Patents

Literature

73results about How to "Clean and environmentally friendly production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

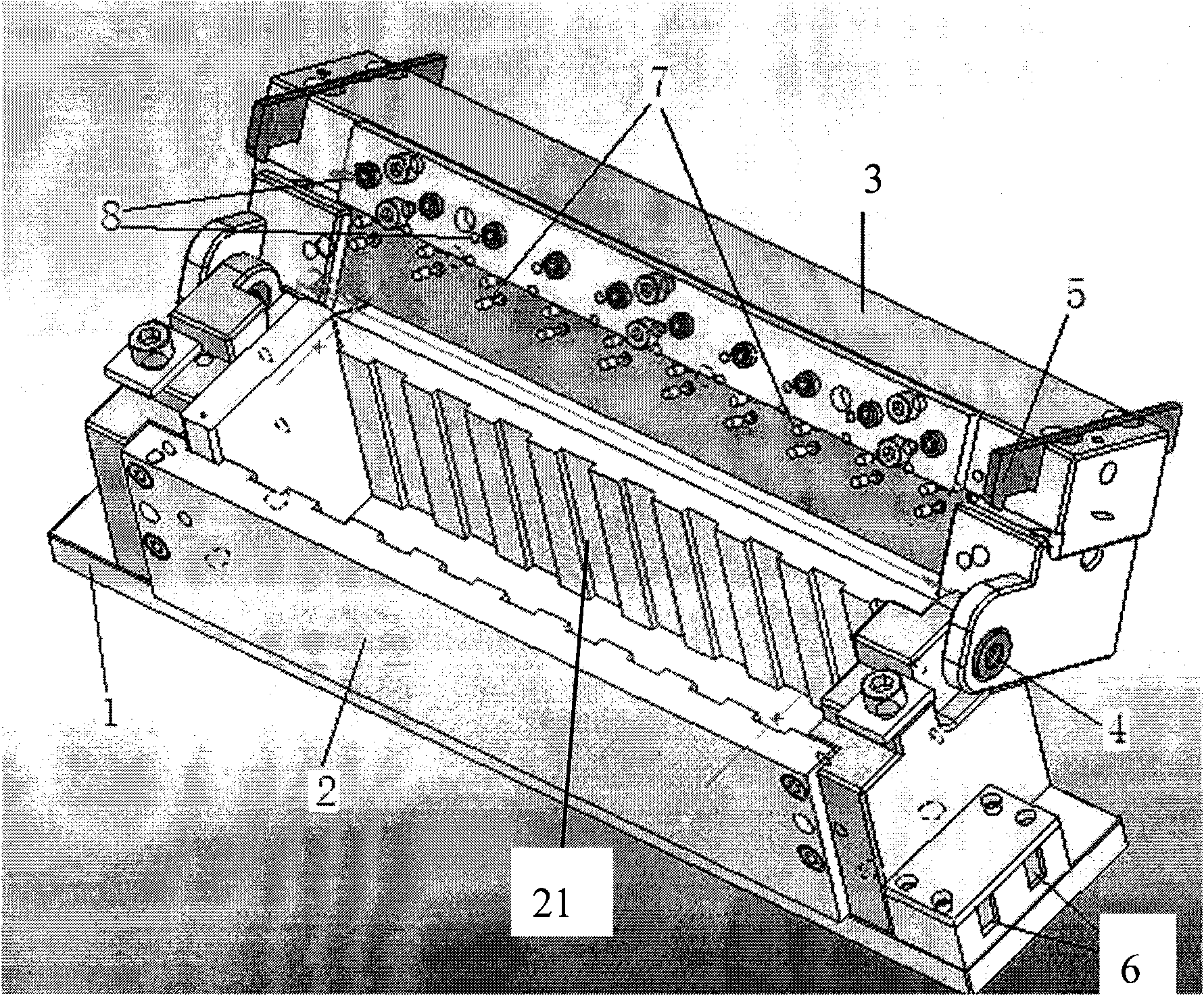

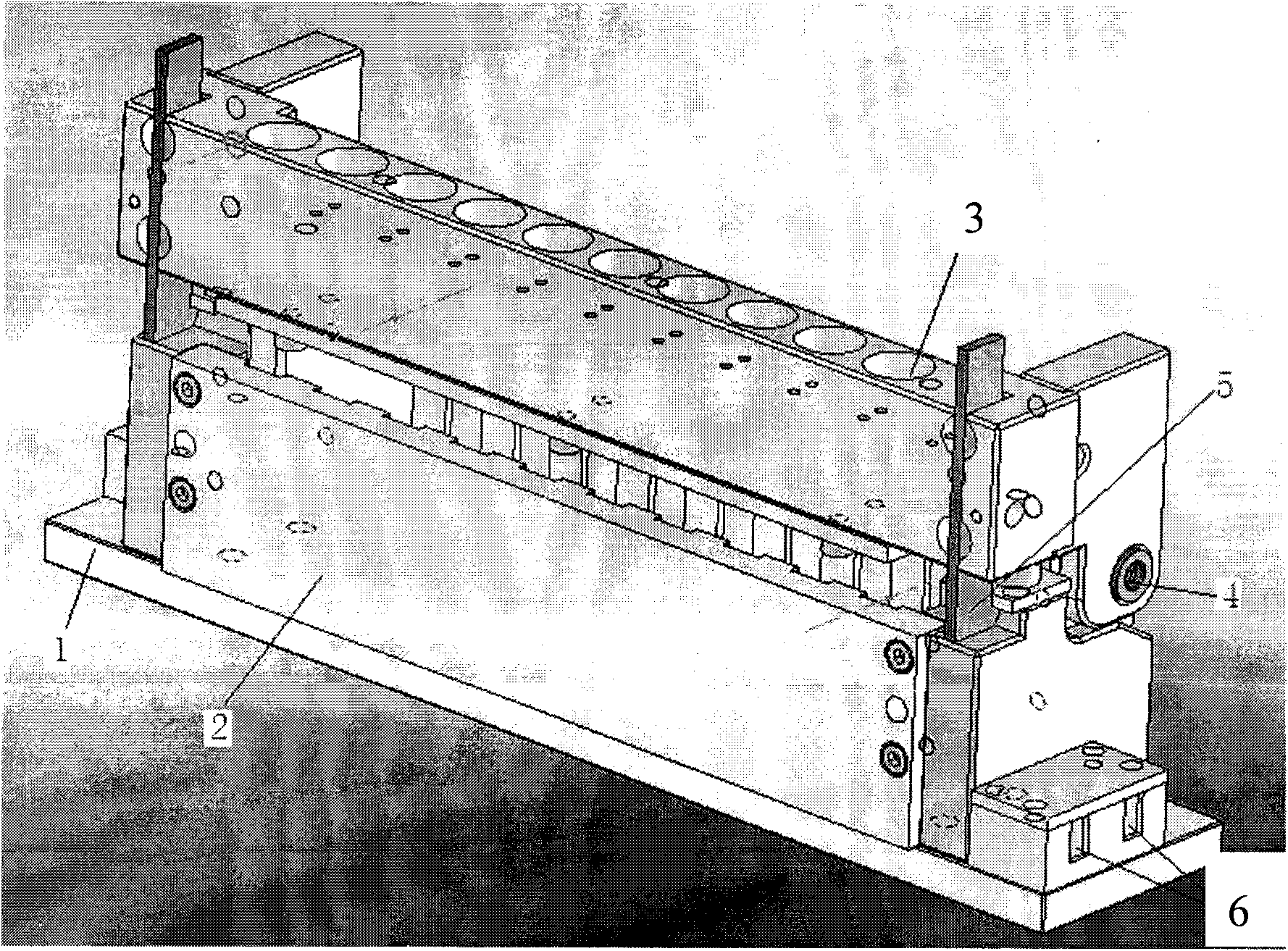

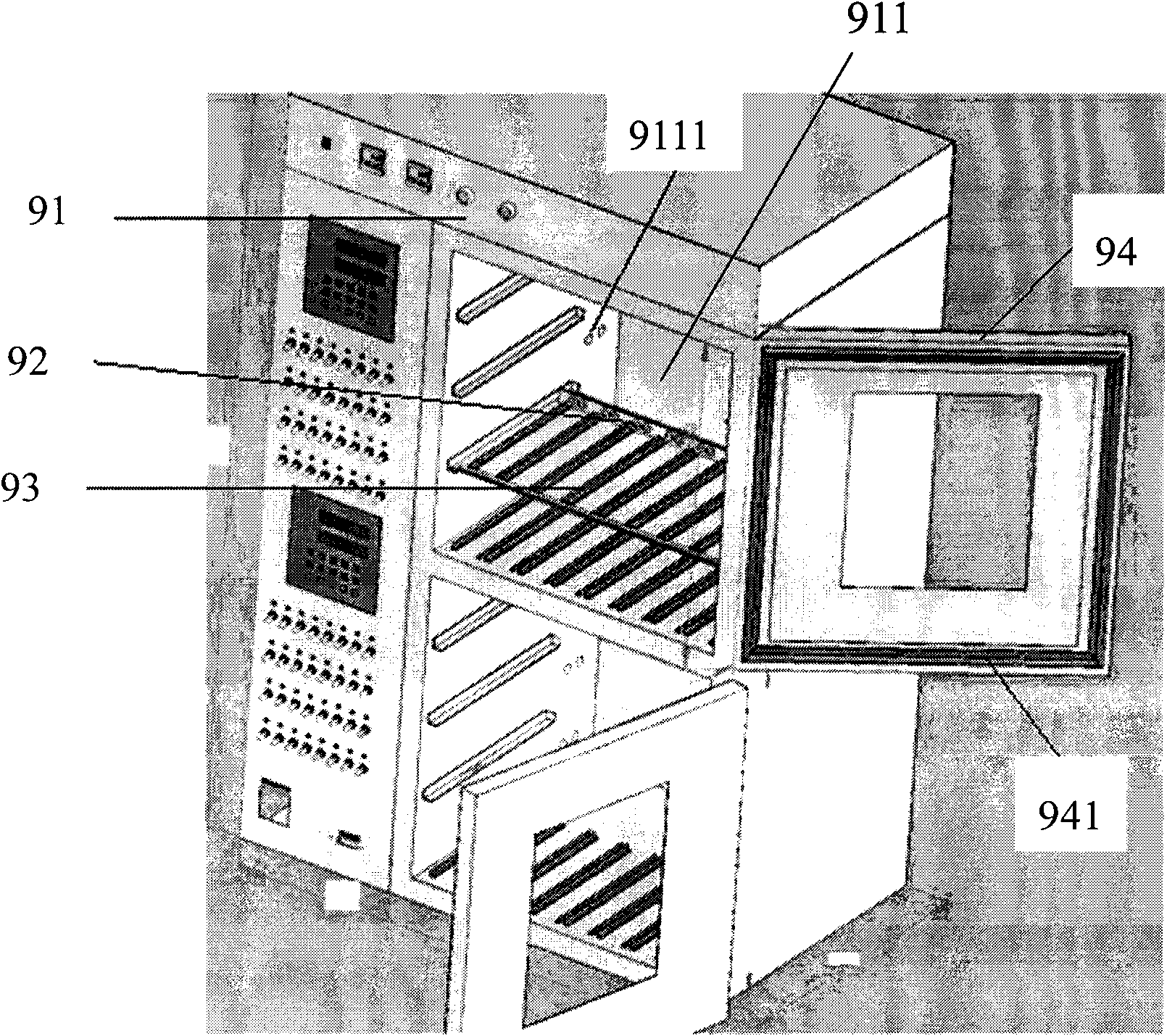

Vacuum formation method of lithium ion battery

ActiveCN101887994AImprove exhaust efficiencyShield negative influenceFinal product manufactureSecondary cells charging/dischargingEngineeringLithium-ion battery

The invention discloses a vacuum formation method of a lithium ion battery. In the method, an electrolyte injection process and a formation process of the battery are completed by adopting an integrated fixture with electrolyte-injecting and charging functions and a vacuum formation device with charging and vacuumizing functions. The vacuum formation device charges the battery arranged in the integrated fixture, and the battery is electrically connected with the vacuum formation device by the integrated fixture. The vacuum formation method of the invention provides an enclosed and controllable microenvironment, thereby reducing electrolyte waste, avoiding overflow loss of electrolyte and corrosion on a battery casing, the fixture or charging equipment, and effectively reducing environmental pollution.

Owner:东莞市鸿德电池有限公司 +1

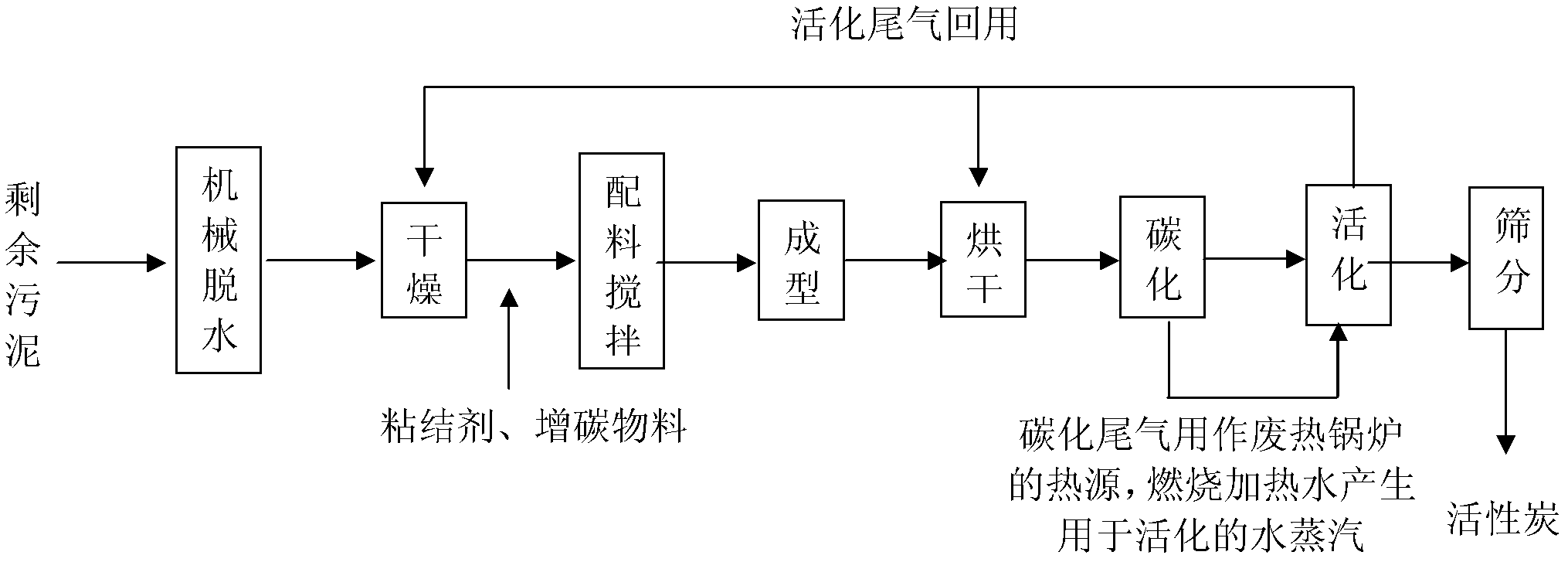

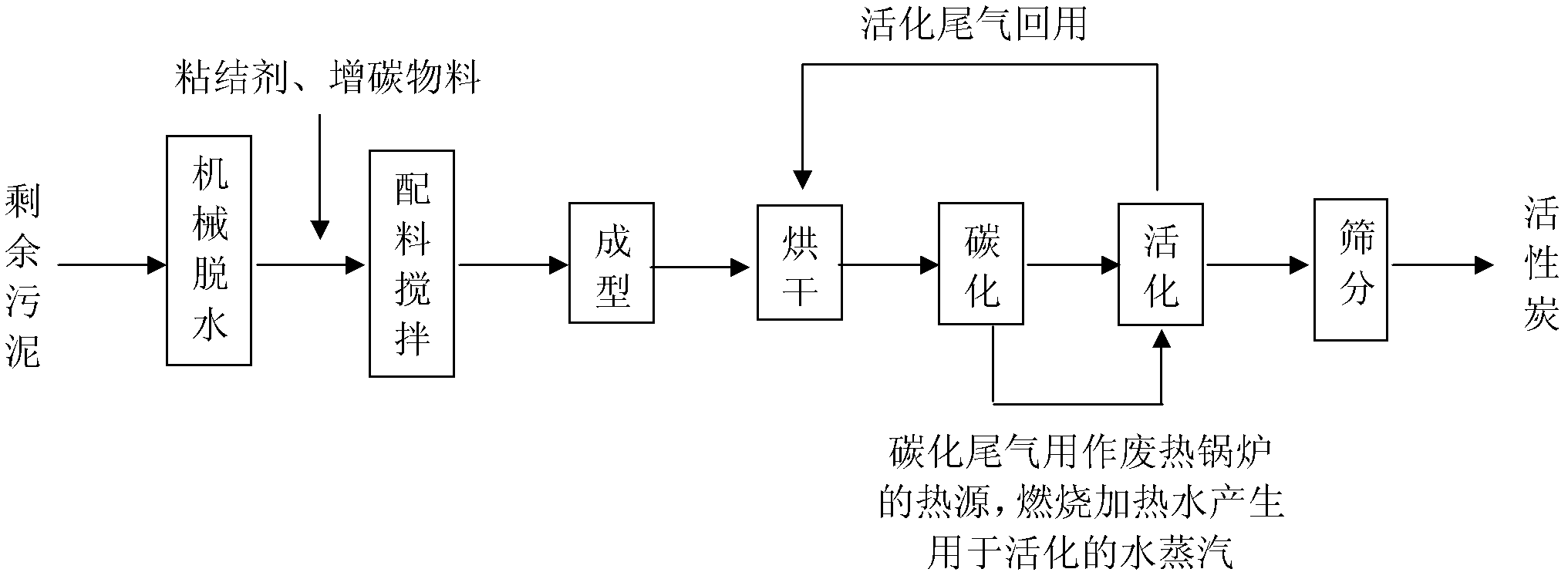

Method for preparing activated carbon by physical activation of excess sludge

InactiveCN102432007AAlleviate shortagesWide variety of sourcesCarbon compoundsEnergy inputActivated carbonSocial benefits

The invention relates to a recycling disposal of industrial solid waste, in particular a method for preparing activated carbon by physical activation of excess sludge. The method comprises taking excess sludge generated by sewage treatment as raw material, utilizing water vapour as activating gas and preparing sludge activated carbon by physical activation. The invention takes large amount of excess sludge generated by sewage treatment as raw material to prepare activated carbon and realizes highly efficient utilization of energy resources by multi-type excess heat recycling, therefore, the generated activated carbon product has low energy consumption. Compared with chemical activation, the physical activation has no large amount of waste water generation during the preparation process and the production process is clean and environment friendly. The invention has excellent economic, ecological and social benefits.

Owner:NANJING UNIV OF TECH

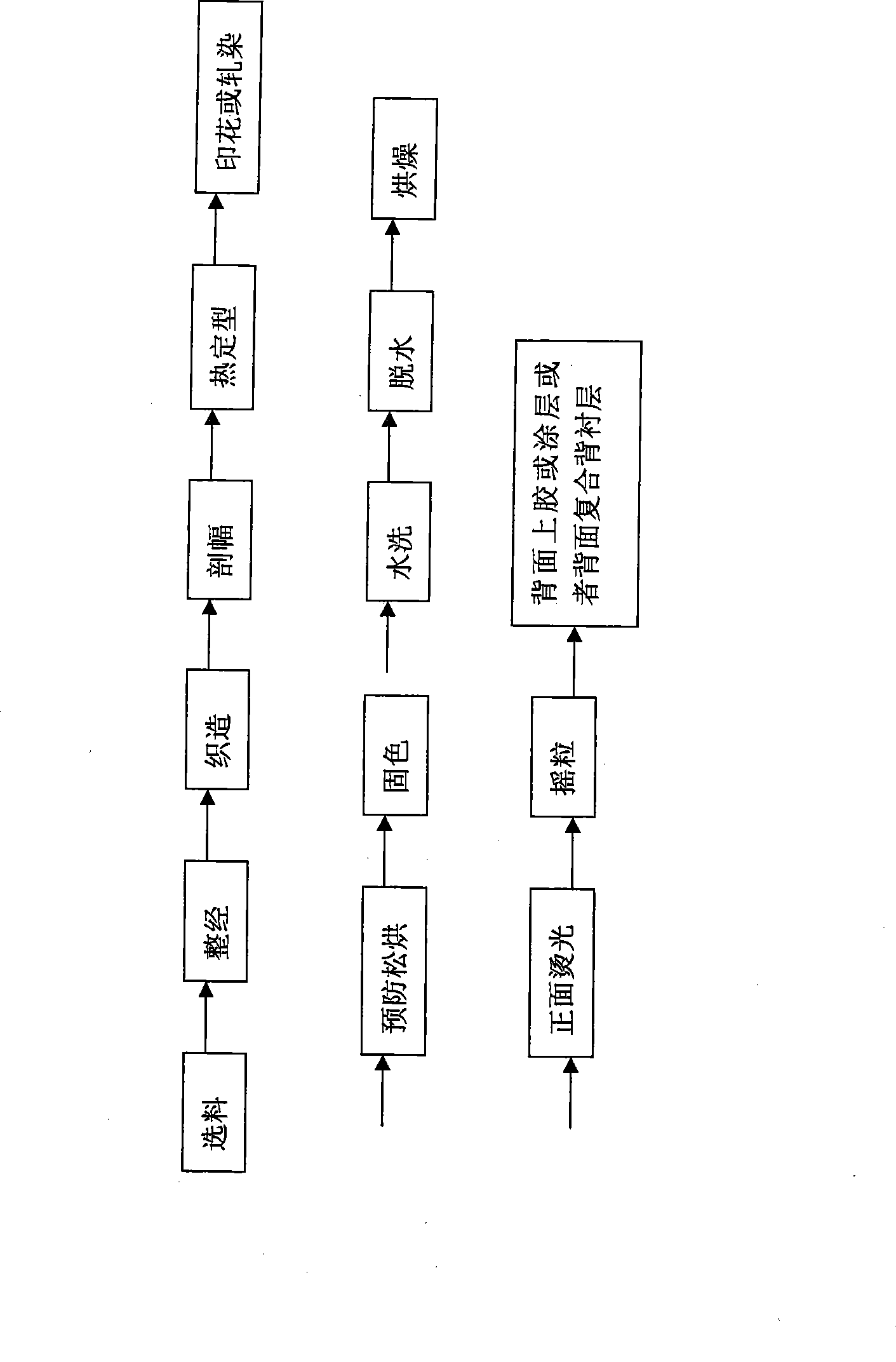

Brocade fabric active and neutral dye combination catalytic fixation printing technique

ActiveCN101597868AReasonable printing processClean and environmentally friendly productionDyeing processUreaAfter treatment

The invention relates to a brocade fabric active and neutral dye combination catalytic fixation printing technique. The technical problem to be solved is to provide a printing technique which can produce a brocade printing clothing plus material with top grade and light mass which is comfortable to wear. The technical proposal is that (1) textile pretreatment, the textile is pretreated by desizing, boiling, and bleaching; (2) presetting, technique conditions are that the temperature is 160 to 165 DEG C and the time is 30 seconds; (3)printing formulation preparation, 40 to 50 % of printing thickener, 0.05 to 1.0% of fixation catalytic agent, 1 to 1.5% of alkaline agent, 1% of reserve salt, 5% of urea, active dye and an amount of neutral dye and rest of water; (4)printing technique, according to the formulation in the step (3), the printing is carried out; the aging temperature is 102 to 105 DEG C, and the aging time is 18 to 20 min; (5) washing and soaping, fixing agent FRC is used for the after-treatment, afterboarding and tentering of the printing plus material. The technique is suitable for textile printing and dyeing industries.

Owner:浙江嘉欣兴昌印染有限公司

Warp knitting terylene ginning velvet carpet and method of processing the same

InactiveCN101476207AIncrease elasticityGood hygroscopicityWarp knittingHeating/cooling textile fabricsEngineeringMildew

The invention provides a warp knitting terylene polar fleece carpet which belongs to the terylene fibre product technique field. The carpet includes a flocked yarn and a bottom yarn, the flocked yarn is made of 500-780dtex DTY terylene continuous yarn with 80-100 pieces per meter network, the bottom yarn is made of 167-333dtex FDY terylene yarn, a flocked surface height of the flocked yarn is 5-12mm, wherein, single yarn denier of the DTY terylene continuous yarn is more than or equal to 3.5dtex. The carpet has advantages that processing technique is shortened, production process is more environmentally friendly and cleaning, and cost is lower; the carpet has high impact resistance, better elasticity and hygroscopic property, abrasive resistance is second only to chinlon, high heat and solarization resisting property, no-mildew, no-moth-eaten, easy to dye or print, portable and easy to clean; the carpet is rich in polar sphere sense, has strong third dimension and flexible pattern, the carpet color is novel and shibui, has better visual effect that is suitable to be placed in high class hotel guest room, white-collar apartment, high class chamber, hotel aisle and household bathroom.

Owner:常熟市锦绣经纬编有限公司

Method for dyeing cotton-dacron-chinlon combined silk fabric

ActiveCN102720078AThe dyeing process is reasonableClean and environmentally friendly productionDry-cleaning apparatus for textilesBleaching apparatusSizingAcid dye

The invention relates to a combined fabric printing and dyeing process, and particularly relates to a method for dyeing a cotton-dacron-chinlon combined silk fabric, which can be used for well synergizing dyeing conditions, contrary to one another, of cotton, dacron and chinlon, thus producing the high-quality combined silk fabric. According to the specific technical scheme disclosed by the invention, the method for dyeing the cotton-dacron-chinlon combined silk fabric comprises the processes of preprocessing, sizing, mercerizing, dyeing and the like, wherein in the dyeing process, the dyeing is implemented by disperse dyes under an acid condition, and then the dyeing is conducted by activated dyes. The method has the beneficial effects of solving the problems related to the disperse dyes for dacron, permanent acidic dyes for chinlon, the activated dyes for cotton, and solving a series of problems of low color fixing rate, poor color fastness, serious staining, high-efficiency soaping, long process flow and the like of the fabric.

Owner:HUAFANG

Method for preparing ultrahigh molecular weight polyethylene (UHMWPE) colored fibre

ActiveCN102199805AUniform colorBright colorFilament forming substance formingMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to ultrahigh molecular weight polyethylene (UHMWPE) colored fibre and a method for preparing the same. The method comprises the following steps: firstly adding nanoscale organic heterocyclic pigments to UHMWPE powder and fully stirring and mixing the pigments and the powder in a double-thread conical mixer to obtain colored polymers; then continuously adding the colored polymers and auxiliaries to an untwisting kettle which can provide at least 1000s<-1> shearing rate to form emulsion-like mixed liquor; performing the secondary shearing and grinding on the mixed liquid by a high shear dispersion and emulsification pump; and then carrying out extrusion spinning, extracting, drying and hot drawing in a screw extruder to form the UHMWPE colored fibre. The method is simple in operation and convenient in collar change, and the obtained colored fibre has bright colour and high ageing resistance; the added pigments are nontoxic and pollution-free and are harmless to thehuman bodies, and the production process is clean and environmentally-friendly; and in the production process, the solvents are never polluted by the pigments and are convenient to recycle, thus further lowering the production cost.

Owner:CHANGSHU SUPERFIBER

Disperse/activated one-emulsion paste printing dye and printing technology thereof

The invention discloses a disperse / activated one-emulsion paste printing dye, mainly prepared from the following components: composite paste slurry, an alkaline agent, reserve salt, urea, activated dye, disperse dye and water, wherein the composite paste is mainly prepared from the following components: 60% of sodium alginate, 20-30% of sodium polyacrylate, 5-15% of polyethylene glycol 2000 and 5% of polyvinyl pyrrolidone. A printing technology of the one-emulsion paste printing dye comprises the steps of printing, drying, baking (at the temperature of 180 DEG C for 7 minutes), washing by cold water, washing by alkaline water (at the temperature of 95 DEG C for 3 minutes), washing by hot water (at the temperature of 80-90 DEG C), washing by cold water, neutralizing and drying; after that, carrying out post-boarding and tentering. The disperse / activated one-emulsion paste printing dye successfully solves the problems that a disperse dye and an activated dye are poor in compatibility during one-emulsion paste printing, the paste pH value is sensitive to the disperse dye, the disperse dye and the activated dye are low in color yield percentage and serious in white ground contamination, a cloth cover effect is poor since the disperse dye and the activated dye are large in dyeing difference of fibers, and the like; the printing technology is more reasonable in process, clean and environment-friendly in production and stable in product quality.

Owner:ZHEJIANG JIAXIN SILK

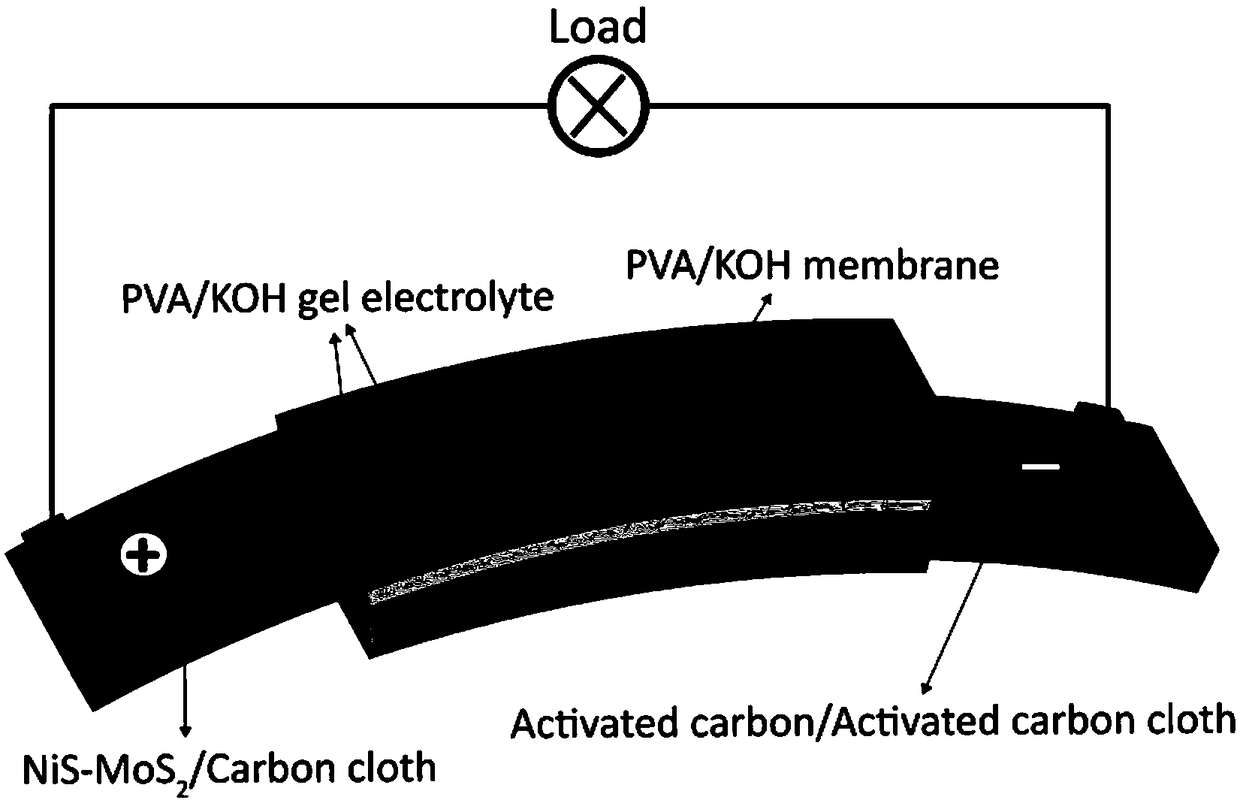

Flexible supercapacitor with nickel sulfide-molybdenum sulfide heterogeneous nano-sheet array structure based on carbon cloth loading and preparation method thereof

ActiveCN109065368ALarge capacityImprove charge and discharge stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNew energy

The present invention relates to a flexible supercapacitor with with NiS-MoS2 heterogeneous nano-sheet array structure based on carbon cloth loading and a preparation method thereof, belonging to thetechnical field of new energy material and device preparation. The flexible supercapacitor grows high-purity, high-density and high-orientation carbon cloth-loaded NiS-MoS2 heterogeneous nanosheet array by using anode material, carbon cloth coated with activated carbon as cathode material, PVA / KOH gel as diaphragm and electrolyte respectively. The anode has the advantages of high purity, high density, tidy appearance, strict controllable growth condition, simple equipment and process, low cost, high capacitance and good charge-discharge stability. The cathode material has excellent conductivity and large double-layer capacitance. The preparation process of the capacitor is simple, economical and environmentally friendly, and no post-treatment is needed. The supercapacitor provided by the invention has the advantages of light weight, large capacity, good cycle charging and discharging stability, and good flexibility, and can be used for power supply equipment of wearable electronic devices.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Environment-friendly preparation method of pentaerythritol acrylic ester and derivate

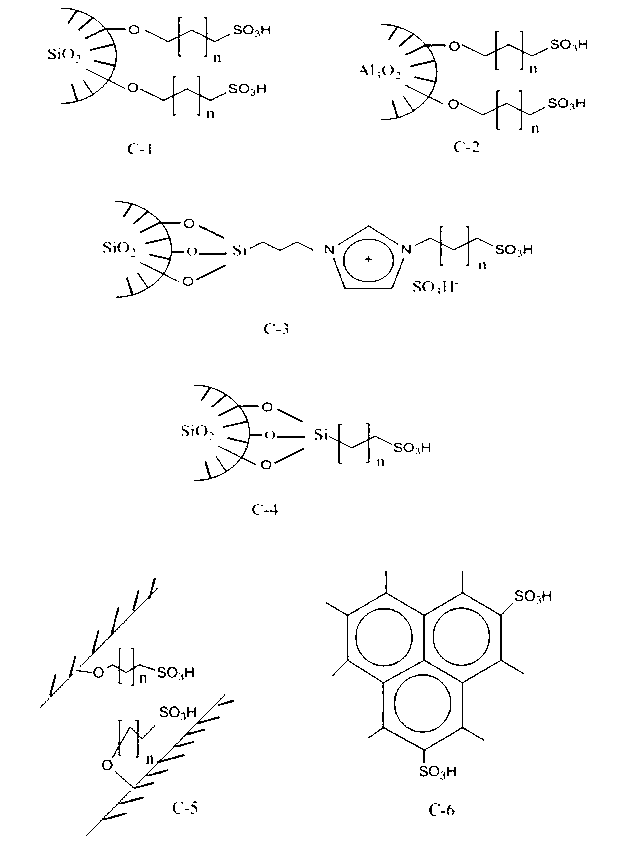

ActiveCN103274940AEasy to recycleEmission reductionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPentaerythritolSorbent

The invention belongs to a preparation method of pentaerythritol acrylic ester and a derivate. The method comprises the following steps of: in the presence of solvents and polymerization inhibitors, catalyzing pentaerythritol (or dipentaerythritol) and acrylic acid by using a chemical binding solid acid catalyst to perform a backflow dehydration esterification reaction; after the reaction is finished, filtering and recycling the chemical binding solid acid catalyst, and then, processing a product by using a solid alkali adsorbent and a decolorizing agent; and finally, performing pressure reduction and filtering to obtain pentaerythritol (or dipentaerythritol) acrylic ester. The preparation method is simple in process, high in yield of the product and high in quality; and wastewater discharge is avoided during production, and the catalyst is recycled.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

Polyamide cotton fabric one-bath dyeing method

InactiveCN102321986AThe dyeing process is reasonableClean and environmentally friendly productionHeating/cooling textile fabricsDyeing processSodium carbonateResist

The invention discloses a polyamide cotton fabric one-bath dyeing method. After pretreatment and pre-setting treatment, the method comprises the following steps: adding water according to a bath ratio of 15:1 of polyamide cotton fabric to be dyed, charging the fabric and running for 5 minutes, orderly charging a molten reactive dye M-2GE with a concentration of 1.8%(owf), 2 ml / l of acetic acid, 2 g / l of disodium hydrogen phosphate, and 3 g / l of resist salt, heating, performing heat preservation and running for 30 minutes, adding 25 g / l of sodium carbonate, 3 g / l of urea, and 20 g / l of sodium sulfate, performing heat preservation and running for 40 minutes, cooling to 60 DEG C, draining, flushing, adding water to obtain a bath ratio of 1:15, adding 3 g / l of soaping agents, heating to 90 DEG C, washing with water for 15 minutes, cooling, draining, washing with water, drying, performing fixation treatment by a environment-friendly neutral dyeing fixing agent FRC, and finally performing setting and tentering.

Owner:无锡市联盛印染有限公司

Method for preparing chitin and chitosan through hydrothermal/two-step enzymic method from shrimp and crab shells and application of the method

InactiveCN110256603AImprove accessibilityRealize multilinkOrganic compound preparationCarboxylic acid salt preparationPollutionImpurity

The invention relates to a method for preparing chitin and chitosan by coupling shrimp and crab shells through a hydrothermal / two-step enzymic method. The method comprises the following steps: removing impurities from shrimp and crab shells, and crushing the shrimp and crab shells; adding organic acid for decalcification treatment, placing filter residues into a hydrothermal reactor, and feeding a reaction medium for hydrothermal reaction; then rapidly relieving the pressure in the reactor, collecting a hydro-thermal treatment product, carrying out solid-liquid separation, and adding protease into a solid material to carry out enzymolysis deproteinization treatment; separating the deproteinized product to obtain solid residues, drying the solid residues to obtain chitin, and adding chitin deacetylase into the chitin for enzyme treatment to prepare chitosan; and finally, treating the organic acid decalcification solution and the protein enzymatic hydrolysate to obtain organic calcium and protein peptide. According to the method, the decalcified shrimp and crab shells are modified through a hydrothermal method, the compact structure of the shrimp and crab shells is broken, the accessibility of subsequent protease and deacetylase is promoted, the enzymolysis efficiency is improved, poly-generation of organic acid calcium, protein peptide, chitin and chitosan is achieved, the production process is rapid, stable and free of pollution, and large-scale industrial application is easy to achieve.

Owner:TIANJIN UNIV OF SCI & TECH

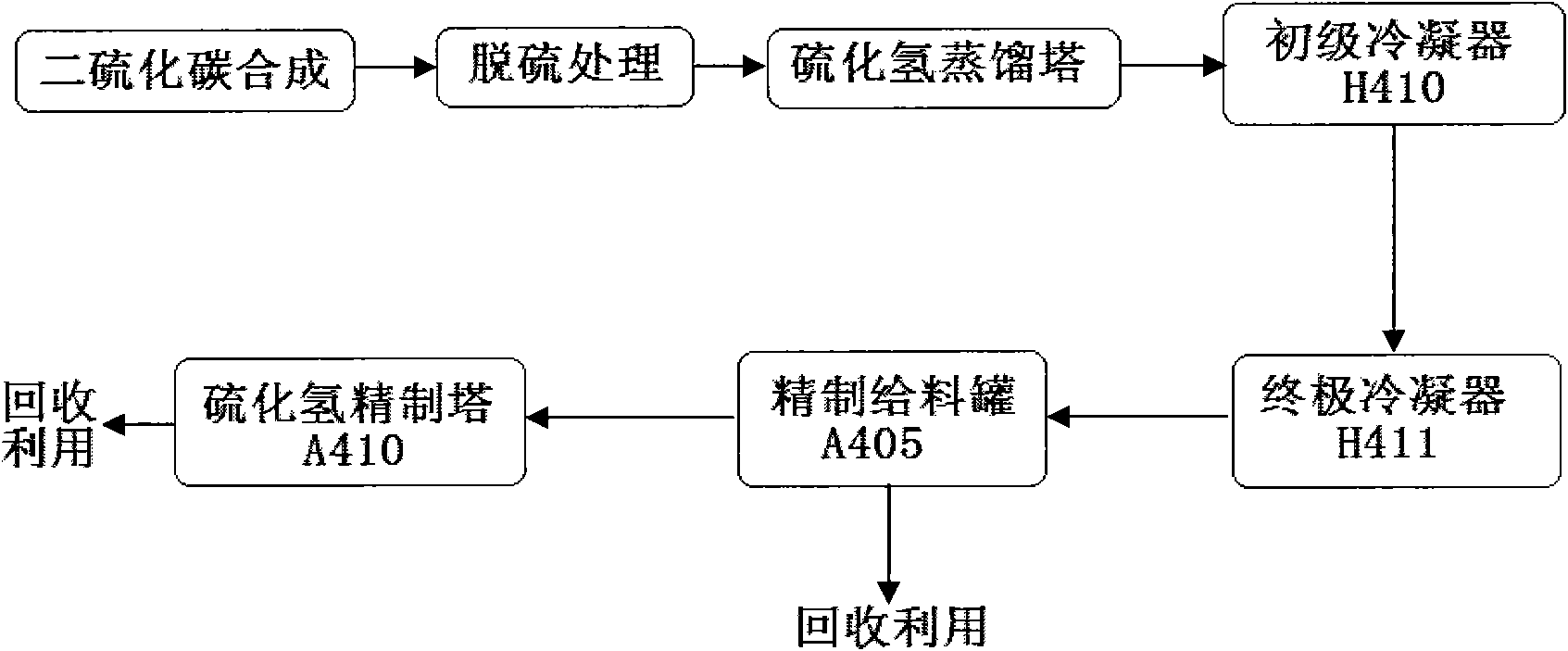

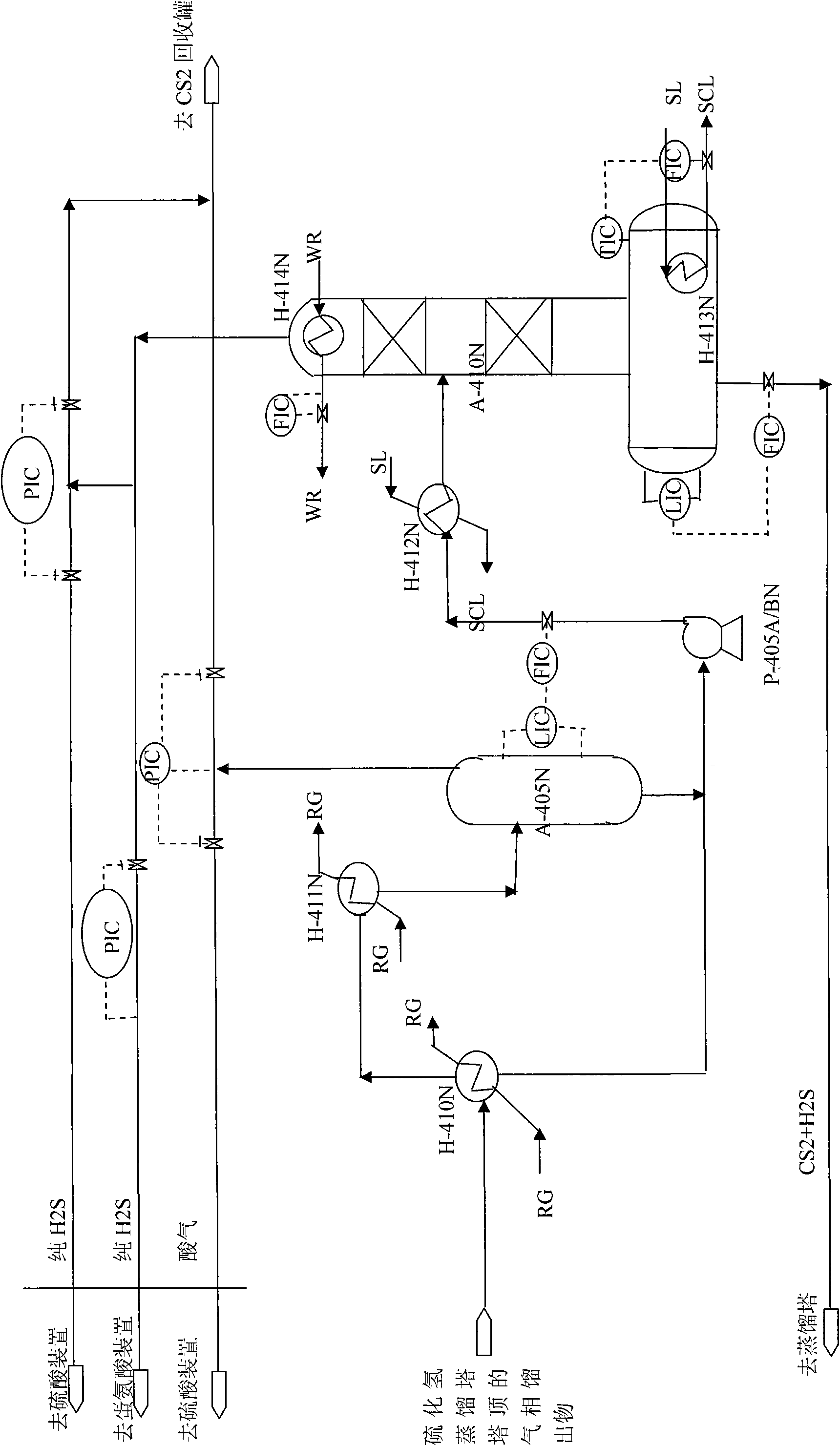

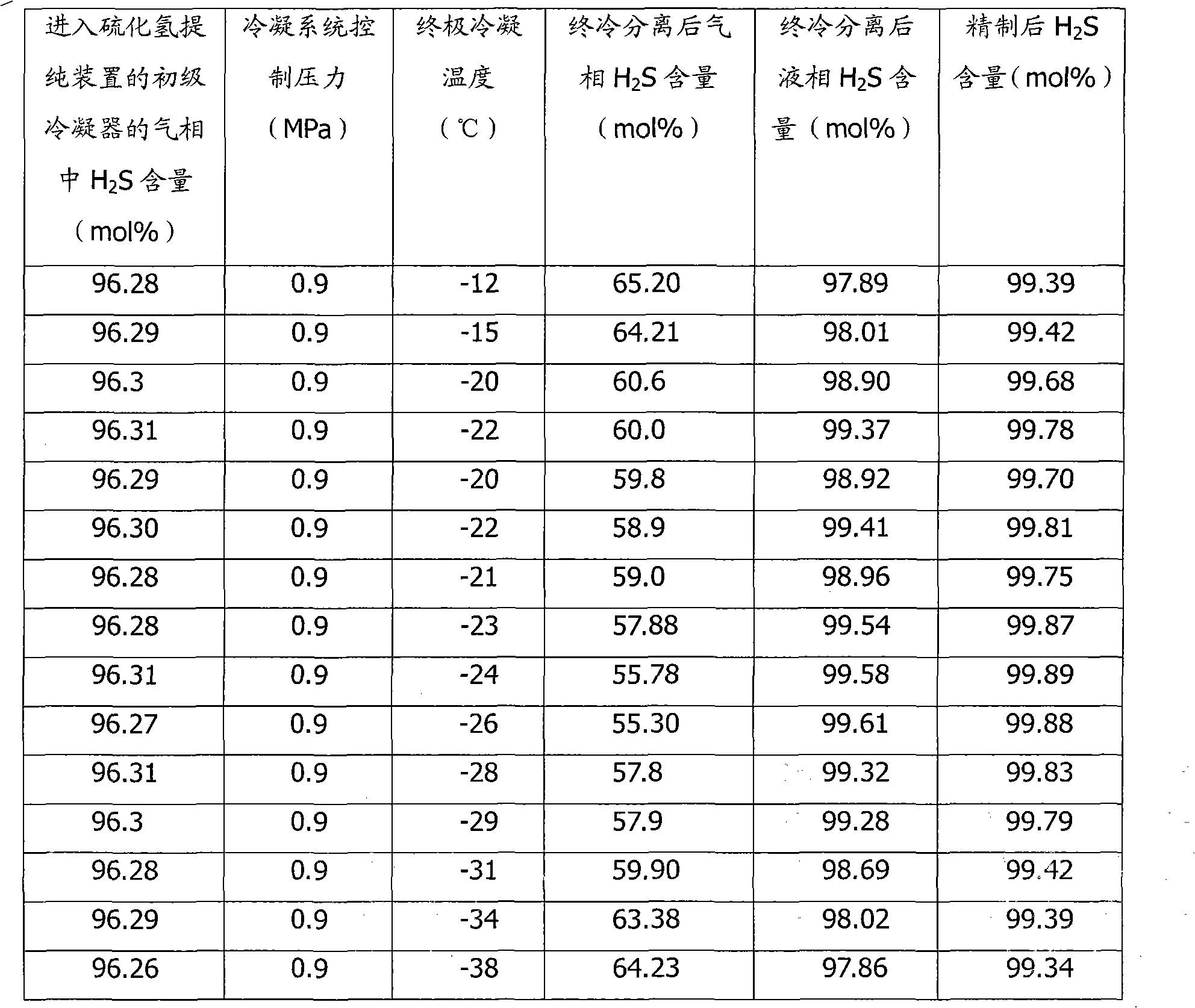

Methods for purifying and comprehensively utilizing hydrogen sulfide byproduct during production of carbon disulfide by methane method

ActiveCN102153053AOvercoming a large number of devicesOvercome stabilityHydrogen sulfidesGas phaseDistillation

The invention relates to a method for purifying a byproduct, namely hydrogen sulfide, during production of carbon disulfide by a methane method, and a method for comprehensively utilizing the byproduct. The method for purifying the byproduct comprises the following steps of: initially separating a mixture of desulfured products through a hydrogen sulfide distillation tower, and further purifying a gaseous phase product; performing two-stage condensation on a gaseous phase distillate at the top of the hydrogen sulfide distillation tower through a primary condenser and an ultimate condenser; and further purifying by using a refining feeding pot and a hydrogen sulfide refining tower so as to finally obtain the high-purity hydrogen sulfide. By adoption of constant-pressure two-level condensation, a lower condensation temperature can be reached to contribute to separation and elimination of inert gases in acidic gases, and the number of sets of equipment is decreased, the safety is enhanced and the equipment investment is reduced at the same time; meanwhile, by the methods, the minimum emission of waste gases and waste liquid during whole purification is realized, so the method is clean and environment-friendly.

Owner:吉林三源化工有限公司

Pressure-sensitive adhesive printed circuit forming method

InactiveCN102833954AEasy to recycleNo pollutionConductive pattern formationEngineeringPressure sensitive

The invention relates to a pressure-sensitive adhesive printed circuit forming method which includes steps of printing a pressure-sensitive adhesive target circuit consisting of pressure-sensitive adhesive on a printed substrate; placing the printed substrate with the pressure-sensitive adhesive target circuit into an oven or at the normal temperature until the pressure-sensitive adhesive target circuit is dried completely; spreading conductive powder onto the pressure-sensitive adhesive target circuit to cover the same completely so as to form a conductive powder layer on the pressure-sensitive adhesive target circuit after the pressure-sensitive adhesive circuit is dried; removing residual conductive powder on the printed substrate by blowing or sucking and recovering the residual conductive powder; pressurizing the printed substrate on a press machine to compact the conductive powder on the pressure-sensitive adhesive target circuit; and coating a protective layer on the conductive powder layer to obtain a pressure-sensitive adhesive circuit. The pressure-sensitive adhesive printed circuit forming method has the advantages that production process is clean and environment-friendly, environment-friendly base materials can be adopted, production efficiency is high, cost is low and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Printed circuit forming method

InactiveCN102833955AClean and environmentally friendly productionNo pollution in the processConductive pattern formationFlexible circuitsMaterials science

The invention relates to a printed circuit forming method which includes steps of printing a target circuit pattern on a substrate through ink; spreading conductive powder onto the target circuit pattern to cover the same completely so as to form a conductive powder layer bonded on the target circuit pattern before the target circuit pattern is dried or cured; removing residual conductive powder on the surface of the substrate by blowing or sucking and recovering the residual conductive powder; drying or curing the ink and the conductive powder layer by heating the substrate or placing the substrate at the normal temperature; pressurizing the substrate on a press to compact the conductive powder layer; and coating a protective layer on the conductive powder layer to obtain a conductive circuit. The printed circuit forming method has the advantages that production process is clean and environment-friendly, cost is low, environment-friendly base materials can be adopted, and the printed circuit forming method is applicable to manufacturing of both rigid circuits and flexible circuits.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Dyeing and finishing technology of Lyocell and cotton and spun silk blended fabric

InactiveCN102926236ASolve the consistency of dyeing the same colorThe dyeing process is reasonableDry-cleaning apparatus for textilesBleaching apparatusEngineeringLyocell

The invention relates to a blended fabric dyeing and finishing technology, and particularly relates to a dyeing and finishing technology of a Lyocell and cotton and spun silk blended fabric. The invention aims at providing a dyeing condition capable of well coordinating Lyocell and cotton and spun silk to produce a high-quality product. The dyeing and finishing technology of the Lyocell and cotton and spun silk blended fabric comprises the processes of pretreatment, dyeing and the like; the pretreatment process comprises desizing and bleaching, wherein the desizing is performed by an enzyme-oxygen cold batch technology, and desizing enzyme, a chelating dispersant, a dewaxing agent and a refining agent are added in the desizing process; and 100% hydrogen peroxide and a stabilizer are added in the bleaching process. Through the invention, the problems of difficult color register and long technological flow are successfully solved; and through the method, the dyeing flow of the fabric is more reasonable, the production is clean and environment-friendly, and the product quality is stable.

Owner:HUAFANG

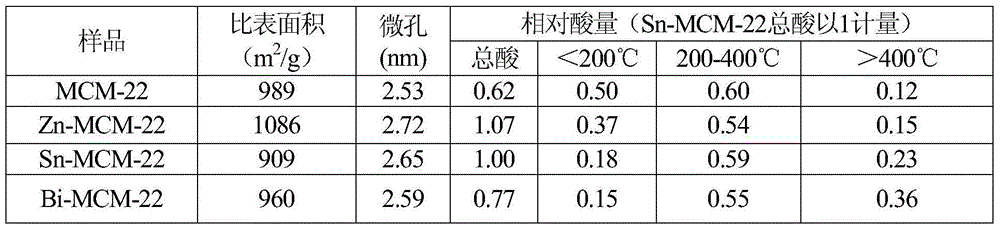

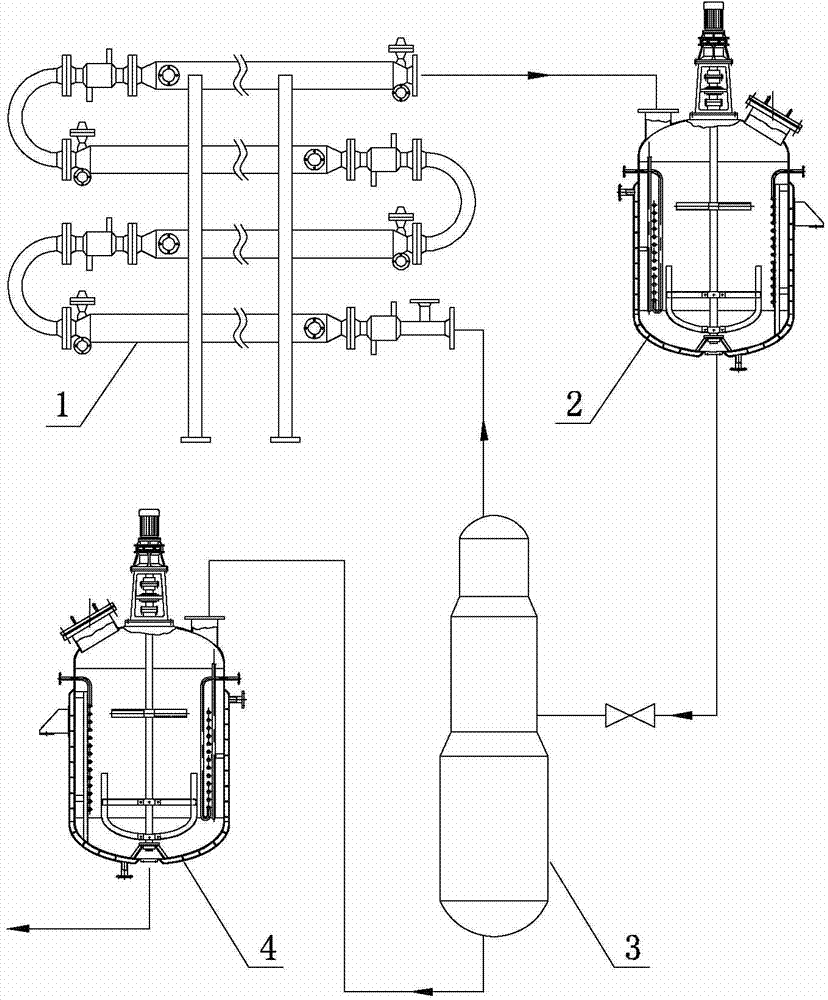

Method for preparation of aryl amides by aromatic carboxylic acid amination

ActiveCN104418763AHigh activityImprove performanceMolecular sieve catalystsOrganic compound preparationCatalytic effectCarboxylic acid

The invention relates to a catalyst for preparation of aryl amides by aromatic carboxylic acid amination. Under the suitable reaction conditions, by catalytic effect of zinc, tin or bismuth and other element modified MCM-22, dehydration reaction of an ammonium salt formed by aryl carboxylic acid and amine ammonium is directly performed, and high yield of benzamide or other aryl amide compounds can be obtained. The catalyst has high activity, acid resistance and stable performance. BY use of the catalyst, continuous amide production process can be achieved, and the production process has the advantages of being clean and environmentally-friendly, and the like, and the product does not contain salts and other impurities.

Owner:沧州磐希化工有限公司

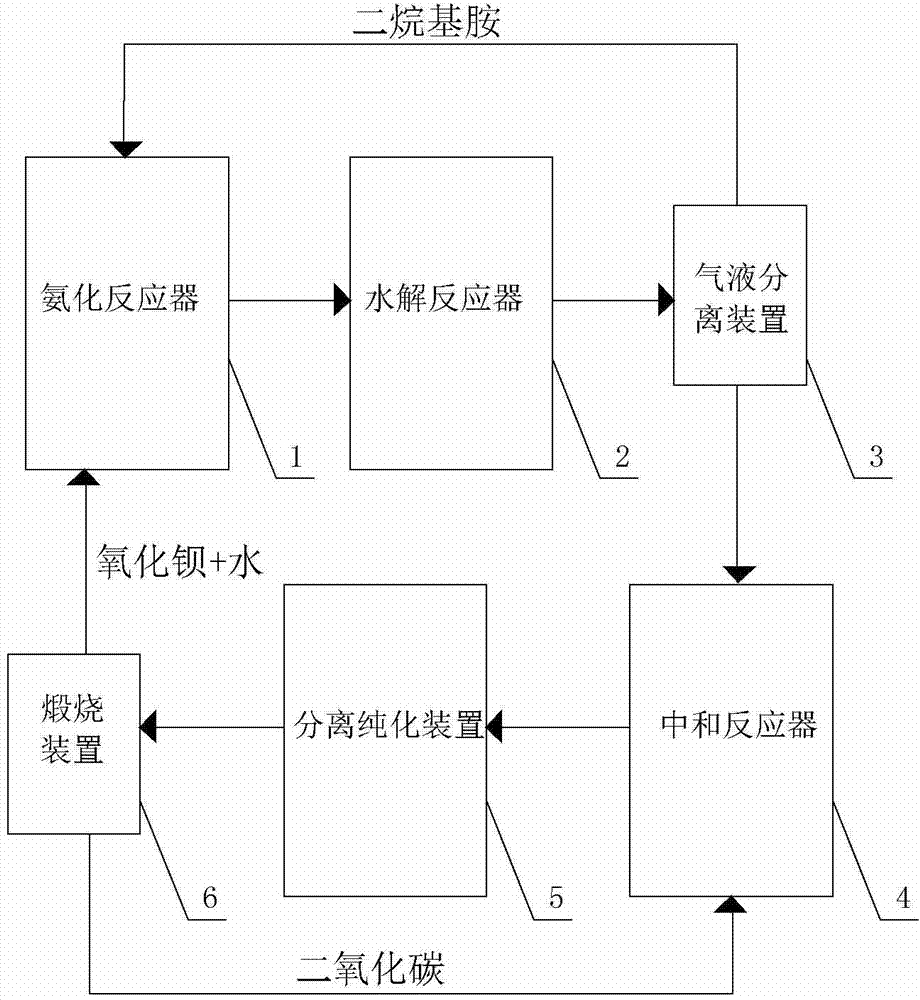

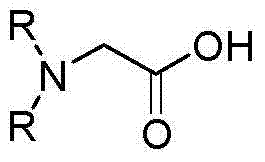

Clean and environment-friendly production method of N,N-dialkylglycine

InactiveCN103880691ATake advantage ofAvoid pollutionOrganic compound preparationAmino-carboxyl compound preparationGlycineBarium salt

The invention aims at the chemical engineering field and relates to a preparation method of N,N-dialkylglycine. The method comprises the following steps: mixing glycolonitrile with dialkyl amine, or mixing formaldehyde, hydrocyanic acid and the dialkyl amine, and carrying out ammonolysis reaction, so as to obtain an N,N-dialkylamino acetonitrile reaction liquid; mixing the N,N-dialkylamino acetonitrile reaction liquid with barium hydroxide, and carrying out hydrolysis reaction, so as to obtain an N,N-dialkyl glycine barium water liquid; carrying out neutral reaction on the N,N-dialkyl glycine barium by virtue of sulfuric acid or carbon dioxide to obtain the N,N-dialkylglycine, and simultaneously filtering a byproduct, namely a barium salt precipitate. The method has the beneficial effects that the N,N-dialkylglycine and the salt are easily separated and purified, the purity and yield of the N,N-dialkylglycine are high, the barium salt precipitate, namely barium carbonate can be re-prepared into barium hydroxide to be recycled, and the production process is environment-friendly and clean.

Owner:CHONGQING UNISPLENDOUR INT CHEM

Suede simulation type superfine fiber synthetic leather and clean production method thereof

ActiveCN107177989AShorten the lengthReduce widthMechanical cleaningPressure cleaningProduction lineWater vapor permeability

The invention relates to suede simulation type superfine fiber synthetic leather and a clean production method thereof. The method comprises the steps of impregnating superfine fiber synthetic leather base cloth through an impregnating tank full of shrinking and kneading liquid, entering a continuous graining machine, drying the superfine fiber synthetic leather base cloth, and obtaining shrinking and kneading base cloth; adopting a flocking production line provided with PUR lattice roller coating equipment, coating PUR on the shrinking and kneading base cloth, sprinkling collagen fiber, adhering on the shrinking and kneading base cloth, cooling and winding, and placing to obtain flocking base cloth; adopting a brushing machine for removing the collagen fiber which is not firmly adhered onto the flocking base cloth, and obtaining the suede simulation type superfine fiber synthetic leather. According to the suede simulation type superfine fiber synthetic leather and the clean production method thereof provided by the invention, a shrinking and kneading technology is adopted, so that the softness, the air permeability and the water vapor permeability of the superfine fiber synthetic leather base cloth are greatly improved; a PUR lattice roller coating composite technology is adopted, so that the collagen fiber is compounded onto the superfine fiber synthetic leather base cloth, and the suede simulation type superfine fiber synthetic leather with the appearance being similar to the appearance of natural suede leather, and the mechanical property and the hygiene property being superior to the mechanical property and the hygiene property of the natural suede leather is obtained.

Owner:JIANGSU KEMEI NEW MATERIALS

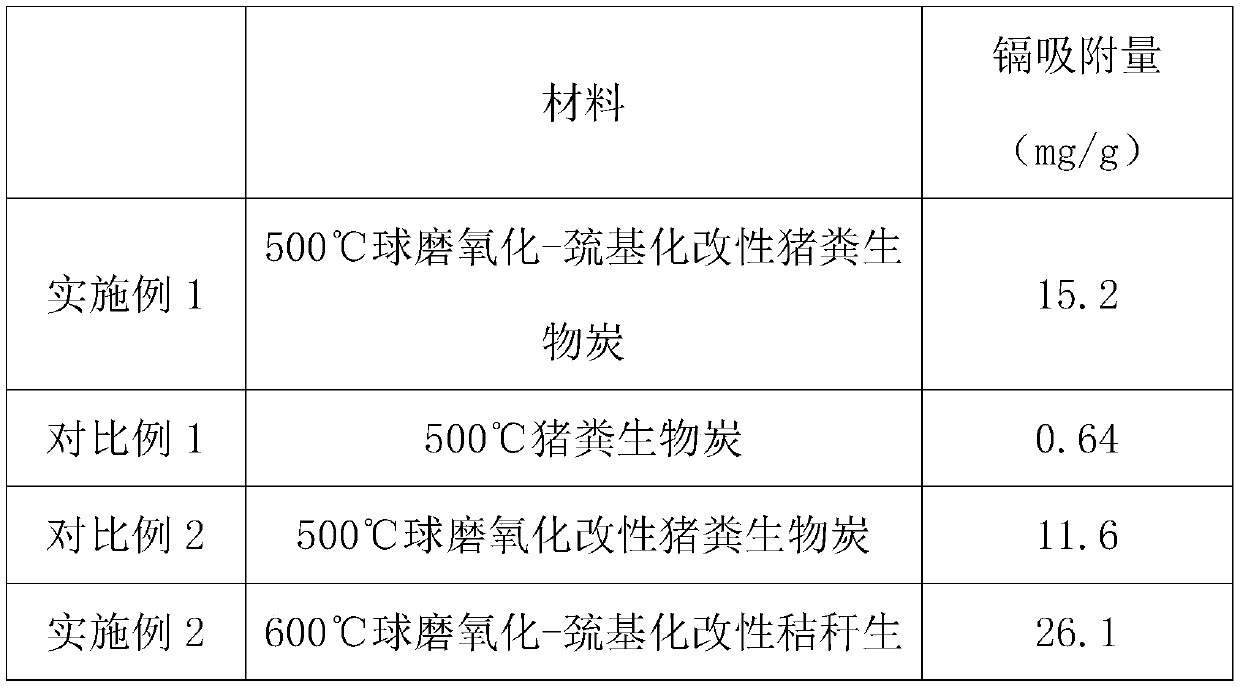

Ball-milling oxidation-sulfhydrylation modified biochar, and preparation method and application thereof

ActiveCN110639471APromote ecological developmentRealize resource reuseOther chemical processesWater contaminantsMicro nanoFiltration

The invention discloses a ball-milling oxidation-sulfhydrylation modified biochar, and a preparation method and an application thereof. The preparation method comprises the following steps: (1) a rawmaterial is pyrolyzed to obtain biochar, wherein the raw material is crop straws generated in the agricultural production process and / or animal wastes generated in the livestock and poultry breeding process; (2) biochar, hydrogen peroxide and water are mixed according to a mass ratio of 1:15:15 to 1:30:60, the obtained mixture is ball-milled to make the particle size of the biochar reaches a micro-nano level, and the ball-milled mixture is filtered to obtain solid ball-milled oxidation modified biochar; (3) the ball-milled oxidation modified biochar is added into an ethanol solution containing1-4% of 3-mercaptopropyltrimethoxysilane according to a mass ratio of 1:20 to 1:200, a reaction is carried out, and curing is performed after the reaction; and (4) the cured biochar is subjected to suction filtration, washing and natural airing to obtain the ball-milled oxidation-sulfhydrylation modified biochar. Resource recycling of agricultural and animal husbandry wastes is achieved, and themodified biochar can be used for removing heavy metals in water or fixing heavy metals in farmland soil.

Owner:NANKAI UNIV

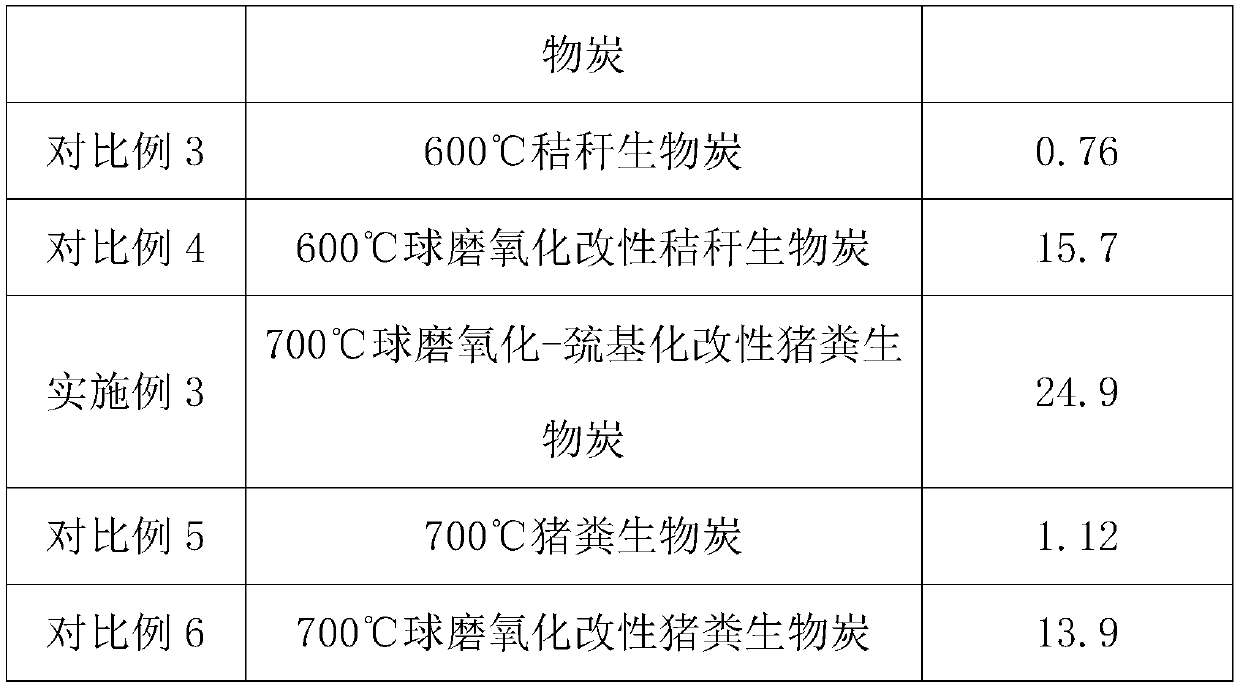

Method for preparing bovine skin gelatin by enzyme treatment

InactiveCN109354624AClean and environmentally friendly productionMeet the national standard requirementsConnective tissue peptidesPeptide preparation methodsGelatinEnzyme

The invention relates to the preparation of gelatin, in particular to a method for preparing bovine skin gelatin by enzyme treatment, which comprises the process steps of raw material pretreatment, enzymolysis reaction, enzyme passivation, glue extraction, separation, concentration, drying and the like. The method solves the technical problems of low gelatin conversion rate, high post-treatment cost caused by pollution and the like in the prior art. The method has the advantages of high gelatin conversion rate, clean and environment-friendly approach, and that the indexes of the prepared gelatin meet the requirements of national standards.

Owner:河北省微生物研究所有限公司

Viscose fabric pretreatment method

InactiveCN102936831ASolve the problem that the hand feels hard when exposed to high temperatureSolve high-efficiency soapingDry-cleaning apparatus for textilesBleaching apparatusPretreatment methodPulp and paper industry

The invention relates to a blended fabric dyeing and finishing technology, and particularly relates to a viscose fabric pretreatment method. The invention aims at providing a fabric dyeing and finishing technology to solve the problems of hard hand feeling in high temperature, efficient soaping, long technological processes and the like of the viscose fabric. The viscose fabric pretreatment method adopts continuous pad dyeing equipment and comprises the steps of singeing, desizing, tentering, preshrinking and the like, wherein caustic soda, chelating dispersing agent, dewaxing agent and refining agent are added in the desizing process; and 100% hydrogen peroxide, stabilizer and soda ash are added in the bleaching process. The method provided by the invention successfully solves the problems of hard hand feeling in high temperature, efficient soaping, long technological processes and the like of the viscose fabric. Through the method, the fabric dyeing process is more reasonable, the production is clean and environment-friendly, and the product quality is stable.

Owner:HUAFANG

Recycling method for high-hardness high-salinity recycled paper paper-making wastewater

ActiveCN108483761AReduce the pressure of purificationEmission reductionTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsSulfate radicalsSulfate radical

The invention discloses a recycling method for high-hardness high-salinity recycled paper paper-making wastewater. Firstly, pre-softening treatment is carried out on high-hardness wastewater by usinglime powder, and efficient interception is carried out on divalent ions and multivalent ions in the wastewater by using a membrane separation method to remove calcium, magnesium, silicon, sulfate radical and other ions. In the process of using the membrane separation method, the characteristics of the ions in the wastewater are changed by using an electromagnetic method, thereby changing deposition speed of calcium carbonate and physical characteristics of deposition to prevent the formation of hard scale so as to greatly reduce the possibility of the scale formation, the separation effect isgood, the inner treated sewage is recycled, the purification treatment pressure of the sewage is reduced, the out-emission of the sewage is reduced, and the production process is cleaner and more environmentally-friendly.

Owner:DONGGUAN TAICHANG PAPER CO LTD

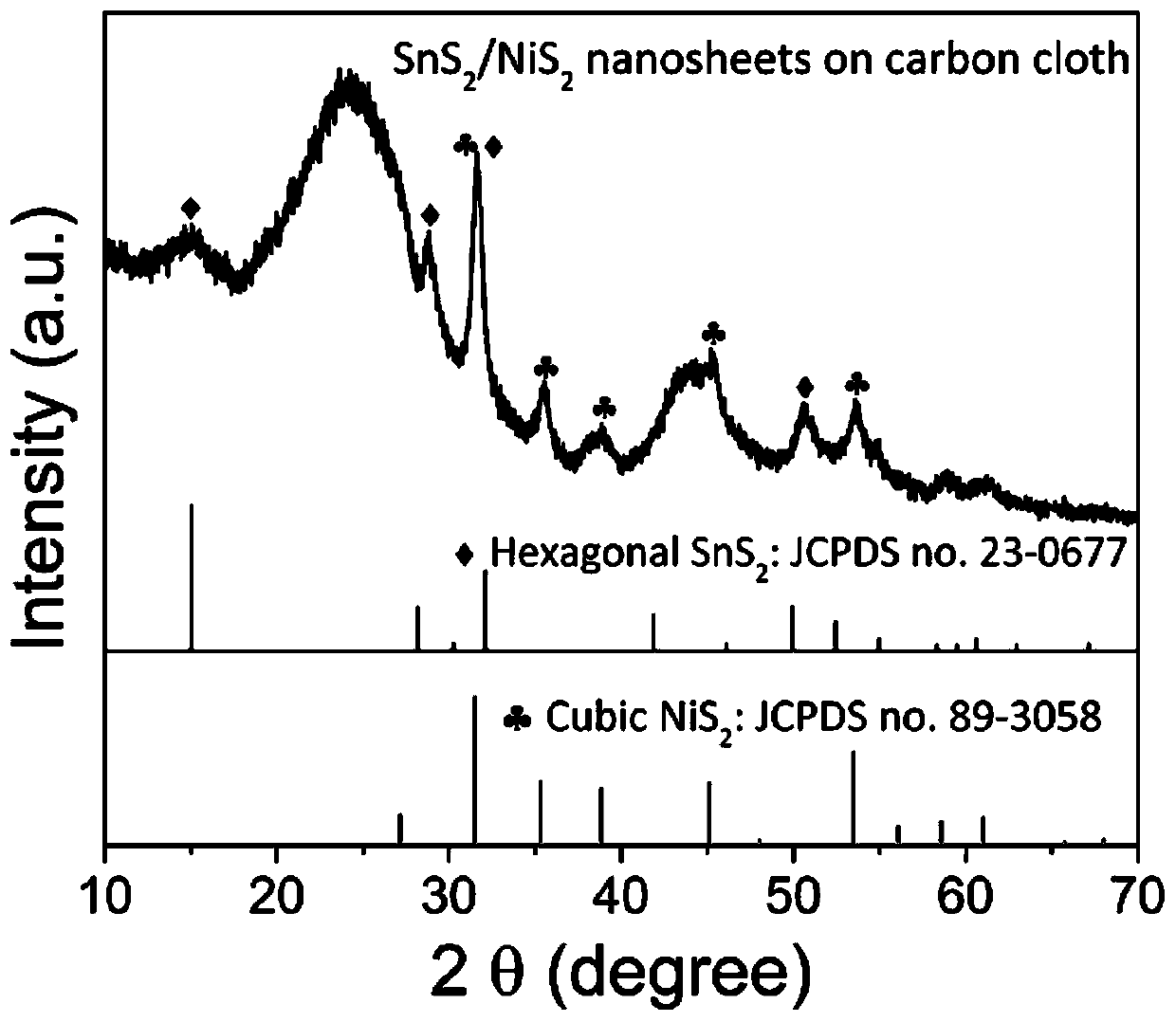

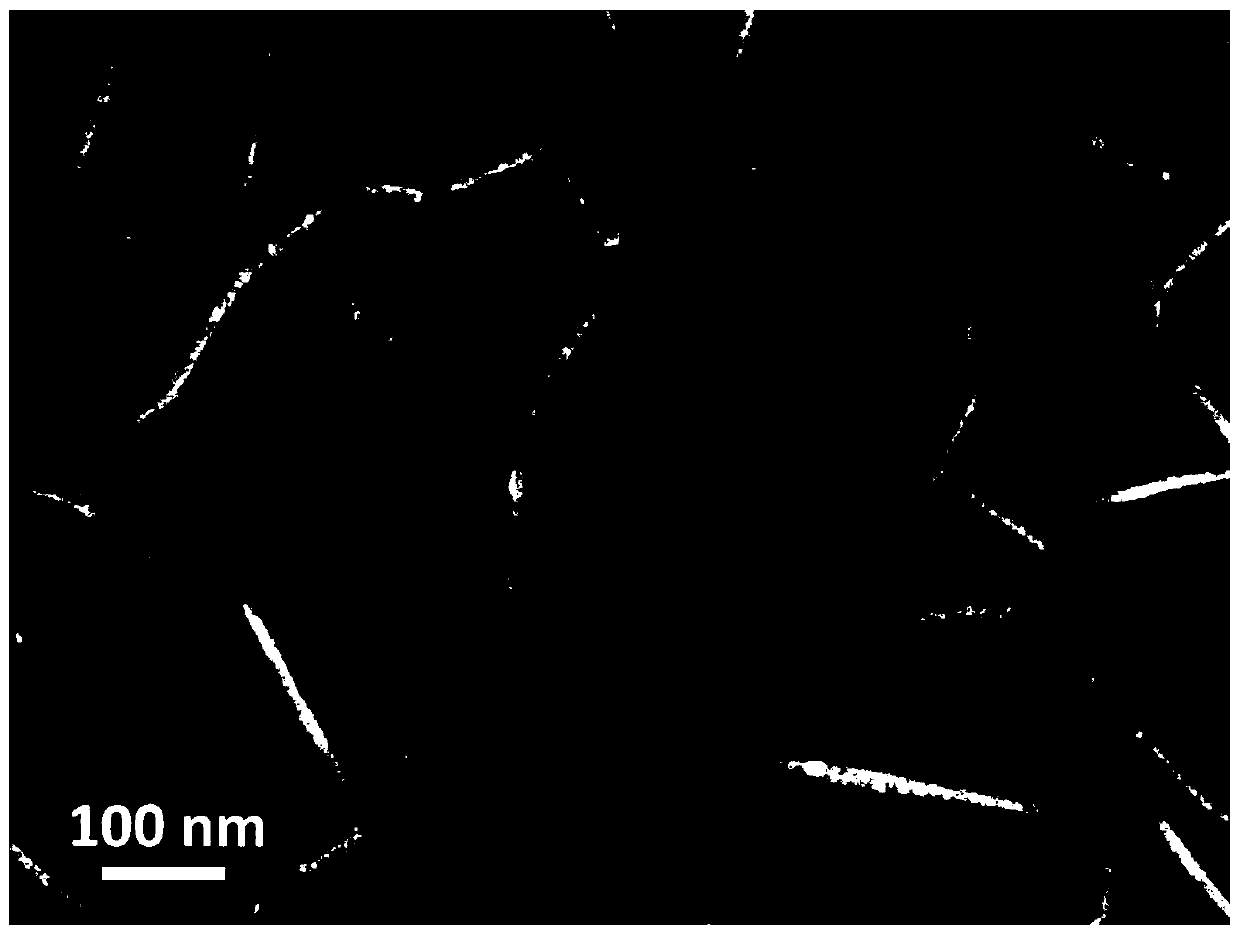

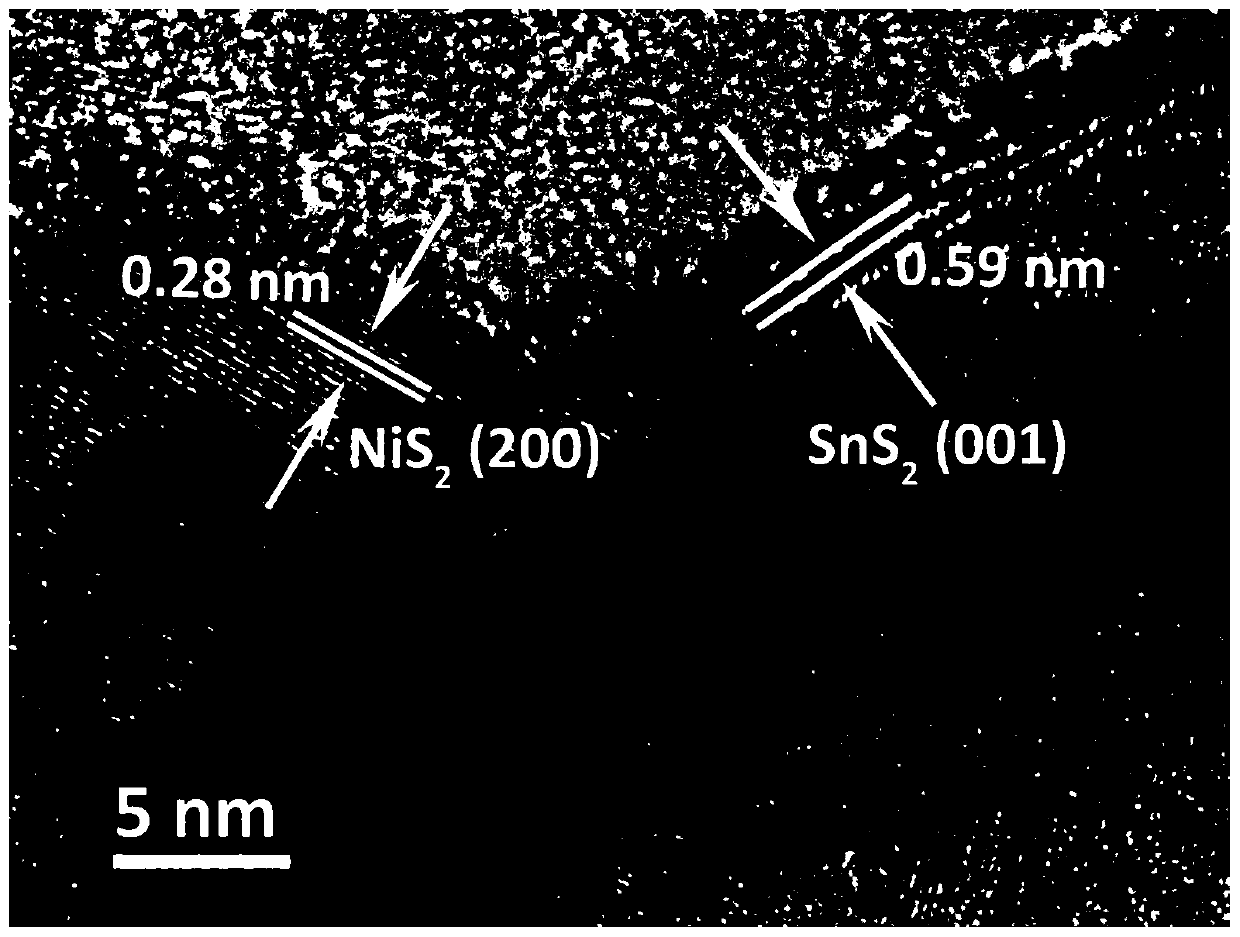

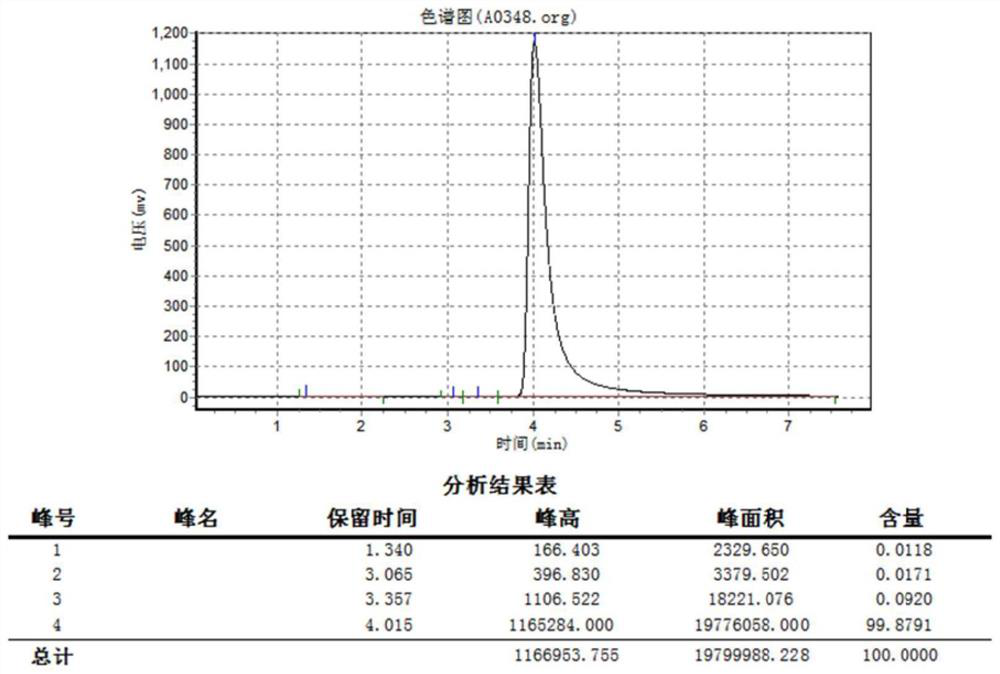

Tin sulfide-nickel sulfide heterogeneous nanosheet array structure and preparation method thereof

InactiveCN110745861AHigh densityIncrease productionMaterial nanotechnologyTin compoundsThio-New energy

The invention relates to a uniformly-compounded tin sulfide-nickel sulfide heterogeneous nanosheet array structure loaded on the surface of a conductive substrate, and a preparation method thereof, and belongs to the technical field of new energy material preparation. The main body part of the product is a uniformly-compounded tin sulfide-nickel sulfide nanosheet, and vertically and closely growson the surface of a conductive substrate to form an array structure. The one-step solvothermal preparation method adopts nickel chloride, stannic chloride and thioacetamide as a nickel source, a tin source and a sulfur source respectively, a mixed solution of alcohol and water as a solvent and the conductive substrate as a skeleton, and effectively controls the growth rate of nickel sulfide by controlling the addition amount of water in order to achieve the synthesis of the product. The product obtained by the method has the advantages of high yield, high purity, controllable morphology and nopost-treatment; and the method has the advantages of simple devices and processes, strict and controllable synthesis growth conditions, high product yield, low cost, and clean and environmentally-friendly production process. Additionally, the product has an excellent electrochemical energy storage performance.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Dyeing method for cool ultrahigh-molecular-weight polyethylene bedding

The invention discloses a dyeing method for cool ultrahigh-molecular-weight polyethylene bedding. The dyeing method comprises the following steps: weaving; pre-setting; cold dyeing; washing and dehydrating; baking; and preparation of a finished product. The method gives full play to the respective performance advantages of ultrahigh-molecular-weight polyethylene and viscose fibers and allows the functions of ultrahigh-molecular-weight polyethylene and viscose fibers to complement each other for development of a high-grade cool bedding fabric; and ultrahigh-molecular-weight polyethylene and viscose fibers are blended according to a ratio of 35: 65, blended yarns with fineness of 18.5 tex are used as a raw material for warp and weft yarns, and reasonable fabric specification and process design are selected, so a prepared product has a smooth cloth surface, moisture-absorption performance, air permeability and soft and tough texture, feels cool and comfortable, can be easily to clean andis a high-grade fabric for summer quilts. According to the invention, only 65% of viscose fibers are dyed, so fried-dough-twist-like dyeing effect is obtained, and the problem that ultrahigh-molecular-weight polyethylene cannot be dyed is overcome. The dyeing method employs a cold dyeing process, does not need heating during dyeing, saves energy, reduces cost, and is clean and environment-friendlyin production.

Owner:IANGSU COLLEGE OF ENG & TECH

Method for synthesizing dihydroxy dimethyl terephthalate by using oxygen catalytic oxidation method

PendingCN114478243AReduce manufacturing costReduce the discharge of three wastesPhysical/chemical process catalystsOrganic compound preparationChemical synthesisDimethyl terephthalate

The invention relates to the technical field of organic chemical synthesis, in particular to a method for synthesizing dihydroxy dimethyl terephthalate by using an oxygen catalytic oxidation method. According to the technical scheme, oxygen (O2) is used as an oxidizing agent, a metal component (M) is Co, Ni, Cr, Mn, Fe, Cu and other elements under the action of a catalyst M / N-C, and DMSS is oxidized to generate DHTA in a proper solvent by controlling proper conditions. Oxygen is used as an oxidizing agent, the process is simplified, and the production cost is reduced. The by-product is a small amount of H2O, the emission of three wastes is greatly reduced, and the production process is clean and environment-friendly.

Owner:CHANGZHOU UNIV

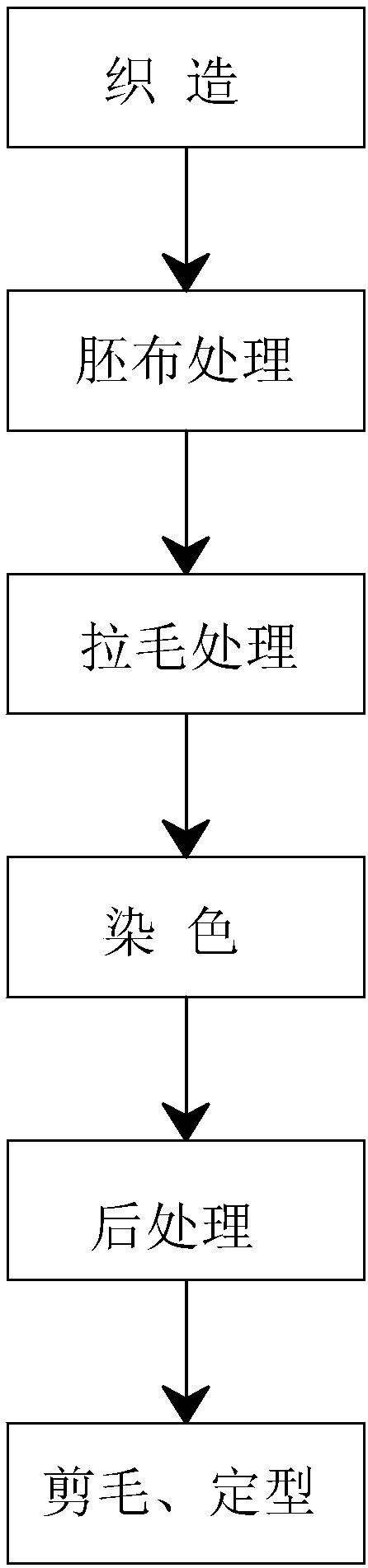

Production process of flannel fabric

InactiveCN107829197AFeel goodReduce the impactSucessive textile treatmentsBiochemical treatment with enzymes/microorganismsPolyesterPulp and paper industry

The invention relates to a production process of a fabric, and discloses a production process of a flannel fabric. By the process, the problem that although the flannel fabric made from polyester fiber and natural silk fiber is good in hand feeling, fluff falls off easily to cause the fluff on the surface of the flannel fabric to be not fine and compact so that the flannel fabric has relative poorquality is solved. The key point of the technical scheme is that the production process of the flannel fabric comprises the following steps: weaving, gray fabric treatment, napping treatment, dyeing,aftertreatment, shearing and sizing, wherein in the weaving process, first yarn serving as warp yarn and second yarn serving as weft yarn are blended with brucite fiber, and the weight proportion ofthe brucite fiber to the first yarn is 45-60%; the weight proportion of the brucite fiber to the second yarn is 10-30%, and the purpose that the surface fluff of the flannel fabric is finer and more compact and is difficult to fall off so that the quality of the flannel fabric is better is achieved.

Owner:绍兴柯桥三和纺织服饰有限公司

Flexible circuit suction filtration forming method

InactiveCN102821554AEasy to recycleNo pollutionConductive pattern formationFiltration separationPorous substrateFiltration

The invention relates to a flexible circuit suction filtration forming method, which comprises following steps that inverse printing of a target circuit graph is conducted on paper or a porous substrate through a printing way: the part of the target circuit graph on the paper or the porous substrate remains white, and the rest part of the paper or the porous substrate is painted with printing materials; after the printing materials are dried, the substrate is placed on a sand core suction filtration plate which is connected with a vacuum pump to be covered by a drum-shaped housing, and the housing compresses the surface of the substrate; conducting medium dispersion liquid with conducting medium micro-particles and concentration of 1microgram / ml to 100microgram / ml is poured into the housing, and the vacuum pump is started to conduct the suction filtration: the conducting medium micro-particles are deposited on the target circuit graphic part to form a conducting medium layer which is identical to the target circuit; after the conducting medium dispersion liquid is completely pumped, the substrate is taken out and placed into a press to be supercharged, and the conducting medium layer is compacted; and then a protective coating is coated on the conducting medium layer to obtain a flexible conducting circuit. The method has characteristics that the production process is clean and environment-friendly and the environment-friendly materials such as recyclable paper can be used as the substrate and has the advantage of low cost.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

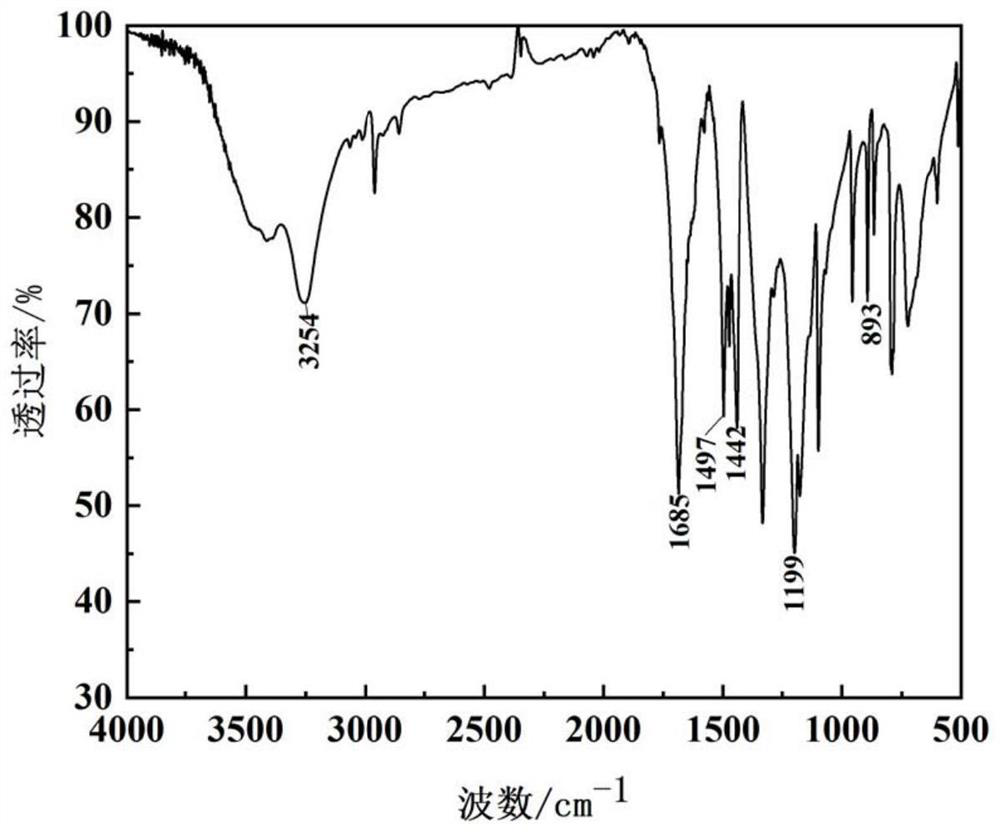

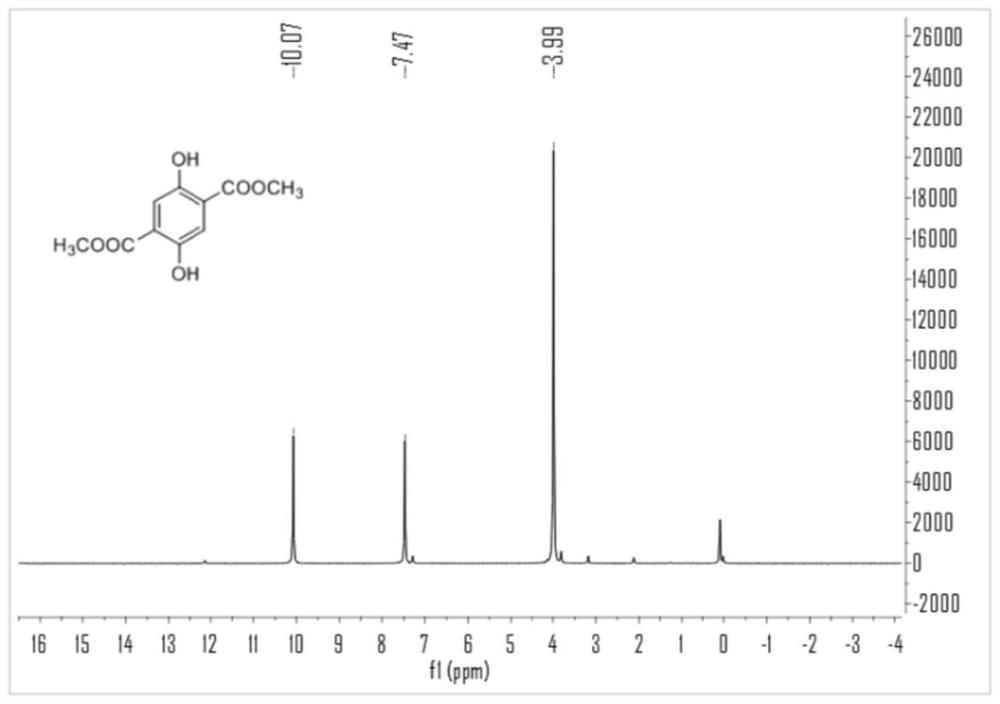

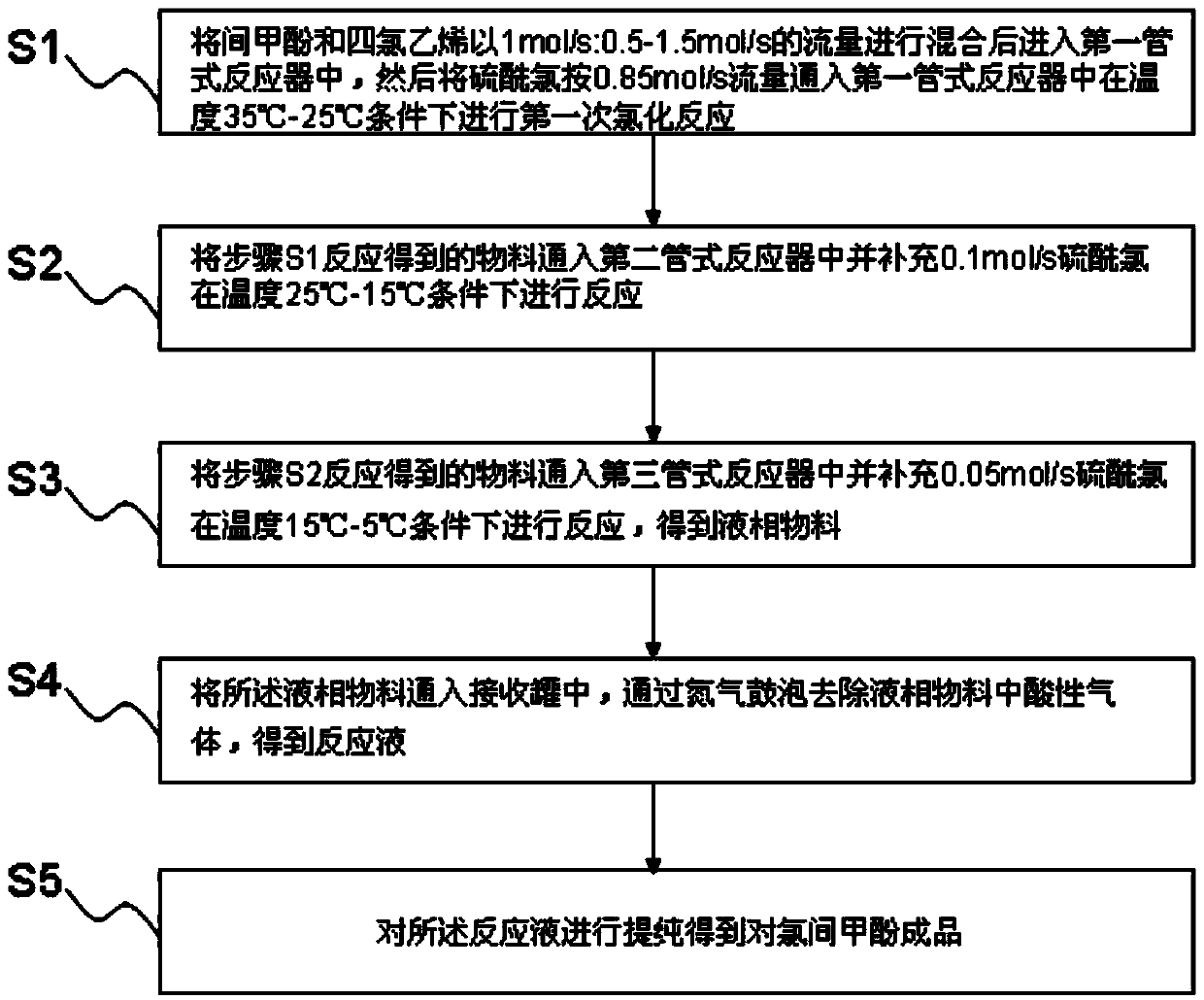

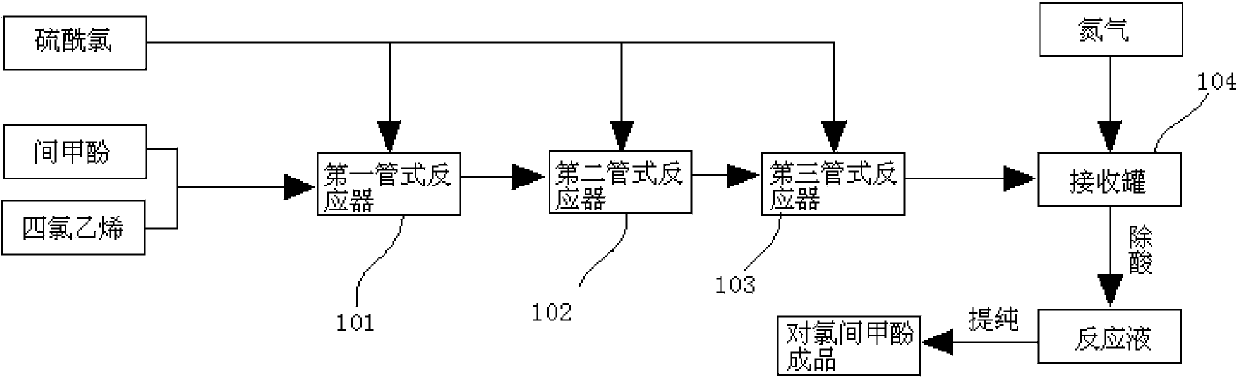

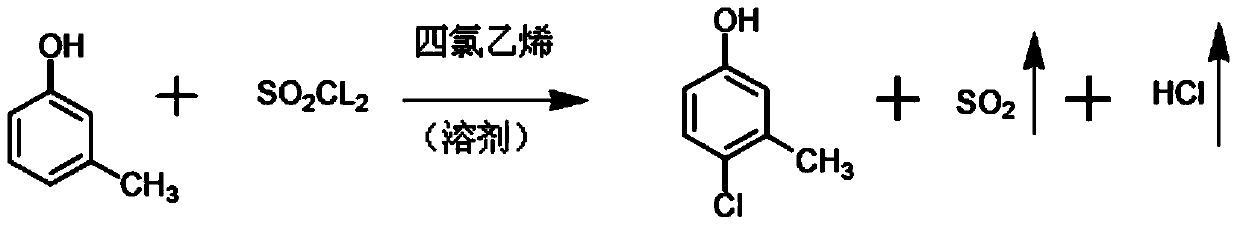

Green synthesis technique of p-chloro-m-cresol

ActiveCN104045521AHigh recovery rateImprove conversion rateOrganic chemistryOrganic compound preparationEthyl ChlorideSolvent

The invention provides a green synthesis technique of p-chloro-m-cresol, which comprises the following step: reacting by using m-cresol as a raw material, tetrachloroethylene as a solvent and sulfuric chloride as a chlorinating agent to prepare the p-chloro-m-cresol, wherein the mole ratio of the m-cresol to the tetrachloroethylene is 1:(0.5-1.5), and the mole ratio of the m-cresol to the sulfuric chloride is 1:(0.9-1.1).Compared with the prior art, the technique provided by the invention has the advantages of short reaction time, high solvent recovery rate, clean and environment-friendly production process and high degree of automation, and the m-cresol conversion rate after the reaction finishes is up to 98%; and thus, the technique has favorable industrialization prospects.

Owner:JIANGSU HUANXIN NEW MATERIAL CO LTD

Polyester-wool blended fabric preparation process

InactiveCN108193516AThe dyeing process is reasonableImprove product qualityHeating/cooling textile fabricsDyeing processPolyesterDying processes

The invention provides a polyester-wool blended fabric preparation process, which comprises: (1) blending polyester fibers and wool fibers to obtain a polyester-wool blended billet cloth; (2) sequentially carrying out refining treatment, dewatering and drying on the polyester-wool blended billet cloth washed with water; (3) dyeing; and (4) carrying out drying shaping on the dyed polyester-wool blended fabric through a shaping machine at a temperature of 120-150 DEG C at a rate of 10-20 m / min. According to the present invention, the polyester-wool blended fabric preparation process solves the problems of difficult color combination and long process in the prior art; and with the method, the dying process of the fabric is reasonable, the production is clean and environmentally friendly, theproduct quality is stable, and the wool polyester fabric is popularized, can be widely used in home textile products, and is suitable for autumn and winter seasons.

Owner:XINCHANG COUNTY TENGSHENG TEXTILE MACHINERY CO LTD

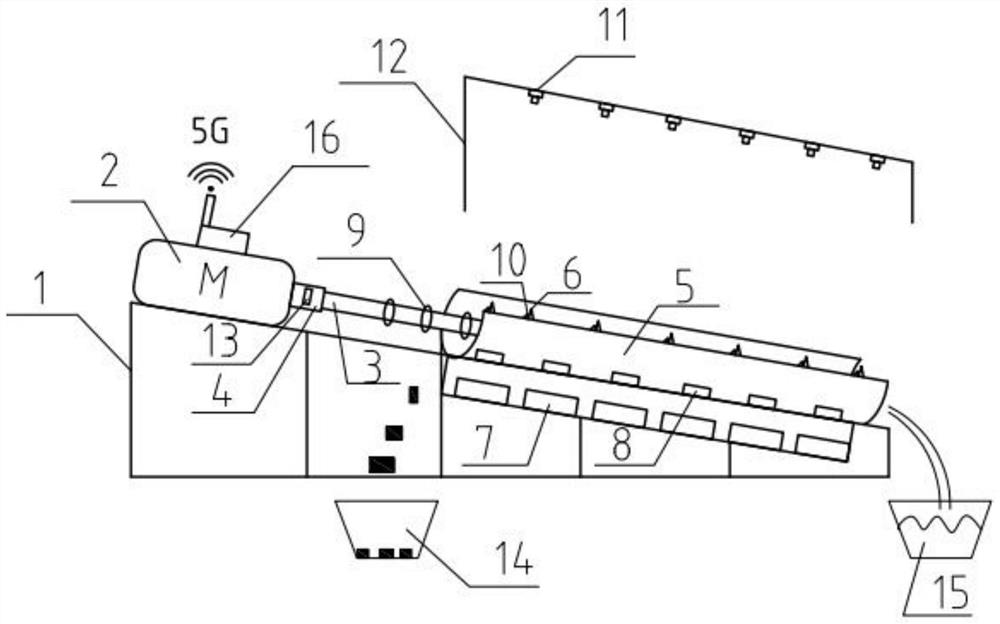

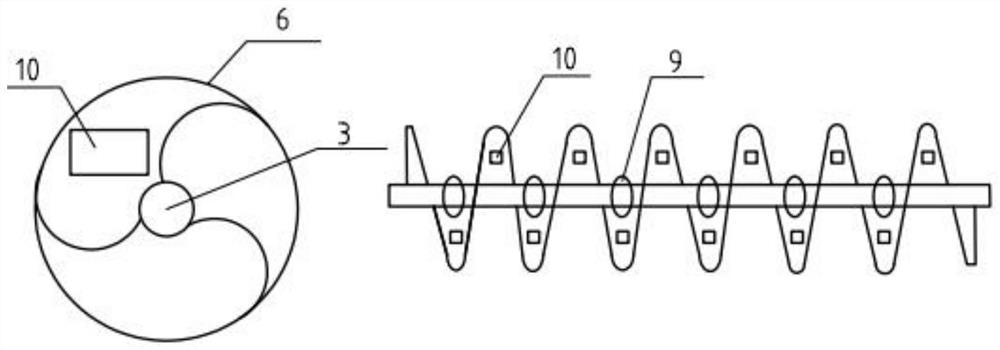

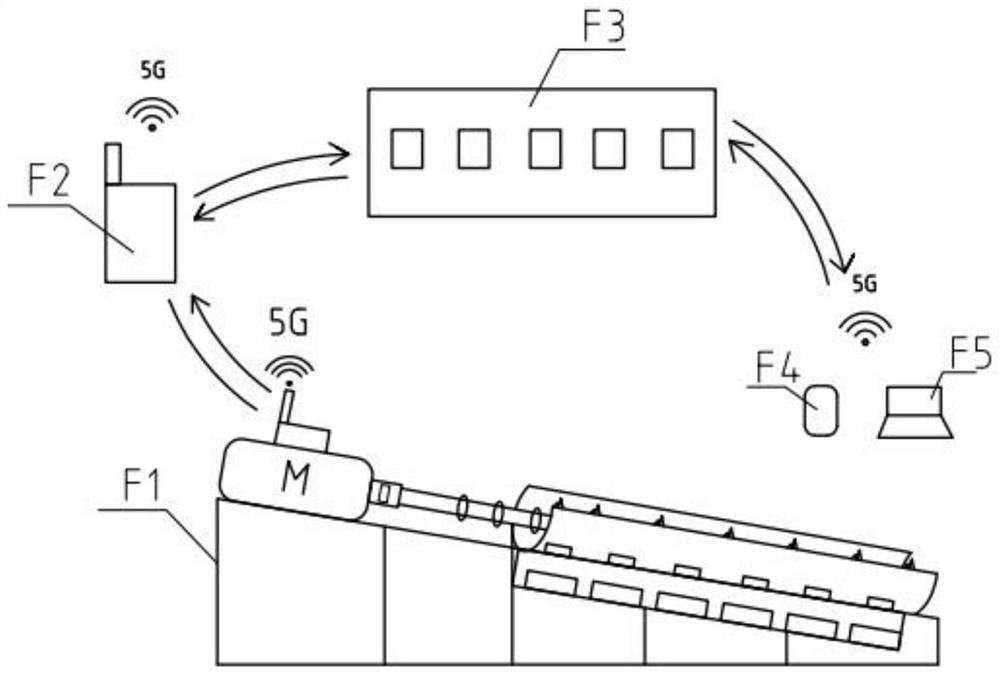

Intelligent continuous solidification separator for crude tin purification and crystallization method

PendingCN113999992AEasy to operatePrecise controlSolution crystallizationHeat exchange cooling cystallizationChemistryMobile end

The invention discloses an intelligent continuous solidification separator for crude tin purification and a crystallization method. The separator comprises a separator support, a motor, a rotating shaft, a U-shaped crystallization tank, a spiral blade, a modular heating body, a bottom patch type temperature sensor, a shaft sleeve type temperature sensor, a blade patch type temperature sensor, a high-definition infrared temperature sensor, an infrared temperature measurement system support, a speed sensor, a material melting pot, a crystal pot, a melt pot and a 5G wireless transceiver. The temperature of the solidification separator is monitored and controlled in real time through a multi-dimensional temperature measurement system and a modular heating system, the rotating speed of a solidification separator is controlled in real time through an intelligent speed regulation system, meanwhile, the high-temperature-resistant 5G wireless transceiver is adopted for real-time online transmission of data, the data is fed back to a mobile terminal after being processed by the server, and the mobile terminal can also directly regulate and control the separator in real time.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com