Cut/ground silicon wafer surface cleaning apparatus

A silicon wafer surface and equipment technology, applied to cleaning methods and appliances, cleaning methods using liquids, electrical components, etc., can solve the problems of unqualified surface quality of cleaned silicon wafers, service life of scrapped cleaning liquid, poor color consistency, etc. , to achieve long-lasting and effective decontamination ability, improved cleaning quality and economic benefits, and consistent color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

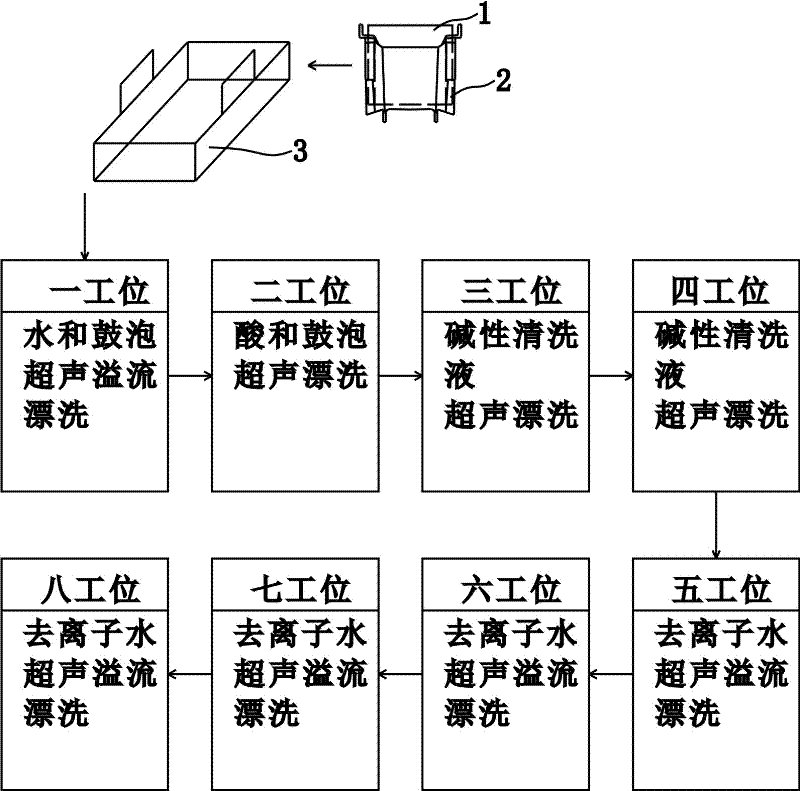

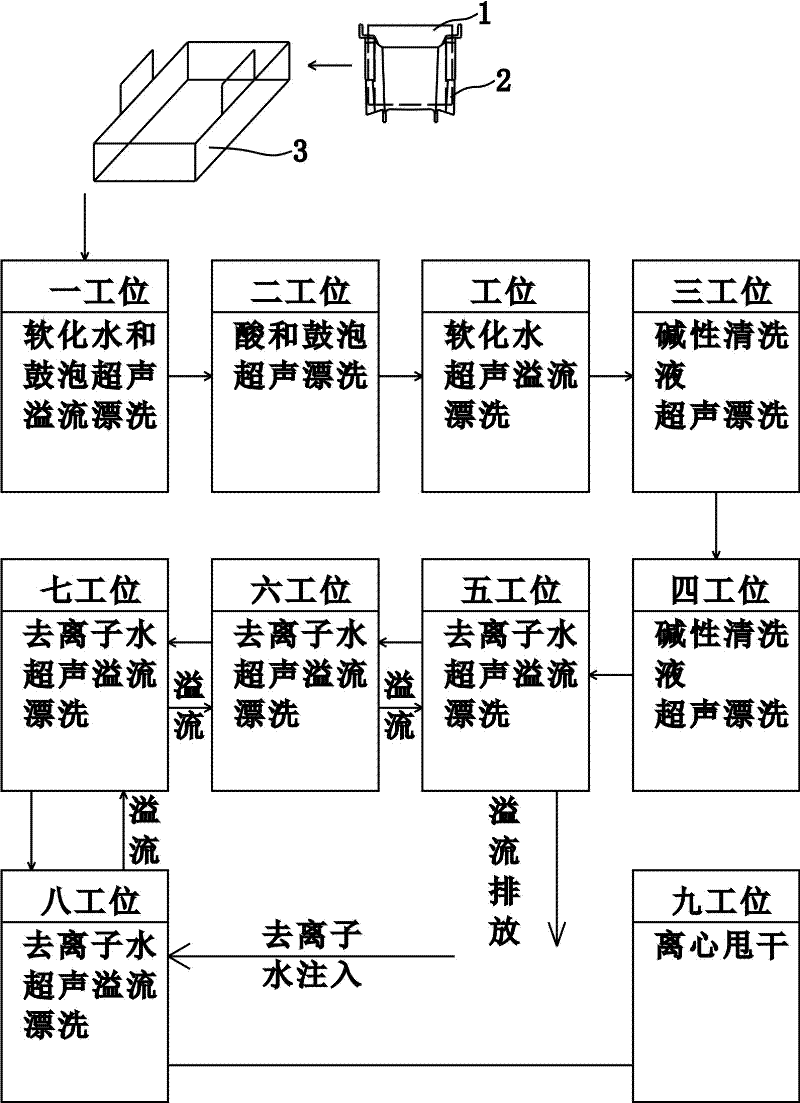

[0018] see figure 2 , this implementation case includes the silicon wafer 1, the carrier of the silicon wafer 1, that is, the flower basket 2 and the basket 3 carrying the flower basket, and the stations for cleaning the silicon wafers and completing the corresponding processes in sequence. The stations include water and bubbling ultrasonic overflow. A cleaning tank with one station for flow rinsing, a cleaning tank with two stations for ultrasonic cleaning in acid solution and bubbling, a station for ultrasonic overflow rinsing with demineralized water, a station for ultrasonic overflow cleaning with alkaline cleaning agent Three-station cleaning tank, four-station cleaning tank with alkaline cleaning agent ultrasonic cleaning tank, five-to-eight-station cleaning tank with high-frequency ultrasonic source deionized water ultrasonic overflow cleaning, equipped with nitrogen , Nine stations for centrifugal drying of silicon wafers, the temperature in the nine stations is 100~1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com