Patents

Literature

53 results about "Chloroxylenol" patented technology

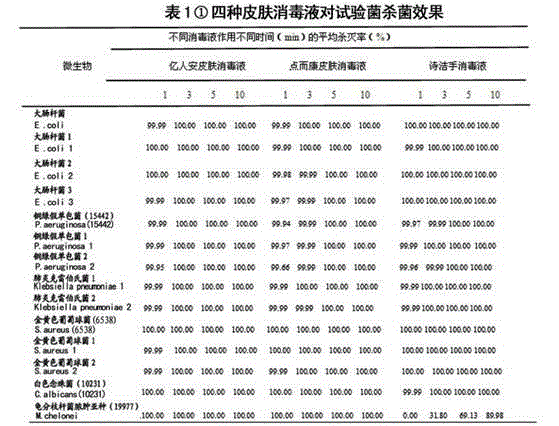

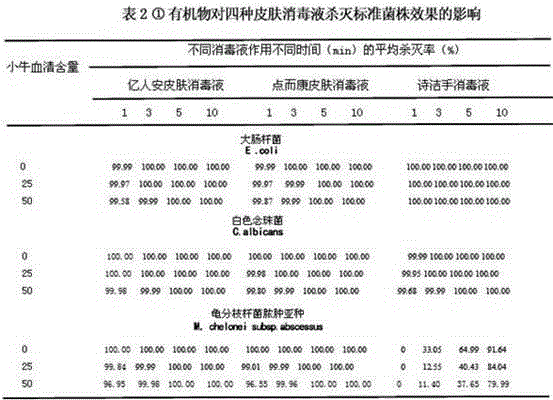

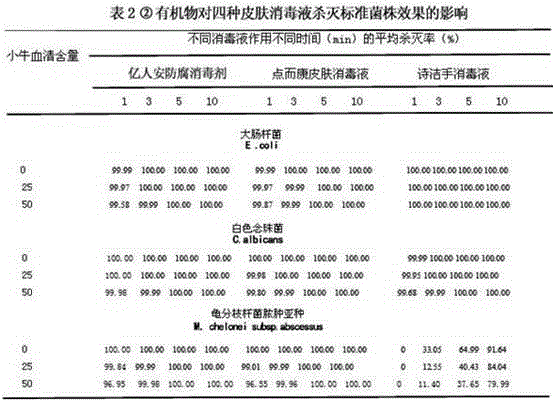

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chloroxylenol, also known as para-chloro-meta-xylenol (PCMX), is an antiseptic and disinfectant which is used for skin disinfection and cleaning surgical instruments. It is also used within a number of household disinfectants and wound cleaners. It is less effective than some other available agents. It is available as a liquid.

Antimicrobial Composition and Method

InactiveUS20080249136A1Improve performanceImprove securityAntibacterial agentsBiocideSodium PyrithioneNitrostyrol

An antimicrobial composition containing a cationic polymer having limited antimicrobial activity (such as a hydrophobically-modified quaternary ammonium cellulose ether) and an antimicrobial compound (such as one or more compounds selected from the group consisting of diiodomethyl-para-tolylsulfone, ortho-phenylphenol, sodium pyrithione, zinc pyrithione, 3-iodo-2-propynylbutylcarbamate, 2-methyl-4-isothiazolin-3-one, 1,2-benzisothiazolin-3-one, 2-n-octyl-4-isothiazolin-3-one, 1-(3-chloroallyl)-3,5,7-triaza-1-azoniaadamantane chloride, 2-(4-thiazolyl)-benzimidazole, β-bromo-β-nitrostyrene, 2,4,4′-trichloro-2-hydroxyphenyl ether, chloroxylenol, chlorocresol, para-tert-amylphenol, N-(4-chlorophenyl)-N′-(3,4 dichlorophenyl)-urea, and para-hydroxybenzoic acid esters). The growth of microorganisms (such as Pseudomonas aeruginosa) can be inhibited by exposing the microorganism to such a composition.

Owner:DOW GLOBAL TECH LLC

Butadiene rubber

The invention relates to a butadiene rubber including following components: 30-50 parts of a cis-polybutadiene mixture, 5-9 parts of cyclohexane, 1-3 parts of cobalt oxide, 2-5 parts of zinc oxide, 3-7 parts of sulfur, 1-3 parts of stearic acid, 1-5 parts of nickel naphthenate, 5-9 parts of triisobutyl aluminium, 2-4 parts of boron trifluoride diethyl etherate, 2-6 parts of heptane, 3-8 parts of hydrogenated gasoline, 15-19 parts of an accelerant NS, 10-13 parts of HAF, 11-15 parts of ASTM-typed 103 oil, 2-8 parts of an aluminum oxygen clinker and 2-5 parts of chloroxylenol. The cis-polybutadiene mixture consists of cis-1,4-polybutadiene and cis-1,3-polybutadiene, wherein a weight ratio of the cis-1,4-polybutadiene to the cis-1,3-polybutadiene is 2:5 in the mixture. The butadiene rubber contains the cis-polybutadiene mixture so that the butadiene rubber is effectively reduced in tear strength, is enhanced in anti-slippery performance and adhesive property, and is low in heat-generating property.

Owner:QINGDAO DTCN NEW MATERIAL TECH DEV

Antimicrobial composition and method

InactiveCN101291581AGrowth inhibitionAntibacterial agentsCosmetic preparationsSodium PyrithioneNitrostyrol

Owner:DOW GLOBAL TECH LLC

Antibacterial EVA (Ethylene-Vinyl Acetate) foam material

The invention relates to an antibacterial EVA (Ethylene-Vinyl Acetate) foam material belonging to the technical field of high-molecular materials. The antibacterial EVA foam material comprises the following components in parts by weight: 80-100 parts of EVA copolymers, 5-10 parts of ethylene-propylene copolymers, 6-12 parts of polyolefin elastomer, 0.5-1 part of a crosslinking agent, 0.5-1 part of barium stearate, 10-15 parts of a microcapsule foaming agent, 5-8 parts of antistatic agent, 1-3 parts of nanometer titanium dioxide and 2-4 parts of chloroxylenol. The antibacterial EVA foam material provided by the invention is soft in texture, smooth in surface, good in rebound vibration resistant effect, favorable in antibacterial and antistatic functions and relatively wide in application range, not only can be used for manufacturing life-saving devices, but also can be used in other fields such as packaging materials and the like.

Owner:NANTONG HAIOU LIFE SAVING & PROTECTION EQUIP

External use medicament for treating fungal dermatopathy

ActiveCN101474284ASignificant effectGood curative effectAntimycoticsHydroxy compound active ingredientsEscherichia coliSide effect

The invention provides an external used medicine for dermatologic diseases, which is characterized in that phellodendron, lightyellow sophora root, common cnidium fruit, broom cypress fruit, pericarpium zanthoxyli and chloroxylenol are used as active medicine ingredients, and the invention is prepared by mixing the active medicine ingredients with assistant ingredients that are acceptable in preparing external used medicines, wherein, the weight proportions of the active medicine ingredients are as follow: 2-8 parts of phellodendron, 1-5 parts of lightyellow sophora root, 1-5 parts of common cnidium fruit, 1-5 parts of broom cypress fruit, 4-15 parts of pericarpium zanthoxyli and 0.1-5 parts of chloroxylenol. The medicine is a combination of traditional Chinese medicine and western medicine, with the sterilizing rate of over 99.9%, and can effectively sterilize diverse bacteria and fungi such as golden brown staphylococcus, colon bacillus, candida albicans, etc. The external used medicine has quick effect on dermatologic diseases, has high cure rate, few side effects and no drug resistance, and can cure both symptom and root diseases.

Owner:重庆灵方生物技术有限公司

A kind of disinfectant and preparation method thereof

InactiveCN102293199AEfficient killingPrevention and Control of TransmissionSoap detergents with organic compounding agentsBiocideDisinfectantPotassium hydroxide

The invention relates to a disinfectant and a preparation method thereof. The formula of the disinfectant is: p-chloro-m-xylenol, coconut oleic acid, potassium hydroxide, isopropanol, pine oil and deionized water, and its weight percentage is, 5.0 -7.0: 6.5-9.5: 3.7-5.4: 15.0-25.0: 3.0-6.0: margin. The preparation includes: (1) adding deionized water and potassium hydroxide, stirring, heating up to 90°C-100°C, and then adding coconut oleic acid to make potassium coconut oleate soap; (2) mixing p-chloro-m-xylenol with Mix isopropanol, heat up to dissolve, then add deionized water and the above-mentioned potassium coconut oleate soap, stir; cool to 30°C-35°C, add pine oil, stir, add deionized water and continue stirring, and the product is ready. The disinfectant solution of the invention can effectively kill 99.999% of intestinal pathogenic bacteria, pyogenic cocci and pathogenic yeasts; the preparation method is simple, the cost is low, and it is suitable for industrial production.

Owner:SHANGHAI SOAP GRP RUGAO

Antibacterial protecting hand sanitizer

InactiveCN102772335AStrong sterilization and disinfection abilityMoisturizes and protectsAntibacterial agentsCosmetic preparationsWhite petrolatumHand sanitizer

The invention discloses an antibacterial protecting hand sanitizer, which is prepared from the following components in parts by weight: 25-30 parts of lauryl polyoxyethylene ether sodium sulfate, 4-6 parts of linear alkyl benzene sulphonic acid triethanolamine, 2-4 parts of 2-hydroxyacetamide diethanol amine, 1-2 parts of ethylene glycol maleate, 0.06-0.1 parts of citric acid, 0.08-0.1 parts of chloroxylenol, 50-70 parts of water, 0.5-1.5 parts of ammonia chloride, 4-5 parts of glycyrrhiza essence and 4-5 parts of petroleum jelly for medical purposes. According to the antibacterial protecting hand sanitizer provided by the invention, not only can effects of efficient sterilization of the existing antibacterial protecting hand sanitizer in the market be provided, but also effects of protecting and moisturizing the skin are provided.

Owner:JIANGSU XINSHI PRECISION CHEM

Sterilization disinfectant formula for nursing

InactiveCN105287743AImprove the bactericidal effectEasy to cleanAntibacterial agentsHydroxy compound active ingredientsCelluloseBetaine

The invention discloses a sterilization disinfectant formula for nursing. The sterilization disinfectant is prepared from, by weight parts, raw materials comprise nursing raw materials and disinfection raw materials, wherein the nursing raw materials are 2-10 parts of lubricating humectant, 5-9 parts of fructus xanthii, 10-12 parts of propylene glycol, 8-10 parts of tea polyphenols, 5-12 parts of sodium chloride solution, 4-8 parts of polysorbate, 2-6 parts of carboxybutyl chitosan, 3-6 parts of lithospermum purpurocaeruleum, 7-10 parts of Chinese parsnip root and 6-8 parts of forsythia suspense; and the disinfection raw materials comprise 3-8 parts of coconut oil, 2-9 parts of lauramide propyl betaine, 5-10 parts of hydroxy propyl cellulose, 10-14 parts of acetic acid chlorhexidine, 4-8 parts of pine needle oil, 5-10 parts of glycerol, 12-16 parts of chloroxylenol and 8-12 parts of benzenesulfonicacid. The sterilization disinfectant is extremely small in irritation to the skin of the human body, and the sterilizing effect and the skin cleaning effect are greatly improved.

Owner:柳青青

Melamine resin modified rubber material

The invention discloses a melamine resin modified rubber material. The material is composed of the following raw materials by weight: 0.6 to 1 part of chloroxylenol, 2 to 3 parts of ammonium trimolybdate, 47 to 50 parts of attapulgite, 0.3 to 0.6 part of hexamethylcyclotrisiloxane, 0.2 to 0.6 part of sulfuric acid with a concentration of 8 to 10%, 26 to 30 parts of melamine, 5 to 8 parts of a formaldehyde solution with a concentration of 37%, 7 to 10 parts of urea, 0.7 to 2 parts of ascorbic acid, 6 to 10 parts of microcrystalline cellulose, 1 to 1.2 part of isopropanol, 3 to 4 parts of maleic anhydride, 210 to 230 parts of chloroprene rubber S40V, 4 to 7 parts of vinyl carboxylic ester, 3 to 4 parts of an antioxidant NBC and 2 to 4 parts of sulphur. According to the invention, the microcrystalline cellulose, through crosslinking effect of maleic anhydride, forms a closer network structure in the melamine resin formed by melamine, urea and formaldehyde, wherein added alkylated ester can effectively promote the crosslinking effect and improve bonding strength, well enhances viscosity and tensile deformation resistant property of resin, exerts certain reinforcing and viscosifying effects to a rubber material, and improves flexure and cracking resistance, hot air aging property and stability.

Owner:FUYANG ANGU BOILER PRESSURE VESSEL MFG

Wood surface corrosion control method

InactiveCN104723424AImprove anti-corrosion performanceImprove mildew resistanceBiocideWood treatment detailsBronopolPolyvinyl chloride

The invention discloses a wood surface corrosion control method. The method comprises the following steps: (1) drying the wood until the water content is about 18%; (2) injecting the preservatives, namely 2-4 parts of propylene glycol, 30-48 parts of propene carbonate, 1-2.3 part of DCOIT, 10-25 parts of p-chloroxylenol, 1-4 parts of alkyl dimethyl benzyl ammonium chloride, 1-2.8 part of sodium chloride, 1-3 parts of sodium chlorate, 1-3 parts of potassium bromide, 5-8 parts of bronopol, 35-46 parts of dithiocyano-methane and 108-116 parts of fatty alcohol polyvinyl chloride ether in part by weight, into the wood under the vacuum high pressure condition; (3) performing high-temperature qualitative treatment for 6-12 hours on the wood after the preservatives are added; and (4) carrying out air drying on the high-temperature qualitatively treated wood to obtain the wood subjected to preservative treatment. The corrosion control method disclosed by the invention is good in corrosion control effect, the preservatives can permeate into the part being 1-2mm of the wood surface, and good mold prevention and corrosion resistance are obtained; the wood is strong in waterproof durability, is loss resistant and long in residual action, the raw materials is easily available, and the cost can be saved.

Owner:HAIMEN JINQILIN REDWOOD INVESTMENT DEV

Compound female balancing washing lotion and preparation method thereof

ActiveCN101474378AEfficient killingBalance environmentSexual disorderPlant ingredientsMonilinia laxaLotion

The invention provides compound female balancing lotion, which is prepared by using 1 to 5 parts of traditional Chinese medicine ethereal oil and 0.1 to 10 parts of chloroxylenol as effective components by weight part, and auxiliary elements common in external lotion; wherein, the traditional Chinese medicine ethereal oil is super-critically extracted by the following traditional Chinese medicines by weight part and carbon dioxide: 5 to 25 parts of zanthoxylum pipertum, 5 to 25 parts of phellodendron amurense, 5 to 25 parts of scutellaria, 5 to 25 parts of hoantchy root, 5 to 15 parts of kuh-seng, 5 to 15 parts of licorice, 5 to 15 parts of dyer woad leaf, 5 to 15 parts of dittany bark, 5 to 15 parts of radix stemonae, 5 to 15 parts of fructus kochiae, and 5 to 15 parts of fructus cnidii. The compound female balancing lotion can efficiently kill various pathogenic microorganisms such as staphylococcus aureus, colon bacillus, candida albicans and the like, takes effect quickly, has high cure rate, and can balance internal environment of vagina, adjust acid-base equilibrium and maintain normal pH value in the vagina.

Owner:重庆灵方生物技术有限公司

Novel chloroxylenol production process by high-temperature chlorination process

ActiveCN102675055AReduce work intensityReduce processing costsOrganic chemistryOrganic compound preparationAutomatic controlBuffer tank

Owner:JIANGSU HUANXIN NEW MATERIAL CO LTD

Disinfection and sterilization type air freshener

The invention discloses a disinfection and sterilization type air freshener. The disinfection and sterilization type air freshener is prepared from the following raw materials in parts by weight: 15-18 parts of ethyl alcohol, 9-11 parts of menthol, 15-17 parts of sodium stearate, 6-11 parts of honeysuckle flower extract, 7-9 parts of folium artemisiae argyi, 13-16 parts of borneol, 3-5 parts of fatty alcohol-polyoxyethylene ether, 4-6 parts of chloroxylenol, 7-8 parts of sulfamic acid, 11-13 parts of eucalyptus leave volatile oil, and the balance of water. The disinfection and sterilization type air freshener has lasting fragrance, can improve the quality of air, keep the air fresh, refresh the mind, and relieve fatigue, and also has the effects of disinfecting, and resisting and inhibiting bacteria.

Owner:QINGDAO KELIKE INFORMATION TECH

Topical formulations for preventing skin infection

InactiveUS20170100383A1Prevent and reduce riskOrganic active ingredientsAerosol deliveryAmmonium compoundsActive agent

A topical formulation comprising a first active agent that is pharmaceutically acceptable salt of a cationic bisbiguanide such as chlorhexidine digluconate (CHG), a secnd active agent which is a cationic quaternary ammonium compound such as cetylpyridinium chloride (CPC), methylisothiazolone, or chloroxylenol, and a propellant; and an aerosol dispenser containing the topical formulation. The topical formulation can be sprayed onto exposed skin to prevent or reduce the risk of skin infection.

Owner:PRACTICAL SOLUTION INC

Novel chloroxylenol production process by high-temperature chlorination process

ActiveCN102675055BReduce work intensityReduce processing costsOrganic chemistryOrganic compound preparationAutomatic controlGas phase

The invention discloses a novel chloroxylenol production process by high-temperature chlorination process. The novel chloroxylenol production process by high-temperature chlorination process includes the steps of firstly, gasifying a certain flow of chlorinating agent, and allowing the gasified chlorinating agent to enter the lower portion of a chlorination tower; secondly, charging a certain flow of liquid material into a preheater, preheating, and allowing the heated liquid material to enter the upper portion of the chlorination tower; thirdly, allowing the preheated material coming down from the upper portion of the chlorination tower to contact with the chlorinating agent gas coming up from the lower portion of the chlorination tower, and allowing for reaction; and fourthly, subjecting the material in the chlorination tower to forced external circulation by a circulating pump, disposing a heat exchanger at an outlet of the circulating pump to adjust interior temperature of the chlorination tower, and disposing an adjusting valve on a gaseous pipeline at the top of the chlorination tower, which passes through a buffer tank, to control interior pressure of the chlorination tower. Whole reaction in the process is fully automated. Operability, environmental protection and safety of the novel production process are greatly improved as compared with those of existing production using a reactor.

Owner:JIANGSU HUANXIN NEW MATERIAL CO LTD

Sterilization disinfectant

The invention discloses a sterilization disinfectant which is prepared from the following raw materials in parts by weight: 6-11 parts of rheum officinale, 5-9 parts of honeysuckle, 4-8 parts of mint, 3-7 parts of liquorice, 3-8 parts of anhydrous citric acid, 2-6 parts of sodium carboxymethylcellulose, 2.5-7 parts of diboron trioxide, 4-8 parts of anhydrous sodium sulphate, 2.5-7 parts of pine needle oil, 3-7 parts of potassium hydroxide solution, 2.5-4 parts of chloroxylenol, 3-5 parts of polyoxyethylene octylphenol ether, 1.2-3 parts of linseed oil and 20 parts of deionized water. The sterilization disinfectant disclosed by the invention is capable of rapidly performing sterilization and disinfection, especially has a remarkable effect to electronic equipment, and has no influence to equipment.

Owner:QINGDAO TORIX ELECTRONICS TECH

Preparation method of chloroxylenol

ActiveCN103214350AImprove securityMild reaction conditionsOrganic chemistryOrganic compound preparationSide effectEvaporation

The invention discloses a preparation method of chloroxylenol, which comprises the following steps of: putting 3, 5-xylenol, a chlorinated succinimide chlorating agent, a carbon tetrachloride solvent and a catalyst into a reaction kettle in a certain proportion, and carrying out reaction for a period of time at a certain temperature; after the reaction is completed, carrying out cooling, crystallization, suction filtering and washing on a solution, extracting most of the carbon tetrachloride solvent through evaporation, and carrying out cooling, crystallization, suction filtering and washing on the obtained object so as to obtain a coarse chloroxylenol product; and carrying out recrystallization on the coarse chloroxylenol product by using chloroform, carrying out activated carbon decoloration on the product, and drying the obtained product so as to obtain white chloroxylenol crystals. The preparation method disclosed by the invention is mild in reaction conditions; the direct utilization of chlorine is avoided, therefore, the method is good in safety, less in side effects, and easy to realize purification; only a small amount of catalyst is required, therefore, the production cost is low; and the method is simple in post-processing, less in pollution, high in yield, energy-saving, and environment-friendly.

Owner:常熟紫金知识产权服务有限公司

Sterilization and disinfection solution for electronic products

InactiveCN104824055AImprove the bactericidal effectImprove disinfection effectBiocideDisinfectantsCelluloseActive agent

The invention provides a sterilization and disinfection solution for electronic products. The sterilization and disinfection solution is prepared from the following raw materials in parts by weight: 3-5 parts of citric acid, 2-7 parts of thyme oil, 4.5-5.5 parts of volatile atractylodes oil, 5-8 parts of a surface active agent, 2.2-4.6 parts of sodium silicate, 4-7 parts of lauroyl triethanolamine, 9-16 parts of radix sophorae flavescentis, 8-16 parts of Common Cnidium Fruit, 7-14 parts of chinaberry bark and root-bark, 3-6 parts of lemon extracting solution, 2-5 parts of sweet almond oil, 5-8 parts of sodium carboxymethylcellulose, 3-5 parts of sculellaria barbata and 4-9 parts of chloroxylenol. The sterilization and disinfection solution for the electronic products has the beneficial effects that sterilization and disinfection effects are excellent, no damage to the electronic products exists, and the effect is long-lasting.

Owner:QINGDAO DONGCHANGRUI TEXTILE

Antibacterial and anti-static clothes softener

The invention discloses an antibacterial and anti-static clothes softener, which comprises the following components in parts by mass: 80-85 parts of water, 0.5-1 part of chloroxylenol, 10-30 parts of dihydride tallow ethyl hydroxyethyl ammonium methyl sulfate, 1-5 parts of stearyl alcohol and 1-1.5 parts of calcium chloride. The invention has the advantages: the adopted raw materials have low toxicity, so that the clothes softener has the characteristics of the raw materials, can be prepared at any time as required without being limited by fields or equipment, is environmentally-friendly and has low cost; and by adopting the clothes softener, clothes can be sterilized and have antistatic effects.

Owner:TAICANG XINLU DYEING & FINISHING

Wood mildew-proof moth-proof agent

InactiveCN109664387AImprove permeabilityDoes not affect mechanical propertiesOrganic compound preparationWood treatment detailsChemistryChloroxylenol

The invention belongs to the technical field of mildew and moth prevention and provides a wood mildew-proof moth-proof agent. The wood mildew-proof moth-proof agent is prepared from murraya paniculata, mint, propylene glycol, disodium ethylenediamine tetraacetate, nano silicon dioxide, dodecyl dimethyl benzyl ammonium chloride, propylene carbonate, green tea, peach leaves, sodium benzoate, chloroxylenol, dimethyl dicarbonate, ammonium chloride and sodium chloride. Compared with the prior art, the wood mildew-proof moth-proof agent has the advantage that the wood mildew-proof moth-proof agent is a low-toxicity sterilizing agent, environmentally friendly, widely applicable to daily life and capable of improving wood permeability without affecting mechanical properties of wood and gives playto anticorrosion and moth-proof performances.

Owner:上海米昂木业有限公司

Sanitation sheet material made of wastepaper, and method for producing sanitation sheet material from wastepaper

This invention relates to an improved smudge free sanitary sheet made of waste paper and a process of preparing the same through processing the surplus newsprint and mors precisely processing used / recycled paper. The sanitary sheets are prepared by the process steps of collecting pre -consumer overprint or post consumer read newspapers; grading the collected waste newspaper; drying and sterilizing the graded newspaper by applying ultraviolet, infrared and / or gamma rays; trimming and cutting the dried sterilized sheets in appropriate sizes; applying on atieast one of the sides of the waste newspaper an aqueous coating comprising of a mixture of resin such as bleached shellac, a dye, a germicide such as Benzaikonium Chloride (BC) and / or PCMX (Chloroxylenol), a safe colour, a known deodorant and optionally cosmetic chemicals such as emollient and a foaming agent such as a detergent.; The improved sanitary sheeets prepaid by the present cost effective invention has taken care of any toxic effect on human skin to make those hygenic and aesthetic and the discarded sheets being biodegradable, the present invention is environment friendly. The sanitary sheets from present invention has various wide applications such as a single use barrier in outpatient beds of clinics or on x-ray tables, safe paper bags for carrying dry stuff, a mat on a publicly used seat like gyrn, safe pet care , paper towel, toilet paper, sanitary napkin, child diapers, adult incontinence products etc.

Owner:桑吉夫.阿加瓦尔

Disinfectant

InactiveCN103548883ARaw materials are easy to getReasonable ratioBiocideDisinfectantsPublic placeDisinfectant

The invention discloses a disinfectant which comprises the following components: 80-90 parts of ethanol, 40-50 parts of chloroxylenol, 45-55 parts of ricinoleic acid, 1.5-3.5 parts of pine needle oil and 0.5-1.0 part of potassium hydroxide solution. The disinfectant is reasonable in proportion and good in disinfection effect, and can be applied to various public places, and raw materials are easily obtained.

Owner:卢逸凡

Efficient concrete accelerator

The invention discloses an efficient concrete accelerator, and belongs to the field of coating additives. The efficient concrete accelerator comprises the following raw materials in parts by weight: 2 to 8 parts of sodium fluoride, 5 to 15 parts of fatty alcohol polyoxyethylene ether, 10 to 20 parts of fatty acid methylformamide, 2 to 6 parts of alumina clinker, 1 to 5 parts of aluminite, 4 to 12 parts of chloroxylenol, 1 to 5 parts of zinc sulfate, 4 to 12 parts of calcium formate, 10 to 16 parts of naphthalene sulfonated formaldehyde condensate, 5 to 15 parts of sodium metaaluminate, 2 to 6 parts of cellulose, 3 to 9 parts of aluminum sulfate and 3 to 12 parts of iron powder. The efficient concrete accelerator is short in setting time, strong in strength, low in cost and suitable for large-scale production, and a production process is simple.

Owner:王嘉文

Sterilizing bactericide

The invention discloses a sterilizing bactericide, which comprises the following ingredients in part by weight: 40 to 70 parts of chloroxylenol, 12 to 18 parts of calcium hypochlorite, 50 to 60 parts of potassium hydroxide solution, 4 to 8 parts of sodium toluene sulfonate, 60 to 120 parts of water and 18 to 38 parts of pine needle oil. Accord to the sterilizing bactericide, a formula and a preparation process are simple, the effect is good, and the sanitation of home furnishing environment is ensured, so the sterilizing bactericide is suitable to be used widely by families.

Owner:QIDONG YUANZHONG HYDRAULIC MACHINERY PLANT

Sanitizer

The invention relates to a sanitizer. The sanitizer comprises following components in parts by weight: 30-60 parts of chloroxylenol, 2-10 parts of piperine, 8-20 parts of dimethyl formamide, 10-15 parts of calcium hypochlorite, 40-50 parts of potassium hydroxide solution, 50-110 parts of water and 2-15 parts of urea. The sanitizer provided by the invention has the advantages of simple components, low preparation cost, no damages on human bodies and environment, and high practicability.

Owner:陈启文

Antibacterial sterilizing skin disinfectant liquid and antibacterial sterilizing antiseptic disinfector and preparation methods thereof

The invention discloses an antibacterial sterilizing skin disinfectant liquid and an antibacterial sterilizing antiseptic disinfector and preparation methods thereof. The antibacterial sterilizing skin disinfectant liquid is mainly prepared from Bo-chrysanthemum, honeysuckle, senecio scandens, dandelion, ethanol, chlorhexidine, mint, and p-chloro dimethylphenol according to a certain weight proportion; and the skin disinfectant liquid has the functions of clearing heat and removing toxicity, diminishing inflammation and sterilizing, has strong disinfection antibacterial effects on skin and sanitation, and is good in sterilization effect.

Owner:ANHUI YIRENAN

CO rubber

The invention relates to a CO rubber including following components, 40-45 parts of an alkane-typed ring-opening co-polymer, 1-2 parts of polypropylene fiber, 3-5 parts of lead stearate, 2-6 parts of a silicate, 7-9 parts of cellulose ether, 5-8 parts of modified starch ether, 3-5 parts of ammonia-soluble alkylaminoketone, 10-12 parts of FEF, 8-10 parts of hydroxypropylethyl cellulose, 11-15 parts of minium, 11-15 parts of an accelerant NBC, 13-18 parts of an accelerant NA-22, 6-7 parts of para-chloroxylenol and 4-5 parts of fatty alcohol polyoxypropylene ether. The alkane-typed ring-opening co-polymer is prepared from epoxy chloropropane, epoxy chloropropane and ethylene oxide in a ring-opening co-polymerization manner. According to the formula of the CO rubber, a short-period thermal-resistant temperature of the rubber can be increased to 170 DEG C and a long-period of the thermal-resistant temperature of the rubber can be increased to 150 DEG C. The CO rubber is enhanced in oil resistance and is reduced in breathability.

Owner:QINGDAO DTCN NEW MATERIAL TECH DEV

Nursing disinfectant

The invention discloses a nursing disinfectant. The nursing disinfectant comprises, by weight, 5-10 parts of ammonium p-toluenesulfonate, 2-3 parts of sodium p-toluenesulfonate, 1-3 parts of sodium sulfite, 4-8 parts of fatty alcohol polyoxyethylene ether sulfate, 4-6 parts of deionized water, and 8-10 parts of p-chloroxylenol. A preparation method of the nursing disinfectant comprises mixing theabove materials and uniformly stirring the materials at 30-40 DEG C. The nursing disinfectant can kill bacterial propagules, viruses, fungi and spores and can also kill bacterial spores.

Owner:胡南南

Mouthwash

InactiveCN104856917AGrowth inhibitionReduce plaqueAntibacterial agentsCosmetic preparationsXylyleneBlumea

The invention discloses mouthwash which is prepared from the following raw materials in part by weight: 12-16 parts of chloroxylenol, 6-12 parts of calcium hypochlorite, 4-8 parts of Japanese honeysuckle flower, 5-10 parts of balsamiferou blumea herb, 4-6 parts of Chinese gall, 4-5 parts of salt, 2-5 parts of sodium hydroxide, 6-12 parts of hydrogen peroxide, 4-7 parts of honeysuckle flower, 6-12 parts of green tea, and 6-11 parts of fruit of great burdock, 10-20 parts of cuttlefish bone and 8-14 parts of stevia rebaudiana flower. According to the invention, the mouthwash can inhibit bacterial growth, can reduce dental plaque, can effectively prevent tooth decay, and is conducive to oral health.

Owner:QINGDAO DONGCHANGRUI TEXTILE

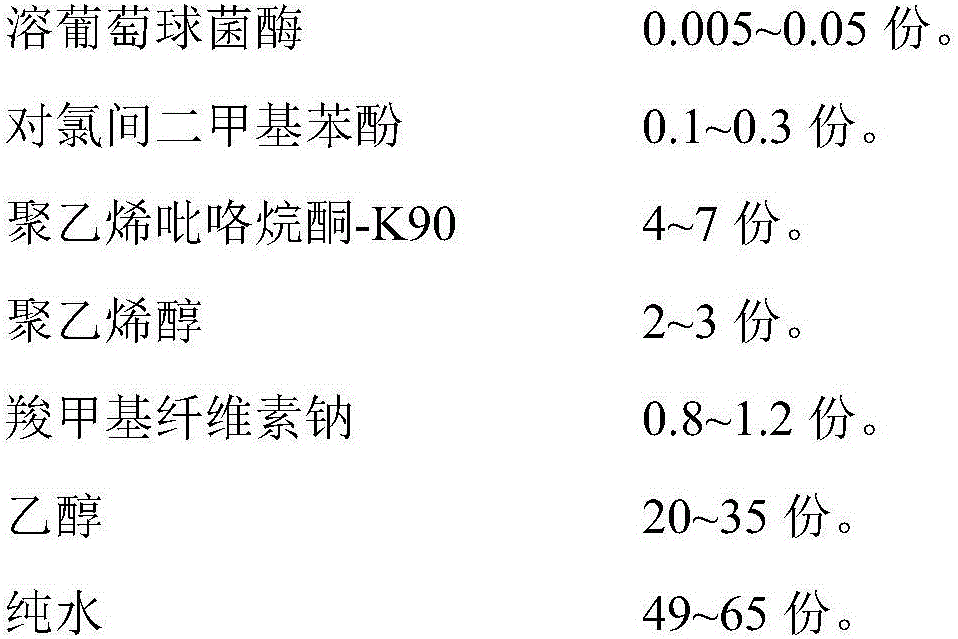

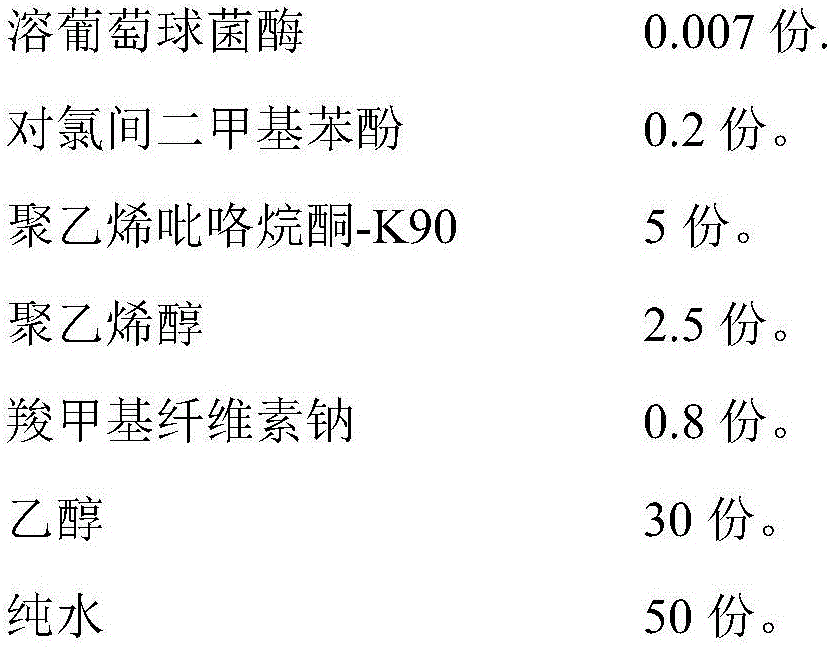

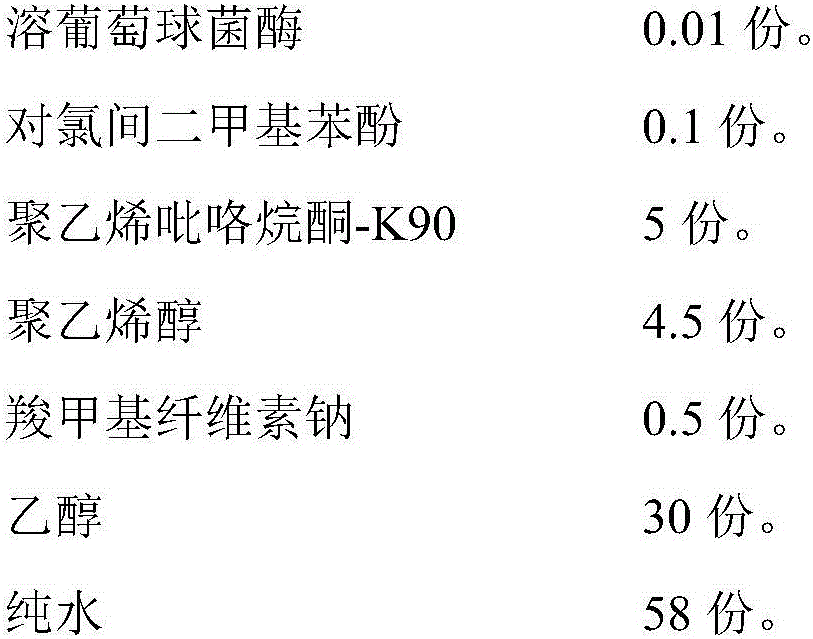

Wound protective film spray and preparation method thereof

ActiveCN107174573AAppropriate viscosityHigh strengthAntibacterial agentsOrganic active ingredientsGlycyl-GlycineAlcohol

The invention relates to wound protective film spray and a preparation method thereof. The wound protective film spray is prepared from the following components in parts by mass: 0.005 to 0.05 part of glycyl-glycine endopeptidase, 0.1 to 0.3 part of chloroxylenol, 4 to 7 parts of polyvinylpyrrolidone-K90, 2 to 10 parts of polyvinyl alcohol, 0.2 to 0.8 part of sodium carboxymethylcellulose, 20 to 30 parts of ethyl alcohol and 49 to 65 parts of pure water. The wound protective film spray disclosed by the invention has the characteistcis of short film forming time, high film strength and long antibacterial time.

Owner:重庆劲太生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com