Patents

Literature

330results about How to "Improve surface cleanliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

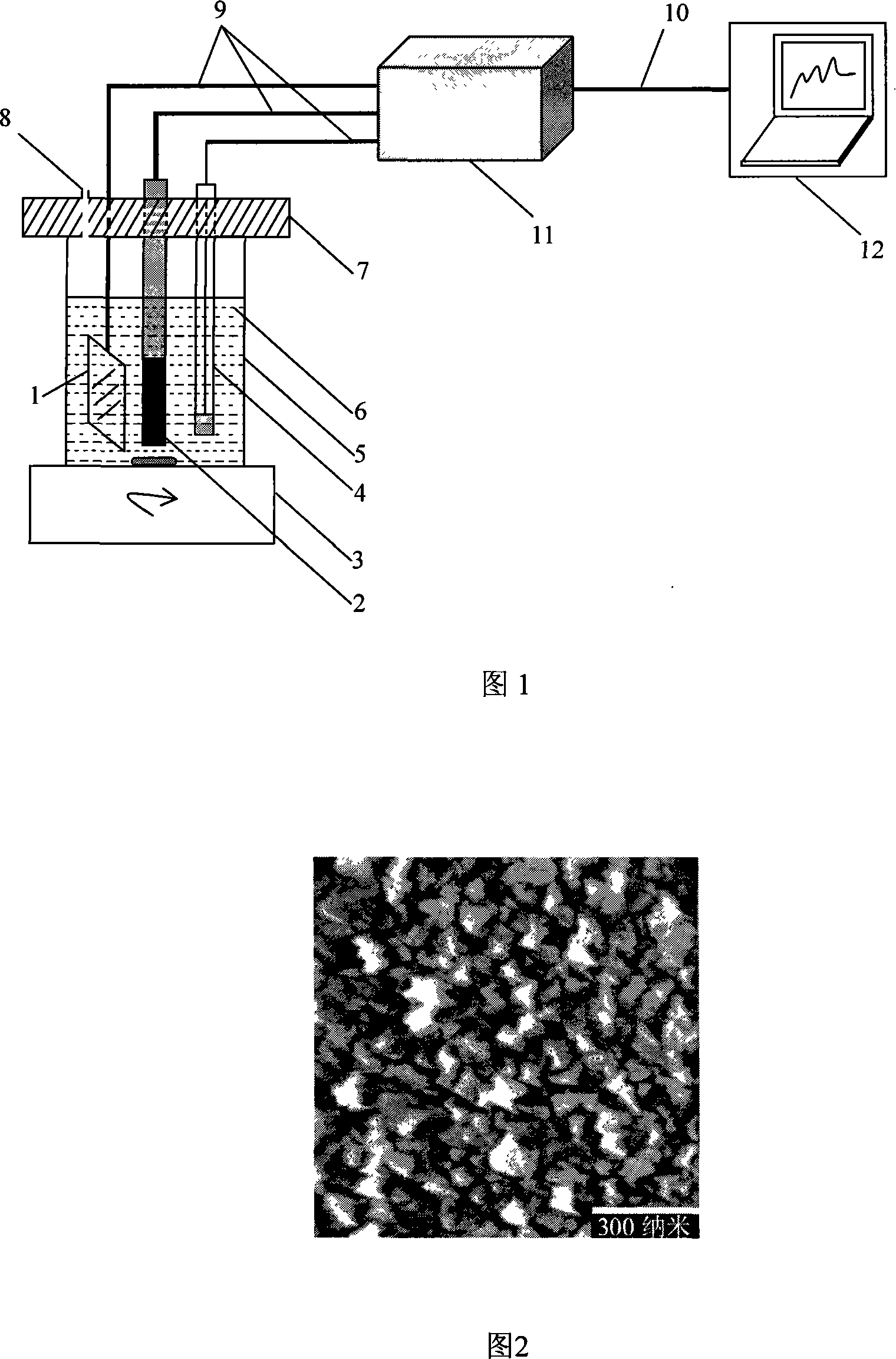

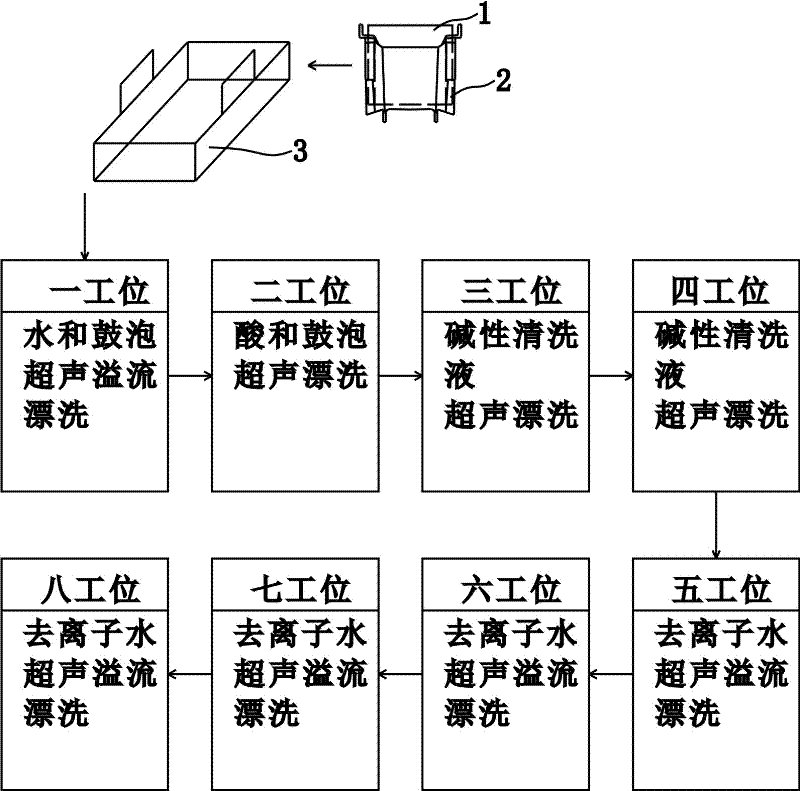

Electrochemical analysis device adopting nano boron-doped diamond film electrode and its uses

InactiveCN101149356AReduce usageIt has the characteristics of green environmental protectionMaterial electrochemical variablesElectrolysisTrace metal

The electrochemical analysis device and its application of the diamond membrane electrode of the nanometer mixed with the boron are used to detect the heavy metal ion with high sensitivity. It includes the electrolysis, the working station and data collecting and controlling system. The electrolysis system is made up of the electrolysis pool with the single room structure, the electrode frame and the working electrode fixed on the electrode frame, the assistant electrode, the reference electrode. The working electrode is the diamond membrane electrode of the nanometer mixed with the boron. The three electrodes are connected with the electrochemical analyzer by the electrode line. The data collecting and controlling system is the computer installed with the electrochemical analyzer. The device has avoided using the electrode containing the hydrargyrum and improved the detection sensitivity, the detection limit can reach 10-9mol / L and it has good repeatability. The detection process does not need to remove oxygen by giving nitrogen; also it can reach the renovation on the electrode surface. The invention can detect many trace metal ion in sample at the same time.

Owner:TONGJI UNIV

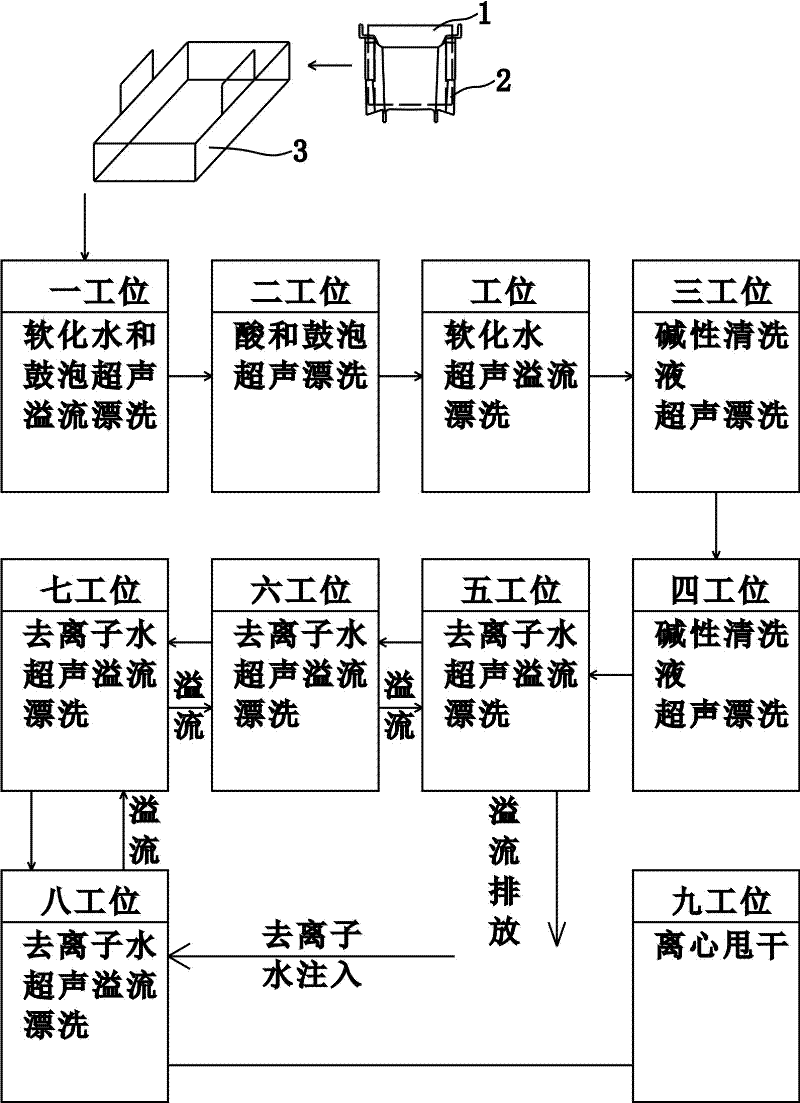

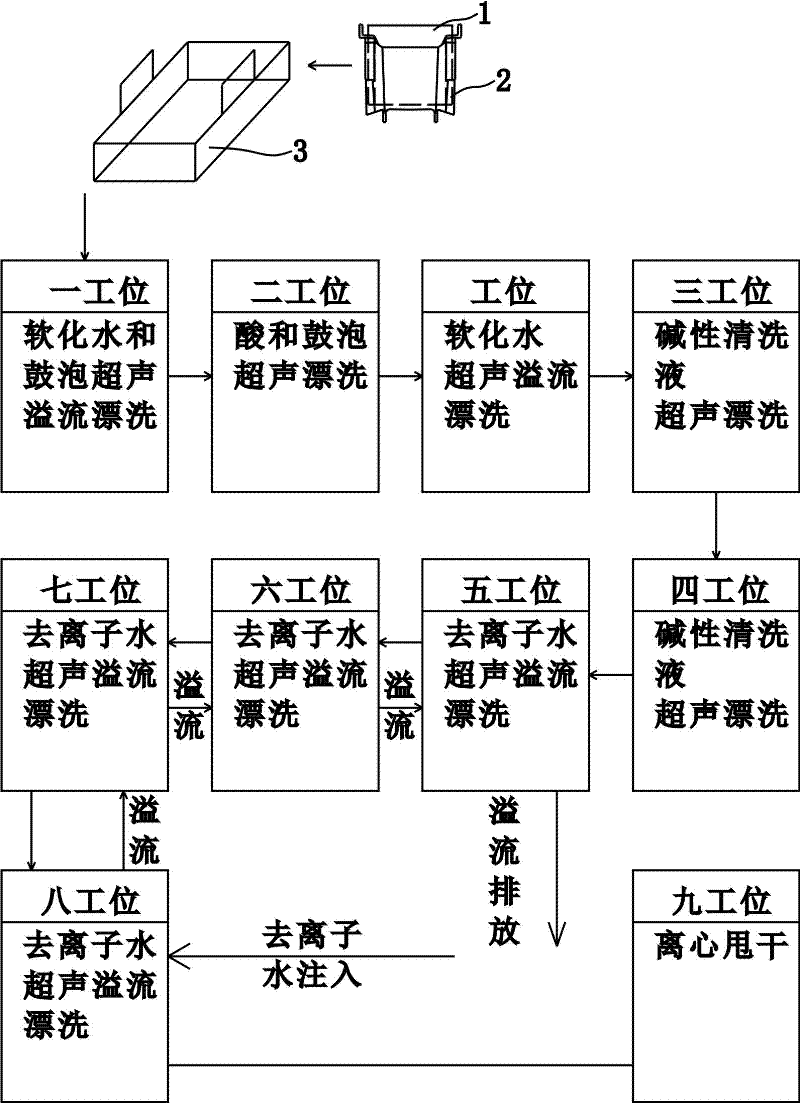

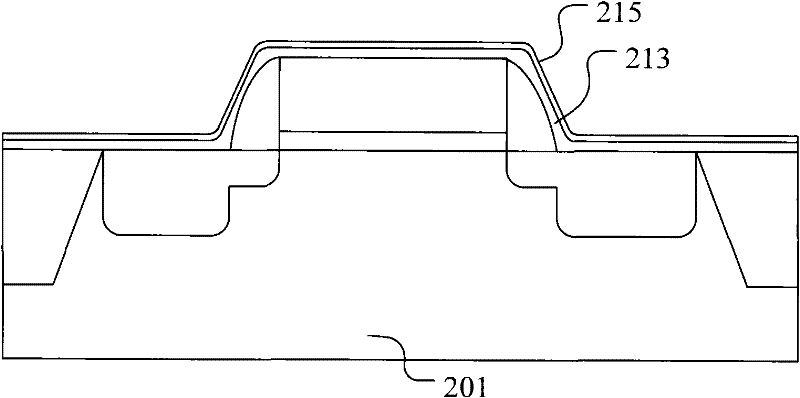

Cut/ground silicon wafer surface cleaning apparatus

InactiveCN102412173AConstant pHConstant concentrationSemiconductor/solid-state device manufacturingCleaning using liquidsSurface cleaningEngineering

The invention discloses a cut / ground silicon wafer surface cleaning apparatus, which comprises a silicon wafer, a silicon wafer carrier and stations sequentially cleaning the silicon wafer and carrying out corresponding cleaning steps, the stations include a cleaning tank of a first station with water and bubble ultrasonic overflow rinsing, a cleaning tank of a second station with acid solution and bubble ultrasonic cleaning and the like. The cut / ground silicon wafer surface cleaning apparatus overcomes the problem of easy acid-alkali neutralization reaction, so that the PH value and concentration of the alkaline cleaner of a third station and a fourth station can be kept constant, and thereby the dirt-removing capability of the alkaline cleaner can be persistently effective. The cut / ground silicon wafers cleaned by the method have high surface cleanliness, good repeatability and a consistent color; the oxidation phenomena of mottling, bluing and blacking are prevented, and the acceptance rate of the cleaned silicon wafers is high; meanwhile, the cleaner does not need to be added in the effective period of cleaning capacity specified by the process, and the cut / ground silicon wafer surface cleaning method is easy to operate.

Owner:沈利军

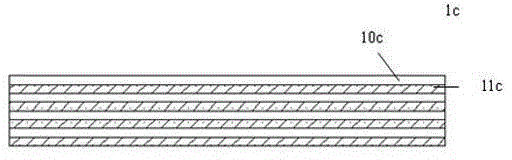

Polyvinyl alcohol-based film, production method thereof and polarizing film produced from polyvinyl alcohol-based film

ActiveCN107200977AGuaranteed drying uniformityGuaranteed Optical ConsistencyPolarising elementsAntioxidantPlasticizer

The invention relates to a composition of a high molecular compound, and particularly discloses a polyvinyl alcohol-based film, a production method thereof and a polarizing film produced from the polyvinyl alcohol-based film. The polyvinyl alcohol-based film comprises the following components as raw materials in parts by mass: 80-95 parts of PVA (polyvinyl alcohol), 5-20 parts of EVOH, 5-25 parts of a plasticizer, 0.001-0.1 part of surfactant and 0.001-0.1 part of an antioxidant; the polyvinyl alcohol-based film is annealed for 2 hours at the temperature of 80 DEG C and the RH (relative humidity) of 50-95%; the crystallinity change of any region of the polyvinyl alcohol-based film is smaller than or equal to 5%. The polyvinyl alcohol-based film is good in size stability, the size change in any direction of the film during swelling can be reduced, the processability of the polyvinyl alcohol-based film is enhanced, the obtained polyvinyl alcohol-based film is good in optical consistency, and bending spots generated during staining are less.

Owner:CHINA PETROCHEMICAL CORP +1

Inorganic surface treatment galvanized steel plate and preparation method thereof

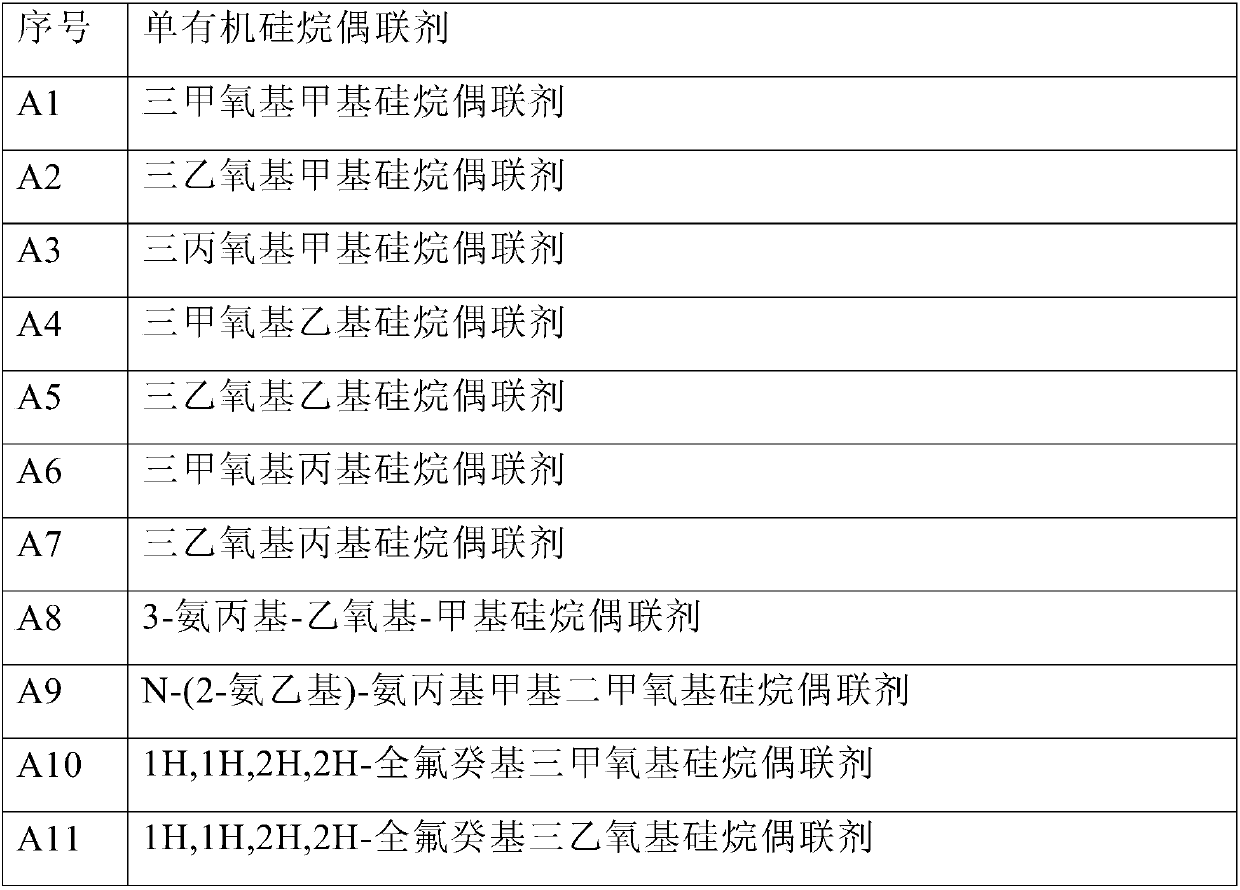

ActiveCN107779853AExcellent anti-rust performanceAchieve "non-stick" propertiesMetallic material coating processesWater basedLubrication

Disclosed are an environment-friendly inorganic surface treatment galvanized steel plate and a preparation method and water-based inorganic surface treatment agent of the environment-friendly inorganic surface treatment galvanized steel plate. According to the environment-friendly inorganic surface treatment galvanized steel plate and the preparation method and water-based inorganic surface treatment agent of the environment-friendly inorganic surface treatment galvanized steel plate, progressive die rapid deep-drawing machining in the micro-motor field can be met, and excellent part anti-red-rust performance and surface conductivity are achieved simultaneously. Under an open environment, by coating and curing the water-based inorganic surface treatment agent containing a single organic silane coupling agent containing hydrophobic groups, a system crosslinking agent, water-soluble nano sol, surface modified high-density polyethylene particles, orthosilicate ester modified graphene oxide, a water-soluble fluorinated compound, a water-soluble phosphorous compound, a water-soluble metallic salt compound and the like on the surface of the galvanized steel plate, the obtained inorganicsurface treatment galvanized steel plate has excellent anti-red-rust performance, the surface conductivity, surface lubrication performance and anti-stamping blackening performance, requirements of progressive die rapid deep-drawing machining and bare service can be met, and therefore, the environment-friendly inorganic surface treatment galvanized steel plate and the preparation method and water-based inorganic surface treatment agent of the environment-friendly inorganic surface treatment galvanized steel plate are especially suitable for the field of micromotors.

Owner:BAOSHAN IRON & STEEL CO LTD

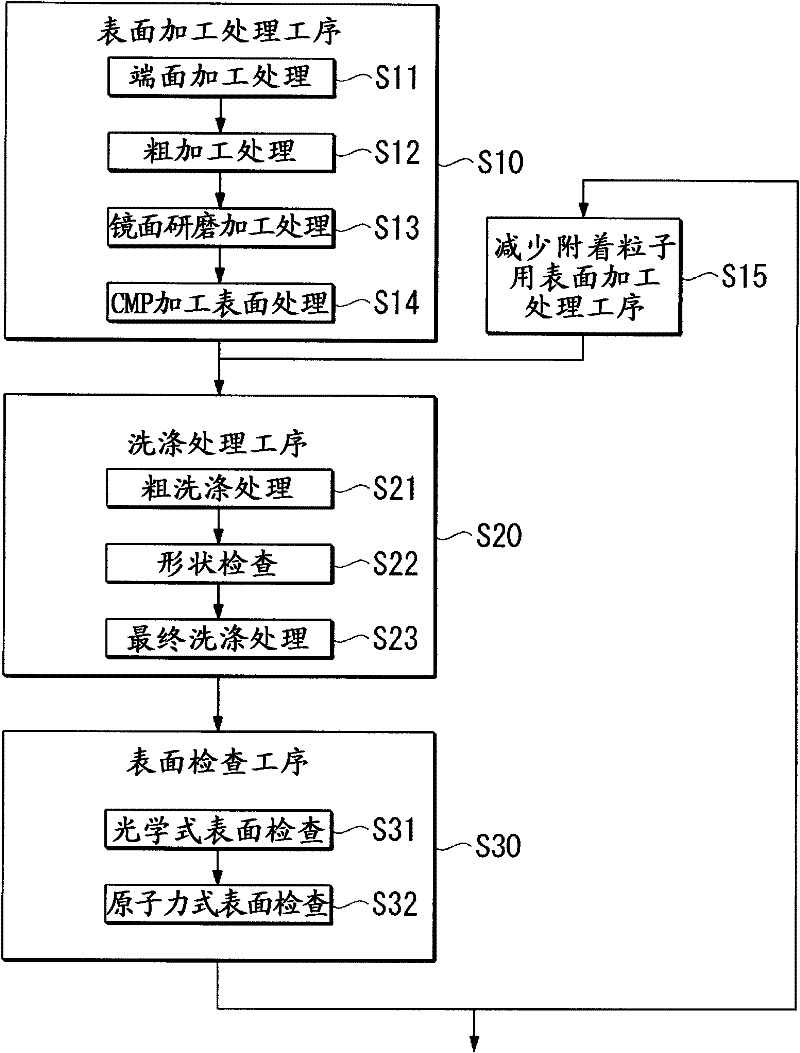

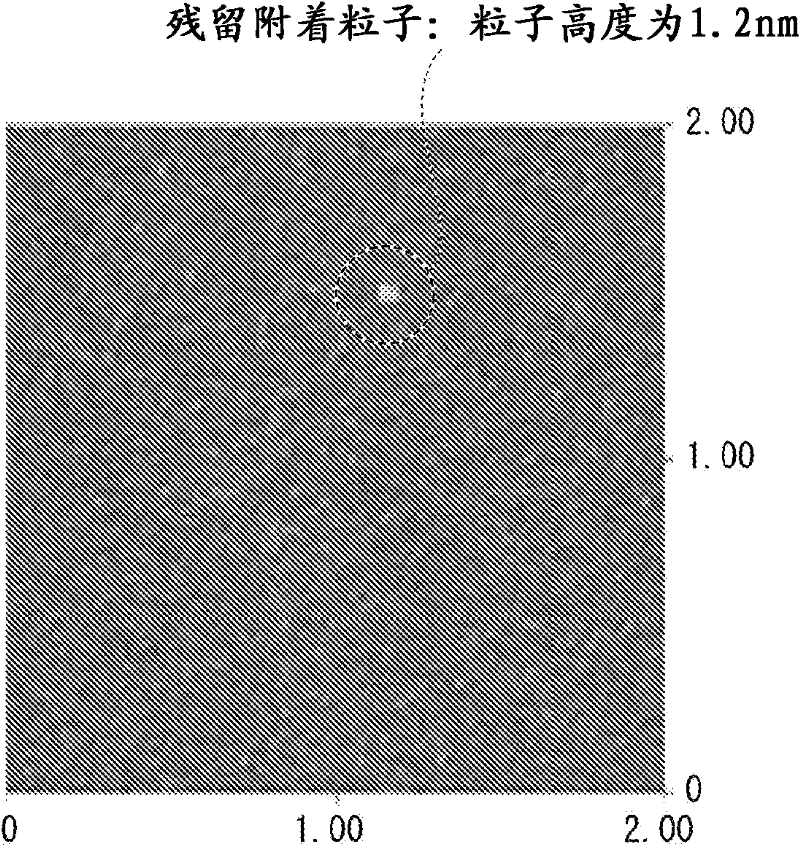

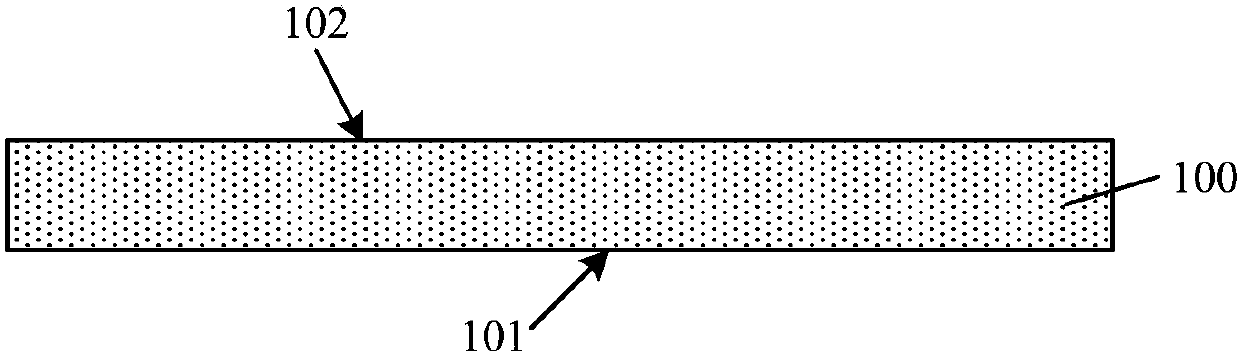

Silicon carbide single crystal substrate

ActiveCN102165563AImprove surface cleanlinessPolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystal substrateHigh surface

Provided is a silicon carbide single crystal substrate having adhered particles that cause crystal defects removed therefrom and has high surface cleanliness. A silicon carbide single crystal substrate wherein the density of first adhered particles having an adhesion height of 100 nm or more on one surface of the substrate is one particle / cm2 or less, and the density of second adhered particles having an adhesion height of less than 100 nm on such surface of the substrate is 1500 particles / cm2 or less is used.

Owner:RESONAC CORPORATION

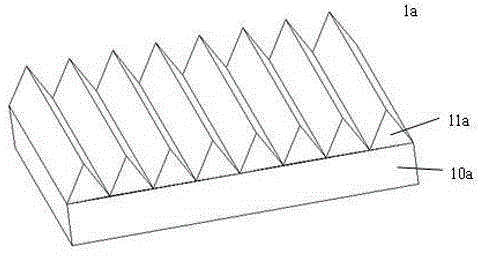

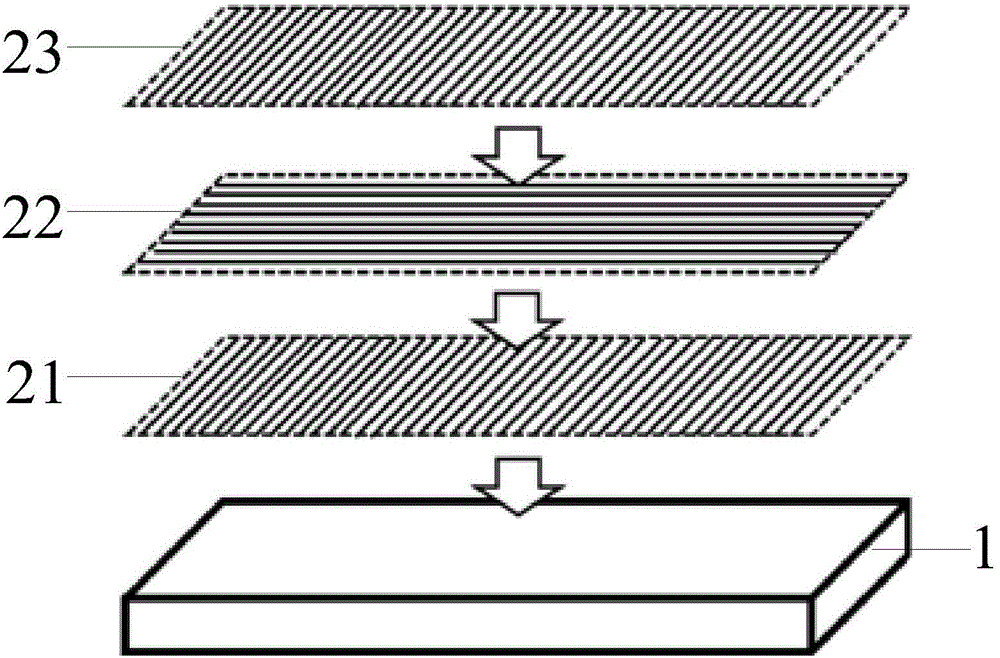

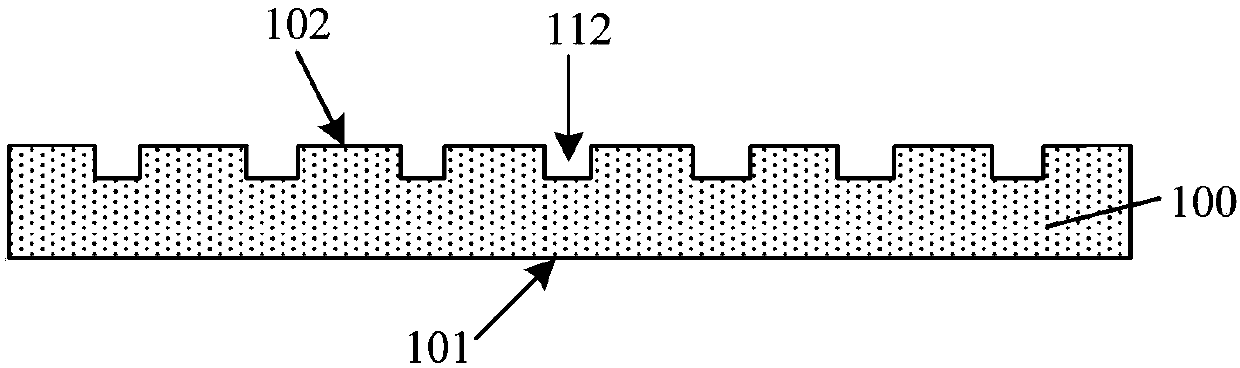

3D printing-based prism film preparation method and device thereof

The invention relates to a 3D printing-based prism film preparation method which comprises the following steps: 1, a three-dimensional digital model of a prism film is established and converted to work instructions of 3D printing equipment, and the work instructions contain a first instruction for printing a substrate layer and a second instruction for printing a prism layer; 2, a first raw material for printing the substrate layer is put into a charging cavity and converted to a liquid state; and the 3D printing equipment sprays the first liquid raw material onto a molding area according to the first instruction, the sprayed first raw material is solidified quickly, a print head reciprocates translationally to print and an entity of the substrate layer is formed by piling up the first raw material layer upon layer; and 3, the second raw material for printing the prism layer is put into the charging cavity and converted to a liquid state; and the 3D printing equipment sprays the second liquid raw material onto the molding area according to the second instruction, the sprayed second raw material is solidified quickly to form a single prism column, and the print head continues to print according to a certain regulations so as to form an entity of the prism layer. By the method and the device, the preparation technology of the prism film can be simplified, and production efficiency can be enhanced.

Owner:FUZHOU UNIV

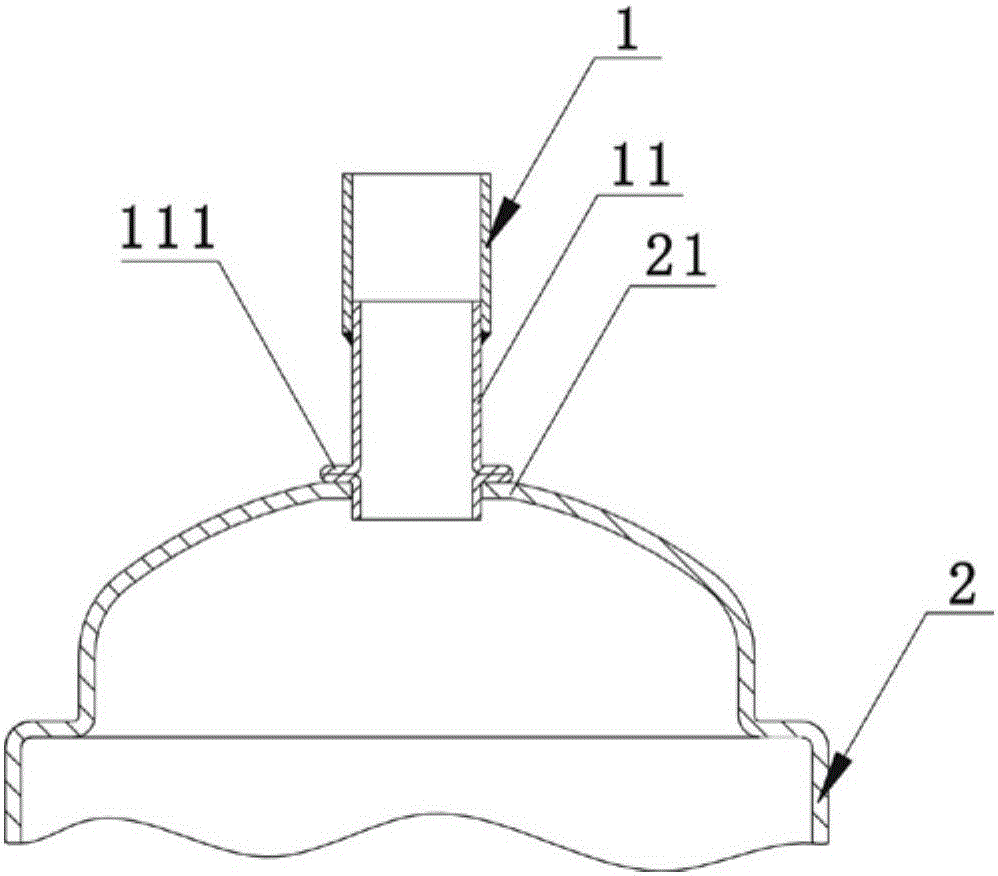

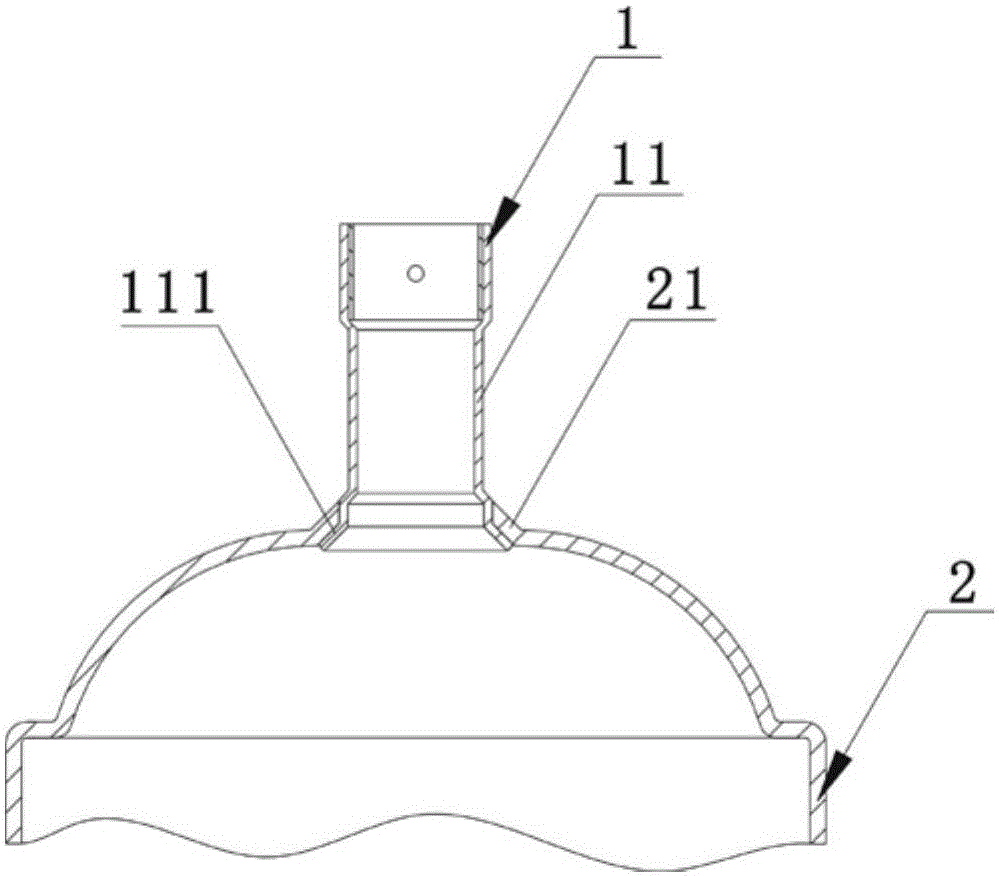

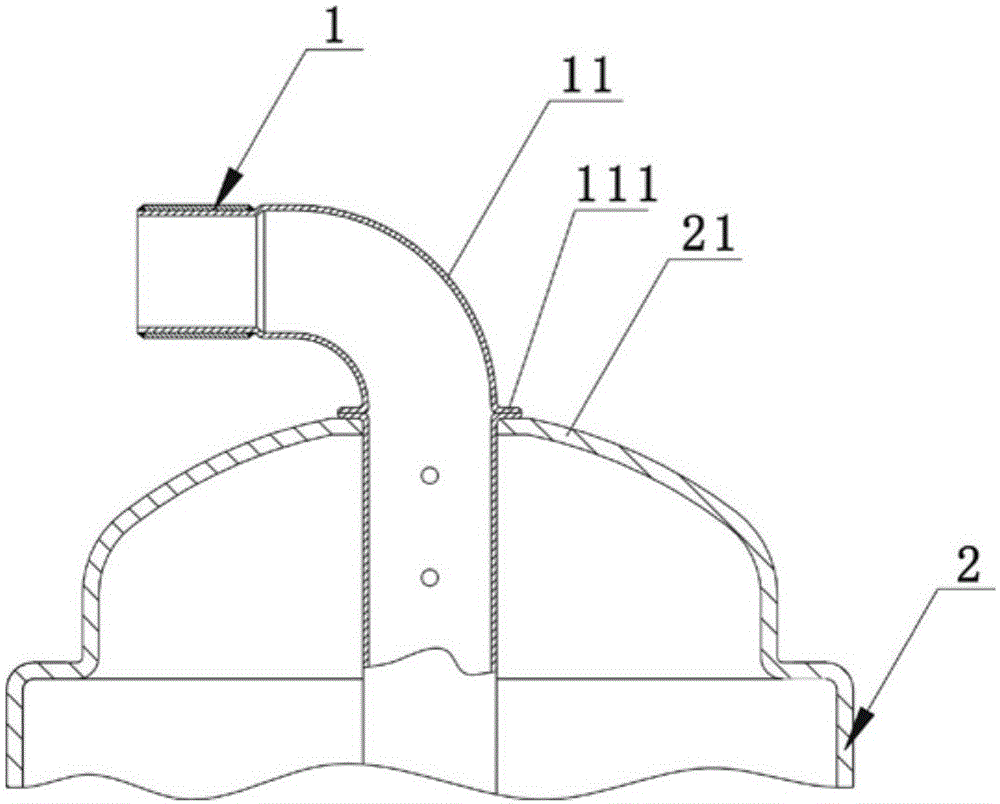

Pipe fitting and shell welding method and application

InactiveCN104999172AImprove surface cleanlinessReduce manufacturing costSoldering apparatusArc welding apparatusPipe fittingEngineering

The invention provides a pipe fitting and shell welding method and application. According to the welding method, one end of a pipe fitting is made of a steel material and stretches into a shell from the neck portion of the shell, and the neck portion of the shell is made of a steel material; one end of the pipe fitting and the neck portion of the shell are connected through welding by means of the welding method adopting electric energy as the heat source, or one end of the pipe fitting and the neck portion of the shell are connected through welding by means of the welding method adopting electric energy as the heat source and furnace brazing.

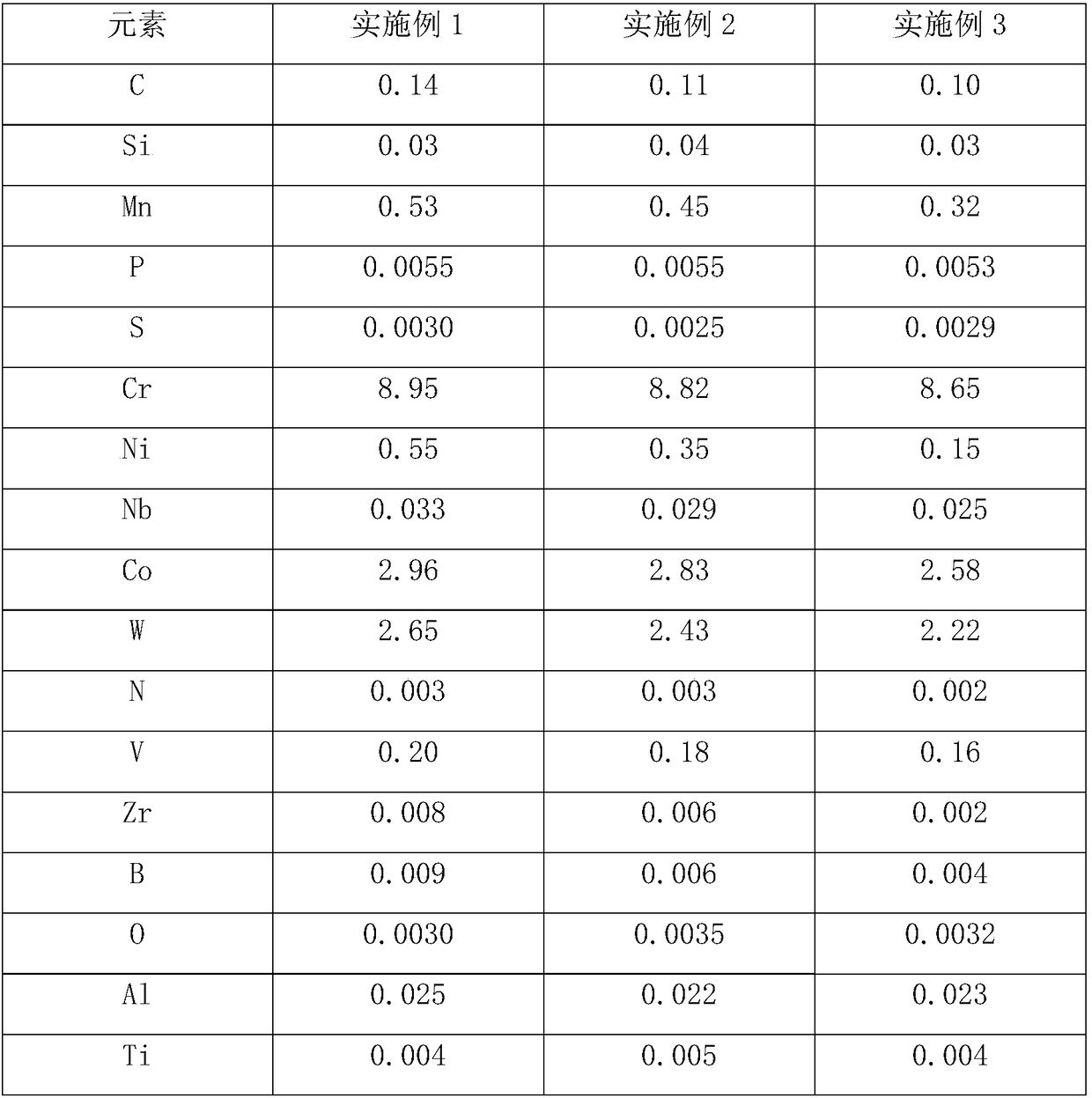

Bright welding wire for heat-resistant steel for ultra-supercritical coal-fired power station

ActiveCN108838579AImprove welding processabilityImprove surface cleanlinessWelding/cutting media/materialsSoldering mediaRoom temperatureMechanical property

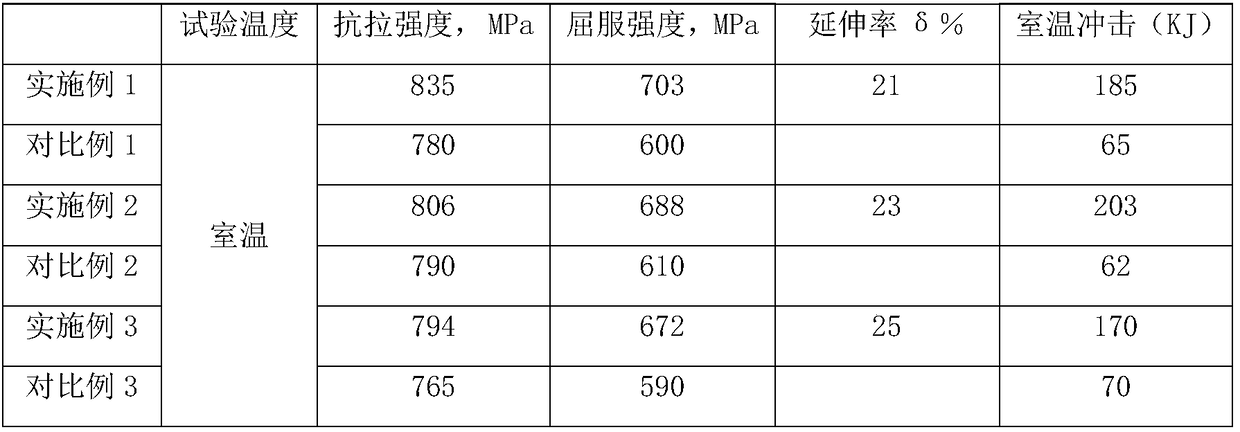

The invention discloses a bright welding wire for heat-resistant steel for an ultra-supercritical coal-fired power station and belongs to the technical field of welding materials. The welding wire comprises, by weight, 0.10-0.15% of C, 8.5-9.0% of Cr, 0.1-0.6% of Ni, 0.3-0.6% of Mn, 2.5-3.0% of Co, 2.0-2.7% of W, 0.020-0.035% of Nb, 0.001-0.010% of Zr, less than or equal to 0.006% of N, 0.16-0.20%of V, 0.003-0.010% of B, less than or equal to 0.20% of Si, less than or equal to 0.006% of P, less than or equal to 0.006% of S, less than or equal to 0.010% of O, less than or equal to 0.03% of Al,less than or equal to 0.01% of Ti and the balance Fe and inevitable impurity elements. The bright welding wire has the advantages that the welding wire has good welding process performance and excellent deposited metal flowability and formability, and the deposited metal after welding has excellent mechanical properties and good room temperature impact toughness.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

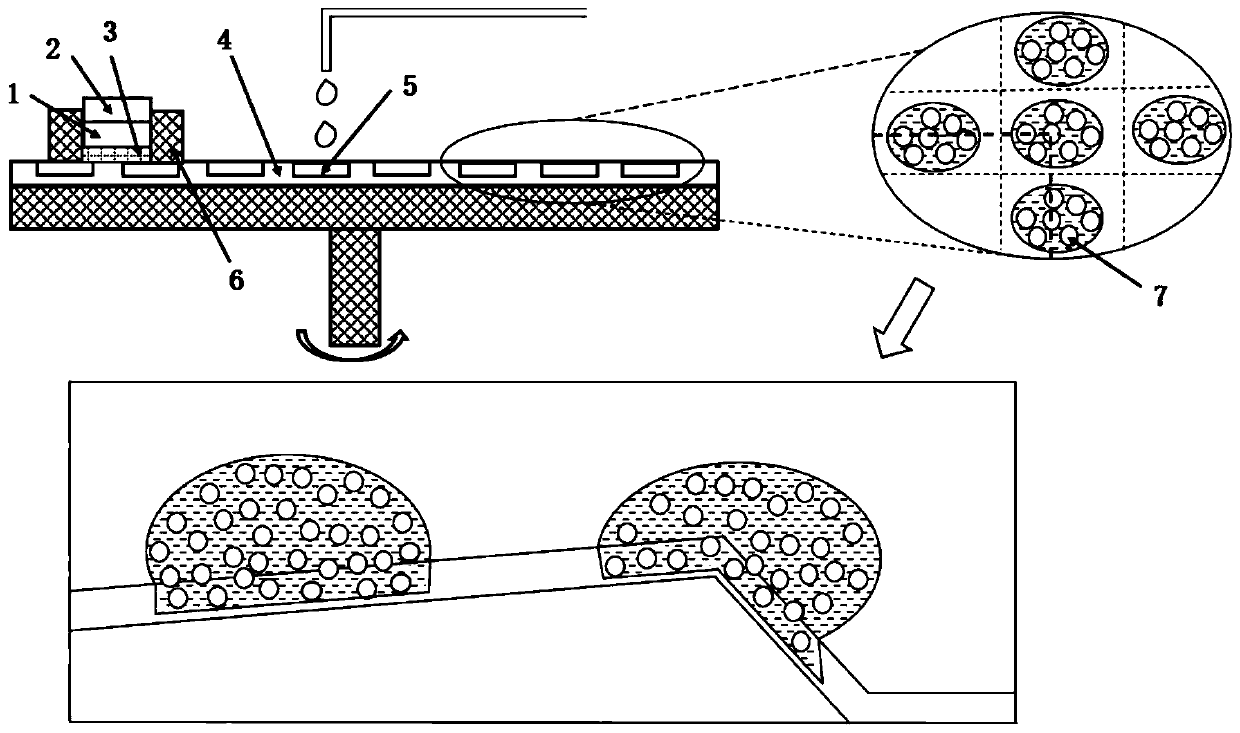

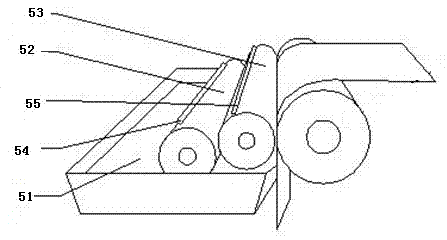

Efficient ultra-precise polishing method based on shear expansion effect

PendingCN111515874AEnhanced controlImprove the uniformity of forcePolishing machinesAbrasion apparatusActive agentPolishing

The invention provides an efficient ultra-precise polishing method based on a shear expansion effect. Abrasive particles, a dispersing agent and an active agent are added into a viscoelastic materialwith non-Newtonian fluid characteristics to prepare a flexible fixation grinding tool, a viscoelastic gum base accounts for 50%-85% of the grinding tool by mass, the abrasive particles account for 10%-45% of the grinding tool by mass, the particle size of the abrasive particles ranges from 0.05-50 microns, the dispersing agent accounts for 1-5% of the grinding tool by mass, and the active agent accounts for 1-5% of the grinding tool by mass. In the polishing process, the contact area between the grinding tool and a workpiece generates a shear expansion effect under the action of shear force, an instantaneous expansion ejection phenomenon and a curing effect are present, and the viscosity, the hardness and the internal resistance of the grinding tool materials are increased. The stress uniformity of the surface of the workpiece is improved, the contact positive pressure of the abrasive particles and the workpiece is increased, so that the removal rate of the materials in the polishing process is increased, damage of local stress concentration to the surface of the workpiece is reduced, and the effect of efficient and high-quality polishing is achieved.

Owner:ZHEJIANG UNIV OF TECH

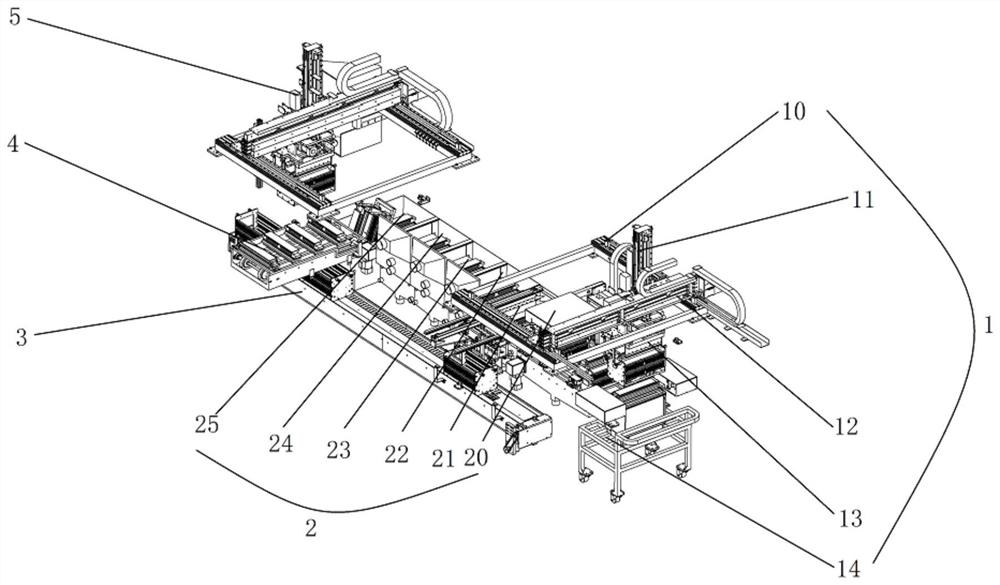

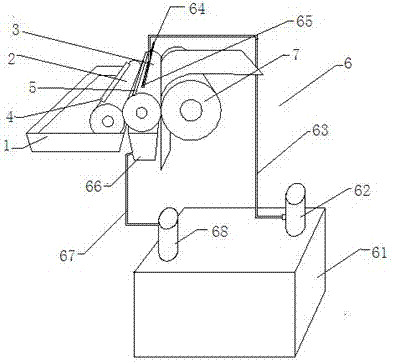

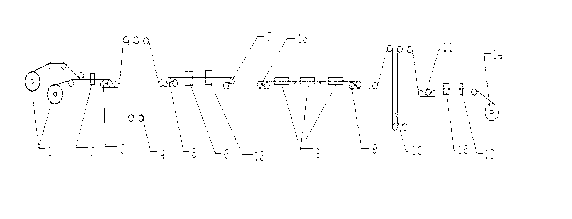

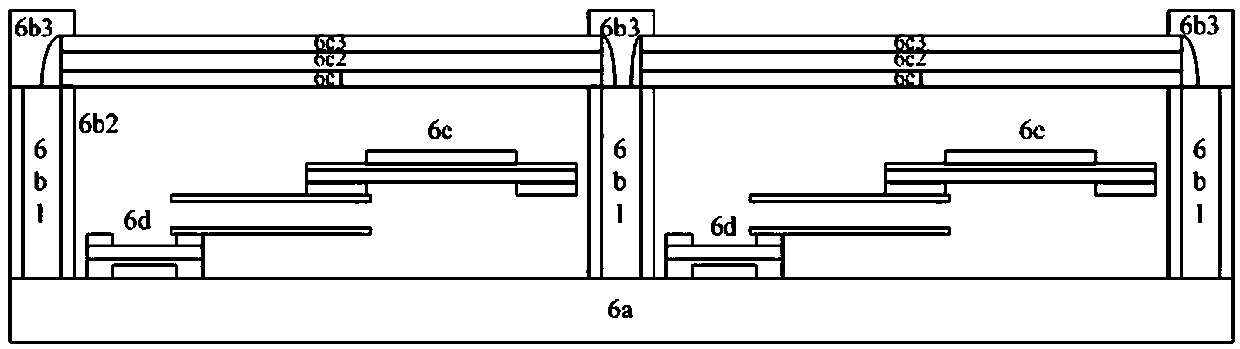

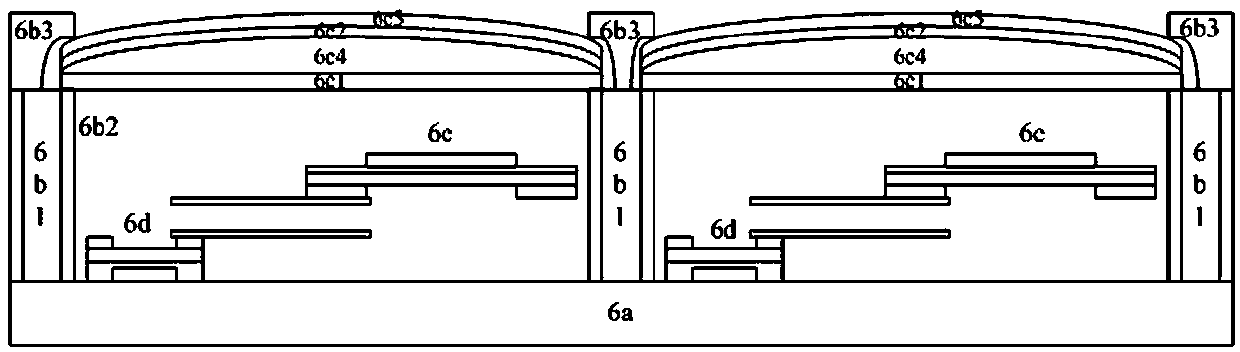

Full-automatic silicon wafer degumming equipment

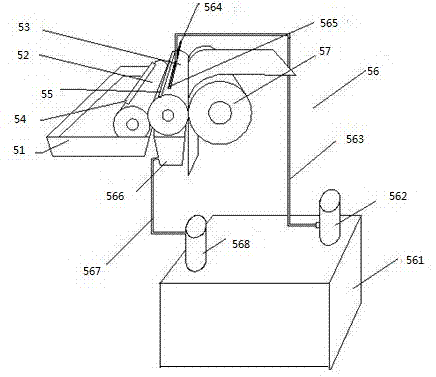

PendingCN112718643ACompact structureEasy to install and maintainCleaning using liquidsMetallurgySilicon chip

The invention provides full-automatic silicon wafer degumming equipment. The equipment comprises a feeding mechanism used for feeding cut monocrystalline silicon rods; a cleaning and degumming device used for cleaning, degumming and gathering the cut monocrystalline silicon rods; a turnover device used for conveying degummed silicon wafers into a separation mechanism; and a degumming carrying device used for carrying the cut monocrystalline silicon rods during cleaning and degumming. The feeding mechanism, the cleaning and degumming device and the turnover device are sequentially arranged in the conveying direction of the cut monocrystalline silicon rods, and after the cut monocrystalline silicon rods are fed through the feeding mechanism and cleaned and degummed through the cleaning and degumming device, the degummed silicon wafers are carried to the separation mechanism through the turnover device to be separated; and the degumming carrying device corresponds to the cleaning and degumming device, so that the carrying of the cut monocrystalline silicon rods in the cleaning and degumming device is facilitated. The equipment has the beneficial effects that automatic pre-cleaning, degumming and cleaning of the silicon wafers are achieved, the productivity of the equipment is improved, and the labor cost is reduced.

Owner:TIANJIN HUANBO SCI & TECH CO LTD

Under-coated coating of water-based UV-light curing vacuum coating

InactiveCN101787243AStrong adhesionImprove surface cleanlinessVacuum evaporation coatingSputtering coatingWater basedSolubility

The invention relates to the technology field of coating, in particular to an under-coated coating of water-based UV-light curing vacuum coating; the invention comprises modified polyurethane acrylic acid, an evocating agent, a surface additive, a latent solvent and water, wherein the modified polyurethane acrylic acid is obtained through synthesis of high molecular polymer, chain extender, an emulsifying agent, alight curing agent, a catalyst and organic amine; the invention not only has high surface cleanness and good leveling property, but also has strong adhesive force, particularly has the water solubility and the oil solubility simultaneously, has wide application range, and conforms to the EU ROHS standard.

Owner:GUANGDONG ZHICHENG CHEM

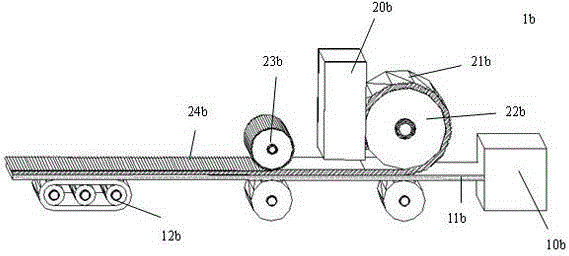

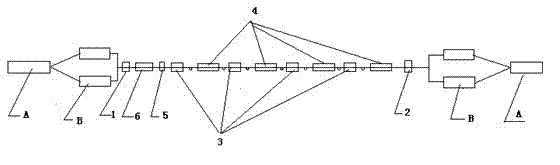

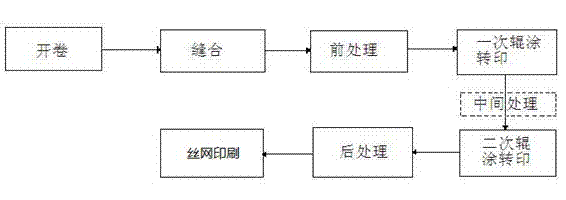

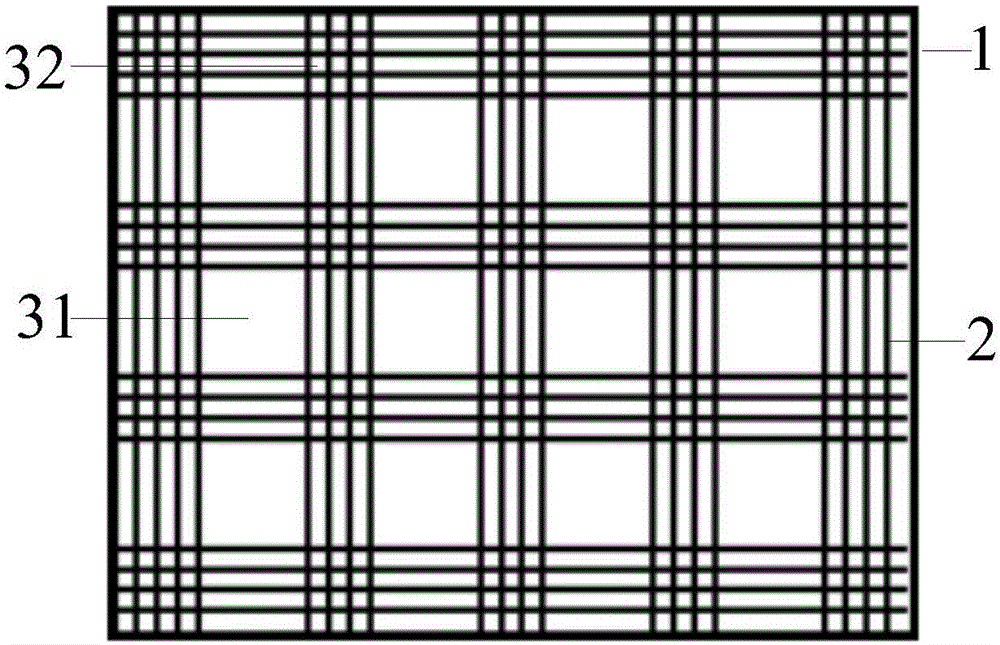

Screen printing production line of image coding steel plate

InactiveCN103158339AStrong three-dimensional senseConsistent speedScreen printersPrinting press partsScreen printingProduction line

The invention provides a screen printing production line of an image coding steel plate. The screen printing production line of the image coding steel plate combines screen printing and roller painting, and not only can obtain accurate underpainting patterns, but also can obtain a thick and strong three-dimension printing layer. Meanwhile, a servo control system which controls rotate speed and starting time of a suction roller and a coating roller of a roller coating equipment element is added at a roller painting section to ensure that actual roller surface line speed is consistent with process rotate speed, accordingly line stopping adjustment is not needed in the process of production, and production efficiency is improved.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

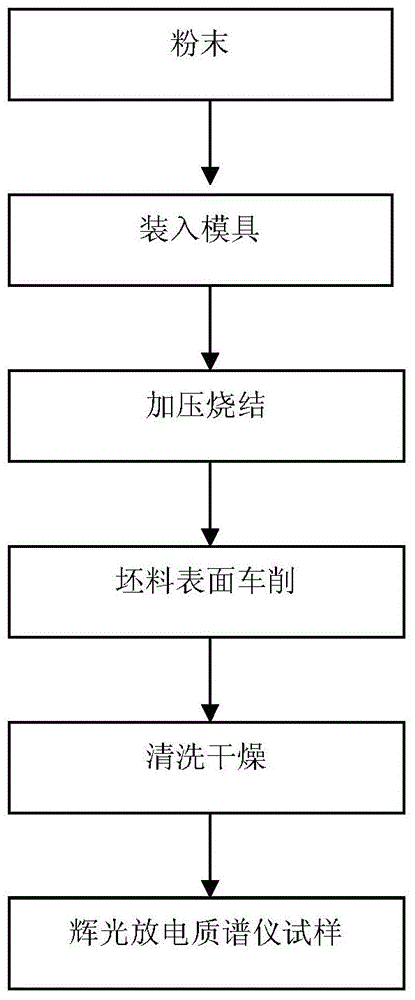

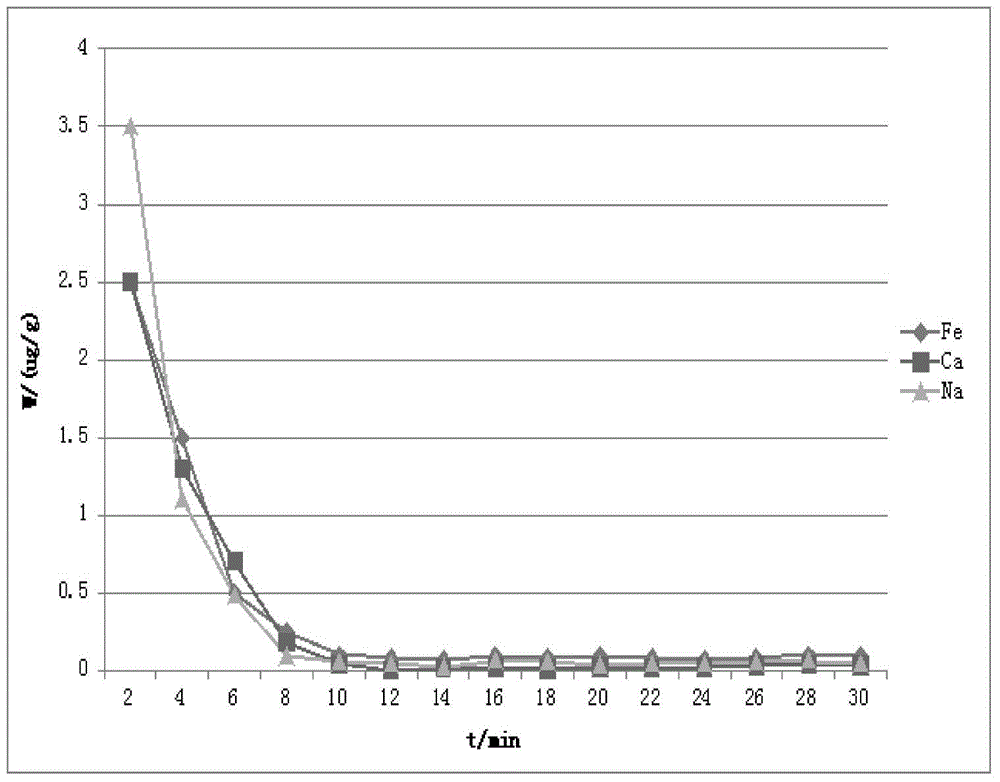

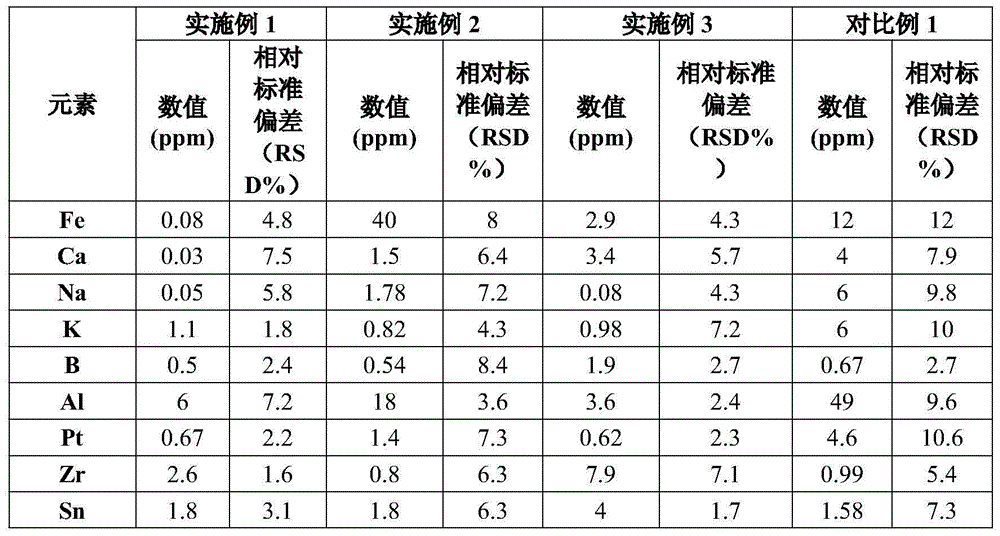

Method for preparing glow discharge mass spectrometer analysis test sample

InactiveCN104458370AGuaranteed accuracy and precisionHigh densityPreparing sample for investigationMaterial analysis by electric/magnetic meansGlow dischargeMass spectrum analysis

The invention discloses a method for preparing a glow discharge mass spectrometer analysis test sample. The method comprises the following steps: a) putting refractory metal powder to be analyzed into a graphite mold which is internally coated with a demolding agent; b) forming the powder by using a pressure sintering method; c) milling a formed blank. By using the method disclosed by the invention, the test sample is relatively high in compactness and is clean in surface while the content of impurities in the sample is kept unchanged as much as possible, so that the accuracy and the precision of the glow discharge mass spectrum analysis result are ensured, and meanwhile the test sample prepared by using the method has the advantages of high analysis speed and high efficiency.

Owner:KUNMING INST OF PRECIOUS METALS

Corrugated fin aluminum foil base material for heat radiation tower and preparation method of corrugated fin aluminum foil base material

InactiveCN110983114AAvoid stamping cracking problemsEasy to processMetal rolling arrangementsMachining processAluminum foil

The invention discloses a corrugated fin aluminum foil base material for a heat radiation tower. The corrugated fin aluminum foil base material comprises, by mass percent, 0.05%-0.15% of Si, 0.2%-0.3%of Fe, not larger than 0.02% of Cu, 0.03% of Mn, not larger than 0.03% of Zn, 001%-0.03% of Ti and the balance Al. The invention further discloses a preparation method of the corrugated fin aluminumfoil base material for the heat radiation tower. The preparation method comprises the steps that a cast-rolled coiled material blank is firstly subjected to cold rolling to the set thickness, then homogenizing annealing is carried out, after homogenizing annealing is carried out, cold rolling is carried out to reach the set thickness, intermediate annealing is carried out, and finally cold rollingis carried out to reach the finished product thickness. The corrugated fin aluminum foil base material has the excellent machining performance, the strength is stable, plasticity is good, the problemof punching cracking of the corrugated fin aluminum foil base material for the heat radiation tower in the corrugated fin aluminum foil machining process is effectively avoided, and the machining efficiency is greatly improved.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Production method of graph code steel plate integrating roller painting printing and silk-screen printing into whole

InactiveCN103158381AStrong three-dimensional senseConsistent speedLiquid surface applicatorsRotary intaglio printing pressScreen printingStart time

The invention provides a production method of a graph code steel plate integrating roller painting printing and silk-screen printing into a whole. The silk-screen printing and the roller painting printing are combined. Not only can an accurate grounding decorative pattern be obtained, but also a printing layer which is thick, solid and strong in third dimension can be obtained. Simultaneously, a servo control system which controls the rotating speed of rollers in a roller painting equipment assembly and controls the starting time is additionally arranged in a roller painting segment, and thereby the actual roller surface linear speed is guaranteed to be consistent with the technology rotating speed. Then line-stop adjustment is not needed in the production process, and the production efficiency is improved.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

Superthin steel strip for battery casing, and producing method thereof

A very-thin steel band used for battery shell is prepared through proportionally adding Mn, Nb and Ti, desulfurizing, smelting in converter, RH vacuum treating, conticasting, hot rolling, winding, acid washing, cold rolling, continuous annealing, shearing and coating oil. Its advantages are high strength and elongation percentage, low yield ratio, high precision and low cost.

Owner:武钢集团有限公司

Rinsing fluid used for removing organics on surface of monocrystalline silicon piece and cleaning method

InactiveCN104479913AEfficient removalImprove surface cleanlinessInorganic non-surface-active detergent compositionsCleaning using liquidsMegasonic cleaningPotassium hydroxide

The invention discloses a rinsing fluid used for removing organics on the surface of a monocrystalline silicon piece and a cleaning method. The rinsing liquid comprises the following compositions in parts by volume: 2.30 parts-4.5 parts of hydrogen peroxide, 0.20 parts-1.15 parts of potassium hydroxide, and 94.35 parts-97.5 parts of pure water, wherein the mass fraction of potassium hydroxide is 45% and pure water is 18 M pure water. The cleaning method comprises the following steps: (1) flushing with tap water; (2) immersing in a lactic acid solution; (3) rinsing with tap water; (4) using pure water for ultrasonic pre-cleaning; (5) using a cleaning liquid for ultrasonic cleaning; (6) using pure water for ultrasonic rinsing; (7) using the rinsing fluid for rinsing; (8) using pure water for rinsing; and (9) performing dip coating and baking. The rinsing fluid and the cleaning are capable of effectively removing organics left on the surface of the monocrystalline silicon piece, improving the clean degree of the monocrystalline silicon piece surface, effectively reducing the cleaning unqualified rate of the monocrystalline silicon piece and the adverse ratio of the monocrystalline silicon piece subjected to etching, improving the quality of the monocrystalline silicon piece and enhancing the market competiveness of the product.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

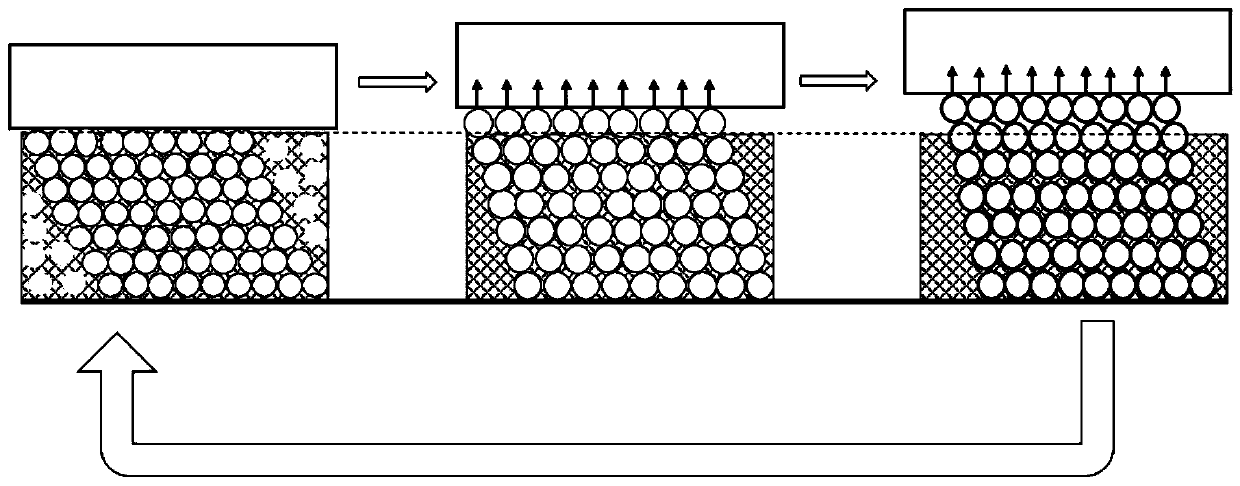

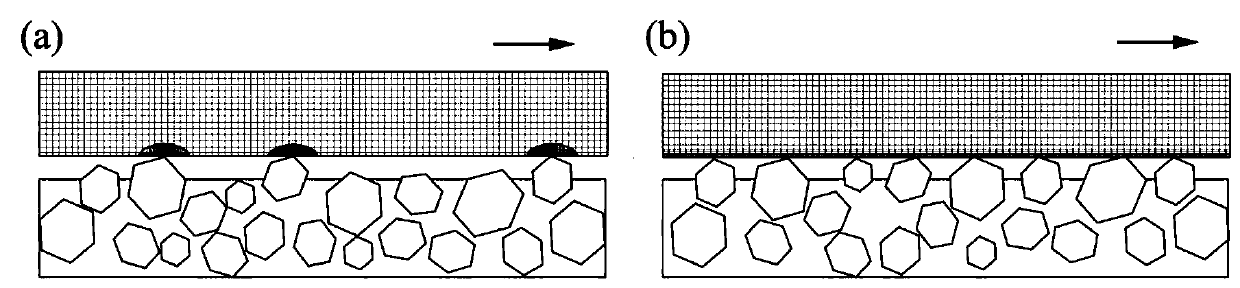

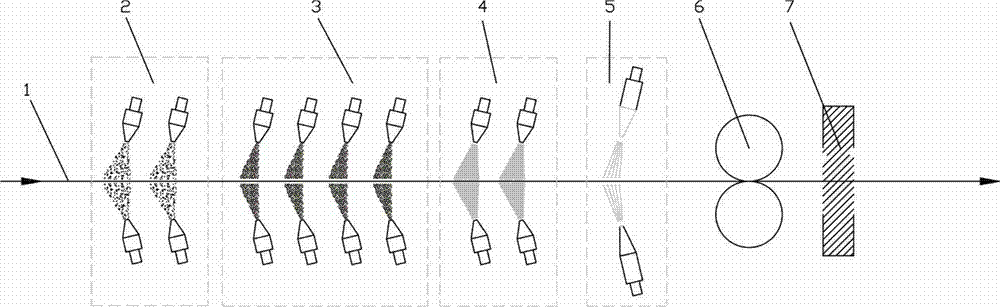

Process arrangement method for mixed jet cleaning

The invention relates to a process arrangement method for mixed jet cleaning. The method employs high-pressure mixed jet descaling units having a plurality of abrasive materials with different granularities. The high-pressure mixed jet descaling units are arranged along a tape transport direction of a metal plate. The high-pressure mixed jet with large granularity abrasive materials is arranged at an original inlet area of the metal plate, with the granularity of 20 meshes-60 meshes and inject pressure of 15 MPa-80 MPa; the high-pressure mixed jet with medium granularity abrasive materials is arranged at downstream of the high-pressure mixed jet descaling unit with the large granularity abrasive materials, with the granularity of 40 meshes-80 meshes and inject pressure of 10 MPa-60 MPa; the high-pressure mixed jet descaling unit with small granularity abrasive materials is arranged at downstream of the high-pressure mixed jet descaling unit with the medium granularity abrasive materials, with the granularity of 60 meshes-120 meshes and inject pressure of 10 MPa-50 MPa; the metal plate realizes the front and back descaling of the metal plate via the above jet descaling units; and the washing of the metal plate is finished by passing the descaled metal plate through a high-pressure pure water cleaning unit, a wiping unit and a compressed air blowing unit. The complete removing treatment of the scales on two sides of the coal metal plate is realized via a jet way.

Owner:BAOSHAN IRON & STEEL CO LTD

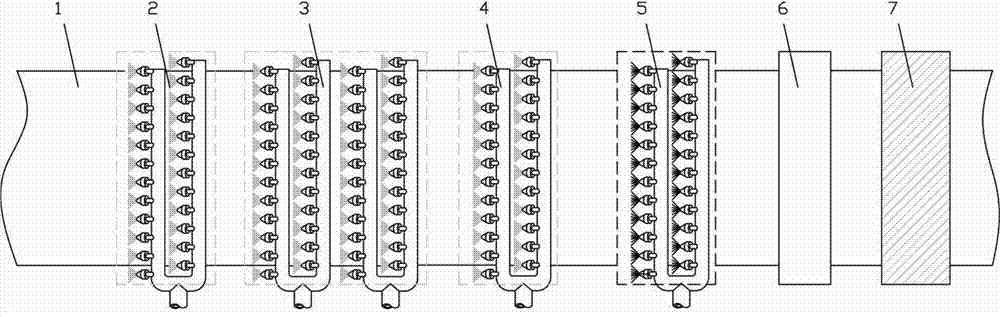

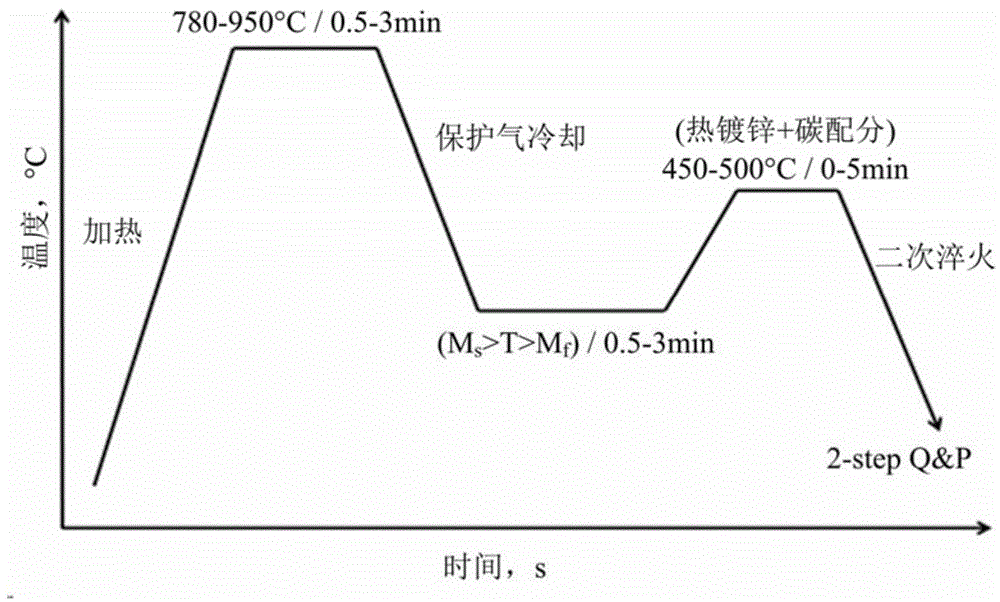

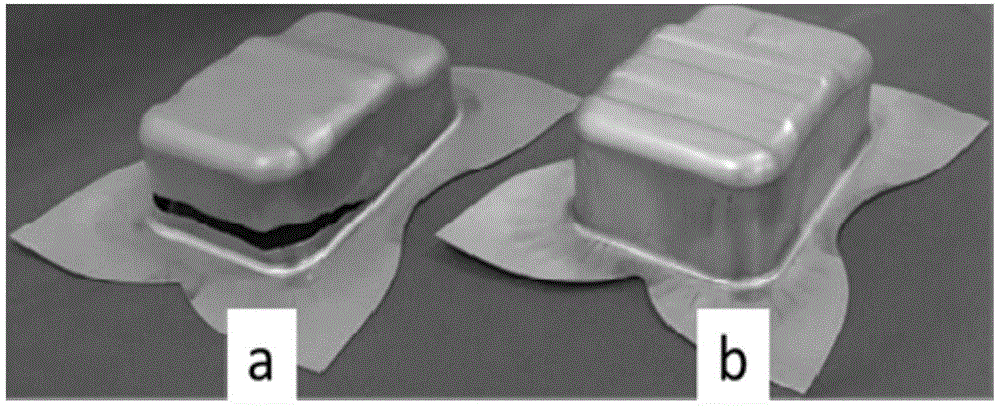

Preparation method of high-strength hot galvanizing Q&P steel

InactiveCN104630647AIncreased strength and plasticitySimple processHot-dipping/immersion processesQuenchingCarbon alloy

The invention discloses a preparation method of high-strength hot galvanizing Q&P steel. The preparation method is characterized by comprising the following steps: preparing low-carbon alloy steel into a to-be-used steel product; heating the to-be-used steel product to an austenitizing temperature and keeping the temperature for 3-5 minutes; performing primary quenching cooling in a cooling cavity with a protective gas until the temperature is between an Ms point and an Mf point, and keeping the temperature for 0.5-3 minutes; heating to 450-500 DEG C, performing distribution processing, keeping the temperature for 0-5 minutes, quickly adding into a constant-temperature galvanizing bath isothermal with the steel product, performing hot galvanizing, further performing distribution processing, and keeping the temperature for 10-60 seconds; and performing secondary quenching cooling until the temperature is reduced to the room temperature. By adopting the preparation method disclosed by the invention, the aim of simultaneously finishing a Q&P process and hot galvanizing treatment is achieved, the process flow is simplified, the production efficiency is improved, and high-strength hot galvanizing alloy steel is prepared.

Owner:DALIAN UNIV OF TECH

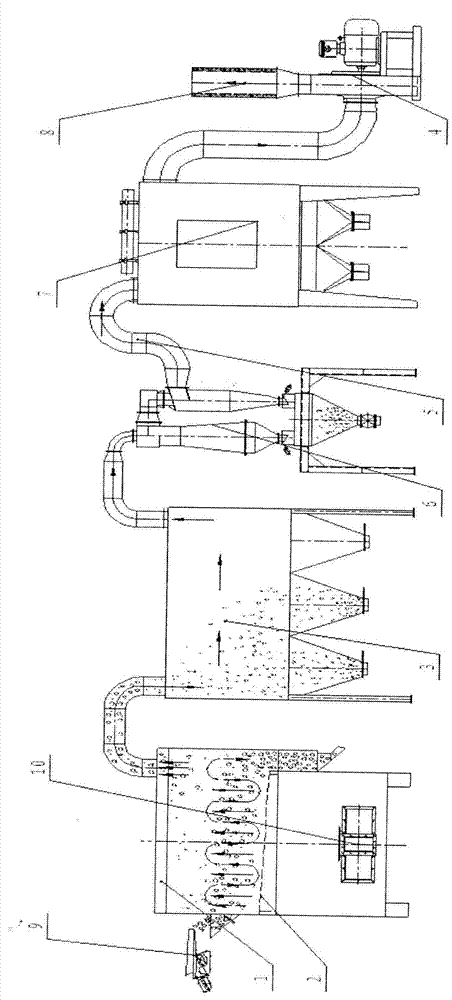

Method and special apparatus for improving surface purity and surface cleanliness of silicon carbide particles

The invention discloses a method and special apparatus for improving surface purity and surface cleanliness of silicon carbide particles. The method is characterized in that cleaning and dust removal are conducted on the surface of silicon carbide through a physical method, namely, silicon carbide particle materials are pushed by strong airflow to rotate at a high speed and to be thrown up, the silicon carbide particle materials are processed through repeated collision and friction, the silicon carbide particle materials can be separated from suspension dust among the silicon carbide particle materials and surface adhesion dust, and finally the requirement for improving the surface purity and the surface cleanliness of the silicon carbide particle materials is met. According to the method, the surface purity and the surface cleanliness of the silicon carbide particle materials are improved through the physical method instead of a chemical method, the suspension dust among the crushed silicon carbide particle materials and the particle surface adhesion dust can be effectively removed, the production cost is reduced to a great extent, production efficiency of the back end working procedure is improved, zero emission of pollutants is basically achieved in the whole production process, and the foundation is laid for large-scale industrial production and realization of automatic control in the production process.

Owner:ZHENGZHOU JINYE TECH DEV

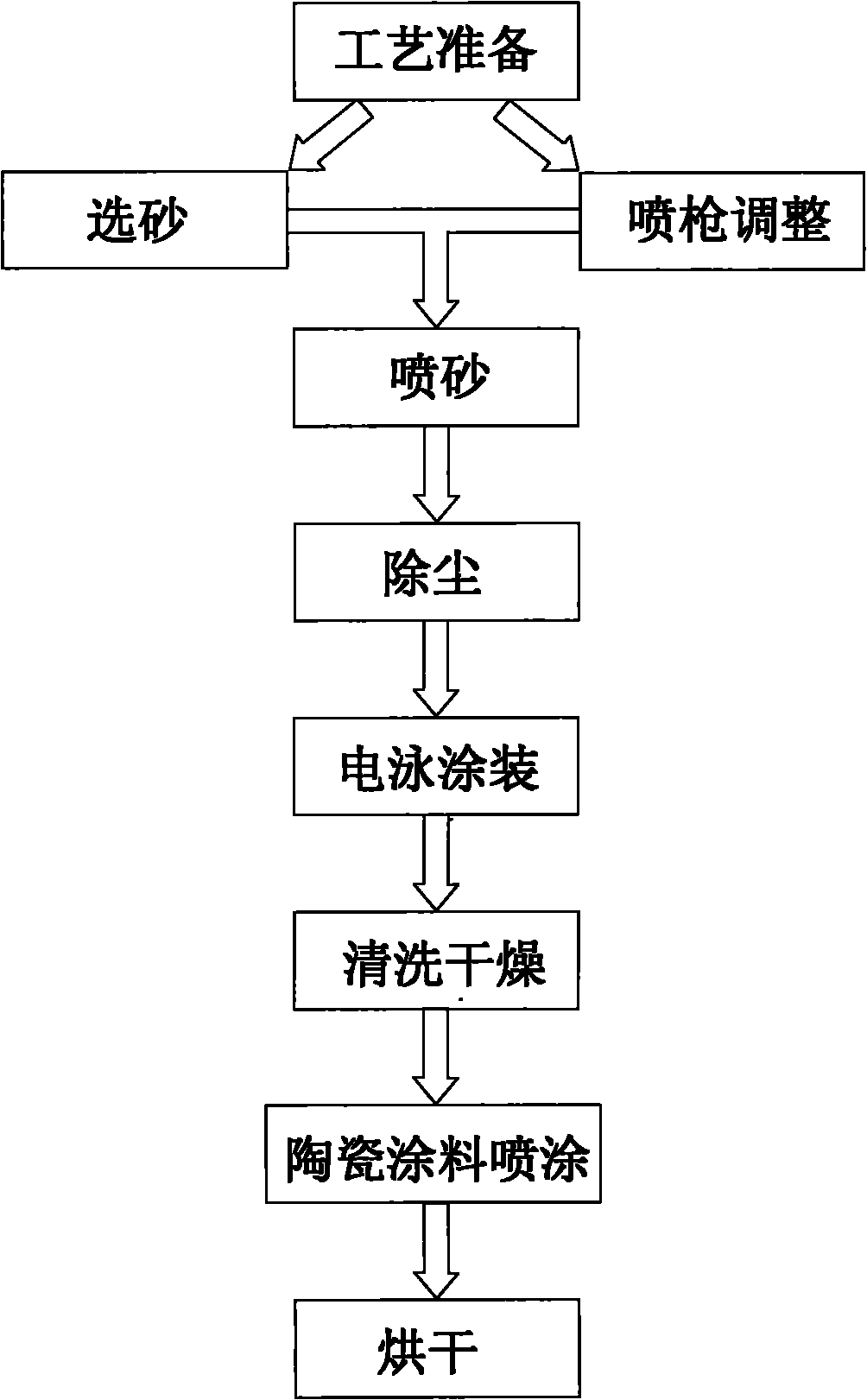

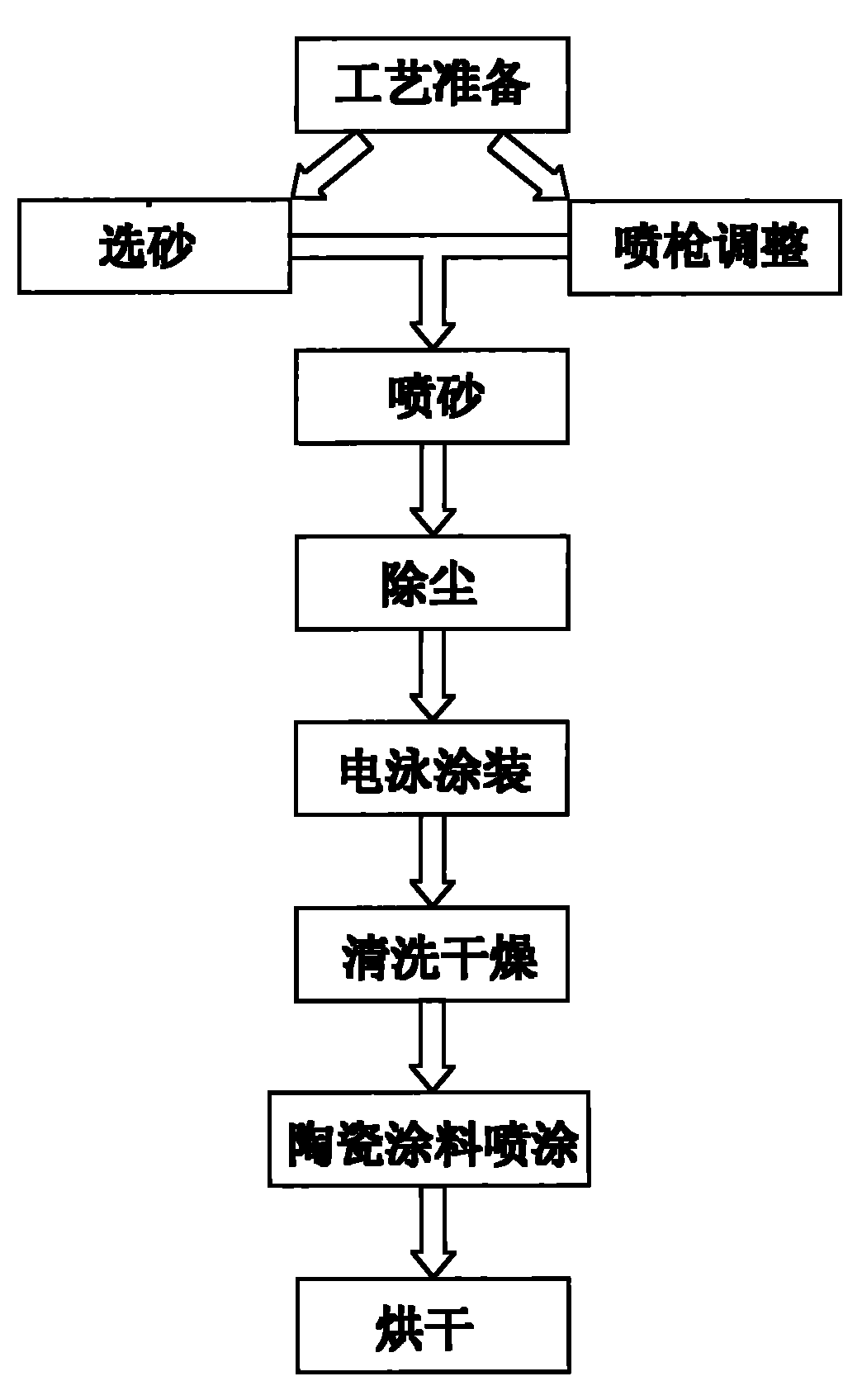

Physical pretreatment and electrophoresis coating process of aluminum magnesium alloy

InactiveCN101967667AReduce pollutionHarm reductionElectrophoretic coatingsAbrasive blastingCeramic coating

The invention provides a physical pretreatment and electrophoresis coating process of an aluminum magnesium alloy, which is divided into two items of physical pretreatment and electrophoresis coating, wherein the physical pretreatment is surface abrasive blasting; and in the surface abrasive blasting process, the size of abrasive grains is determined according to the roughness required by the surface of a workpiece. The invention also discloses the process steps of the physical pretreatment and the electrophoresis coating of the aluminum magnesium alloy, which comprise abrasive selecting, spray gun adjusting, abrasive blasting, dedusting, electrophoresis coating, cleaning and drying, ceramic coating spraying and drying. The physical pretreatment and electrophoresis coating process of the aluminum magnesium alloy adopts the treatment process combining the abrasive blasting treatment and the electrophoresis coating, not only reduces the environment pollution and the damages to the human body, but also has the advantages of simple process operation, low cost, environment protection, no toxin, good surface cleanness, tight and firm combination of the coating obtained by an electrophoresis coating and a substrate of the workpiece, good adhesion, compact and attractive surface coating of the aluminum magnesium alloy, and obvious corrosion resistance enhancement.

Owner:DONGGUAN EONTEC CO LTD

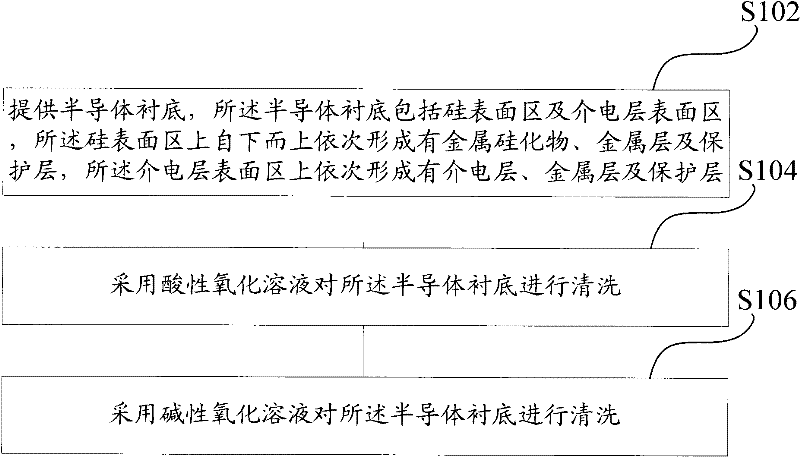

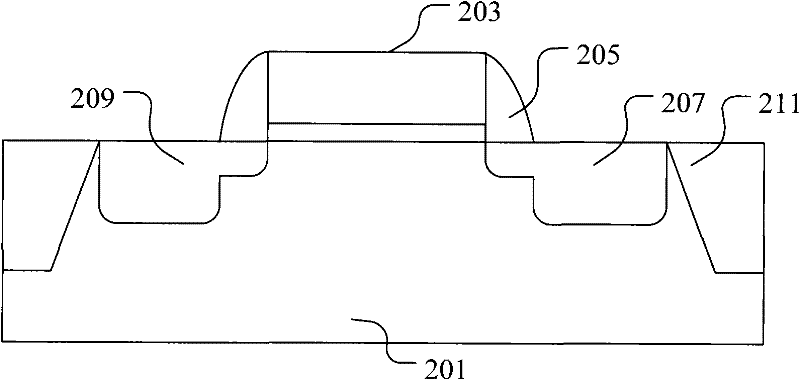

Cleaning method of metal silicide

InactiveCN102290325AImprove surface cleanlinessEfficient removalSemiconductor/solid-state device manufacturingCleaning using liquidsSalicideMetal silicide

A method for cleaning a metal silicide, comprising: providing a semiconductor substrate, the semiconductor substrate includes a silicon surface region and a dielectric layer surface region, the silicon surface region is sequentially formed with metal silicide, metal A dielectric layer, a metal layer and a protective layer are sequentially formed on the surface area of the dielectric layer; the semiconductor substrate is cleaned with an acidic oxidation solution; the semiconductor substrate is cleaned with an alkaline oxidation solution Clean up. In the metal silicide cleaning method of the present invention, after cleaning with an acidic oxidation solution, the semiconductor substrate is cleaned with an alkaline oxidation solution, which effectively removes impurity particles adhering to the surface of the substrate during the cleaning process with an acidic oxidation solution, and improves the efficiency of the semiconductor substrate. Surface cleanliness of the substrate.

Owner:CSMC TECH FAB1 +1

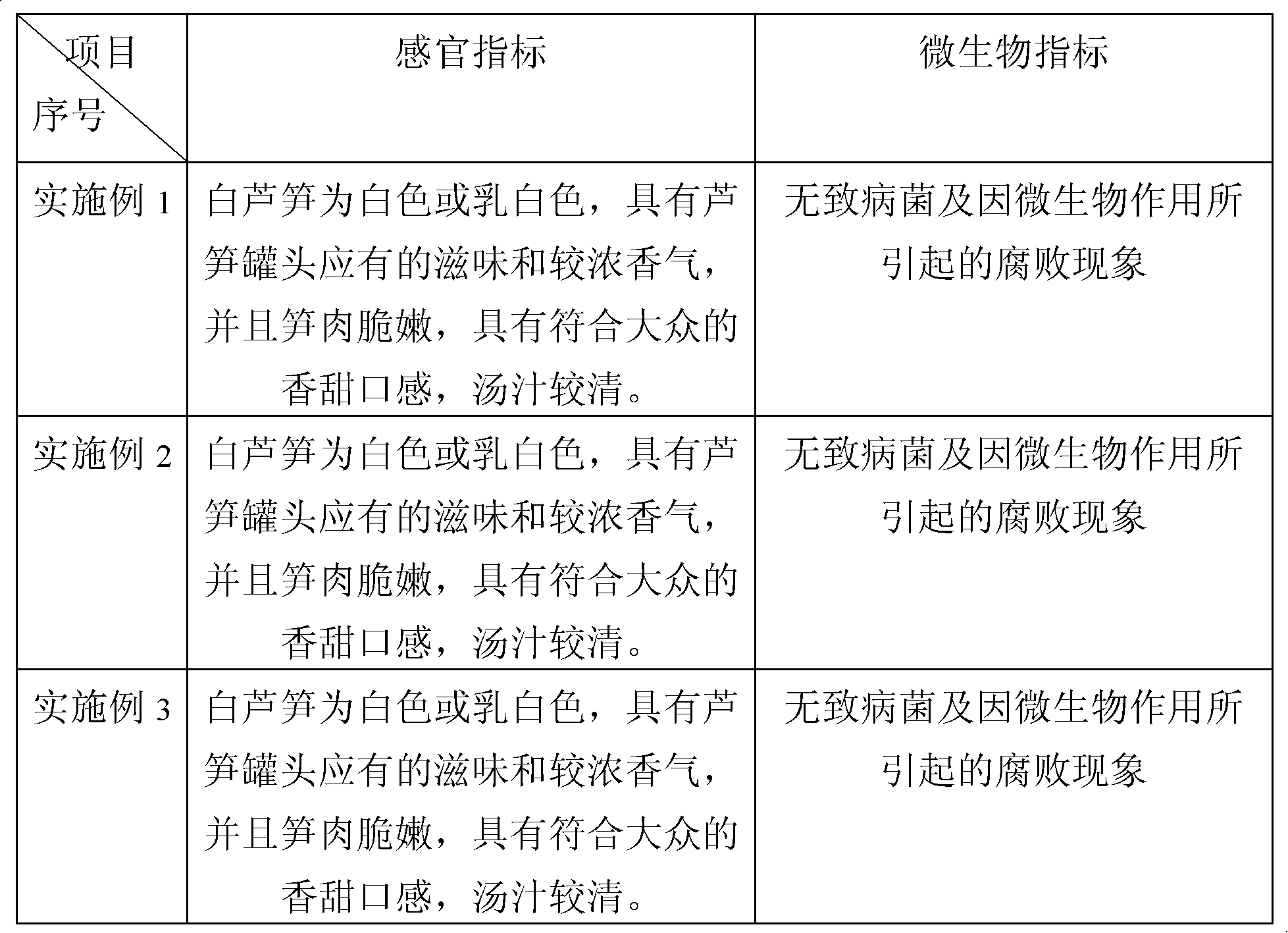

Method for processing canned white asparagus by vacuum acidification

ActiveCN102715228AImprove surface cleanlinessPrevent spoilageFruits/vegetable preservation by heatingChemistrySodium erythorbate

The invention discloses a method for processing canned white asparagus by vacuum acidification, comprising the following steps: carrying out ultrasonic cleaning with a frequency of 20-30 kHz on processed white asparagus for 10-15 min, wherein the cleaning effect is good, the speed is fast, and the white asparagus materials are prevented from tender stem deterioration caused by long time soaking; after cleaning, precooking, then carrying out spray cooling on the precooked white asparagus with cold water under the high pressure of 30*10<5>-40*10<5> Pa for 1 min, rapidly cooling the white asparagus, then conducting vacuum acidification by using a compound liquid of disodium hydrogen phosphate and citric acid under the vacuum degree of 0.070-0.085 MPa for 1.5-2h to achieve the purpose of preventing browning; and finally adding 0.01% phytic acid and 0.01% sodium erythorbate in the liquid of the canned white asparagus to carry out color protection on the white asparagus and further carry out acidification. The prepared canned white asparagus has good whiteness and strong fragrance, the pulp has popular sweet mouthfeel, and the liquid is clear.

Owner:福建立兴食品股份有限公司

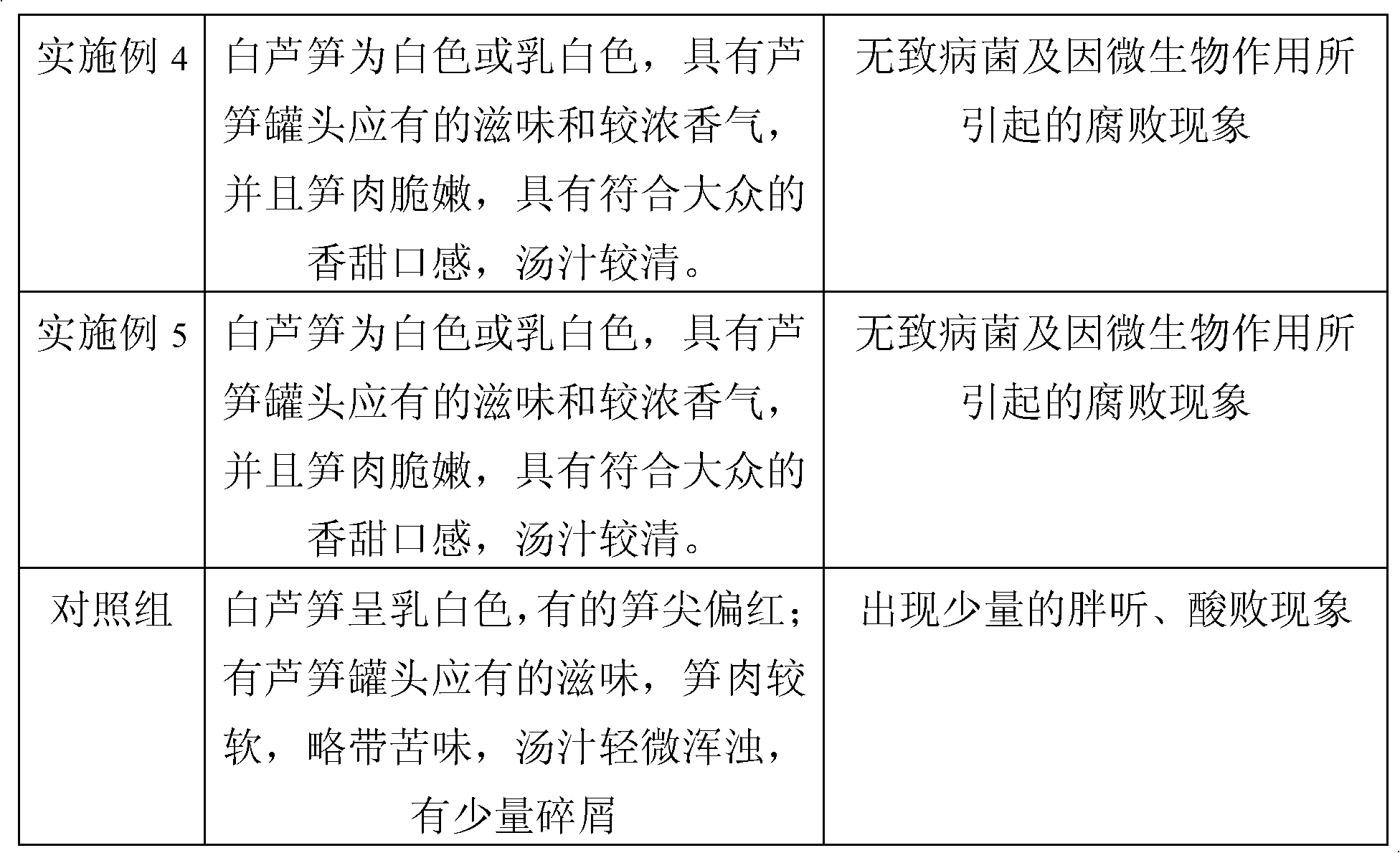

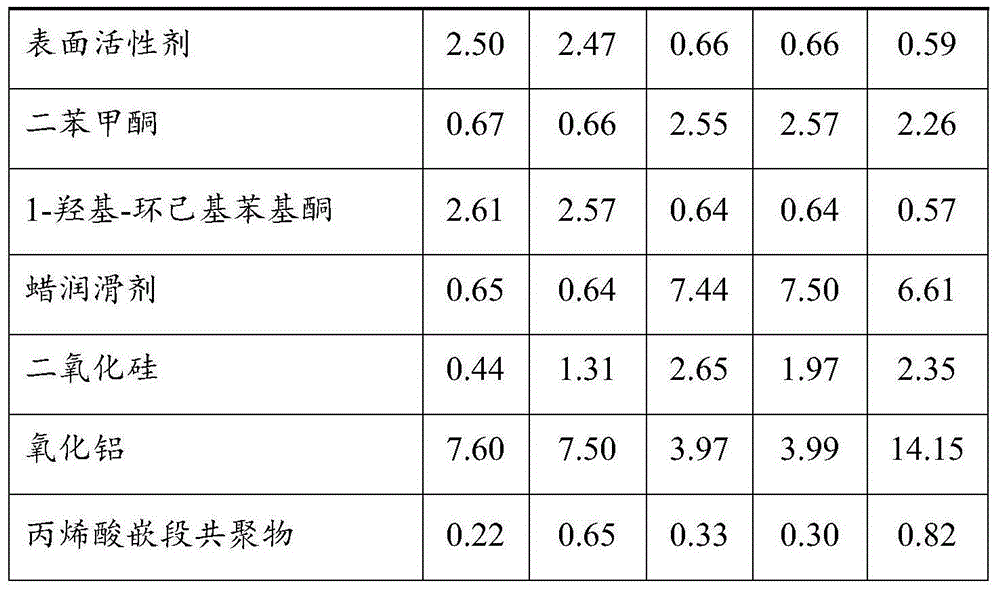

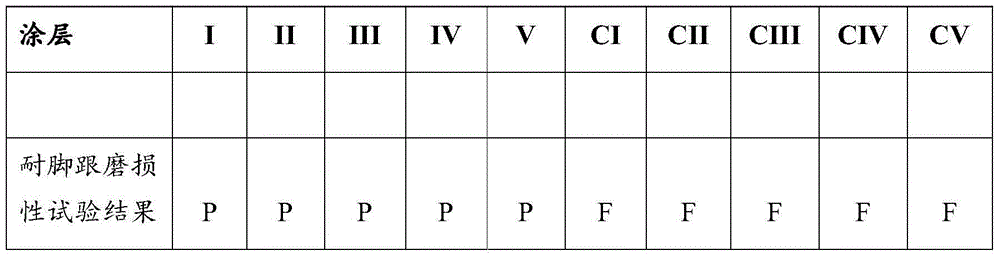

Durable UV curable coatings

InactiveCN104603216AReduce the degree of dirtImprove surface cleanlinessBuilding constructionsThin material handlingUltravioletPhotoinitiator

Described herein are UV curable coating comprising: an acrylate component a photoinitiator, an amine synergist, and an abrasive; along with methods of making and using same.

Owner:AFI LICENSING

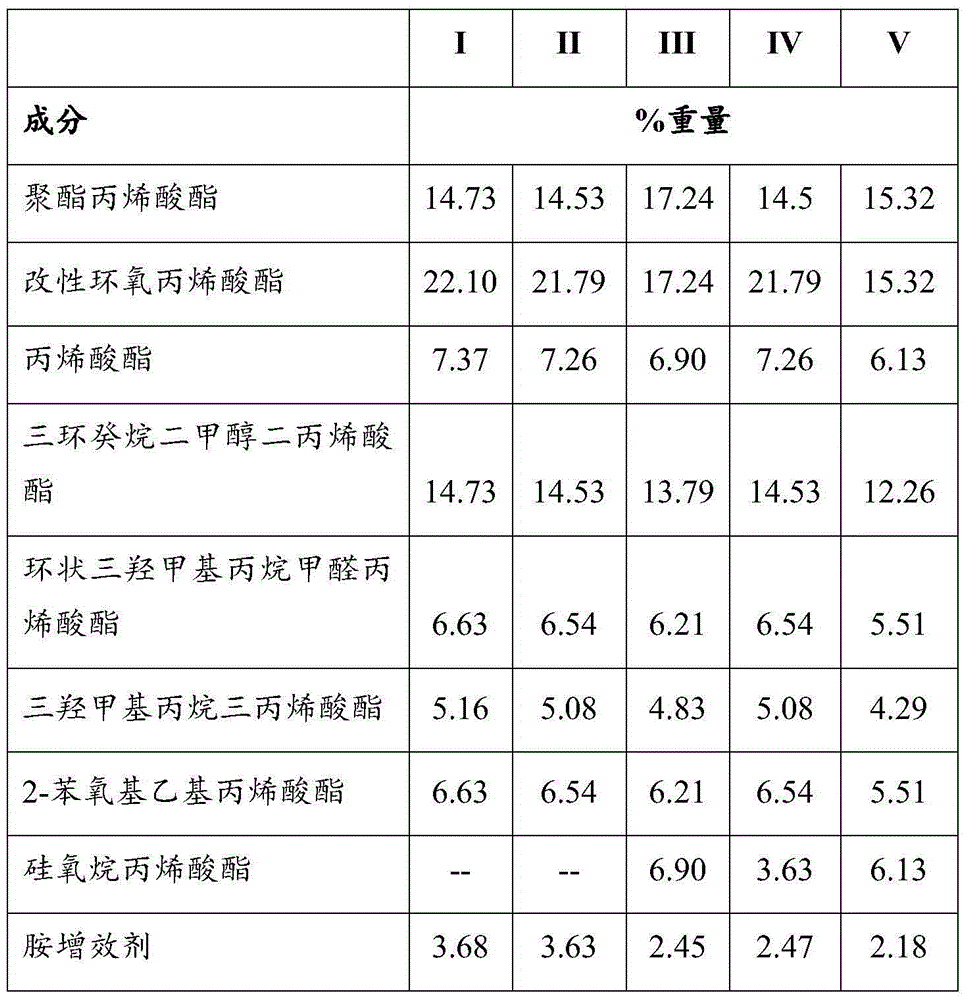

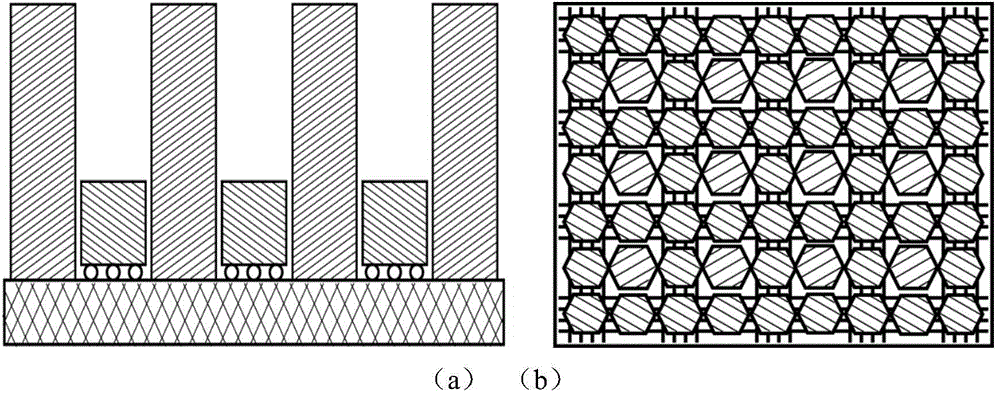

Selective area growing method for III-nitride micro graphic structure and structure

InactiveCN104637788ASimple processLow costSemiconductor/solid-state device manufacturingSemiconductor devicesMicrometerElectric properties

The invention discloses a selective area growing method for III-nitride micro graphic structure and a structure. A carbon nanotube array is taken as a micrometer / nanometer composite size mask; nanometer grade growing windows in bundle clusters and micrometer grade growing windows among the bundle clusters are arranged at intervals; according to the remarkable difference between the growth rates of III-nitride in the micrometer grade growing windows and the nanometer grade growing windows, an III-nitride dual-size micro graphic structure in which micro graphic structures which are the same in shapes and are different in sizes are arranged at intervals can be made on the micrometer / nanometer composite size mask. By adopting the carbon nanotube mask, the advantage of nanoheteroepitaxy can be brought into full play, the crystal quality of a micro graphic structural material is improved, and the residual stress is lowered; the nanotube has the characteristics of high thermal conductivity and high electrical conductivity, so that the heat dissipation of subsequently-manufactured micro-electron and photoelectron devices and the improvement on the electric property are facilitated.

Owner:PEKING UNIV

Production line for spraying color steel plate

InactiveCN102990366AGuaranteed uptimeGood molding effectElectrostatic cleaningOther manufacturing equipments/toolsColor imageProduction line

The invention provides a production line for spraying a color steel plate, wherein a plurality of tension rollers are used to flatten a steel belt in each process section, and especially, stable constant tension is provided for an air-brush section. Meanwhile, in the production line for spraying the color steel plate, provided by the invention, corona treatment is performed on the surface of the steel belt before a spraying section to form a plurality of small pits in the surface of the steel belt, so as to improve the surface roughness of the surface of the steel belt, so that adhesive force between the surface of the steel belt and a color image layer is improved, the color image layer hardly undergoes paint peel-off phenomenon, and the formability of the steel belt is improved.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

Metal wire thermal treatment surface oxidation resistance method

InactiveCN104480291APrevent oxidationHinder entryFurnace typesHeat treatment furnacesAlcoholSurface oxidation

The invention discloses a metal wire thermal treatment surface oxidation resistance method. The method includes the following steps that (1) a container and a cotton ball are prepared, ethyl alcohol is then poured into the container or water and ethyl alcohol are poured into the container in a certain proportion, and the cotton ball is immersed in liquid of the container; (2) the temperature of a tube heating furnace is adjusted to 820-890 DEG C, a metal wire to be thermally treated moves in the tube heating furnace at a certain speed continuously, and meanwhile the wetted cotton ball extracted from the container is used for wiping the metal wire at a metal wire furnace feed tube opening; alternatively, production is conducted through the metal wire thermal treatment surface oxidation resistance method in the mode that mixed liquid of ethyl alcohol and water is injected along with a metal wire. No protective gas needs to be added in the thermal treatment process, no surface grinding processing is needed after thermal treatment, the surface cleanliness of the metal wire is greatly improved, and production efficiency of the metal wire is improved while the quality of the metal wire is guaranteed.

Owner:绍兴永昊精密电热器件有限公司

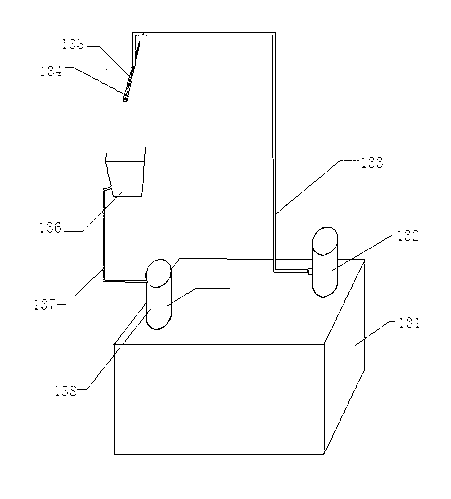

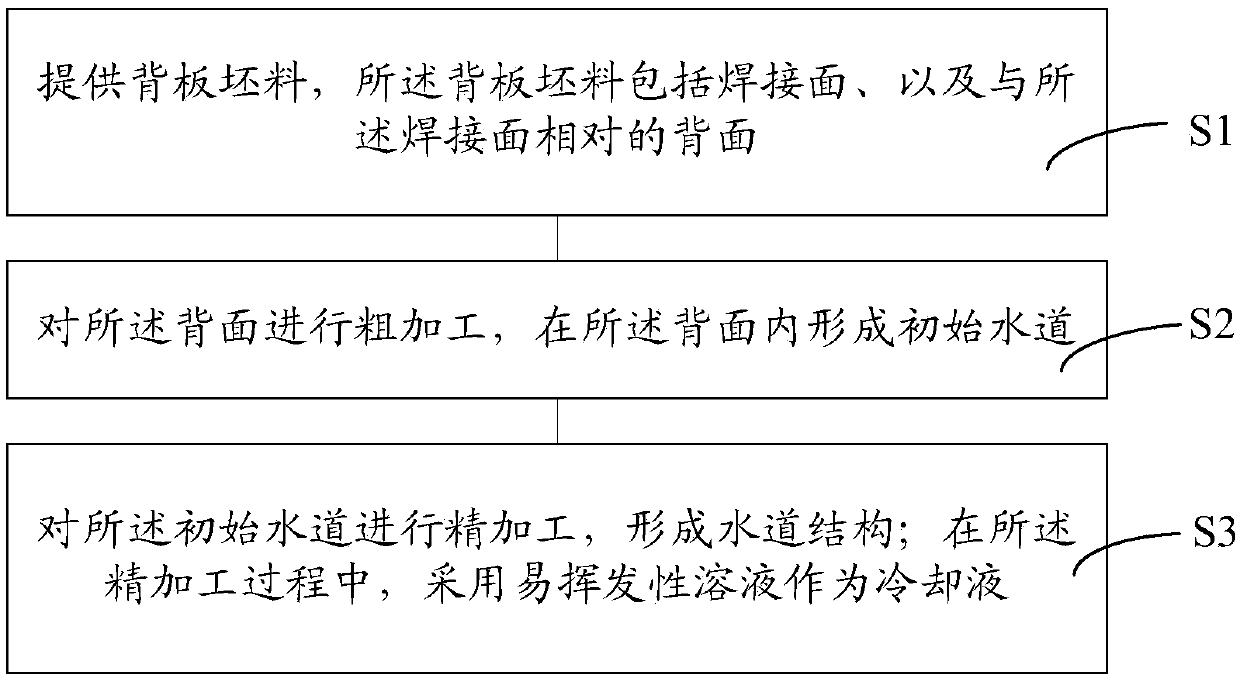

Manufacturing method for backboard and target material assembly

InactiveCN107717024AImprove surface cleanlinessHigh lusterVacuum evaporation coatingSputtering coatingEngineeringMachining process

The invention provides a manufacturing method for a backboard and a target material assembly. The manufacturing method includes the steps that a backboard blank material is provided, and comprises a welding face and a back face opposite to the welding face; the back face is subjected to rough machining, and an initial water channel is formed in the back face; the initial water channel is subjectedto finish machining to form a water channel structure; and in the finish machining process, an easy volatile solution is adopted to serve as cooling liquid. According to the manufacturing method forthe backboard, in the finish machining process on the initial water channel, the easy volatile solution is adopted to serve as the cooling liquid, the cooling liquid is not likely to form residues inthe water channel structure after volatizing of the cooling liquid, and therefore the surface cleanness degree and the luster degree of the water channel structure can be improved, remaining impurities in the water channel structure can be reduced or avoided, and therefore the forming quality of the water channel structure is improved, and therefore the quality of the backboard is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Fingerprint recognition device, touch screen display and intelligent equipment for intelligent robot

ActiveCN108038470AImprove securityImprove surface cleanlinessPrint image acquisitionInput/output processes for data processingEquipment SafetyDisplay device

The invention relates to a fingerprint recognition device. The fingerprint recognition device comprises a substrate, a driving circuit and a photoelectric sensor array and cover plates, wherein the driving circuit and the photoelectric sensor array are arranged on the substrate and are used for recognizing fingerprints; and the cover plates are opposite to the substrate, are used for protecting the driving circuit and the photoelectric sensor array and can be protruded upwards so as to drain drips and / or grease. According to the fingerprint recognition device, a touch screen display, intelligent equipment and an intelligent robot, bulges are formed according to different thermal expansion coefficients between two layers of the cover plates, so that slipping of water stain or greasy dirt isfacilitated, the surface cleanness of the fingerprint recognition device is increased, and then the recognition success rate is increased; and furthermore, a plurality of fingerprint recognition devices are integrated into the touch screen display, so that the equipment safety is improved.

Owner:BEIJING UNISROBO TECH CO LTD

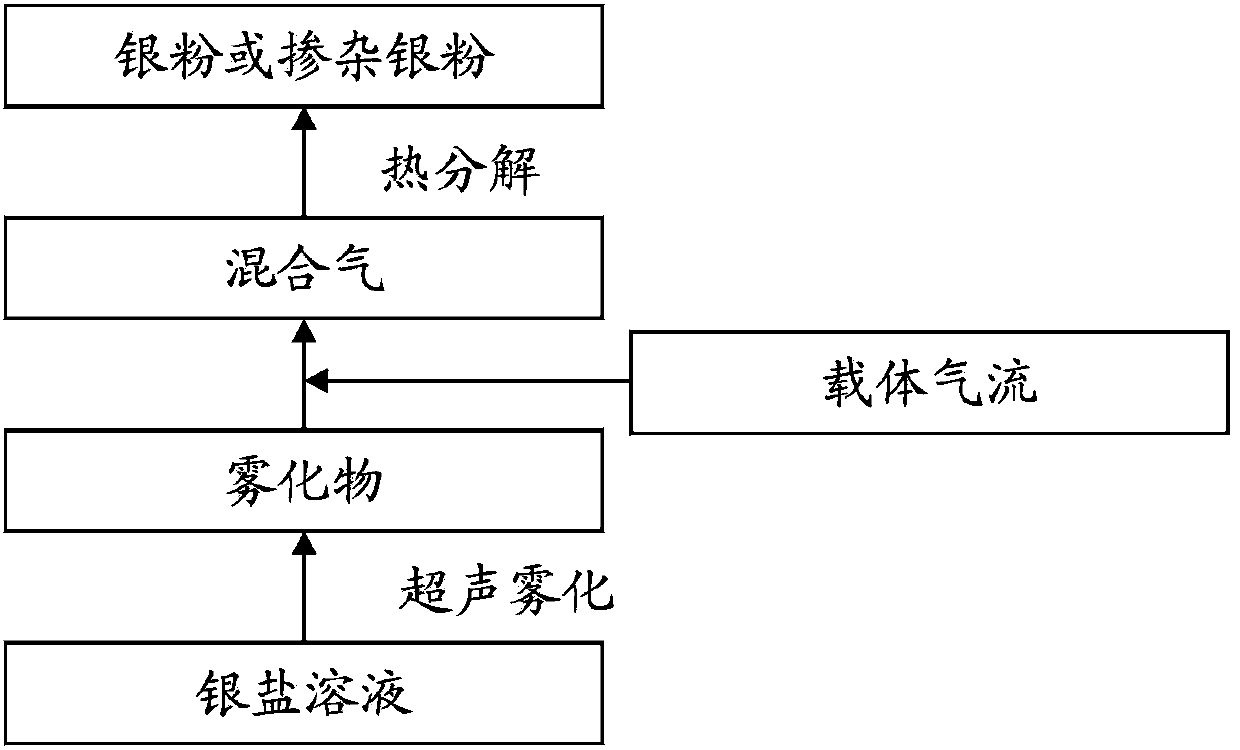

Preparation method of silver powder or doped silver powder

The invention discloses a preparation method of silver powder or doped silver powder. The preparation method comprises the steps of firstly, preparing silver salt solution, and then carrying out ultrasonic atomization on the silver salt solution to obtain atomized matter, wherein the ultrasonic atomization power is 0.2-10kw, the ultrasonic atomization frequency is 1.7-2.4MHz, and the atomization speed is 0.5-500kg / h; mixing the atomized matter with carrier airflow, carrying out thermal decomposition, and collecting to obtain the silver powder or doped silver powder, wherein the silver salt solution has the silver ion molar concentration of 0.0001-4mol / L or contains doped metal ions, and microwave heating is preferentially adopted by the thermal decomposition. After the preparation method is adopted, the silver powder or doped silver powder with the particle sizes of 0.01-5 mu m can be prepared, and power bonding agglomeration can be prevented; the microwave thermal decomposition is short in heating time and high in efficiency, and dopant in the doped silver powder can be evenly distributed; continuous production is realized, the cost is low, and the product quality is stable.

Owner:刘建

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com