Recycled aggregate medium-dry hard concrete prepared by using building waste and preparation method of recycled aggregate medium-dry hard concrete

A technology for dry-hard concrete and construction waste, which is applied in the field of semi-dry-hard concrete and its preparation, and can solve the problems that construction quality and service life cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

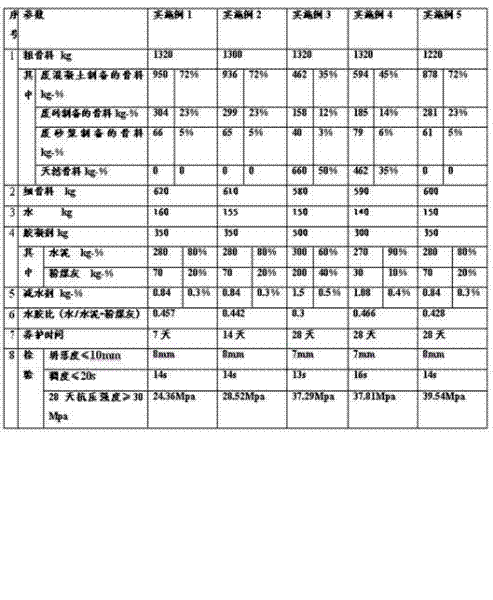

[0014] Below in conjunction with embodiment, the present invention is described in further detail and completeness:

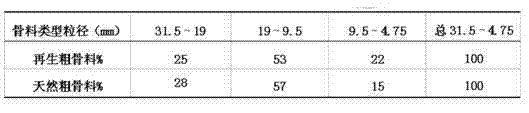

[0015] Recycled aggregate semi-dry hard concrete prepared from construction waste. According to the "Common Concrete Mix Proportion Design Regulations" (JGJ55-2000), with the C30 concrete mix ratio as the benchmark, refer to the "Technical Specifications for Highway Cement Concrete Pavement Construction" (JTG F30-2003), "General Portland Cement" (GB 175 -2007) and "Technical Specifications for the Application of Fly Ash Concrete" (GBJ 146-90).

[0016] 1. Raw materials

[0017] It is composed of the following raw materials by weight, coarse aggregate 1200-1320, fine aggregate 580-620, gelling agent 320-420, water reducer and water, the gelling agent is cement and fly ash, cement accounts for 60-90% of the gelling agent, fly ash accounts for 10-40% of the gelling agent, the water reducing agent is 0.3-0.5% of the cement content, and the water is 150±10. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com