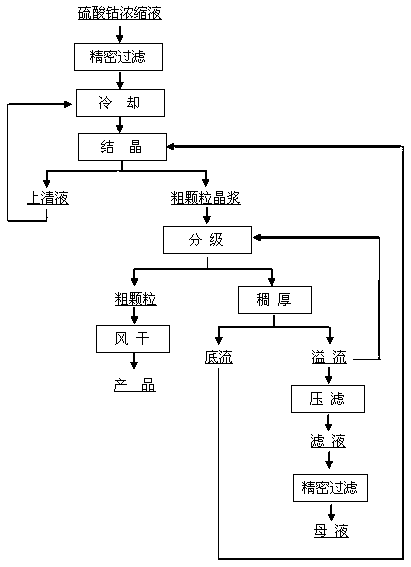

Continuous crystallization system of cobalt sulfate with coarse grain and low water insoluble matters as well as process thereof

A technology of crystallization system and water-insoluble matter, which is applied in the direction of cobalt sulfate, solution crystallization, and crystallization separation, etc., can solve problems such as no removal method of cobalt sulfate water-insoluble matter, no consideration of heat exchanger cleaning, and high requirements for equipment sealing. Achieve the effect of high degree of automation, convenient cleaning and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

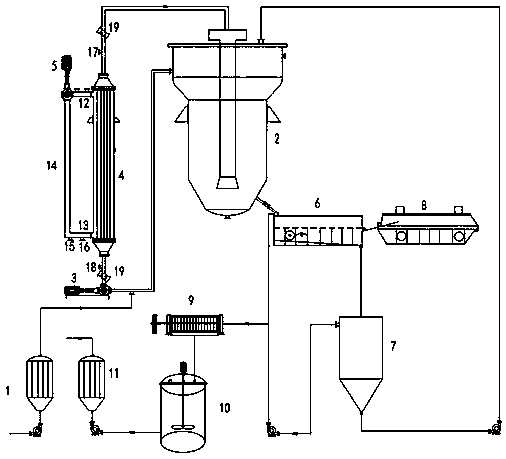

[0037] A continuous crystallization system and technology of cobalt sulfate with coarse particles and low water insolubles, the production steps are as follows.

[0038] (a) First, the volume 45m 3 The Oslo cooling crystallizer is filled with Co90g / L stock solution, turn on the crystallization circulation pump frequency 30Hz, open the cooling water valve of the external cooler and start the cooling water circulation pump, the cobalt sulfate concentrate with a density of 1.40g / L is finely filtered with 0.02μm and mixed with the crystallizer The supernatant is mixed into the external cooler to form a supersaturated solution, and enters the crystallizer through the crystallizer guide tube to grow on the original crystal nucleus.

[0039] (b) When the crystals in the aging area of the crystallizer reach 0.5mm or more, the cobalt sulfate is continuously discharged into the dehydrator, and the coarse cobalt sulfate containing 1% free water is obtained after classification, and the...

Embodiment 2

[0044] A continuous crystallization system and technology of cobalt sulfate with coarse particles and low water insolubles, the production steps are as follows.

[0045] (a) First the volume is 90m 3 The Oslo cooling crystallizer is filled with Co140g / L stock solution, turn on the crystallization circulation pump frequency 50Hz, open the cooling water valve of the external heat exchanger and start the cooling water circulation pump, the density of 1.55g / L cobalt sulfate concentrate is filtered through 0.1μm and crystallized The supernatant of the crystallizer is mixed into the external heat exchanger to form a supersaturated solution, and enters the crystallizer through the crystallizer draft tube to grow on the original crystal nucleus.

[0046] (b) When the crystals in the aging area of the crystallizer reach more than 1mm, the cobalt sulfate is continuously discharged into the cylindrical sand washing machine, and after classification, the coarse-grained cobalt sulfate co...

Embodiment 3

[0051] A continuous crystallization system and technology of cobalt sulfate with coarse particles and low water insolubles, the production steps are as follows.

[0052] (a) First, the volume of 75m 3 The Oslo cooling crystallizer is filled with Co115g / L stock solution, turn on the crystallization circulation pump frequency 40Hz, open the cooling water valve of the external cooler and start the cooling water circulation pump, the cobalt sulfate concentrate with a density of 1.45g / L is filtered through 0.06μm and mixed with the crystallizer The supernatant is mixed into the external cooler to form a supersaturated solution, and enters the crystallizer through the crystallizer draft tube to grow on the original crystal nucleus.

[0053] (b) When the crystal in the aging area of the crystallizer reaches more than 0.75mm, the cobalt sulfate is continuously discharged into the shaking table, and after classification, the coarse cobalt sulfate containing 3% free water is obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com