Sodium vanadate crystallization system and method

A crystallization system, sodium vanadate technology, applied in the field of vanadium chemical industry, achieves good application prospects, efficient operation, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

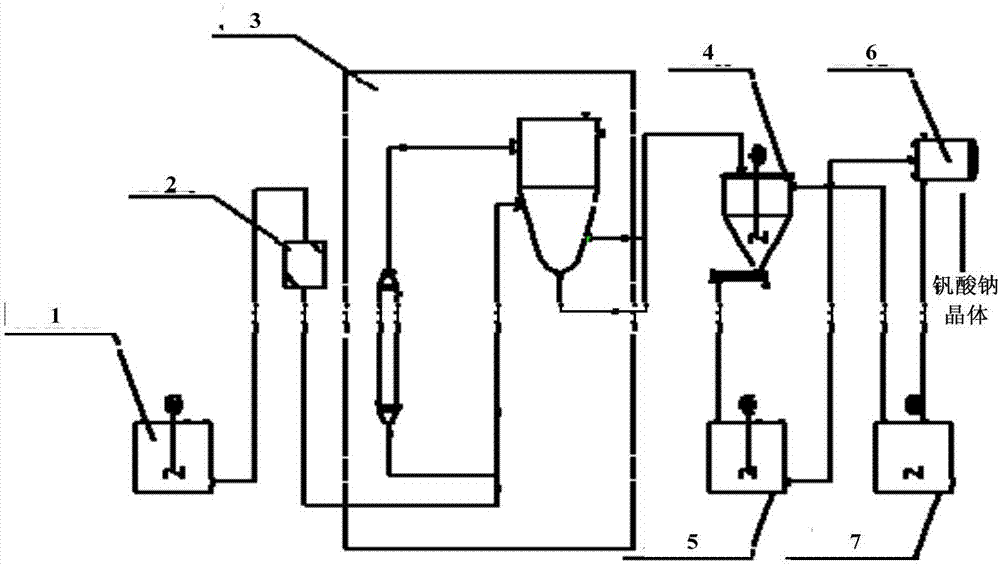

[0034] A sodium vanadate crystallization system, comprising: a buffer tank 1, a heat exchanger 2, a crystallizer 3, a thickener 4, a magma storage tank 5, a filter press 6 and a mother liquor tank 7 arranged in sequence, the mother liquor tank 7 is connected with thickener 4.

[0035] A delivery pump is arranged between the buffer tank 1 and the heat exchanger 2; the heat exchanger 2 is a spiral plate heat exchanger; the crystallizer 3 is a continuous crystallizer; the filter press is a metal mesh filter press machine.

[0036] Sodium vanadate was crystallized using the above crystallization system:

[0037] The 80°C sodium orthovanadate solution stored in the buffer tank 1 is transported to the heat exchanger 2 through the delivery pump. The heat exchanger 2 is a spiral plate heat exchanger, and the cooling medium is demineralized water to cool down the sodium orthovanadate solution After reaching 56°C, transport it to the continuous crystallizer 3; adopt the cooling method...

Embodiment 2

[0039] This embodiment utilizes the crystallization system provided in Example 1 to crystallize sodium vanadate:

[0040] The 85°C sodium metavanadate solution stored in the buffer tank 1 is transported to the heat exchanger 2 through the delivery pump. The heat exchanger 2 is a spiral plate heat exchanger, and the cooling medium is demineralized water to cool down the sodium metavanadate solution After reaching 60°C, transport it to the continuous crystallizer 3; adopt the cooling method of supernatant liquid circulation, control the cooling rate to 5°C / h, cool the solution to 42°C for crystallization, and obtain crystal slurry at the bottom of the crystallizer, after crystallization After feeding at the bottom of the device, the magma enters the thickener 4 to thicken to obtain the thickened magma and supernatant. The solid content in the thickened magma is 27wt%, and the resulting supernatant is stored in the mother liquor tank 7 After the thickened magma is stored in the mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com