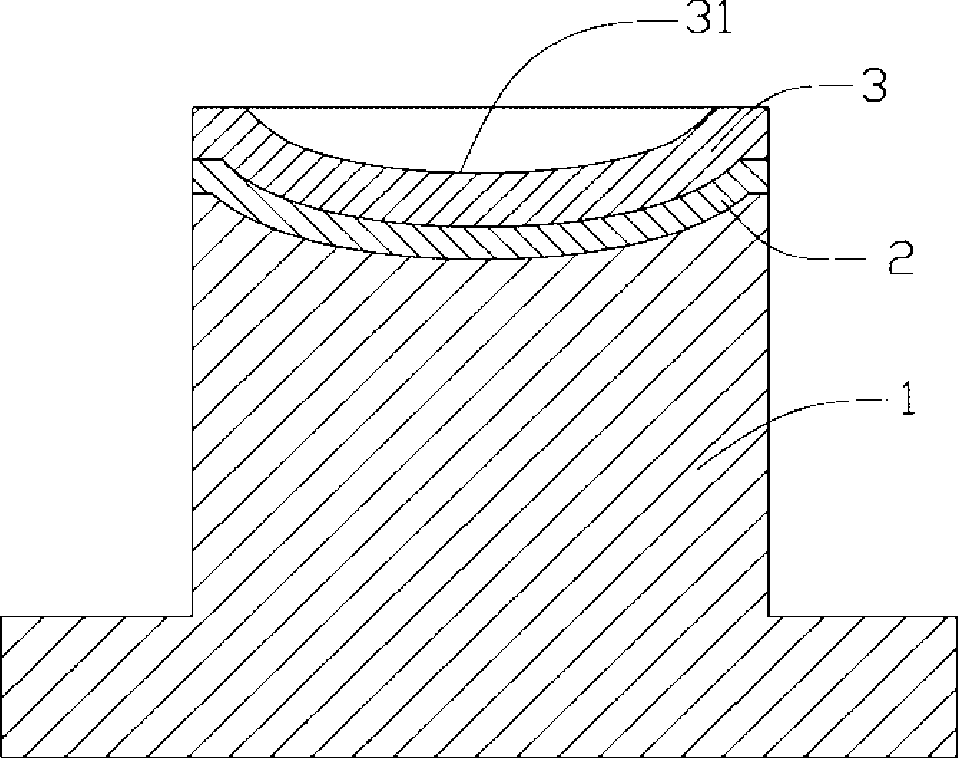

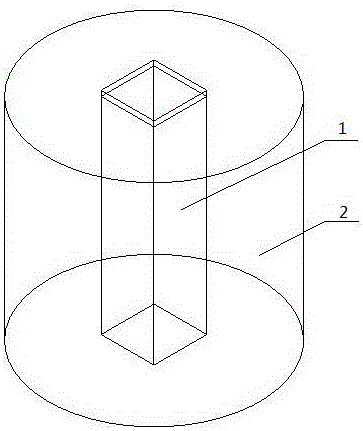

Method and apparatus for delivery of molecules to cells

ActiveUS20140295558A1Rigid enoughBioreactor/fermenter combinationsBiological substance pretreatmentsBoron carbonitrideCarbon nitride

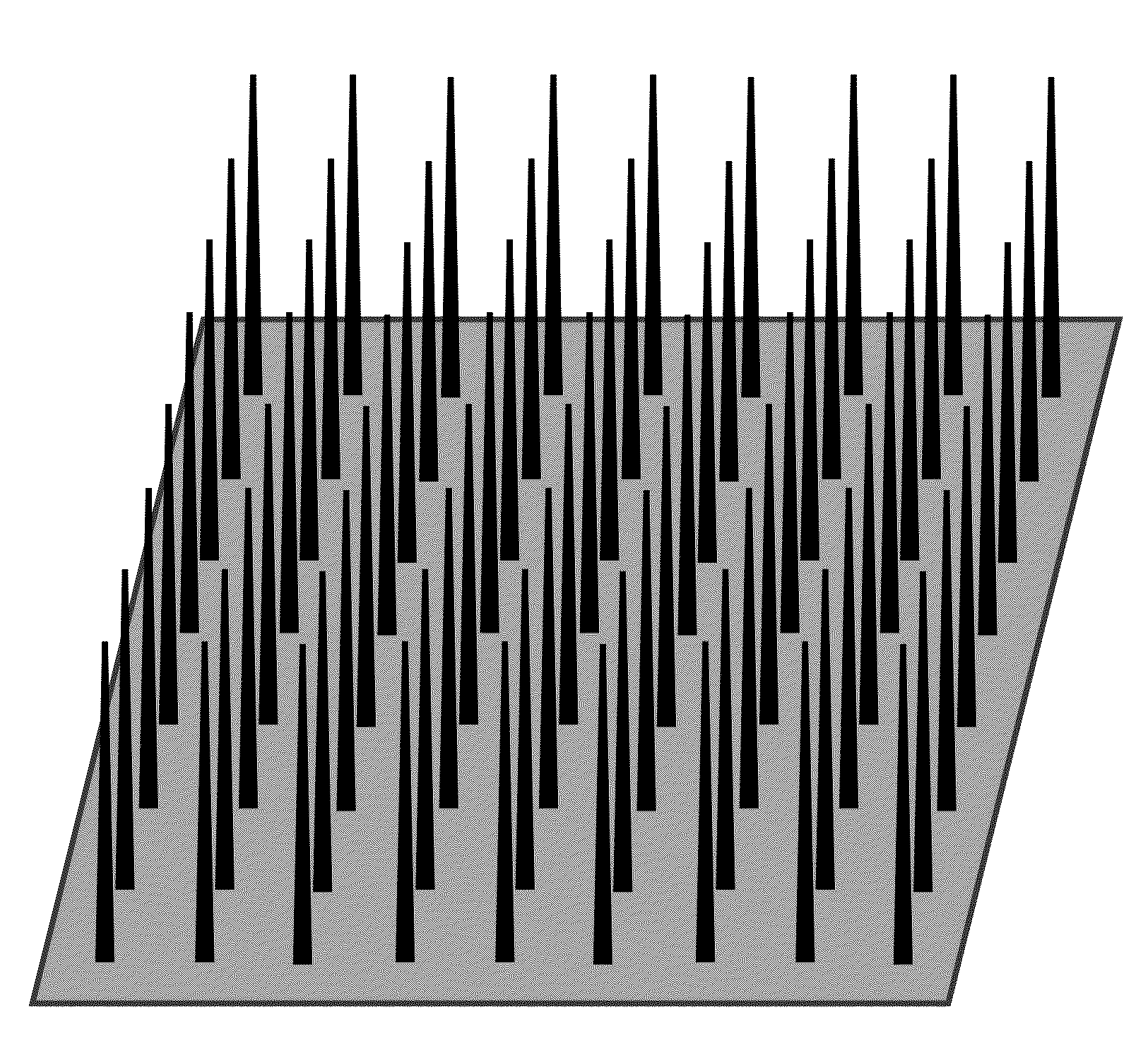

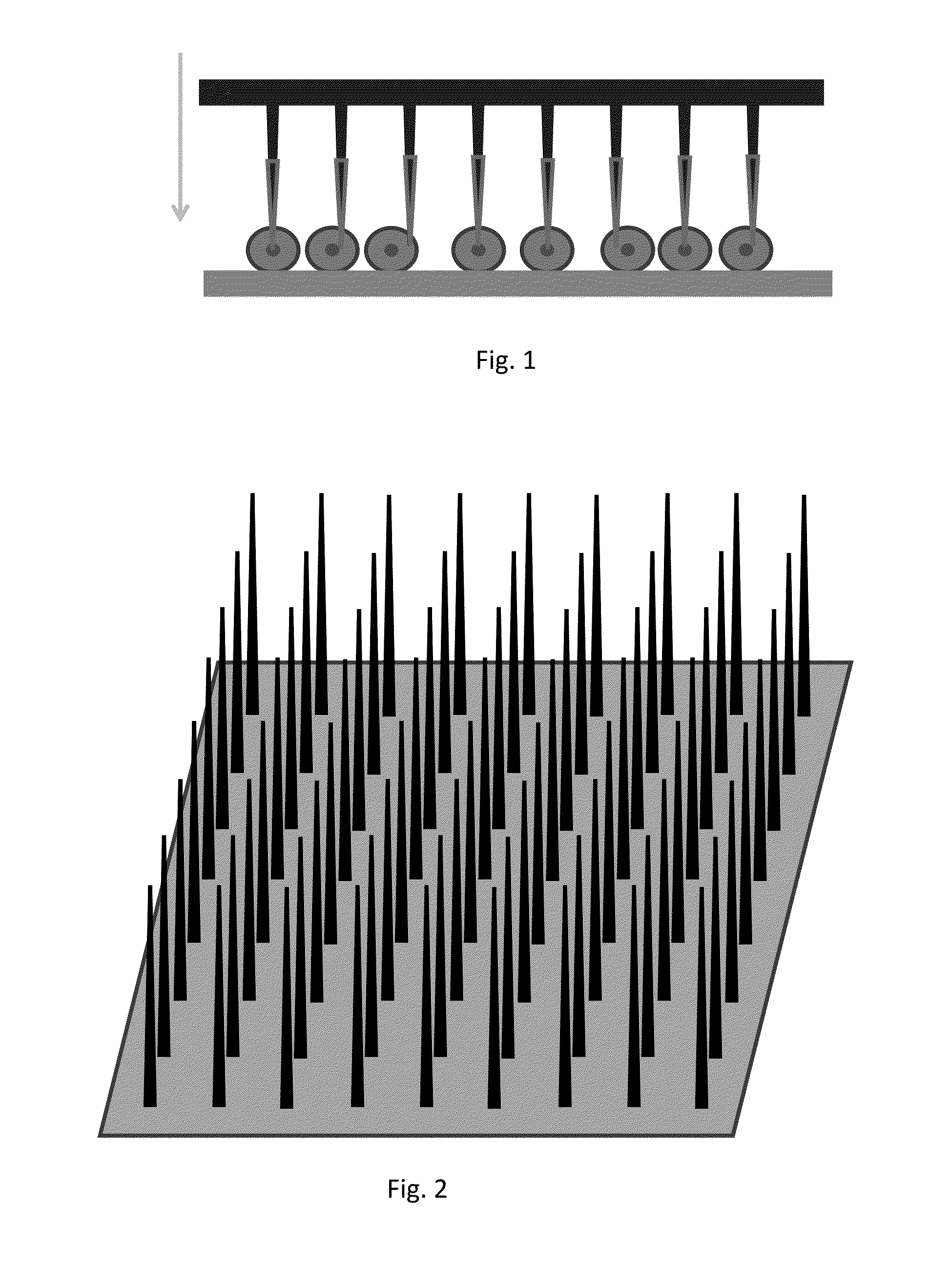

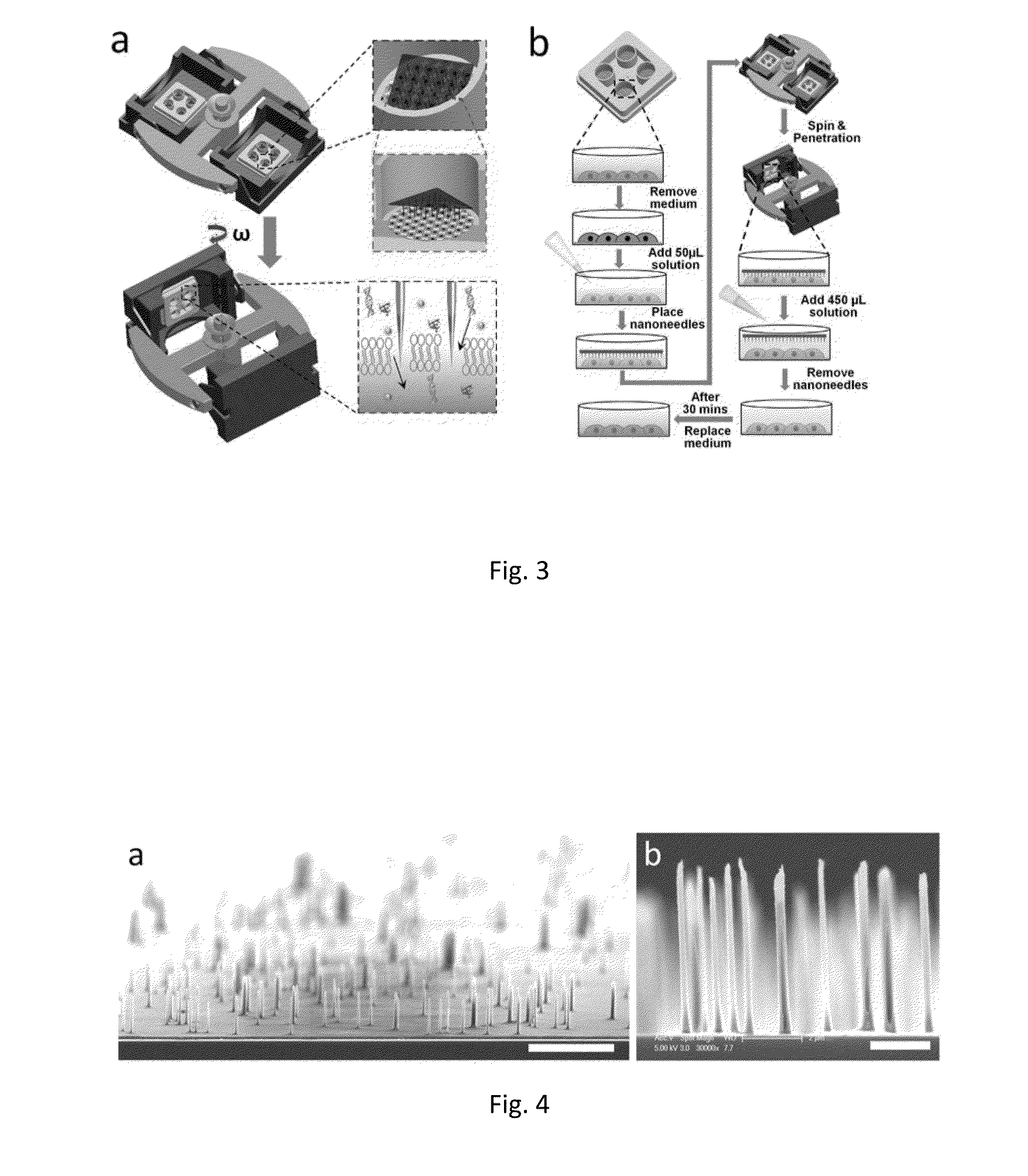

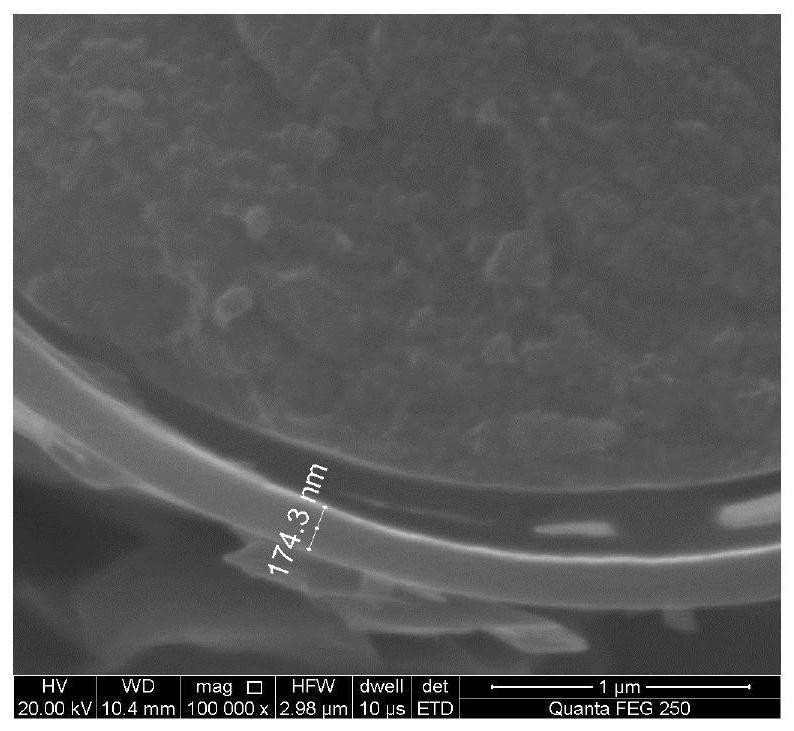

The present invention is concerned with a system and method for introducing a substance into cells. The system has an assembly including a plurality of elongate non-hollow nanoneedles forming a nanoneedle array or patch for delivering the substance into the cells, at least some of the nanoneedles have a non-uniform diameter with a wider upper end, a narrower lower end for penetration into the cells and a length from substantially 200 nm to 100 um. The lower end has a diameter from substantially 20-436 nm. Adjacent nanoneedles are spaced apart by substantially 5-50 um. The nanoneedles are made from a material selected from the group consisting of diamond, cubic boron nitride, carbon nitride, boron nitride, boron carbon nitride, metal borides and essentially boron materials, allowing the nanoneedles to maintain sufficient thinness and yet adequate rigidity during penetration. The nanoneedles are applied onto the cells grown on substrates at a preferred rate from 1 to 5 m / s. Alternatively, the nanoneedles are applied onto the cells grown on substrates by centrifugation force from 0.5 to 10 nN. Yet alternatively, the cells suspended in a fluid are applied to the nanoneedle array at a rate of 1 to 10 m / s.

Owner:CITY UNIVERSITY OF HONG KONG

Silicon boron zirconium carbonitride ceramic composite material and preparation methods thereof

The invention provides a silicon boron zirconium carbonitride ceramic composite material and preparation methods thereof and relates to a ceramic composite material and a preparation method thereof. The objective of the invention is to overcome the problems that a conventional silicon boron carbonitride ceramic composite material has insufficient thermal shock damage resistance and high temperature ablation resistance and cannot safely take service in a high temperature ablation environment with a temperature of more than 1500 DEG C. The silicon boron zirconium carbonitride ceramic composite material is prepared from raw materials consisting of silicon powder, graphite powder, hexagonal boron nitride powder, zirconium powder and boron powder through ball milling, mixing and hot pressed sintering. One of the preparation methods comprises the following steps: weighing the raw materials in proportion; subjecting the raw materials to ball milling and mixing; and then carrying out sintering so as to obtain the silicon boron zirconium carbonitride ceramic composite material. The other preparation method comprises the following steps: subjecting weighed zirconium powder and boron powder to ball milling and mixing; then adding silicon powder, graphite powder and hexagonal boron nitride powder and continuing ball milling and mixing; and then carrying out sintering so as to obtain the silicon boron zirconium carbonitride ceramic composite material. The preparation methods provided by the invention are applicable to preparation of the silicon boron zirconium carbonitride ceramic composite material.

Owner:HARBIN INST OF TECH

Porous boron carbonitride nanosheet layer and porous boron nitride nanosheet layer as well as preparation methods and applications of porous boron carbonitride nanosheet layer and porous boron nitride nanosheet layer as absorbing materials

ActiveCN109775673ASeparableAdsorptiveProductsOther chemical processesBoron carbonitrideRoom temperature

The invention provides a preparation method of a porous boron carbonitride nanosheet and a preparation method of a porous boron nitride nanosheet. The preparation method of the porous boron carbonitride nanosheet comprises the steps of mixing a boron source and a solvent, performing heating and dissolution, adding a carbonitride source, placing in a closed reaction vessel, performing heating and stirring, evaporating water, and performing grinding and heat treatment in inert gas to obtain the porous boron carbonitride nanosheet. The preparation method of the porous boron nitride nanosheet comprises the steps of performing heat treatment on the porous boron carbonitride nanosheet in ammonia, and cooling to a room temperature in inert gas to obtain the porous boron nitride nanosheet. The porous boron carbonitride nanosheet and the porous boron nitride nanosheet are applied to an absorbing material which has higher CO2 absorbing performance, separation performance and cyclic absorbing performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

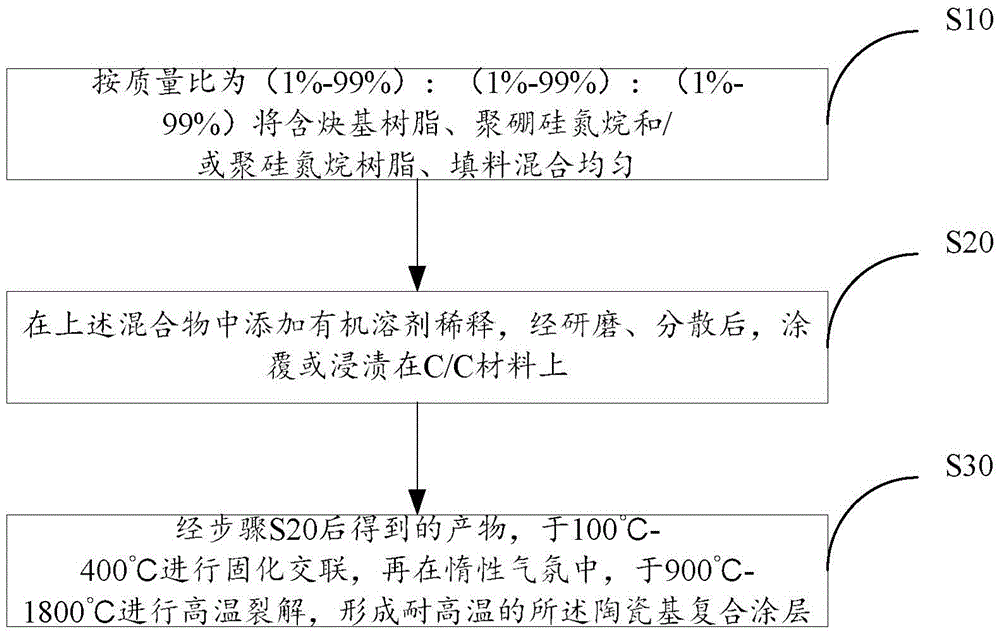

Ceramic-based composite coating and preparation method thereof

ActiveCN105623506AEnhanced interface bindingExtended service lifeFireproof paintsBoron carbonitrideSurface oxidation

The invention provides a ceramic-based composite coating. Alkynyl-containing resin, polyborosilazane and / or polysilazane and a filling material serve as main raw materials, and are diluted by a proper organic solvent to obtain a solution; the solution is coated or immersed on a C / C material after being grinded and dispersed, and is then subjected to curing cross-linking and high temperature pyrolysis to form a high temperature-resistant ceramic-based composite coating. According to the ceramic-based composite coating provided by the invention, as alkynyl is contained in a precursor, not only temperature of the curing cross-linking can be reduced, but also more free carbons can be formed during the high temperature pyrolysis, and are helpful to form indissolvable metallic carbide and SiC; the formation of the carbide can enhance the interface adhesive strength between the ceramic-based composite coating and a carbon material, and can have dual high temperature-resistant advantages of both high temperature silicon carbonitride or silicon-boron carbonitride ceramic and a metallic carbide material. Moreover, the service life of base materials under severe environments such as high temperature, ablation and the like is prolonged, and the ceramic-based composite coating can be used to solve the problem on surface oxidation resistance of a thermal ablation resistant material.

Owner:CHINA ACADEMY OF ENG PHYSICS FUNCTION MATERIAL RES INST

Boron-carbon-nitrogen material phase regulated dissolvent heat constant pressure synthesis method

InactiveCN1803597AEnables high-volume synthesisAchieve selective synthesisUltra-high pressure processesNitrogen and non-metal compoundsBoron carbonitrideSynthesis methods

The solvent thermal constant-pressure synthesis method to adjust and control phase of boron carbonitride material comprises: preparing liquids for boron resource, carbon source and nitrogen source respectively; putting into the kettle; forcing 40~2000MPa constant pressure then heating the kettle to 220~1000Deg with 0.01~60Deg / min speed; after reaction, cooling to room temperature, and taking post-treatment to the product. Wherein, it can adjust and control the system temperature and pressure independently as well as the reaction speed and direction, and obtains large-size diamond, cubic boron nitride and carbonitride crystal block.

Owner:SHANDONG UNIV

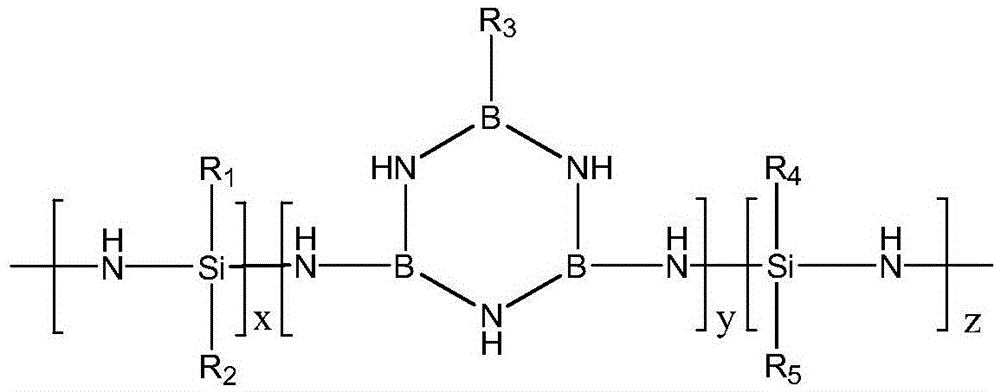

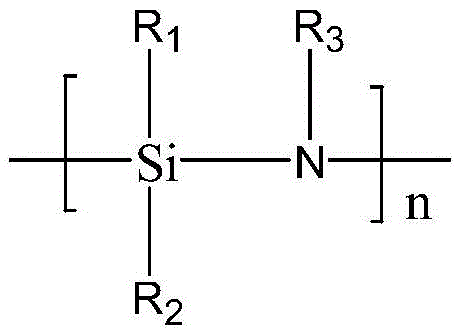

Silicon boron carbon nitrogen ceramic and preparation method thereof

The invention relates to silicon boron carbon nitrogen ceramic and a preparation method thereof, and in particular, the preparation method is as follows: using a double carbon chain or multiple carbon chain structure unit based amine as a reactant for aminolysis of chlorosilane and then hydroboration for synthesis of poly boron silicon alkyl amine, using the poly boron silicon alkyl amine as a precursor for pyrolysis preparation of the silicon boron carbon nitrogen ceramic. By introduction of a double carbon chain into a precursor structure for synthesis of the poly boron silicon amine alkane, C-N bond bonding is formed to promote the production of a silicon carbonitride and help to improve the high temperature performance of the silicon boron carbonitride ceramic. The preparation method for preparing the silicon boron carbonitride ceramic has the advantages high composition and structure designability and the like, and is suitable for the preparation of high purity ceramic. The silicon boron carbonitride ceramic prepared by the preparation method is controllable in composition, adjustable in carbon and boron content, and capable of preparing the silicon boron carbonitride ceramic having excellent high temperature performances, and can be used in aerospace, high temperature systems, machinery, metallurgy, chemical industry and other fields.

Owner:TIANJIN UNIV

Fluorine modified boron carbonitride photocatalytic material and application thereof to efficient reduction of carbon dioxide

ActiveCN108855187AImprove efficiencyImprove stabilityPhysical/chemical process catalystsCarbon monoxideBoron carbonitridePotassium fluoride

The invention discloses a fluorine modified boron carbonitride photocatalytic material and application thereof to efficient reduction of carbon dioxide, and belongs to the field of photocatalytic materials. The fluorine modified boron carbonitride photocatalytic material is prepared from graphite phase boron carbonitride synthesized through high-temperature polymerization reaction and potassium fluoride jointly through heat treatment reaction; the fluorine modified boron carbonitride photocatalytic material is an inorganic nonmetal copolymerization material; the characteristics of high stability, chemical corrosion resistance, high temperature resistance, high heat conductivity, visible-light response and the like are realized; the fluorine modified boron carbonitride photocatalytic material can catalyze and reduce carbon dioxide gas under the driving of visible light; the problems of high cost, instability, environment pollution and the like caused by the reason that the existing catalytic material for photocatalytic reduction on carbon dioxide mainly uses (noble) metal oxide (sulfide) as major materials are solved; the preparation method is simple; the raw materials are cheap andcan be easily obtained; the environment pollution is low; the large-scale industrial production is easy; obvious economic and social benefits are realized.

Owner:FUZHOU UNIV

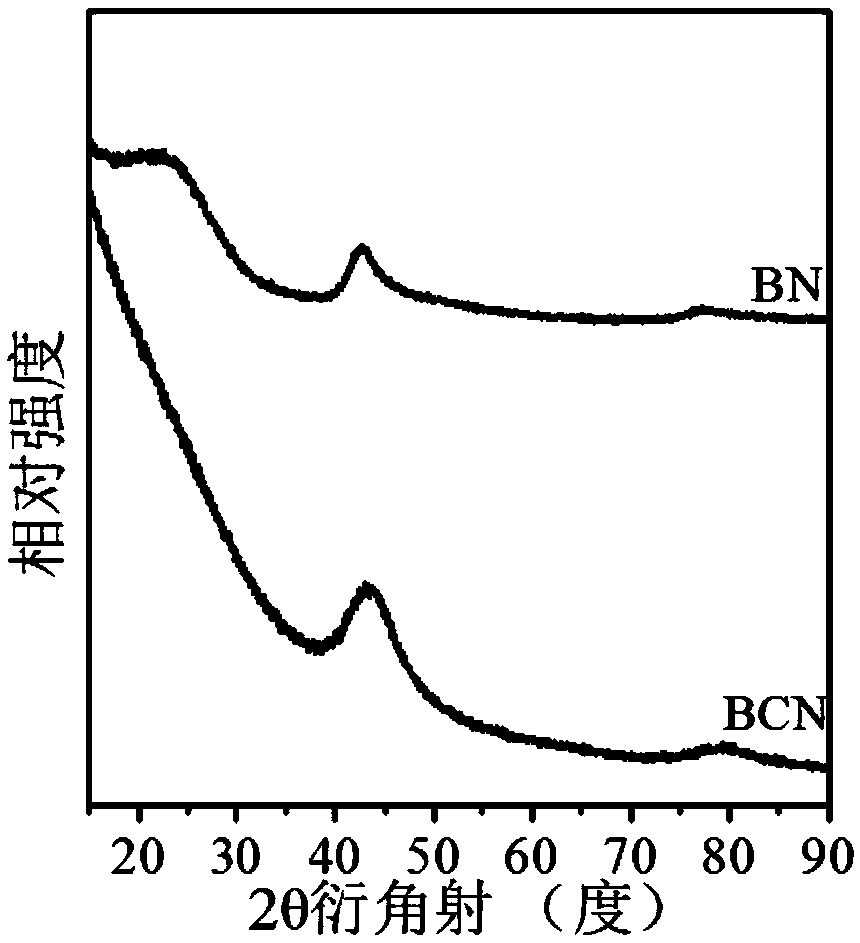

Boron nitride material and method of preparation thereof

ActiveCN109196139APolycrystalline material growthNitrogen compoundsBoron carbonitrideOptoelectronics

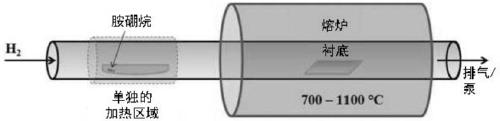

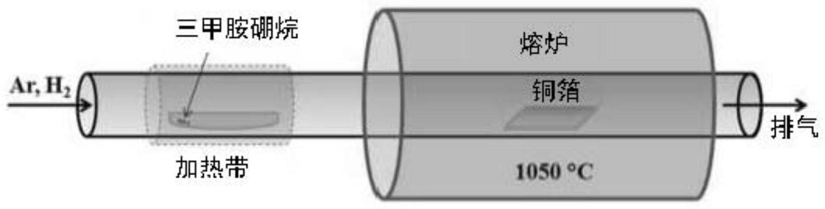

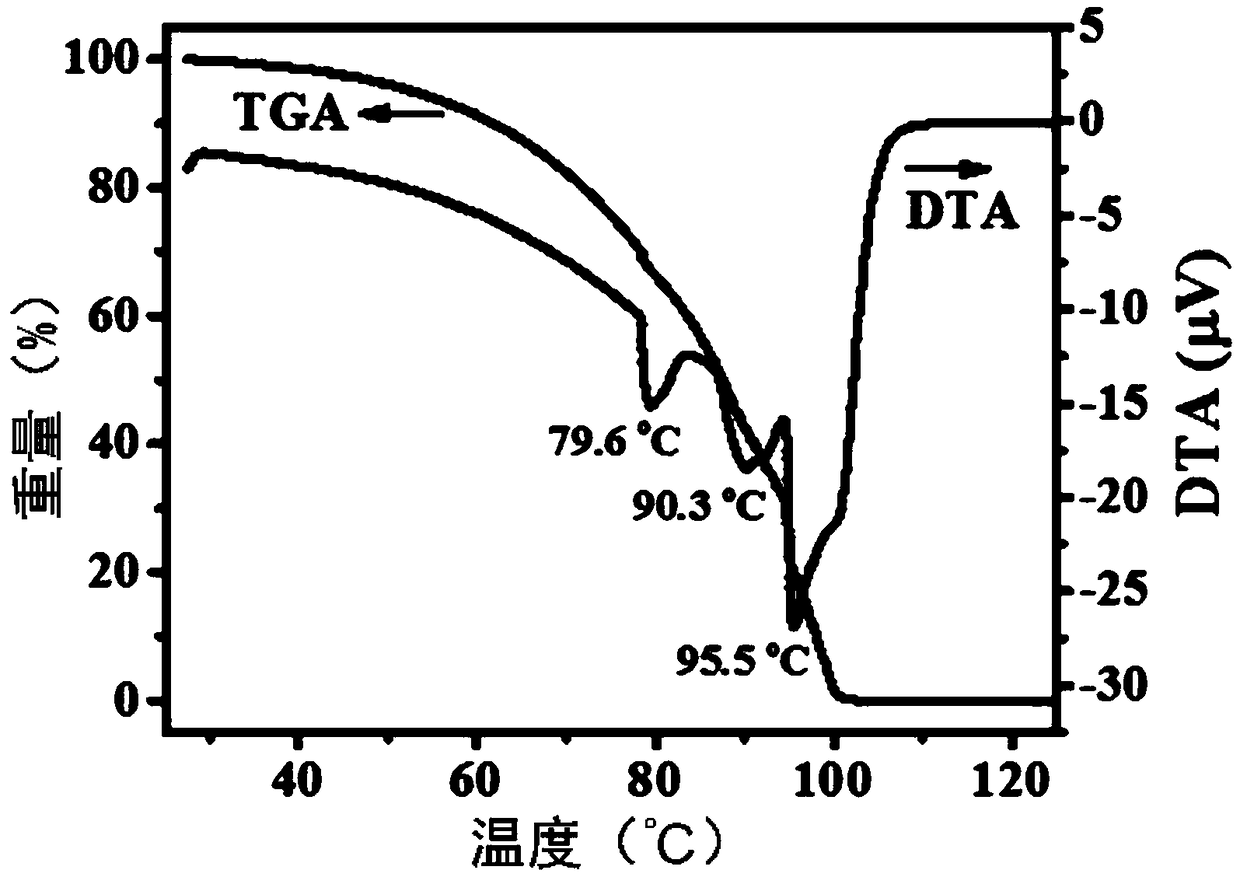

A method of preparing a boron nitride material, such as boron nitride (BN) or boron carbonitride (BCN), is provided. The method may include providing a substrate, and sublimating an amine borane complex onto the substrate to obtain the boron nitride material. The amine borane complex may include, but is not limited to, borazine, amino borane, trimethylamine borane and triethylamine borane. In addition, the temperature at which the sublimating is carried out may be varied to control composition of the boron nitride material formed. In addition, various morphologies can be obtained by using thepresent method, namely films, nanotubes and porous foam.

Owner:NANYANG TECH UNIV

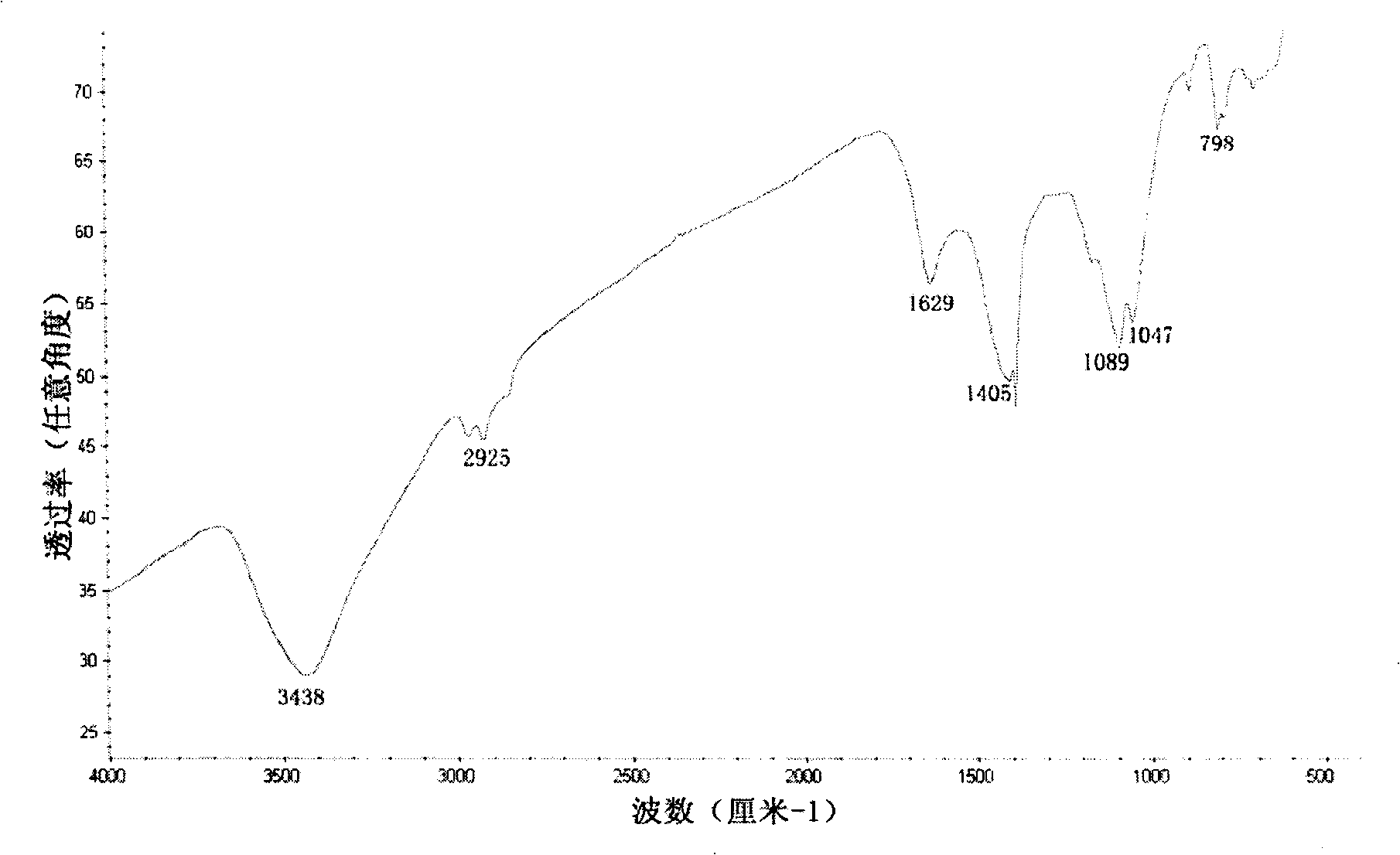

Controllable hydrothermal constant pressure synthesis method for preparation of boron-carbon-nitrogen material

InactiveCN1803596ARich varietyControllable granularityNitrogen and non-metal compoundsBoron carbonitrideSynthesis methods

The controllable hydrothermal constant-pressure synthesis method for boron carbonitride material comprises: treating the deionized water, preparing liquids for boron resource, carbon source and nitrogen source respectively; putting into the kettle; forcing 20~2000MPa pressure then heating the kettle to 240~1000Deg with 0.01~60Deg / min speed for reaction 6~480h. Wherein, it can adjust and control the system temperature and pressure independently as well as the reaction speed and direction. All the product of diamond, cubic boron nitride and carbonitride crystal block have wide application.

Owner:SHANDONG UNIV

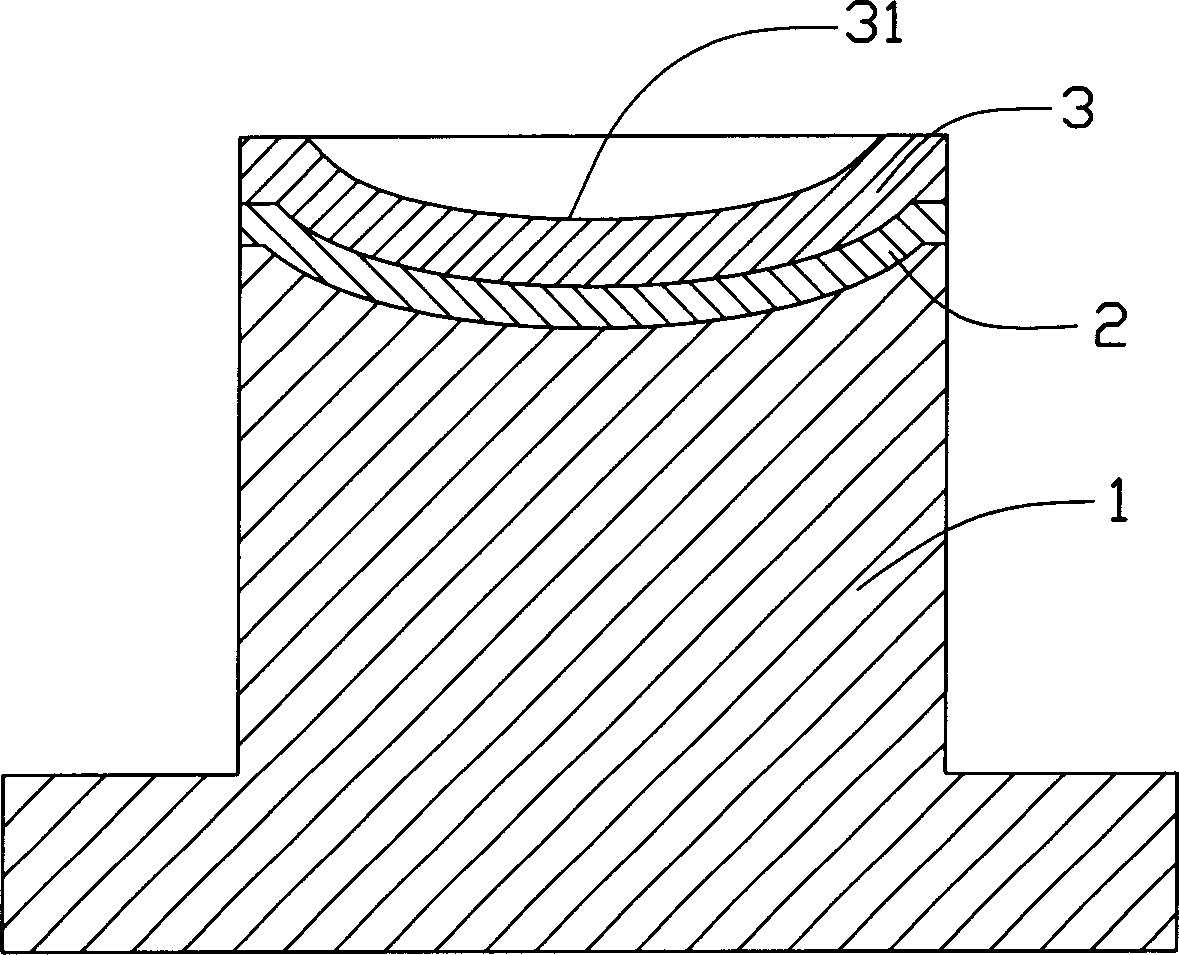

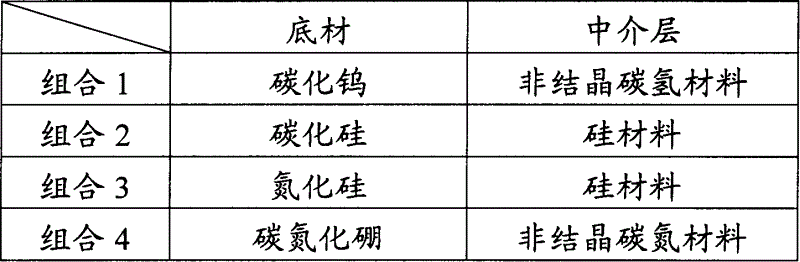

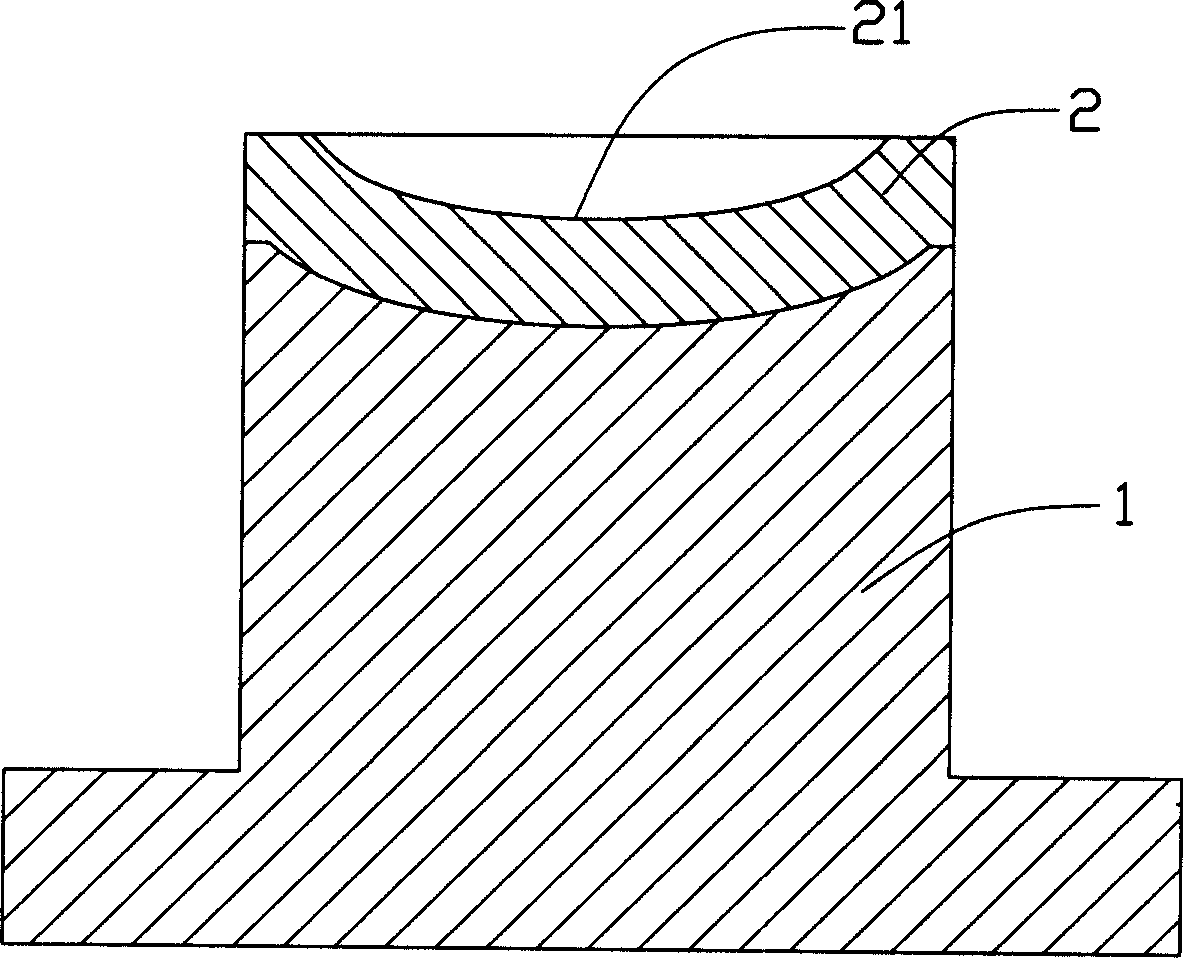

Mould core for moulded glass and manufacture thereof

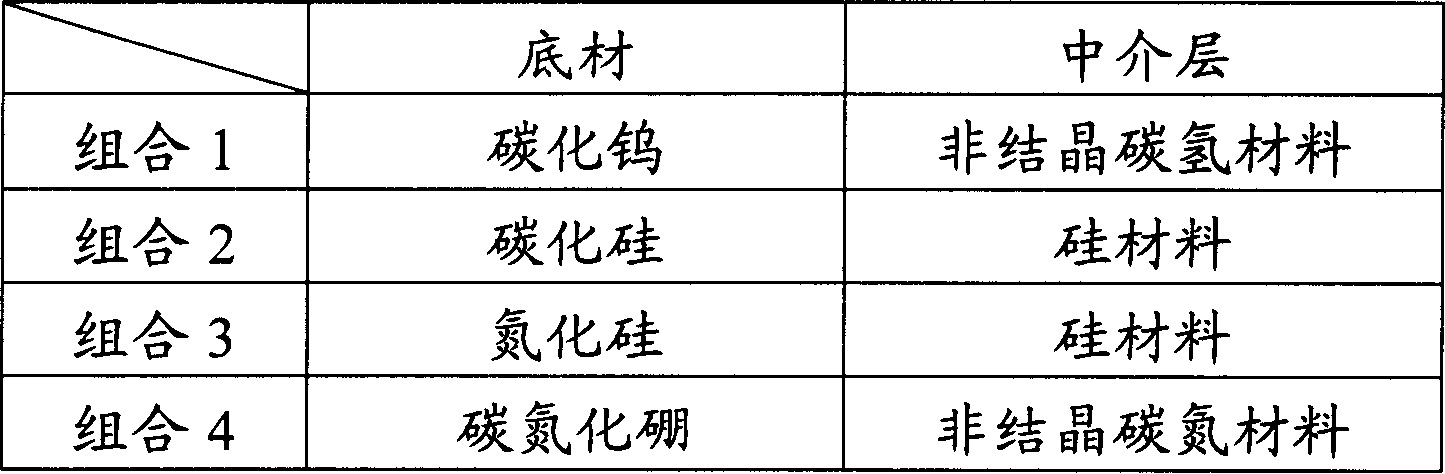

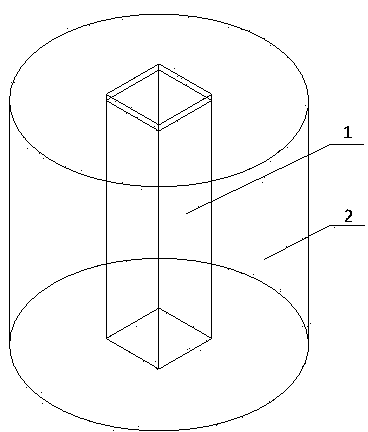

InactiveCN1680202AExtended service lifeTightly boundGlass pressing apparatusGlass press-moulding apparatusTectorial membraneBoron carbonitride

A moulded glass mould core and its production are disclosed. The moulded glass mould core consists of substrate, medium layer and protecting film. The medium layer is arranged on the substrate , the protecting film is arranged on the medium layer, the protecting film has a moulded face of moulded groove, the material of the substrate is tungsten carbide, silicon carbide, silicon nitride and boron carbonitride, the material of the medium layer is agraphitic hydrocarbon material, silicon and agraphitic carbonitride material.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Preparation method of ultrahard anti-abrasion PCD (Poly Crystal Diamond) material containing enhanced core

The invention discloses a preparation method of an ultrahard anti-abrasion PCD (Poly Crystal Diamond) material containing an enhanced core. The enhanced-core-containing PCD (Poly Crystal Diamond) material is obtained by cutting cubic boron nitride (c-BN), cubic boron carbon nitride (c-BC2N), boron carbide (B4C) or nano twin-crystal cubic boron nitride (nt-CBN) serving as the enhanced core into small columns, burying the column bodies of the enhanced core into diamond micro powder, putting the diamond micro powder into a pyrophyllite block and performing synthesis under high-temperature and high-pressure conditions. The novel ultrahard anti-abrasion material prepared by the preparation method disclosed by the invention integrates two characteristics, which are similar to ultrahigh hardness of natural diamonds and toughness of a poly crystal material, of an ultrahard extreme material, so that the application ranges of the ultrahard extreme material and the PCD material are expanded and the increasing requirements on the performance of ultrahard anti-abrasion materials of the mechanical manufacturing and petroleum / geological exploration industries are met.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

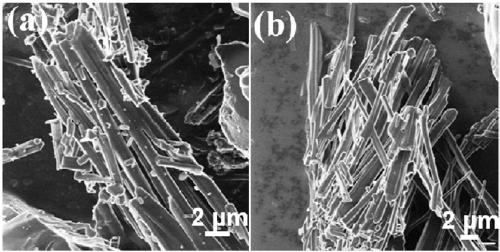

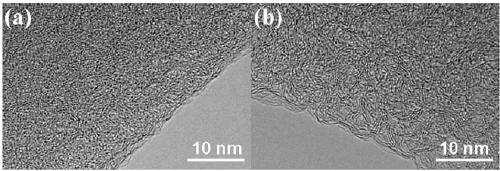

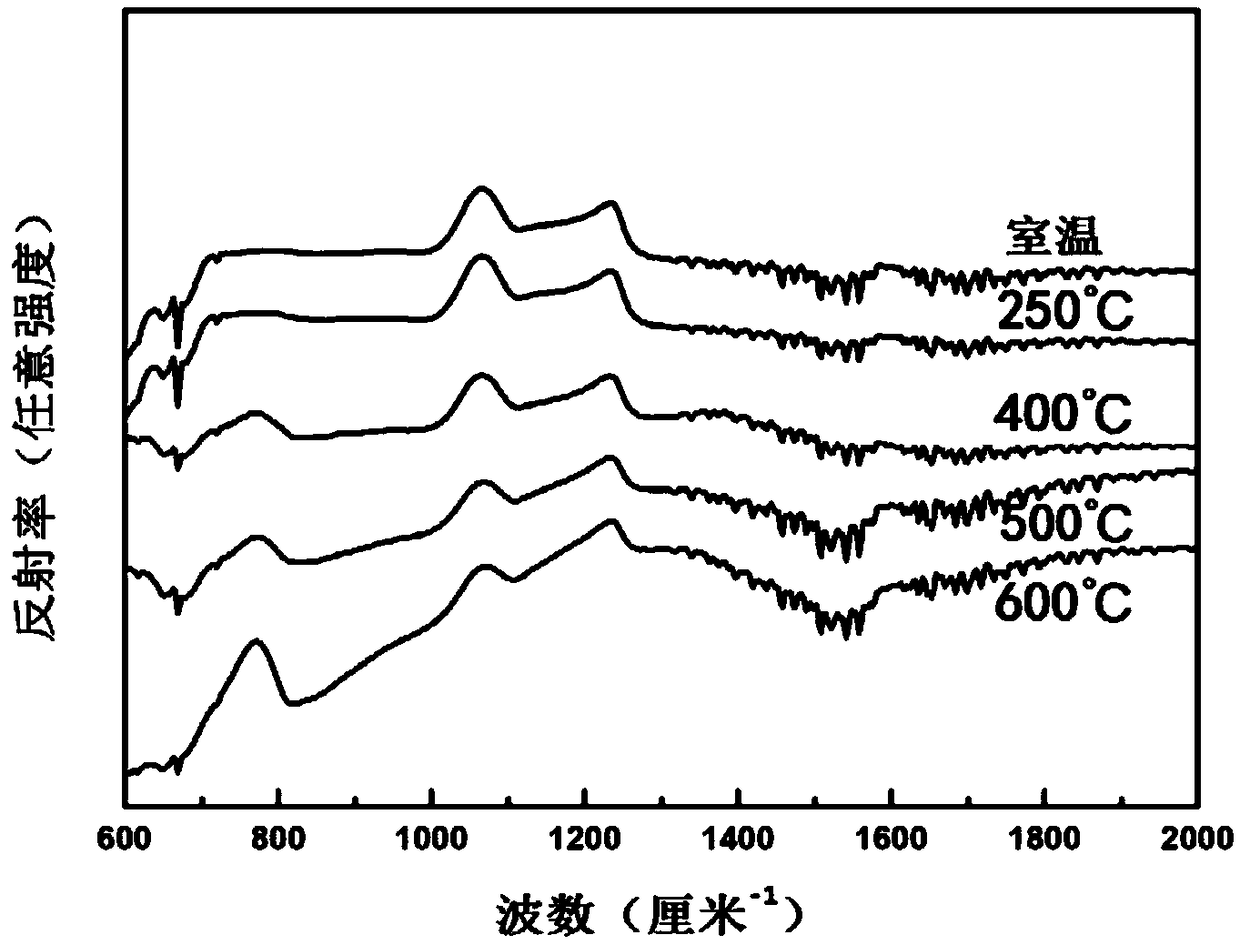

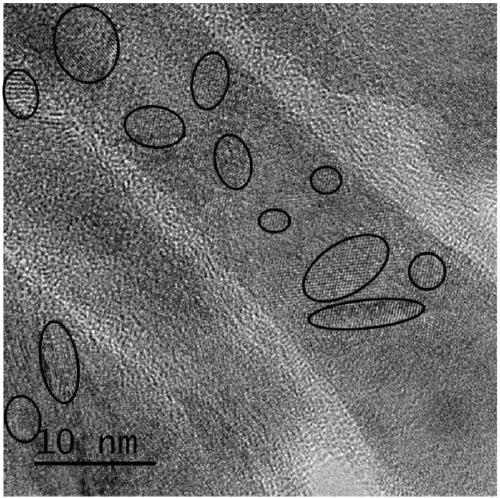

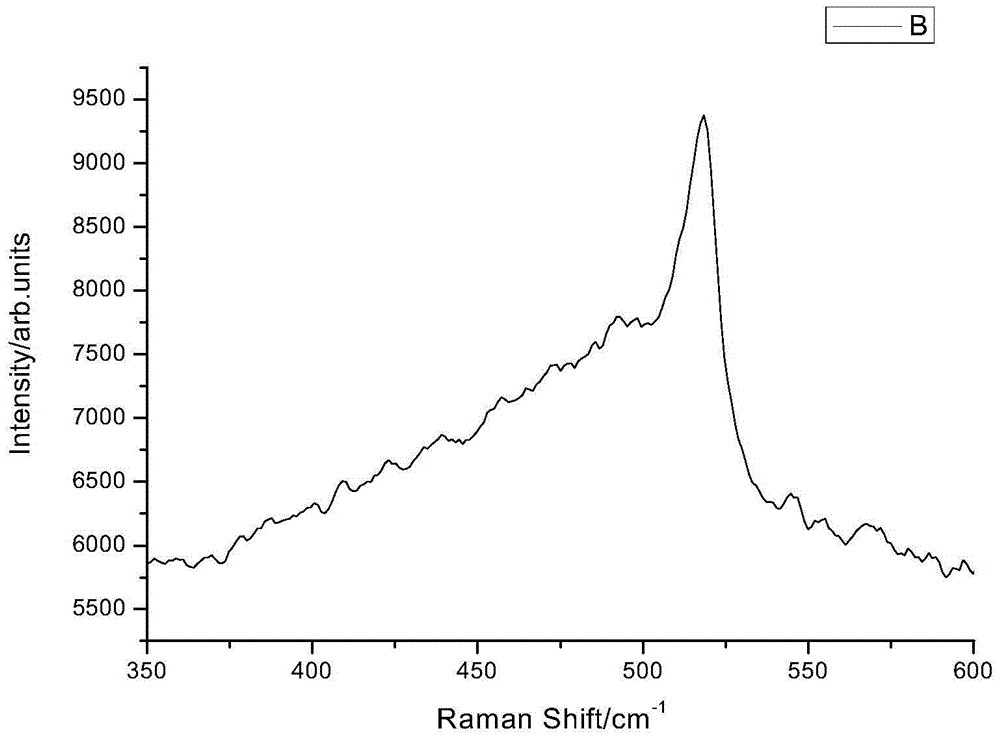

Boron-carbon-nitrogen film encapsulating highly-oriented boron nitride nanocrystal and preparation method of boron-carbon-nitrogen film

ActiveCN109161844AOrderly and controllable growth orientationFully regulated growthVacuum evaporation coatingSputtering coatingBoron carbonitrideRadio frequency magnetron sputtering

The invention relates to a boron-carbon-nitrogen film encapsulating highly-oriented boron nitride nanocrystal and a preparation method of the boron-carbon-nitrogen film, and belongs to the technical field of film materials and preparation thereof. The boron-carbon-nitride film is of an amorphous structure containing boron nitride nanocrystals and growing on a silicon substrate. According to the preparation method, boron nitride containing carbon is used as a target material, and the boron-carbon-nitrogen film is prepared in a deposition chamber of a radio frequency magnetron sputtering device,wherein the substrate temperature ranges from room temperature to 600 DEG C, working gases comprise an argon gas and a nitrogen gas, flow rates are 50 sccm and 0-50 sccm respectively, and the workingpressure is 1 to 3 Pa. Ordered and controllable growth of the orientation of boron nitride nanocrystals in a film can be realized by adjusting technological parameters, and the obtained boron-carbon-nitride film has an optical band gap of about 2.7 to 4.5 eV, and has good and adjustable optical properties. The preparation method provided by the invention has the advantages of simple and safe process, mature technology, high sputtering rate, uniform deposition film, controllable size and the like, and is suitable for industrial mass production and promotion.

Owner:JILIN UNIV

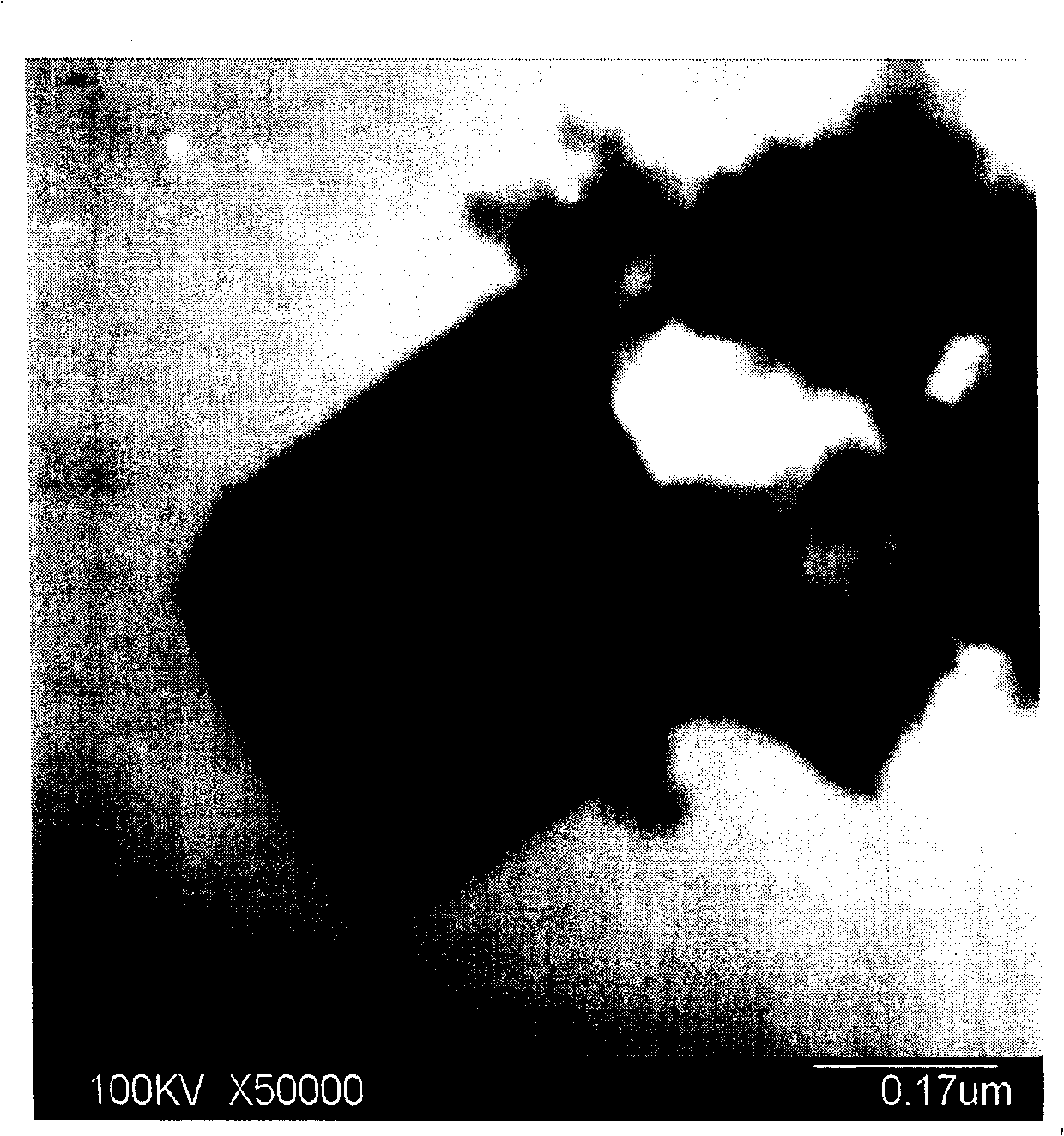

Preparation method for boron carbonitride nanosheet loaded metal nano particle hybrid material

InactiveCN105880629AThe synthesis process is simpleShort cycleNanotechnologyMetal nitrateBoron carbonitride

The invention belongs to the technical field of nano materials, and relates to a preparation method for a boron carbonitride nanosheet loaded metal nano particle hybrid material. The boron carbonitride nanosheet loaded metal nano particle hybrid material is prepared by taking metal nitrate, glycine and boric acid as raw materials through a one-step thermal treatment method. A synthetic method for the boron carbonitride nanosheet loaded metal nano particle hybrid material provided by the invention is simple in synthesis process, and the needed raw materials are cheap and easily available raw materials on the market; and the prepared a boron carbonitride nanosheet loaded metal nano particle hybrid material is soft and porous, and has a very good application prospect on application fields such as capacitors, hydrogen storage carriers and biosensors.

Owner:JIANGSU UNIV

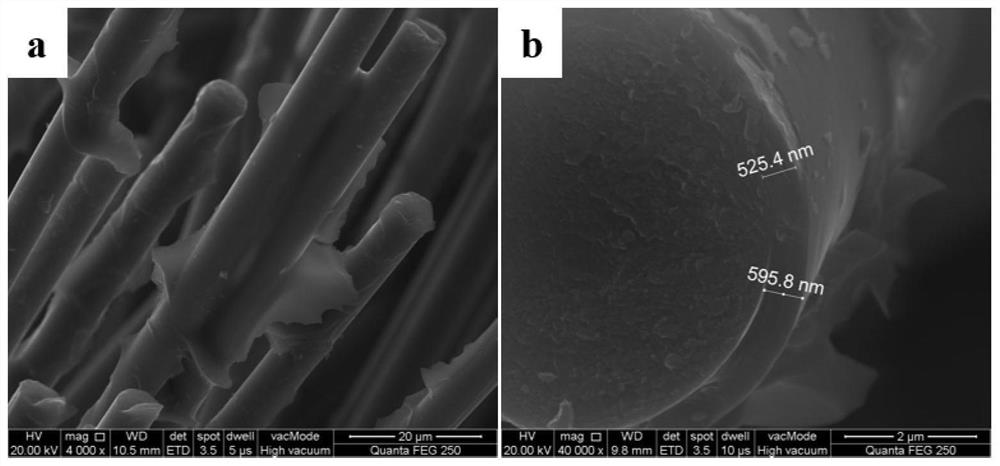

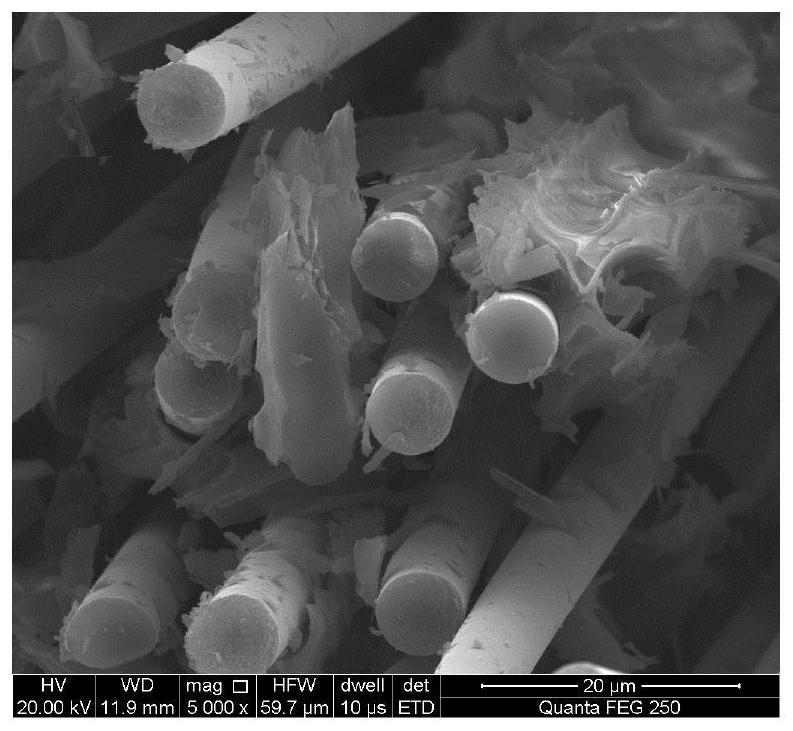

Method and apparatus for delivery of molecules to cells

ActiveUS9394547B2Bioreactor/fermenter combinationsBiological substance pretreatmentsCentrifugationCarbon nitride

The present invention is concerned with a system and method for introducing a substance into cells. The system has an assembly including a plurality of elongate non-hollow nanoneedles forming a nanoneedle array or patch for delivering the substance into the cells, at least some of the nanoneedles have a non-uniform diameter with a wider upper end, a narrower lower end for penetration into the cells and a length from substantially 200 nm to 100 um. The lower end has a diameter from substantially 20-436 nm. Adjacent nanoneedles are spaced apart by substantially 5-50 um. The nanoneedles are made from a material selected from the group consisting of diamond, cubic boron nitride, carbon nitride, boron nitride, boron carbon nitride, metal borides and essentially boron materials, allowing the nanoneedles to maintain sufficient thinness and yet adequate rigidity during penetration. The nanoneedles are applied onto the cells grown on substrates at a preferred rate from 1 to 5 m / s. Alternatively, the nanoneedles are applied onto the cells grown on substrates by centrifugation force from 0.5 to 10 nN. Yet alternatively, the cells suspended in a fluid are applied to the nanoneedle array at a rate of 1 to 10 m / s.

Owner:CITY UNIVERSITY OF HONG KONG

Die produced glass model core and producing method thereof

InactiveCN101164931AExtended service lifeTightly boundVacuum evaporation coatingSputtering coatingTectorial membraneBoron carbonitride

This invention relates to the glass mould kernel for die casting. It consistes of: a basic layer, a medium layer and a protective film. The basic layer is covered by aid medium layer, and the protective film is over the medium layer. Said protective film has the surface with a trough. The basic material is made of boron carbonitride, and the medium layer is made of non-crystalline carbonitrides. This invention provides also a method for manufacturing said product.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

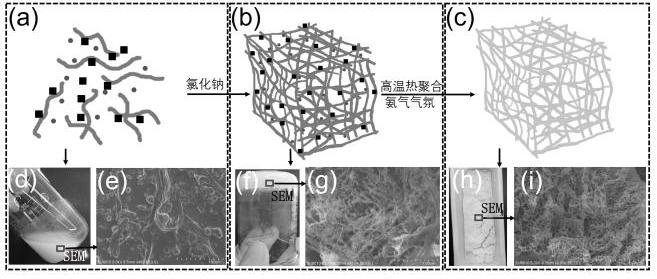

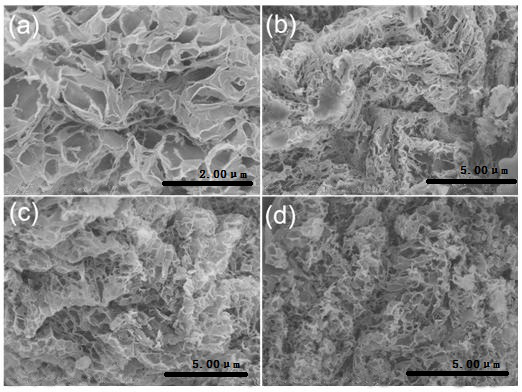

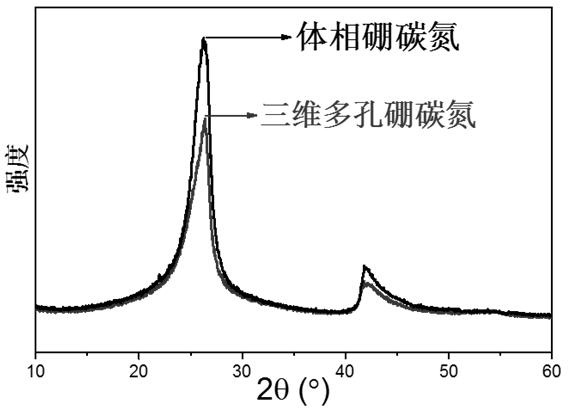

A kind of three-dimensional porous boron carbon nitrogen material and its preparation method and application

ActiveCN108341404BLow priceSimple preparation processPhysical/chemical process catalystsNitrogen and non-metal compoundsBoron carbonitrideCharge separation

The invention belongs to the technical field of nanomaterial preparation and relates to a three-dimensional porous boron carbon nitrogen material, a preparation method thereof and its application in the field of photocatalysis. This method uses boric acid, urea and starch as raw materials and mixes them with sodium chloride salt, then adds an appropriate amount of water and ultrasonics to dissolve it, mix it evenly, and leave it to stand at normal temperature and pressure. After a few hours, a precursor with a three-dimensional porous structure will be formed. The body is then thermally polymerized at high temperature in an ammonia atmosphere to synthesize a three-dimensional porous boron carbon-nitrogen material. The preparation method provided by the invention has simple process, cheap materials, and mild and controllable conditions. The obtained boron carbon nitrogen material has a significantly increased specific surface area, smaller pore size, significantly improved charge separation, has good photocatalytic properties, and has broader applications in the fields of photoelectricity, catalysis, photodegradation of organic pollutants, adsorption, and energy storage. Applications.

Owner:FUZHOU UNIV

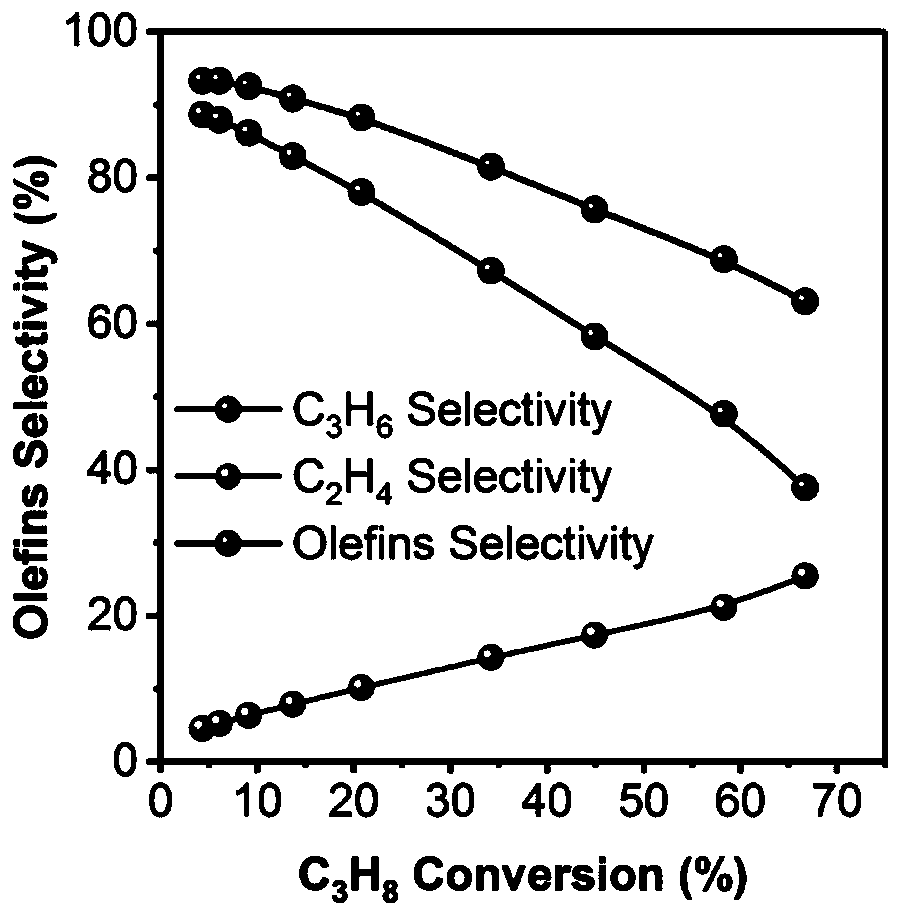

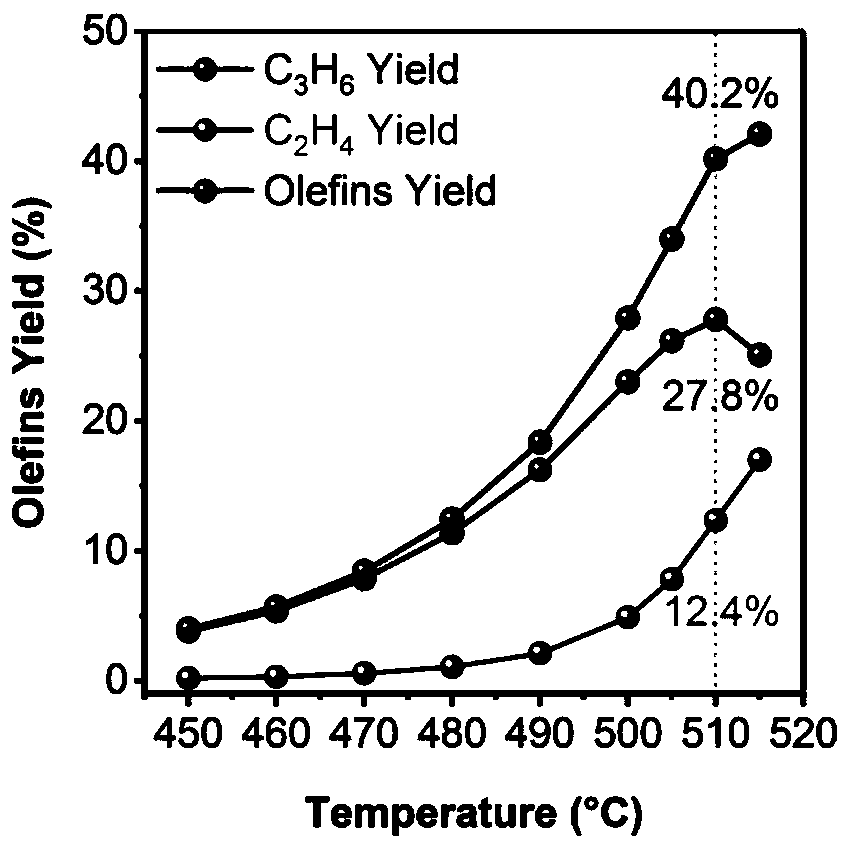

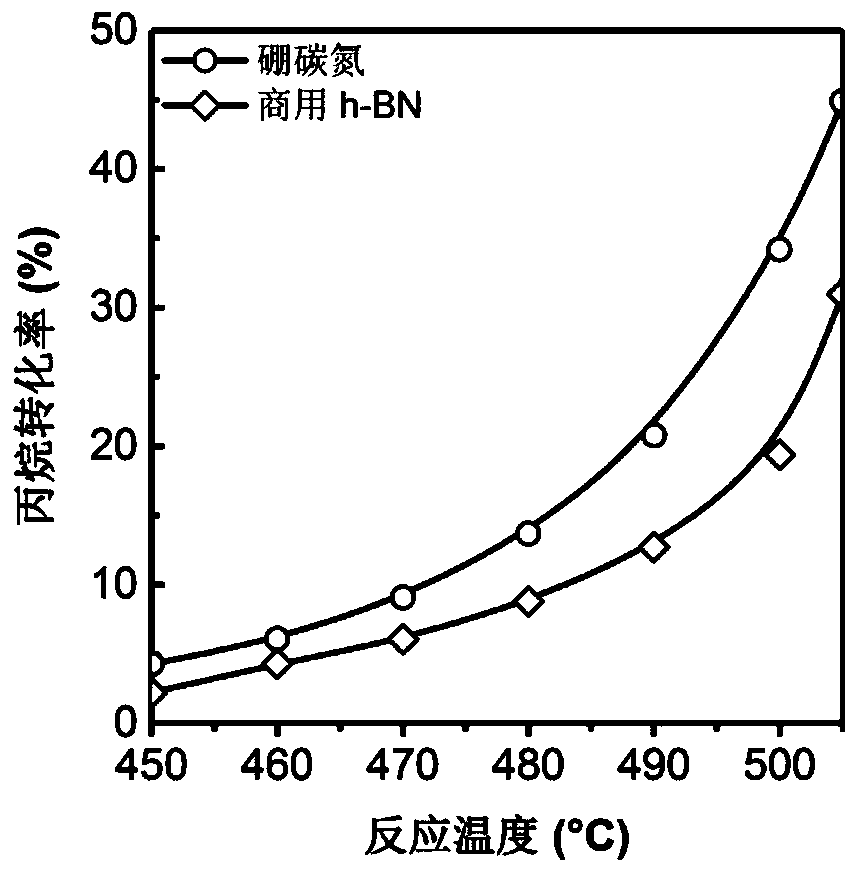

Application of boron carbonitride material in catalyzing oxidative dehydrogenation of light alkane to prepare olefin

InactiveCN110743593AHigh yieldSimple preparation processPhysical/chemical process catalystsHydrocarbonsAlkaneBoron carbonitride

The invention belongs to the technical field of catalyst application, and particularly relates to an application of a boron carbonitride material in catalyzing the oxidative dehydrogenation of a lightalkane to prepare an olefin. Under the reaction atmosphere, B-O sites at the serrated site of the boron carbonitride material react with the alkane to form hydroxyl groups to induce a reaction to start, the carbon in the boron carbonitride material reacts with an oxidant to form carbonyl groups to become another active site in the reaction, the carbonyl groups react with hydrogen in the light alkane to become hydroxyl groups at a certain temperature, and thereby the hydrogen in the light alkane is removed to obtain the corresponding olefin. The boron carbonitride material has a stable two-dimensional structure, and the selectivity of the olefin in the product is improved while the thermal stability of the material is ensured. At the same time, a single material has two active sites, the density of the active sites is increased, and thereby the yield of the olefin is improved under the same reaction condition.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

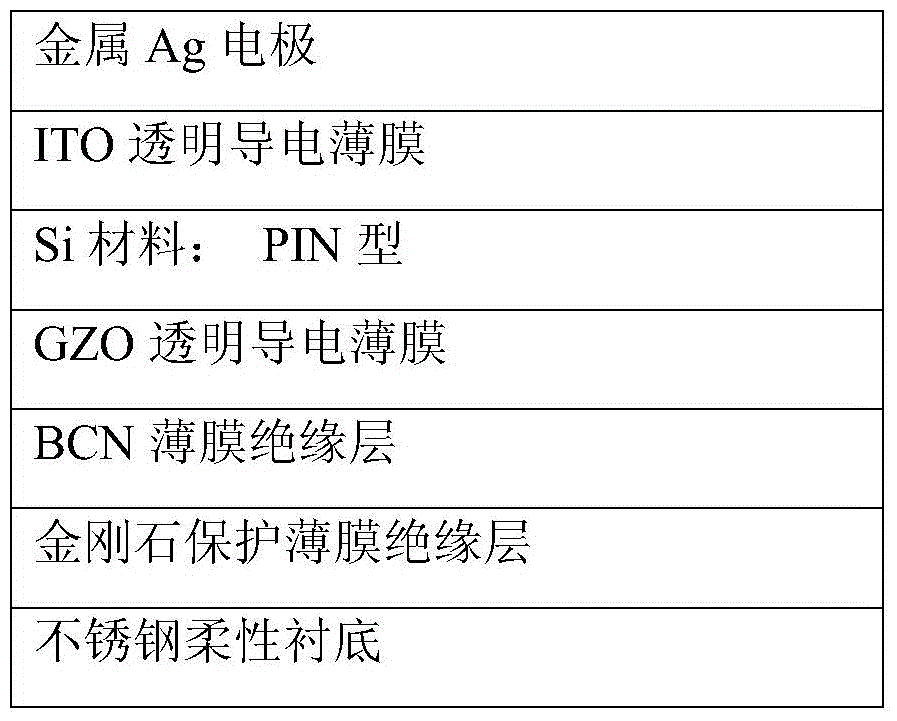

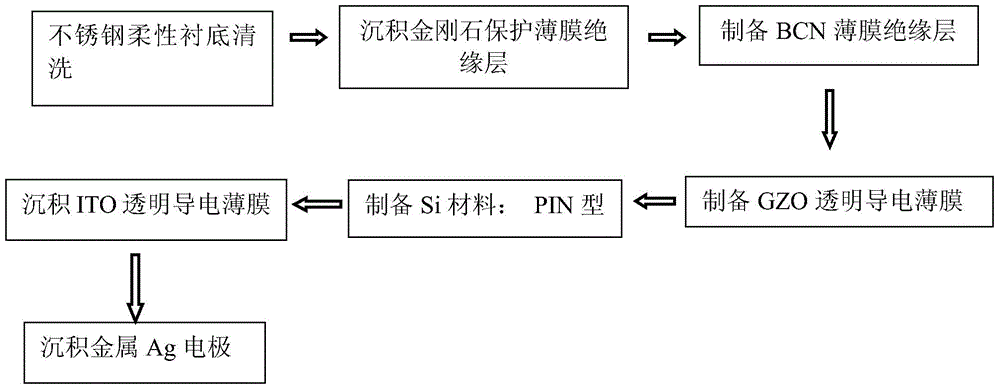

Si-based flexible stainless steel structured solar battery and preparation method

ActiveCN105047740ASolve the principle of poor corrosion resistanceImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationBoron carbonitrideManufacturing technology

The invention belongs to the technical field of manufacturing of solar batteries, and in particular relates to a film solar battery of an Si-based flexible substrate added with a protective layer and a preparation method. The solar battery sequentially comprises a metal Ag electrode, an ITO (Indium Tin Oxide) transparent conductive film, an N-type Si crystal film, an intrinsic I-type nano-crystalline silicon film, a P-type nano-crystalline silicon film, a GZO (Gallium Zinc Oxide) transparent conductive film, a BCN (Boron Carbonitride) film insulated layer, a diamond protective film insulated layer and a stainless steel flexible substrate from top to bottom, wherein the intrinsic I-type nano-crystalline silicon film is used as an intermediate layer. According to the invention, the principle that the diamond film is combined with BCN is adopted; therefore, the problem of poor corrosion resistance of the film solar battery is solved; the service life of the film solar battery is prolonged; no any obvious film damage phenomenon exists through the method; thus, the photoelectric conversion efficiency of the solar battery is increased; and in addition, the stability of the photo-induced property of the solar battery is improved.

Owner:河南迎基太阳能科技有限公司

Model glass kernel and manufacturing method thereof

InactiveCN1689996AExtended service lifePhysical stabilityGlass pressing apparatusTectorial membraneBoron carbonitride

The present invention is mold core for molding glass and its making process. The mold core includes base and protecting film on the base and with one notched molding surface. The protecting film is made of fullerene, which is prepared through graphic discharge process and is plated onto the surface of the base material through ion beam evaporation process. The base is made of ceramic material, including tungsten carbide, silicon carbide, silicon nitride, boron carbonitride, etc.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

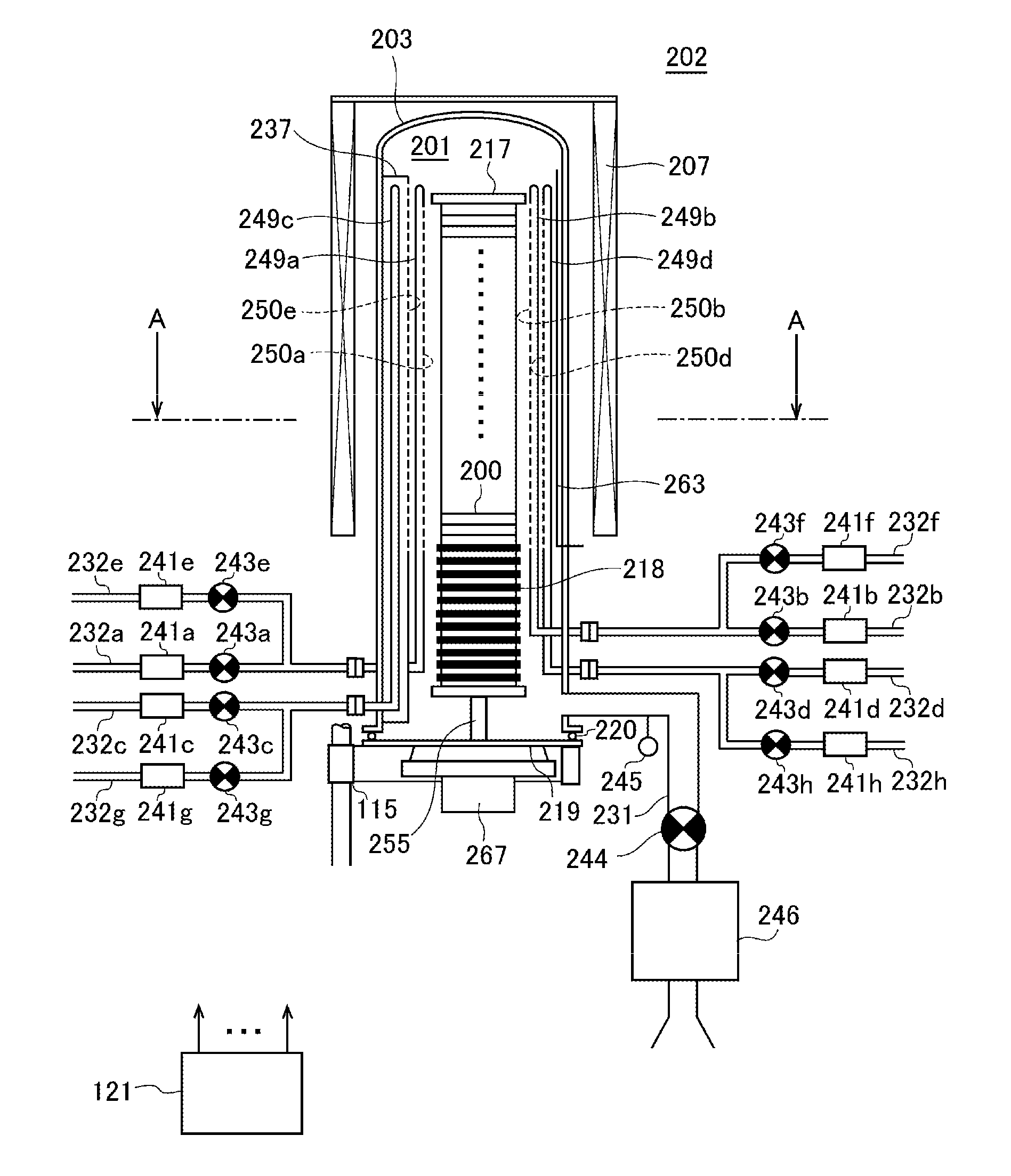

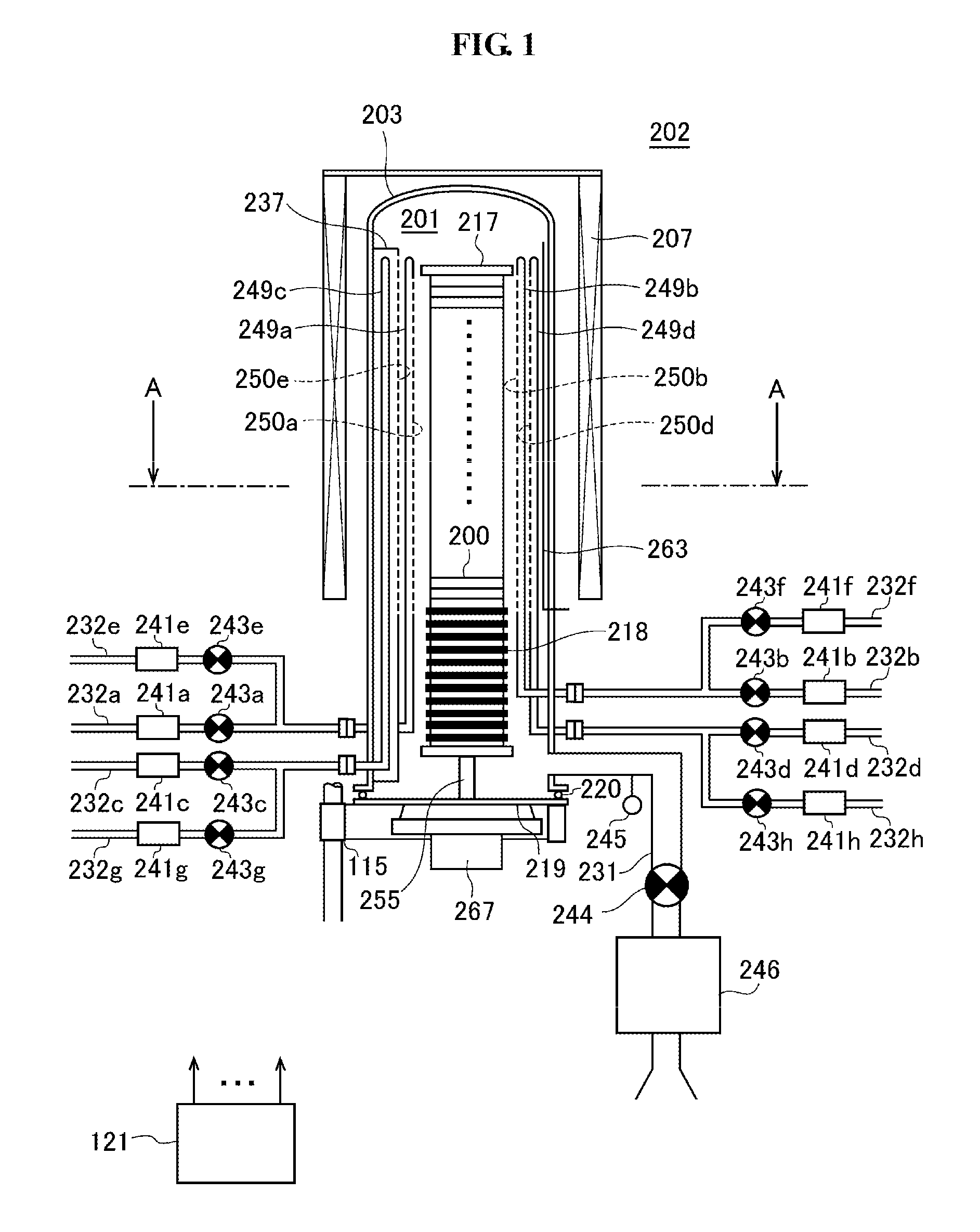

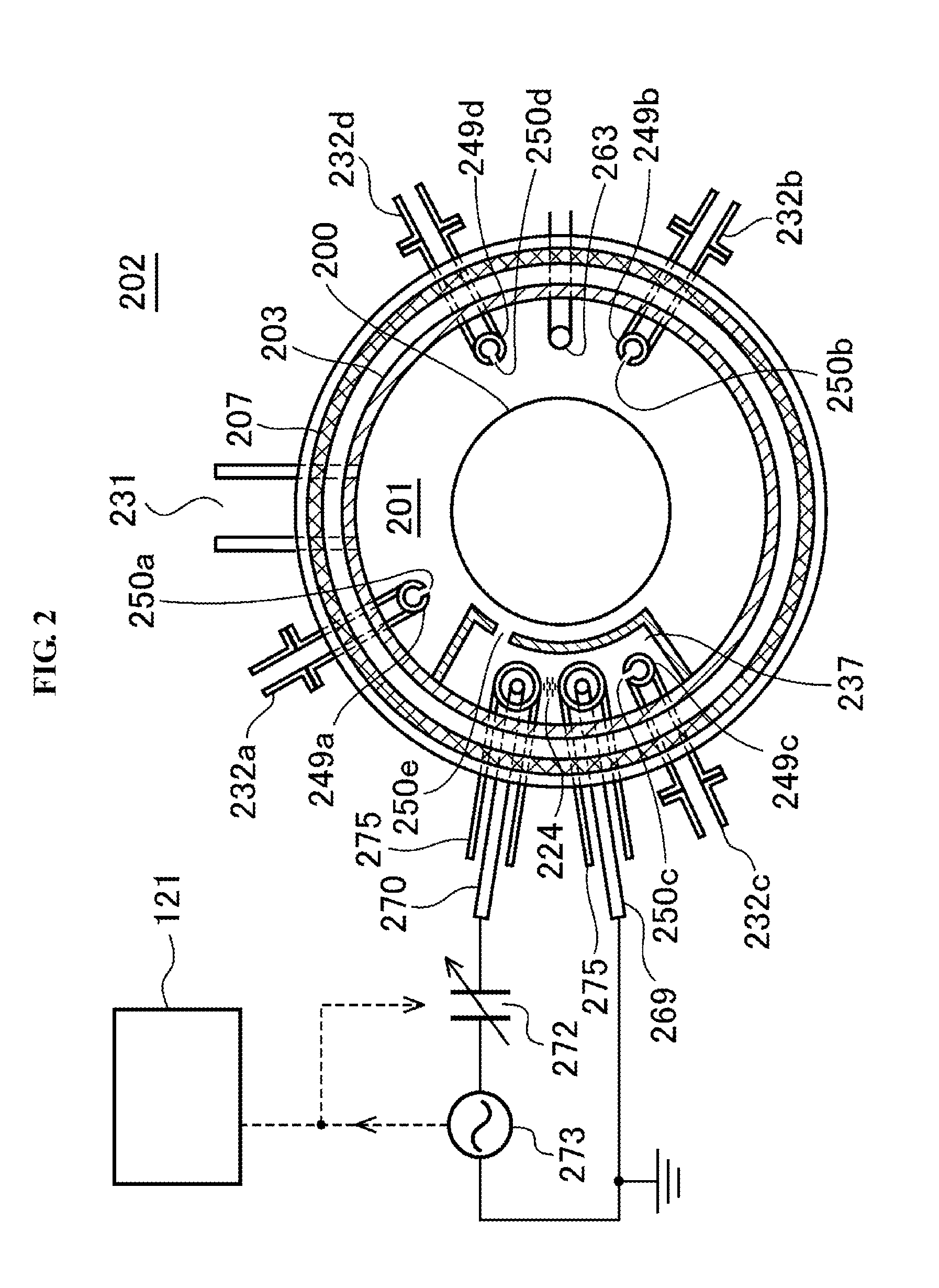

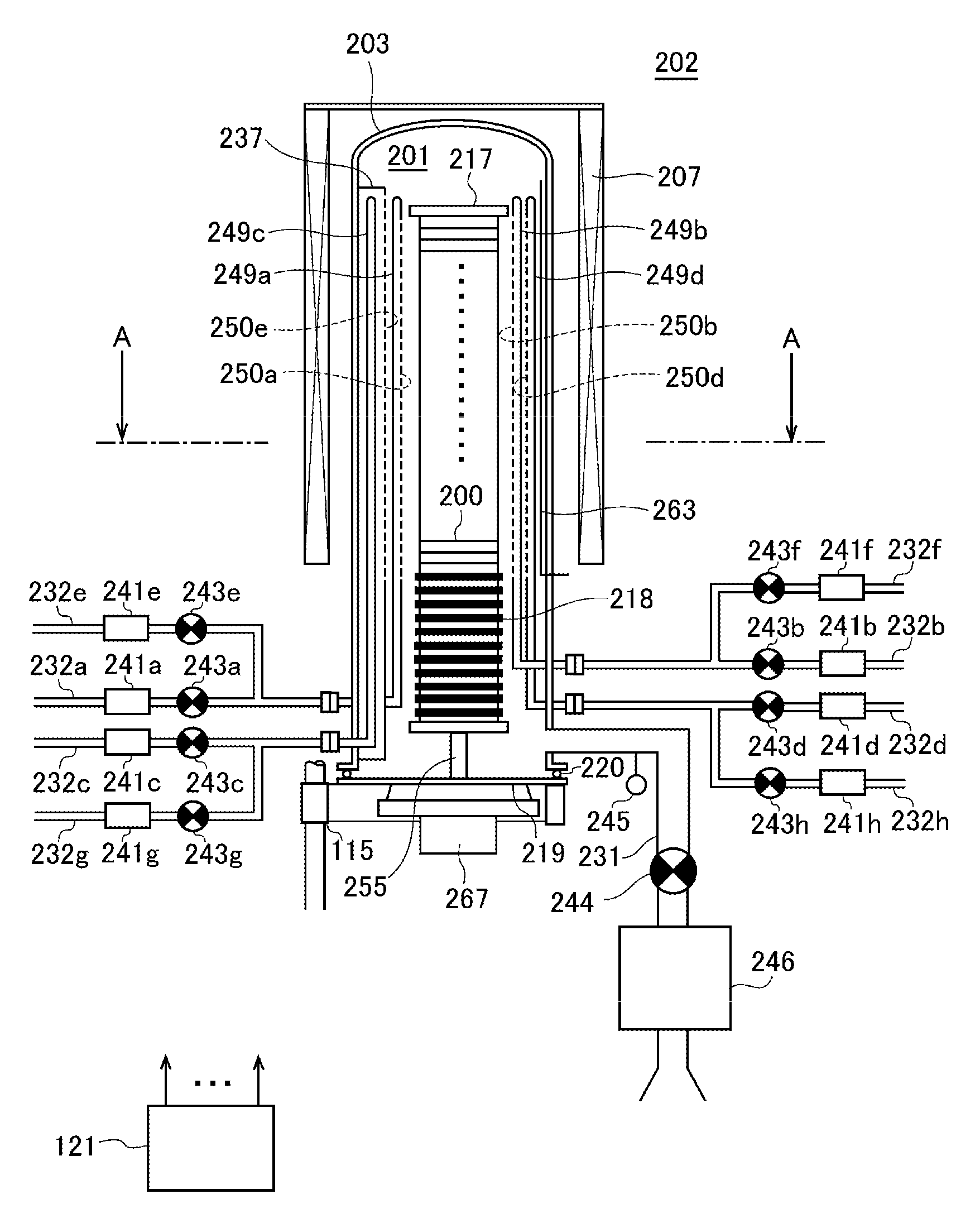

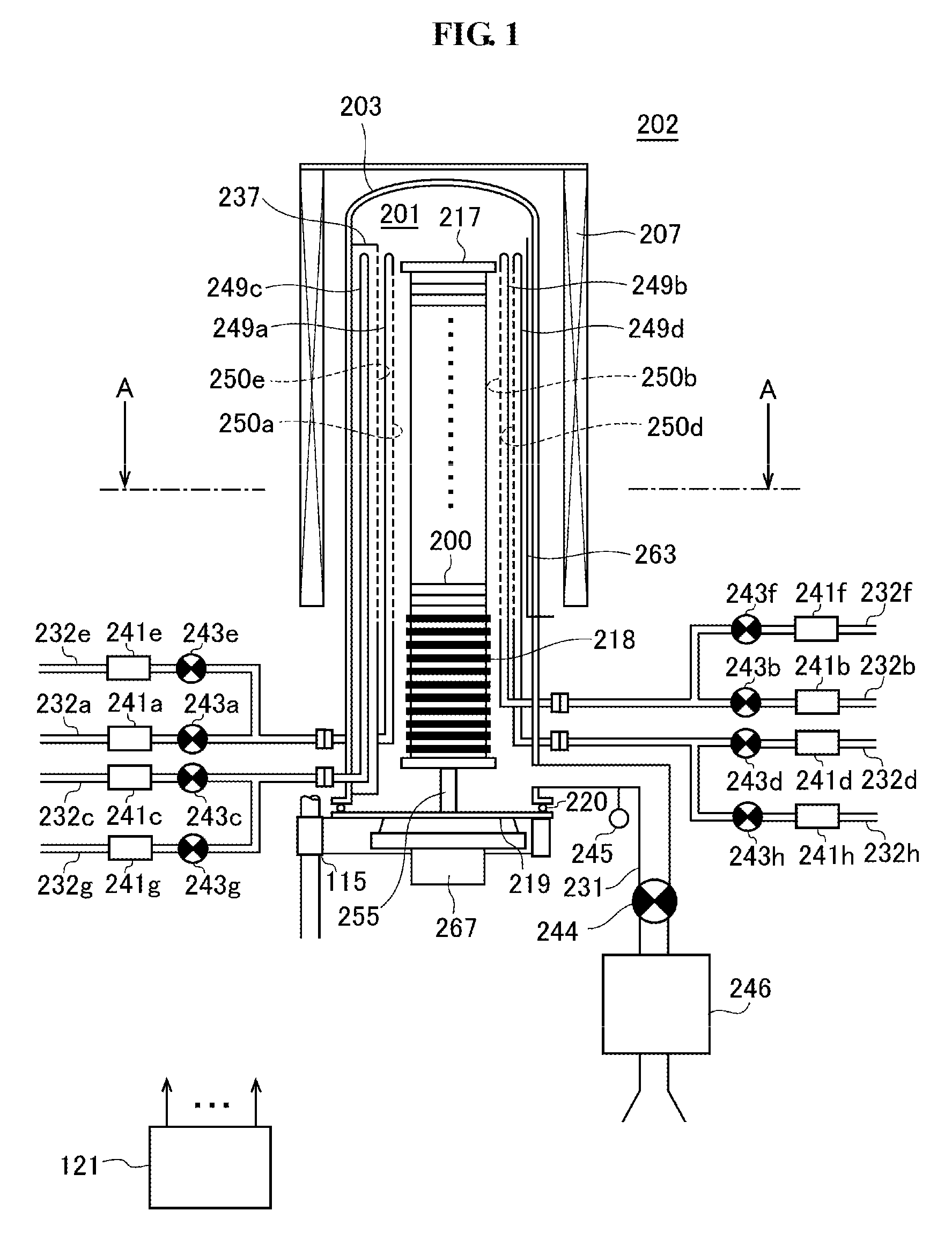

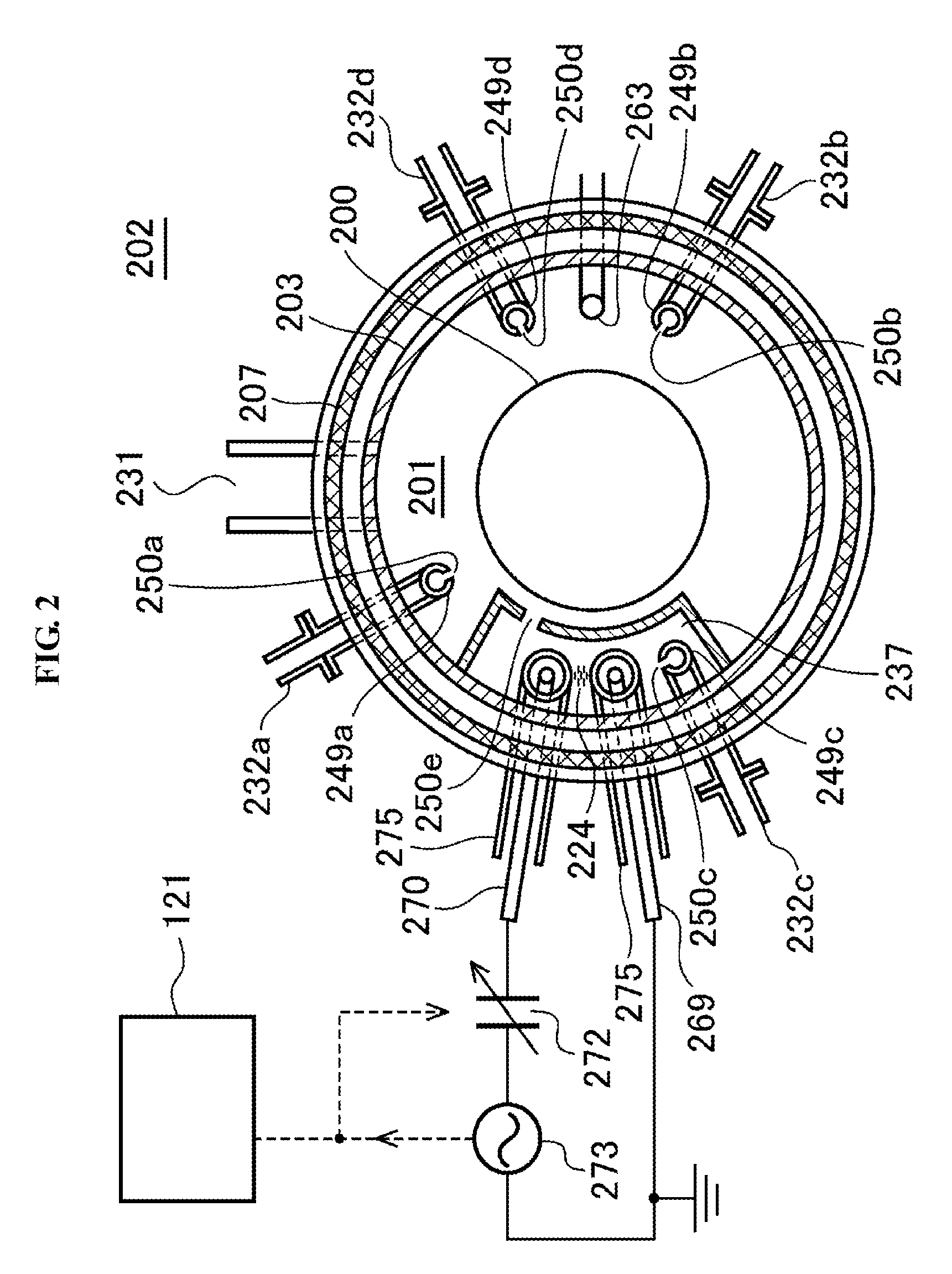

Method of manufacturing semiconductor device, substrate processing apparatus and non-transitory computer-readable recording medium

ActiveUS20140370692A1Improve controllabilityIncrease productivityLiquid surface applicatorsSemiconductor/solid-state device manufacturingBoron carbonitrideHalogen

Provided is a method of manufacturing a semiconductor device, which is capable of increasing the controllability of the concentration of carbon in a film by increasing the yield when a boron carbonitride film or a boron nitride film is formed. The method includes forming a film containing boron, carbon and nitrogen or a film containing boron and nitrogen on the substrate by performing, a predetermined number of times, a cycle including supplying a source gas consisting of boron and a halogen element to a substrate and supplying a reactive gas consisting of carbon, nitrogen and hydrogen to the substrate.

Owner:KOKUSA ELECTRIC CO LTD

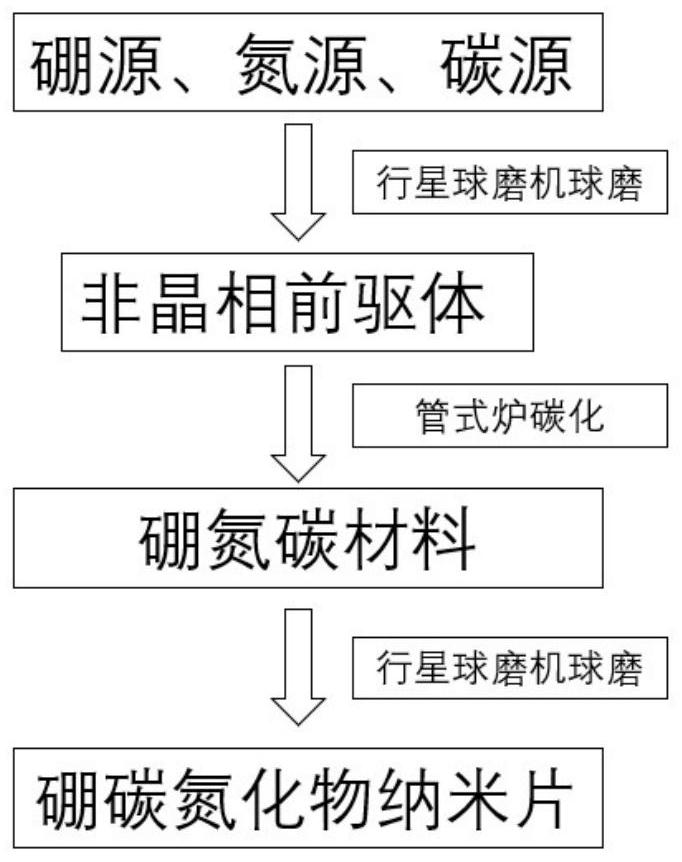

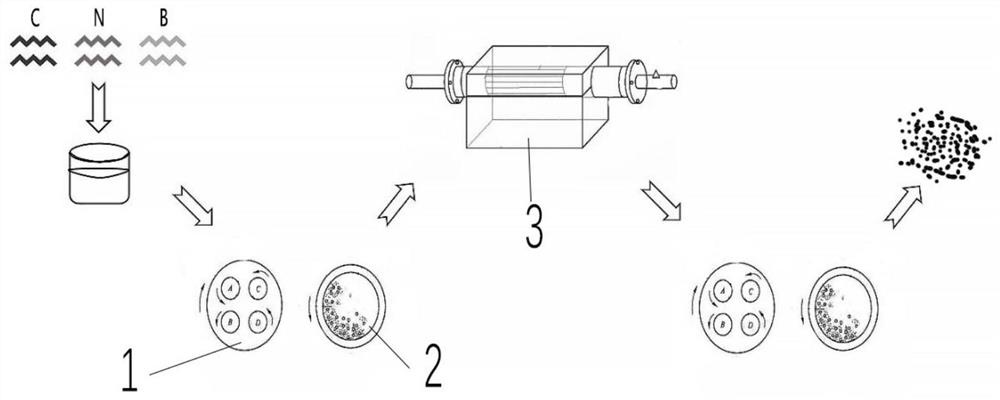

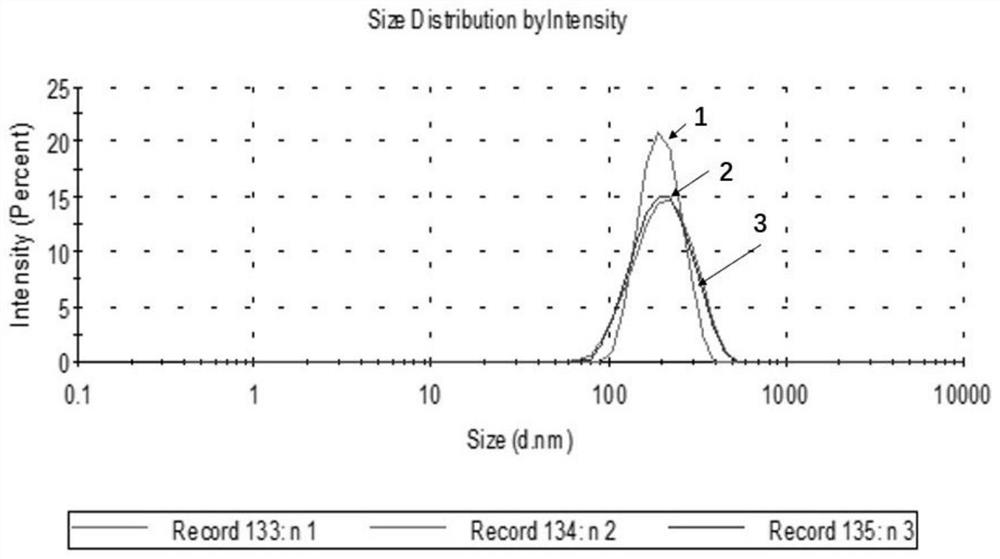

Boron carbonitride nanosheet as well as preparation method and application thereof

PendingCN113184814AReduce energy consumptionReduce manufacturing costMaterial nanotechnologyPhysical/chemical process catalystsBoron carbonitrideBall mill

The invention provides a boron carbonitride nanosheet as well as a preparation method and application thereof, the preparation method comprises the following steps: mixing a boron source, a carbon source and a nitrogen source, then stirring, drying and grinding to obtain an amorphous phase precursor, and then carrying out heat treatment, ball milling and purification. The boron carbonitride nanosheet disclosed by the invention can be applied to a supercapacitor electrode material, a heat-insulating and wave-absorbing material or a catalytic adsorption material; according to the preparation method disclosed by the invention, through ball-milling high-temperature heat treatment, the process of firstly dispersing and then separating out crystals in an aqueous solution or other solvents is omitted, so that the energy consumption of solvent evaporation is saved, and the production cost is reduced; and by optimizing the manufacturing process, the process of dissolving the raw materials in water or other solvents and then separating out is omitted, the solid raw materials are mixed and then placed in the planetary ball mill to be uniformly and finely mixed, the contact area of the raw materials is increased, the reaction is expanded, and therefore the reaction rate and the reaction degree are increased.

Owner:SHANGHAI UNIV OF ENG SCI

Method of manufacturing semiconductor device, substrate processing apparatus and non-transitory computer-readable recording medium

ActiveUS9449813B2Improve controllabilityIncrease productivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingBoron carbonitrideHydrogen

Provided is a method of manufacturing a semiconductor device, which is capable of increasing the controllability of the concentration of carbon in a film by increasing the yield when a boron carbonitride film or a boron nitride film is formed. The method includes forming a film containing boron, carbon and nitrogen or a film containing boron and nitrogen on the substrate by performing, a predetermined number of times, a cycle including supplying a source gas consisting of boron and a halogen element to a substrate and supplying a reactive gas consisting of carbon, nitrogen and hydrogen to the substrate.

Owner:KOKUSA ELECTRIC CO LTD

Controllable hydrothermal constant pressure synthesis method for preparation of boron-carbon-nitrogen material

InactiveCN100430313CSmall granularityHigh phase purityNitrogen and non-metal compoundsBoron carbonitrideSynthesis methods

The controllable hydrothermal constant-pressure synthesis method for boron carbonitride material comprises: treating the deionized water, preparing liquids for boron resource, carbon source and nitrogen source respectively; putting into the kettle; forcing 20~2000MPa pressure then heating the kettle to 240~1000Deg with 0.01~60Deg / min speed for reaction 6~480h. Wherein, it can adjust and control the system temperature and pressure independently as well as the reaction speed and direction. All the product of diamond, cubic boron nitride and carbonitride crystal block have wide application.

Owner:SHANDONG UNIV

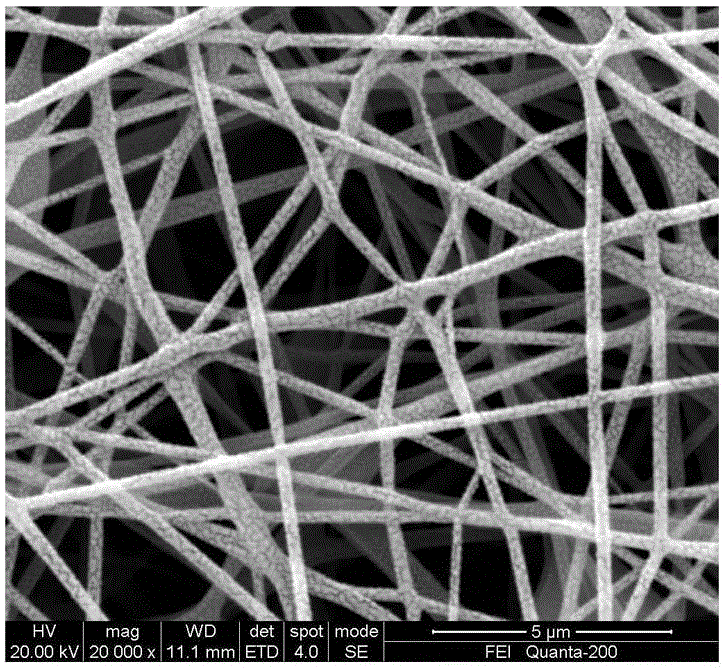

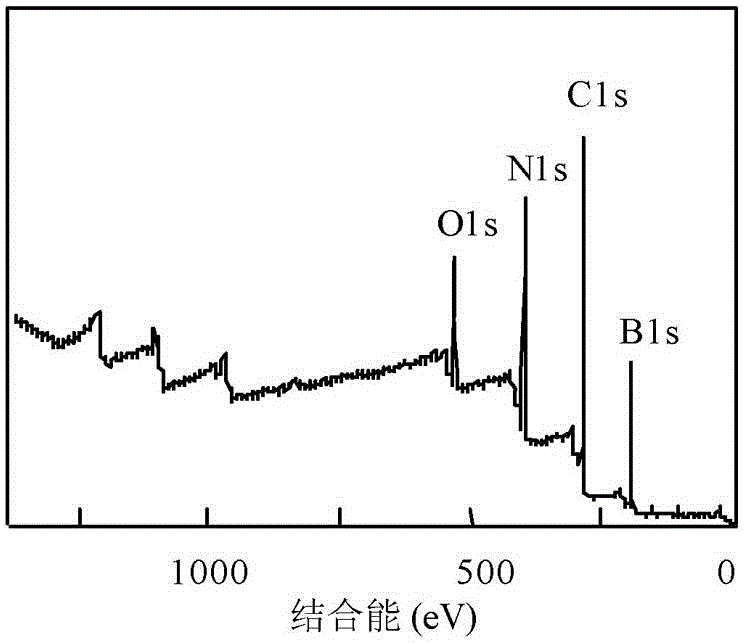

A kind of boron carbon nitrogen nano paper and preparation method thereof

ActiveCN104480574BEasy to operateLarge specific surface areaFilament/thread formingArtificial filament chemical after-treatmentCross-linkFiber

Owner:NAT UNIV OF DEFENSE TECH

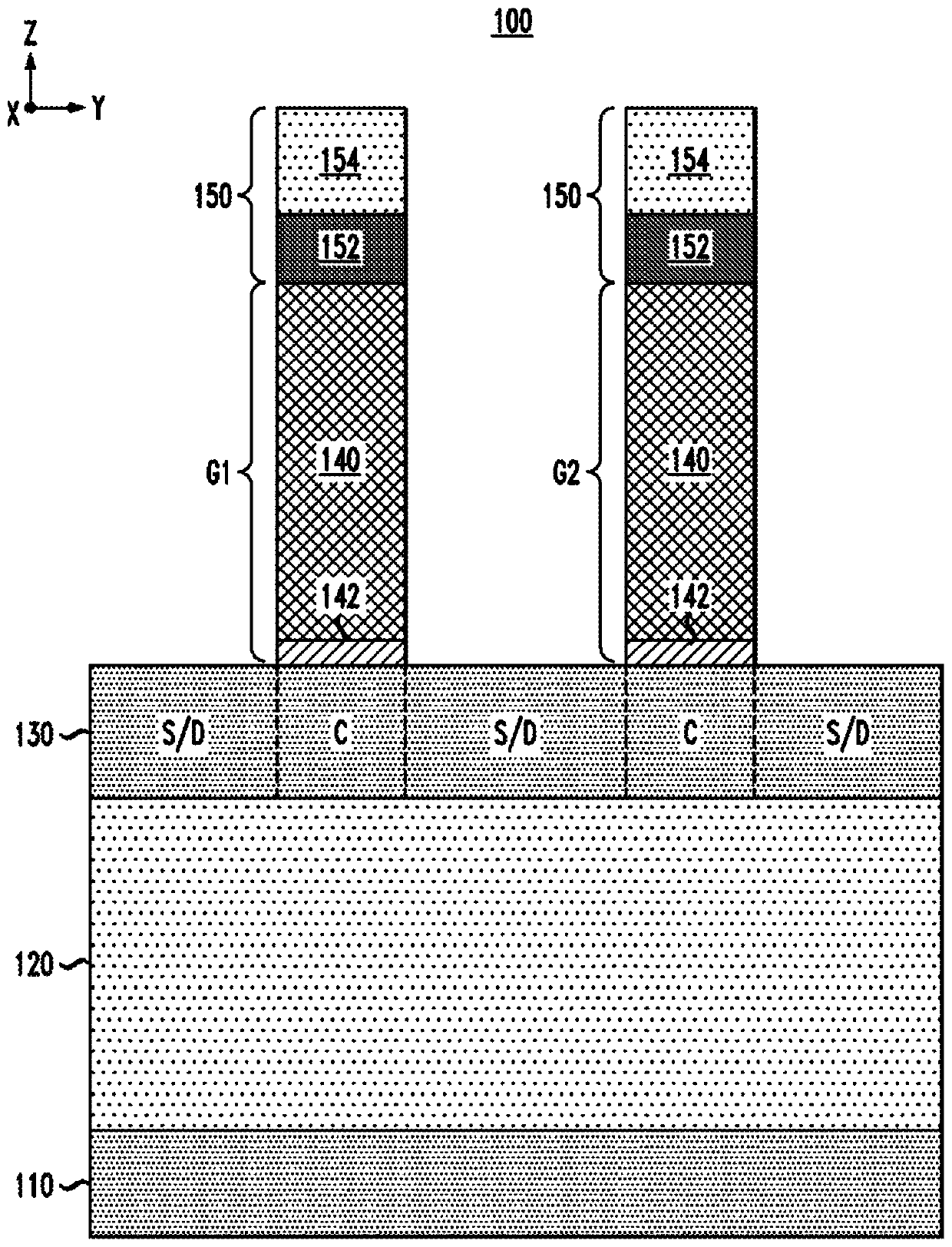

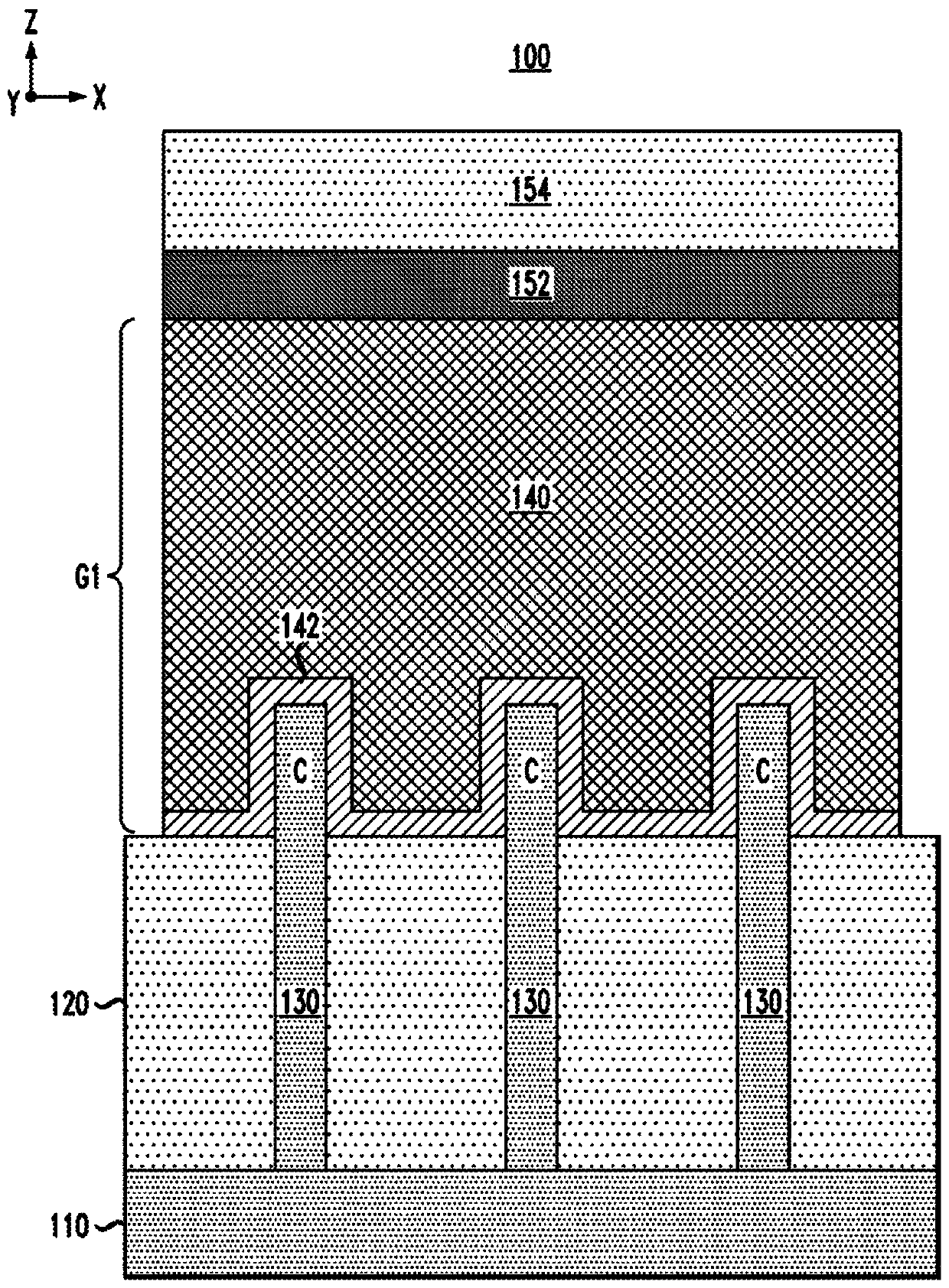

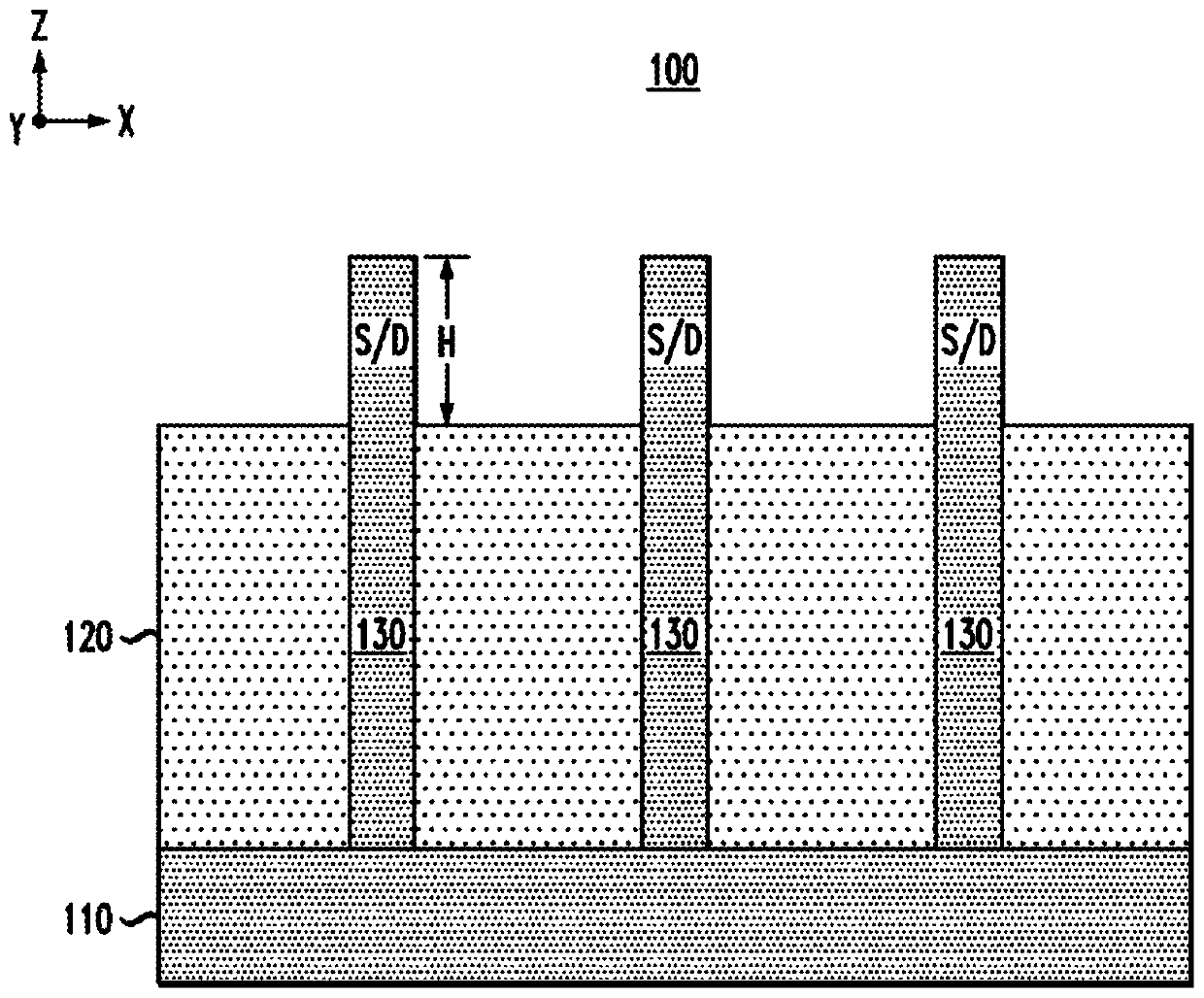

Utilizing multilayer gate spacer to reduce erosion of semiconductor fin during spacer patterning

PendingCN110603647ASolid-state devicesSemiconductor/solid-state device manufacturingBoron carbonitrideDevice material

FinFET devices comprising multilayer gate spacers are provided, as well as methods for fabricating FinFET devices in which multilayer gate spacers are utilized to prevent or otherwise minimize the erosion of vertical semiconductor fins when forming the gate spacers. For example, a method for fabricating a semiconductor device comprises forming a dummy gate structure over a portion of a vertical semiconductor fin of a FinFET device, and forming a multilayer gate spacer on the dummy gate structure. The multilayer gate spacer comprises a first dielectric layer and a second dielectric layer, wherein the first dielectric layer has etch selectivity with respect to the vertical semiconductor fin and the second dielectric layer. In one embodiment, the first dielectric layer comprises silicon oxycarbonitride (SiOCN) and the second dielectric layer comprises silicon boron carbon nitride (SiBCN).

Owner:IBM CORP

A preparation method of reinforced polycrystalline cubic boron nitride composite superhard material

ActiveCN103755317BAddressing ever-increasing demandsSolve the embarrassing situation in the applicationSuperhard materialBoron carbonitride

The invention discloses a method for preparing a reinforced polycrystalline cubic boron nitride composite superhard material. Such as cubic carbon boron nitride c-BC2N, boron carbide (B4C) and nano-twinned cubic boron nitride are added to the PCBN material. The reinforcing phase of superhard materials such as (nt-CBN) is a new method of high temperature and high pressure sintering to synthesize superhard composite materials, which belongs to the field of superhard materials. The steps are: cutting a material with extremely high hardness into reinforced core cylinders, embedding the reinforced core cylinders in the powder, putting pyrophyllite blocks into them, and synthesizing under high temperature and high pressure conditions to obtain PCBN materials with reinforced cores. The strengthened PCBN composite superhard material prepared by the present invention has both the toughness of PCBN and the ultrahigh hardness comparable to natural diamond materials, which solves the increasingly higher requirements of the modern machining industry for cutting tools and the application of some extremely superhard materials. The embarrassing situation in this field has broadened the application field of superhard materials.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

A kind of preparation method of carbon/carbon-boron nitride antifriction composite material

ActiveCN109665855BImprove mechanical propertiesImprove friction and wear propertiesFiberBoron carbonitride

The invention discloses a method for preparing a carbon / carbon-boron nitride friction-reducing composite material. The graphitized C / C green body is acidified, washed to neutral to obtain a pretreated C / C green body, and then soaked In a solution containing a modifier, react to obtain a functionalized C / C green body, and then immerse the functionalized C / C green body in the h-BN slurry, and dry to obtain a C / C-BN prefabricated body, C / C-BN prefabricated body is carbonized and densified by carbon source, and graphitized to obtain C / C-BN antifriction composite material; the modifier is selected from silane coupling agent or polyvinyl alcohol (PVA) . The invention adopts the slurry impregnation method firstly to obtain the BN matrix. After functionalizing the C / C body, the BN powder can be effectively introduced into the C / C body during the slurry impregnation process. This method can effectively avoid the damage of carbon fibers and ensure the excellent structural strength of C / C‑BN composites. The obtained C / C‑BN composites have excellent friction and wear properties.

Owner:CENT SOUTH UNIV

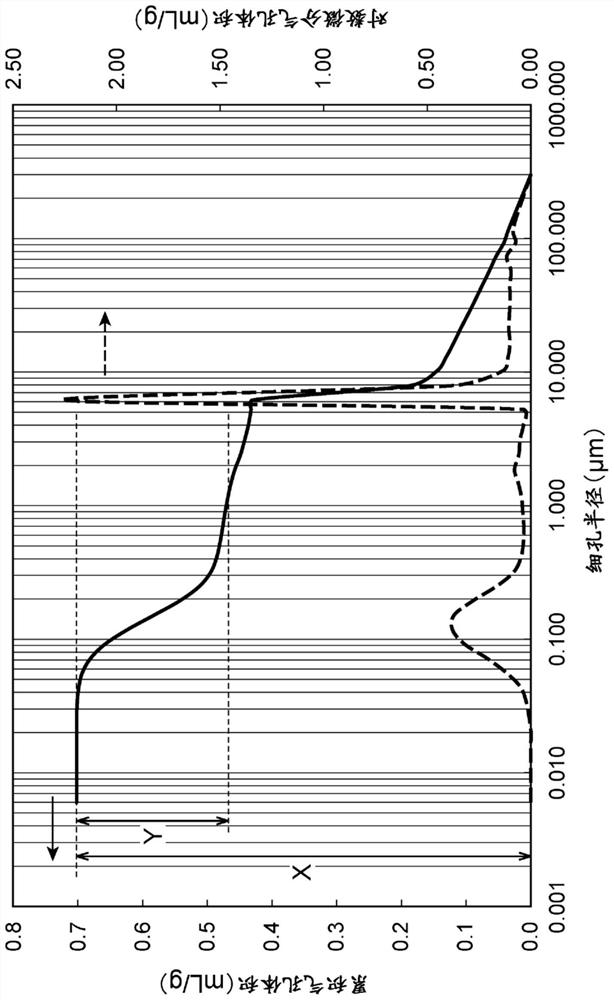

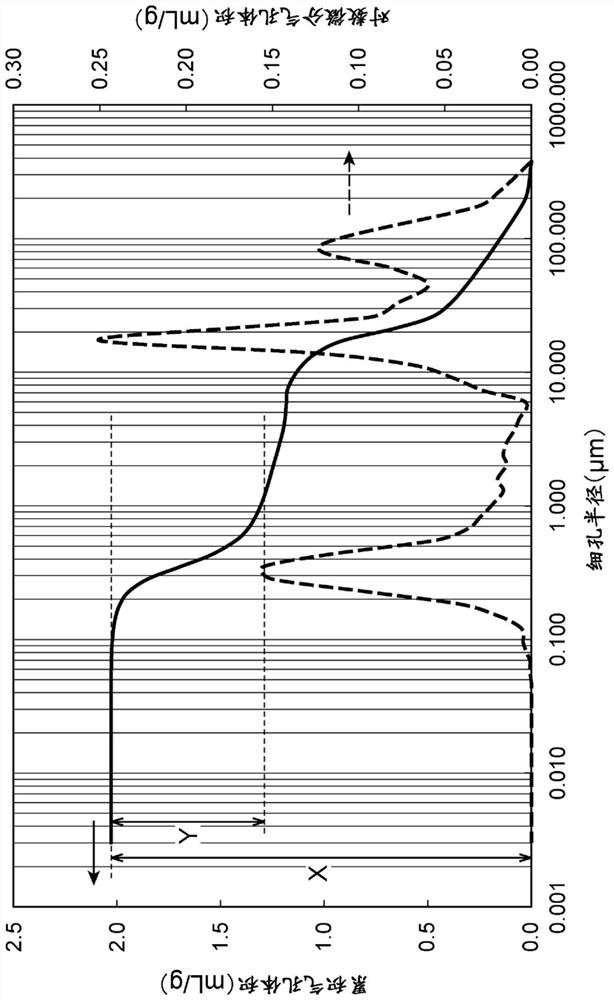

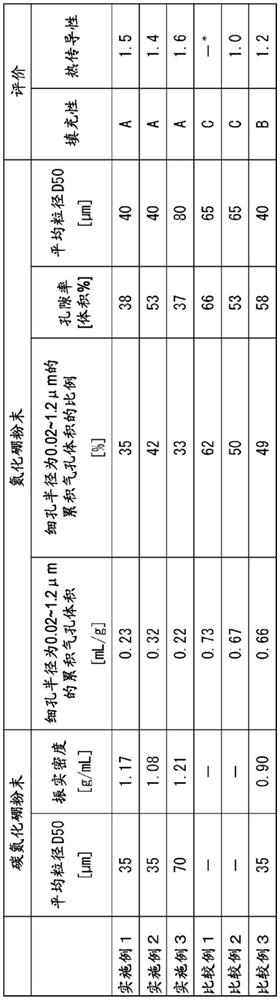

Boron nitride powder, method for producing same, boron carbonitride powder, composite material, and heat dissipation member

PendingCN114514195AEasy to fillFast heat conductionHeat-exchange elementsNitrogen and non-metal compoundsPorosityBoron carbonitride

One aspect of the present invention provides a boron nitride powder containing aggregated particles formed by aggregating primary particles of boron nitride, the boron nitride powder having a cumulative pore volume of 0.65 mL / g or less at a pore radius of 0.02-1.2 [mu] m as measured by a mercury porometer.

Owner:DENKA CO LTD

A preparation method of c/c-sic composite material containing carbon-rich boron nitride interface phase

The invention discloses a preparation method of a C / C-SiC composite material containing a carbon-rich boron nitride interface phase. The method is as follows: 1) Add AM and MBAM to the precursor solution A containing boric acid and urea to mix and dissolve, then add the initiator ammonium persulfate APS to initiate the polymerization reaction to form sol solution B; 2) immerse the carbon fiber preform in the sol solution In B, dry after impregnation, repeat impregnation, drying, and heat treatment to obtain a carbon fiber prefabricated part containing a carbon-rich boron nitride interface phase; layers of C / C‑SiC composites. The interfacial phase in the prepared material, on the one hand, can prevent liquid silicon from corroding fibers because there is no chemical reaction between BN and liquid silicon; Carbon can improve the wettability of the interface to silicon, thereby increasing the bonding strength between the interface and the matrix. The coupling of the two effects ultimately greatly improves the mechanical properties of the C / C‑SiC material.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

A kind of preparation method of ordered mesoporous silicon boron carbon nitrogen material

ActiveCN107381589BSimple preparation processUniform pore sizeBoron compoundsCross-linkBoron carbonitride

The invention relates to a preparation method of an ordered mesoporous silicon-boron-carbon-nitrogen material. The preparation method comprises the following steps: under the protection of nitrogen gas, dripping butyldichloroborane and dichloromethylsilane solutions into a hexamethyldisilazane solution at the same time; then raising the temperature and stirring to obtain a clarified transparent solution; raising the temperature of an oil bath and reacting to obtain a polyborosilazane precursor solid; dissolving the polyborosilazane precursor solid into a solvent and evaporating the oil bath to obtain a self-assembled polyborosilazane precursor; carrying out heat treatment to obtain a cross-linked self-assembled polyborosilazane precursor; under an ammonia gas atmosphere, raising the temperature and carrying out cracking; then cooling to room temperature, so as to obtain the ordered mesoporous silicon-boron-carbon-nitrogen material. The ordered mesoporous silicon-boron-carbon-nitrogen material prepared by the preparation method provided by the invention has large specific surface area and extremely excellent high-temperature stability, oxidation resistance, hydrothermal stability and chemical stability.

Owner:DONGHUA UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com