Intelligent continuous solidification separator for crude tin purification and crystallization method

A technology of separator and crude tin, which is applied in the field of intelligent continuous solidification separator and crystallization, can solve the problems of inaccurate control of temperature, insufficient temperature range of crystallizer, and product quality not necessarily up to national standards, etc., to achieve precise control and precision The effect of high tin direct yield and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

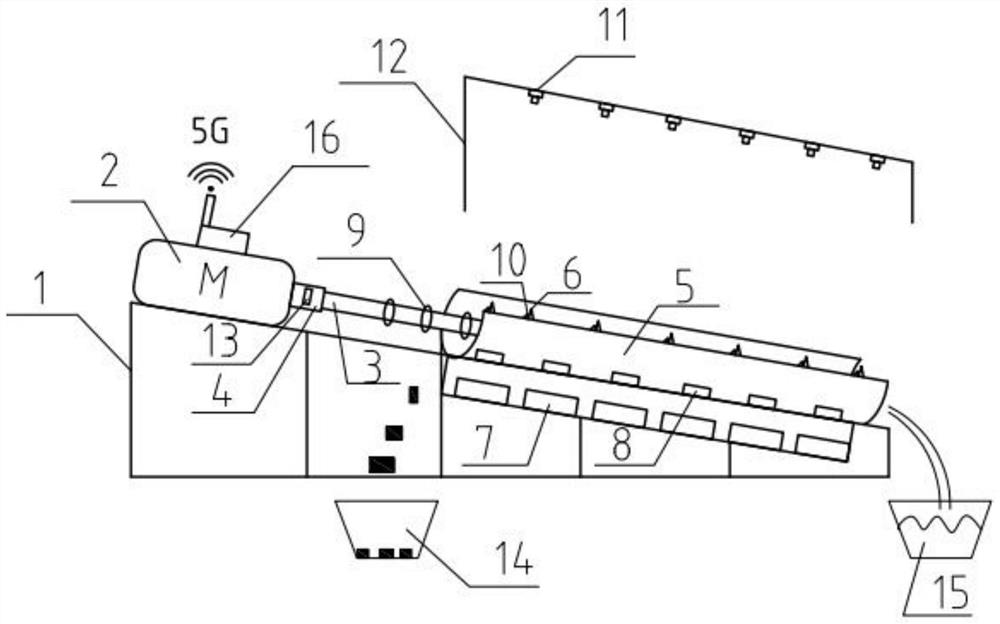

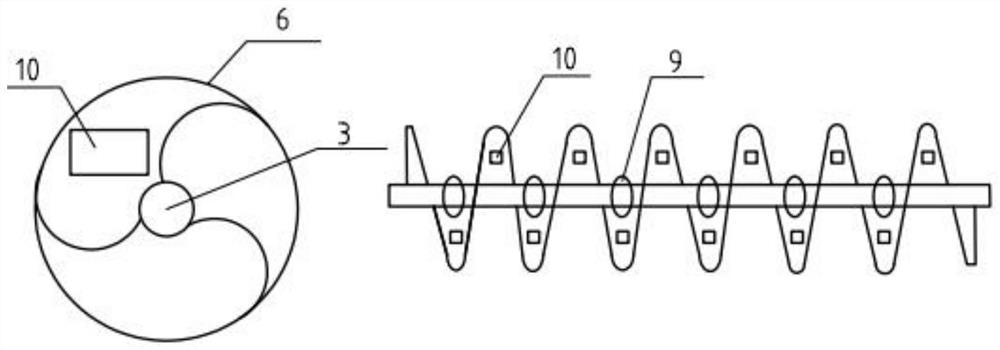

[0061] An intelligent continuous solidification separator for crude tin purification, including a separator bracket, a motor, a rotating shaft, a shaft sleeve, a U-shaped crystallization tank, a spiral blade, a modular heating element, a bottom patch temperature sensor, a shaft Sleeve temperature sensor, blade patch temperature sensor, high-definition infrared temperature sensor, infrared temperature measurement system bracket, speed sensor, crystal pot, melt pot, 5G wireless transceiver. The separator bracket is used to support the coagulation separator, the motor is connected with the rotating shaft through the shaft sleeve, the speed sensor is installed on the shaft sleeve, and the rotating shaft is driven by the motor. A number of helical blades and sleeve-type temperature sensors are distributed on the rotating shaft. Blade patch-type temperature sensors are installed on both sides of the helical blade, and the sleeve-type temperature sensor is sleeved on the rotating shaf...

Embodiment 2

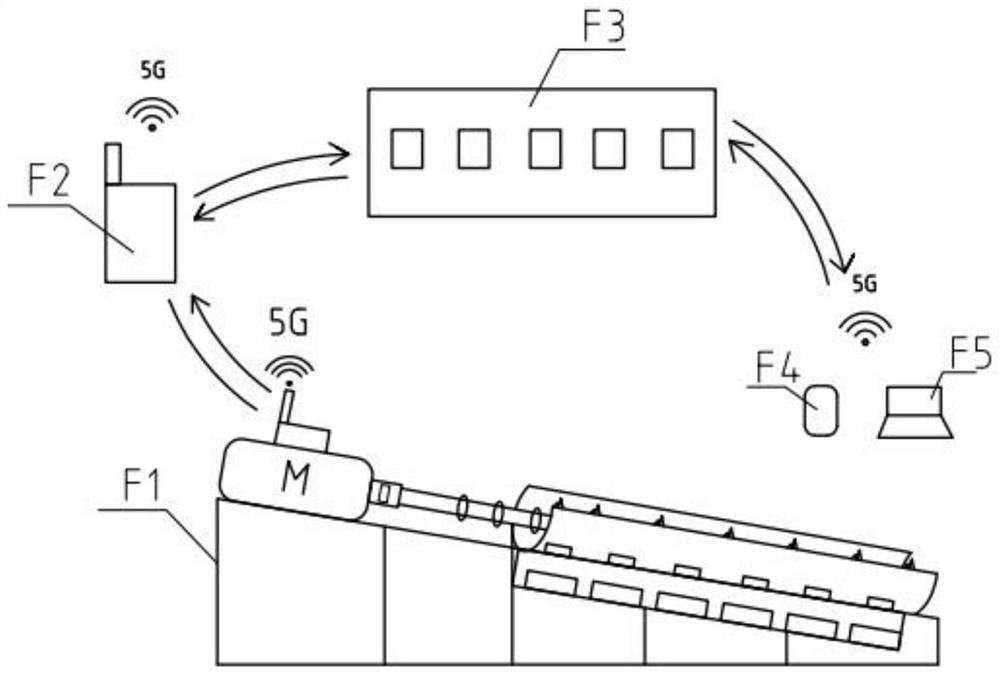

[0064] This embodiment is the application of the above-mentioned embodiment 1, an unmanned intelligent solidification and crystallization method for crude tin purification, including:

[0065] Step 1. Take a certain amount of thick tin liquid and put it into the end of the coagulation separator tank. Access the data center through the mobile phone or PC to obtain the working status of the coagulation separator. After confirming that the coagulation separator is in a shutdown state, start it up remotely and set the 11-segment module The heating element temperature and the rotational speed of the rotating shaft.

[0066] Step 2. After waiting for a period of time, the multi-dimensional temperature measurement system and intelligent speed control system collect temperature and speed signals, and upload them to the data center through the 5G wireless transceiver through the smart gateway. The data center compares and calculates the collected data The signal is sent to the mobile pho...

Embodiment 3

[0074] This embodiment is the application of the above-mentioned embodiment 1, an unmanned intelligent solidification and crystallization method for crude tin purification, including:

[0075] Step 1. Take a certain amount of crude tin liquid and put it into the end of the coagulation separator tank. Access the data center through the mobile phone or PC to obtain the working status of the coagulation separator. After confirming that the coagulation separator is in the shutdown state, start it up remotely and set the 6-segment module The heating element temperature and the rotational speed of the rotating shaft.

[0076] Step 2. After waiting for a period of time, the multi-dimensional temperature measurement system and intelligent speed control system collect temperature and speed signals, and upload them to the data center through the 5G wireless transceiver through the smart gateway. The data center compares and calculates the collected data The signal is sent to the mobile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com