Full-automatic silicon wafer degumming equipment

A silicon wafer degumming, fully automatic technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as poor compatibility, low work efficiency, slow speed, etc., to reduce the number of operators , Reduce labor cost, high cleanliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

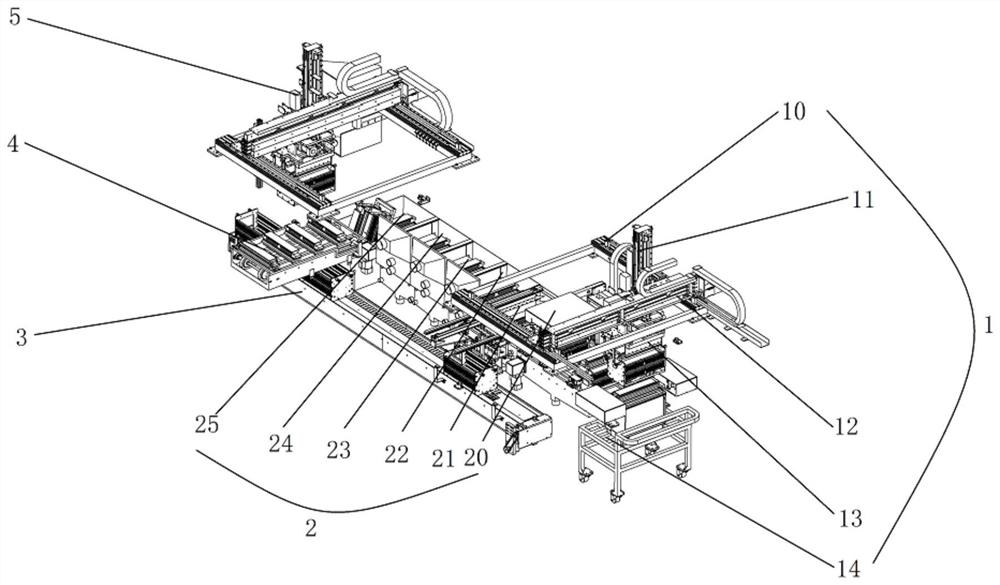

[0038] figure 1 It shows a schematic structural diagram of an embodiment of the present invention, and specifically shows the structure of this embodiment. This embodiment relates to a fully automatic silicon wafer degumming and degumming equipment, which is used for degumming and cleaning single crystal silicon rods after cutting. The degumming and cleaning device can separate the silicon wafer from the material seat, and remove the residual glue on the silicon wafer at the same time; it has a turnover device, which can transfer the degummed silicon wafer to the slicing mechanism for slicing and inserting; it has degumming The handling device transports the cut silicon wafers when they are degummed, and realizes the automatic production of pre-cleaning, degumming and cleaning of the cut single crystal silicon rods, reduces labor intensity, inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com