Patents

Literature

1222results about How to "Keep fresh" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

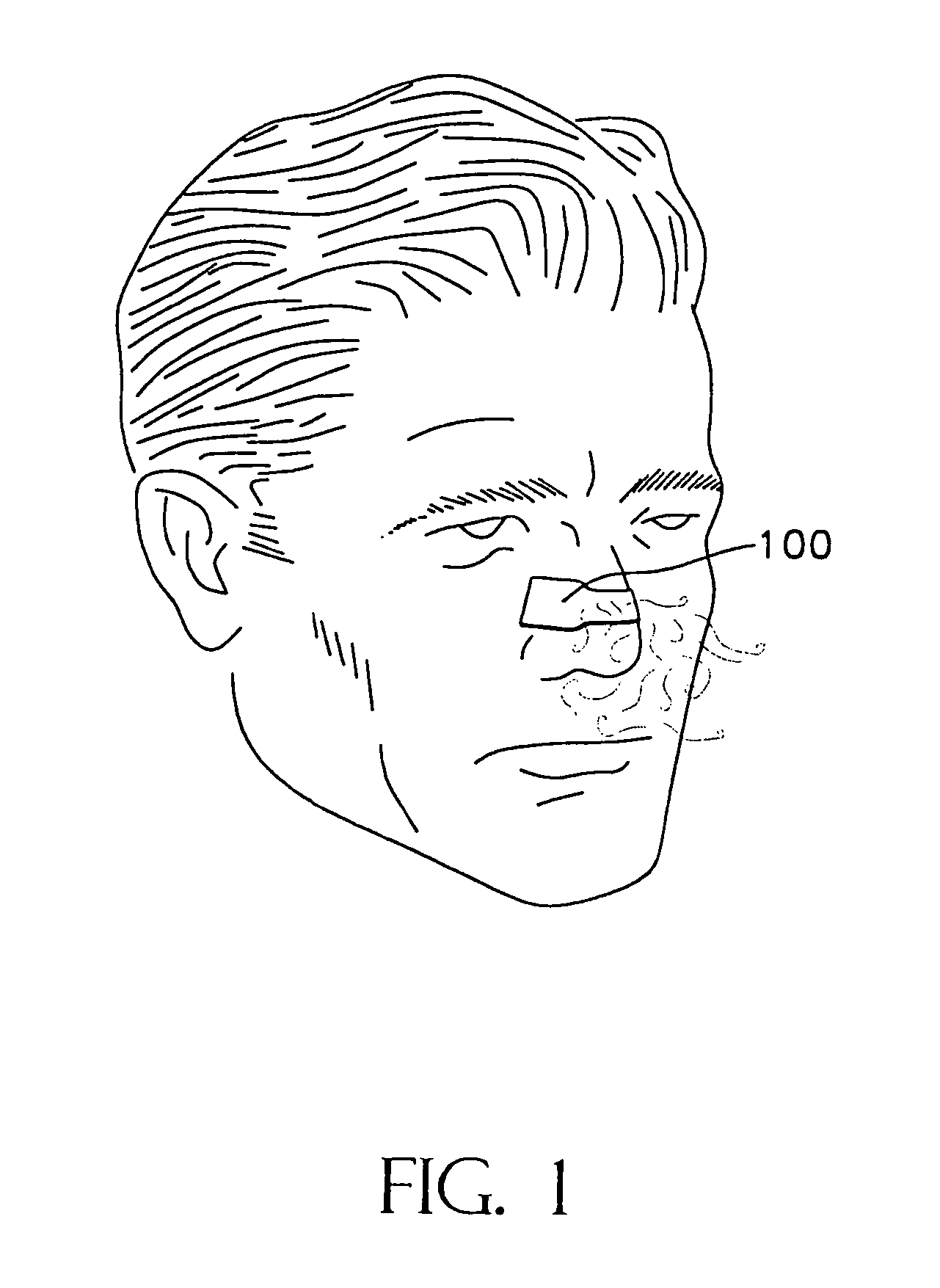

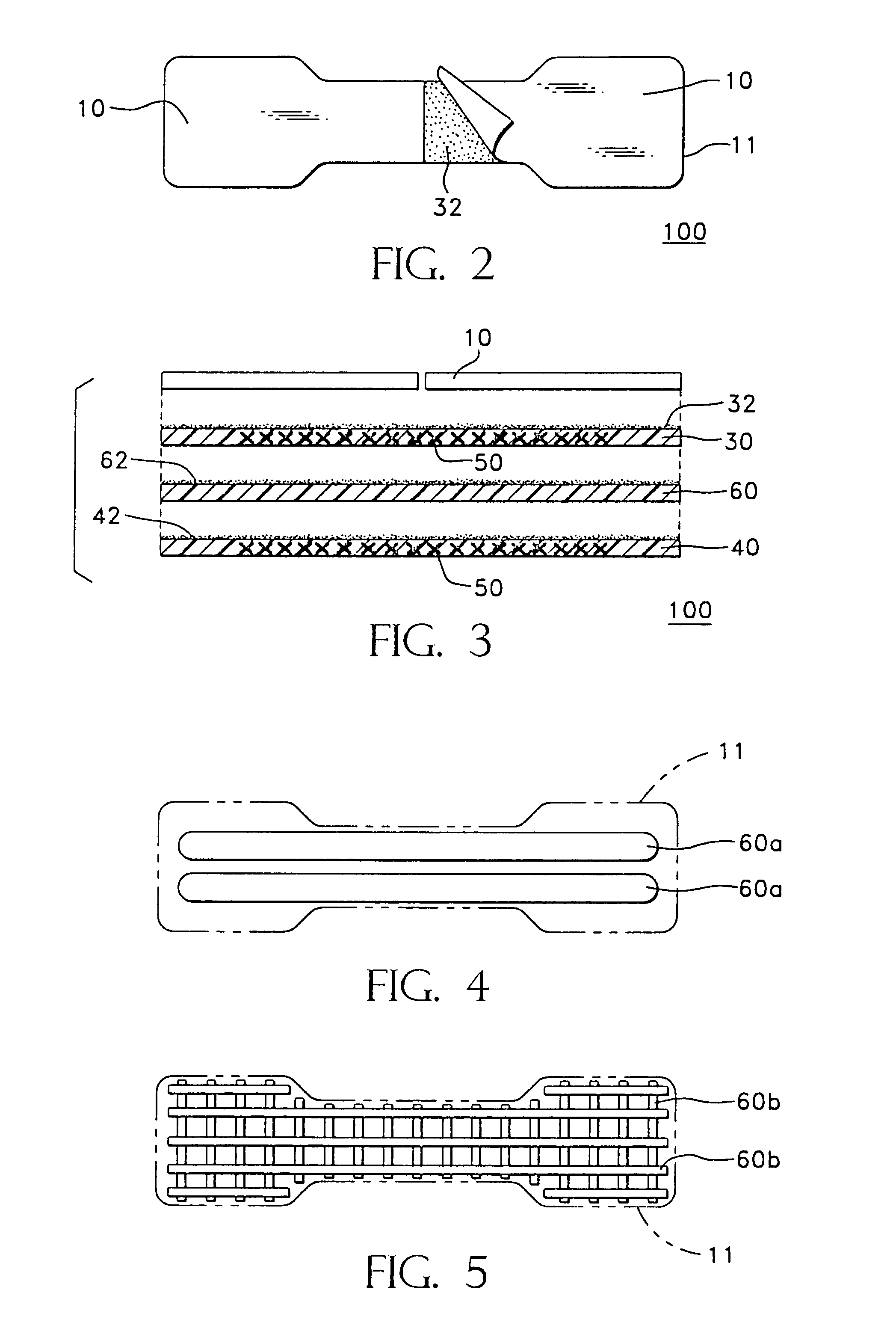

Adhesively applied external nasal strips and dilators containing medications and fragrances

InactiveUS20050066965A1Improve deliveryExtending olfactory effectivenessRespiratorsBreathing filtersPressure sensitiveDrug

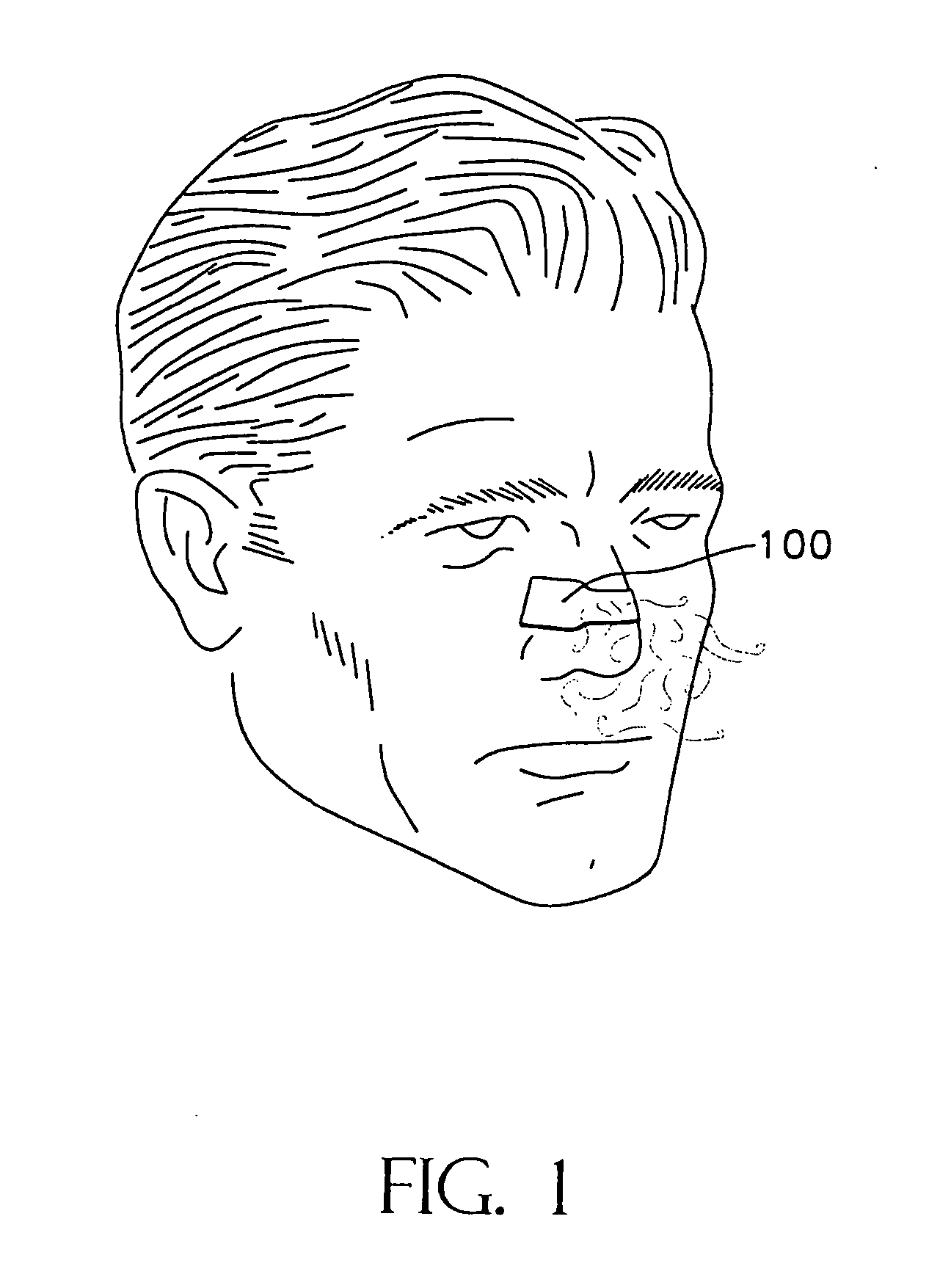

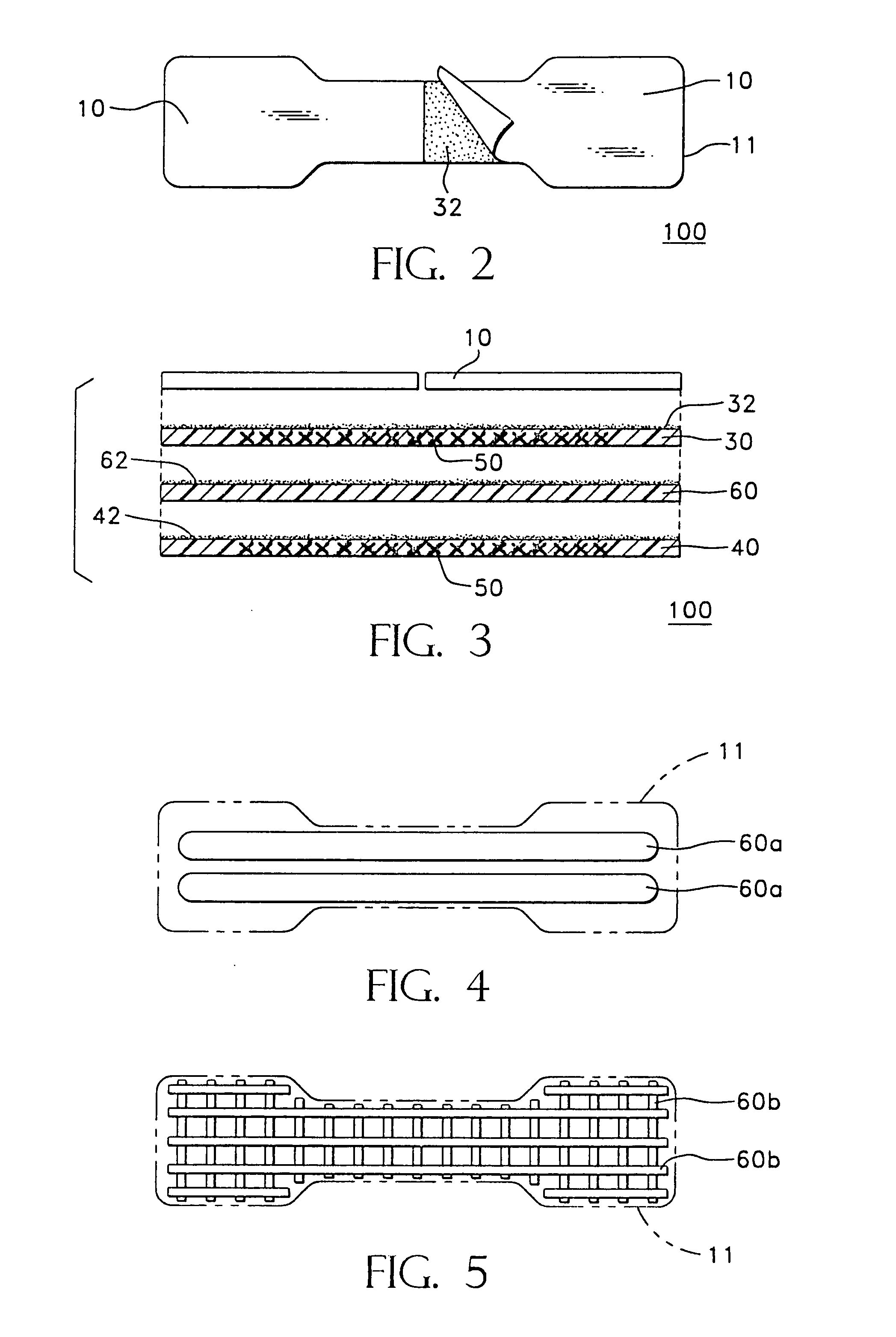

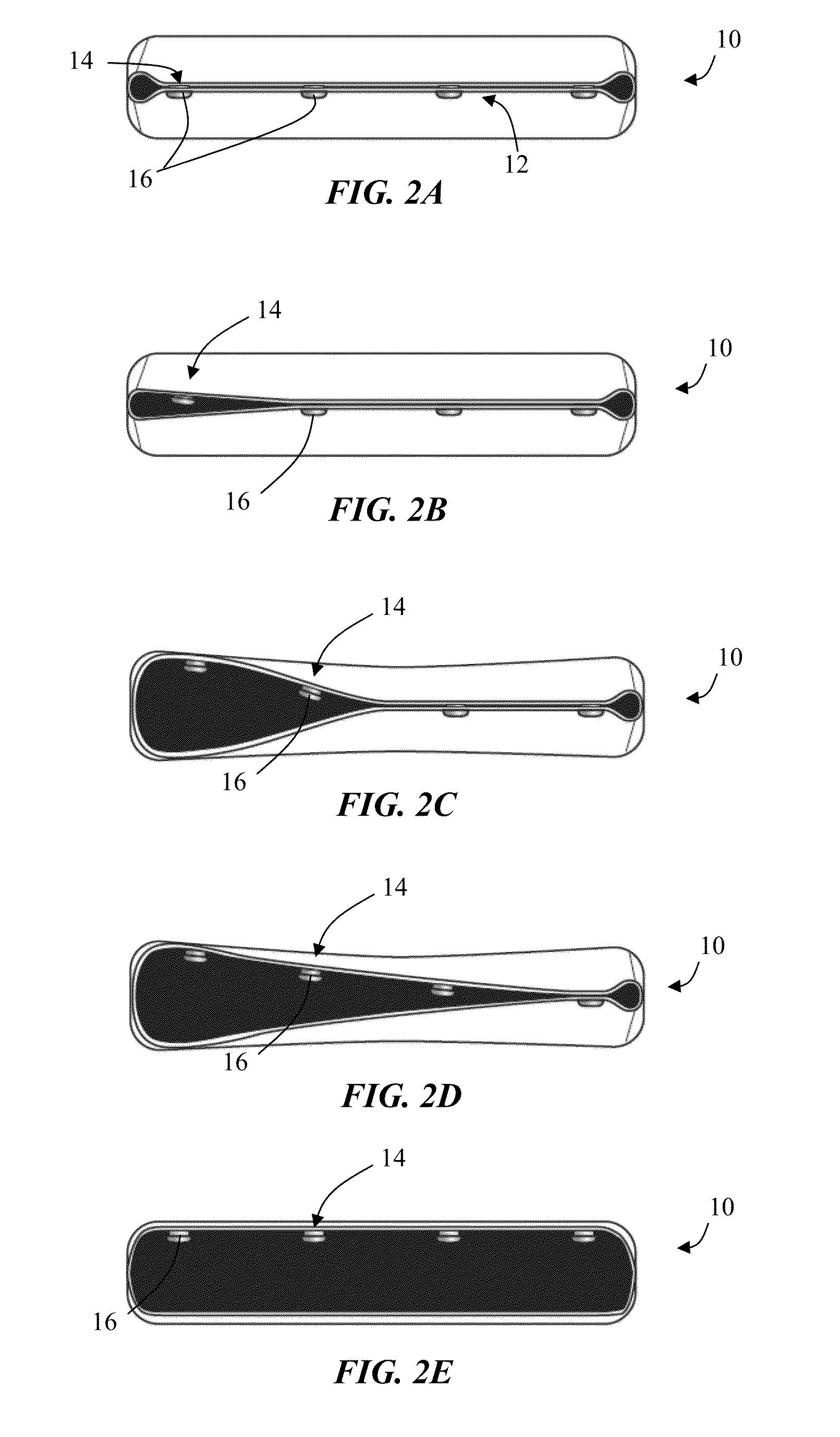

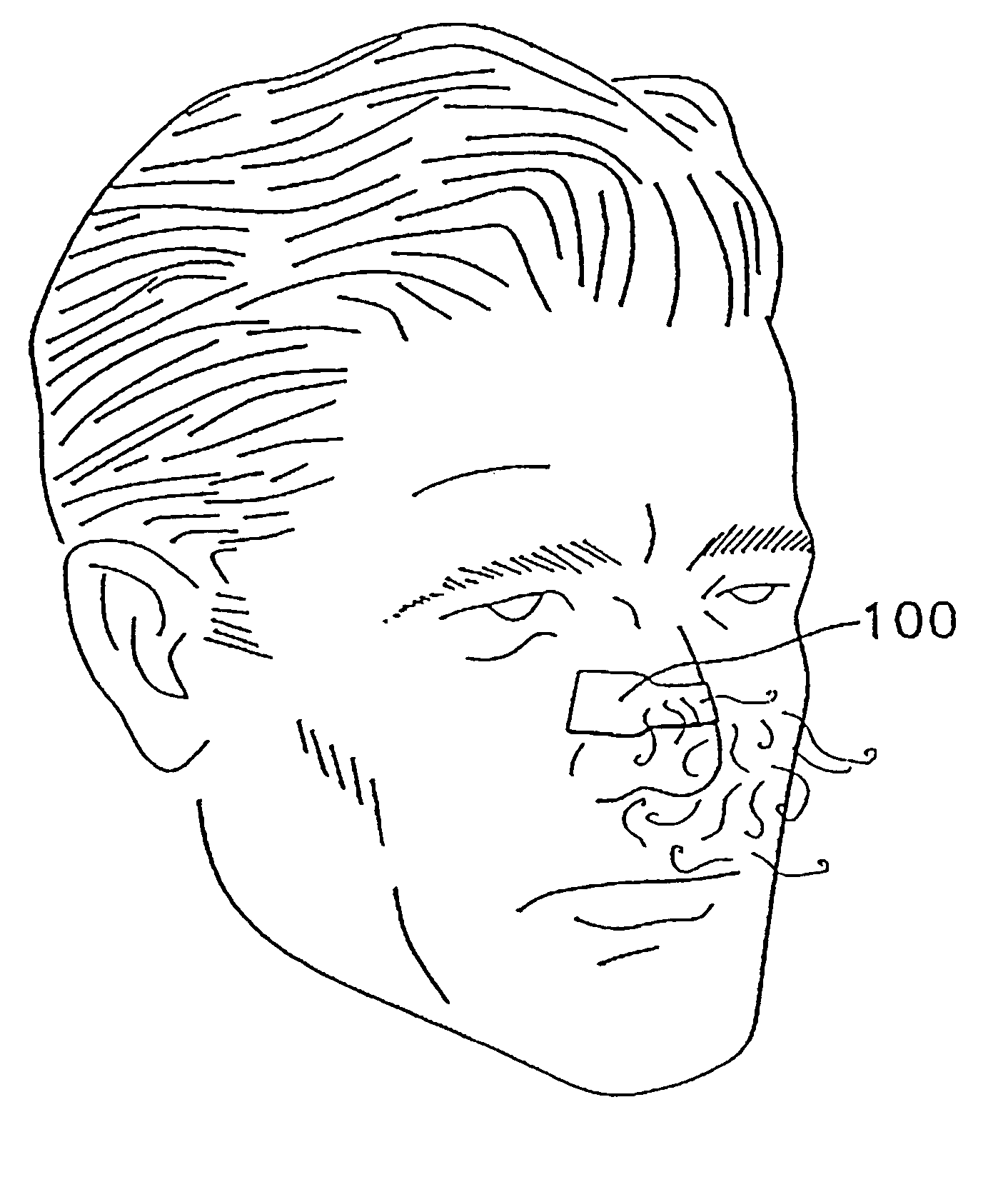

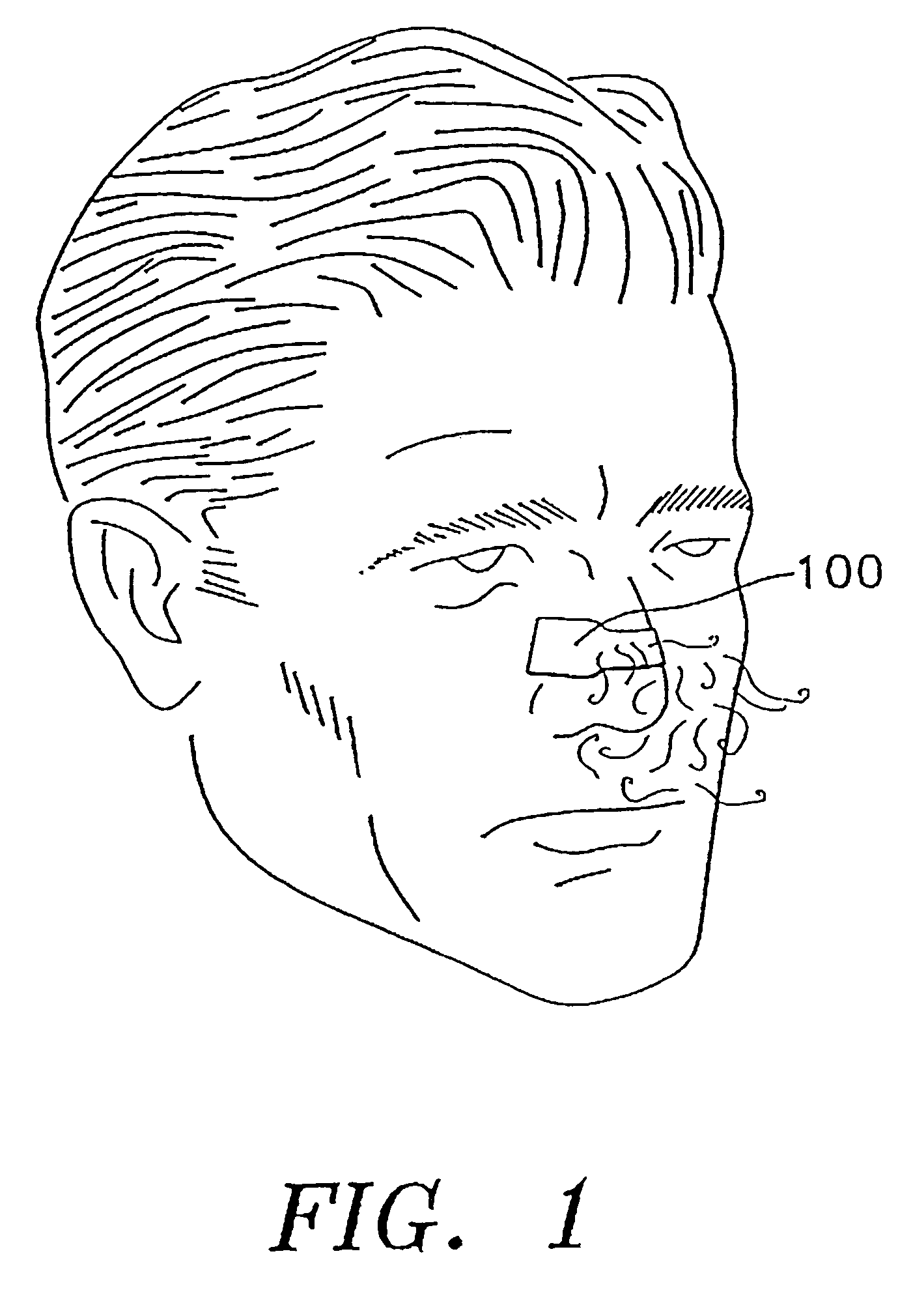

Nasal dilators and strips, methods of their manufacture, and methods for improving the breathing of individuals are provided. The strips and dilators include an elongated substrate, with or without a dilating component or portion, having top and bottom surfaces and a pressure-sensitive adhesive disposed on the bottom surface. The dilator is designed to provide a gentle expanding force to the nasal wall tissue when the dilator is adhesively attached to the nose. This invention further includes a cosmetic fragrance, an aromatic medication and / or transdermal medication disposed on the strips or dilators. In order to improve the shelf-life and in-use olfactory effectiveness of such products, fragrance delivery mechanisms are used. Separation of volatile oils and adhesives are also provided to minimize adhesive residue.

Owner:WINTER BREATH

Adhesively applied external nasal strips and dilators containing medications and fragrances

InactiveUS7013889B2Extending olfactory effectivenessEfficient deliveryRespiratorsBreathing filtersTransdermal medicationBreathing process

Owner:WINTER BREATH

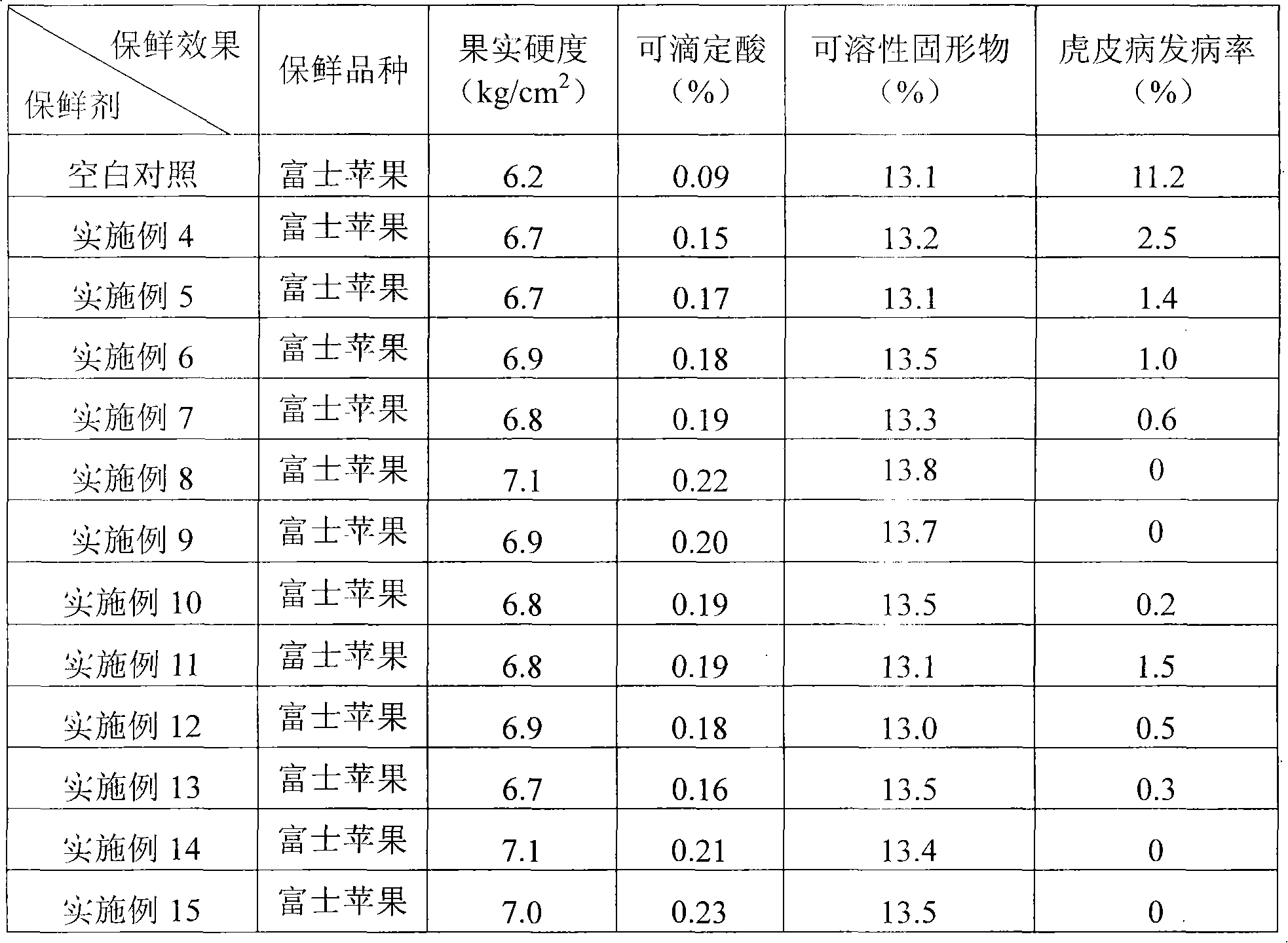

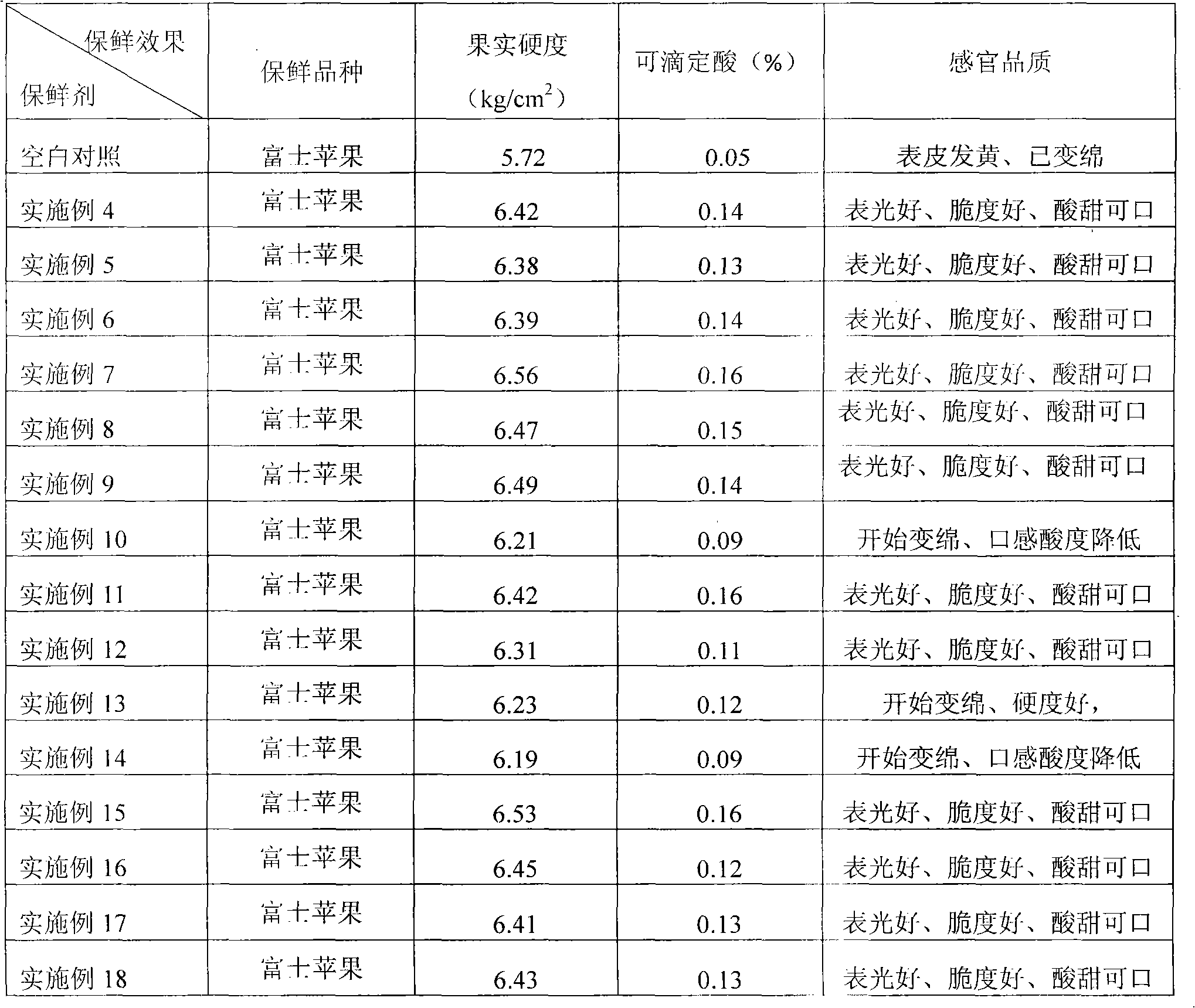

Cyclopropene preservative, and preparation and packaging methods thereof

ActiveCN102119719AExtended storage timeImprove qualityDead plant preservationFruit and vegetables preservationChemistryCyclopropene

The invention provides a cyclopropene preservative, which is characterized by containing 0.1 to 99 mass percent of cyclopropene coating material powder, 0.1 to 98 mass percent of compound, composition or material releasing water molecules, and 0 to 98 mass percent of one or more assistants. The invention also provides the preparation method and packaging method of the cyclopropene preservative. The preservative is convenient for use and has a remarkable preservation effect.

Owner:山东营养源食品科技有限公司

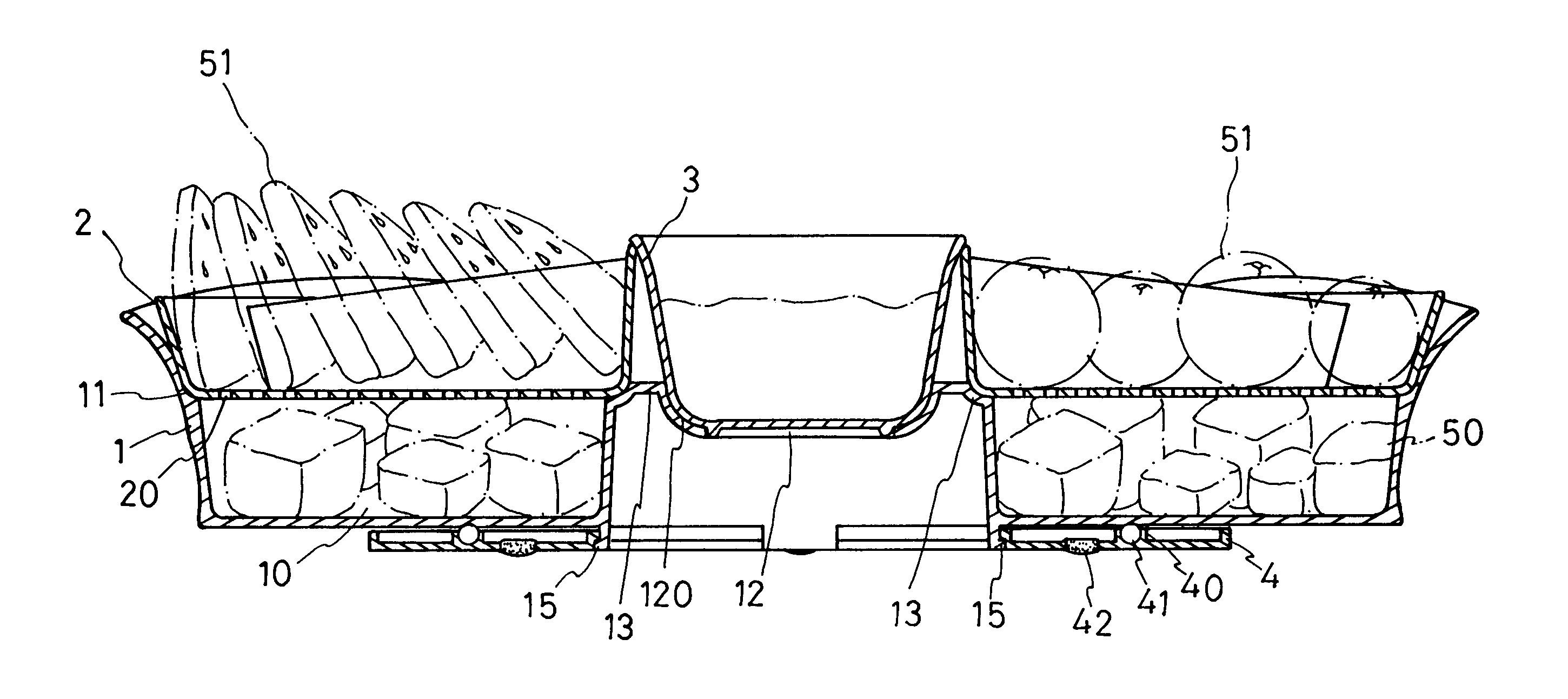

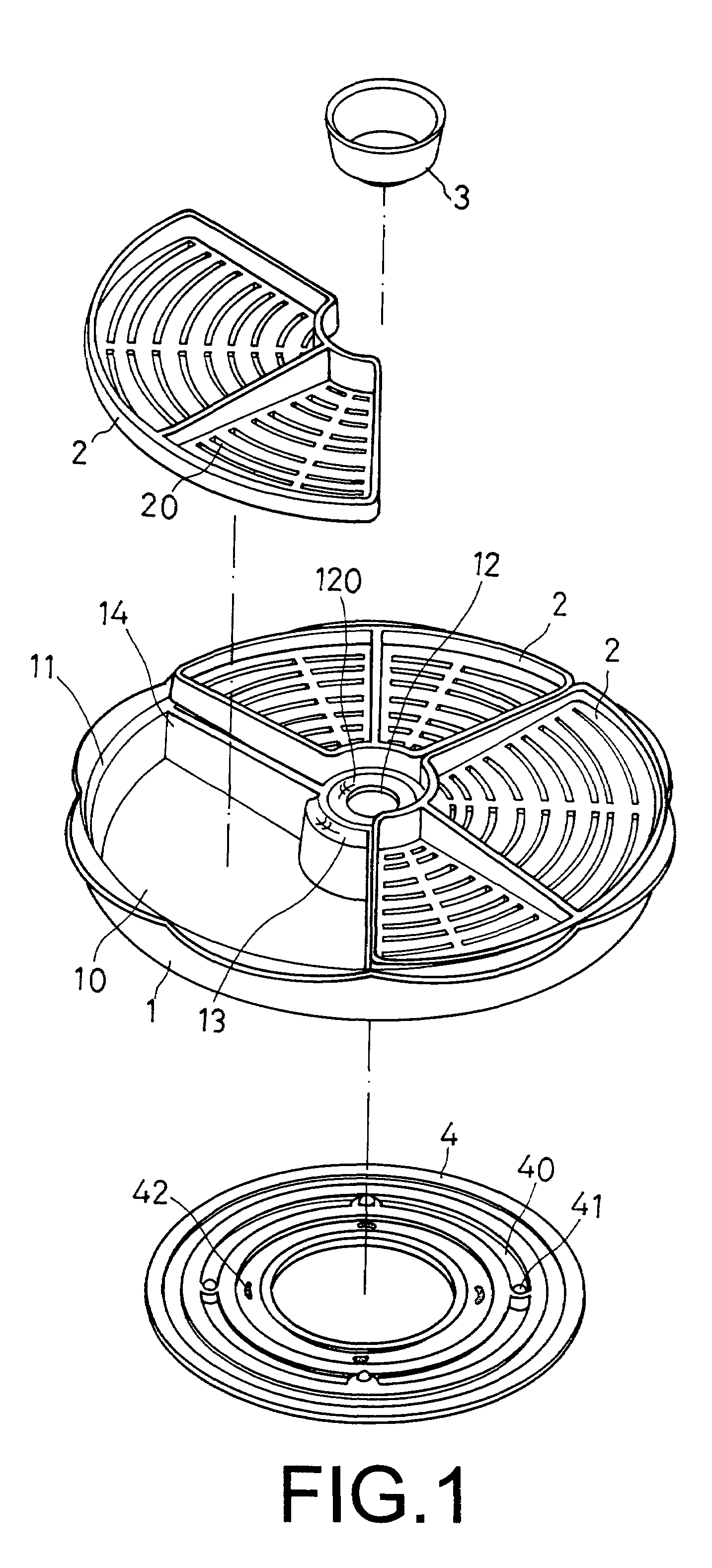

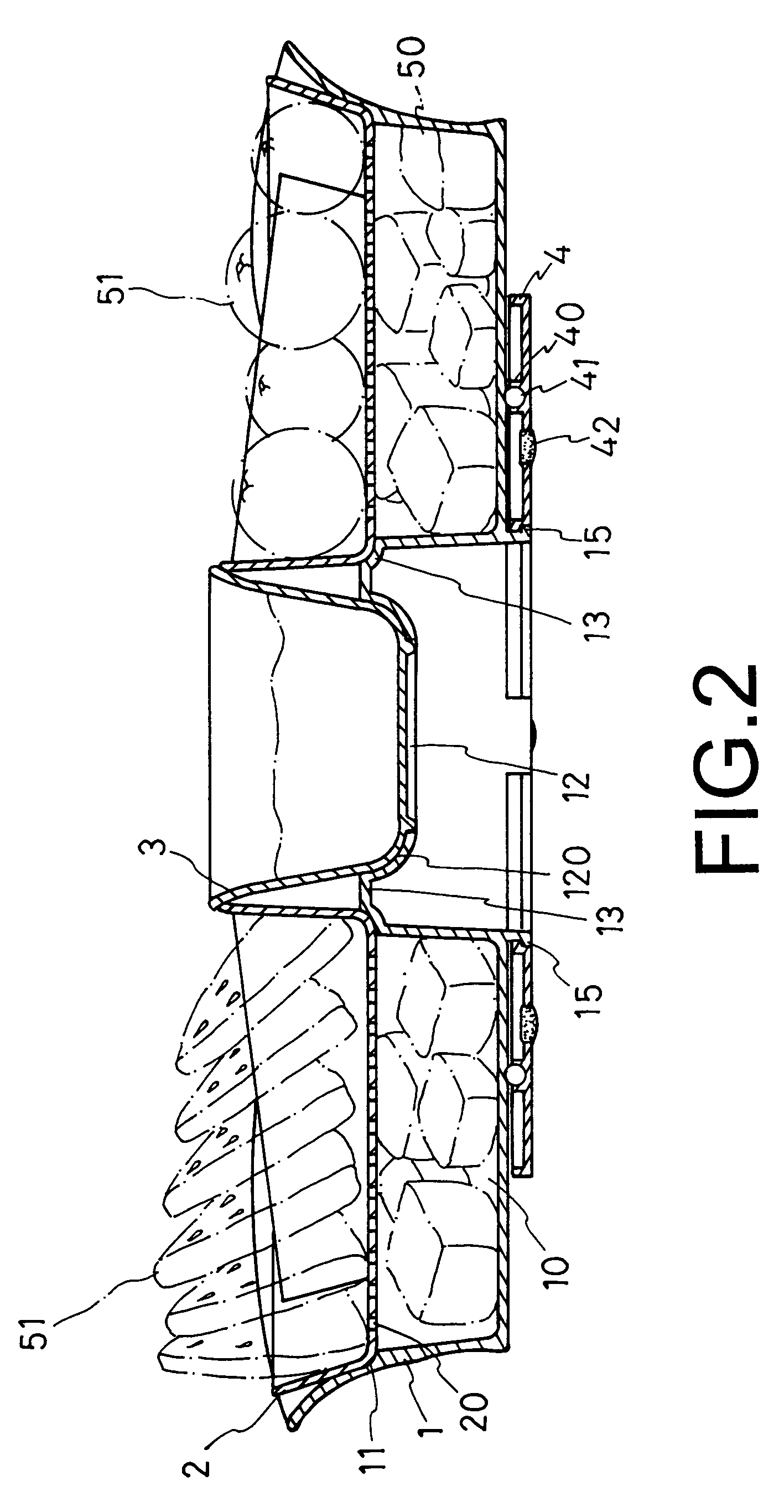

Serving tray with function of keeping food fresh

A serving tray with function of keeping food fresh in the present invention includes a rotary tray provided with at least one compartment; at least one receiving pan; and a base plate disposed below the rotary tray. In using, after a user puts ice cubes into the at least one compartment, places various food items, such as vegetables, fruits or the like, respectively in the at least one receiving pan, and then locates the at least one receiving pan above the at least one compartment, the food items will soon be spread with cool air coming from the ice cubes and penetrating through a plurality of perforated holes of the at least one receiving pan, thus enabling the food items to be kept fresh in cool temperature in a longer period for being tasted more delicious, and maintained with their individual unique flavors in a sanitary condition.

Owner:YANG HENG TE

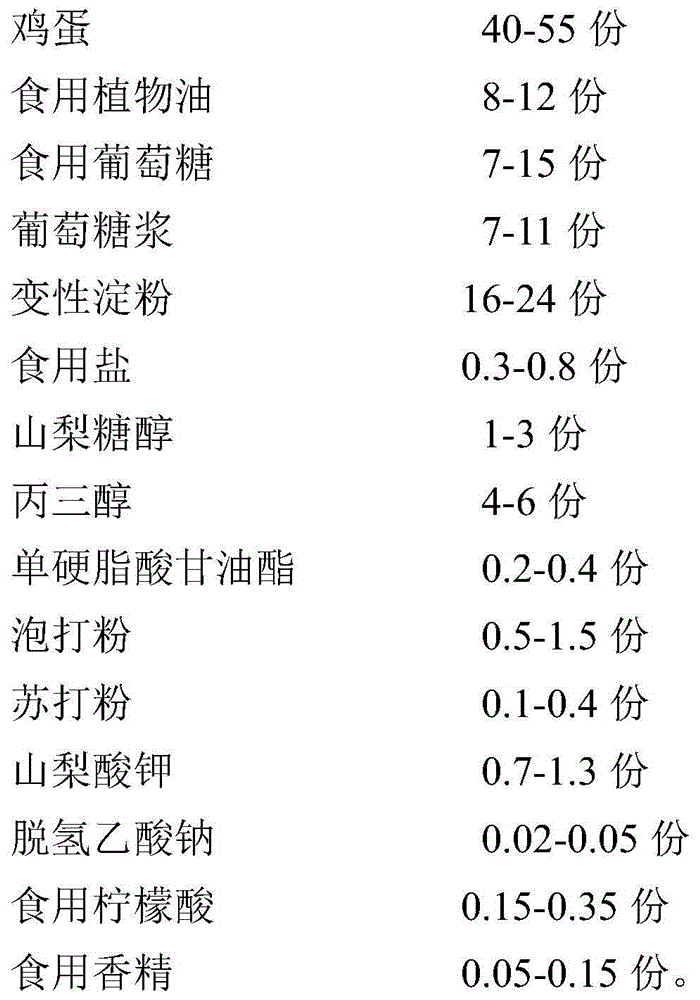

Steamed egg cake and preparation method thereof

InactiveCN104585809AReduce spoilageSolve the problem of anti-mildew preservationSugar food ingredientsFood preparationVegetable oilGlycerol

The invention relates to the technical field of foods, in particular to a steamed egg cake and simultaneously discloses a preparation method of the steamed egg cake. The steamed egg cake is prepared from the following raw materials in parts by weight: 55-65 parts of low-gluten wheat flour, 30-40 parts of white granulated sugar, 40-55 parts of egg, 8-12 parts of edible vegetable oil, 7-15 parts of edible glucose, 7-11 parts of glucose syrup, 16-24 parts of modified starch, 0.3-0.8 part of edible salt, 1-3 parts of sorbitol, 4-6 parts of glycerol, 0.2-0.4 part of glycerin monostearate, 0.5-1.5 parts of baking powder, 0.1-0.4 part of soda powder, 0.7-1.3 parts of potassium sorbate, 0.02-0.05 part of sodium dehydroacetate, 0.15-0.35 part of edible citric acid and 0.05-0.15 part of edible essence. The steamed egg cake provided by the invention keeps the most original and fresh taste of the food, is fine in cake texture, soft in texture, rich in elasticity, soft in mouth feeling and rich in nutrition and is suitable for both the old and the young.

Owner:HENAN HENGRUI STARCH TECH CO LTD

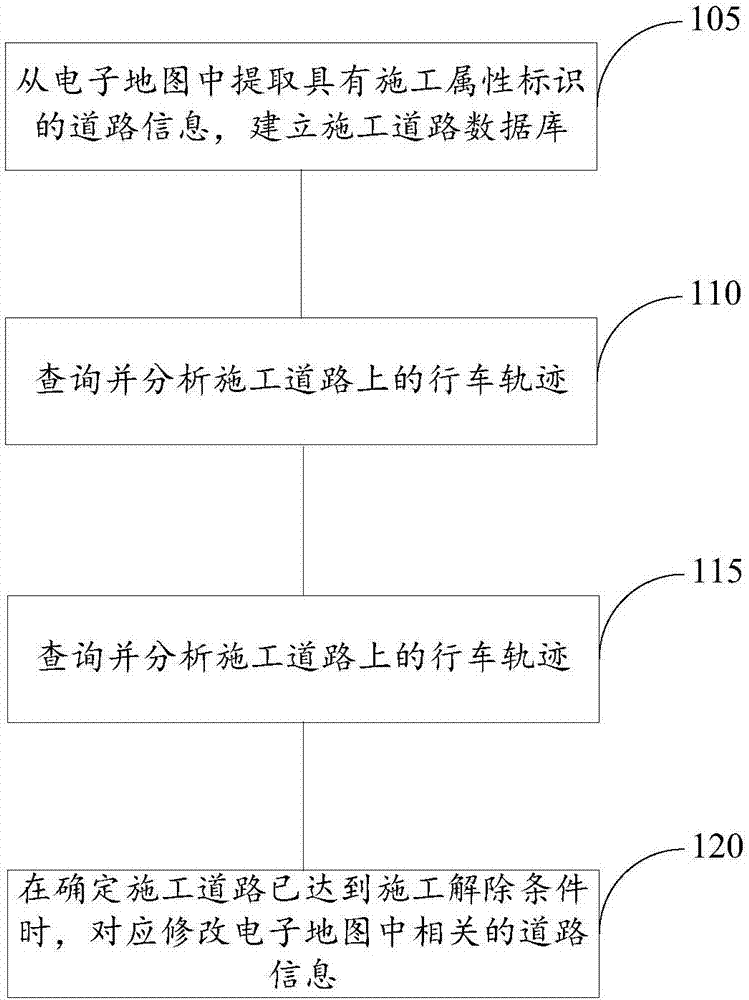

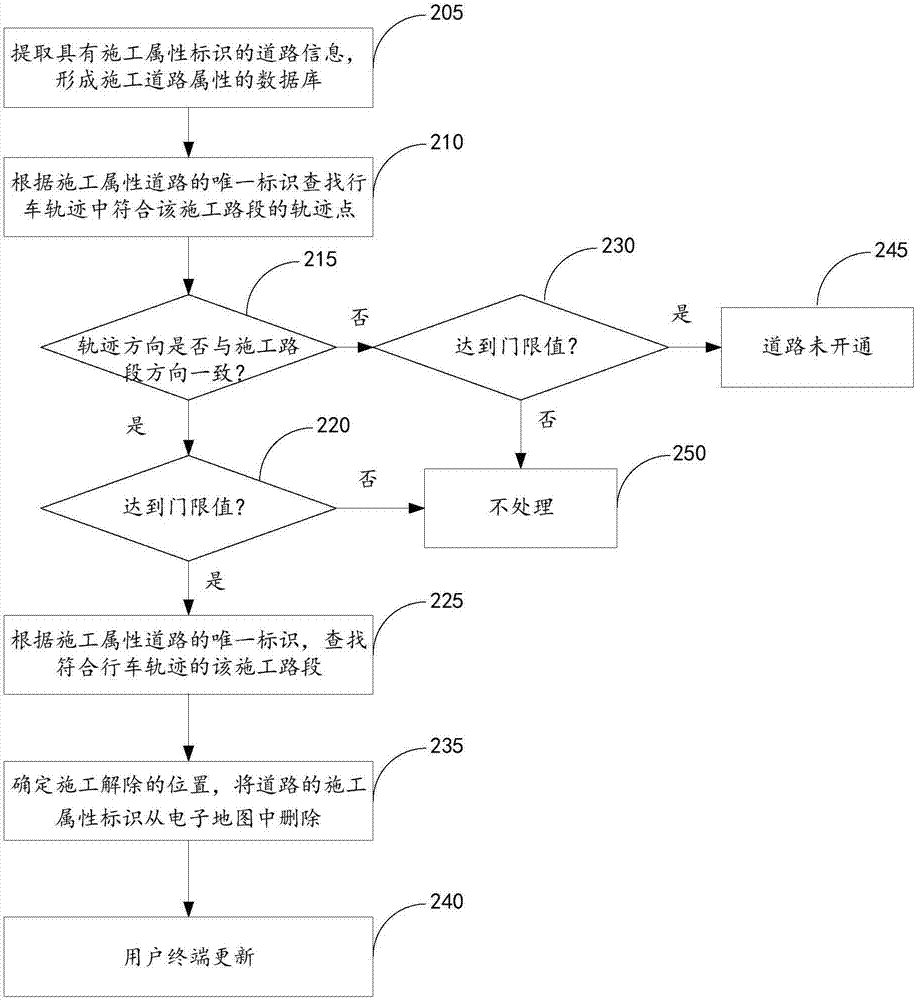

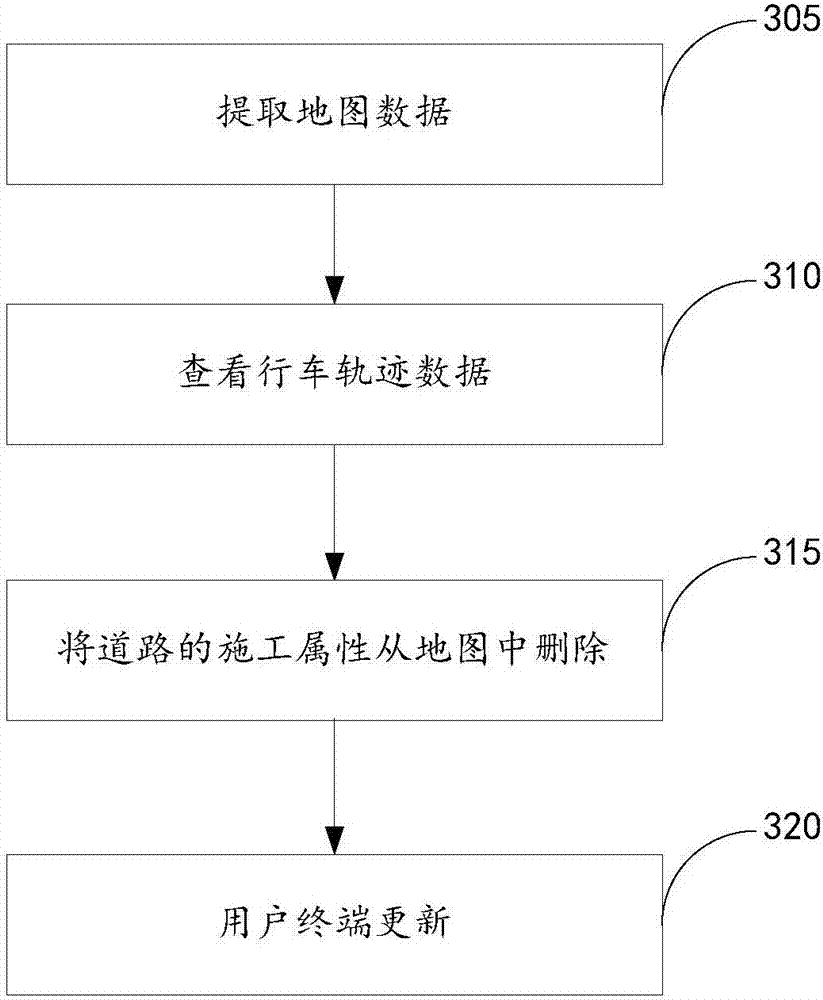

Method and device for updating map data, navigation system and server

ActiveCN107247718AReduce labor costsGuaranteed freshnessGeographical information databasesSpecial data processing applicationsElectronic mapData analysis

The invention discloses a method and a device for updating map data, a navigation system and a server. The method comprises: extracting road information with construction attribute identifier from an electronic map, establishing a construction road database; querying and analyzing wheel paths on construction roads; according to analysis on the wheel paths and information of the construction roads, determining whether the construction road achieves a construction dissolving condition, and when the construction road achieves a construction dissolving condition is determined, correspondingly correcting road information in the electronic map, removing the construction attribute identifier on the construction roads, and marking the related roads as conducted and passable. The method and the device realize removing of construction attribute identifiers through big data analysis, on-site acquisition by an acquisition team is not needed, so manual operation cost is reduced. Through a communication network, the data is updated to user terminals in time, so as to ensure freshness of an electronic map.

Owner:NAVINFO

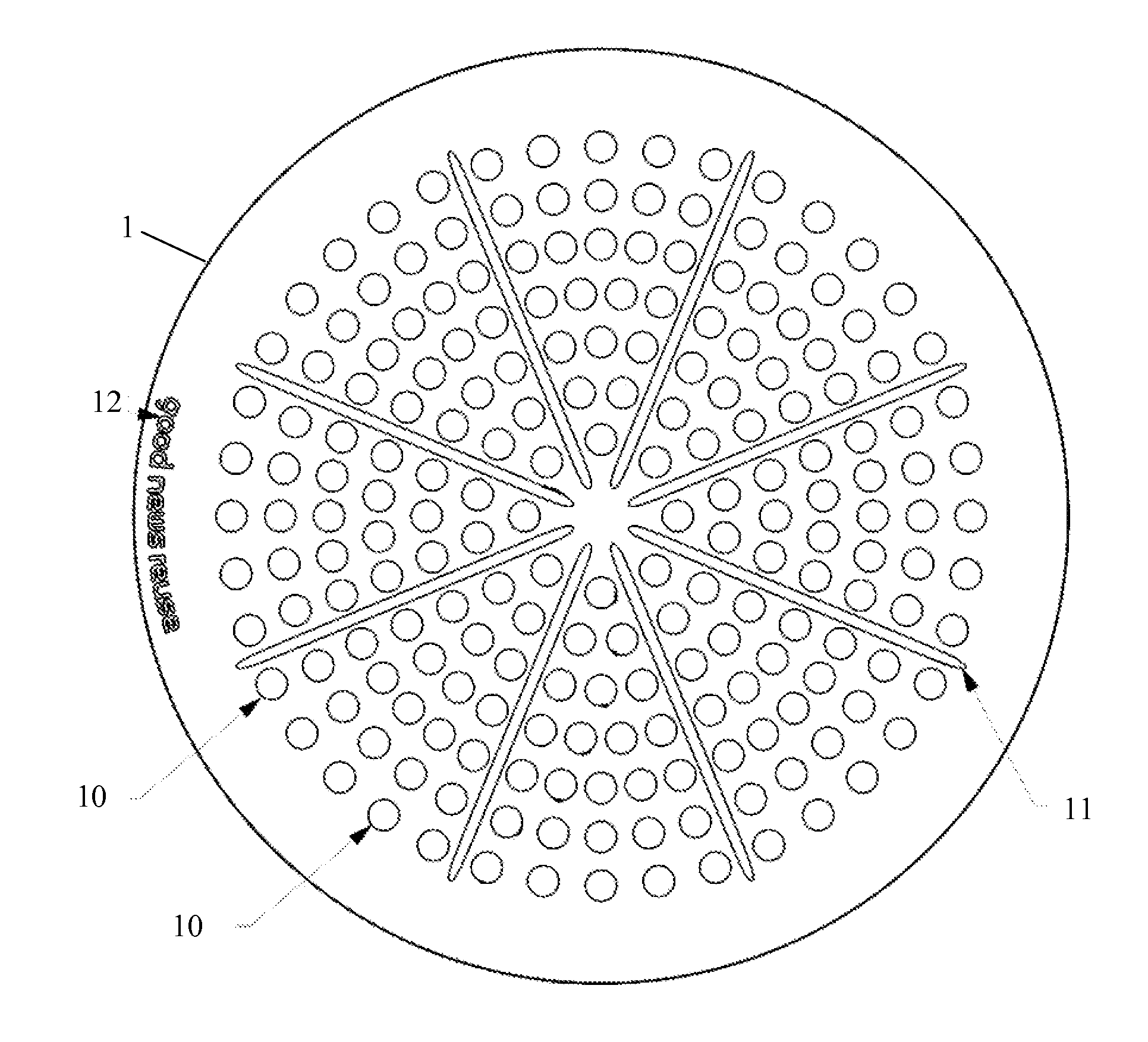

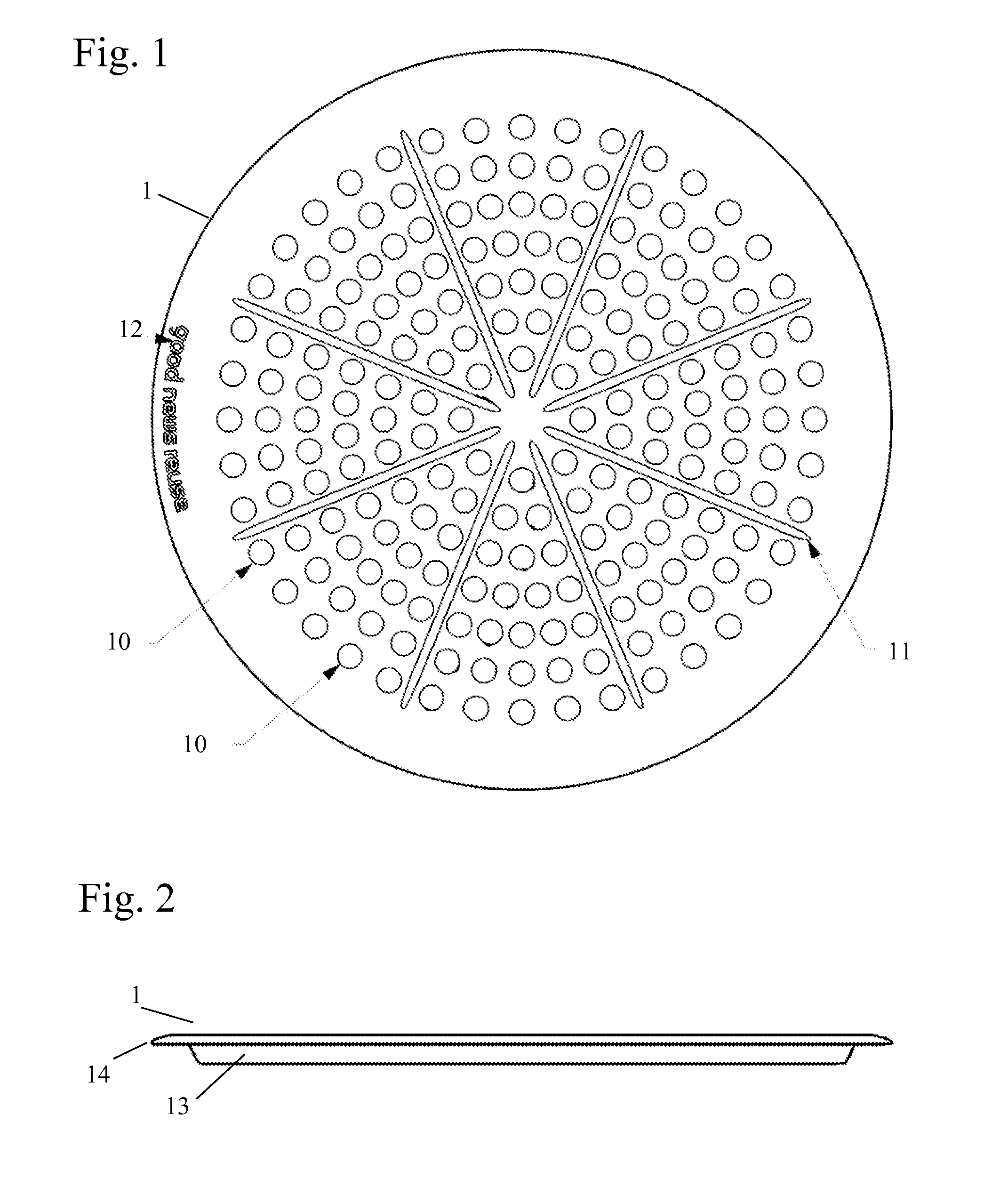

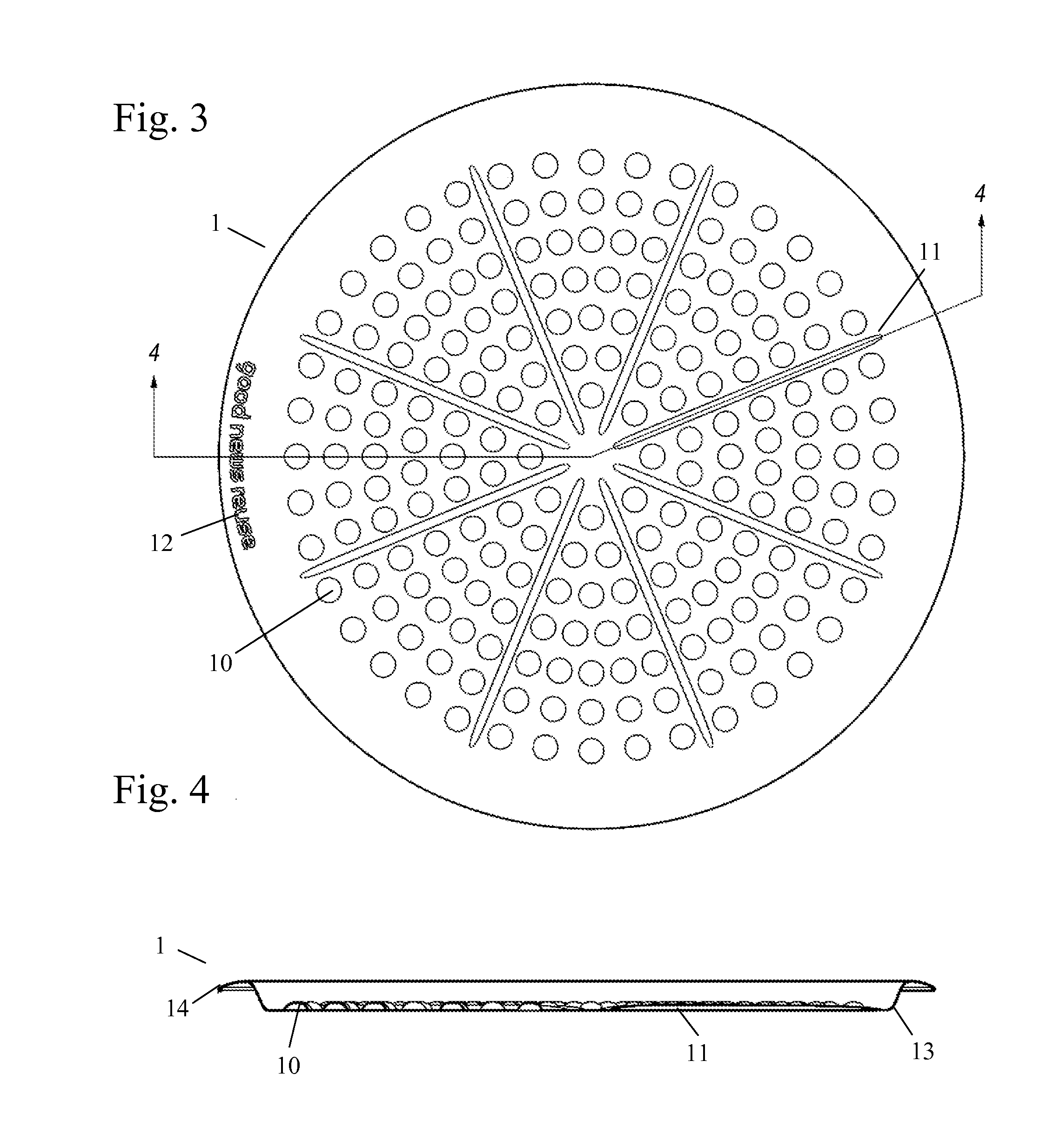

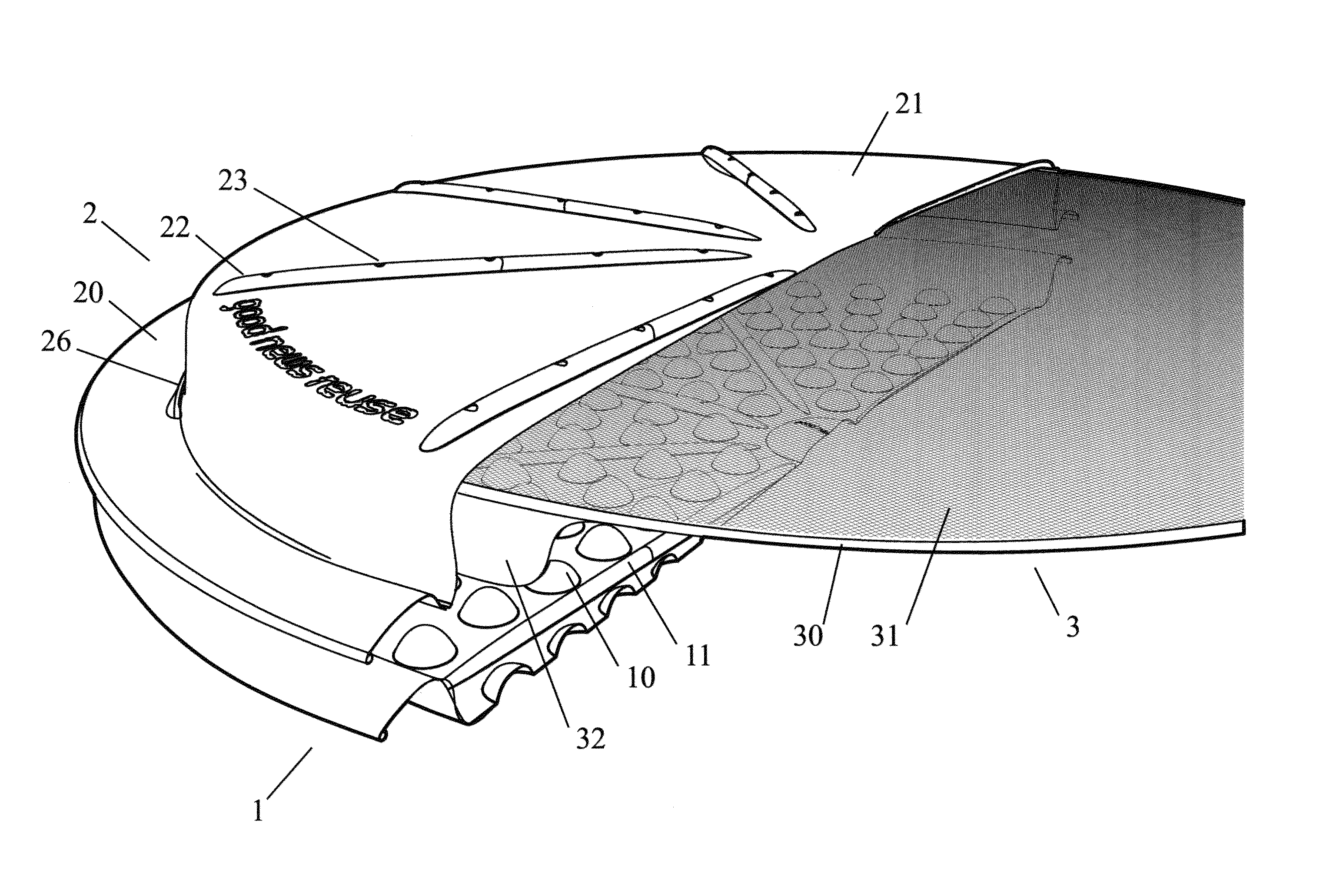

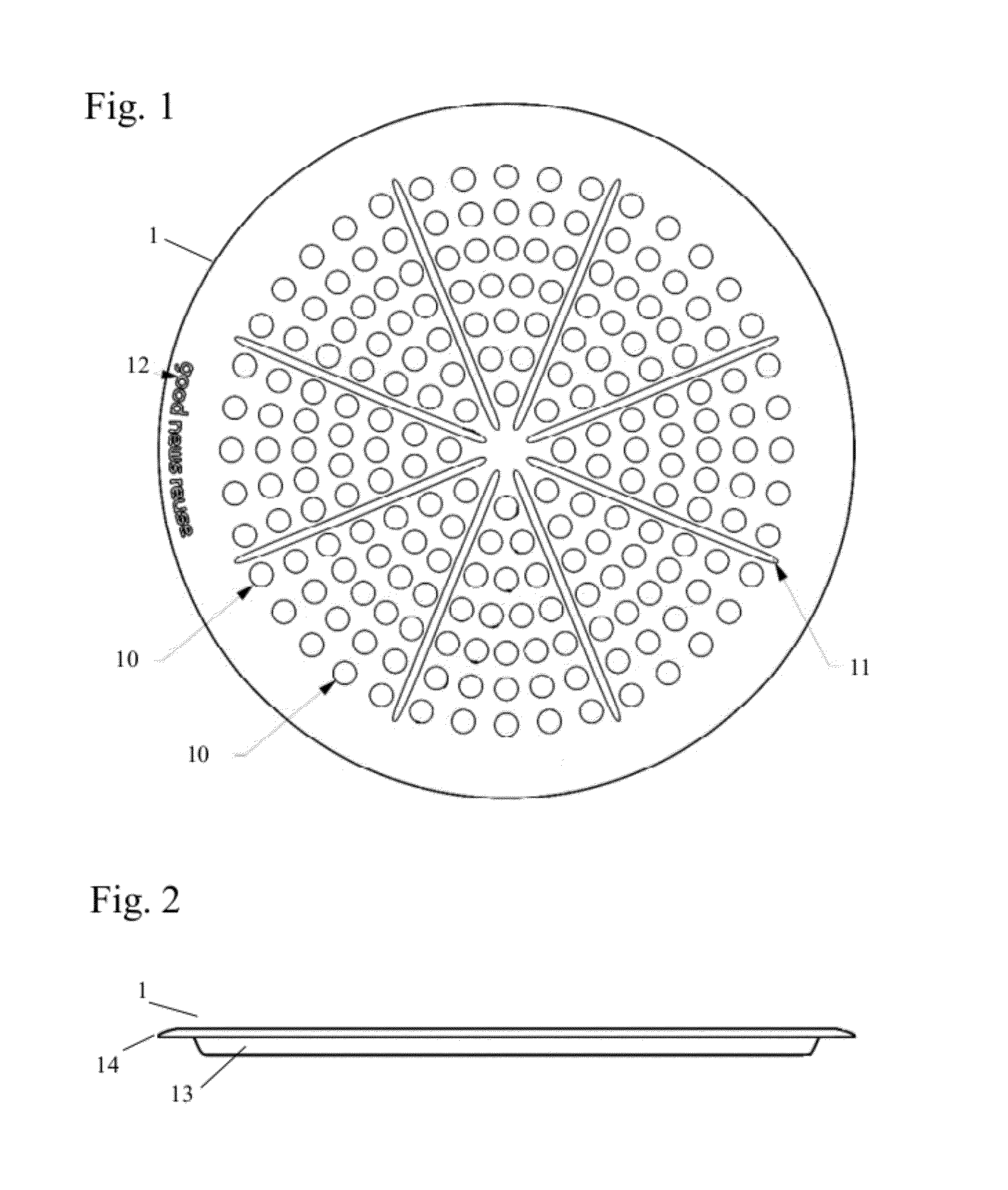

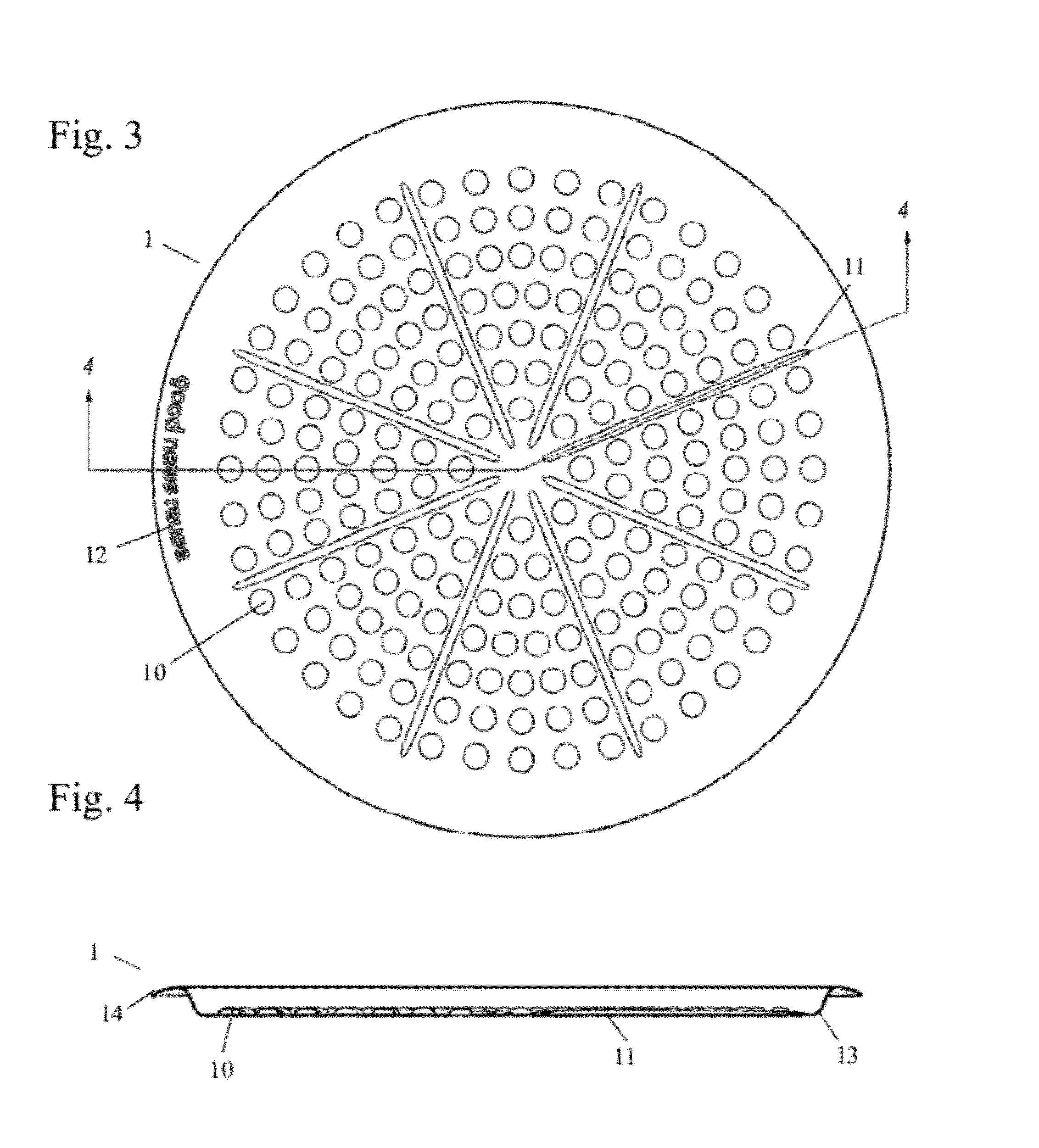

Reusable Pizza Pan Set

ActiveUS20120175367A1Facilitates rigidity and convective heat flow and condensation flowStay crisperPackage recyclingCapsHeat flowEngineering

A reusable and stackable pizza pan set for holding, transporting, reheating and serving pizza. The set has a bottom, lid and removable Vapor Transport Mechansim. A domed lid facilitates convection heat flow and the flow of condensation. The lid has perforated radial raised ribs that allow heat escape and enables stacking. The lid nests securely into the bottom to prevent dislodging during transport. The bottom has raised circular domes to elevate the pizza above the surface. Raised radial raised ribs enable the bottoms to be stacked. A removable Vapor Transport Mechanism (VTM), a mesh screen that fits within the domed lid, collects and prevents excessive condensation from dripping onto pizza. The reusable pizza pan set retains pizza quality by keeping the pizza hot while reducing sogginess, thereby maintaining a fresh-from-the-oven, cardboard-free taste with a crispy crust.

Owner:LOPES SUSAN +1

Processing method of handmade yellow tea

ActiveCN103444916ATo achieve aromaYellowish colorPre-extraction tea treatmentClimate change adaptationMoisture regainTea leaf

The invention belongs to field of tea leaf, and in particular relates to a processing method of handmade yellow tea. The processing method of handmade yellow tea comprises the following steps: picking fresh tea leaves, washing fresh tea leaves, sunning, performing primary roasting, shaping, spreading and cooling, performing primary drying, performing primary piling for yellowing, performing secondary drying, performing secondary piling for yellowing, extracting stalks, and refiring for extracting aroma. The processing method of the handmade yellow tea is a special processing method of Huoshan yellow tea, the fresh leaves are washed and dedusted to keep clean, the piling for yellowing is performed in a moisture regain machine after the primary drying is performed with the stacking thickness of about 10cm, piling for yellowing is performed after the primary drying is performed, secondary piling for yellowing is performed after the secondary drying is performed so as to further convert inclusions and achieve unique aroma taste of the yellow tea. By adopting the processing method, the processed Huoshan yellow tea has the characteristics of being similar in form of sparrow tongue, slight yellow of color and luster, lasting fragrance, mellow taste, sweet aftertaste, yellow bright, clean soup color, being durable for making tea, and being capable of being preserved for two years after being sealed at a normal temperature.

Owner:安徽抱儿钟秀茶业科技有限公司

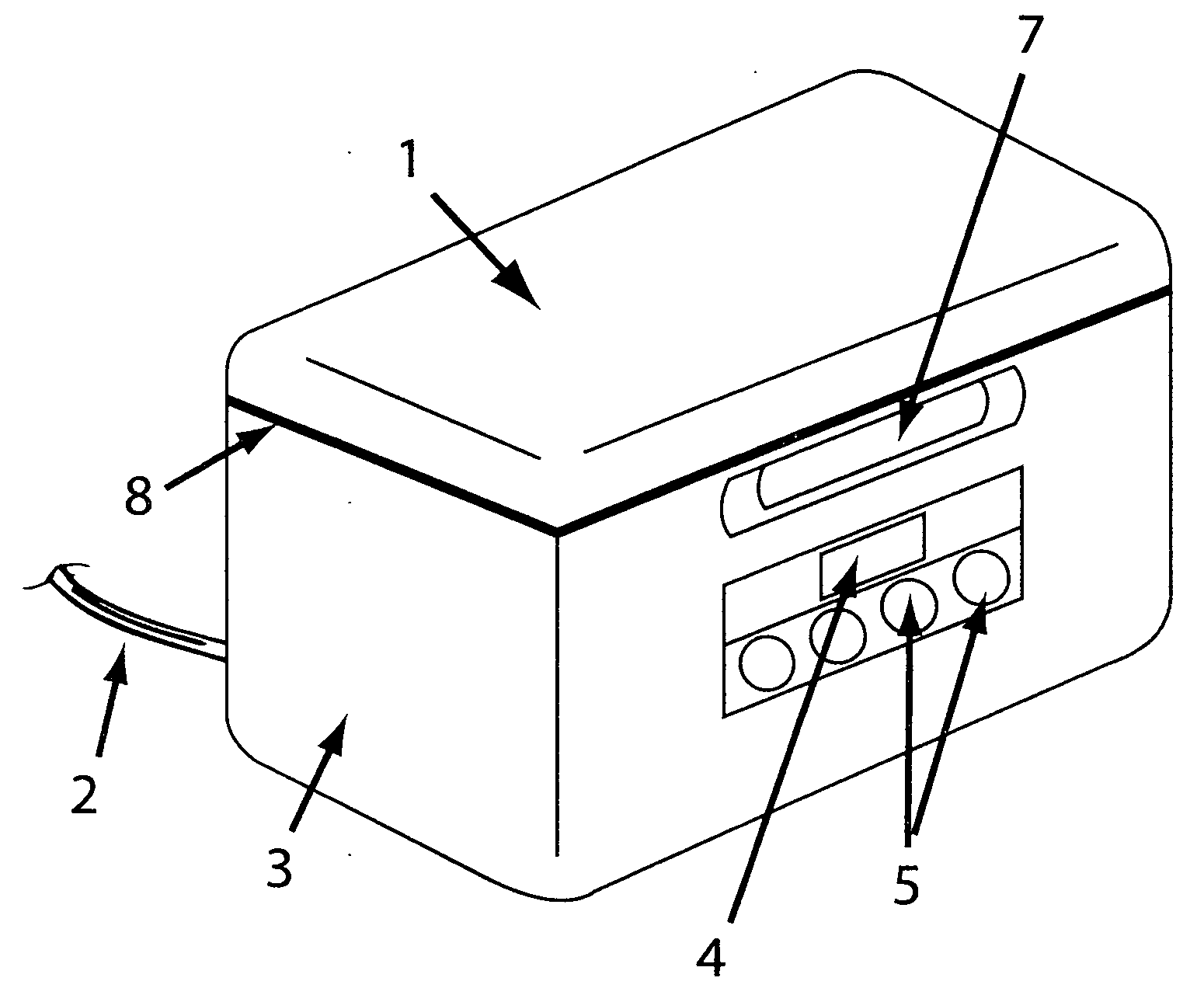

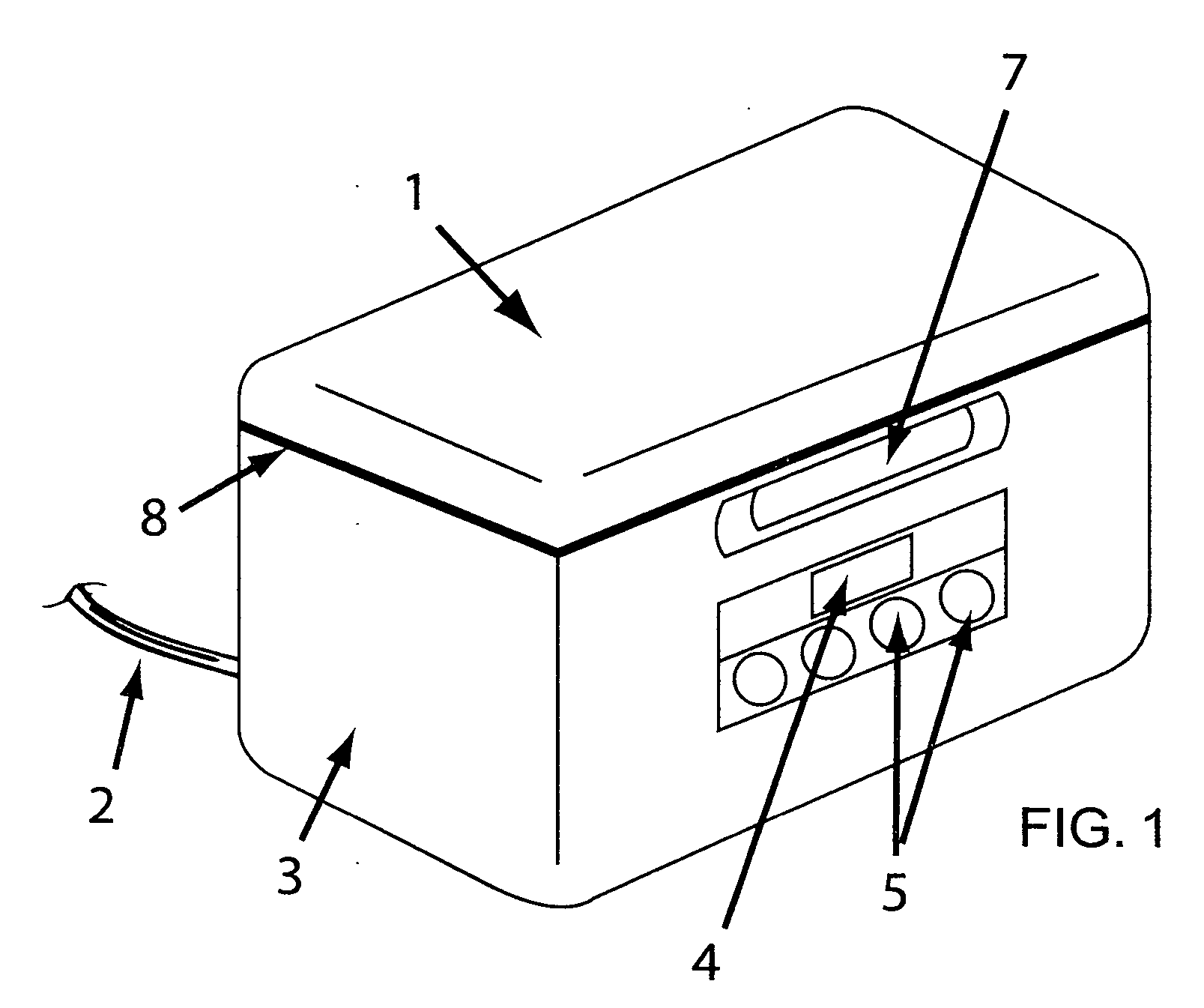

Universal preparation and organization station/facility and airtight apparatus/appliance for the storage of baked goods and/or foodstuffs with a built in vacuum pump

InactiveUS20070000396A1Retain there freshnessFast, easy, and convenient way to prepare and storeAir-treating devicesKitchen equipmentPollutantBaked goods

The invention is an all in one apparatus / appliance system for the preparation and storage of baked goods and other foodstuffs. It provides a preparation station to prepare different types of goods for consumption, while also providing a universal storage area for baked goods and foodstuffs in general. It is equip with many features which allows storage and preparation to be easy, safe, effective, and convenient. It has a built in vacuum pump that expels air from within the apparatus to form a vacuum seal. This seal provides an air-free environment for foodstuffs and retards the formation of mold or other contaminants. This apparatus will aid in food organization and cleanliness.

Owner:KIECK TIMOTHY ADAM

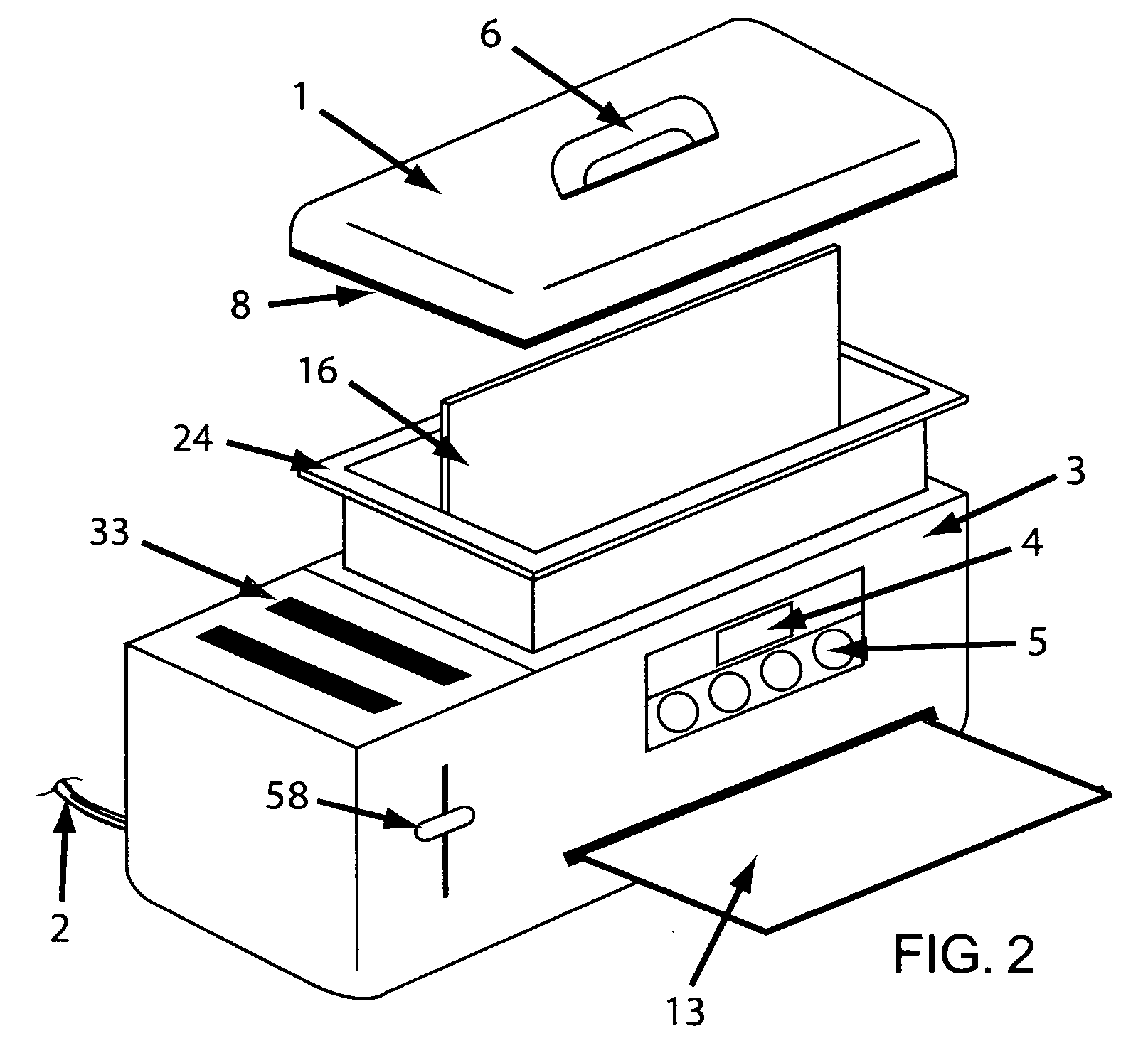

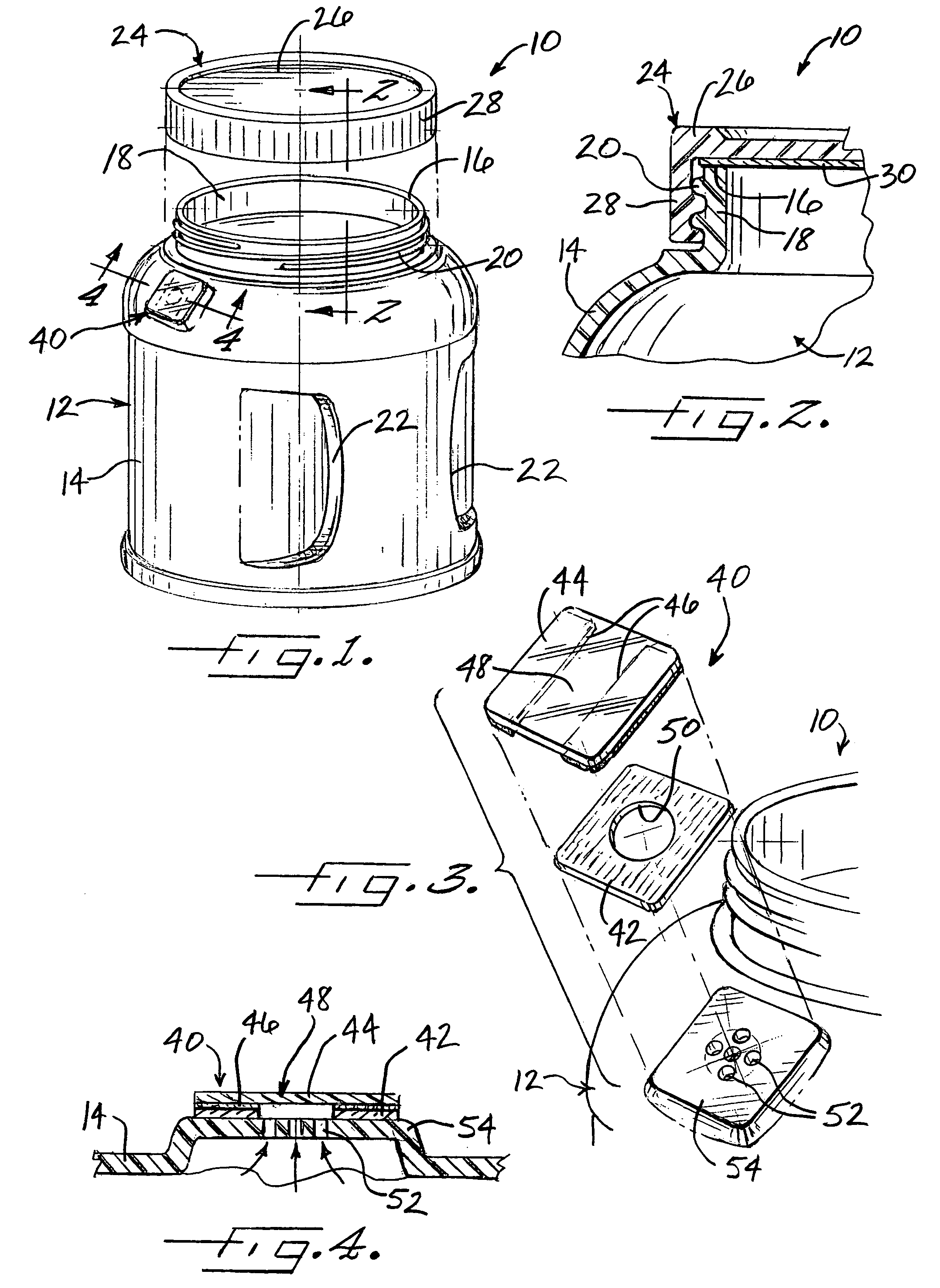

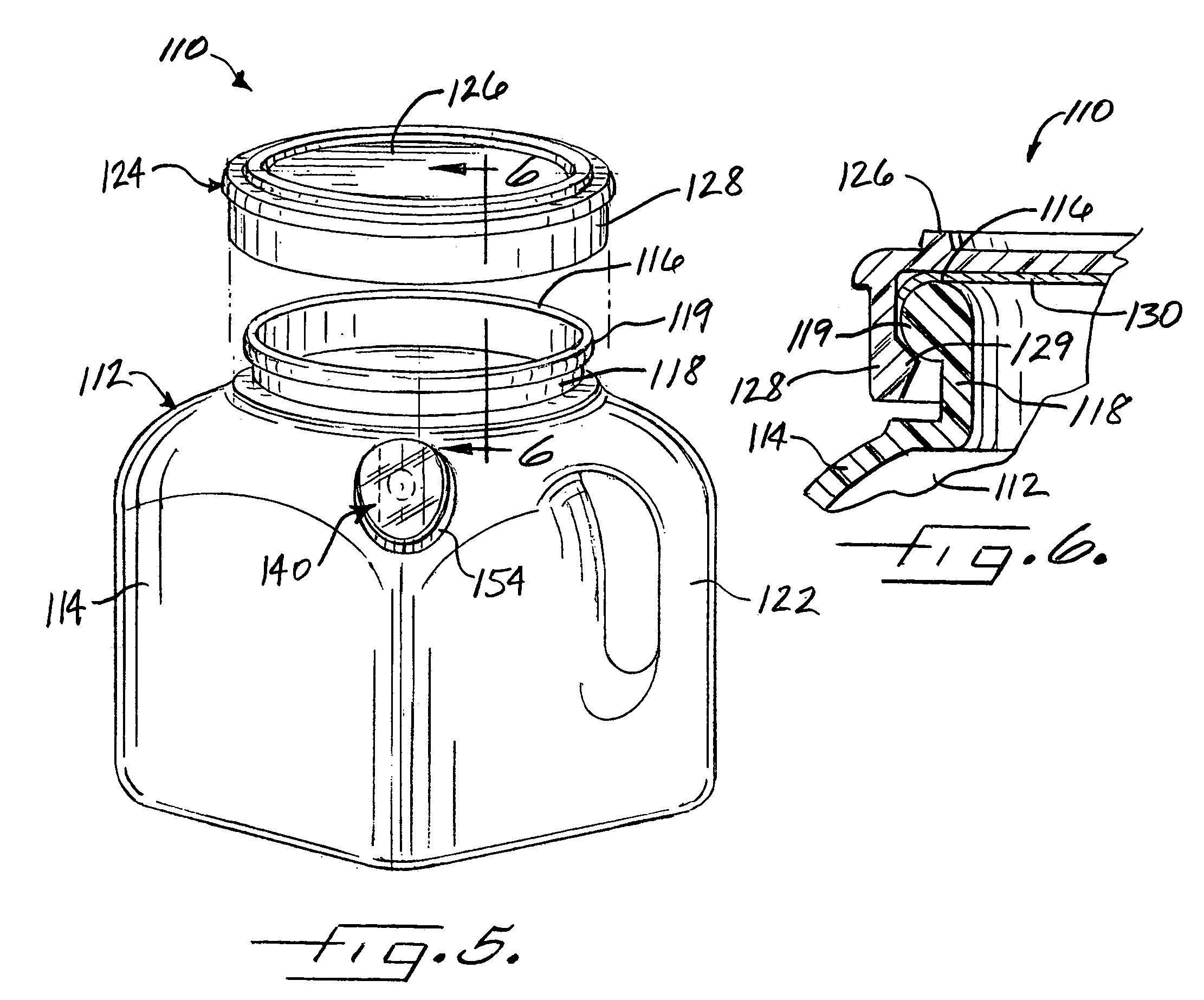

Container with gas release feature

A gas release container comprises a container body having a bottom wall and a side wall extending upwardly from the bottom wall and terminating at an upper edge, a removable closure affixed to the upper edge in a substantially gas-tight manner, and a gas release valve in a wall of the container body and operable to release gas from the container when the pressure differential between the interior and the exterior of the container is sufficient to open the valve. The removable closure can include a flexible gas-barrier membrane sealed to the upper edge of the container body. A lower surface of the membrane and the upper edge of the side wall comprise heat-sealable polymer materials, and the membrane is heat-sealed to the upper edge, preferably by induction sealing. The closure can include an overcap.

Owner:SONOCO DEV INC

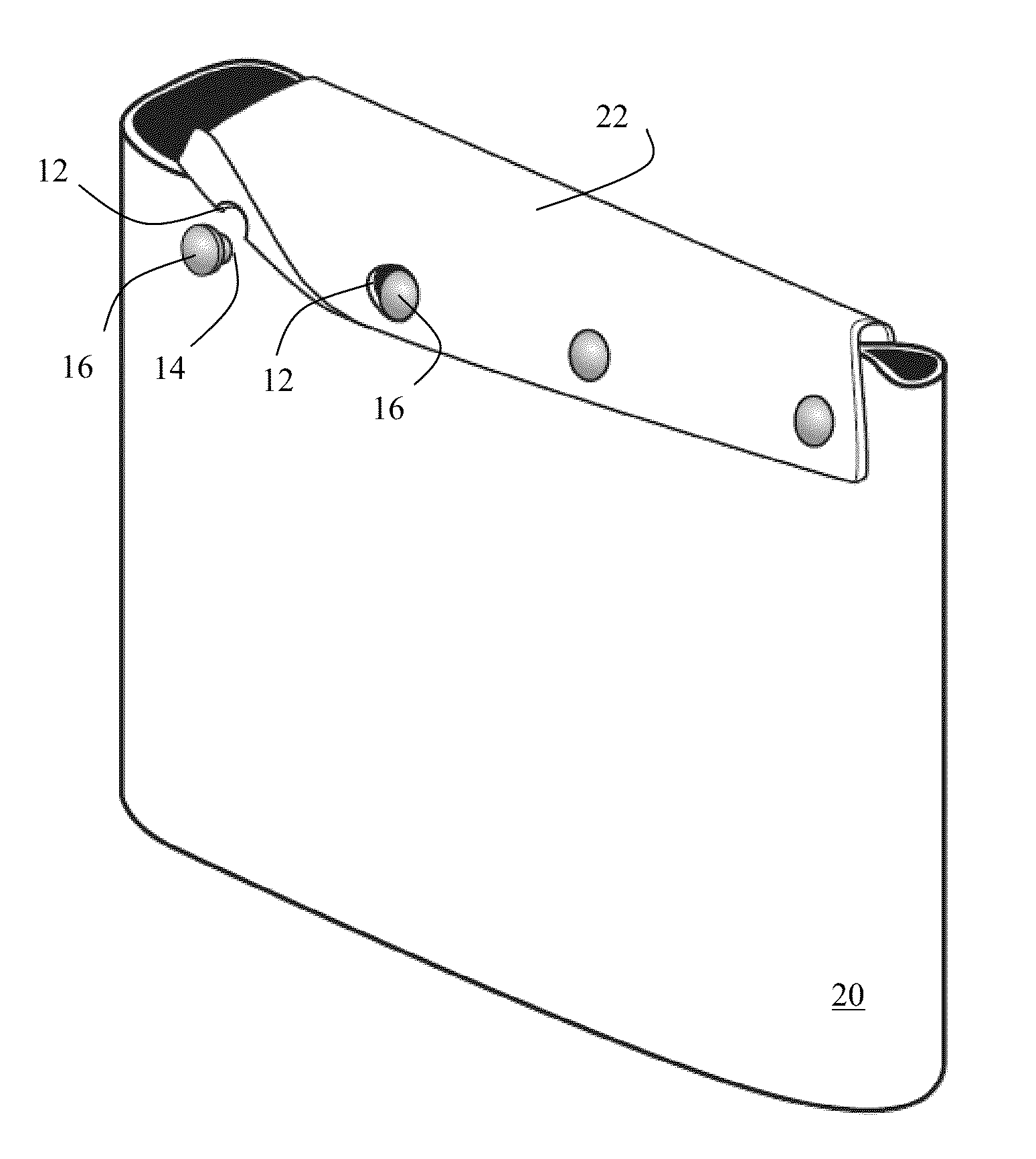

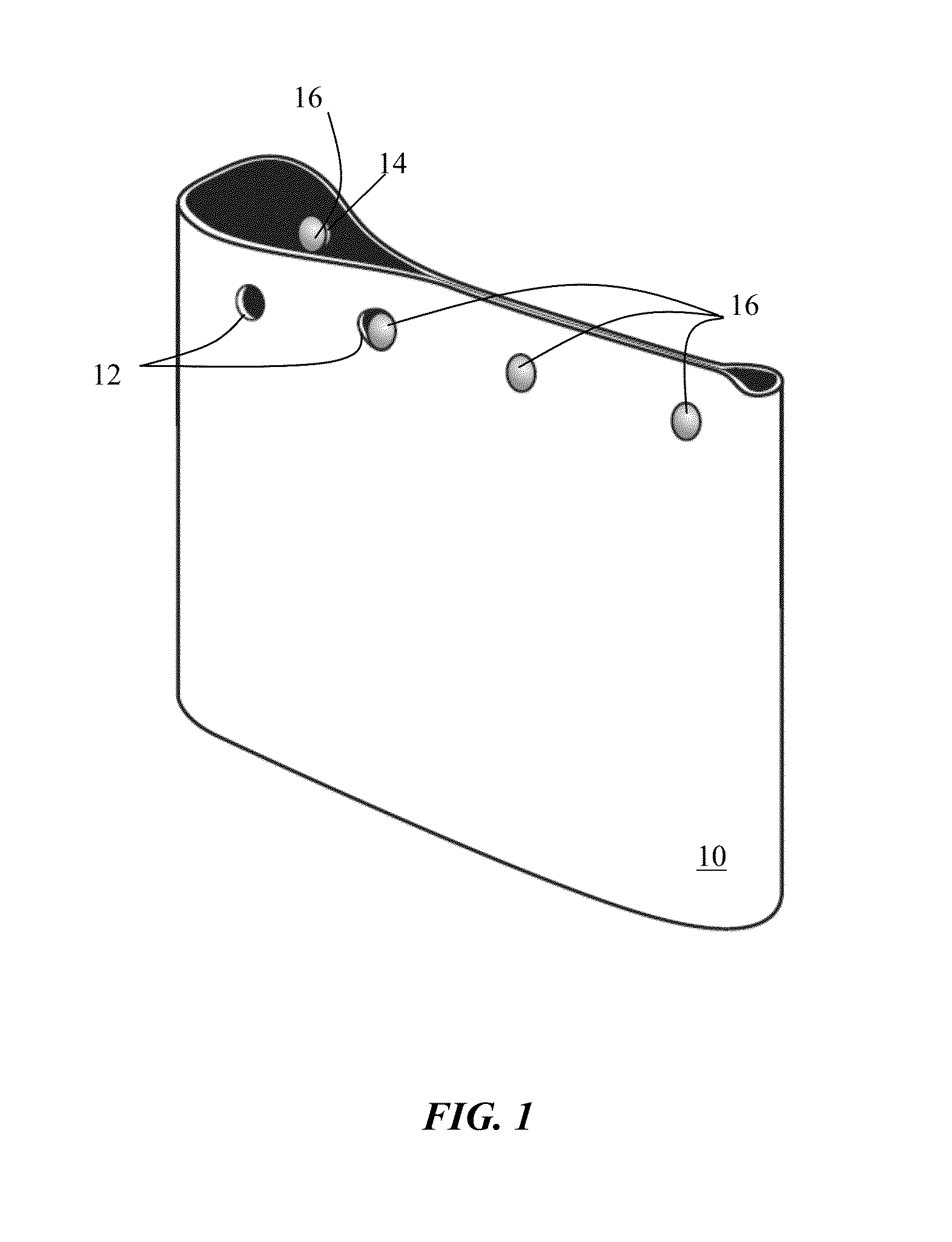

Food pouch

ActiveUS20140226921A1Less wastefulEasy to useClosuresClosure using stoppersIngested foodClosed state

A flexible pouch is provided. The flexible pouch includes a bottom section, vertical walls extending up from the bottom section to form a pouch defining an opening opposite the bottom section, and a closure mechanism including one or more projecting members and one or more receiving members dispersed around upper sections of the vertical walls proximal to the opening. In a closed state, a projecting member and a corresponding receiving member removably couple to at least partially close the opening. The flexible pouch can be used for food storage, for example.

Owner:LUFT IND

Microencapsulated fragrances and methods of coating microcapsules

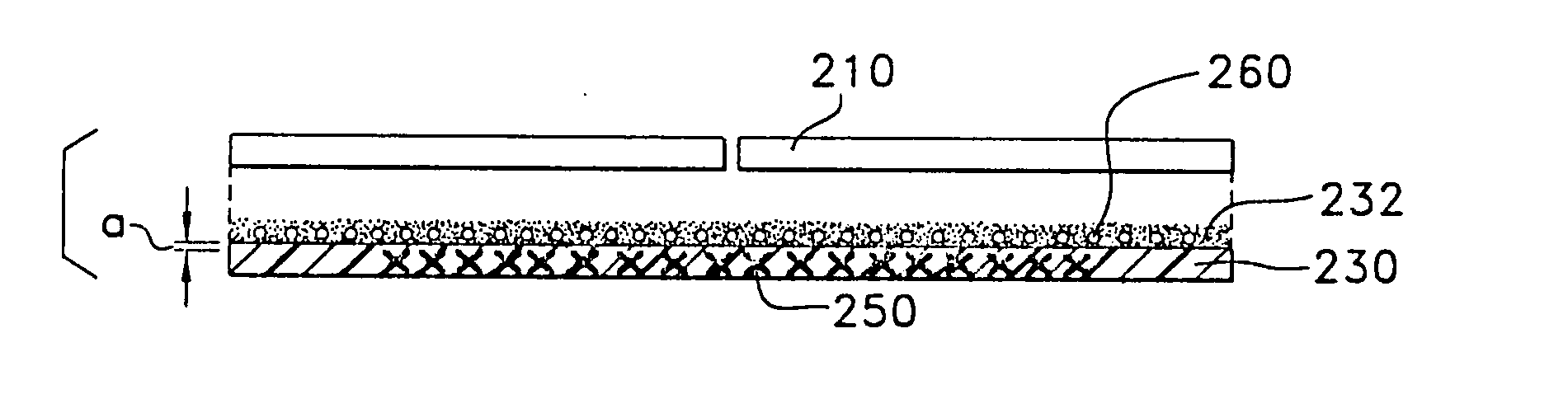

InactiveUS7011093B2Extending olfactory effectivenessMinimizing adhesive residueOrganic active ingredientsBreathing filtersTransdermal medicationPharmaceutical Substances

Nasal dilators and strips, methods of their manufacture, and methods for improving the breathing of individuals are provided. The strips and dilators include an elongated substrate, with or without a dilating component or portion, having top and bottom surfaces and a pressure-sensitive adhesive disposed on the bottom surface. The dilator is designed to provide a gentle expanding force to the nasal wall tissue when the dilator is adhesively attached to the nose. This invention further includes a cosmetic fragrance, an aromatic medication and / or transdermal medication disposed on the strips or dilators. In order to improve the shelf-life and in-use olfactory effectiveness of such products, fragrance delivery mechanisms are used. Separation of volatile oils and adhesives are also provided to minimize adhesive residue.

Owner:WINTER BREATH

Cyclopropene preservative and preparation method thereof

ActiveCN102119718AExtended storage timeImprove qualityDead plant preservationFruit and vegetables preservationPreservativeCyclopropene

The invention provides a cyclopropene preservative, which is characterized by containing 0.1 to 99 mass percent of cyclopropene coating material powder, 0.1 to 98 mass percent of compound, composition or material releasing water molecules, and 0 to 98 mass percent of one or more assistants. The invention also provides the preparation method and using method of the cyclopropene preservative. The preservative is convenient for use and has a remarkable preservation effect.

Owner:山东营养源食品科技有限公司

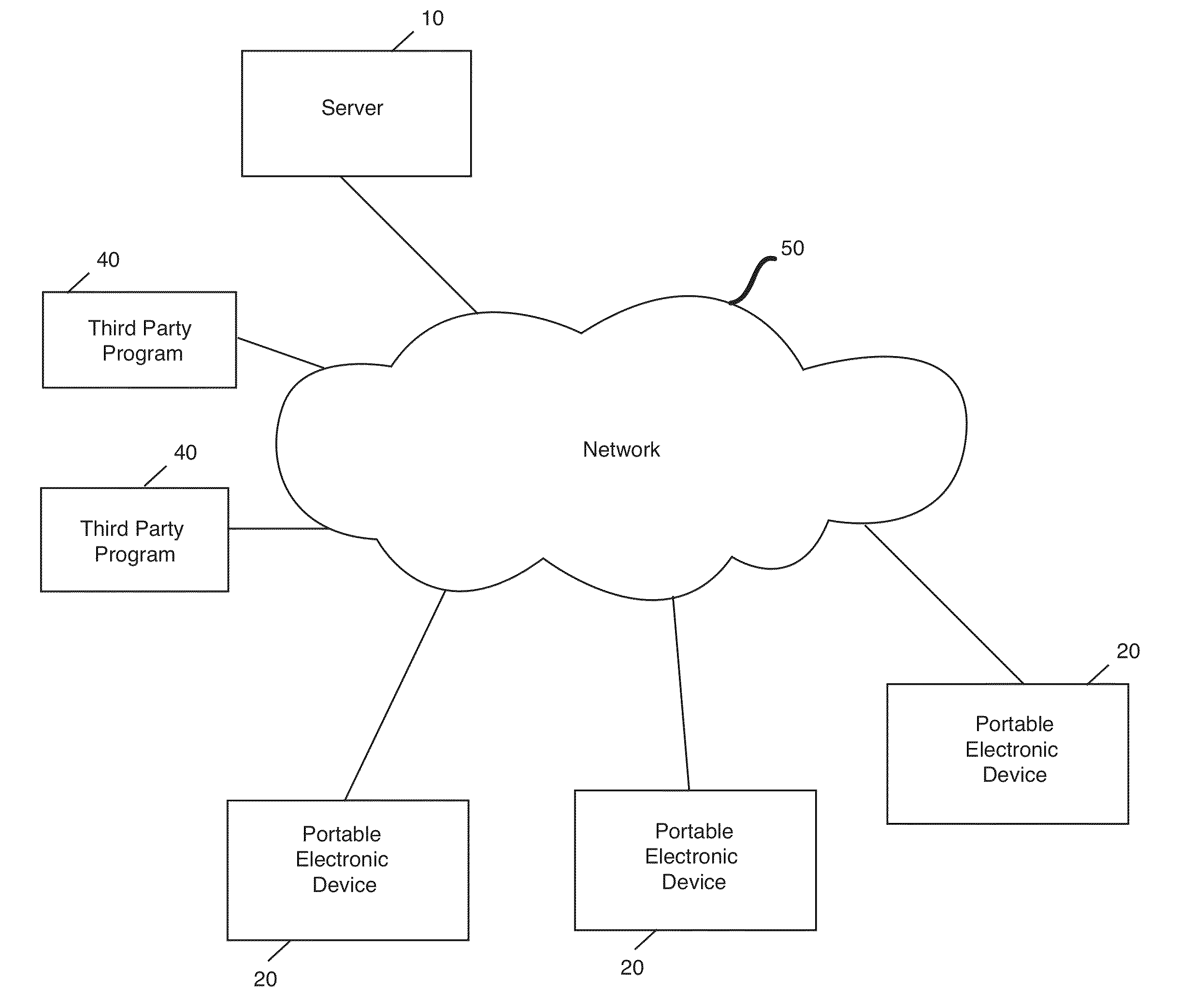

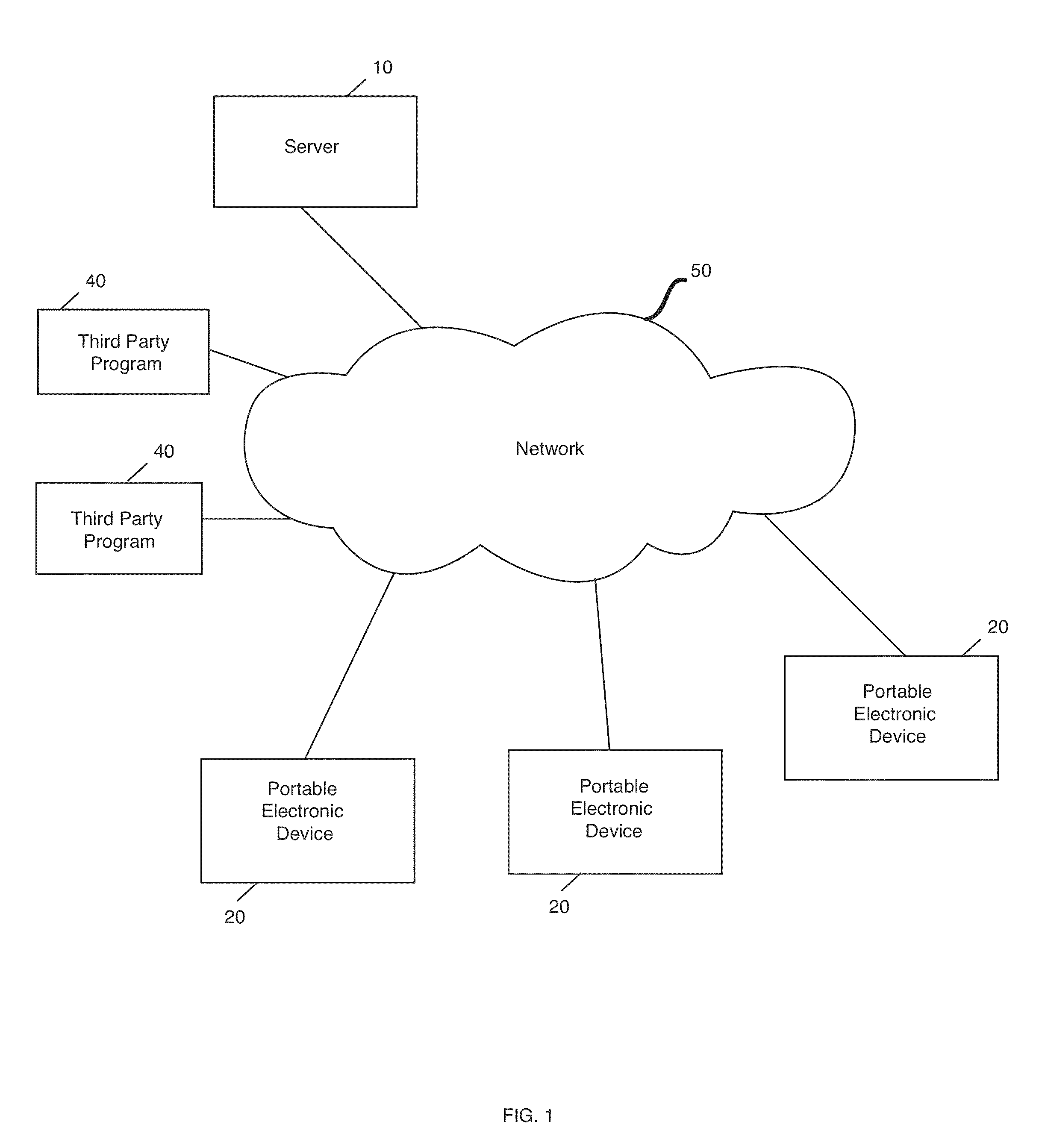

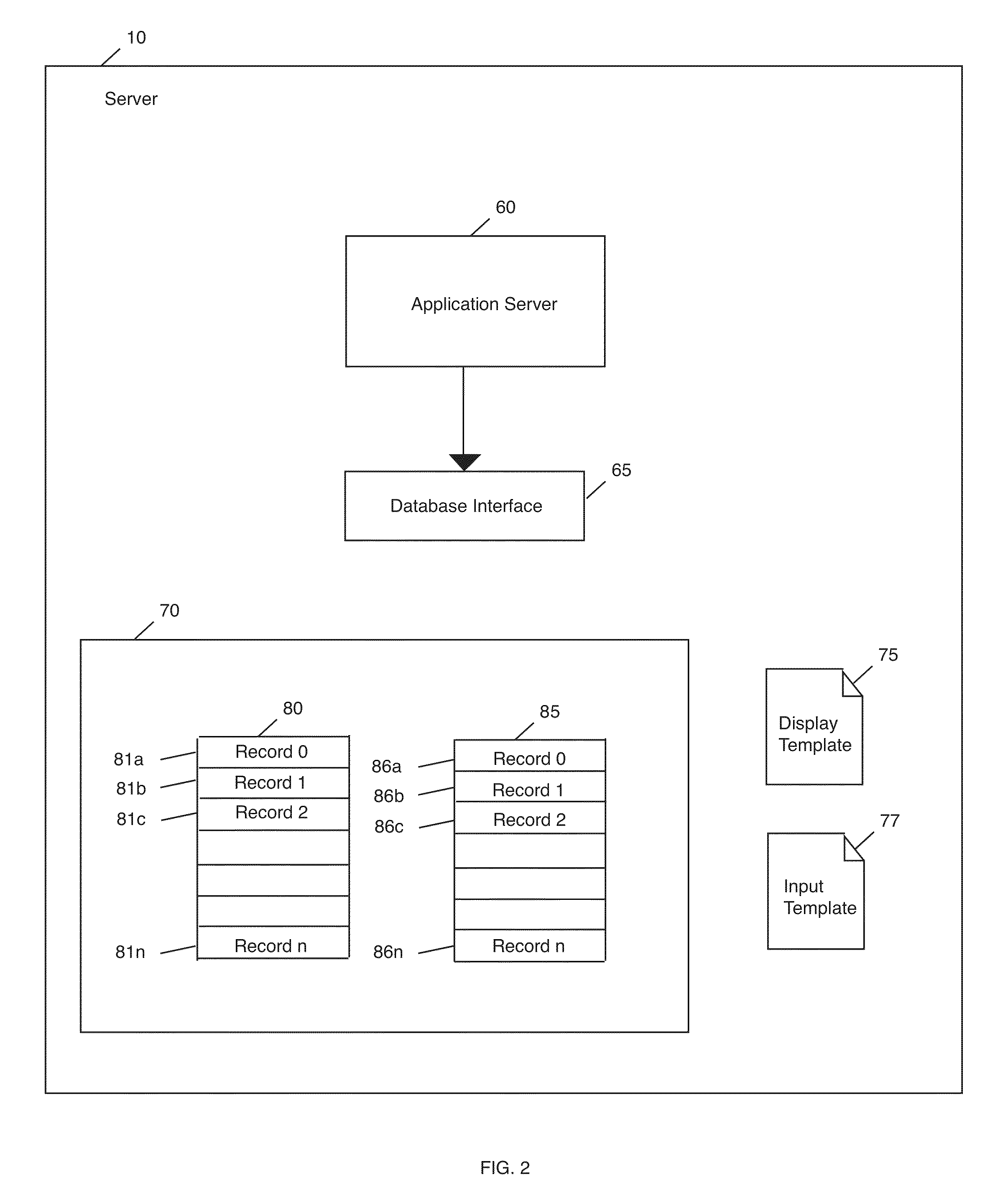

System and Method For Event Related Commerce Utilizing A Portable Electronic Device

InactiveUS20140046818A1Enhance event related experienceImprove experienceDiscounts/incentivesFinanceComputer scienceElectric equipment

Commerce for event related products can be enhanced by utilizing a portable electronic device. Event related products can be goods or services that can be related to any type of event (i.e. sporting events, business events, shopping events, etc.). Commerce can be the marketing, buying, and selling of event related products. The enhancement of commerce can also mean an enhancement of an experience or an improvement of an event related product. Event related marketing, buying, and selling can occur before, during, and after an event utilizing a portable electronic device such as cell phone, tablet, pda (personal digital assistant), etc. Utilizing a portable electronic device can enhance the commerce experience related to the event including for the event itself.

Owner:CHUNG SCOTT LEE +1

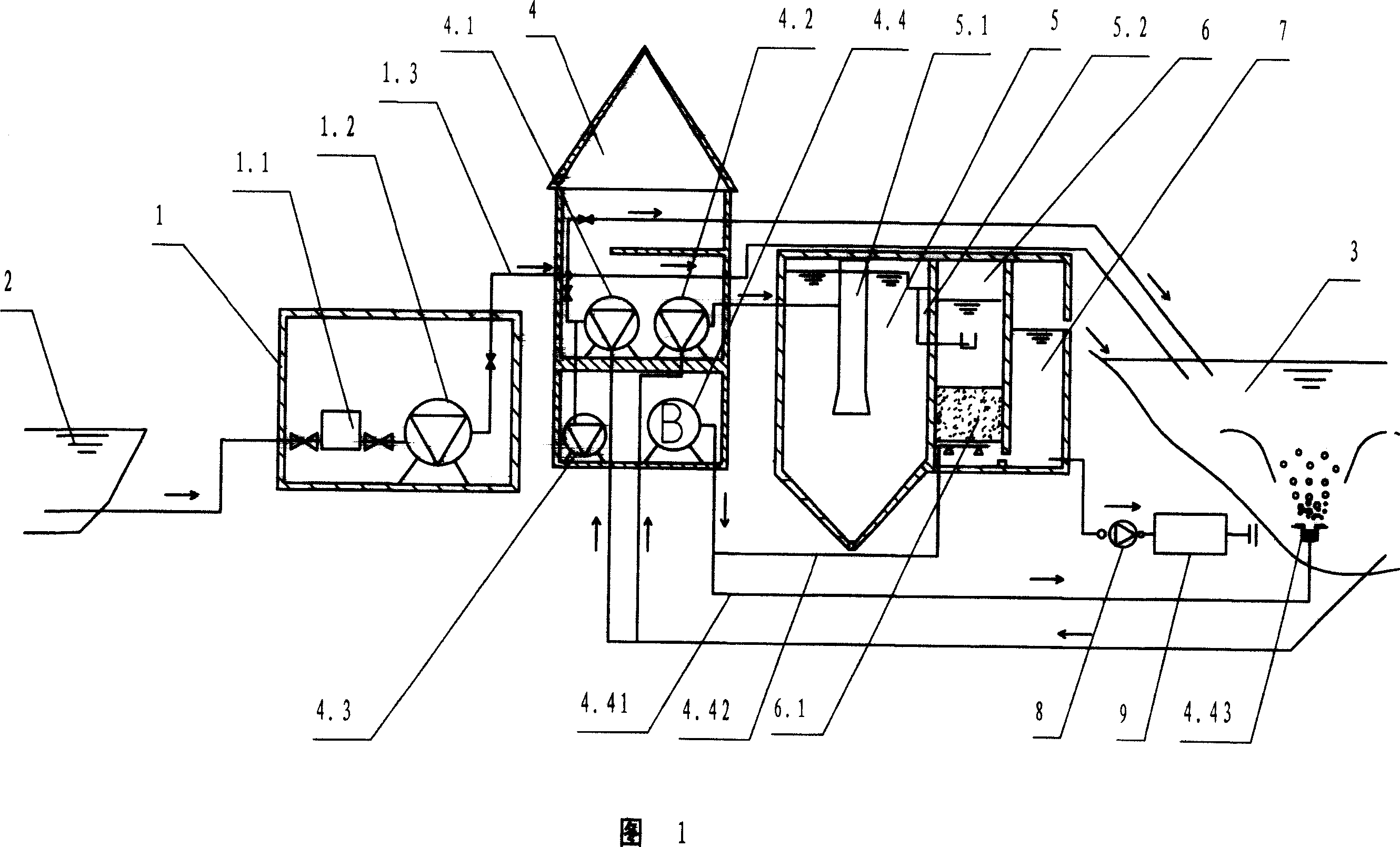

Water quality purification method in source-free water area and facilities

InactiveCN101041539AReasonable stockImprove water qualityWater cleaningWater aerationAutomatic controlPurification methods

The invention discloses a water purifying method of waterless source waters and device, which comprises the following steps: including recharge craft, hydrologic cycle craft, water quality physical disposing craft; water quality chemical disposing craft, accelerate vertical motion of water and aerate craft, rainwater collecting and purifying craft, ecological restoring craft and composite control device; proceeding automatic control; installing make-up water pump room, device room, element depositing tank, filtering tank, purifying tank, catch frame, pump, make-up water pipe, circulating pump, disposing pump, charging pump and air blower; installing make-up water pump room, device room, element depositing tank, filtering tank, purifying tank, clean water pump under floor.

Owner:BEIJING DRAINAGE GRP CO LTD

Reusable pizza pan set

ActiveUS9446889B2Facilitates rigidity and convective heat flow and condensation flowKeep freshPackage recyclingCapsHeat flowEngineering

A reusable pizza container configured to enclose a hot pizza for temporary storage or transport and to prevent moisture from entering into the top, bottom or side surfaces of the pizza. The container has a lid, a removable Vapor Transport Mechanism, and a bottom. The lid facilitates convection heat flow and the flow of moisture along the interior sides of the lid. Raised radial ribs enable the lids to be stacked. The raised radial ribs in the lid have perforations to allow hot vapor to escape and minimize moisture within the enclosed area. The lid nests securely into the bottom to prevent dislodging of moisture during transport. The removable Vapor Transport Mechanism (VTM), a micromesh membrane that fits within the lid, allows vapor to pass upwards through the membrane but prevents moisture from dripping downwards onto the upper pizza surface. The bottom has an interior moat that collects the moisture that flows along the interior sides of the lid to prevent it from entering the sides of the pizza thereby preventing moisture from entering the bottom surface of the pizza. The bottom has raised circular domes to elevate the pizza above the surface and to prevent moisture from entering the bottom surface of the pizza.

Owner:LOPES SUSAN +1

Water soluble preservative film for fruits and vegetables and preparation method of preservative film

ActiveCN102898668ASuitable for freshnessSuitable for storageFruits/vegetable preservation by coatingPolymer sciencePolyvinyl alcohol

The invention relates to a water soluble preservative film for fruits and vegetables and a preparation method of the preservative film. The water soluble preservative film for the fruits and vegetables is mainly prepared by the following materials in percentage in weight: 50 to 80% of polyvinyl alcohol with alcoholysis degree of less than 90%; 10 to 30% of polyhydroxy plasticizer, 1 to 5% of auxiliary film forming agent, 3 to 8% of low temperature antifreeze agent, 3 to 10% of adsorbent filling agent and 0.3 to 2% of film-forming adding additive. The preparation method comprises the following two steps of: 1, after metering contents of components of the preservative film in the formula, obtaining a uniform aqueous solution with concentration of 15 to 25% in water; and 2, uniformly casting the prepared solution on a clear steel band, and drying the solution to obtain the film through a dried drying tunnel with temperature of 120 to 180 DEG C. The preservative film has a high barrier property against oxygen, carbon dioxide and nitrogen and the like, and has a high bidirectional permeable exchange capacity for steam, thereby guaranteeing free breathing and water exchange of the fruits and vegetables in a preserving process.

Owner:深圳市乾健科技有限公司

Preparation method of non-woven fabric for shoe linings

InactiveCN105019143AEasy extractionIncrease relative volatilityInsolesNon-woven fabricsActivated charcoal powderAfter treatment

The invention relates to the field of preparation of non-woven fabrics for shoe linings and discloses a preparation method of non-woven fabric for shoe linings. The preparation method comprises following steps of: (1) taking and adding natural perfume to water, adding sea-foam stone powder to a solution, allowing mixed liquor to stand and obtaining sea-foam stone powder loaded with natural perfume by centrifugal and drying treatment; (2) additionally taking activated charcoal powder, aluminum chloride, polyoxyethylene, carboxymethylcellulose, dispersants, silane coupling agents and sea-foam stone powder loaded with natural perfume in order to obtain a mixture; (3) fusing isotatic polypropylene slices and the mixture and performing spinning, drawing, web-forming and hot-rolling operation in order to obtain base cloth of the non-woven fabric; (4) utilizing finishing liquor to process one of surfaces of the base cloth of the non-woven fabric and performing roll-pressing operation on the base cloth after treatment; (5) drying the base cloth of the non-woven fabric subjected to roll-pressing operation and thus obtaining the non-woven fabric for shoe linings. The preparation method of non-woven fabric for shoes is good in deodorization function and breathability and high in hardness so that the shape of a vamp can be kept for a long time.

Owner:LANXI YIMING WEAVING

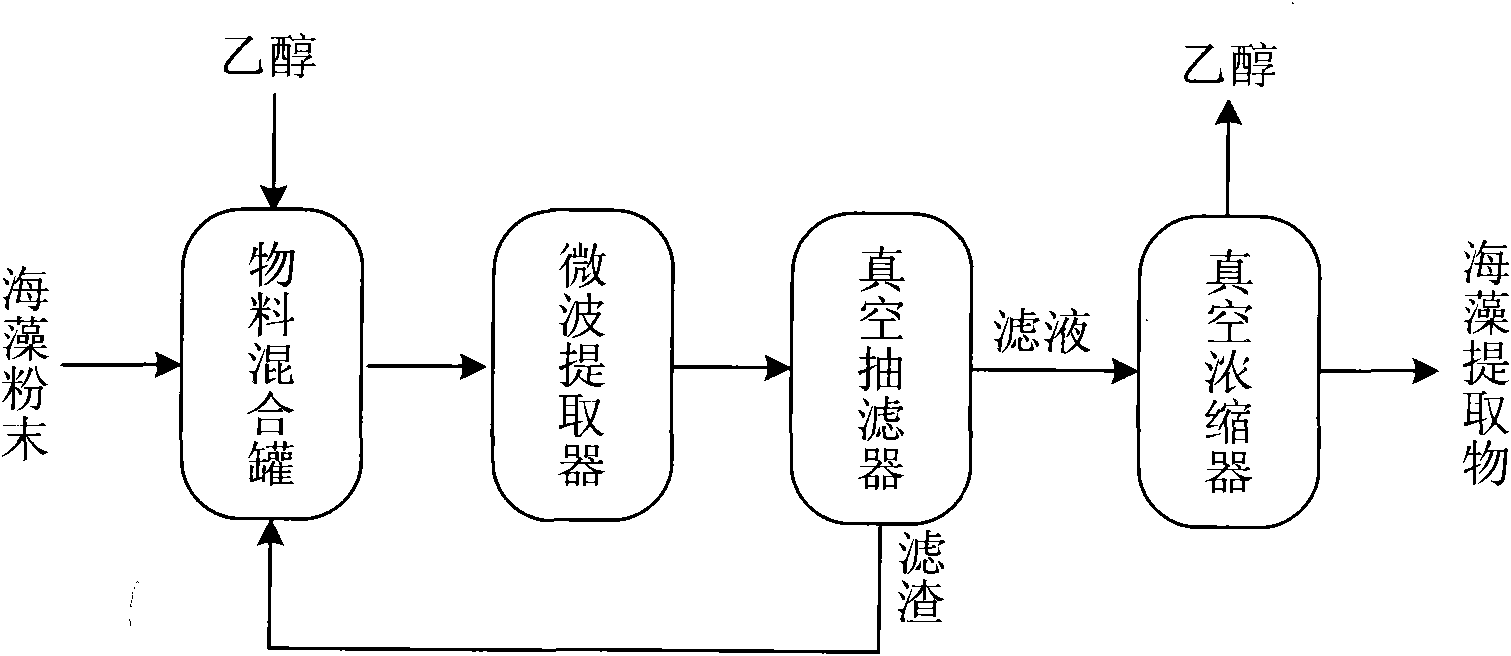

Seaweed flavor powder

The invention relates to edible seaweed, in particular to a seaweed flavor powder, and the flavor powder consists of 50 parts by weight of seaweed extract, 25-100 parts by weight of modified starch or / and dextrin and 1-5 parts by weight of emulsifier, wherein the emulsifier is glycerel monostearte or / and sucrose ester; the modified starch is crosslinked starch or / and gelatinized starch; and the seaweed extract is prepared by carrying out continuous microwave extraction on the edible seaweed by adopting 70-100% of ethanol. The seaweed flavor powder can retain aroma and taste of the seaweed and has the unique flavor of fresh, sweet, salty and fragrant. The seaweed flavor powder can be used as seaweed tea and seaweed soup, or be used on the surfaces of biscuits, cakes and bread or be added therein, or be added into dry noodles and instant noodles for producing foods with seaweed flavor.

Owner:GUANGZHOU UNIVERSITY

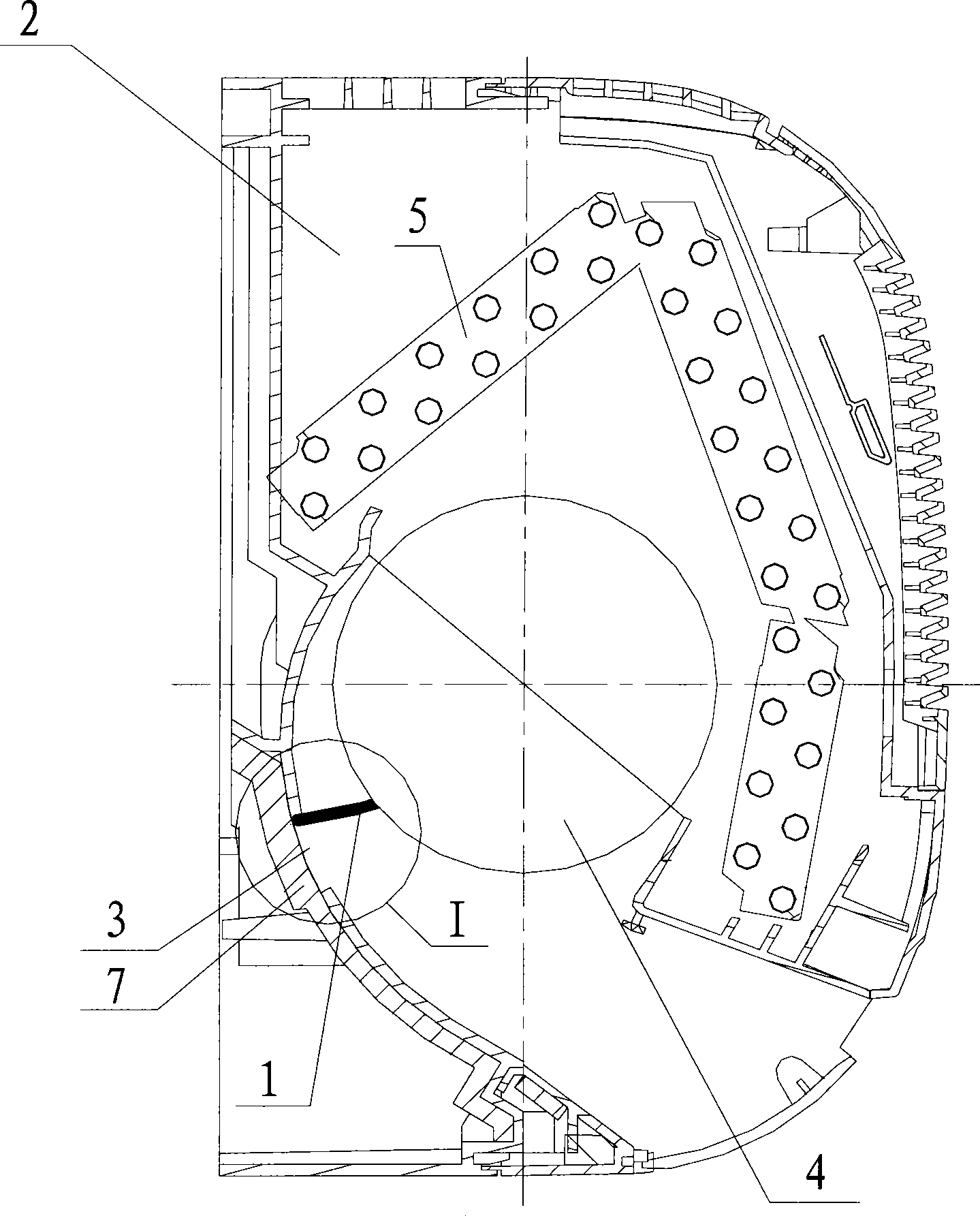

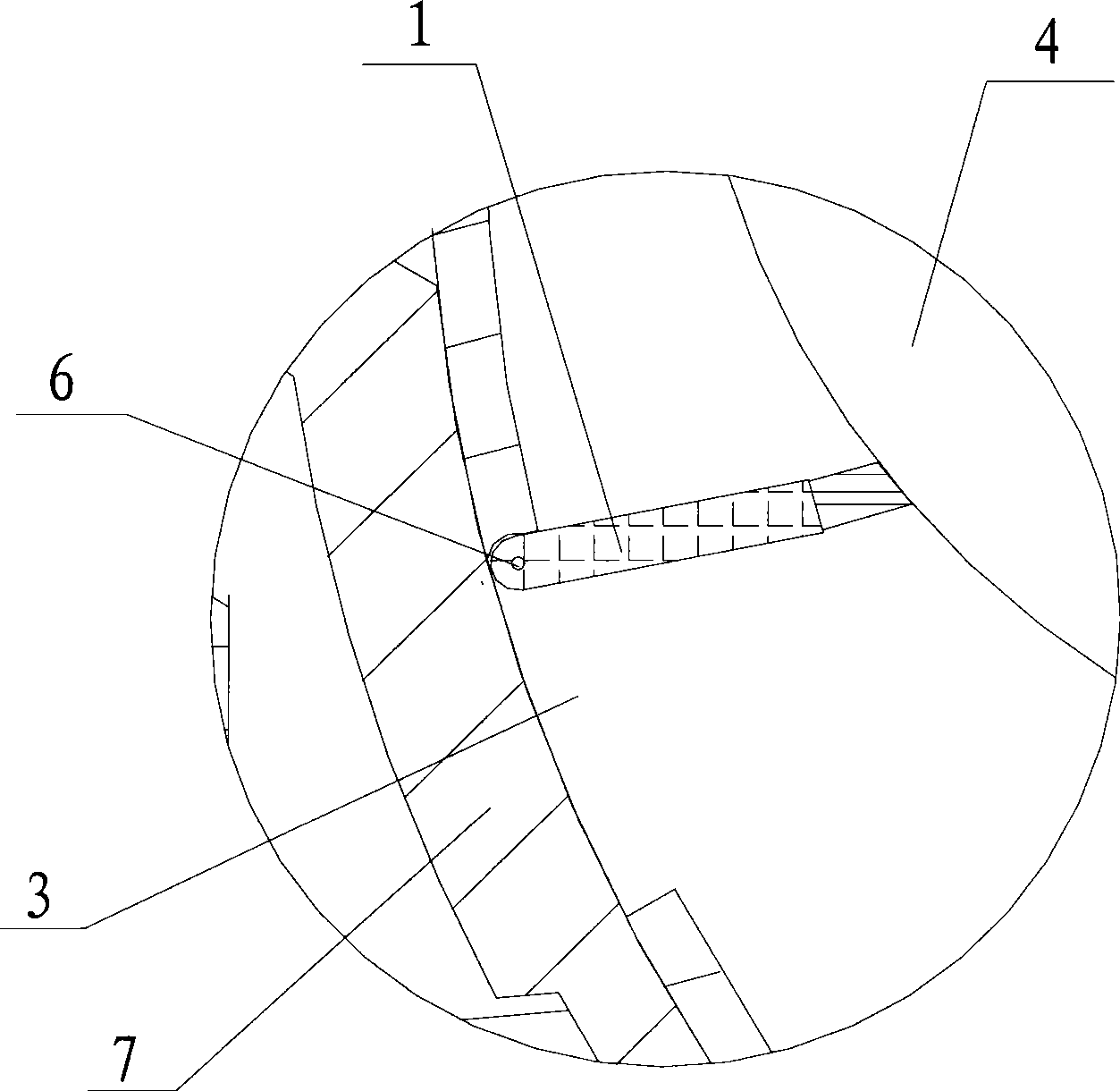

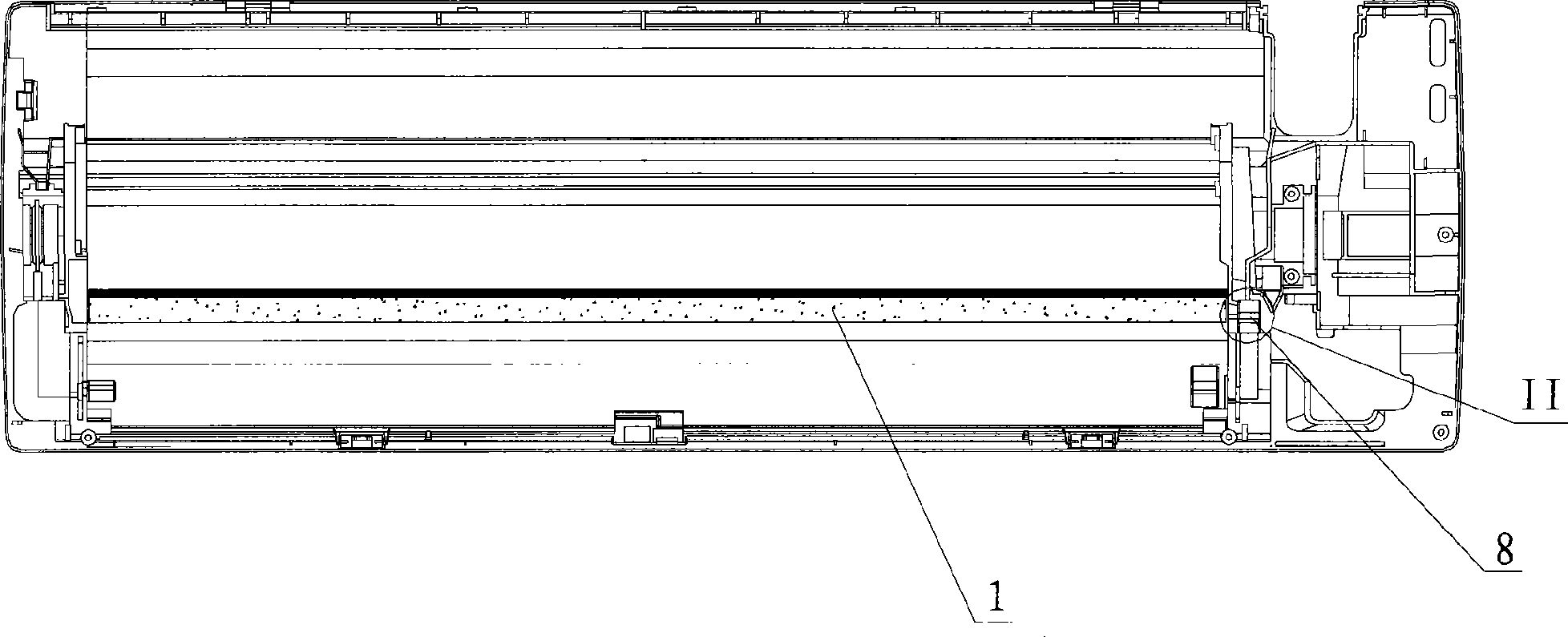

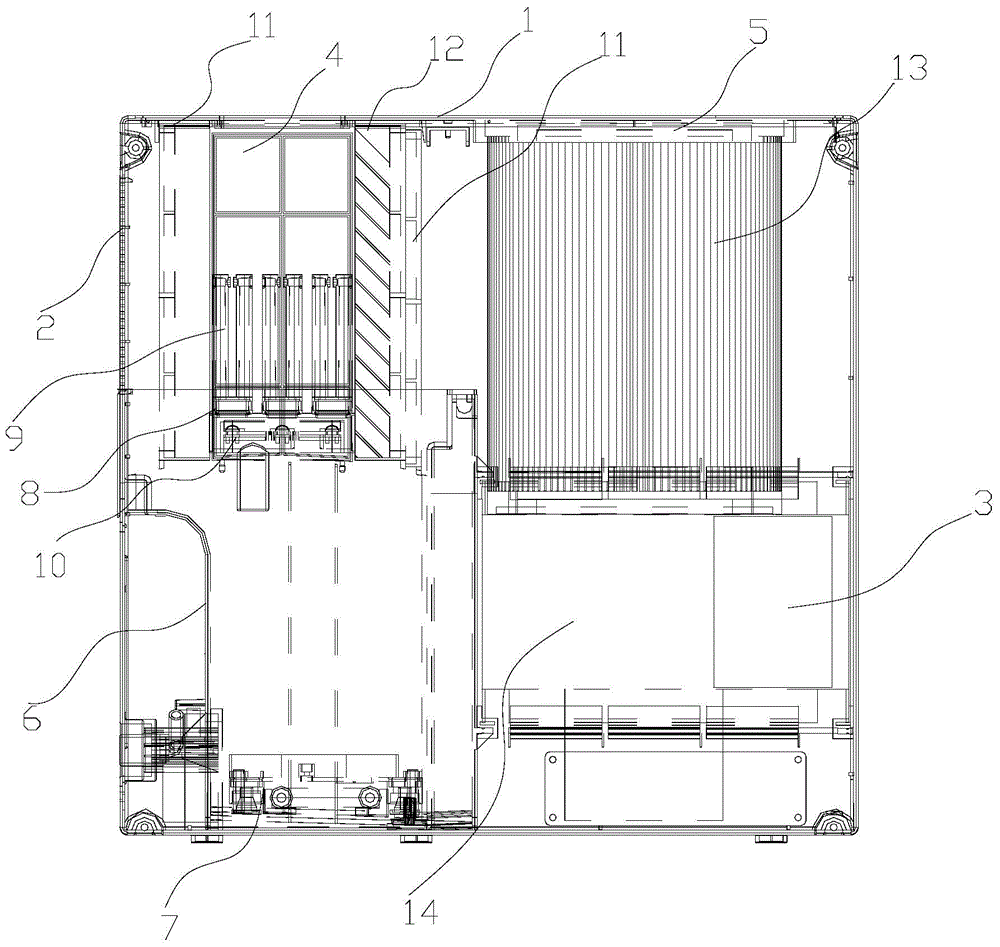

Air conditioner with automatic indoor unit fan cleaning function

InactiveCN101498481AImprove working conditionReduce loadLighting and heating apparatusSpace heating and ventilation detailsTransverse planeFresh air

The invention provides an air conditioner which has the function of automatically cleaning an indoor unit fan and is capable of solving problems caused by dust accumulation of a fan in the prior art. The air conditioner comprises an indoor unit, an indoor unit base and a fan and is characterized in that the indoor unit base is provided with a cleaning brush for cleaning the fan and a driving motor for driving the cleaning brush, and the cleaning brush is connected with the driving motor. When the tangential fan needs cleaning, a transverse air plate is closed, a fresh air exchanging fan is started, and the air conditioner operates in an air supply mode. When cleaning brush contact with the fan, the dust on the fan is cleared by the cleaning bush operating for a certain time.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

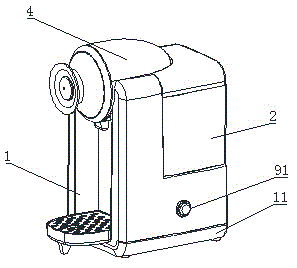

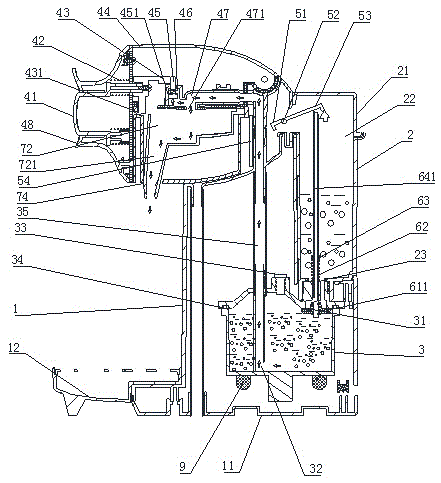

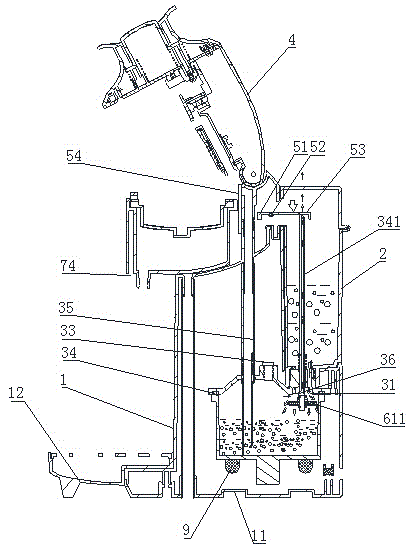

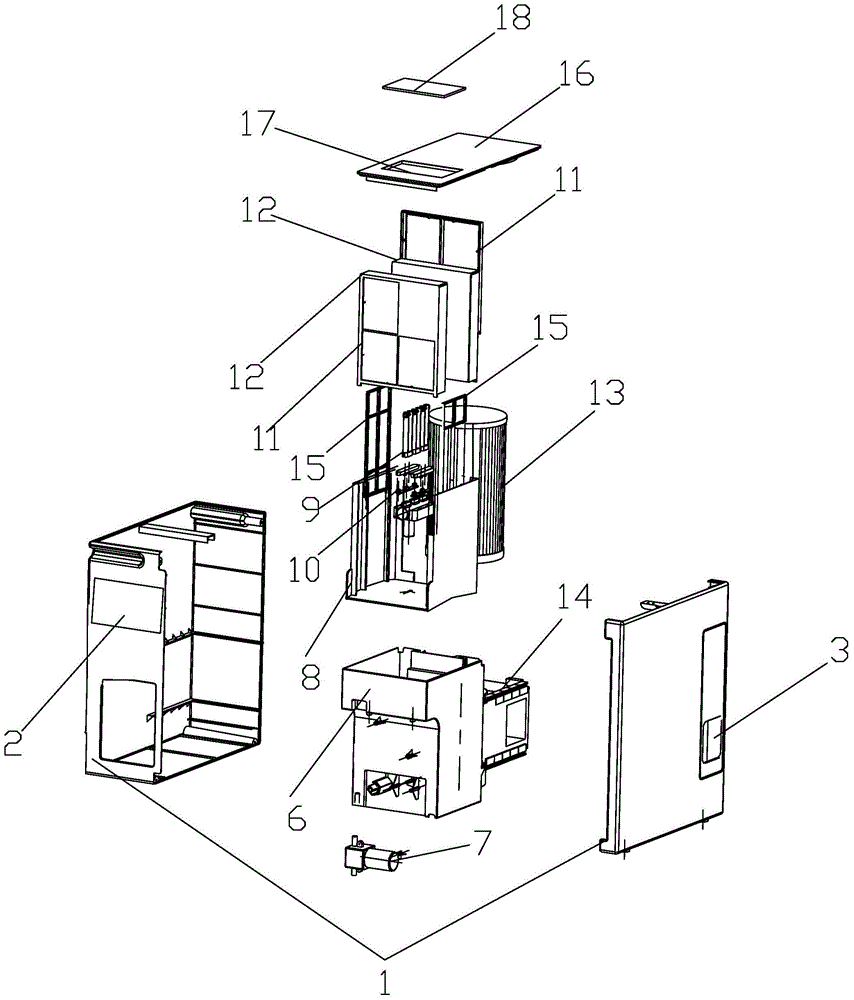

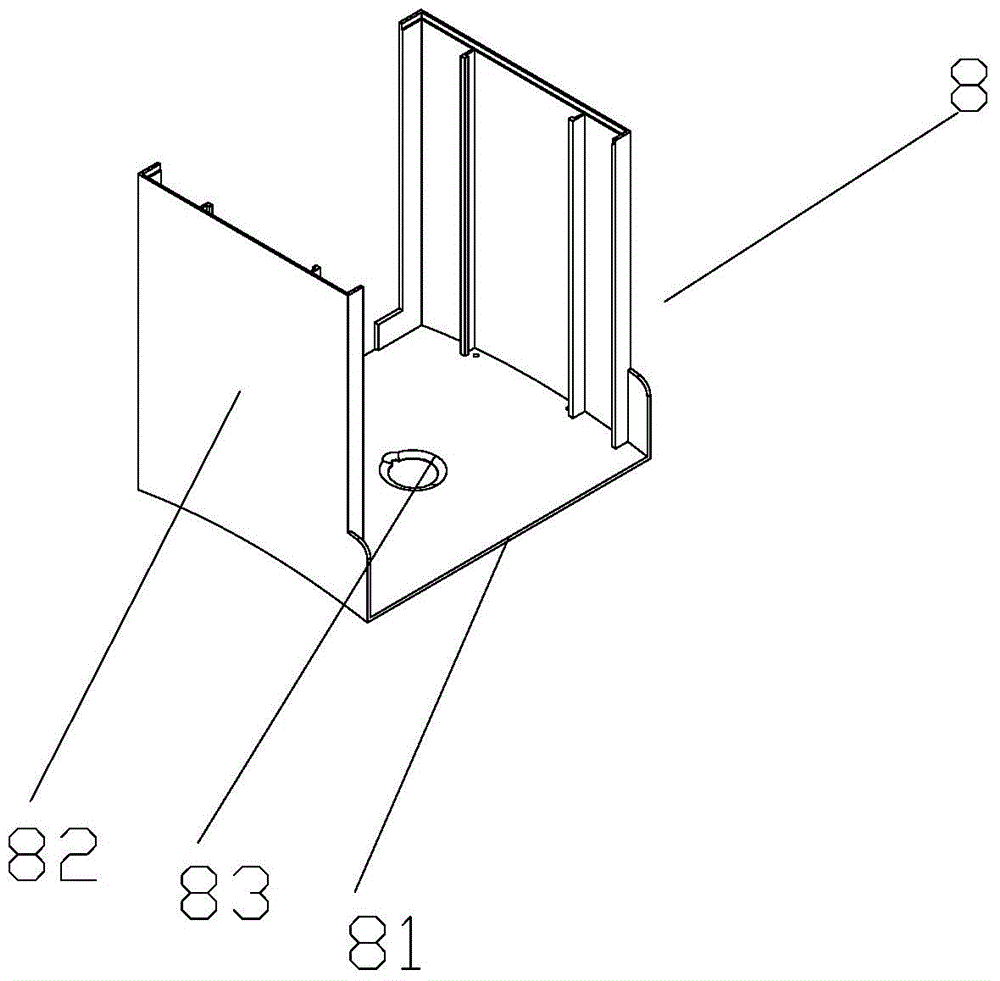

Indoor air purifier

InactiveCN104534583AKeep freshReduce use costMechanical apparatusLighting and heating apparatusIndoor airWater pipe

The invention discloses an indoor air purifier. A water washing zone and an air filter zone are arranged in a shell along the air inlet direction; the water washing zone is provided with a spraying device, the spraying device is connected with a water pump through a water pipe, the spraying device comprises at least one group of spraying structure composed of two spraying pipes, the spraying pipes are communicated with water pipes, water spray holes are formed in the spraying pipes, and the water spray holes in the two spraying pipes of the same spraying mechanism are opposite in position; the air filter zone comprises an air filter barrel with one closed end and a centrifugal fan, the open end of the air filter barrel sleeves the air inlet of the centrifugal fan, and the air outlet of the centrifugal fan is opposite to the air outlet of the purifier. According to the air purifier, dust particles in the air which passes through the water washing zone are effectively removed, the air filter barrel is capable of further filtering the washed air to remove the toxic and harmful gas incapable of being removed by water, the purified air is clean and fresh, and the use cost of the purifier can be effectively lowered.

Owner:苏州盟通利环境科技有限公司

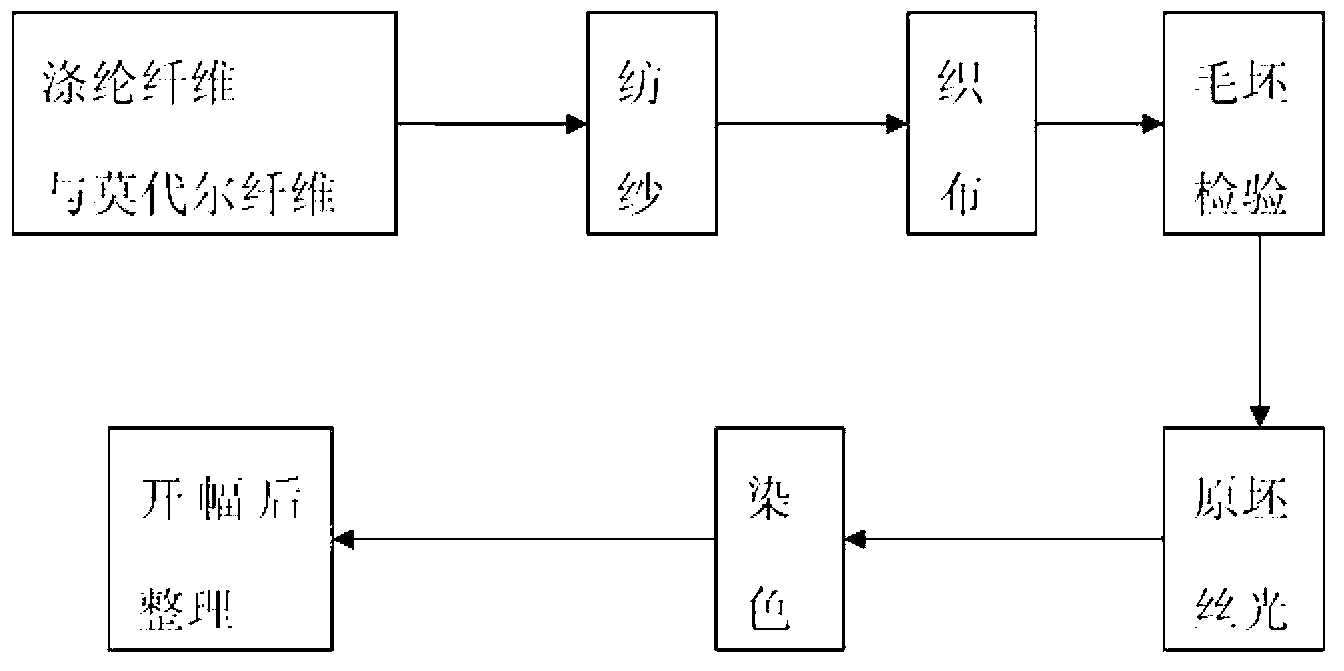

Blending silky single jersey cloth of polyester fiber and modal fiber and preparation method thereof

ActiveCN103173916ABright colorGood moisture conductivityMercerising of indefinite length fabricsWeft knittingAnti wrinklePolyester

The invention relates to blending silky single jersey cloth of polyester fiber and modal fiber and a preparation method thereof. The polyester fiber and the modal fiber serve as raw materials and the single jersey cloth is prepared. According to weight percentages, the raw materials comprise 55% to 75% of the polyester fiber and 25% to 45% of the modal fiber. The cloth is glossy like silky cloth, bright in color, anti-fade after being washed for a plurality of times and good in wet permeability. The knitted cloth blended with the modal fiber has good wet permeable effect and is widely used for sewing top grade T-shirts and sportswear, sweat generated when a person does exercise can be discharged to surfaces of clothes rapidly and be evaporated, the skin stays fresh and cool and the exercise can be done comfortably. The size of the cloth is stable, hanging down feeling is good, the cloth is stiff and smooth, anti-wrinkle performance is good and teasing, pilling and wrinkling do not occur.

Owner:GAOMI FUYUAN PRINTING & DYEING

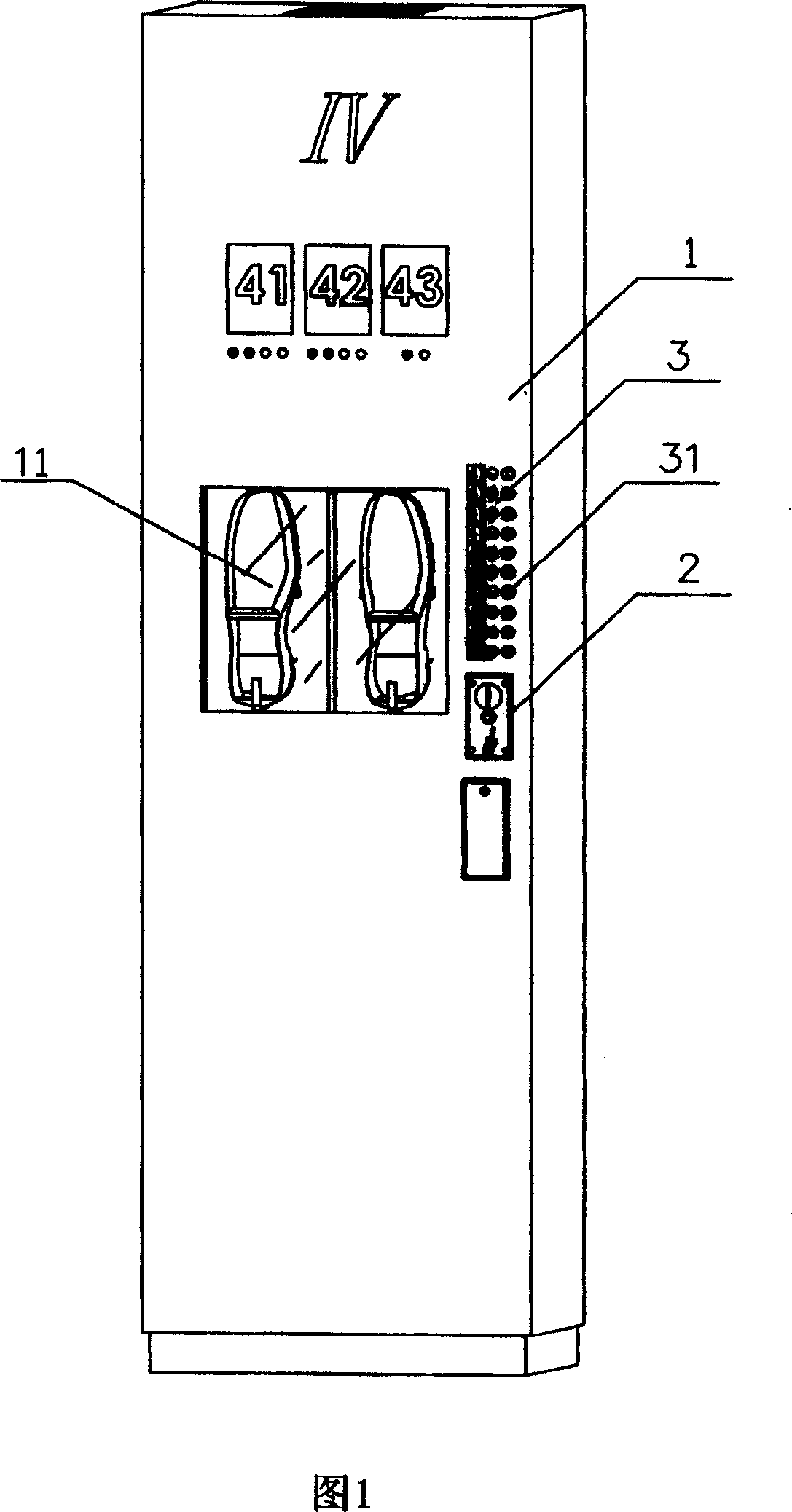

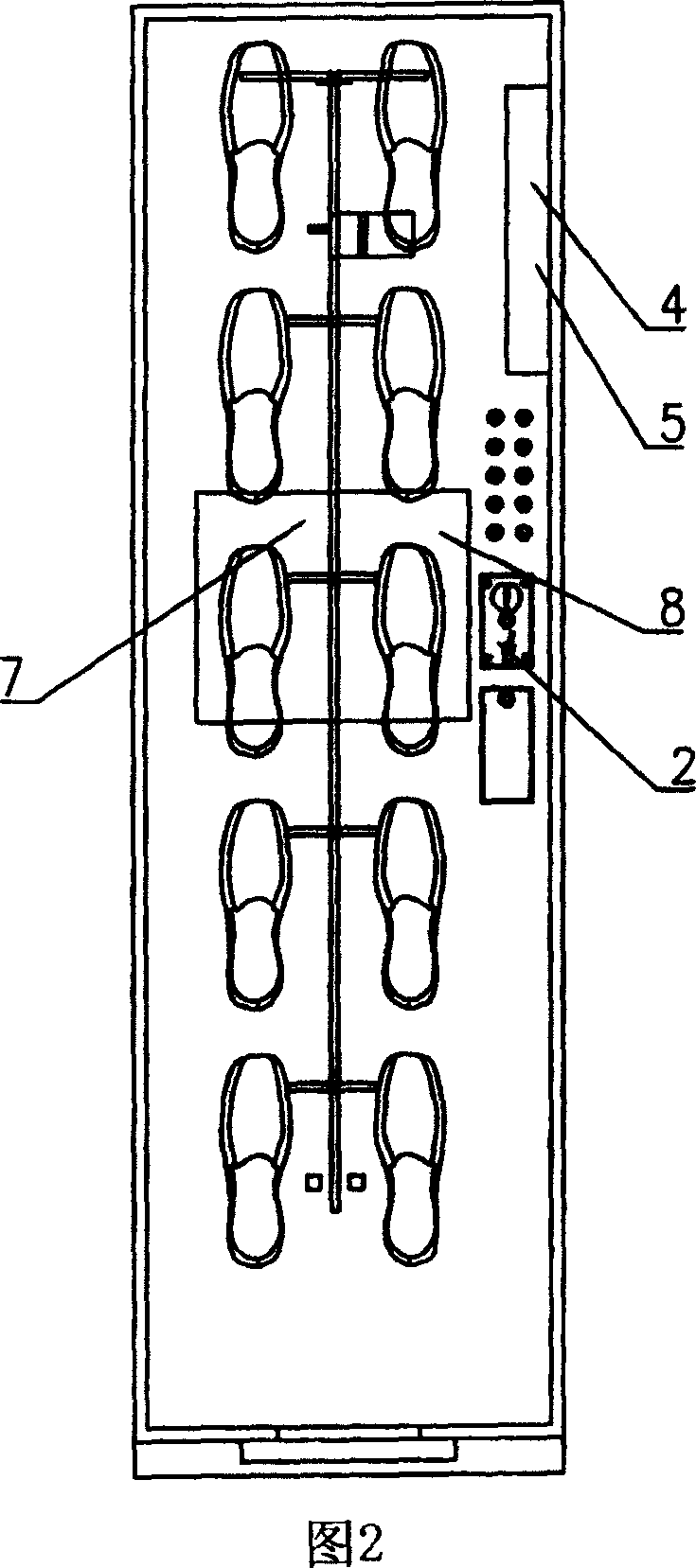

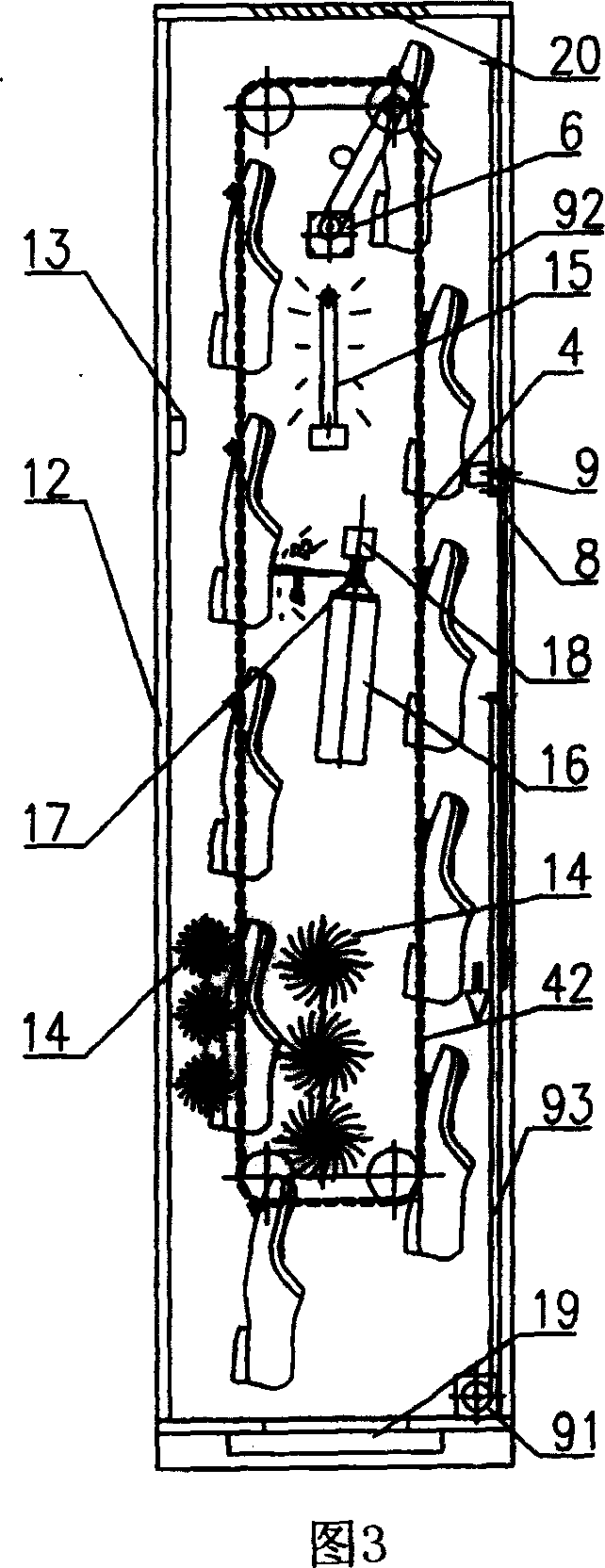

Automatic shoes box

InactiveCN101057732AEasy accessEasy access to shoesWardrobesFootwear cleanersKey pressingElectricity

The invention relates to an automatic shoe chest, comprising one chest body, driving device and motor running driving device and controlling units, a plurality of same or different shoe hanging parts installed on driving device; shoe taking port and selection button unit on chest body. The controlling unit is electrically connected with button unit and can control driving device operation according to selection button unit input, and convey various shoes to shoe taking port correctly. The chest body is also equipped with shoe-cleaning device, disinfecting device and deodorizing device. The device can be installed in bowling bowl stadium, badminton stadium and table tennis stadium and other sport places, the exercisers can get needed shoe only by inputting relevant information, and the changed shoes can be placed on shoe hanging parts.

Owner:上海中路实业有限公司

Production method of instant day lilies

The invention relates to a production method of instant day lilies. The production method comprises steps as follows: raw material selection; soaking; cleaning; fixation; cooling: placing fixed day lilies in an ice-water bath containing edible acetic acid for quick cooling; cold air dehydration: placing cooled day lilies in a shaking type airing bed and cold-airing the day lilies with air of an air cooler for 30-50 min to remove part of moisture; material mixing; sterilization, packing and the like. The day lilies are soaked with proper amounts of edible salt and citric acid for color protection, then high-temperature steam (103-108 DEG C) is used for fixation and enzyme deactivation, and browning of the day lilies and product pollution are avoided; the temperature of the day lilies is quickly decreased to 4-8 DEG C with an acetic acid aqueous solution ice-bath technology, the original color and nutria ingredients are kept, and the instant day lilies are easy to store and convenient to carry, have advantages that the day lilies are convenient to eat, safe, tasty, efficient to absorb, suitable for people of all ages and the like and have higher promotional value.

Owner:XIHUA UNIV

Method for preparing salted fish

The invention relates to a preparation method of salted fish, which comprises the following processing steps: preparing raw material fish; unfreezing, washing and finishing raw material fish; preparing seasonings; salting; roasting; cooling; and packaging to obtain finished product. The formula of the salting raw material, based on 1 kilogram of fish, comprises 10 to 15 grams of gourmet powder, 20 to 35 grams of white spirit distilled grain, 25 to 65 grams of chicken essence, 0.2 grams of Taomeisu (colour former), 0.2 grams of Yimeise (seasoning), 20 to 60 grams of table salt, 0.4 to 0.6 grams of raw ginger powder, 15 to 25 grams of white sugar, 15 to 25 grams of star anise, 2 to 4 grams of cassia bark, 10 to 15 grams of fennel fruit, 6 to 15 grams of mint and 0.1 to 0.5 grams of potassium sorbate. In the invention, the salting raw material combines the fennel fruit, cassia bark, star anise and mint components, and the effects of the components produce a synergetic effect to remove the mud smell in the fish, add unique fragrance to the fish and enable the fish to exert the effects of dispelling cold, removing damp, tonifying stomach, dispelling cold in stomach, regulating qi and tonifying spleen; and the salting process, the salt, gourmet powder, white sugar, raw ginger powder, chicken essence, Taomeisu and Yimeise are added, so that the color of the salted fish is bright, the meat is fresh and delicious, the fragrance is strong, and the fish is chewable and good for health.

Owner:HANGZHOU BAXIAN FOWLS

Ice temperature fresh-keeping method for bred large yellow croaker

InactiveCN101695313AImprove freshnessAdd flavorMeat/fish preservation by freezing/coolingFlavorFresh fish

The invention discloses an ice temperature fresh-keeping method for bred large yellow croaker, which comprises the following steps: pre-treating the large yellow croaker into fillets, penetrating and flavoring the fillets through flavoring prepared by the method at a temperature of 20 + / - 5 DEG C, drying the fillets at the temperature of between 15 and 20 DEG C till the water content of the fillets is 45 to 65 percent, then packing the fillets in vacuum, and refrigerating the fillets in an icebox or a freezer and the like at the ice-temperature preservation temperature of between 1 DEG C below zero and 14 DEG C below zero. After the bred large yellow croaker is pretreated, flavored, dried and packed in vacuum, the freezing point of the fillets in a packing bag can be reduced to 14.6 DEG C below zero, so the ice temperature band of the bred large yellow croaker is broadened, and the large yellow croaker cannot be frozen at the temperature of between 1 DEG C below zero and 14 DEG C below zero. The invention provides the ice temperature fresh-keeping method which can broaden the ice temperature band of the bred large yellow croaker and keep the conditions of freshness, flavor, texture and the like of the fresh fish. The method avoids the freezing phenomenon of the large yellow croaker during refrigerating and fresh keeping in the icebox or the freezer, and keeps the original freshness and flavor of the bred large yellow croaker better.

Owner:NINGBO UNIV

Fish preservative and preparation method thereof

ActiveCN103444838AGuaranteed flavorGuaranteed tasteMeat/fish preservation using chemicalsFlavorPullulan

The invention discloses a fish preservative. The fish preservative consists of the the following components in percentage by weight: 5-8% of trehalose, 0.1-0.5% of sodium phytate, 5-10% of pullulan, 0.2-0.5% of chitosan, 3-5% of disodium EDTA and the balance being purple perilla liquid. The fish preservative disclosed by the invention has good color protection, freshness preservation, water retention, deodorization and anti-corrosion functions, is capable of greatly prolonging the preservation time of fishes under the premise of ensuring the flavor and the mouth feel of the fishes and is high in food safety. The invention also discloses a preparation method of the fish preservative, mainly comprising the following steps: (1) preparing purple perilla liquid, namely putting perilla leaves into water to cook and filter so as to obtain filtrate which is the purple perilla liquid; (2) blending, namely uniformly mixing the trehalose, the sodium phytate, the pullulan, the chitosan, the disodium EDTA and the purple perilla liquid in a ratio to obtain the fish preservation. The preparation method disclosed by the invention is simple in processing step, low in production cost and easy to operate.

Owner:ZHEJIANG MARINE DEV RES INST

Tuna fresh keeping method

ActiveCN105076349AGuaranteed food qualityExtend freshnessMeat/fish preservation using chemicalsMeat/fish preservation by dryingPropolisSodium erythorbate

The invention discloses a tuna fresh keeping method to solve a problem that present tuna fresh keeping methods reduce the quality of tuna. The method mainly comprises the following steps: 1, preprocessing tuna bodies; 2, immersing tuna in a composite fresh keeping agent; 3, carrying out surface air drying; and 4, packaging, and refrigerating. The composite fresh keeping agent comprises, by mass, 5-10% of mycose, 0.03-0.05% of nisin, 0.05-0.1% of konjak mannan, 0.1-0.3% of sodium phytate, 2-3% of calcium chloride, 0.2-0.5% of chitosan, 3-5% of disodium EDTA, 0.3-0.5% of sodium erythorbate, 0.3-0.5% of sodium citrate, and the balance of a propolis water extraction liquid. The fresh keeping method has the advantages of easy implementation, high efficiency, low cost, good fresh keeping effect, great prolongation of the fresh keeping time of tuna, maintenance of the original eating quality of tuna, good safety, facilitation of improvement of the economic benefit of ships, and suitableness for being popularized and applied.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

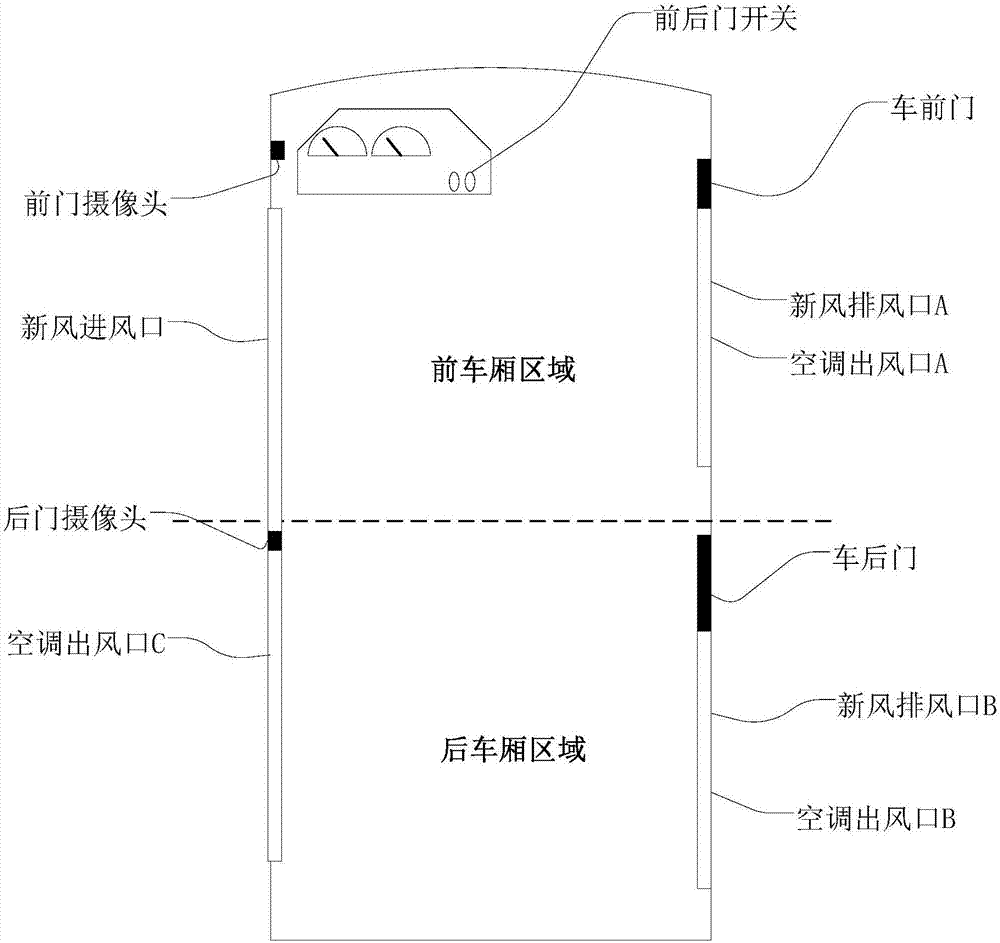

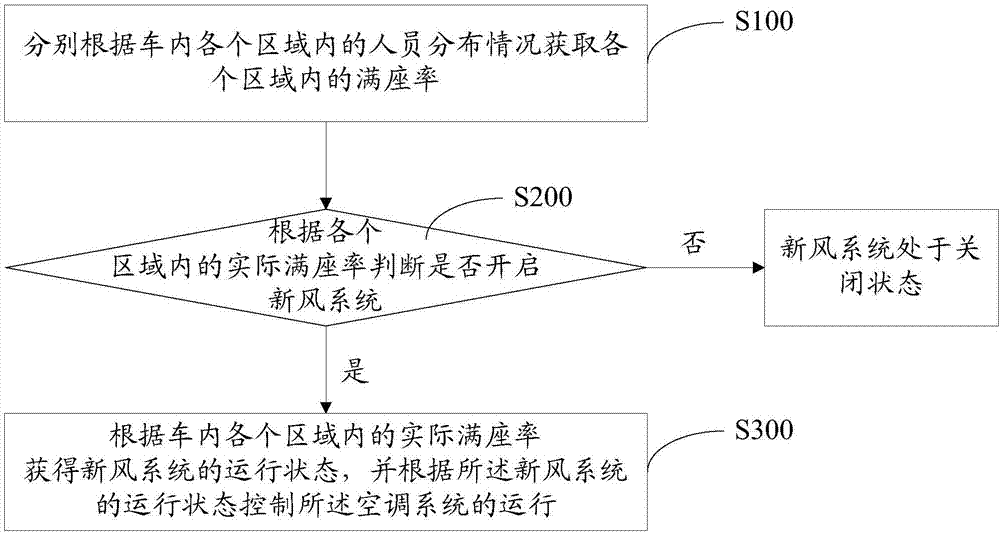

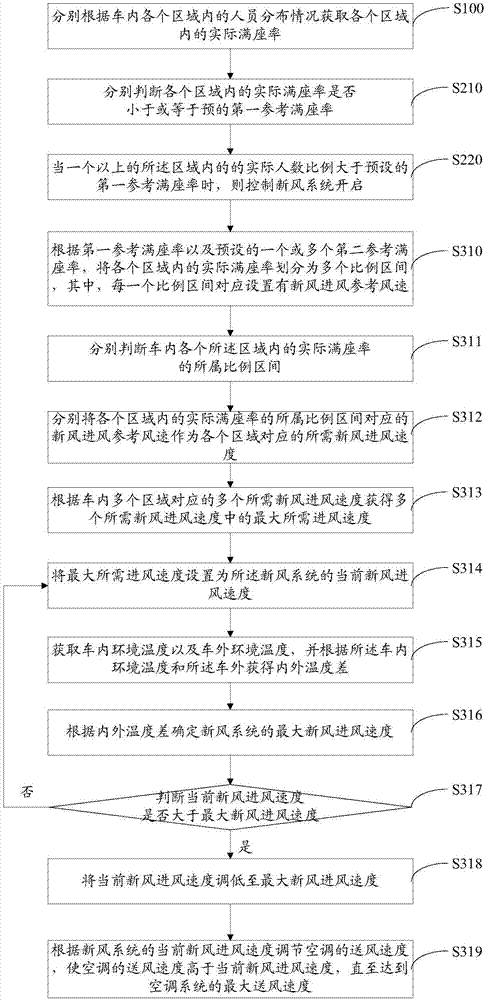

Fresh air system and air conditioning system linkage control method and air conditioning device

ActiveCN107215176AImprove reliabilityGuaranteed cooling effectAir-treating devicesVehicle heating/cooling devicesFresh airHeating effect

The invention provides a fresh air system and air conditioning system linkage control method. The method comprises the following steps that according to a staff distribution condition of each area in a vehicle, the actual full seating rate of each area is obtained respectively; according to the actual full seating rate of each area, whether a fresh air system is opened or not is judged; after the fresh air system is opened, according to the actual full seating rate of each area in the vehicle, the operating state of the fresh air system is obtained, and an air conditioning system is controlled to operate according to the operating state of the fresh air system. The invention further provides an air conditioning device. According to the fresh air system and air conditioning system linkage control method and the air conditioning device, through the linkage control of the fresh air system and the air conditioning system, fresh air in the vehicle can be guaranteed, and the cooling or heating effect of the air conditioning system can also be guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com