Regenerated cement concrete for pavement and its preparing process

A technology for recycling cement and concrete, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc. The effect of improved impact resistance, good durability and reasonable ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below by way of examples.

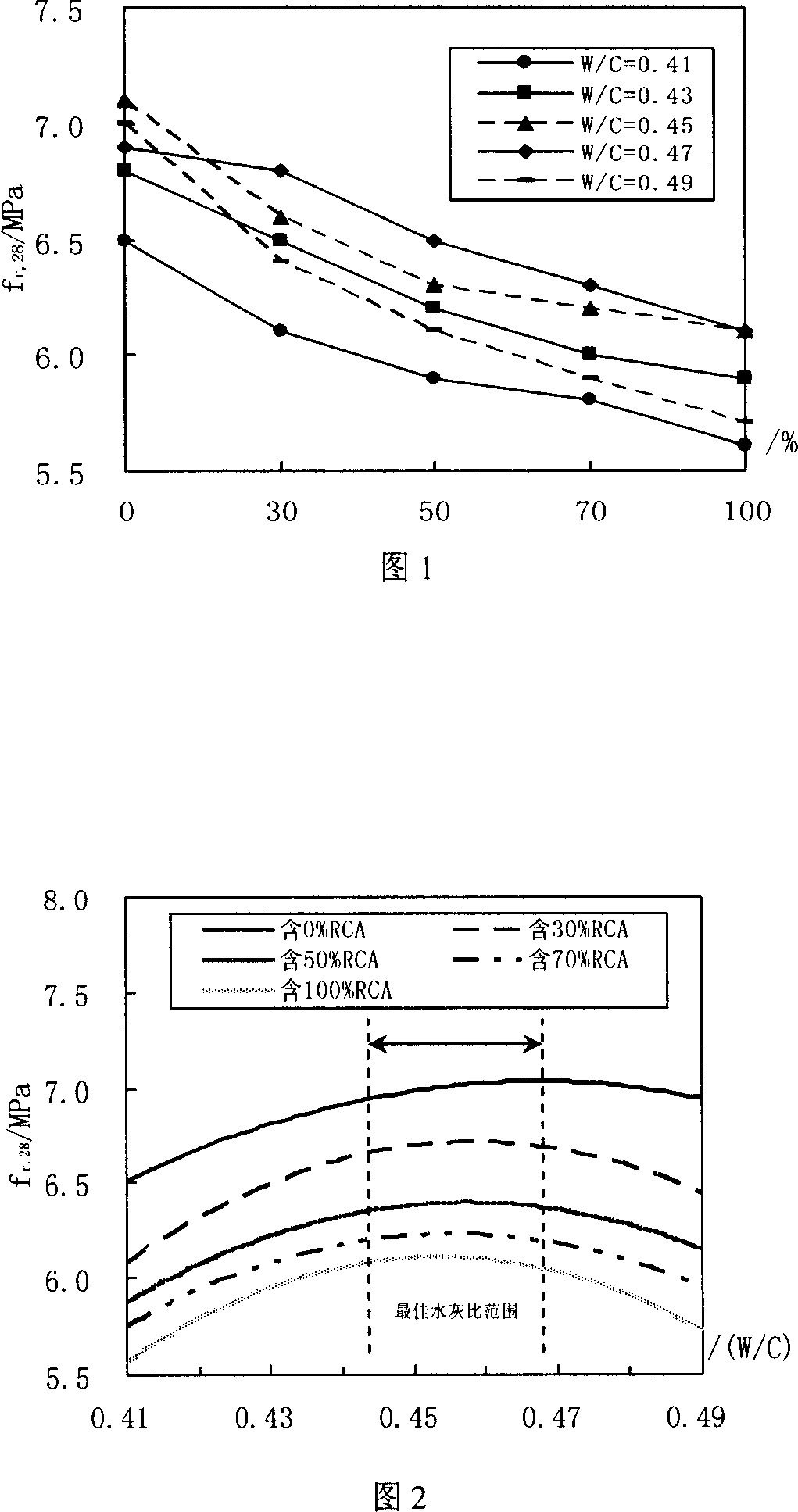

[0028] A recycled cement concrete for roads is prepared from raw materials with the following mass ratios. The water-cement ratio is the effective water-cement ratio (that is, the mass ratio of mixing water to the corresponding amount of cement). The amount that regenerated coarse aggregate replaces natural coarse aggregate in embodiment 1,2,3 is 30%, the amount that regenerated coarse aggregate replaces natural coarse aggregate in embodiment 4,5,6 is 50%, embodiment 7, In 8 and 9, the amount of recycled coarse aggregate replacing natural coarse aggregate is 70%.

[0029] Example

[0030] Recycled coarse aggregate: The strength grade of the base concrete is required to range from C15 to C40, the maximum particle size is 20mm, the natural water content shall not exceed 4%, the saturated water absorption shall not exceed 8%, the mud content shall be less than 3%, and the Loss Abrasion A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com