Patents

Literature

905results about How to "Stable concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

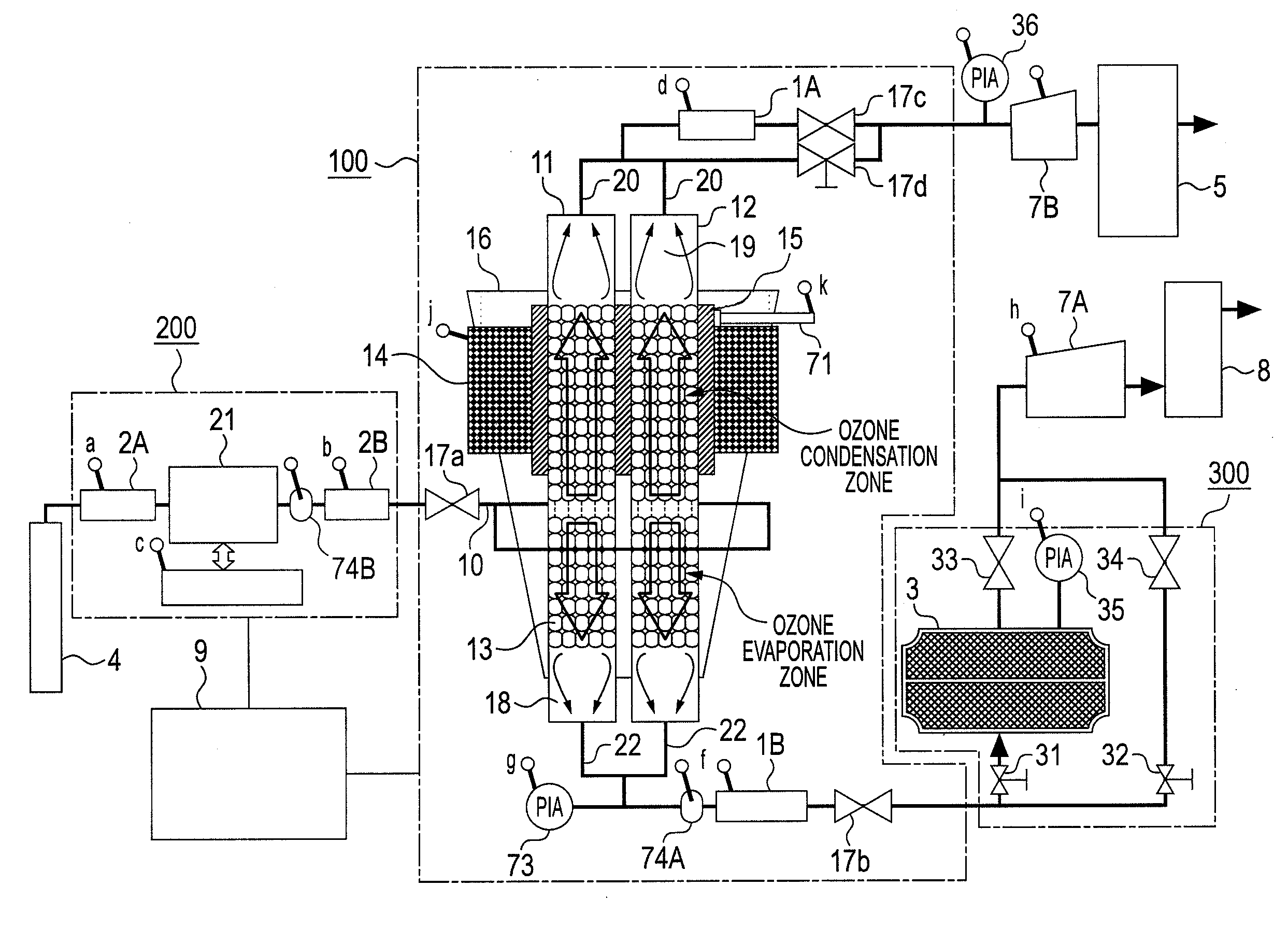

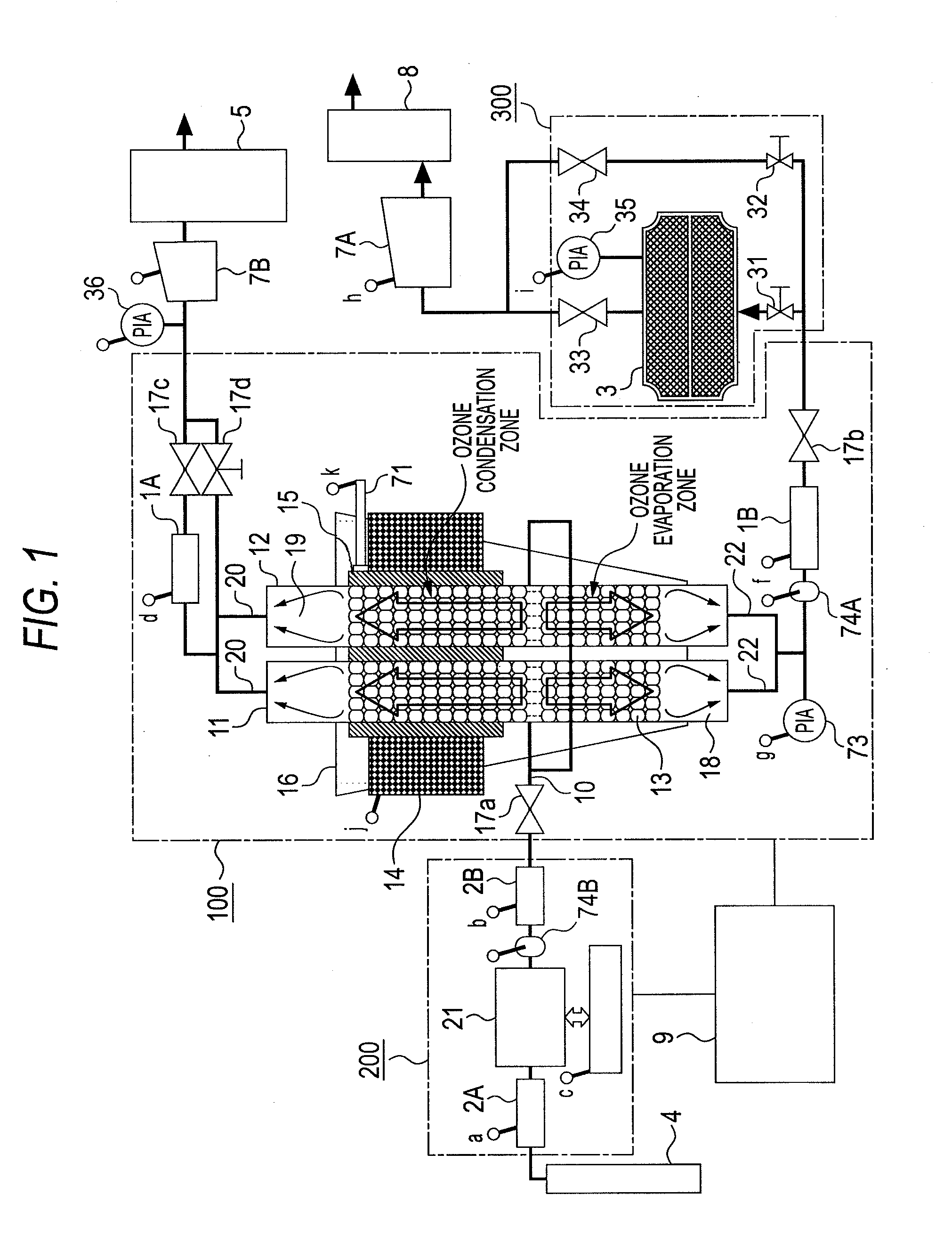

Apparatus for concentrating and diluting specific gas and method for concentrating and diluting specific gas

ActiveUS20100162752A1Improve processing efficiencySmall sizeSolidificationGas treatmentSpherical shapedVaporization

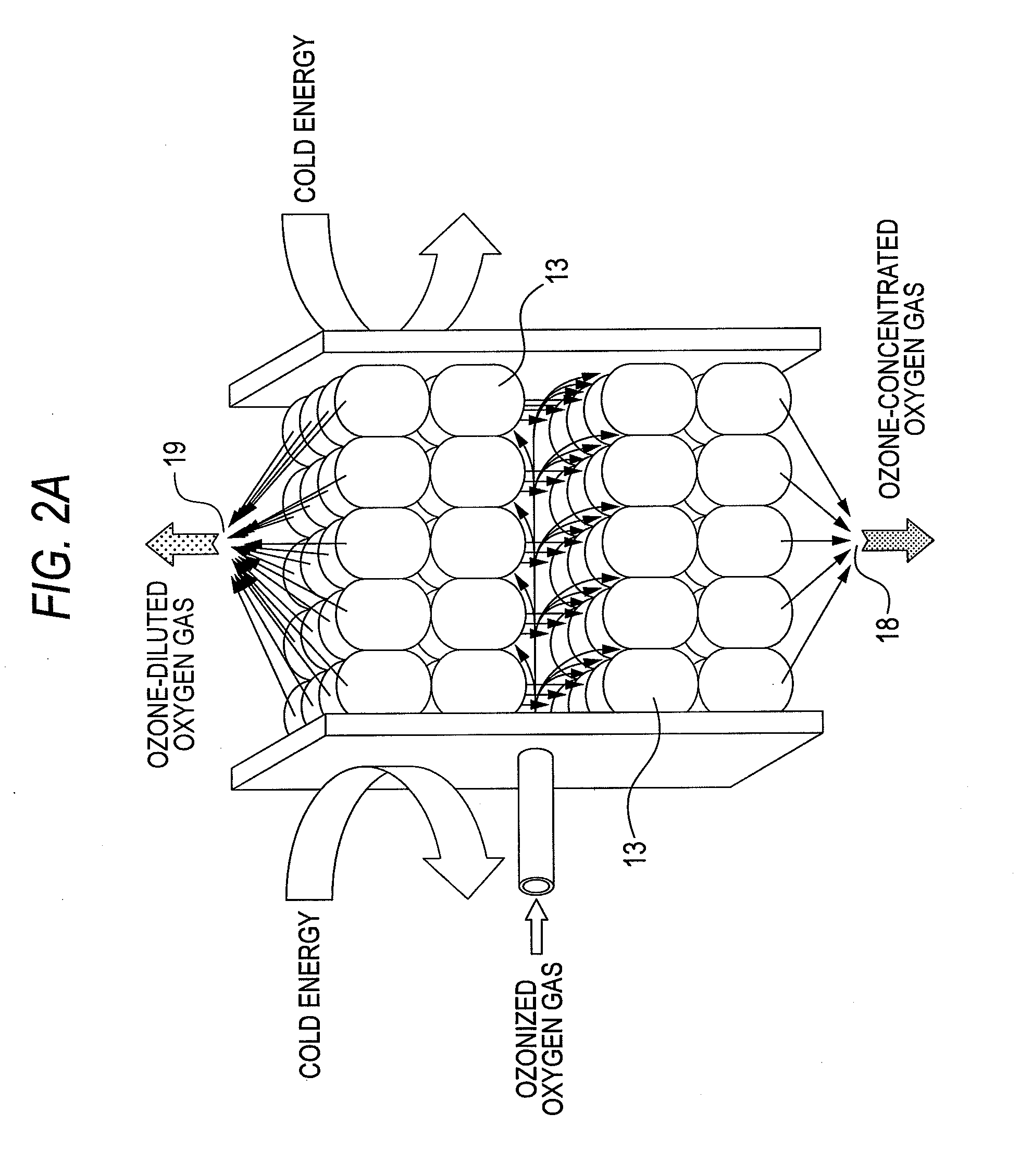

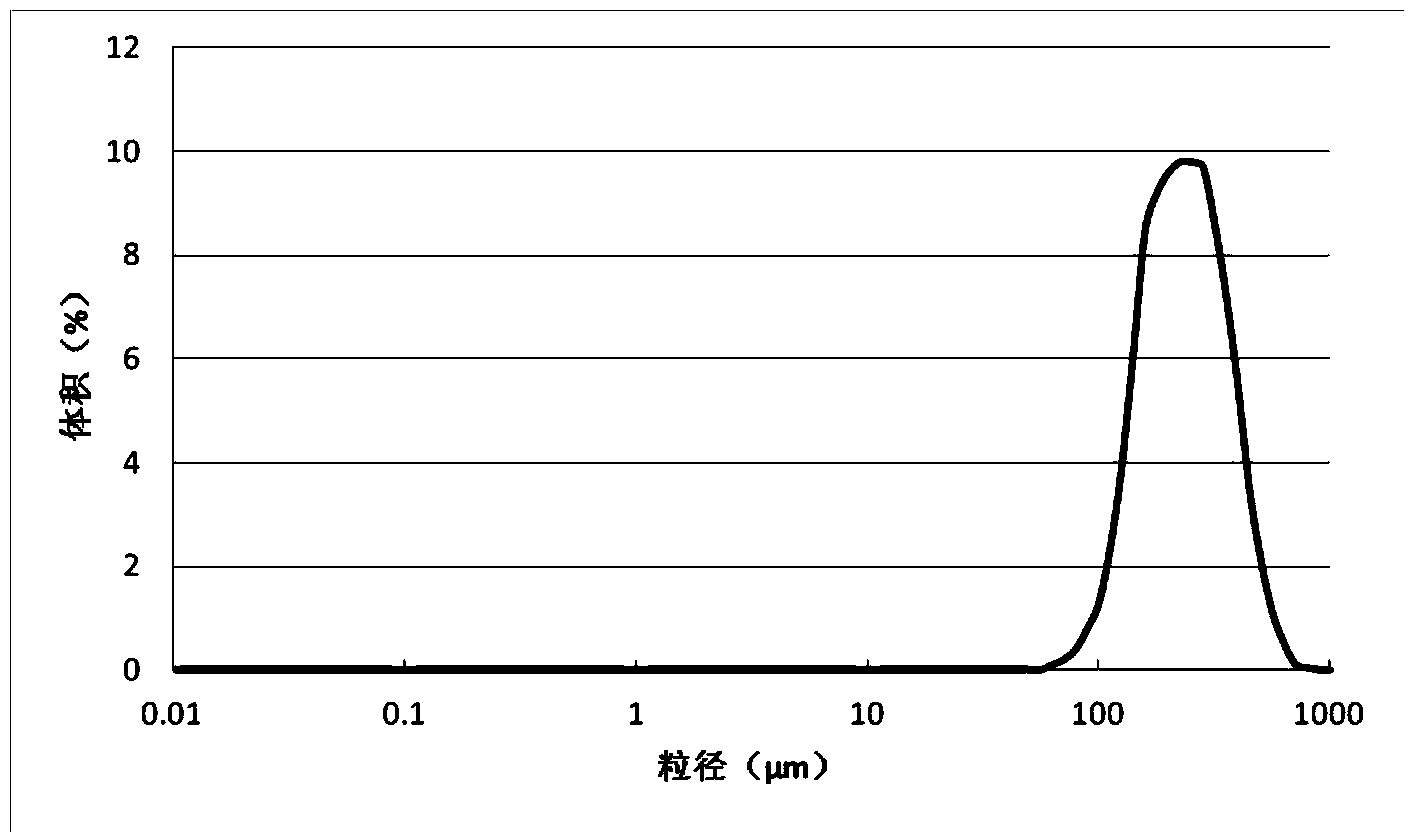

One ozone concentrating chamber is provided therein with a part of a cooling temperature range where ozone can be selectively condensed or an oxygen gas can be selectively removed by transmission from an ozonized oxygen gas, and a part of a temperature range where condensed ozone can be vaporized, and condensed ozone is vaporized by moving condensed ozone with flow of a fluid or by gravitation to the part where condensed ozone can be vaporized, whereby the ozonized oxygen gas can be increased in concentration. Such a constitution is provided that a particle material 13 for condensation and vaporization filled in the ozone concentrating chambers 11 and 12 has a spherical shape of a special shape with multifaceted planes on side surfaces, or an oxygen transmission membrane 130 capable of selectively transmitting an oxygen gas in an ozone gas is provided.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

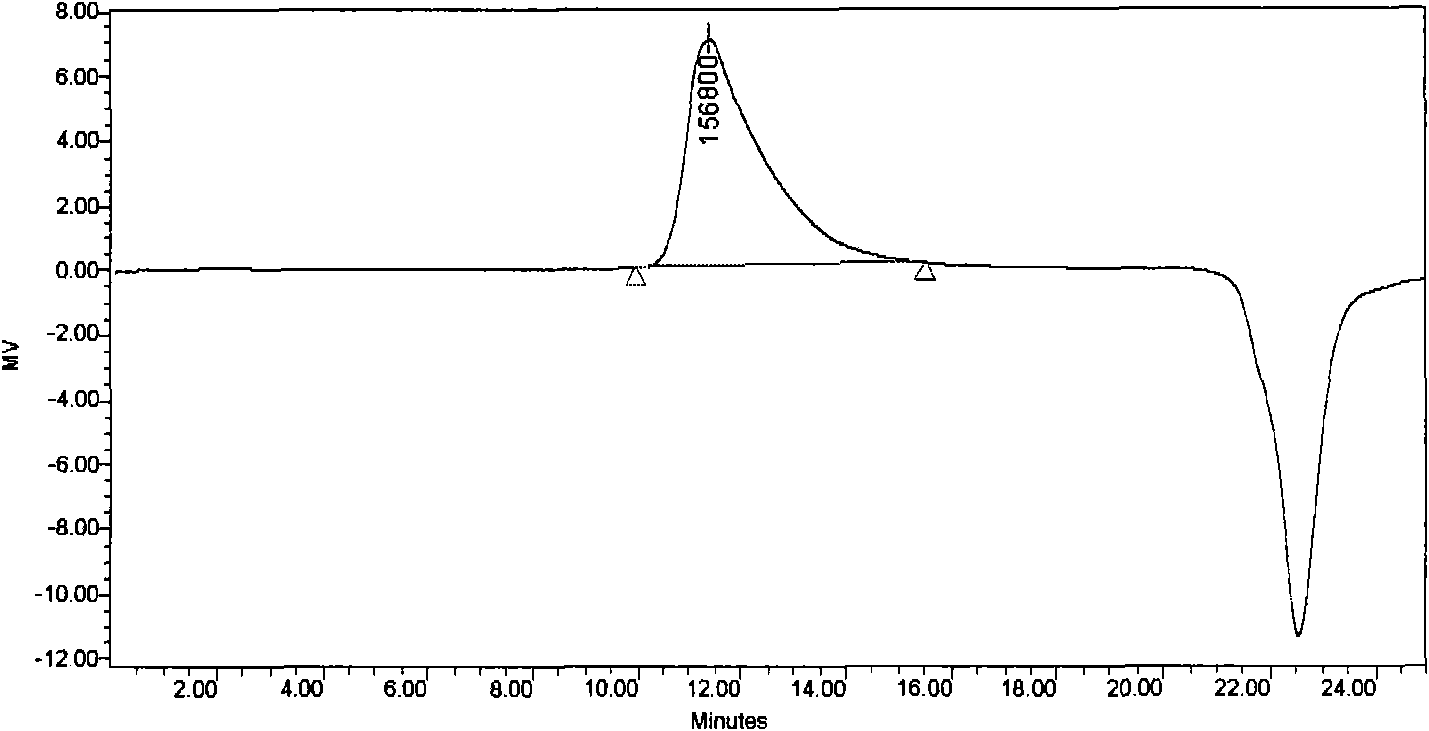

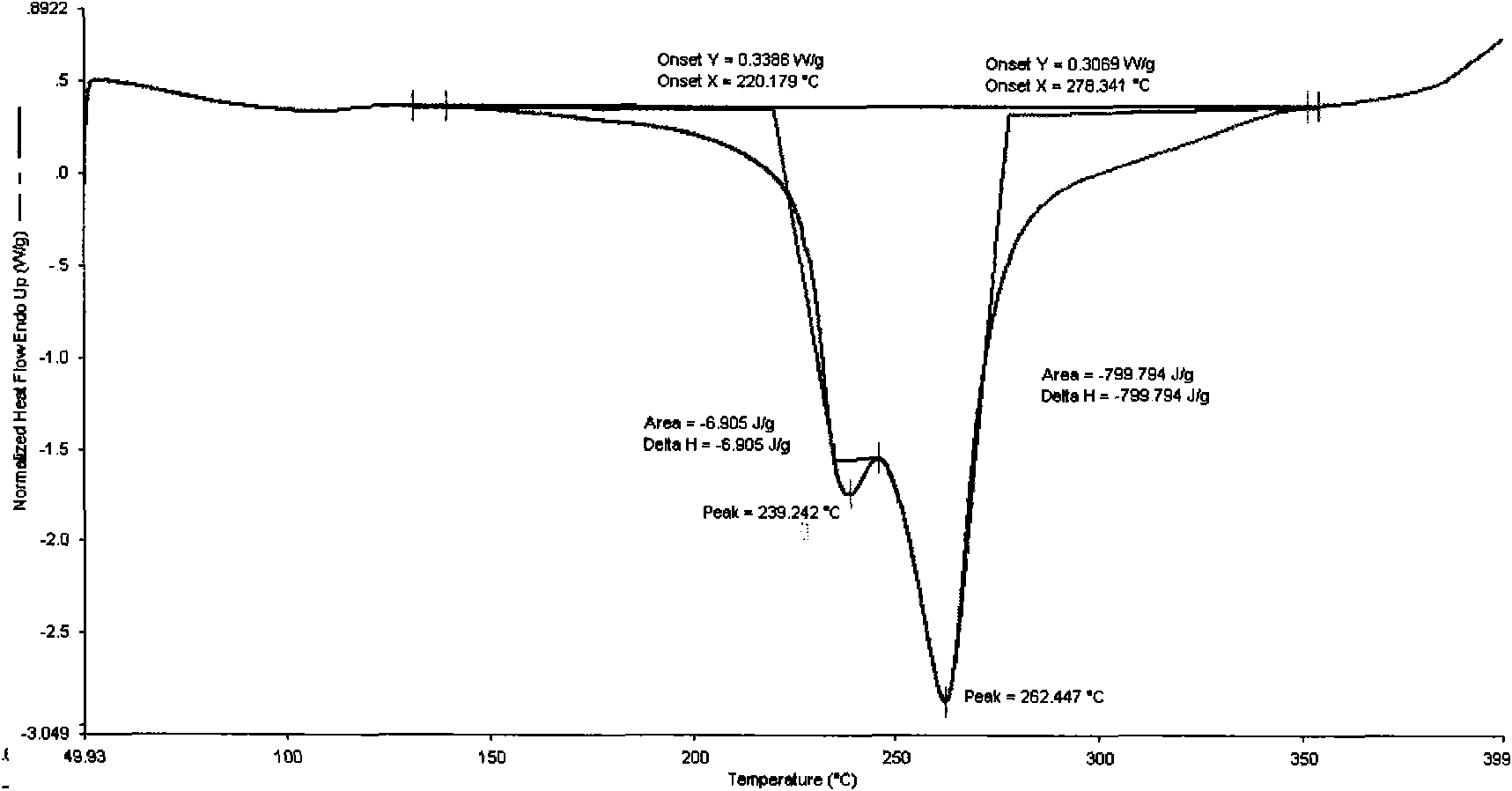

Injectable crosslinked hyaluronic acid gel and preparation method thereof

The invention relates to an injectable crosslinked hyaluronic acid gel and a preparation method thereof. The injectable crosslinked hyaluronic acid gel is prepared by blending hyaluronic acid gel granules and chlorinated sodium phosphate physiological buffer solution; the hyaluronic acid gel granules are prepared by comprising the steps of crosslinking treatment, emulsion crosslinking granulation, purification and drying and swelling, filling and sterilization technologies. The hyaluronic acid gel granules are uniform in granule size, the residual of the crosslinking agent is less than 0.2ppm, the injection pushing is proper, and the in-vivo degradation time can last more than 8-12 months. The implant has an excellent esthetical restoration effect, is applicable to being injected to and subcutaneous dermis deep layer to subcutaneous superficial layer, restoration of moderate to severe wrinkles or folds, and can satisfy the restoration demand of wrinkles or folds caused due to skin aging.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

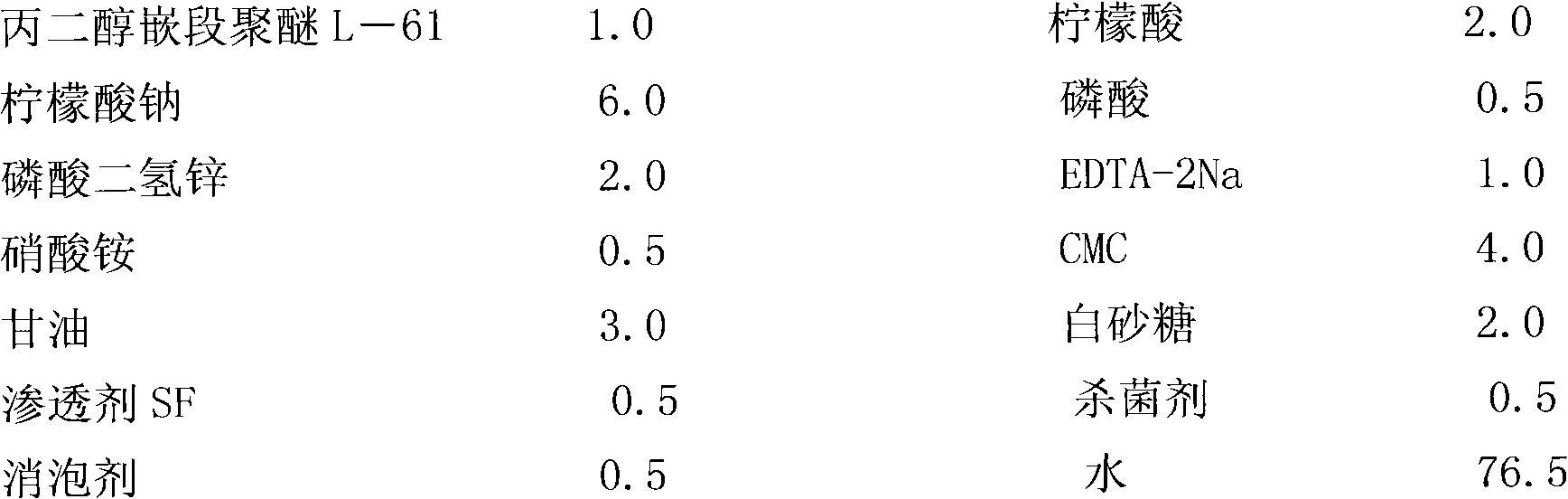

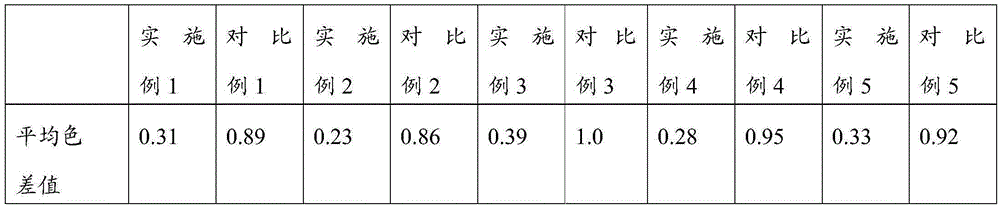

Alcohol-free concentrated fountain solution and preparation method thereof

InactiveCN102303465AStable concentrationPrint color difference is smallPrinting pre-treatmentAlcohol freePhysical well being

The invention provides an alcohol-free concentrated fountain solution and a preparation method thereof. The alcohol-free concentrated fountain solution is prepared from the following components based on 100 parts by weight: 0.5-5 parts of low-foam wetting agent, 8-20 parts of pH value regulator, 3-20 parts of printing plate protective agent, 5-10 parts of a water film regulator, 0.2-1.0 part of decontamination intensifier, 0.1-1.0 part of bactericide, 0.1-1.2 parts of defoamer and the balance of water. The concentrated fountain solution provided by the invention is environmentally-friendly, provides guarantee for the health of workers, and can improve the quality of the printing products.

Owner:冯星枢 +1

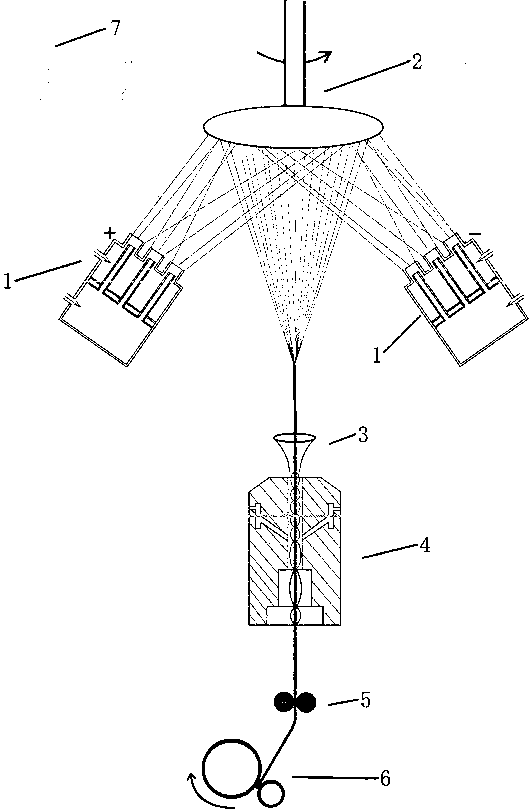

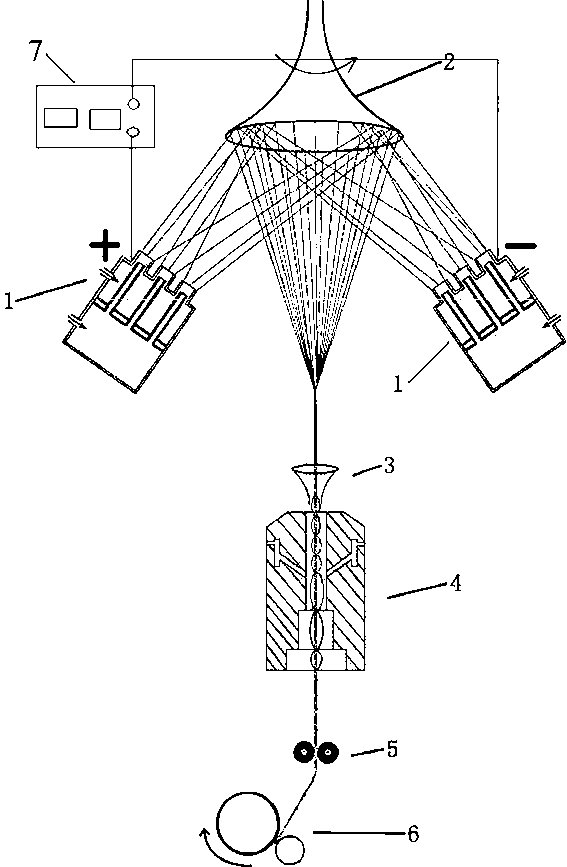

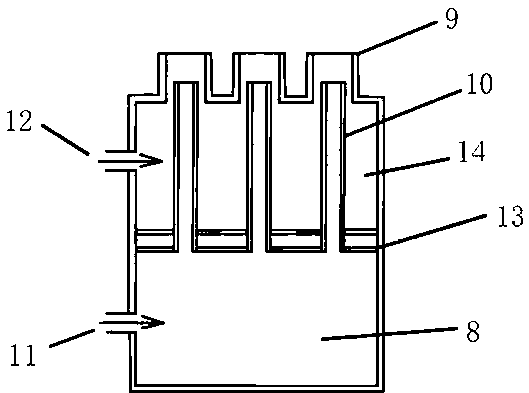

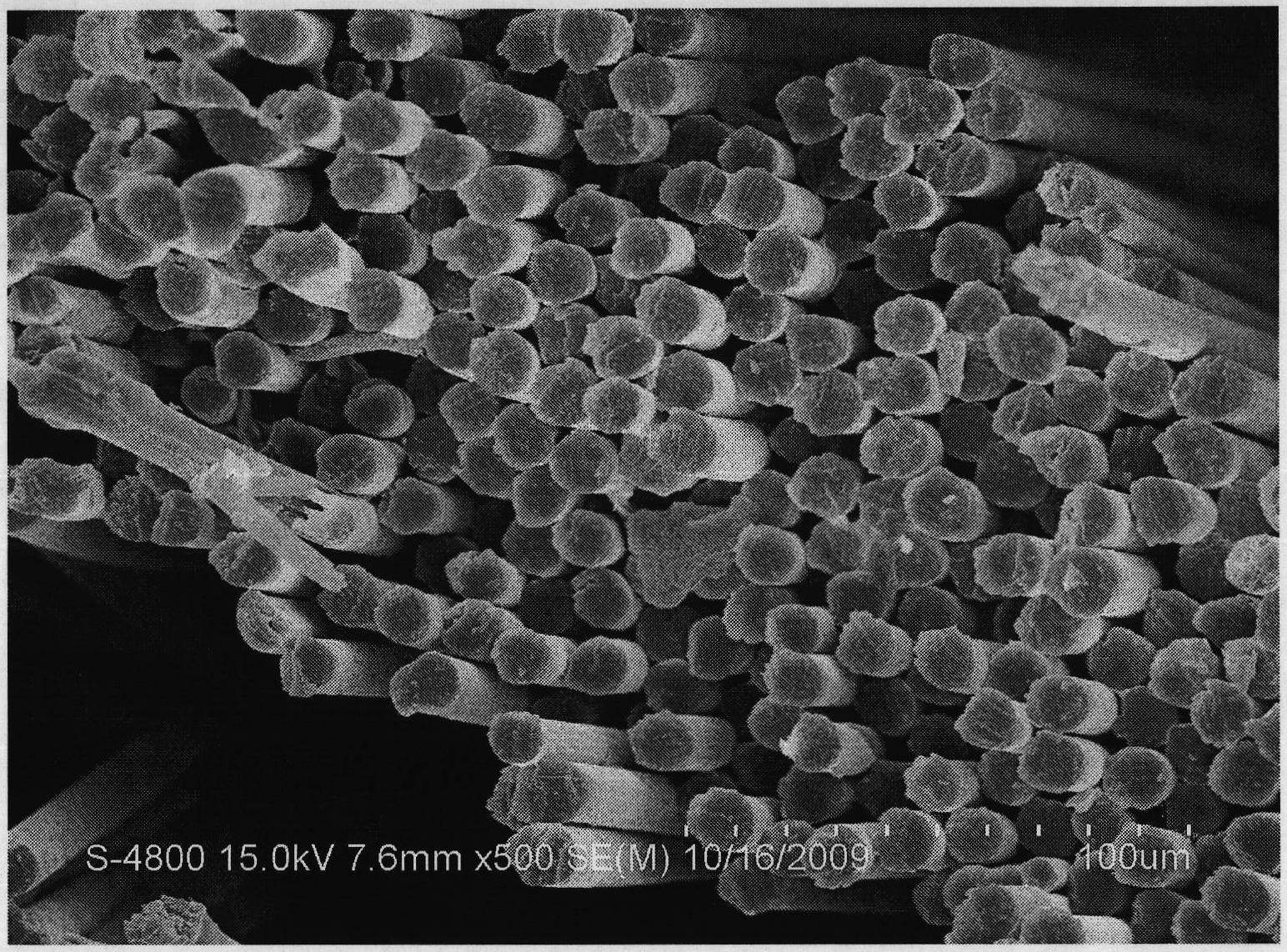

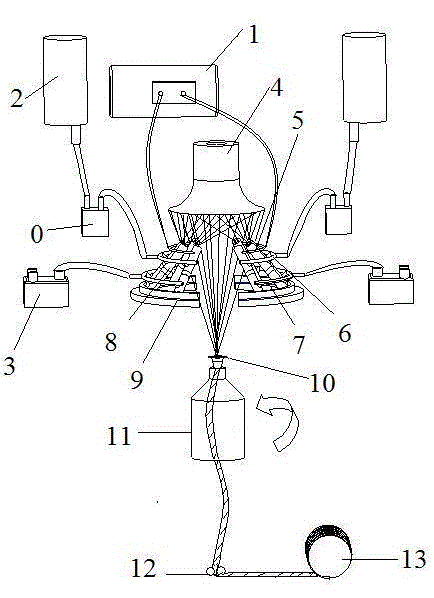

Jet yarn spinning device for electrostatic spun nano fiber and preparing method

InactiveCN102703998AIncrease productionReduce volatilitySpinnerette packsFilament/thread formingYarnNanofiber

The invention discloses a jet yarn spinning device for an electrostatic spun nano fiber, which includes a collecting device, wherein two thread jetting devices are arranged on the two sides of the collecting device and connected with a high-voltage electrostatic generator; a buncher is arranged below the collecting device; the two thread jetting devices are arranged between the collecting device and the buncher and symmetrically and oppositely arranged along the axis; a jet nozzle twister is arranged below the buncher; a delivery roller is arranged below the jet nozzle twister; a winding mechanism is arranged below the delivery roller; and the collecting device, the buncher, the jet nozzle twister and the delivery roller are arranged along the same axis from top to bottom. The electrostatic spun nano fiber spinning device integrates thread jetting, collecting, drawing, twisting and winding, and can continuously prepare the electrostatic spun nano fiber yarns. The nano fiber spinning method has simple process, high yarn yield, is suitable for multiple polymer yarn solutions, and realizes the continuous and scaled preparation of the nano fiber yarns.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Water high light wearable intaglio ink and preparing method thereof

The invention relates to a water-base printing ink and its producing method, especially water-base high light friction resistance gravure oil and the producing method thereof. The oil is suitable for packing print in the soft packing field such as food, drink, medicine, health products, chemicals and etc. The water-base high light friction resistance gravure oil is composed of acrylic resin, acrylic emulsion, dye, ethanol, built-up agent, dispersant, deionized water, water-base emulsifying wax, antifoamer, leveling agent. The inventive product completely meets the requirement of the gravure oil, has a reliable quality and can replace the solvent gravure oil, which can be dilute by the tap water of ethanol. The printing device can be washed directly by the tap water. The product has a high concentration, a low viscosity, a good printing adaptability has no harm to the environment and human body. The presswork has a clear pattern, a bright color, a powerful attached fastness, a good water resistance and friction resistance, has no harmful residue after drying and is not easy to fade and shed.

Owner:浙江永在油墨有限公司

Sports drink

ActiveCN1729875AFast absorptionApplicable requirementsVegetable proteins working-upFood preparationAdditive ingredientPotassium

The invention provides a sports beverage, wherein the essential components include low-molecular polymer barley sugar, starch gum, modified starch, soybean oligopeptide, black plum extract and alkaline electrolyte, the beverage may also comprise various vitamins, taurine and inositol. The sports beverage can be made into solid form or liquid form.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH

Acrylonitrile copolymer spinning solution with high molecular weight and narrow distribution and preparation method thereof

InactiveCN101805936AHigh molecular weightHigh solid contentMonocomponent synthetic polymer artificial filamentPolymer scienceAlcohol

The invention discloses an acrylonitrile copolymer spinning solution and a preparation method thereof. The spinning solution is a mixed solvent solution of an acrylonitrile copolymer; the acrylonitrile copolymer is formed by polymerization of a first acrylonitrile monomer and a comonomer, and the comonomer comprises unsaturated carboxylic acid monomers; the mass of the first acrylonitrile monomer is 90-99.5% of the total mass of monomers, and the mass of the comonomer is 0.5-10% of the total mass of monomers; the mixed solvent is a mixture comprising dimethyl sulfoxide and at least one of water, alcohol solvents and ketone solvents; and the mass percent concentration of the monomers in the spinning solution is 15-30%. In the invention, the mixed solvent of the dimethyl sulfoxide is adopted in the process of acrylonitrile copolymerization, and the proportion of each solvent is controlled to carry out copolymerization reaction in homogeneous phases; and meanwhile, the second comonomer is continuously replenished in a certain time of reaction to stabilize the instantaneous composition of the acrylonitrile copolymer to obtain the polyacrylonitrile copolymer spinning solution with high molecular weight, narrow molecular weight distribution and uniform chain structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

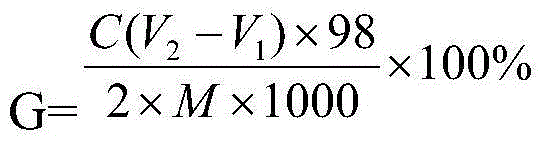

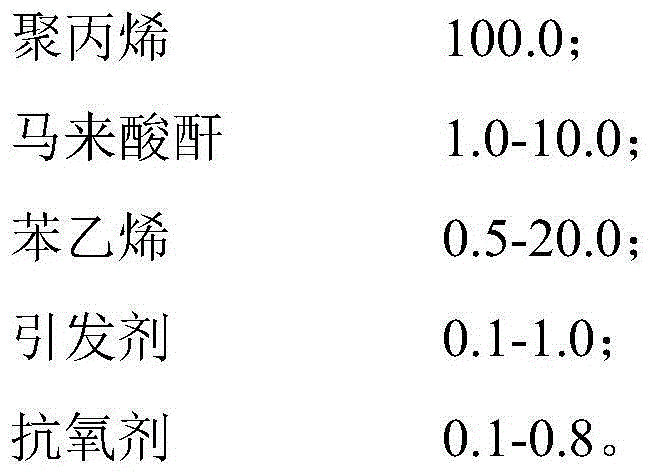

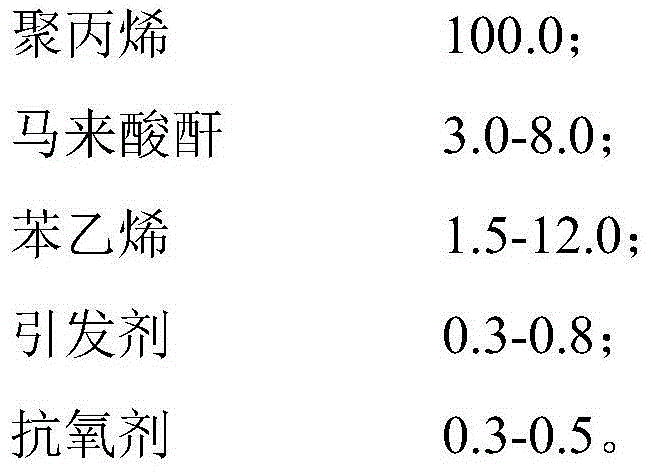

Preparation method of maleic anhydride grafted polypropylene

The invention provides a preparation method of maleic anhydride grafted polypropylene. According to the method, maleic anhydride is grafted to a polypropylene molecular chain through melting free radical grafting reaction. In the melting grafting reaction initiated by a peroxide initiator, the initiator and auxiliary monomer styrene are prepared into a solution, and the solution is continuously metered and input to a plurality of positions of different screw barrel sections of a double-screw extruder. The adopted extruder is the double-screw extruder of which the draw ratio is greater than or equal to 48: 1 or a double-order double-screw extruder. The usage of the maleic anhydride in raw materials is 1.0-10.0 weight percent of that of polypropylene. According to the preparation method, the functional maleic anhydride grafted polypropylene which is high in grafting rate can be obtained, and the molecular weight of the functional maleic anhydride grafted polypropylene is not obviously reduced compared with the molecular weight of the polypropylene in the raw materials.

Owner:EAST CHINA UNIV OF SCI & TECH

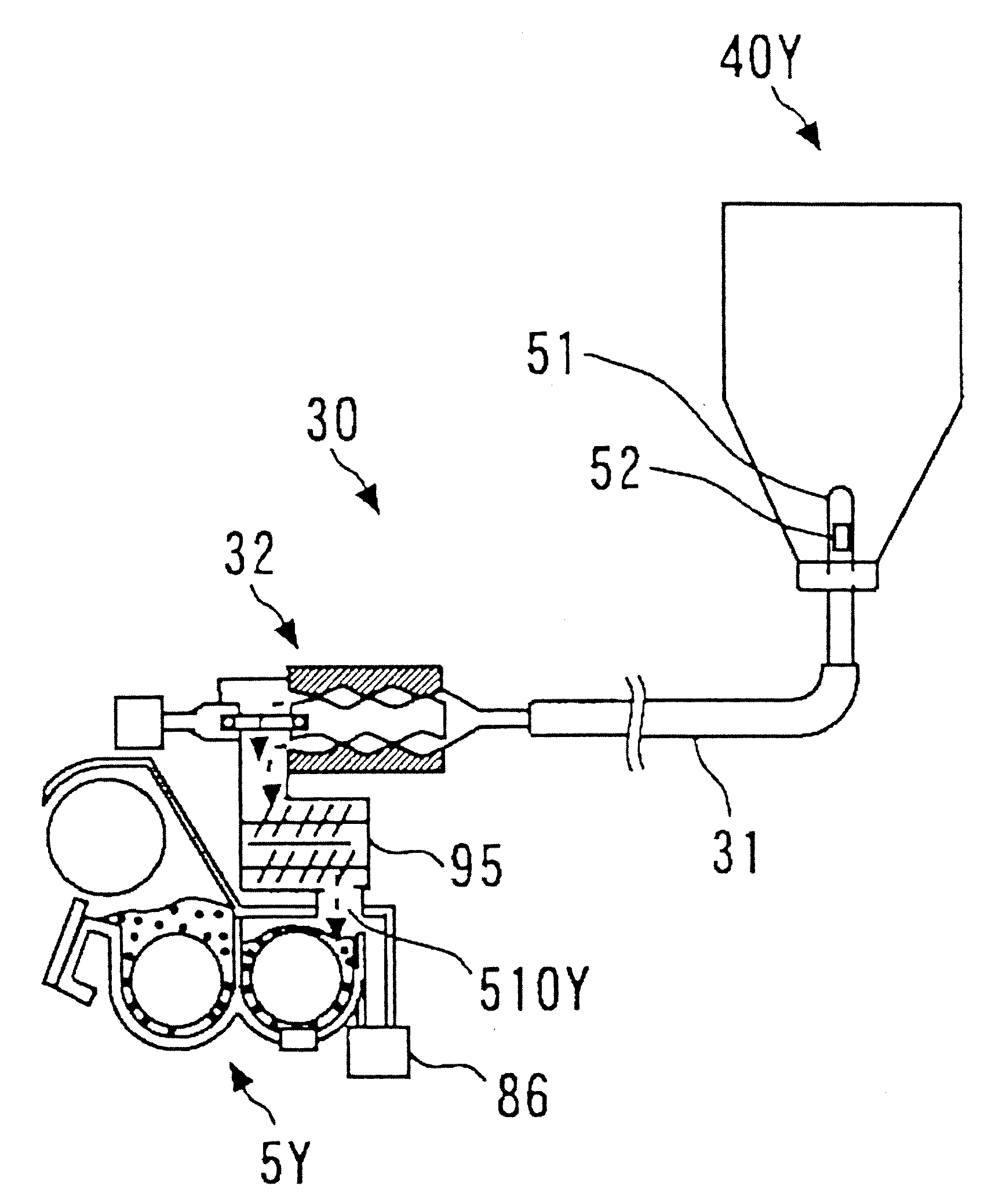

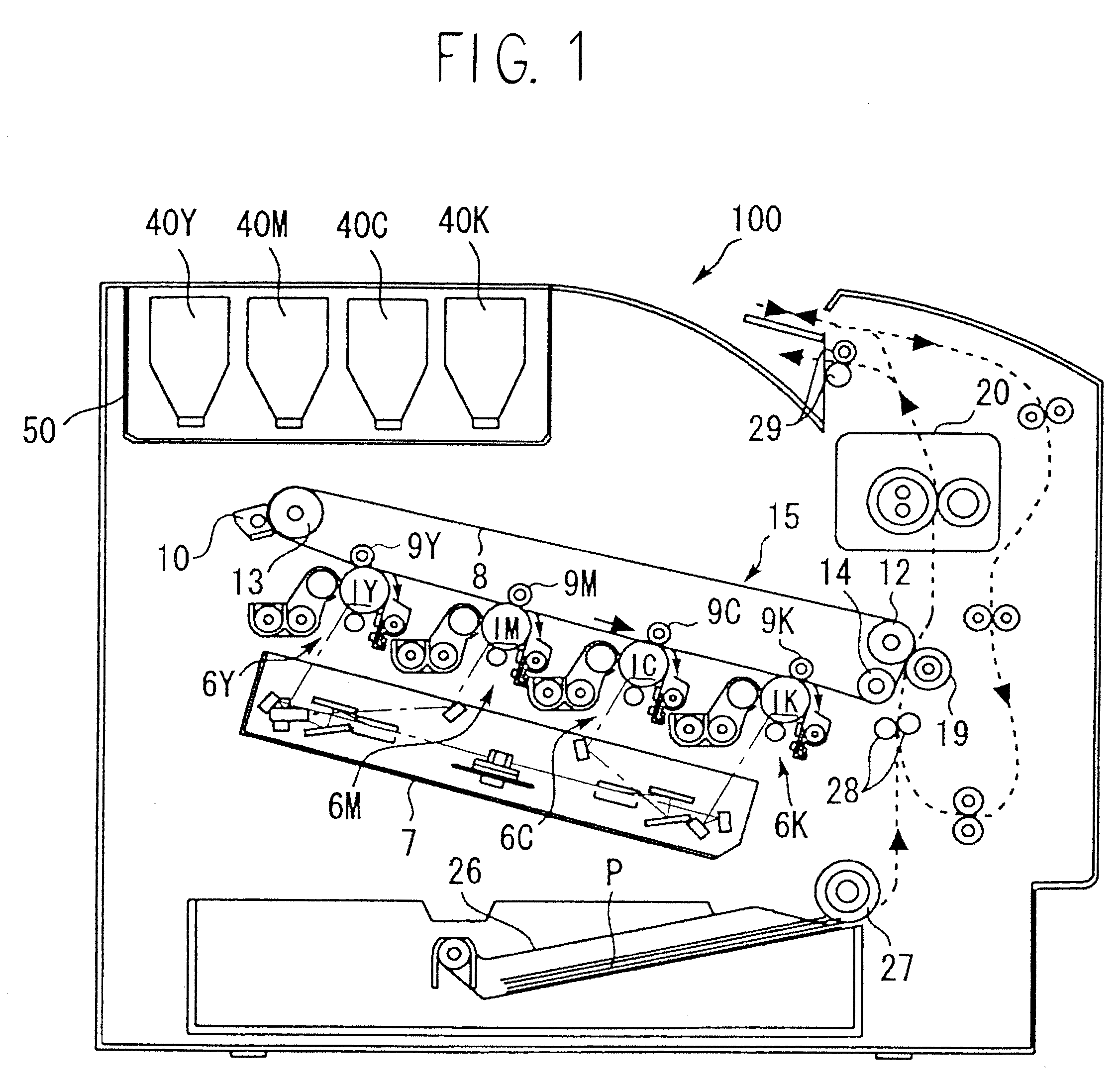

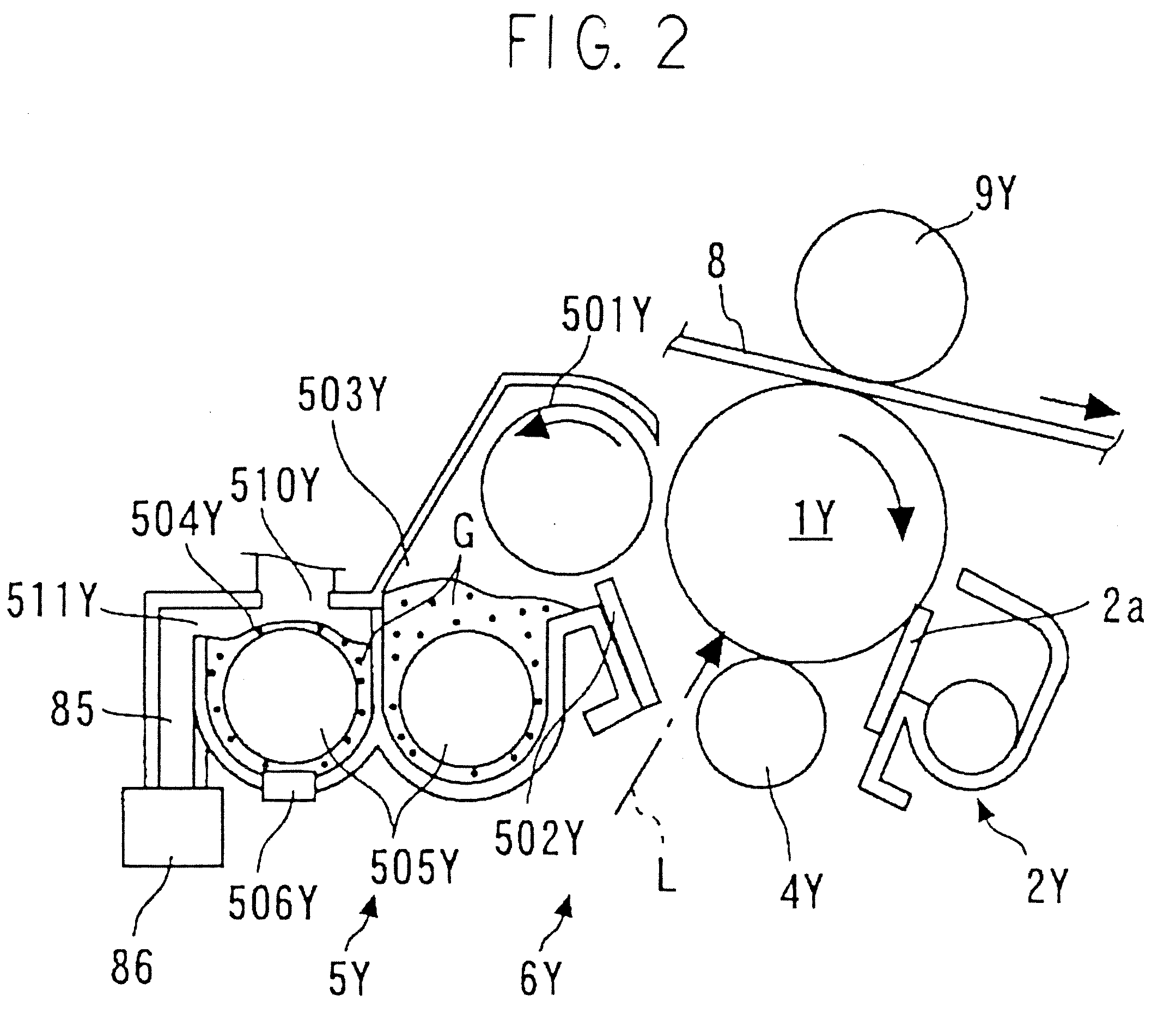

Developer supply device and image forming apparatus comprising same

InactiveUS20070280742A1Stable toner concentrationIncrease freedomElectrographic process apparatusDevelopersCharge carrierImage formation

The invention provides a developer supply device, a developer container, a developer and an image forming apparatus such that the developer is discharged stably from the developer container with a stable toner concentration in the developer, without damaging the developer, and in a relatively simple and small-size device having a relatively high degree of freedom as regards layout. The developer supply device comprises a partially or wholly deformable developer container and a pump for suctioning the developer held in the developer container, together with a gas, and for discharging the developer towards a developing unit. The toner comprises an additive formed so as to have a volume average particle size of 50 to 500 nm. The carrier is formed so as to have a weight average particle size of 20 to 60 μm. The developer is formed so that the carrier concentration thereof is 1 to 30 wt %.

Owner:RICOH KK

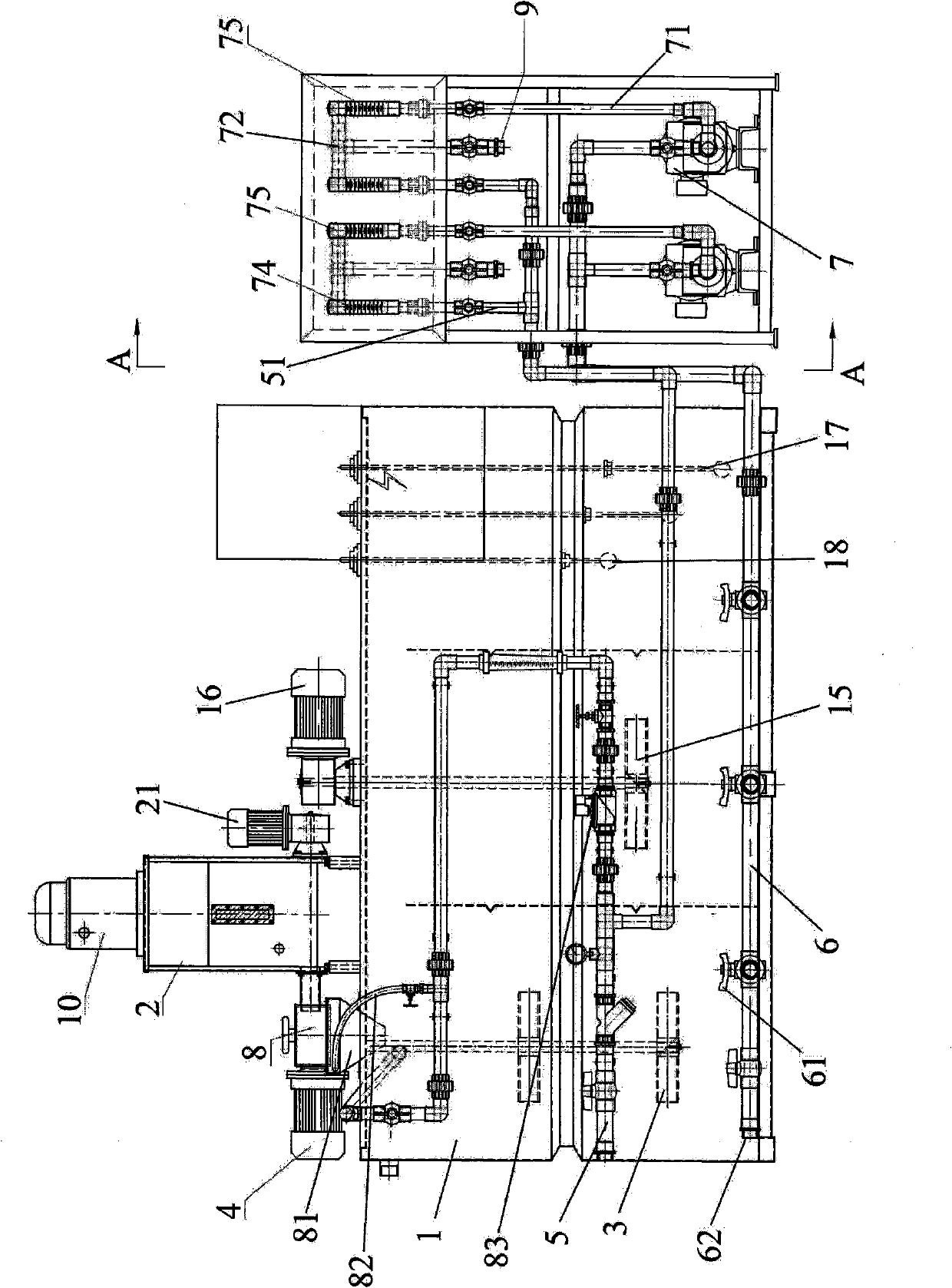

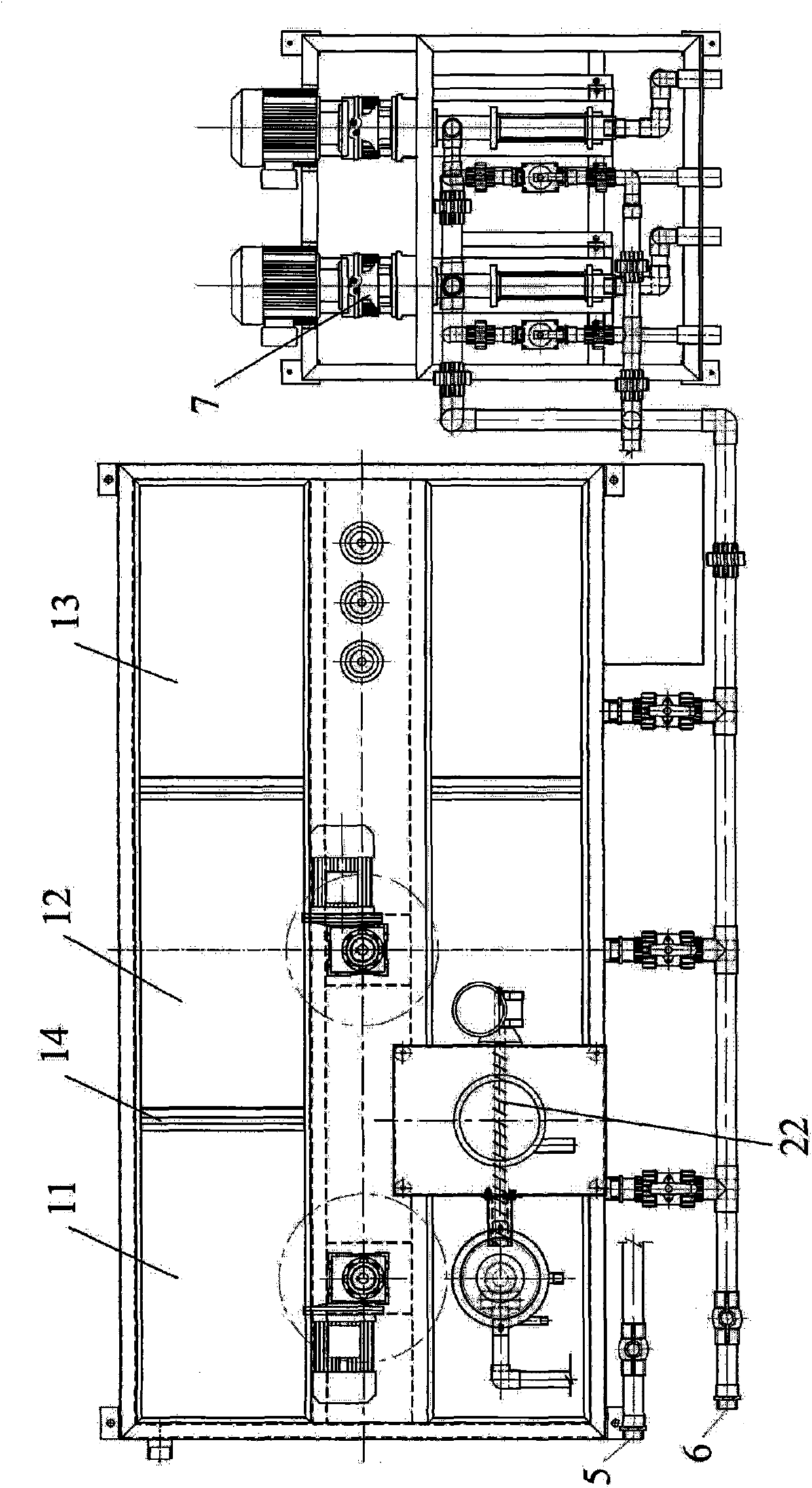

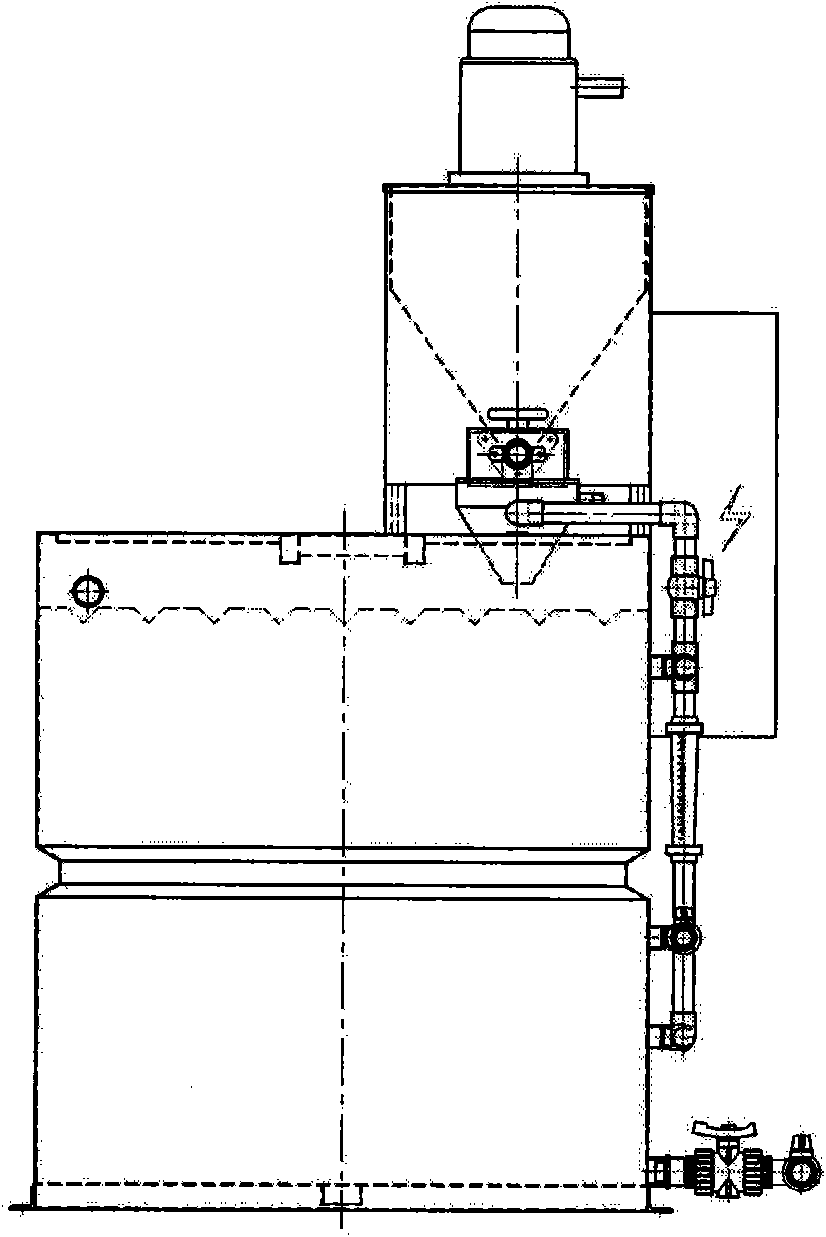

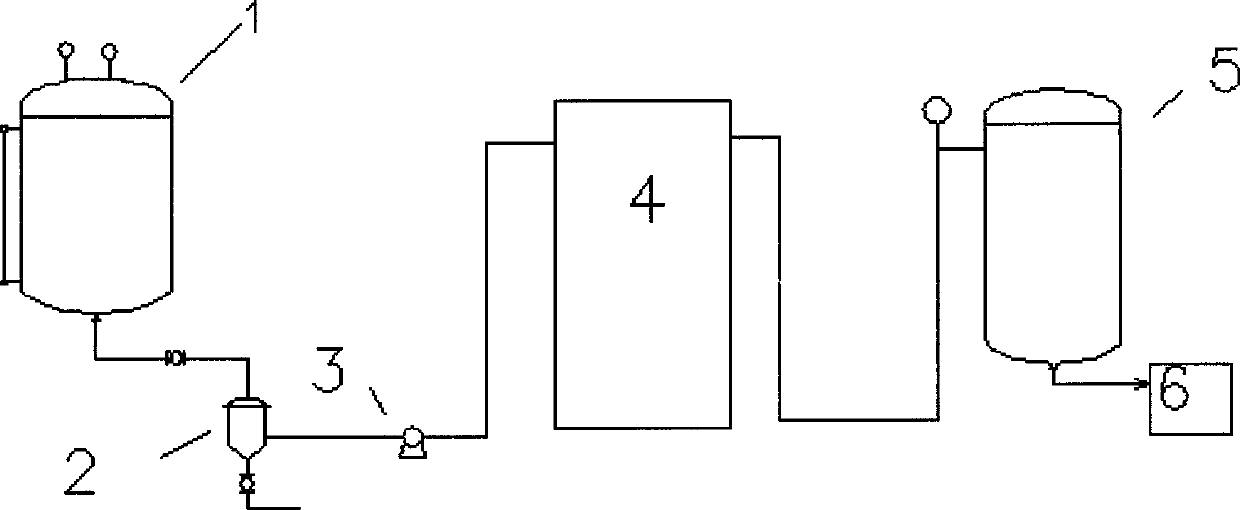

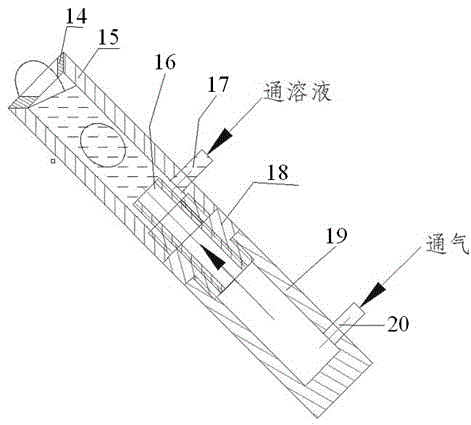

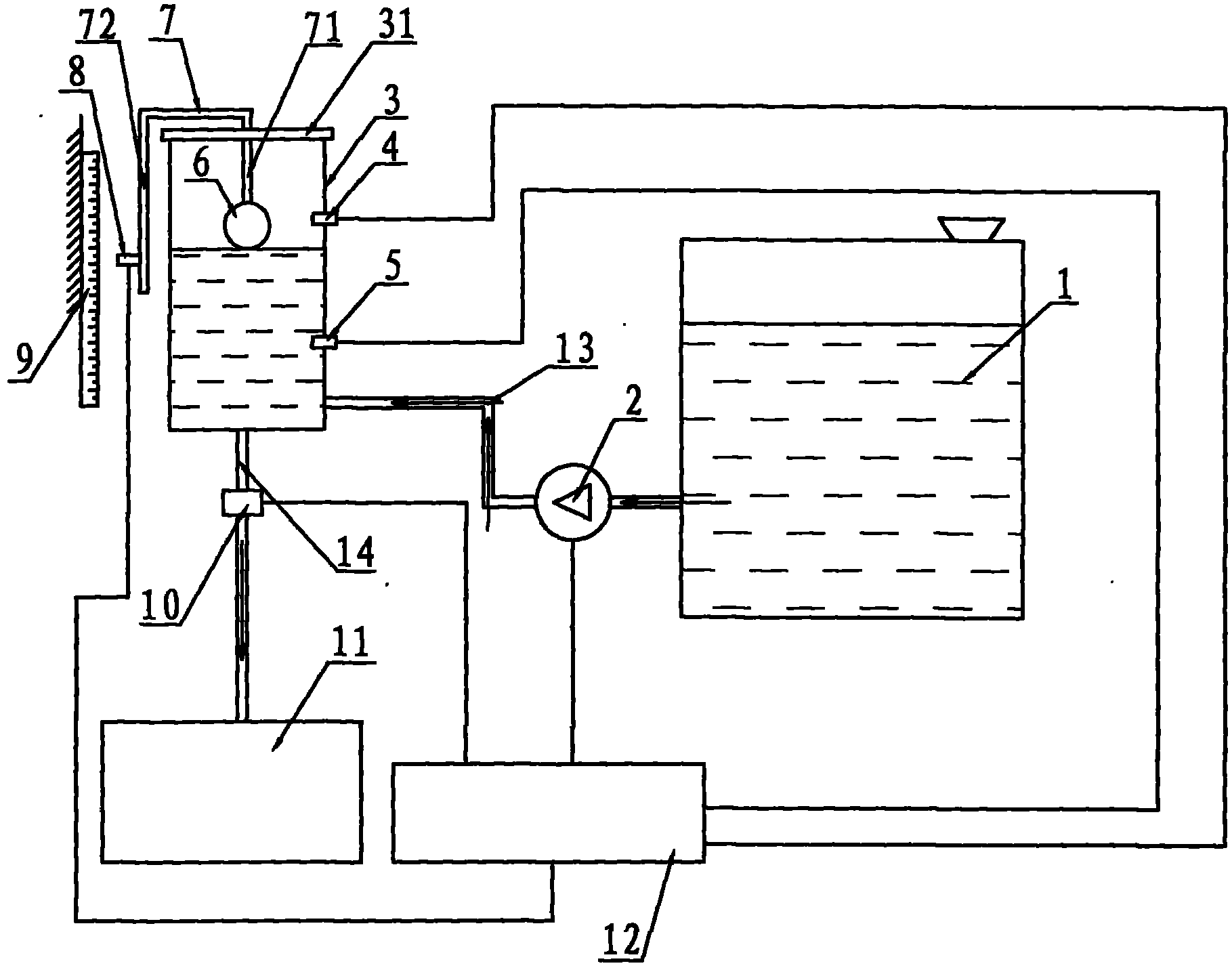

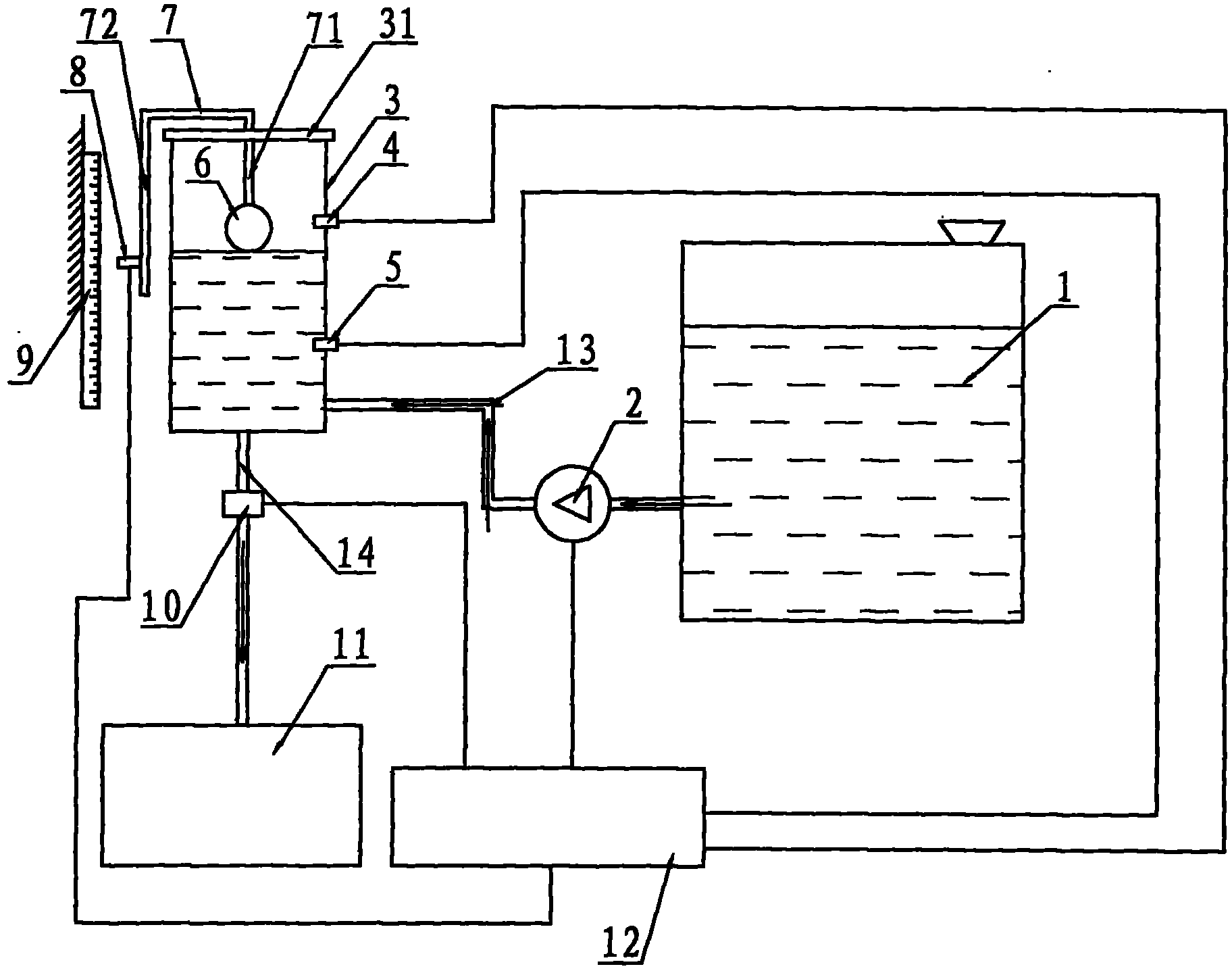

Automatic dosing device for sewage treatment

InactiveCN102020406AStir wellStable concentrationSludge treatment by de-watering/drying/thickeningLow speedMedicine

The invention discloses an automatic dosing device for sewage treatment, which consists of a medicine dissolving box, a medicinal powder dosing device, a medicine dissolving mixer, a mixer driving motor, a water inlet pipe, a medicine outlet pipe and a dosing pump. A pre-infiltrating device is arranged between the medicinal powder dosing device and the medicine dissolving box; the medicine dissolving box are separated by two overflow weirs to form a dissolving tank, a curing tank and a storing tank which are adjacent in turn; and a homogenizing stirrer is arranged in the curing tank. The pre-infiltrating device is arranged in the automatic dosing device for sewage treatment and is used for soaking dry flocculant powder, medicine solution flows into the dissolving tank by means of gravity and is stirred and mixed, the curing tank and the storing tank are arranged, low-speed stirring is carried out in the curing tank, and medicine solution meets the requirements of homogenization, curing and activity; the medicine solution passes through the overflow weirs to flow into the solution storing tank, so that the dissolving and stirring of the dry powder, the homogenization and curing of the solution and the dosing of the liquid medicine are synchronously carried out, and the efficiency and the liquid medicine utilization rate are improved; and the dry powder is accurately weighed, the caking of the dry powder is avoided, the concentration of the liquid medicine is ensured, and the medicine solution can be diluted on line according to requirement of actual application concentration.

Owner:开源环保(集团)有限公司

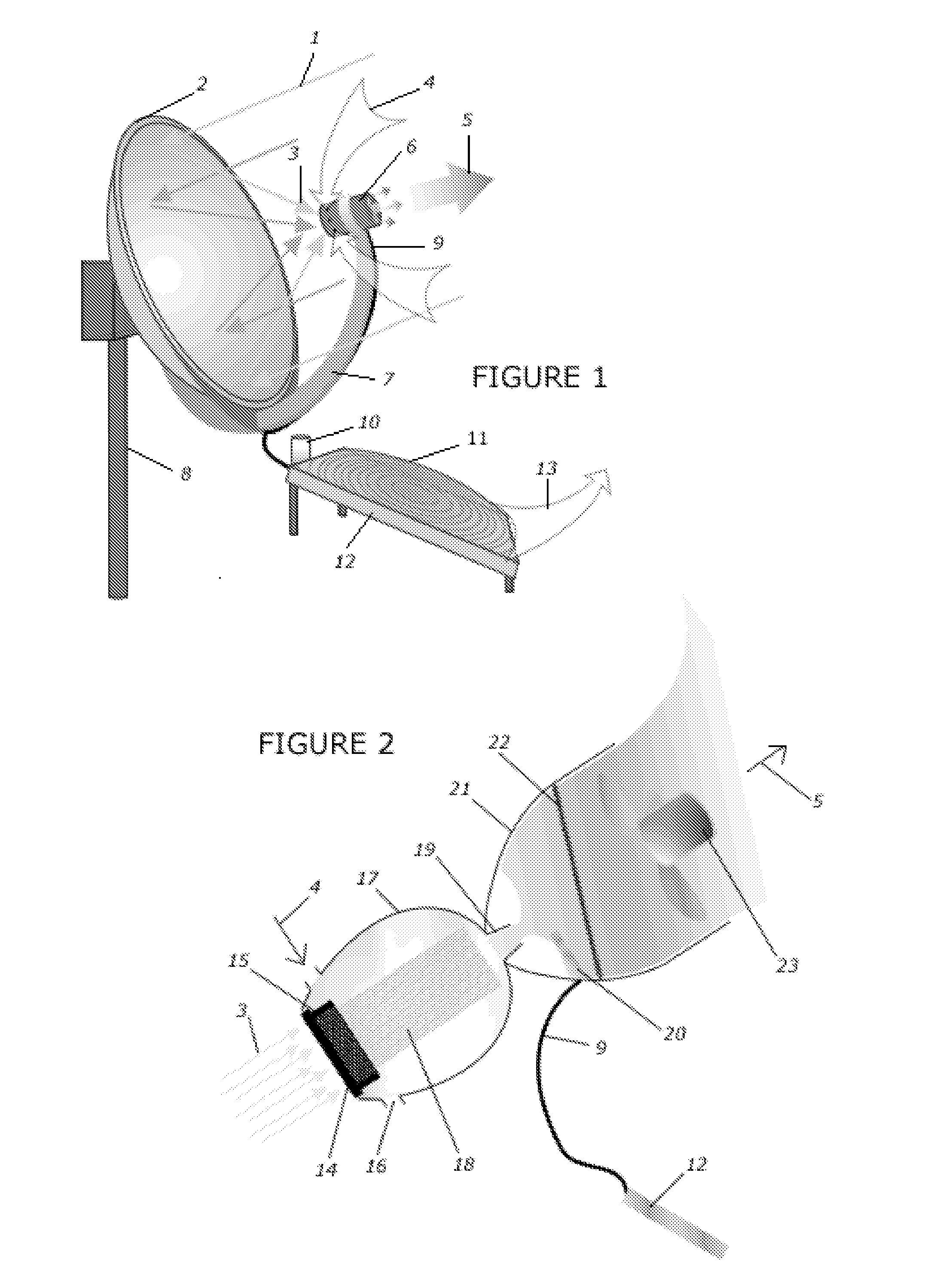

Solar Atmospheric CO2 Cleaner

InactiveUS20080196581A1High value by-productStabilize increasing CO concentrationSolar heating energyGas treatmentAtmospheric airAtmosphere of Earth

An increasing level of carbon dioxide gas in the earth's atmosphere has been determined and is generally accepted by the scientific community. The human contribution to increases in the percentage of carbon dioxide in the atmosphere has been identified as a driving force of global climate change.The impact of global climate change might be mitigated by means to reduce or stabilize the percentage of carbon dioxide in the atmosphere.The invention provides a means for cleaning the atmosphere of carbon dioxide molecules by dissociation and refining the by-products into valuable fuels and other substances. It is taught that solar energy can be used to energize a photonic crystal producing the power and specific frequency required for localized excitation of CO2 molecules in a specific vibration mode and to the majority exclusion molecular structures comprising atmospheric gases sufficient to break covalent bonds of CO2, thereby producing reactant by-product that can be collected and refined into valuable substances and fuel.

Owner:COOLEY WARREN LYNN

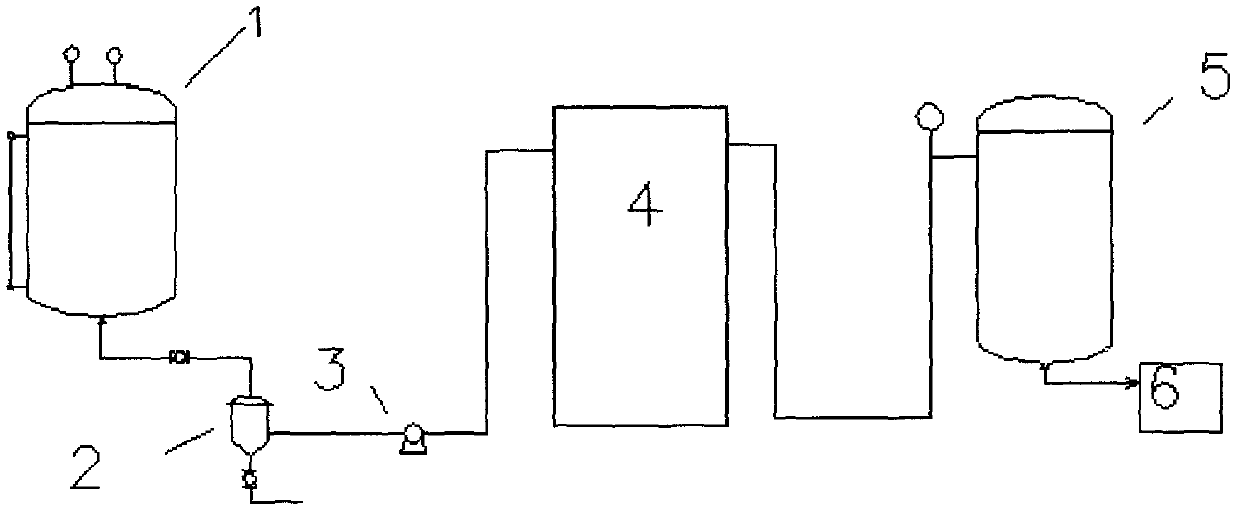

Device and method for continuously producing sodium methyl taurate in pipeline mode

InactiveCN102675160ALess energy consumptionStable concentrationSulfonic acids salts preparationHeat conductingDistillation

The invention relates to a device and a method for producing sodium methyl taurate, in particular to a device and a method for continuously producing sodium methyl taurate in a pipeline mode. The method comprises the following steps of: adding sodium hydroxyethyl sulfonate, water, methylamine and catalyst into a storage tank, pumping the materials into a continuous pipeline reactor through a boosting pipeline pump under the high pressure of 10 to 25MPa, heating to the temperature of between 150 and 300 DEG C through heat conducting oil, and reacting for 10 to 60 minutes in the pipeline reactor; and feeding the materials into an evaporator after reaction, performing multistage distillation, decolorizing, moisturizing, refining, and thus obtaining the qualified sodium methyl taurate. The device is simple and high in process safety, the reaction conditions are easy to control, continuous production is realized, the yield reaches over 90 percent, the sodium methyl taurate is stable in quality, and large-scale production can be realized with low investment in the industry.

Owner:HUANGGANG YONG AN PHARMA

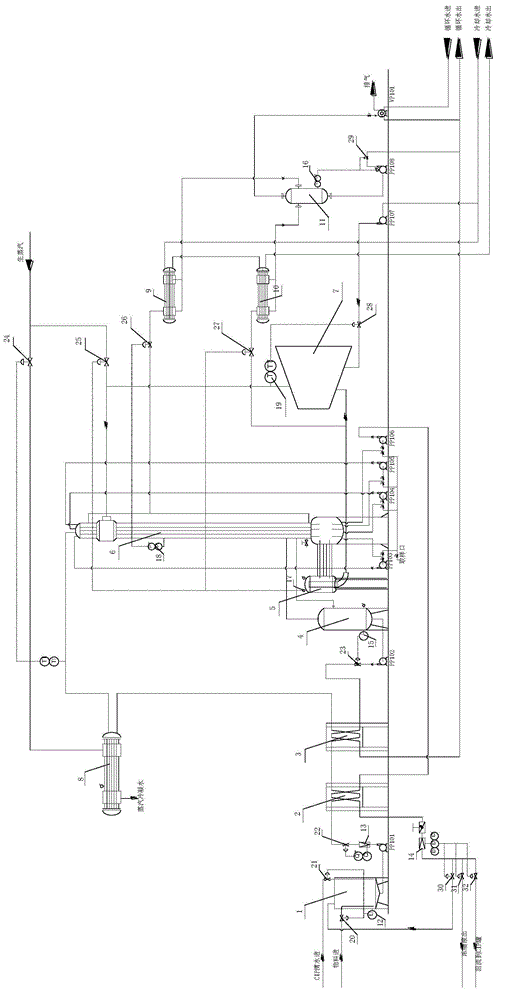

MVR continuous evaporation system

InactiveCN104667550AStable feed flowThere will be no cut-off stateEvaporator accessoriesMultiple-effect evaporationVapor–liquid separatorSteam condensation

The invention discloses an MVR continuous evaporation system. The system can be applied to the requirements on different evaporation pressures, and automatic control of continuous and stable feeding and continuous discharging can be realized. The system disclosed by the invention comprises a raw material balance tank, a main body evaporator, a gas-liquid separator, a condensate storage tank, a steam compressor, a vacuum system and at least three heat exchange devices which are connected by virtue of pipelines, control valves and related pumps, wherein the bottom of the raw material balance tank is connected with the inlet of a feeding pump and is connected with an interval inlet of the top end of the main body evaporator by virtue of a heat exchange device; multiple evaporation intervals are contained in the main body evaporator; a gas-liquid collection cavity is formed in the bottom end of the main body evaporator and is connected with the next evaporation interval by virtue of a booster pump; the concentrated solution in the final evaporation interval is used for preheating the raw materials by virtue of the heat exchange devices; the shell pass of the main body evaporator is connected with the condensate storage tank; and steam condensate is connected with the heat exchange devices by virtue of the condensate storage tank, and the raw materials can be preheated.

Owner:NANJING UNIV OF TECH

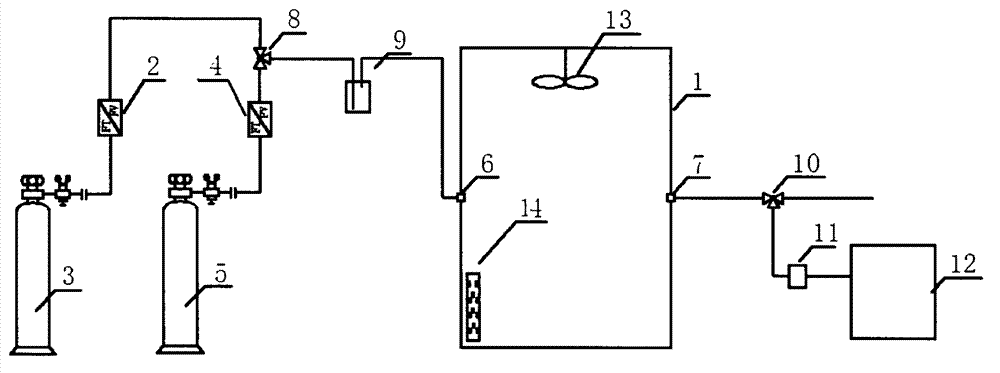

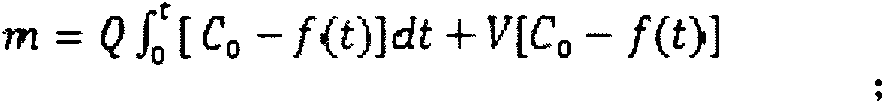

Air cleaner testing device and testing method thereof

ActiveCN103091121AIncrease credibilityVisually document service lifeComponent separationStructural/machines measurementPollutantAir cleaners

The invention provides an air cleaner testing device and a testing method of the air cleaner. Purification performance of the air cleaner in a room is evaluated accurately. The air cleaner testing device and the testing method are simple to operate and are high in reliability. The air cleaner testing device comprises an environmental chamber, a polluted gas continuous air supply and a clean gas continuous air supply. An air inlet and an air outlet are arranged in the environmental chamber. The polluted gas continuous air supply and the clean gas continuous air supply are connected with an input end of a gas flow controller through a pipeline. The output end of the gas flow controller is connected with the air inlet. A gas sample device and a pollutant detecting device are connected with the air outlet of the environmental chamber. By means of the air cleaner testing device and the testing method, stable air supply of different kinds of density and different flows can be obtained by adjusting the proportioning. Characteristics that pollutants in the room are low in density and continuous to discharge can be simulated effectively. Compared with a traditional testing method, the performance of the air cleaner in the room can be tested reasonably. Reliability is high.

Owner:ZHEJIANG ERMA ENVIRONMENT TECH CO LTD

Jet yarn spinning machine for electrostatic-spun nanofibers and use method thereof

ActiveCN103147179AEnables continuous batch preparationReduce volatilityFilament/thread formingContinuous wound-up machinesYarnFiber

The invention relates to a jet yarn spinning machine for electrostatic-spun nanofibers. The machine comprises a high-voltage static electricity generator, a liquid storage tank with a pressurizing device, a cross-flow air pump, a gathering unit, a spinning unit, a semicircular base, a buncher, a jet nozzle twister, a yarn guide roller and a winding mechanism. The jet yarn spinning machine integrates the functions of spinning, gathering, drafting, twisting and winding and can be used for continuously producing electrostatic-spun nanofiber yarn. The yield of electrostatic-spun nanofibers is greatly increased; and the twister is simple in structure and high in production efficiency. A nanofiber yarn forming method is simple in process and high in yarn yield, is applicable to multiple polymer spinning solutions and can realize the continuous batch preparation of nanofiber yarn.

Owner:河南中纤新材料科技有限公司

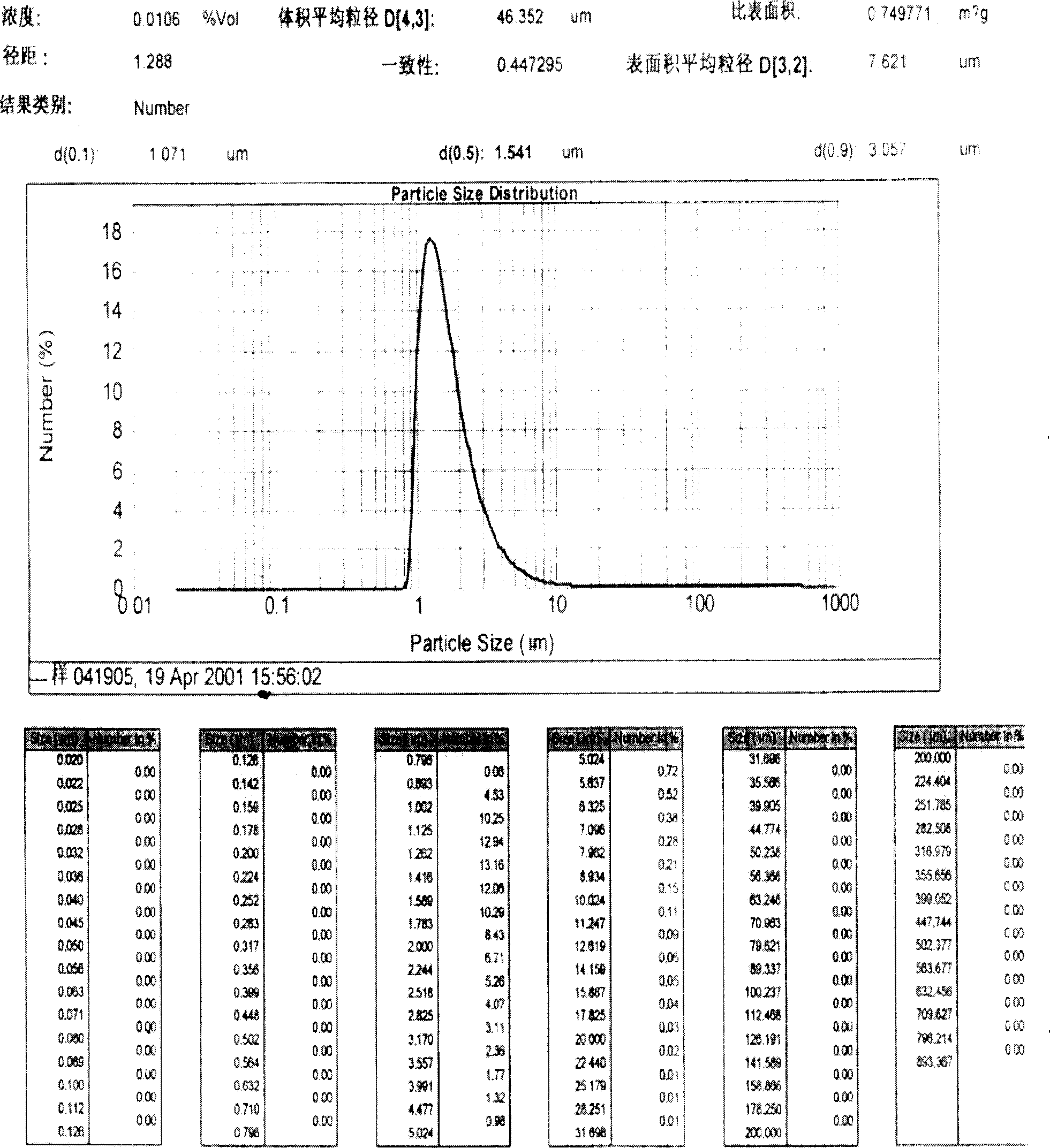

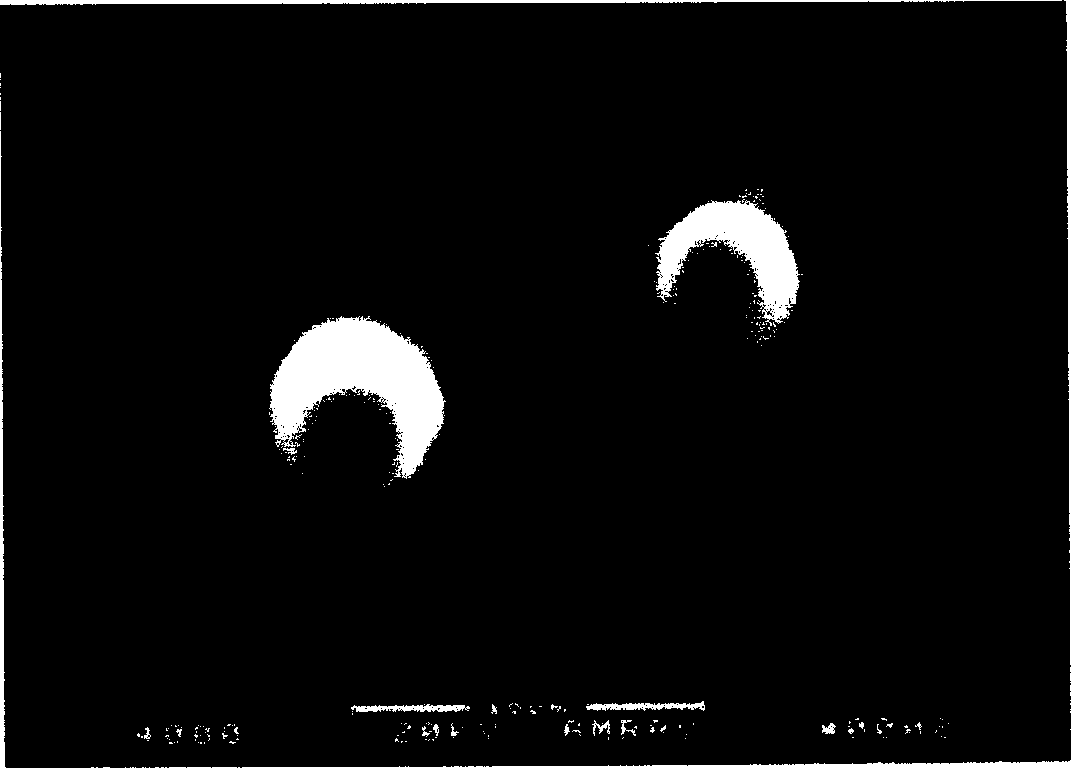

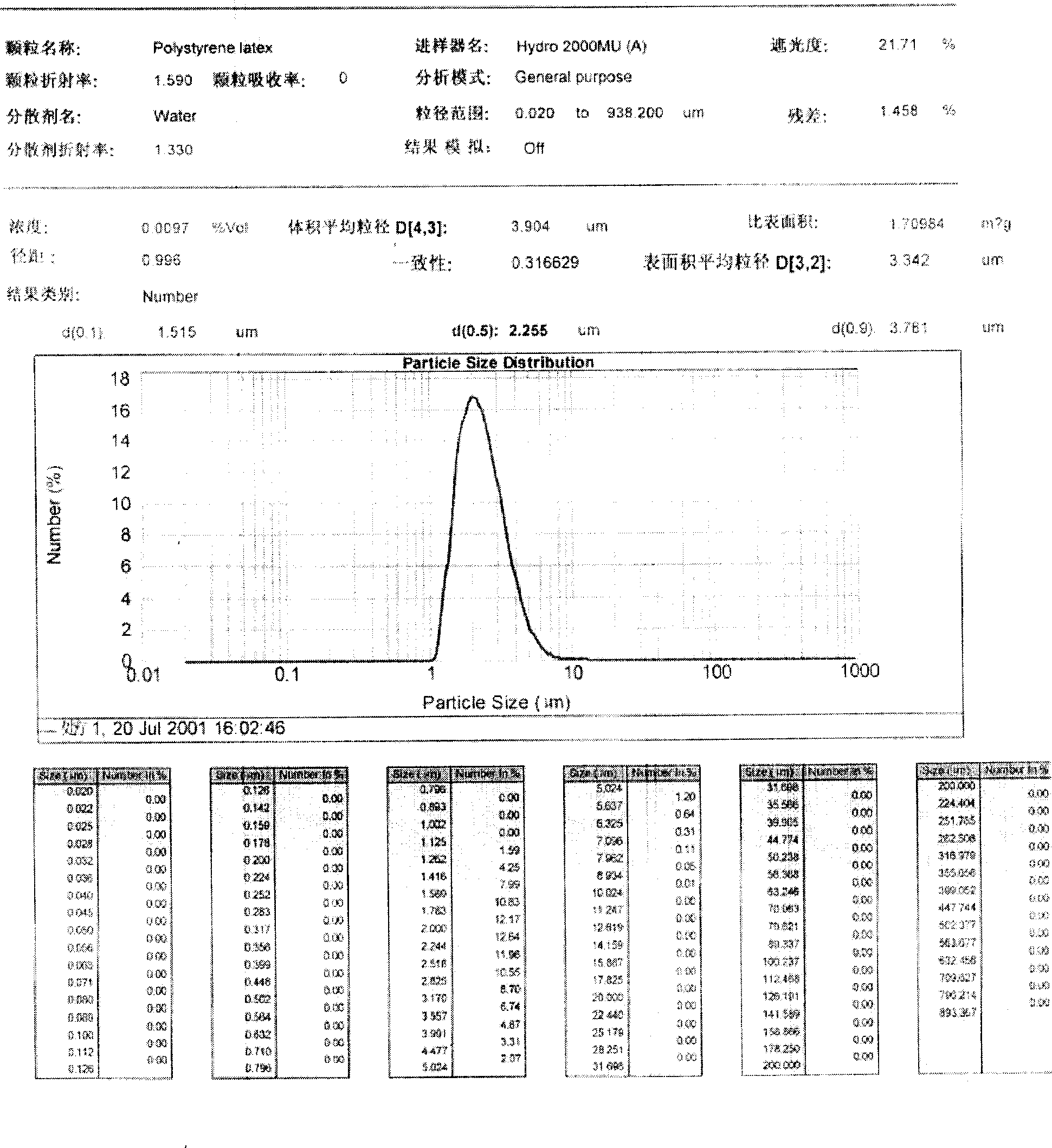

Slow-releasing bFGF-PLGA microball and its prepn and use

InactiveCN1398584AImproved particle size distributionGood conditionPeptide/protein ingredientsSkeletal disorderDiseaseMicrosphere

The present invention provides one kind of slow-releasing basic fibroblast growdth factor (bFGF) microsphere and its preparation and use. The microsphere has coated bFGF as medicine, and matrix of polylactide-co-glycolide (PLGa). The slow-releasing bFGF microsphere is prepared by using PVA or mixed PVA-PEG liquid as dispersing medium and through w / o / wt% re-emulsion and drying process and mechanical stirring. Its freeze dried power has good dispersivity and low organic solvent residue. The present invention can be used for local administration or vein administration of treating fracture, bone defect and other diseases.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Constant volume type accurate automatic liquid replenishing device

ActiveCN102148285AStable concentrationGuaranteed cleaning qualityFinal product manufactureCleaning using liquidsControl systemLiquid storage tank

The invention discloses a constant volume type accurate automatic liquid replenishing device. The device comprises a liquid storage tank, a mechanical liquid replenishing pump, a sizing tank, an upper liquid level sensor, a lower liquid level sensor, a floating ball, a U-shaped floating ball rod, a constant volume sensor, a ruler, an electromagnetic directional valve, a cleaning groove and a control system, wherein the inner side wall of the sizing tank is provided with the upper liquid level sensor and the lower liquid level sensor; the primary liquid replenishing volume can be acquired through the diameter of the sizing tank and the drop distance of the floating ball; the drop distance of the floating ball is controlled by the constant volume sensor; the electromagnetic directional valve is opened during liquid replenishing; after the constant volume sensor drops for a predetermined distance, a signal is transmitted to the control system by the constant volume sensor and the electromagnetic directional valve is immediately closed, so that the liquid can be accurately replenished in the cleaning groove, the concentration of a solution in the cleaning groove is kept stable, and the cleaning quality of a silicon slice is substantially guaranteed.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Slow-releasing bFGF-PLA-PEG microball and its prepn and use

InactiveCN1398585AImproved particle size distributionGood conditionPeptide/protein ingredientsGranular deliveryDiseaseMicrosphere

In the present invention the microsphere has coated bFGF as medicine, and matrix of lactic acid-glycol copolymer (PLA-PEG). The slow-releasing bFGF microsphere is prepared by using PVA-PEG mixed liquid as dispersing medium and through evaporation and mechanical stirring. It has excellent slow-releasing performance of over two-week releasing period. Its freeze dried powder has good dispersivity and low organic solvent residue. The present invention can be used for local administration or vein administration of treating fracture, bone defect and other diseases.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

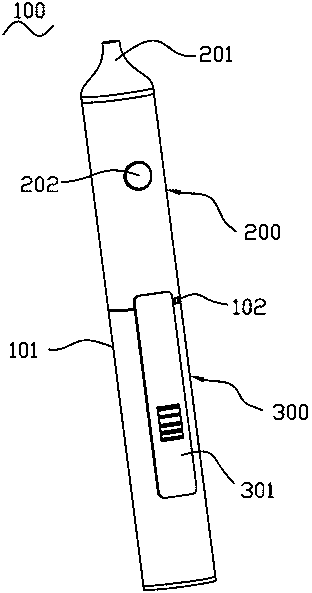

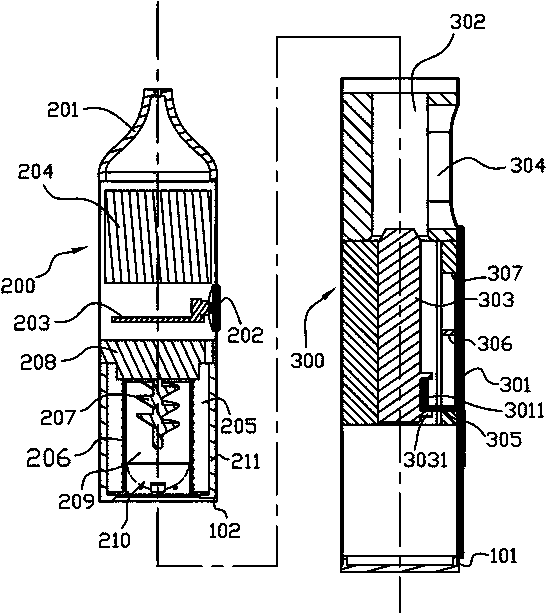

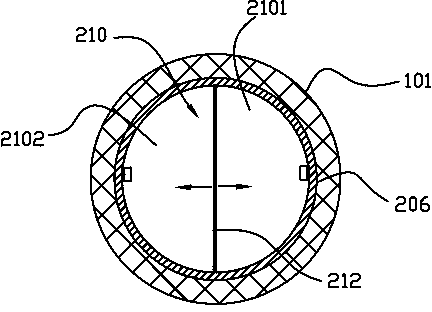

Baking type smoking device enabling amount of heated tobacco to be controlled

The invention discloses a baking type smoking device enabling the amount of heated tobacco to be controlled. The baking type smoking device enabling the amount of heated tobacco to be controlled is used for heating and baking solid tobacco so that tobacco smoke can be generated and taken by people. The baking type smoking device enabling the amount of heated tobacco to be controlled comprises a shell, a smoking nozzle and an air inlet which is formed in the shell, wherein an airflow channel is formed between the smoking nozzle and the air inlet, a heating device used for baking solid tobacco is arranged in the airflow channel, a storage bin used for containing the solid tobacco and a feeding mechanism are further arranged in the shell, the heating device is provided with a heating cavity which can be communicated with the storage bin, the feeding mechanism can feed at least a part of the solid tobacco in the storage bin into the heating cavity in a quantitative mode according to the preset smoking quantity so that the solid tobacco can be baked through the heating device, and thus tobacco smoke is generated. According to the baking type smoking device enabling the amount of heated tobacco to be controlled, a proper amount of tobacco can be provided according to the preset smoking quantity (the puff number) selected by a smoker, in this way, the quality of smoke generated each time the smoker smokes can be guaranteed, and waste can be avoided.

Owner:SHENZHEN FIRST UNION TECH CO LTD

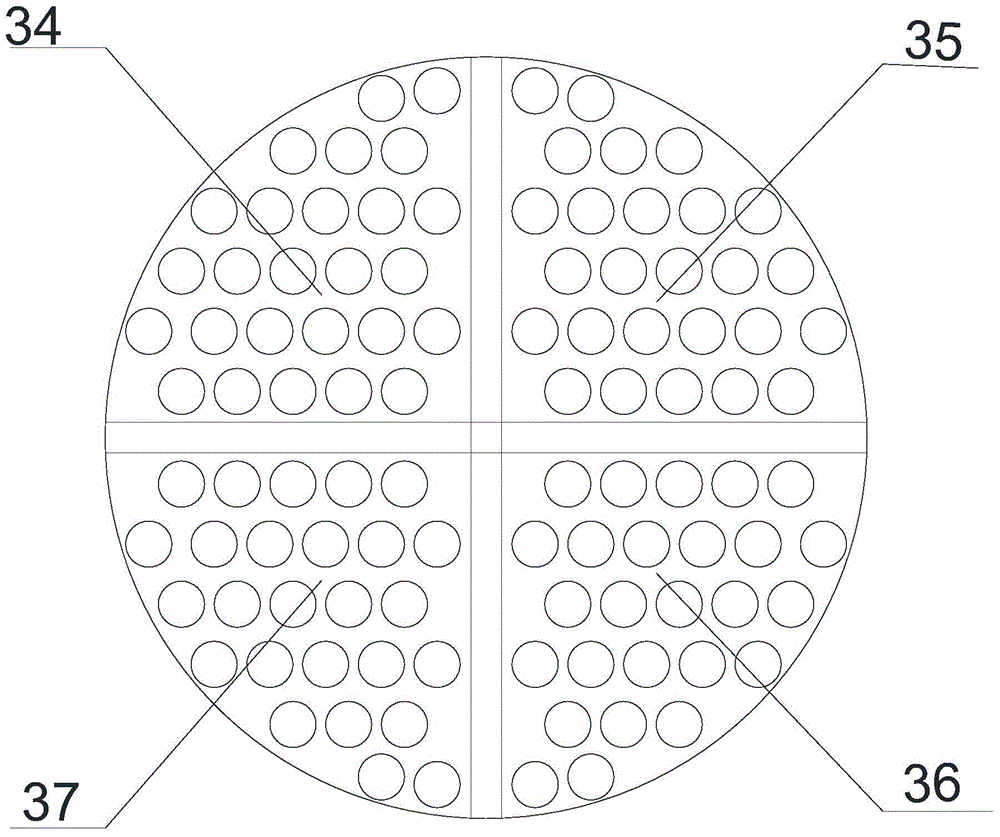

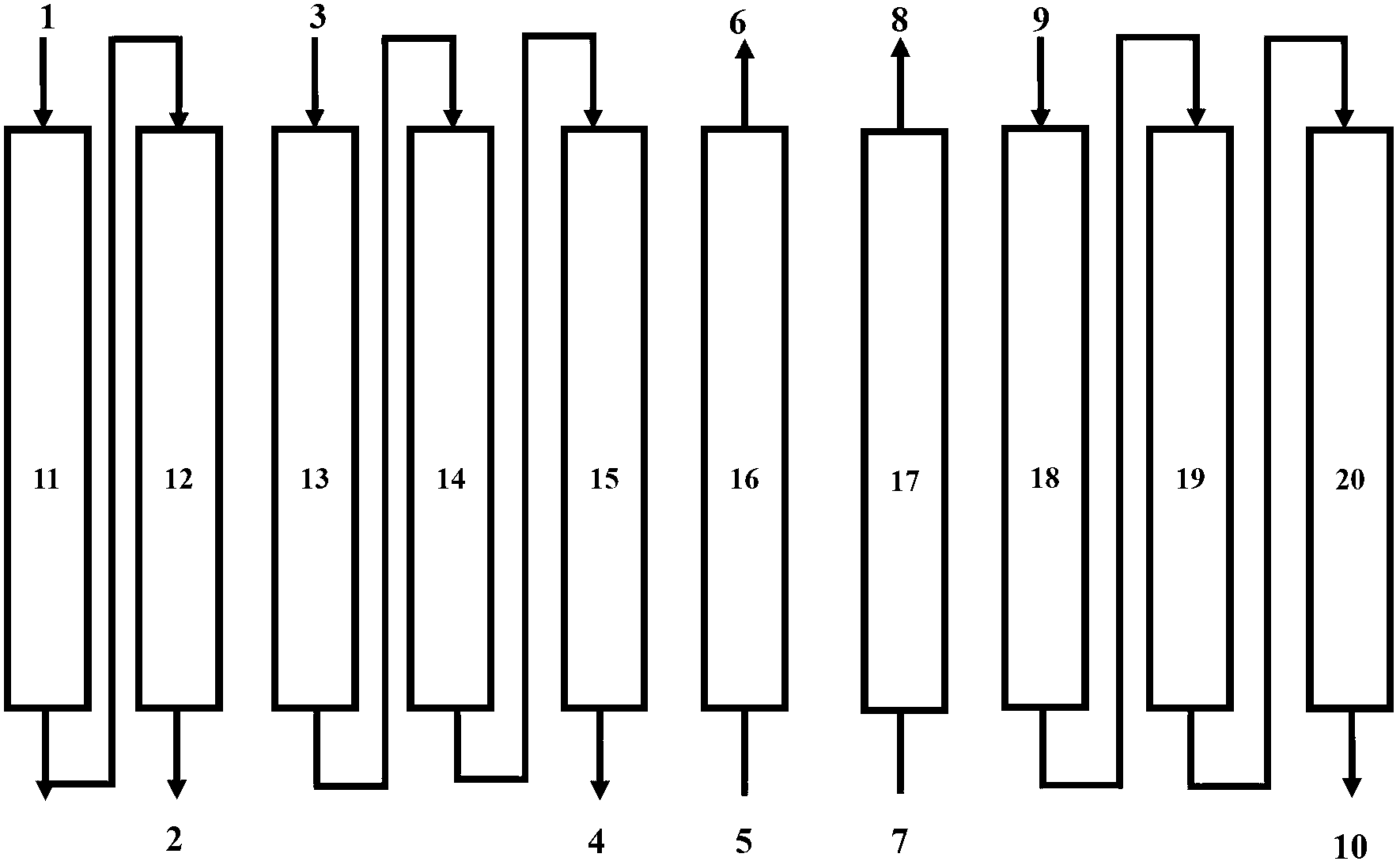

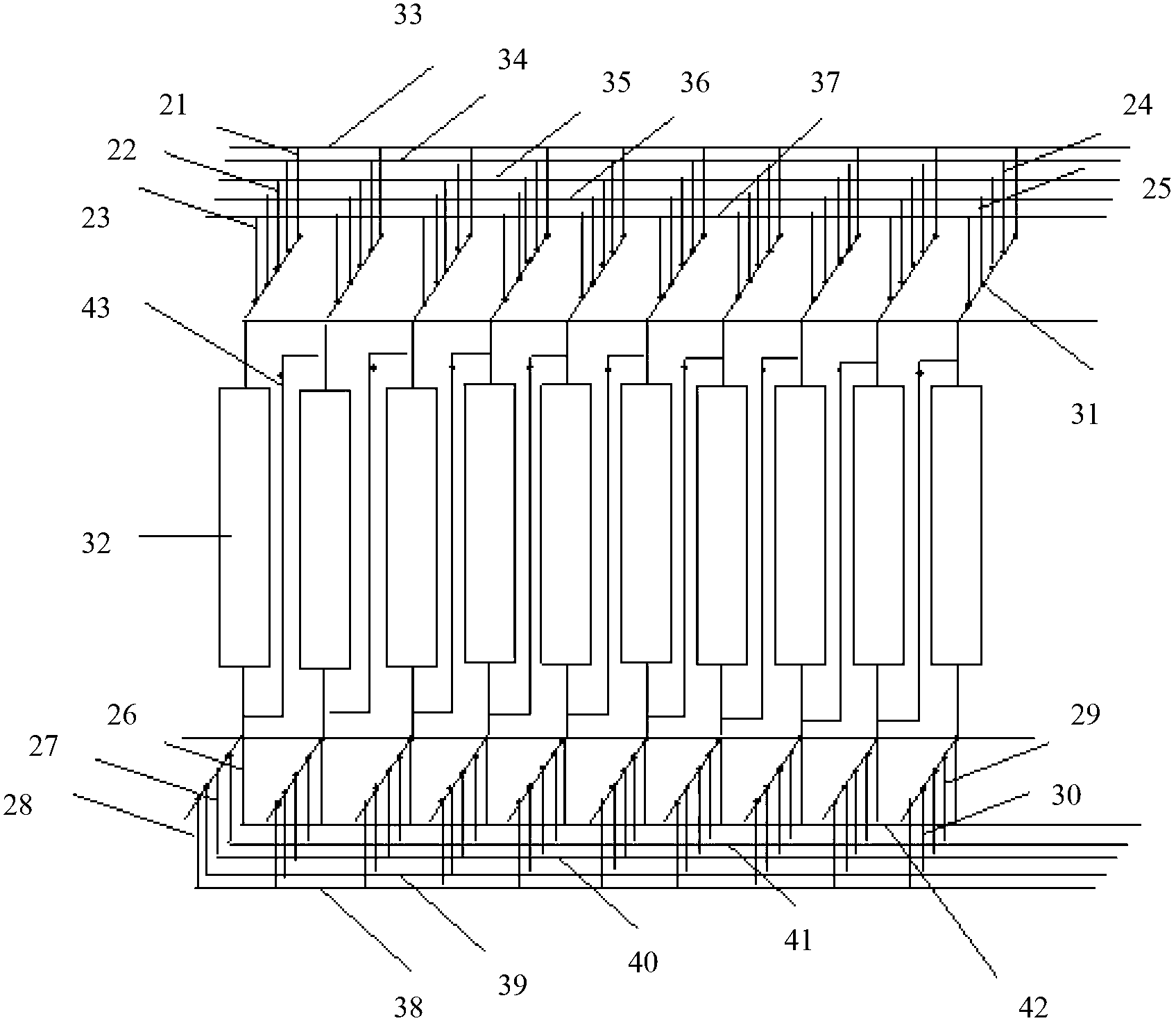

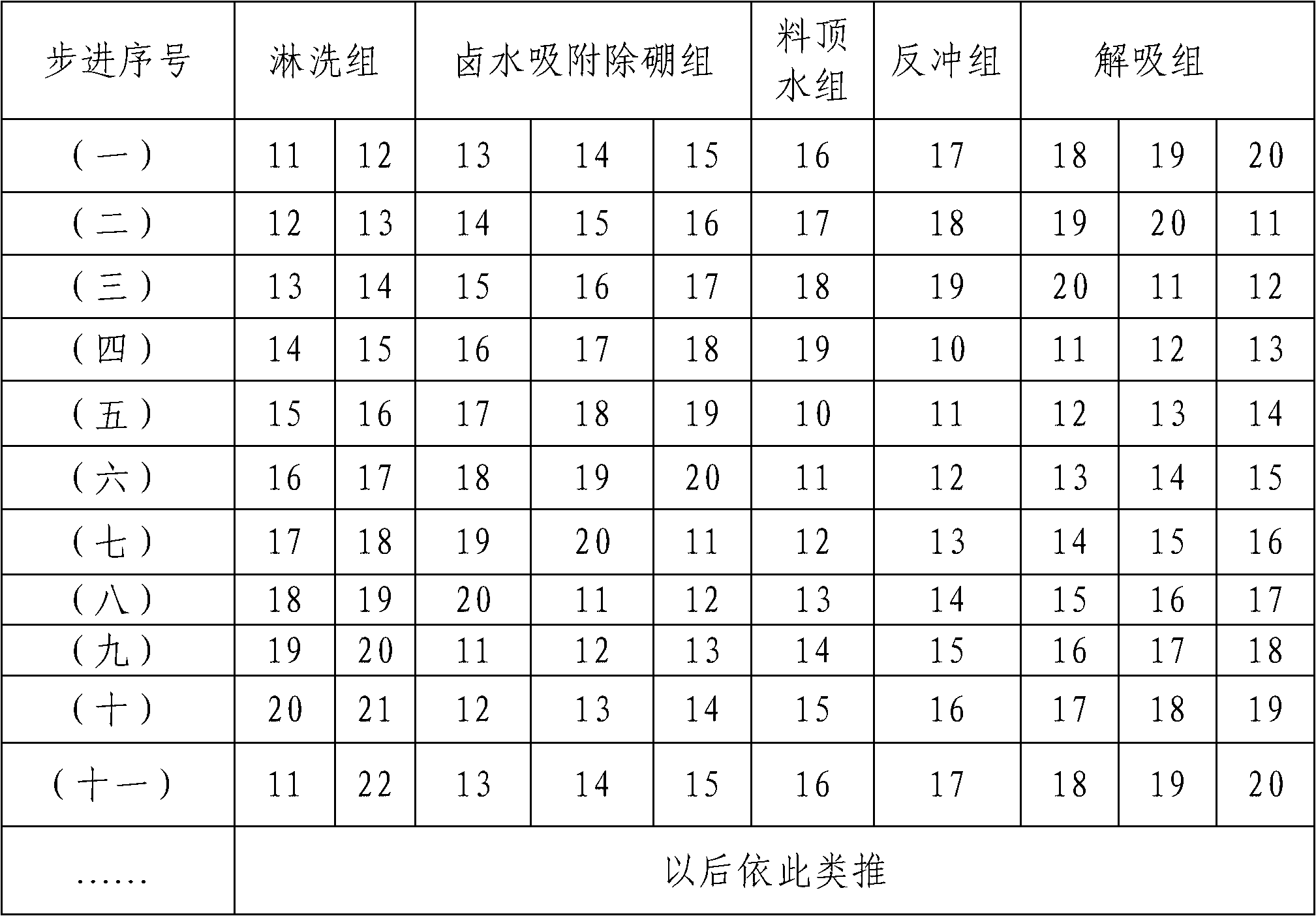

Continuous ion exchange device and method for removing boron from salt lake magnesium chloride brine

ActiveCN102703703AImprove efficiencyIncrease profitProcess efficiency improvementHigh concentrationSalt lake

The invention discloses a continuous ion exchange device and method for removing boron from salt lake magnesium chloride brine. The device comprises resin, a plurality of resin columns used for loading the resin, a feeding header pipe and a discharging header pipe, wherein the feeding header pipe is communicated with the upper end of the same resin column; the discharging header pipe is communicated with the lower end of the same resin column; the resin columns are successively connected in series by a serial pipeline; a brine adsorption boron removal group, a leaching group, a desorption group, a back-washing group and a material top water group which are moved and circularly operated in sequence are formed therebetween; and each feeding branch pipe and each discharging branch pipe are respectively provided with a control valve used for harmoniously controlling all groups of resin columns to realize ion exchanging, leaching and desorbing processes in turn. Compared with the prior art, the continuous ion exchange device disclosed by the invention is simple, is convenient to operate, and has the advantages of high automation degree, small resin use amount, high use ratio, stable product concentration and high concentration of qualified liquid.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

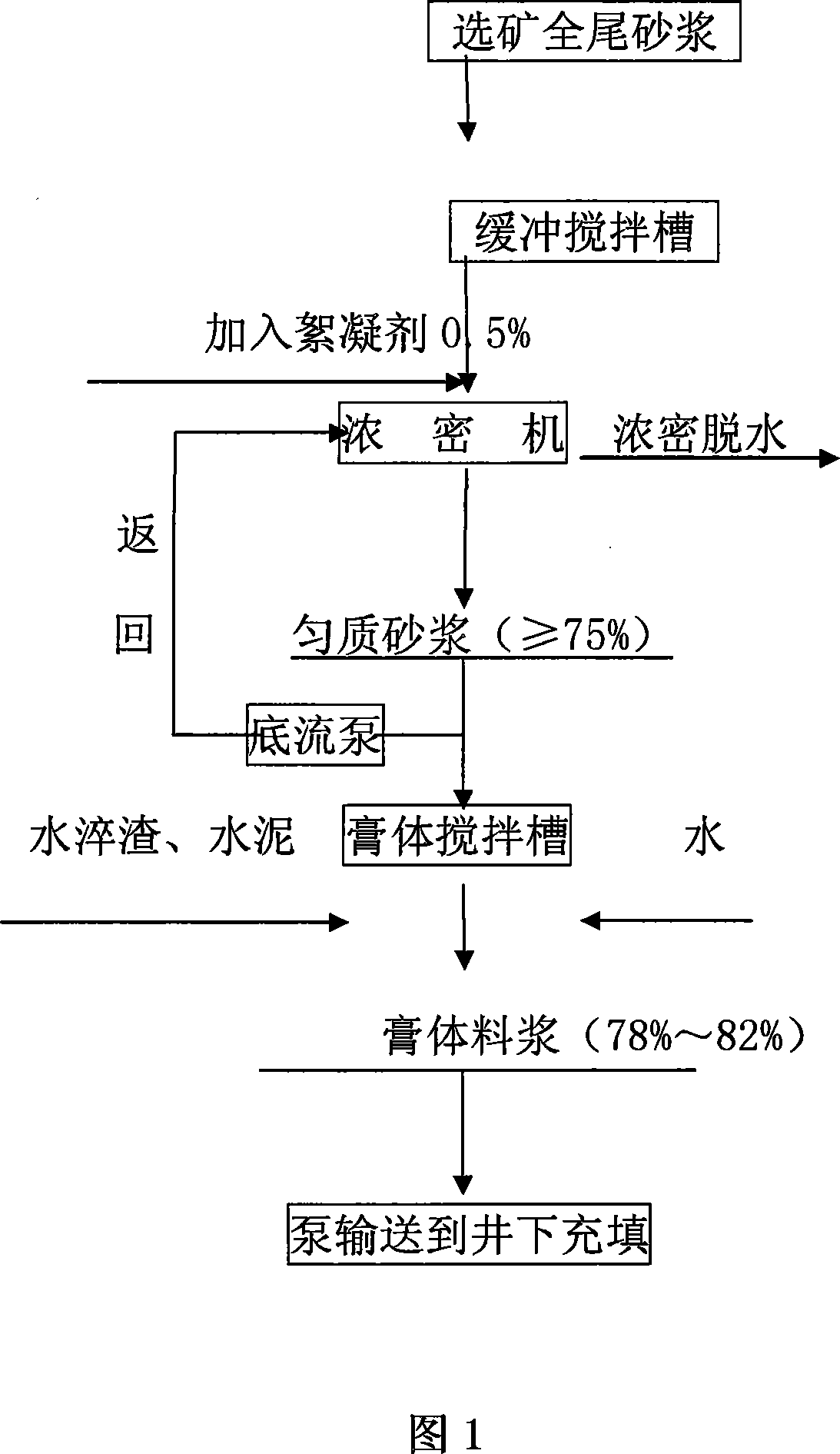

Whole tailings depth controllable homogeneous concentration method

InactiveCN101215975AUniform and stable concentrationStable concentrationSedimentation separationMaterial fill-upSlagHigh concentration

The invention provides a whole tailing depth controllable uniform condensation method, which comprises the following processing steps: concentration of whole tailing ranges from 10 percent to 30 percent; the whole tailing is fed into a buffering agitator tank for homogenization and stabilization; the whole tailing flows into a CH thickener; flocculant with the concentration of 0.5 percent is added to the full tailing; an underflow pump is adopted for loop control to keep the mortar uniform; 12 hours later, the uniform concentration of the mortar reaches 74.5 percent to 76.5 percent; the uniform whole tailing is discharged and fed to an agitator; the uniform whole tailing is mixed with granulated blastfurnace slag, cement and water and becomes cream with the concentration of 78 percent to 82 percent; the cream is fed to a downhole goaf to fill the downhole goaf. The invention has the remarkable advantages of simple process flow, high concentration efficiency, small dissipation of energy and stable concentration of the whole tailing.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Lamelliferous color master batch and manufacturing method thereof

InactiveCN105291295AConcentration remains stableGuaranteed stabilityComposite materialColoring agents

The invention relates to the field of plastic coloring, in particular to a lamelliferous color master batch for plastic coloring and a manufacturing method of the lamelliferous color master batch. The manufacturing method of the lamelliferous color master batch includes the steps that the lamelliferous color master batch is a cuboid or cube, the side length ranges from 1 mm to 10 mm, the width ranges from 1 mm to 10 mm, and the thickness ranges from 0.2 mm to 1.5 mm; the lamelliferous color master batch comprises components of, by weight percentage, 10%-90% of carriers, 0.01%-70% of a coloring agent, 0%-5% of a coupling agent, 0%-30% of a dispersing agent and 0%-70% of padding; and through a double-screw extruder, the components are molded into a flat material strip through a flat orifice die of an extruder head, cooling and granulating are conducted, and the lamelliferous color master batch is obtained finally. By means of the lamelliferous color master batch, the condensation of the color master batch in a plastic product is kept stable, and the stability of the color of the plastic product is guaranteed.

Owner:东莞市普凯塑料科技有限公司

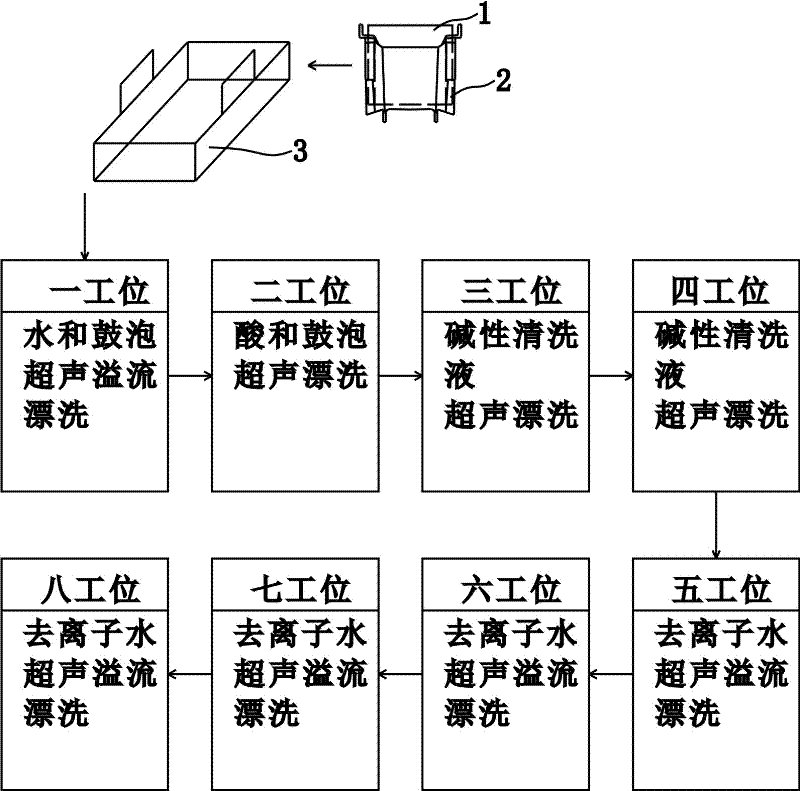

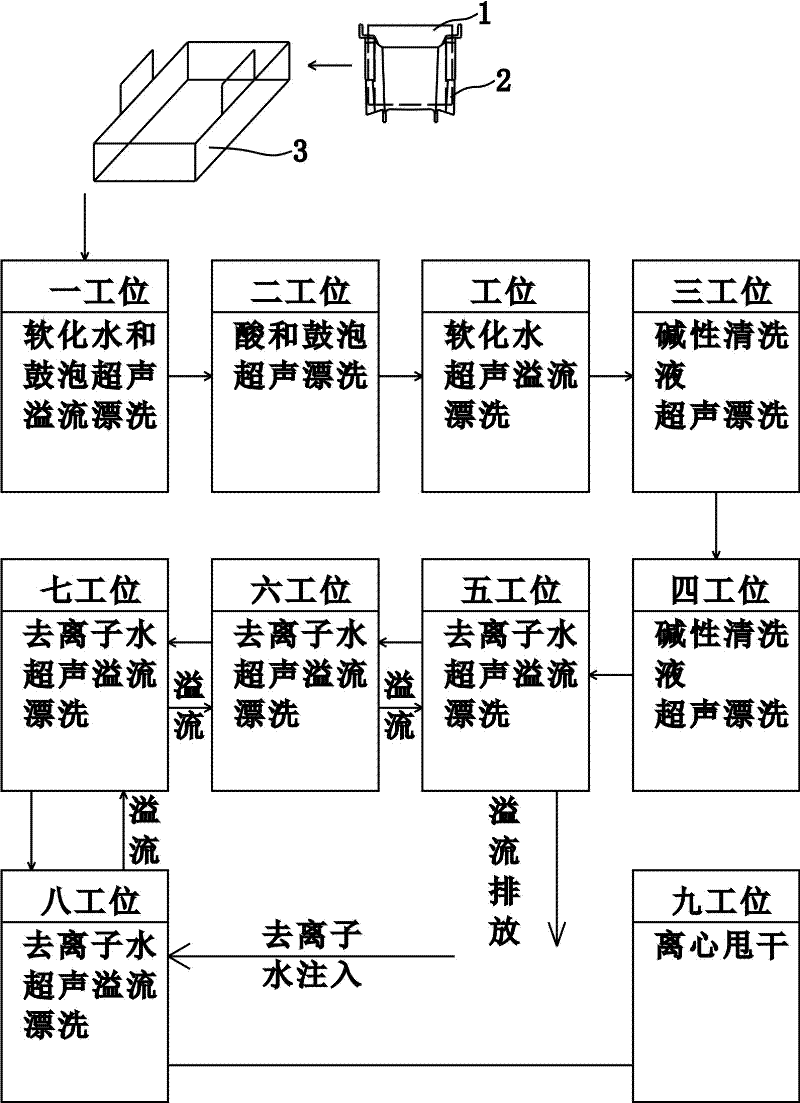

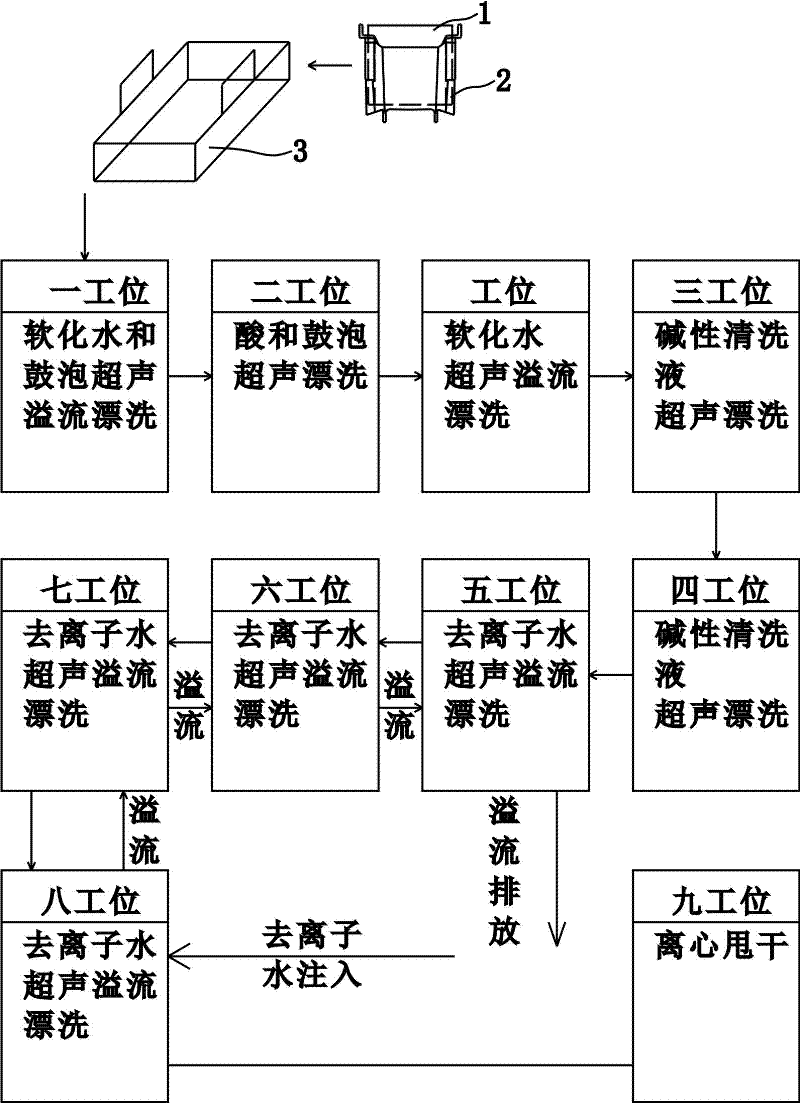

Cut/ground silicon wafer surface cleaning apparatus

InactiveCN102412173AConstant pHConstant concentrationSemiconductor/solid-state device manufacturingCleaning using liquidsSurface cleaningEngineering

The invention discloses a cut / ground silicon wafer surface cleaning apparatus, which comprises a silicon wafer, a silicon wafer carrier and stations sequentially cleaning the silicon wafer and carrying out corresponding cleaning steps, the stations include a cleaning tank of a first station with water and bubble ultrasonic overflow rinsing, a cleaning tank of a second station with acid solution and bubble ultrasonic cleaning and the like. The cut / ground silicon wafer surface cleaning apparatus overcomes the problem of easy acid-alkali neutralization reaction, so that the PH value and concentration of the alkaline cleaner of a third station and a fourth station can be kept constant, and thereby the dirt-removing capability of the alkaline cleaner can be persistently effective. The cut / ground silicon wafers cleaned by the method have high surface cleanliness, good repeatability and a consistent color; the oxidation phenomena of mottling, bluing and blacking are prevented, and the acceptance rate of the cleaned silicon wafers is high; meanwhile, the cleaner does not need to be added in the effective period of cleaning capacity specified by the process, and the cut / ground silicon wafer surface cleaning method is easy to operate.

Owner:沈利军

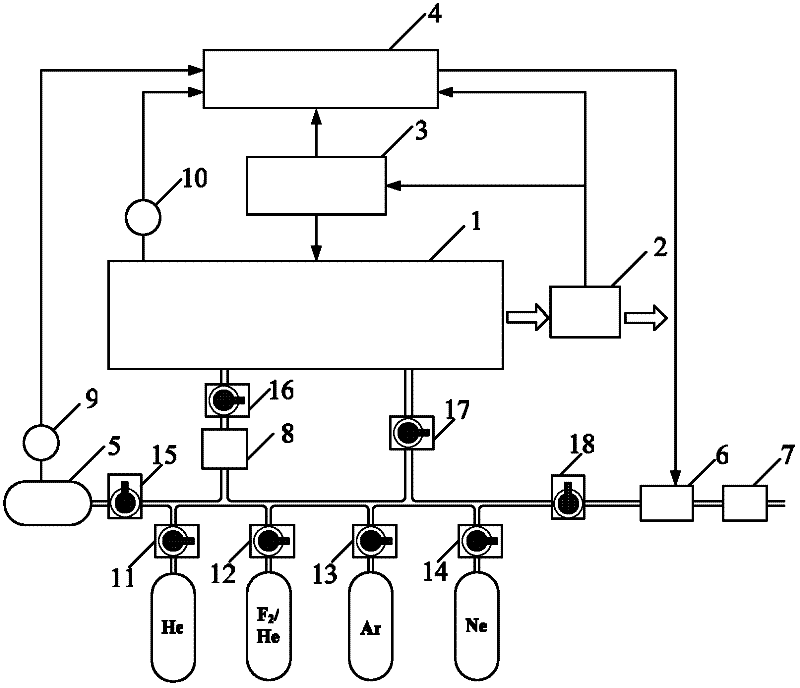

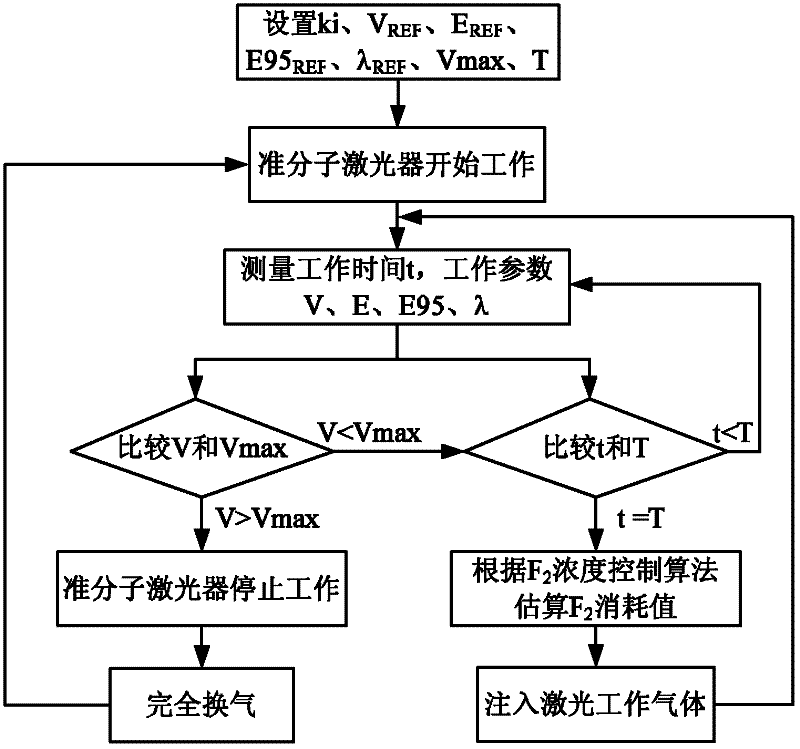

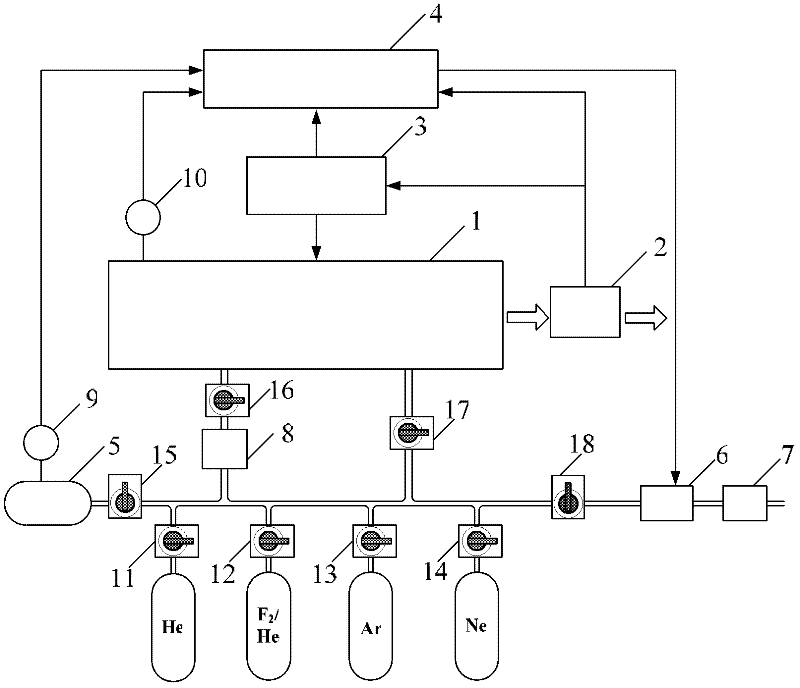

Gas management apparatus and method for excimer laser

The invention relates to a gas management apparatus and a method for an excimer laser. The apparatus comprises: an excimer laser; a monitoring and controlling module; controllable electromagnetic valves that are used for controlling flow directions of laser working gases; gas injection tank that is used for matching laser working gases with different concentrations; a halogen gas processing apparatus and a vacuum pump that are used for discharging laser working gases; and a pressure transducer that is used for monitoring pressure intensities of the laser working gases. According to the invention, working parameters of an excimer laser are monitored, wherein the working parameters include a working voltage, pulse energy, a width of a spectral line, and a wavelength; consumption of laser working gas is estimated according to quantitative relations between the working parameters of the excimer laser and the concentration of the laser working gas, wherein the working parameters are measured by an experiment; changes of pressure intensity of the laser working gas within a laser cavity as well as openings and closures of the controllable electromagnetic valves are controlled by employing pressure monitoring and signal feed back methods, so that the laser working gas is injected with an accurate value into the laser cavity. According to the invention, stability for outputting laser pulse by an excimer laser can be improved; life of laser working gas can be effectively prolonged; and a gas change rate of the laser can be reduced.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

OCC line residual pulp efficient recycling production method

ActiveCN106283809AEfficient recyclingLarge amount of processingPulp de-wateringPulp beating/refining methodsFiberWastewater

The invention relates to an OCC line residual pulp efficient recycling production method. The method comprises the steps of low-concentration tailing collecting and conveying, finely-screened tailing collecting and conveying, trench off-machine water total discharged residue collecting and conveying, tailing concentration, tailing pulp grinding, tailing mixing, diluting and concentration regulating, medium-concentration sand removing, fine screening, multi-tray concentration, pulp grinding and pulp storage. The step of trench off-machine water total discharged residue collecting and conveying specifically comprises the steps that total trench off-machine water of OCC line machines is recycled through an inclined screen of a wastewater treating plant, and recycled residual pulp is pumped into a residual pulp treating line after the concentration is regulated. Compared with the prior art, by means of development and application of key processes such as tailing collecting, concentration, re-grinding, diluting, sand removing, fine screening, concentration and fine pulp obtaining and key equipment improvement, fibers and recyclable fine fibers in tailings and filler are efficiently recycled, and the residue pulp treatment line is large in treatment amount and high in yield.

Owner:LIANSHENG PAPER IND LONGHAI

Preparation method of injectable chitosan grafted cyclodextrin compound drug-carrying hydrogel

InactiveCN107233575ASolve the phenomenon of explosive releaseLong-term releaseAerosol deliveryOintment deliveryCompounding drugsFreeze-drying

The invention discloses a preparation method of injectable chitosan grafted cyclodextrin compound drug-carrying hydrogel. The preparation method comprises the steps of carrying out amination and hydroformylation on cyclodextrin, reacting by virtue of hydroformylated cyclodextrin with chitosan so as to obtain chitosan grafted cyclodextrin, soaking molecules of obtained chitosan grafted cyclodextrin into medical liquid, uniformly stirring, filtering, carrying out freeze drying so as to obtain drug-carrying chitosan grafted cyclodextrin, adding drug-carrying chitosan grafted cyclodextrin into a chitosan water solution, adding beta-sodium glycerophosphate, so as to obtain the injectable chitosan grafted cyclodextrin compound drug-carrying hydrogel. The preparation method has the beneficial effects that reaction conditions are mild, and the operation is relatively simple and convenient; the stability of a drug concentration in a gel system of the prepared hydrogel can be maintained for a long time, and a drug can be effectively and controllably released for a long time, so that the utilization rate of the drug is increased; and the preparation method has relatively wide application prospects.

Owner:HENAN INST OF ENG

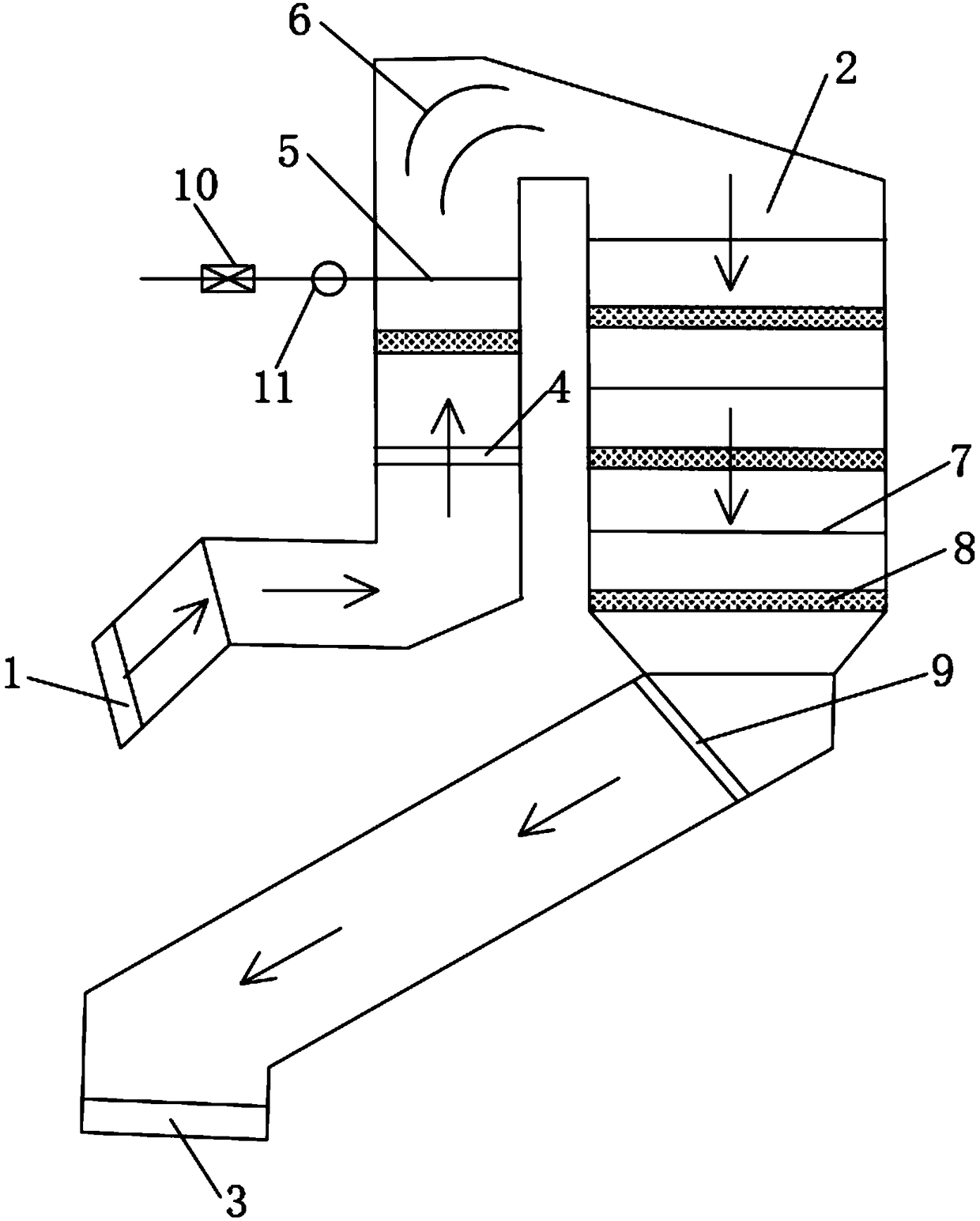

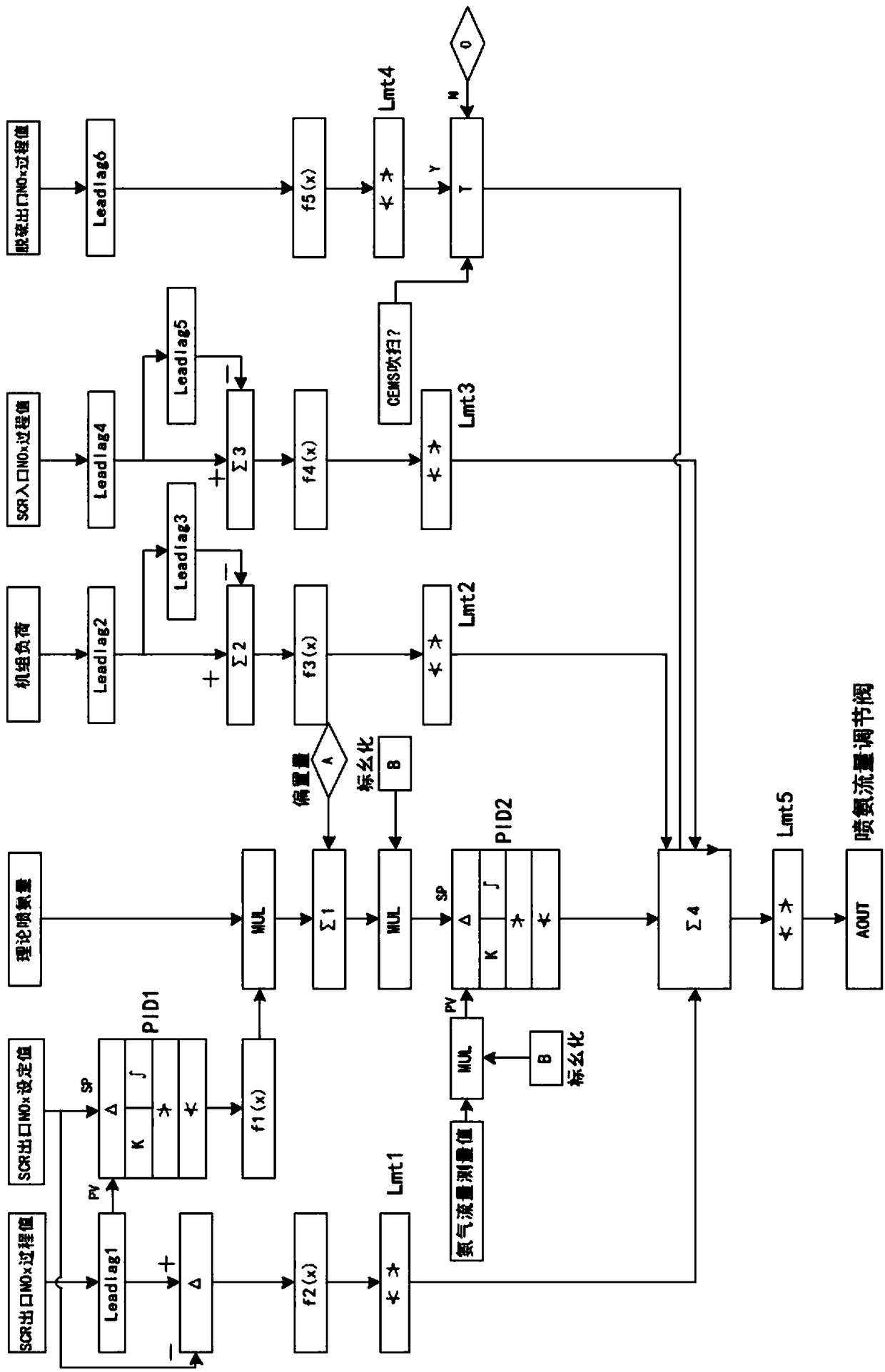

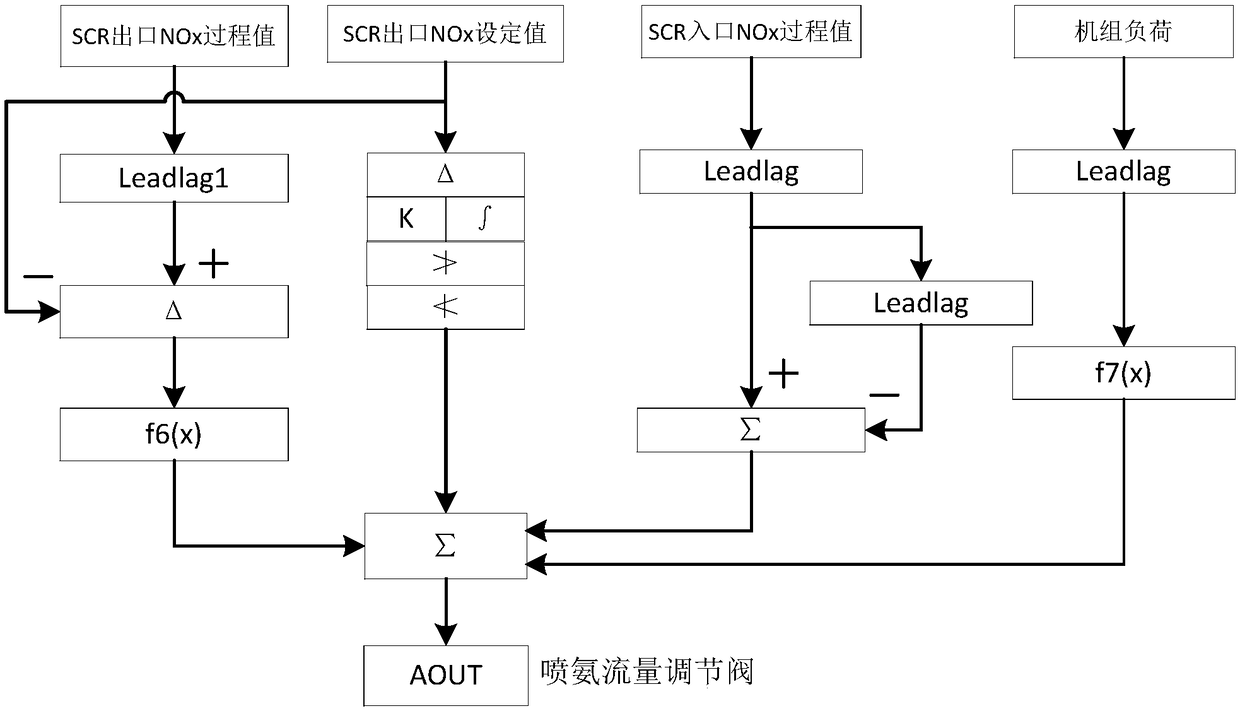

Denitration ammonia spraying flow adjusting device based on cascade PID (proportion integration differentiation) and feedforward and working method of device

PendingCN109092035AReduce escapeEasy to controlDispersed particle separationControllers with particular characteristicsAir preheaterAutomatic control

The invention relates to a denitration ammonia spraying flow adjusting device based on cascade PID (proportion integration differentiation) and feedforward and a working method of the device. Existingdenitration ammonia spraying automatic control logic cannot stably control the concentration of NOx at an outlet of an SCR (selective catalytic reduction) reactor, and the labor intensity of operators is increased. The device comprises the SCR reactor, an electric control valve, a flowmeter and the like, wherein the SCR reactor is arranged between a boiler economizer and an air preheater; an inlet of the SCR reactor is adjacent to the boiler economizer, and an outlet of the CR reactor is adjacent to the air preheater; a No.1 ammonia spraying grille, a guide plate, a No.2 ammonia spraying grille and a catalyst layer are sequentially arranged in the flow direction of flue gas, the No.1 ammonia spraying grille is adjacent to the inlet of the SCR reactor, and the No.2 ammonia spraying grilleis adjacent to the catalyst layer. By means of the device, the control problem caused by the large delay characteristic of a denitration system can be solved, control overshoot can be reduced, and accurate control of the ammonia spraying amount can be realized.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

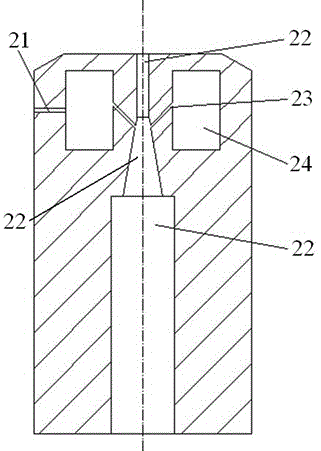

Multiple spray-head combined type air-injection electrostatic spinning machine

ActiveCN103173873AIncrease productivityPrevent volatilizationFilament/thread formingSpinningLiquid storage tank

A multiple spray-head combined type air-injection electrostatic spinning machine is mainly composed of spinning units, an air conveying pipe, a liquid conveying pipe, conductive wires, a high-voltage electrostatic generator, transverse flow air pumps, metering pumps, a receiving device and liquid storage tanks, wherein the spinning units are installed on a base in an inserted mode, air inlets of the spinning units are communicated with the air conveying pipe through air conveying branch pipes, liquid inlets of the spinning units are communicated with the liquid conveying pipe through liquid conveying branch pipes, two ends of the air conveying pipe are communicated with the transverse flow air pumps, and two ends of the liquid conveying pipe are communicated with the liquid storage tanks through the metering pumps; and the receiving device is installed above the spinning unit, metal portions of the spinning units are connected with the positive pole of the high-voltage electrostatic generator through the conductive wires, and the receiving device is connected with the negative pole of the high-voltage electrostatic generator through one conductive wire. The multiple spray-head combined type air-injection electrostatic spinning machine obviously improves the yield of nanofibers, has the advantages of being simple and high in production efficiency, and can achieve continuous and mass production of the nanofibers.

Owner:河南中纤新材料科技有限公司

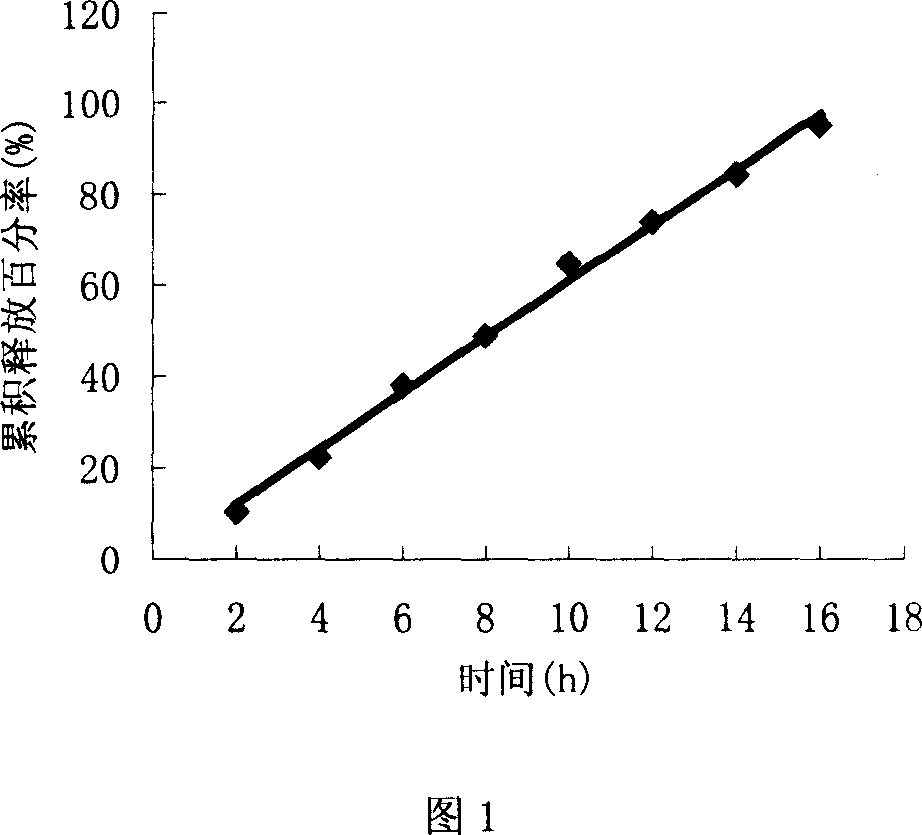

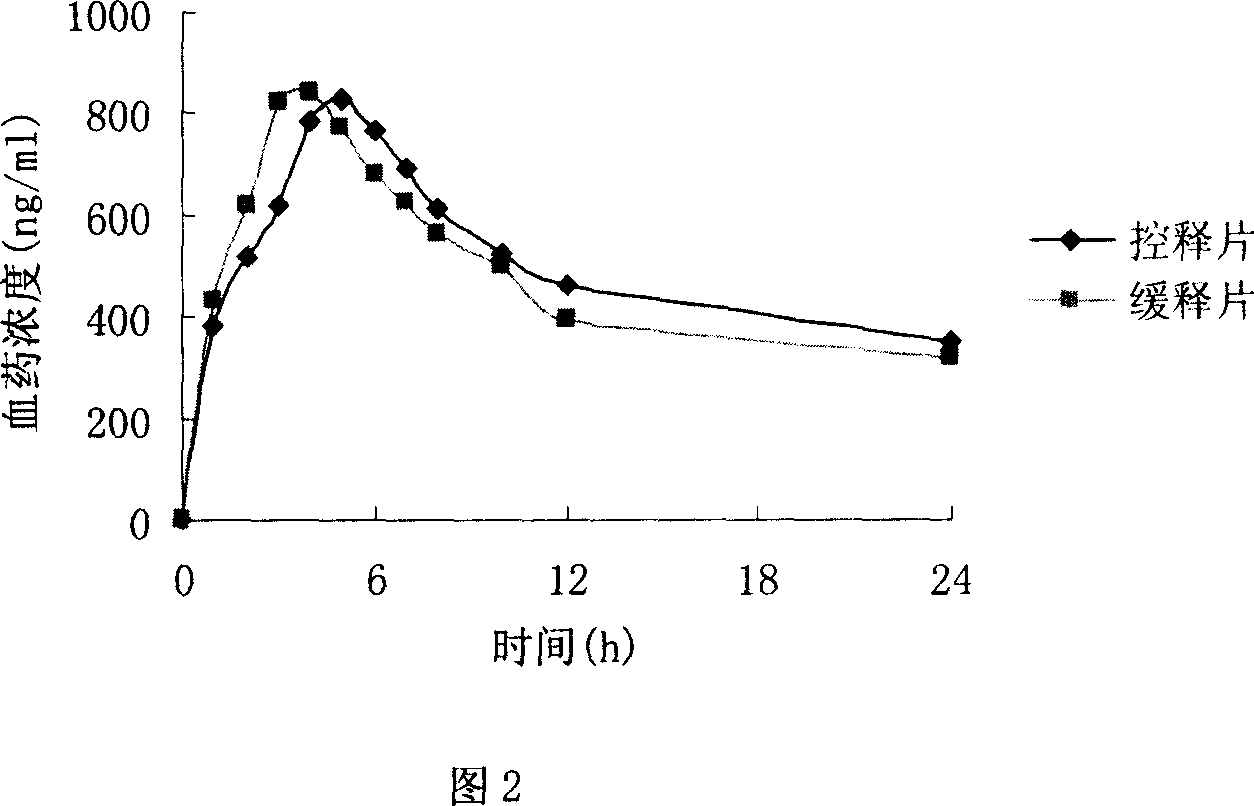

Orally taken control released trimetazidine medicine composition

InactiveCN1931143AImprove effectivenessImprove securityOrganic active ingredientsPharmaceutical non-active ingredientsTrimetazidinePlasticizer

The present invention relates to one kind of orally taken control released trimetazidine medicine composition and its preparation process. The trimetazidine medicine composition consists of trimetazidine or its physiologically acceptable salt in effective dosage and pharmaceutically acceptable medicine excipient capable of reaching release controlling osmotic pump effect. The medicine excipient is one or several selected from osmotic pressure active matter, permeation assistant, diluent, colorant, lubricant, moistener or adhesive, filming material, pore creating agent, plasticizer and solvent.

Owner:GUANGZHOU PUIS PHARMA FACTORY

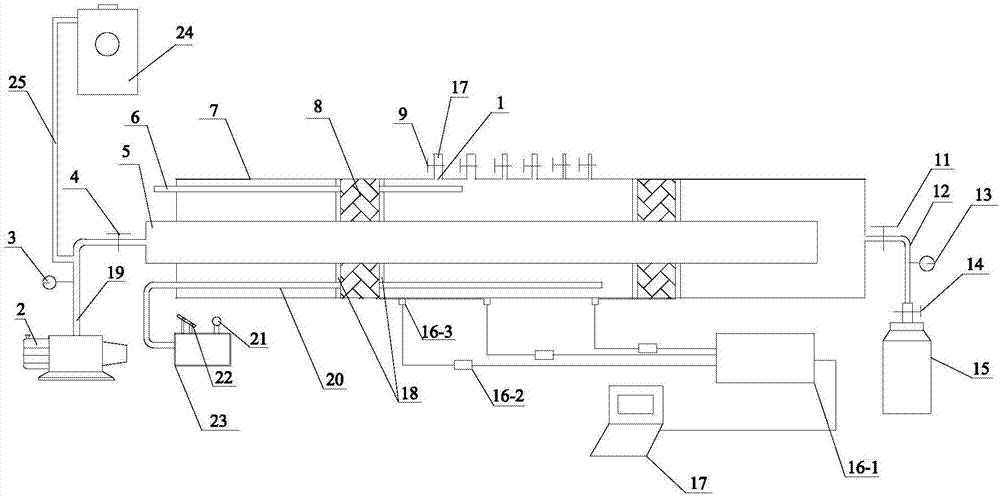

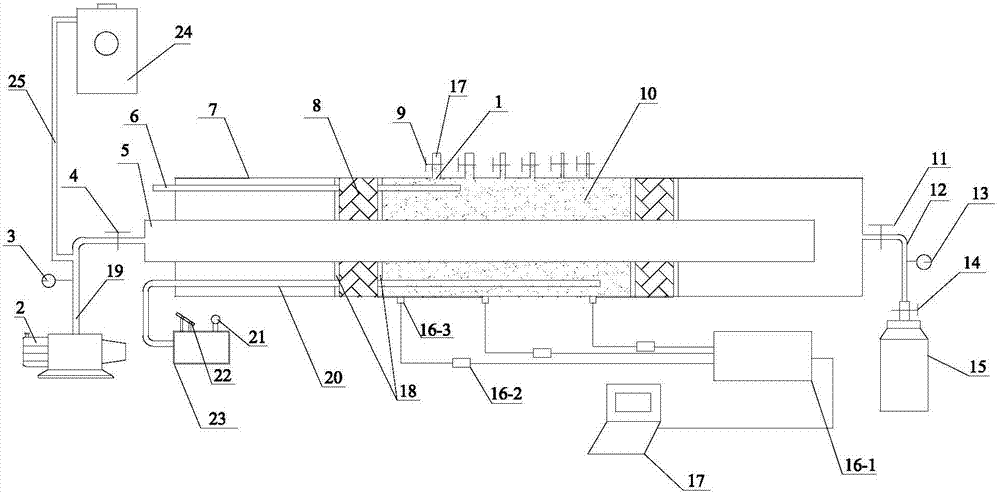

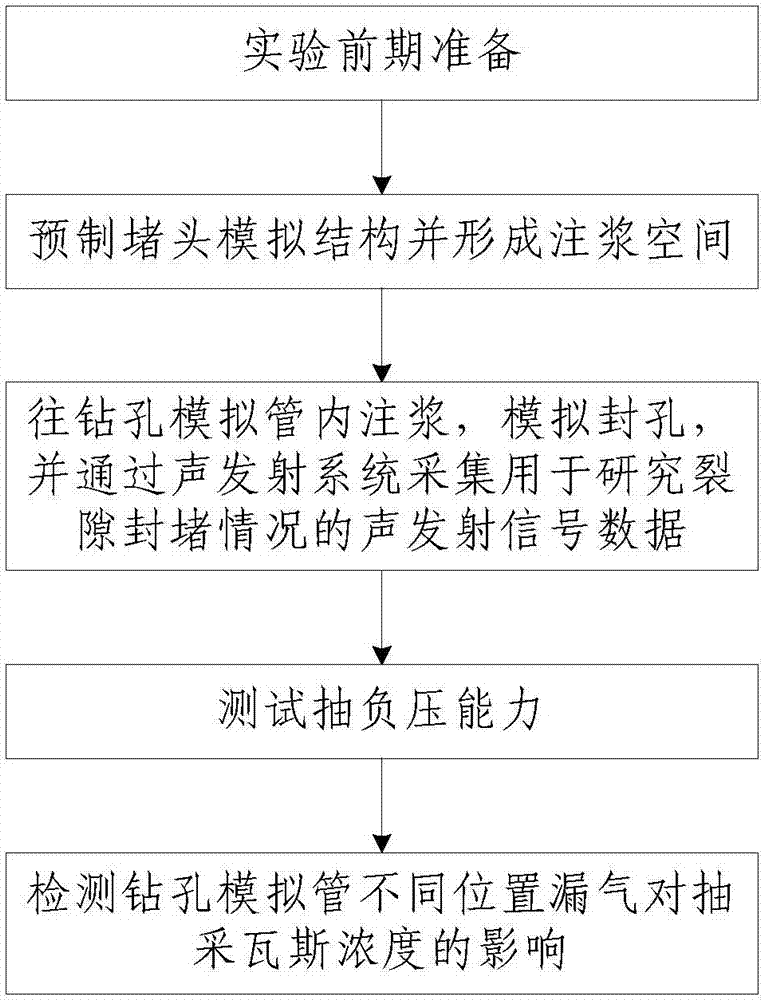

Drill hole gas extraction laboratory simulation system and method

ActiveCN107542486ASimple structureNovel and reasonable designSurveyMining devicesVacuum pressureDrill hole

The invention discloses a drill hole gas extraction laboratory simulation system which comprises a drill hole simulation pipe, a hole sealing slip casting system, a gas pressure simulation loading system, a gas detector, a sound emission system and a computer; the two ends inside the drill hole simulation pipe are provided with plug simulation structures, a plurality of crack simulation holes areformed in the wall of the drill hole simulation pipe, a crack simulation pipe is connected to each crack simulation hole, and a gas leakage detection switch is connected to each crack simulation pipe;the hole sealing slip casting system comprises a slip casting pipe, a slip returning pipe, a slip casting handle and a slip casting pressure gauge; the gas pressure simulation loading system comprises a vacuum pump, a gas tank, a vacuum pressure gauge, a vacuumizing switch, a gas tank switch, a gas pressure gauge and a gas extraction switch. The invention further discloses a drill hole gas extraction laboratory simulation method and a hole sealing material sealing performance testing method. The on-site situation can be truly simulated, little manpower and material resources consumed by experiments are consumed, the experiment effect is good, the experiment result accuracy is high, and practicability is high.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com