Spinning method of super-soft high-conductivity wet polyester yarn

A high moisture conductivity, polyester technology, applied in the direction of yarn, textiles and papermaking, can solve the problems of not significantly improving the softness and moisture absorption and moisture conductivity of yarns and fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

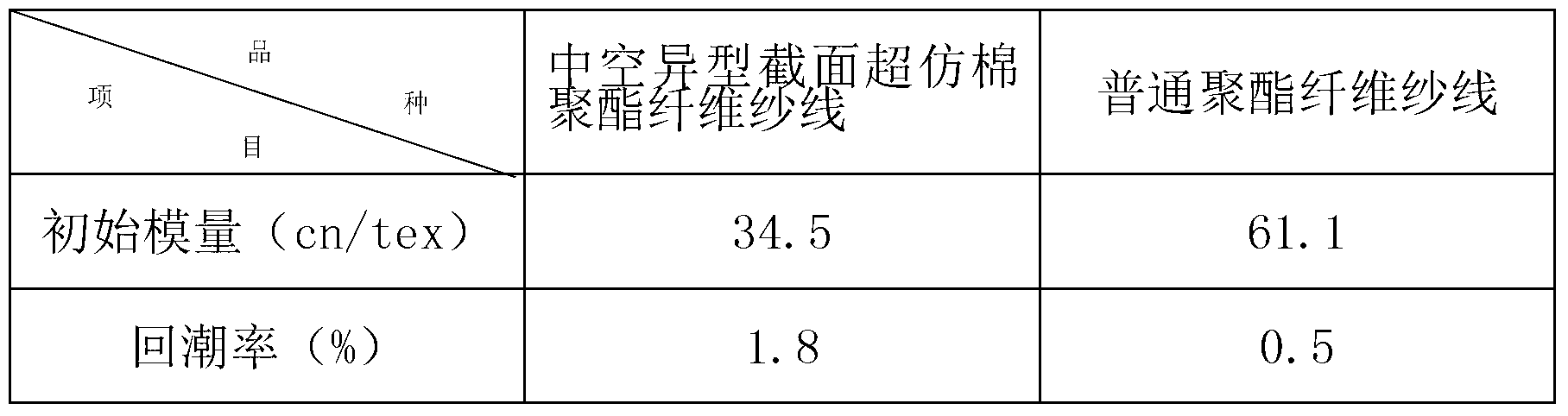

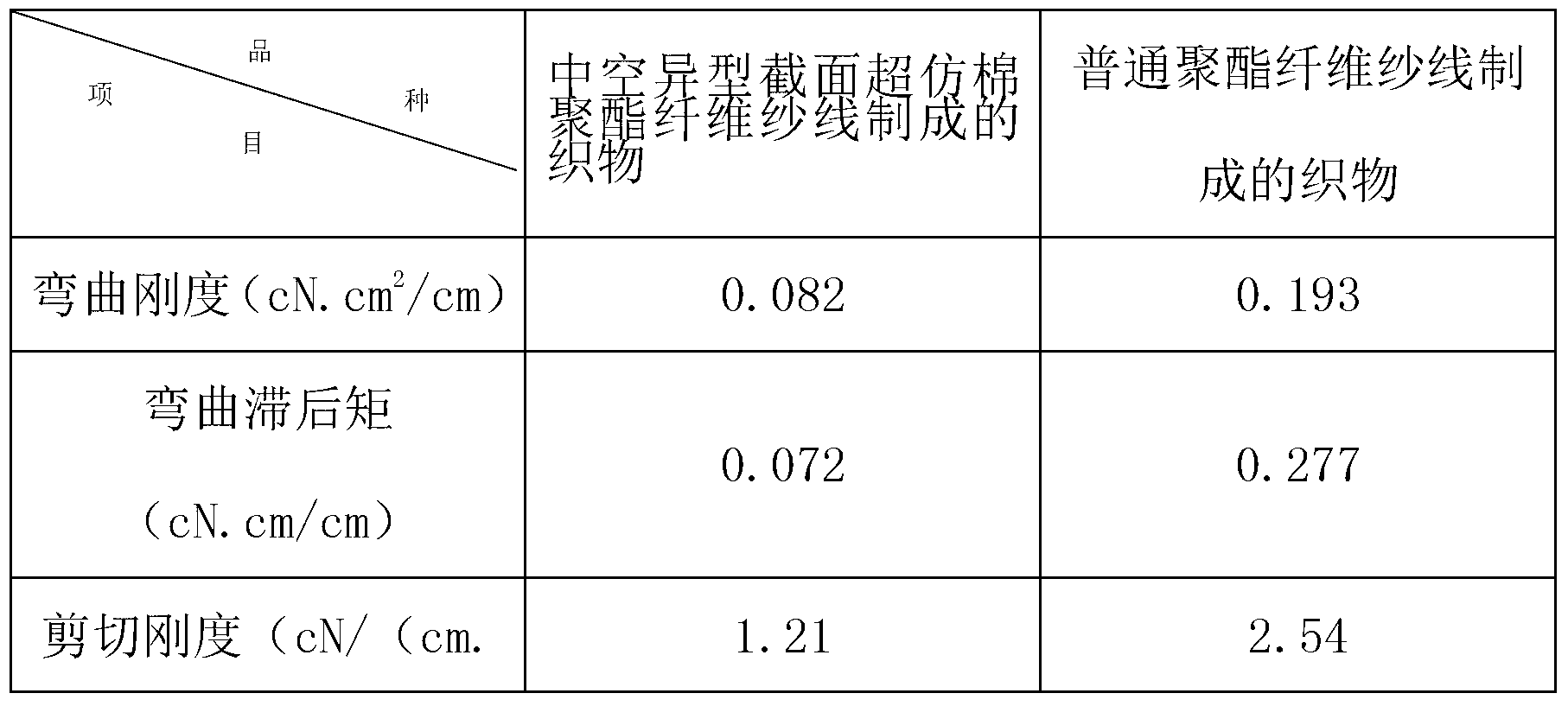

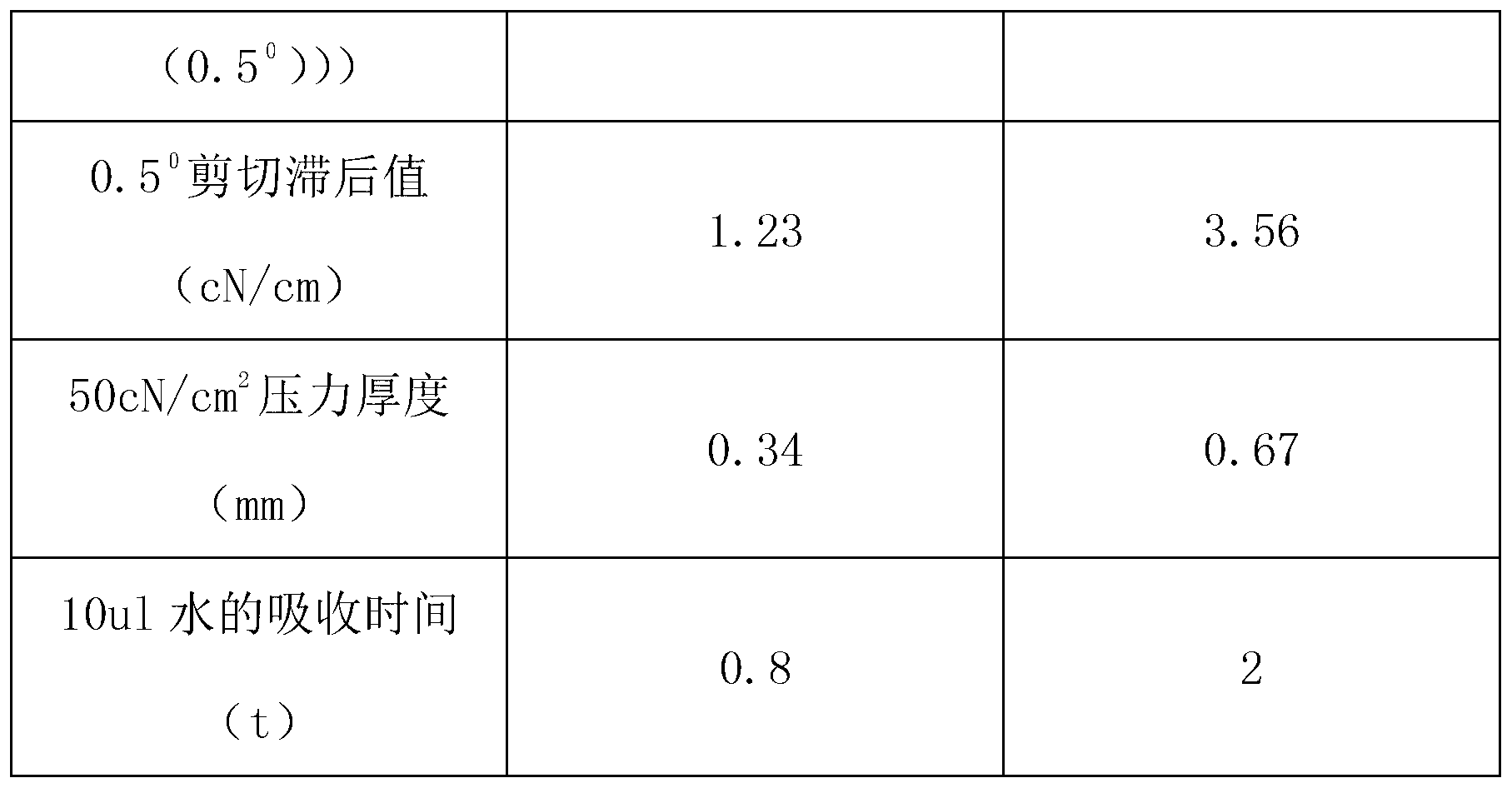

[0008] The present invention uses new-type hollow special-shaped section super imitation cotton polyester fiber as raw material, in the spinning process of forming this fiber, by changing the shape of the spinneret hole, the fiber has a hollow special-shaped section, and applies chemical and physical methods to increase The flexible group and hydrophilic group in the fiber, the fiber produced has excellent properties such as super softness, easy dyeing, good moisture permeability, and warmth retention. In the spinning process of the present invention, the technological process is the same as that of conventional yarns, and the spinning process uses low-twist and low-torque spinning technology for spinning, so that the yarn produced has a reduced initial modulus, is softer, and has stronger moisture absorption performance. In this process, water-soluble vinylon filaments and hollow special-shaped cross-section super-imitation cotton polyester fiber strands are used for core-spun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com