Multistage continuous crystallization method of short rod-like methionine crystals

A methionine and short rod-shaped technology, which is applied in the field of multi-stage continuous crystallization of short rod-shaped methionine crystals, can solve the problems of difficult to meet the industrial production requirements of methionine, high cost of material use, poor crystal morphology, etc. Intermediate operation steps, the effect of reducing the difference between product batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

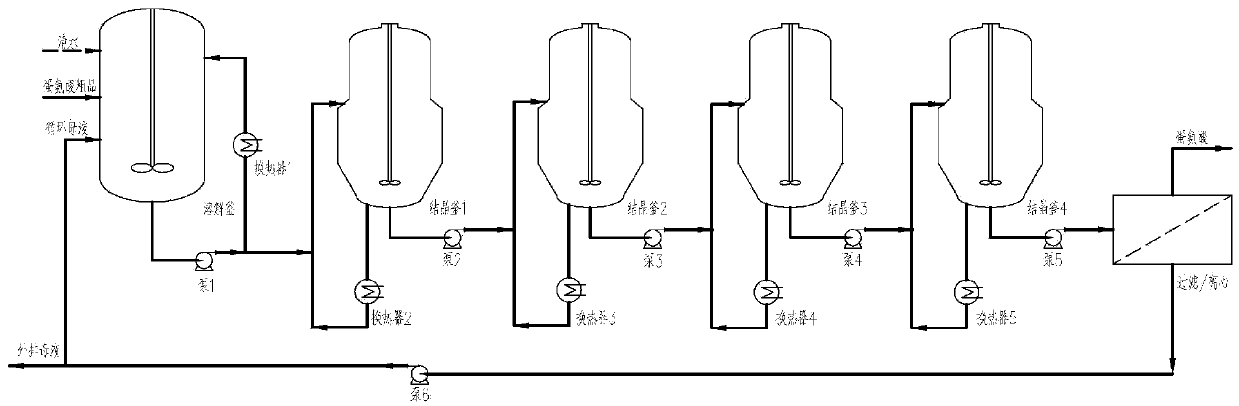

[0055] In this embodiment, a method for crystallization of methionine crystals is provided, the method for crystallization of methionine crystals is as follows: figure 1 As shown, the following steps are included: four continuous crystallization tanks are connected in series. Equip a 20% methionine feed solution in a 2L dissolution tank (add 0.080kg / h DL-methionine raw material with a purity of 90%, 0.14L / h water and 0.22L / h circulating mother liquor), heat to dissolve, and control the temperature at 130°C to obtain a clarified feed liquid; pump the clarified feed liquid into the first-stage 1L crystallization tank at a flow rate of 0.36L / h (20% solution / h), and control the temperature of the crystallization tank to 80°C, the average residence time of the slurry The time is controlled at 2.0h; the slurry in the first-stage crystallization tank is pumped into the second-stage 1L crystallization tank, the temperature of the crystallization tank is controlled at 60°C, and the ave...

Embodiment 2

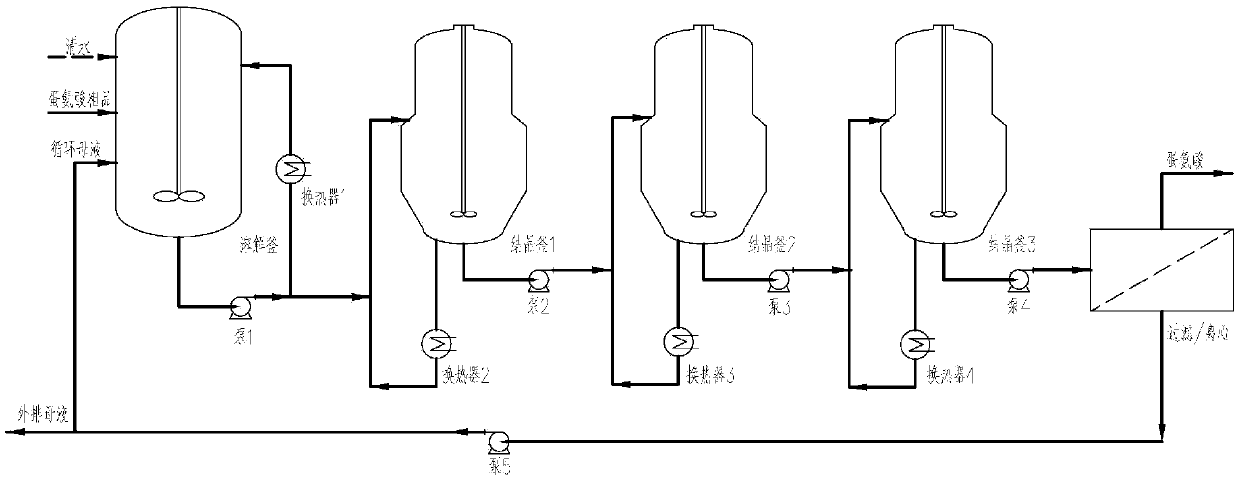

[0057] In this embodiment, a method for multistage continuous crystallization of short rod-shaped methionine crystals is provided. The crystallization method of said methionine crystals is as follows: figure 2 As shown, the following steps are included: three continuous crystallization tanks are connected in series. Equip a methionine feed solution with a concentration of 15% in a 5L dissolution tank (add 0.38kg / h DL-methionine raw material with a purity of 95%, 1.92L / h water and 0.48L / h circulating mother liquor), and dissolve at high temperature, temperature control to 110°C to obtain a clarified feed liquid; pump the clarified feed liquid into the first-stage 2L crystallization tank at a flow rate of 2.4L / h (60% solution / h), and control the crystallization tank temperature to 60°C, the average residence time of the slurry The time is controlled at 0.5h; the slurry in the first-stage crystallization kettle is pumped into the second-stage 2L crystallization kettle, the tempe...

Embodiment 3

[0062] In this embodiment, a method for multistage continuous crystallization of short rod-shaped methionine crystals is provided. The crystallization method of said methionine crystals is as follows: Figure 6 As shown, the following steps are included: two continuous crystallization tanks are connected in series. Prepare a methionine feed solution with a concentration of 10% in a 1L dissolution tank (add 0.060kg / h DL-methionine raw material with a purity of 90%, 0.22L / h water and 0.32L / h circulating mother liquor), heat to dissolve, and control the temperature at 80°C to obtain a clarified feed liquid; pump the clarified feed liquid into the first-stage 1L crystallization tank at a flow rate of 0.54L / h (60% solution / h), and control the temperature of the crystallization tank to 40°C, the average residence time of the slurry The time is controlled at 0.5h; the slurry in the first-stage crystallization kettle is pumped into the second-stage 1L crystallization kettle, the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Master granularity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com