Patents

Literature

195results about How to "Low flexural strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

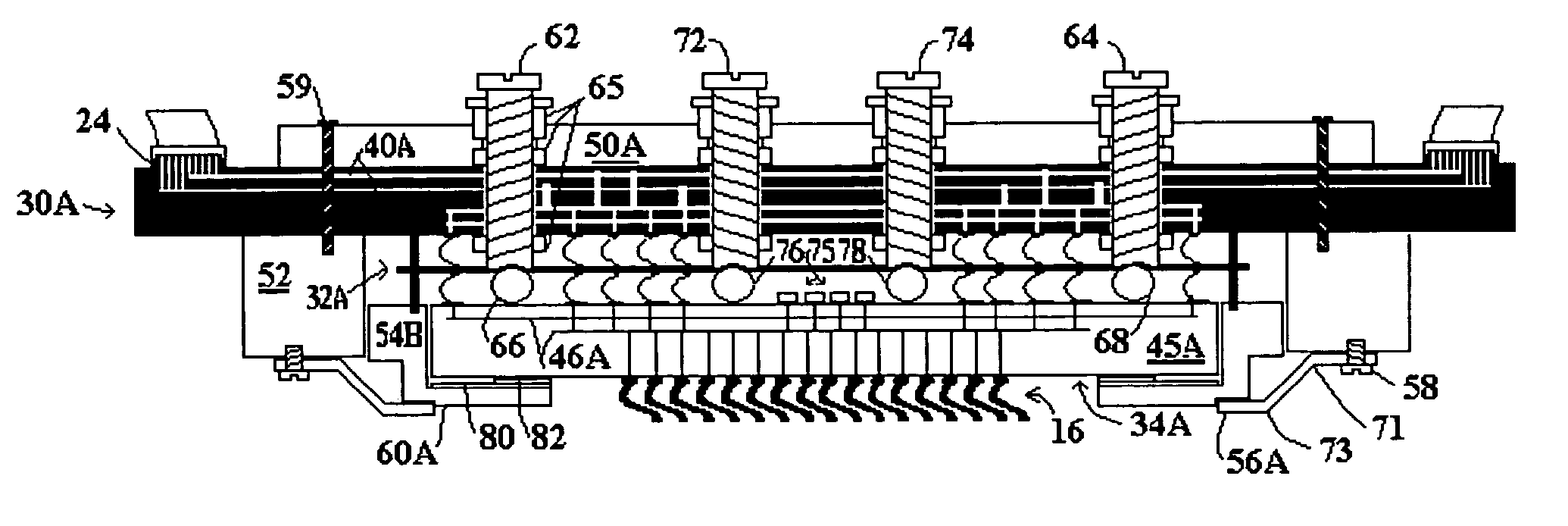

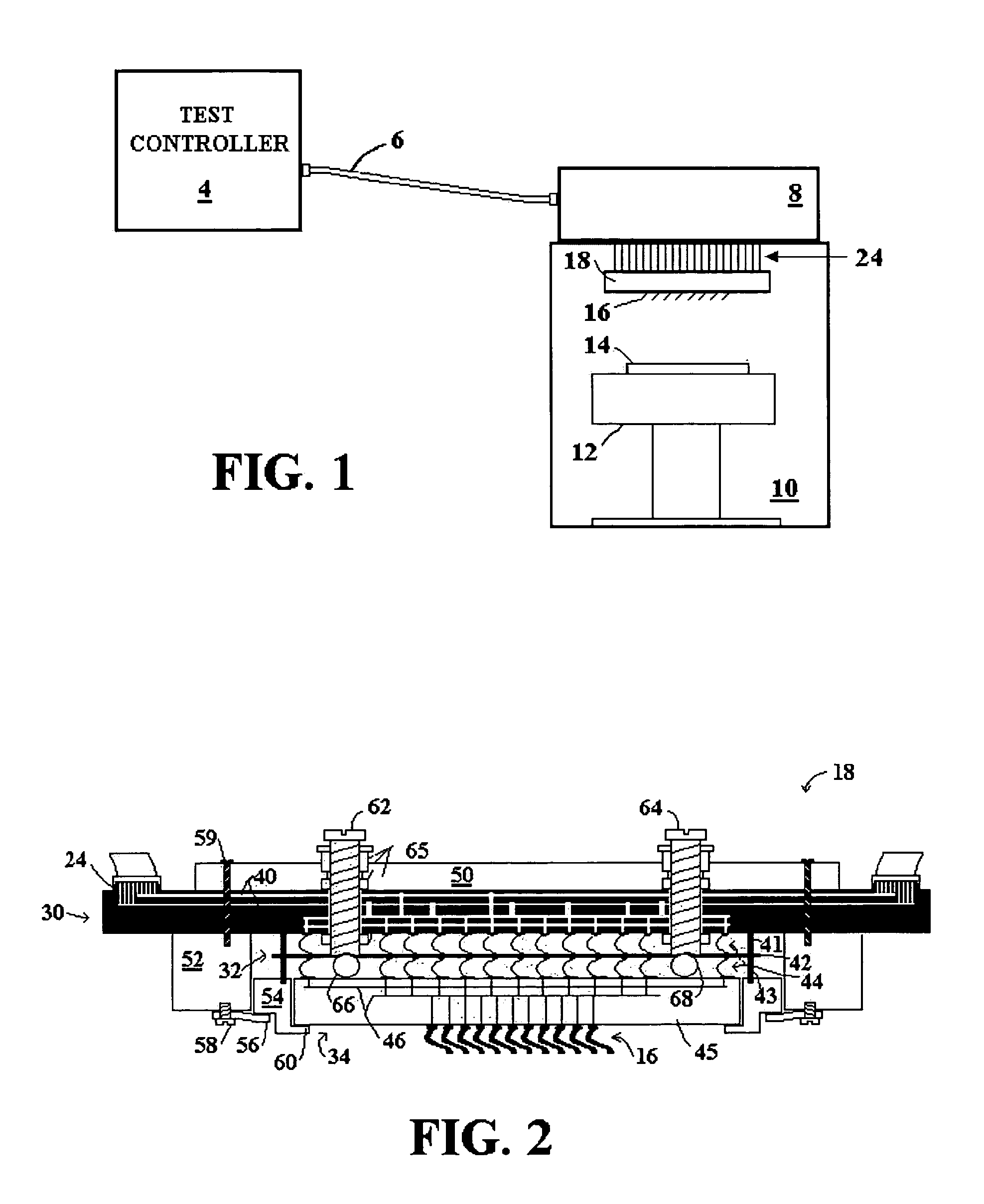

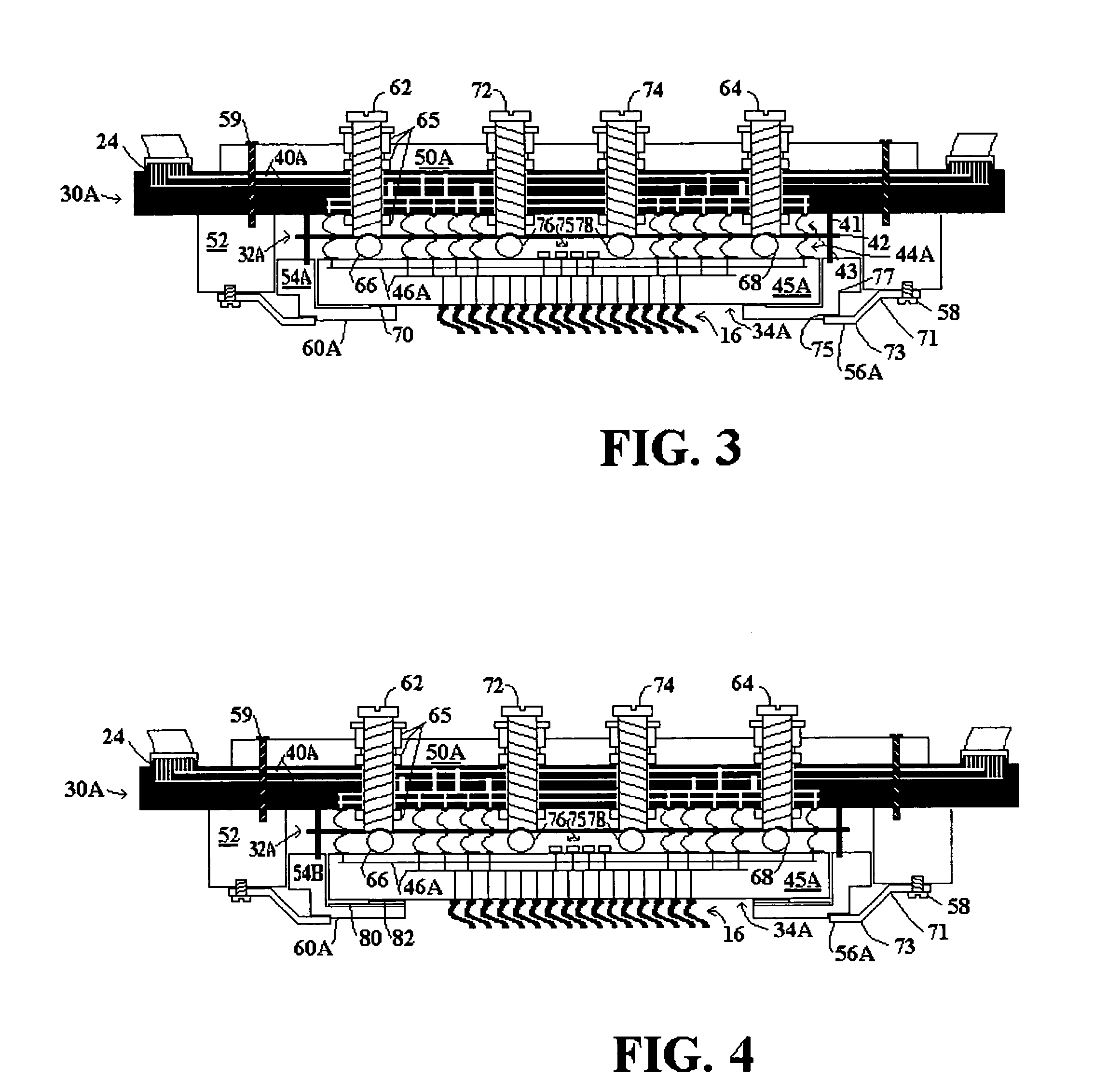

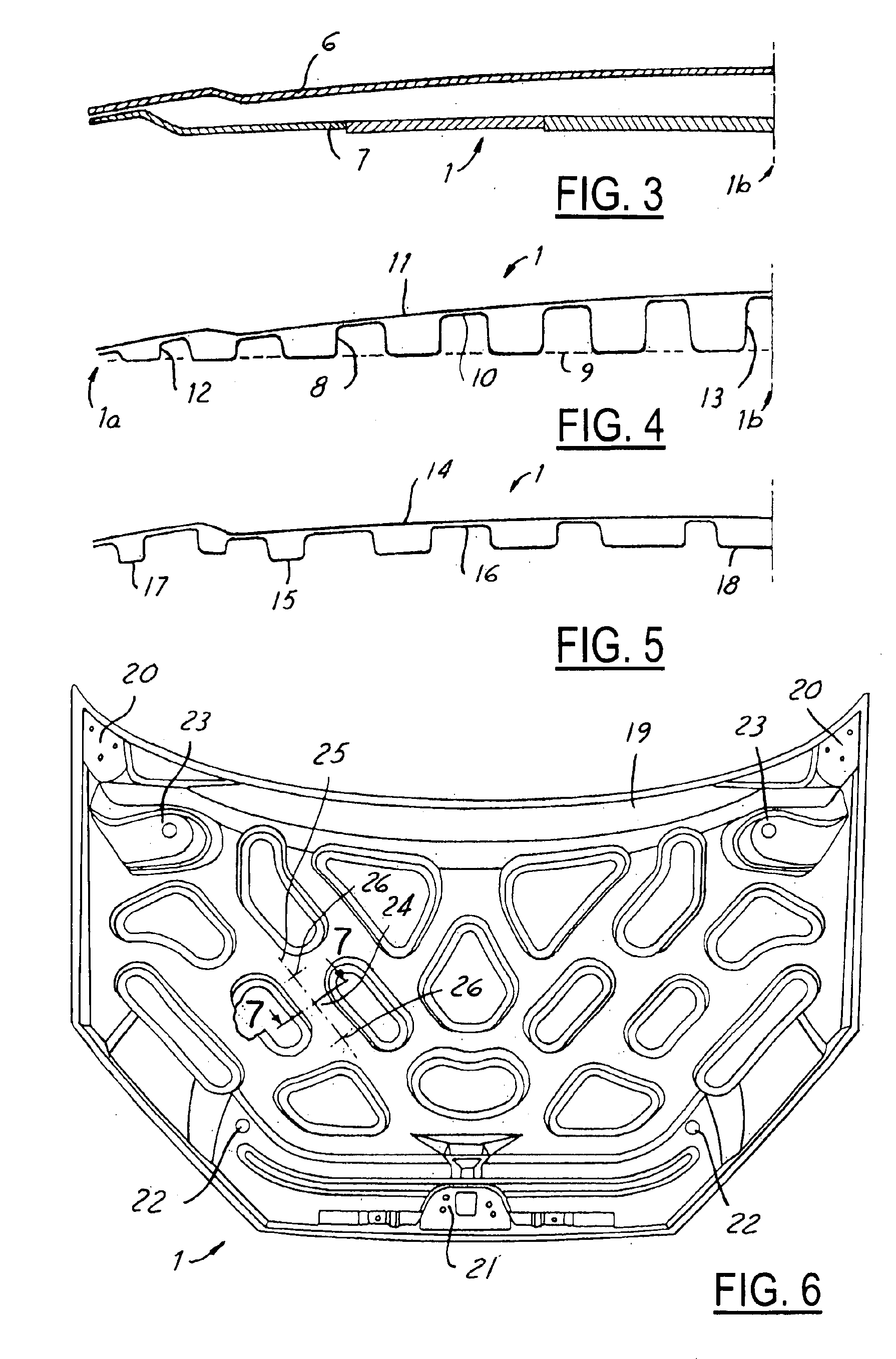

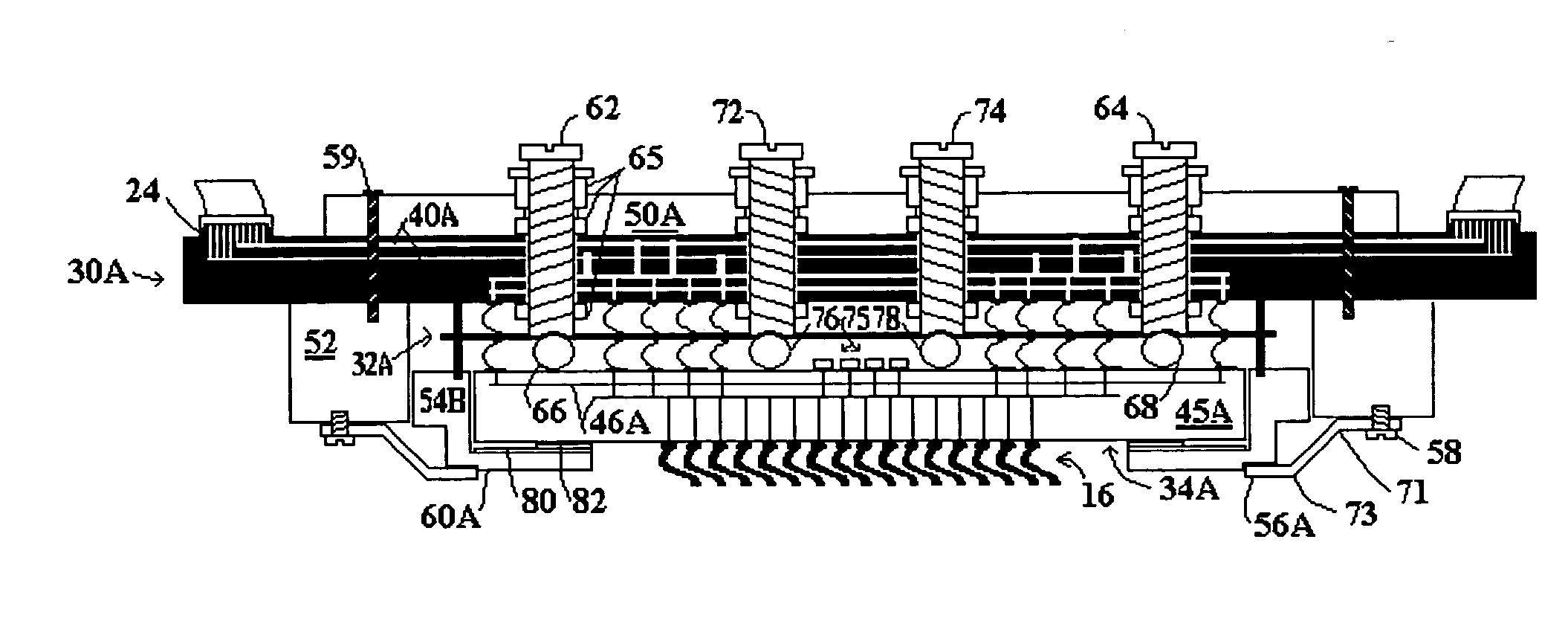

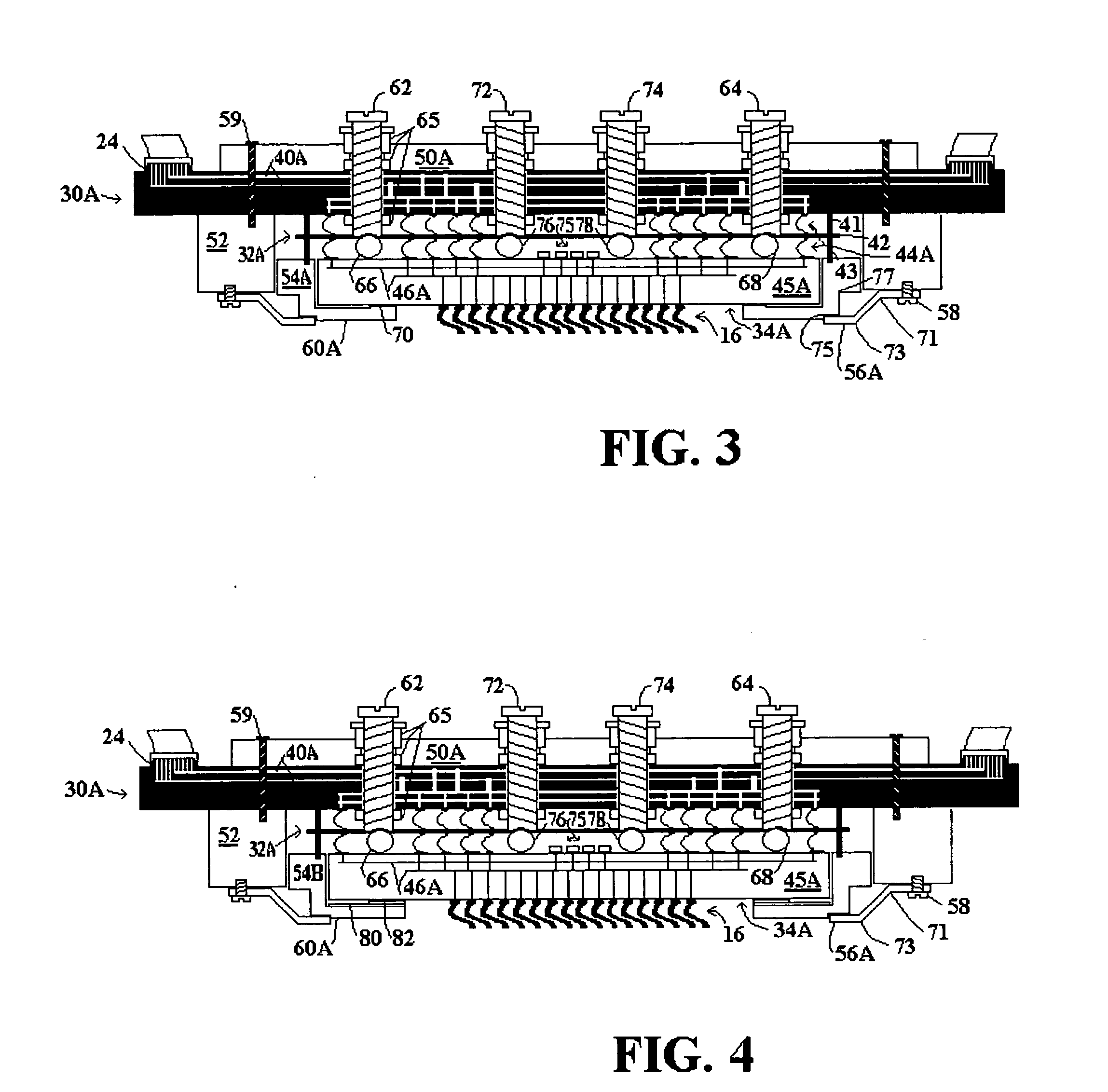

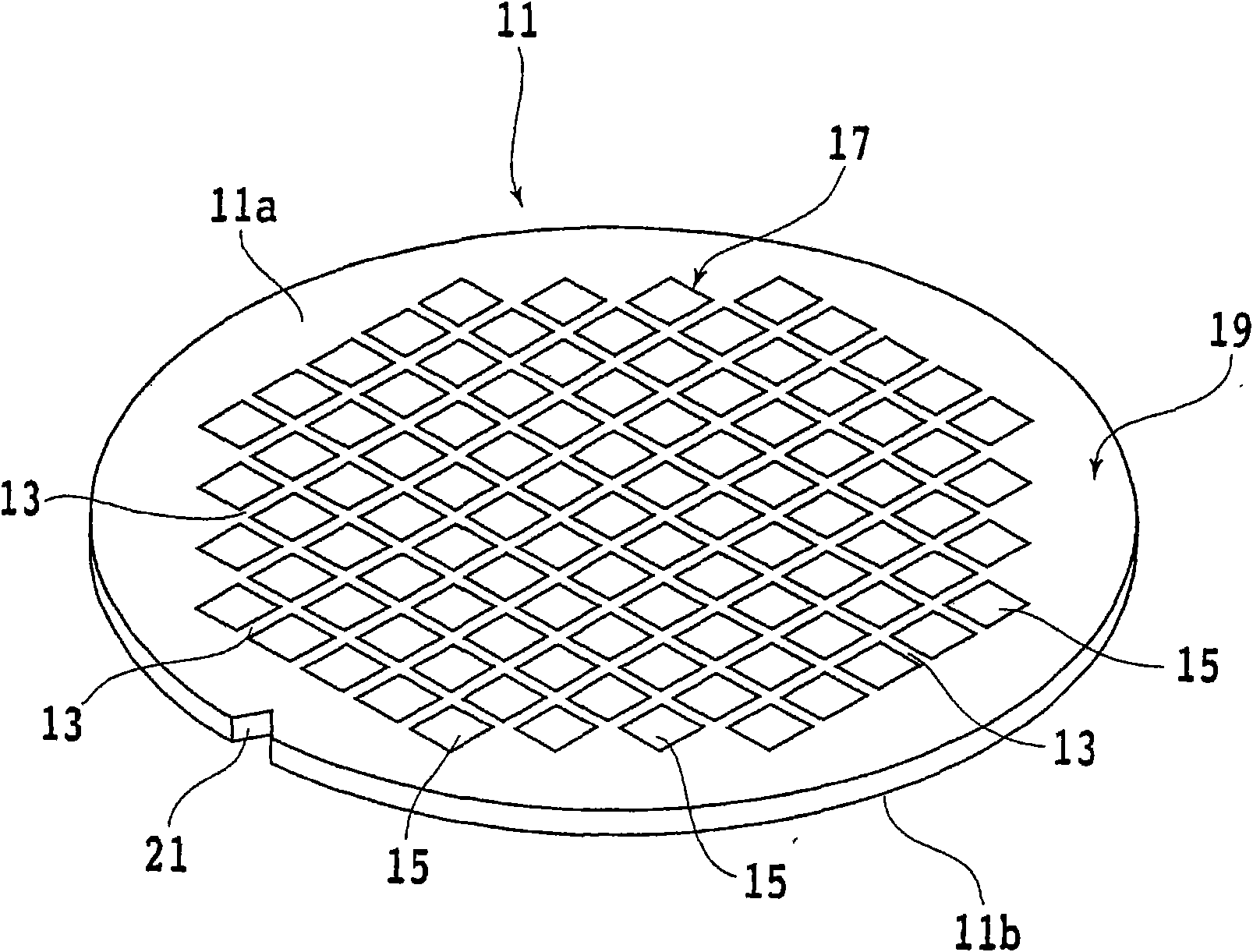

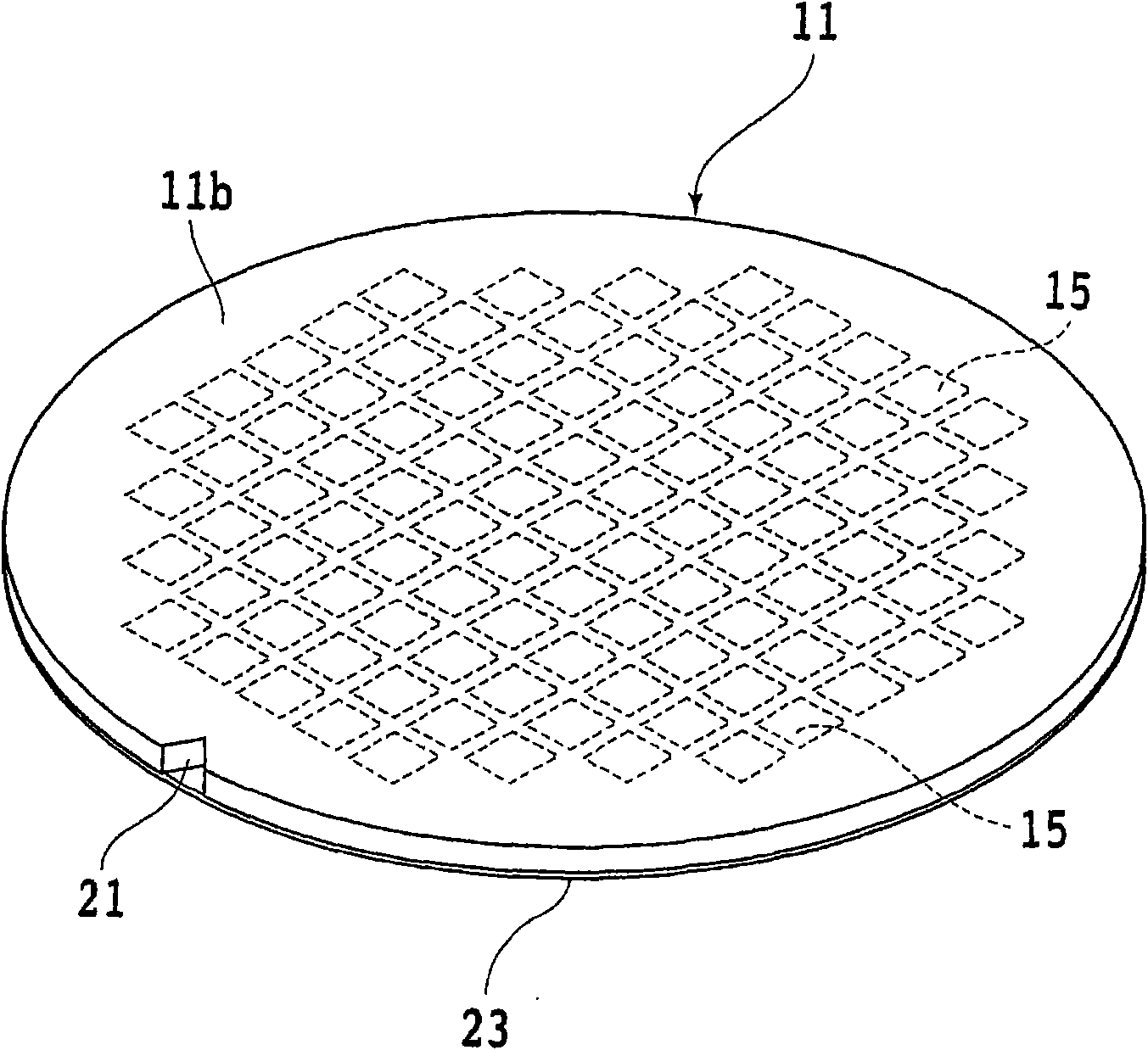

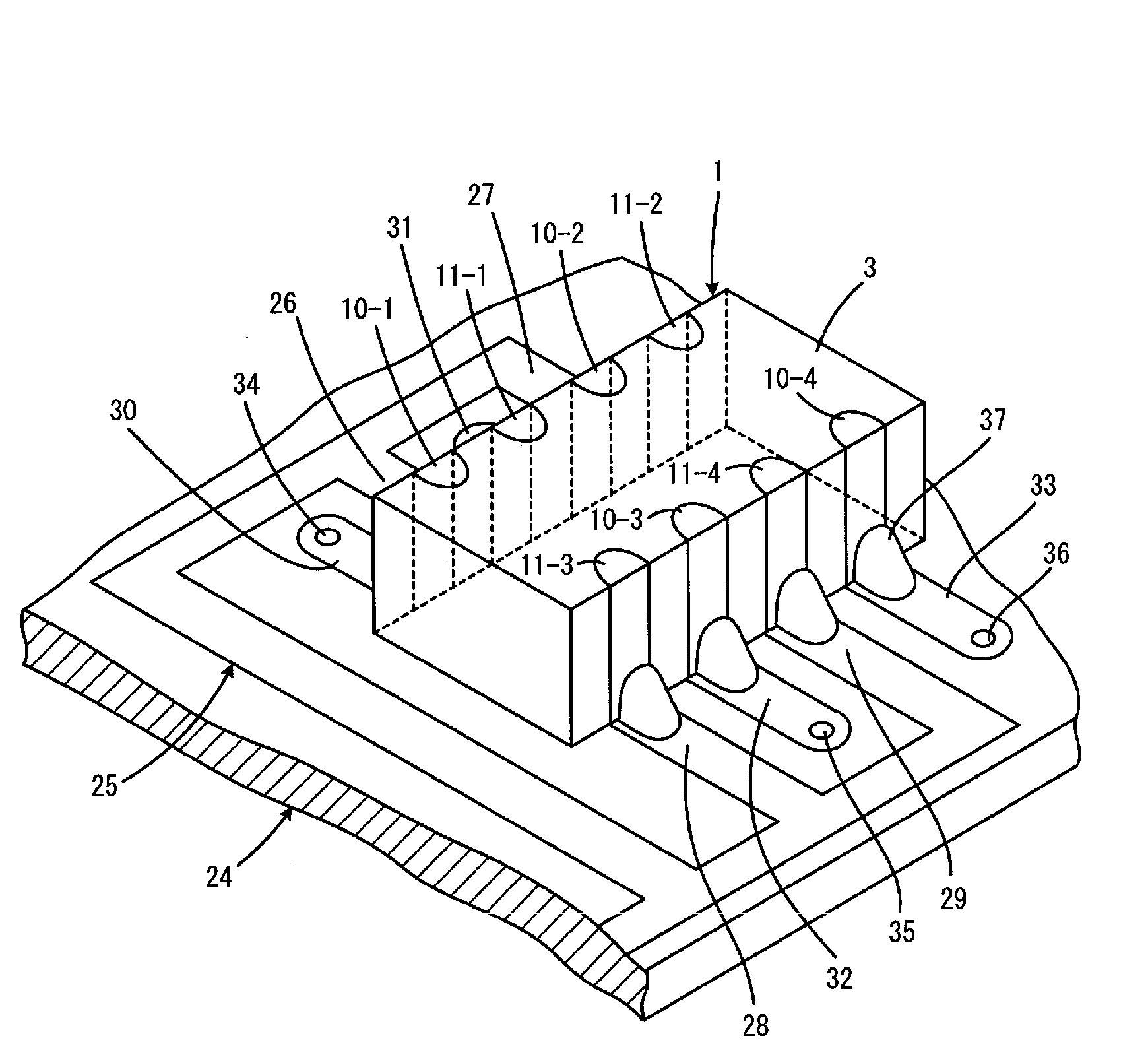

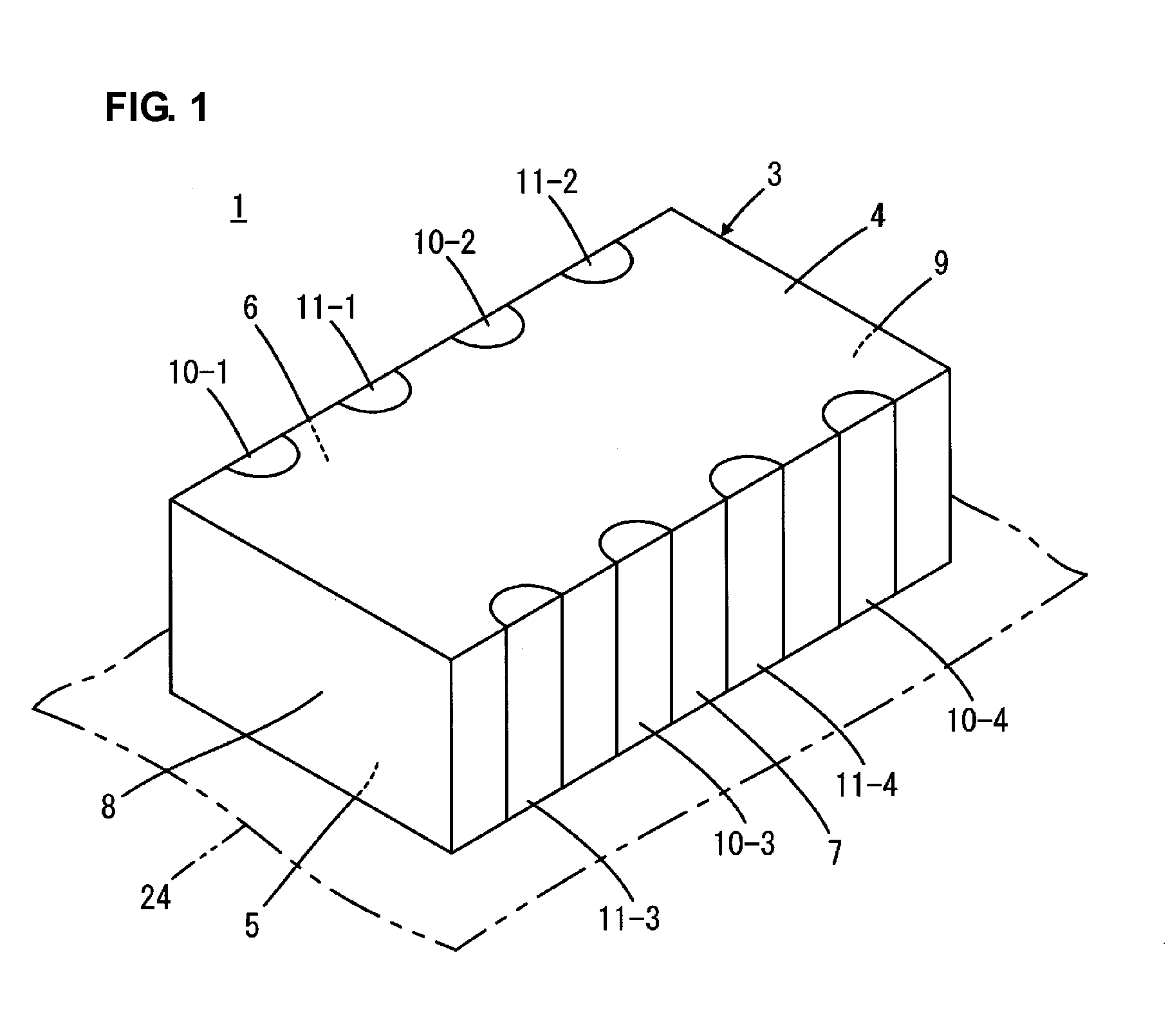

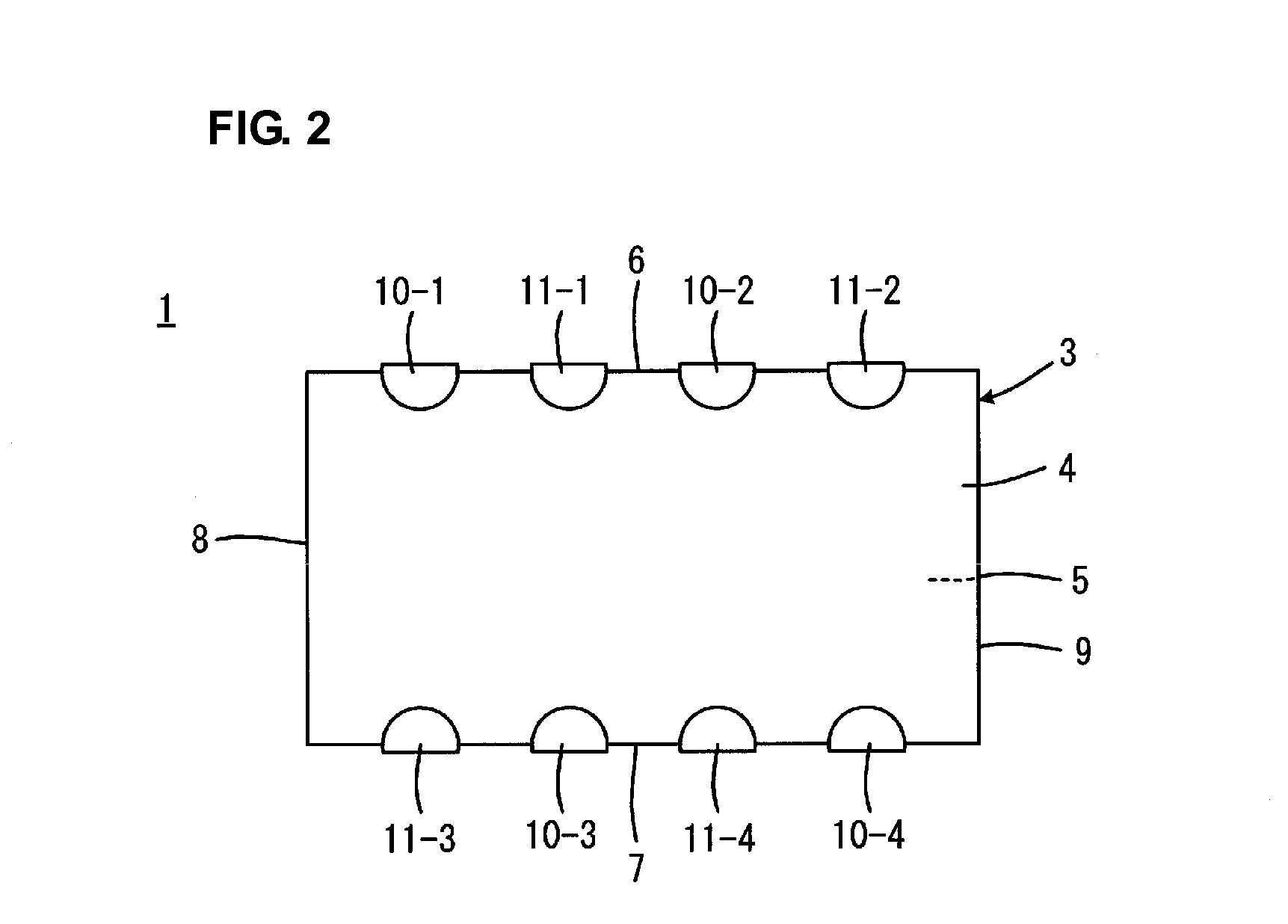

Probe card configuration for low mechanical flexural strength electrical routing substrates

InactiveUS7071715B2Add supportLow flexural stiffness/strength substrateSemiconductor/solid-state device testing/measurementElectronic circuit testingProbe cardTransformer

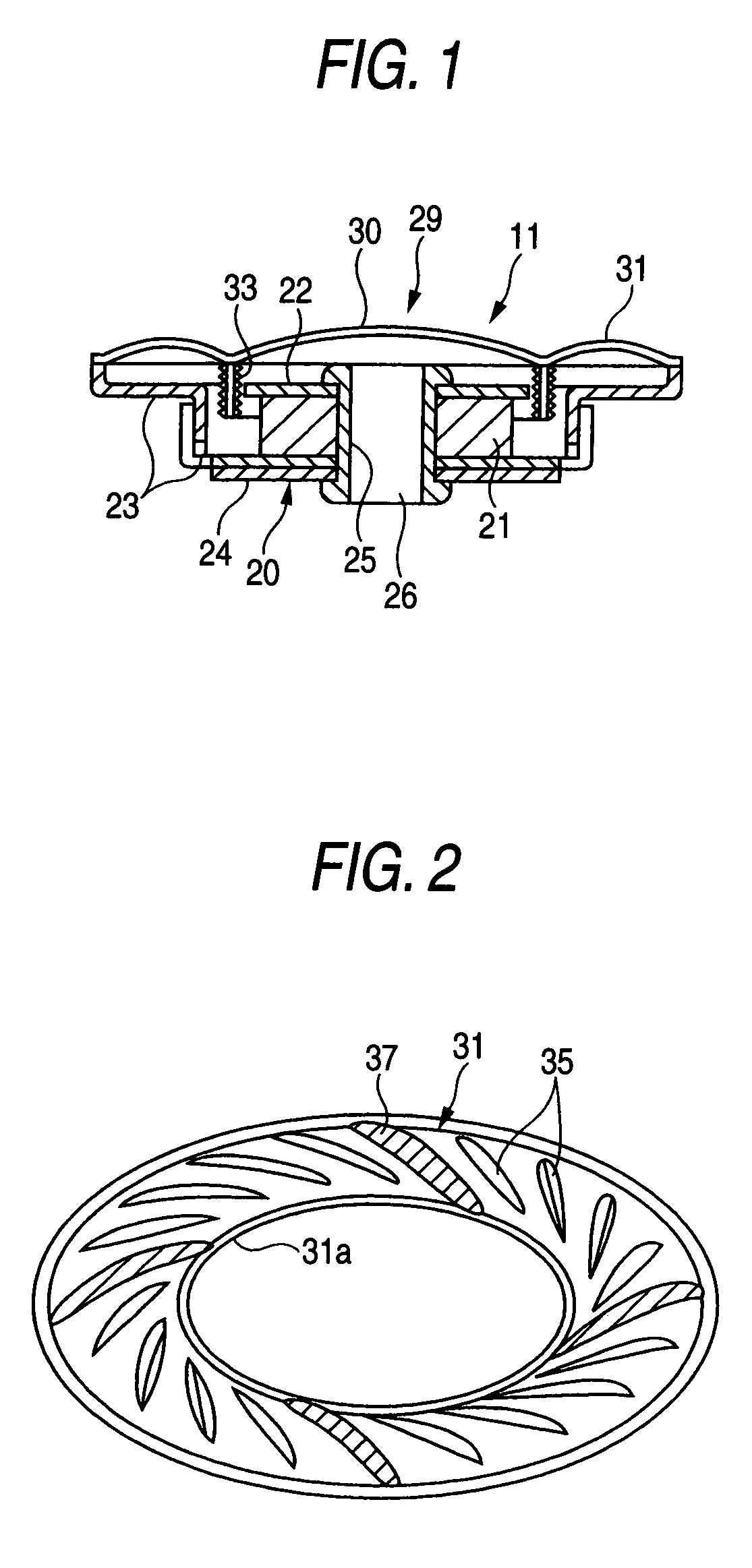

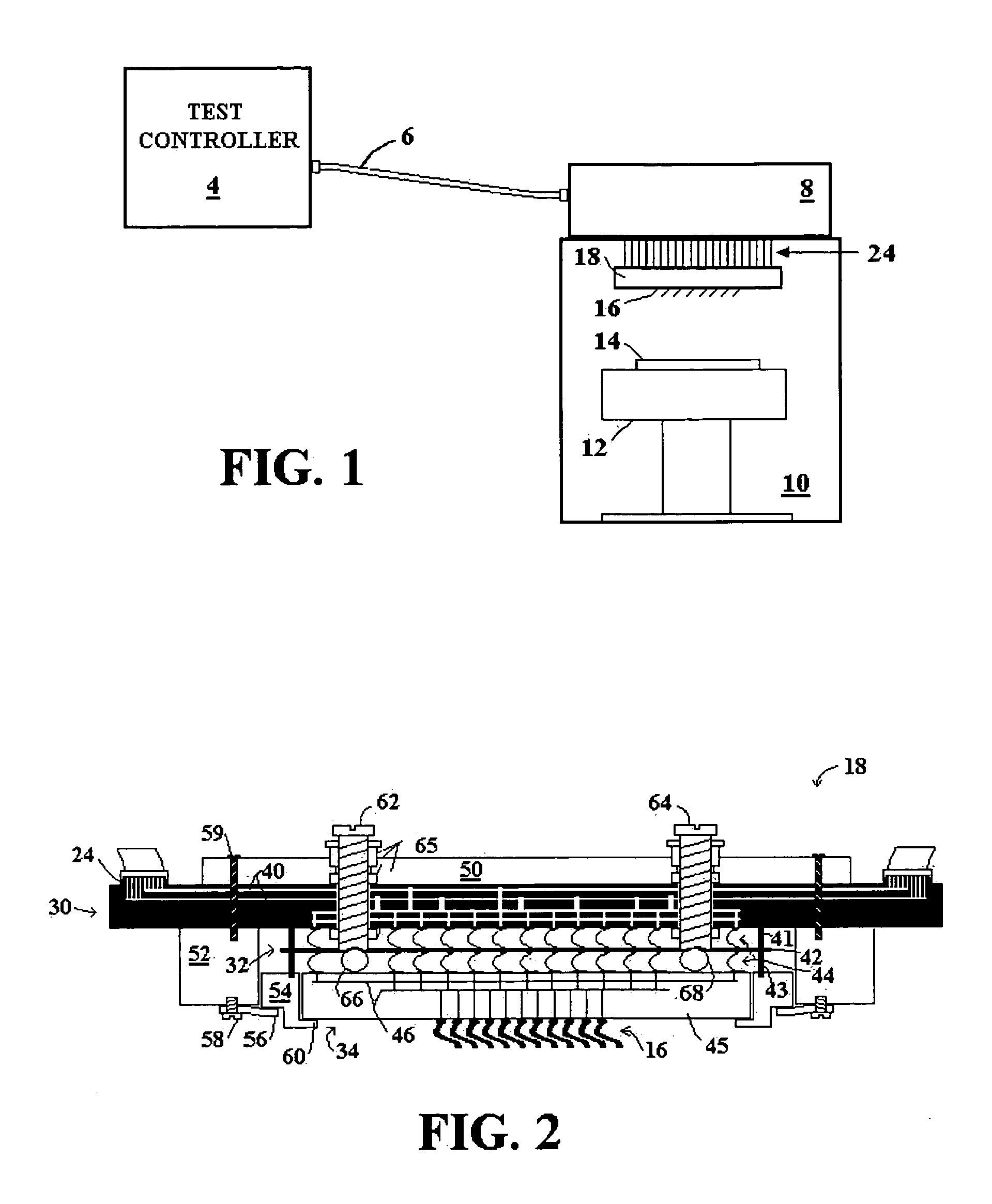

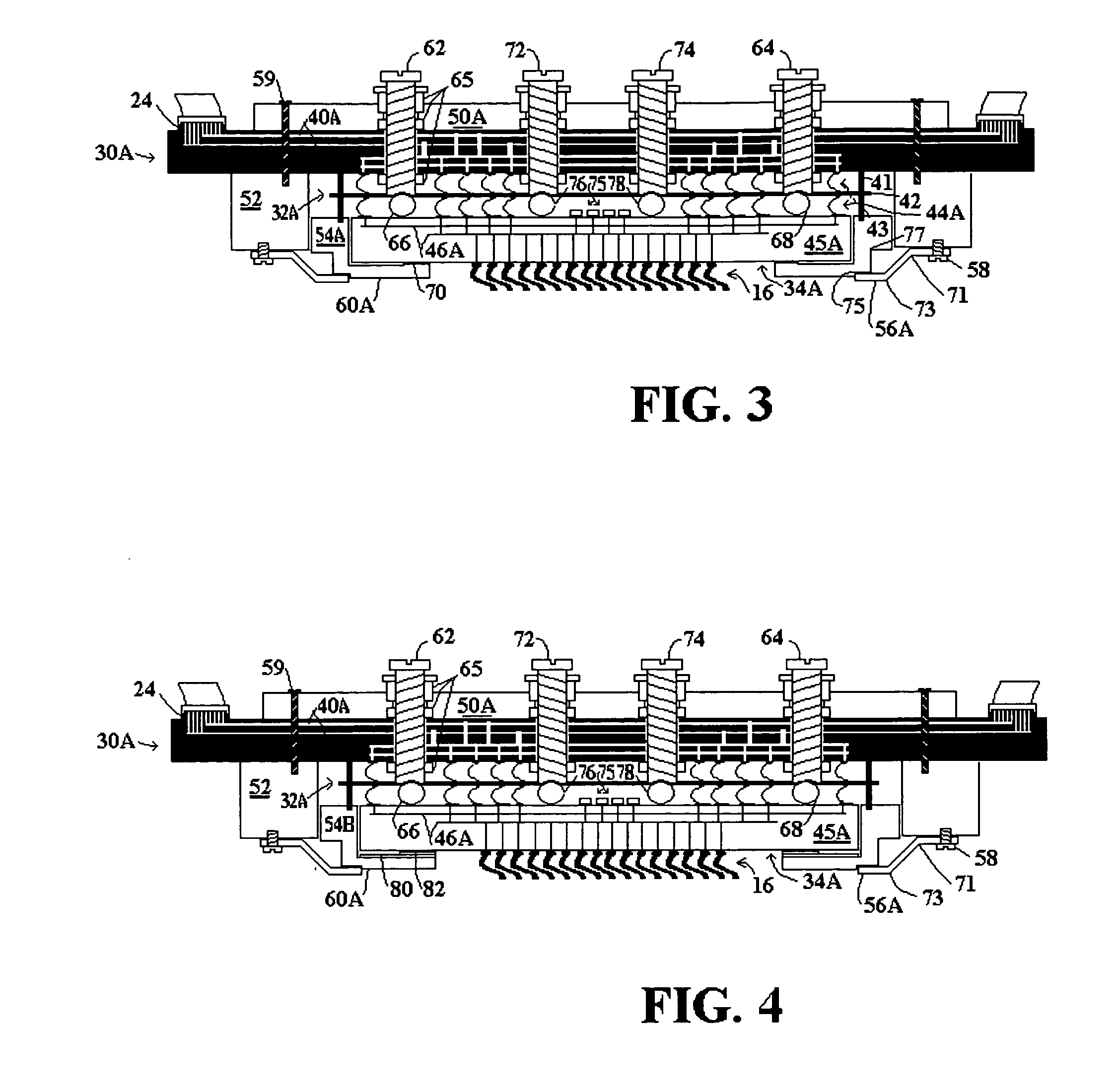

A mechanical support configuration for a probe card of a wafer test system is provided to increase support for a very low flexural strength substrate that supports spring probes. Increased mechanical support is provided by: (1) a frame around the periphery of the substrate having an increased sized horizontal extension over the surface of the substrate; (2) leaf springs with a bend enabling the leaf springs to extend vertically and engage the inner frame closer to the spring probes; (3) an insulating flexible membrane, or load support member machined into the inner frame, to engage the low flexural strength substrate farther away from its edge; (4) a support structure, such as support pins, added to provide support to counteract probe loading near the center of the space transformer substrate; and / or (5) a highly rigid interface tile provided between the probes and a lower flexural strength space transformer substrate.

Owner:FORMFACTOR INC

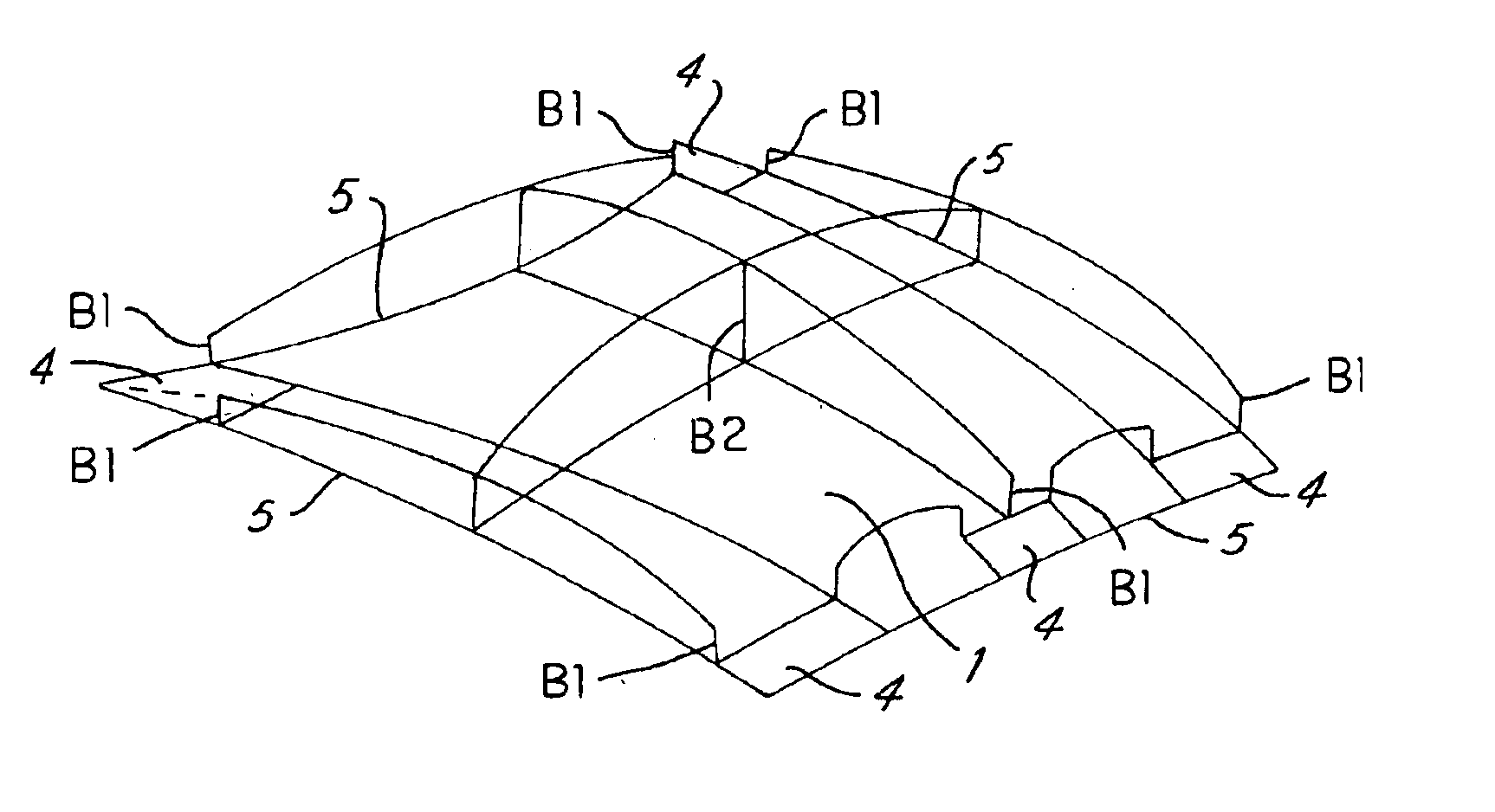

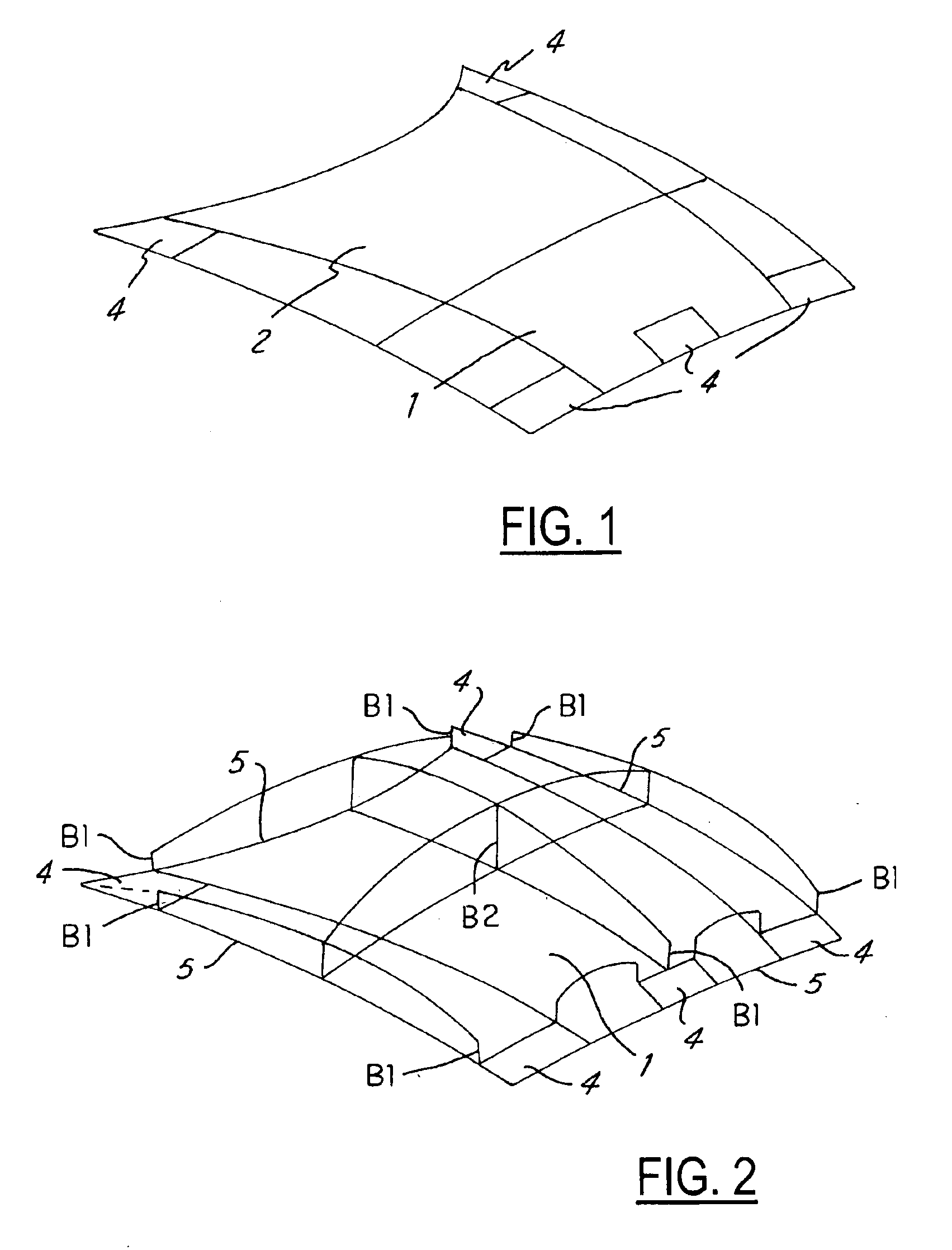

Engine hood for motor vehicles for the protection of pedestrians

InactiveUS6883627B1Easy to adaptEven mass distributionVehicle seatsPedestrian/occupant safety arrangementMobile vehicleFlexural strength

An engine hood for motor vehicles possesses a deformable head impact zone for the protection of pedestrians in the event of a collision with the motor vehicle. The engine hood is composed of two or more load-bearing shells and has a flexural strength profile which is low adjacent the edges and increases continuously toward the middle of the hood. At the same time, the engine hood has a uniform mass distribution ovcr the entire surface. Consequently, irrespective of the position the engine hood, the same characteristic for the head impact is achieved everywhere. The advantageous embodiment of the engine hood provides a reinforcing panel with regularly arranged beads, at most three beads forming a junction point so as to reduce local rigidities.

Owner:FORD GLOBAL TECH LLC

Probe card configuration for low mechanical flexural strength electrical routing substrates

InactiveUS20050156611A1Add supportLow flexural stiffness/strength substrateSemiconductor/solid-state device testing/measurementElectronic circuit testingProbe cardTransformer

A mechanical support configuration for a probe card of a wafer test system is provided to increase support for a very low flexural strength substrate that supports spring probes. Increased mechanical support is provided by: (1) a frame around the periphery of the substrate having an increased sized horizontal extension over the surface of the substrate; (2) leaf springs with a bend enabling the leaf springs to extend vertically and engage the inner frame closer to the spring probes; (3) an insulating flexible membrane, or load support member machined into the inner frame, to engage the low flexural strength substrate farther away from its edge; (4) a support structure, such as support pins, added to provide support to counteract probe loading near the center of the space transformer substrate; and / or (5) a highly rigid interface tile provided between the probes and a lower flexural strength space transformer substrate.

Owner:FORMFACTOR INC

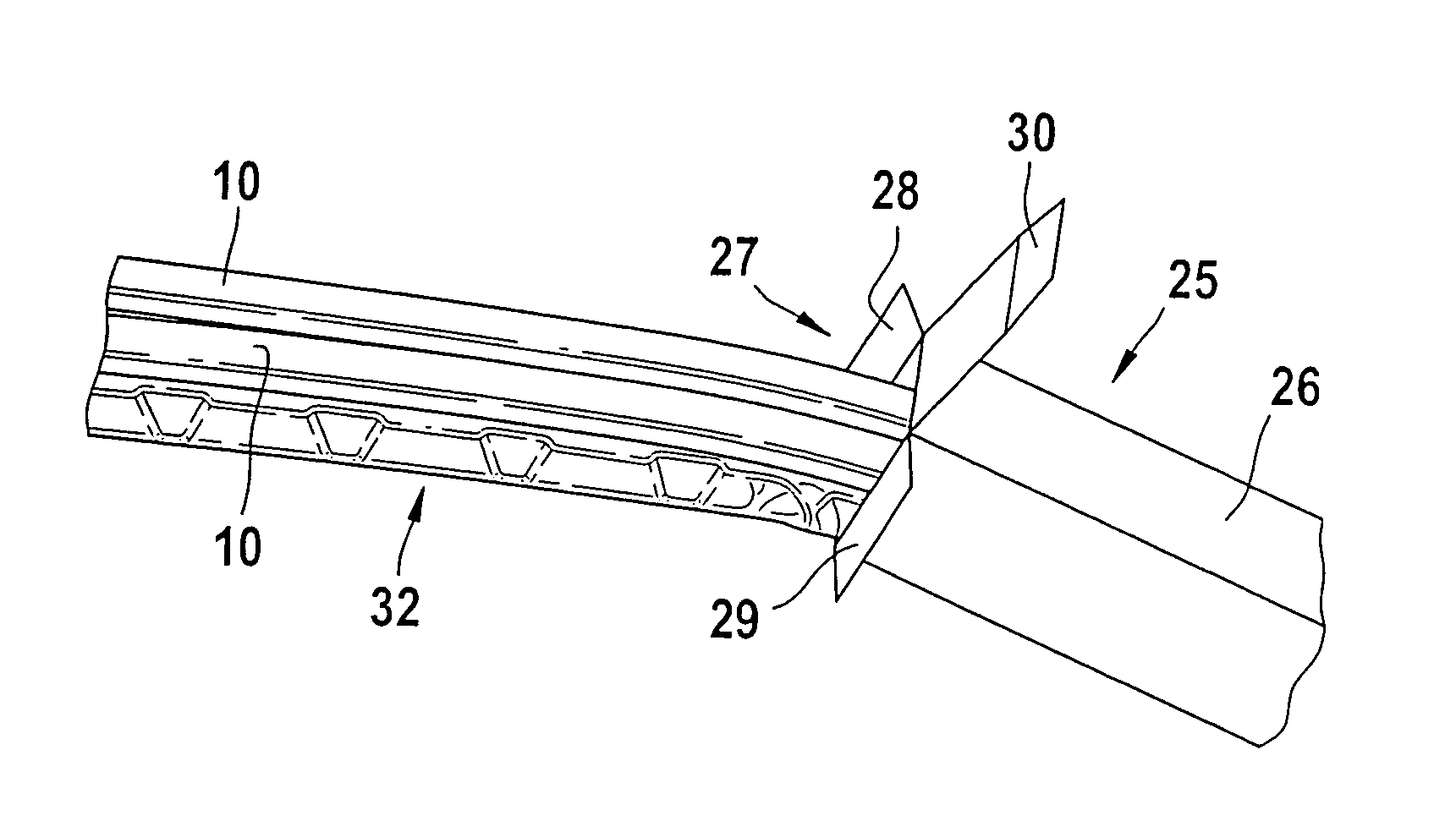

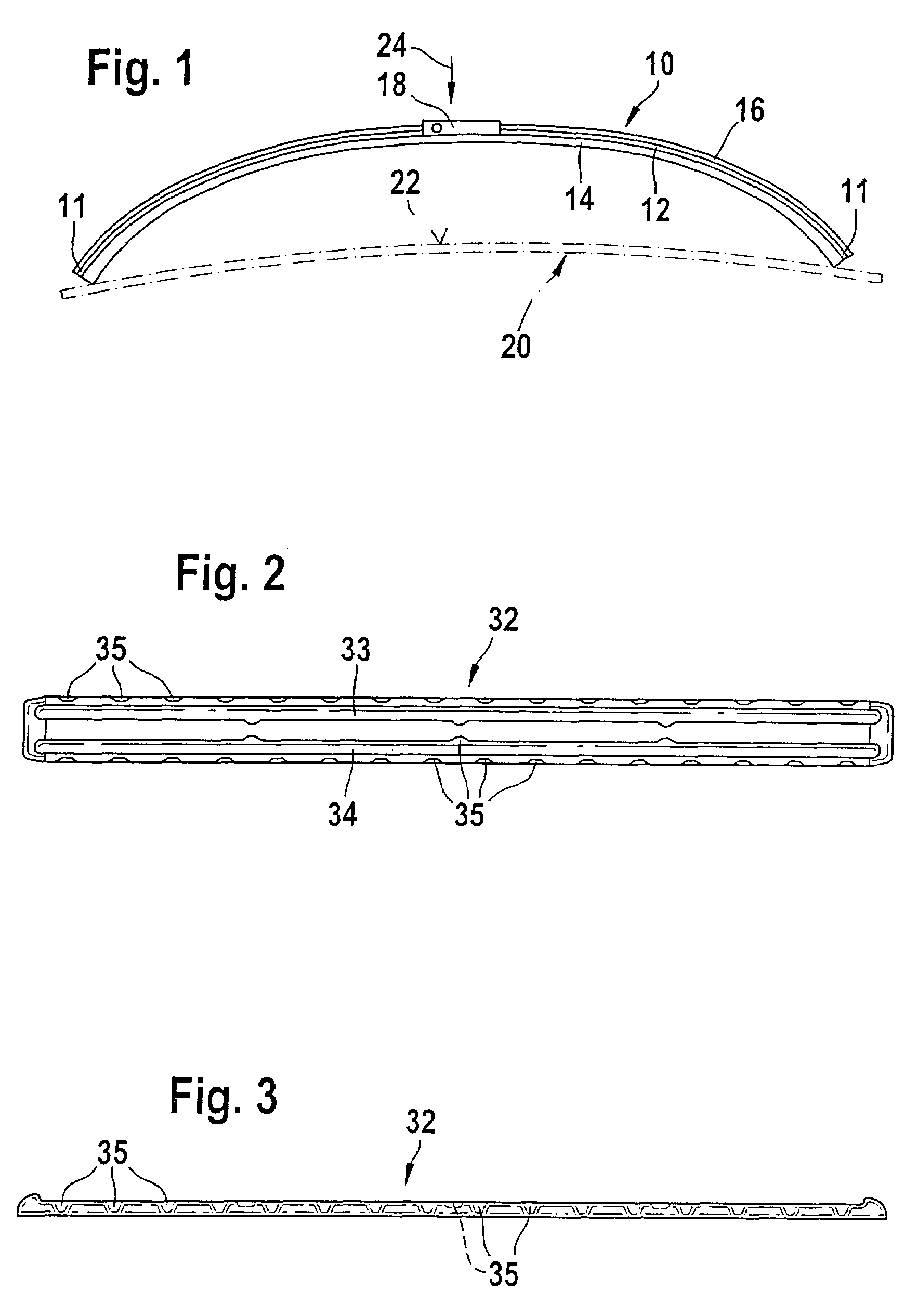

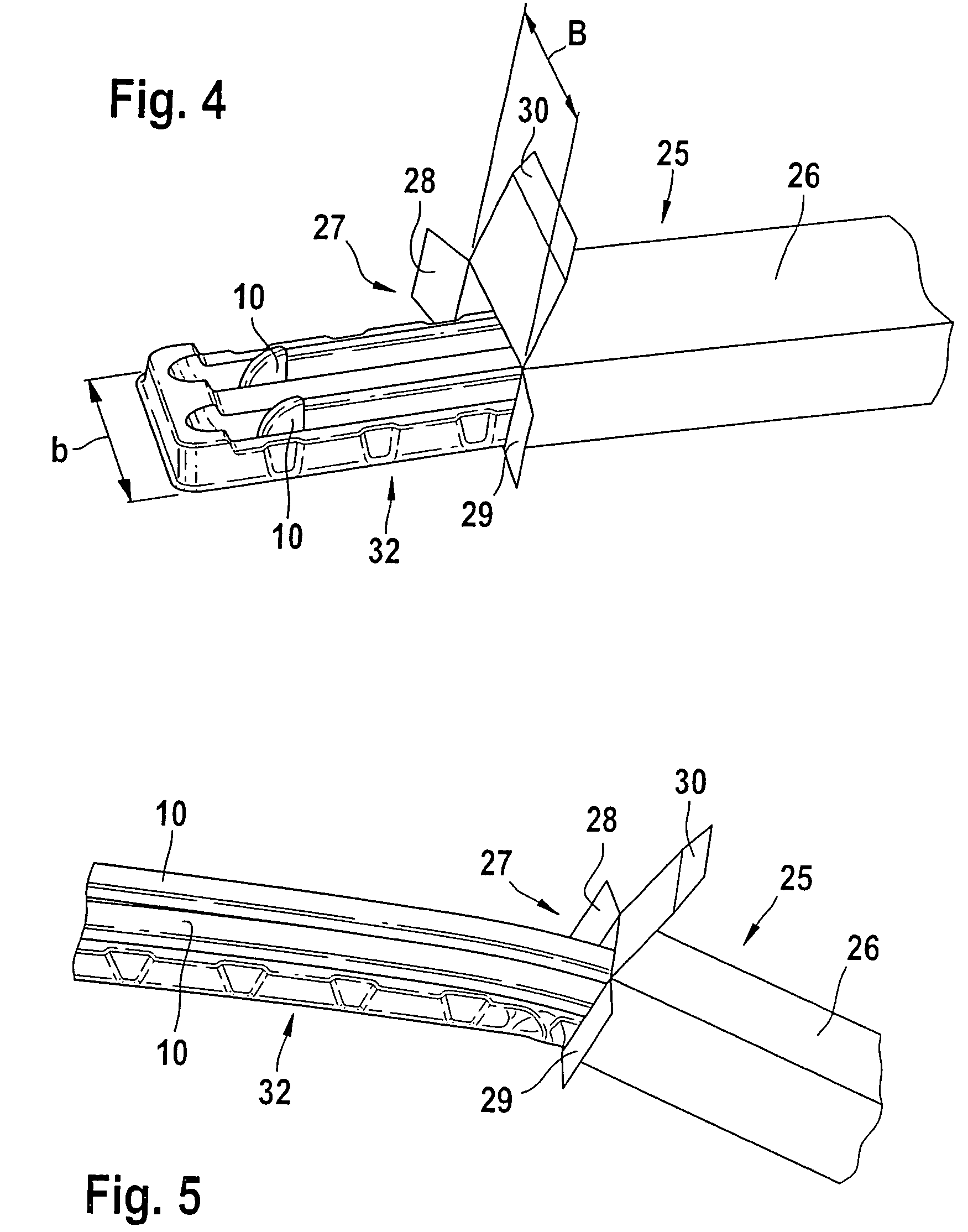

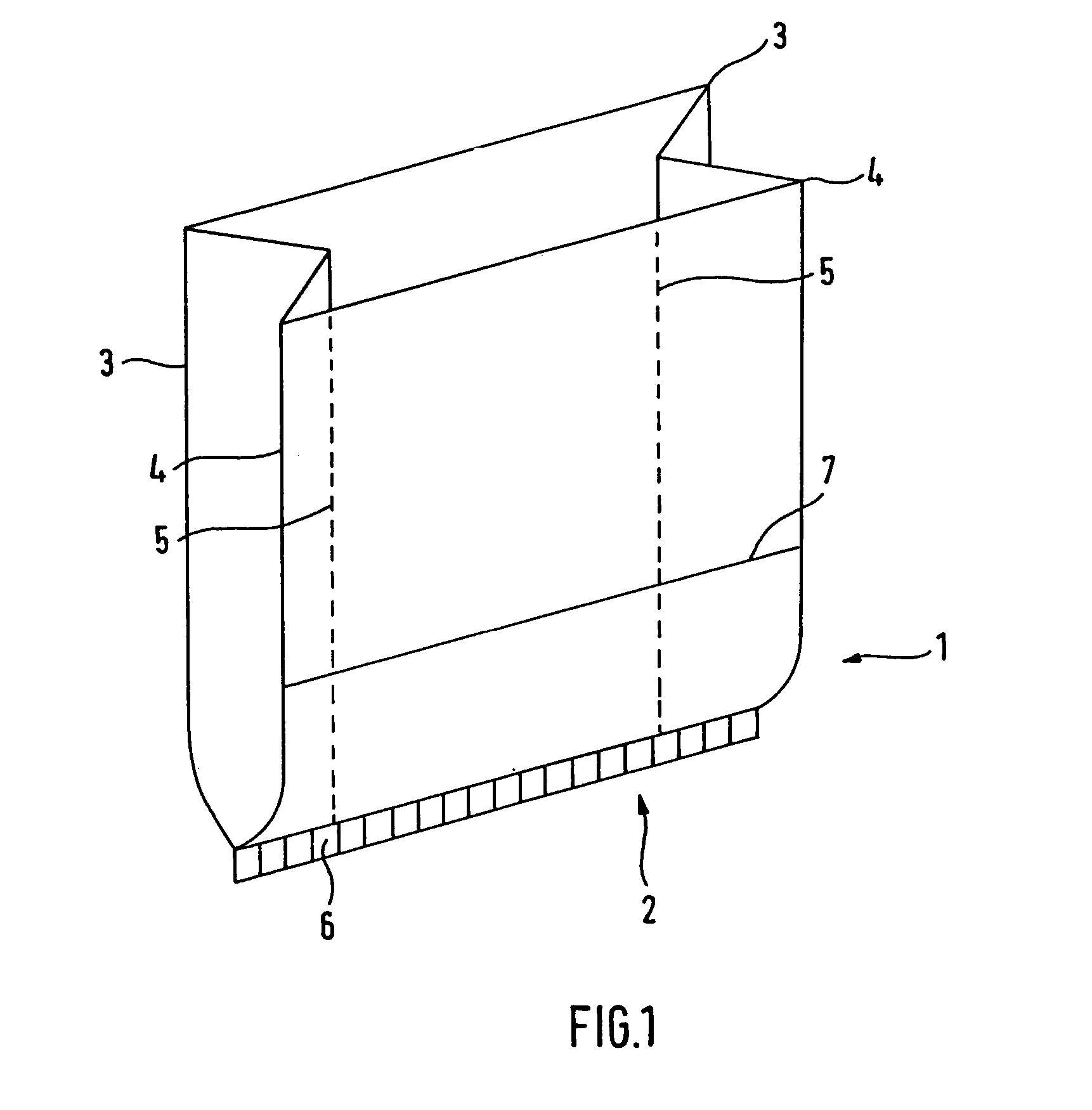

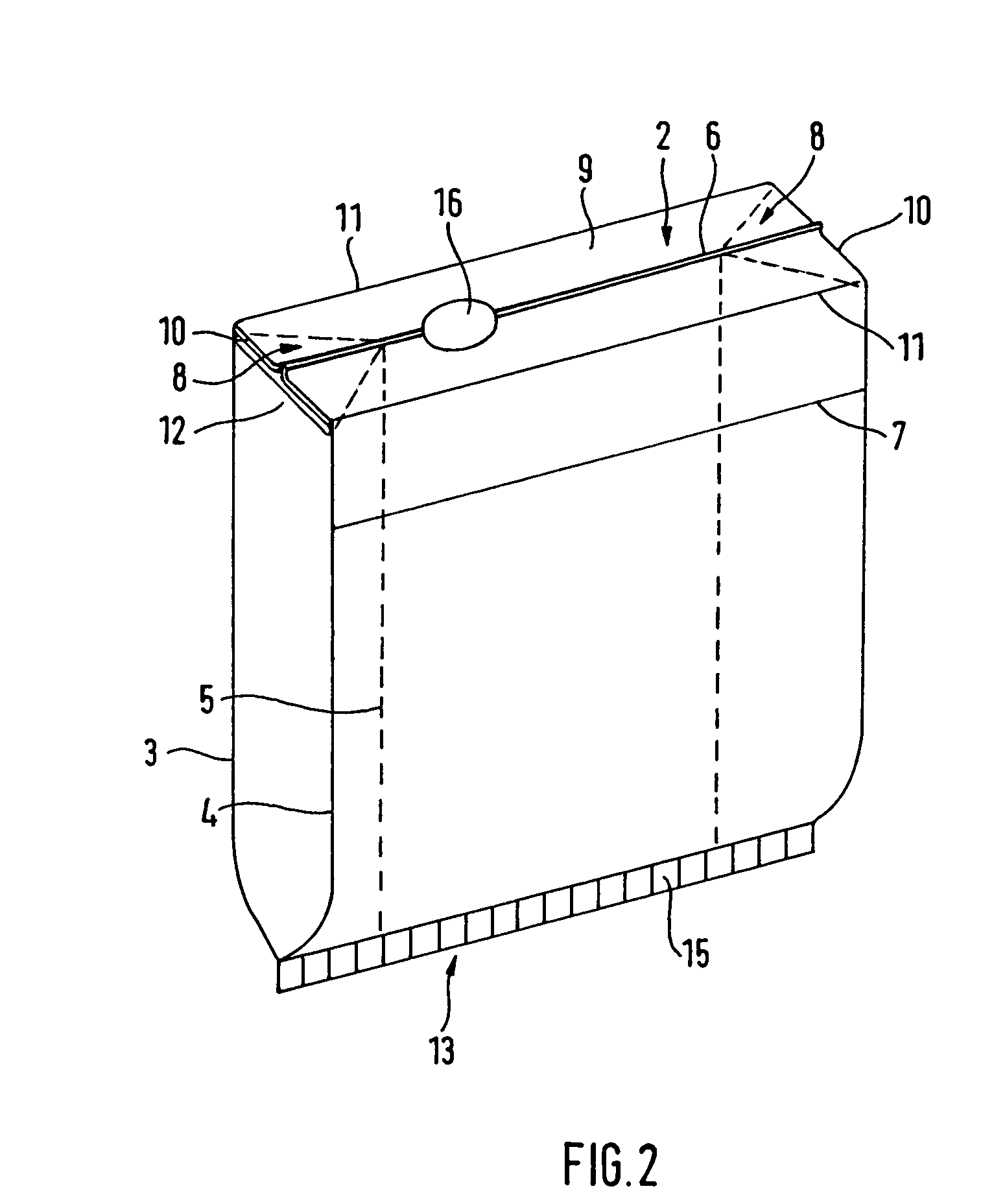

Packaging for widescreen wipers of motor vehicles

ActiveUS7337900B2Simple wayCost-effective manufacturingPackaging vehiclesContainers for machinesFlexural strengthEngineering

A package (25) for wiper blades (10) features a folded box (26) as well as an insert (32). In order to prevent the wiper blades (10) from abruptly relaxing during removal from the box (26), the insert (32) is embodied of a material whose flexural strength in the curvature direction of the wiper blades (10) is less than that of the wiper blades (10) so that when pulling the insert (32) out of the folded box (26), the wiper blades (10) continuously bend from their extended state in the folded box (26) into their curved shape in an unstressed state.

Owner:ROBERT BOSCH GMBH

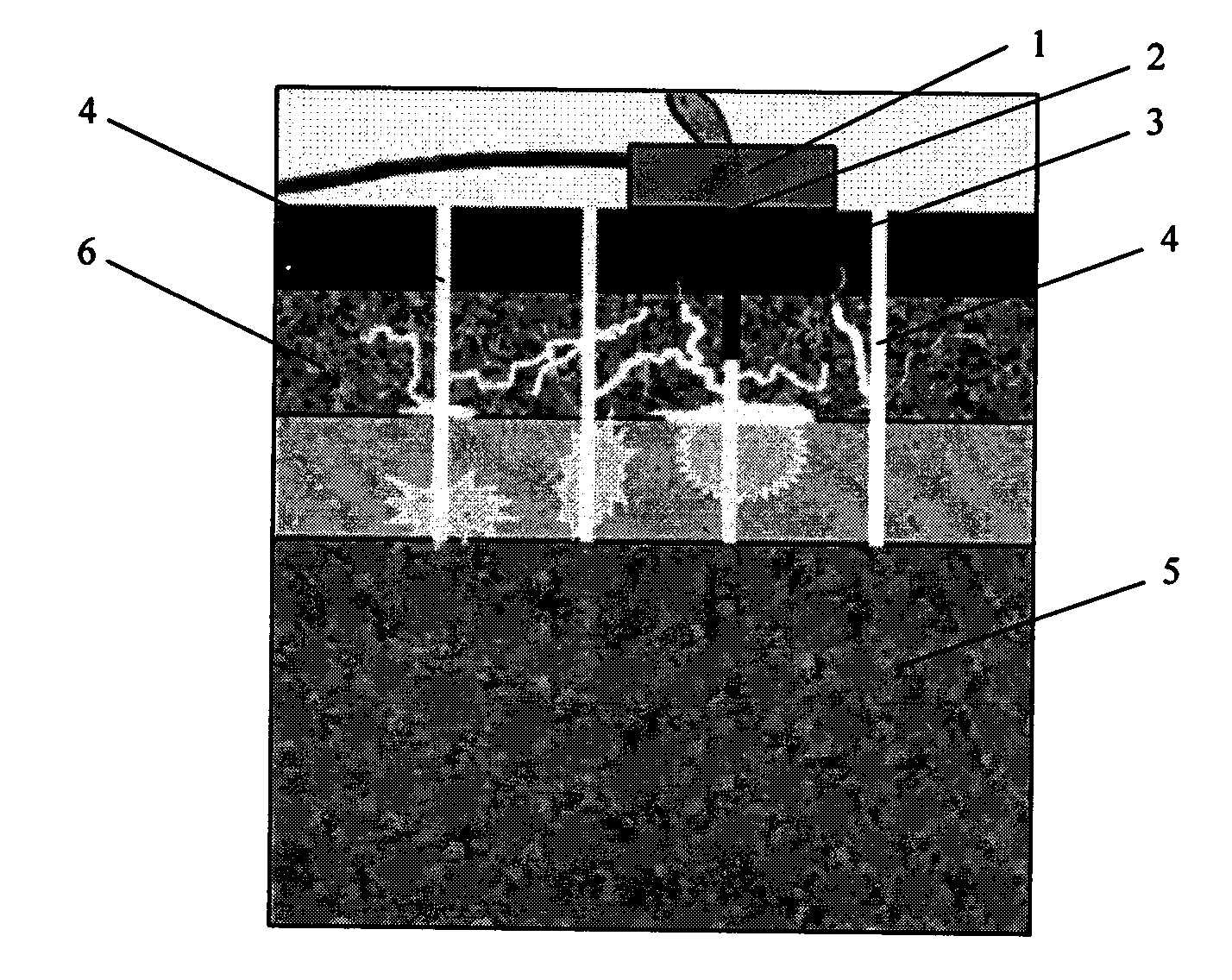

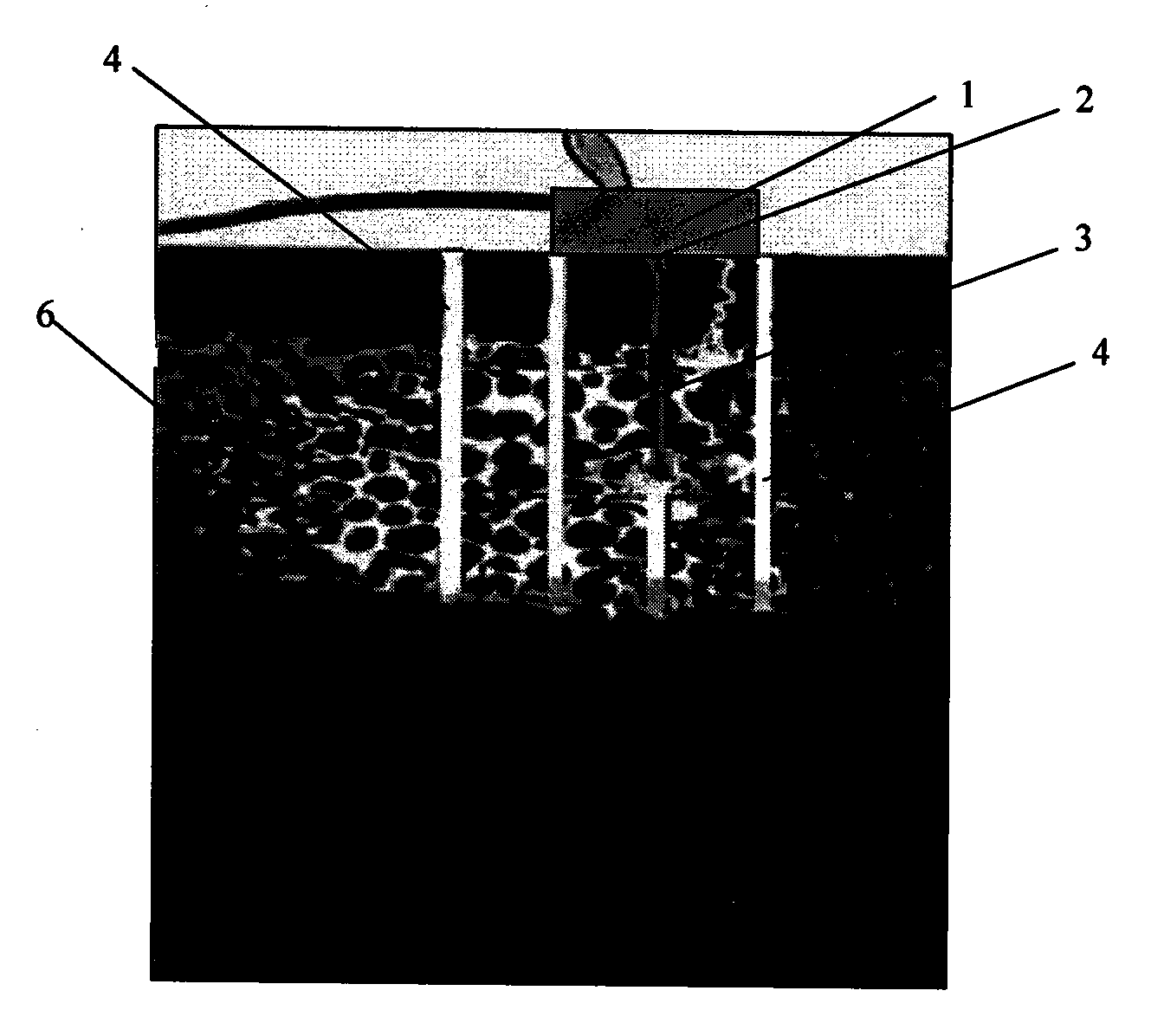

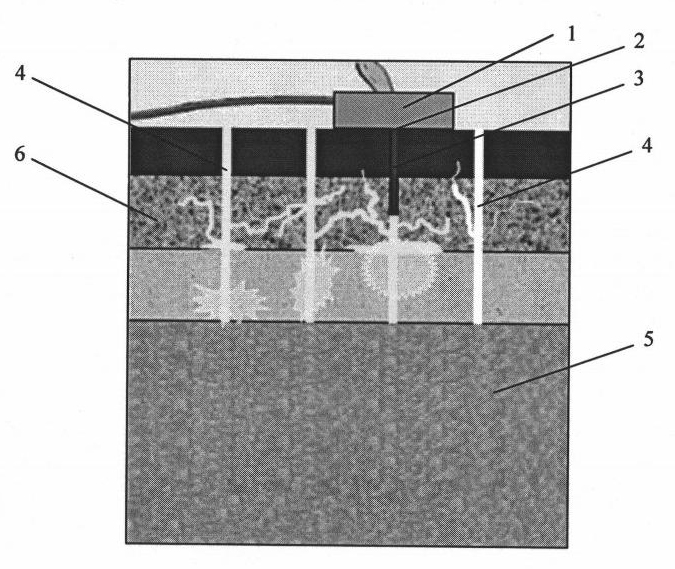

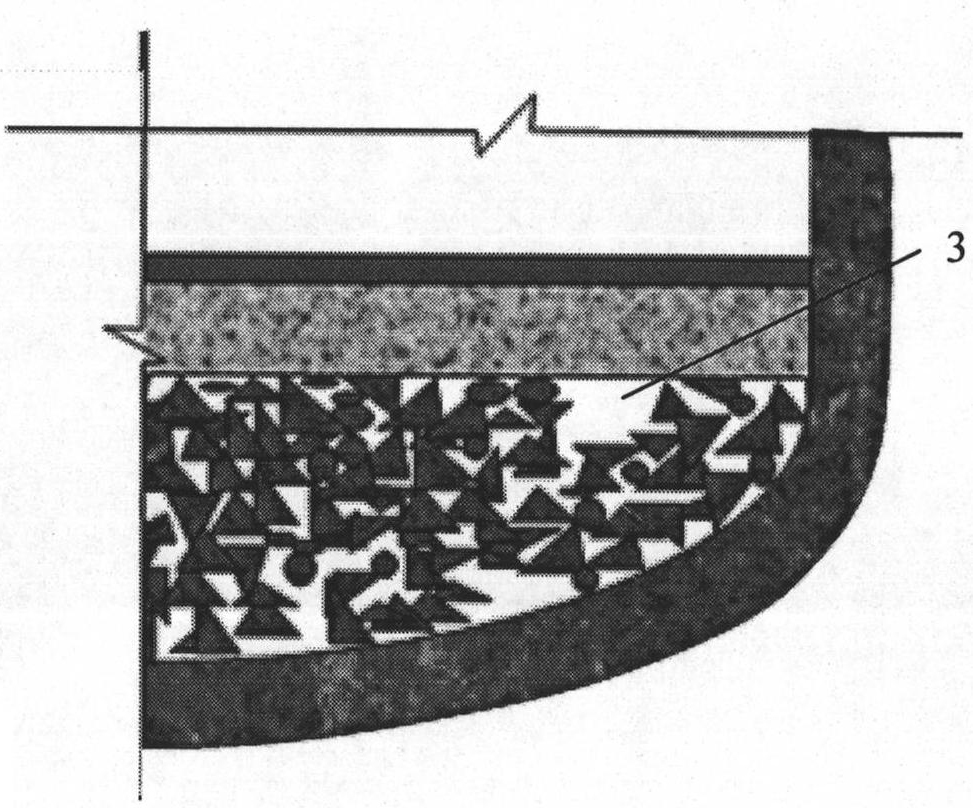

Road base reinforcing high-polymer loading and grouting method

ActiveCN102031747AIncreased durabilityIncrease elasticityRoads maintainenceRoad surfaceTherapeutic effect

The invention discloses a road base reinforcing high-polymer loading and grouting method. Aiming at semi-rigid road surface with an incompact base, and flexible base road surface, additional load is applied to the road surface by a loading device, an expansive force of the reacted high-polymer material is prevented from supporting the road surface; and by injecting the high-polymer material into the base, the volume of the reacted material rapidly expands, and the incompact base is solidified so as to fulfill the aim of reinforcing the base. The method has the characteristics of good treatment effect, rapid construction, no curing need, high pertinence, high controllability, fund conservation and the like; and compared with the conventional maintenance method, the method is obviously innovative in technical principle, construction method and other aspects. The unique road base reinforcing method can save a lot of funds and construction period, avoids bad social impact due to long-term traffic closure, and contributes to protecting environment and saving resources.

Owner:王复明

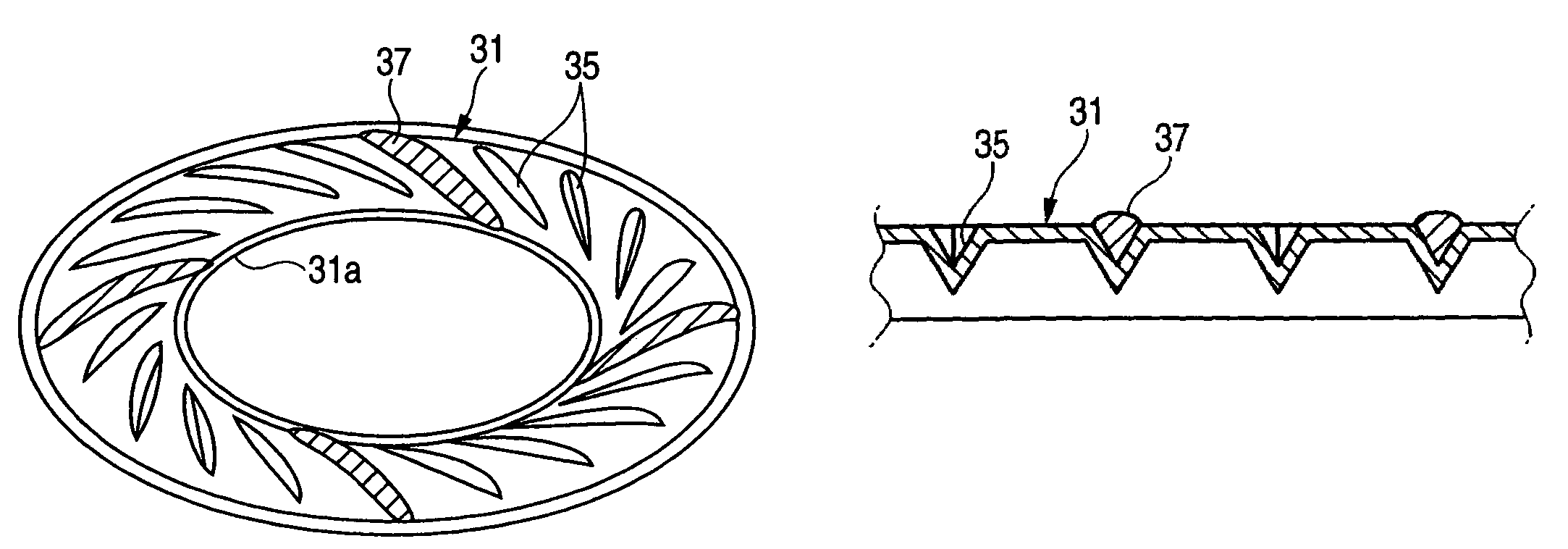

Speaker and speaker diaphragm

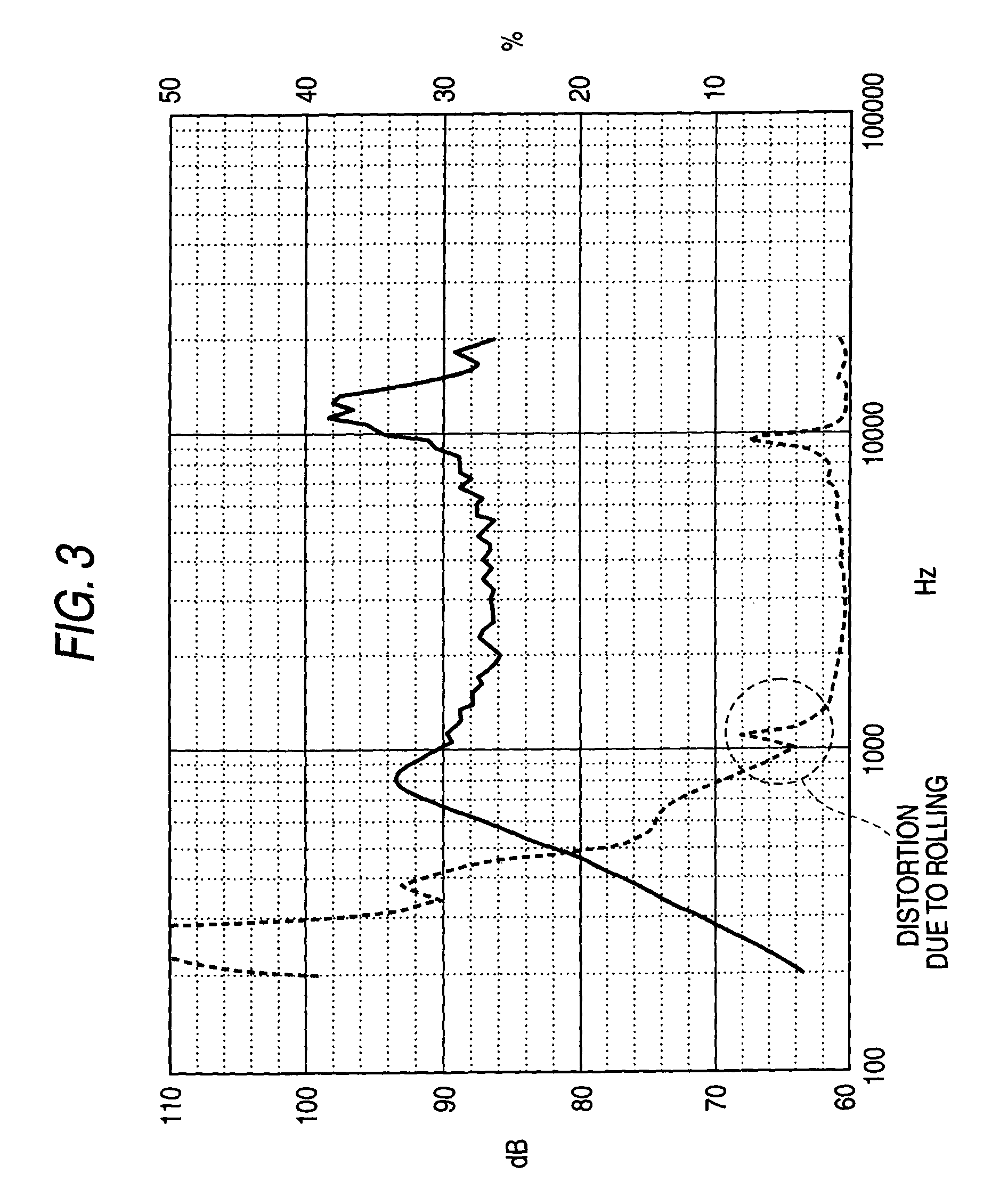

InactiveUS6957714B2Improve flexural strengthImprove performanceLoudspeaker diaphragm dampingLoudspeaker diaphragm shapeFlexural strengthEngineering

The speaker has a diaphragm main body 30 supported resiliently on a frame 23 via an edge portion 31 around its outer circumference, and the groove ribs 35 integrally formed in the edge portion 31, wherein a regulation member 37 for partially improving a flexural strength of the edge portion 31 is provided on a part of the front or back face of the edge portion 31.

Owner:PIONEER CORP +1

Self-Repairing Concrete Used Urea-Formaldehyde Resin Polymer Micro-Capsules and Method for Fabricating Same

ActiveUS20110060074A1Low flexural strengthImprove flexural strengthDischarging arrangementMouldsPolymer scienceFilling materials

A self-repairing concrete includes urea-formaldehyde resin polymer micro-capsules, in which the urea-formaldehyde resin polymer micro-capsules are mixed for a fixed function of micro-cracks. The quality mixture ratio is: concrete / micro capsules / water=100:1-15:15-50. The manufacturing method is weighing a full amount of water in a container, adding urea-formaldehyde resin polymer micro-capsules, stirring, until fully dispersed microcapsules; pouring the water into the mixing container, adding the corresponding quality of cement; stirring; adding sand and gravel filling materials, conducting worksite watering, ⅓ volume for each time, vibrating, and air exhausting; until the paste filling mold.

Owner:SHENZHEN UNIV +2

Probe card configuration for low mechanical flexural strength electrical routing substrates

InactiveUS20060244470A1Add supportLow flexural stiffness/strength substrateSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsProbe cardTransformer

A mechanical support configuration for a probe card of a wafer test system is provided to increase support for a very low flexural strength substrate that supports spring probes. Increased mechanical support is provided by: (1) a frame around the periphery of the substrate having an increased sized horizontal extension over the surface of the substrate; (2) leaf springs with a bend enabling the leaf springs to extend vertically and engage the inner frame closer to the spring probes; (3) an insulating flexible membrane, or load support member machined into the inner frame, to engage the low flexural strength substrate farther away from its edge; (4) a support structure, such as support pins, added to provide support to counteract probe loading near the center of the space transformer substrate; and / or (5) a highly rigid interface tile provided between the probes and a lower flexural strength space transformer substrate.

Owner:FORMFACTOR INC

Grinding wheel

InactiveCN101659033AReduces eye cloggingReduce the number of trimmingSemiconductor/solid-state device manufacturingLapping machinesEngineeringGrinding wheel

The invention provides a grinding wheel, which can decrease the finishing time of a grinding tool and prevent a wafer from generating crackles. The grinding wheel is arranged on a wheel seat of a grinding device in the free assemble and unassemble way, the grinding device comprises a grinding fluid supply member for supplying a grinding fluid, a main shaft driven to rotate and the wheel seat connected with the frontend of the main shaft. The grinding wheel is characterized in that the grinding wheel comprises an annular base with an internal wall, an external wall and an installation portion arranged on the wheel seat, and a plurality of grinding tools annularly arranged at the free end of the annular base, wherein a plurality of through holes which are spaced apart at prescribed intervalsare formed on the external wall of the annular base along the circumference direction, the plurality of through holes penetrate through the internal wall for discharging the grindstone dust and the grinding fluid.

Owner:DISCO CORP

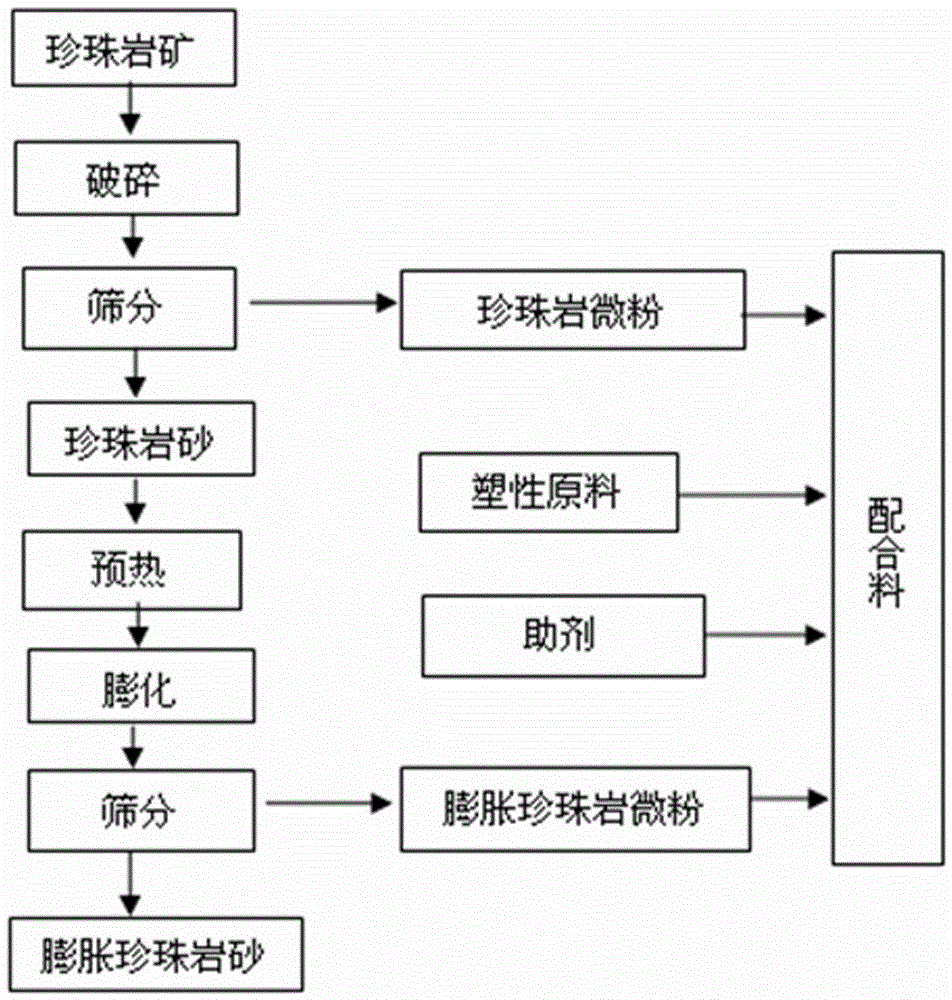

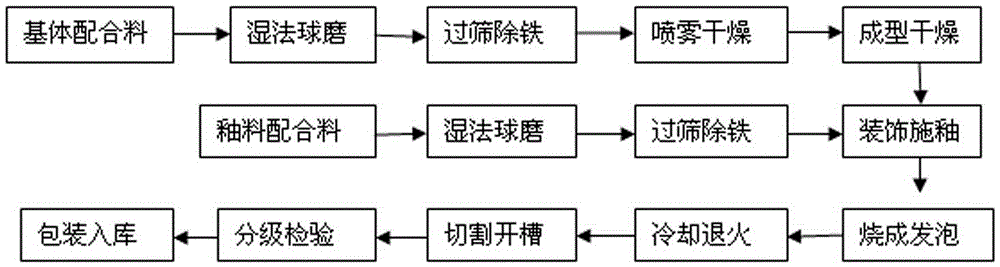

Thermal insulating decorative ceramic plate produced by comprehensive utilization of perlite waste and production method thereof

The invention discloses a thermal insulating decorative ceramic plate produced by comprehensive utilization of perlite waste and a production method thereof. A matrix formula consists of: 25%-100% of perlite micropowder, 20%-80% of expanded perlite micropowder, 2%-25% of Guangdong black mud, 0%-10% of limestone, 0.1%-5% of fluorite, 0.1%-2% of black silicon carbide, 0.5%-15% of bentonite, 0.1%-5% of sodium metasilicate nonahydrate, 0.1%-0.5% of sodium humate, and 0.1%-1.0% of sodium tripolyphosphate. A glaze formula consists of: 50-90% of expanded perlite powder, 50-90% of low temperature frit, 0.1-5% of zinc oxide, 0.1-5% of fluorite, 0-5% of apatite, 0.1-2.0% of sodium tripolyphosphate, 0.5-5% of kaolin, and 0.1-0.5% of sodium methyl cellulose. The production method is characterized by naked firing in a roller kiln at a low temperature of 900DEG C-1050DEG C. After firing, the thermal insulating decorative ceramic plate with a water absorption rate of less than 0.5%, a volume density of less than 500kg / m<3>, a rupture modulus of greater than 3.5Mpa, a thermal conductivity coefficient of less than 0.08 / W / (m.k), and a combustion level of A can be obtained.

Owner:XINYANG KEMEI NEW MATERIALS

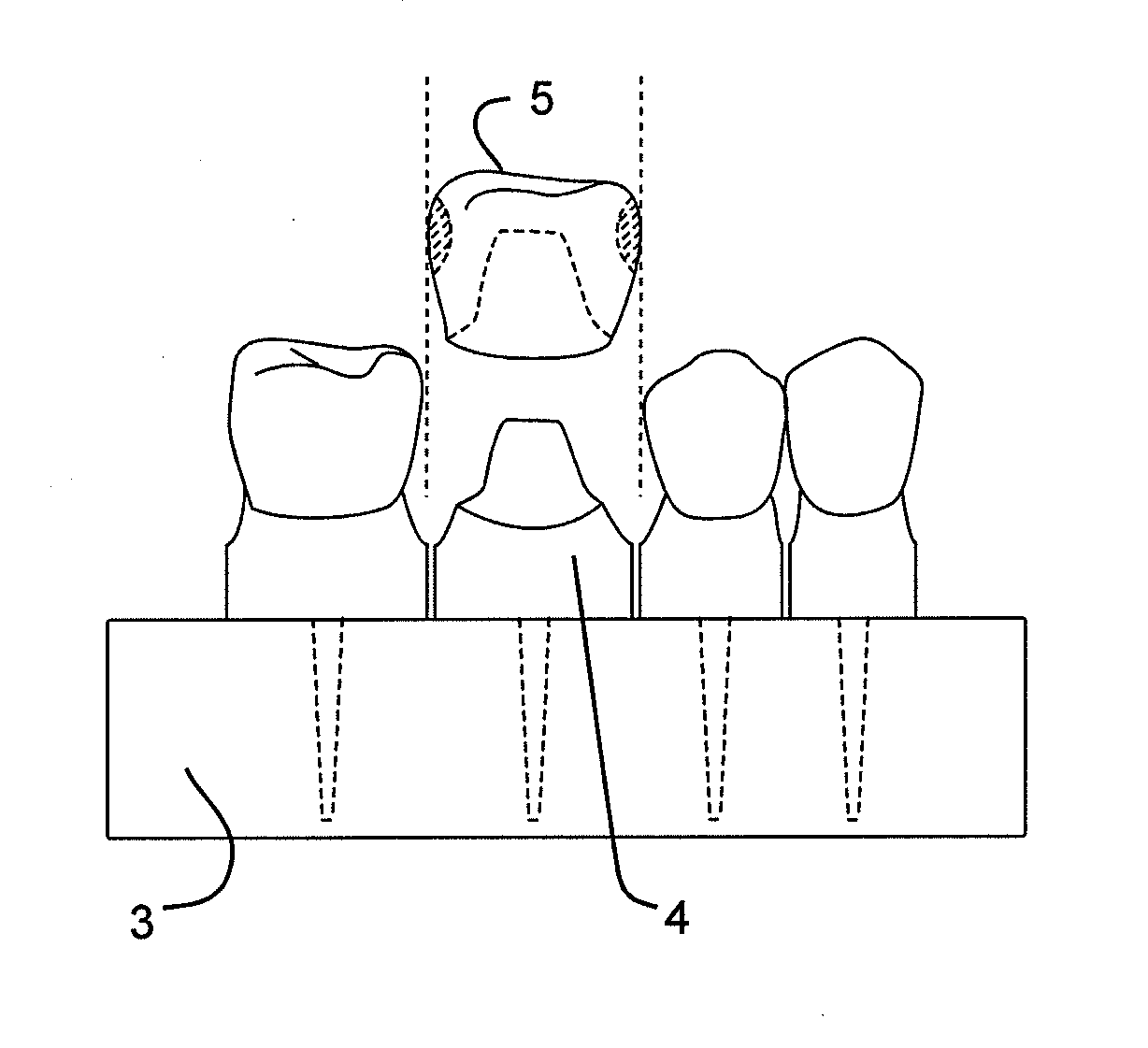

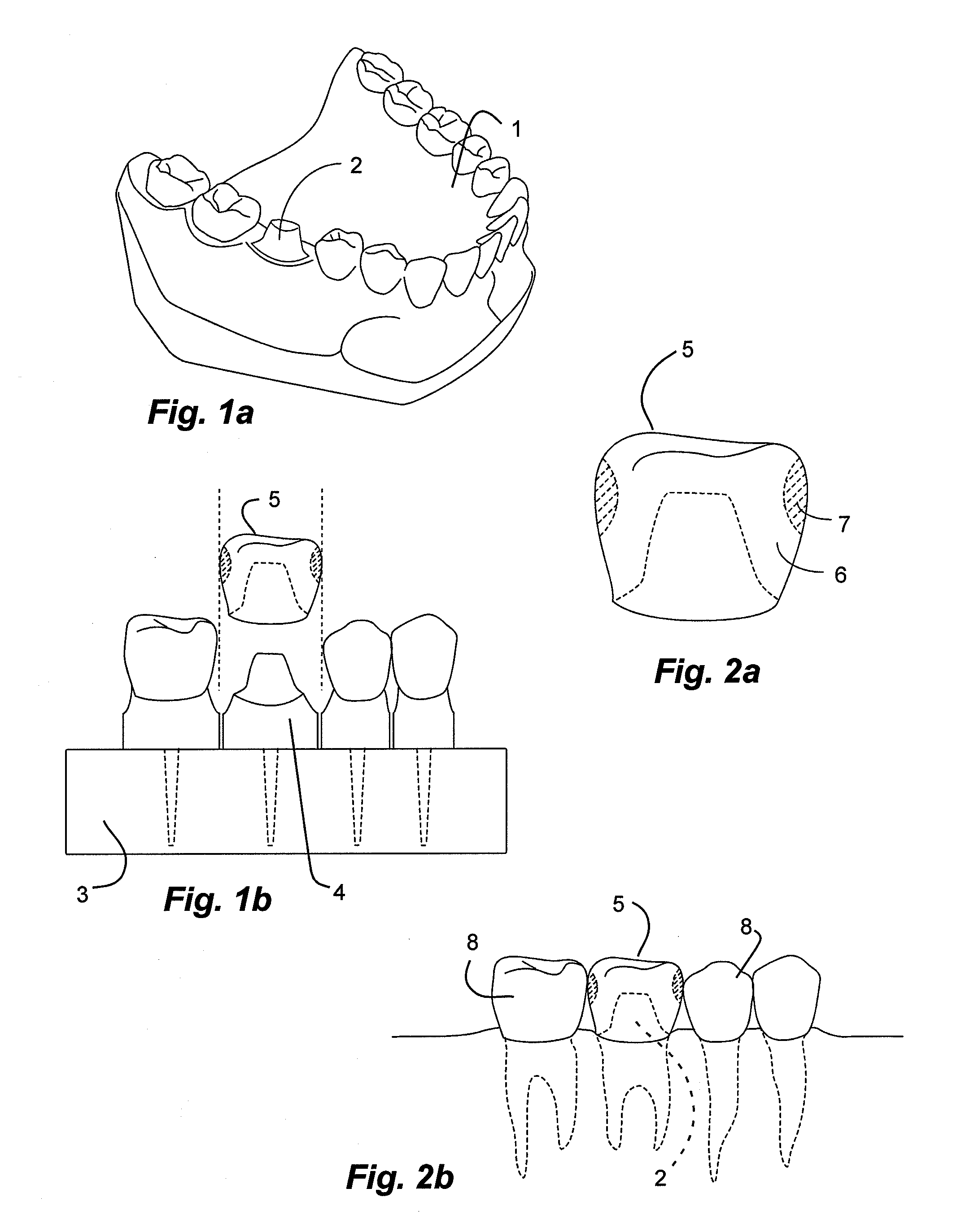

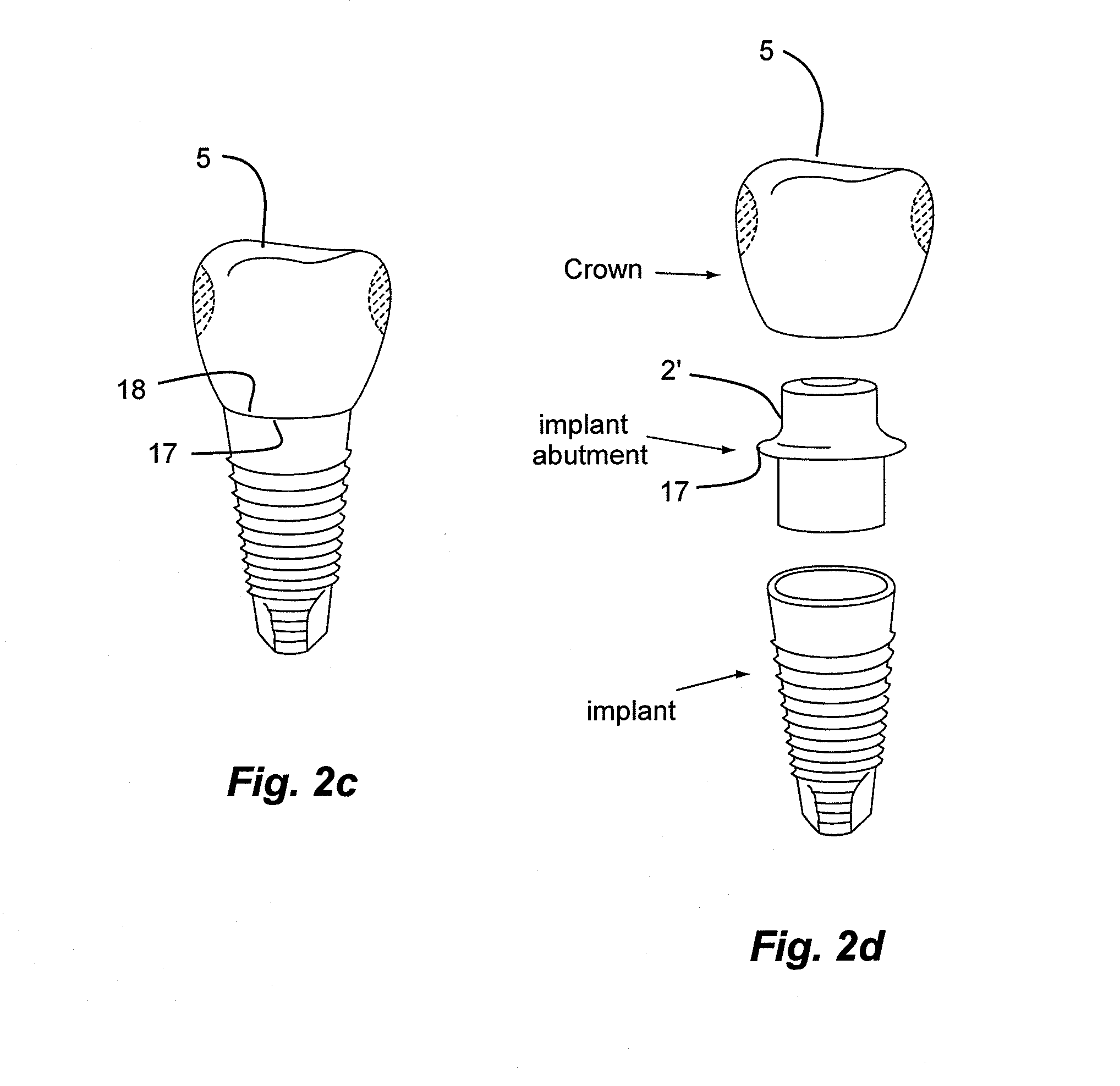

Method of making a dental prosthesis

ActiveUS20150111172A1Improve flexural strengthReduce generationImpression capsFastening prosthesisRestorative materialDentures

A method of making a dental crown or bridge restoration comprises forming a precursor crown outside of a patient's mouth with a first restorative material, with a buccal contour on the buccal wall substantially the same as a buccal contour on a final crown restoration, and an open space on or around at least one of the mesial side wall or the distal side wall; and filling and securing a second material, different from the first restorative material, inside the open space or pocket of the precursor crown while outside the patient's mouth, and with the precursor crown having a strength substantially equivalent to the final crown restoration, and with the buccal contour being substantially the same as the buccal contour on the final crown, prior to filling and securing the second material.

Owner:B & D DENTAL

Carbon fiber, process for production thereof, prepregs, and golf club shafts

InactiveUS20070196648A1High compressive strengthTensile modulusSynthetic resin layered productsMonocomponent synthetic polymer artificial filamentCarbonizationGolf Ball

A carbon fiber tow composed of many carbon filaments and having a strand tensile strength of 3.8 to 5.5 GPa, a strand tensile modulus of 180 to 220 GPa and a carbon crystal size (Lc) of 13 to 18 Å. This carbon fiber tow can be produced by subjecting a precursor fiber tow composed of many polyacrylonitrile filaments which have a lightness difference (ΔL) of 50 or below and fineness of 1.1 to 1.7 dtex to oxidative stabilization and subjecting the stabilized fiber tow to carbonization with the maximum temperature within the range of 1,100 to 1,300° C. in an inert atmosphere while raising the temperature from 1,000° C. to the maximum temperature at a temperature rise rate of 100 to 2,000° C. / min.

Owner:TORAY IND INC

Low-temperature co-fired ceramic material highly matched with high-temperature conductive silver paste and preparation method of low-temperature co-fired ceramic material

The invention discloses a low-temperature co-fired ceramic material highly matched with high-temperature conductive silver paste and a preparation method of the low-temperature co-fired ceramic material. The low-temperature co-fired ceramic material is prepared by sintering the following components in percentage by mass (100% in total): 35%-50% of CaO, 30%-45% of B2O3 and 15%-25% of SiO2. The prepared low-temperature co-fired ceramic material contains a large quantity of microfine crystal grains (CaSiO3) and a small amount of glass and is typical microcrystalline glass ceramic; and the low-temperature co-fired ceramic material is low in dielectric constant and extremely low in loss, good in matching rate with high-temperature conductive silver paste, good in panel flatness and good in comprehensive property, and the dielectric constant and the loss in multiple frequency bands are stable.

Owner:昆明云基新材料有限公司

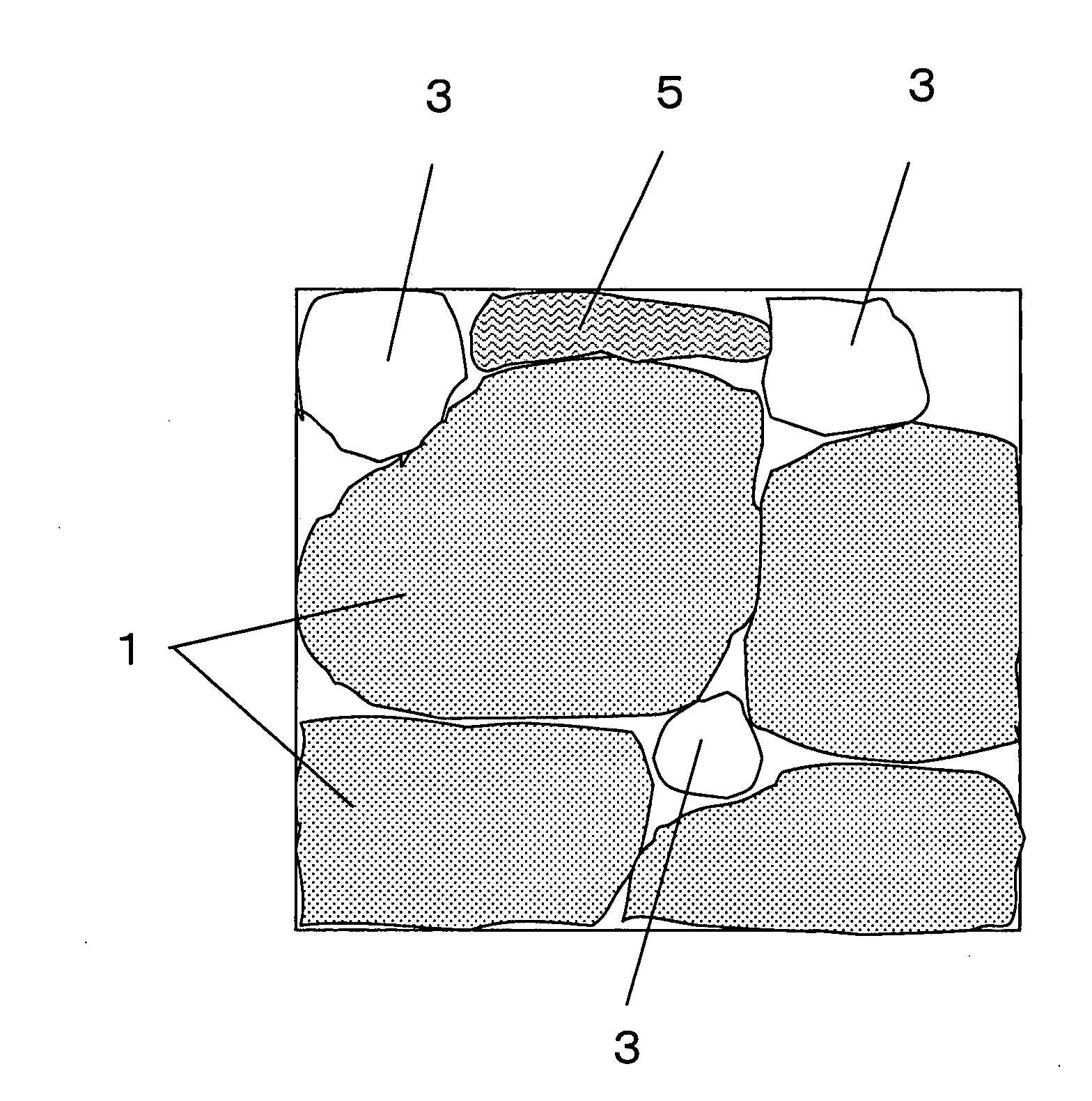

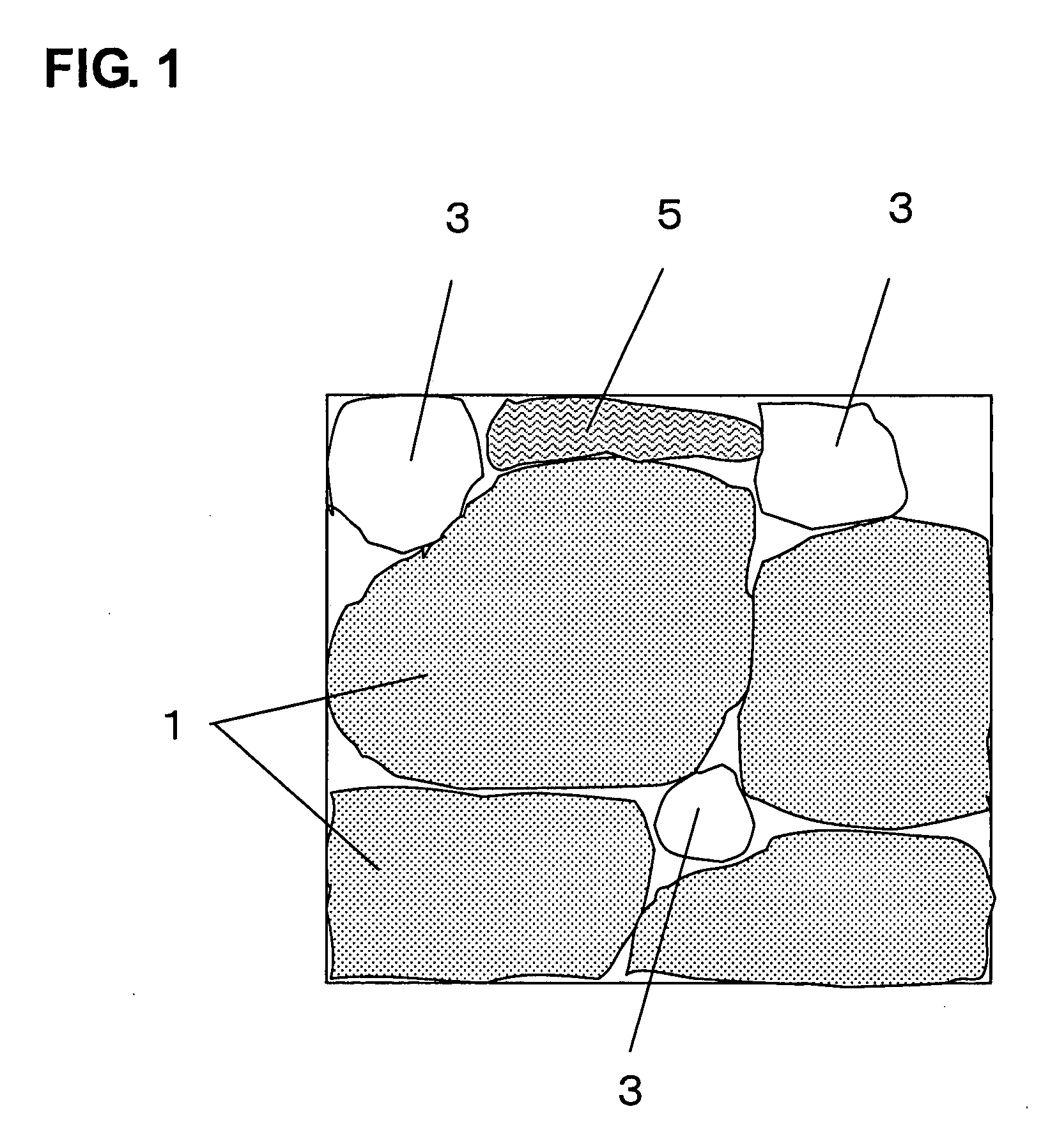

Composite Ceramic and Method for Making the Same

InactiveUS20080118722A1Improve toughnessLow mechanical strengthLayered productsThin material handlingAlkaline earth metalComposite ceramic

A composite ceramic of the present invention includes granular alumina particles (A) having an aspect ratio of 3 or less, granular zirconia particles (B) having an aspect ratio of 3 or less, and a columnar crystal (C) having an aspect ratio of 3 or more, the columnar crystal including a complex metal oxide containing an alkaline-earth metal element and aluminum element. The composite ceramic has high flexural strength, toughness, and hardness, and achieves excellent hot-water resistance and high flexural strength after hydrothermal degradation resistance test.

Owner:KYOCERA CORP

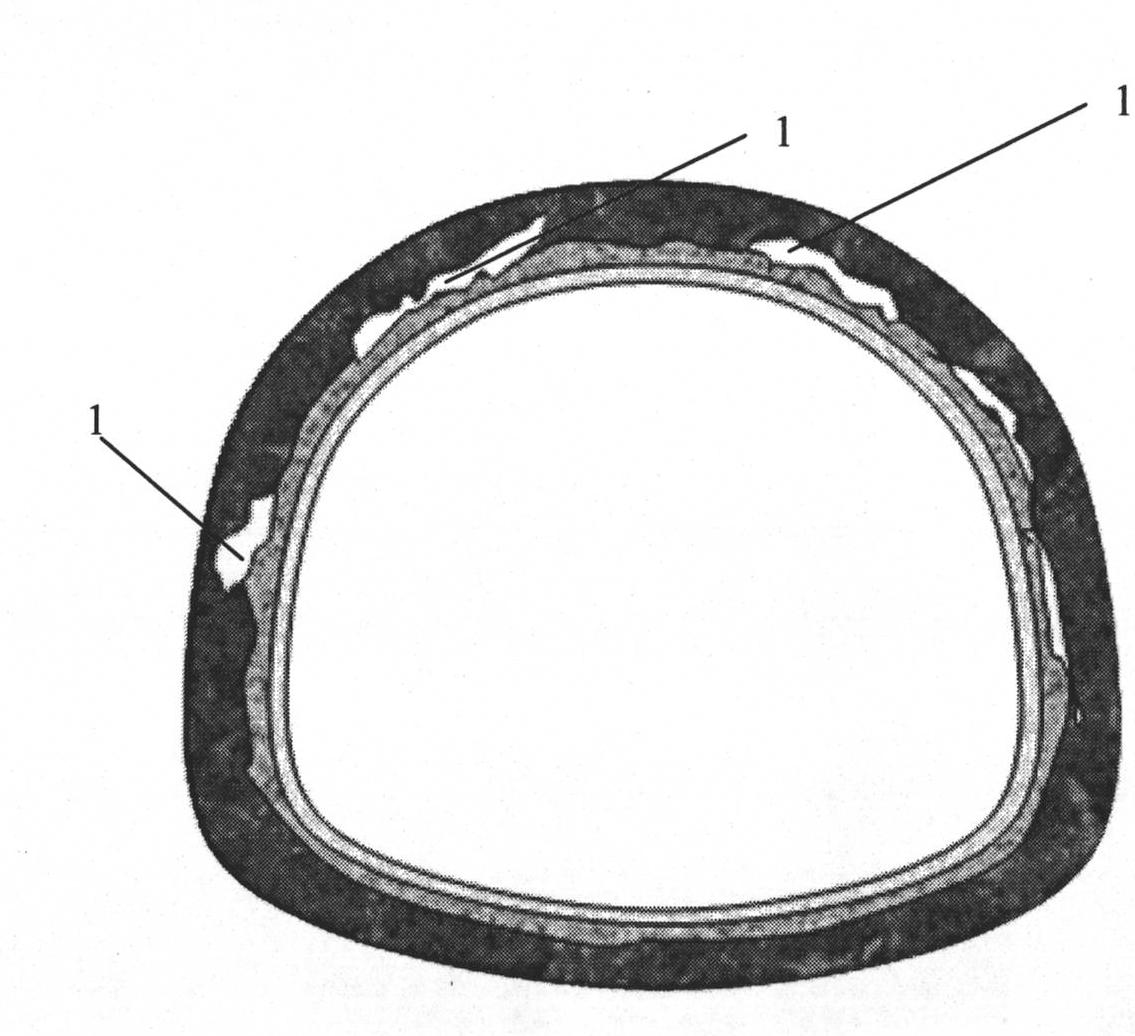

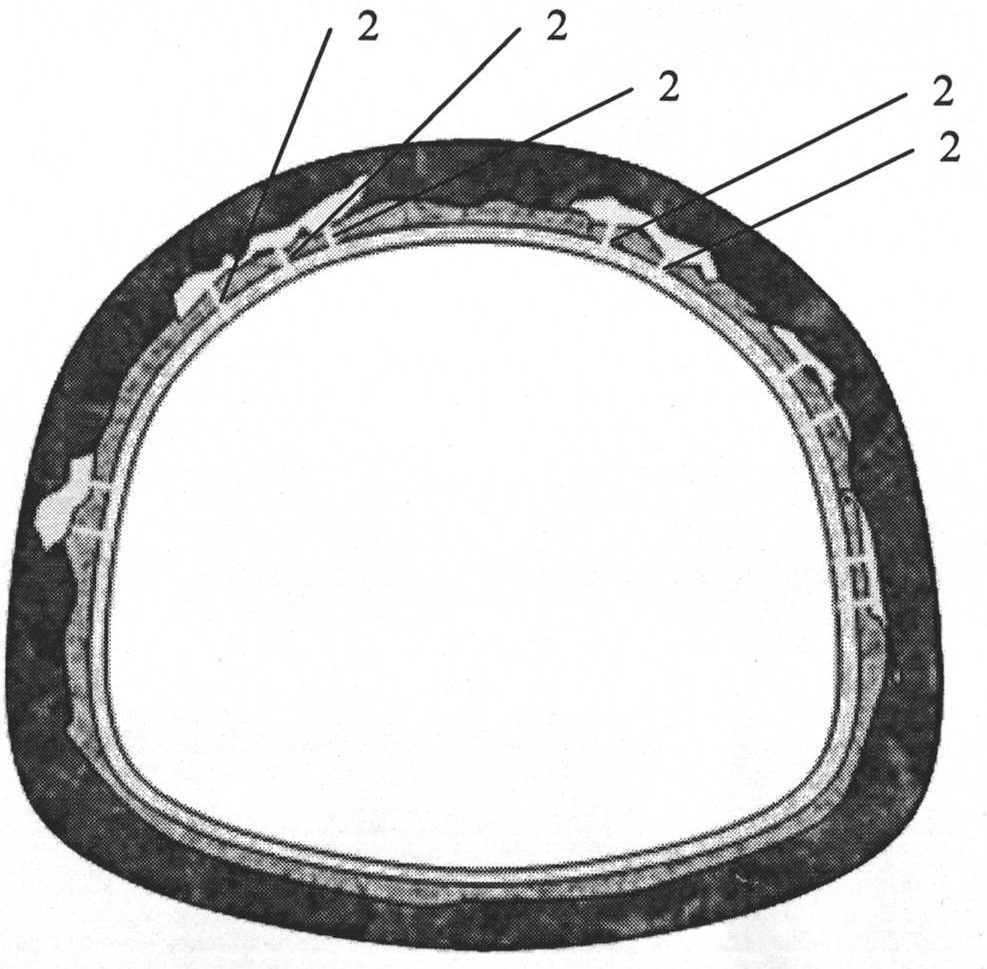

High polymer grouting technology for treating tunnel void and construction method thereof

InactiveCN102052081AIncreased durabilityIncrease elasticityUnderground chambersTunnel liningFast fillingTherapeutic effect

The invention discloses high polymer grouting technology for treating a tunnel void and a construction method thereof. The technology comprises the following steps of: detecting the tunnel void on the basis of a ground penetrating radar (GPR) or a falling weight deflectometer (FWD); and injecting a high polymer material to a void part according to the condition of the tunnel void, wherein after the material reacts, the volume is expanded quickly and the material is cured to quickly fill the void. The technology has the characteristics of good treatment effect, quick construction, no requirement on curing, obvious target, high controllability, cost conservation and the like. Compared with the traditional tunnel void treating method, the technology is innovative obviously in the aspects of technical principle and construction method and develops a new, quick, economical and practical way for maintaining a tunnel and enabling the tunnel to be durable.

Owner:ZHENGZHOU URETEK TECH

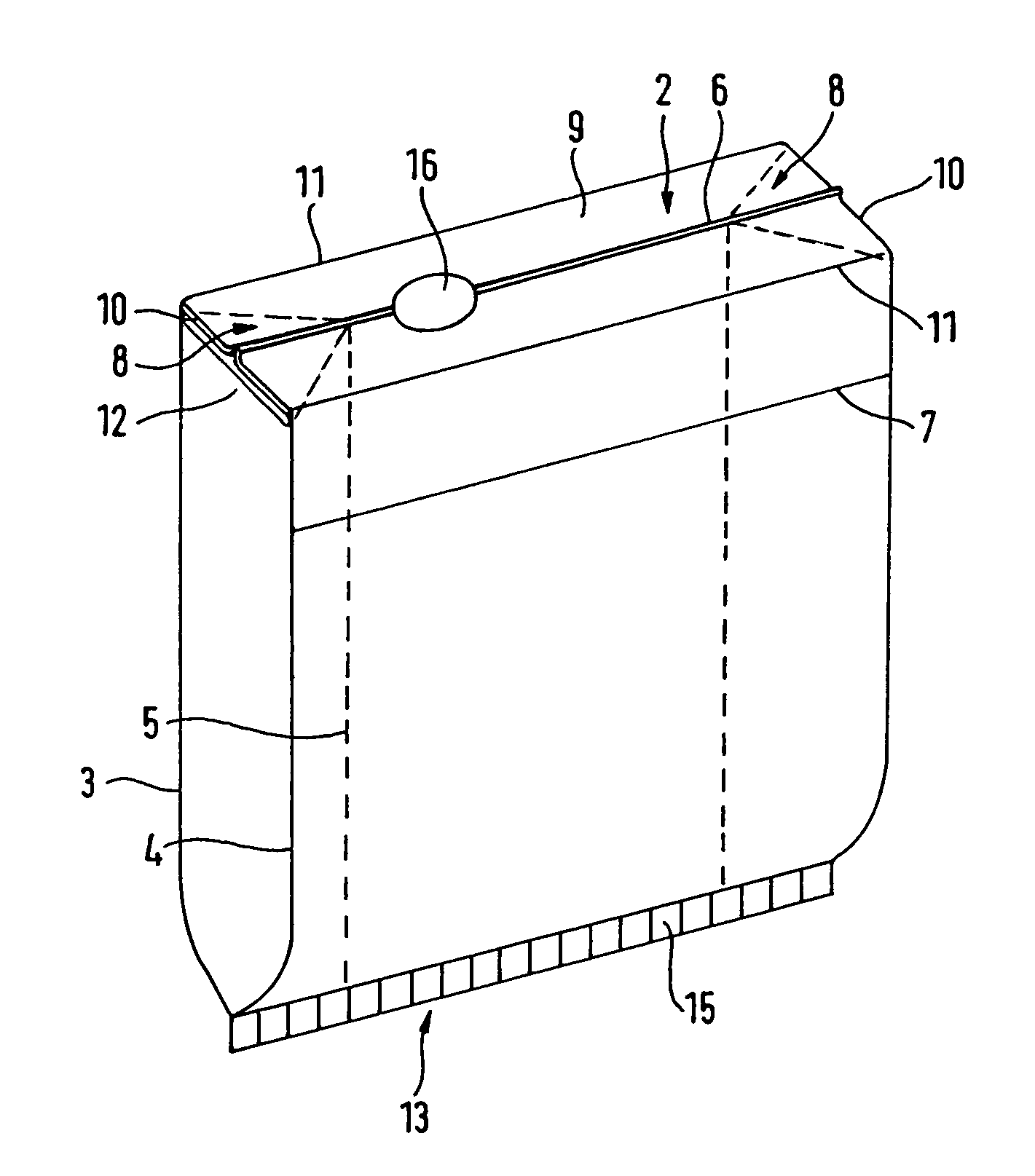

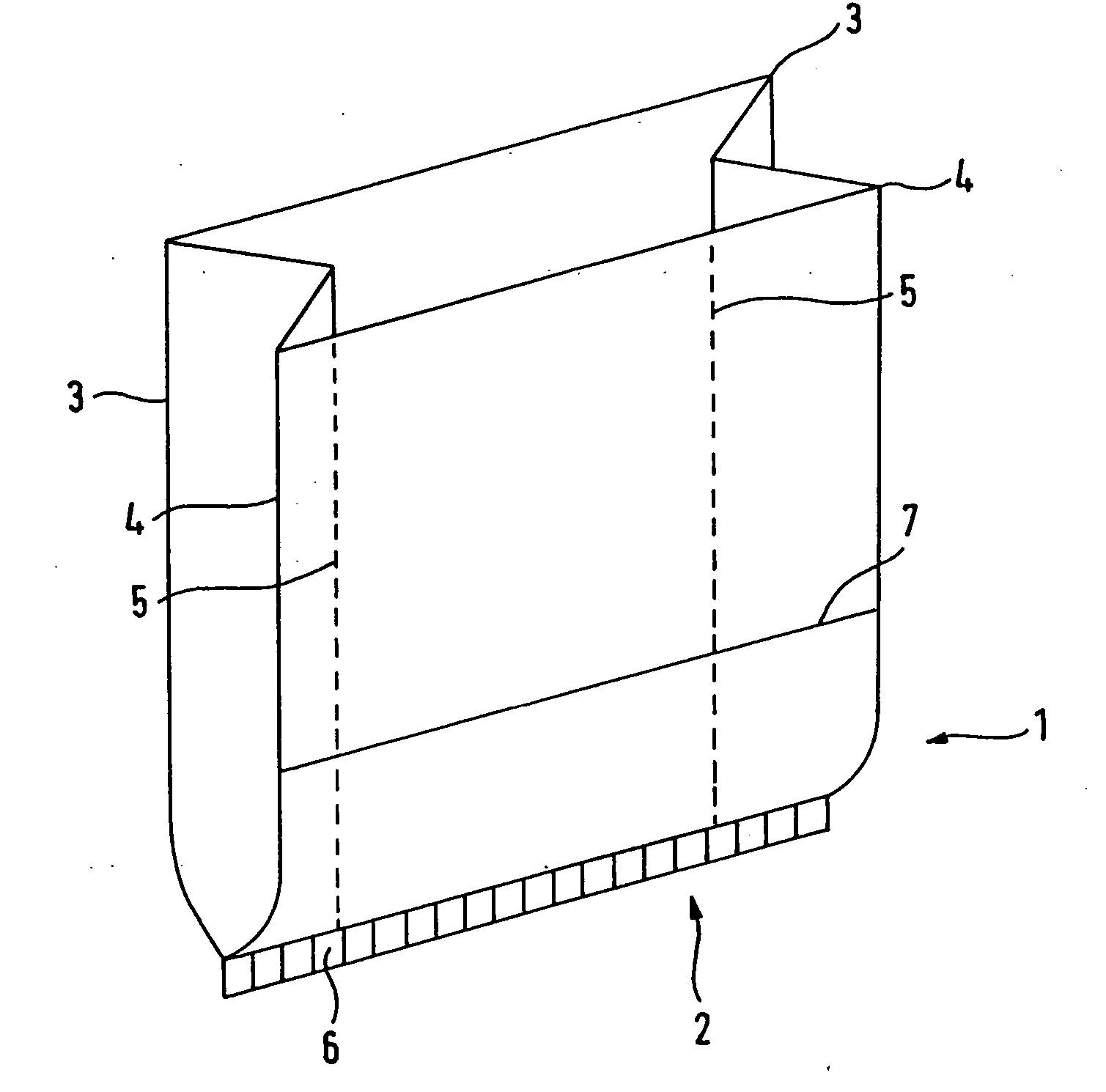

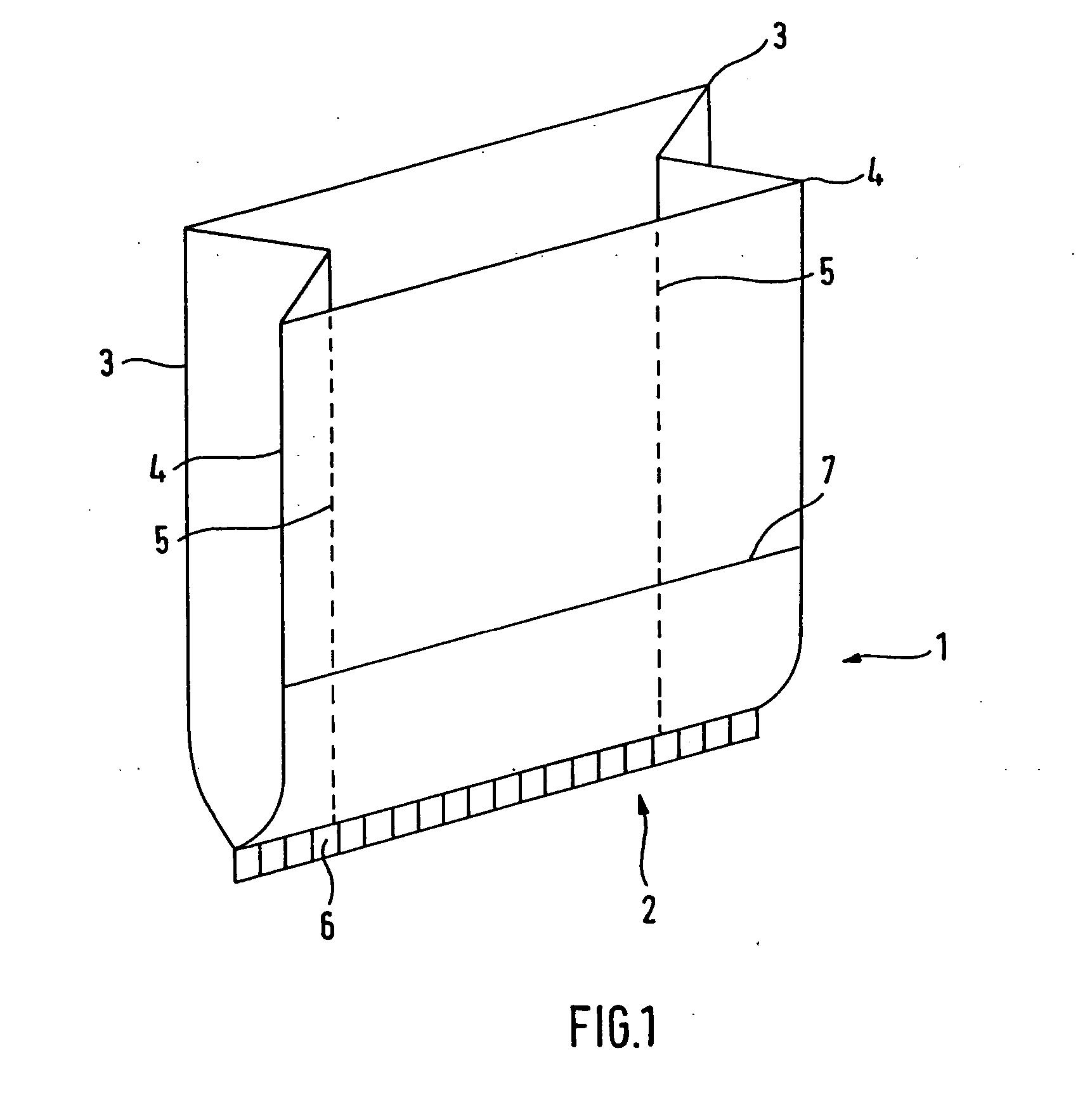

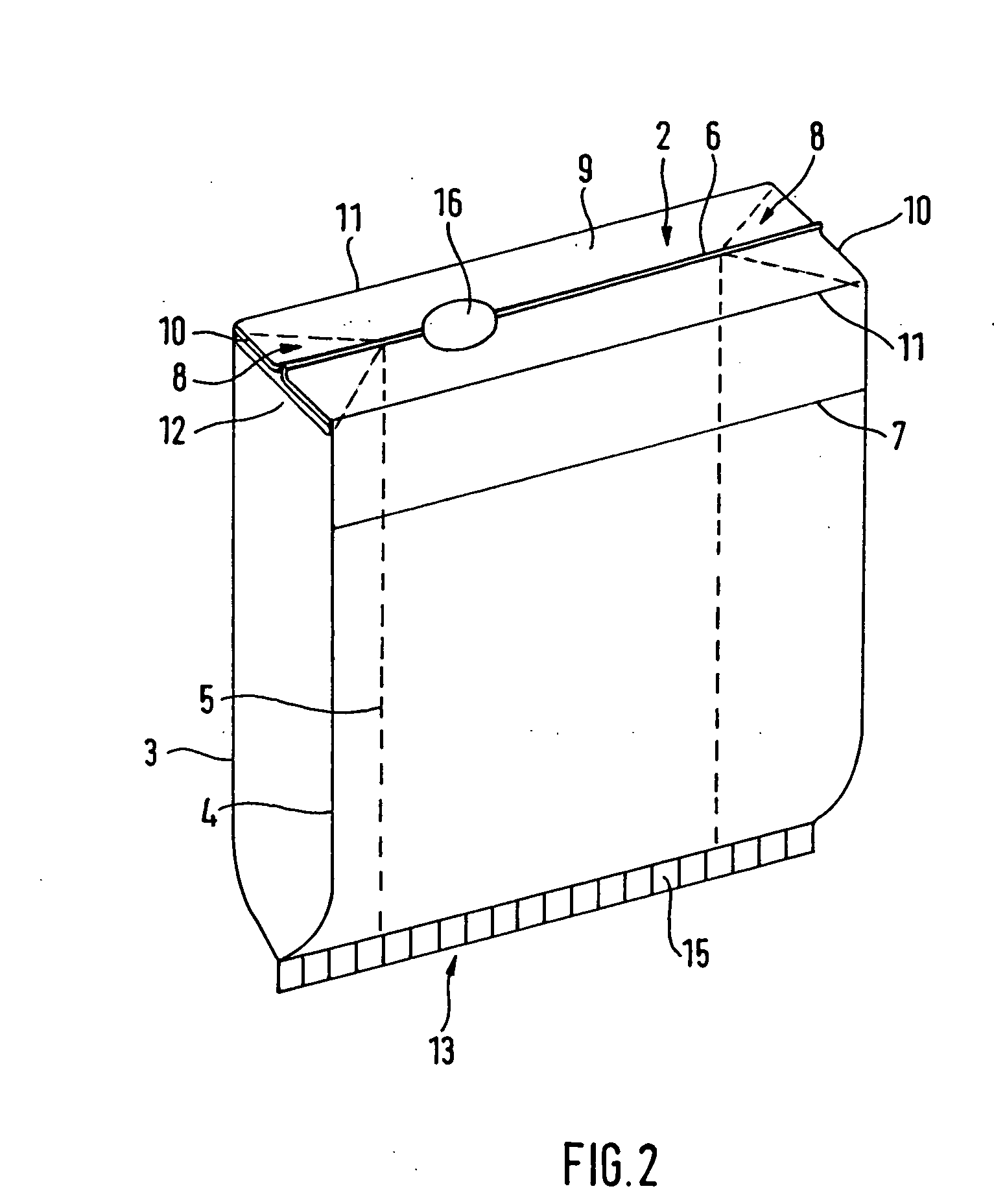

Filter bag and method for the production thereof

ActiveUS8002862B2Low flexural strengthEasy to installEnvelopes/bags making machineryMechanical working/deformationFolded formWeld seam

Described is a filter bag for a vacuum cleaner which may include a tubular bag with a closed free end area and an opposed, at least partially closed area as well as with a retaining plate. The bag is made from a bag material having at least one non-woven layer, and the at least partially closed area is folded forming a bottomPlies of the bag material which lie the one above the other are formed in areas, and is at least partially closed by a weld seam extending centrally in the bottom, the plies of the bag material which lie the one above the other being at least partially connected to one another.

Owner:EUROLIFTERS HLDG NV

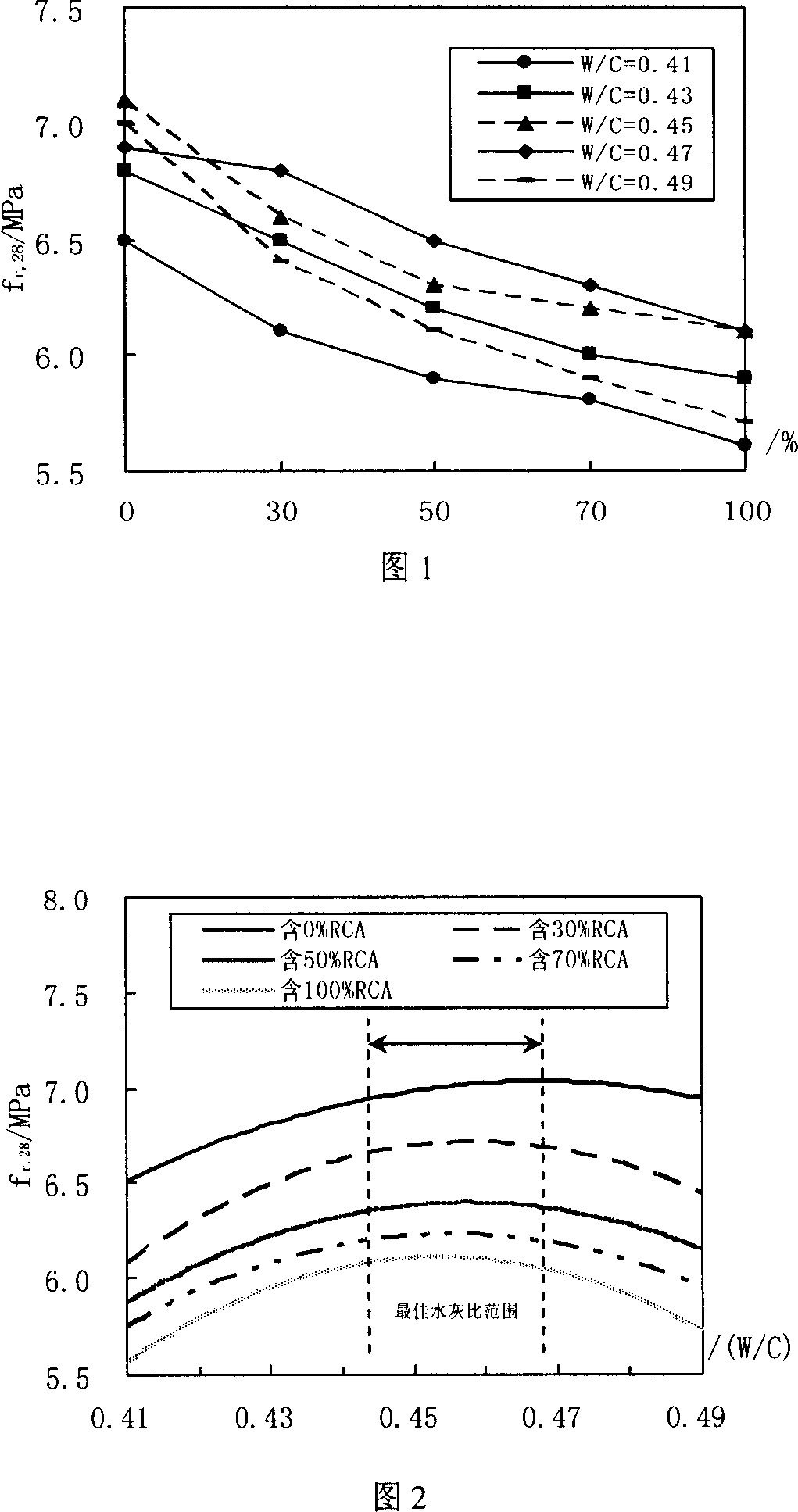

Regenerated cement concrete for pavement and its preparing process

InactiveCN1951859AImprove flexural strengthImprove toughnessSolid waste managementFiberSuperplasticizer

The invention discloses a new road regenerating cement concrete and preparing method, which comprises the following parts: 15%-37% regenerating rough aggregate, 15%- 37% natural rough aggregate, 16%-18% cement, 22%-24% sand, 8%-10% water (mixing water and additional water), 0.6%-1.2% steel fiber corresponding to the sum of component bulk and 0.1%-0.5% high-effect water reducer corresponding to cement quantity. The invention overcomes low bending-proof strength, which improves cracking-proof flexibility and impaction-proof ability greatly.

Owner:王军龙

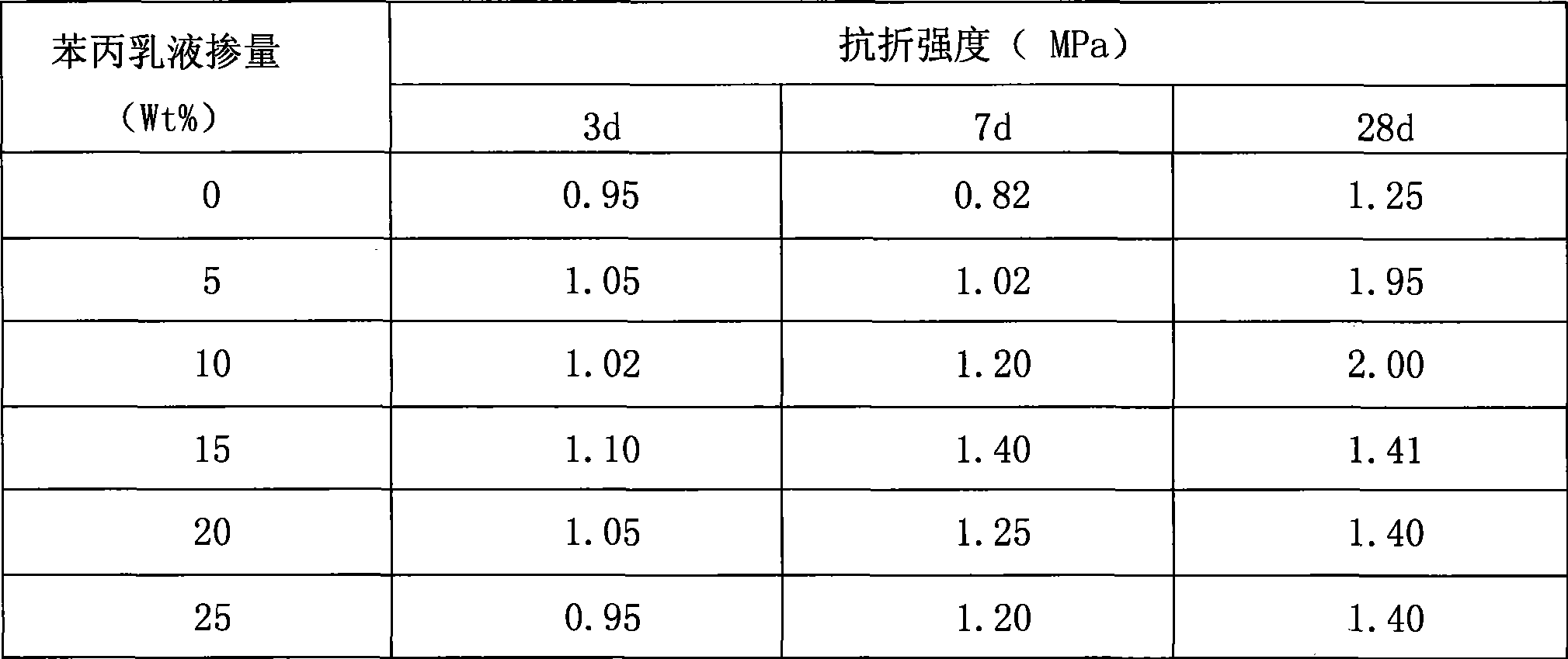

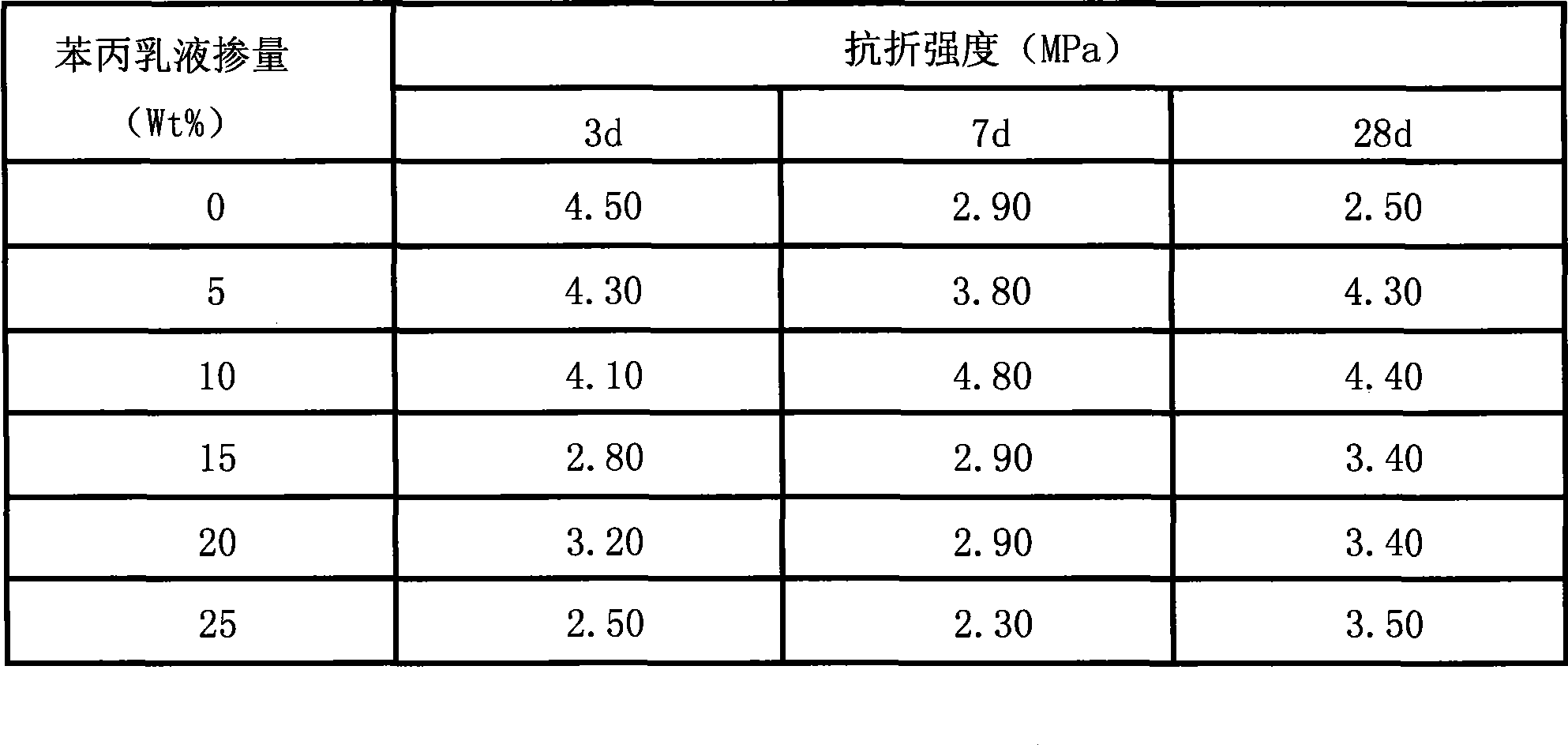

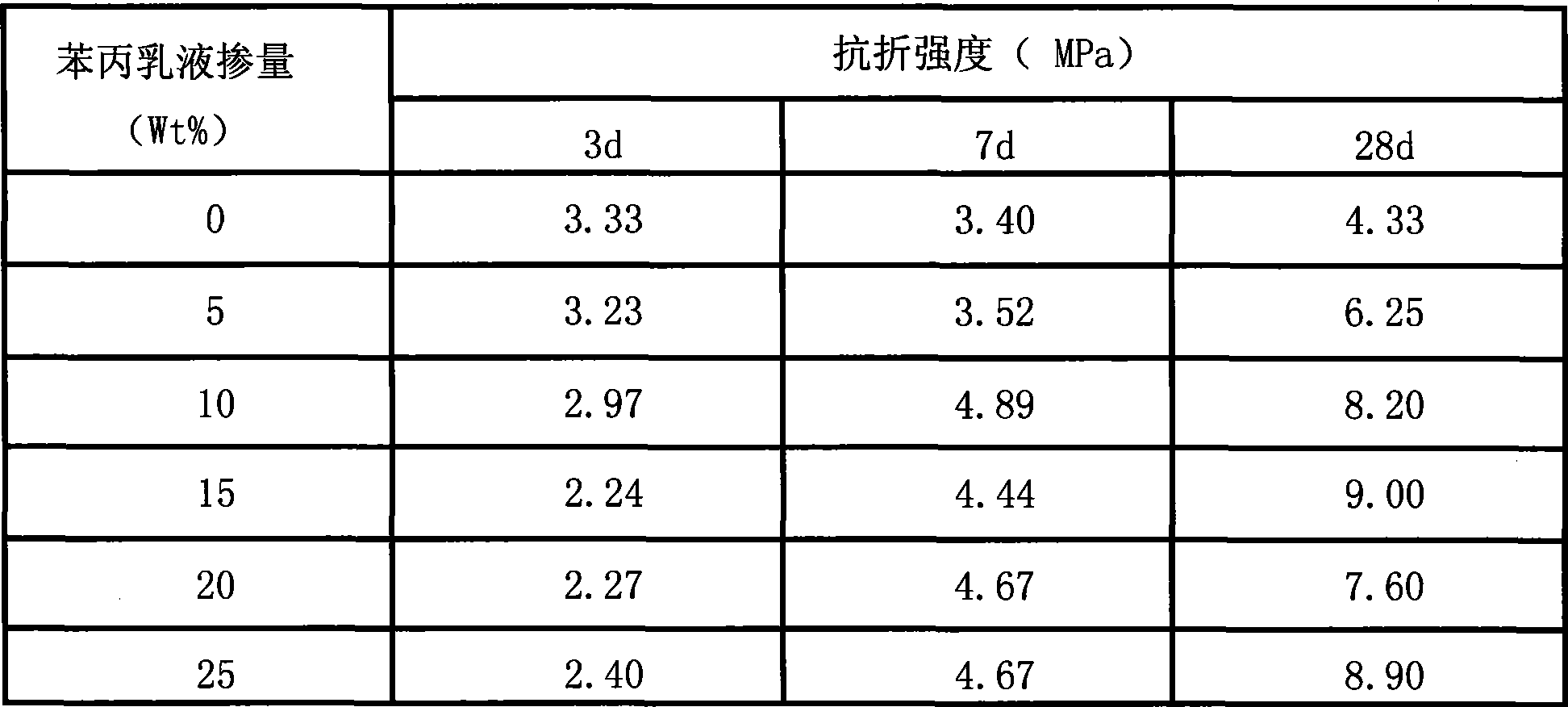

Method for preparing geopolymer and organic macromolecule composite gelled material

The invention discloses a method for preparing a geopolymer and organic macromolecule composite gelled material. In the method, slag or fly ash capable of providing geopolymer components and styrene / butyl acrylate copolymer emulsion are utilized to produce a slag or fly ash geopolymer and organic macromolecule composite gelled material under the action of silicate excitants; wherein the amount of styrene / butyl acrylate copolymer emulsion is 5-25 percent of the weight of phosphatic slag or slag, and the amount of the alkali excitant sodium silicate is 20-22 percent of the weight of the phosphatic slag or slag; and the flexural strength of the geopolymer polymer and organic macromolecule composite is superior to the inorganic aluminosilicate polymer in 28-day age, and the 28-day maximum flexural strength is 1.76 times of that of the inorganic aluminosilicate polymer. The preparation process has no discharge of waste water, waste gas and waste slag, does not need heating, is green, environment-friendly and energy-saving, reduces the consumption, and is one effective approach for large-scale resource utilization of industrial solid wastes.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Reinforced cement foaming board and preparation method thereof

InactiveCN103172327AGuaranteed carbonization indexStrength does not shrinkCeramic shaping apparatusCeramicwareFiberPolymer science

The invention relates to a reinforced cement foaming board and a preparation method thereof. The reinforced cement foaming board comprises the following components in percentage by weight: 27.00-35.50% of water, 28.0-61.0% of Portland cement, 0-32.70% of coal ash at grade I or a mixture of coal ash and recycled filler, 0-2.00% of wollastonite powder, 0.10-0.30% of fiber, 0.37-0.65% of ammonium stearate, 1.00-2.00% of a mixture of 10 parts of calcium sulphate and 1 part of calcium formate, 0.10-0.20% of naphthalenesulfonate formaldehyde condensation compound, 0.90-1.20% of hydrogen peroxide and reinforcement net. The reinforced cement foaming board provided by the invention has the advantages of low apparent density, low heat conductivity coefficient, good noise reduction effect, high strength, no crack and shock resistance.

Owner:上海中驰建筑工程有限公司

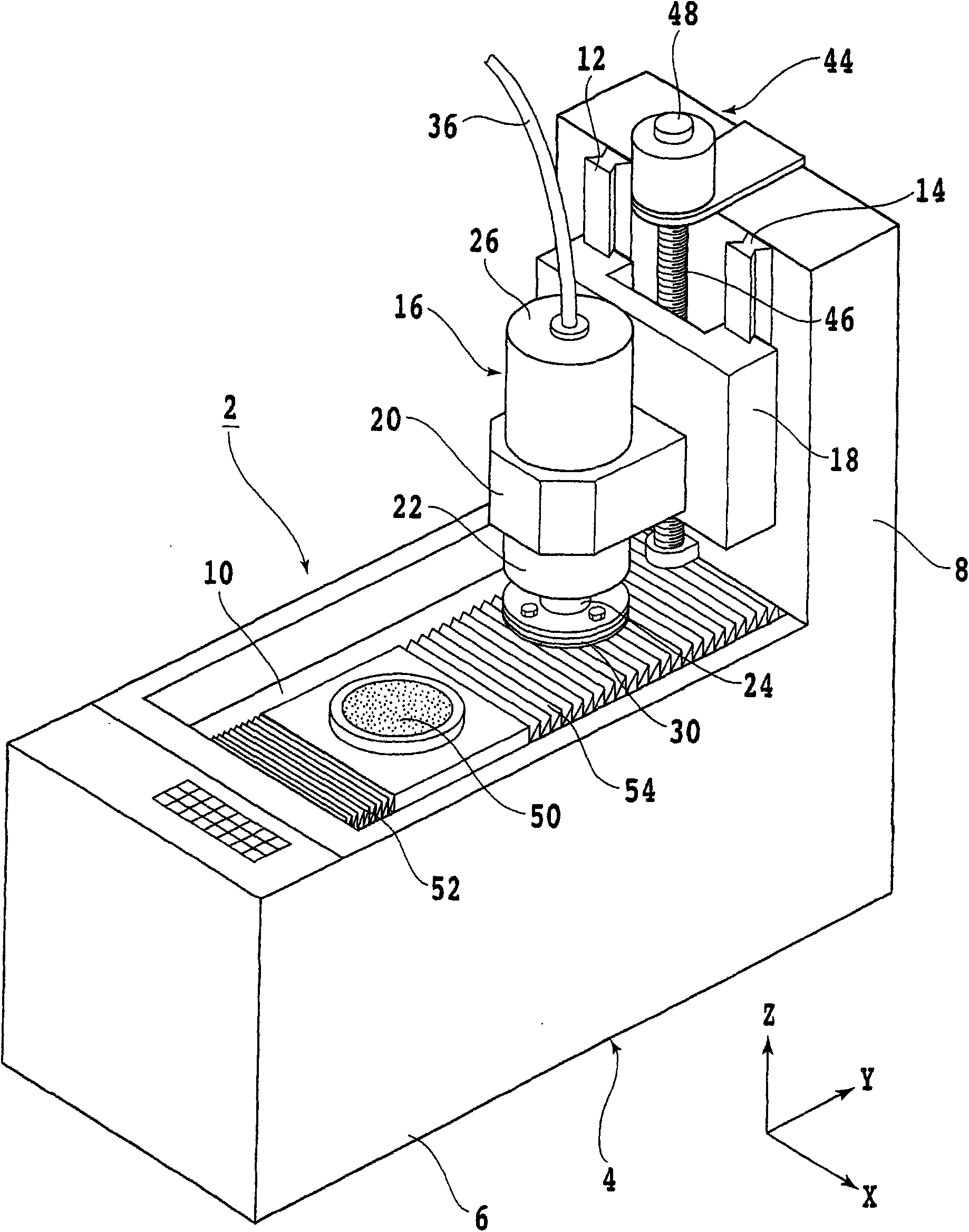

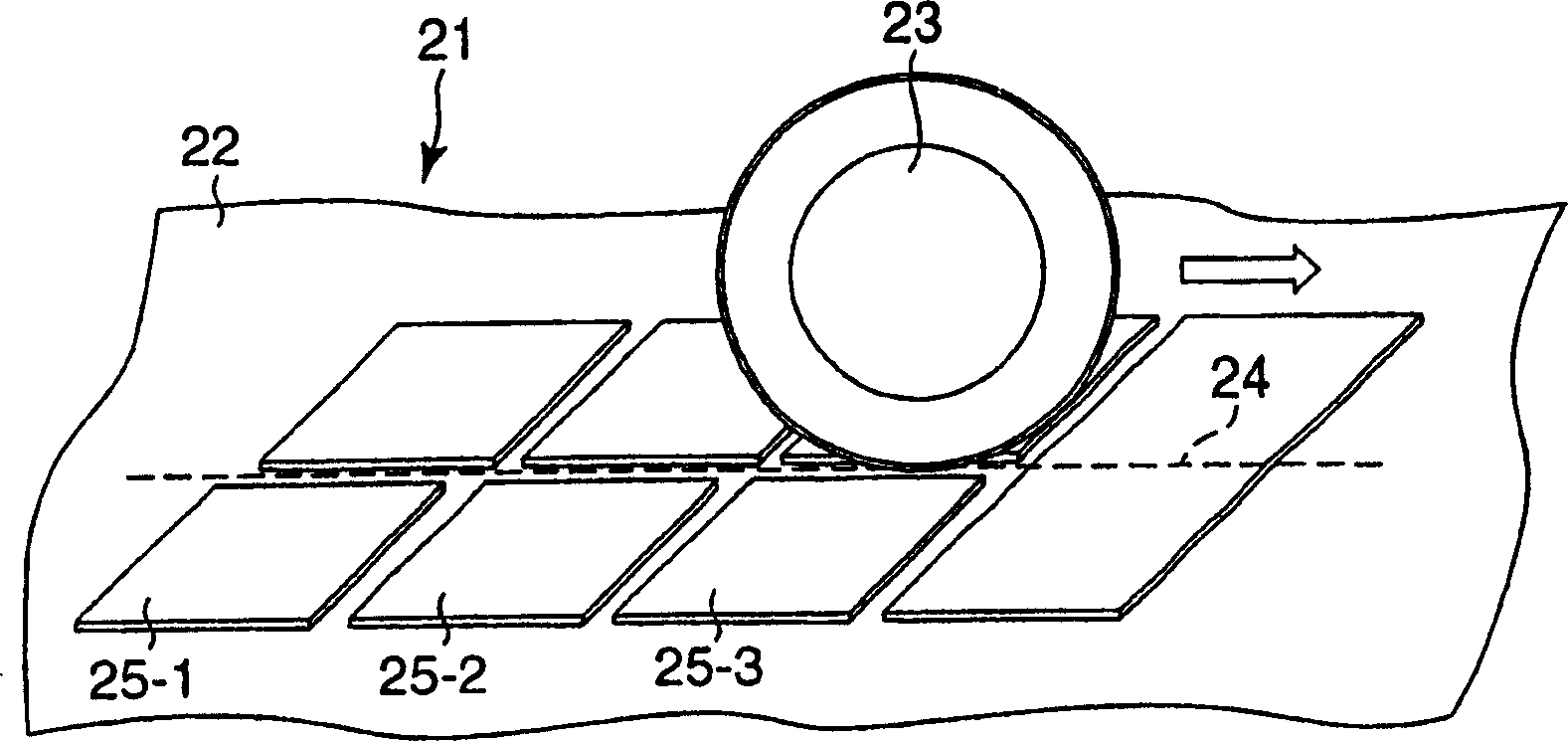

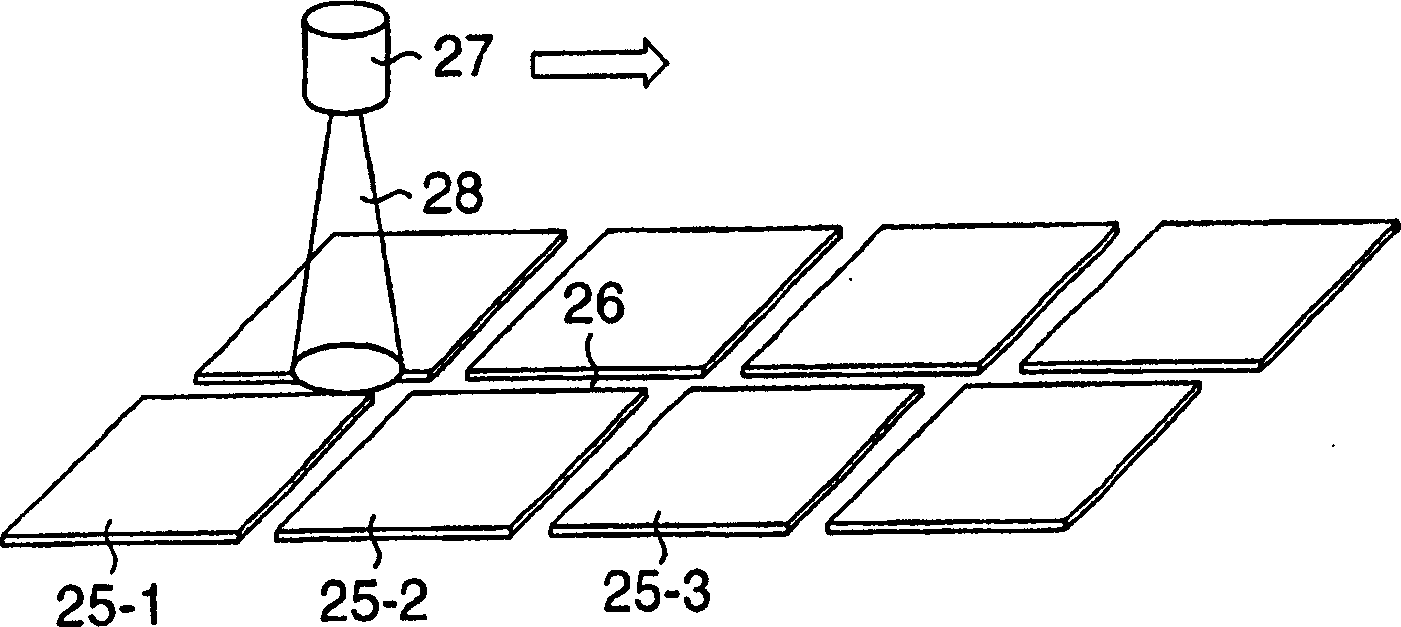

Method and equipment for manufacturing semiconductor devices

InactiveCN1525536ALow flexural strengthAvoid breakingSemiconductor/solid-state device manufacturingProcess regionSemiconductor package

Owner:KK TOSHIBA

Filter bag and method for the production thereof

ActiveUS20070175190A1Easily fitted into vacuum cleanLow flexural strengthCombination devicesAuxillary pretreatmentFolded formEngineering

Described is a filter bag for a vacuum cleaner which may include a tubular bag with a closed free end area and an opposed, at least partially closed area as well as with a retaining plate. The bag is made from a bag material having at least one non-woven layer, and the at least partially closed area is folded forming a bottomplies of the bag material which lie the one above the other are formed in areas, and is at least partially closed by a weld seam extending centrally in the bottom, the plies of the bag material which lie the one above the other being at least partially connected to one another.

Owner:EUROLIFTERS HLDG NV

Lightweight high-strength ultra heat preservation building block

InactiveCN101016204AImprove insulation effectSerialized continuously adjustableConstruction materialSolid waste managementSlagFoam glass

The invention discloses a light-quality high-strength hyper-insulating architectural block, which comprises the following parts: 20%-40% cement, 19%-25% coal slag, 12%-25% basalt, 5%-15% mineral slag and 6%-15% doped material, wherein the doped material is composed of 80%- 90% modifier material and 10%-20% composite additive; the modifier material is one or two or more composition of vermiculite, pumice, foam glass, pearlite or diatomite according to random proportion; the compound additive is composed of 2.3% sodium hexametaphosphate, 0.7% triethanolamine and residual calcium oxide or sodium sulphate or their composition according to certain proportion.

Owner:HEILONGJIANG HUIFENG ENERGY TECH DEV

Monolithic ceramic capacitor

ActiveUS20080291600A1Good effectIncrease capacitanceFixed capacitor electrodesFixed capacitor dielectricCapacitanceElectrical conductor

A multi-terminal monolithic ceramic capacitor arranged to reduce an equivalent series inductance and having an array structure is provided. A first same-polarity-connection conductor and a second same-polarity-connection conductor are provided inside a capacitor body so as to extend over at least two capacitors. The first same-polarity-connection conductor is electrically connected to a plurality of first external terminal electrodes, and the second same-polarity-connection conductor is connected to a plurality of second external terminal electrodes. In the monolithic ceramic capacitor which is mounted on a wiring substrate, the overall capacitance can be maintained even if an accident, such as cracking of a solder joint, occurs in one of the external terminal electrodes.

Owner:MURATA MFG CO LTD

Method for manufacturing porous silicon carbide ceramic

InactiveCN104649709ALow flexural strengthLower sintering temperatureCeramicwareRotary evaporatorAdhesive

The invention discloses a method for manufacturing a porous silicon carbide ceramic. The porous silicon carbide ceramic manufactured by using the method overcomes the defect that silicon carbide is difficult to sinter, has an intercommunicated open pore structure, and can realize near size sintering. The method is implemented through the following technical scheme: silicon carbide and aluminum oxide are used as main raw materials, the ratio of the silicon carbide to the aluminum oxide is 5:3, graphite is used as a pore forming agent, and the content of the pore forming agent is controlled to be 15-30wt%. Alcohol is used as a dispersion medium, a proper amount of phenolic resin is added as an adhesive, and dispersed slurry is obtained in a ball milling manner, wherein the mass ratio of powder to milling balls is 1:2. The solvent is removed from the slurry by adopting a rotary evaporator to obtain dried powder. The dried powder is pressed into a green body by a cold press under the pressure of 30-90MPa, the obtained green body is heated to the sintering temperature of 1400-1550 DEG C in a quick heating furnace, natural cooling is carried out after the sintering temperature is kept for 1-4 hours, and the rate from room temperature to the sintering temperature and from cooling after sintering to room temperature is about 5 DEG C per minute in the sintering process.

Owner:宋永法

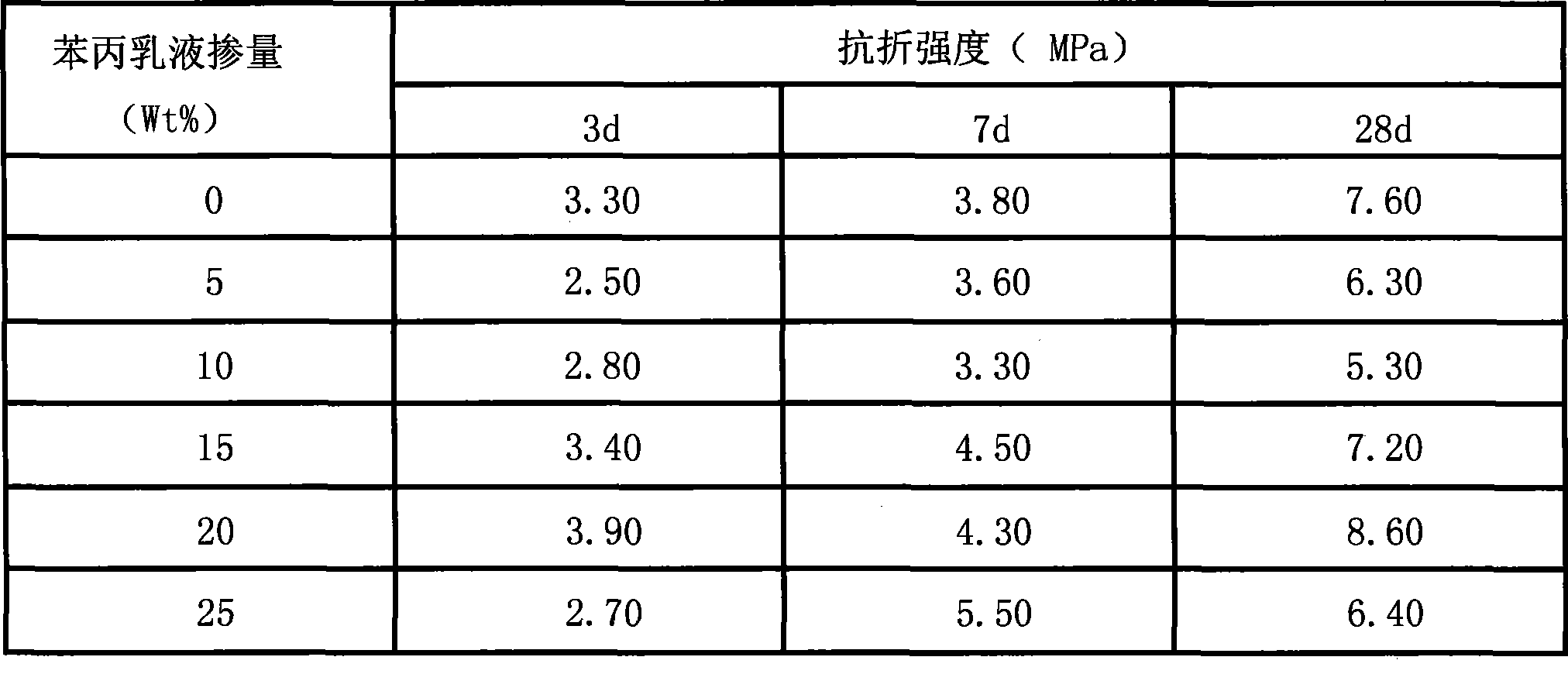

Method for preparing inorganic aluminosilicate polymer and inorganic macromolecule composite gelled material

InactiveCN101544484AIncrease profitPromote resource utilizationCement productionSlagResource utilization

The invention discloses a method for preparing an inorganic aluminosilicate polymer and organic macromolecule composite gelled material. In the method, phosphatic slag or slag capable of providing inorganic aluminosilicate components and styrene / methacrylate copolymer emulsion are utilized to produce phosphatic slag or slag inorganic aluminosilicate polyer and organic macromolecule composite gelled material under the action of sodium silicate excitants; wherein the amount of the styrene / methacrylate copolymer emulsion is 5-25 percent of the weight of the phosphatic slag or slag, and the amount of the alkali excitant sodium silicate is 13 percent of the weight of the phosphatic slag or slag; and the flexural strength of the inorganic aluminosilicate polymer and organic macromolecule composite is superior to the inorganic aluminosilicate polymer in 28-day age, and the 28-day maximum flexural strength is 2.08 times of that of the inorganic aluminosilicate polymer. The preparation process has no discharge of waste water, waste gas and waste slag, does not need heating, is green, environment-friendly and energy-saving, reduces the consumption, and is one effective approach for large-scale resource utilization of industrial solid wastes.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Black high-strength microcrystalline glass and its preparation method

The invention discloses a black high-strength microcrystal glass, which comprises the following parts: 70% SiO2, 3. 5% Lithia, 17% alumina, 0.1%-0.5% ferric trioxide, 0.5%- 1% cobalt trioxide, 0.5%-1% nickel trioxide, 3. 1% -3. 5% at least one of titania, zirconia and phosphorus pentoxide, 1%-1. 5% at least one of magnesia, zinc oxide, barium oxide and boric oxide, 2. 0%-2. 1% potassium oxide and or sodium oxide and 1% arsenic oxide and or antimony oxide. The making method of microcrystal glass comprises the following steps: grinding evenly; adding reducer to allocate composite material; fusing under 1580 -1650 deg. c; shaping; annealing; coring under 600-800 deg. c for 1-4h; heating to 700-1000 deg. c to crystallize for 1-12h.

Owner:ZHEJIANG UNIV

High bending force resistant permanent magnet materials and preparation method thereof

ActiveCN103106992AReduce stray magnetic fieldEasy to useMagnetic materialsRheniumManufactured material

The invention discloses high bending force resistant permanent magnet materials and a preparation method thereof. The magnet materials comprise, by weight, 22-30% neodymium, 4.4-6% praseodymium, 0.044-0.06% lanthanum, 2-5% boron, 0.044-0.06% molybdenum, 0.044-0.06% nickel, 0.044-0.06% rhenium, 0.044-0.06% scandium and the balance ferrum. The high bending force resistant permanent magnet materials are uniform in organization, strong in structure and capable of improving bending force resistant performance of the materials and magnetic performance. The preparation method of the magnet material takes full use of praseodymium-neodymium waste to directly produce raw materials used by alloy, composition proportion is flexible, quality is well controlled, cost is lowered, the process is simple and powder waste with high oxygen content is fully used.

Owner:XUZHOU NANFANG YONGCI MATERIAL

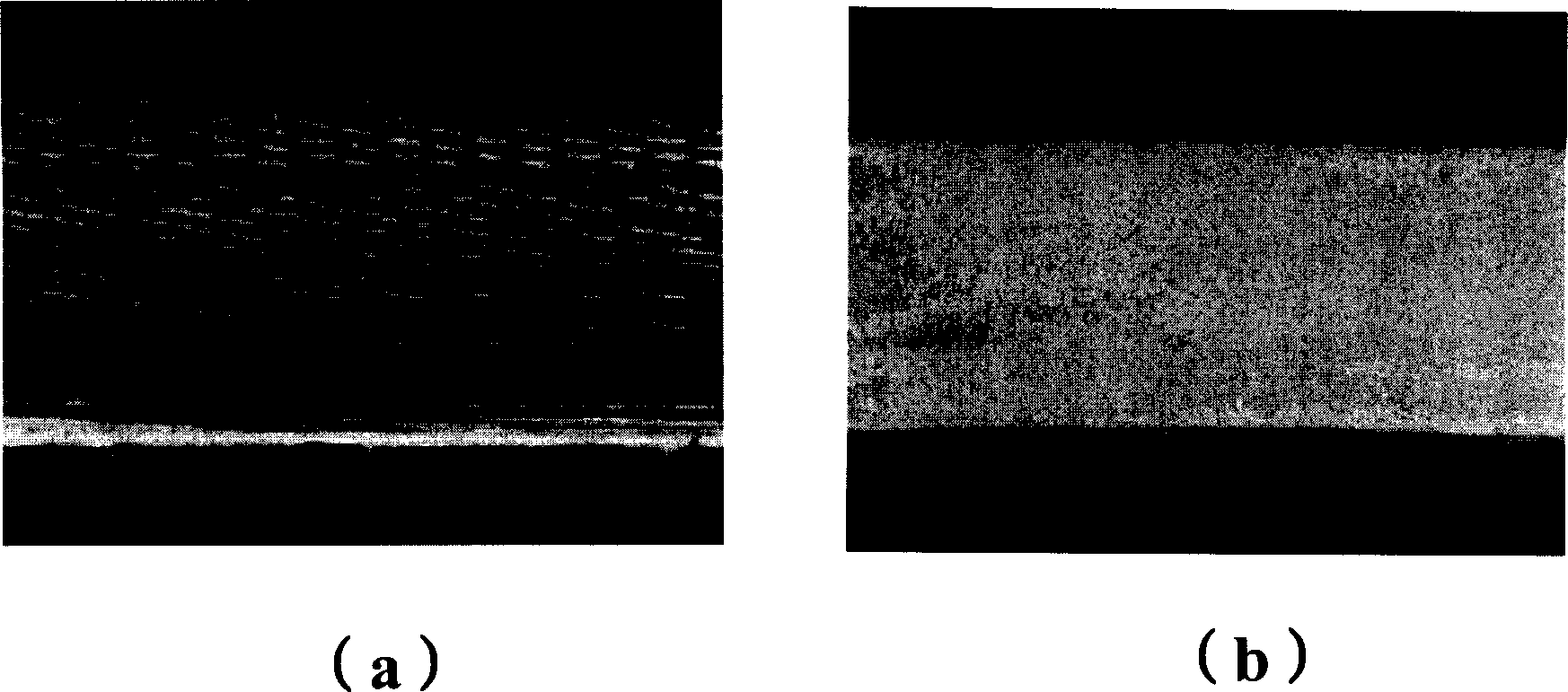

Method for separating flat ceramic workpieces with a calculated radiation spot length

InactiveUS20060145399A1Little expenditure of energyLow flexural strengthElectric discharge heatingInsulating layers/substrates workingInternal stressMaterials science

The invention is directed to a method for splitting a flat ceramic workpiece through provocation of a separation crack due to stresses occurring as a result of temporal and local application of heat by means of laser along a desired splitting line and, following this, a temporal and local removal of heat by means of a coolant, wherein the beam spot length is calculated from the following formula l=8×d×24 / WLF, where l is the length of the beam spot, WLF is the thermal conductivity of the ceramic to be split, and d is the thickness of the ceramic to be split, so that the length of the beam spot generated on the workpiece by the laser is selected depending upon the thermal conductivity of the ceramic and upon the thickness of the workpiece. Particularly with workpieces with high internal stress, process parameters such as the laser power or the forward feed speed are changed over the course of the process in order to influence the magnitude of the induced thermal stresses.

Owner:JENOPTIK AUTOMATISIERUNGSTECHN

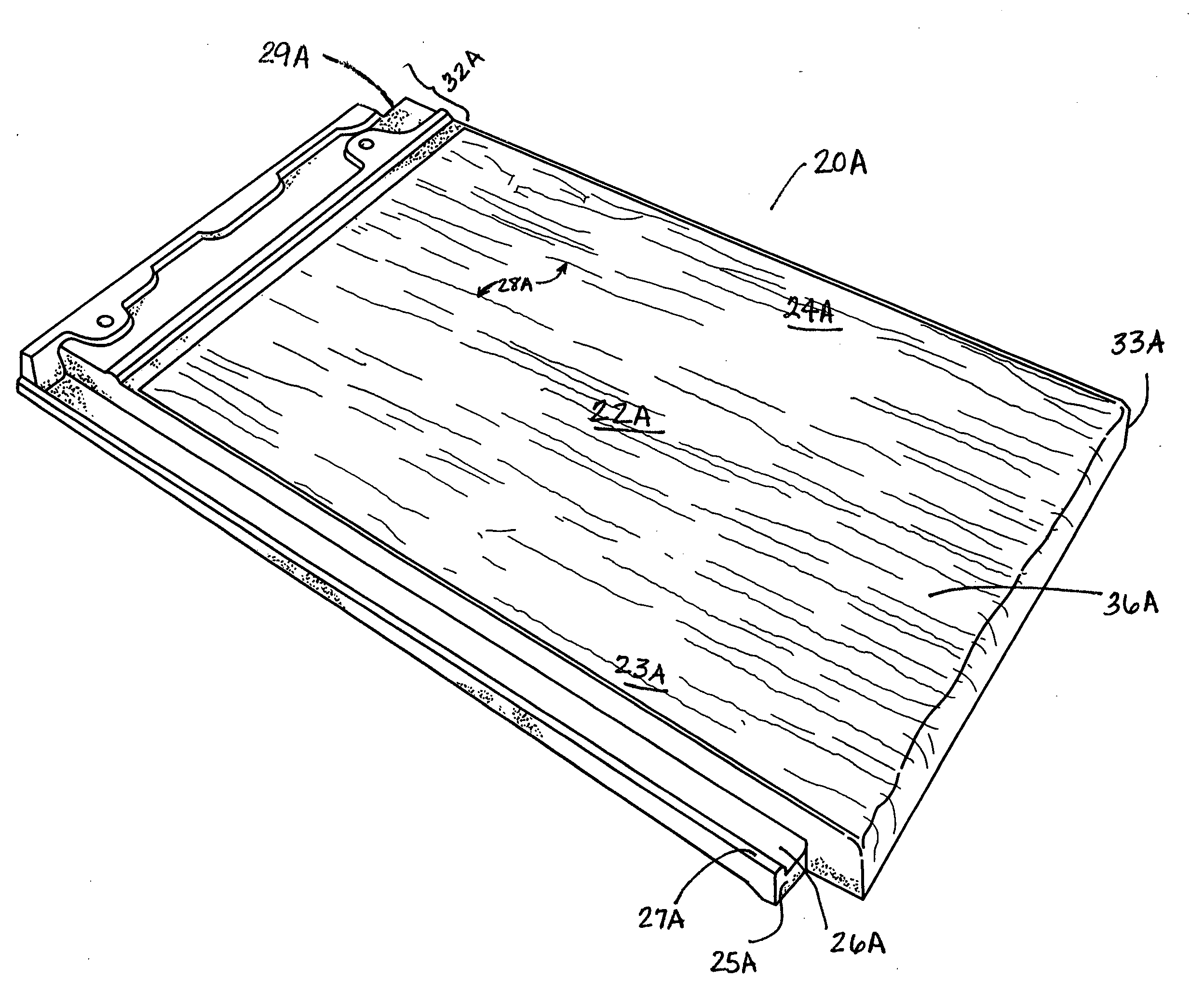

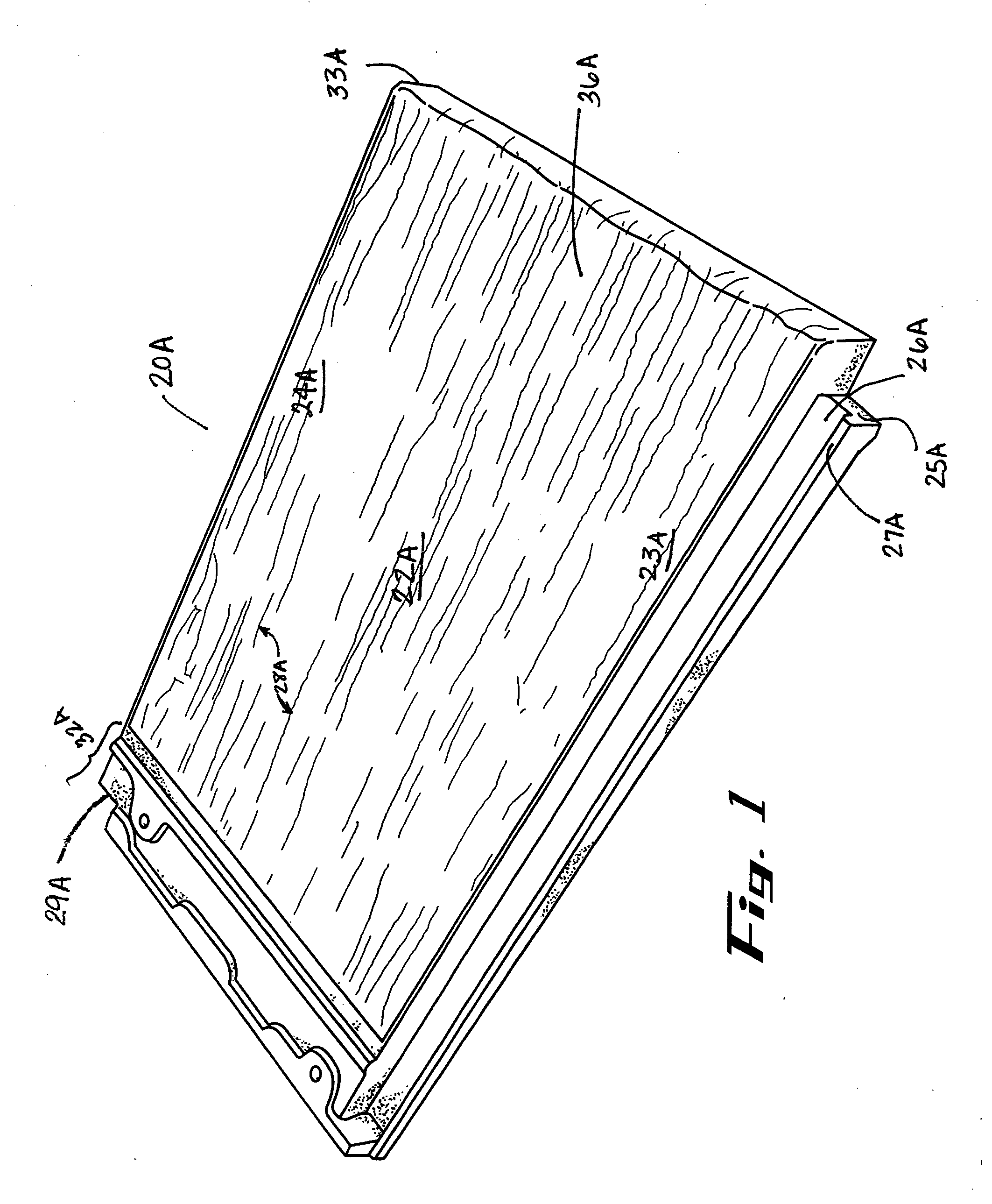

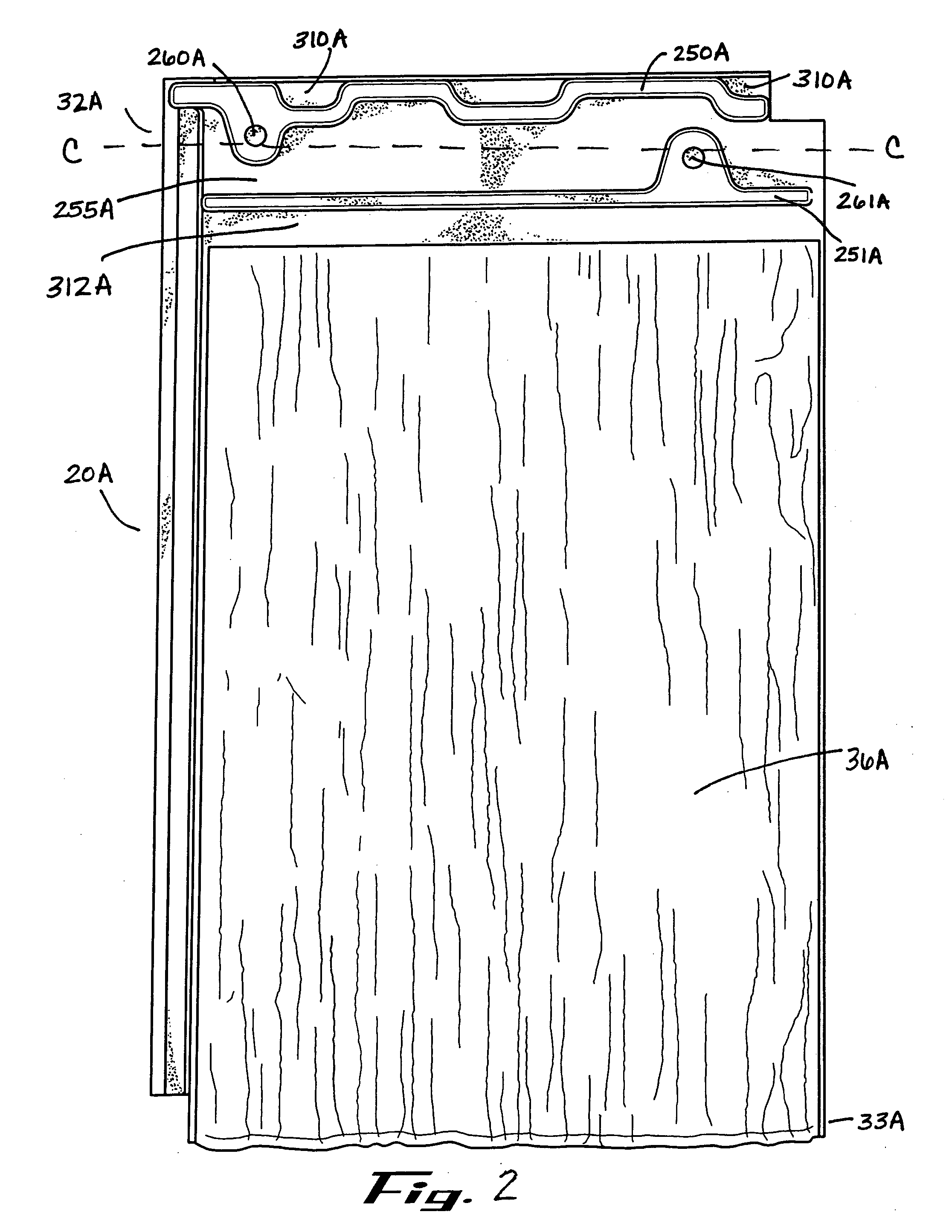

Roofing system and roofing tile

InactiveUS20050257477A1Improve weathering capabilityImprove characteristicRoof covering using tiles/slatesLower faceUltimate tensile strength

The present invention provides an improved roofing tile and roofing tile system that simulates the appearance of wood shake and has an improved strength to weight ratio. One embodiment of the roofing tile system includes two unique tile profiles, an “A” profile and a “B” profile, wherein tiles having an “A” profile are alternately or randomly installed adjacent tiles having a “B” profile to simulate the appearance of wood shakes. In addition, each roofing tile is formed of a clay material and includes ribs that extend normally from a lower face of the tile, which improves the strength to weight ratio of each tile. Furthermore, each tile includes touch points that extend from the a face of the tile to engage receiving portions on a tile positioned vertically adjacent to the tile, which prevents the tiles from moving relative to each other.

Owner:BORAL ROOFING

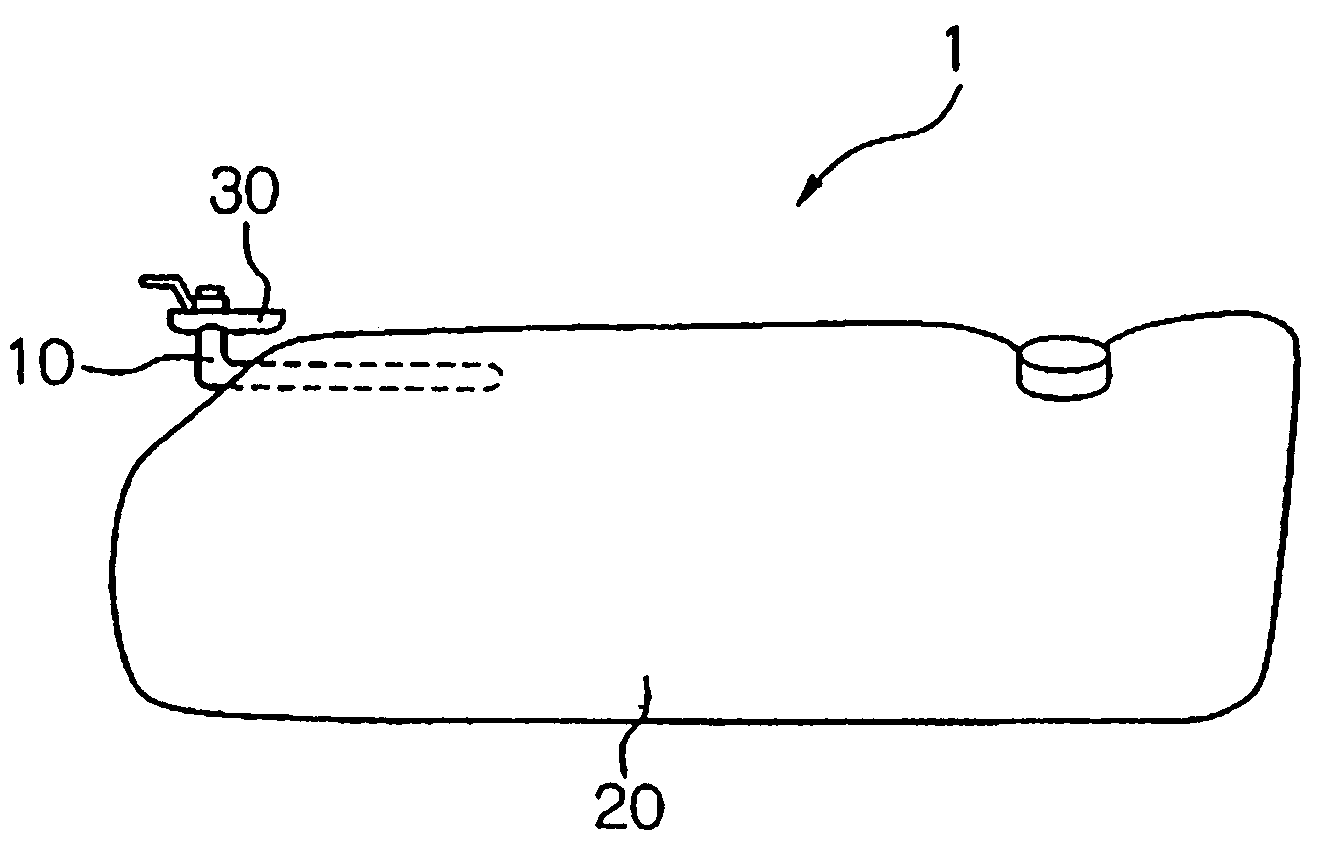

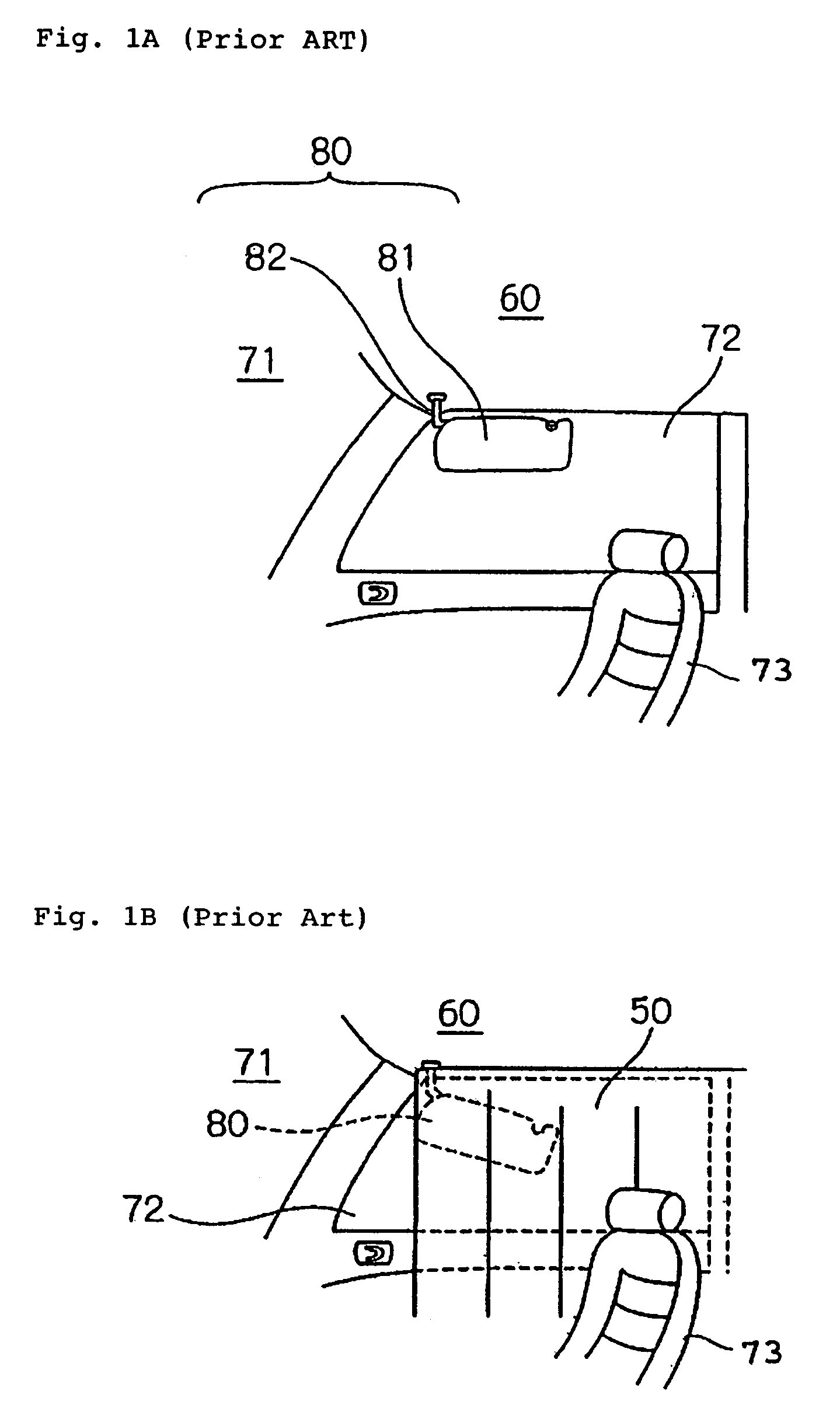

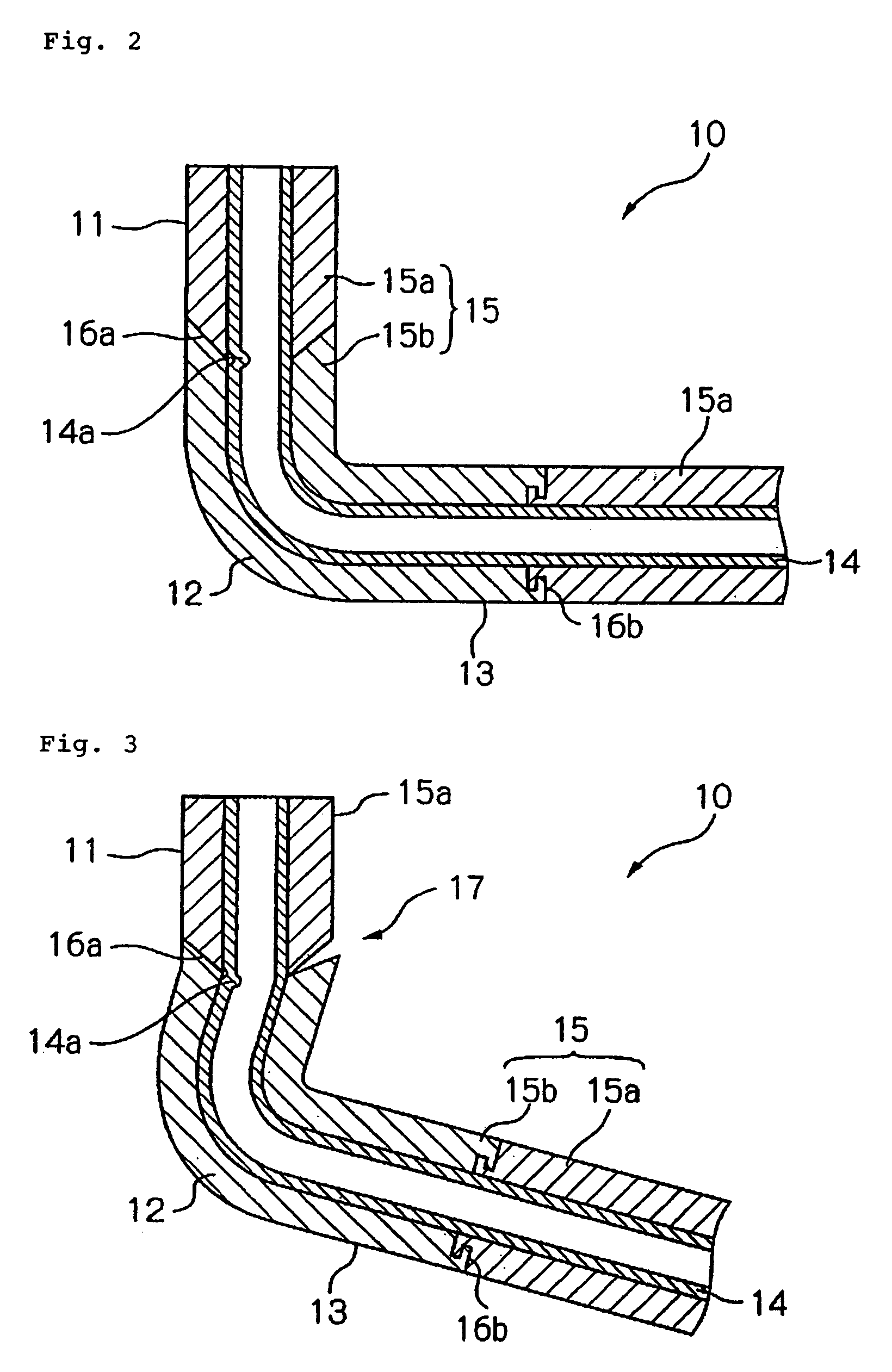

Automobile sun visor stay that maintains safety in emergencies

InactiveUS7059652B2Good lookingWeight increaseAntiglare equipmentMonocoque constructionsEngineeringMechanical engineering

Owner:HAYASHI TELEMPU CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com