Maize protein colored textile fiber and method for producing same

A technology for color spinning fibers and proteins, applied in the field of textile materials, can solve the problems of poor color fastness and poor gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

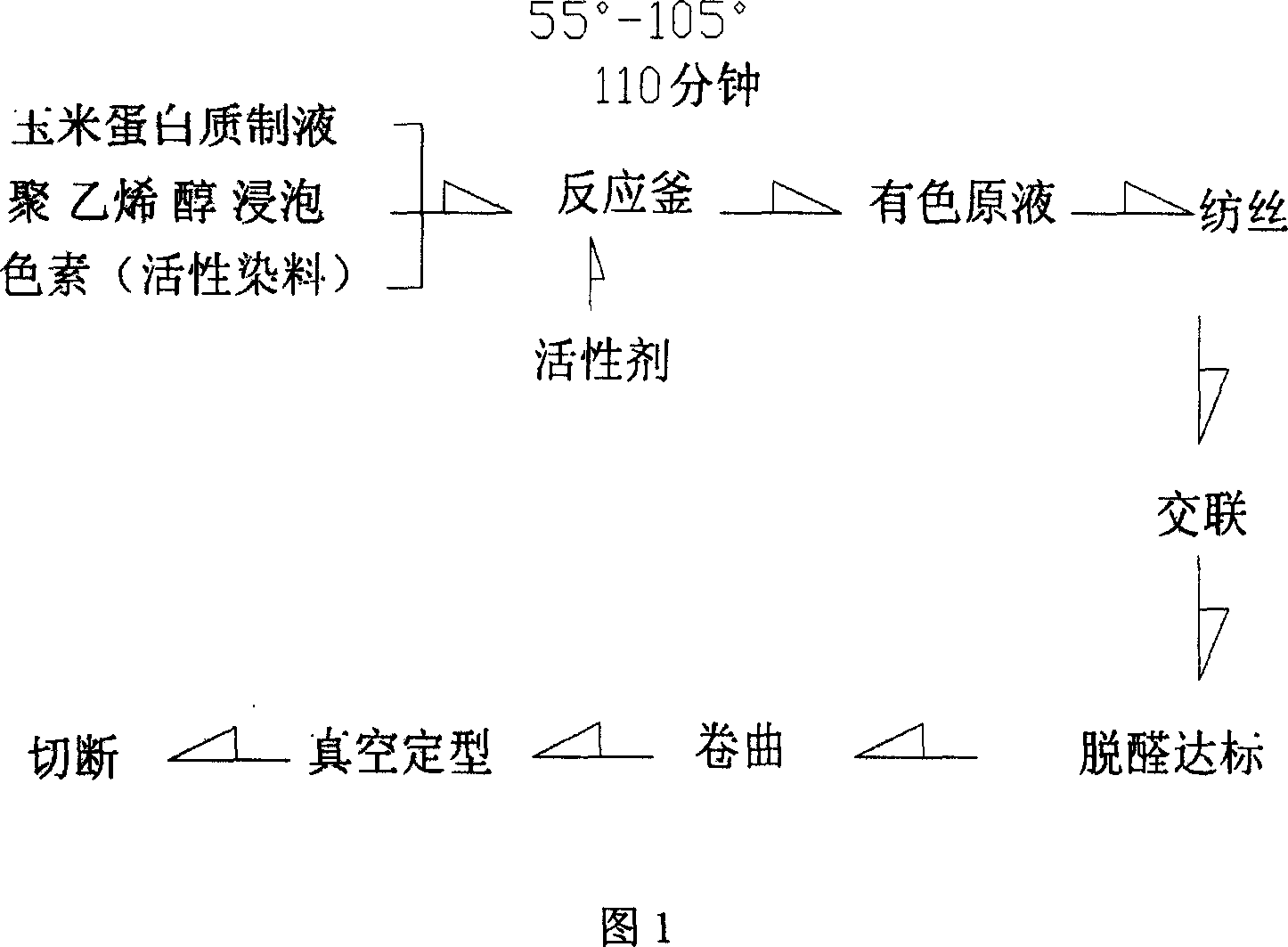

[0007] (1) Preparation of corn protein, soaking in polyethylene, and preparation of color paste;

[0008] (2) Add corn protein, soaked polyethanol, and color paste to the reaction kettle, heat at 55°C-105°C, and react for 100-120 minutes;

[0009] (3) Add active agent colored liquid preparation;

[0010] (4) spinning;

[0011] (5) cross-linking;

[0012] (6) dealdehyde; (reach national standard)

[0013] (7) curly;

[0014] (8) cut off;

[0015] (9) vacuum setting;

[0016] (10) PACKAGE.

[0017] Use active agent, formulate by weight percentage:

[0018] Sodium phosphate - 0.1-0.3%

[0019] Sodium perborate - 0.2-0.5%

[0020] Sodium tetraborate - 0.4-0.6%

[0021] Ethylamine - 0.2-0.4%

[0022] Bioethanol - 0.4-0.6%

[0023] Dibenzoyl peroxide - 0.6-0.8%

[0024] Reactive dyes, formulated in percent by weight:

[0025] Active Green ED-2G 0.3-0.5%

[0026] Active Yellow ED-2G 0.3-0.5%

[0027] Reactive red ED-3B 0.3-0.5% A variety of reactive dyes, reactive dye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com