Patents

Literature

411results about "Crystallization regulation/control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods for controlling crystal growth, crystallization, structures and phases in materials and systems

InactiveUS20060037177A1Growth inhibitionExisting techniquePolycrystalline material growthOxygen/ozone/oxide/hydroxidePhase formationEnergy regulation

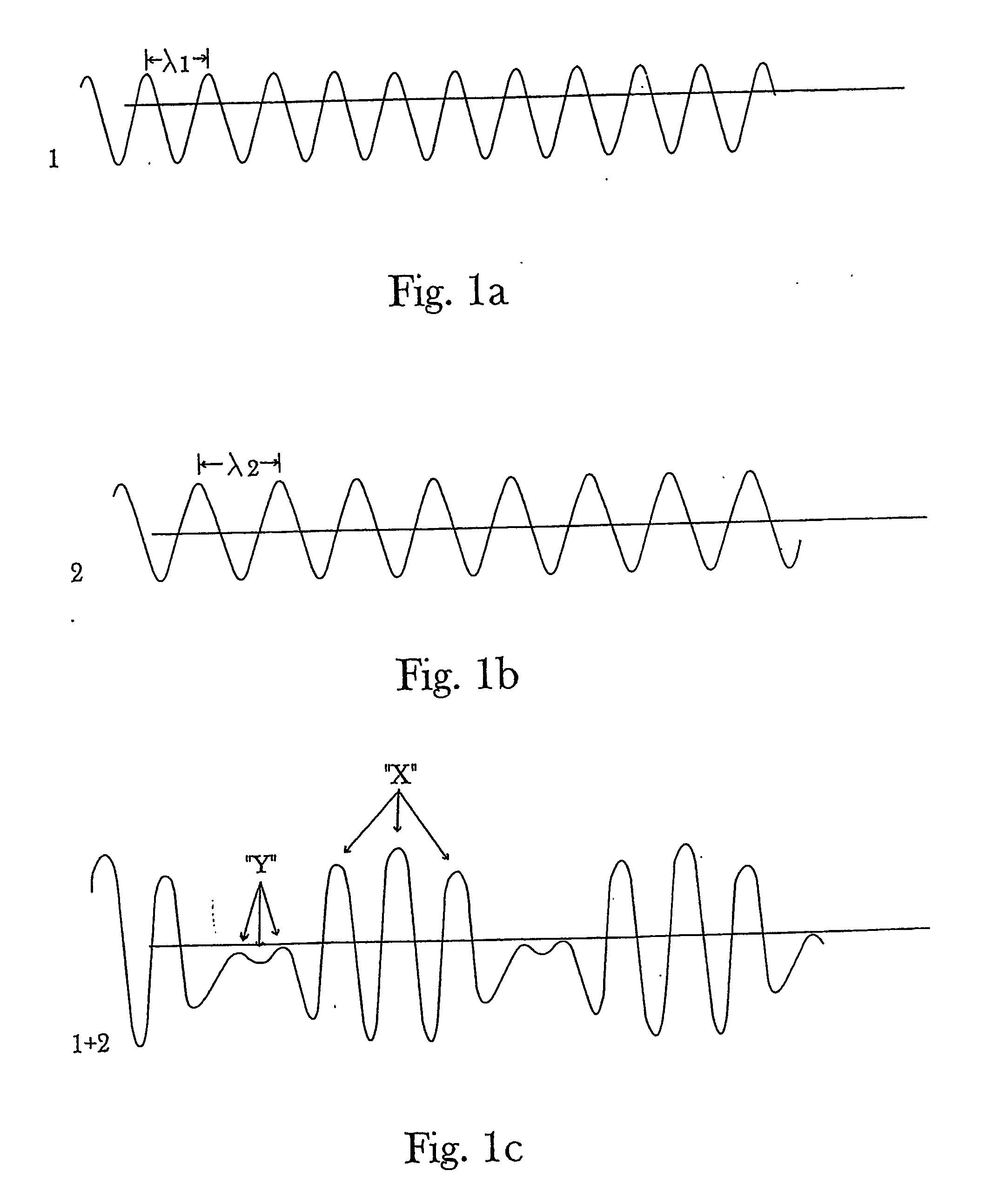

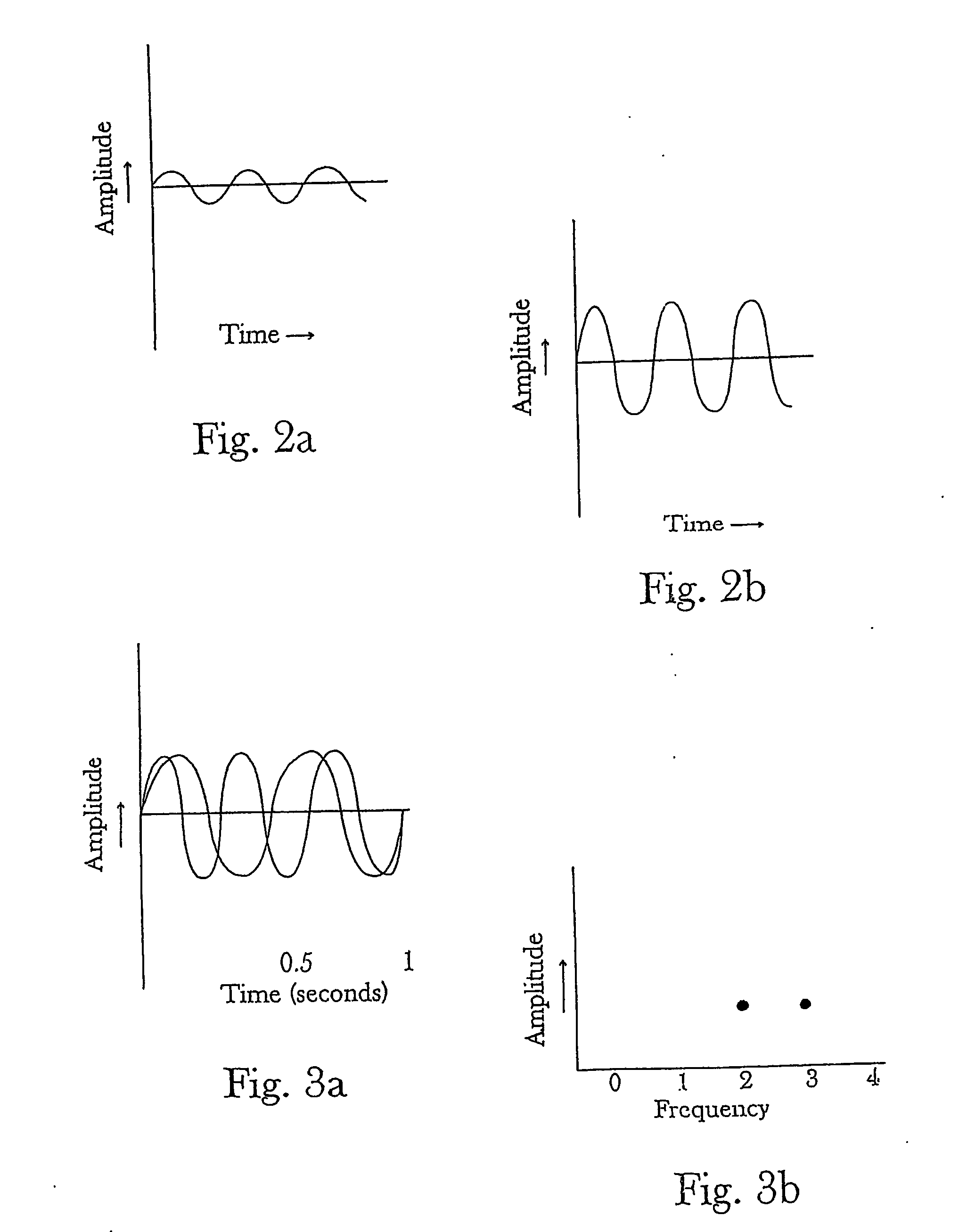

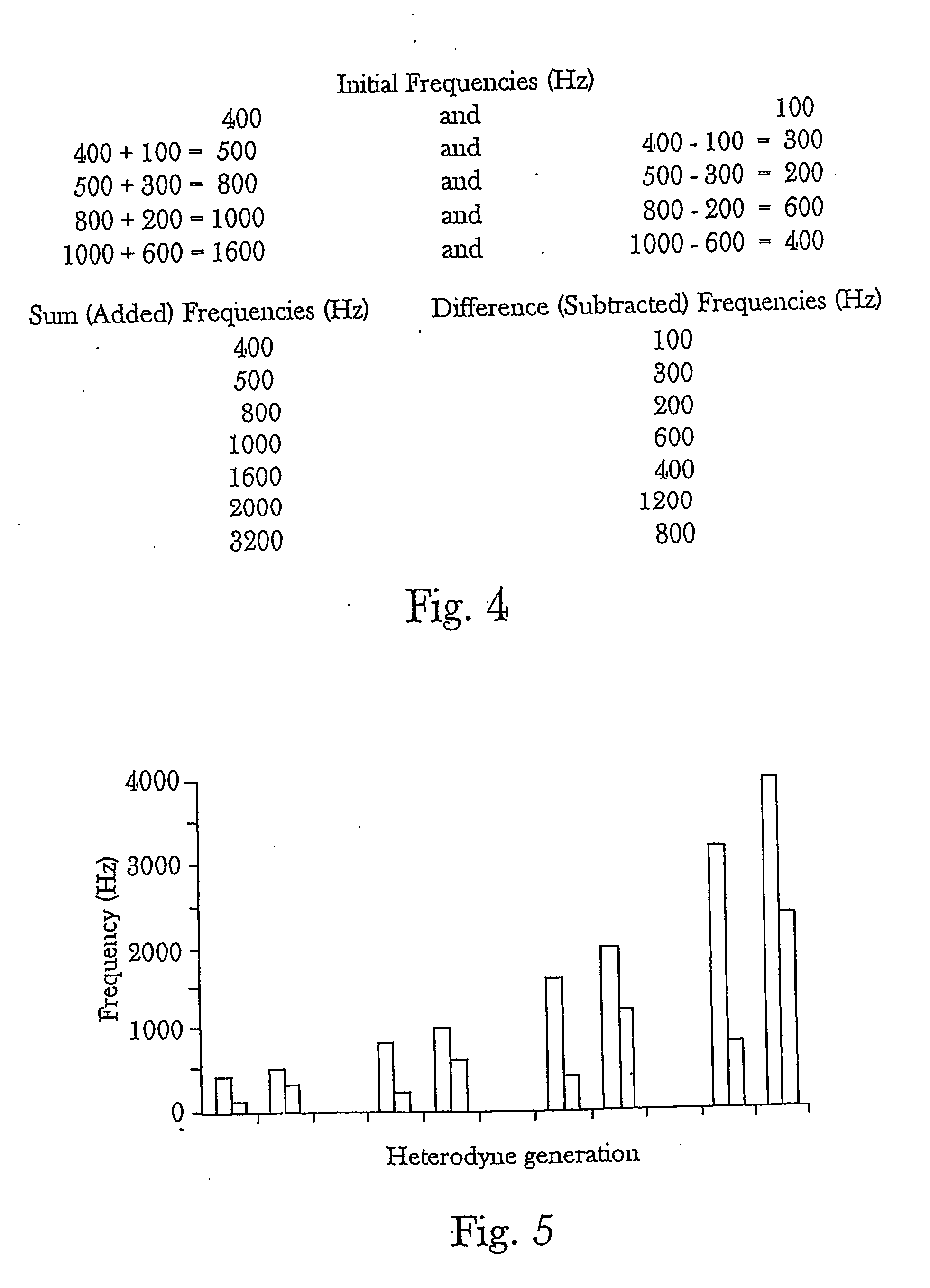

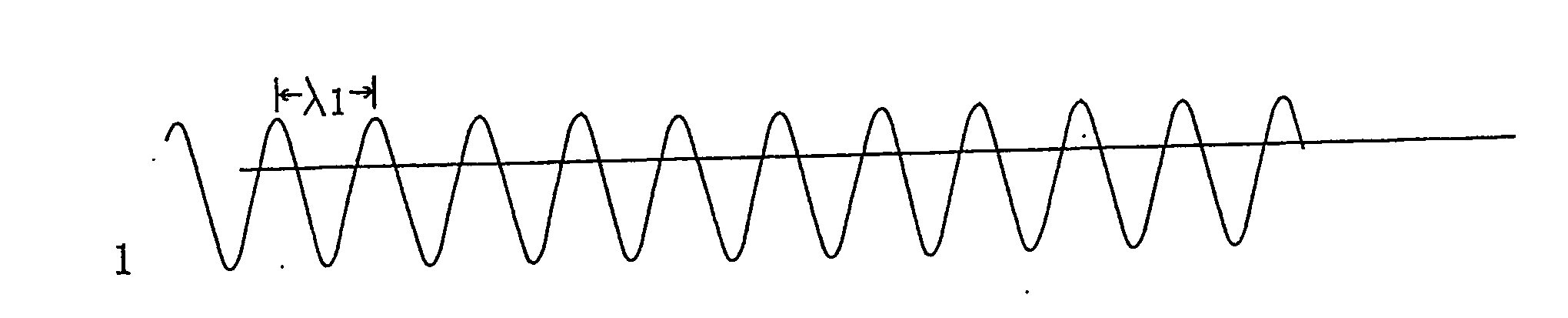

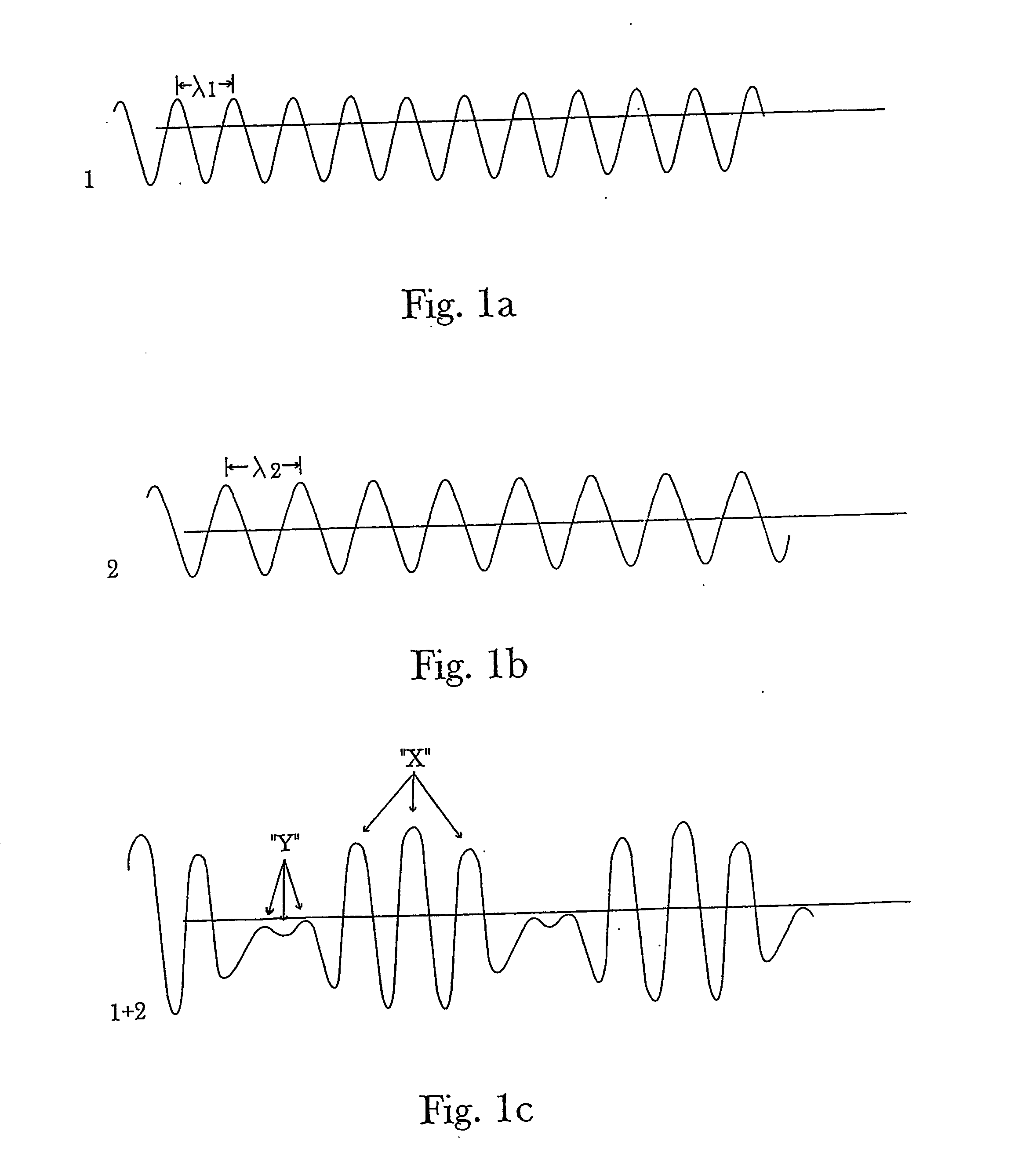

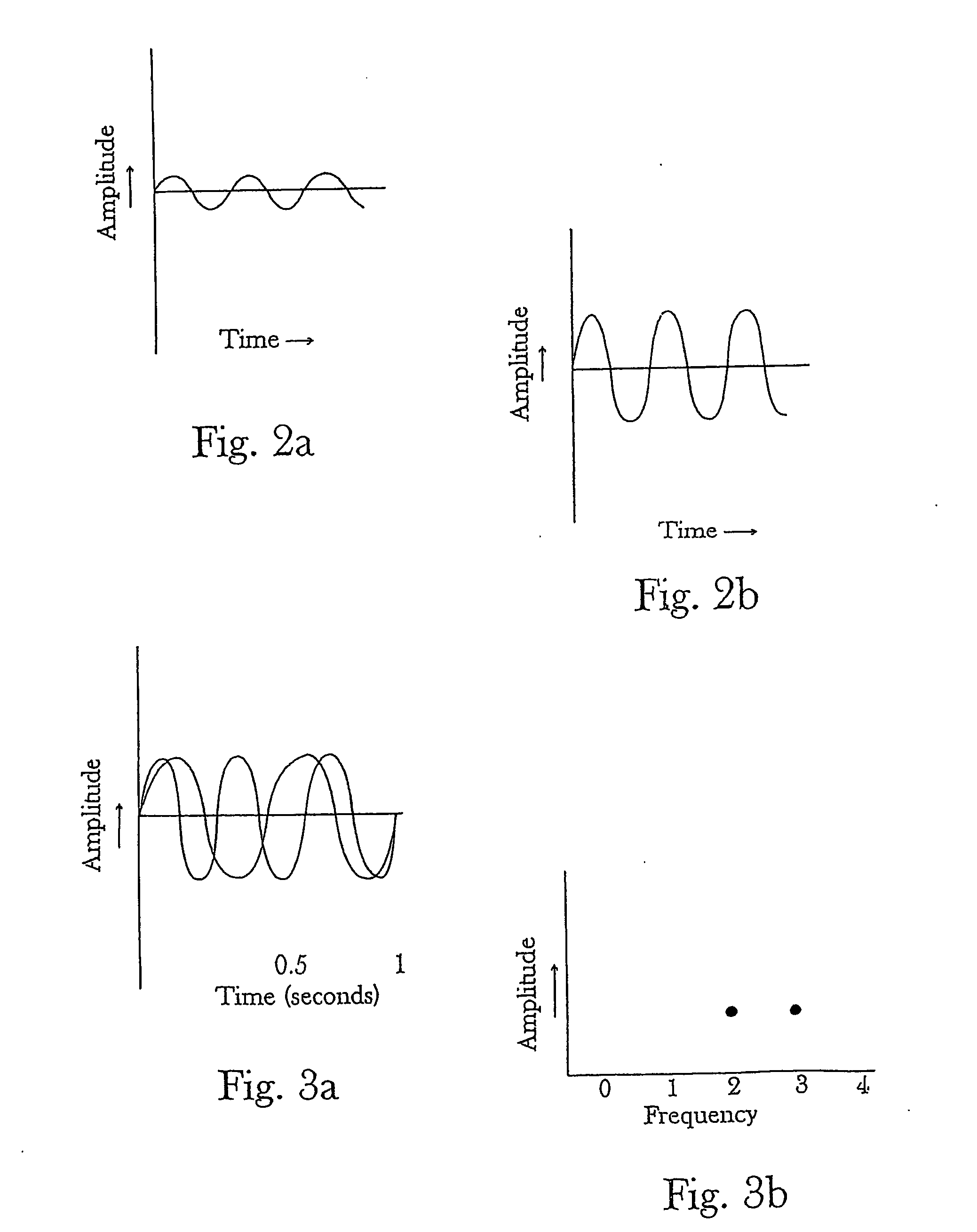

This invention relates to novel methods for affecting, controlling and / or directing various crystal formation, structure formation or phase formation / phase change reaction pathways or systems by exposing one or more components in a holoreaction system to at least one spectral energy pattern. In a first aspect of the invention, at least one spectral energy pattern can be applied to a crystallization reaction system. In a second aspect of the invention, at lest one spectral energy conditioning pattern can be applied to a conditioning reaction system. The spectral energy conditioning pattern can, for example, be applied at a separate location from the reaction vessel (e.g., in a conditioning reaction vessel) or can be applied in (or to) the reaction vessel, but prior to other (or all) crystallization reaction system participants being introduced into the reaction vessel.

Owner:GR INTELLECTUAL RESERVE LLC

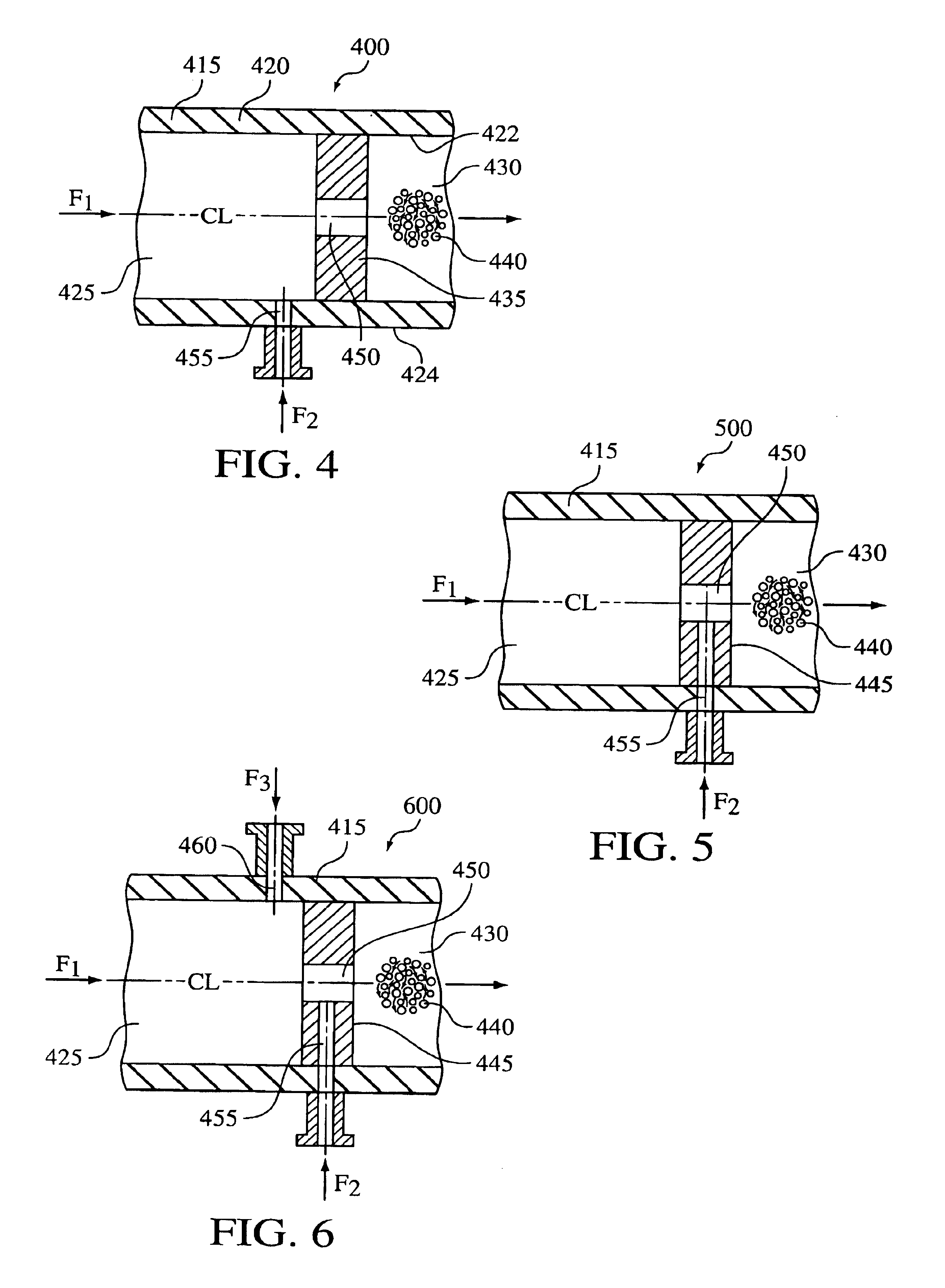

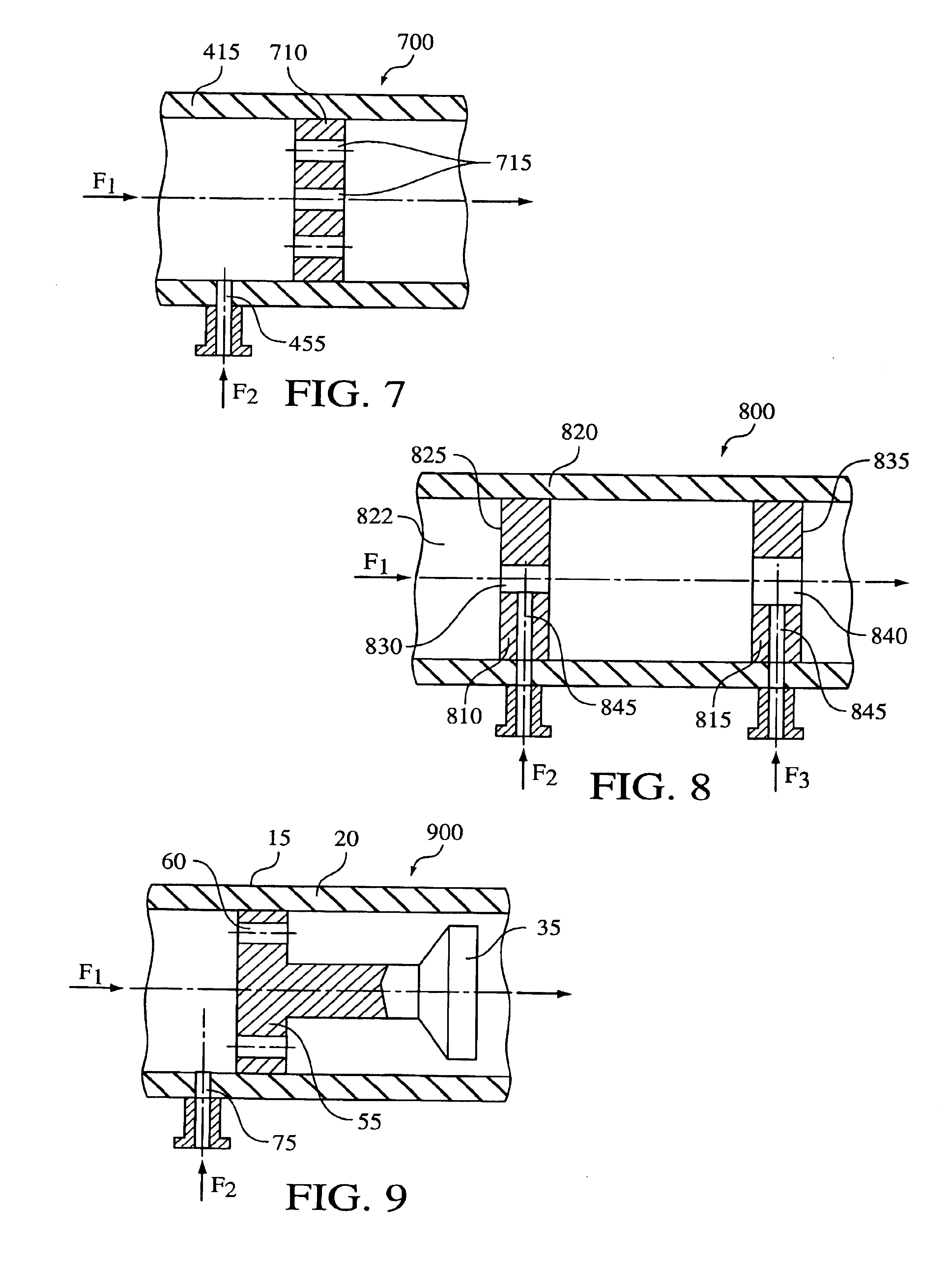

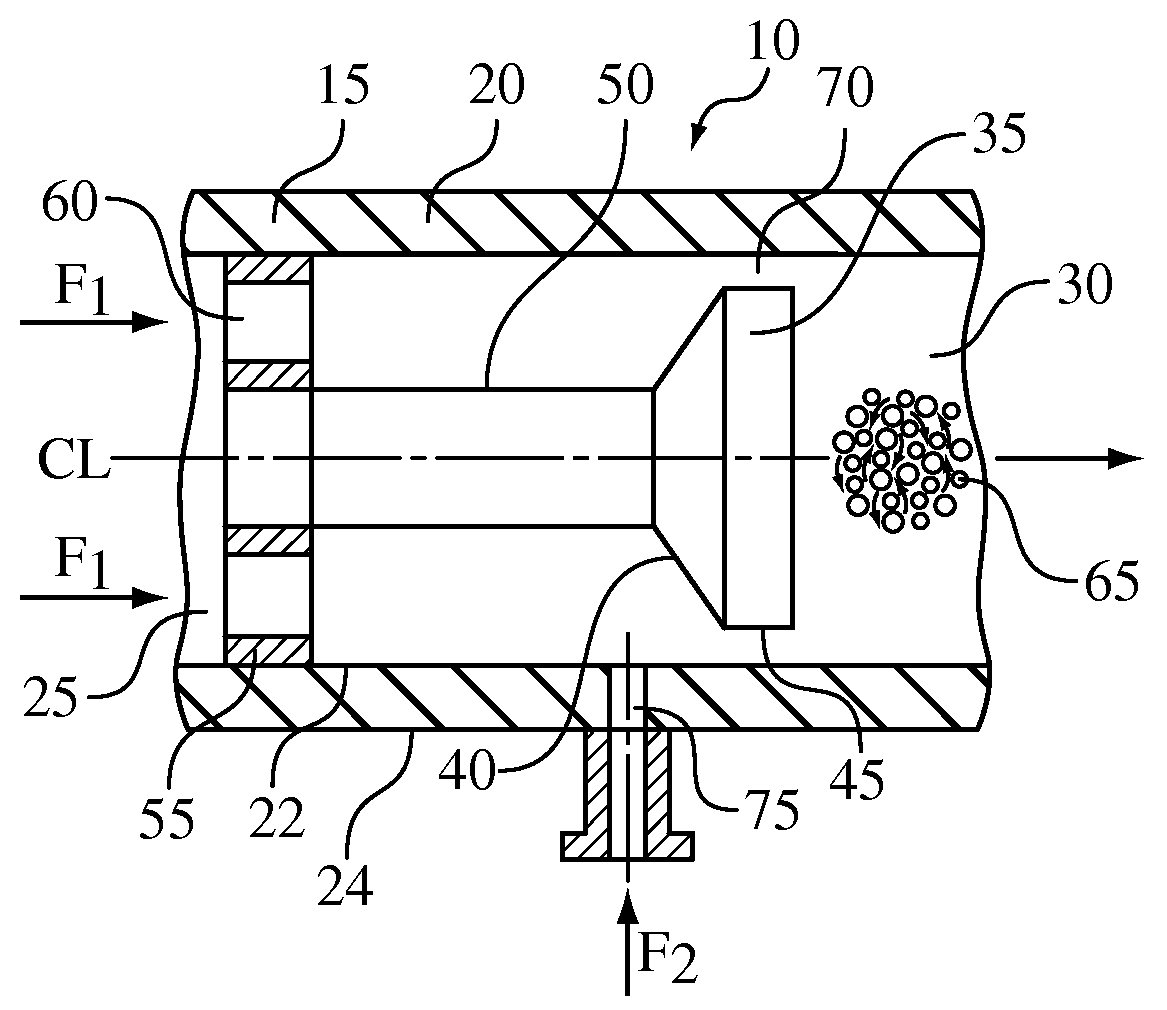

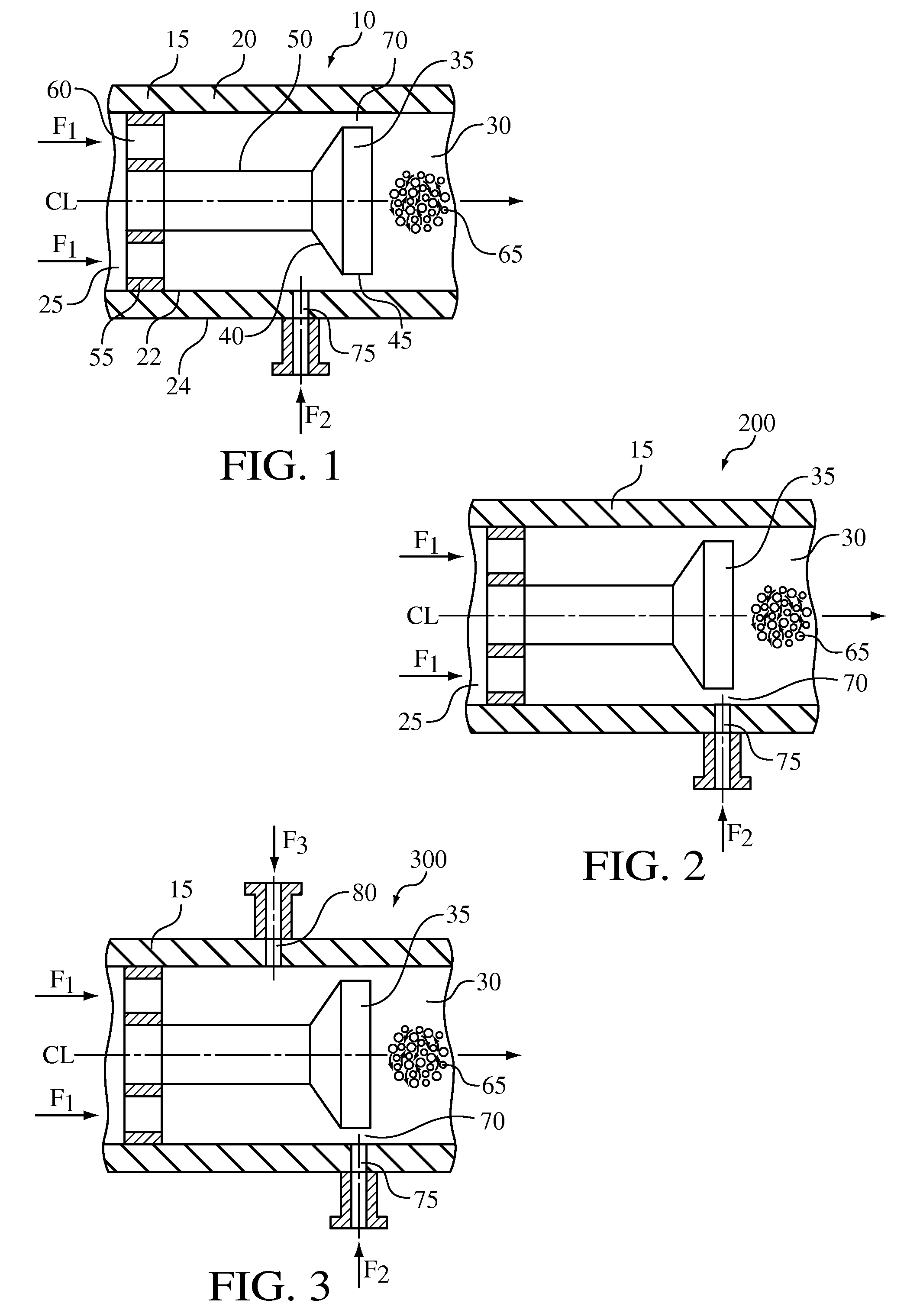

Hydrodynamic cavitation crystallization process

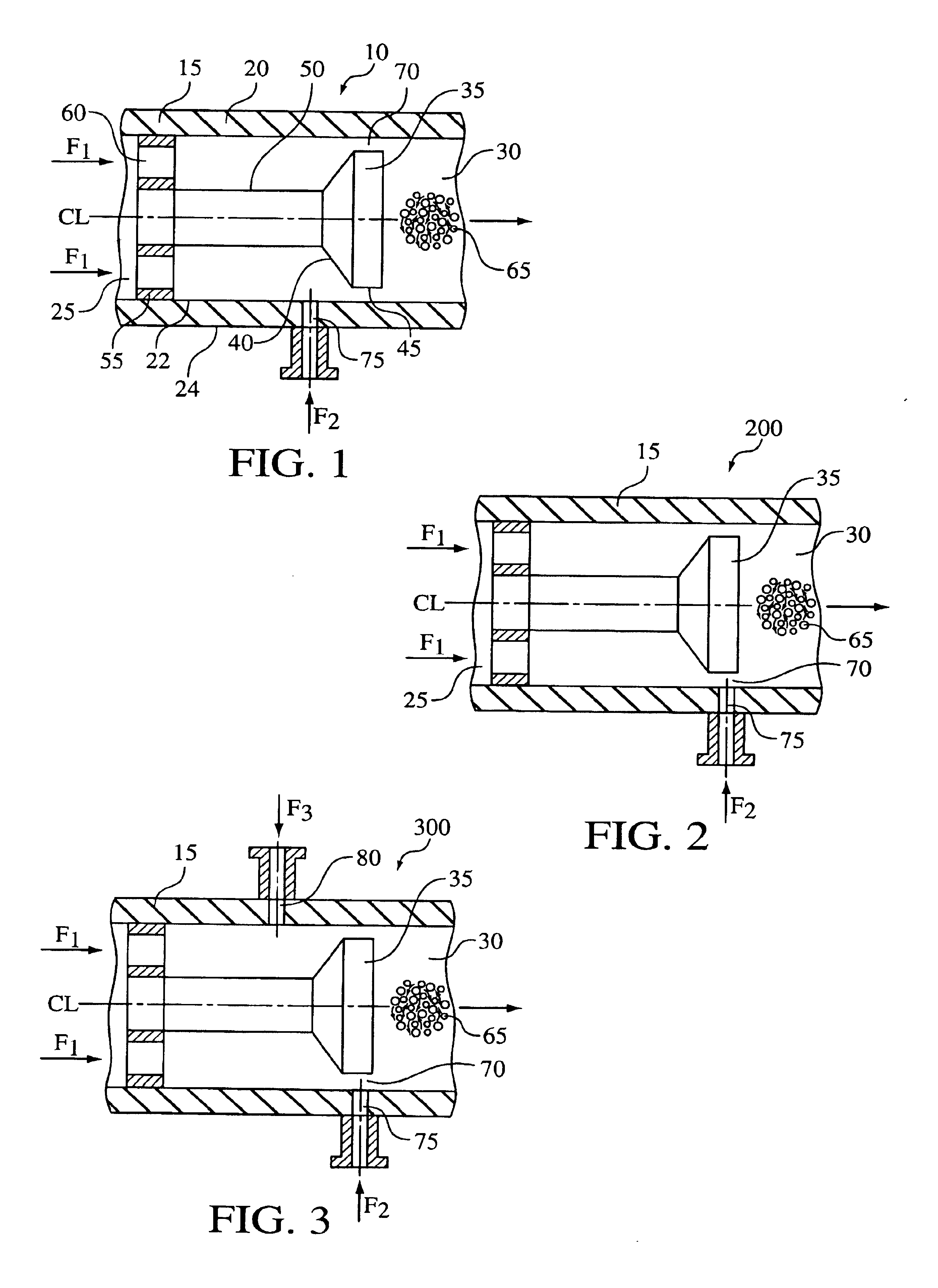

A device and process for crystallizing a compound using hydrodynamic cavitation comprising the steps of mixing at least one stream of a solution of such compound to be crystallized with at least one stream of an anti-solvent and passing the mixed streams at an elevated pressure through a local constriction of flow to create hydrodynamic cavitation thereby causing nucleation and the direct production of crystals.

Owner:ARISDYNE STSTEMS INC

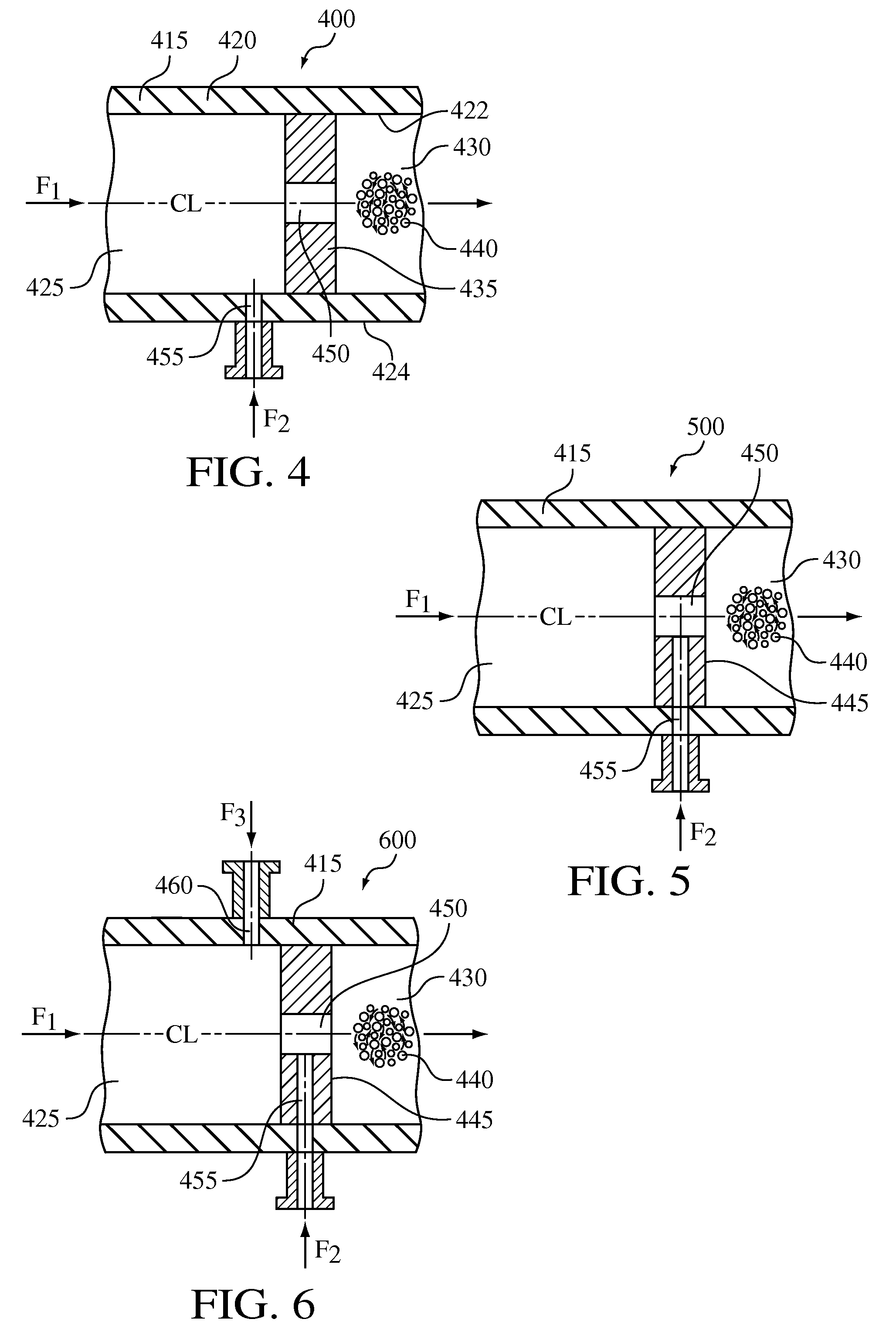

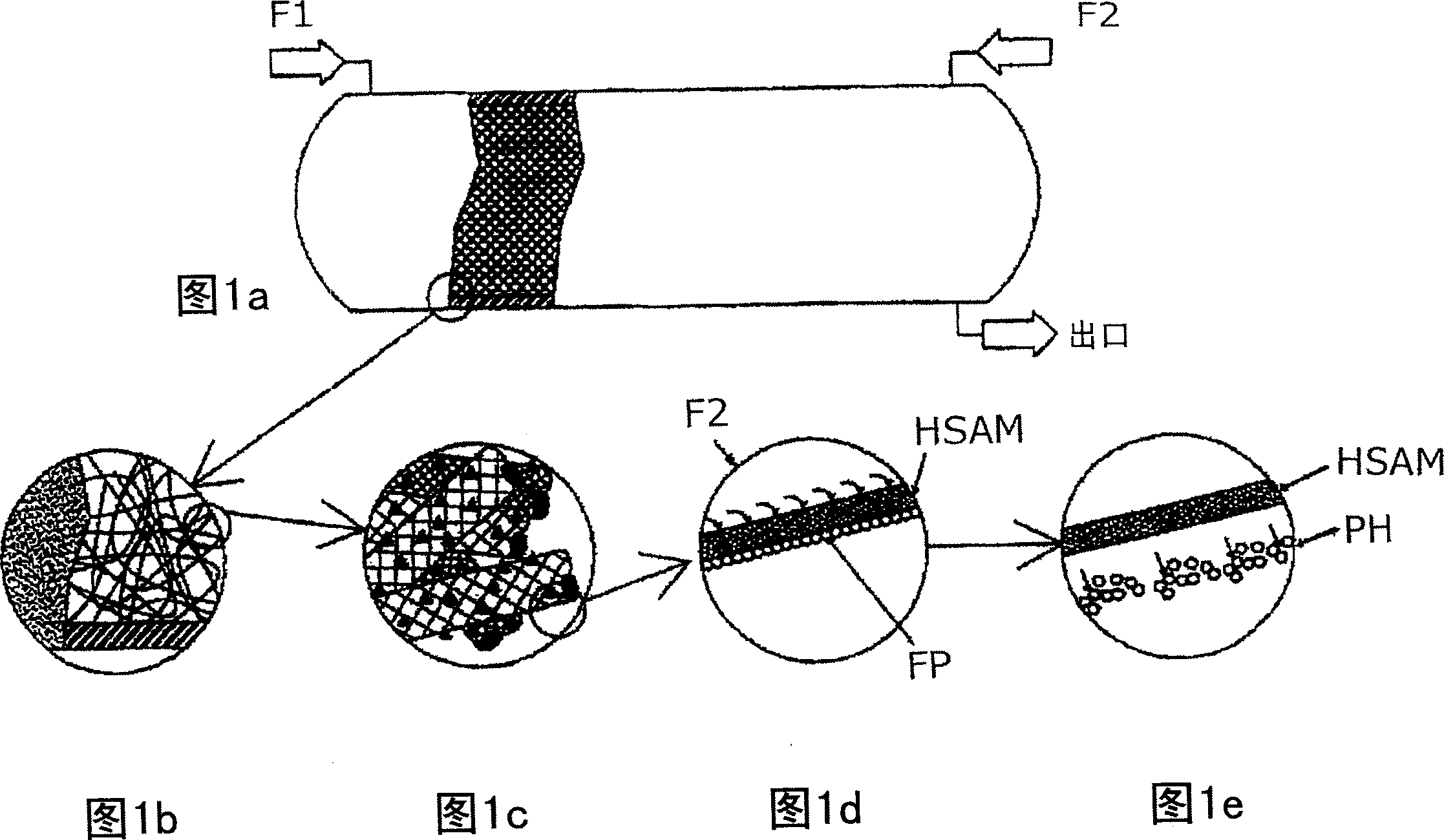

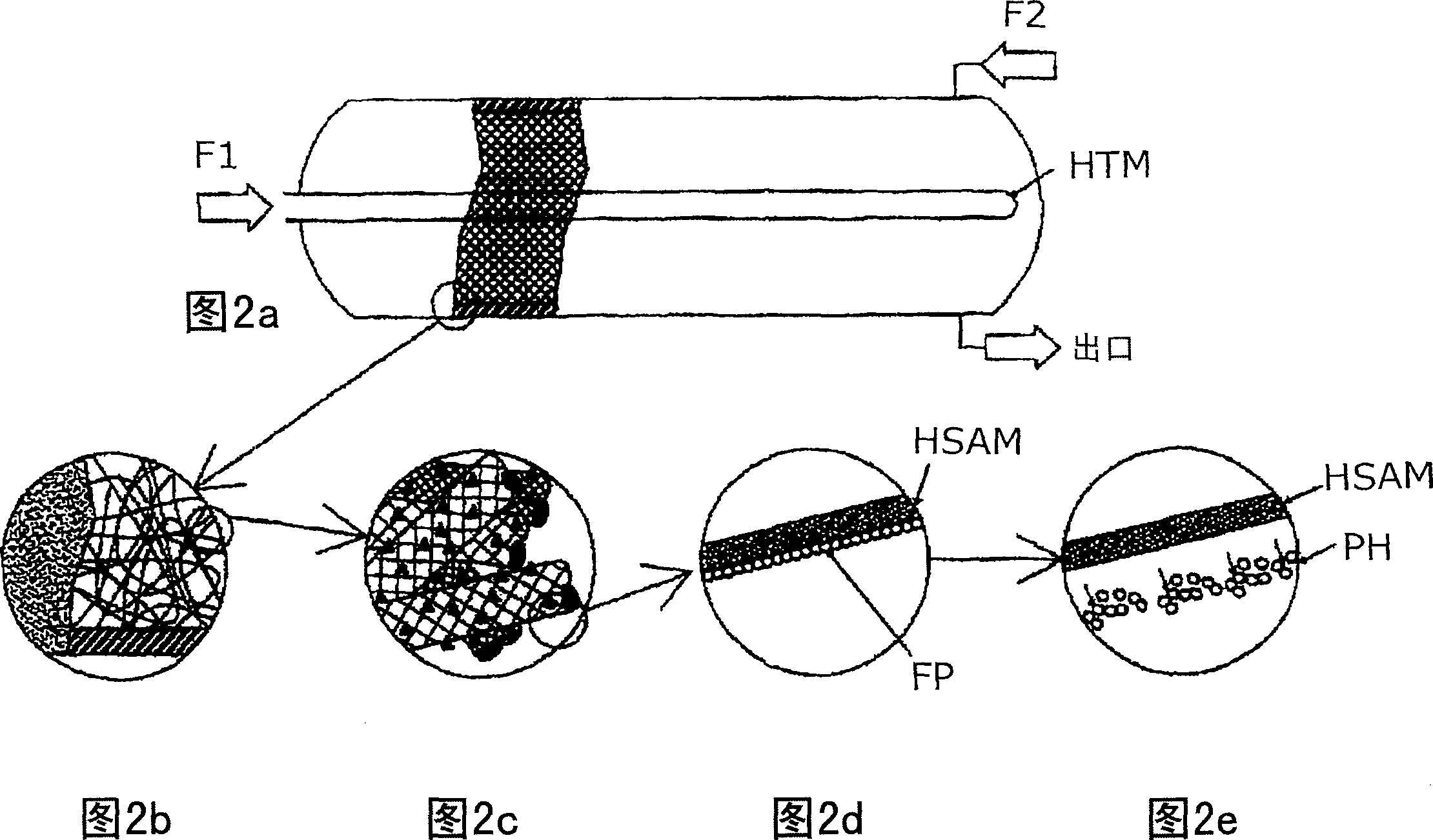

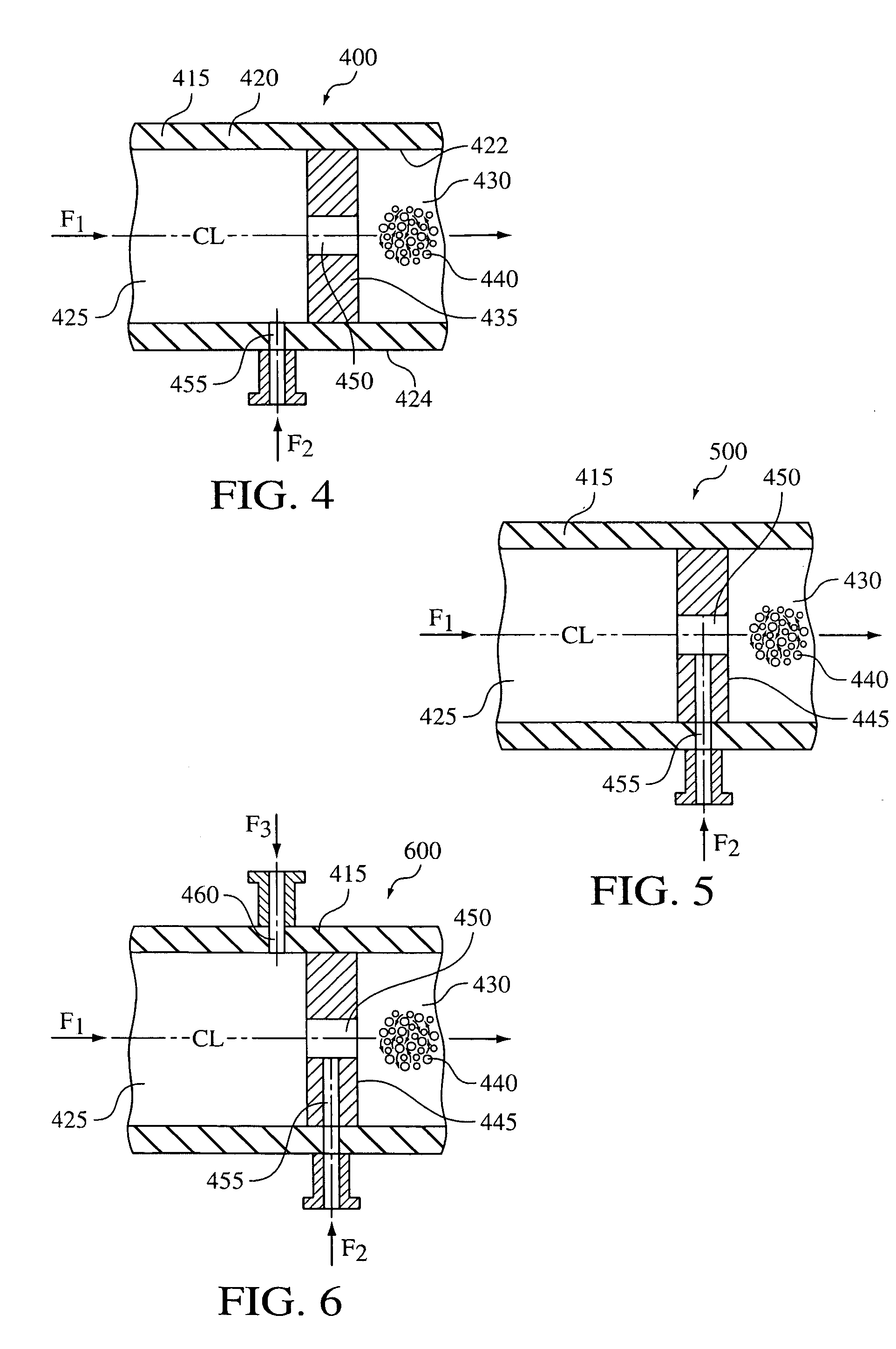

Hydrodynamic cavitation crystallization device and process

InactiveUS20080194868A1Polycrystalline material growthFrom normal temperature solutionsAnti solventCavitation

A device and process for crystallizing a compound using hydrodynamic cavitation comprising the steps of mixing at least one stream of a solution of such compound to be crystallized with at least one stream of an anti-solvent and passing the mixed streams at an elevated pressure through a local constriction of flow to create hydrodynamic cavitation thereby causing nucleation and the direct production of crystals. The compound to be crystallized can be, for example, an active pharmaceutical ingredient.

Owner:CAVITECH HLDG

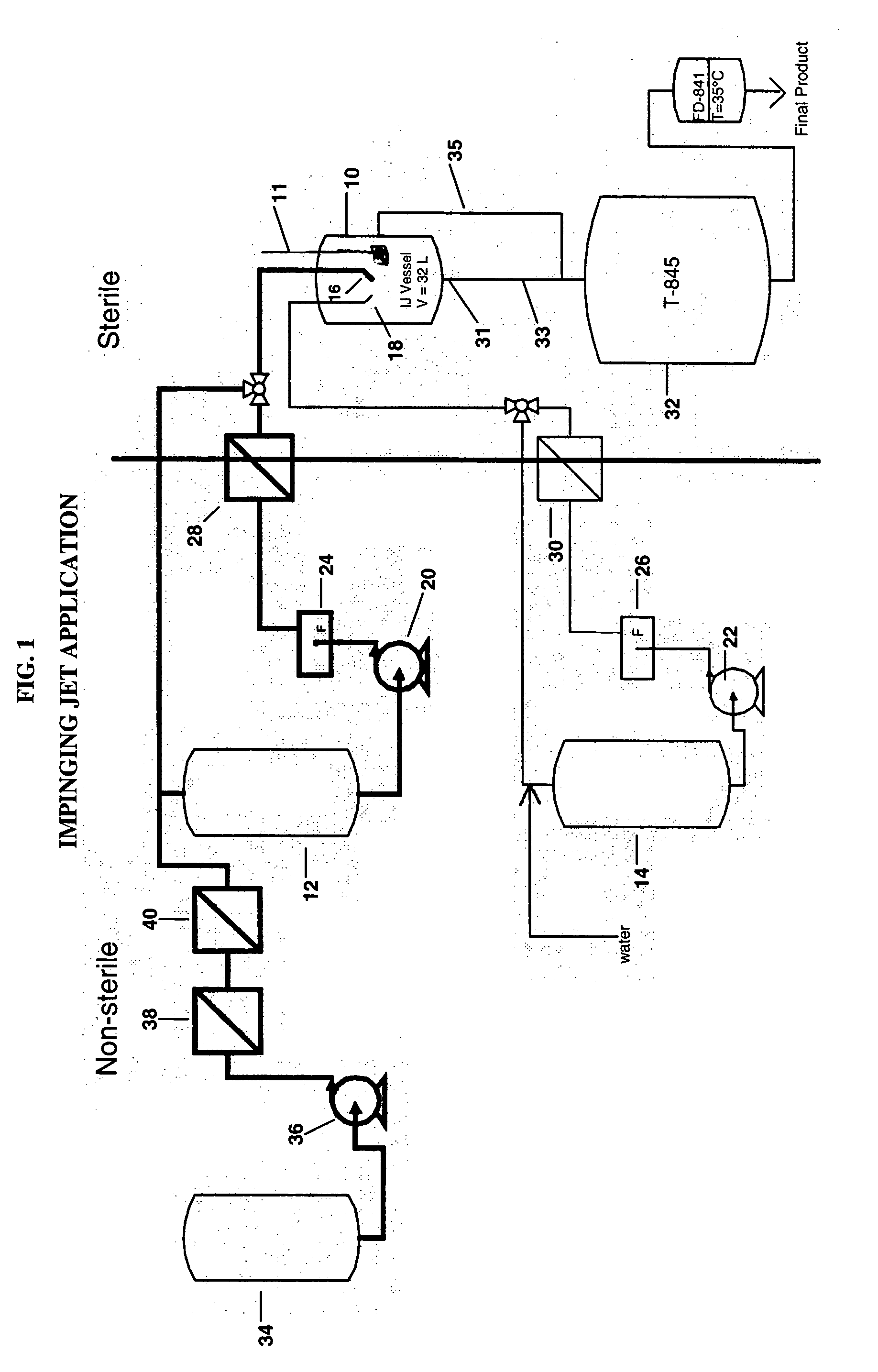

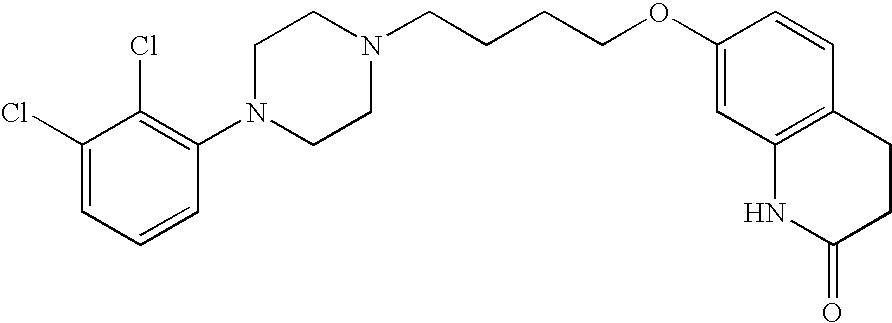

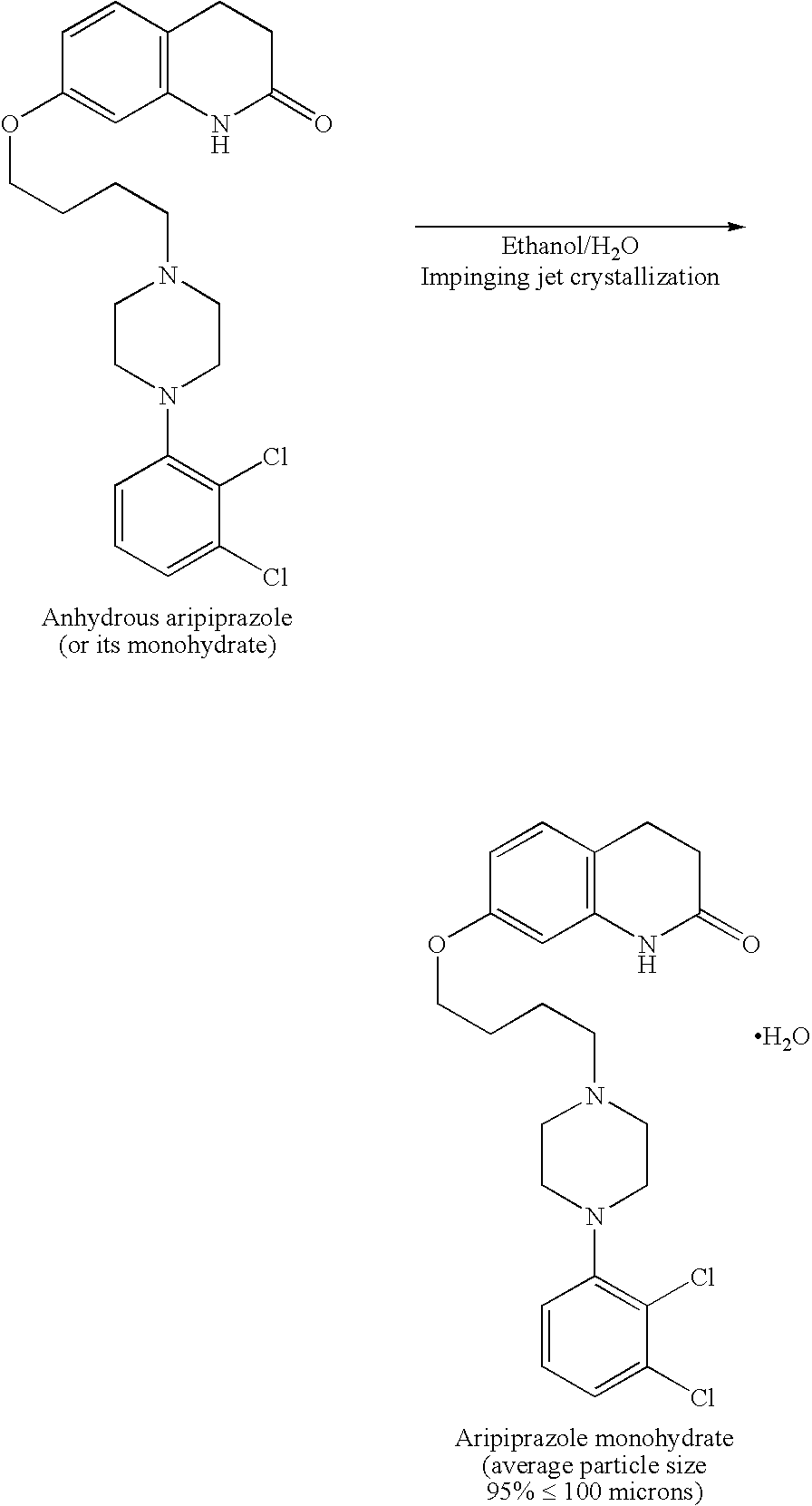

Process for making sterile aripiprazole of desired mean particle size

InactiveUS20050152981A1Enable formationHigh strengthOrganic active ingredientsPowder deliveryIntramuscular injectionFreeze-drying

A process is provided for making sterile aripiprazole having an average particle size less than 100 microns but preferably greater than 25 microns employing an impinging jet crystallization procedure. The resulting bulk aripiprazole of desired particle size may be used to form a sterile freeze-dried aripiprazole formulation, which upon constitution with water and intramuscular injection releases aripiprazole over a period of at least about one week and up to about eight weeks.

Owner:BRISTOL MYERS SQUIBB CO

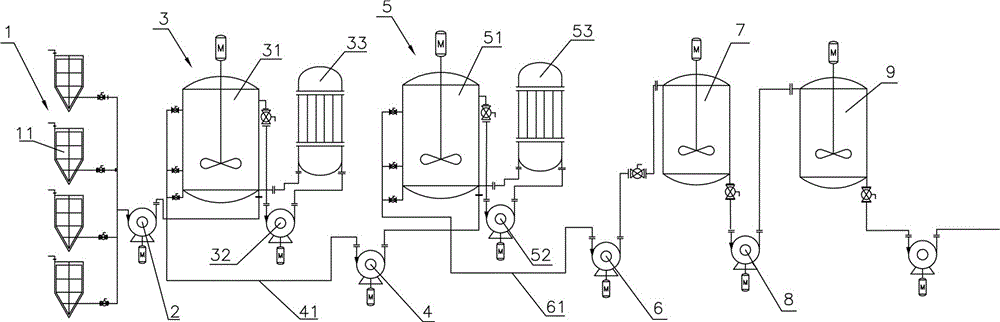

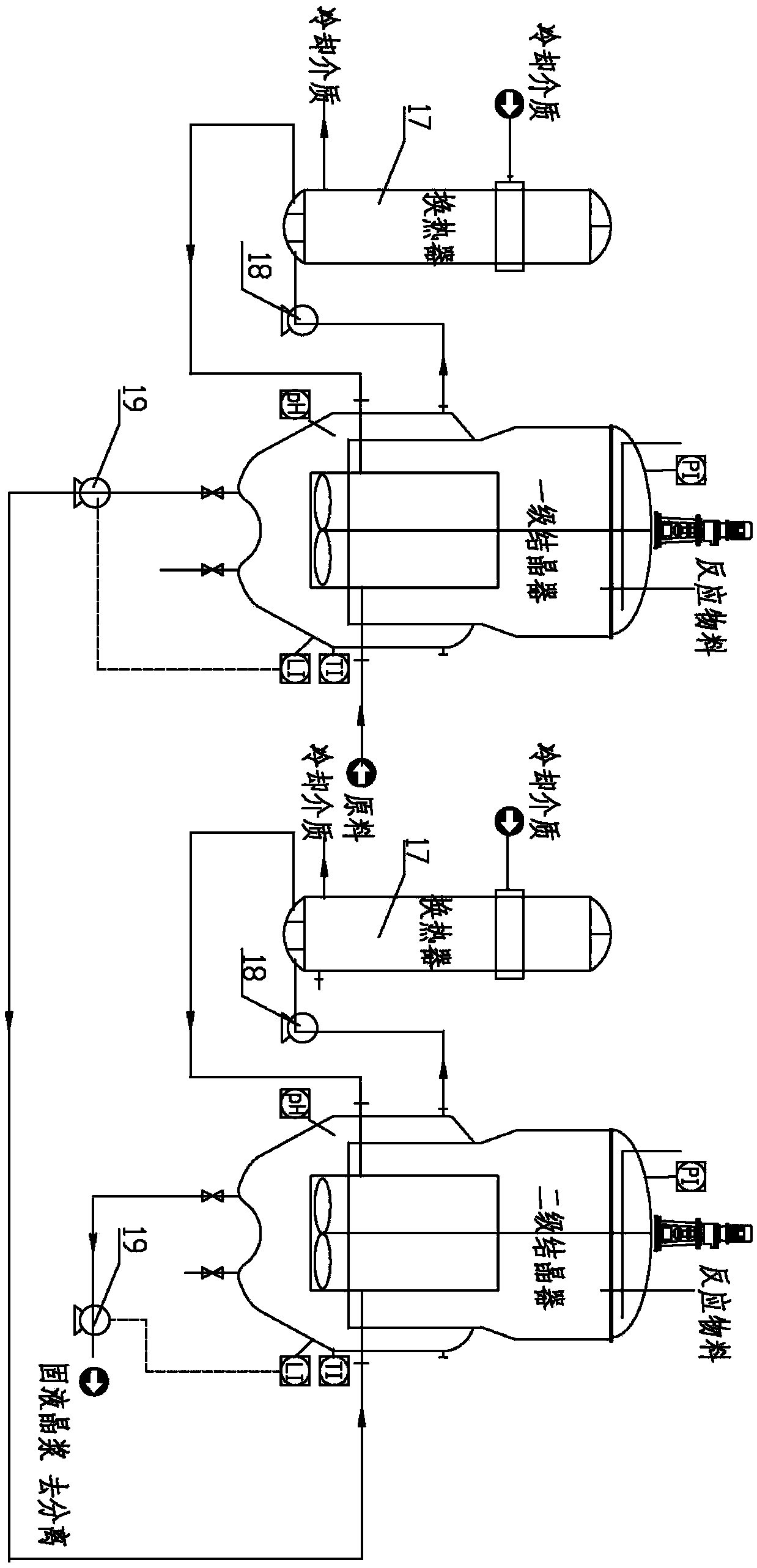

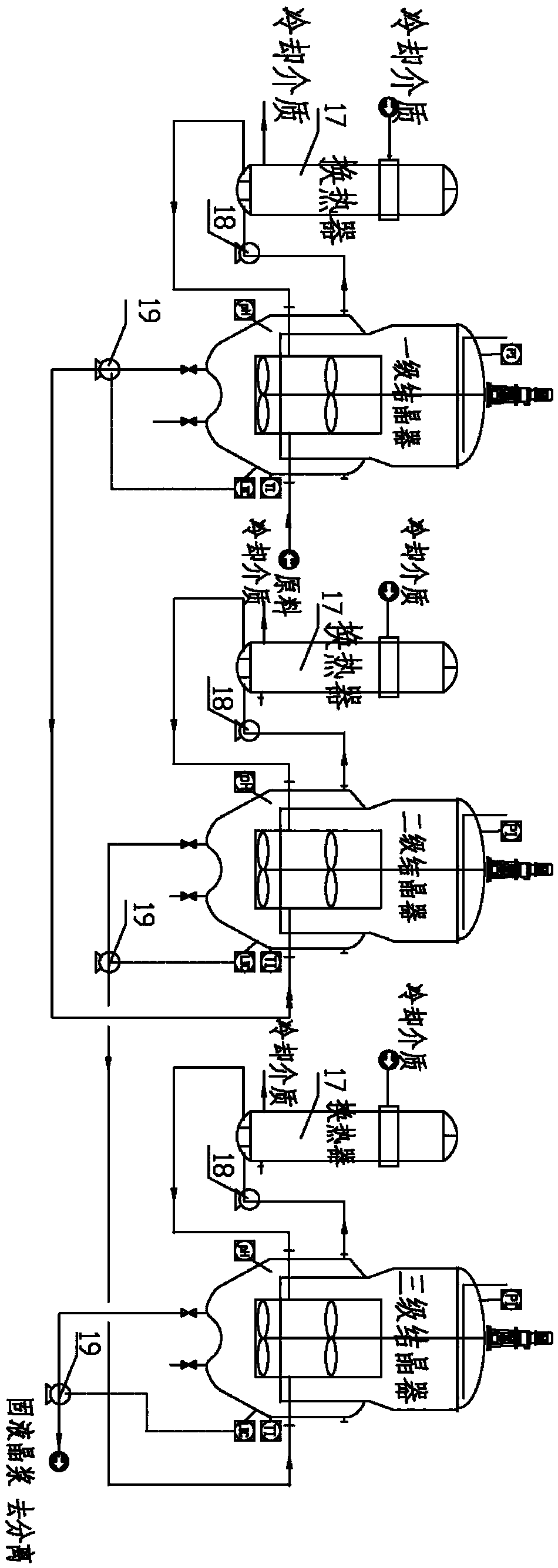

Continuously controllable acesulfame crystallization device

ActiveCN106267879AIncrease productivityQuality improvementOrganic chemistrySolution crystallizationGranularityEngineering

The invention discloses a continuously controllable acesulfame crystallization device. The continuously controllable acesulfame crystallization device comprises: a crystal growing device, a first conveying pump, a first-grade crystallizer, a second conveying pump, a second-grade crystallizer, a third conveying pump, a thickening device, a fourth conveying pump and a crystal slurry tank; the crystal growing device comprises at least one crystal growing kettle; a discharging hole of each crystal growing kettle is connected with a stop valve in series and then is communicated with an inlet of the first conveying pump; the first-grade crystallizer comprises a first-grade crystallizing kettle, a first-grade cooler and a first-grade circulating pump; an outlet of the first conveying pump is communicated with a lower circulating hole of the first-grade crystallizer; the second-grade crystallizer comprises a second-grade crystallizing kettle, a second-grade cooler and a second-grade circulating pump; the discharging hole of the first-grade crystallizing kettle is communicated with the inlet of the second conveying pump; the outlet of the second conveying pump is communicated with the lower circulating hole of the second-grade crystallizer; the discharging hole of the second-grade crystallizing kettle is communicated with the thickening device through the third conveying pump; the outlet of the thickening device is communicated with the inlet of the crystal slurry tank through the fourth conveying pump. The crystallization device provided by the invention is high in production efficiency and an obtained acesulfame crystal has good quality and large granularity.

Owner:南通宏信化工有限公司

Systems for Preparing Fine Articles and Other Substances

InactiveUS20070265357A1Improve conductivityImprove thermal conductivityPowder deliveryGranule coatingNanocrystalSolvent

This invention relates to controlled preparation of fine particles such as nano-crystalline films and powders with at least one solvent being in a supercritical state. It provides methods, measures, apparatus and products produced by the methods. In other aspects, the invention relates to further treatment of formed particles such as encapsulation of formed primary particles, and methods and measures for collection of formed substances in a batch wise, semi-continuous or continuous manner.

Owner:SCF TECH AS

Systems for preparing fine particles and other substances

The invention relates to controlled preparation of fine particles such as nano-crystalline films and powders with at least one solvent being in a supercritical state. It provides methods, measures, apparatus and products produced by the methods. In other aspects the invention relates to further treatment of formed particles such as encapsulation of formed primary particles, and methods and measures for collection of formed substances in a batch wise, semi-continuous or continuous manner.

Owner:SCF TECH AS

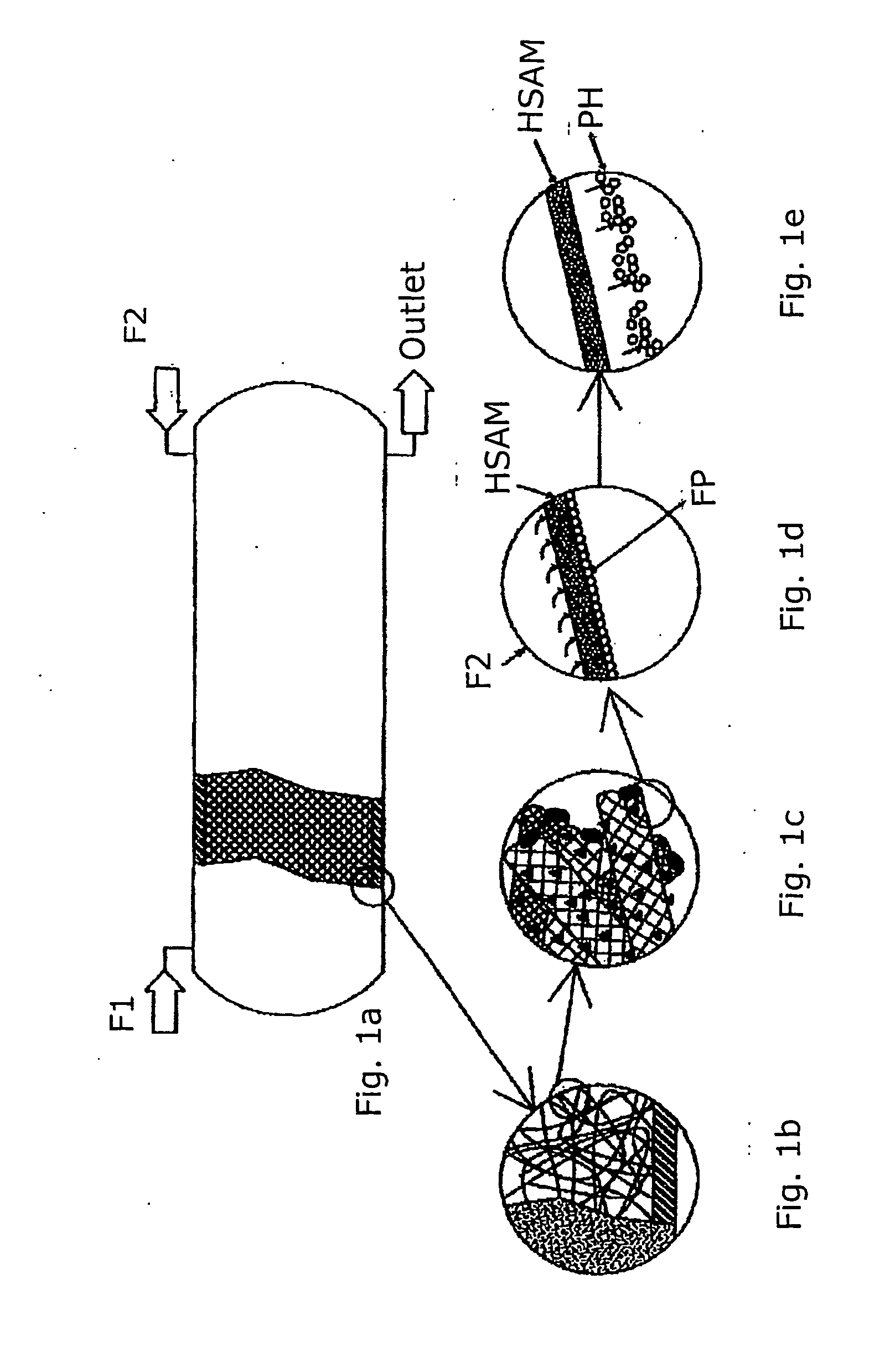

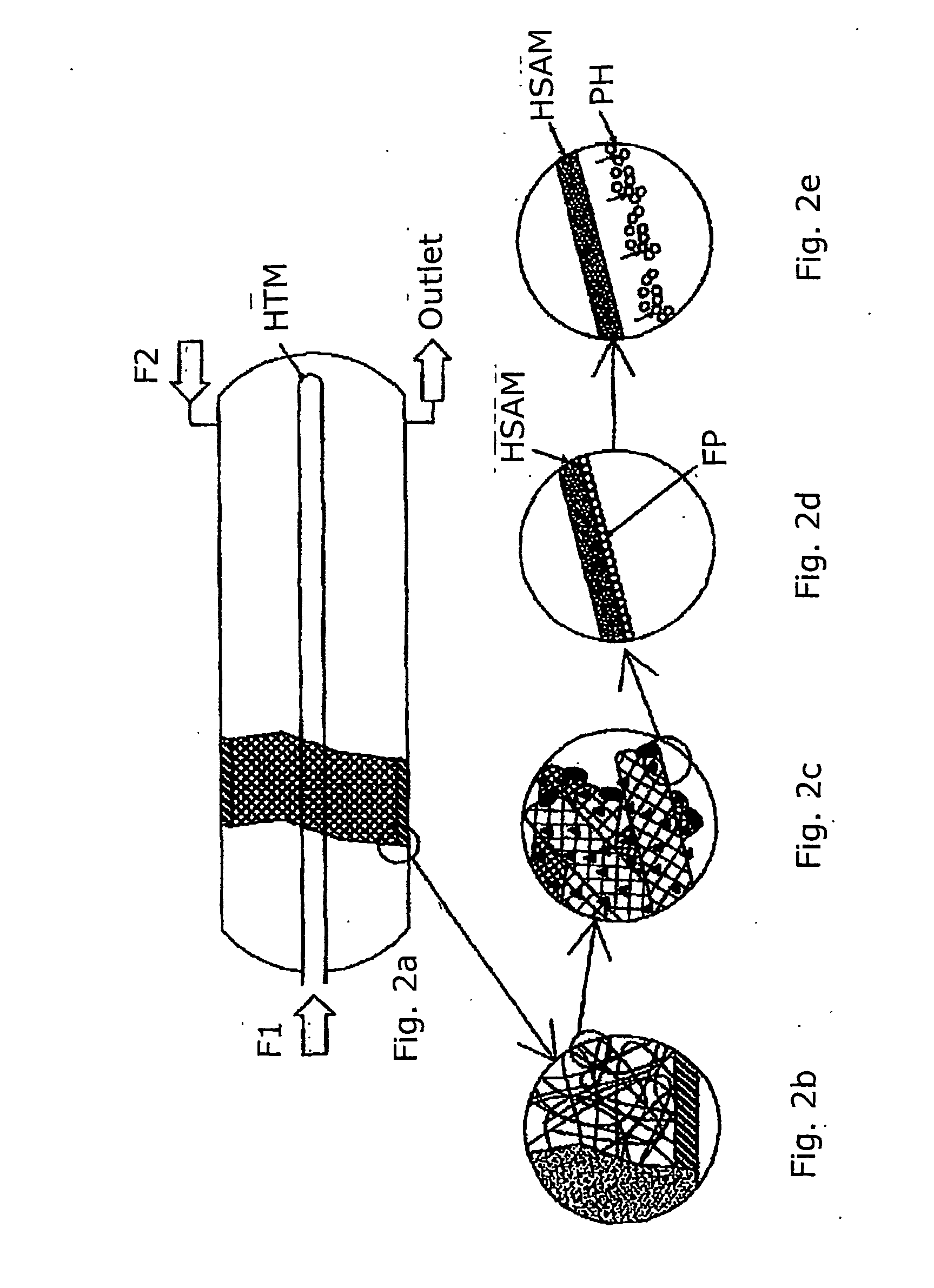

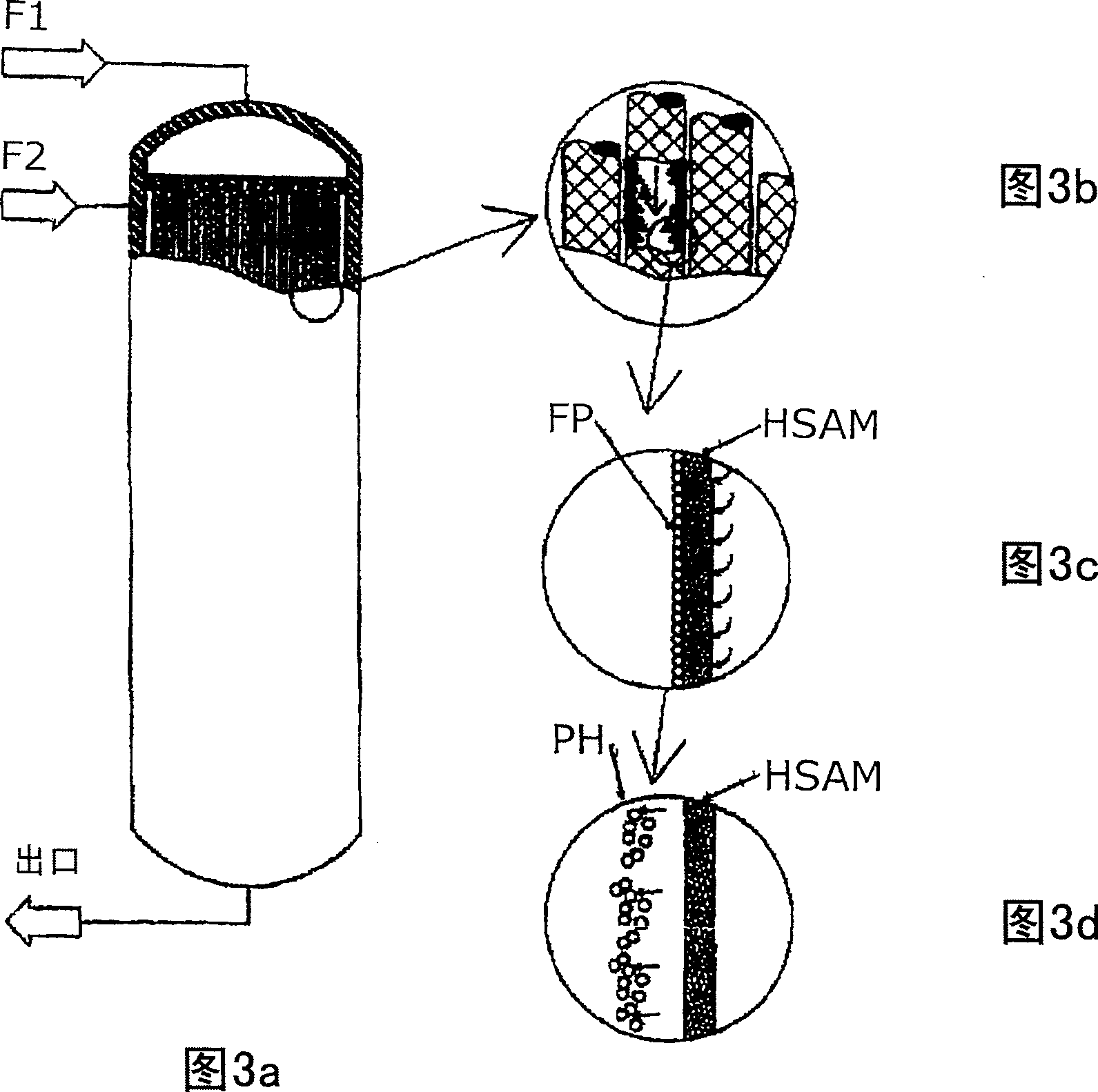

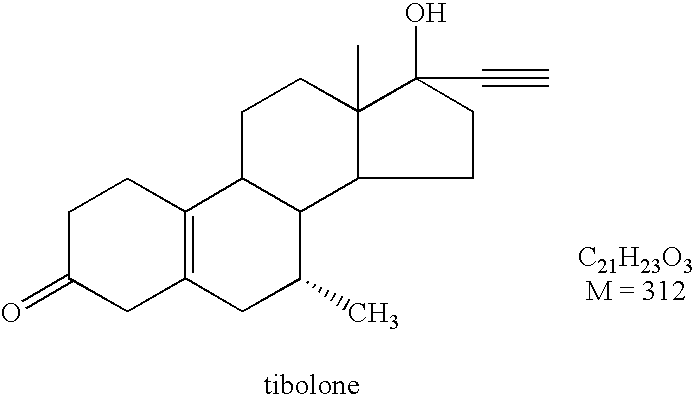

Antisolvent solidification process

The present invention relates to a antisolvent solidification process wherein a liquid medium comprising at least one organic or inorganic compound which is to be solidified is forced through a membrane into one or more antisolvents, or wherein one or more antisolvents are forced through a membrane into a liquid medium comprising at least one organic or inorganic compound which is to be solidified, yielding a composition comprising solid particles comprising said organic and / or inorganic compound(s).

Owner:NV ORGANON

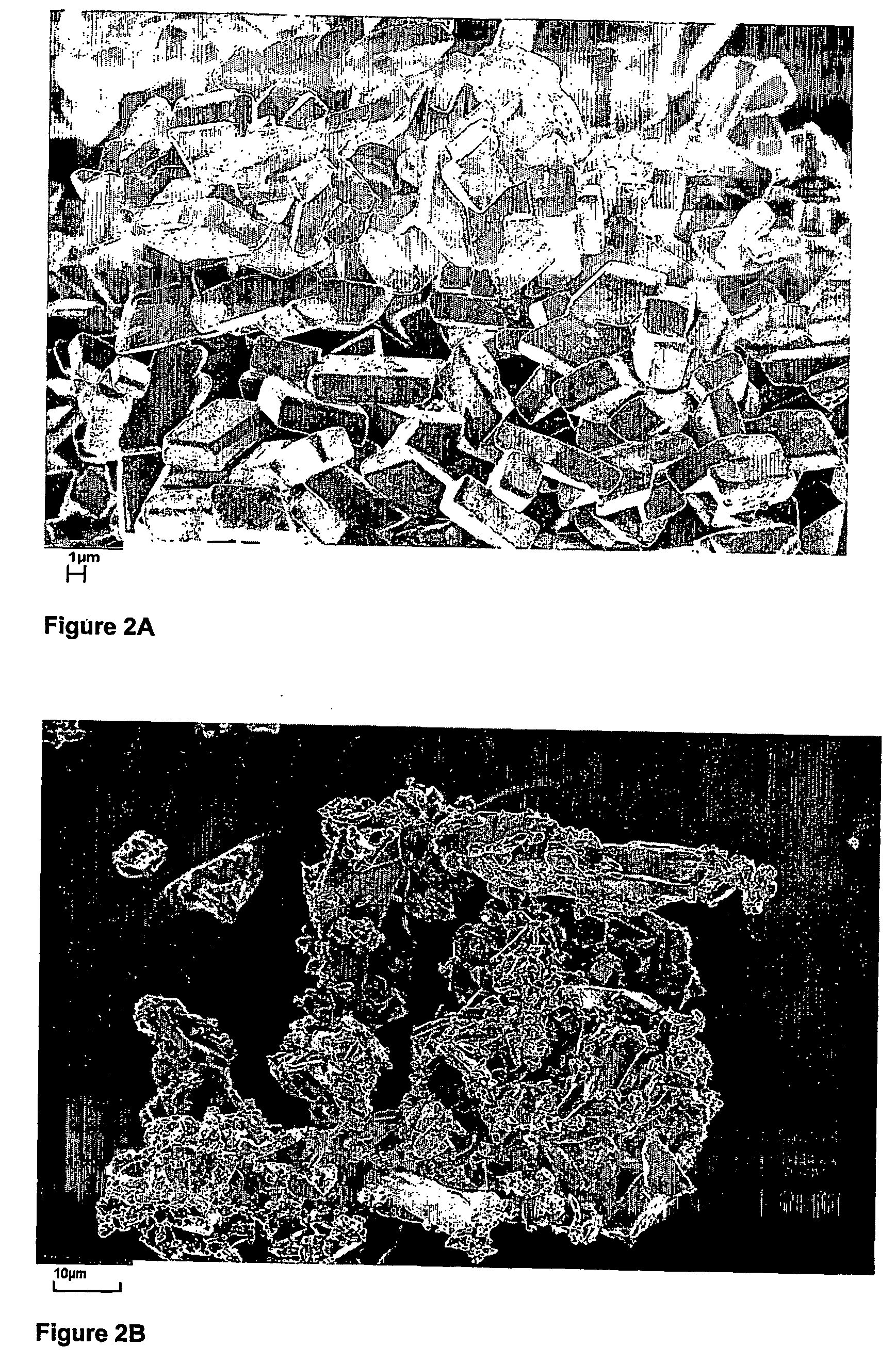

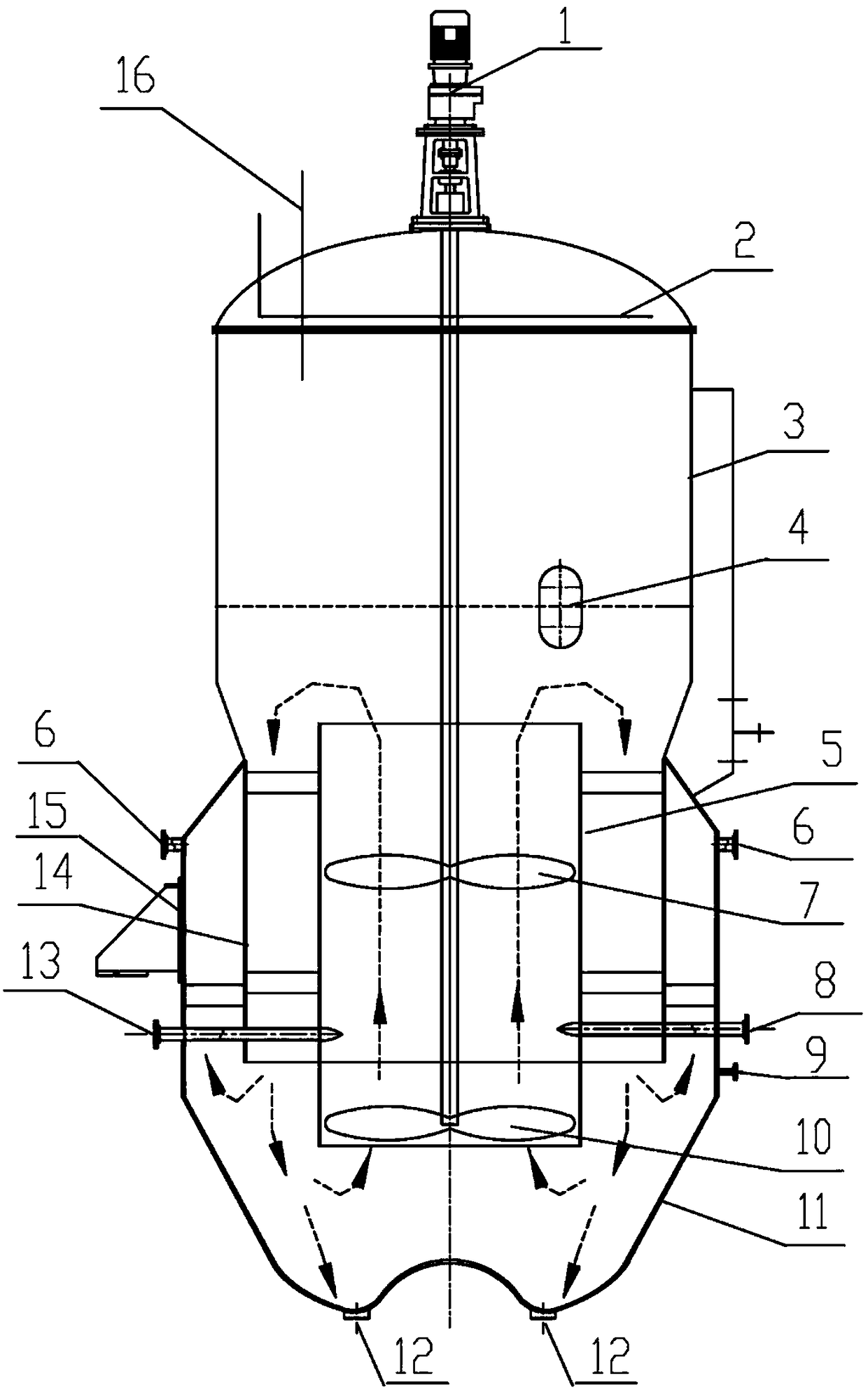

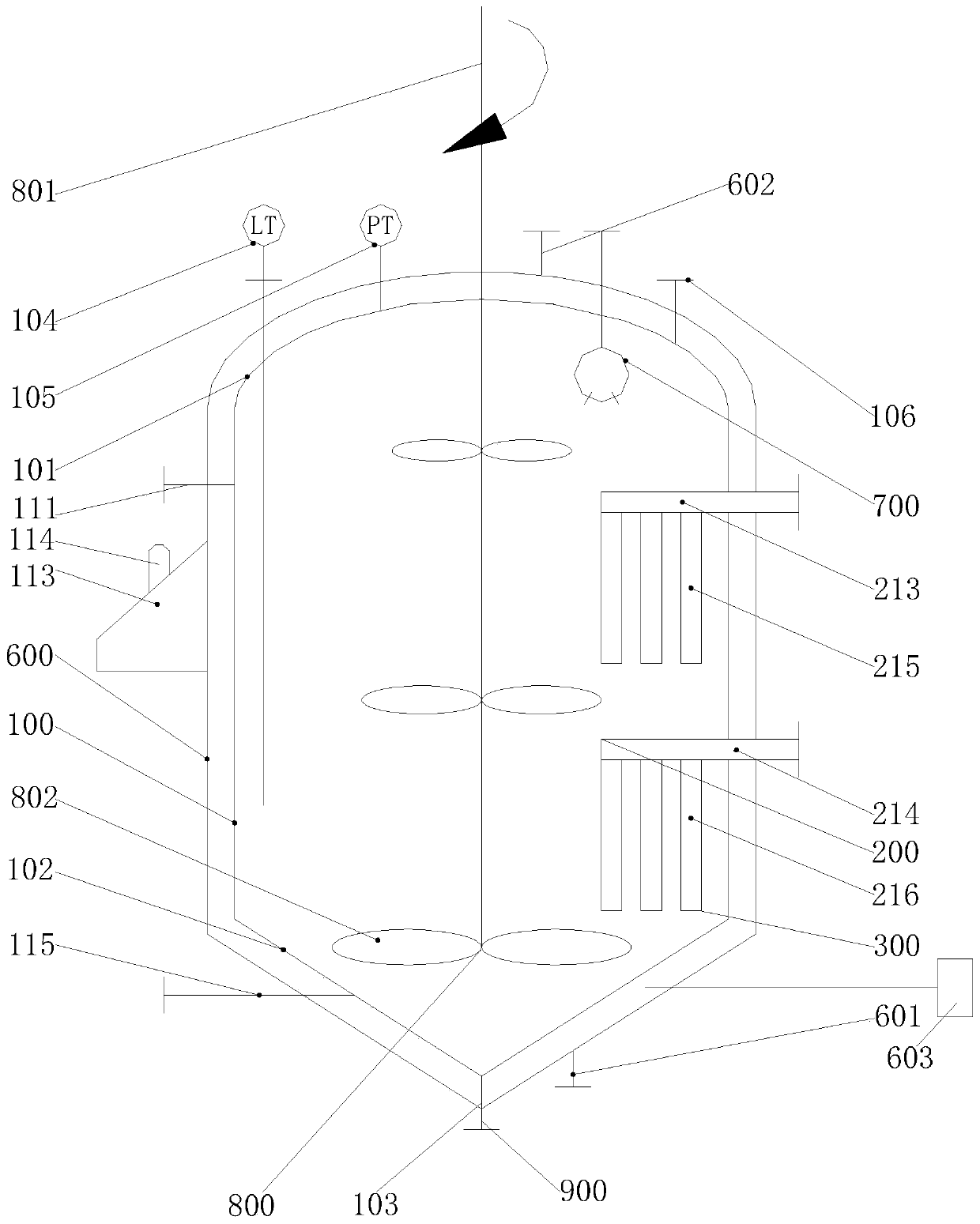

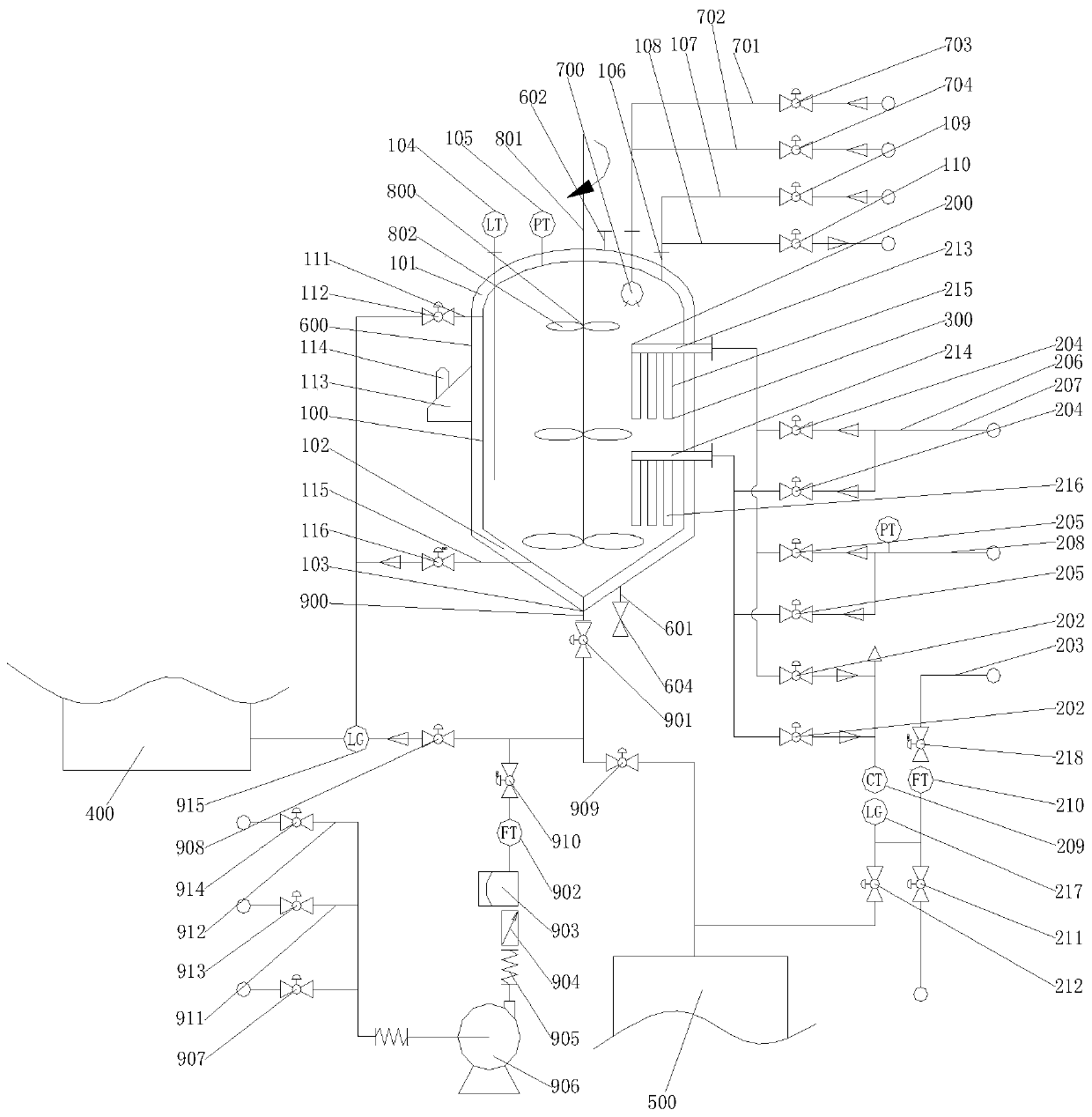

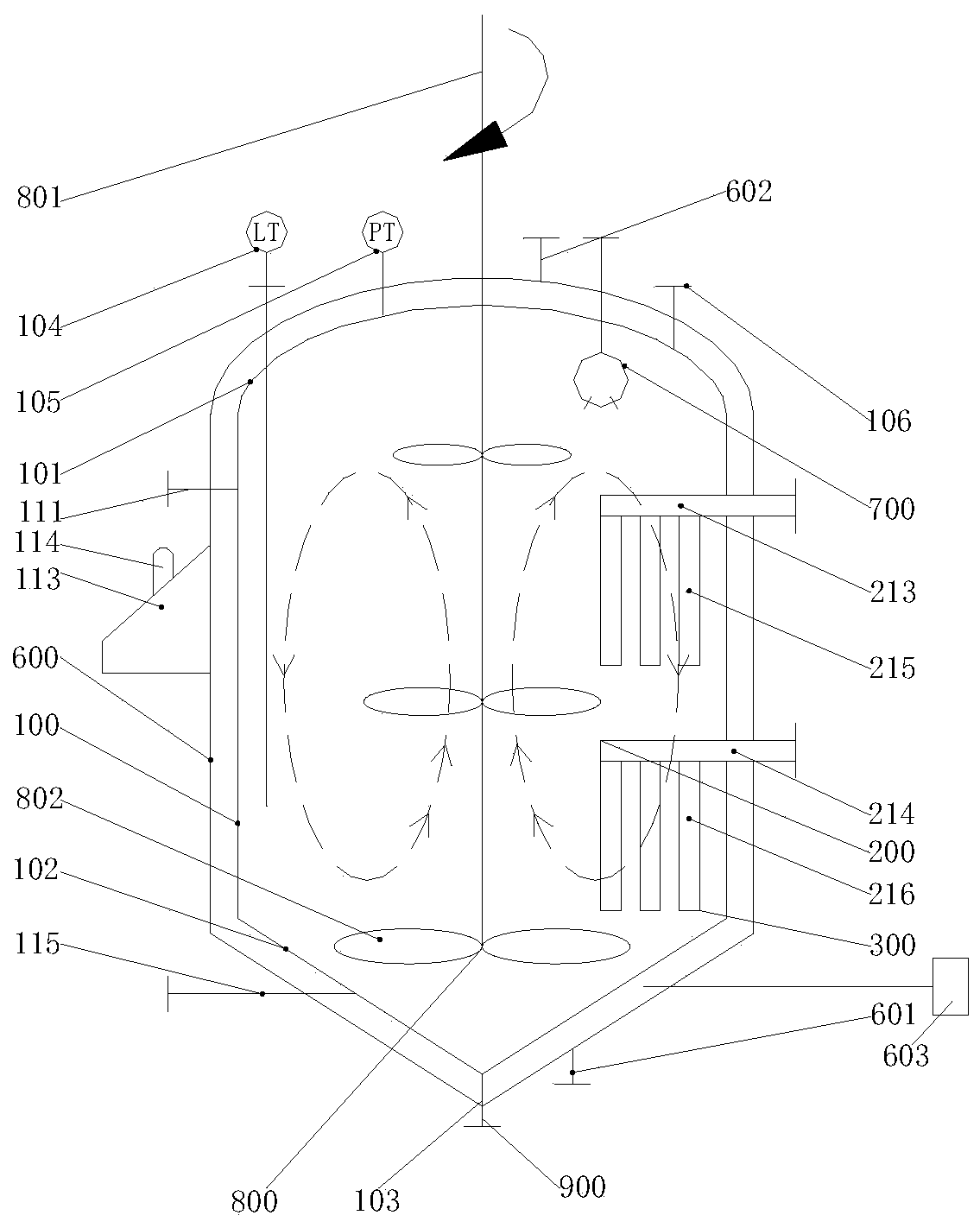

Self-circulating crystallizer and multistage continuous crystallization method

ActiveCN108939599AReduce the chance of collision nucleationStable particle sizeEvaporator accessoriesSolution crystallizationGranularityEvaporation

The invention relates to a self-circulating crystallizer and a multistage continuous crystallization method. The crystallizer sequentially comprises a kettle head, an upper cylinder body, a middle cylinder body and a bottom hole-shrinkage cylinder body with a W-shaped bottom from top to bottom, wherein a steam outlet and / or a feeding hole are / is arranged on the kettle head, an annular spraying pipe is arranged at the lower part of the kettle head; a middle straight cylinder section is arranged in the middle cylinder body, a flow guiding cylinder is arranged in the middle straight cylinder section, and a stirrer is arranged in the flow guiding cylinder; the diameter of the middle cylinder body is larger than that of the upper cylinder body, and the diameter of the upper cylinder body is larger than that of the middle cylinder body; and the lower part of the upper cylinder body and the upper part of the middle cylinder body are respectively connected with the circumference of the top ofthe middle straight cylinder section via a hole-shrinkage transition section, and a discharging hole is formed in the W-shaped bottom. The invention provides the method for realizing multistage continuous evaporation, cooling or reaction crystallization through the series connection of the crystallizer, the prepared crystals are large in granularity and uniform in particle size, the problems thatthe product granularity is small, equipment is seriously scaled, a pipeline is blocked, and the like in the continuous crystallization process are improved, and the operation period of the continuouscrystallization process is prolonged.

Owner:TIANJIN UNIV

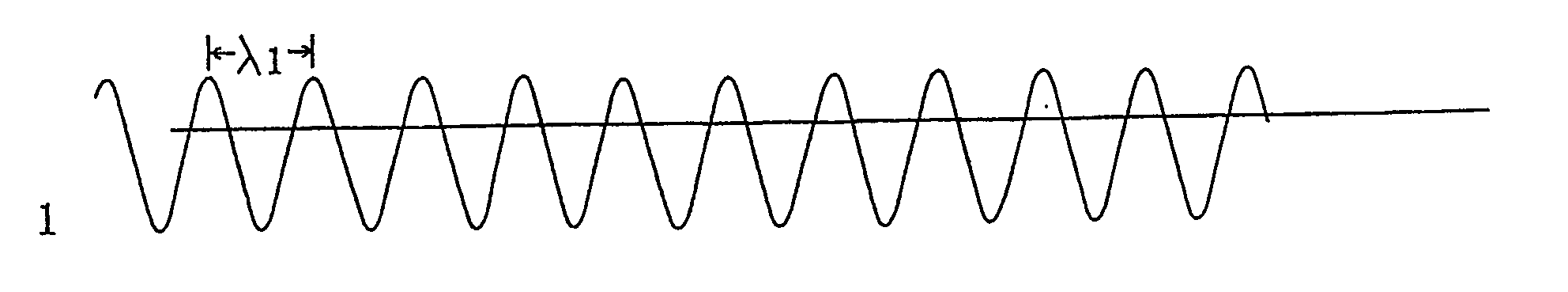

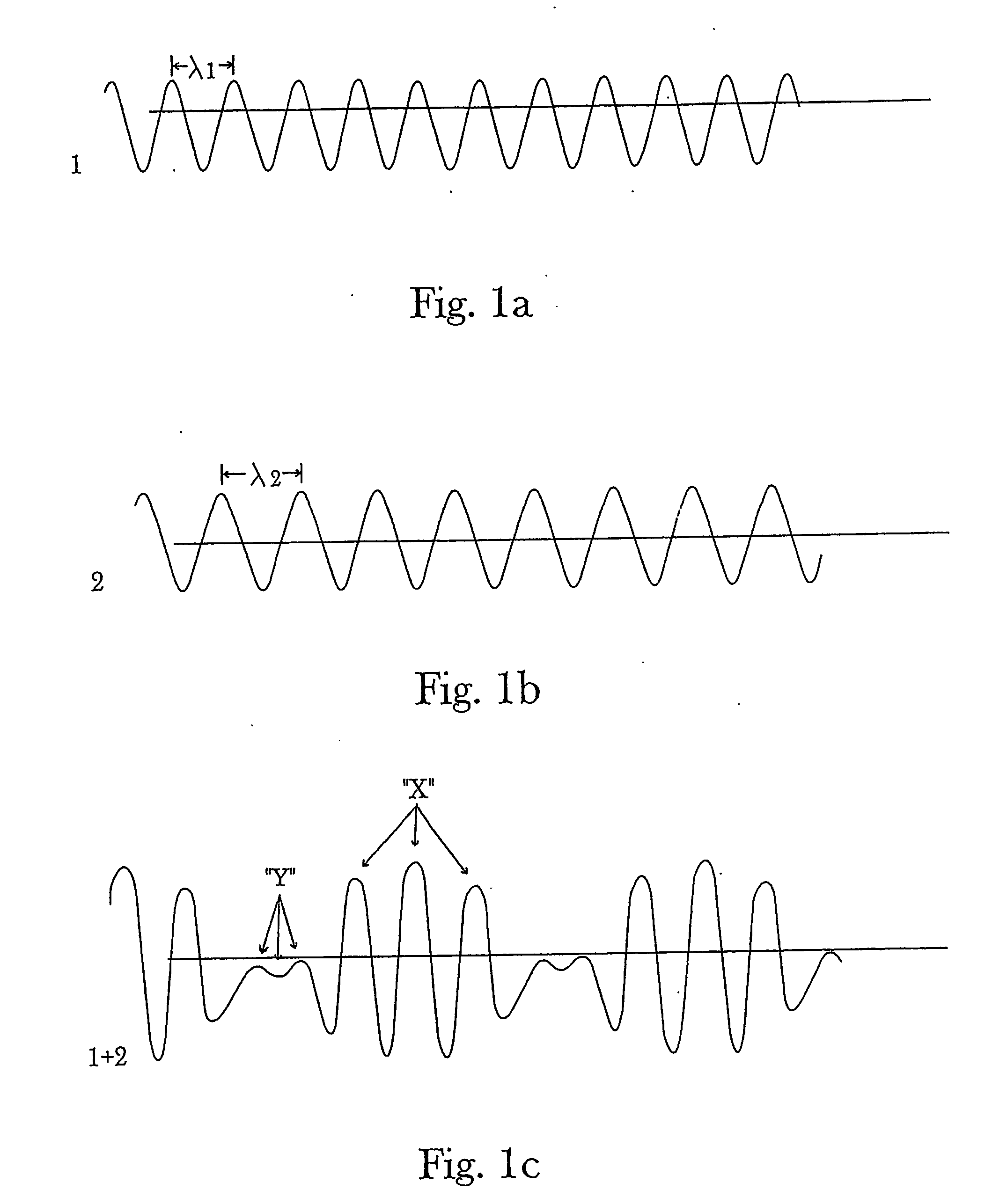

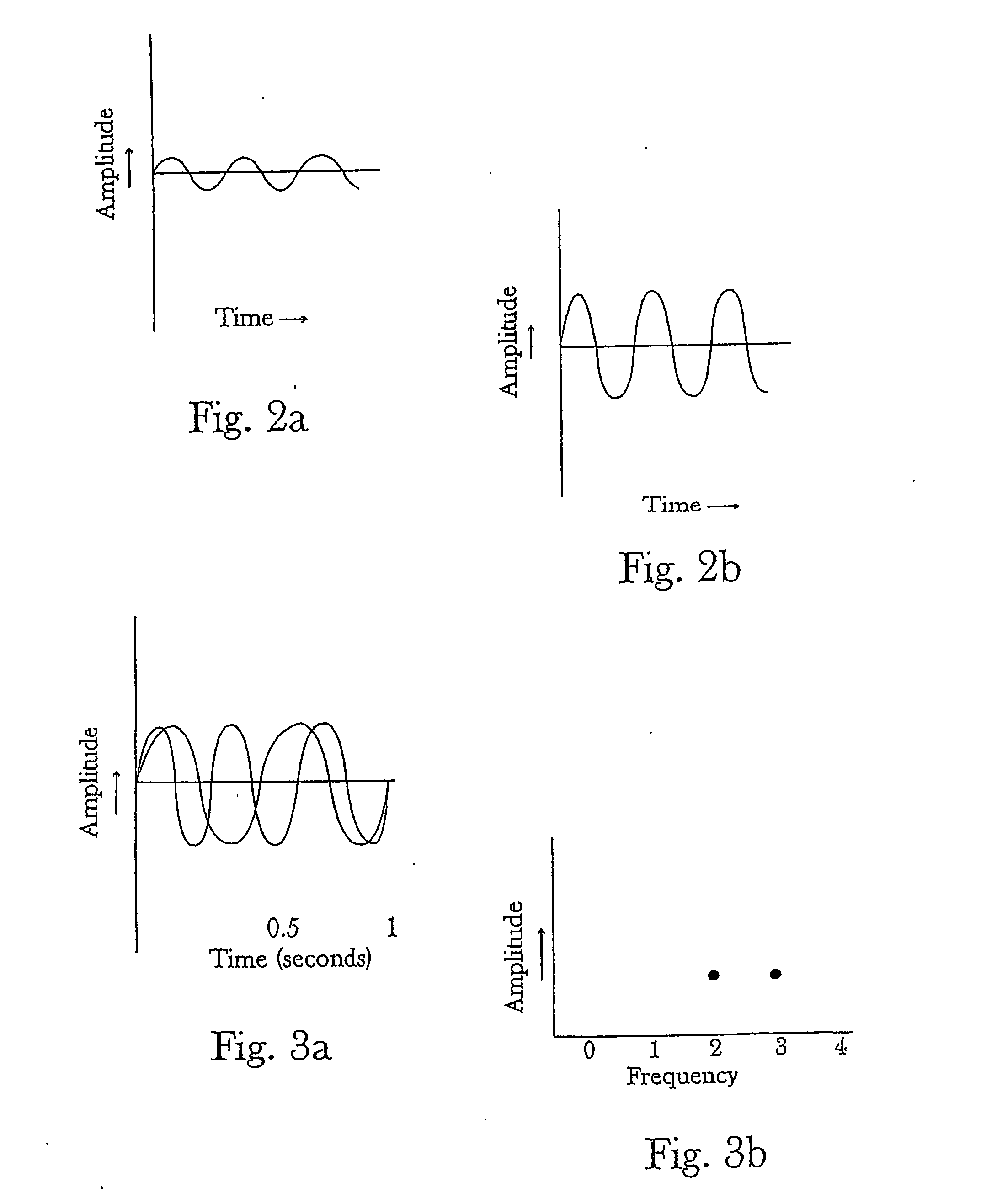

Controlling chemical reactions by spectral chemistry and spectral conditioning

InactiveUS20050139485A1Minimize and reduce and eliminate frequencyInhibition formationAntibacterial agentsFrom normal temperature solutionsChemical reactionCompound (substance)

This invention relates to novel methods for affecting, controlling and / or directing various reactions and / or reaction pathways or systems by exposing one or more components in a holoreaction system to at least one spectral energy pattern. In a first aspect of the invention, at least one spectral energy pattern can be applied to a reaction system. In a second aspect of the invention, at least one spectral energy conditioning pattern can be applied to a conditioning reaction system. The spectral energy conditioning pattern can, for example, be applied at a separate location from the reaction vessel (e.g., in a conditioning reaction vessel) or can be applied in (or to) the reaction vessel, but prior to other reaction system participants being introduced into the reaction vessel.

Owner:GR INTELLECTUAL RESERVE LLC

Electrochemistry technical field

InactiveUS20050139484A1High dissolution rateEasy to processElectrolysis componentsFrom normal temperature solutionsEngineeringReactive system

The invention relates to novel methods for affecting, controlling and / or directing various reactions and / or reaction pathways or systems by exposing one or more components in a holoreaction system to at least one spectral energy pattern. In a first aspect of the invention, at least one spectral energy pattern can be applied to a reaction system. In a second aspect of the invention, at least one spectral energy conditioning pattern can be applied to a conditioning reaction system. The spectral energy conditioning pattern can, for example, be applied at a separate location from the reaction vessel (e.g., in a conditioning reaction vessel) or can be applied in (or to) the reaction vessel, but prior to other reaction system participants being introduced into the reaction vessel.

Owner:GR INTELLECTUAL RESERVE LLC

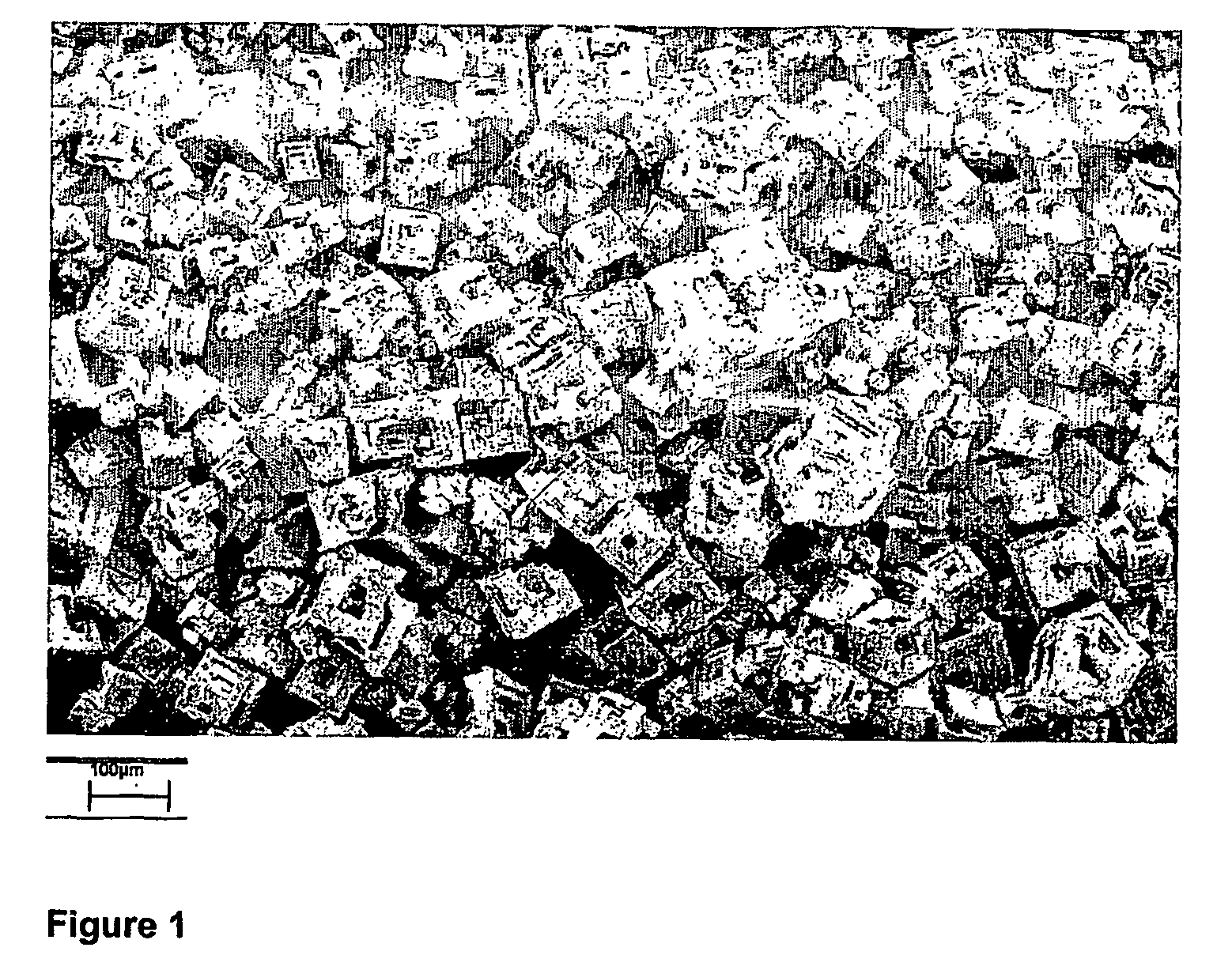

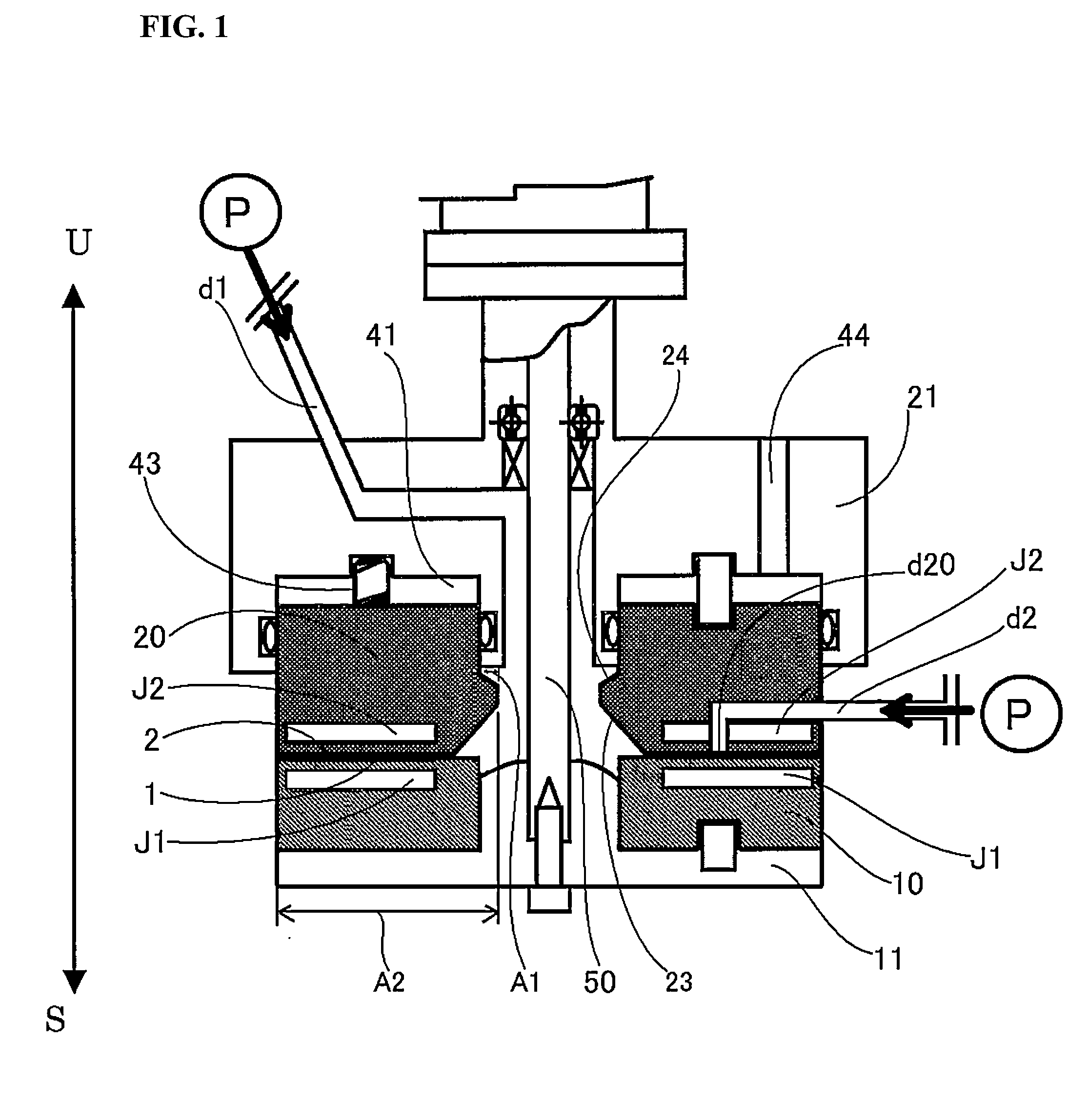

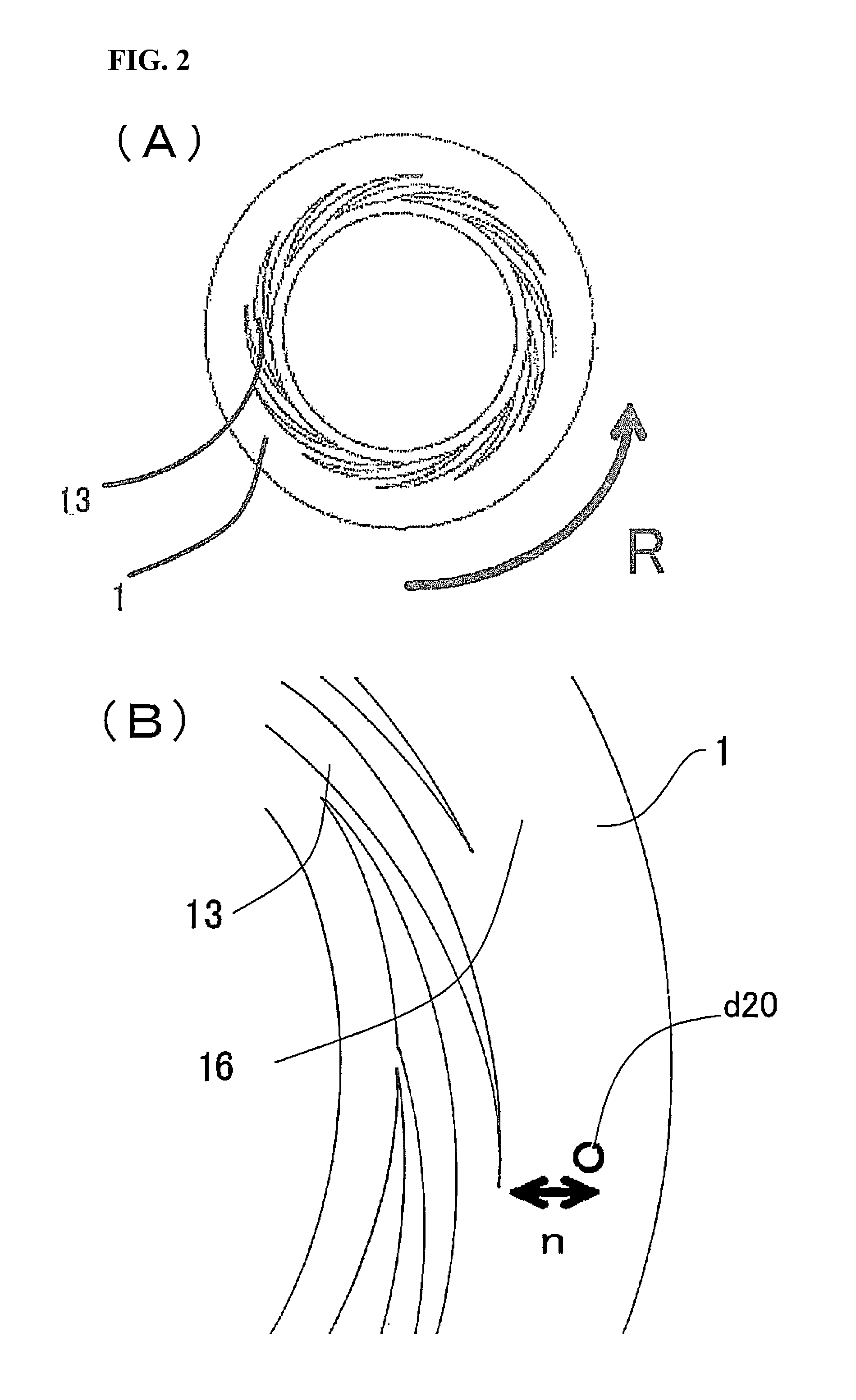

Method for producing microparticles having controlled crystallite diameter

ActiveUS20140155247A1Low costWeaken energySolution crystallizationChemical/physical/physico-chemical stationary reactorsMicroparticleChemistry

At least two types of fluids to be processed are mixed in a thin film fluid formed between at least two processing surfaces which are approachably and separably disposed facing each other. At least one processing surface rotates relative to the other, and a substance to be separated giving a controlled crystallite diameter is caused to separate. Specific conditions related to a fluid to be processed are varied to control the crystallite diameter of the substance to be separated. The specific conditions are the type of substance to be separated; the concentration of the substance to be separated included in the raw material fluid and / or substance included in the separating fluid; the pH of the raw material fluid and / or separating material fluid; the introduction temperature of the raw material fluid and / or separating fluid; and the introduction velocity of the raw material fluid and / or separating fluid.

Owner:M TECHN

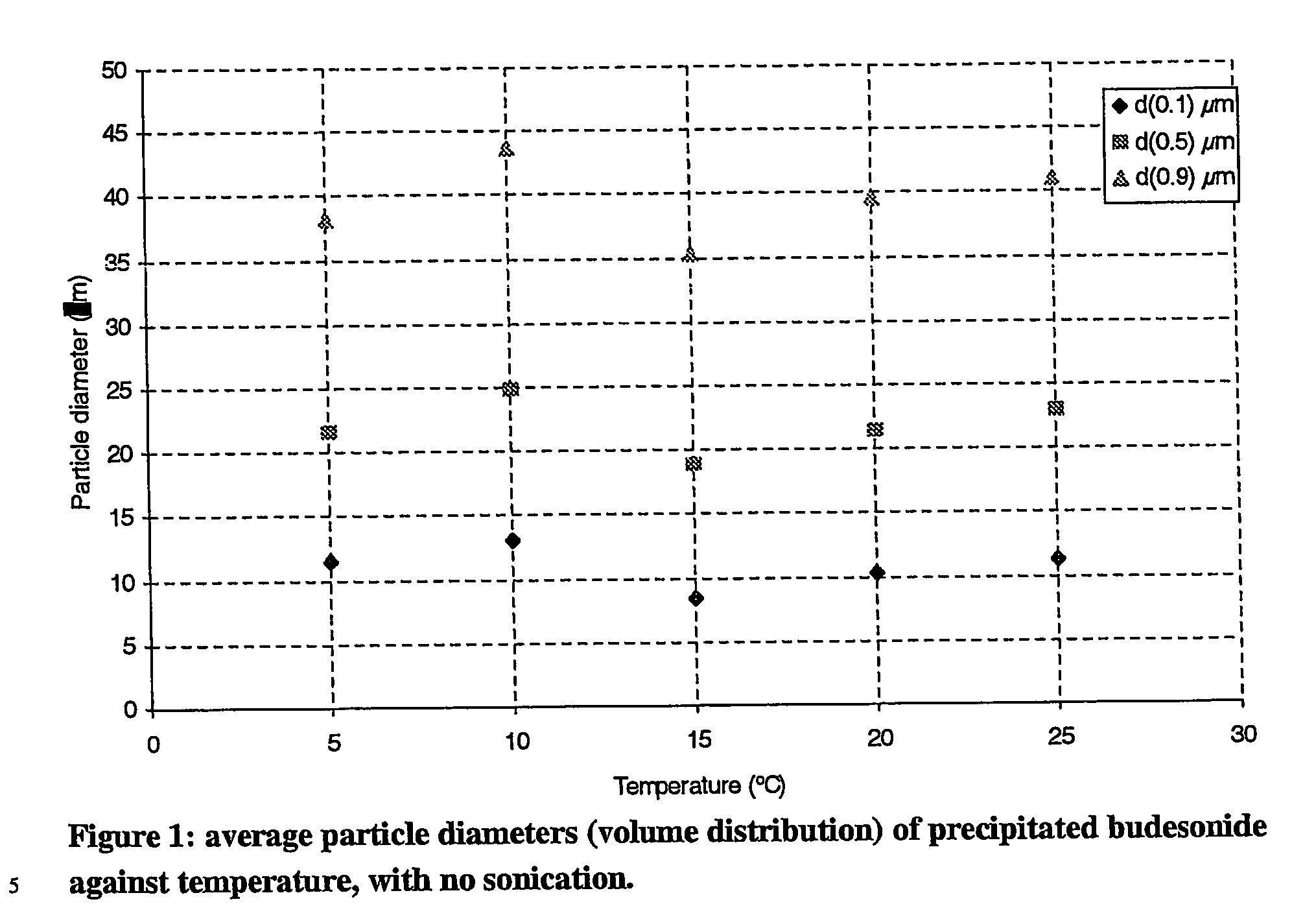

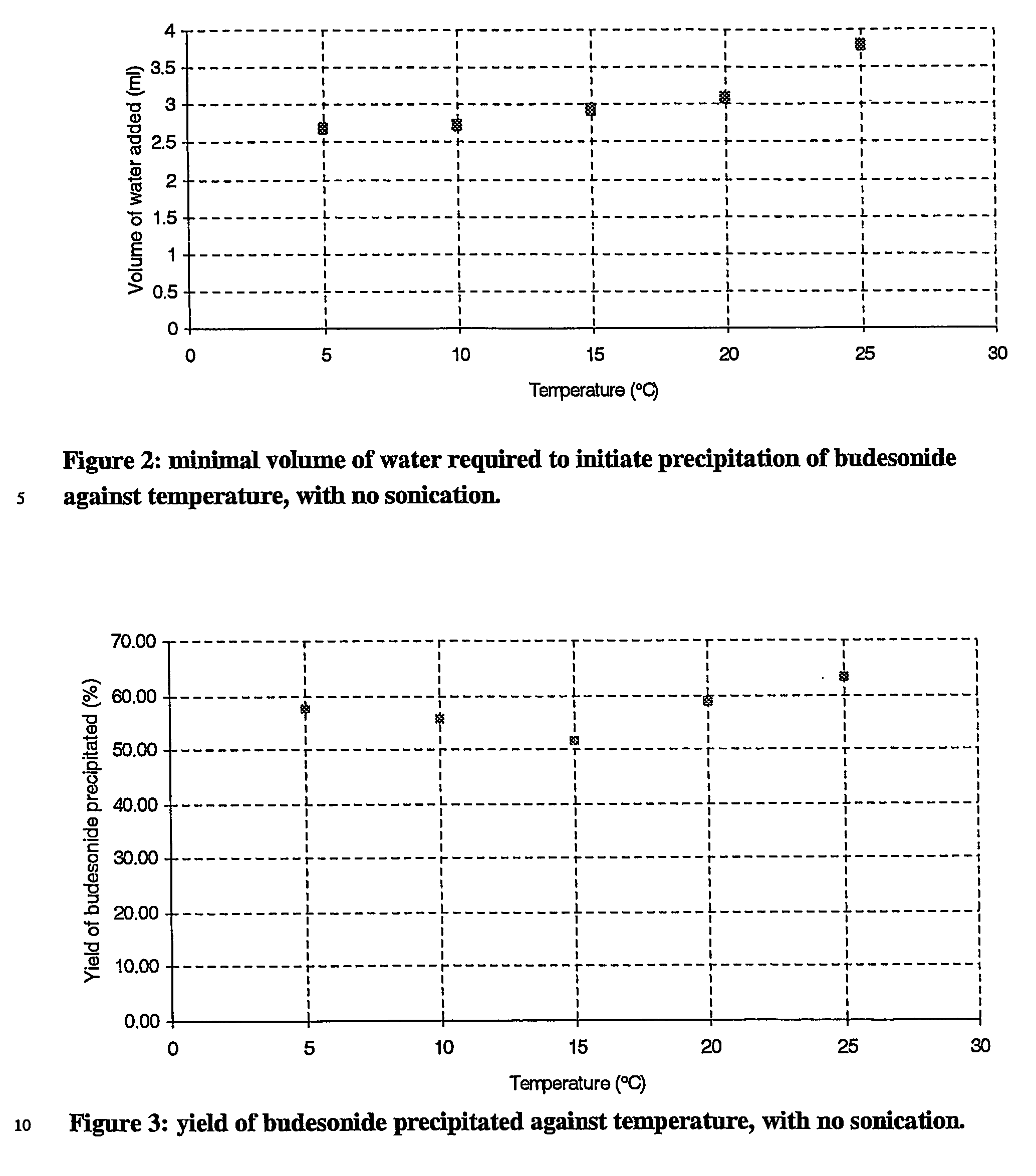

Novel process

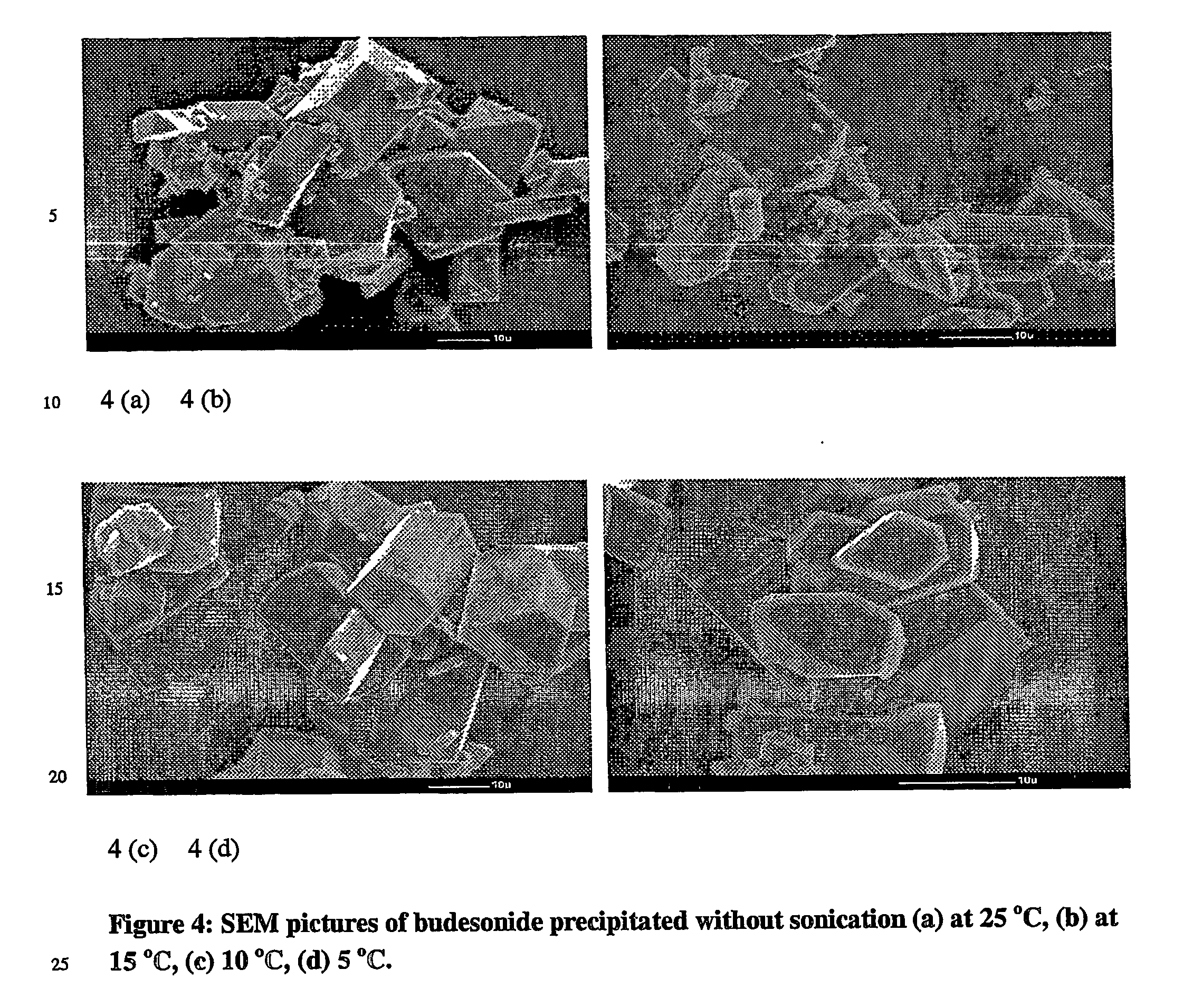

InactiveUS20060188579A1Improve stabilityExtended shelf lifePowder deliveryOrganic active ingredientsCrystalline particlePhotochemistry

Owner:ASTRAZENECA AB

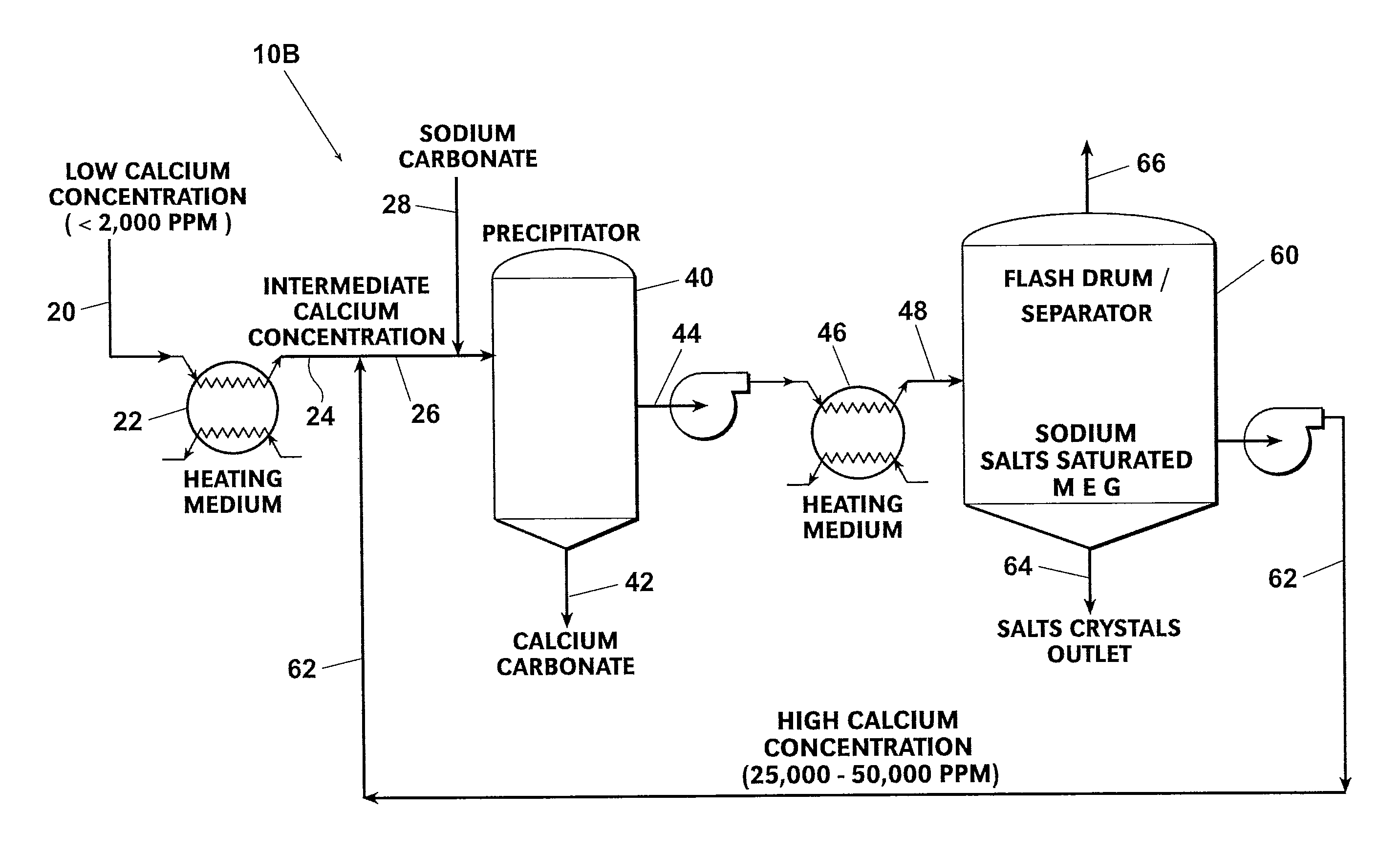

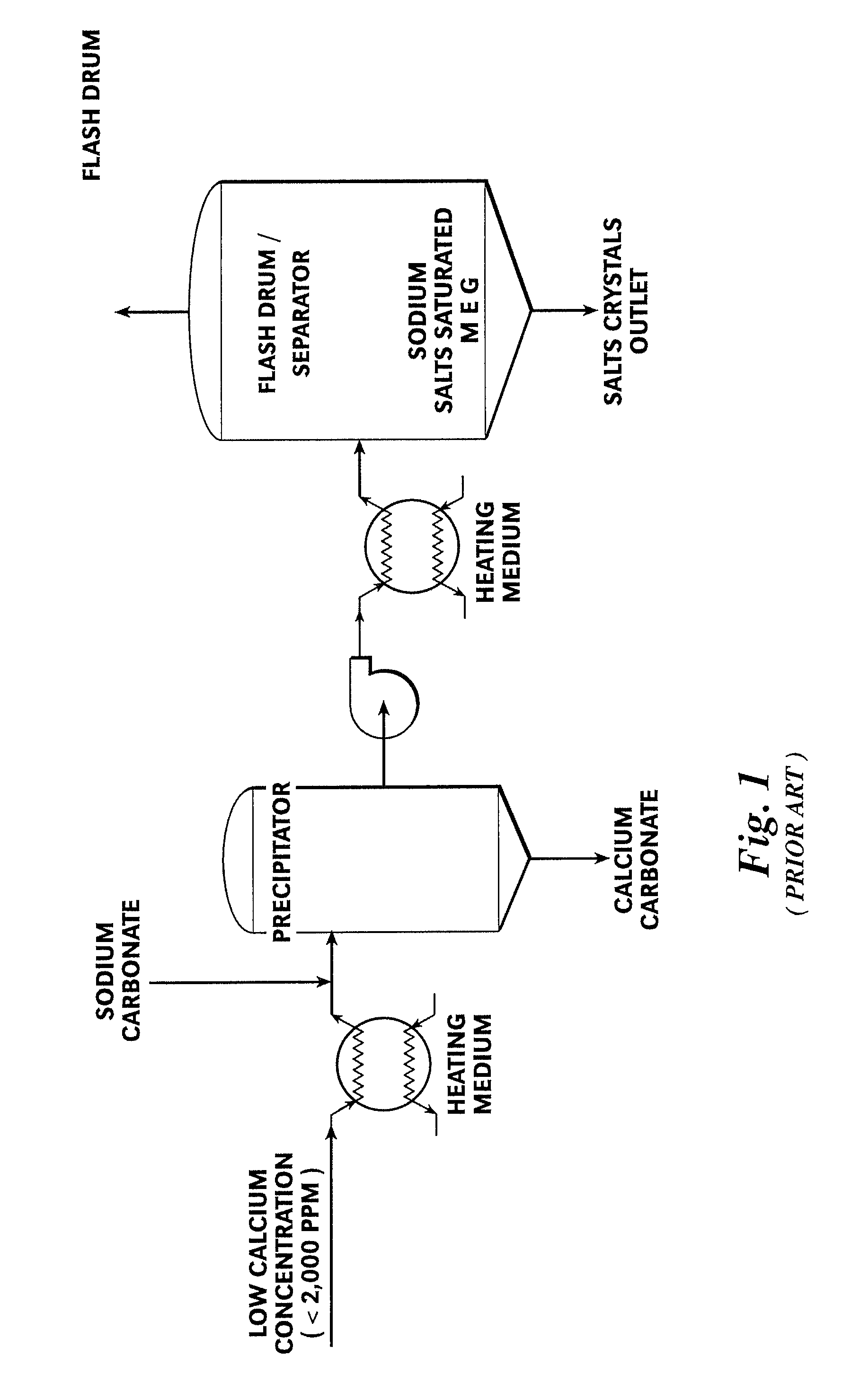

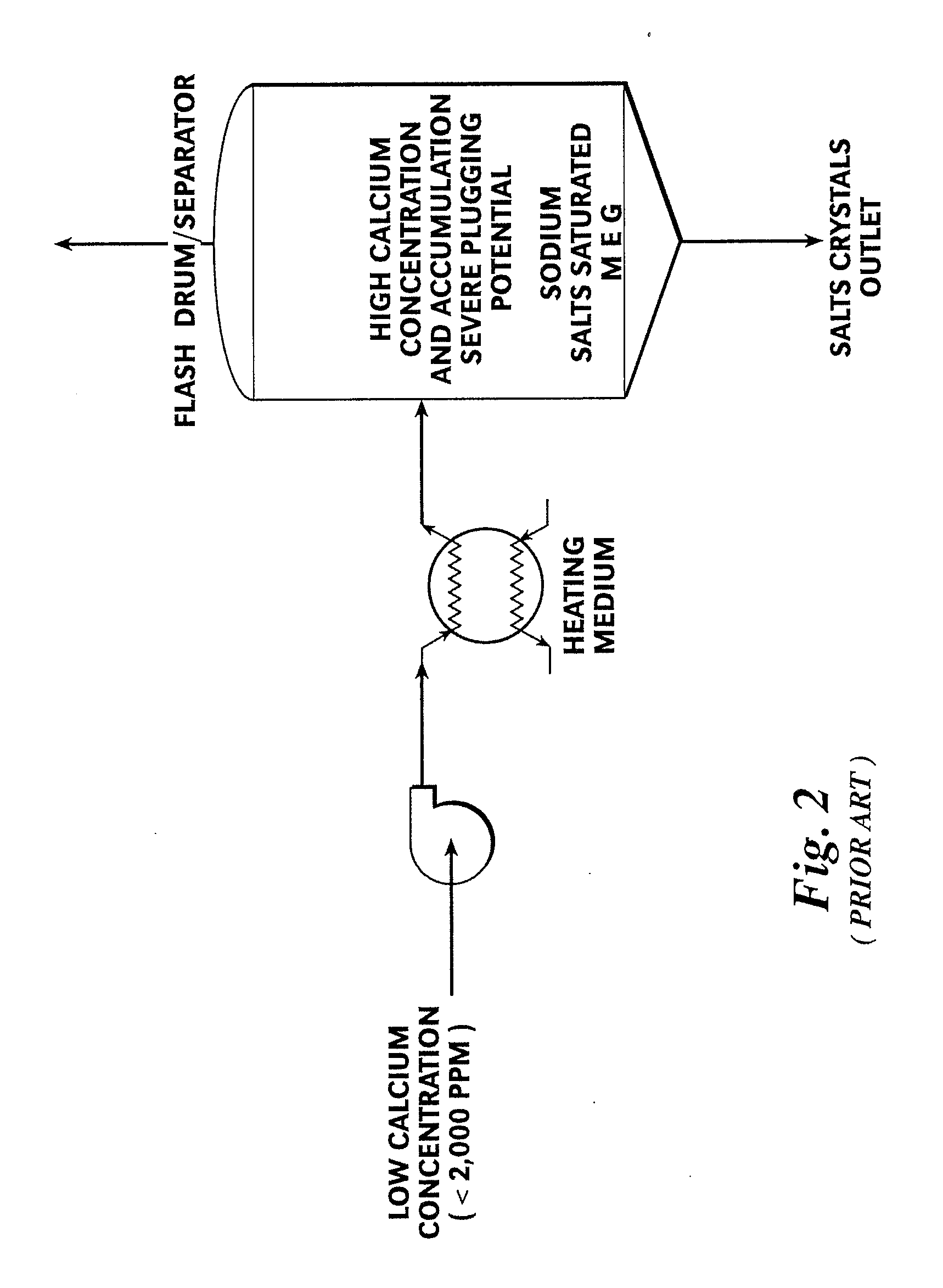

Process Scheme to improve Divalent Metal Salts Removal from Mono Ethylene Glycol (MEG)

ActiveUS20130118989A1Less floor-space/volumeSpeed reactionGas treatmentMultiple-effect/fractional condensationStream flowDivalent metal

A MEG reclamation process includes the step of increasing above 2,000 ppm the divalent metal salts concentration of a rich (wet) MEG feed stream flowing into a precipitator. The increasing step includes routing a salts-saturated MEG slipstream from the flash separator it to the precipitator. The slipstream may be mixed with a fresh water feed stream, a portion of the rich MEG feed stream, or some combination of the two. The rich MEG feed stream also may be split into two streams, with a portion of the stream being heated and routed to the flash separator and the other portion being combined as above with the removed slipstream. The process can be performed on the slipstream after dilution and prior to entering the precipitator or after being loaded into the precipitator. Removal of the insoluble salts may be done in either a batch or continuous mode.

Owner:CAMERSON INT CORP

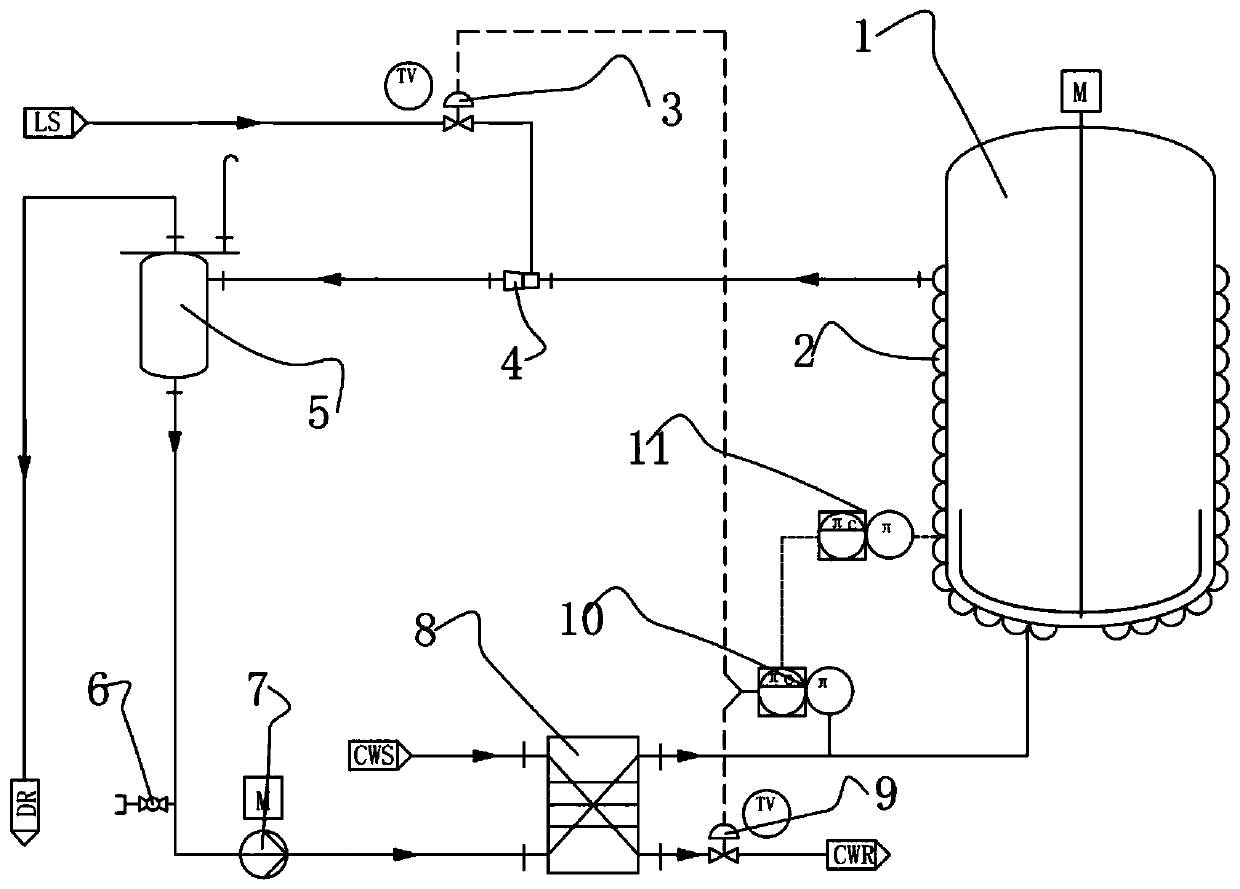

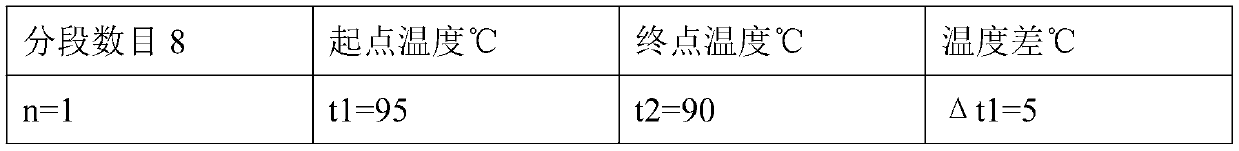

Crystallizing kettle temperature control system and control method

InactiveCN109692495AStable temperature controlWide range of temperature controlSolution crystallizationHeat exchange cooling cystallizationLower limitTemperature control

The invention discloses a crystallizing kettle temperature control system and control method, wherein the temperature control system is composed of a crystallizing kettle provided with an outer coil pipe, a water storage tank, a heat exchanger, a DCS control system and a conveying pipeline; before materials enter a crystallizing kettle, steam is introduced, and the crystallizing kettle is preheated by heating circulating water; when the crystallizing operation begins, a steam regulating valve is closed, freezing water is introduced, the temperature of the circulating water is reduced by a heatexchanger, and the crystallization kettle is cooled. The temperature control method DCS controls to set different temperature difference [delta]t according to different temperature t sections of thecrystallizing kettle to ensure the quality of crystallization products and improve the crystallization speed of the products. The crystallizing kettle temperature control system integrates heating andcooling of the crystallizing kettle, can flexibly and steadily control the temperature of the crystallizing kettle, has a wide range of temperature control, can also achieve a good cooling effect forthe crystallizing reaction with the terminal temperature of crystallization as low as 5 DEG C, can effectively and smoothly control the temperature in the crystallizing kettle, ensures the smooth progress of the crystallizing process, and also increases the lower limit of the cooling.

Owner:CHINA PETROLEUM & CHEM CORP +1

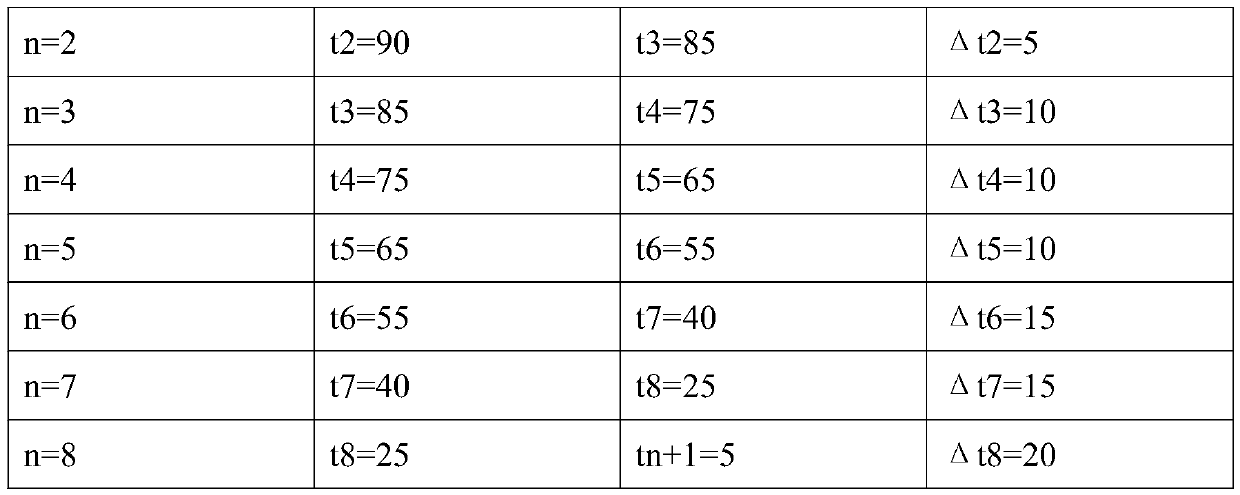

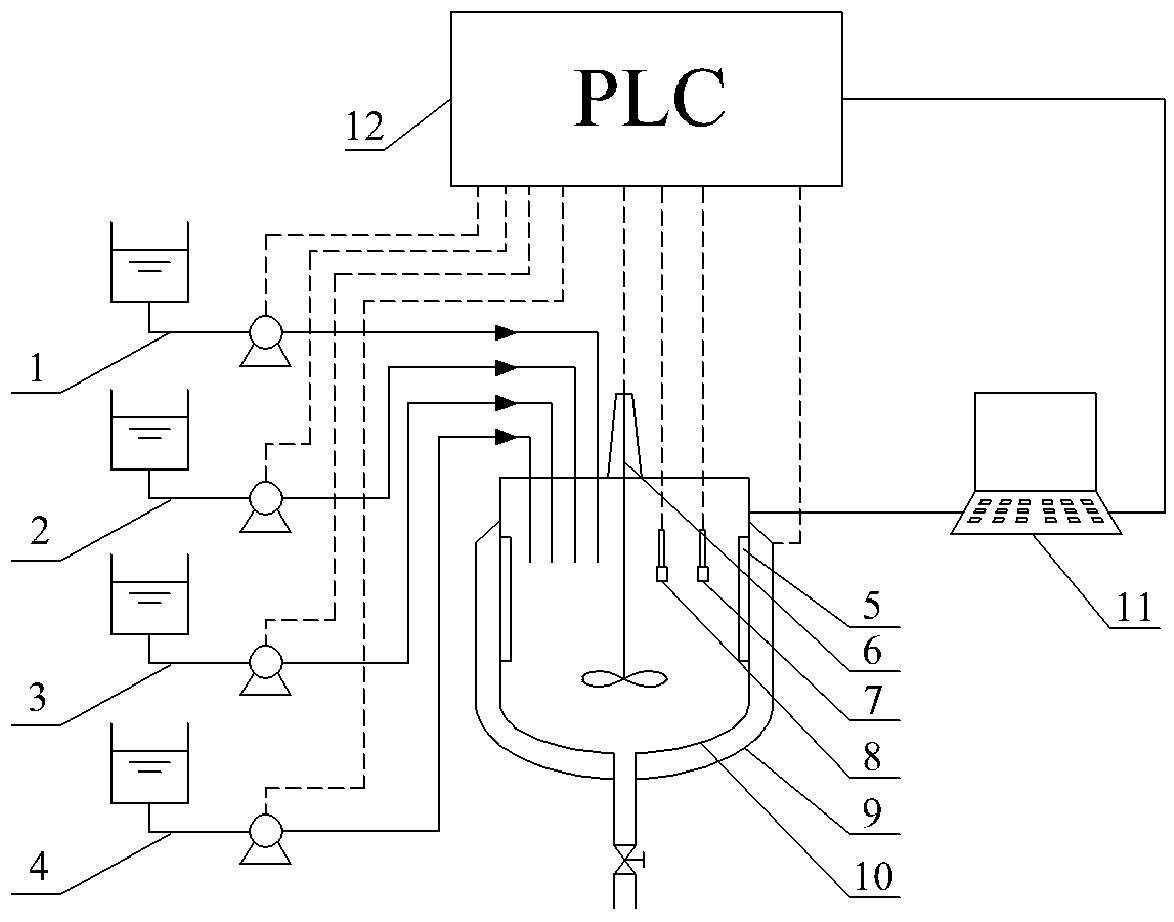

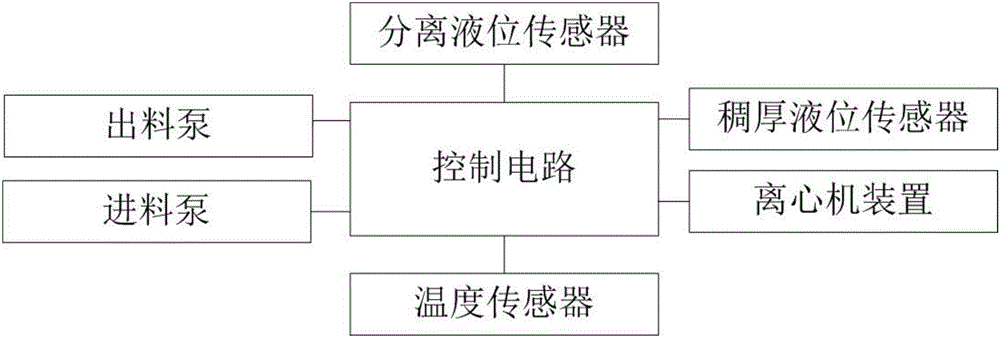

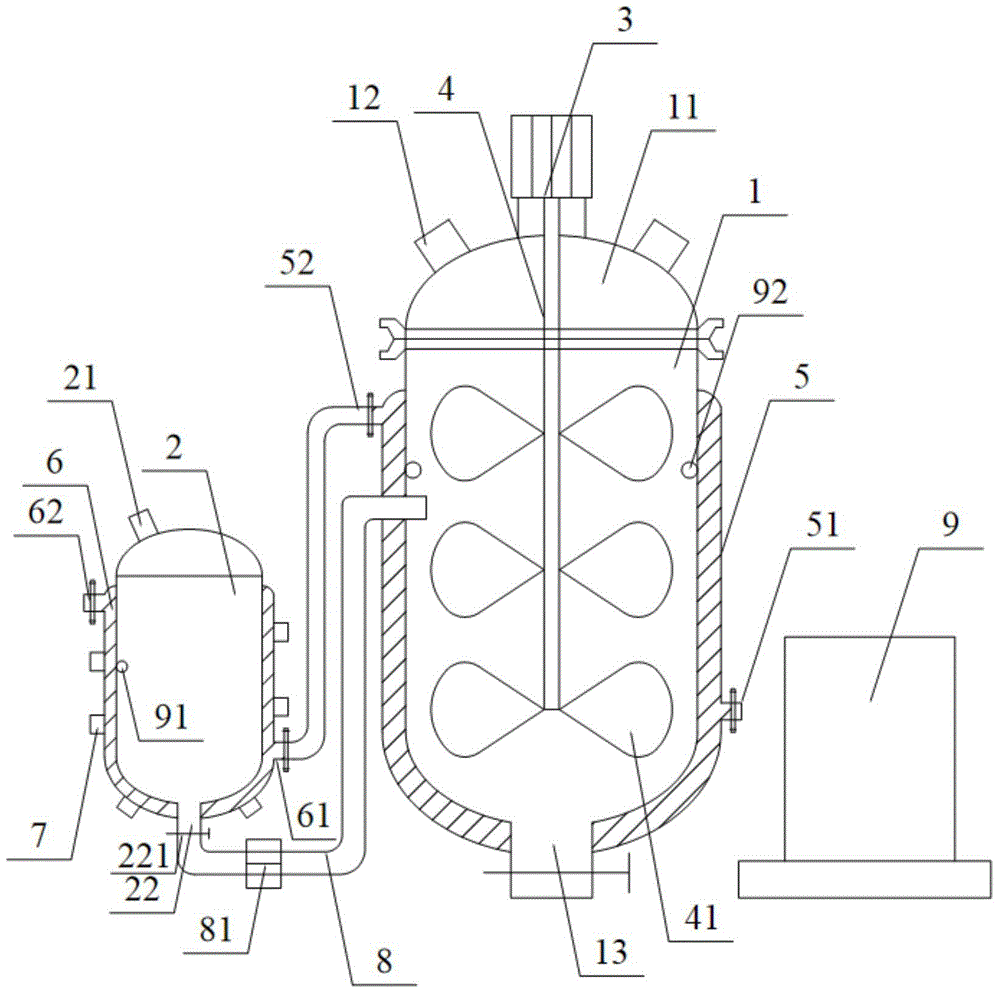

Efficient and intelligent reaction crystallization device

InactiveCN107855088AQuality assuranceGood lookingProcess control/regulationSolution crystallizationWater bathsAutomatic control

The invention discloses a device capable of controlling reaction crystallization process efficiently, intelligently and accurately. The device comprises a main device reaction kettle, a constant temperature water bath device is mounted on the outer side of the main device, a feeding device is mounted on the upper portion of the main device, a stirring device, a pH electrode and a conducting electrode are mounted on the upper portion of the main device; the constant temperature water bath device, the feeding device, the stirring device, the pH electrode, the conducting electrode and the like are connected with a programmable logic controller PLC automatic control system to realize automatic intelligent control, simultaneously particle sizes of the products are in real-time monitored by a on-line particle size measurement system. The device is simple and clear in whole structure, fully automatic measurement, feedback and control during the reaction crystallization process are realized, manual operating cost and manual operating errors are reduced to make the reaction crystallization process perform in a setting reaction condition all the time, accordingly quality and stability of thedesired products are guaranteed.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

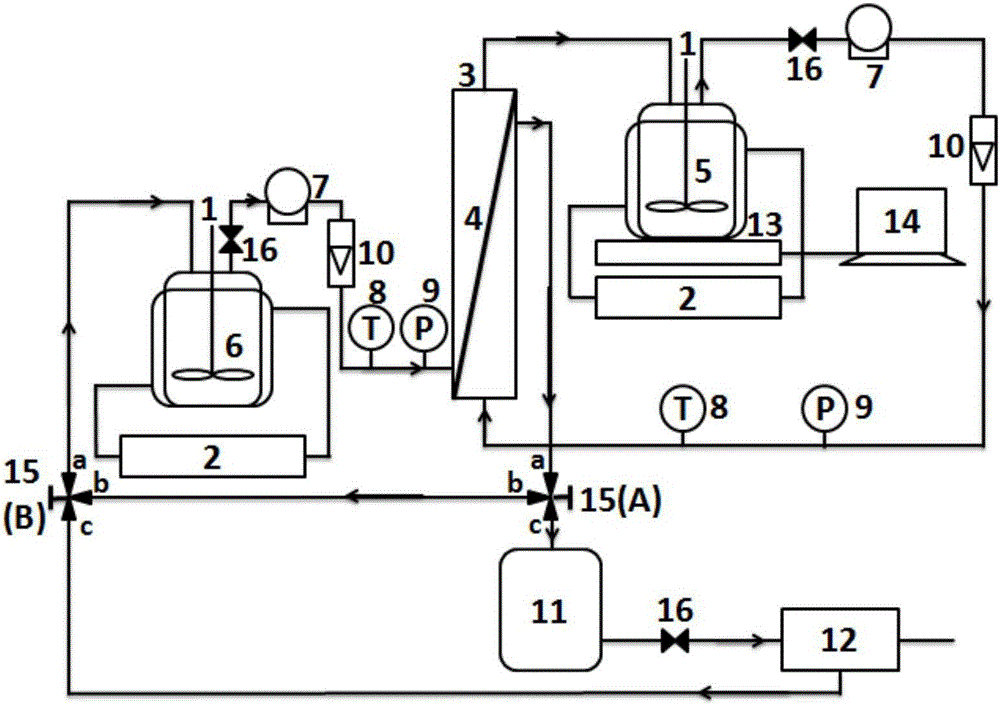

Solventing-out crystallization device and method through auxiliary control of films

ActiveCN106166400AGood dispersionIncrease contact areaSemi-permeable membranesSolution crystallizationFiltrationOperant conditioning

The invention provides a solventing-out crystallization technique device and method through auxiliary control of films, and belongs to the technical field of crystallization engineering. When a crystallization solution is added to a raw material pot, a solventing-out agent is added to a material-liquid pot, electronic scales, a computer, a stirring device and temperature controlling devices are started, and after a system is stable, squirm pumps of the material-liquid pot are started, so that solventing-out agents can circulate between the material-liquid pot and a film assembly; and after the solventing-out agent is stable in circulation, the squirm pump connected to the raw material pot is started so that the crystallization solution enters the film assembly. The solventing-out agent and the crystallization solution which are in sufficient contact in the film assembly can perform nucleation growth in the film assembly, and then the solventing-out agent and the crystallization solution, after the nucleation growth, can flow into an external storing pot for filtration and post-treatment; and the solventing-out agent and the crystallization solution can also perform nucleation growth outside the film assembly, and after solutes are wholly dissolved, filtration is performed. The electronic scales record the addition quantity of the solventing-out agent in a real-time manner, and the addition quantity of the solventing-out agent is systematically controlled through controlling films and operation conditions, so that ideal crystal products are obtained.

Owner:DALIAN UNIV OF TECH

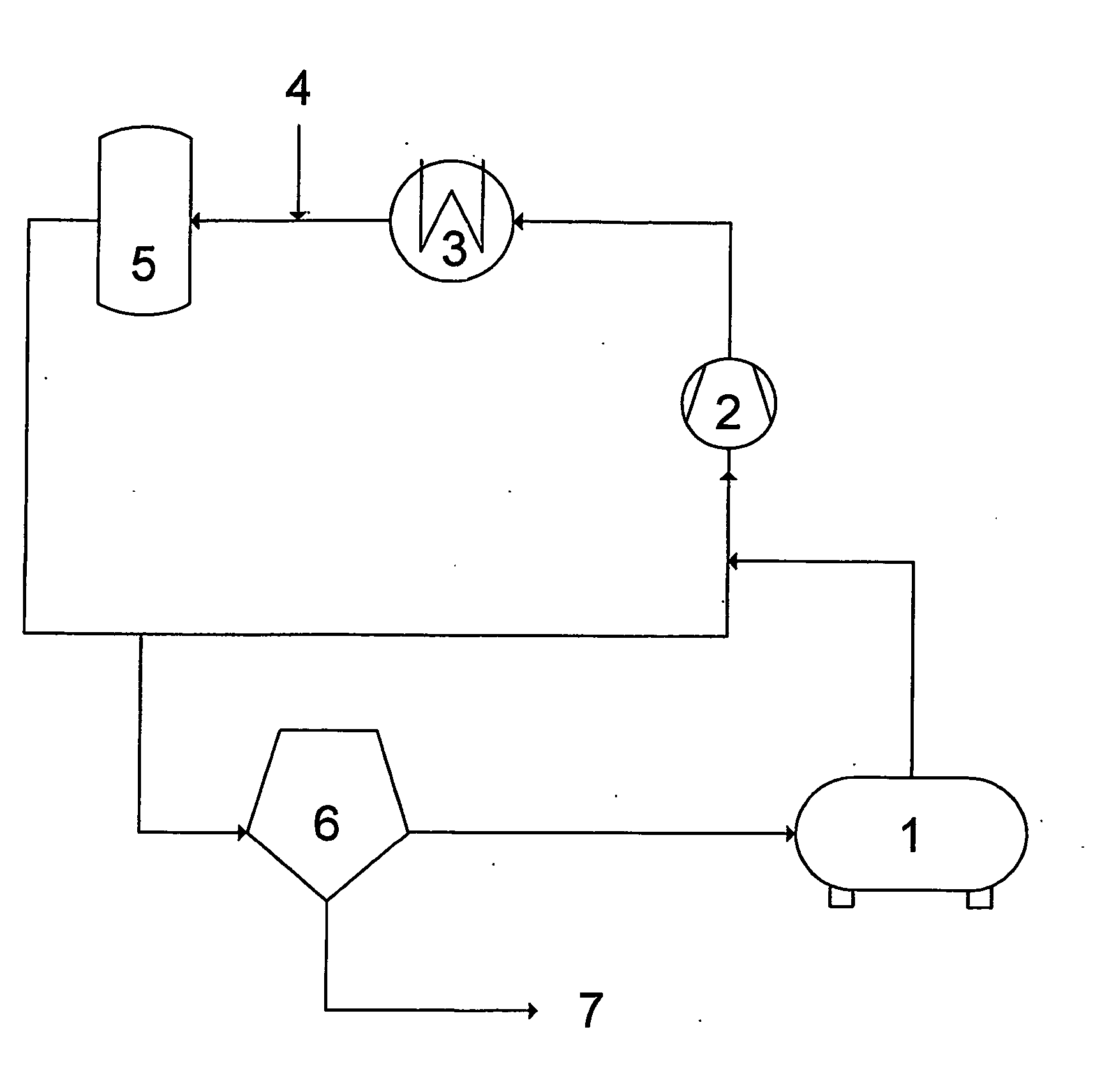

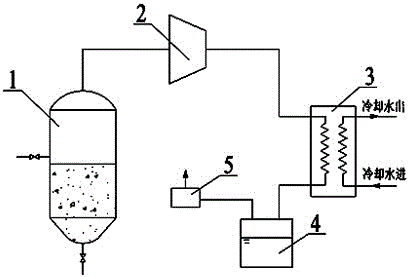

Constant-gradient cooling crystallization system and operation method thereof

InactiveCN106492499AImprove work efficiencyReduce vacuumSolution crystallizationCrystallization by component evaporationVacuum pumpingEngineering

The invention relates to a constant-gradient cooling crystallization system and an operation method thereof and belongs to the technical field of crystallization. The constant-gradient cooling crystallization system comprises a crystallizer, a compressor, a condenser, a condensation water tank and a vacuum pump; an exhaust of the crystallizer is connected with an entry of the compressor, an exit of the compressor is connected with an air-side entry of the condenser, the air-side entry of the condenser is connected to the condensation water tank, and the vacuum pump is connected to the condensation water tank. By the arrangement that the compressor is taken as vacuum-pumping equipment of the condenser, control on crystal size and cooling rate is realized through matching of compression ratio of the compressor and sucking rate; the constant-gradient cooling crystallization system is simple in structure, few in accessory equipment, convenient in regulating and controlling of crystallization process, and uniform in crystal size.

Owner:JIANGSU LEKE ENERGY SAVING TECH CO LTD

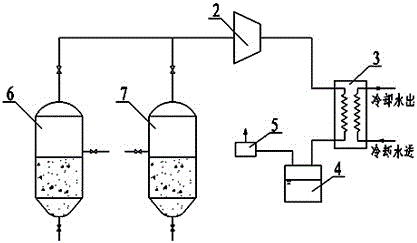

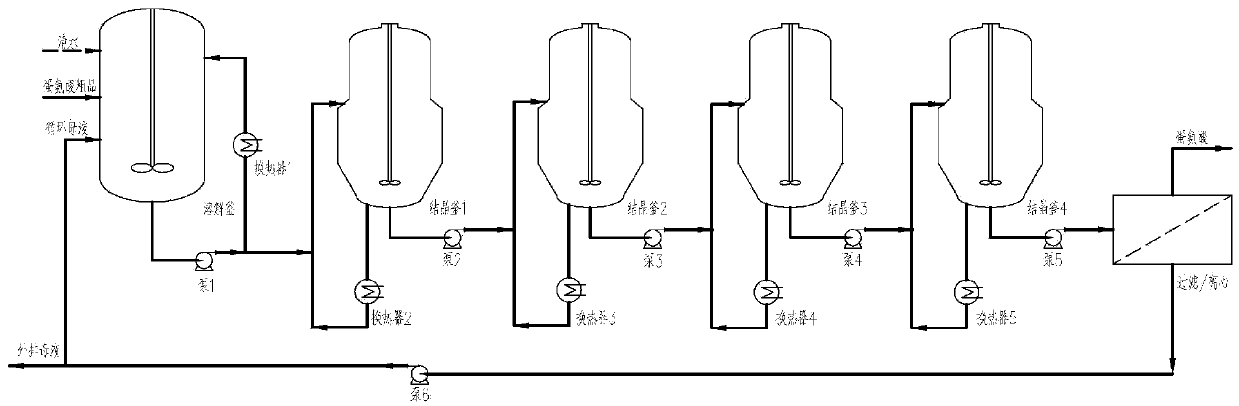

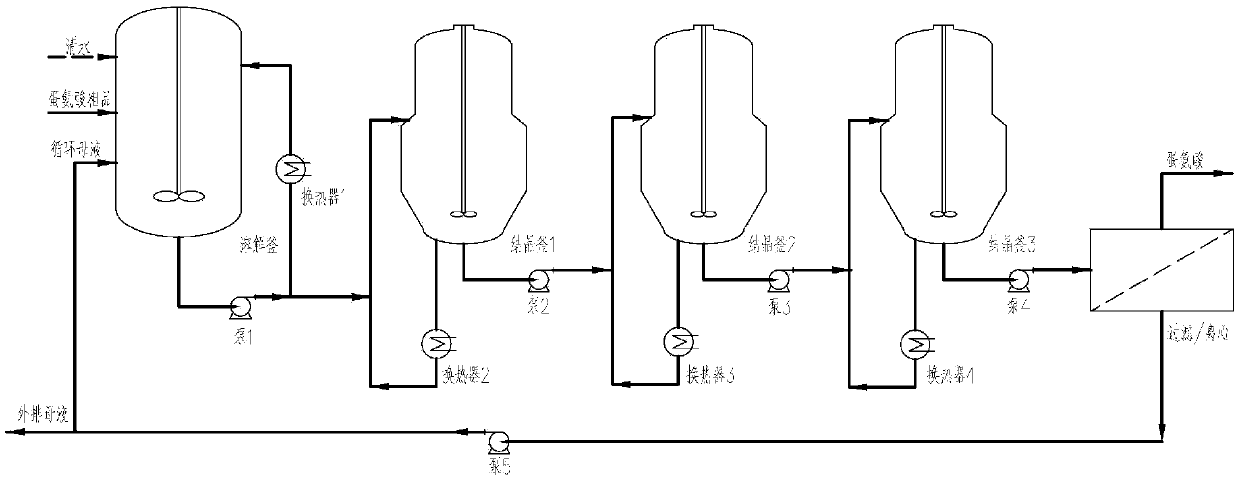

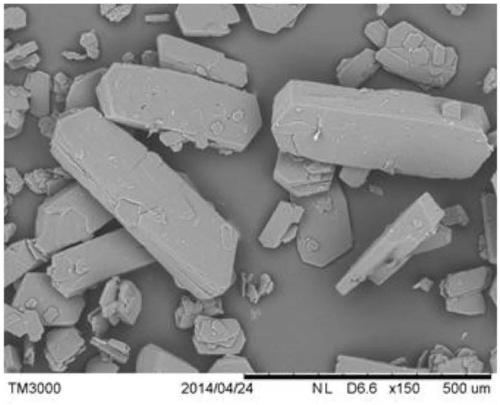

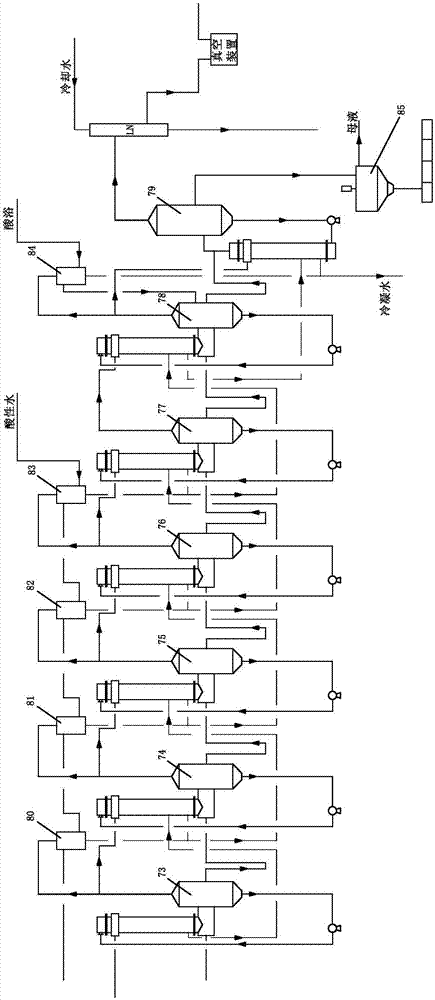

Multistage continuous crystallization method of short rod-like methionine crystals

ActiveCN109608372ASmall particle sizeControl granularityOrganic compound preparationOrganic chemistry methodsSlurryMethionine biosynthesis

The invention provides a multistage continuous crystallization method of short rod-like methionine crystals. The method includes: connecting a plurality of crystallizers in series; under the action ofa circulating device, dissolving a methionine raw material at 80-130DEG C; letting the dissolved feed solution enter a first stage crystallization kettle, and controlling the kettle temperature at 60-80DEG C; enabling the slurry to enter a second stage crystallization kettle, and controlling the kettle temperature at 40-60DEG C; enabling the slurry to enter a third stage crystallization kettle, and controlling the kettle temperature at 25-40DEG C; letting the slurry enter a fourth stage crystallization kettle, and controlling the kettle temperature at 15-25DEG C; letting the final slurry flowout of the crystallization kettle and enter a solid-liquid separation system, discharging the separated solid out of the system, and returning part of the mother liquor into a dissolution kettle forfurther circulation, with the circulation volume being 20-60% of the mother liquor volume. The stage number of the crystallization kettles is supposed to be optimized according to the actual situation, and the general ideal situation is 2-4 stages. The prepared methionine crystals have short rod-like crystal habit, the crystal size is uniform, the bulk density is high, the fluidity is good, the quality is stable, the operation is simple, and the production efficiency is high, therefore the method is suitable for large-scale industrial production.

Owner:TIANJIN UNIV +1

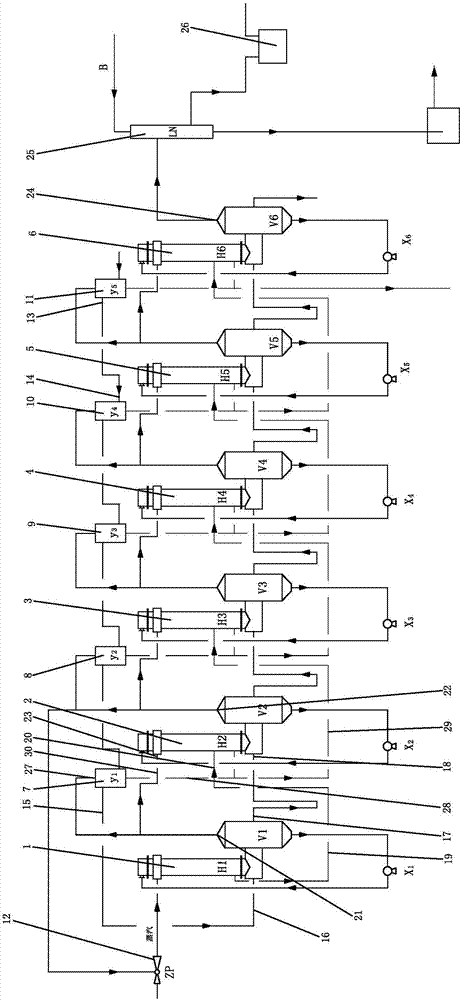

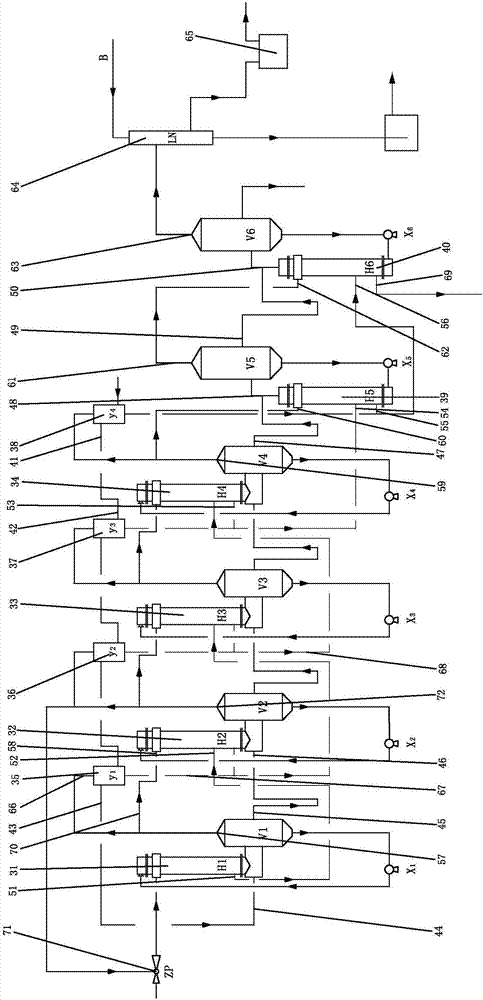

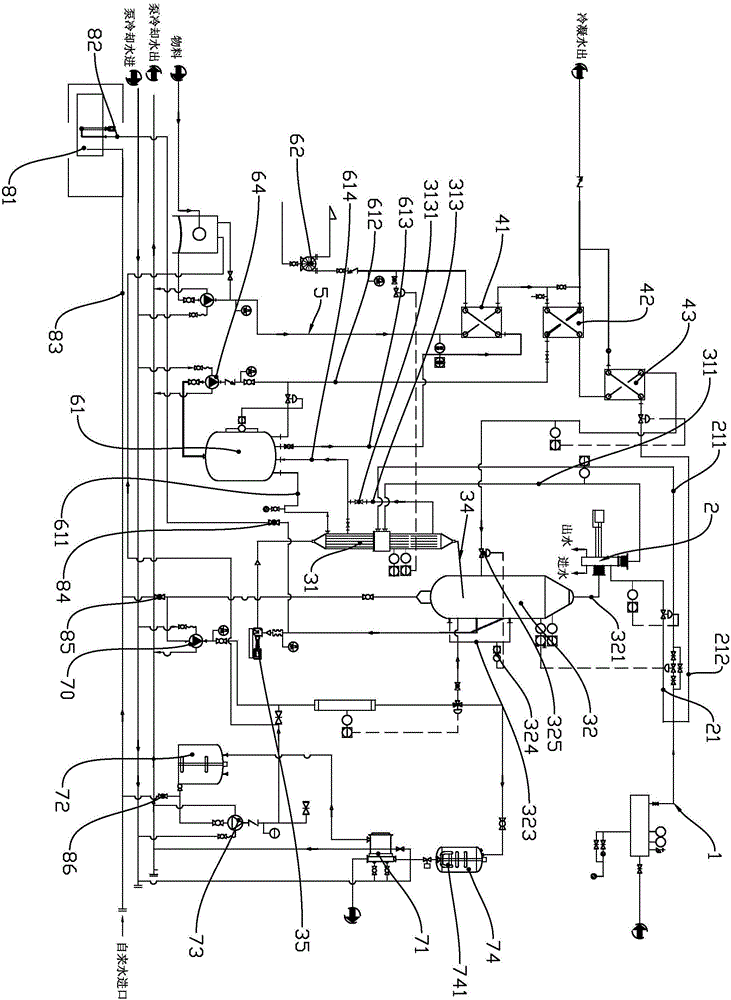

Multi-effect evaporation concentration technology, multi-effect evaporation crystallization technology and multi-effect evaporation concentration device of solution containing sulfuric acid and sulfate

The invention discloses a multi-effect evaporation concentration technology, a multi-effect evaporation crystallization technology and a multi-effect evaporation concentration device of a solution containing sulfuric acid and sulfate. The technologies and the device are characterized in that low-temperature-difference heat transfer flow evaporation is adopted; step-by-step secondary steam series preheating is adopted; an acid bath is led as an evaporation crystallization carrier; and last-effect or last-two-effect evaporation crystallization is adopted. The evaporation concentration and crystallization device mainly comprises (1-n)-effect evaporation crystallizers, (1-n)-effect circulating pumps, 1-(n-1)- or 1-(n-2)-stage preheaters, condensers and vacuum devices. According to the technologies and the device, a steam-water ratio of acid bath 5-7-effect evaporation crystallization reaches an advanced level of 0.17-0.19; a steam-water ratio of acid water and two-bath 6-8-effect evaporation crystallization reaches an advanced level of 0.13-0.15; a steam-water ratio of a low-concentration acid water 7-9-effect evaporation concentration device can further reach an advanced level of 0.09-0.11, but the state-of-the-art steam-water ratio of 16-stage flash evaporation crystallization is 0.255 in the current industry.

Owner:许达人 +1

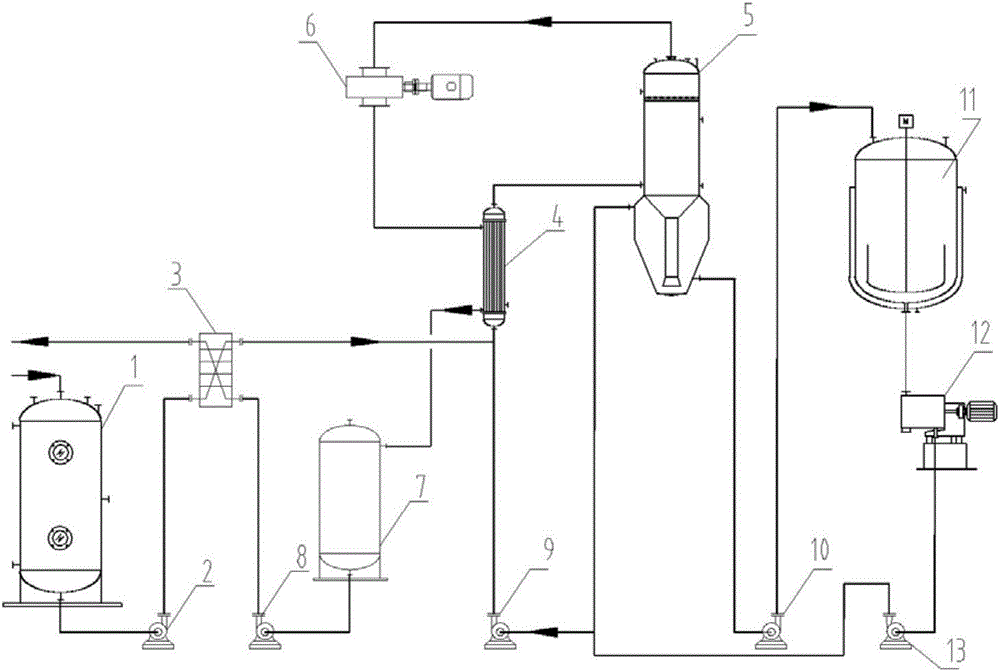

Energy-saving evaporative crystallization equipment for sodium chloride solution and control method thereof

InactiveCN106334333AGood evaporation and crystallization effectLow costChemical industrySolution crystallizationPhysical chemistryEnergy conservation

The invention discloses energy-saving evaporative crystallization equipment for a sodium chloride solution. The energy-saving evaporative crystallization equipment for the sodium chloride solution comprises a preheating device, an evaporating device, a crystal separating device and a control device. After adoption of the energy-saving evaporative crystallization equipment for the sodium chloride solution, the conventional steam-heating evaporative crystallization way is replaced, a compressor is used for compressing secondary steam separated by an OSLO separator, the compressed secondary steam is used as heating steam, and the own cycle of the equipment is achieved by setting a circuit, so that steam is not generated for heating, condensing equipment is not needed, and a good evaporative crystallization effect can be achieved only by using a small amount of electric energy. Therefore, the energy-saving evaporative crystallization equipment for the sodium chloride solution opens up a new way for reducing the cost, saving the energy and protecting the environment during treatment of the sodium chloride solution, and has the advantages of cleanness, energy conservation, intelligence, automatism, high working efficiency and the like.

Owner:深圳市捷晶科技股份有限公司

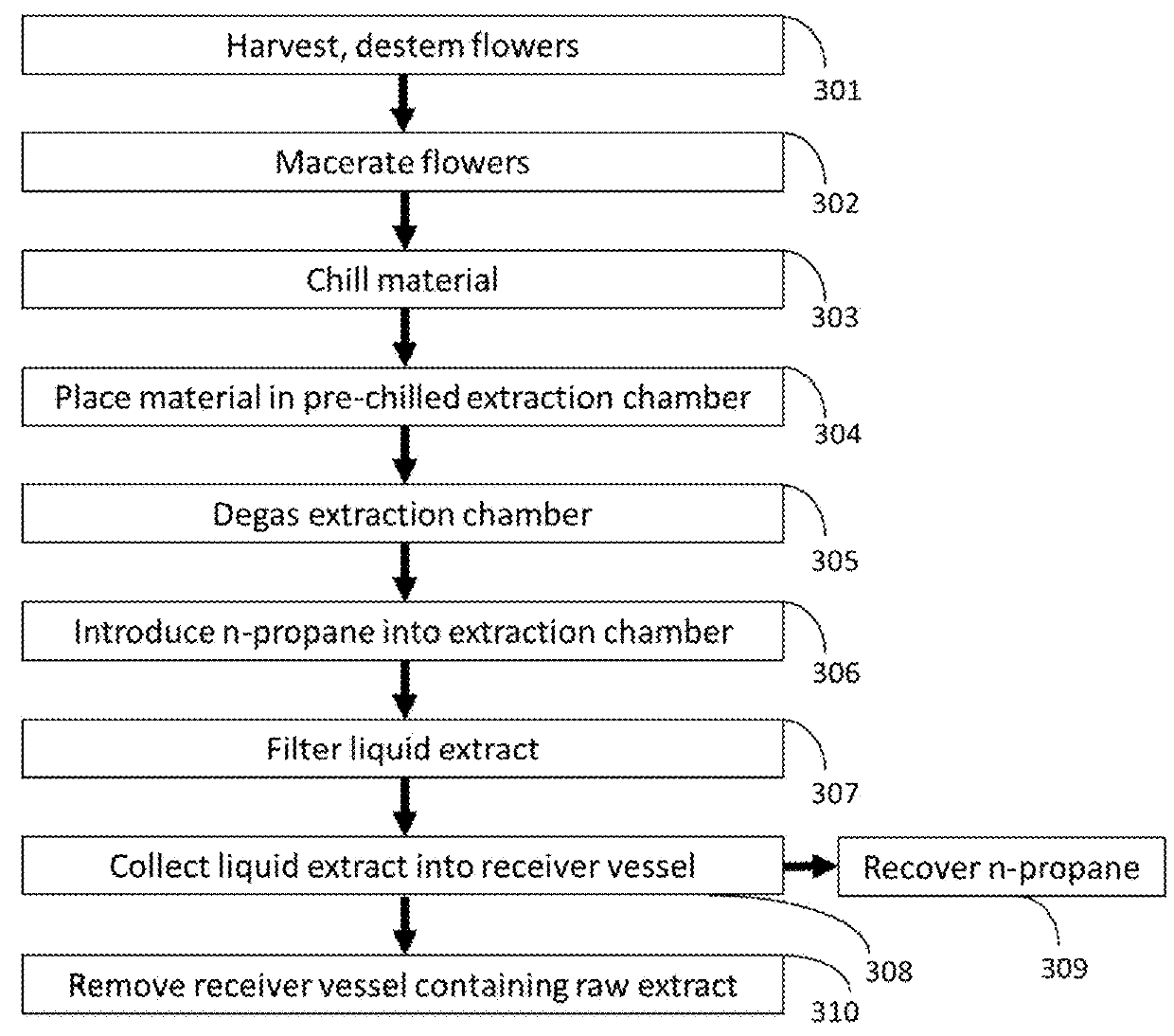

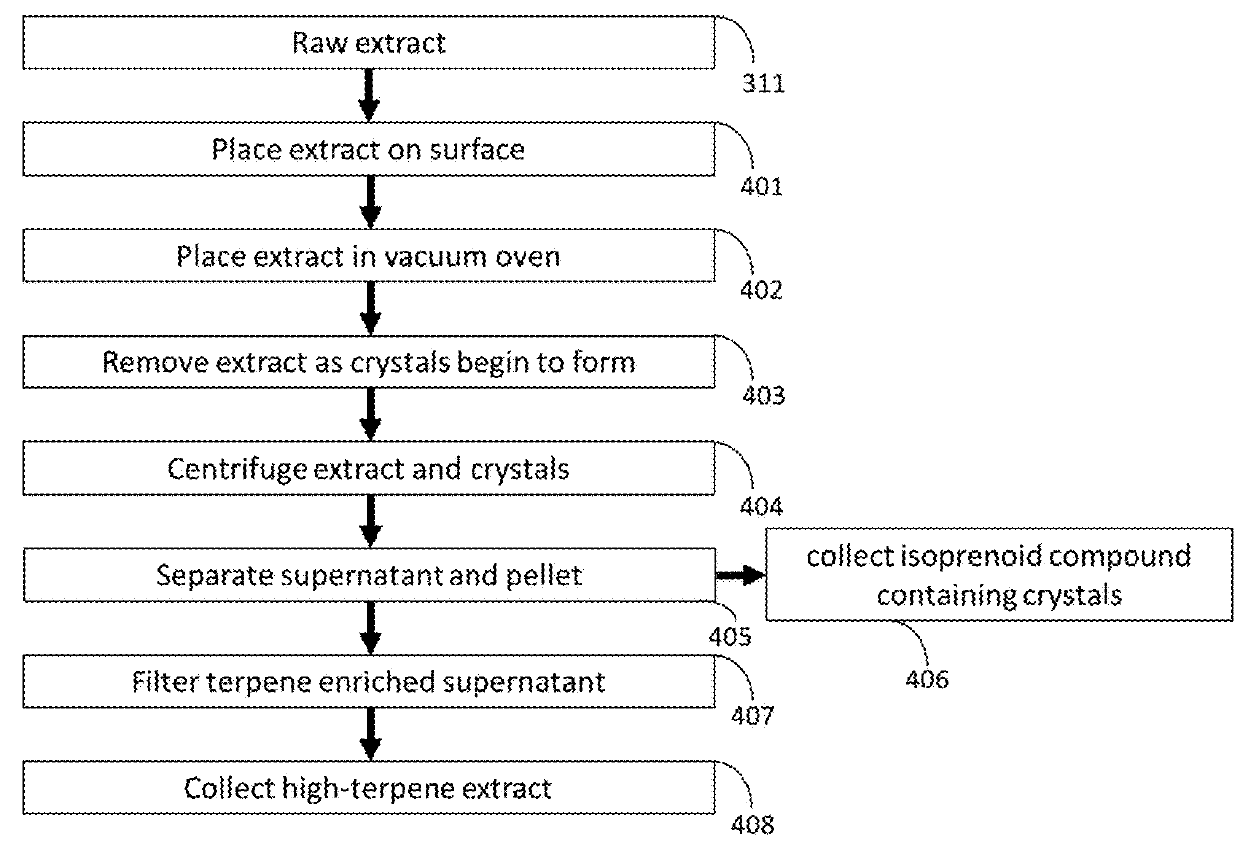

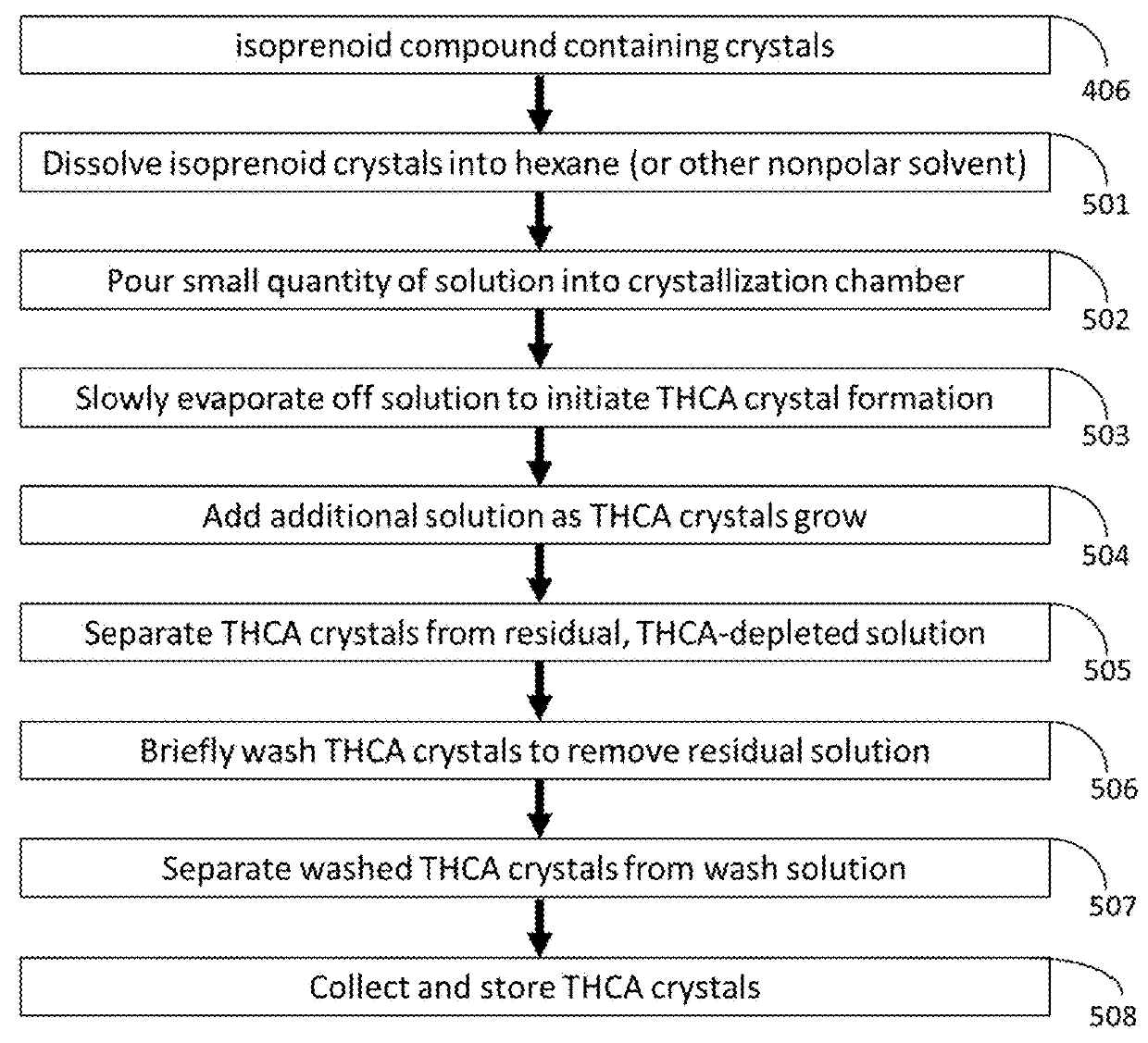

Methods for Purification of Non-Psychoactive Isoprenoid Compounds from Biological Extracts

ActiveUS20180273501A1Improve stabilityPrevent degradationOrganic chemistry methodsCentrifugal force sediment separationCannabisPrenylation

A method for the extraction and isolation of the terpene and isoprenoid compounds from plant material, followed by a centrifugal force induced selective crystallization of isoprenoids resulting in a separation of terpene and isoprenoid fractions. This this method is suitable for the extraction of cannabinoids from Cannabis and the enrichment tetrahydrocannabinolic acid and reduction of tetrahydrocannabinol in an extract. The purity of tetrahydrocannabinolic acid resulting from centrifugal crystallization is such that dissolution and selective recrystallization of tetrahydrocannabinolic acid is possible resulting in >99.9% pure tetrahydrocannabinolic acid, w / w.

Owner:CONCENTRATED CONSULTING GRP LLC

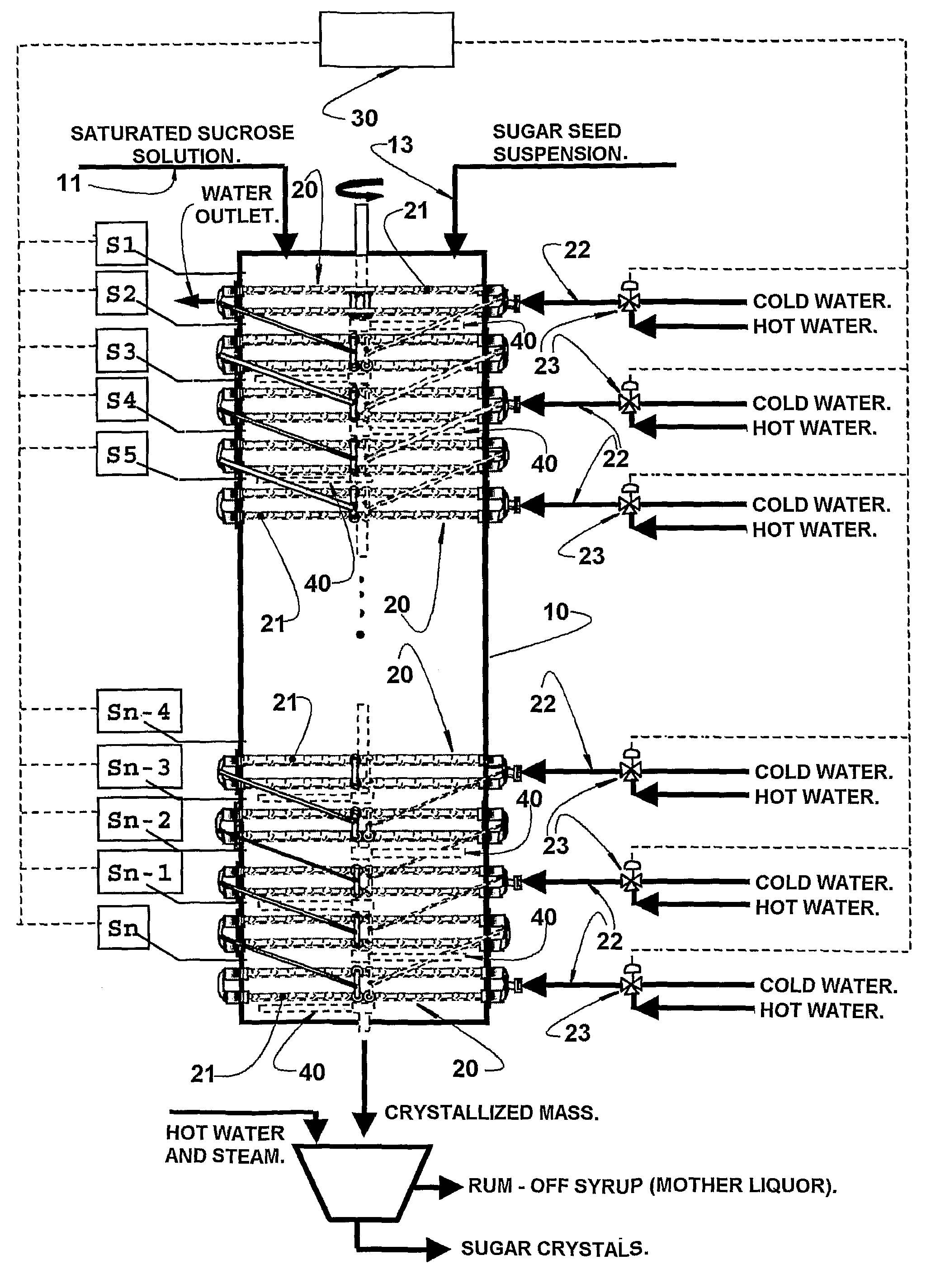

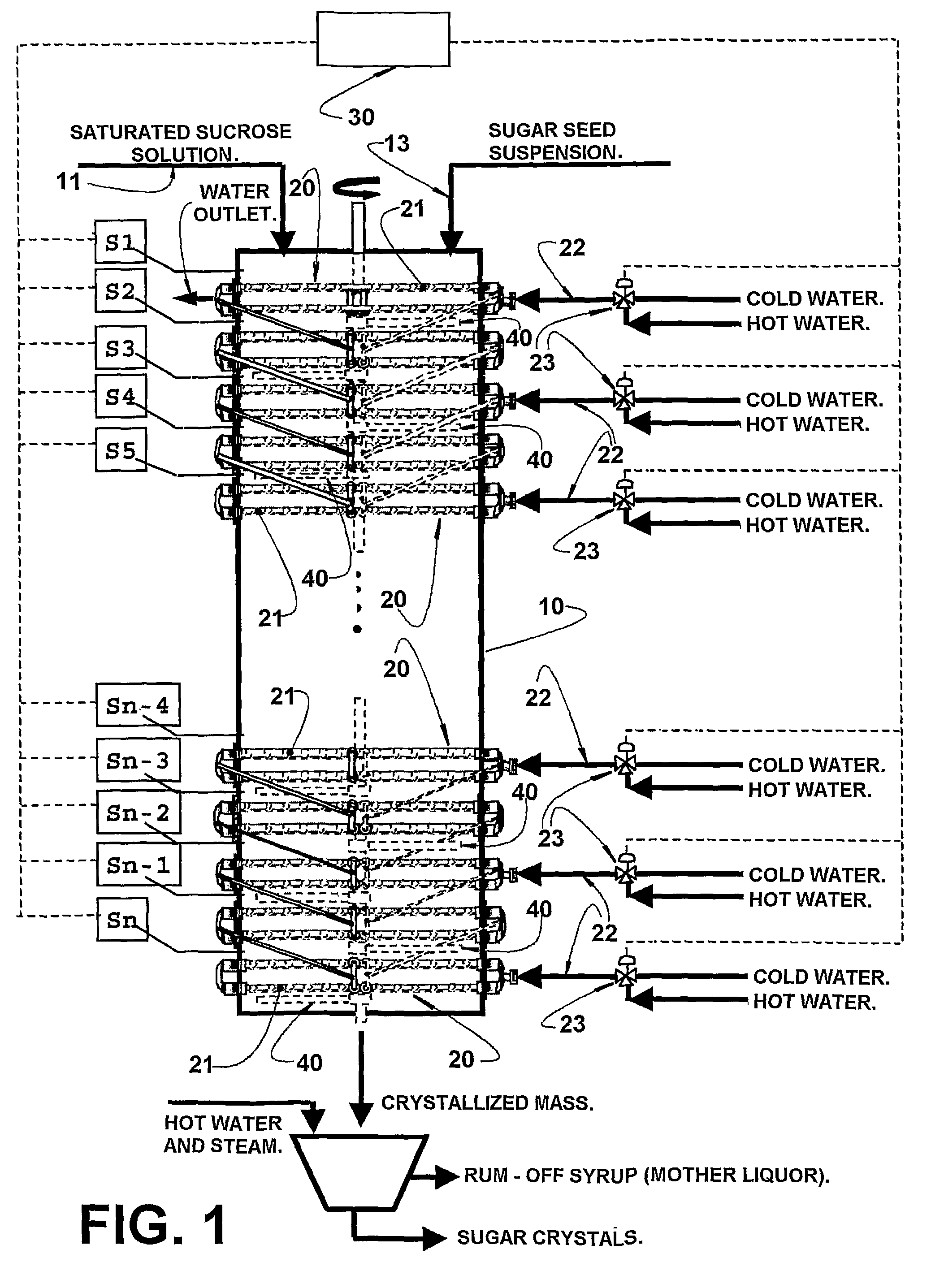

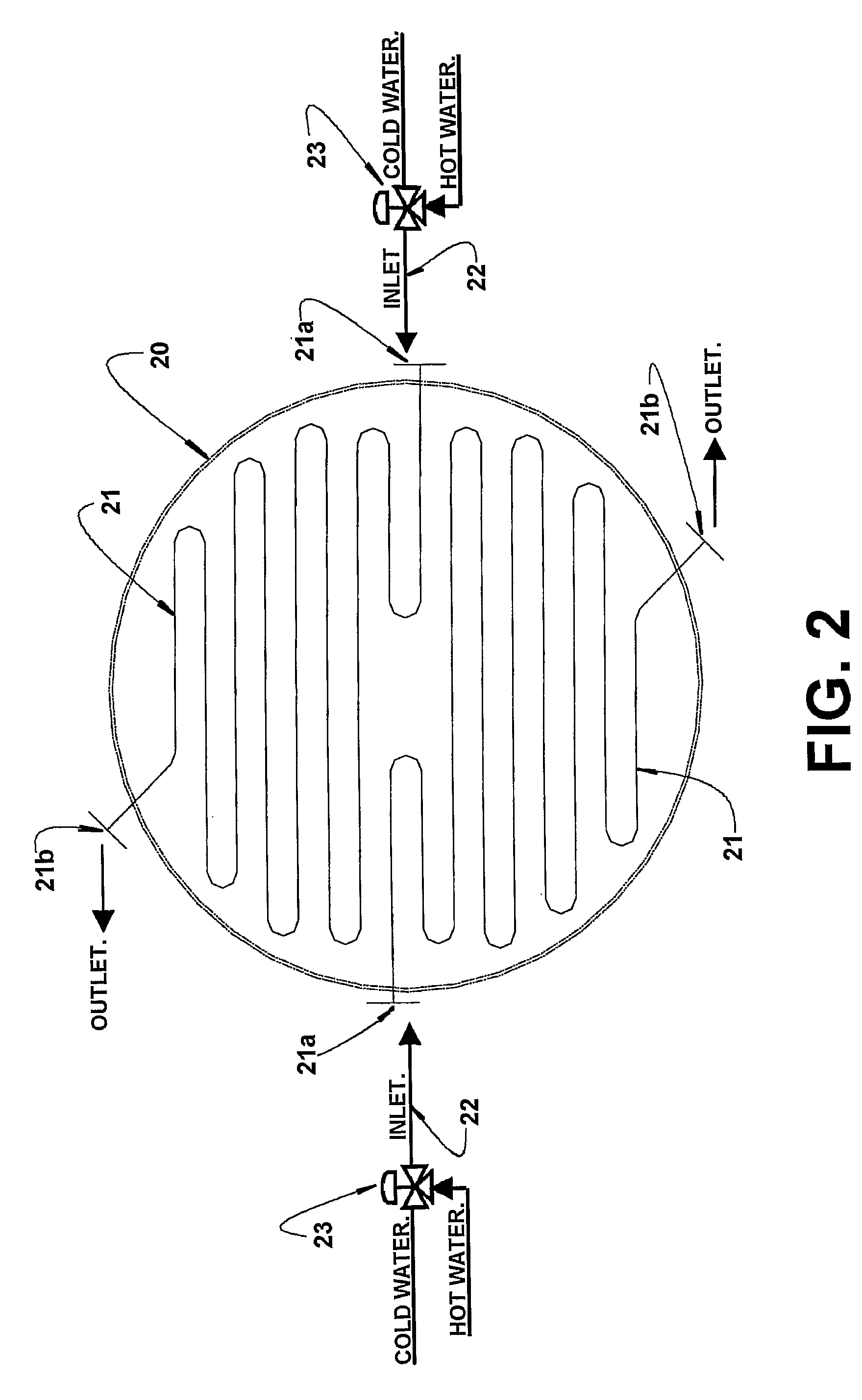

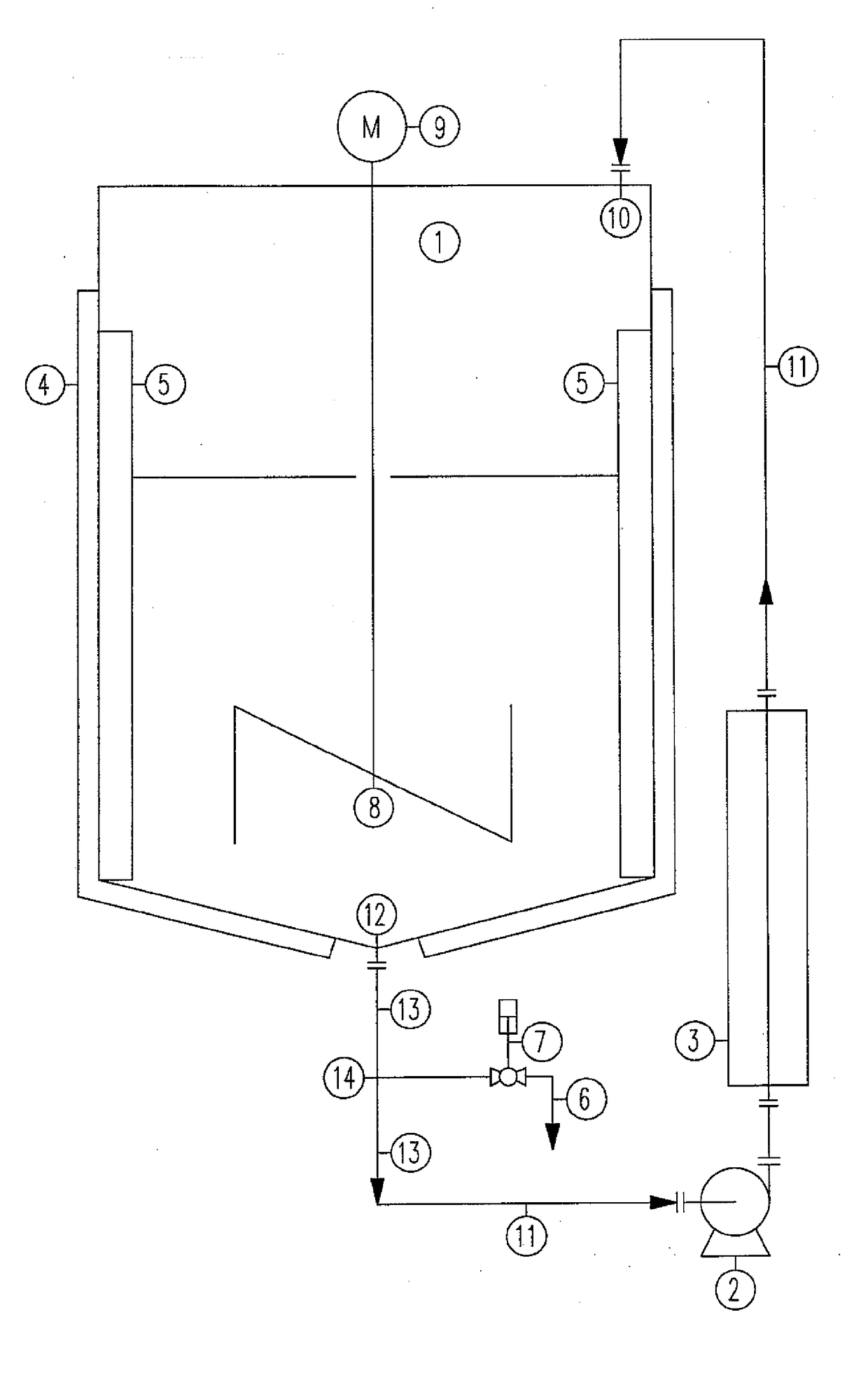

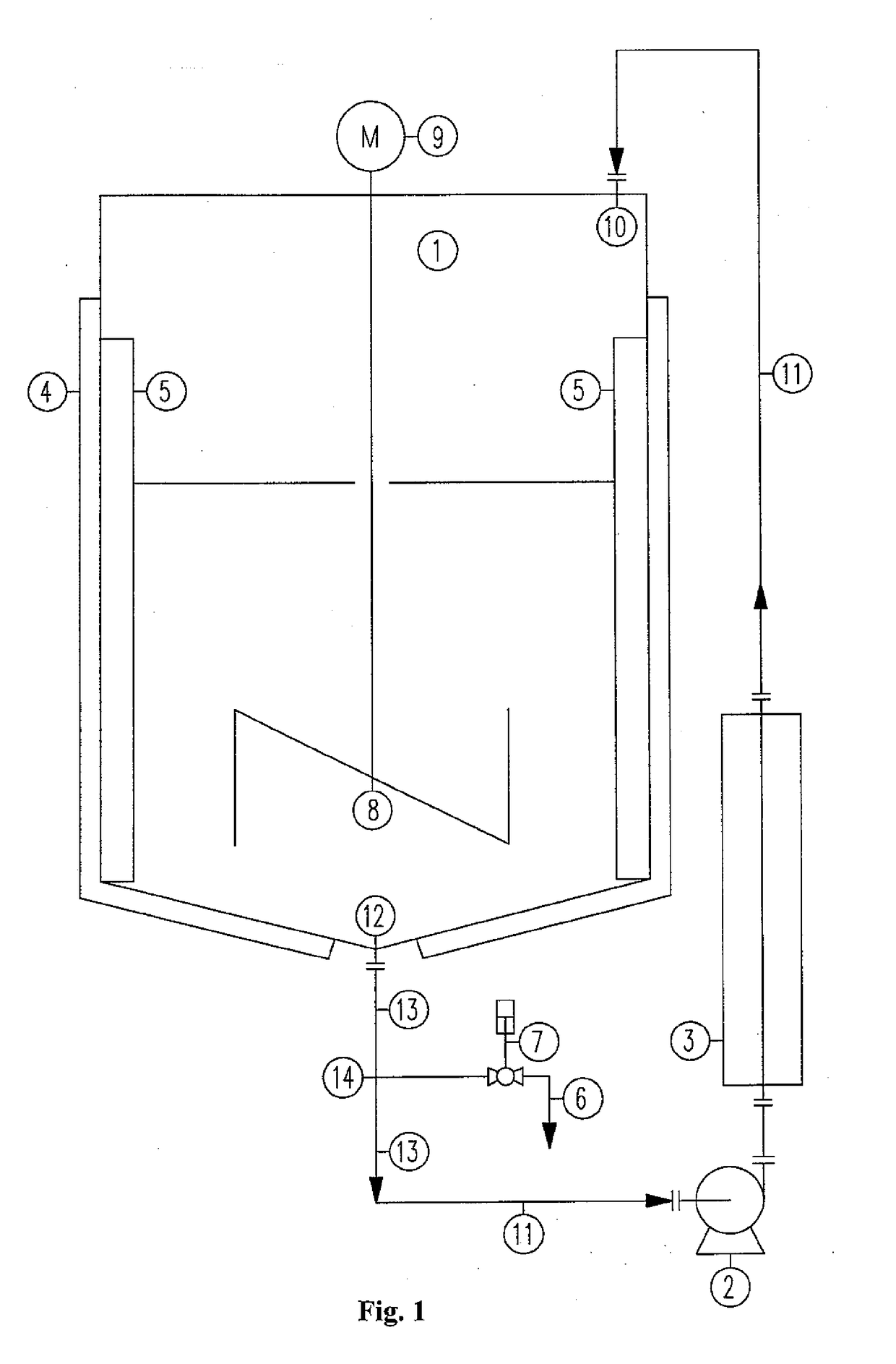

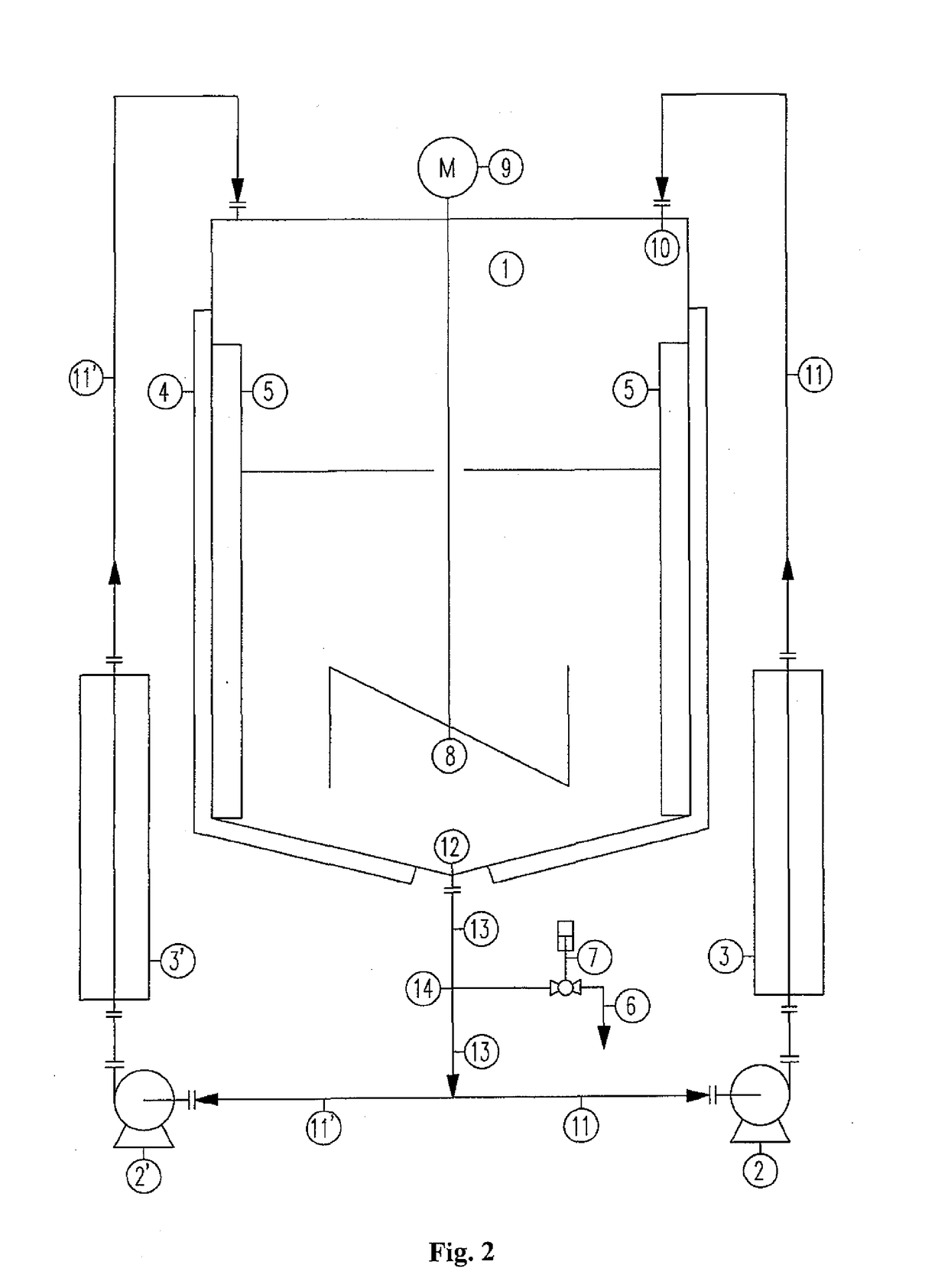

Process and equipment for sugar crystallization by controlled cooling

InactiveUS20100275907A1Sugar crystallisationHeat exchange cooling cystallizationContinuous flowSucrose solution

A process is proposed for crystallizing, by progressively cooling, in multiple stages arranged in series in a crystallization vessel (10), a descending continuous flow of a saturated sucrose solution at a temperature from about 78° to about 120° C., each stage maintaining the sucrose solution being crystallized at a predetermined temperature, until reaching a temperature from about 25 to 40° C., obtaining substantially pure sucrose crystals. A suspension containing sugar seeds is introduced in the crystallizing equipment, in the first stage, jointly with the saturated sucrose solution of 1.05-1.15. In another embodiment of the invention, the saturated solution is fed and its temperature is controlled, already in the first stage of the vessel (10), to obtain a supersaturation between 1.05 and 1.15, inducing the formation of small crystals used as crystallization seeds.

Owner:DEDINI S A IND DE BASE

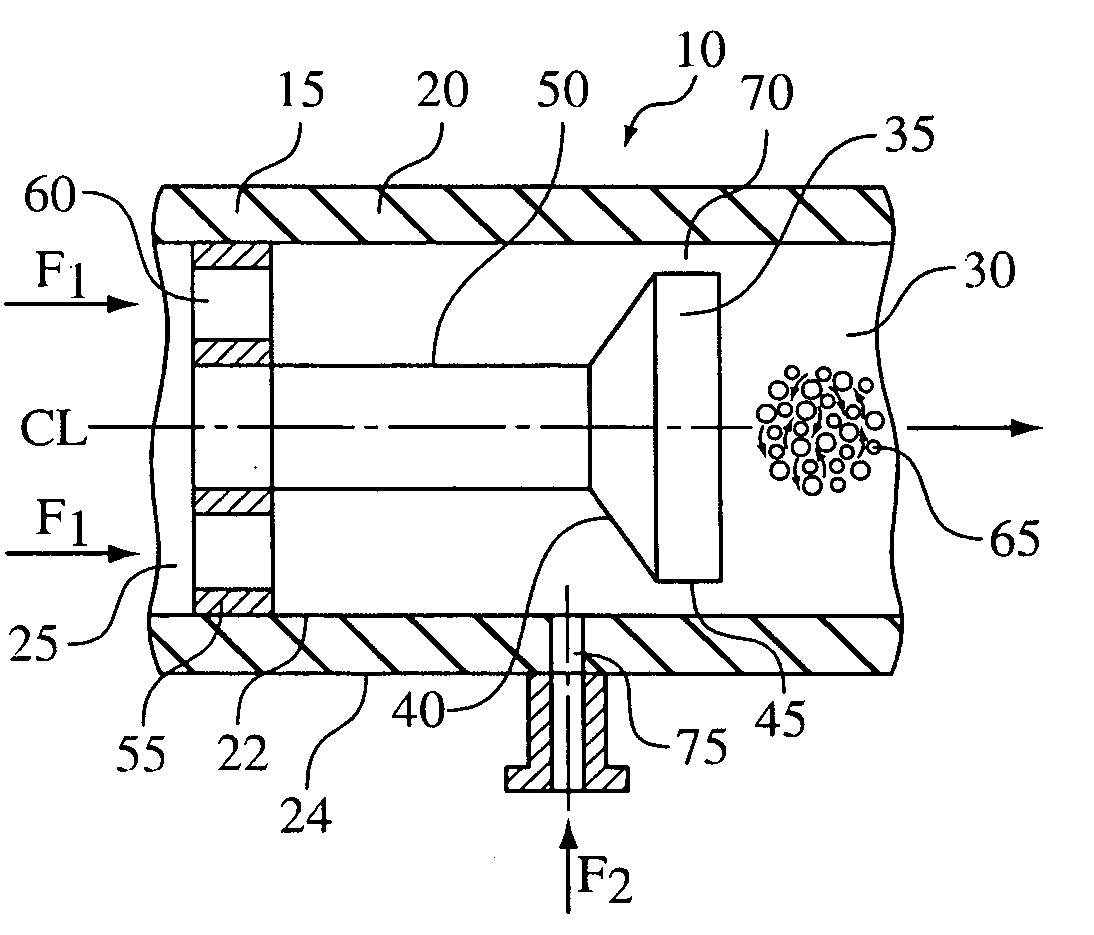

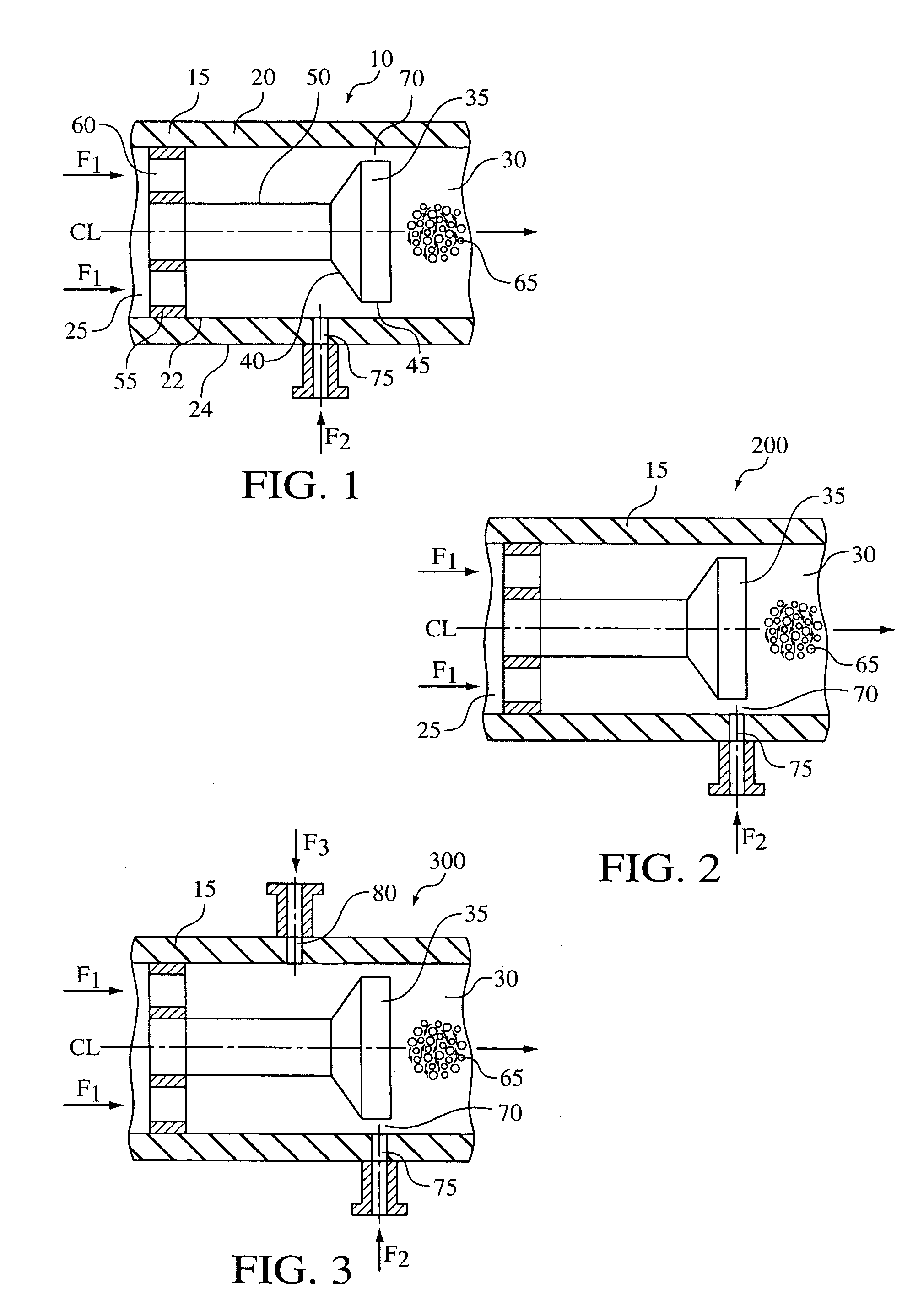

Hydrodynamic cavitation crystallization device and process

A device and process for crystallizing a compound using hydrodynamic cavitation comprising the steps of mixing at least one stream of a solution of such compound to be crystallized with at least one stream of an anti-solvent and passing the mixed streams at an elevated pressure through a local constriction of flow to create hydrodynamic cavitation thereby causing nucleation and the direct production of crystals.

Owner:CAVITECH HLDG

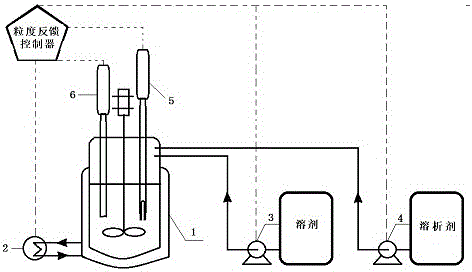

Feedback control method for crystal product granularity in dilution crystallization process

ActiveCN106178583AEliminates manipulations to control crystallizationLower the nucleation barrierSolution crystallizationHeat exchange cooling cystallizationGranularitySolvent

The invention relates to a feedback control method for crystal product granularity in the dilution crystallization process. The method includes the specific steps: estimating the sum of crystal granules according to expected average grain diameter of crystal products, comparing the sum of crystal granules N in crystallization mother liquor measured through an on-line granularity measurement apparatus in real time with the sum of crystal granules Ns specified in production, and synchronously controlling feeding rate of a crystal breaking system, dilution agent and solvent till the crystal products with expected granularity distribution are produced. Compared with the conventional granularity control method in the dilution crystallization process, the method has the advantages that the crystal products with expected granularity distribution can be produced automatically and conveniently as required by only regulating one parameter of the specified sum of crystal granules Ns without re-optimizing new process parameters and the grinding and screening process through plenty of experimental operation, and a granularity controllable regulation function of producing the crystal products with specified granularity distribution as required is realized.

Owner:JIANGYIN HUACHANG FOOD ADDITIVE CO LTD

MVR continuous evaporative crystallization system

InactiveCN105879426AIncrease profitImprove energy savingEvaporator accessoriesSolution crystallizationEngineeringVacuum pump

The invention relates to a MVR continuous evaporative crystallization system which comprises a heating system, an evaporative crystallization system, a crystallization separation system and a condensation system. The heating system comprises a live steam compensation pipeline, a steam compressor and a material preheating device. The evaporative crystallization system comprises a circulation evaporator and a crystallizer. The crystallization separation system comprises a centrifugal machine. The condensation system comprises a condensate collection tank. The circulation evaporator comprises is connected with the condensate collection tank through a condensate water inlet pipe. The material preheating device comprises a primary preheater, a secondary preheater and a tertiary preheater. A second branch pipe, used for conveying live steam, connected to the steam compressor is connected into the tertiary preheater. The condensate collection tank is connected with the secondary preheater through a condensate water outlet pipe. The condensate collection tank is connected with the primary preheater through a non-condensation gas pipe. A non-condensation gas outlet of the primary preheater is connected with a vacuum pump. The MVR continuous evaporative crystallization system has the advantages of being high in heat utilization rate, good in energy-saving performance, low in pollution, high in efficiency and stable in work.

Owner:WENZHOU TAIKANG EVAPORATOR

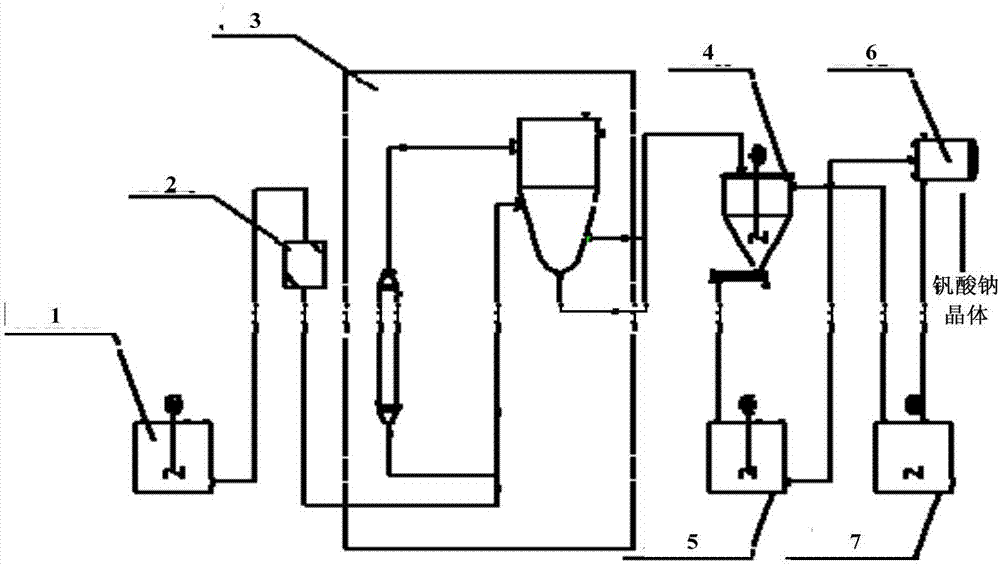

Sodium vanadate crystallization system and method

InactiveCN107376399ASlow crystallization rateAchieve crystallization controlSolution crystallizationVanadium compoundsSlurryFilter press

The invention relates to a sodium vanadate crystallization system and a sodium vanadate crystallization method. The system comprises a buffer tank, a heat exchange tank, a crystallizer, a thickener, a crystal slurry storage tank, a filter press and a mother solution tank which are sequentially arranged, wherein the mother solution tank is connected with a supernate discharging hole of the thickener. According to the system, a sodium vanadate solution stored in the buffer tank is conveyed into the heat exchanger, is cooled and is conveyed into the crystallizer to be crystallized and separated, crystal slurry at the bottom of the crystallizer is conveyed into the thickener to be thickened, supernate is stored into the mother solution tank, the thickened crystal slurry is conveyed into the crystal slurry storage tank and is separated into sodium vanadate crystals and separation liquid by virtue of the filter press, and meanwhile, the separation liquid is stored into the mother solution tank. According to the method, the particle size and moisture of the sodium vanadate crystals can be effectively controlled, the problem of blockage of the sodium vanadate crystals is solved, the efficiency of the crystallization system is improved, the crystallization control of the sodium vanadate solution is realized under a high-alkali condition, and the stable and efficient operation of the crystallization system are guaranteed; and the method has good application prospects.

Owner:HEBEI IRON AND STEEL +1

Crystallization tank for traditional Chinese medicine extraction

InactiveCN105664519ASame temperatureAchieve recrystallization extractionVibration crystallizationSolution crystallizationUltrasonic sensorGranularity

The invention relates to a crystallization tank for traditional Chinese medicine extraction. The crystallization tank comprises a crystallization tank body and a crystal seed generation tank, wherein a tank cover is arranged on the crystallization tank body; a plurality of material addition ports are formed in the tank cover; a motor is arranged above the crystallization tank body and connected with a stirring shaft; a plurality of paddles are arranged on the stirring shaft; a first cooling jacket is arranged around the crystallization tank body; a discharge port is formed in the bottom of the crystallization tank body; a second cooling jacket is arranged around the crystal seed generation tank; a plurality of ultrasonic transducers are uniformly arranged on the outer wall of the second cooling jacket; a feeding port and a conveying port are formed in the top and the bottom of the crystal seed generation tank respectively; the conveying port is connected with a conveying pipeline, and the other end of the conveying pipeline extends into the upper part of the crystallization tank body. With the adoption of the crystallization tank for traditional Chinese medicine extraction, the quantity of added crystal seeds and the granularity can be effectively controlled, the controllability of the crystallization process is improved, the quality of produced traditional Chinese medicine crystals is good, the purity is high, the granularity is uniform, and convenience is brought for the following preparation process.

Owner:TIANJIN ANZHIHEHE GENE TECH CO LTD

Filtering concentration device and method for small ternary precursor particles

ActiveCN110102081AIncrease concentrationHigh filtration precisionSolution crystallizationMembrane filtersEngineeringSingle crystal

The invention relates to the technical field of filtering concentration devices, in particular to a filtering concentration device and method for small ternary precursor particles. The filtering concentration device comprises a cylinder, a first head, a second head and a material inlet, wherein one or more groups of rack pipes are arranged on the inner wall of the cylinder, micro-porous filtrationmediums communicated in the rack pipes are arranged on the rack pipes, and the parts, outside the cylinder, at the ends of the rack pipes automatically run by controlling valves, the liquid level, the pressure, the flow and a touch screen PLC. The filtering concentration device has the advantages that the concentration of the ternary product solid particles in a reaction kettle is increased by 20%-200%, the direct yield is improved to 98%, the product morphology is improved, the size of the particles is uniform, the size distribution is more narrow, and the device is more suitable for production of the small single crystal particles; the reaction period is shortened, the solid particles can return to the reaction kettle in time to participate in a reaction for crystal growth, the yield isimproved, the production cost is reduced, the inlet material flow speed can be increased, the product cannot be lost, the inlet amount of the reaction kettle can be increased, the concentration effect is good, and the production efficiency is high.

Owner:ZHEJIANG DONGOU FILTERING MASCH MFG CO LTD

Discontinuous crystallization unit for the production of ball-shaped crystals

InactiveUS20170128854A1Easy to controlPolycrystalline material growthFrom normal temperature solutionsCooling curveCirculator pump

Owner:ERUCA TECH SRO

Popular searches

Electrical/wave energy microorganism treatment Water Crystallization regulation/control Electrical/wave energy enzyme treatment Single crystal growth details Crystallization auxillary selection Alkali metal halide formation shape Transportation and packaging Semiconductor/solid-state device manufacturing Chemical/physical processes

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com