Sterilization and pasteurization material and application thereof

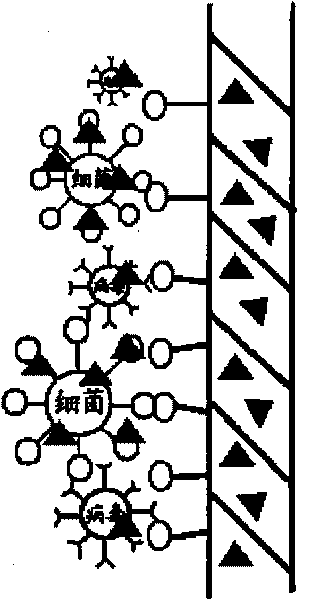

A sterilization and disinfection technology, applied in application, disinfection, clothing, etc., can solve problems such as enhancing the possibility of cross-infection, and achieve the effects of preventing droplet transmission, soft texture and fast water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

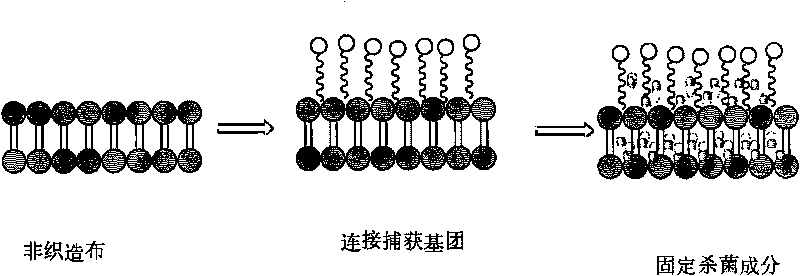

[0027] (1) Fix the functional groups that capture bacteria and viruses on the non-woven fabric: after cleaning the ultra-fine fiber non-woven fabric, put the 3- (Trimethoxysilyl) propyl dimethyl octadecyl quaternary ammonium chloride and an aqueous solution of an appropriate amount of initiator (such as dibenzoyl peroxide) are evenly sprayed on the nonwoven fabric to make it wet, and after ten minutes Then cross-link at 120-130° C. for 5 minutes.

[0028] (2) Dip-dyeing the sterilizing and disinfecting components onto the nonwoven fabric: triclosan is made into a sol of 5% (weight volume percentage), sprayed on the nonwoven fabric processed through step (1), and rolled and dried High-efficiency sterilization and disinfection materials are obtained.

[0029] The schematic diagram of the whole process is as figure 2 shown.

Embodiment 2

[0031] (1) Fix the functional groups that capture bacteria and viruses on the non-woven fabric: soak the ultra-fine fiber polypropylene non-woven fabric in acetone for 24 hours, wash it with distilled water until it is odorless, dry it at a constant temperature of 105°C, and then put it into a agent (such as dibenzoyl peroxide) and a concentration of 10% of the propylene functional group-containing sulfur compound allyl mercaptan in the polymerization bottle, exhaust oxygen with nitrogen for 5 minutes; then cross-link at 100 ° C After 30 minutes, take out the nonwoven fabric, wash it with acetone and 90°C hot water for 3-4 times to remove residual initiator and monomer, and then boil it with deionized water for 1 hour.

[0032] (2) Dip-dyeing the sterilizing and disinfecting components on the non-woven fabric: make a 10% solution of p-chloroxylenol, spray it on the non-woven fabric treated in step (1), and obtain high-efficiency sterilization by rolling and drying Disinfect ma...

Embodiment 3

[0034] (1) Fix the functional groups that capture bacteria and viruses on the non-woven fabric: soak the polyvinyl alcohol non-woven fabric in 7% ammonium hydrogen phosphate solution for 2 minutes, and dry at a constant temperature of 105°C; then the treated non-woven fabric The cloth was immersed in concentrated sulfuric acid and heated at 80°C for 90 minutes under the protection of nitrogen; finally, the nonwoven was washed with distilled water until neutral.

[0035] (2) Dip-dyeing the sterilizing and disinfecting components on the nonwoven fabric: preparing 10% silver nitrate solution, spraying it on the nonwoven fabric treated in step (1), rolling and drying to obtain the highly efficient sterilizing and disinfecting material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com