Polyethylene catalyst carrier material with ultrahigh molecular weight and preparation method thereof

A catalyst carrier and ultra-high molecular weight technology, which is applied in the field of ultra-high molecular weight polyethylene catalyst carrier material and its preparation, can solve the problems of inability to prevent a large number of molecular chain entanglement, molecular chain entanglement, random distribution, etc., and improve the entanglement. knot phenomenon, preventing tangle agglomeration, reducing the effect of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

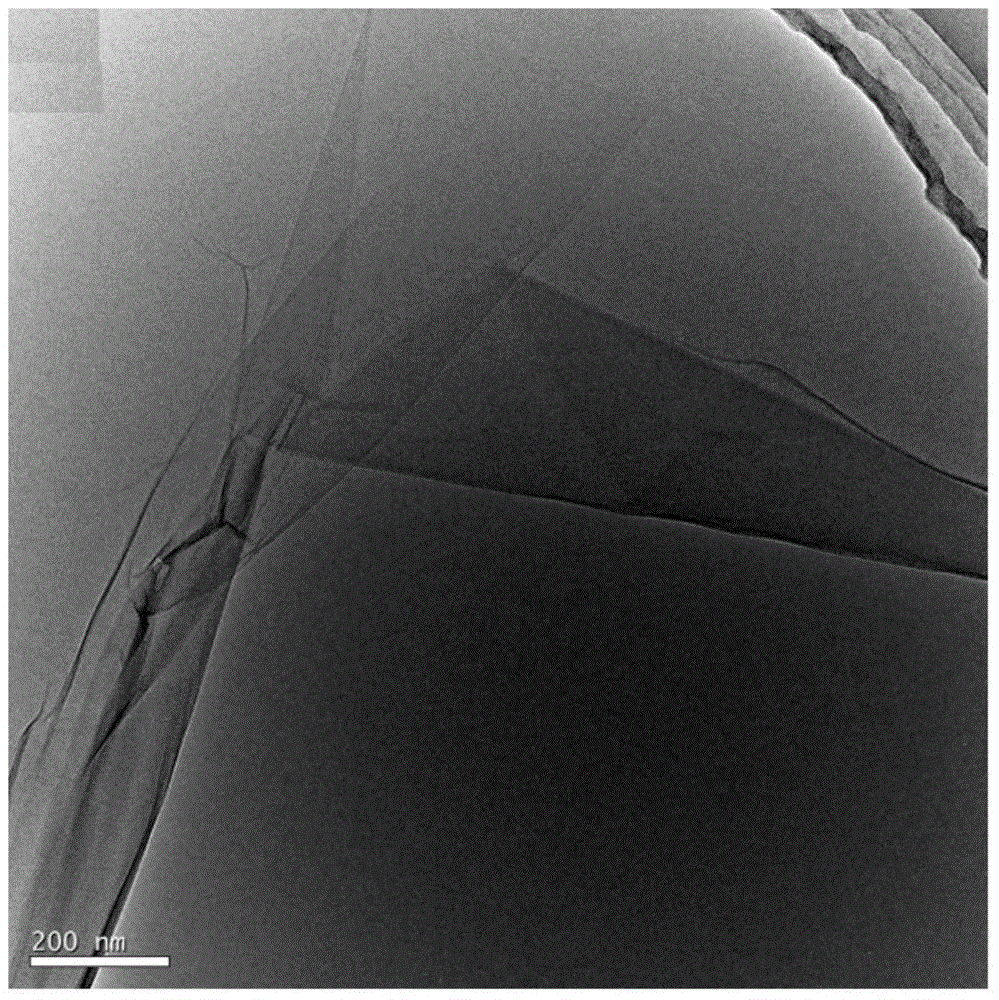

[0073] This embodiment provides a kind of graphene oxide used for ultra-high molecular weight polyethylene catalyst support material, and this graphene oxide is prepared by the following method:

[0074] Add 23mL of concentrated sulfuric acid with a concentration of 98wt% into a dry beaker, cool it to about 0°C in an ice bath, add a solid mixture of 1g graphite powder and 0.5g sodium nitrate, stir, and slowly add 3g potassium permanganate. Stirring and reacting at a temperature of 20°C for 2 hours, the first mixed solution was obtained, and the solution was viscous and dark green;

[0075] Raise the temperature of the first mixed solution to about 35°C, and continue to stir and react for 30 minutes to obtain the second mixed solution, which turns from dark green to brown;

[0076] Continuously and slowly add 46 mL of deionized water dropwise to the second mixed solution, control the temperature at about 100 ° C, continue stirring for 20 min, stop stirring, and then add 3 mL of...

Embodiment 2

[0079] This embodiment provides a kind of silica sol used for ultra-high molecular weight polyethylene catalyst support material, and this silica sol is prepared by the following method:

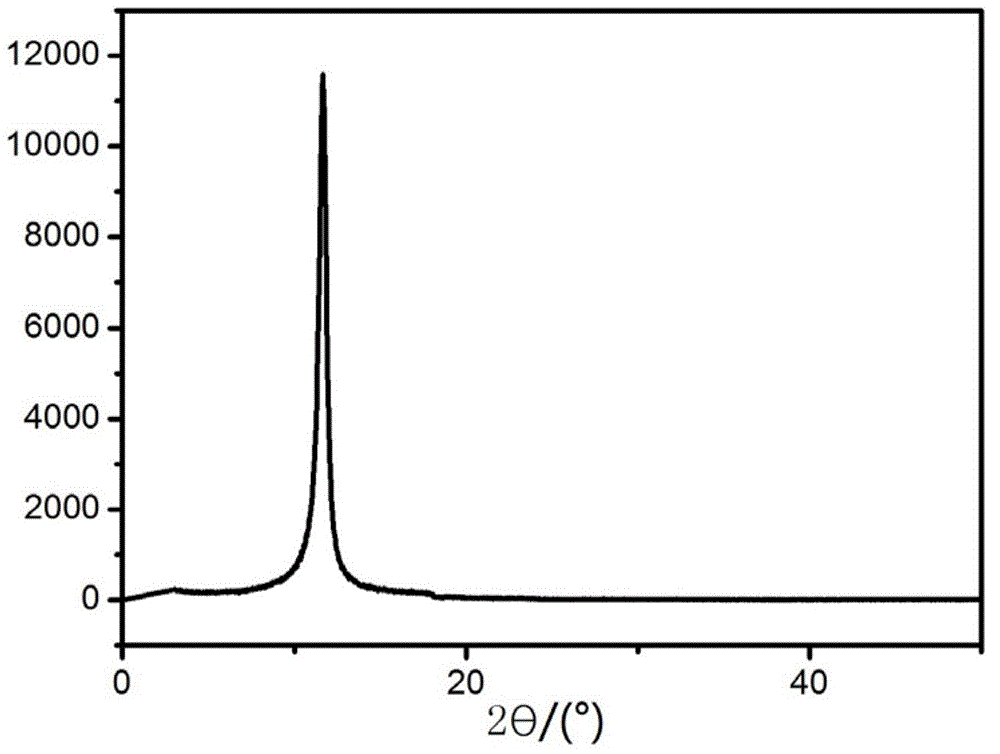

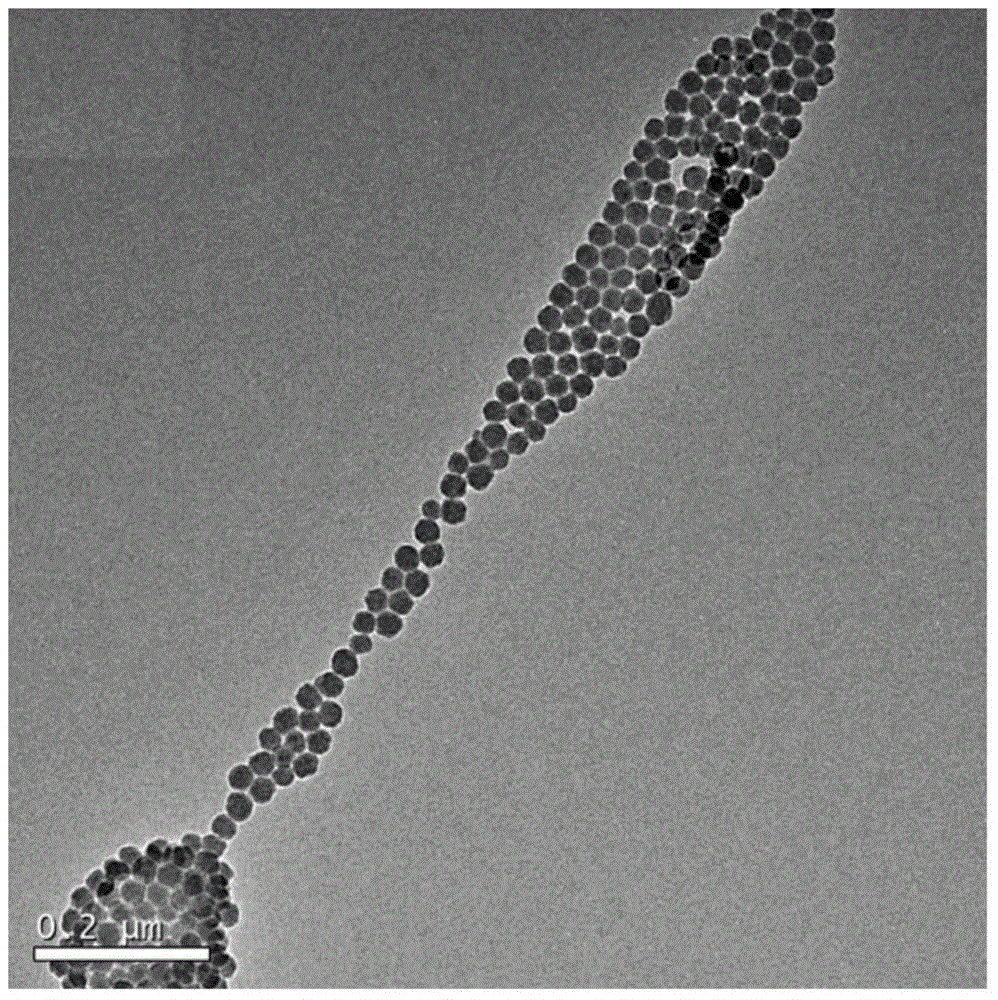

[0080] In 90mL of ethanol, add 3.8mL of ammonia water and 4.6mL of deionized water, put it in a constant temperature tank at 50°C and stir, add 2mL of tetraethyl orthosilicate after 5 minutes, and form a silica sol (30nm particle size) after 12 hours of reaction. Such as Figure 1c shown.

Embodiment 3

[0082] The present embodiment provides a kind of ultra-high molecular weight polyethylene catalyst support material, and this support material is the spherical composite support material of graphene / silicon dioxide / butylmagnesium chloride, and this support material is prepared by the following method:

[0083] The graphene oxide obtained in Example 1 was ultrasonically prepared in deionized water for 30 minutes to form a uniform graphene oxide aqueous solution with a concentration of 10 mg / mL, and the graphene oxide aqueous solution and the silica sol obtained in Example 2 were mixed at a solid content of 1:7.5. The mass ratio was mixed, stirred for 30 minutes, and ultrasonically dispersed evenly for 1 hour, and the mixed dispersion liquid obtained (such as Figure 1d shown);

[0084] Adjust the air intake of the spray gun, spray the mixed dispersion liquid into the liquid nitrogen, make the solution atomize first and then solidify instantly, volatilize to remove the liquid ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com