Patents

Literature

499results about "Crystallization plant arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

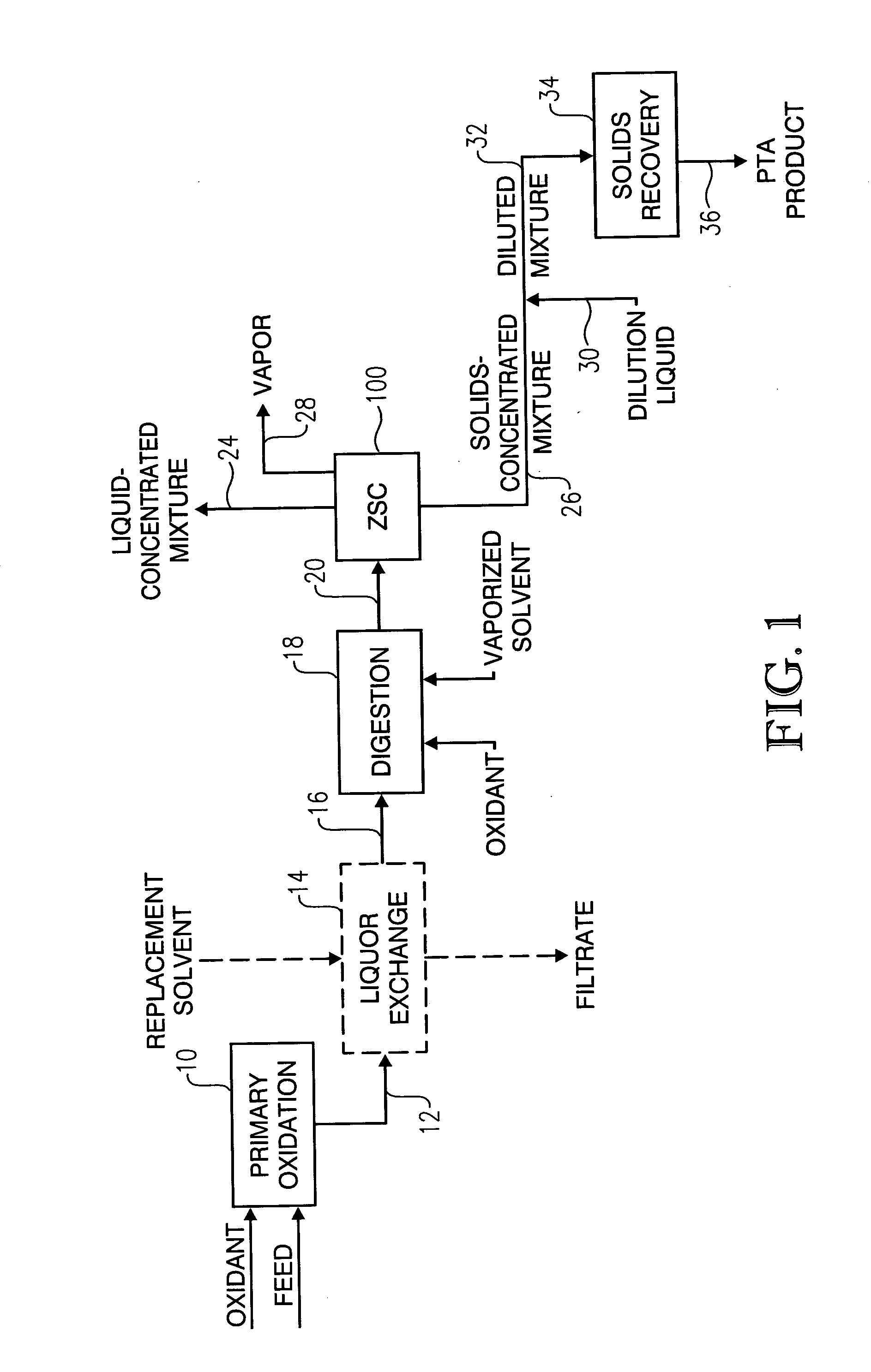

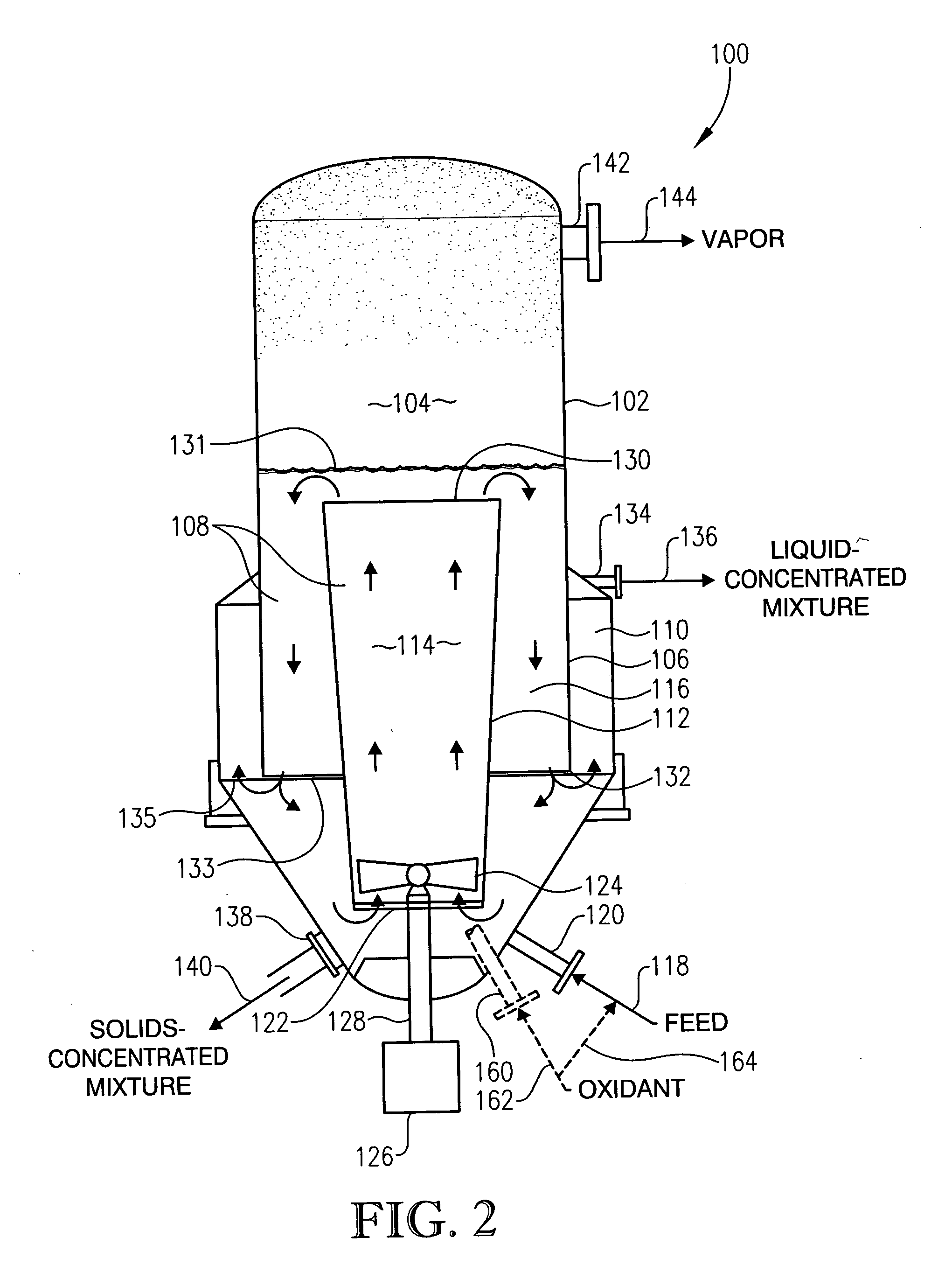

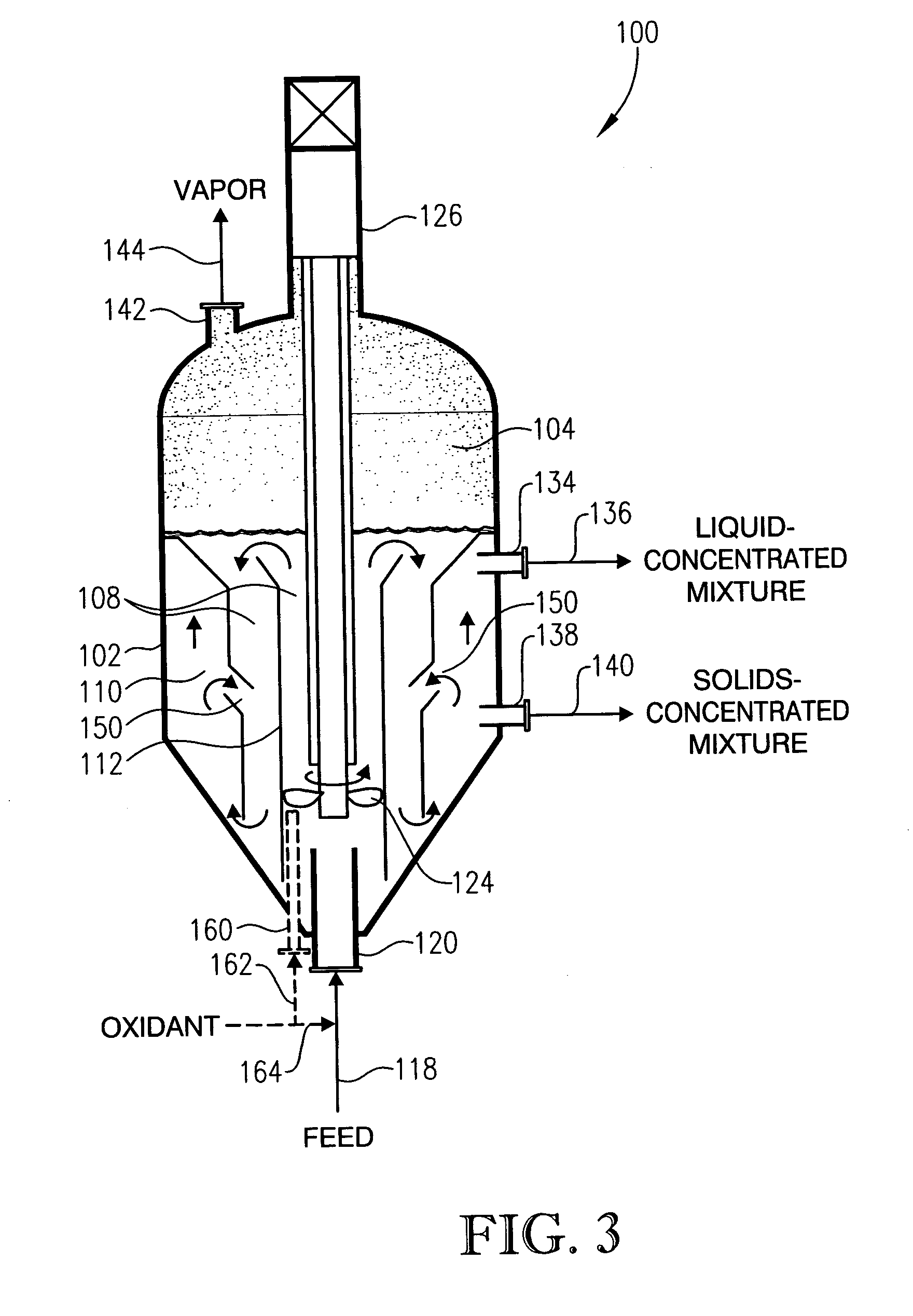

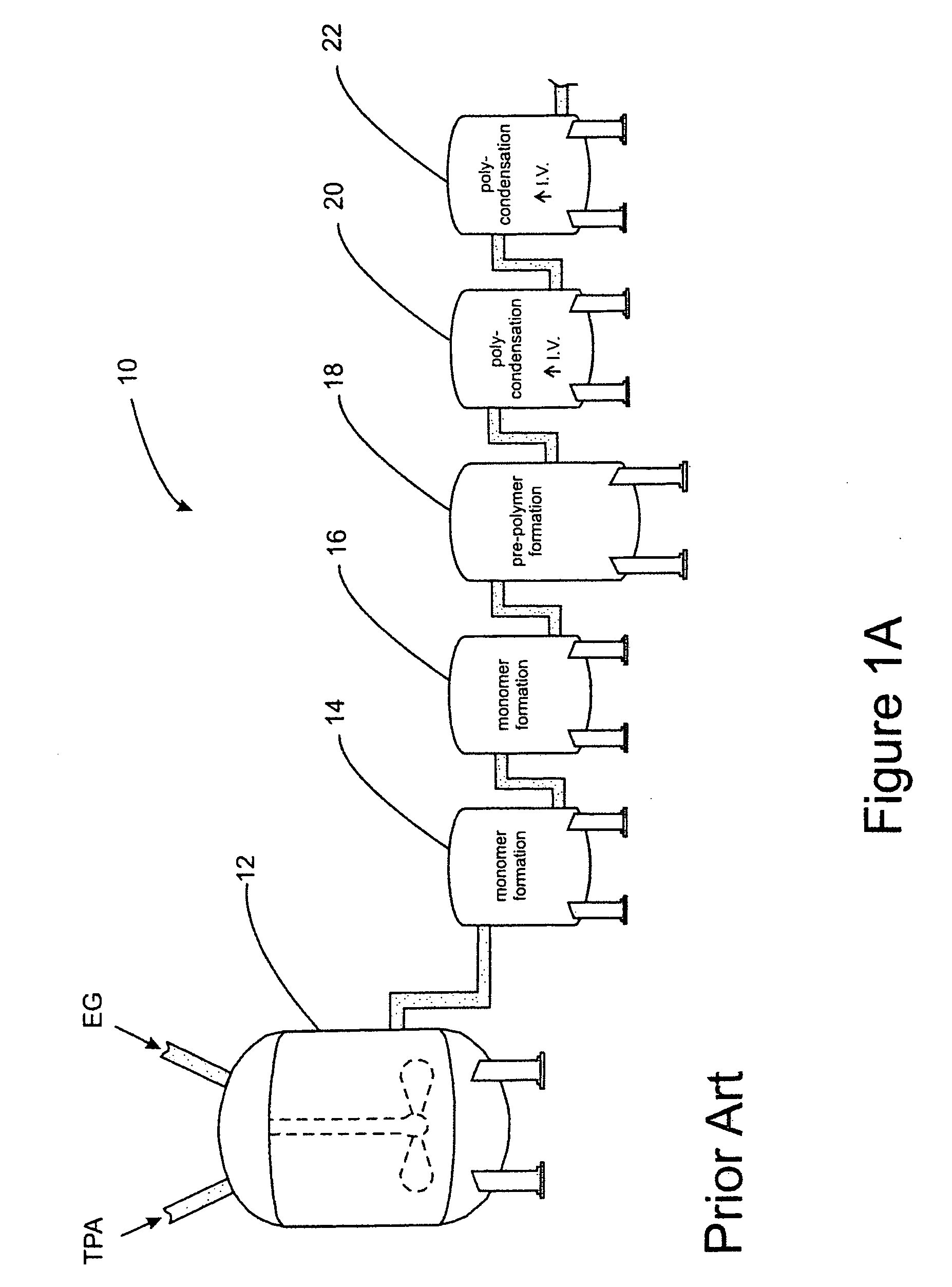

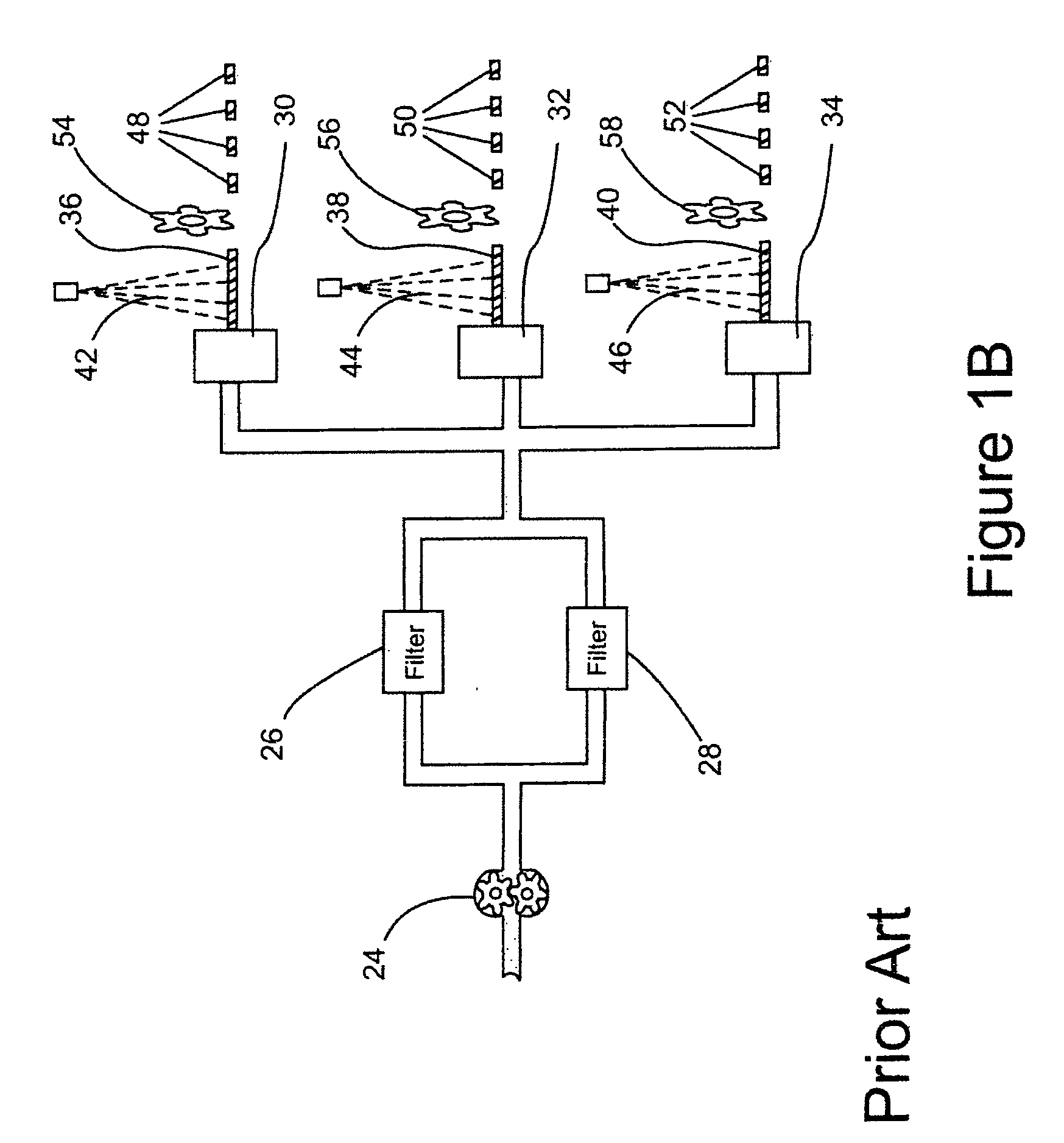

Optimized production of aromatic dicarboxylic acids

ActiveUS20060047166A1Organic compound preparationCrystallization by component evaporationDicarboxylic acidCarboxylic acid

Disclosed is an optimized process and apparatus for more efficiently producing and purifying aromatic dicarboxylic acids (e.g., terephthalic acid). The optimized system employs at least one zoned slurry concentrator to enhance purification of the aromatic dicarboxylic acid.

Owner:ALPEK POLYESTER SA DE CV

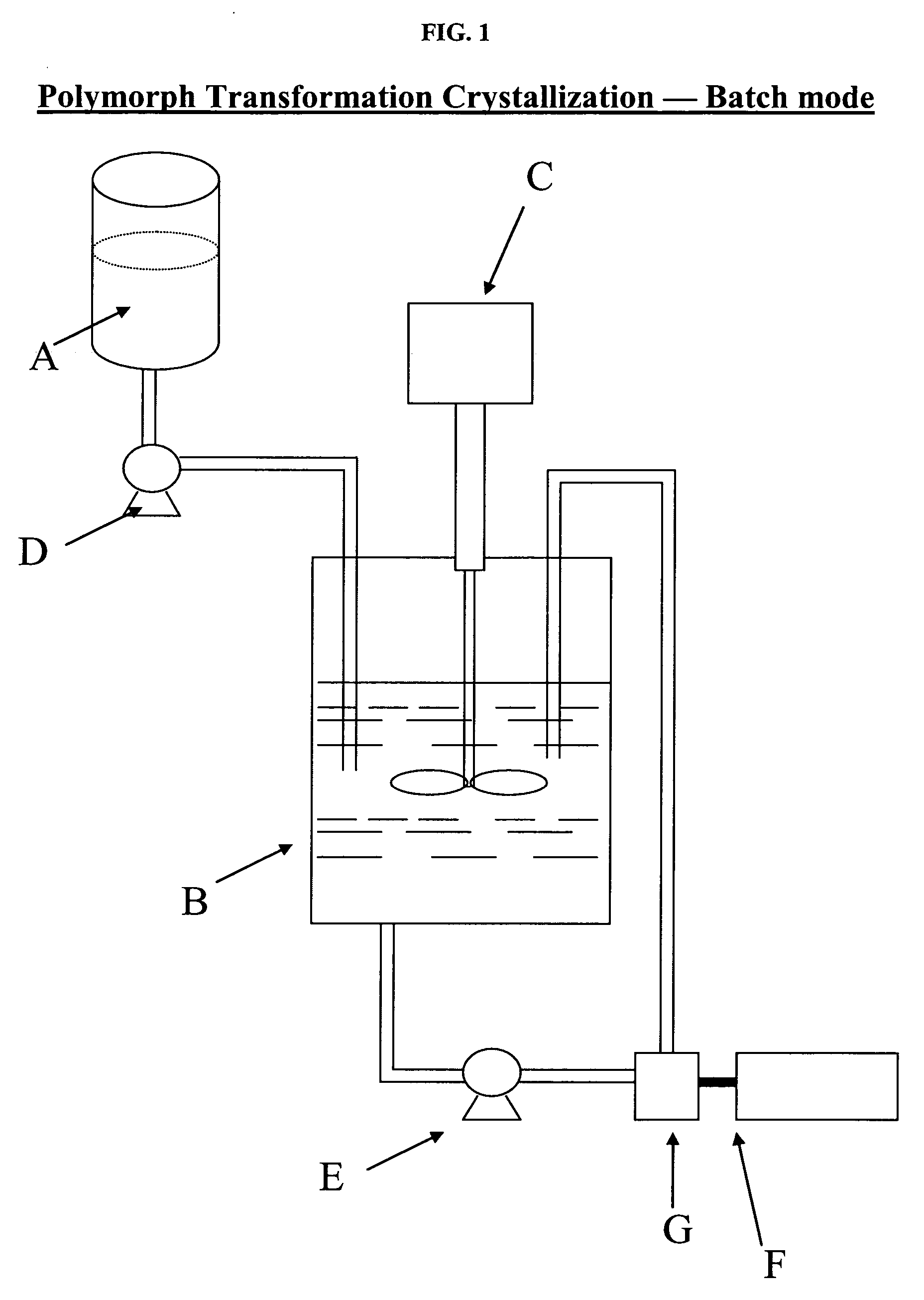

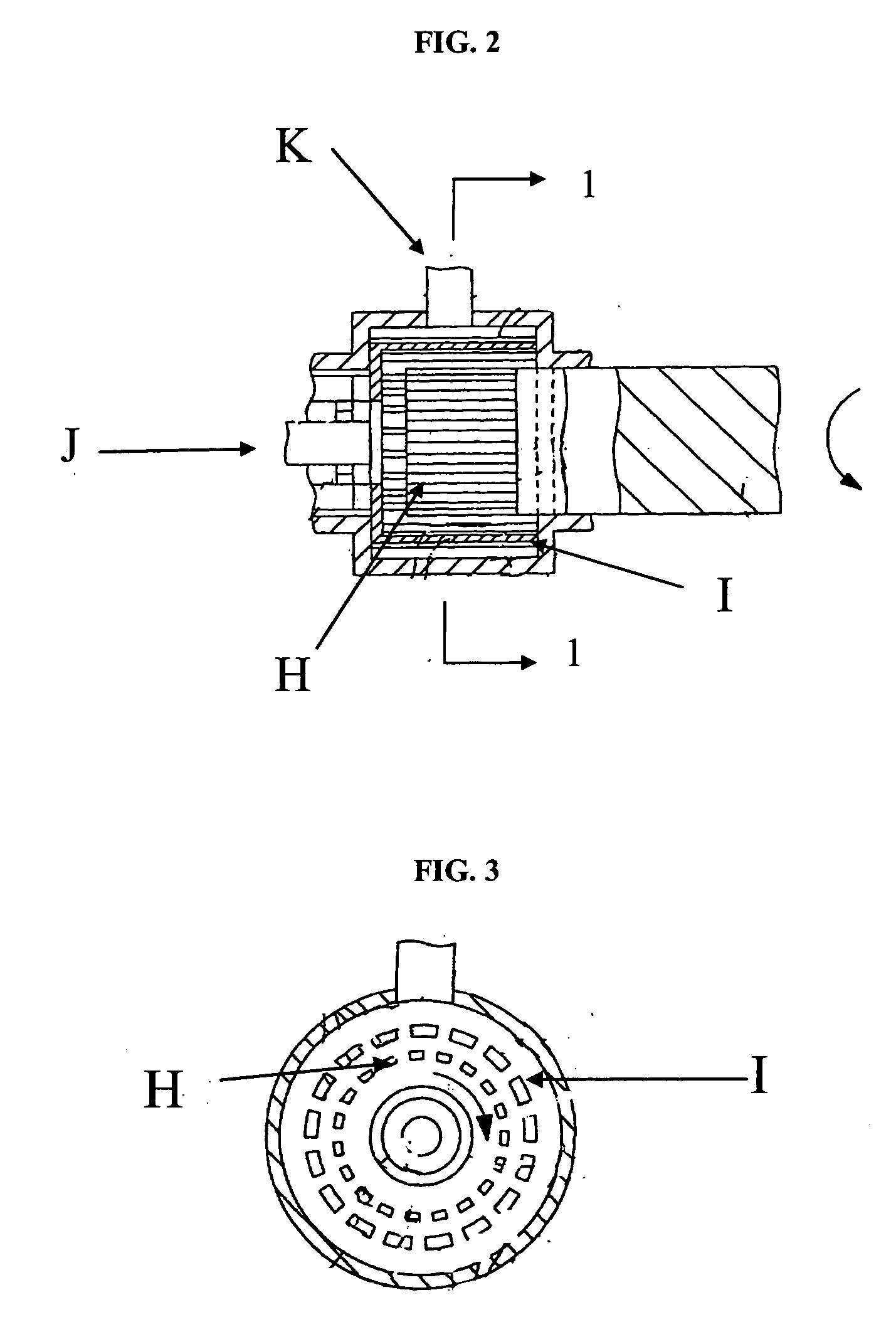

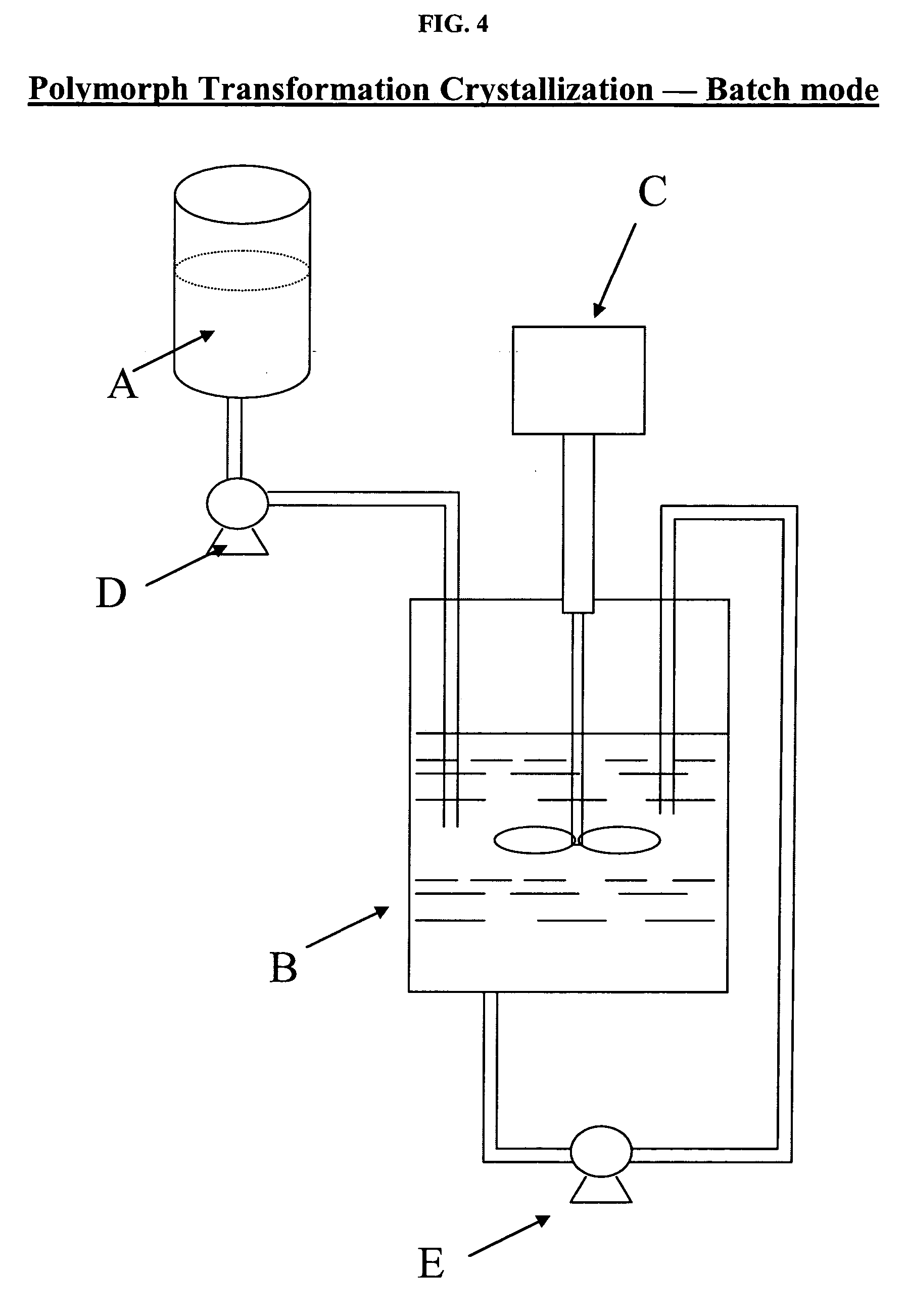

Crystallization via high-shear transformation

The invention relates to a process or apparatus for transforming a first polymorph of a chemical material into a second polymorph of the same chemical material, utilizing an apparatus comprising a vessel connected to a re-circulation system, the process comprising the steps of: suspending said first polymorph in a solution to form a slurry in the vessel, re-circulating the slurry and removing the slurry from the vessel.

Owner:BRISTOL MYERS SQUIBB CO

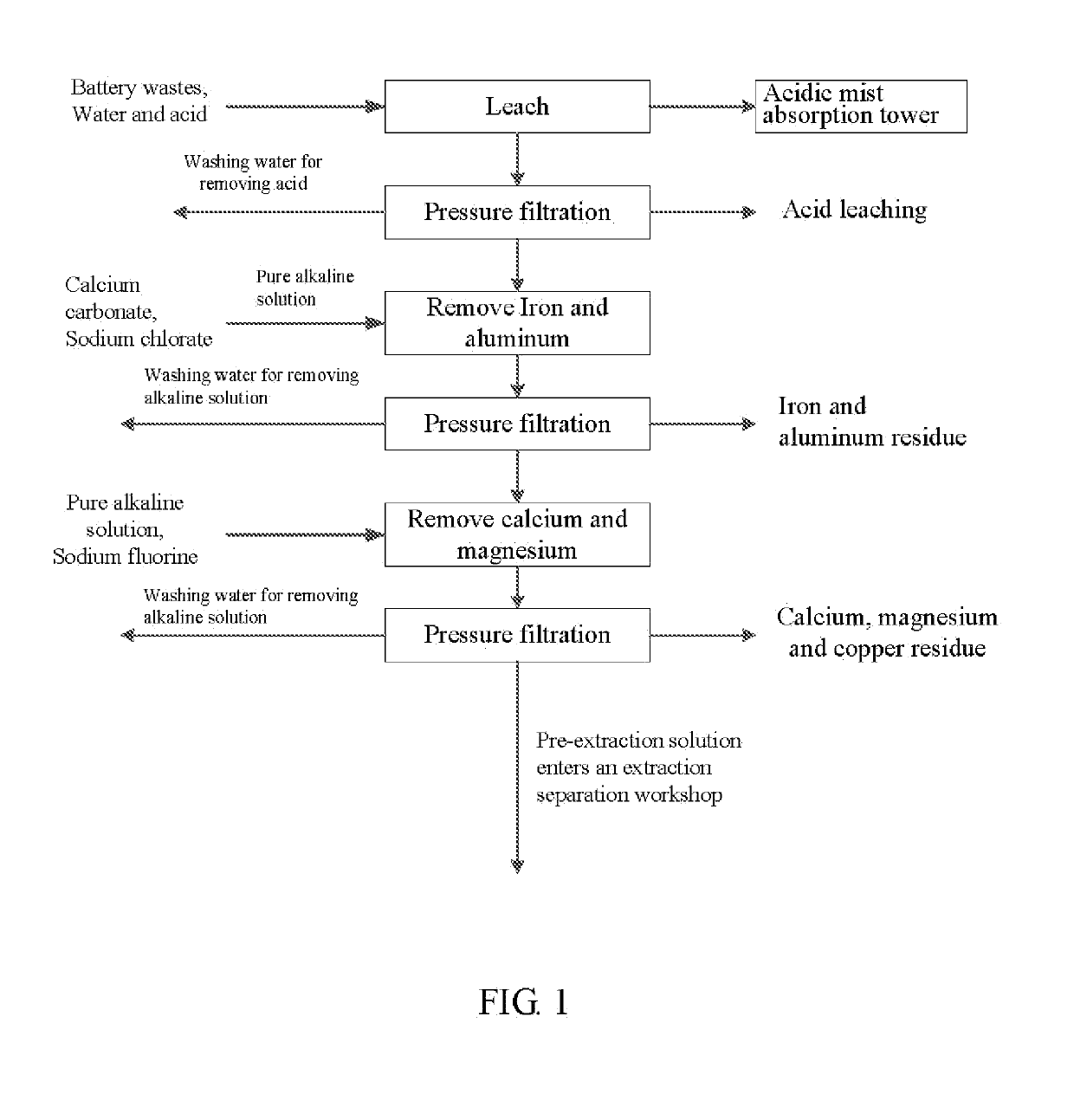

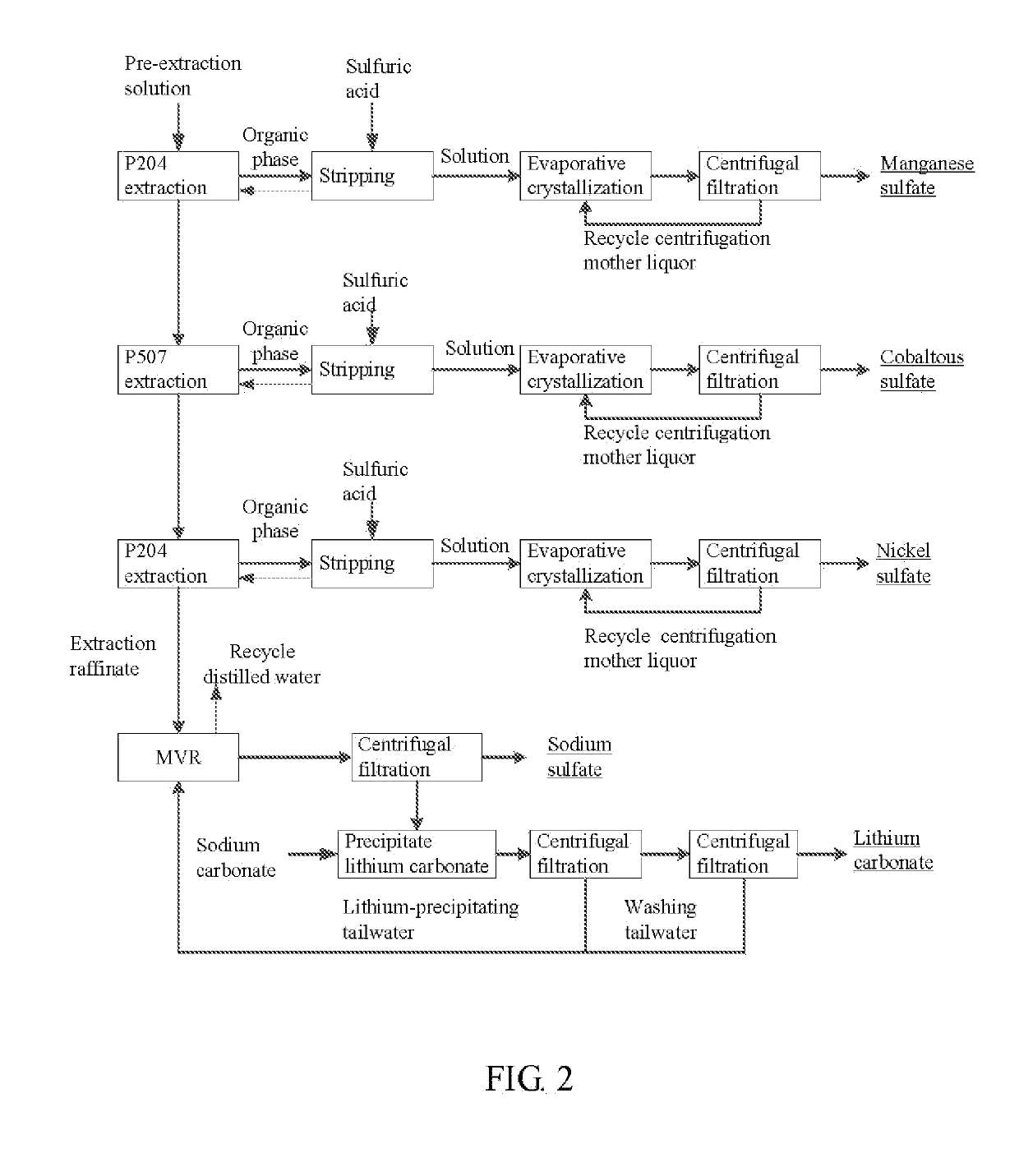

Method for preparing nickel/manganese/lithium/cobalt sulfate and tricobalt tetraoxide from battery wastes

ActiveUS20190152797A1Reduce productionHigh puritySolvent extractionCobalt sulfatesManganeseCobalt Sulfate

A method for preparing nickel / manganese / lithium / cobalt sulfate and tricobalt tetraoxide from battery wastes adopts the following process: dissolving battery wastes with acid, removing iron and aluminum, removing calcium, magnesium and copper, carrying extraction separation, and carrying out evaporative crystallization to prepare nickel sulfate, manganese sulfate, lithium sulfate, cobalt sulfate or / and tricobalt tetraoxide. By using the method, multiple metal elements, such as nickel, manganese, lithium and cobalt, can be simultaneously recovered from the battery wastes, the recovered products are high in purity and can reach battery grade, battery-grade tricobalt tetraoxide can also be directly produced. The method is simple in process, low in, energy consumption and free in exhaust gas pollution, and can realize zero release of wastewater.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

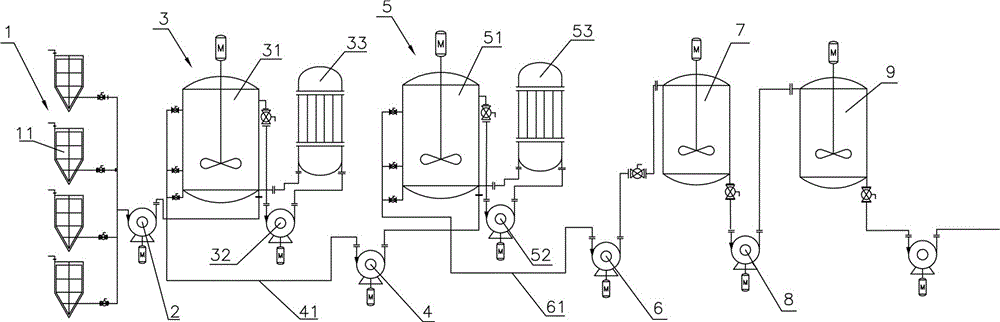

Continuously controllable acesulfame crystallization device

ActiveCN106267879AIncrease productivityQuality improvementOrganic chemistrySolution crystallizationGranularityEngineering

The invention discloses a continuously controllable acesulfame crystallization device. The continuously controllable acesulfame crystallization device comprises: a crystal growing device, a first conveying pump, a first-grade crystallizer, a second conveying pump, a second-grade crystallizer, a third conveying pump, a thickening device, a fourth conveying pump and a crystal slurry tank; the crystal growing device comprises at least one crystal growing kettle; a discharging hole of each crystal growing kettle is connected with a stop valve in series and then is communicated with an inlet of the first conveying pump; the first-grade crystallizer comprises a first-grade crystallizing kettle, a first-grade cooler and a first-grade circulating pump; an outlet of the first conveying pump is communicated with a lower circulating hole of the first-grade crystallizer; the second-grade crystallizer comprises a second-grade crystallizing kettle, a second-grade cooler and a second-grade circulating pump; the discharging hole of the first-grade crystallizing kettle is communicated with the inlet of the second conveying pump; the outlet of the second conveying pump is communicated with the lower circulating hole of the second-grade crystallizer; the discharging hole of the second-grade crystallizing kettle is communicated with the thickening device through the third conveying pump; the outlet of the thickening device is communicated with the inlet of the crystal slurry tank through the fourth conveying pump. The crystallization device provided by the invention is high in production efficiency and an obtained acesulfame crystal has good quality and large granularity.

Owner:南通宏信化工有限公司

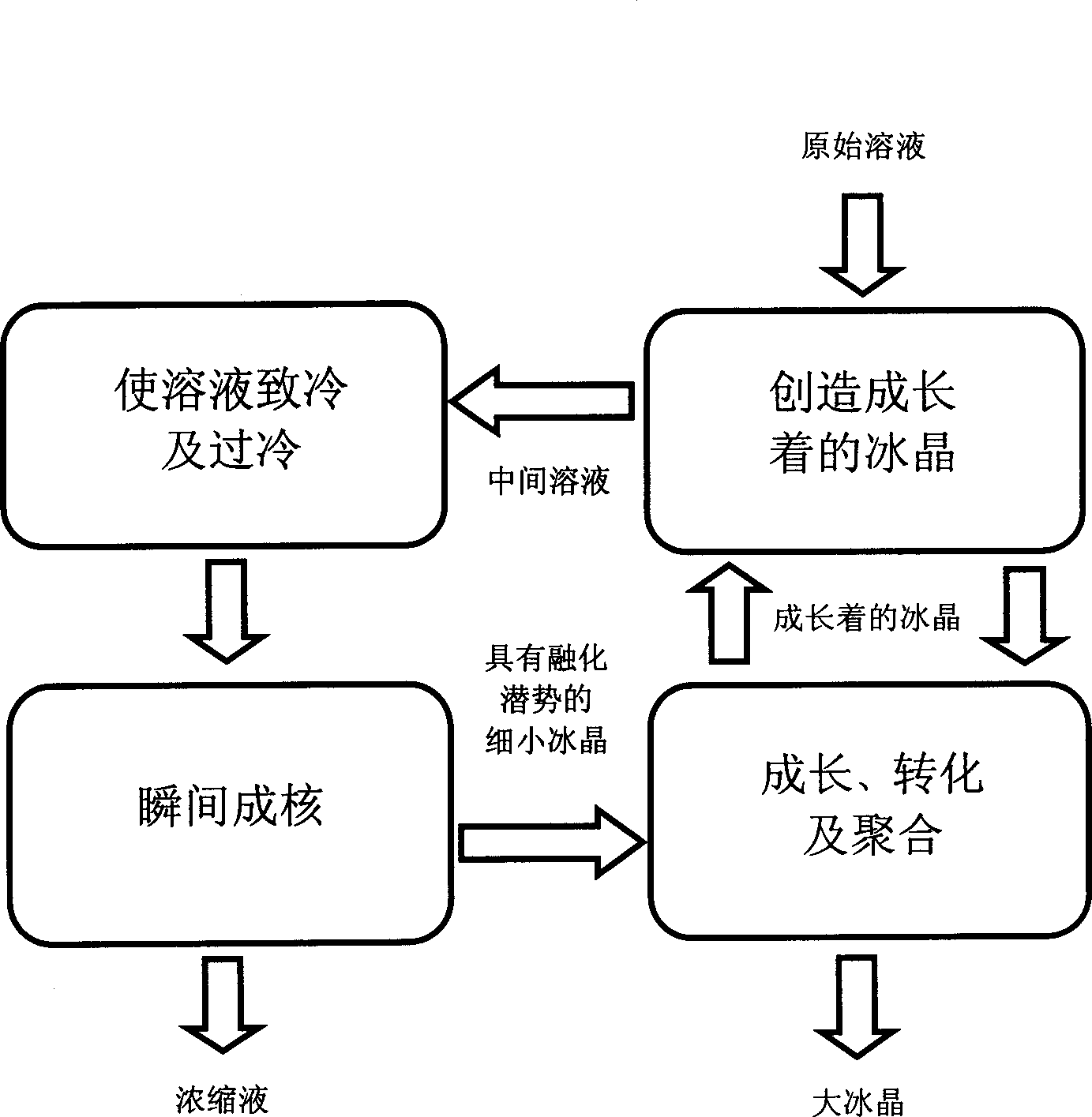

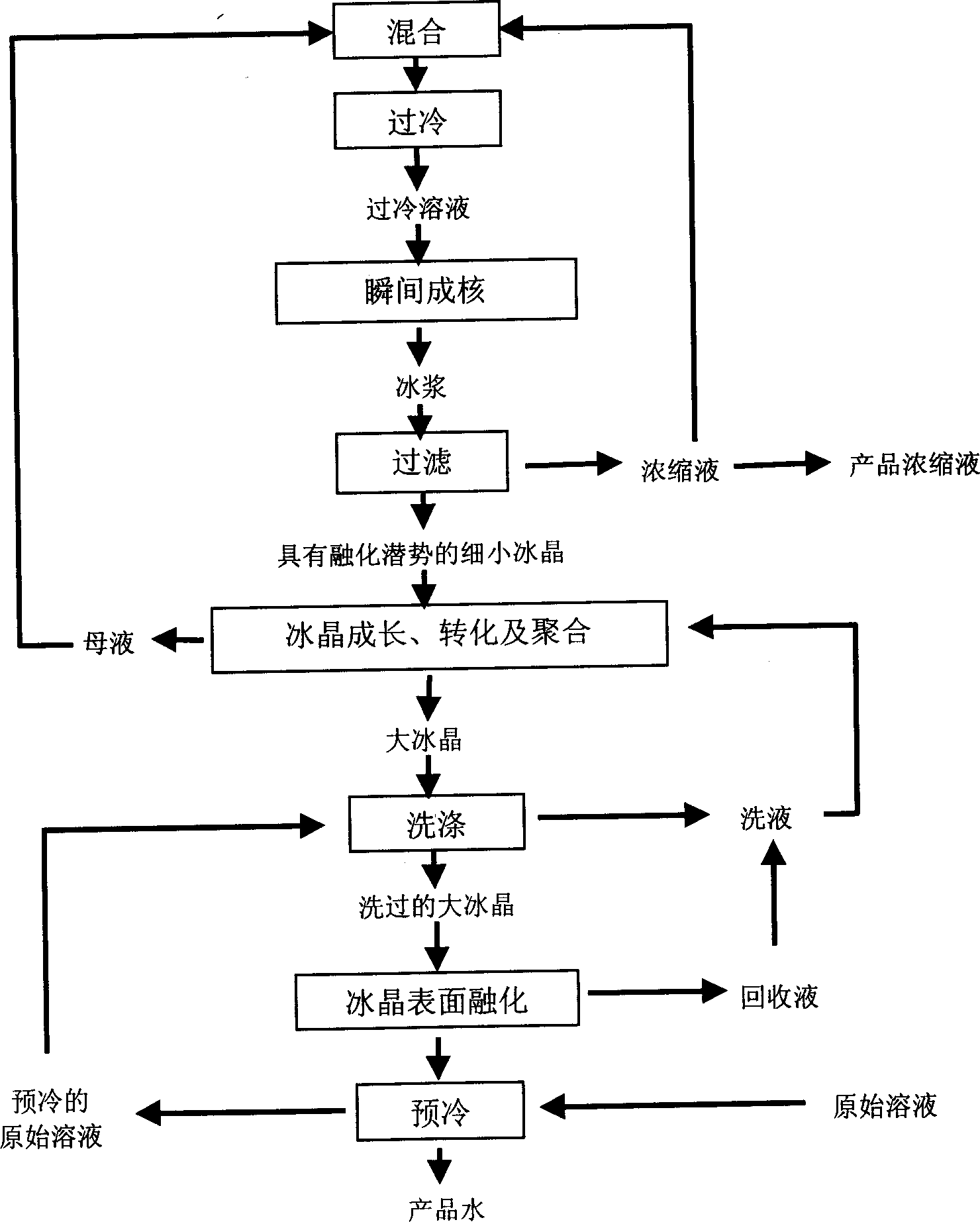

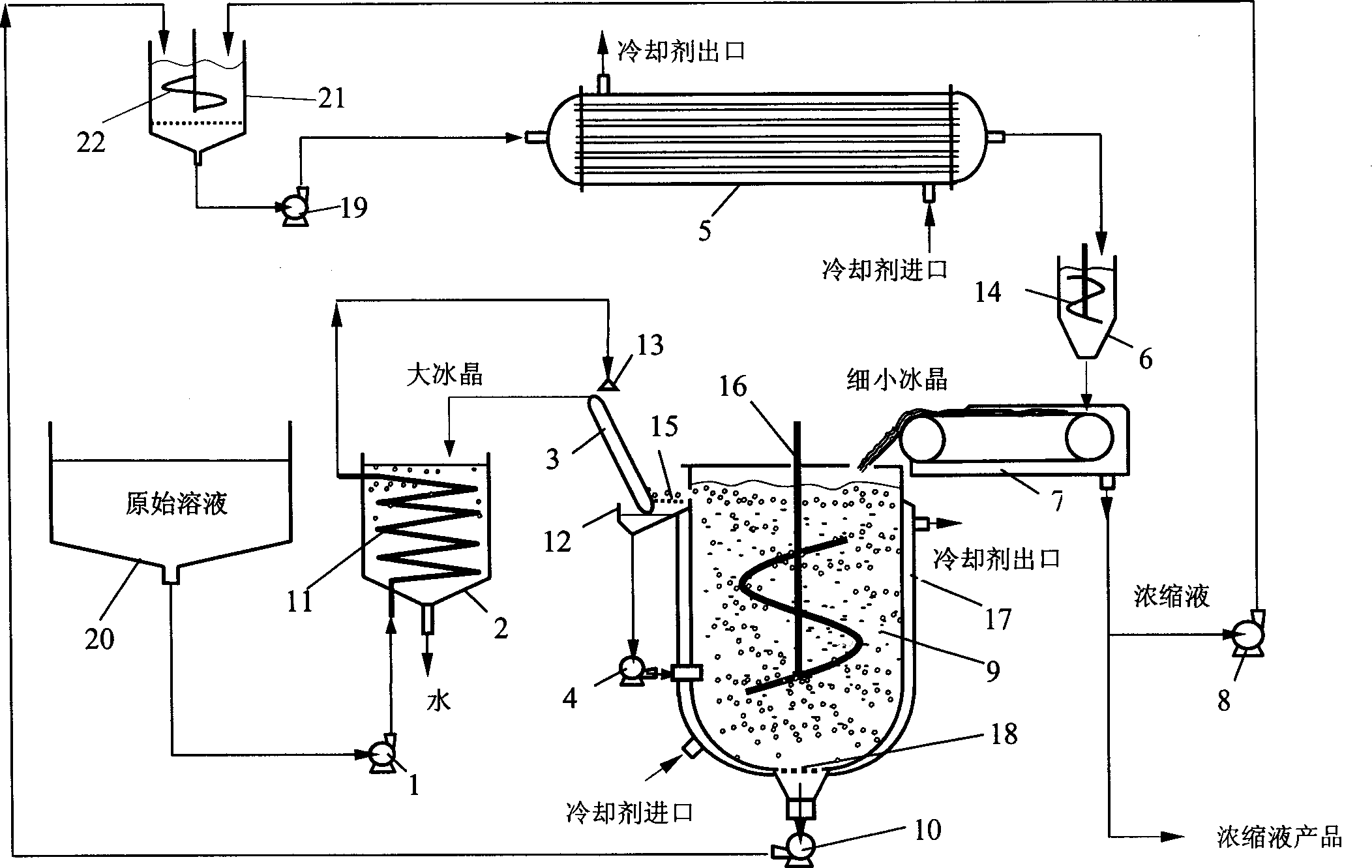

Freeze concentration for aqueous solutions

The invention is an efficient physical method of freezing and concentrating aqueous solutions based on the transformation of ice crystals. It results in a very high ice crystal growth rate, produces granular, aggregated large ice crystals without internal entrainment, and avoids scraping of ice crystals during freezing to save energy. The method mainly consists of the following processes: cooling the solution to a supercooled state without nucleation or ice formation on the heat transfer surface; instantly nucleating the supercooled solution to produce fine ice crystals and concentrating the solution; with the help of absorption-exotherm The growth, transformation and polymerization of ice crystals in a well-balanced and controlled environment produce large, granular or spherical ice crystals at high rates. Both single-stage and multi-stage operations can be used in this method and the main steps can be arranged flexibly. The equipment for implementing this method mainly includes refrigeration heat exchangers, nucleators, filters and multifunctional crystallizers, each of which has its own characteristics to meet the requirements of the method.

Owner:梁保民 +1

Method for extracting nylon from waste materials

InactiveUS20060031997A1Shorten the dissolution timeReduce the temperaturePlastic recyclingRotary piston pumpsNylon materialSolvent

The invention relates to a method for recovering nylon from a nylon-containing material by contacting the nylon-containing material with an alkanol-containing solvent at elevated temperature and at a pressure higher than the equilibrium pressure of the alkanol-containing solvent at the elevated temperature, thereby dissolving the nylon in the alkanol-containing solvent, removing the alkanol-containing solvent containing dissolved nylon from any undissolved solids, and decreasing the temperature of the alkanol-containing solvent containing dissolved nylon to precipitate the dissolved nylon.

Owner:INTERFACE INC

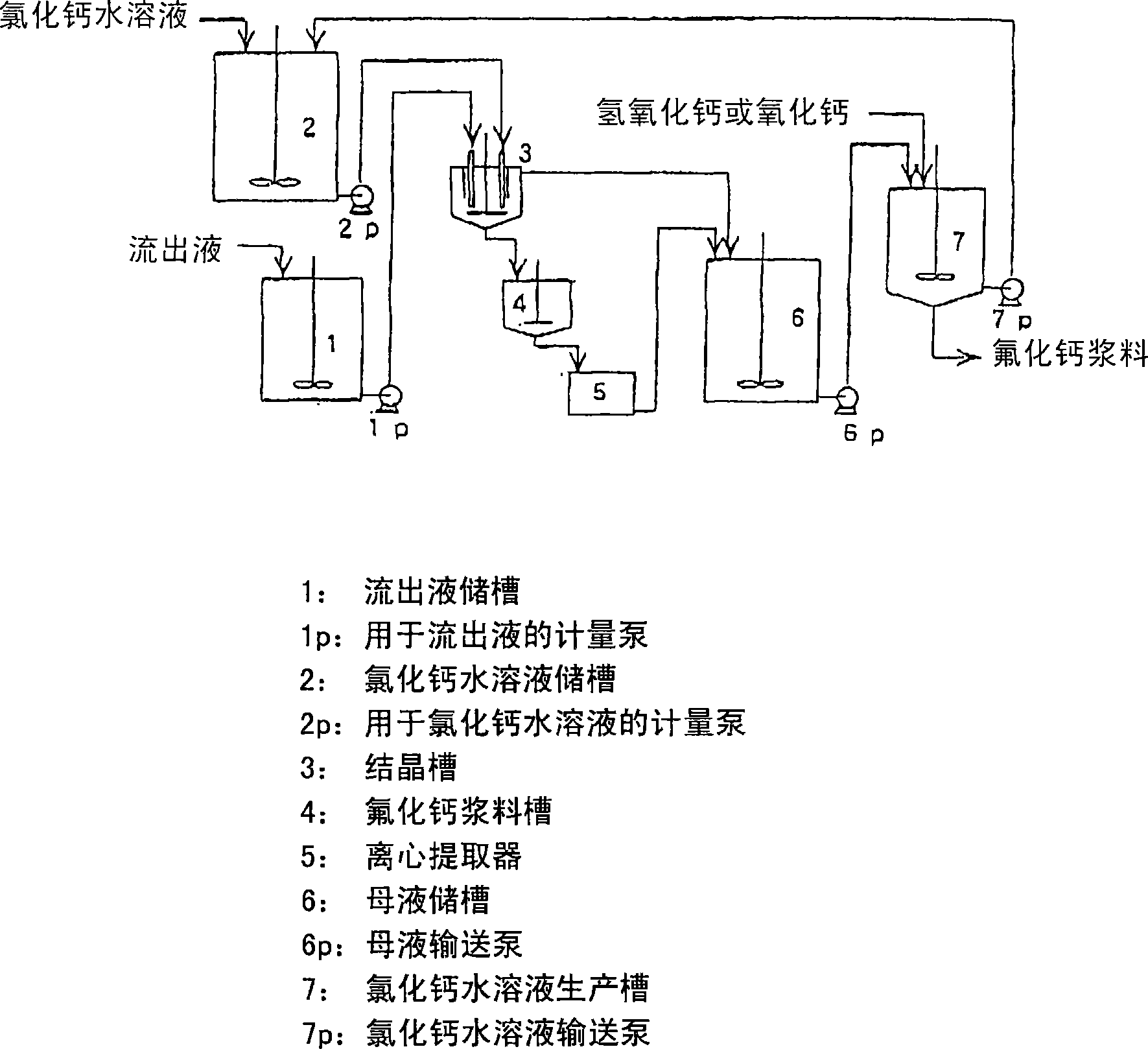

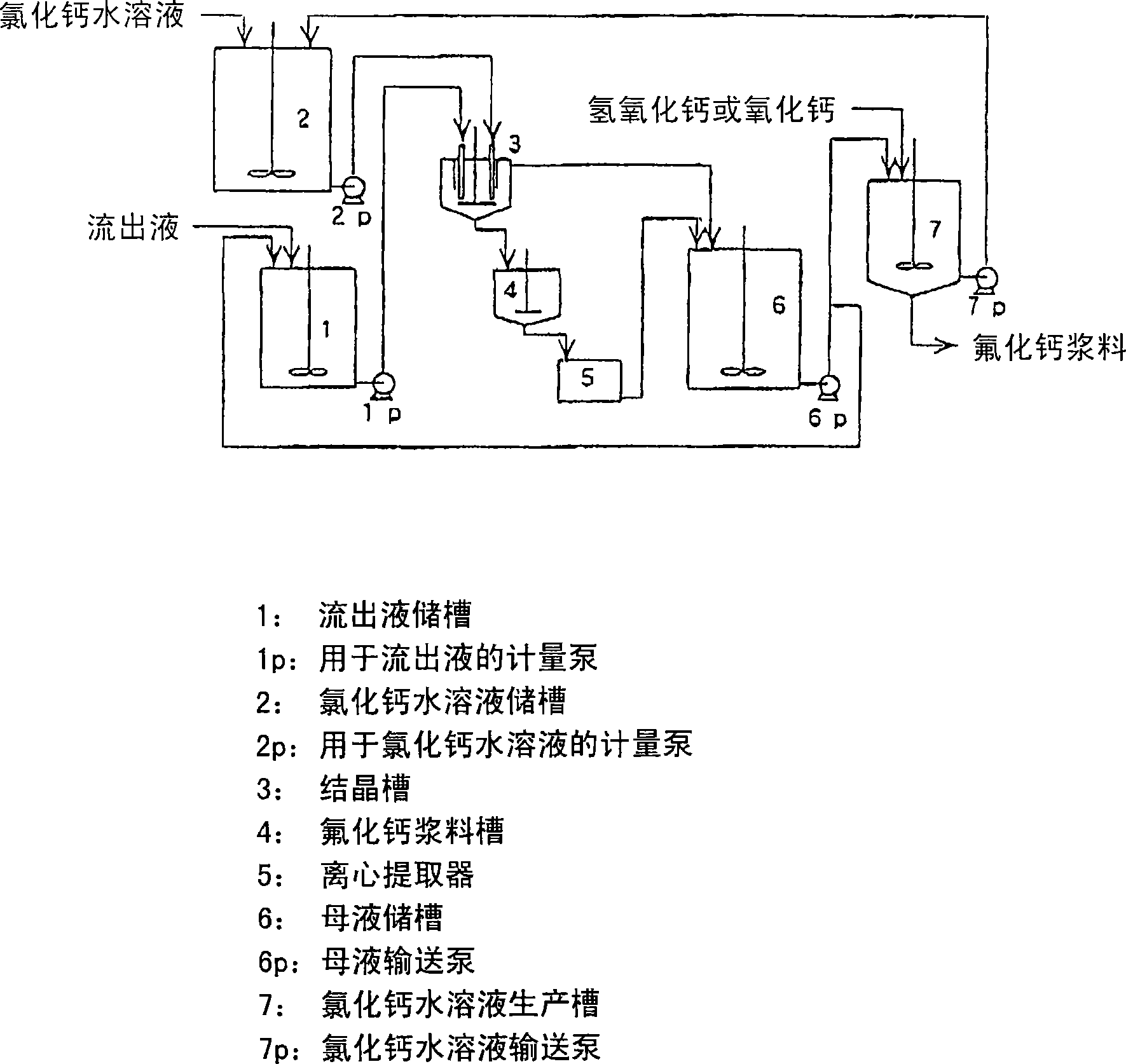

Method for producing calcium fluoride, reusing method and recycling method thereof

ActiveCN1906129AWater treatment parameter controlSpecific water treatment objectivesSolubilityLarge particle

In order to recycle the fluoride, calcium fluoride having a particle size and purity suitable for the production of hydrogen fluoride is recovered from the fluoride-containing effluent or the hydrofluoric acid-containing effluent. The method involves reacting a fluoride-containing effluent or a hydrofluoric acid-containing effluent with an aqueous solution of calcium chloride under acidic conditions formed by hydrochloric acid, under which calcium fluoride has a relatively high solubility. Calcium fluoride can be precipitated with high purity and large particle size. The hydrochloric acid residue from or formed by the reaction reacts with inexpensive calcium compounds such as calcium hydroxide, calcium oxide, and calcium carbonate to produce an aqueous calcium chloride solution that is reused to treat effluents containing hydrofluoric acid . The obtained calcium fluoride can be used as a raw material for producing hydrogen fluoride, and the remaining calcium chloride aqueous solution can be provided for other industrial purposes.

Owner:MORITA CHEMICAL IND CO LTD

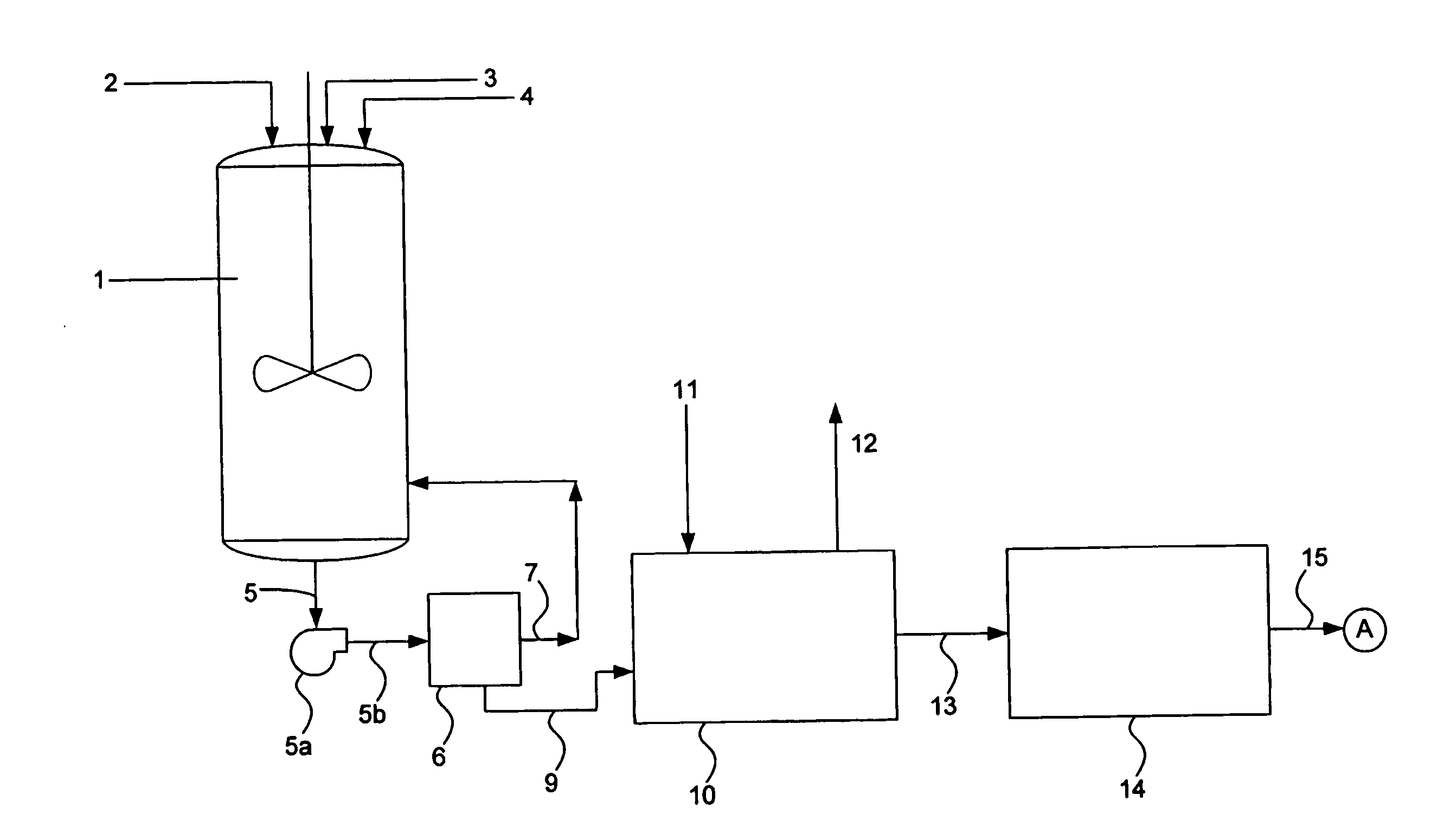

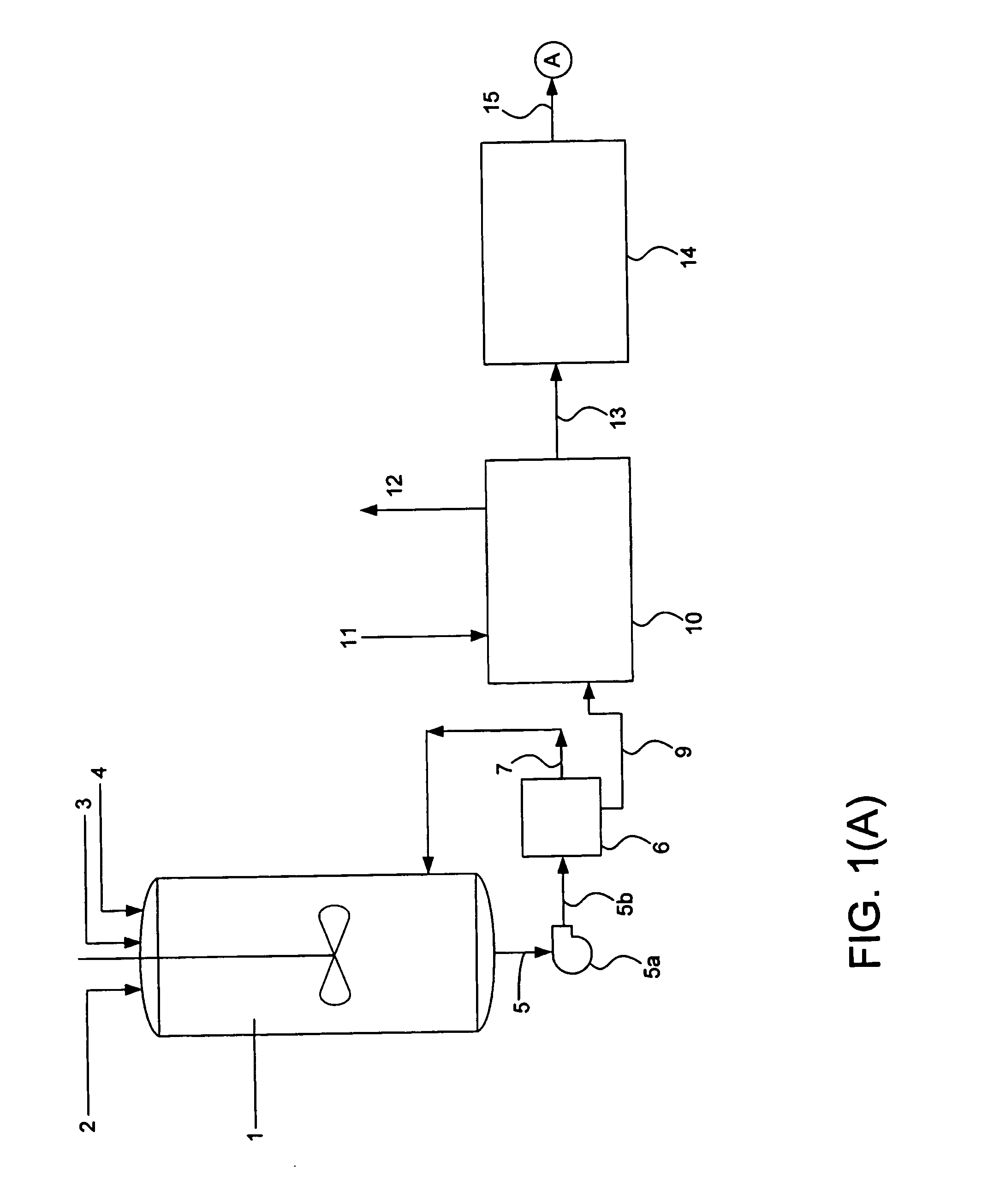

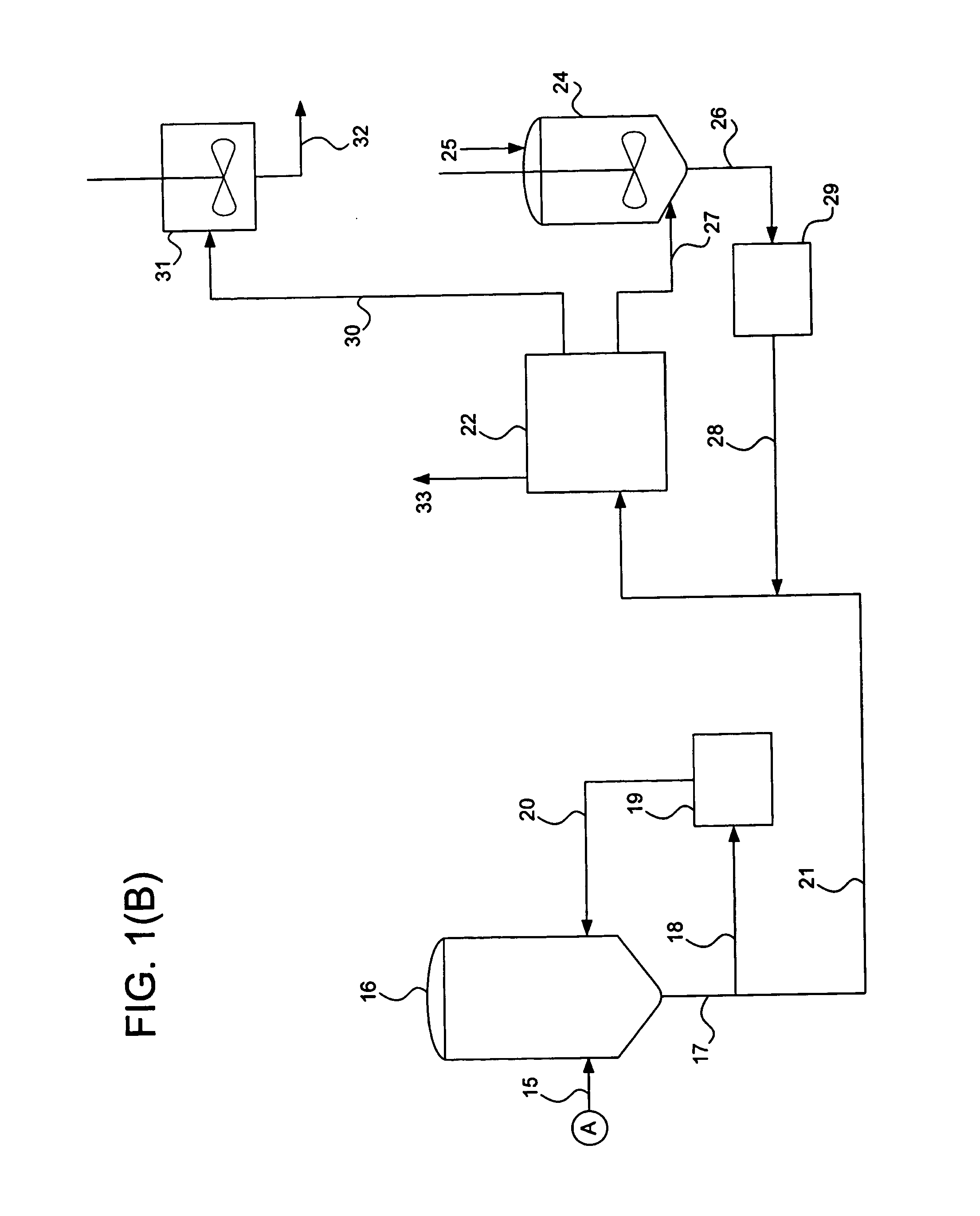

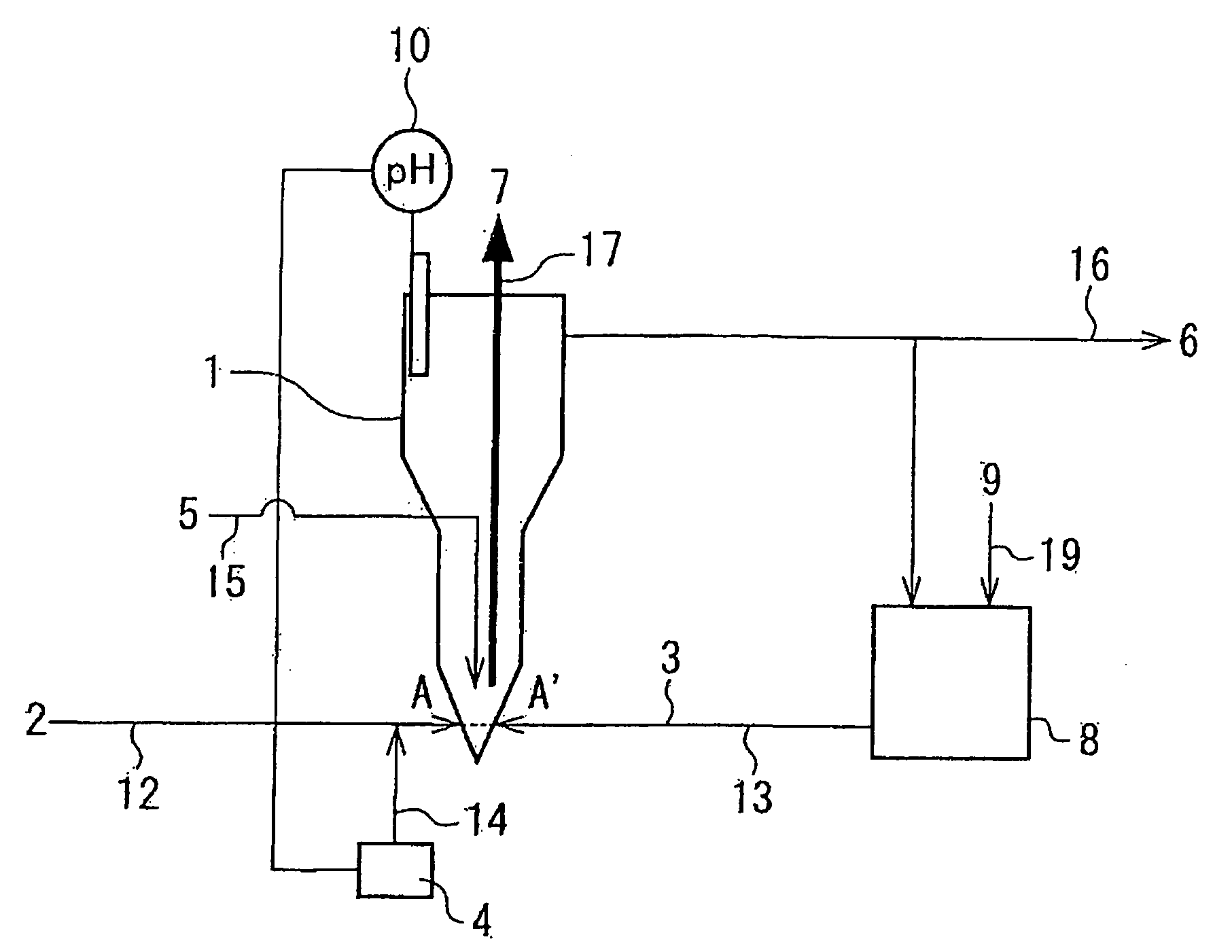

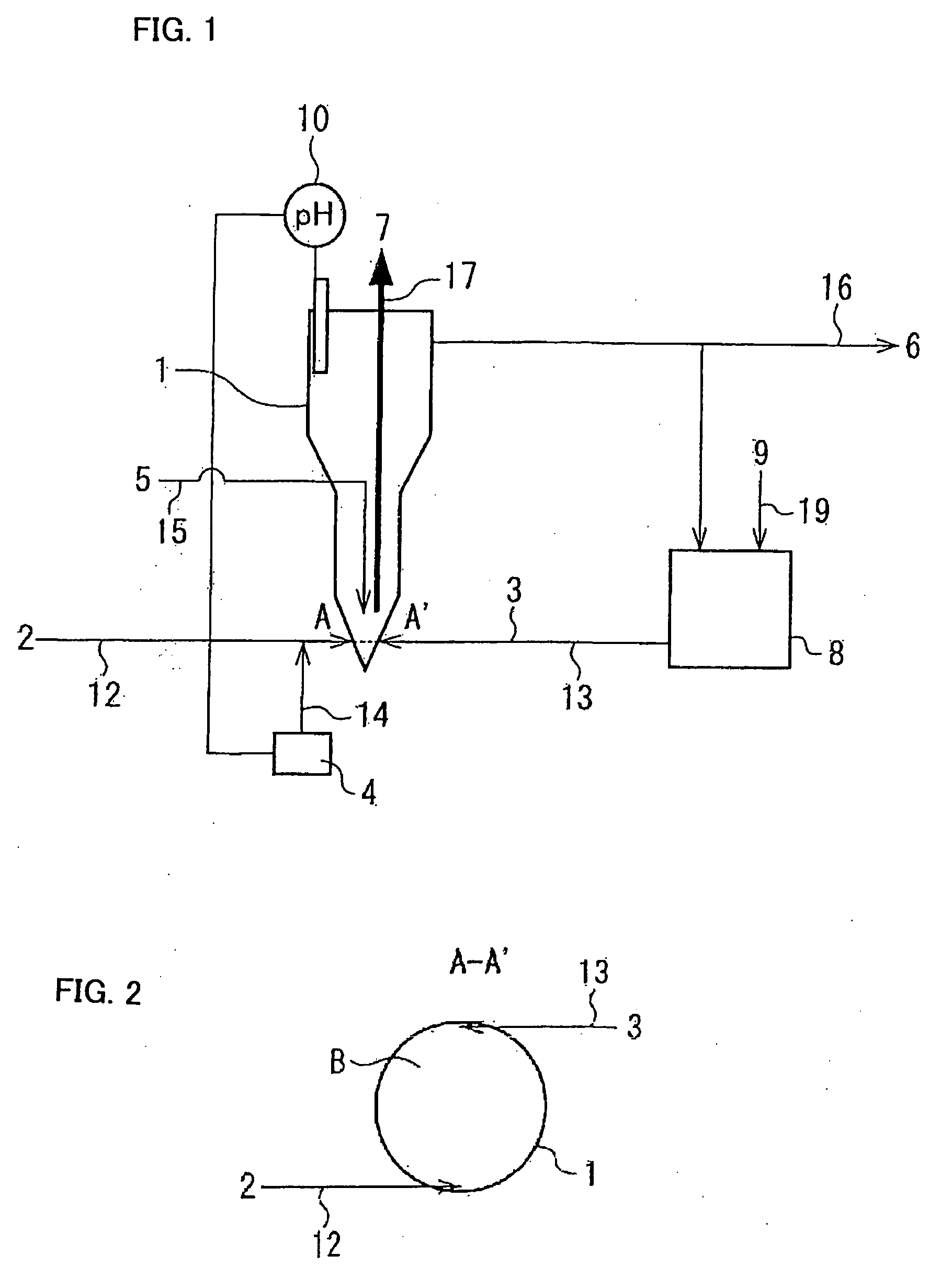

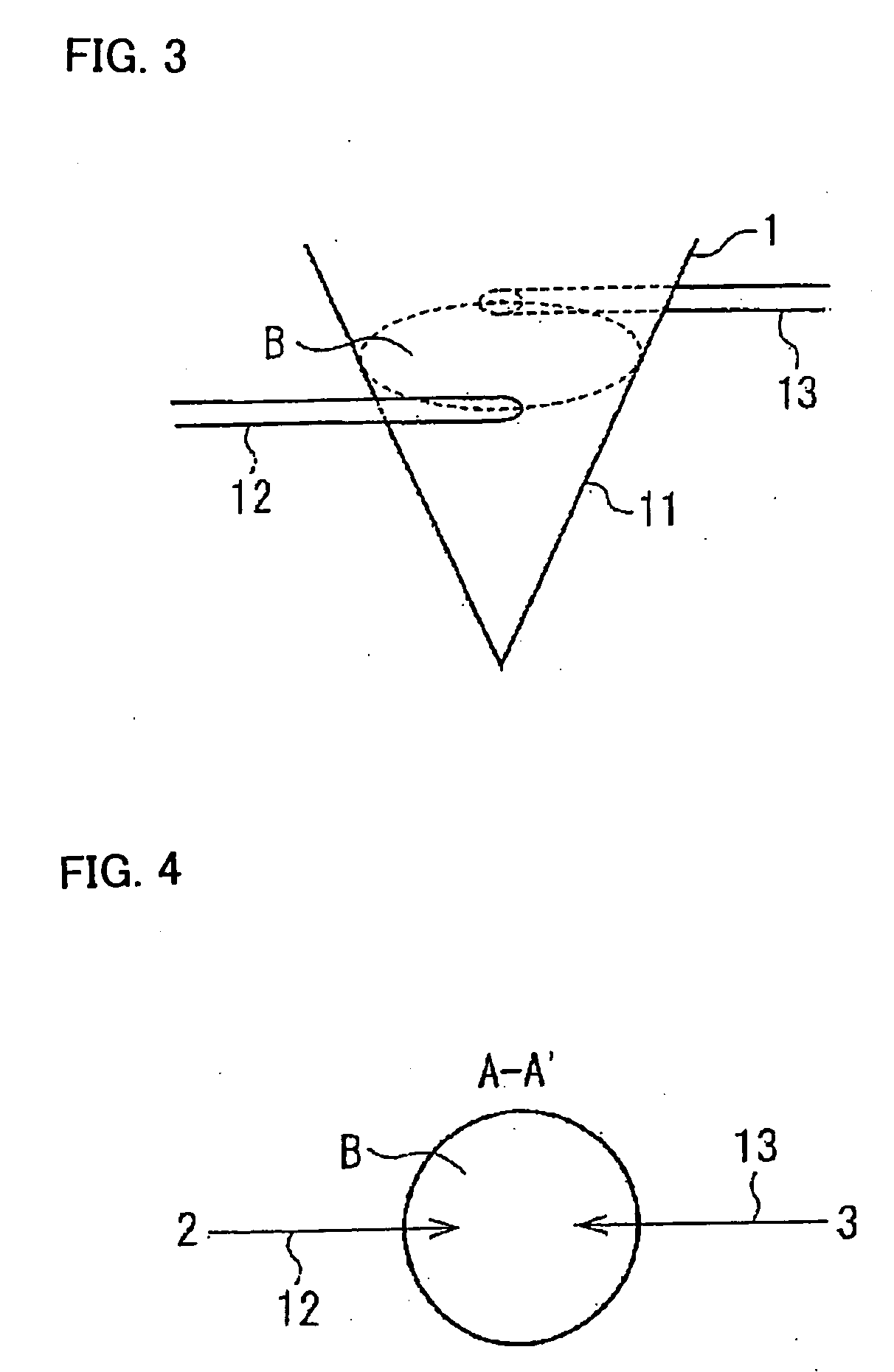

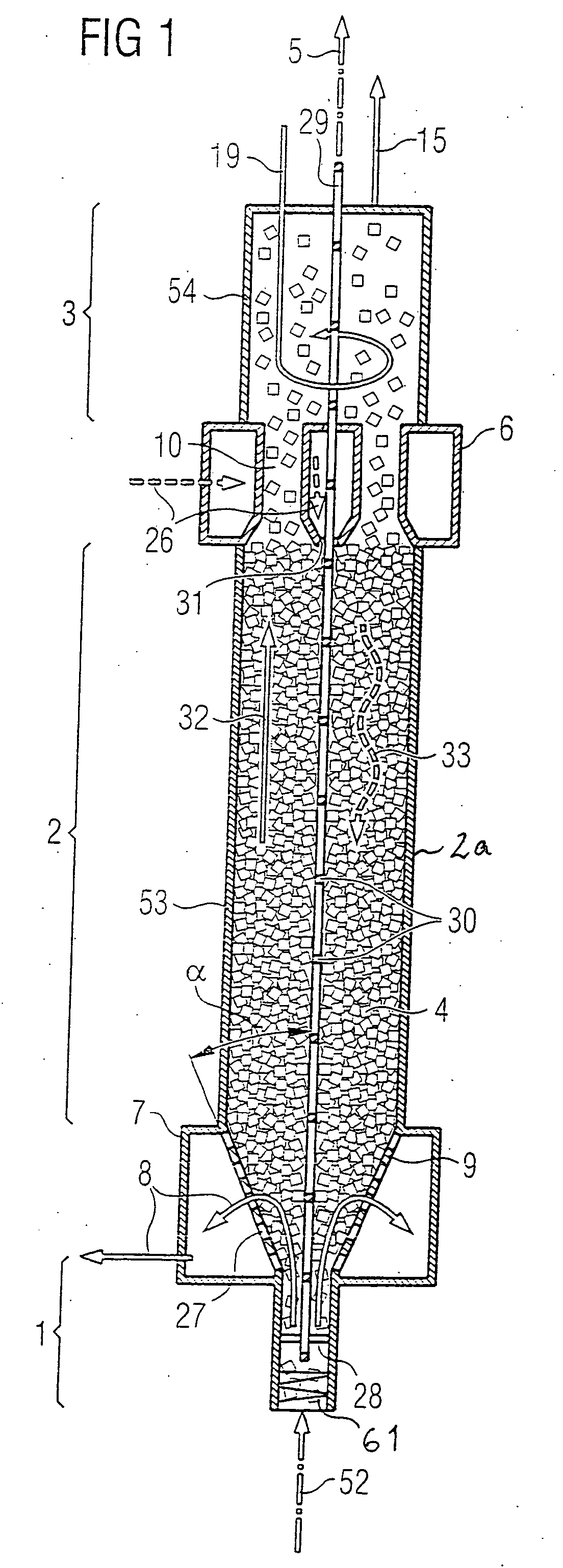

Method and apparatus for removing ions in liquid through crystallization method

InactiveUS20060196835A1MoreMix thoroughlyWater/sewage treatment by centrifugal separationWater contaminantsPhysical chemistryChemical agent

It is an object of the present invention to improve the phosphorus recovery rate in a method and apparatus for removing ions to be removed in a liquid to be treated by crystallizing out crystal particles of a poorly soluble salt of the ions to be removed in the liquid to be treated in a crystallization reaction tank. As one means for attaining this object, in one embodiment of the present invention there is provided a method for removing ions to be removed in a liquid to be treated by crystallizing out crystal particles of a poorly soluble salt of the ions to be removed in the liquid to be treated in a crystallization reaction tank, which comprises adding a chemical agent required for the crystallization reaction into a part of a treated liquid flowing out from the crystallization reaction tank and dissolving the chemical agent therein, and supplying the resulting solution into the crystallization reaction tank as a circulating liquid, wherein the liquid to be treated and the circulating liquid are introduced into the crystallization reaction tank tangentially to a transverse section of the crystallization reaction tank.

Owner:EBARA CORP

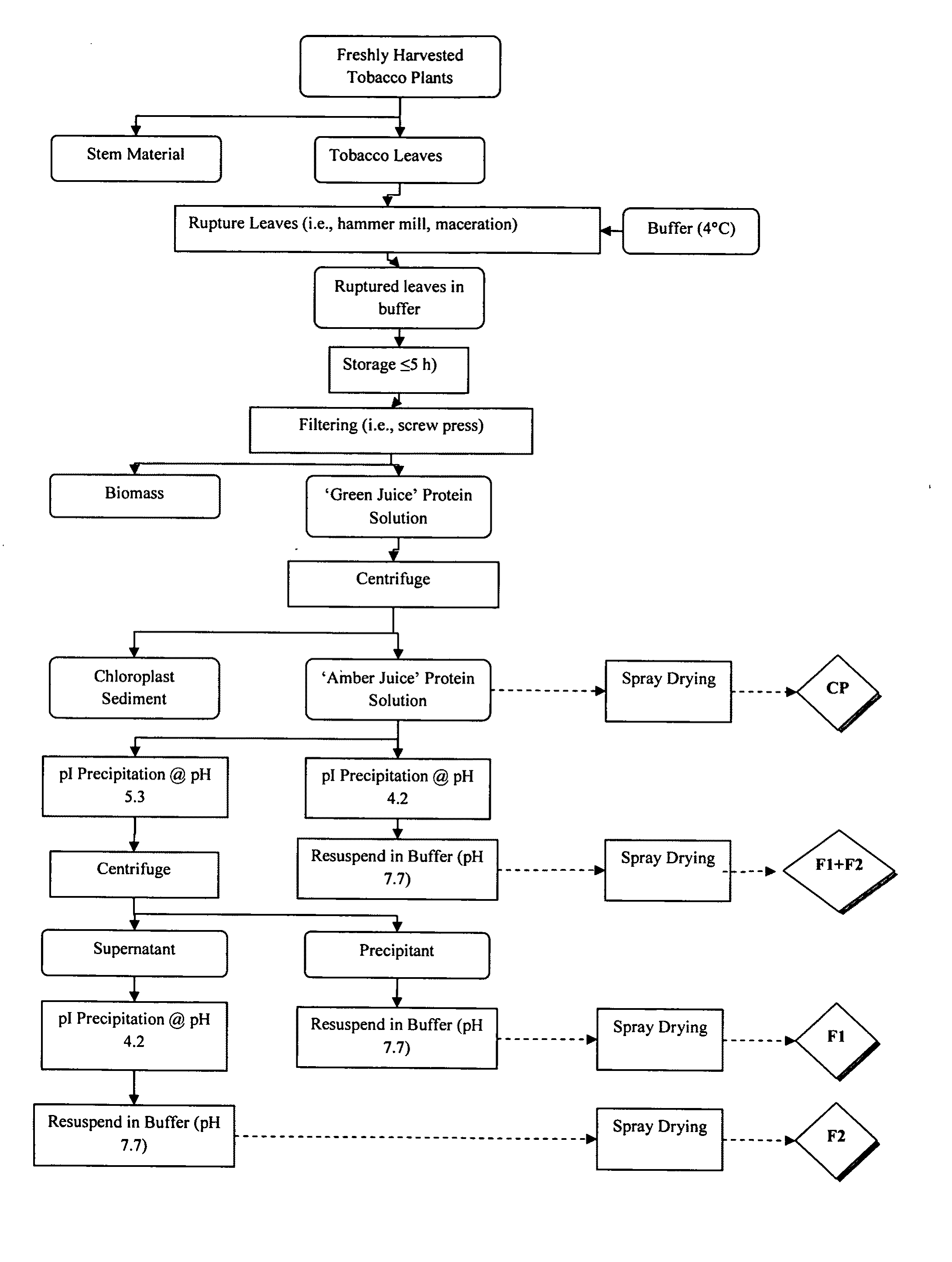

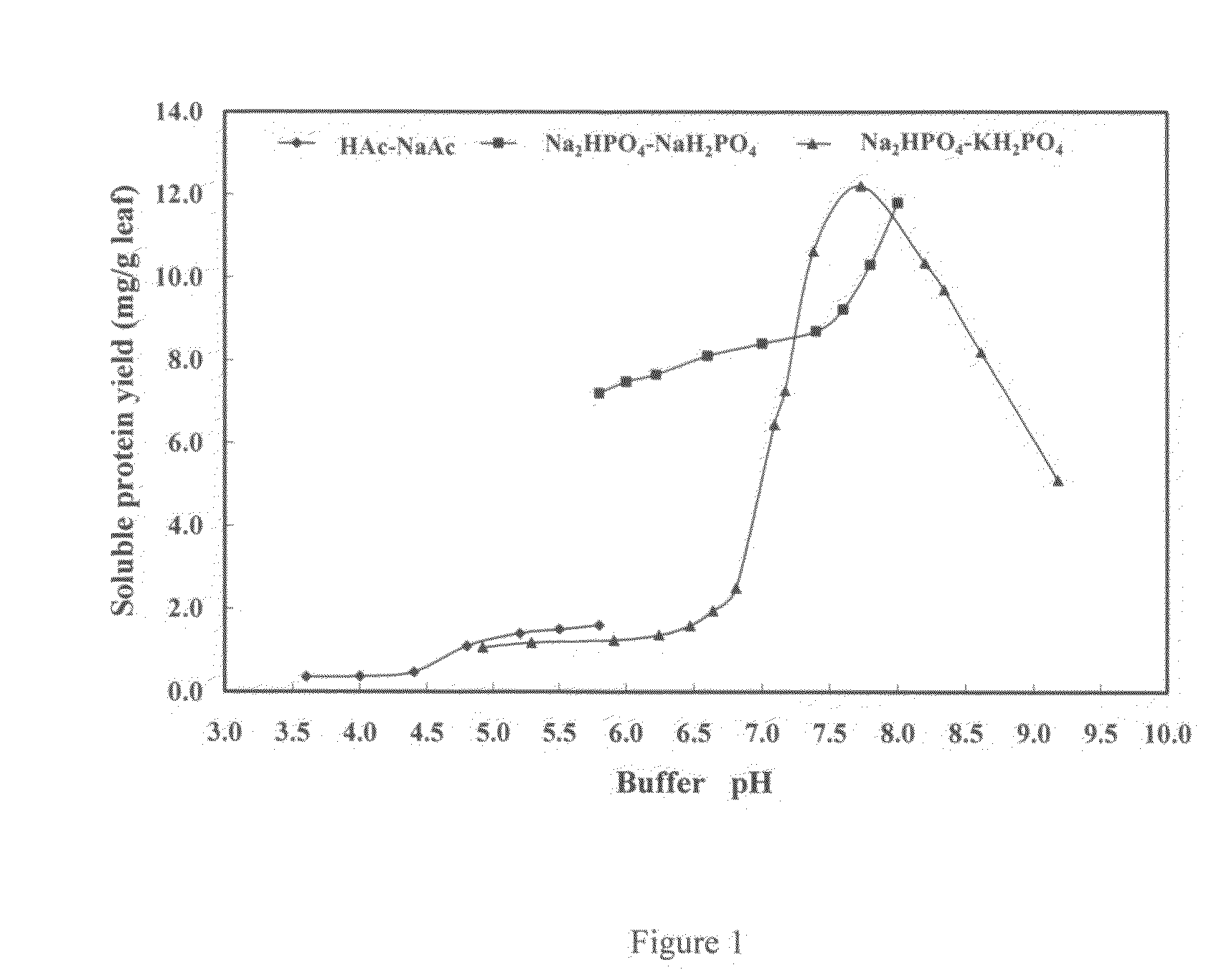

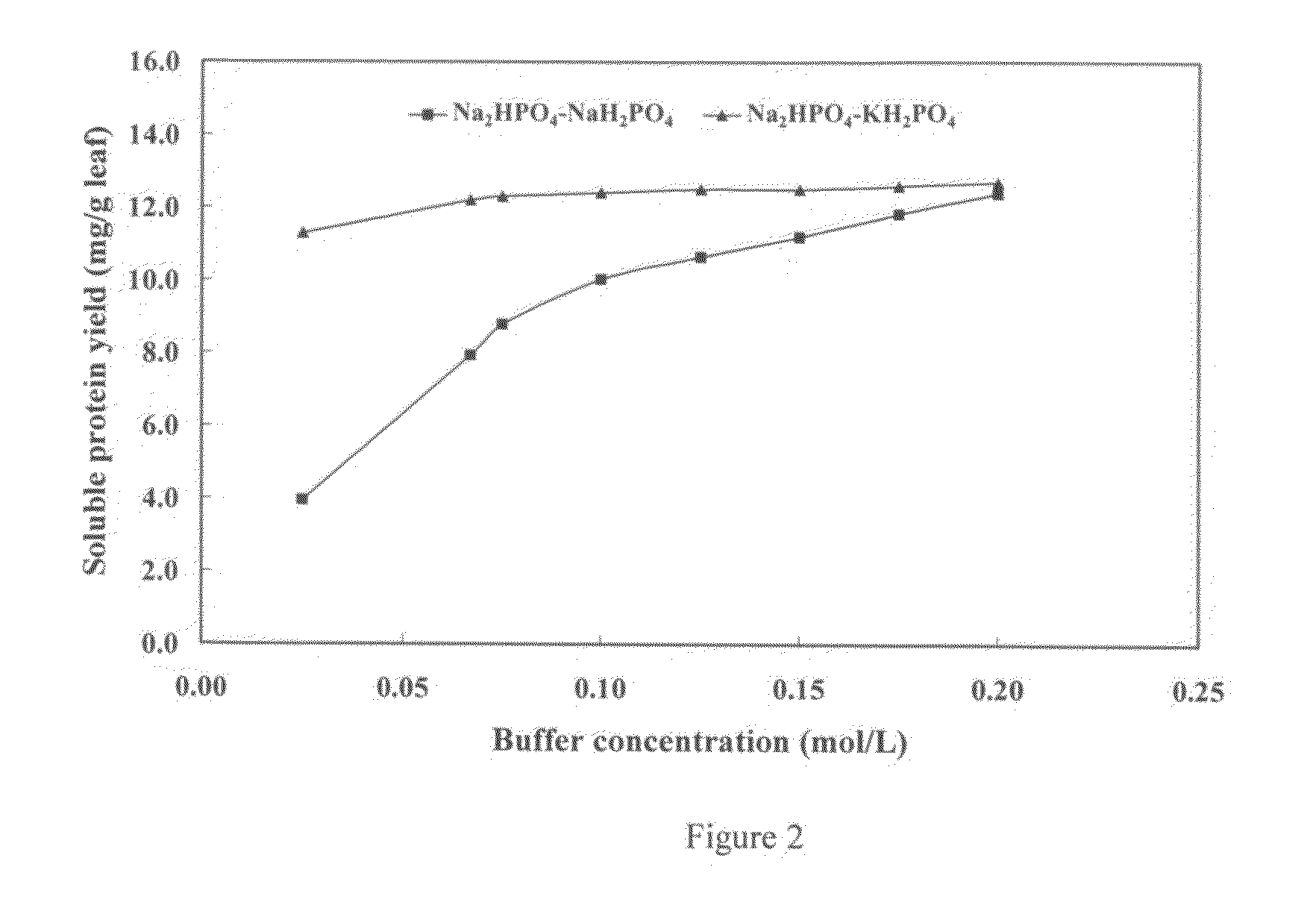

Novel methods for recovery of leaf proteins

ActiveUS20100093054A1Minimizes numberScalable to levelSolvent extractionPeptide preparation methodsIndustrial scaleComputational biology

A novel method for processing soluble plant leaf proteins is described. While leaf proteins are considered potentially the most abundant source of protein in nature, the lack of efficient processing techniques for leaf proteins has limited their commercial use. The method described in this patent provides a means of extracting and purifying leaf proteins from plants which is suitable for leaf protein production on an industrial scale.

Owner:LEAFPRO LLC +1

Washing Apparatus, A Method Of Purifying A Wash Material And Use Of The Washing Apparatus

ActiveUS20060013748A1Exhaust apparatusElement comparisonBiomedical engineeringEnvironmental engineering

Owner:EVONIK SUPERABSORBER GMBH

apparatus and process for producing crystals

InactiveUS20110288060A1Organic active ingredientsNervous disorderUltrasonic radiationUltrasound Radiation

This invention provides an oscillating baffled reactor apparatus for preparing crystalline particles of at least one substance comprising: a reactor vessel; means for supplying a first flowing stream; means for oscillating fluid within the reactor vessel; a plurality of baffles; source of ultrasonic radiation; and means for collecting said particles.

Owner:PROSONIX

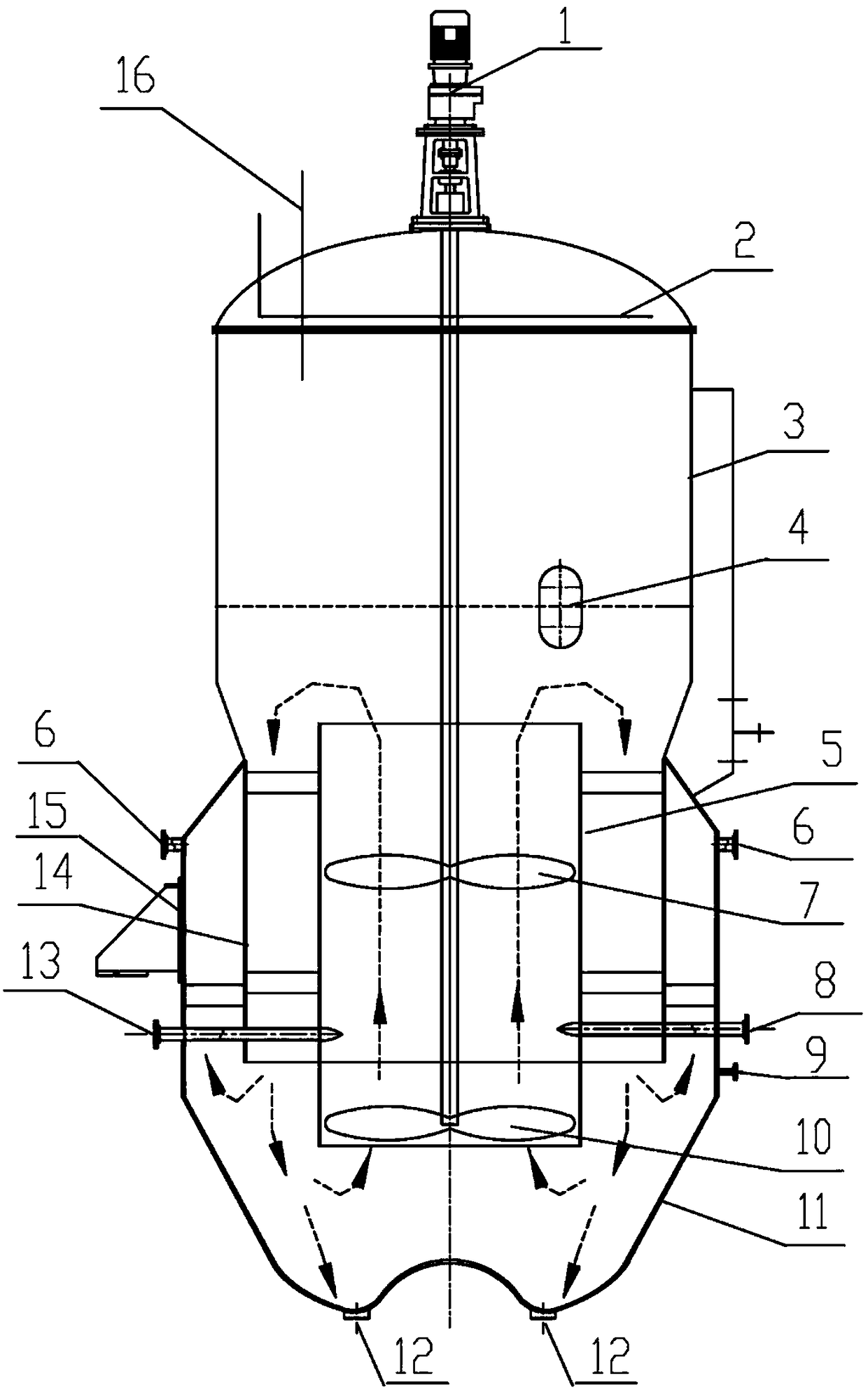

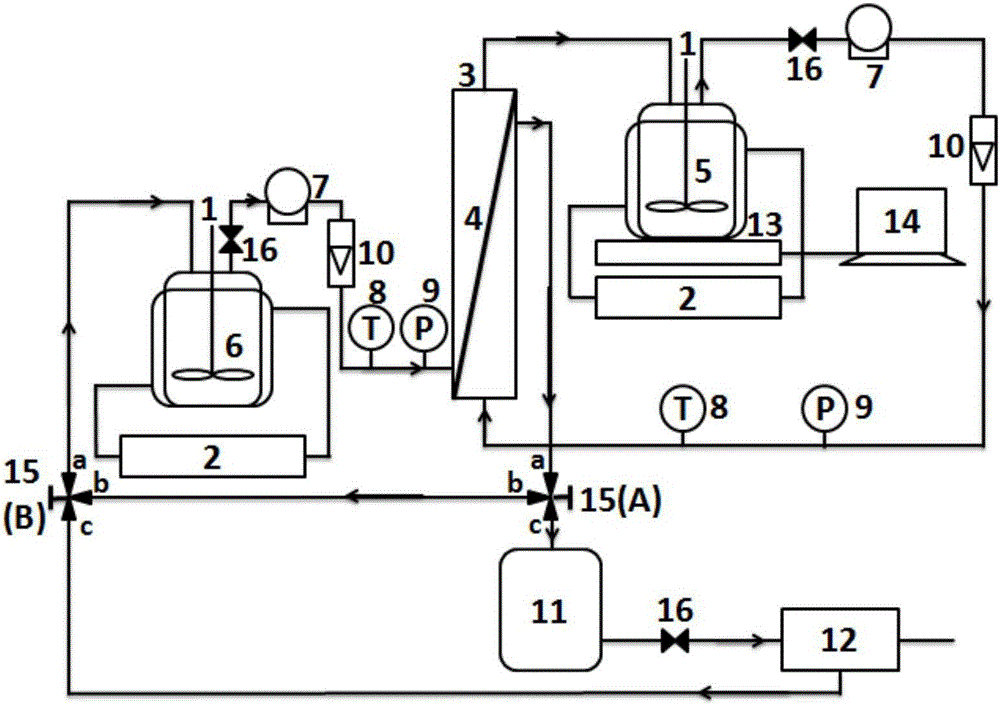

Self-circulating crystallizer and multistage continuous crystallization method

ActiveCN108939599AReduce the chance of collision nucleationStable particle sizeEvaporator accessoriesSolution crystallizationGranularityEvaporation

The invention relates to a self-circulating crystallizer and a multistage continuous crystallization method. The crystallizer sequentially comprises a kettle head, an upper cylinder body, a middle cylinder body and a bottom hole-shrinkage cylinder body with a W-shaped bottom from top to bottom, wherein a steam outlet and / or a feeding hole are / is arranged on the kettle head, an annular spraying pipe is arranged at the lower part of the kettle head; a middle straight cylinder section is arranged in the middle cylinder body, a flow guiding cylinder is arranged in the middle straight cylinder section, and a stirrer is arranged in the flow guiding cylinder; the diameter of the middle cylinder body is larger than that of the upper cylinder body, and the diameter of the upper cylinder body is larger than that of the middle cylinder body; and the lower part of the upper cylinder body and the upper part of the middle cylinder body are respectively connected with the circumference of the top ofthe middle straight cylinder section via a hole-shrinkage transition section, and a discharging hole is formed in the W-shaped bottom. The invention provides the method for realizing multistage continuous evaporation, cooling or reaction crystallization through the series connection of the crystallizer, the prepared crystals are large in granularity and uniform in particle size, the problems thatthe product granularity is small, equipment is seriously scaled, a pipeline is blocked, and the like in the continuous crystallization process are improved, and the operation period of the continuouscrystallization process is prolonged.

Owner:TIANJIN UNIV

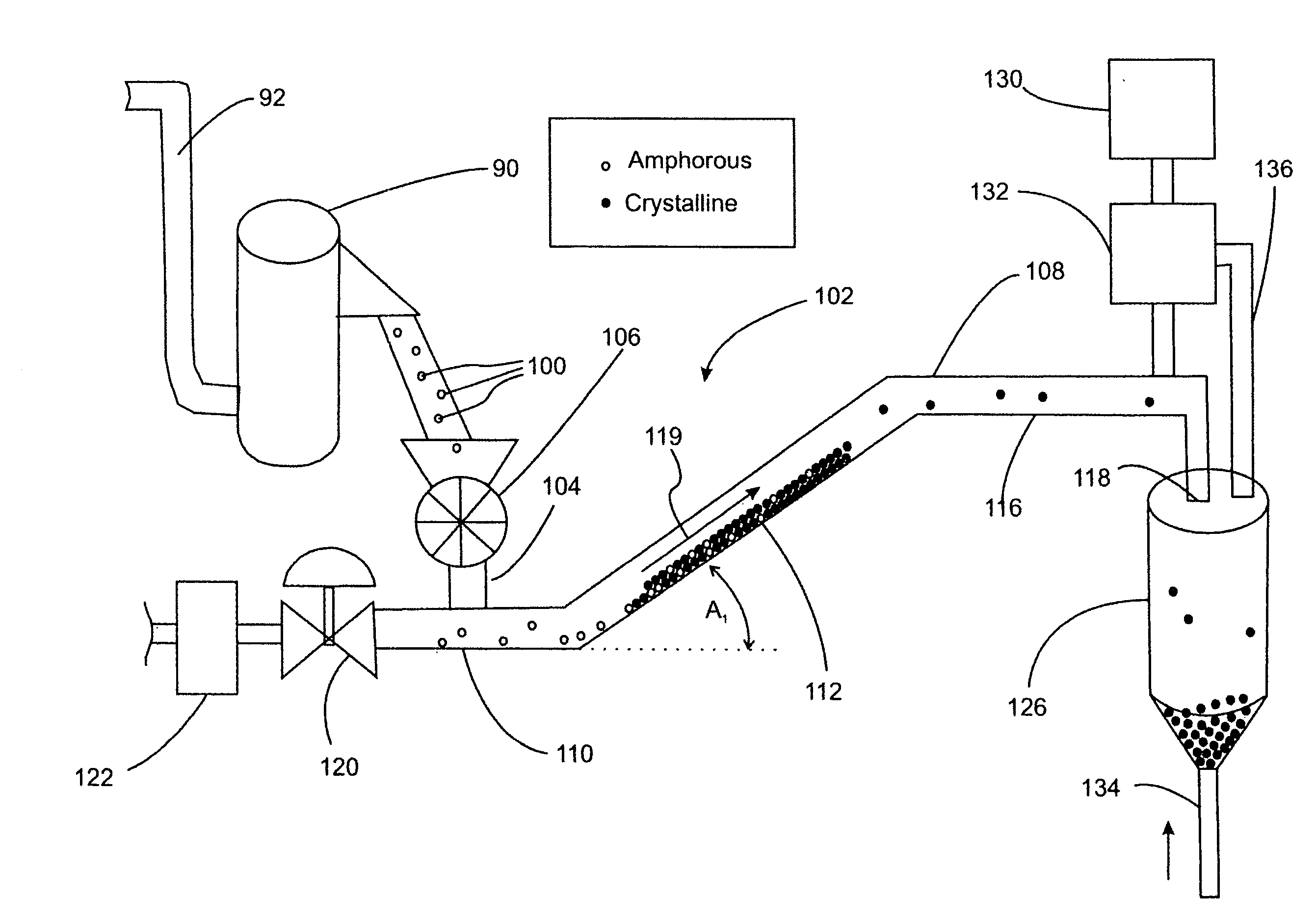

Crystallizing conveyor

ActiveUS20070274789A1Promote crystallizationSave a lot of costCrystallization by component evaporationBulk conveyorsProduct gasEngineering

A method of crystallizing a plurality of polymeric pellets includes a step of introducing the pellets into a pneumatic conveying system with an initial average temperature. The plurality of polymeric pellets are pneumatically transferred from the inlet to an outlet with a conveying gas. While residing within the conveying system, the pellets have a sufficient temperature for crystallization to occur. A pneumatic conveying system implementing the methods of the invention is also provided.

Owner:ALPEK POLYESTER SA DE CV

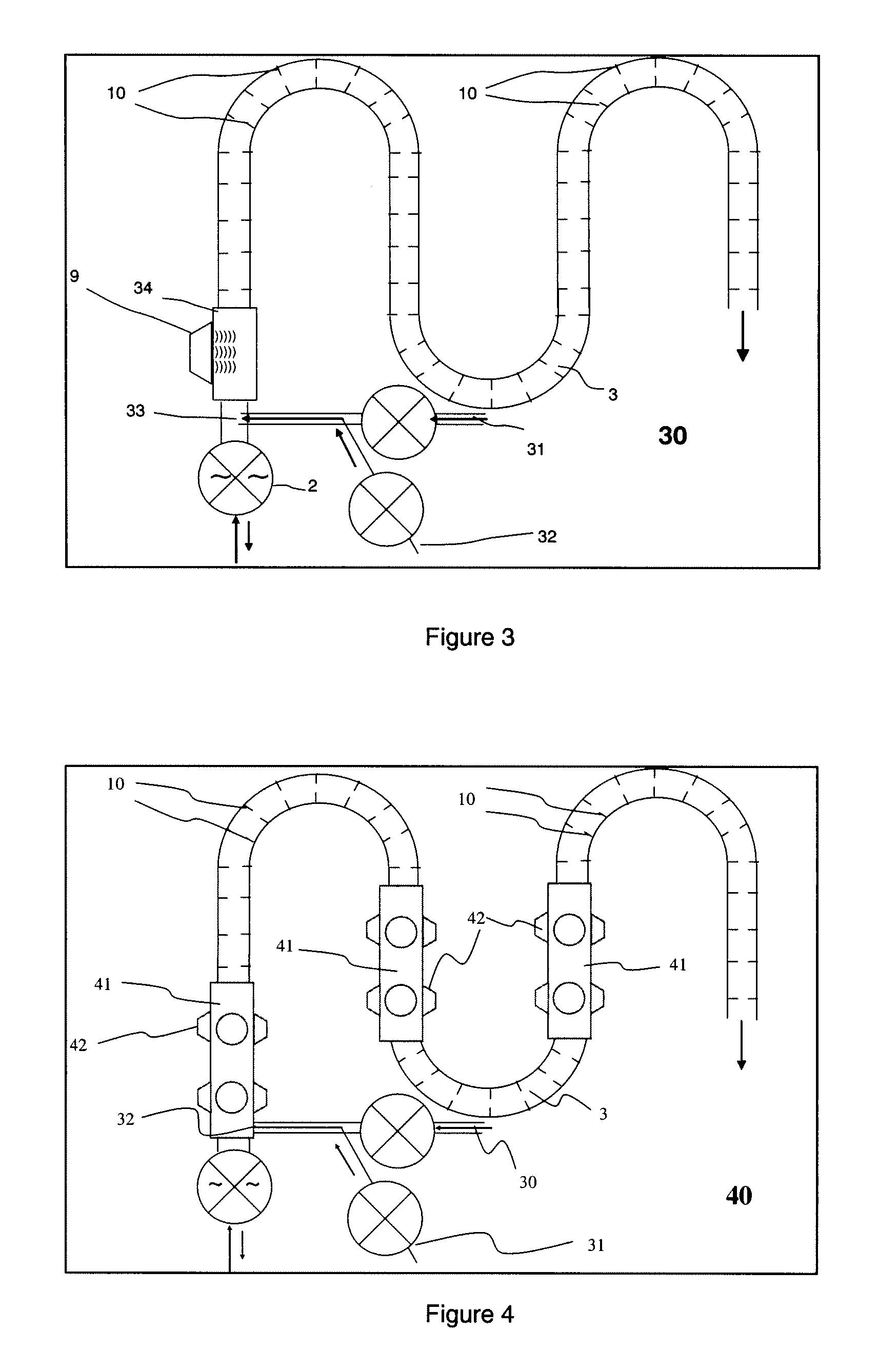

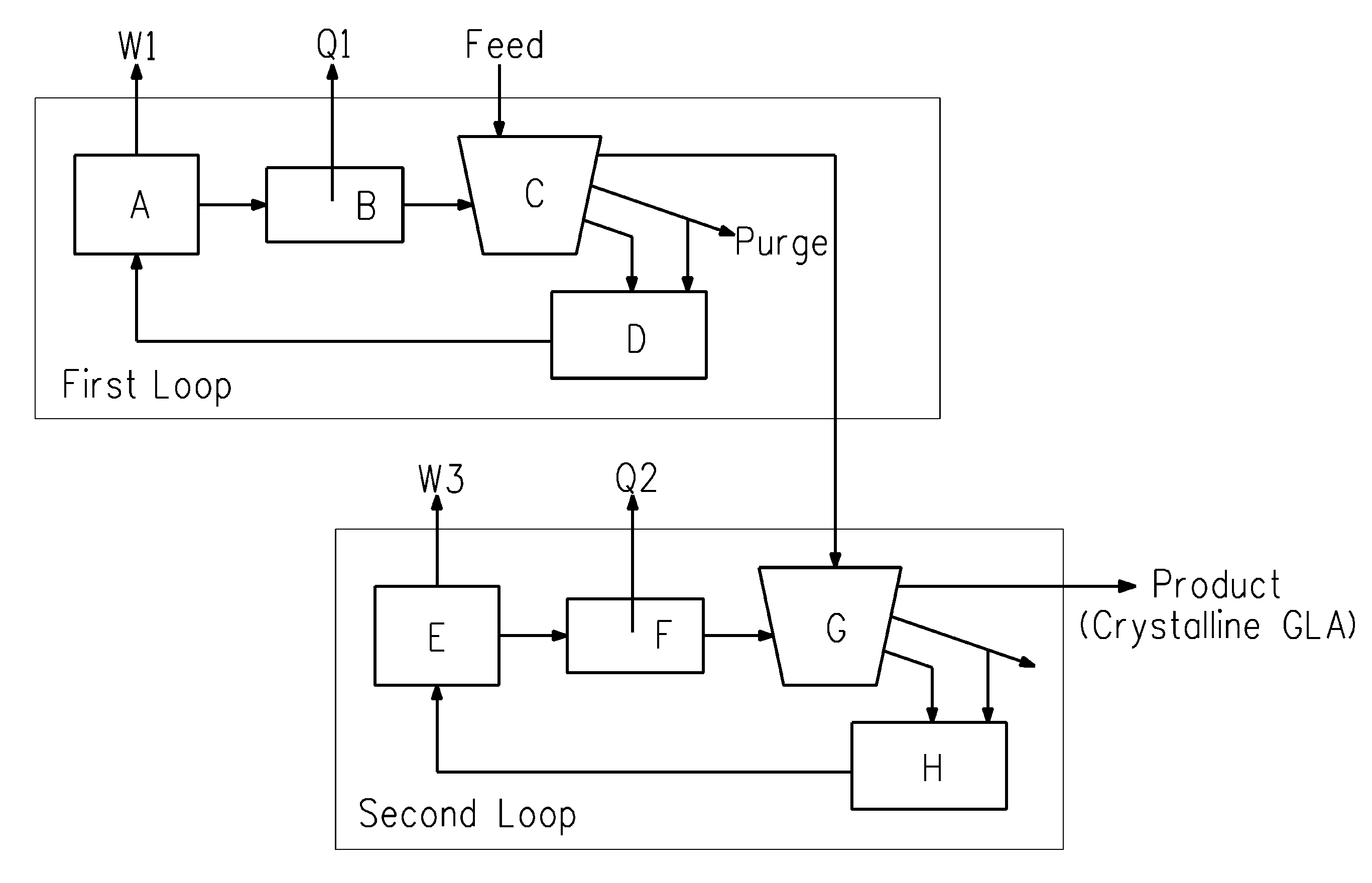

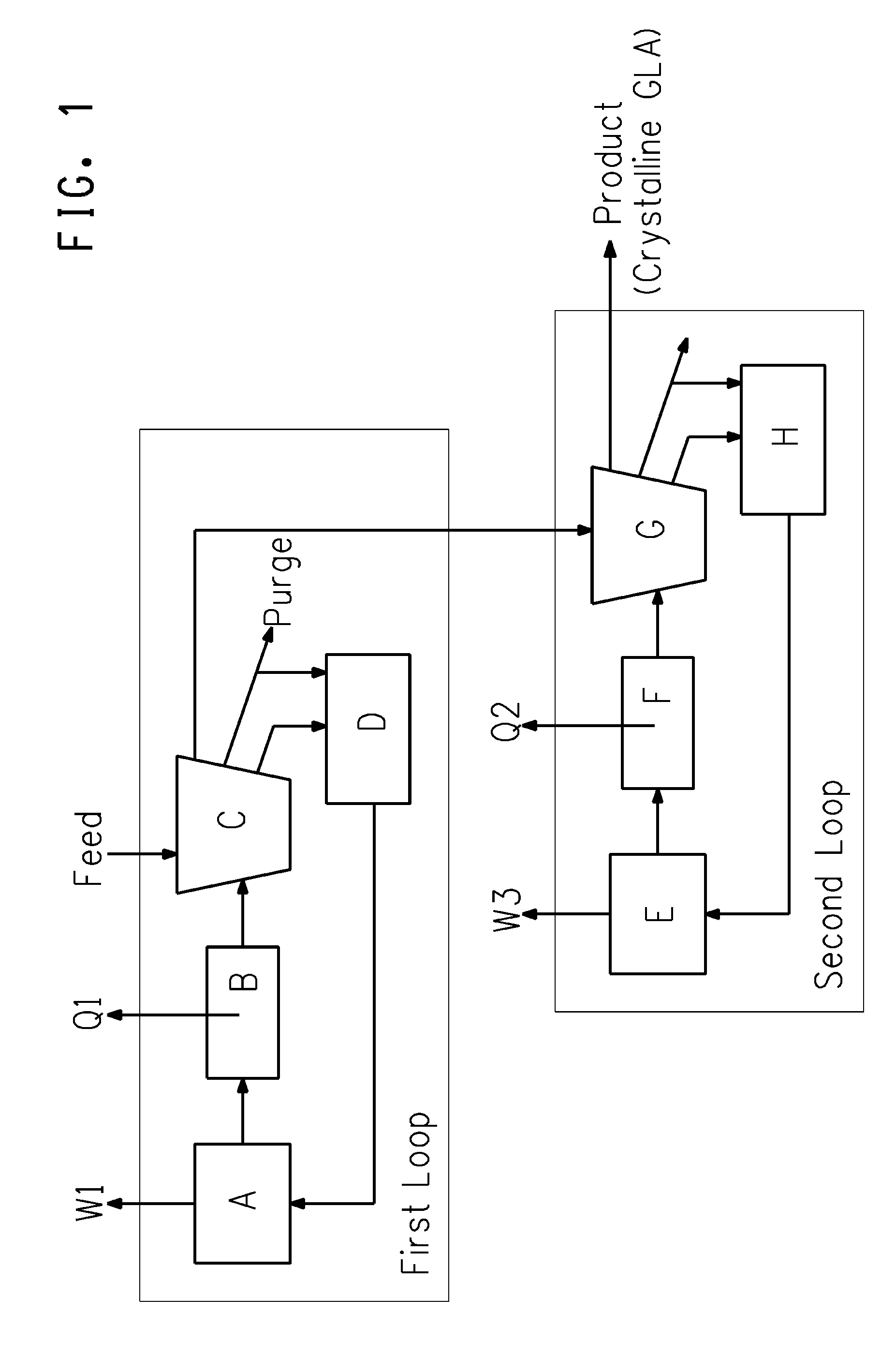

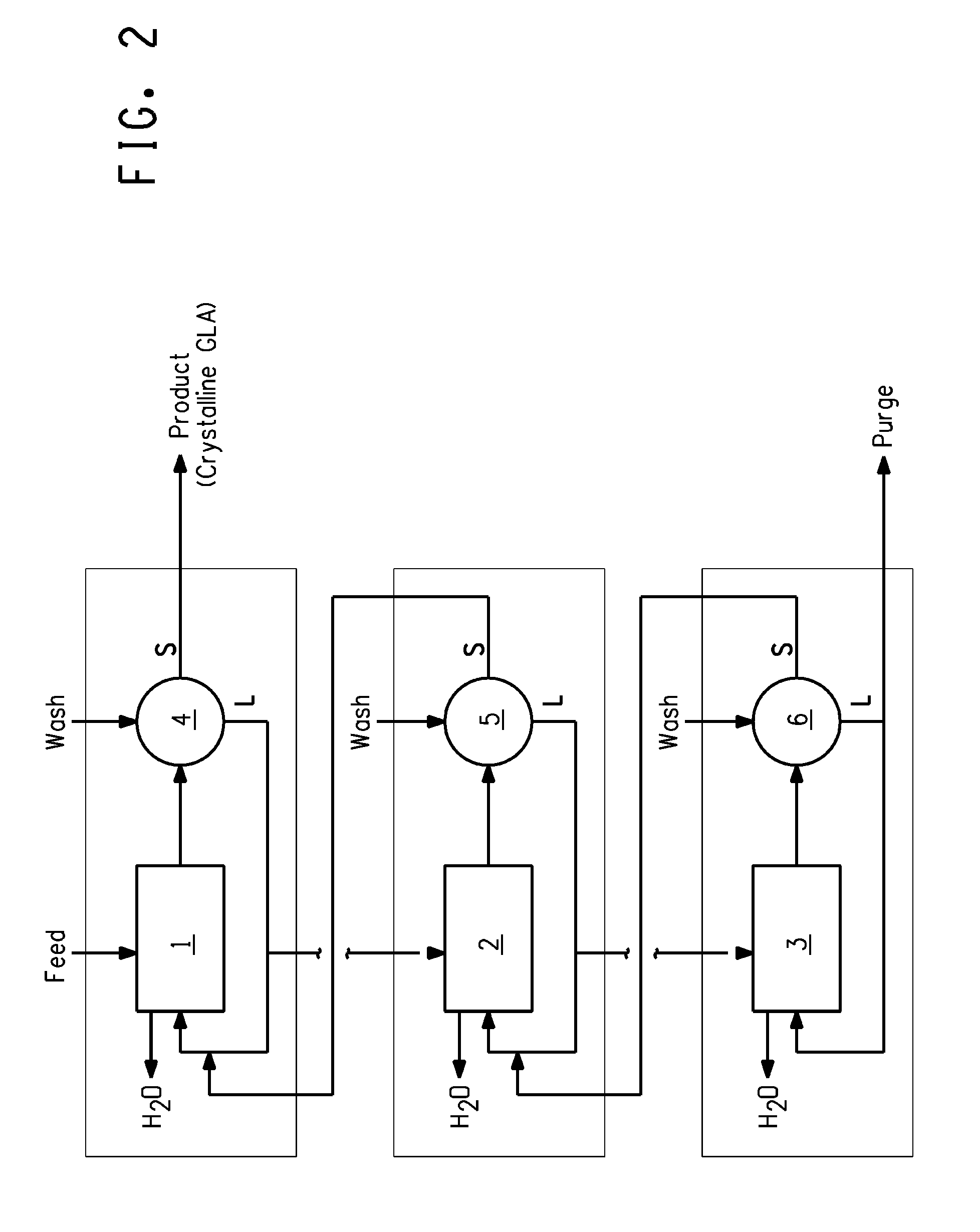

Multi-stage glycolic acid crystallization

ActiveUS7439391B2High yieldLow levelOrganic compound preparationCrystallization by component evaporationGlycollic acidCrystallization

The present invention relates to a high yield process to prepare high purity crystalline glycolic acid using a multi-loop crystallization process characterized by high liquid and / or solid recycle, said process suitable for large scale purification and producing high purity glycolic acid with low diglycolic acid content.

Owner:PURETECH SCI LLC

Process and apparatus for purification of industrial brine

Processes and apparatus for purifying brine are provided including (1) providing an aqueous brine solution comprising one or more inorganic salts and one or more organic compounds and (2) conducting at least one unit operation for removing organic compounds from the brine solution to obtain a purified brine solution.

Owner:BLUE CUBE IP

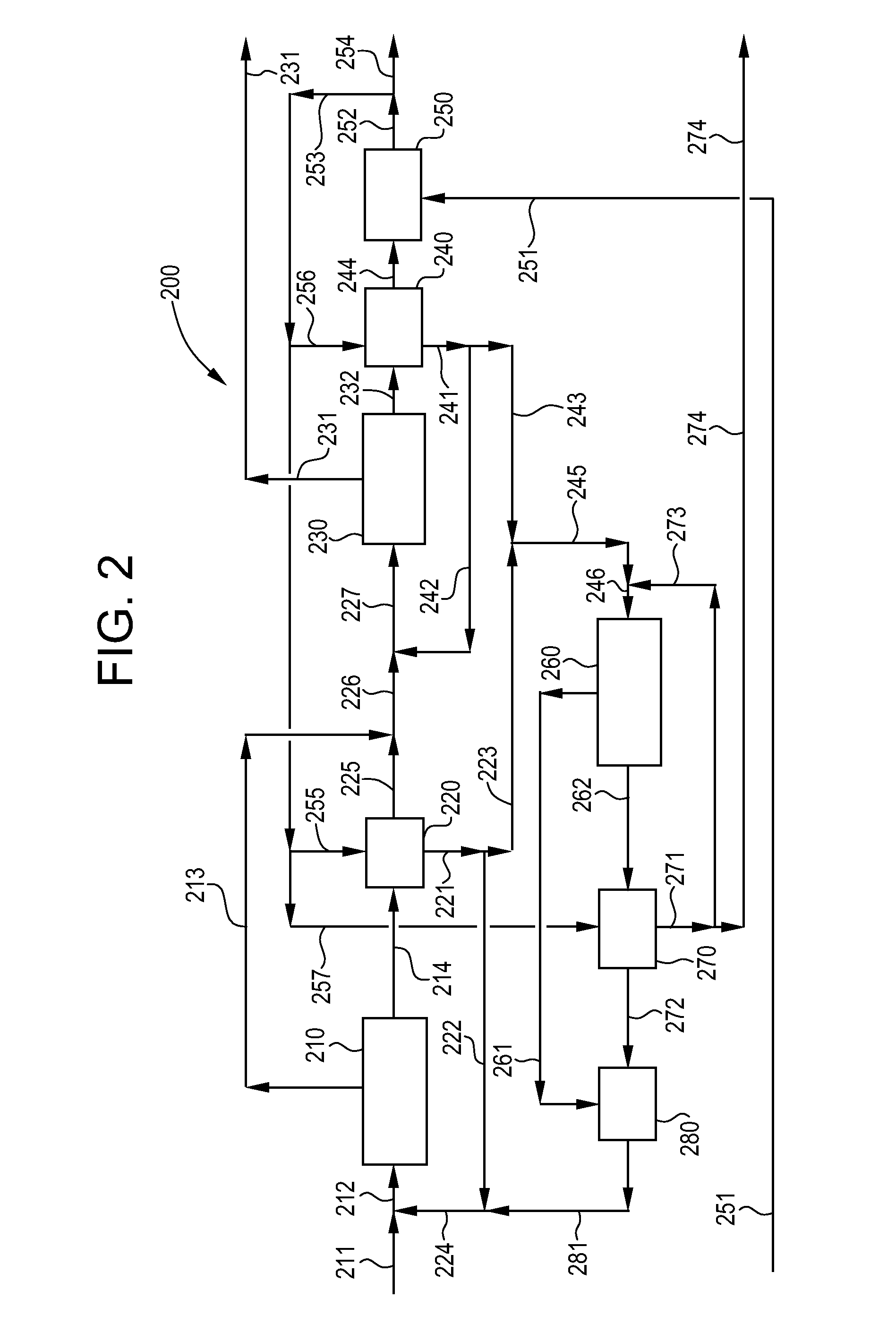

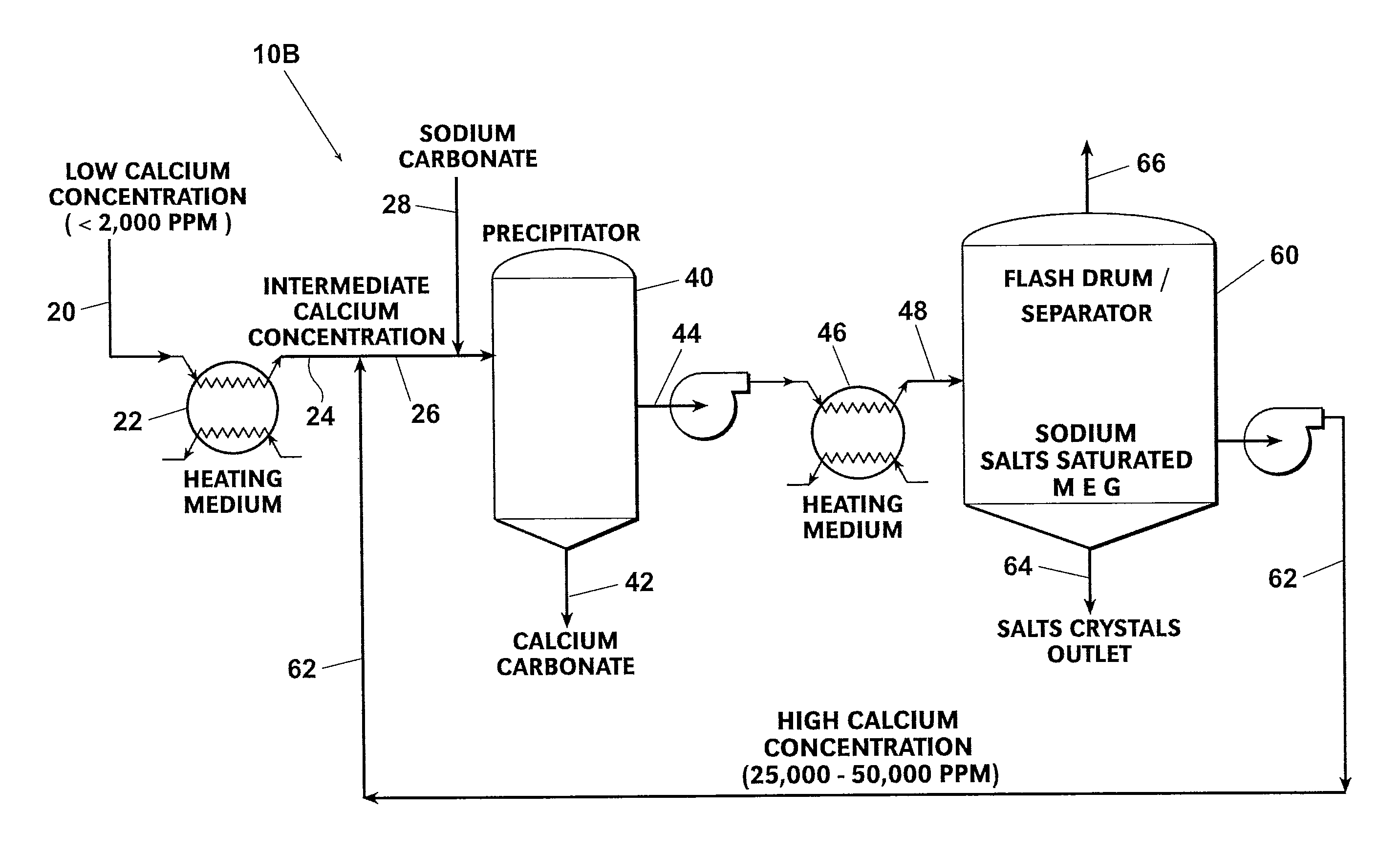

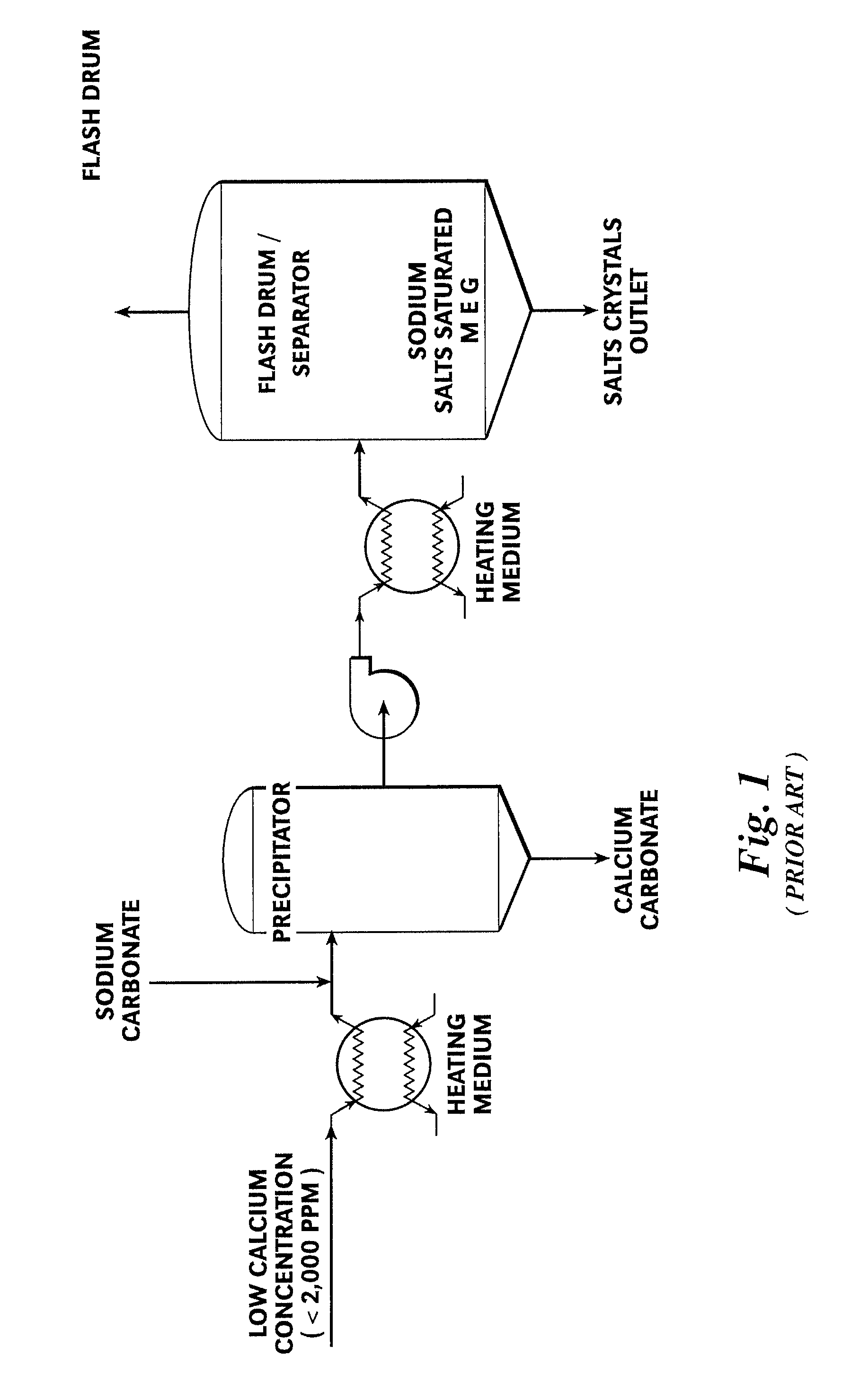

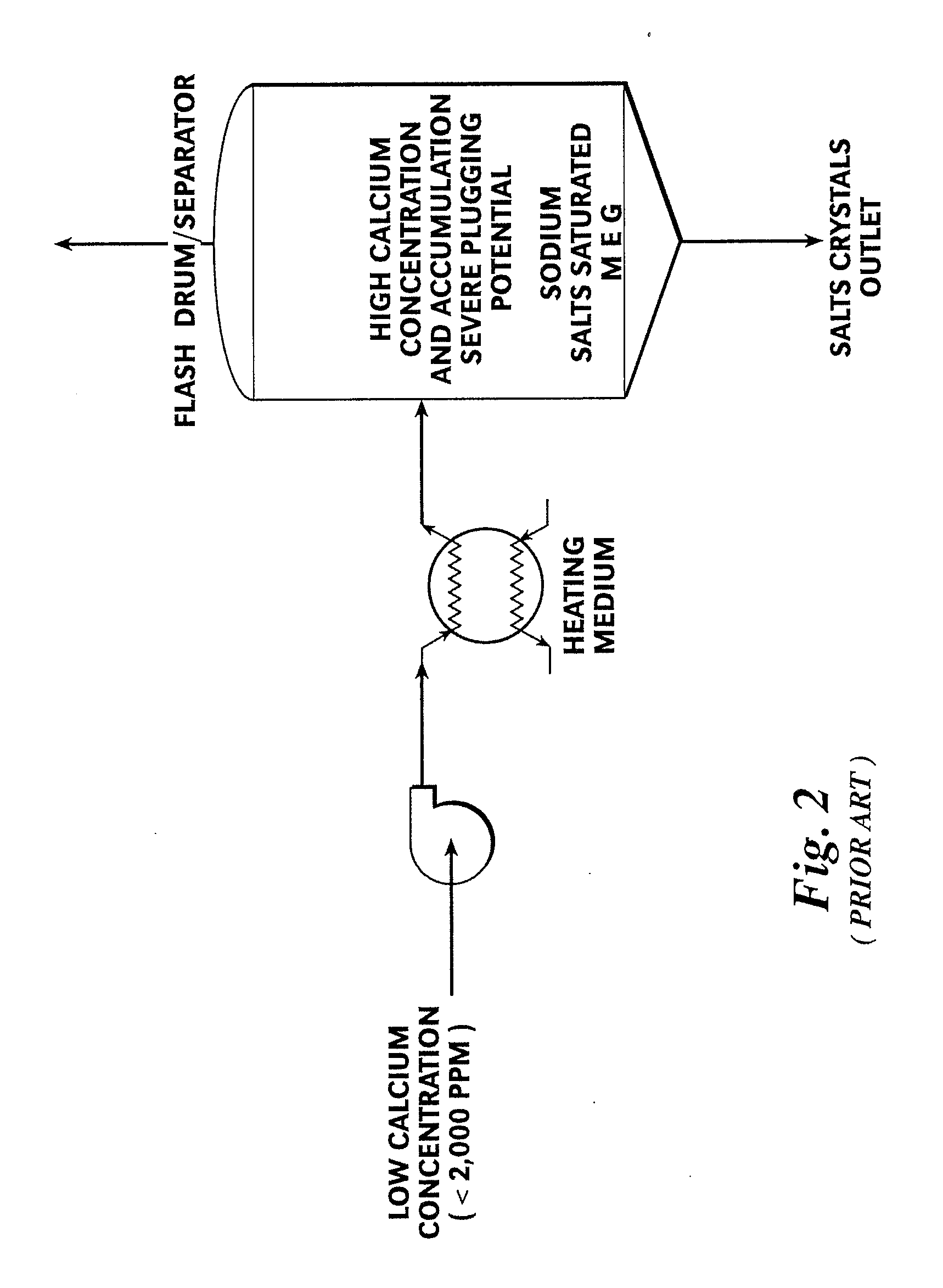

Process Scheme to improve Divalent Metal Salts Removal from Mono Ethylene Glycol (MEG)

ActiveUS20130118989A1Less floor-space/volumeSpeed reactionGas treatmentMultiple-effect/fractional condensationStream flowDivalent metal

A MEG reclamation process includes the step of increasing above 2,000 ppm the divalent metal salts concentration of a rich (wet) MEG feed stream flowing into a precipitator. The increasing step includes routing a salts-saturated MEG slipstream from the flash separator it to the precipitator. The slipstream may be mixed with a fresh water feed stream, a portion of the rich MEG feed stream, or some combination of the two. The rich MEG feed stream also may be split into two streams, with a portion of the stream being heated and routed to the flash separator and the other portion being combined as above with the removed slipstream. The process can be performed on the slipstream after dilution and prior to entering the precipitator or after being loaded into the precipitator. Removal of the insoluble salts may be done in either a batch or continuous mode.

Owner:CAMERSON INT CORP

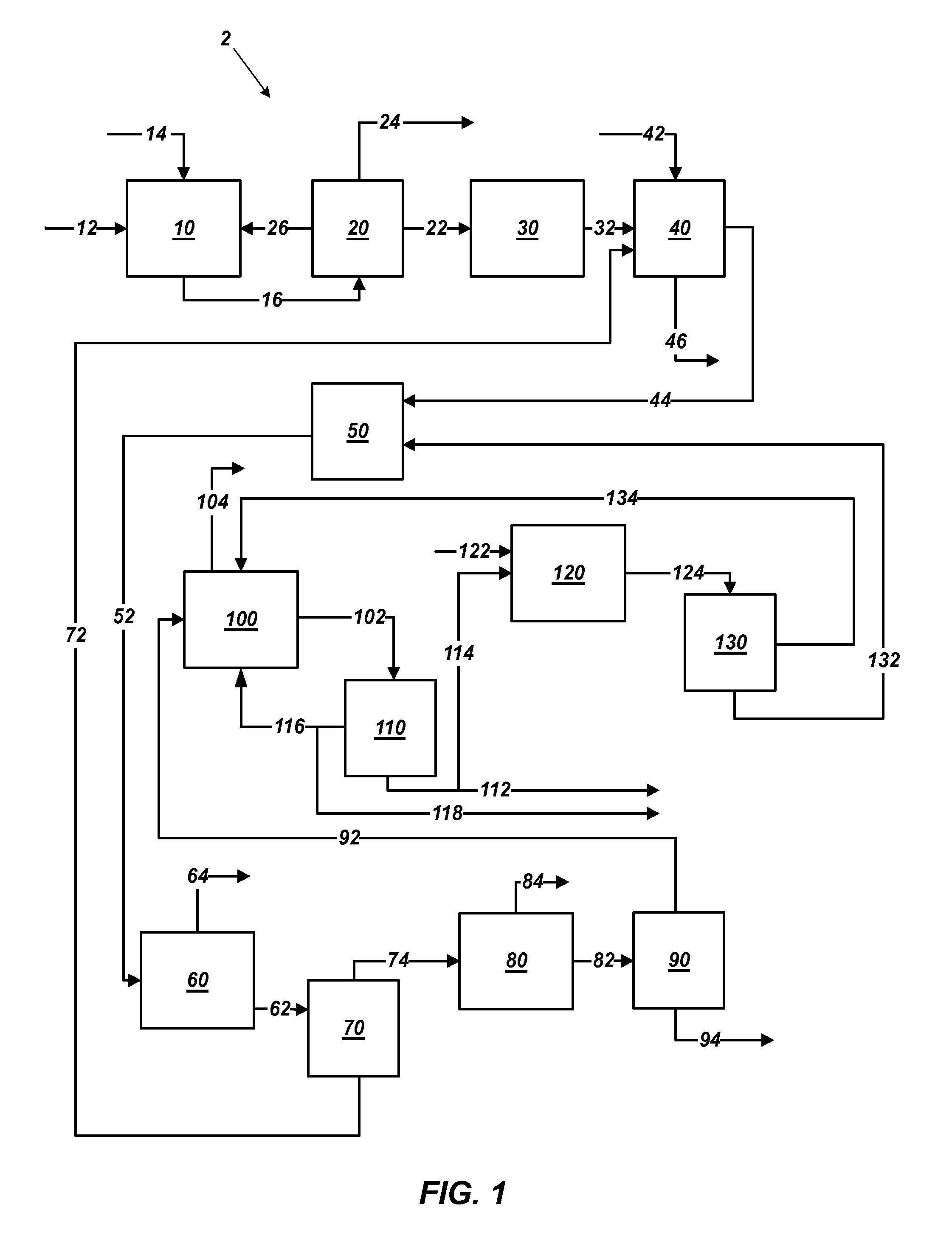

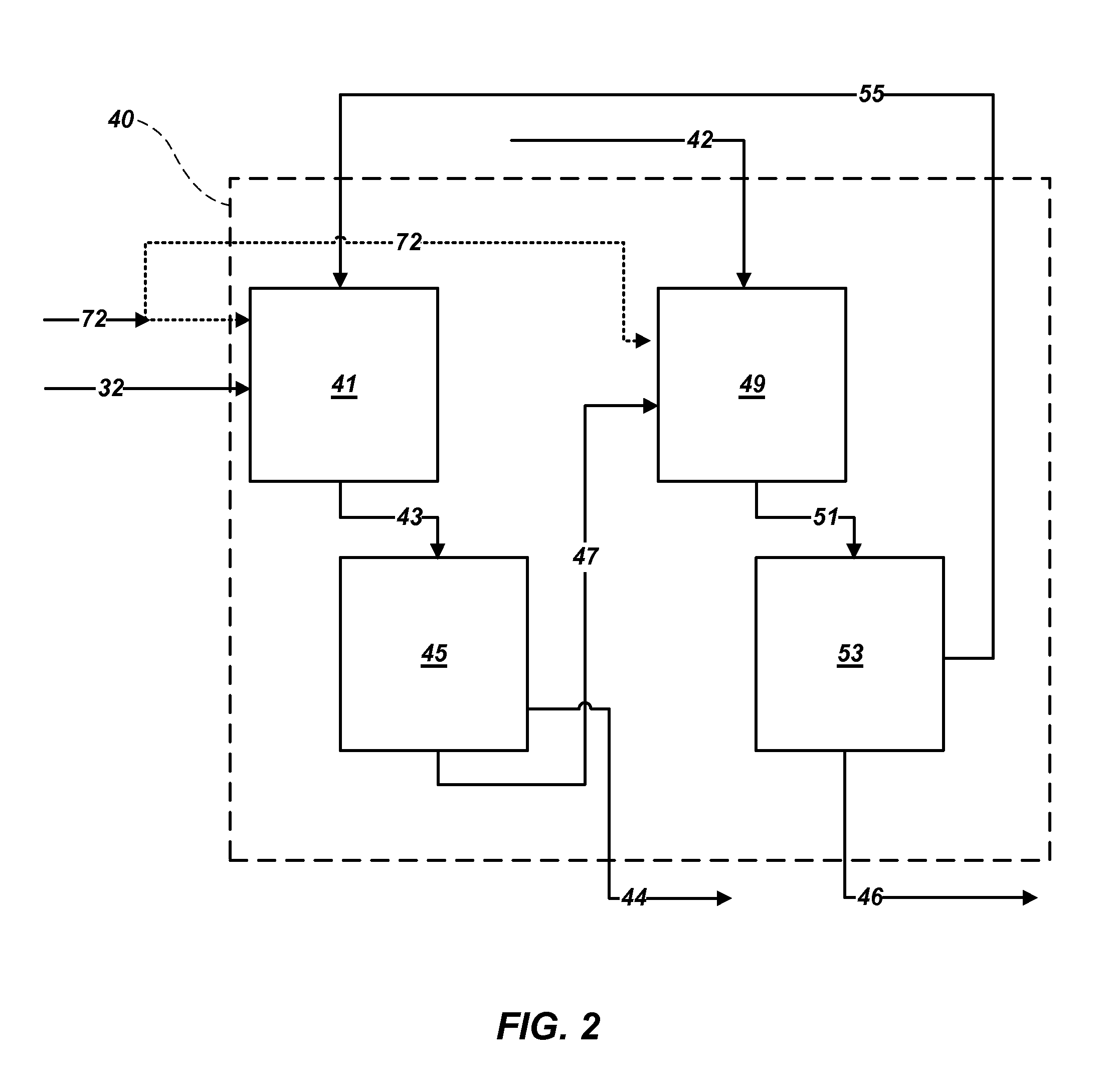

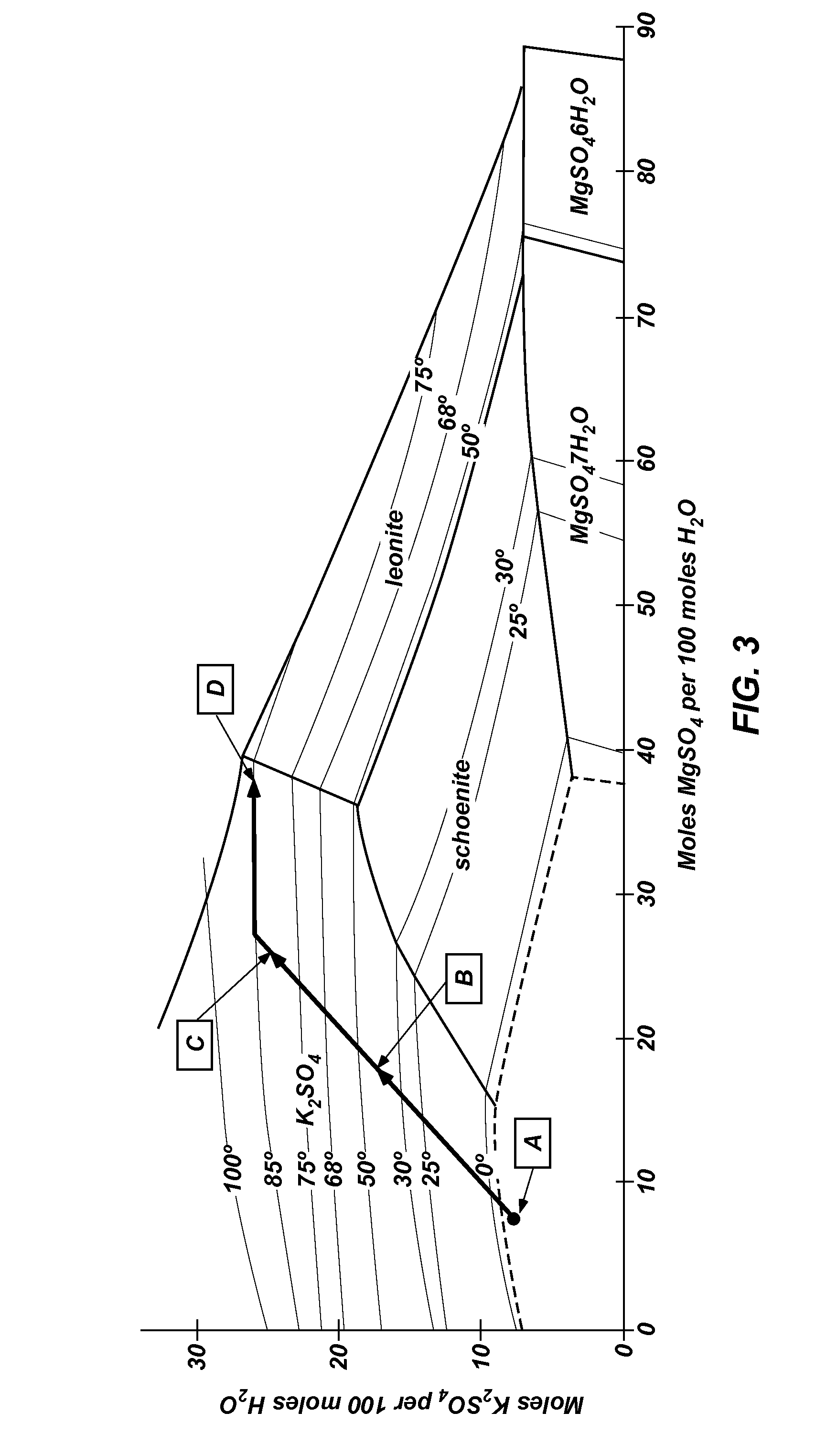

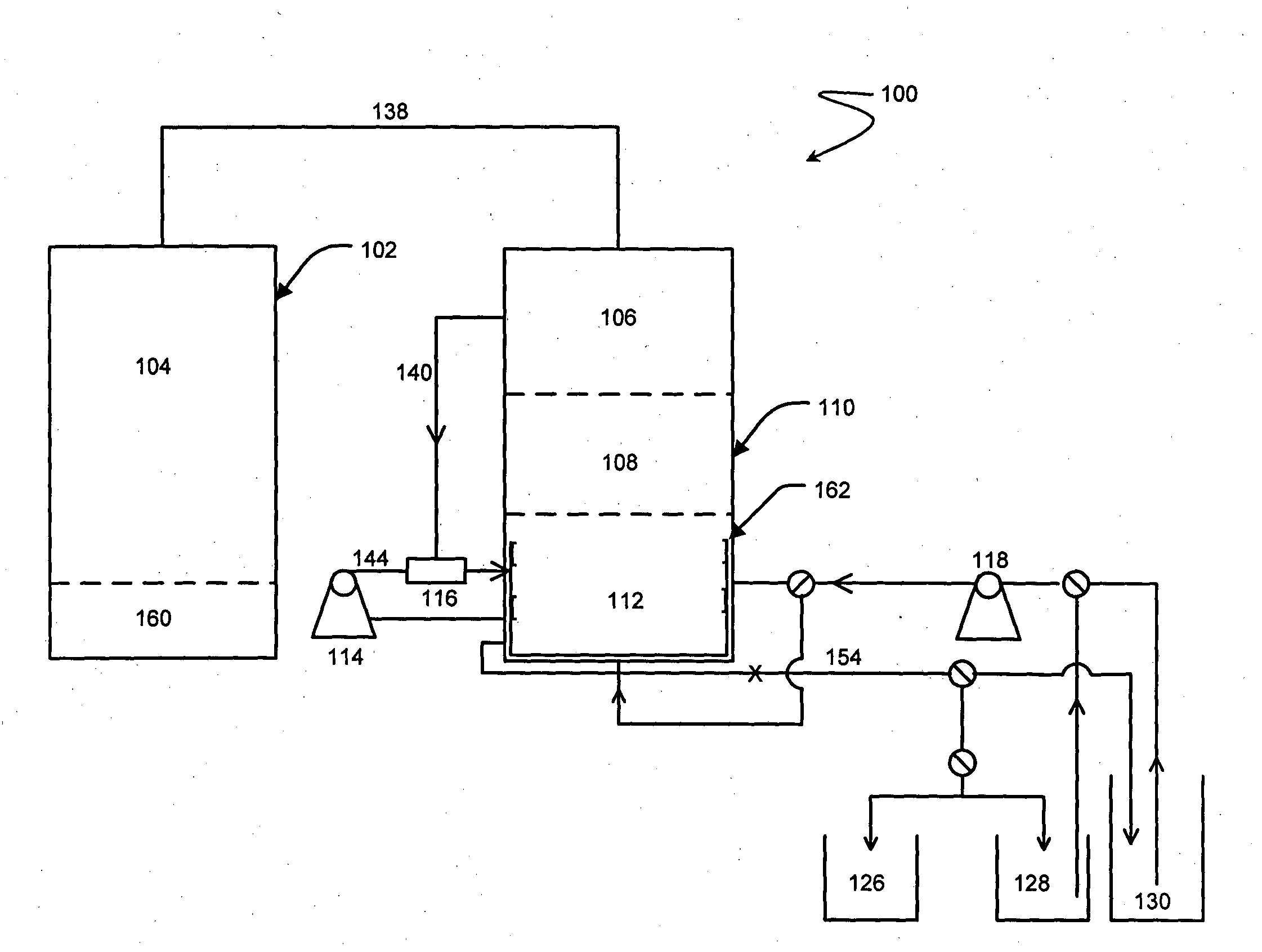

Methods of processing polyhalite ore, methods of producing potassium sulfate, and related systems

ActiveUS20130121900A1Improve concentrationLimit economic riskSolution crystallizationCrystallization by component evaporationWater solublePotassium sulfate

Methods of forming potassium sulfate include calcining polyhalite ore particles to convert the polyhalite ore particles to a water-soluble composition. At least a portion of the water-soluble composition is dissolved in an aqueous medium to form an aqueous solution comprising K+, Mg2+, and SO42− ions and a calcium-containing solid. The calcium-containing solid is separated from the aqueous solution to form a filtrate comprising K+, Mg2+, and SO42− ions. A potassium-containing salt is dissolved in the filtrate to increase the concentration of K+ and SO42− ions to from a concentrated liquor, and K2SO4 is crystallized from the concentrated liquor. A system for processing polyhalite ore includes a countercurrent leaching apparatus, a first mix tank, an evaporator, and at least one crystallizer.

Owner:INTERCONTINENTAL POTASH CORP USA

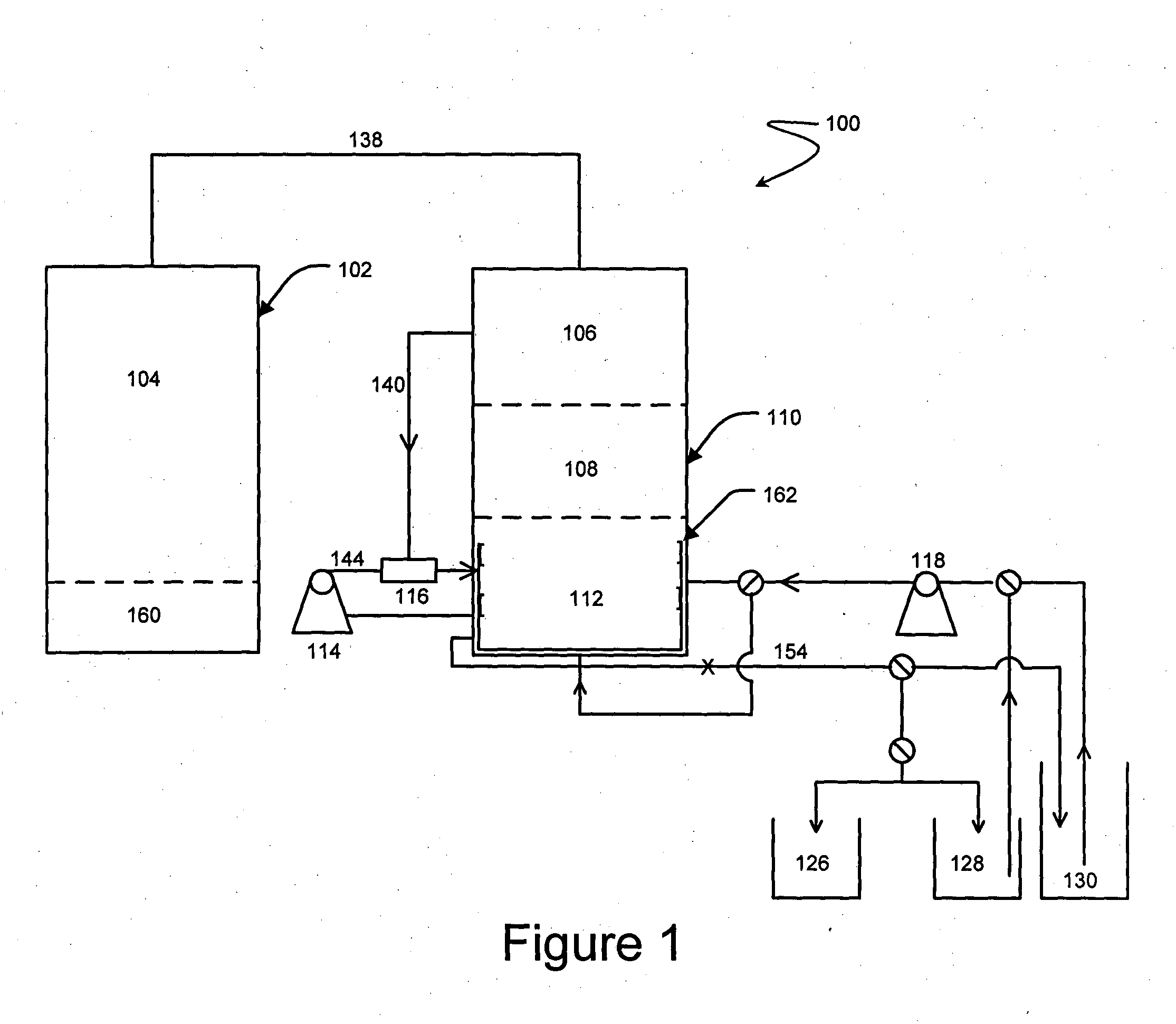

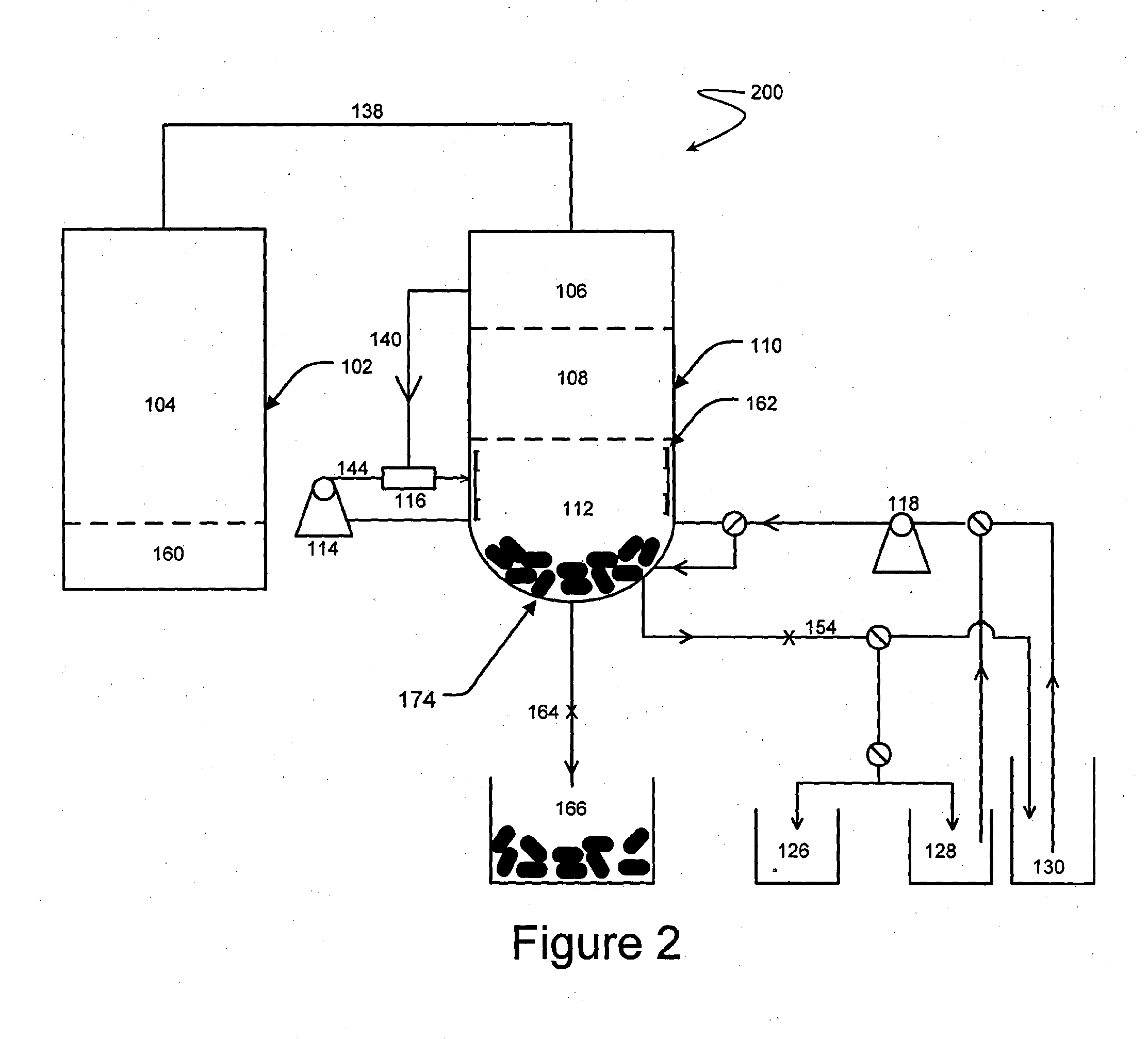

System and method for hydrate-based desalination

ActiveUS20140158635A1Simple and efficient solutionLow costLiquid degasificationGeneral water supply conservationSaline waterWater use

The present invention relates to systems and methods for desalinating and / or treating polluted water. More particularly, the present invention relates to systems and methods for desalinating and / or treating polluted water using gas hydrates. In particular, the system comprises a desalination tank configured to form gas hydrates using a suitable hydrate former taken from a storage tank that is operatively connected to the desalination tank. With all operations, including formation of gas hydrates, discharging of highly saline water, washing the gas hydrates and dissociation of gas hydrates being conducted in a single pressurized tank such as the desalination tank, the present apparatus provides a simple and efficient solution at a low manufacturing and operating cost.

Owner:KATYAL AMIT

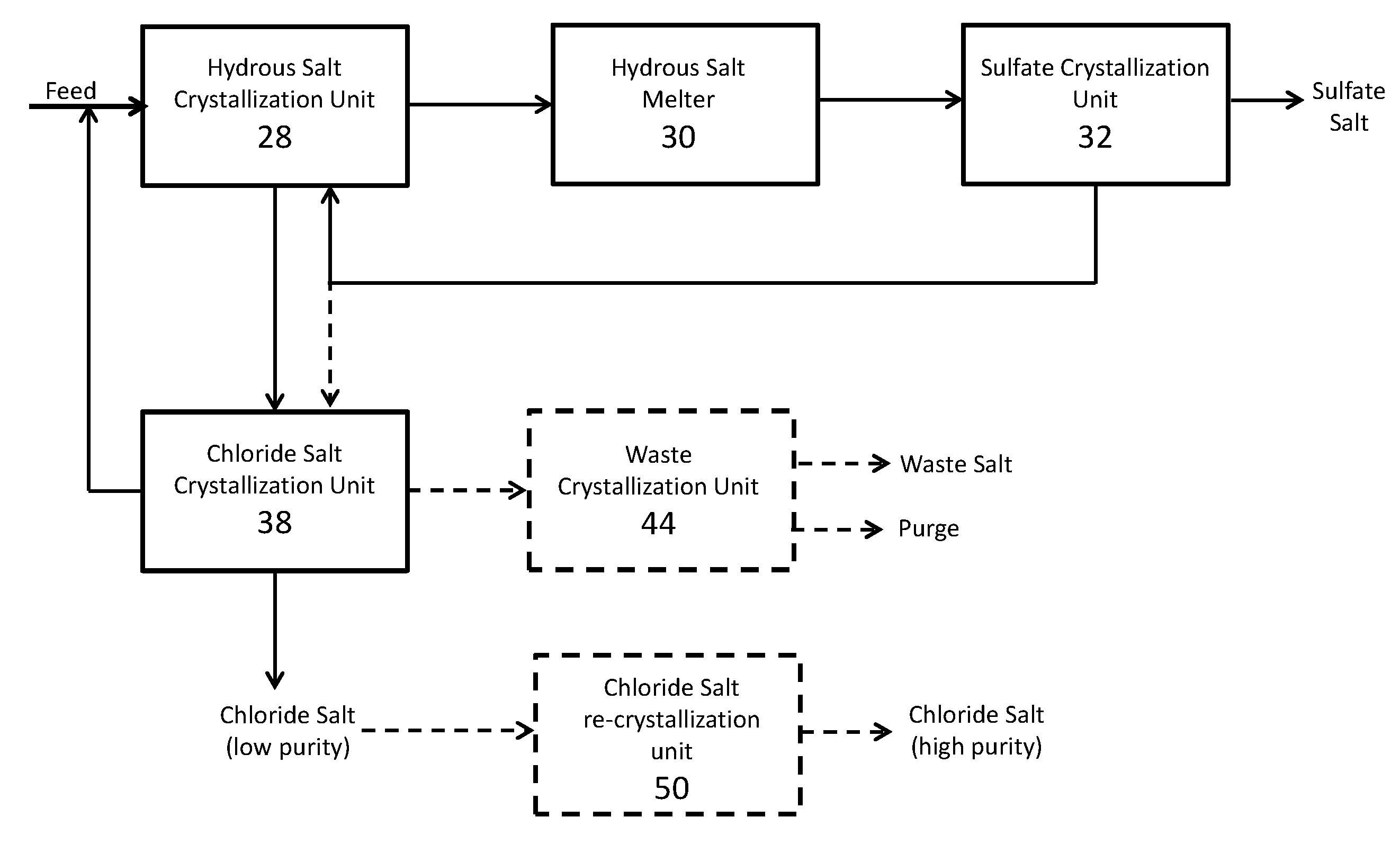

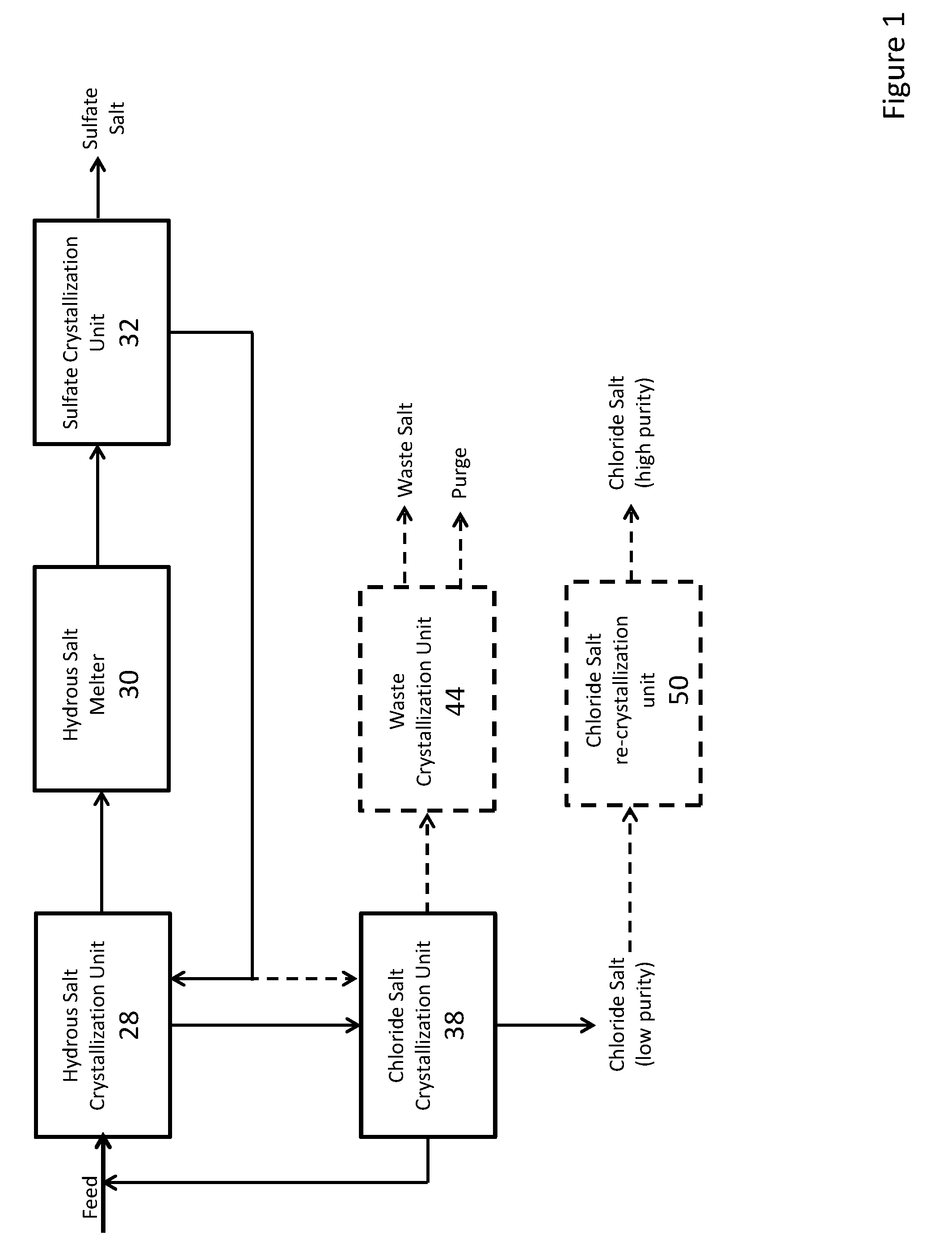

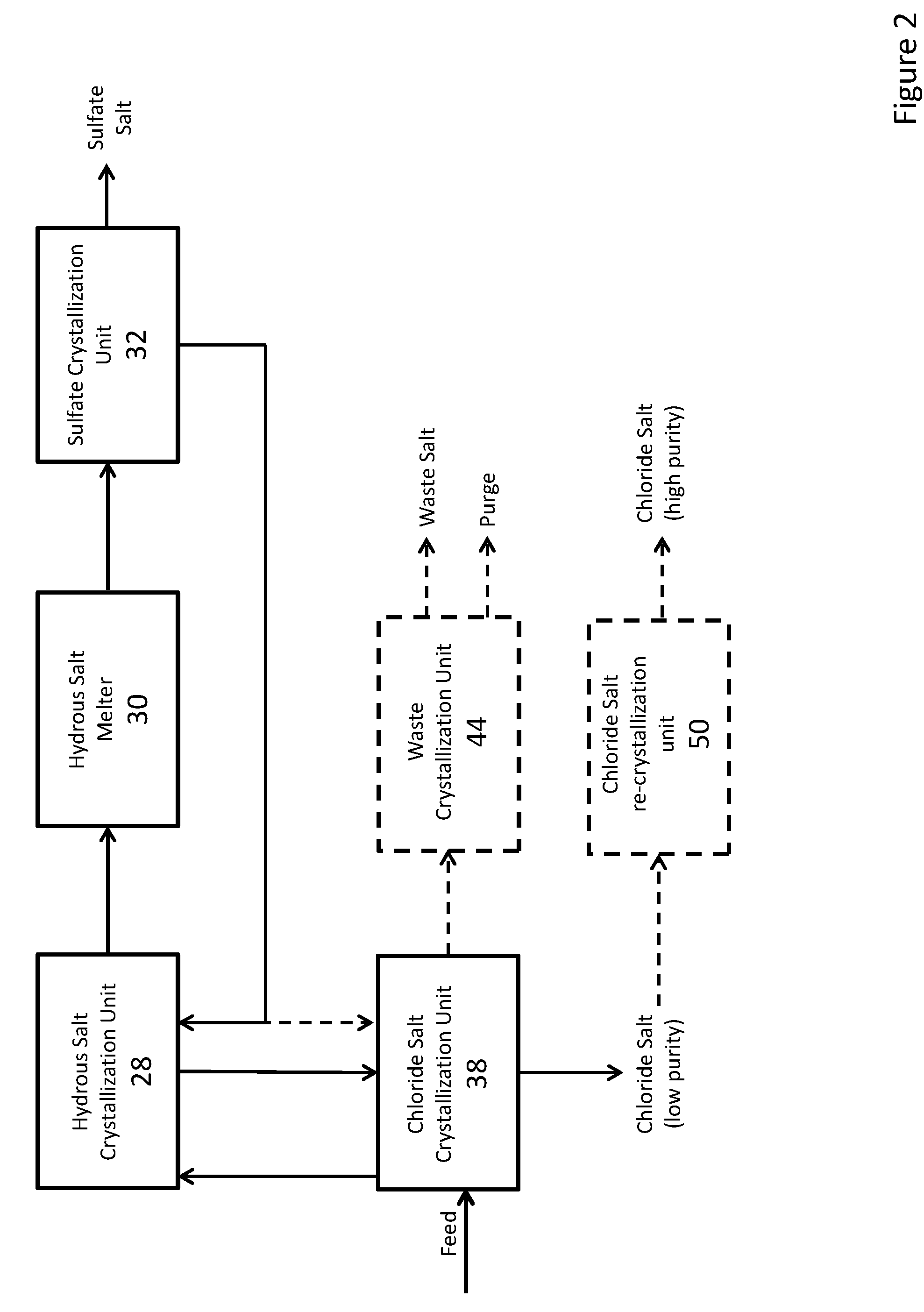

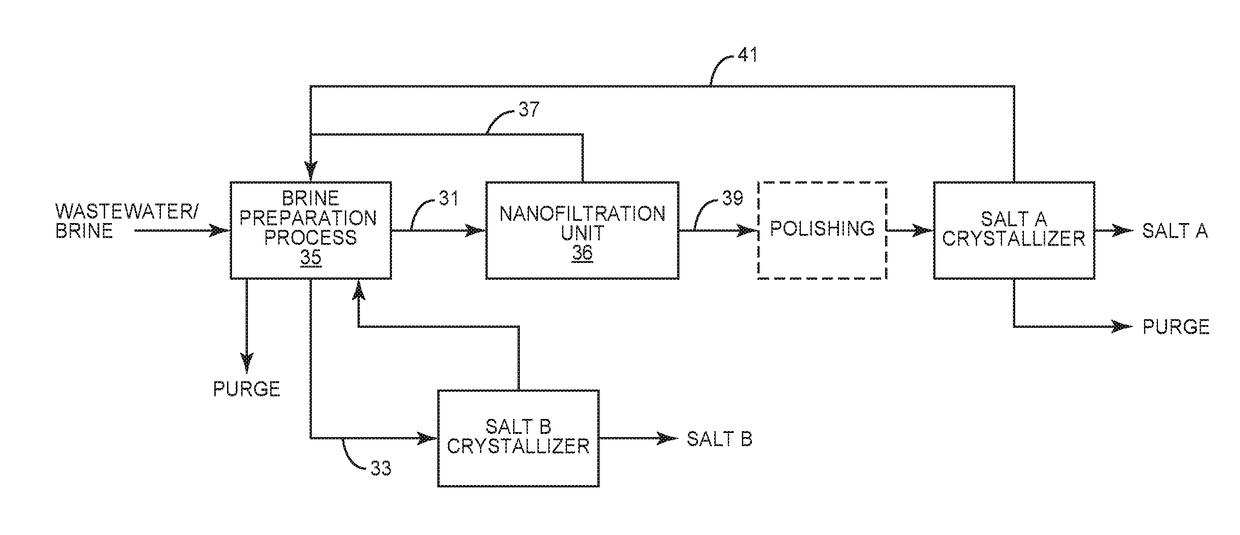

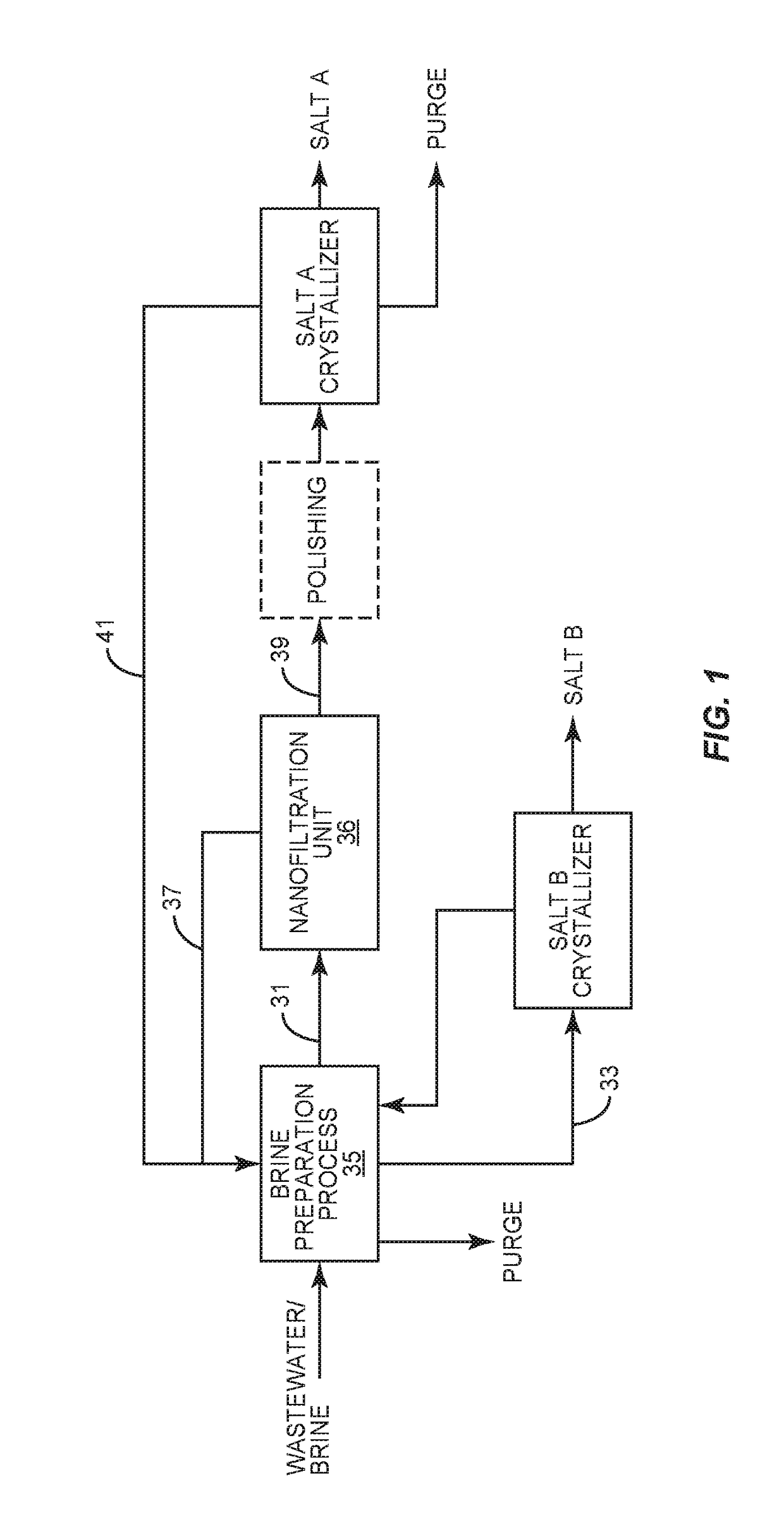

Process for recovering sulfate and chloride salts from wastewater, mixed salts, and brines

ActiveUS20160280571A1Reduce the amount requiredSafe releaseWaste water treatment from quariesSulfate preparationMetal chlorideChloride salt

A process is described for recovering alkali-chloride and alkali-sulfate salts from a salt solution. The salt solution comprises alkali metal, chloride and sulfate ions and is directed to a hydrous salt crystallization unit which crystallizes hydrated sulfate salts that comprise sulfate and at least one alkali metal. A purged solution from the hydrous salt crystallization unit is directed to a chloride salt crystallization unit while the hydrated sulfate salt crystals are melted to form an aqueous sulfate solution which is directed to a sulfate crystallization unit. Anhydrous sulfate salts are crystallized from the aqueous sulfate solution to form sulfate salt crystals comprising sulfate and at least one alkali metal. In the chloride salt crystallization unit, chloride salt is crystallized to form chloride salt crystals. A purge from the chloride salt crystallization unit is directed to the hydrous salt crystallization unit.

Owner:VEOLIA WATER TECH INC

Solventing-out crystallization device and method through auxiliary control of films

ActiveCN106166400AGood dispersionIncrease contact areaSemi-permeable membranesSolution crystallizationFiltrationOperant conditioning

The invention provides a solventing-out crystallization technique device and method through auxiliary control of films, and belongs to the technical field of crystallization engineering. When a crystallization solution is added to a raw material pot, a solventing-out agent is added to a material-liquid pot, electronic scales, a computer, a stirring device and temperature controlling devices are started, and after a system is stable, squirm pumps of the material-liquid pot are started, so that solventing-out agents can circulate between the material-liquid pot and a film assembly; and after the solventing-out agent is stable in circulation, the squirm pump connected to the raw material pot is started so that the crystallization solution enters the film assembly. The solventing-out agent and the crystallization solution which are in sufficient contact in the film assembly can perform nucleation growth in the film assembly, and then the solventing-out agent and the crystallization solution, after the nucleation growth, can flow into an external storing pot for filtration and post-treatment; and the solventing-out agent and the crystallization solution can also perform nucleation growth outside the film assembly, and after solutes are wholly dissolved, filtration is performed. The electronic scales record the addition quantity of the solventing-out agent in a real-time manner, and the addition quantity of the solventing-out agent is systematically controlled through controlling films and operation conditions, so that ideal crystal products are obtained.

Owner:DALIAN UNIV OF TECH

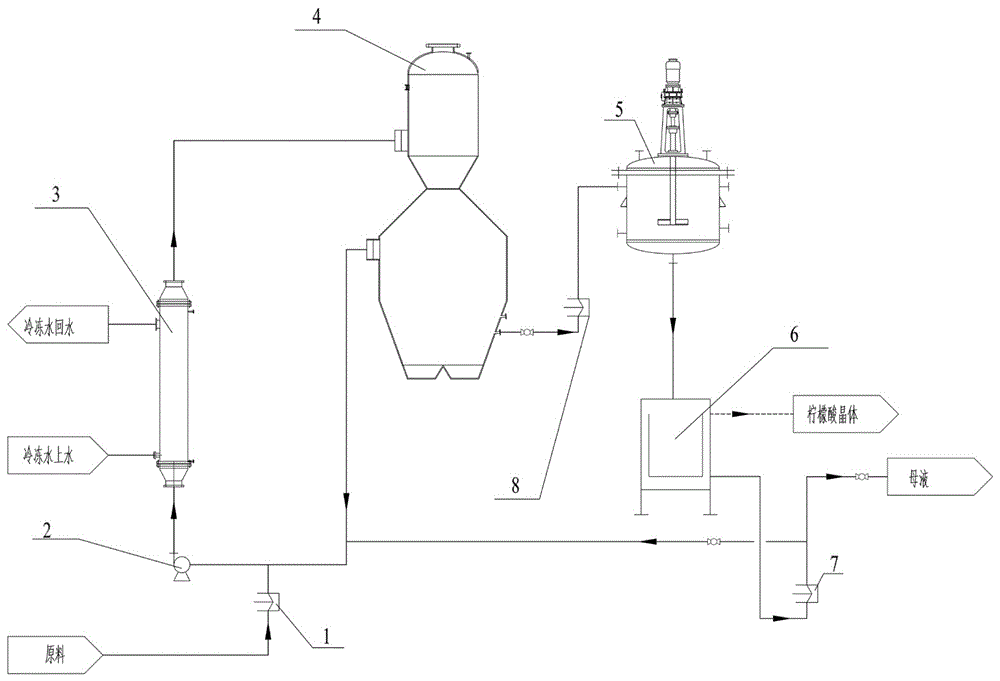

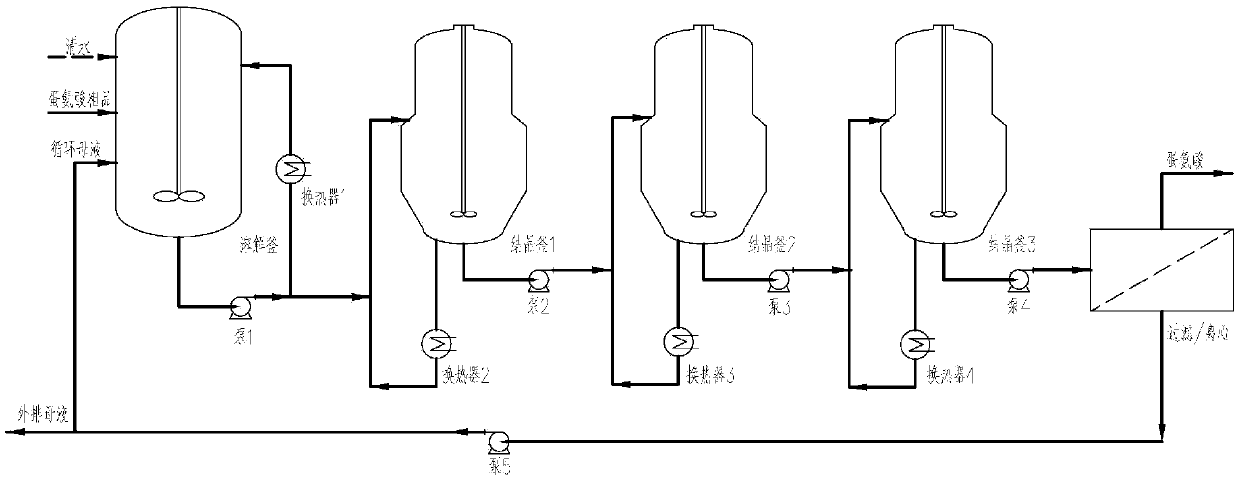

Citric acid continuous cooling crystallization system and method thereof

InactiveCN105797422AIncrease productivityStable feeding and dischargingSolution crystallizationHeat exchange cooling cystallizationSlurryCitric Acid Monohydrate

The invention relates to a citric acid continuous cooling crystallization system and a method thereof. In an existing method of producing citric acid monohydrate crystal, intermittent processing equipment is used, product size distribution is uneven, a crystal product is agglutinated seriously, and difference between product batches is large. According to the crystallization method, a citric acid solution is heated and concentrated through two-effect heat exchange, then is input into a circulating pipeline composed of an indirect cooler and a cooling crystallizer through a feed pump and is continuously cooled for cooling crystallization in the circulating pipeline under the action of a circulating pump, and citric acid monohydrate slurry is obtained through cooling crystallization; the citric acid monohydrate slurry is discharged through a discharging pump, conveyed to a crystal slurry buffering tank to be buffered and then input into a centrifugal separation device for solid-liquid separation. According to the continuous cooling crystallization method, intermittent crystallization operation of using a crystallization kettle for feeding and discharging and conducting cooling in the kettle in the past is replaced, the feeding, discharging and cooling flow path is stabilized, continuity and stability of product quality can be effectively ensured, and production efficiency and product quality of citric acid monohydrate are greatly improved.

Owner:西安航天华威化工生物工程有限公司

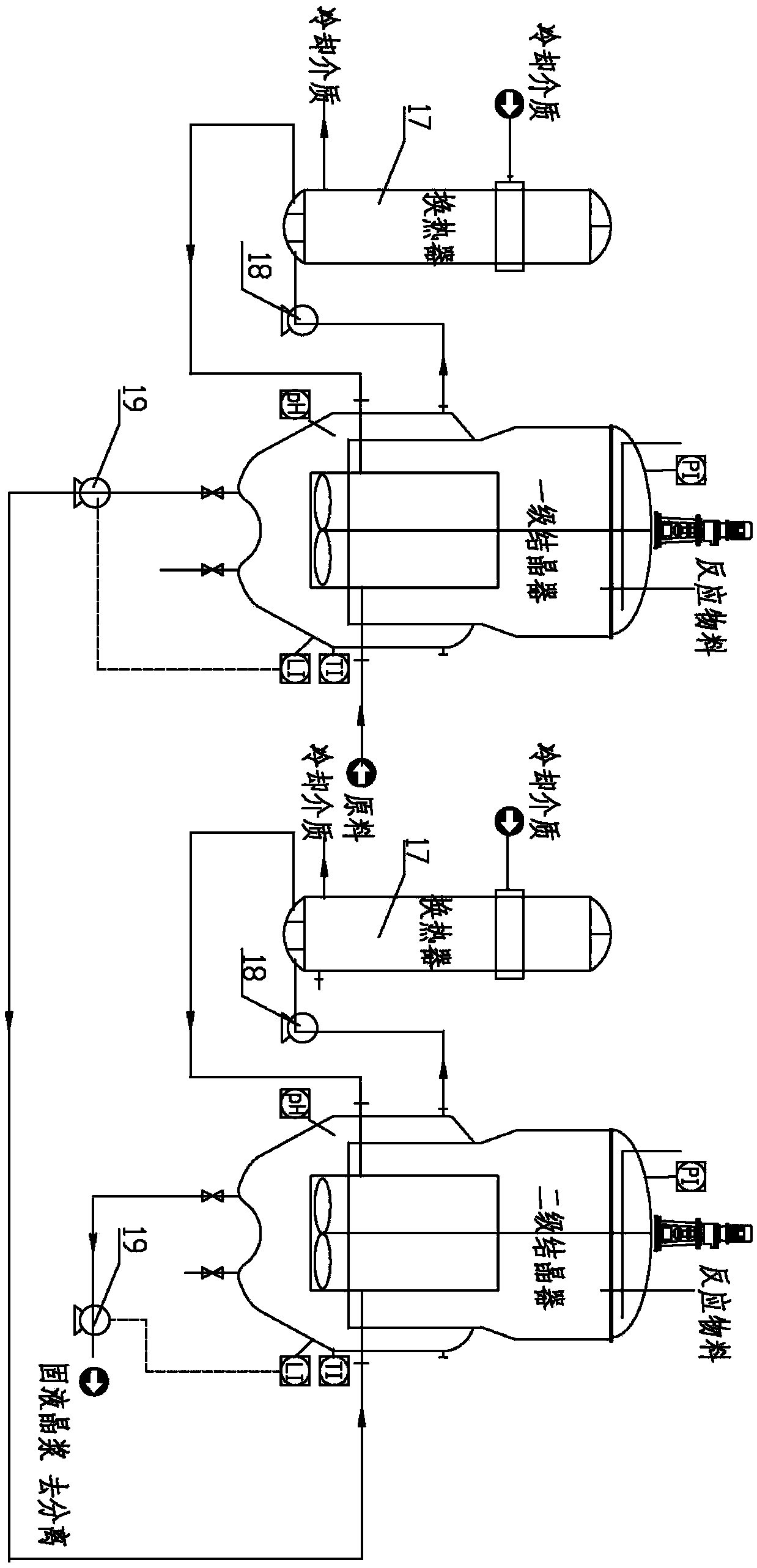

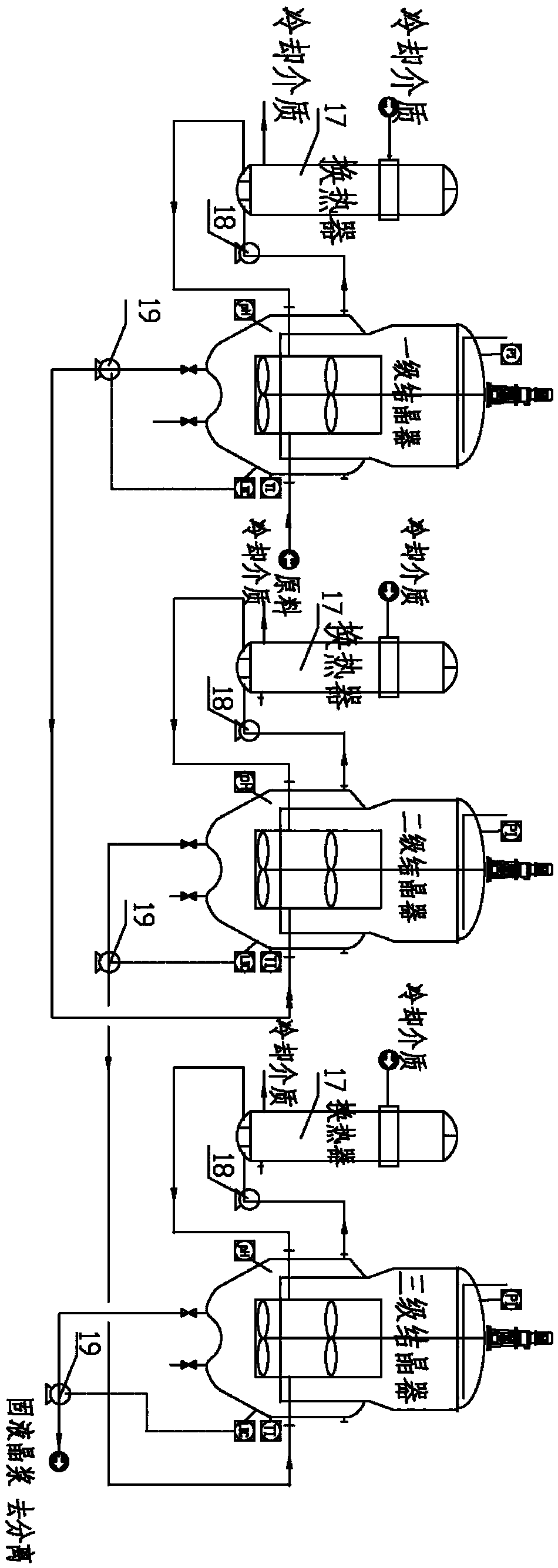

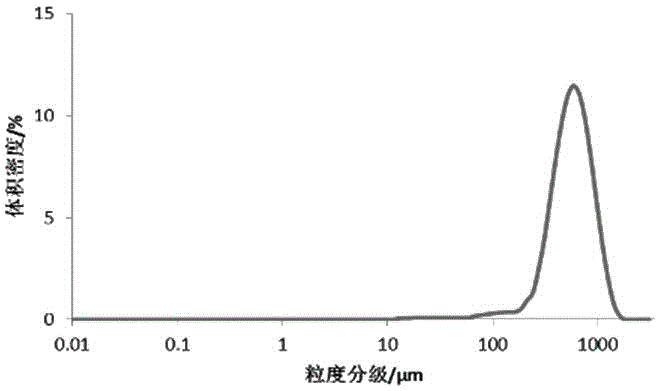

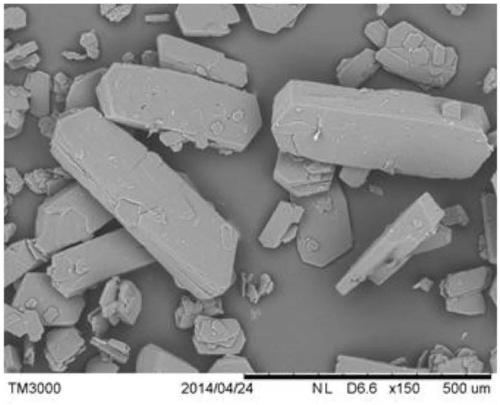

Multistage continuous crystallization method of short rod-like methionine crystals

ActiveCN109608372ASmall particle sizeControl granularityOrganic compound preparationOrganic chemistry methodsSlurryMethionine biosynthesis

The invention provides a multistage continuous crystallization method of short rod-like methionine crystals. The method includes: connecting a plurality of crystallizers in series; under the action ofa circulating device, dissolving a methionine raw material at 80-130DEG C; letting the dissolved feed solution enter a first stage crystallization kettle, and controlling the kettle temperature at 60-80DEG C; enabling the slurry to enter a second stage crystallization kettle, and controlling the kettle temperature at 40-60DEG C; enabling the slurry to enter a third stage crystallization kettle, and controlling the kettle temperature at 25-40DEG C; letting the slurry enter a fourth stage crystallization kettle, and controlling the kettle temperature at 15-25DEG C; letting the final slurry flowout of the crystallization kettle and enter a solid-liquid separation system, discharging the separated solid out of the system, and returning part of the mother liquor into a dissolution kettle forfurther circulation, with the circulation volume being 20-60% of the mother liquor volume. The stage number of the crystallization kettles is supposed to be optimized according to the actual situation, and the general ideal situation is 2-4 stages. The prepared methionine crystals have short rod-like crystal habit, the crystal size is uniform, the bulk density is high, the fluidity is good, the quality is stable, the operation is simple, and the production efficiency is high, therefore the method is suitable for large-scale industrial production.

Owner:TIANJIN UNIV +1

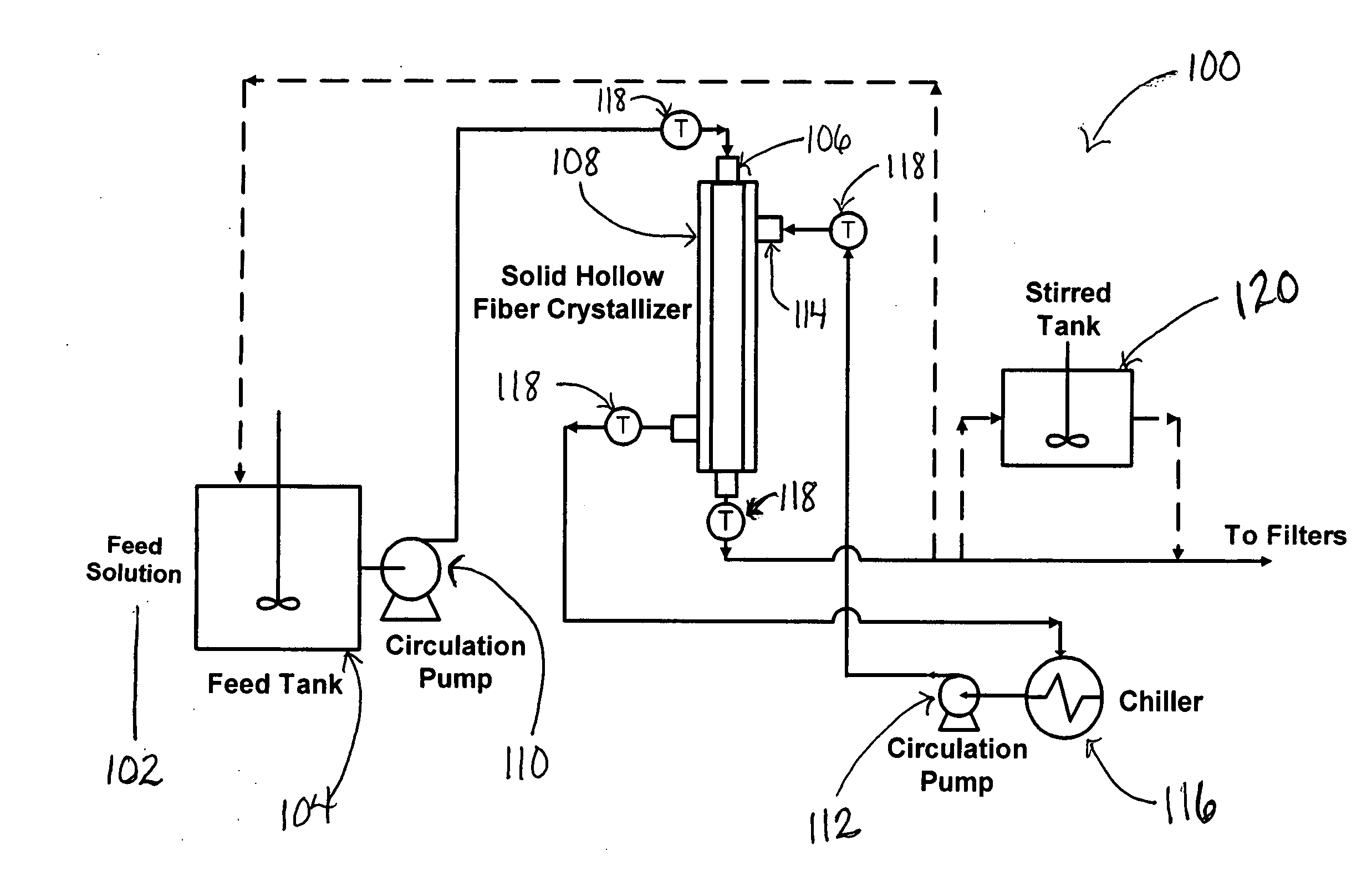

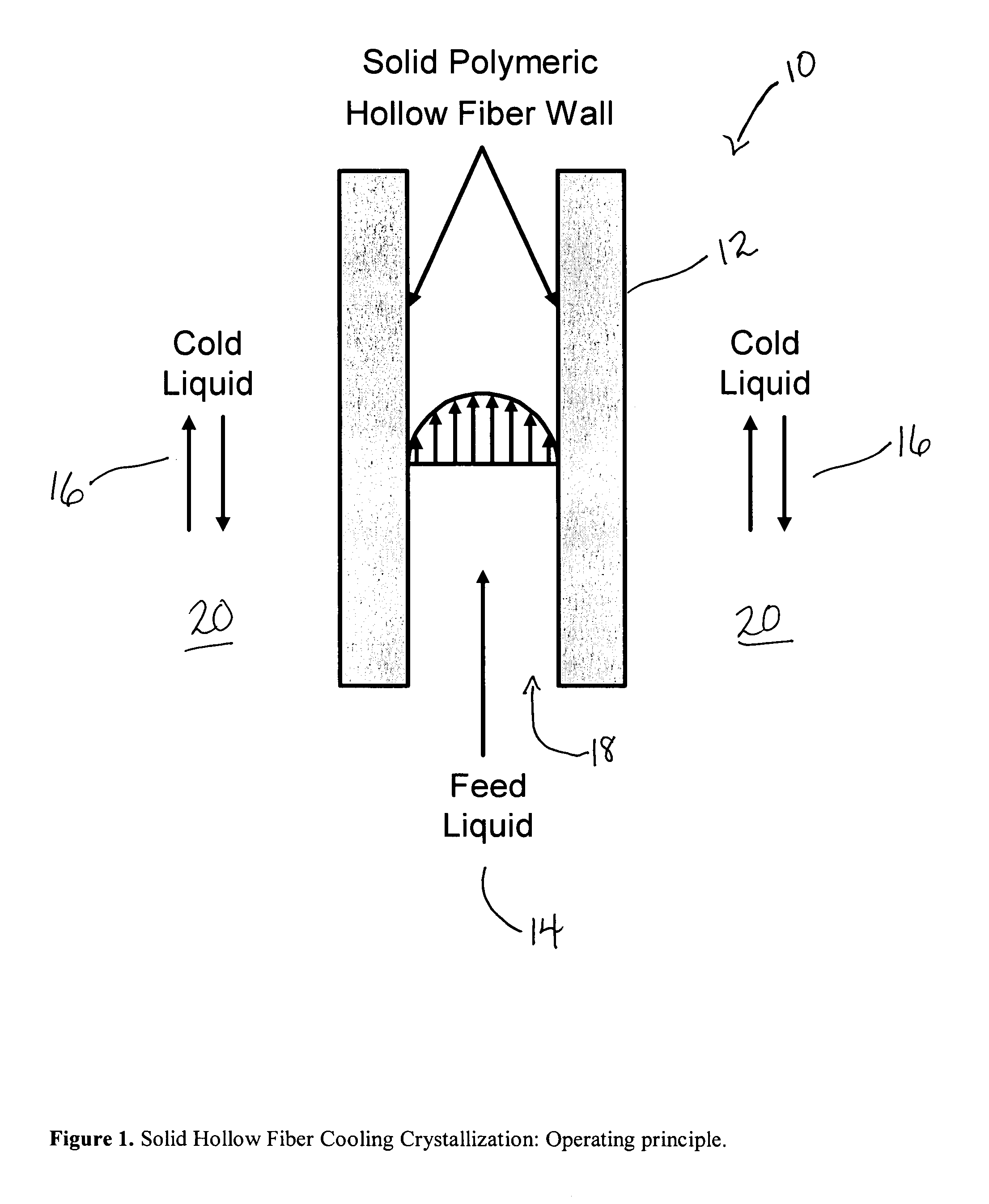

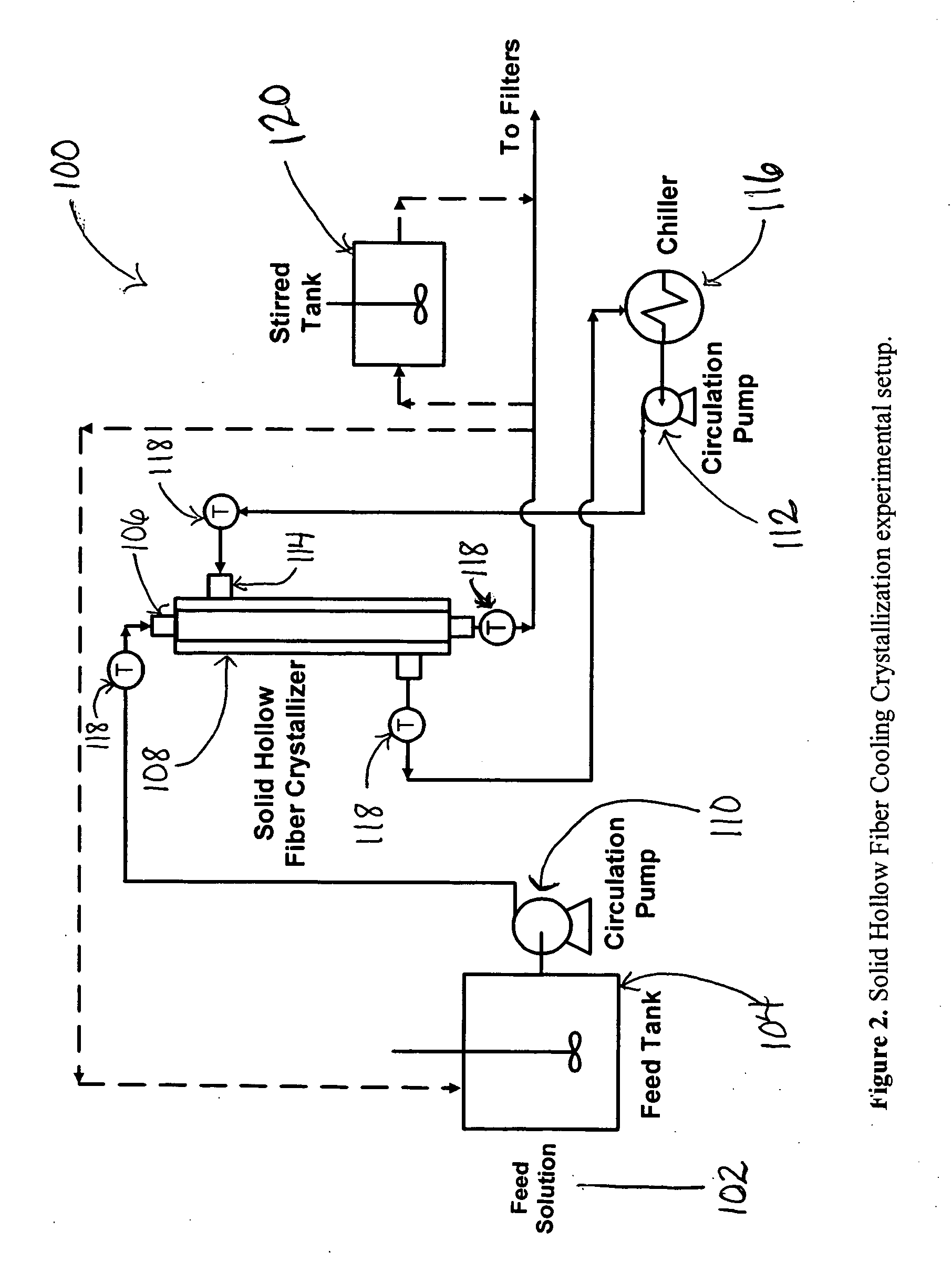

Solid hollow fiber cooling crystallization systems and methods

InactiveUS20060096525A1Increase nucleation rateNarrow crystal size distributionAfter-treatment apparatusPolycrystalline material growthFiberHollow fibre

A solid hollow fiber cooling crystallizer and method for crystallizing aqueous and organic solutions are provided. The solid hollow fiber crystallizer (SHFC) for carrying out cooling crystallization of inorganic / organic microsolutes / macrosolutes from solution generally includes a bundle of non-porous hollow fibers mounted within a shell where a feed solution for crystallization flows through the lumen side of the hollow fibers and a cooling solution flows through the shell side to form nuclei and subsequently crystals in the feed solution at a temperature below its saturation temperature. The solid hollow fiber crystallizer may be combined with a mixing device, such as a completely stirred tank or static mixer, to further effectuate crystallization. The solid hollow fiber crystallizer may be operated in a number of modes including feed recycle mode, once through mode, SHFC-in-line static mixer in series mode, and SHFC-CST in series mode. The advantages of solid hollow fiber cooling crystallization in comparison to conventional crystallization processes include improved temperature control between crystallizing solution and coolant, higher nucleation rates, improved control of crystal size and crystal size distribution, smaller crystal size, capability for decoupling crystal nucleation and crystal growth, decreased fouling of process equipment, and improved process scale-up.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

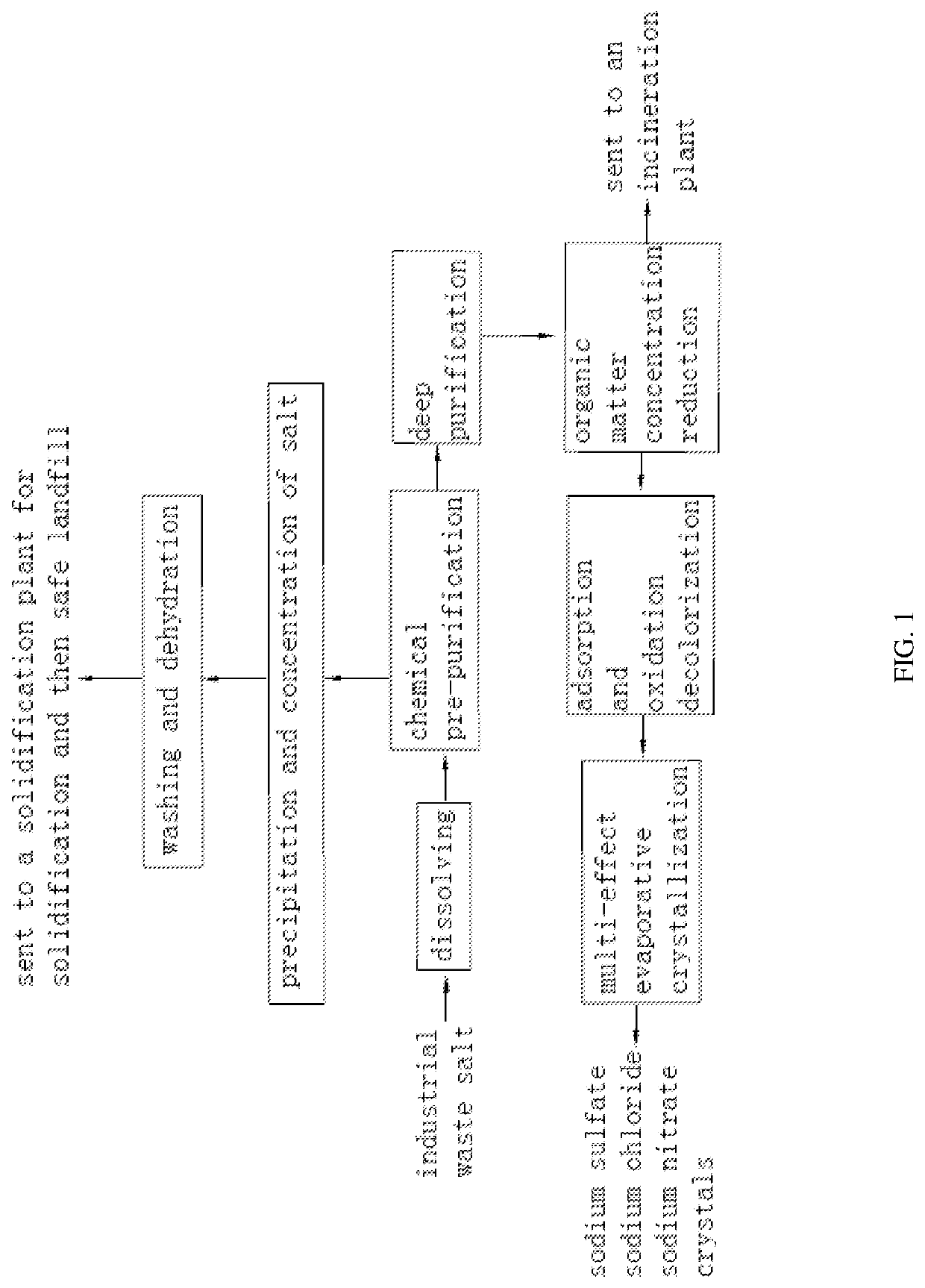

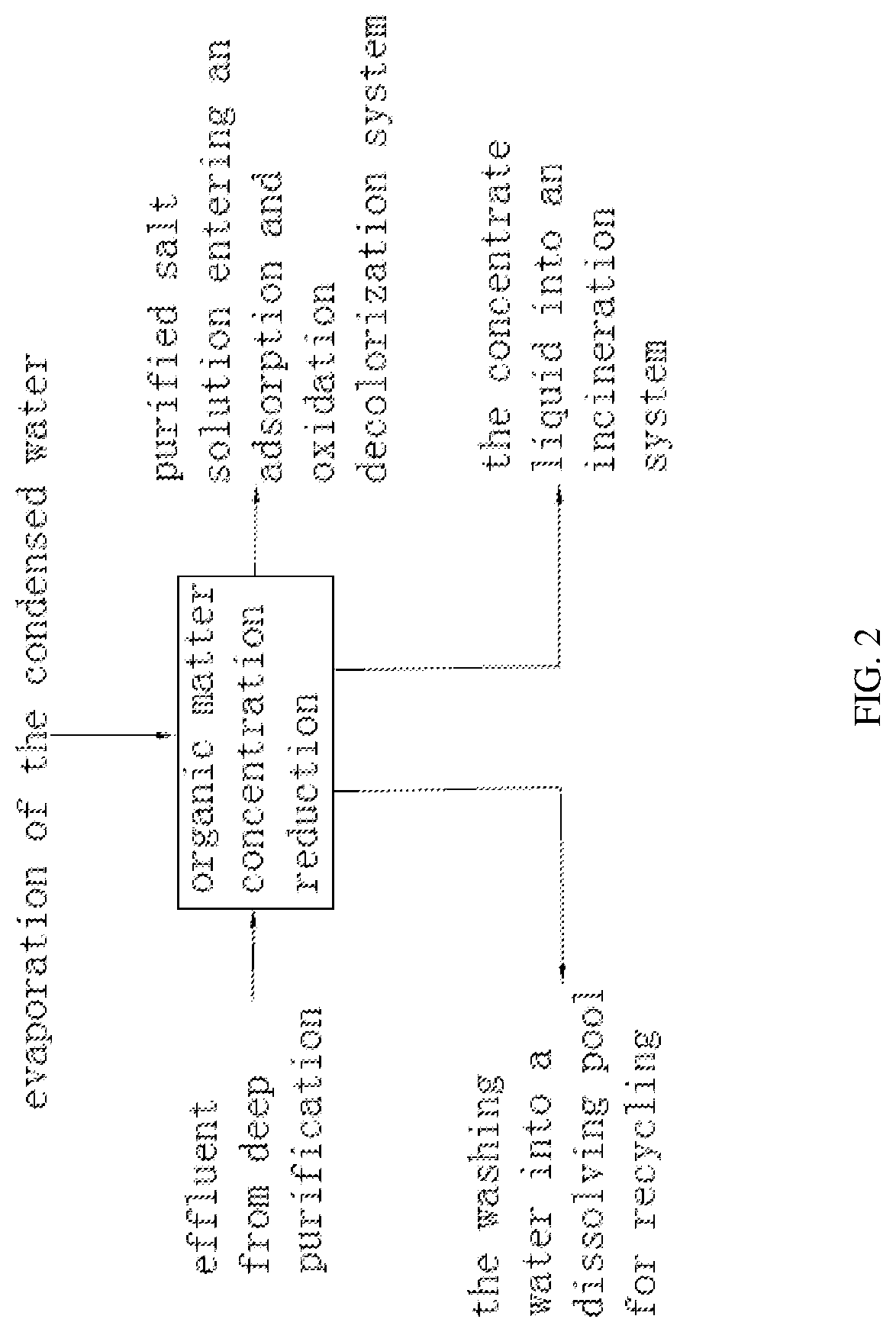

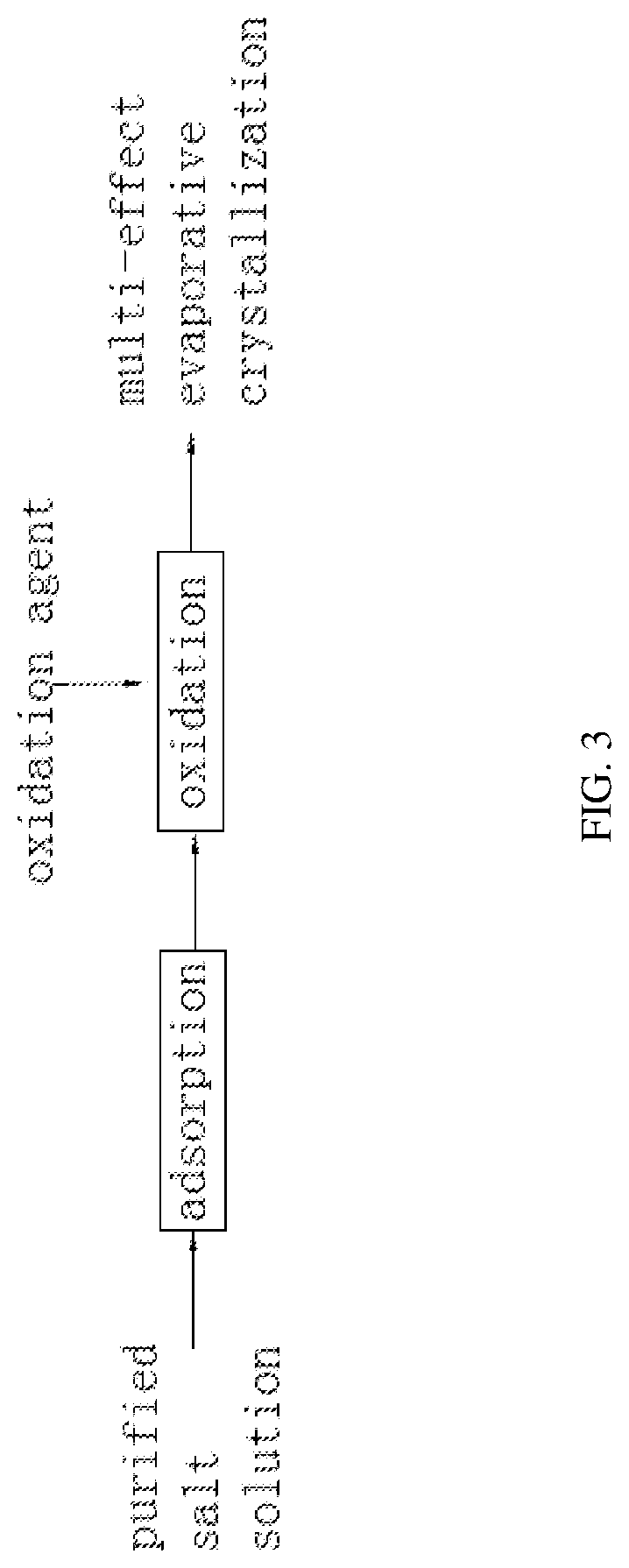

Industrial waste salt resourceful treatment method and device

ActiveUS20210347649A1Reduce difficultyReduce pretreatment costsSludge treatmentUltrafiltrationEnvironmental engineeringCrystallization temperature

An industrial waste salt resourceful treatment method comprises the following steps: the industrial waste salt is sequentially subject to dissolving, chemical pre-purification, deep purification, organic matter concentration reduction, adsorption and oxidation decolorization and multi-effect evaporative crystallization to respectively obtain sodium sulfate, sodium chloride and sodium nitrate crystals; the crystallization temperature of sodium sulfate is in a range of 75° C. to 85° C.; the crystallization temperature of sodium chloride is in a range of 60 to 70° C.; and the crystallization temperature of sodium nitrate is in a range of 45° C. to 55° C. An industrial waste salt resourceful treatment device is further provided.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

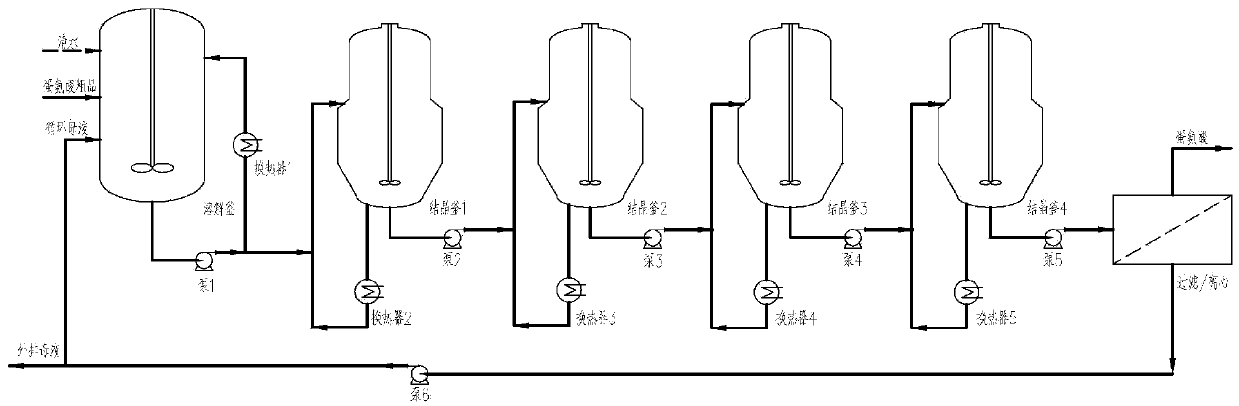

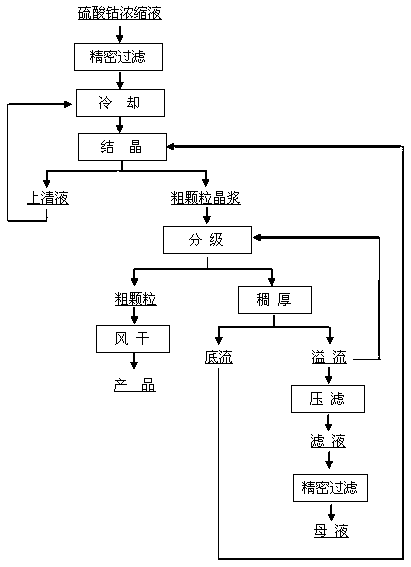

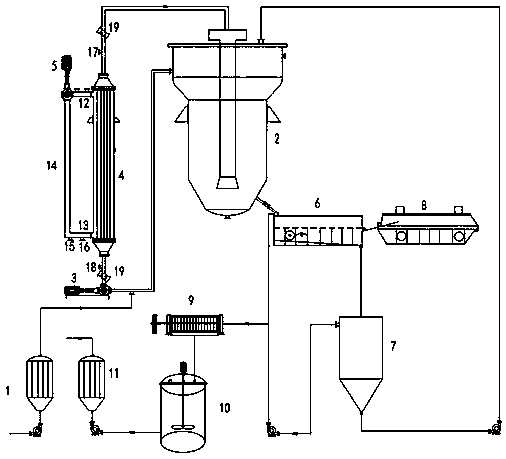

Continuous crystallization system of cobalt sulfate with coarse grain and low water insoluble matters as well as process thereof

ActiveCN107837557ARealize continuous productionHigh degree of automationCobalt sulfatesSolution crystallizationWater insolubleLotion

The invention discloses a continuous crystallization system of cobalt sulfate with coarse grain and low water insoluble matters as well as a process thereof. The continuous crystallization system comprises a filtering machine set, a cooling crystallization set, a discharging set, and connecting pipelines. The continuous crystallization process is as follows: a cooling crystallizer is full of a stock solution or mother liquor, a crystallization circulating pump is opened, cobalt sulphate concentrate which is precisely filtered and a crystallizer supernatant are mixed and enter an external cooler in order to form a supersaturated solution, and the solution enters a crystallizer through a crystallizer guide shell and grows on an original crystal nucleus; cobalt sulfate from an Oslo cooling crystallizer aging zone is discharged and enters a grader, and air drying of cobalt sulfate of coarse grain is directly carried out in order to obtain a qualified cobalt sulfate product; the grader fines enter a thickener, and underflow of the thickener returns the crystallizer and is used as a crystal seed; a part of the thickener overflow returns and is used as a washing lotion for grading, and apart of the thickener overflow is filtered by a filter press and a precision filter and enters an evaporative concentration process. The process has the advantages of good continuity, large proportionof products with coarse grain, low content of water insoluble matters, high crystallization rate, and the like.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

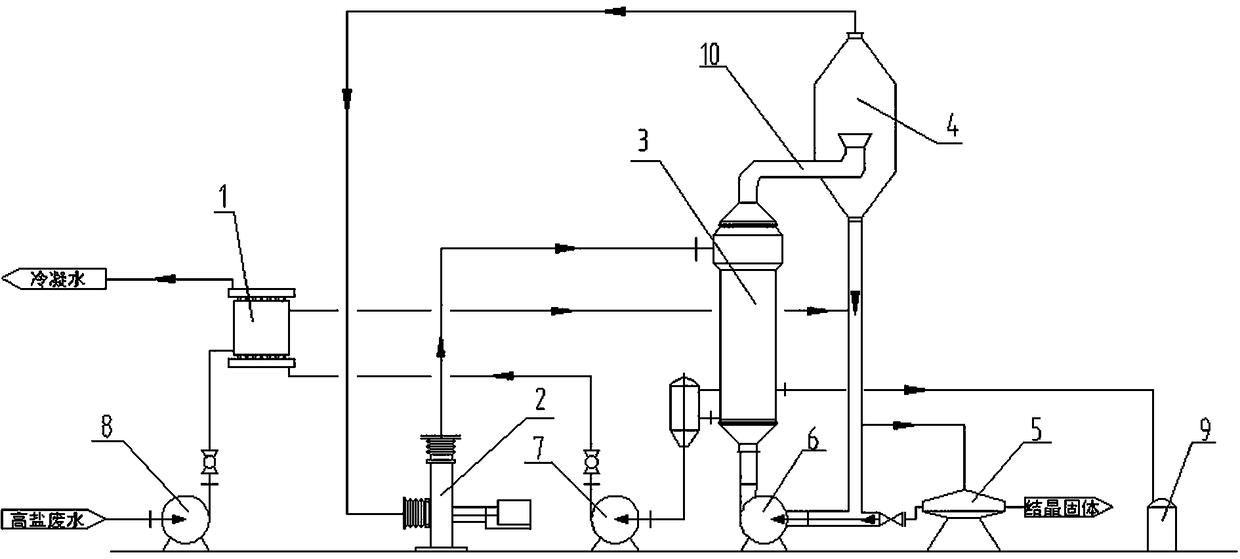

High salinity wastewater energy-saving evaporative crystallization system and technology thereof

PendingCN108910997AGood energy saving effectLess investmentSolution crystallizationCrystallization by component evaporationWastewaterCondensate pump

The invention provides a high salinity wastewater energy-saving evaporative crystallization system and a technology thereof. The system comprises a wastewater preheater, a heating chamber, an evaporation chamber, a steam compressor, a vacuum system, a solid-liquid separation device, a circulating pump, a feed pump, and a condensate water pump. High salinity wastewater enters the heating chamber for preheating, enters the evaporation chamber for steam heating, and undergoes flash evaporation under vacuum and at low pressure; the evaporated steam enters the steam compressor for compression and warming, and the compressed steam enters the heating chamber again to heat the wastewater; condensate water is then used to preheat the high salinity wastewater, and the heat taken away by the evaporated water is further recovered. The heating chamber and the evaporation chamber of the invention adopt an integrated structure, the wastewater directly enters the evaporation chamber for flash evaporation after being heated, the concentrated liquor enters the circulating pump through the bottom of the evaporation chamber to be circulated to the heating chamber for continuous heating, and the liquidforms an inner circulation until the crystallization starts. The invention has the advantages of energy conservation and high efficiency, small equipment occupation, less equipment investment, etc.,and zero discharge of wastewater is finally achieved.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

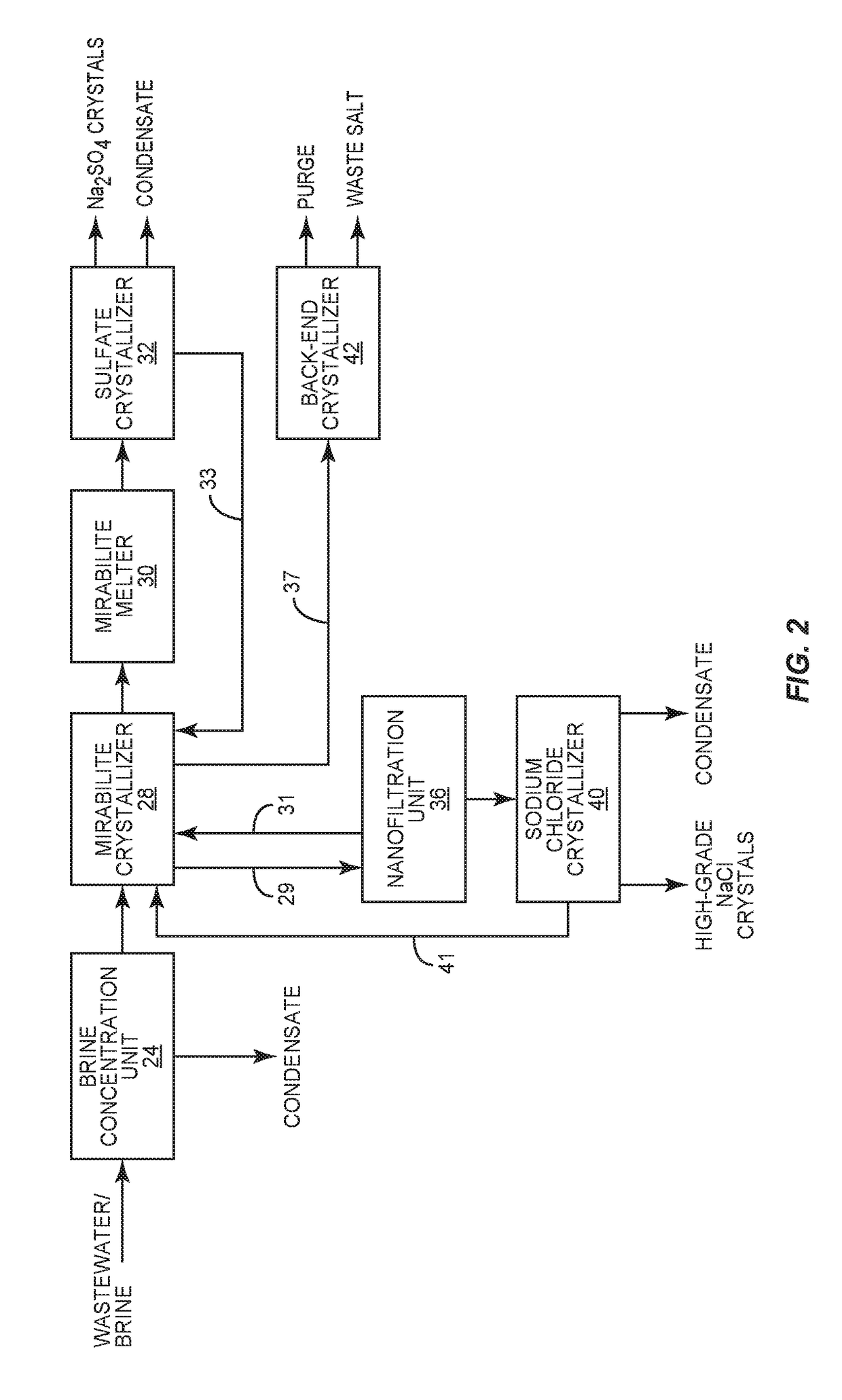

Enhanced process for selective salt recovery from wastewater, waste salts, and brines

ActiveUS20180029904A1Enhances sulfate depletionFacilitating hydrated salt crystallizationWater contaminantsAlkali metal sulfite/sulfate purificationSulfateSalt water

A process for treating wastewater or waste brines that include sodium and chloride ions. The waste brine is concentrated and thereafter directed to a Mirabilite crystallizer that produces hydrated sulfate salt crystals and a first solution. The hydrated crystals are melted to form an aqueous sulfate solution that is directed to a sodium sulfate crystallizer which produces sodium sulfate salt crystals. The first solution produced by the Mirabilite crystallizer is directed to a nanofiltration device which produces a permeate stream and a reject stream containing sulfate removed by the nanofiltration device. The permeate stream is directed to a sodium chloride crystallizer that produces sodium chloride salt crystals. The reject stream is recycled to the Mirabilite crystallizer.

Owner:VEOLIA WATER TECH INC

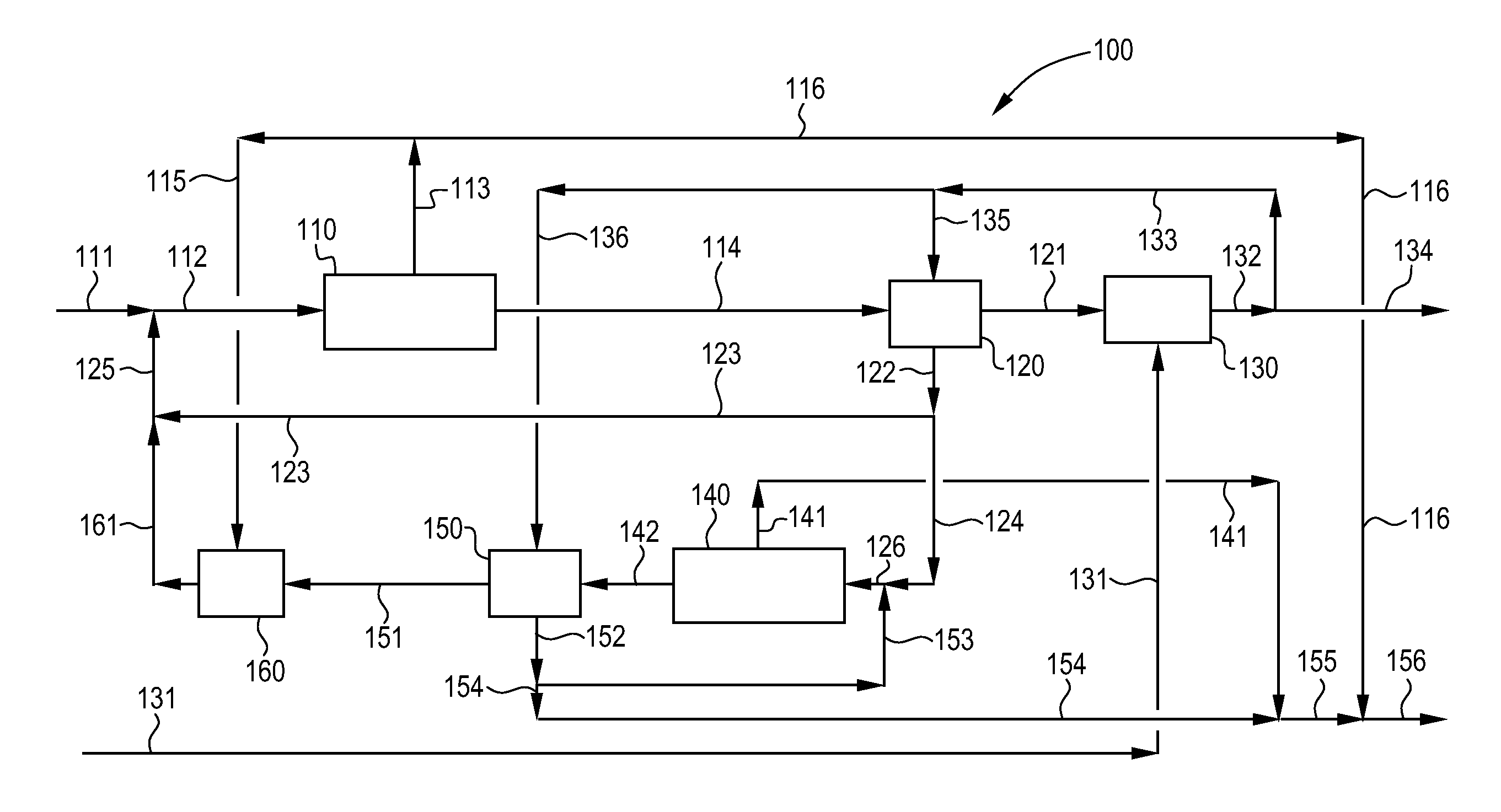

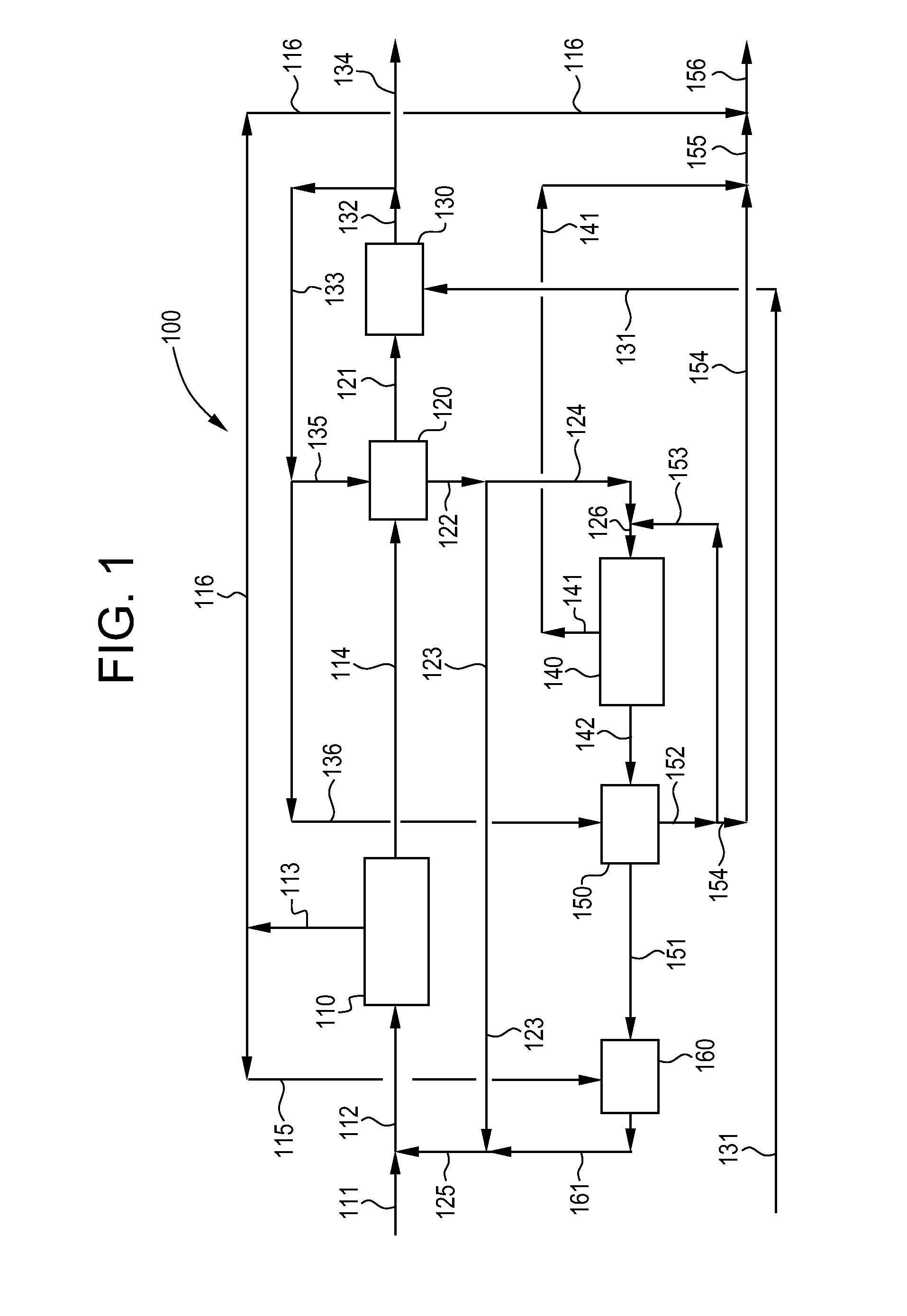

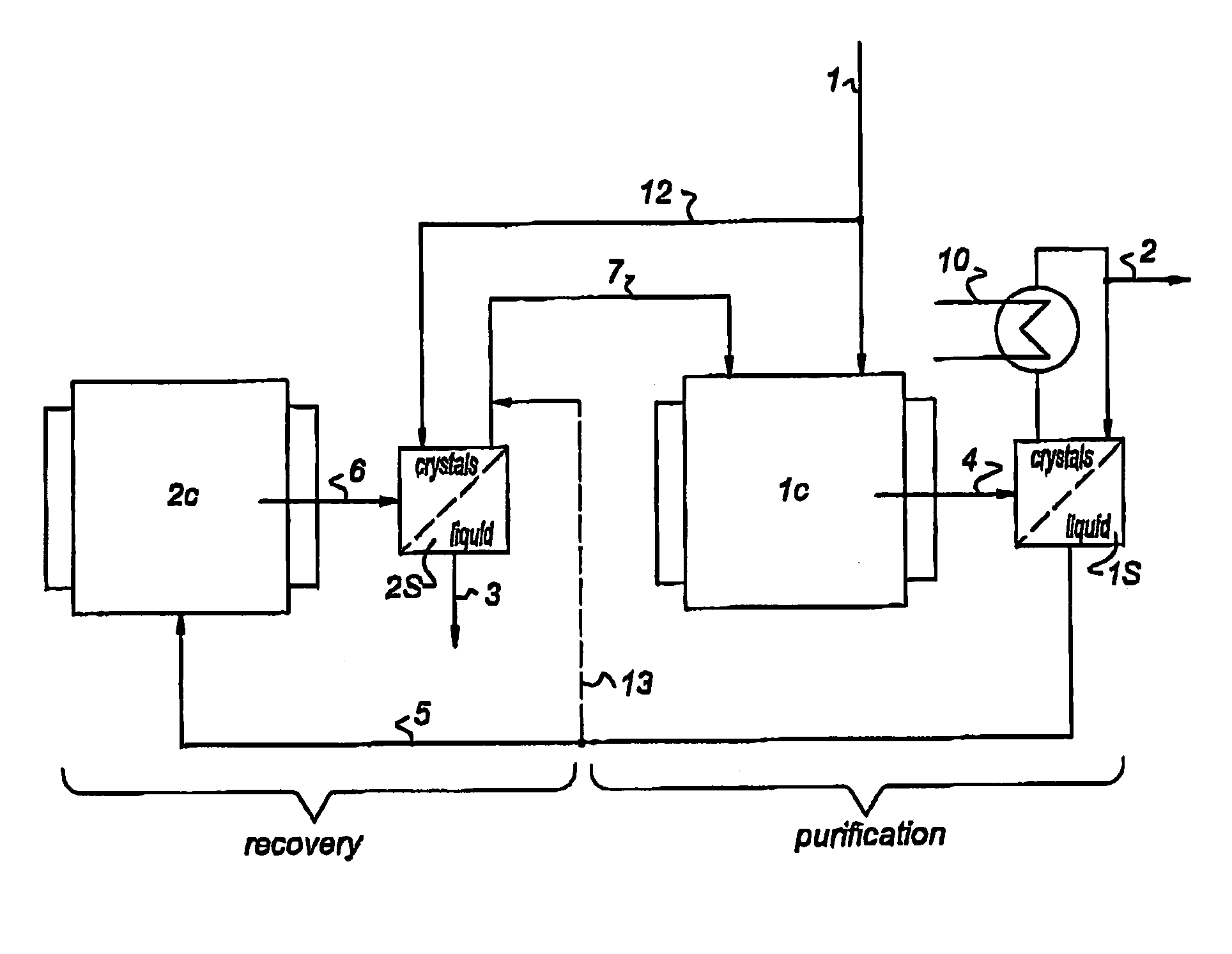

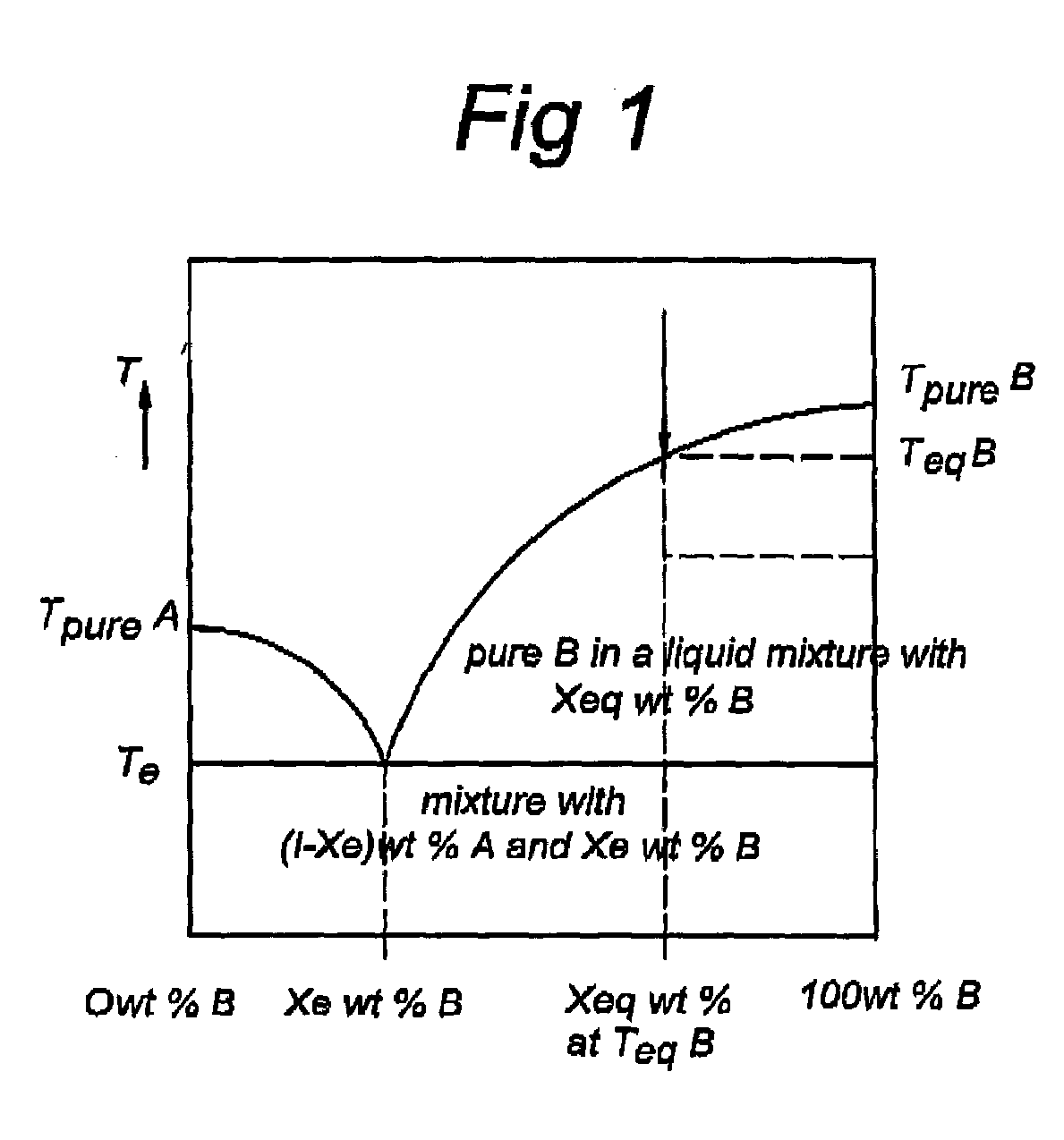

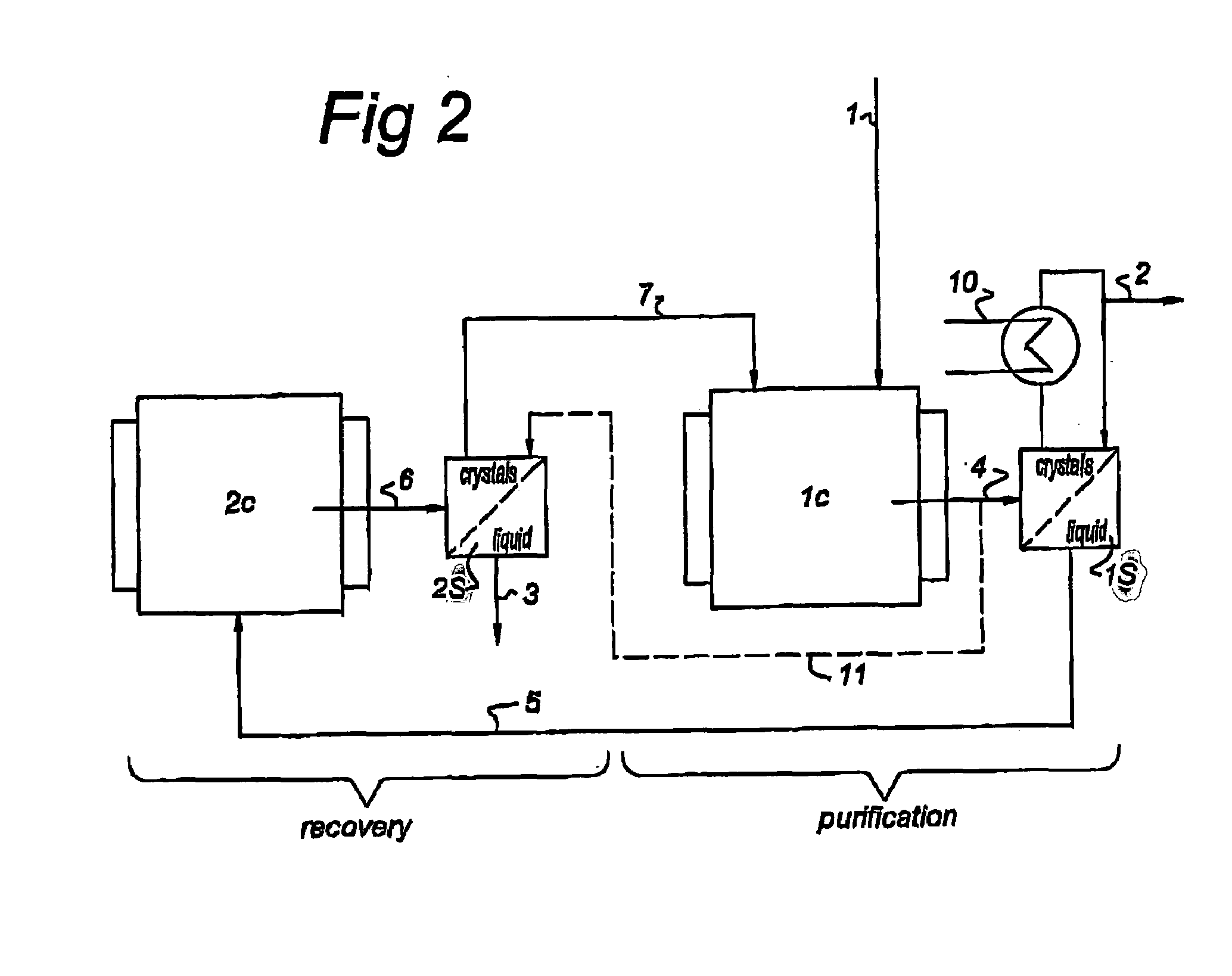

Method and apparatus for recovering a pure substance from an impure solution by crystallization

The invention relates to an apparatus for the purification of a substance from a solution, a suspension or a mixture of liquids by crystallization, preferably in a continuous manner. The apparatus comprises a first crystallizer (1c) comprising an input (1) for receiving a liquid comprising the substance and an output (4) for discharging a slurry of liquid and crystals. The apparatus comprises also a first separator (1s) connected to the output 4 of the first crystallizer (1c) having a product output (2), and being with a residue output (5) connected to an input of a second crystallizer (2c), and a second separator (2s) being with an input connected to an output (6) of the second crystallizer (2c), a crystal output (7) of the second separator (2s) being connected to an input of the first crystallizer (1c).

Owner:NIRO PROCESS TECH

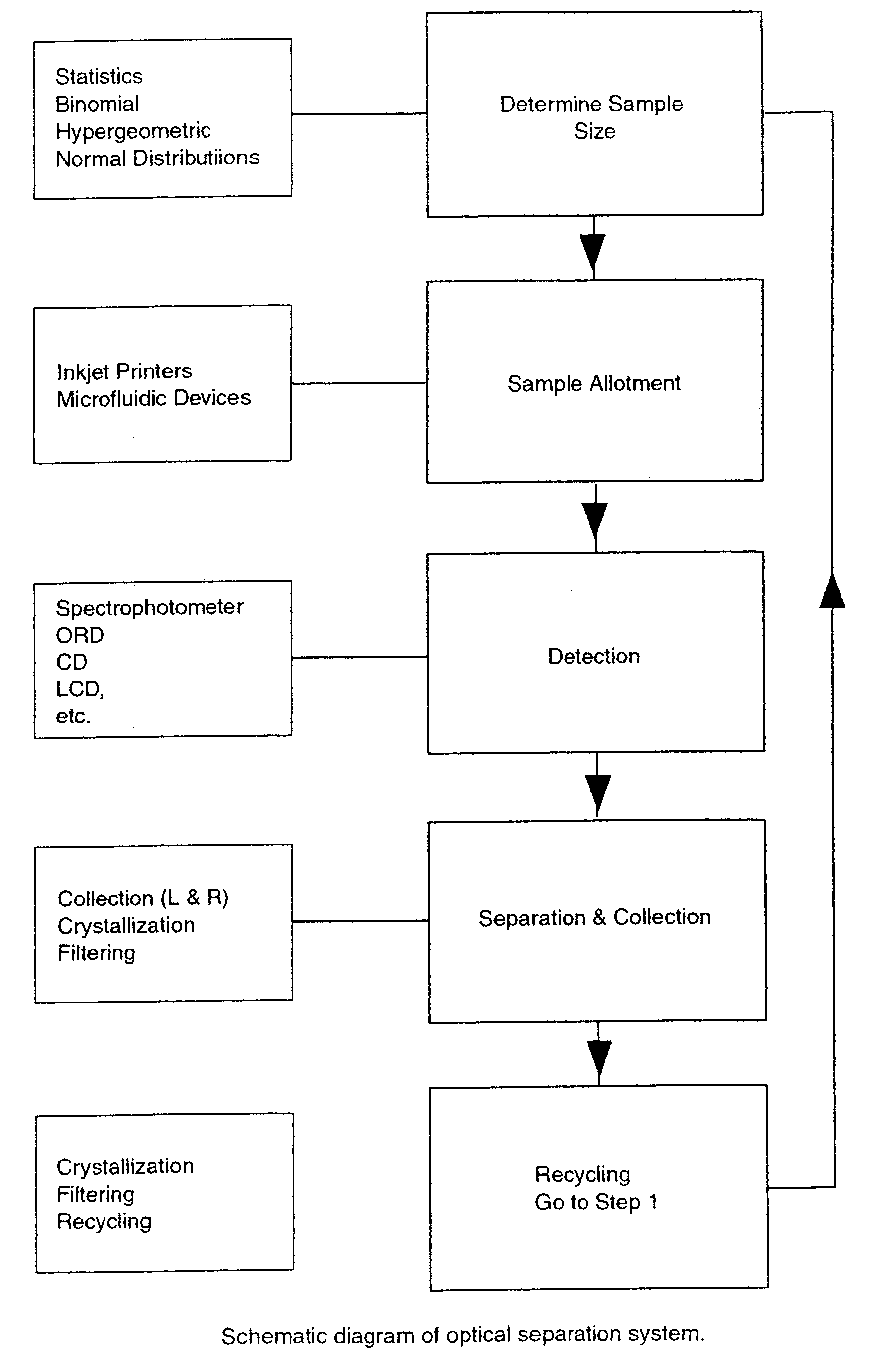

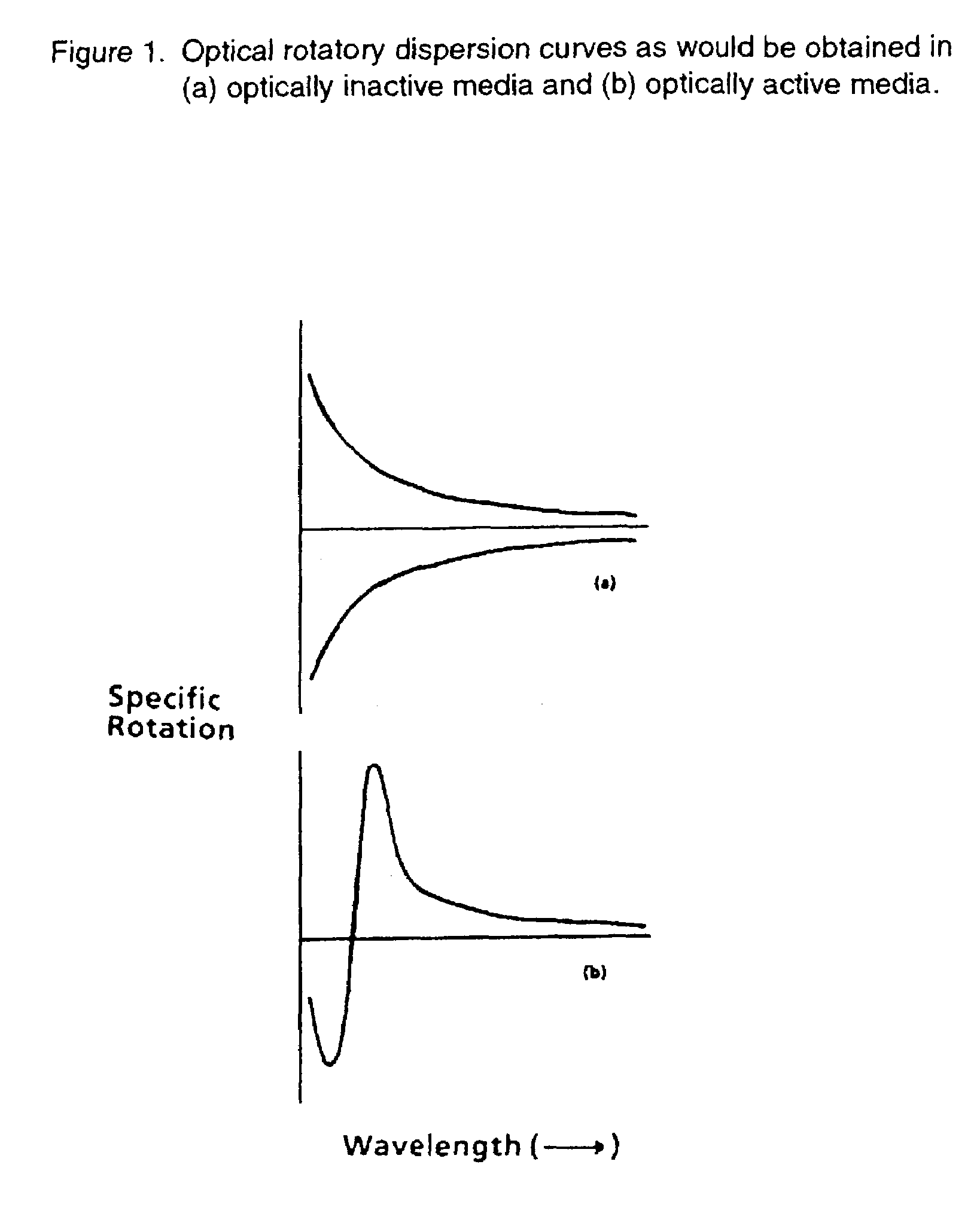

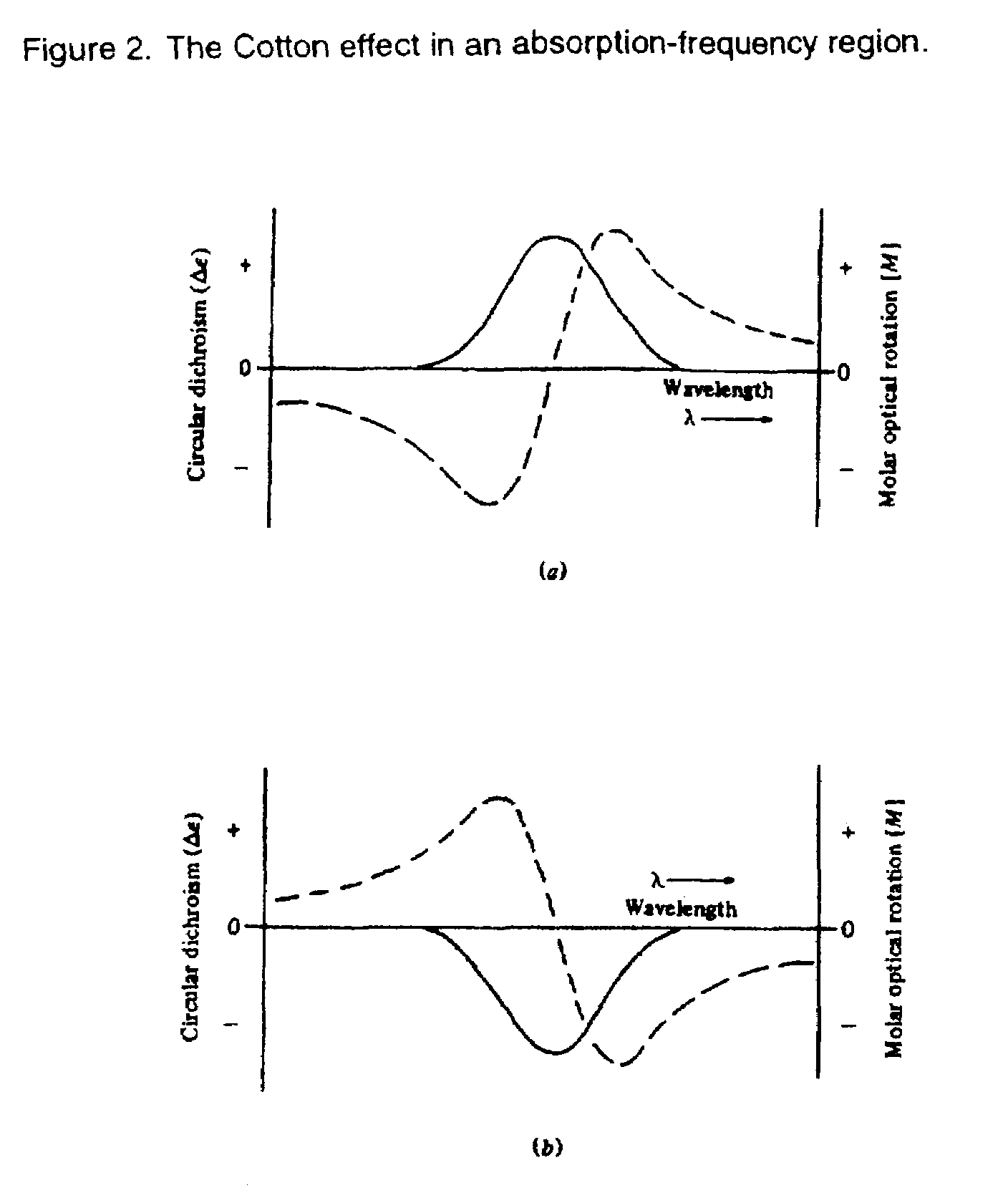

Optical isomer separation method

InactiveUS7001526B1Sensitive highHighly sensitive and fast spectrophotometerAnalysis by material excitationWater/sewage treatmentSmall sampleEnantiomer

Methods for separation of two optical isomers in a racemate into its constituent isomers by statistical means are described, whereby the saturated racemate solution is first allotted into small samples by means of microfluidic or inkjet techniques to obtain small sample quantities (picoliters to microliters) with one isomer in measurable excess of the other. The samples are then tested by means of spectrophotometers used for measuring Cotton Effects or Circular Dichroism or other related effects which measure the difference in the absorption of right and left circularly polarized light, so that there is a predetermined minimum excess of one enantiomer. Collecting them in three different receptacles then separates the three types of samples. The right and left excess samples are then used in the crystallization process to obtain right or left handed isomers respectively. The third type of sample that is collected is again re-circulated through the sampling process so that right and left excess samples are collected again out of the neutral samples (with less than minimum excess of one kind or the other) and the process continued to crystallize out the two isomers.

Owner:TIN HLA NGWE

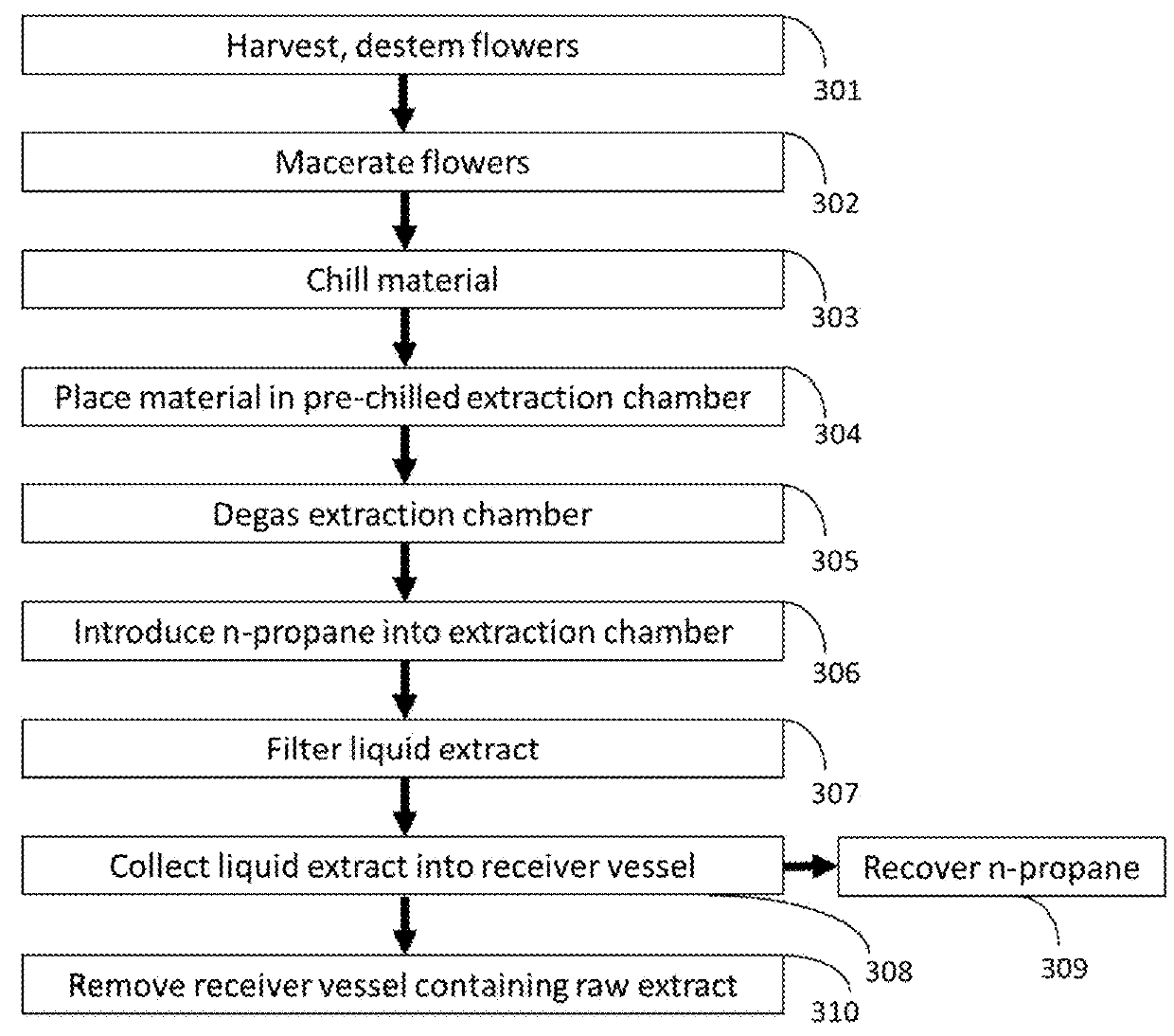

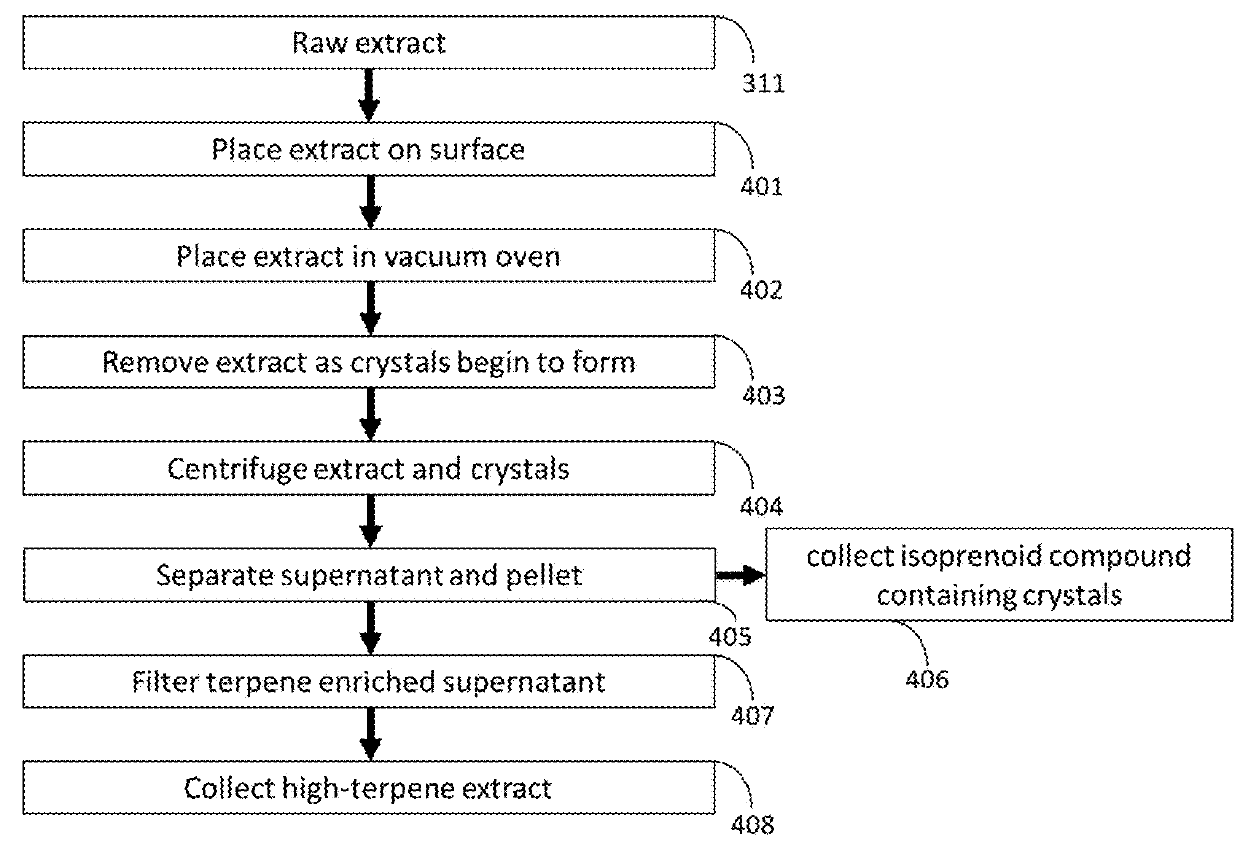

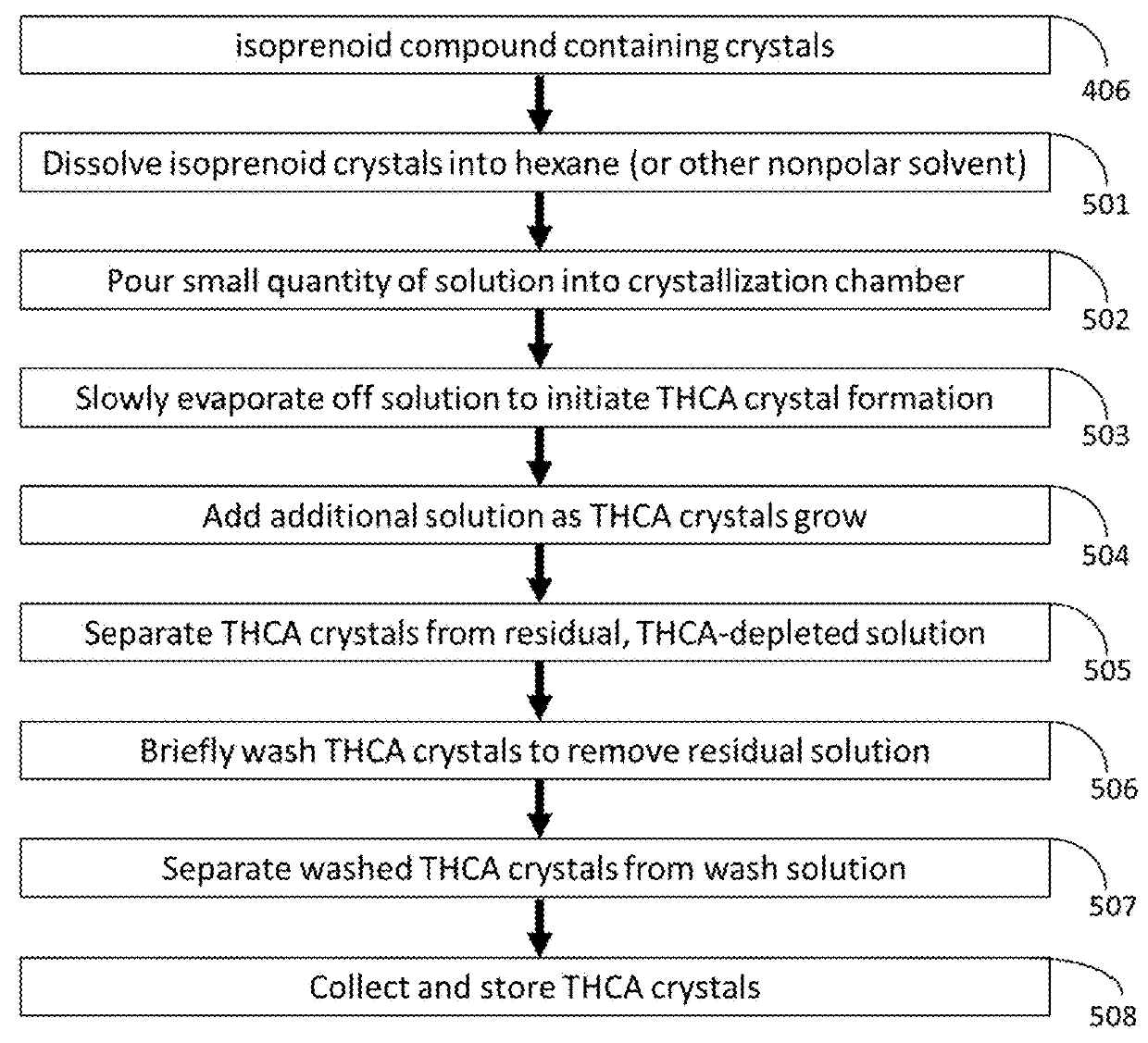

Methods for Purification of Non-Psychoactive Isoprenoid Compounds from Biological Extracts

ActiveUS20180273501A1Improve stabilityPrevent degradationOrganic chemistry methodsCentrifugal force sediment separationCannabisPrenylation

A method for the extraction and isolation of the terpene and isoprenoid compounds from plant material, followed by a centrifugal force induced selective crystallization of isoprenoids resulting in a separation of terpene and isoprenoid fractions. This this method is suitable for the extraction of cannabinoids from Cannabis and the enrichment tetrahydrocannabinolic acid and reduction of tetrahydrocannabinol in an extract. The purity of tetrahydrocannabinolic acid resulting from centrifugal crystallization is such that dissolution and selective recrystallization of tetrahydrocannabinolic acid is possible resulting in >99.9% pure tetrahydrocannabinolic acid, w / w.

Owner:CONCENTRATED CONSULTING GRP LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com