Patents

Literature

145results about How to "Good moisture conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blended stain color yarn and method for making same

The present invention essentially provides a novel blended fiber segment-color yarn. The technical proposal is that a blended segment-color yarn is composed of colorful fiber and natural fiber, wherein the color fiber is any one or any combination of terylene, acrylon, regenerated cellulose fiber, natural color cotton, artificial dyed cotton and bamboo charcoal fiber; the natural fiber is pure cotton fiber or mixed fiber of cotton fiber and any other fiber; the colorful fiber and the natural fiber are blended and twisted after cotton cleaning, cotton combing and drawing. The yarn has the advantages of rational structure, simple processing, moderate fiber fracture strength, high extensibility, fine spinning and weaving property, etc. With the excellent moisture absorption of natural fiber and the good moisture conductivity of synthesized fiber, clothes made of the yarns feel soft and are gas-permeable.

Owner:浙江云山纺织印染有限公司

High-elasticity warm healthy knitted fabric

InactiveCN102517769AIncrease elasticityGood moisture conductivityWeft knittingWarp knittingSurface layerAnimal fiber

Owner:SUZHOU CHUANGYU WEAVING

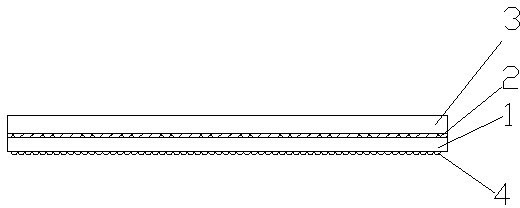

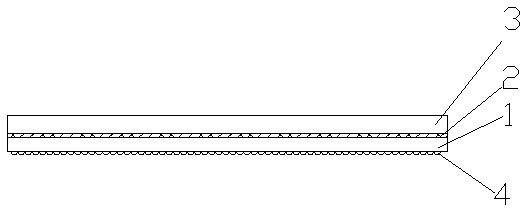

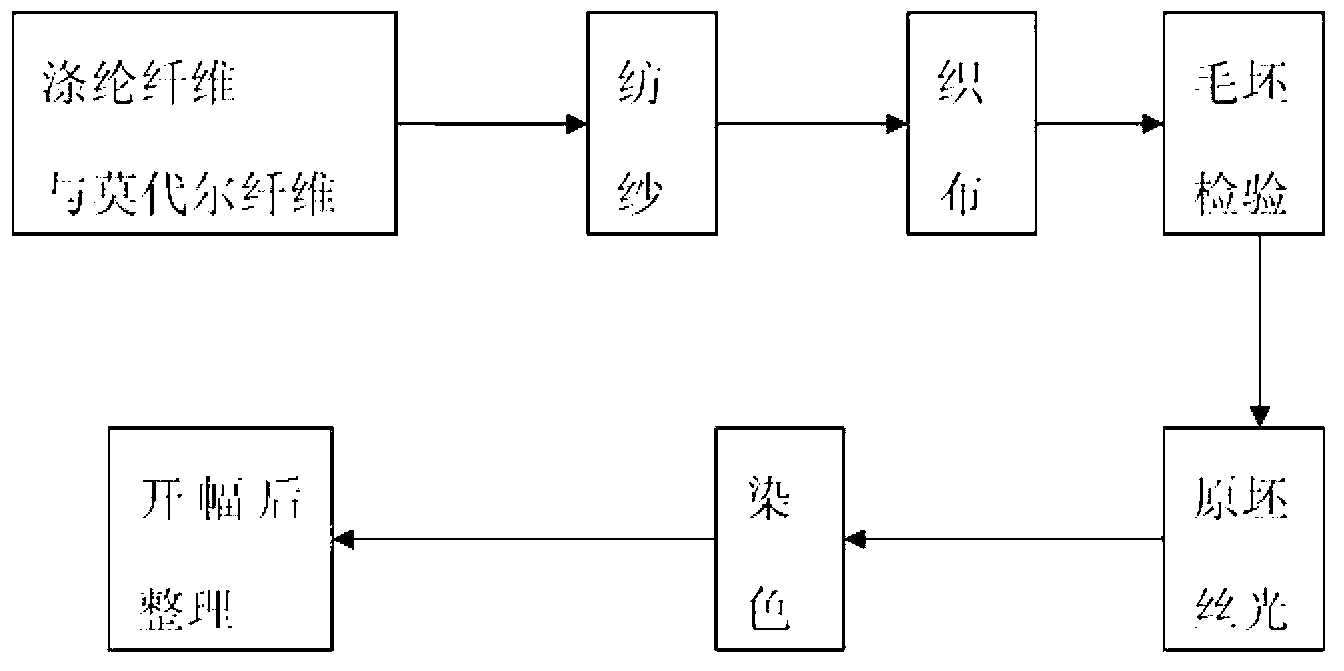

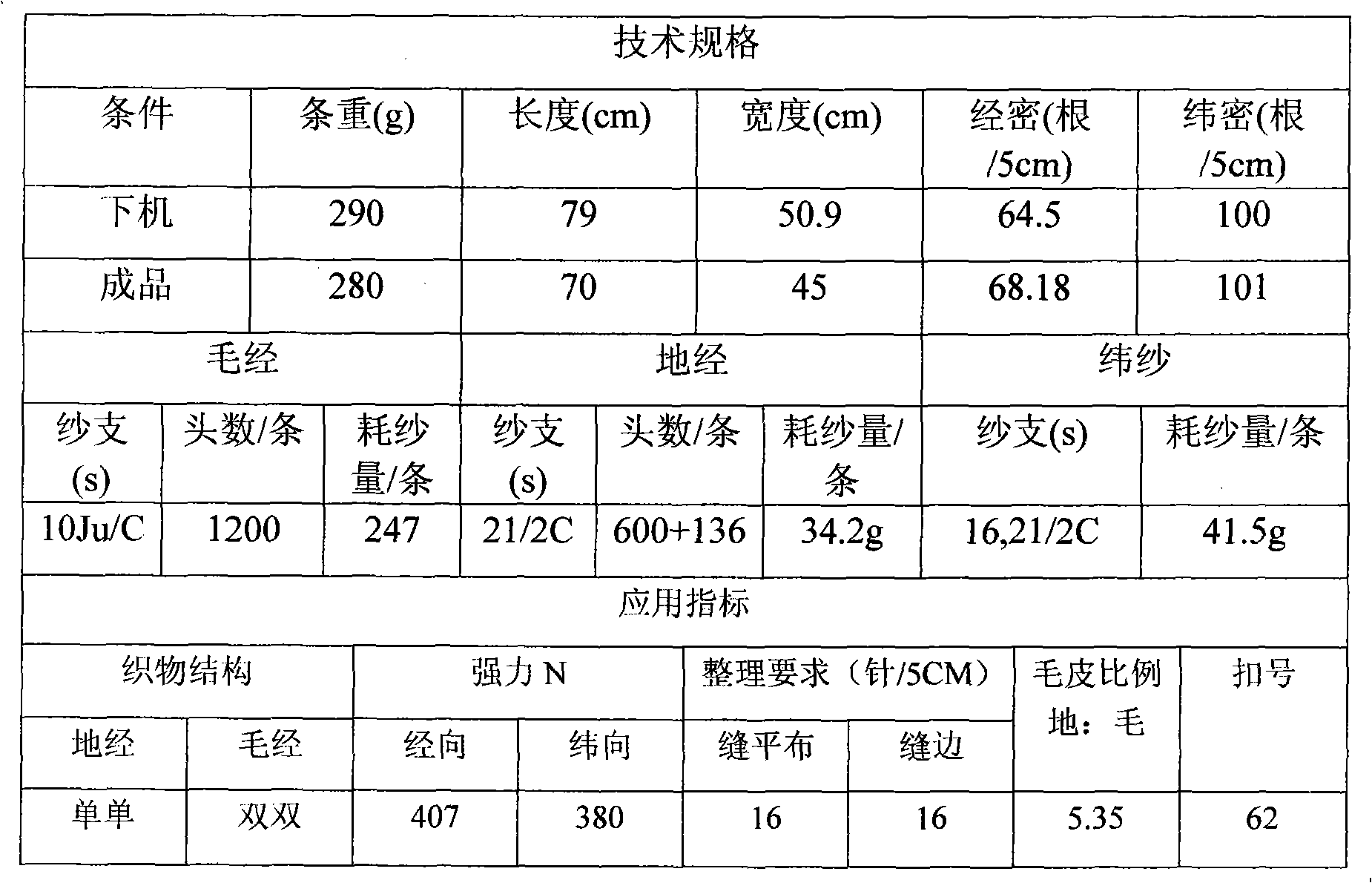

Blending silky single jersey cloth of polyester fiber and modal fiber and preparation method thereof

ActiveCN103173916ABright colorGood moisture conductivityMercerising of indefinite length fabricsWeft knittingAnti wrinklePolyester

The invention relates to blending silky single jersey cloth of polyester fiber and modal fiber and a preparation method thereof. The polyester fiber and the modal fiber serve as raw materials and the single jersey cloth is prepared. According to weight percentages, the raw materials comprise 55% to 75% of the polyester fiber and 25% to 45% of the modal fiber. The cloth is glossy like silky cloth, bright in color, anti-fade after being washed for a plurality of times and good in wet permeability. The knitted cloth blended with the modal fiber has good wet permeable effect and is widely used for sewing top grade T-shirts and sportswear, sweat generated when a person does exercise can be discharged to surfaces of clothes rapidly and be evaporated, the skin stays fresh and cool and the exercise can be done comfortably. The size of the cloth is stable, hanging down feeling is good, the cloth is stiff and smooth, anti-wrinkle performance is good and teasing, pilling and wrinkling do not occur.

Owner:GAOMI FUYUAN PRINTING & DYEING

Method for producing jute natural antibiotic bath mat

InactiveCN101260588AGood antibacterialGood antibacterial effectBleaching apparatusDyeing processMoisture absorptionEngineering

The invention relates to a manufacturing method for a jute natural antibacterial floor towel, blending jute and cotton, adequately utilizing the characteristics of the jute such as excellent moisture absorption and moisture wicking, high strength and tensile stretch and good antibacterial and bacteriostatic capability. Jute fibre is humidified before spinning, and the humidified percentage reaches 12-15 percent; the mixture ratio of jute and cotton is 20-50 percent / 50-80 percent during spinning, the relative humidity of spinning environment reaches 83-86 percent, and the relative humidity of textile environment reaches above 85 percent; in order to make up strength and fix short fiber, the sizing ratio is adjusted below 1 percent, and softening treatment and flexible treatment are performed. The manufacturing method for the jute natural antibacterial floor towel changes the jute performance that jute can not be woven, and has the advantages of anti-bacteria, anti-corrosion, anti-wrinkle, moisture absorption, ventilation, flatness and flexibility, good slip resistant and so on.

Owner:石磊

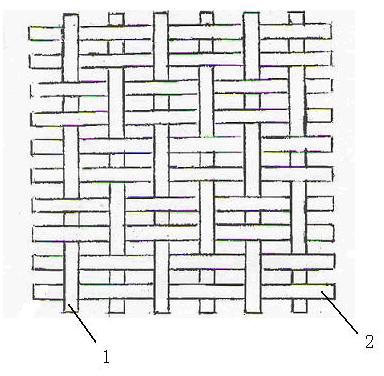

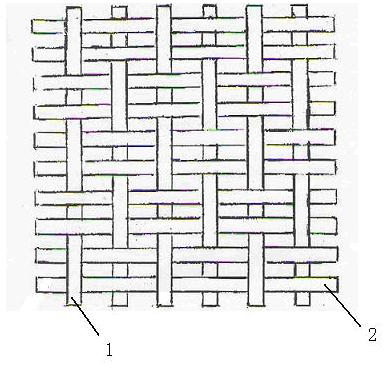

Novel health-care underwear textile fabric

InactiveCN103284336AGood for healthGood moisture absorptionWoven fabricsUndergarmentsPolyesterCellulose fiber

The invention discloses a novel health-care underwear textile fabric. The novel health-care underwear textile fabric comprises the following components, by mass, 20%-25% of regenerated cellulose fibers, 15%-20% of soybean protein fibers, 15%-20% of milk protein fibers, 25%-30% of modified viscose and 15%-20% of polyester fibers, and is formed by warp and weft being interwoven, wherein the warp is made of the regenerated cellulose fibers, the soybean protein fibers and the milk protein fibers in a blending mode, and the weft is made of the modified viscose and the polyester fibers in a blending mode. Through the method, the fabric has superior moisture-absorbing and moisture-preserving functions, can keep cool and dry and stiff and smooth anytime, further has superior breathability and elasticity, is good in shape-keeping performance, cannot produce static, at the same time, has antimicrobial effect and health-care and nursing performance, and is beneficial to health of people.

Owner:WUXI HOUSETEX INDS

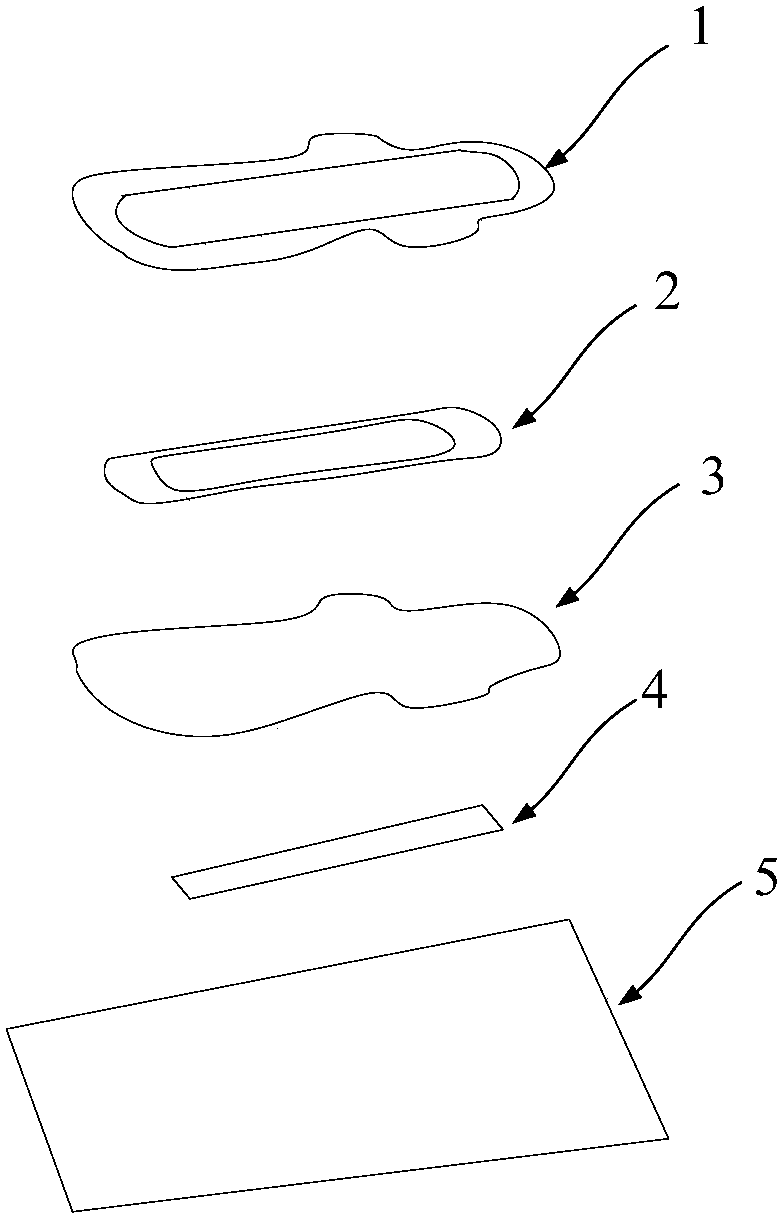

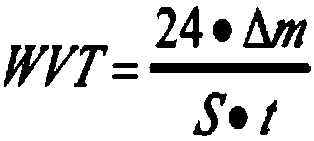

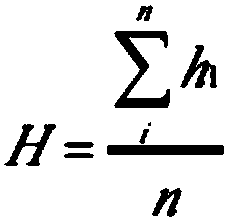

Unidirectional moisture-transported fabric preparation method and unidirectional moisture-transported fabric prepared thereby

InactiveCN108130710AGood moisture conductivityKeep dryFibre typesUltrasonic/sonic fibre treatmentSlurryEngineering

The invention discloses a unidirectional moisture-transported fabric preparation method and a unidirectional moisture-transported fabric prepared thereby. The preparation method comprises the steps: successively carrying out alkali decrement treatment and hydrophilic finishing on a fabric after impurity removal, and then drying and baking the fabric after the hydrophilic finishing; carrying out coating treatment on the inner surface of an inner layer of the baked fabric in the step one by a water repellent slurry, and drying and baking the fabric after completion of coating; carrying out soaping treatment of the baked fabric in the step two by using a soaping liquid, and drying and baking the fabric after the soaping treatment; and carrying out plasma treatment on the inner surface of theinner layer of the baked fabric in the step three, and thus obtaining the unidirectional moisture-transported fabric. According to the preparation method, the alkali decrement treatment, hydrophilic finishing, single-face water repellent finishing and plasma finishing of the spaced fabric are carried out for endowing the fabric with a good moisture-transported performance, so that water led out from the inner layer is absorbed, diffused and distributed to the surface rapidly under the effect of capillary effect, and the fabric having dry and cool inner layer and having the unidirectional moisture-transported function is formed.

Owner:WUHAN TEXTILE UNIV +1

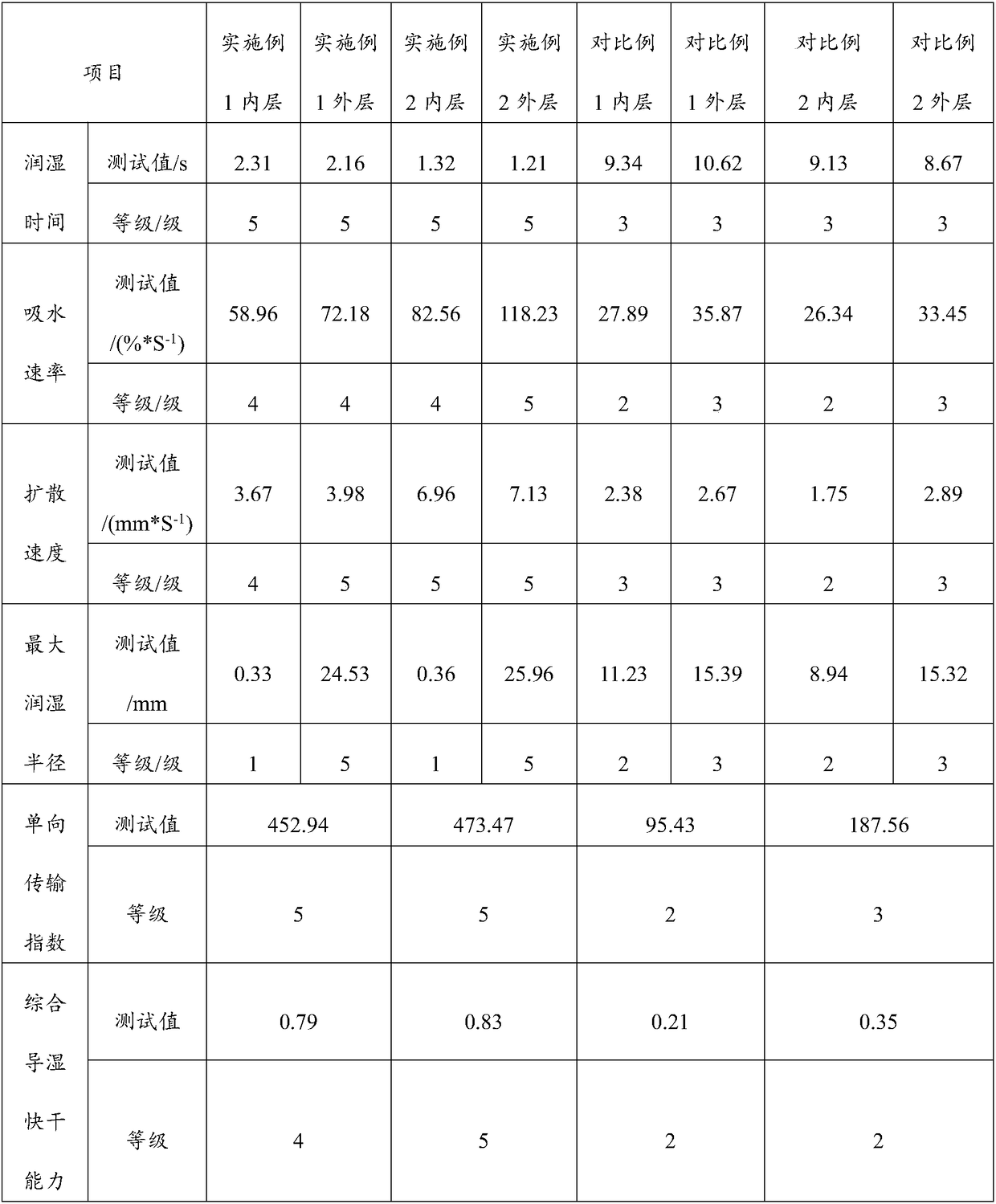

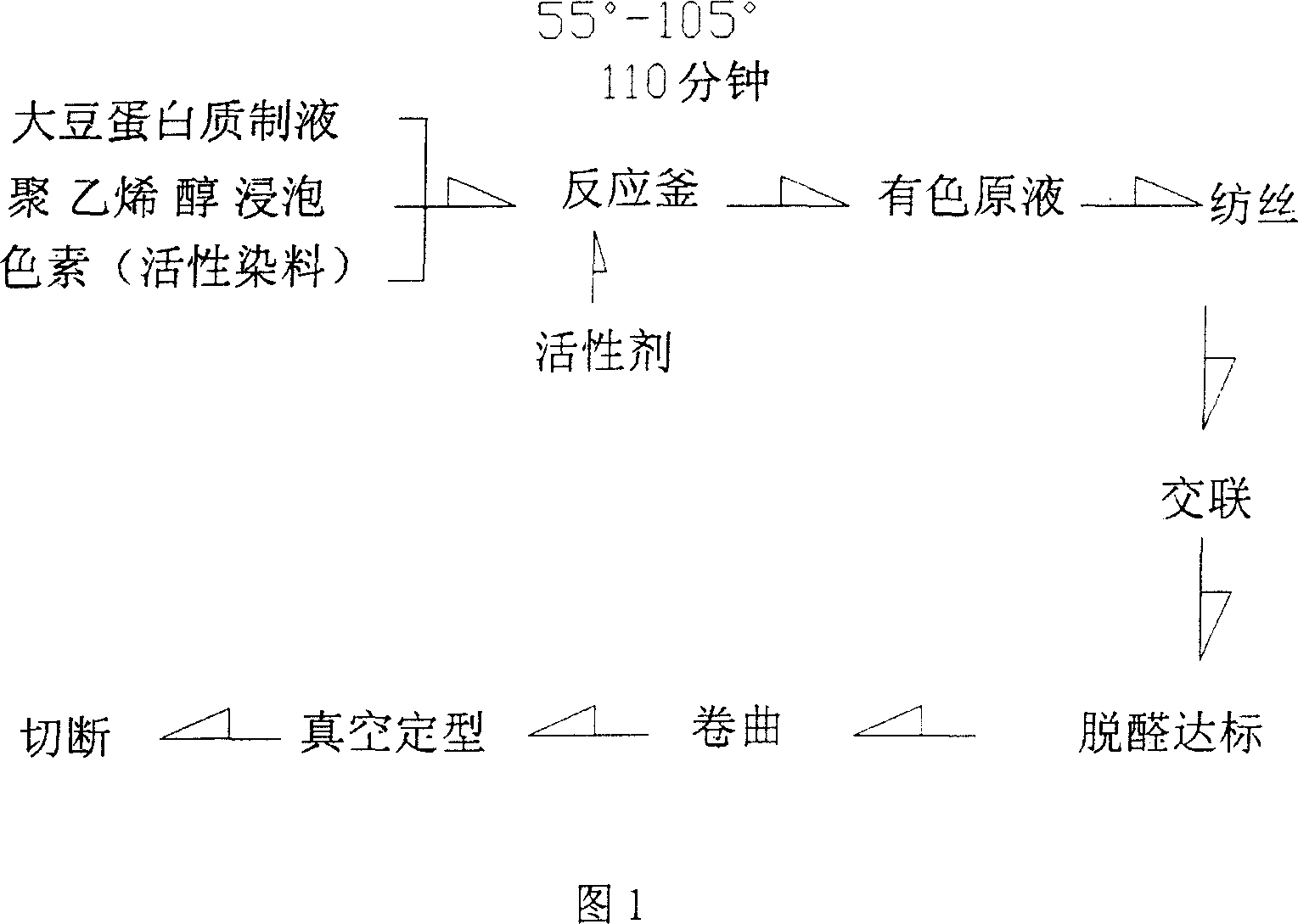

Maize protein colored textile fiber and method for producing same

InactiveCN1952225AHigh color fastnessNo pollution in the processMonocomponent protein artificial filamentDye addition to spinning solutionTextile fiberPhysical chemistry

The invention provides a colored fiber of corn protein and manufacture method. There is activated dye in corn protein. The manufacture method is that activated dye is added in the process for confecting spinning solution and plant protein colored fiber with the density of 0.7-3.0dtex is slubbed by wet spinning technology after ripening and polymerizing in reaction vessel. Because of activated dye added in confecting process, strike and fixation rates are improved. In detection method the cooler fiber has good fastness with five degree and enough light. There are no pollution and public disaster in the activated dye. The fiber is provided with good moisture conduction, light gravity, dry heat resistance and so on. It is knitted and tatted to various ultrathin or thickening apparel fabrics with high grade.

Owner:韩晓根 +1

Windproof warm-keeping composite garment fabric

ActiveCN103340483AReduce air permeabilityImprove breathabilitySynthetic resin layered productsCeramic layered productsPolyesterPolymer science

The invention discloses a windproof warm-keeping composite garment fabric. The windproof warm-keeping composite garment fabric comprises a windproof waterproof moisture-permeable outer layer, a far infrared warm-keeping layer, a moisture-guiding sweat-discharging inner layer and a mesh lining in sequence from outside to inside. The windproof waterproof moisture-permeable outer layer is made of high count and high density base cloth and a polytetrafluoroethylene microporous membrane in a laminated and composite mode through adhesive, the moisture-guiding sweat-discharging inner layer is made of polypropylene fibers having good moisture conductivity and / or polypropylene fibers having irregular sections, and the yarn count of each polypropylene fiber is 45s-60s. The far infrared warm-keeping layer is made of warm-keeping layer base cloth and a far infrared ceramic nanofiber membrane in a composite mode, the mesh lining is a warp knitted mesh fabric, and the warp knitted mesh fabric is made of polyester fibers with irregular sections. The windproof warm-keeping composite garment fabric has good windproof, warm-keeping and moisture-permeable performance, and has a good using effect.

Owner:SWOTO PROTECTION & TECH CO LTD +1

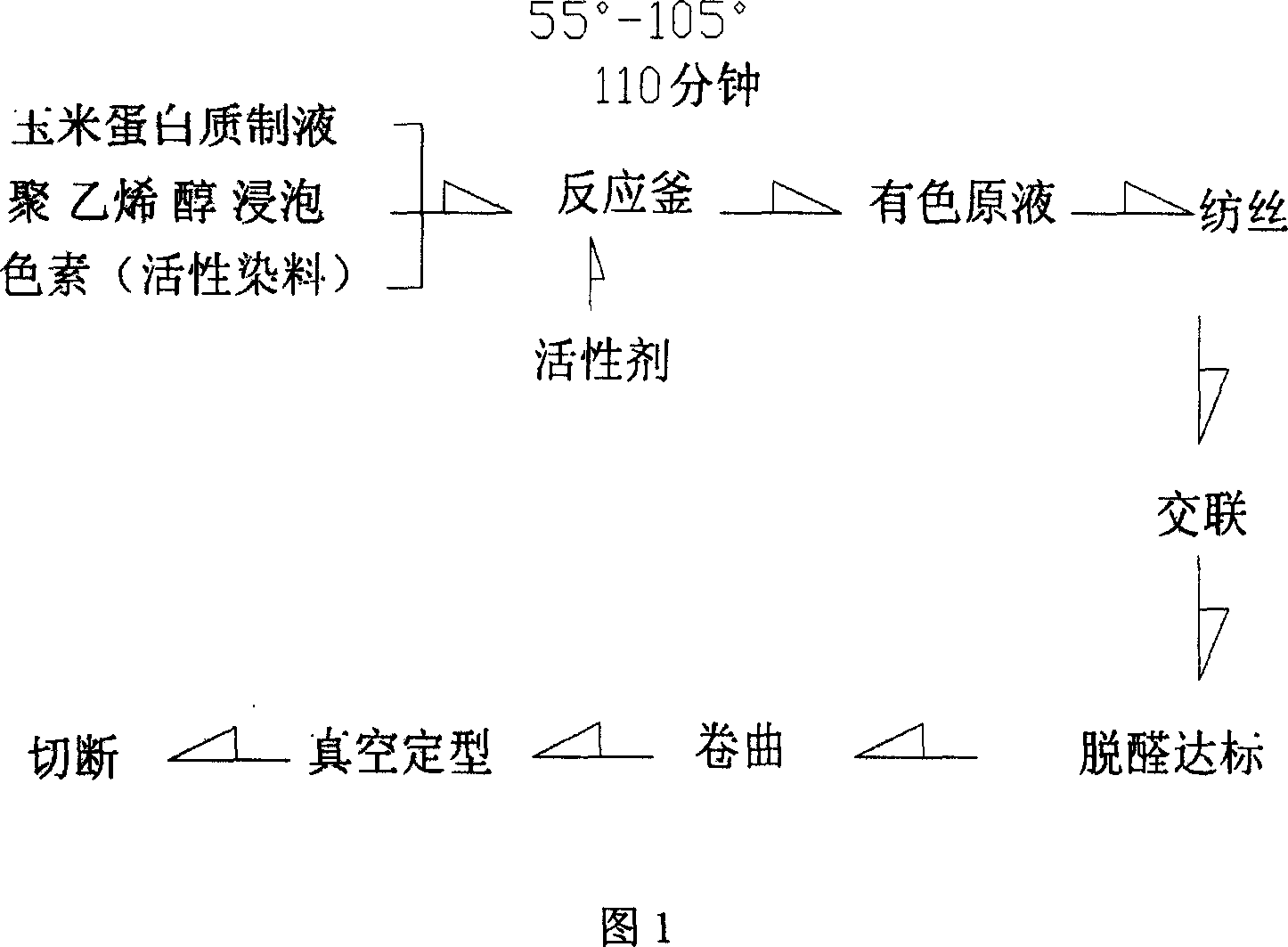

Double-layer single-side moisture transporting fabric and application thereof

InactiveCN106827730AGood moisture absorption and releaseReach the function of one-way moisture guideWeft knittingSynthetic resin layered productsYarnSingle fiber

The invention discloses a double-layer single-side moisture transporting fabric and an application thereof. The double-layer single-side moisture transporting fabric is formed by compounding two layers of fabric, namely an inner skin-friendly fabric layer and an outer fabric layer, wherein the inner skin-friendly fabric layer is a polypropylene fiber knitted fabric; the outer fabric layer is a modal fiber knitted fabric; the single fiber density of the inner skin-friendly fabric layer is greater than that of the outer fabric layer; the double-layer single-side moisture transporting fabric can be used for preparing an underwear fabric and a sportswear fabric. Through the design of the fabric texture structure, a double-sided isomeric knitted fabric is constructed by yarns with permanent functionality, thereby achieving single-side moisture transporting effect of the fabric.

Owner:LILANG CHINA

Polyester yarn having high moisture conductivity performance and manufacturing method thereof

InactiveCN101158074AImproved capillary wickingIncrease the number of poresFilament/thread formingYarnPorosityYarn

The invention relates to a terylene yarn with high moisture-transmitting property and a production method thereof. The terylene yarn is made by blended spinning of a straight-line section terylene fiber and a cruciform section terylene fiber. The production steps include (1) the straight-line section terylene fiber and the cruciform section terylene fiber are selected based on the ratio of fiber number; (2) the terylene yarn is produced after treatment of fiber strand and mixing. Number of inner capillary porosity and capillary wicking of the produced terylene are greatly increased and the moisture-transmitting property is obviously improved. The terylene yarn can be used for producing high moisture-transmitting fabric textile separately or together with other fiber yarn, thereby being widely applicable to fields of cloths, decoration and industry.

Owner:DONGHUA UNIV

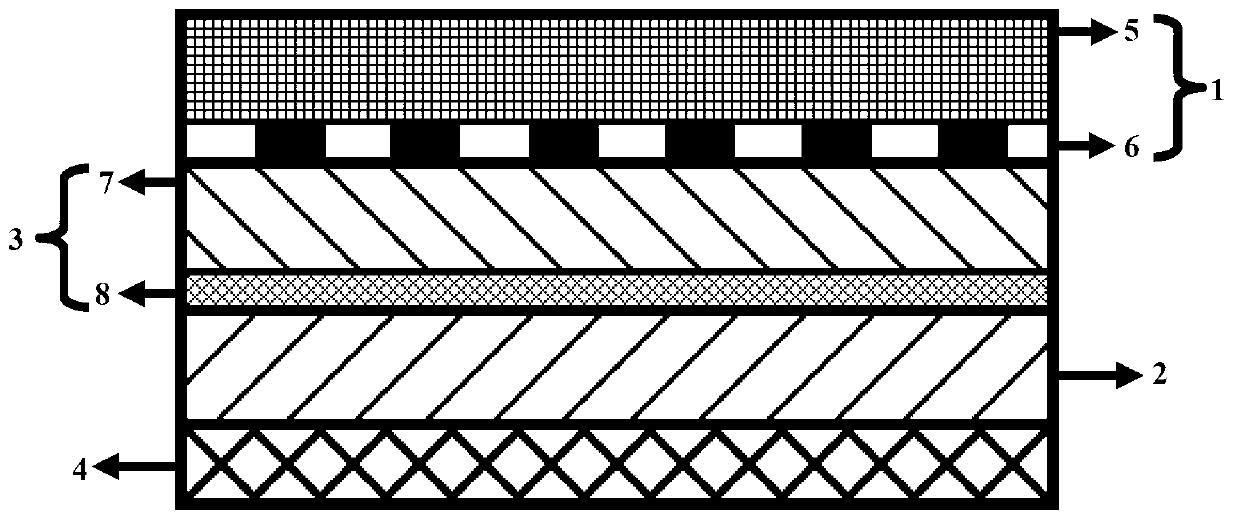

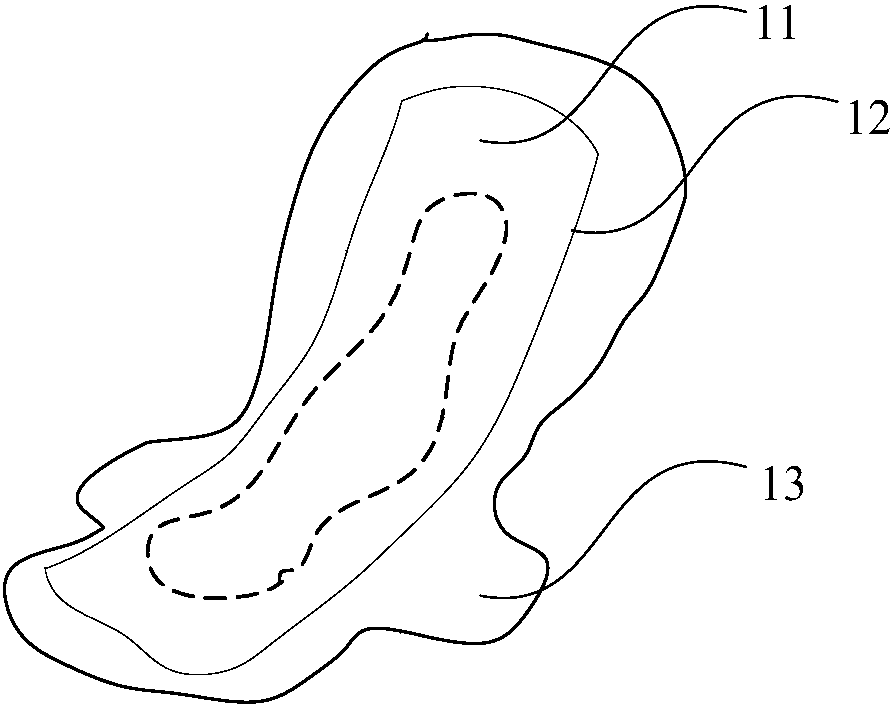

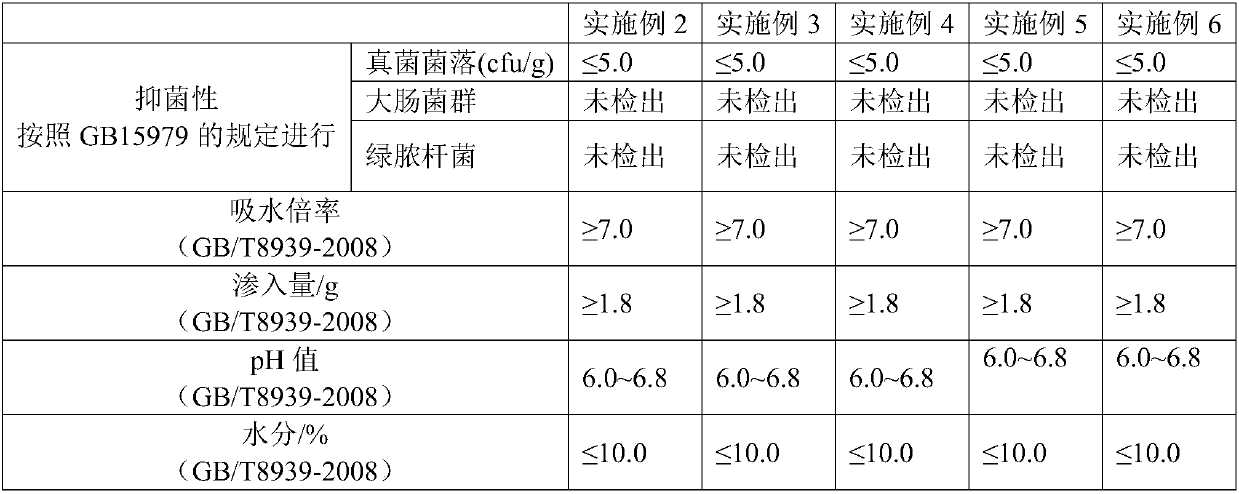

Black sanitary towel

ActiveCN107898560AWith adsorption and deodorizationAntibacterialBio-packagingSanitary towelsEngineeringMoisture absorption

The invention provides a black sanitary towel. The black sanitary towel comprises a sanitary towel body, and the sanitary towel body comprises a surface non-woven fabric layer, an absorption core anda bottom impermeable membrane from top to bottom in sequence; the surface non-woven fabric layer comprises a middle sheet, retaining walls and side wings; the middle sheet is arranged in the middle ofthe surface non-woven fabric layer and used for cooperating with the bottom impermeable membrane and completely wrapping the absorption core; the side wings are arranged at the two sides of the surface non-woven fabric layer and used for fixing the sanitary towel body; the retaining walls are arranged at the two sides of the middle sheet and used for preventing an absorbed material which is absorbed by the middle sheet or the middle core from leaking from the sides; the side wings are fixedly connected with the middle sheet through partial retaining walls; the surface non-woven layer and thebottom impermeable membrane are both black. The black sanitary towel can meet the basic requirement of sanitary towels and have the advantages of bacterial inhibition, odor removal, moisture absorption and ventilation, soft and comfortable performance and complete degradation.

Owner:上海贝睿斯生物科技有限公司

High-strength anti-radiation fabric

The invention discloses high-strength anti-radiation fabric, which comprises an inner layer, an outer layer and an intermediate layer. The intermediate layer is made of cushioning material, the outer layer is made by weaving of well-combed pure cotton yarns and metal wires, the intermediate layer is made of cushioning material formed by polyester low-elasticity yarns and metal wires in the non-fabric form, the inner layer is made by weaving of infrared yarns formed via cotton and polyester blending, the surface of the outer layer is provided with lead plastic fabric, and the surface of the lead plastic fabric is provided with a cloth layer. By adopting the technical scheme, the damage of external electromagnetic radiation to the body can be avoided effectively; the high-strength anti-radiation fabric is soft and has good washable performance, good heat insulating performance and good moisture transmission performance; since the infrared yarns are functional healthy fibers, the fabric can be adhered to the body and has a unique healthcare function; and since the lead plastic fabric is provided with the cloth layer, the strength and the softness of the lead plastic protective fabric can be improved effectively, and the lead plastic protective fabric cannot be easily torn as a result of external forces.

Owner:CHANGSHU ZHONGWANG JINGWEI WEAVING

Luminous sportswear textile fabric

InactiveCN103829429AGood moisture conductivityConducive to sweating and dispersing dampnessSynthetic resin layered productsProtective garmentHemp fiberPolyester

The invention relates to luminous sportswear textile fabric. The luminous sportswear textile fabric comprises a lining layer and a surface layer, wherein the lining layer comprises, by weight, 20-30 parts of bast fibers, 20-30 parts of cotton fibers, 46-54 parts of viscose acetal fibers, 2-6 parts of spandex fibers and 4-8 parts of Teflon fibers, and the surface layer comprises, by weight, 50-54 parts of polyester fibers, 28-34 parts of wool fibers and 22-30 parts of real silk. The luminous sportswear textile fabric has the advantages of storing light and emitting light, discharging sweat and absorbing humidity, and being natural, environmentally friendly, safe, comfortable and the like, overcomes the defect that existing night sportswear fabric is not complete in function, and meets the requirement for the performance of the night sportswear fabric.

Owner:JIANGSU SANFONDO TEXTILE BIOLOGICAL SCI & TECH

Protein functional fiber

InactiveCN1676689AGood skin affinityBacteriostaticConjugated cellulose/protein artificial filamentsFiberPolymer science

This invention discloses a kind of functional fiber which contains protein. It is made up of protein, high polymer and the substances containing metallic element. Among these, the protein takes up A of the total quantity, the high polymer taking up B and the substances containing non-metallic element taking up C. Then we get 1<=A<=67, 10<=B<99 and 0 D01F 8 / 02 0 7 3 2004 / 3 / 29 1676689 2005 / 10 / 5 000000000 Li Guanqi Henan 457000 Li Guanqi Li Heze zhang chaolin 41109

Owner:李官奇

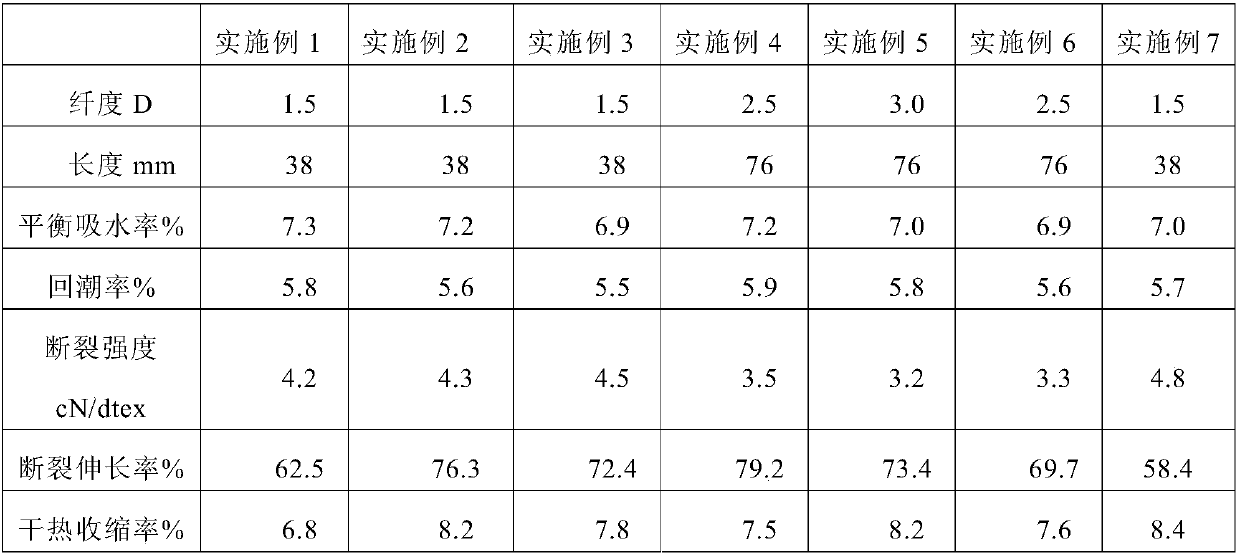

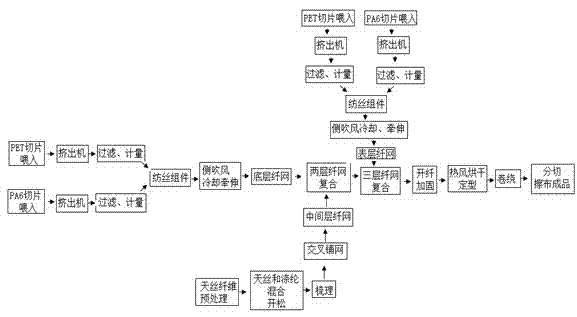

Manufacturing process of profiled, hollow, three-dimensional crimp and acrylic fibers and application thereof and dyeing and finishing process of fabric

InactiveCN105839206AReduce rigiditySoft and smoothHollow filament manufactureFilament/thread formingPolymer scienceAcrylic fibre

The invention discloses manufacturing process of profiled, hollow, three-dimensional crimp and acrylic fibers and application thereof and dyeing and finishing process of fabric and comprises the process of fiber spinning, the manufacturing process of home textile fabric by utilizing acrylic fibers as weft filaments and the process of dyeing and finishing the above fabric. The profiled, hollow, three-dimensional crimp and acrylic fibers manufactured by the invention are adopted so that rigidity of fibers is reduced and fibers feel smooth and soft. Hydrophilic groups are introduced into fibrous macromolecules such that material contact angles are reduced. Moisture makes the fiber surface wet and spreads at a quicker pace. Multiple capillaries are formed between the hollow structure of fibers and fiber assemblies of fabric so that an excellent moisture conducting system is formed and moisture conducting performance of the fabric is markedly improved. The hollow structure of fibers helps loosen fiber assemblies and contains more still air so that a unique heat preservation system is formed. Heat preservation performance of the fabric is markedly enhanced so that the fabric has the heat preservation performance and is more light-weighted.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Composite fibers prepared from lotus leaf extract and lotus seed extract, and preparation method of composite fibers

ActiveCN107988652AHigh dry breaking strengthHigh wet breaking strengthConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentUltraviolet lightsCellulose fiber

The invention provides composite fibers prepared from a lotus leaf extract and a lotus seed extract. The composite fibers are prepared by taking the lotus leaf extract and the lotus seed extract as adding raw materials and taking regenerated cellulose fibers as a carrier. The lotus leaf extract and the lotus seed extract contain multiple nutrient elements, and the nutrient elements exist in the composite fibers in forms such as metal oxides, so that the composite fibers have a function of emitting far-infrared rays and further have effects of accumulating heat and keeping warm; furthermore, the lysine and phenylalanine in zinc, magnesium, aluminum, iron and titanium oxides as well as the lotus seed extract have a better absorption effect on ultraviolet light, so that the composite fibers have an ultraviolet-proof function. The composite fibers provided by the invention contain hydroxyl groups and amino groups, thus having good wet permeability and air permeability; the composite fibersare higher in protein content, so that the skin-friendly property is improved. The composite fibers provided by the invention are glossy, bright and soft, good in dyeing performance, excellent in color fastness, good in fiber softness, washable and high in mechanical strength.

Owner:杭州优标科技有限公司

Nano antibacterial vortex spinning yarns and production technology thereof

InactiveCN108442005ASoft textureImprove comfortContinuous wound-up machinesOpen-end spinning machinesEngineeringAbnormal shaped

The invention discloses nano antibacterial vortex spinning yarns and a production technology thereof. Each nano antibacterial vortex spinning yarn comprises a yarn body, wherein the yarn body is of acore spun yarn structure and comprises core yarns and wrapping yarns; the wrapping yarns are wrapped outside the core yarns; the core yarns comprise irregular-cross-section polyester filaments, and tencil fibers and silver fibers which are located outside the irregular-cross-section polyester filaments; the surfaces of the irregular-cross-section polyester filaments are coated with a nano titaniumdioxide photocatalyst; the wrapping yarns are prepared from natural plant fibers formed by mixing soybean protein fibers and bamboo fibers. The nano antibacterial vortex spinning yarns disclosed by the invention have a soft texture, do not easily balling up and have good skin-friendly performance and air permeability; the irregular-cross-section polyester filaments are adopted and the wet permeability is good; the nano titanium dioxide photocatalyst and the silver fibers are matched so that the antibacterial performance is good; the soybean protein fibers and the bamboo fibers are provided with irregular grooves in the longitudinal direction and are matched with the irregular-cross-section polyester filaments to form a heat-dissipation and wet-conduction groove with a stereoscopic structure, so that bacterium breeding can be avoided.

Owner:SUZHOU CITY XINGJINGZE FIBER TECH CO LTD

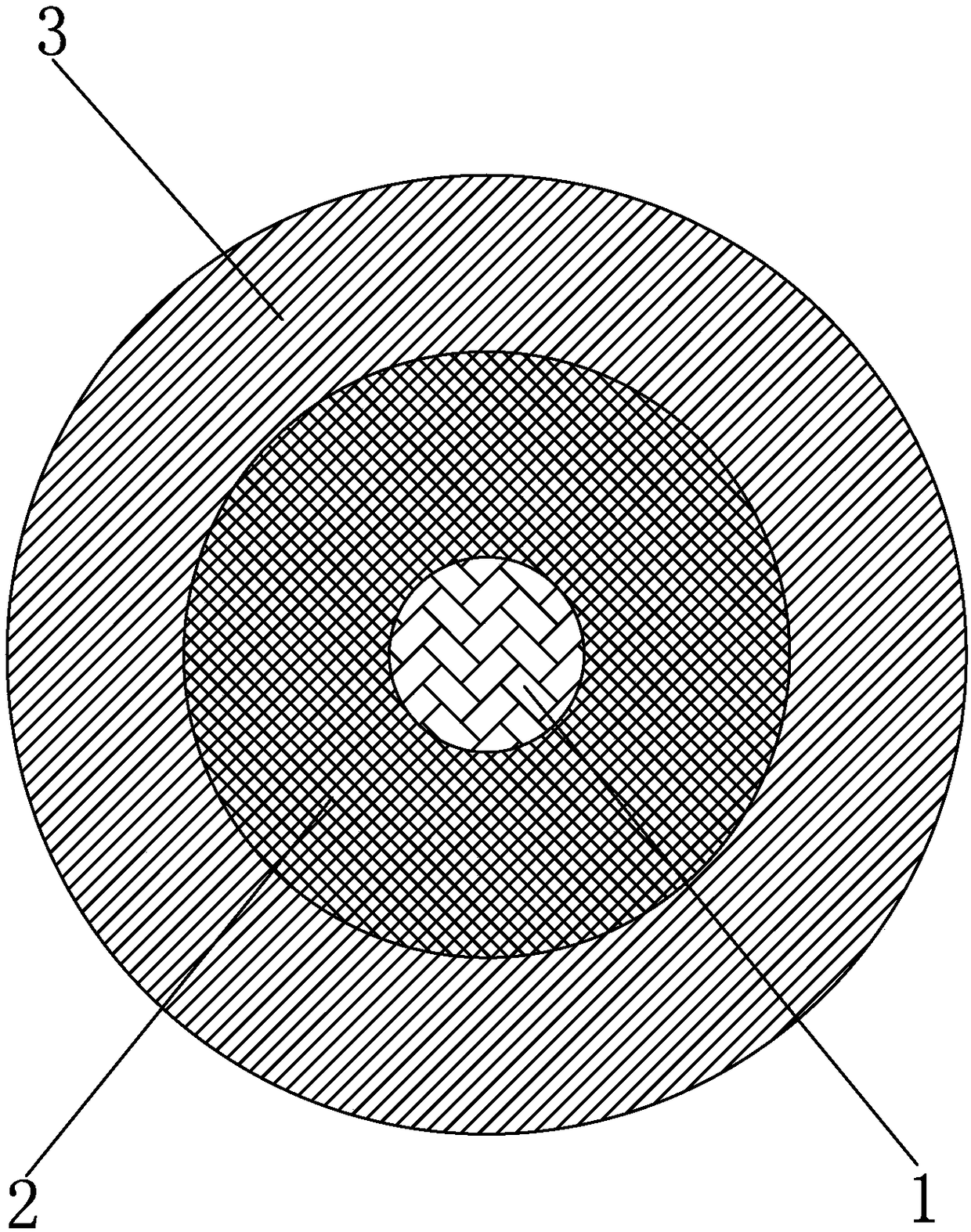

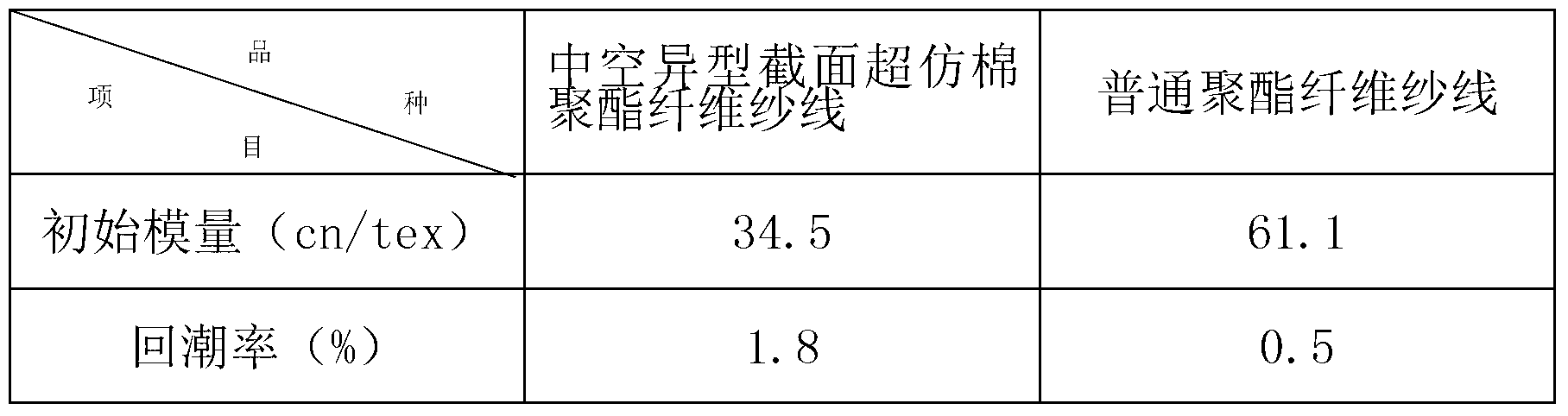

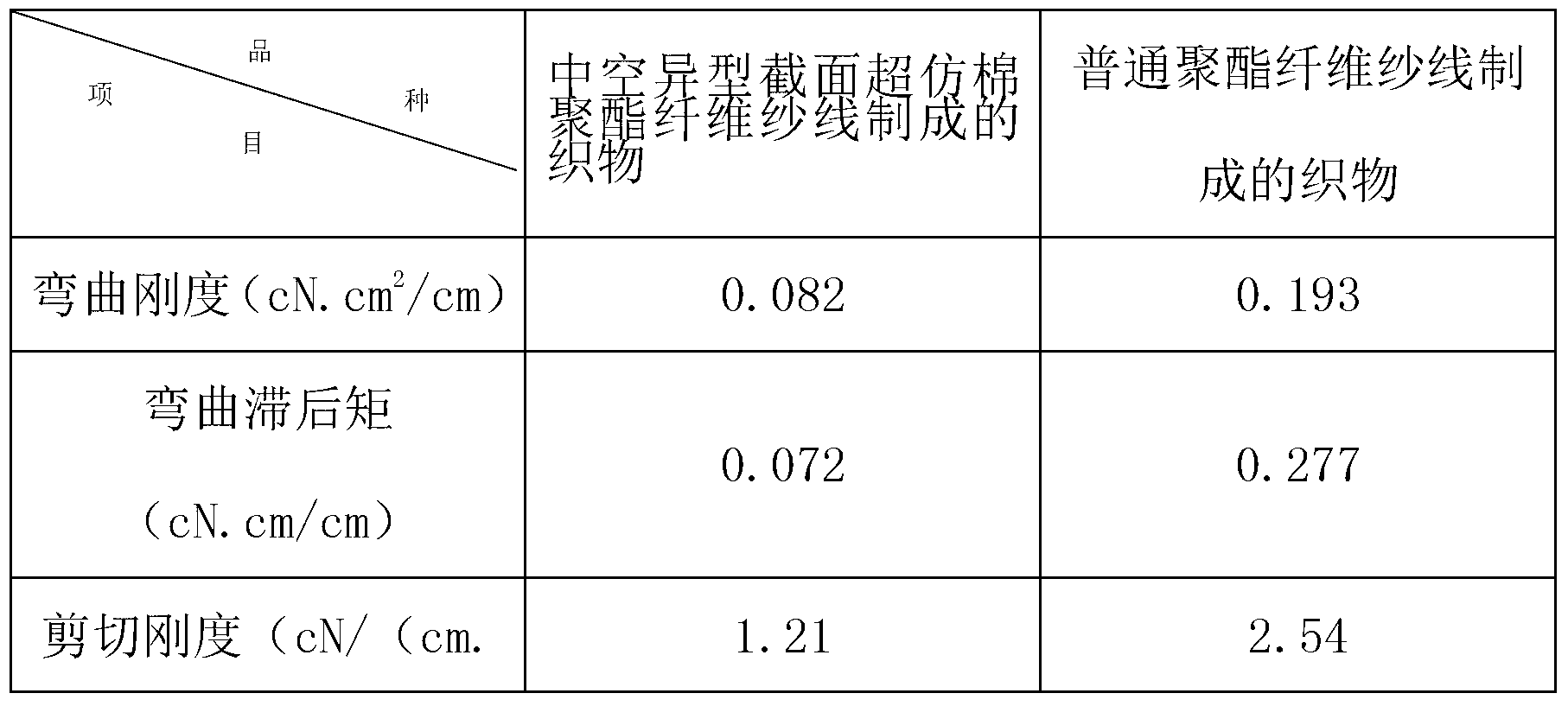

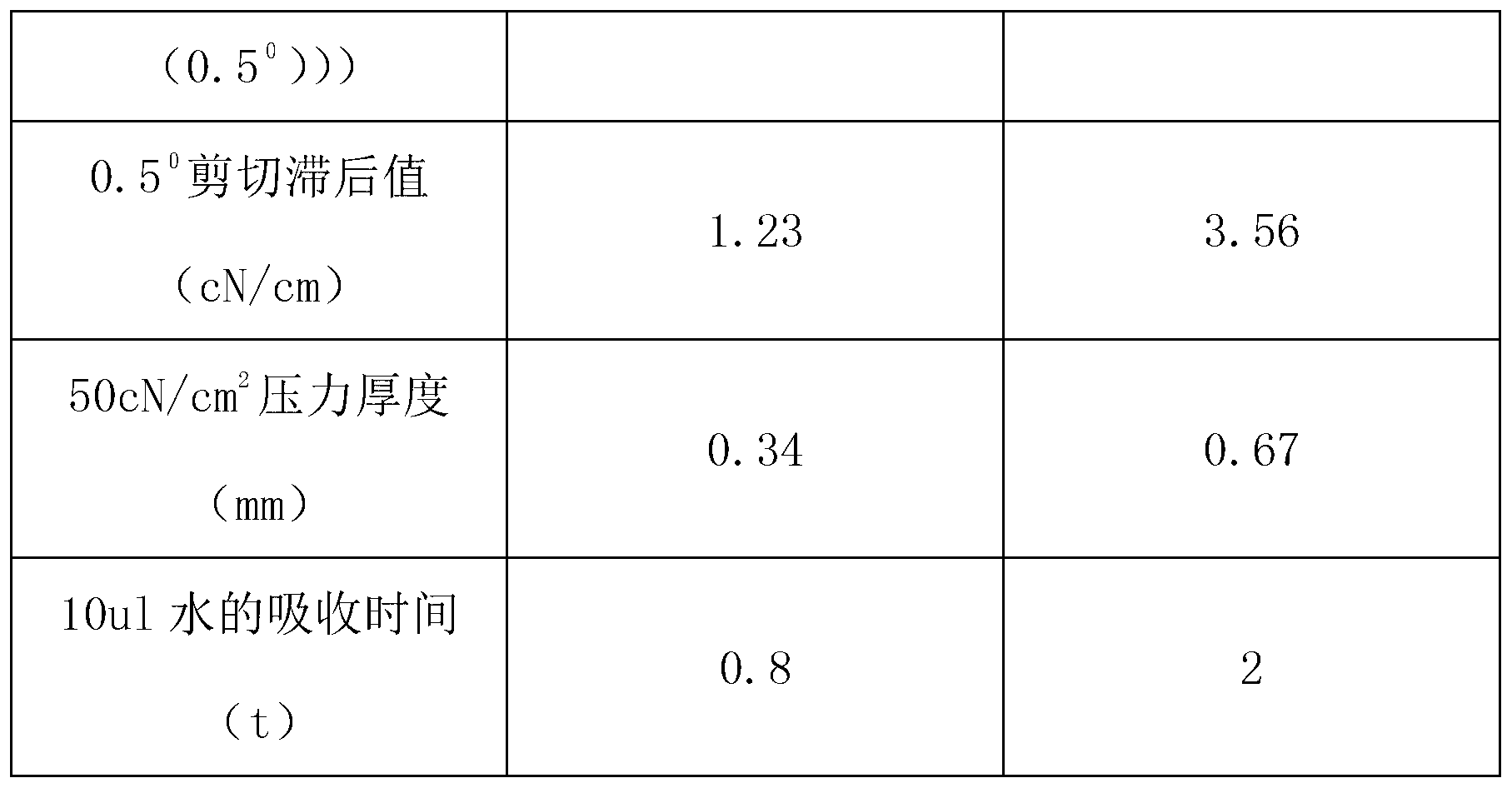

Spinning method of super-soft high-conductivity wet polyester yarn

The invention provides a spinning method of super-soft high-conductivity wet polyester yarn. The spinning method includes the following steps that hollow specially-shaped section super cotton imitating polyester fibers are used as raw materials, in a spinning process, a low-twist low-torsion technology is applied to a spun yarn procedure, and besides, water-solubility vinylon filament yarn and polyester fiber line strip core wrapping drafting spinning yarn are applied, therefore, not only can softness and moisture absorption and conduction performances of yarn be improved, but also softness and moisture absorption and conduction performances of textiles can be further improved due to the fact that the water-solubility vinylon filament yarn can be dissolved during the process of textile finishing.

Owner:NANTONG DOUBLE GREAT TEXTILE

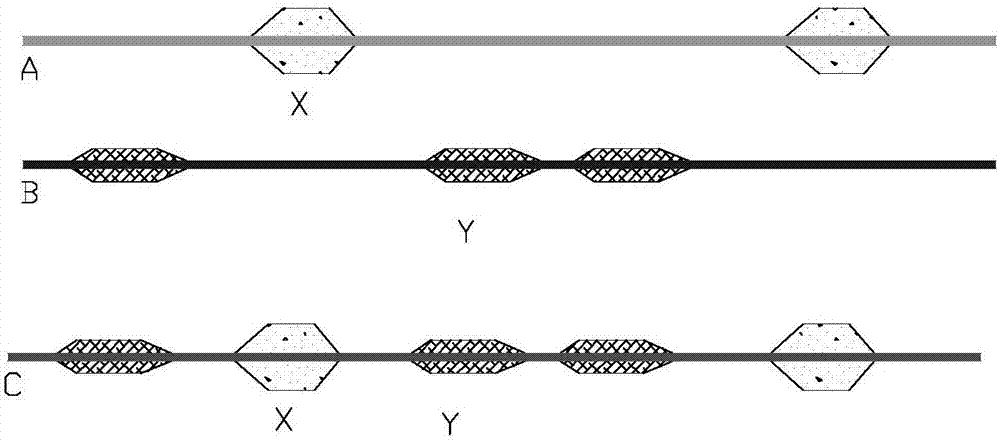

Production technology of discoloring antibacterial anti-ultraviolet fabric

The invention discloses a production technology of discoloring antibacterial anti-ultraviolet fabric. Through a yarn design, by using color characteristics of functional fiber, fancy yarn is developed and prepared to produce the fabric, and the textile meets functional requirements of the market and has fashion characteristics, so that the market space of the functional fiber is expanded. The production technology of discoloring antibacterial anti-ultraviolet fabric is antibacterial, anti-ultraviolet, cool, permeable in moisture and air, discoloring, fashionable and unique in fabric style, and can be used in both sides.

Owner:南通北岸纺织科技有限公司

Soybean protein colored spinning fiber and its production method

InactiveCN1928169AHigh color fastnessNo pollution in the processMonocomponent globulin artificial filamentDye addition to spinning solutionFiberSoybean protein

The invention provides a soybean protein colored fiber and production method. There is activated dye in soybean protein colored fiber. The production method is described as: during the process of making up filature original fluid, activated dye is put in, then colored fiber of plant protein whose density is 0.7-3.0dtex is ripened, get together and slubbed through technology of wet method filature in reactor. Because activated dye is put in during making up fluid coloring and sessile rates are increased. Coloring firming degree of the colored fiber can reach five grades after measuring.

Owner:韩晓根 +1

Bacteriostatic radiation protection material

ActiveCN102071510ASolve discomfortSolve the shortcomings of not easy to rinseShieldingWoven fabricsFiberMilk protein

The invention discloses a bacteriostatic radiation protection material, which is formed by warp protein silver fiber and weft protein silver fiber through warp and weft intersection spinning, wherein the protein silver fiber is formed by 40 to 56 percent of milk protein fiber and 44 to 60 percent of sliver fiber in percentage by volume through blended spinning. The bacteriostatic radiation protection material has the texture and the comfort degree similar to or exceeding the those of cashmere products, has the functions that: the human body is protected and nursed, and the bacteriostatic radiation protection material can be repeatedly washed, and the defect that the existing radiation protection clothes are uncomfortable to wear or can not be easily rinsed is overcome.

Owner:北京京港恒星科技发展有限公司

Tencel fiber and linen fiber blended yarn and spinning process thereof

The invention provides a tencel fiber and linen fiber blended yarn which comprises tencel fiber with the blending ratio of 70% and linen fiber with the blending ratio of 30%, and further provides a spinning process of the tencel fiber and linen fiber blended yarn. The process includes the steps of blowing-carding, drawing, roving, spinning and winding. Compact siro spinning is adopted as the spinning mode and combines the advantages of siro spinning and compact spinning, the evenness CV value, the slub index and the fine index are quite good, the single yarn is high in strength, the structureis compact, the wear resistance is high, the yarn hairiness is lower, harmful hairiness with the length of 3 mm or above is quite low, the yarn is bright and clean, the fabric quality is high, and theyarn is a high-quality yarn raw material for jean fabrics. The prepared blended yarn is a high-quality yarn which is environmentally friendly, elegant, comfortable and rich in style.

Owner:上海纺织(集团)大丰纺织有限公司

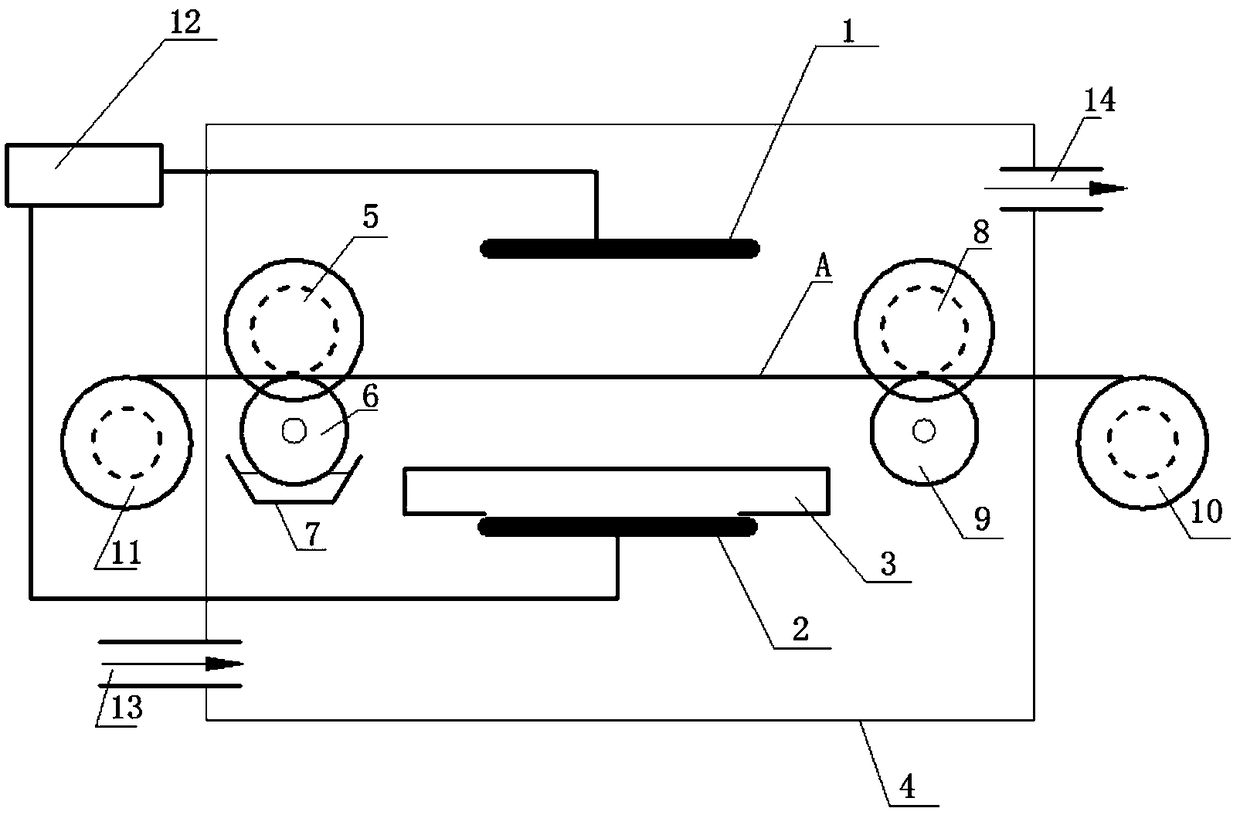

Device and method for online treatment of antifouling and moisture-penetrable fabric

InactiveCN108893971AImprove processing efficiencyGood moisture conductivityStain/soil resistant fibresUltrasonic/sonic fibre treatmentLiquid storage tankEngineering

The invention discloses a device and a method for online treatment of an antifouling and moisture-penetrable fabric and belongs to the technical field of textile fabric treatment. The device comprisesan upper electrode, a lower electrode, a medium, a treatment chamber, a film laminating roller, a coating roller, a liquid storage tank, a film laminating wind up roll, a supporting roller, a wind uproll, a backing-off roller, a power supply, an air inlet hole and an exhaust hole. According to the device and method provided by the invention, hydrophobic treatment is carried out on a single faceof the fabric while the other face is protected, so that the fabric has excellent moisture guiding performance, wherein one face is super-hydrophobic while the other face is hydrophilic. Constant temperature plasma continuous online treatment is carried out to the fabric, so that the treatment efficiency is improved, and the fabric is environment-friendly and energy-saving and efficient.

Owner:NANTONG SAIHUI TECH DEV

Polyamide 56 fiber as well as preparation method and application thereof

ActiveCN110373736AGood moisture wicking effectImprove comfortYarnSynthetic polymer filament chemical after-treatmentEvaporationMoisture permeability

The invention provides a polyamide 56 fiber as well as a preparation method and application thereof. The moisture regain of the polyamide 56 fiber is 3.8% or more. The polyamide 56 fiber provided by the invention can effectively improve the moisture conductivity and moisture permeability of a natural fiber when blended with the natural fiber, so that a fabric can quickly absorb the moisture from the surface of the skin and quickly transfer the moisture to the outer surface of the fabric for evaporation, the interior of the fabric keeps dry, and the comfort of the human body is significantly enhanced.

Owner:CATHAY R&D CENT CO LTD +2

Preparation method of moisture-absorbing sweat-releasing antibacterial polyester filament

PendingCN110714236AThe process method is simple and efficientImprove antibacterial propertiesFilament forming substance formingMonocomponent polyesters artificial filamentPolyesterFiber

The invention belongs to the technical field of chemical fiber processing, and particularly relates to a preparation method of moisture-absorbing sweat-releasing antibacterial polyester filament, including the steps of (1), pre-crystallizing polyester chips in a crystallizer, venting and drying the pre-crystallized polyester chips; (2), subjecting silver powder to coating treatment to obtain the silver powder of which the surface is coated with SiO2 and having the grain size being 3-20 micrometers; (3), mixing and melting the polyester chips and the coated silver powder by regulating a screw extruder and an output injection pump; (4), feeding a melt obtained by mixing and melting into a spinning box, spinning by extruding in a spinning assembly through a metering pump to obtain slivers incross structure; (5), subjecting the slivers to cooling by ring air, drafting, elasticizing, winding and packaging finally. Since the silver powder is coated, aggregation of the silver powder is reduced, the polyester fiber has better antibacterial performance, and the silver powder in the fiber is not easy to come off.

Owner:青岛银原素纺织科技有限公司

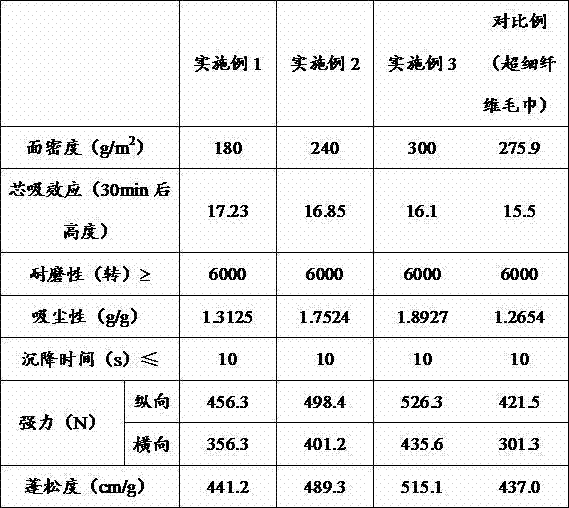

Rubbing cloth and production method thereof

The invention discloses rubbing cloth and a production method thereof. The rubbing cloth has three layers. The surface layer and the bottom layer of the rubbing cloth are respectively superfine fiber filament layers. The middle layer of the rubbing cloth is a staple fiber mesh layer. The invention further discloses the production method of the rubbing cloth. The rubbing cloth has the advantages that the back of the rubbing cloth can fast absorb moisture and fine silt on the surface of a car body during wiping, car scratching is avoided, water marks are prevented, fiber chip dropping is avoided, the front side of the rubbing cloth can well polish the car body and is loosen and thick in touch, fine in cloth surface, good in wear resistance and high in strength, the rubbing cloth can be washed, the rubbing cloth is brand new in design concept and function and is ideal car wiping material, the rubbing cloth can also be used as good wiping material of computer and mobile phone screens and glasses, and the rubbing cloth is promising in market prospect.

Owner:山东星地新材料股份有限公司

Protein-containing functional fiber

InactiveCN1676686AGood antibacterial effectHigh occlusion rateFilament/thread formingArtifical filament manufactureFiberPolymer science

This invention publishes a kind of functional fiber which contains protein. It is made up of protein, high polymer and the substances containing non-metallic element. Among these, the protein takes up A of the total quantity, the high polymer taking up B and the substances containing non-metallic element taking up C. Then we get 1<=A<=67, 10<=B<99 and 0 D01F 1 / 10 D01D 5 / 00 0 6 1 2004 / 3 / 30 1676686 2005 / 10 / 5 000000000 Li Guanqi Henan 457000 Li Guanqi Li Heze zhang chaolin 41109

Owner:李官奇

Method for preparing waterproof moisture-permeable coated fabrics

InactiveCN107916577AImprove washing resistanceGood moisture permeabilityUltrasonic/sonic fibre treatmentCoatingsMoisture permeabilityEngineering

The invention discloses a method for preparing waterproof moisture-permeable coated fabrics. The method includes thoroughly washing and drying the surfaces of fabrics, then placing the fabrics in low-temperature plasma devices and carrying out low-temperature plasma treatment on the fabrics in oxygen atmosphere to obtain pretreated textile fabrics; driving the fabrics by setting machines to transmit the fabrics through impregnation liquid, impregnating the fabrics and then rolling out redundant impregnation liquid by the aid of rollers; driving pad-rolled fabrics by the setting machines to sequentially transmit the pad-rolled fabrics through 8 drying tanks and carrying out setting steps on the fabrics. The pickup is 80-89% after the redundant impregnation liquid is rolled out by the rollers. The method for preparing the waterproof moisture-permeable coated fabrics has the advantages that moisture-permeable micro-pores can be formed in films, and the moisture-permeable micro-pores in the films are excellent in moisture transmissibility; the moisture permeability of coated textile fabrics can be improved under double moisture-permeable effects, the waterproof moisture-permeable coated fabrics are excellent in washing fastness, and accordingly the method has an excellent market promotion value.

Owner:SUZHOU EMBROIDERY COLORFUL WORLD EMBROIDERY CRAFT CO LTD

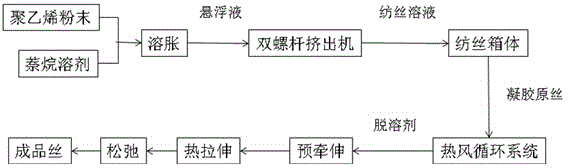

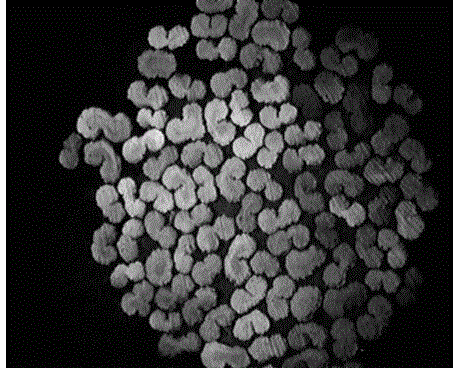

A preparing method of a polyethylene fine-denier moisture-conducting fiber

InactiveCN106032583AImprove performanceSoft and comfortableDry spinning methodsMonocomponent polyolefin artificial filamentConventional polyethyleneWind circulation

A preparing method of a polyethylene fine-denier moisture-conducting fiber is disclosed. The polyethylene fine-denier moisture-conductive fiber the fineness of which ranges from 22 dtex to 1776 dtex is obtained by swelling ultra-high-molecular-weight polyethylene used for fiber and having a molecular weight of 4-8 million in decalin to obtain a suspension, dissolving and shearing through a twin-screw extruder to allow polyethylene macromolecular chains to be fully untwisted to form a uniform spinning solution, spinning through a spinneret plat, removing the decalin in a silk bundle in a hot-wind circulation system, pre-stretching, performing one or more thermal stretch steps and performing one or more loosing steps. The hot-wind circulation system is a sealed heating chamber having nitrogen circulated therein. The polyethylene fine-denier moisture-conductive fiber is lighter, thinner and softer than conventional polyethylene fibers, maintains high-strength and high-modulus characters. The cross section of the fiber has an oval shape, an egg shape, a dog bone shape, a bean shape or other special shapes. The fiber is provided with micro grooves and slots at the axial direction. Moisture-conducting performance of the fiber is obviously improved than that of wet-process fibers. The fiber is obviously improved in wearability, and fabric of the fiber has moisture conducting and rapidly drying and refreshing properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-component blending health-care yarn semi-worsted with tea fibers and preparation method as well as applications thereof

The invention discloses a multi-component blending health-care yarn semi-worsted with tea fibers. The multi-component blending health-care yarn comprises the tea fibers, antibacterial odor-resistant acrylic fibers, Jutecell fibers and cashmere fibers. The tea fibers are 20-35% by weight, the antibacterial odor-resistant acrylic fibers are 15-35% by weight, the Jutecell fibers are 15-30% by weight, and the cashmere fibers are 15-30% by weight. The performance indexes of the blending yarn are as follows: breaking strength of a single yarn is 12.9-18.1cN / tex, the variable coefficient Cv value of the breaking strength of the single yarn is 9.3-15.7%, and the variable coefficient Cv value of yarn evenness is 13.9-21.9%. Compared with the prior art, the multi-component blending health-care yarn semi-worsted with the tea fibers has health-care functions of antibiosis, bacteriostat, sterilization, deodorization, itching, skin protection, physical fitness, skin moisture and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com