Selective area growing method for III-nitride micro graphic structure and structure

A technology of selective area growth and pattern structure, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of poor uniformity, poor repeatability and high cost of micro pattern structure, and achieve flexible and controllable mask pattern shape and pattern size change. Large-scale, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

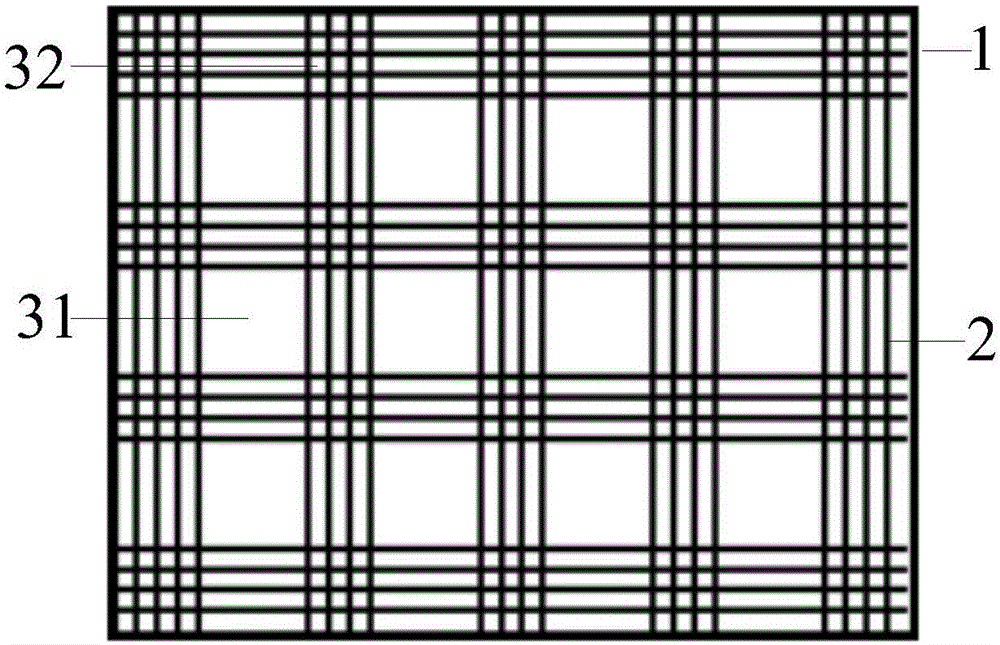

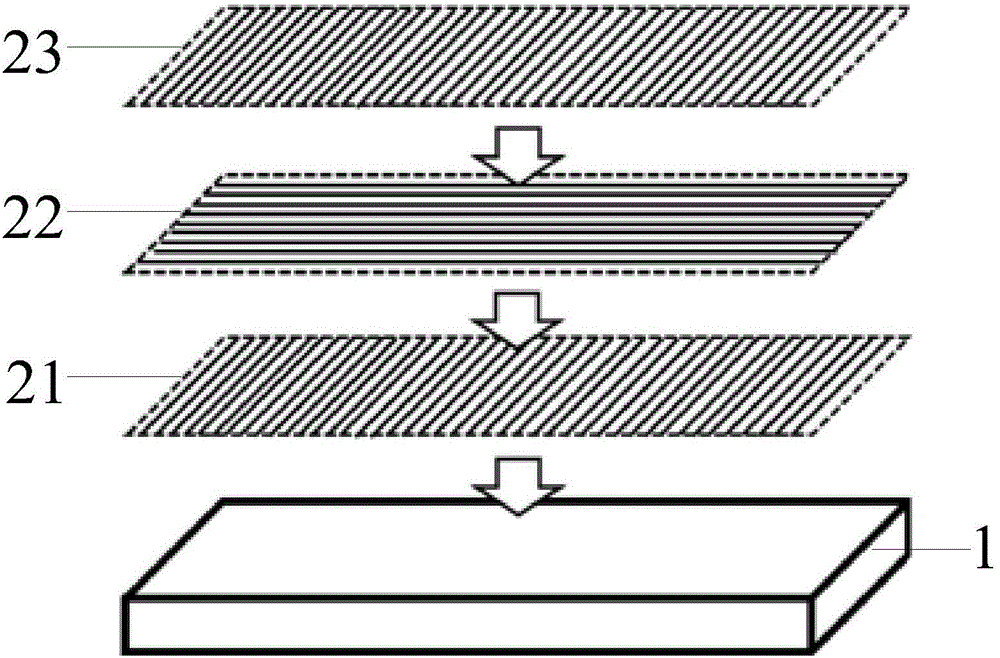

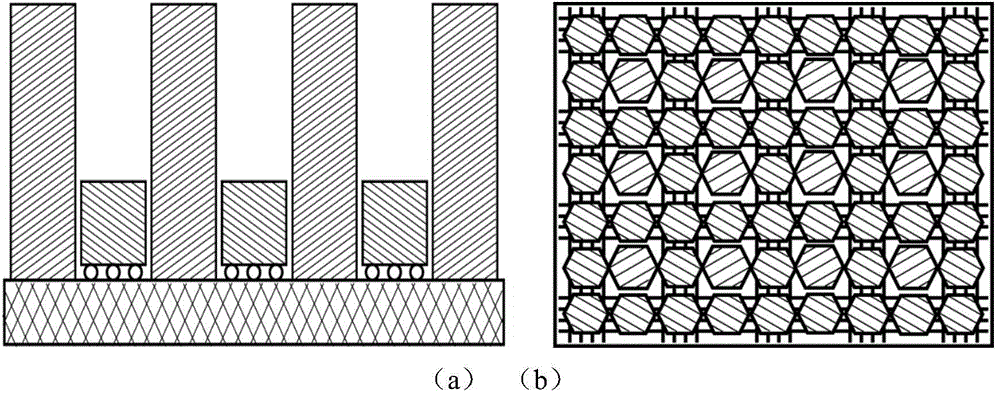

[0043] In this embodiment, a c-plane sapphire substrate is used as the substrate, and three layers of carbon nanotube films are laid on the substrate as a carbon nanotube mask to prepare a GaN double-sized micron hexagonal prism microscopic pattern structure. Such as figure 2 As shown, three layers of carbon nanotube arrays 21-23 are respectively laid on the substrate 1 as a carbon nanotube mask, the first layer 21 is perpendicular to the second layer 22, and the third layer 23 is perpendicular to the second layer; each layer The carbon nanotube film includes a plurality of cluster structures arranged in parallel, the diameter of each cluster is between 2 and 4 μm, and the distance between adjacent clusters is between 2 and 4 μm. As a micron-scale growth window, the cluster The distance between the inner adjacent carbon nanotubes is 200-500nm, and serve as nanoscale growth windows to form a micron / nano compound size mask in which micron scale growth windows and nanoscale grow...

Embodiment 2

[0055] In this embodiment, the high-temperature nitriding process in embodiment one is canceled, that is, step b) in step 3) is cancelled, and the other steps are the same as in embodiment one, and a GaN double-size micron hexagonal pyramid microscopic pattern structure can be obtained, such as Figure 4 shown.

Embodiment 3

[0057] In this embodiment, the c-plane sapphire substrate is used as the substrate, and four layers of carbon nanotube films are laid on the substrate as a carbon nanotube mask to prepare a GaN double-sized micron inverted trapezoidal microscopic pattern structure.

[0058] The selective growth method of the GaN double-size micron inverted trapezoidal micro-pattern structure in this embodiment includes the following steps:

[0059] 1) Substrate 1 adopts c-plane sapphire.

[0060] 2) laying a carbon nanotube mask on the substrate 1:

[0061] On the growth substrate of the carbon nanotube array, a layer of neatly arranged and uniformly sized nanoscale iron powder is deposited by electron beam evaporation as a catalyst, and then by LPCVD method, acetylene is used as a carbon source at low pressure and high temperature to grow quasi Ordered, parallel arrays of carbon nanotubes are peeled off and laid on the growth substrate of Group III nitrides; the formed carbon nanotubes are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com