A kind of boron carbon nitrogen nano paper and preparation method thereof

A boron carbon nitrogen nanometer and boron carbon nitrogen technology, which is applied in the field of boron carbon nitrogen nano paper and its preparation, can solve the problems of high molecular weight and structural requirements of precursors, and achieve good operability, high specific surface area and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

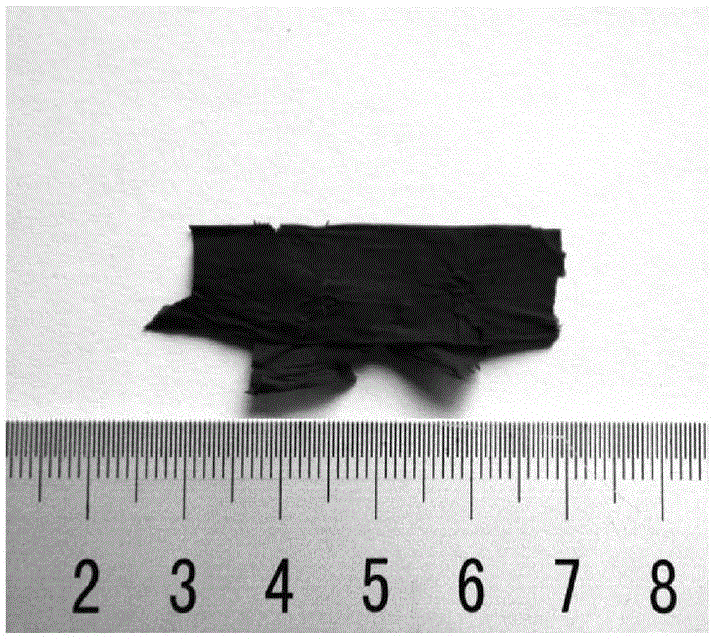

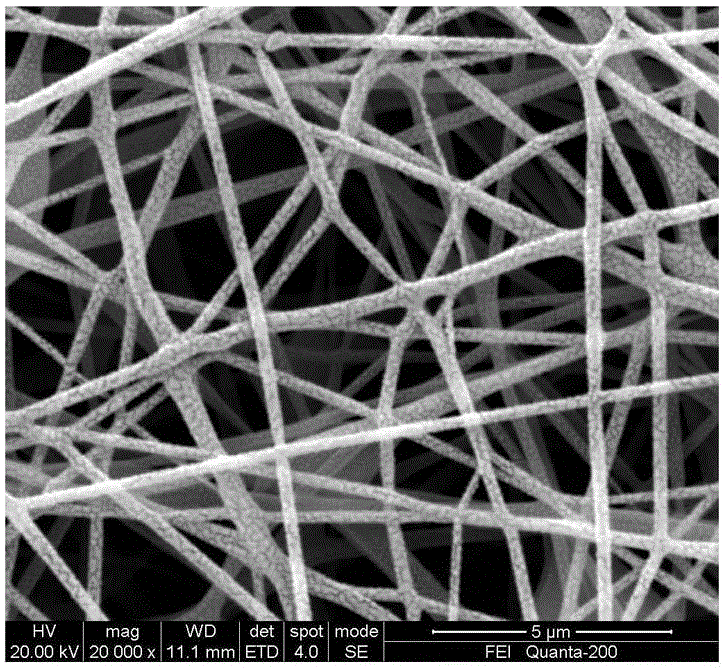

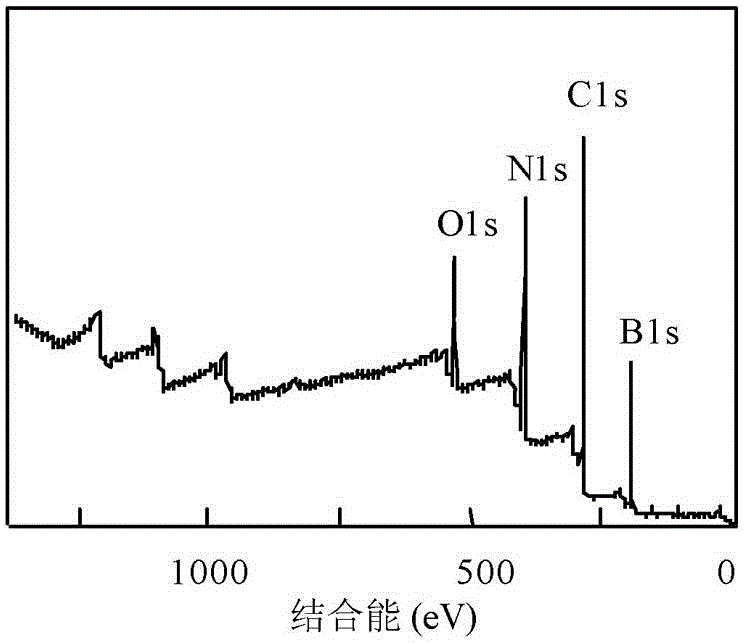

[0030] A boron carbon nitrogen nano paper of the present invention is composed of boron carbon nitrogen nano fibers interwoven into a network structure. The chemical composition of the boron carbon nitrogen nano paper is: B 0.82 C 5 N 1.35 . The diameter of the boron carbon nitrogen nanofiber is 100nm-300nm.

[0031] A preparation method of the above-mentioned boron carbon nitrogen nano paper of the present embodiment, comprising the following steps:

[0032] (1) Polyacrylonitrile (PAN) was dissolved in N-N-dimethylformamide (DMF) to prepare a precursor solution with a mass concentration of PAN of 12wt%.

[0033] (2) Add boric acid to the precursor solution obtained in step (1), the mass ratio of boric acid to polyacrylonitrile is 1:5, stir and dissolve to obtain a spinning solution.

[0034] (3) The spinning solution obtained in step (2) is placed in an electrospinning device, and under the action of an electrostatic field of 15kV, the boron carbon nitrogen nanofibrils o...

Embodiment 2

[0038] A boron carbon nitrogen nano paper of the present invention is composed of boron carbon nitrogen nano fibers interwoven into a network structure. The chemical composition of the boron carbon nitrogen nano paper is: B 0.61 C 5 N 0.67 . The diameter of the boron carbon nitrogen nanofiber is 150nm-500nm.

[0039] The preparation method of boron carbon nitrogen nanopaper in this example is basically the same as that in Example 1, the only difference being that the mass concentration of PAN in the precursor solution obtained in step (1) is 10%.

Embodiment 3

[0041] A boron carbon nitrogen nano paper of the present invention is composed of boron carbon nitrogen nano fibers interwoven into a network structure. The chemical composition of the boron carbon nitrogen nano paper is: B 0.90 C 5 N 0.90. The diameter of the boron carbon nitrogen nanofiber is 150nm-500nm.

[0042] The preparation method of boron carbon nitrogen nanopaper in this example is basically the same as that in Example 1, the only difference being that the mass concentration of PAN in the precursor solution obtained in step (1) is 13%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com