Patents

Literature

147results about How to "High luster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

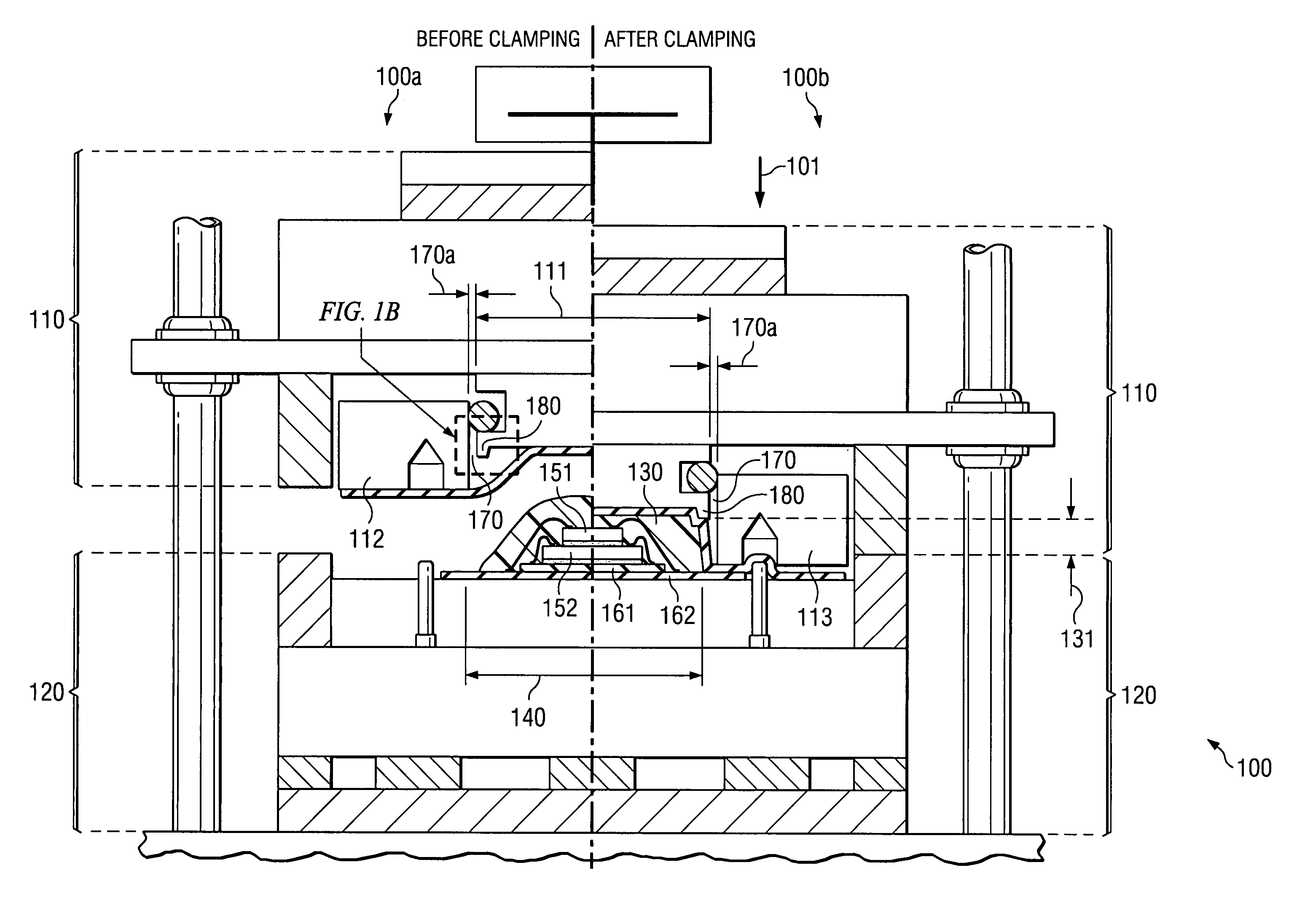

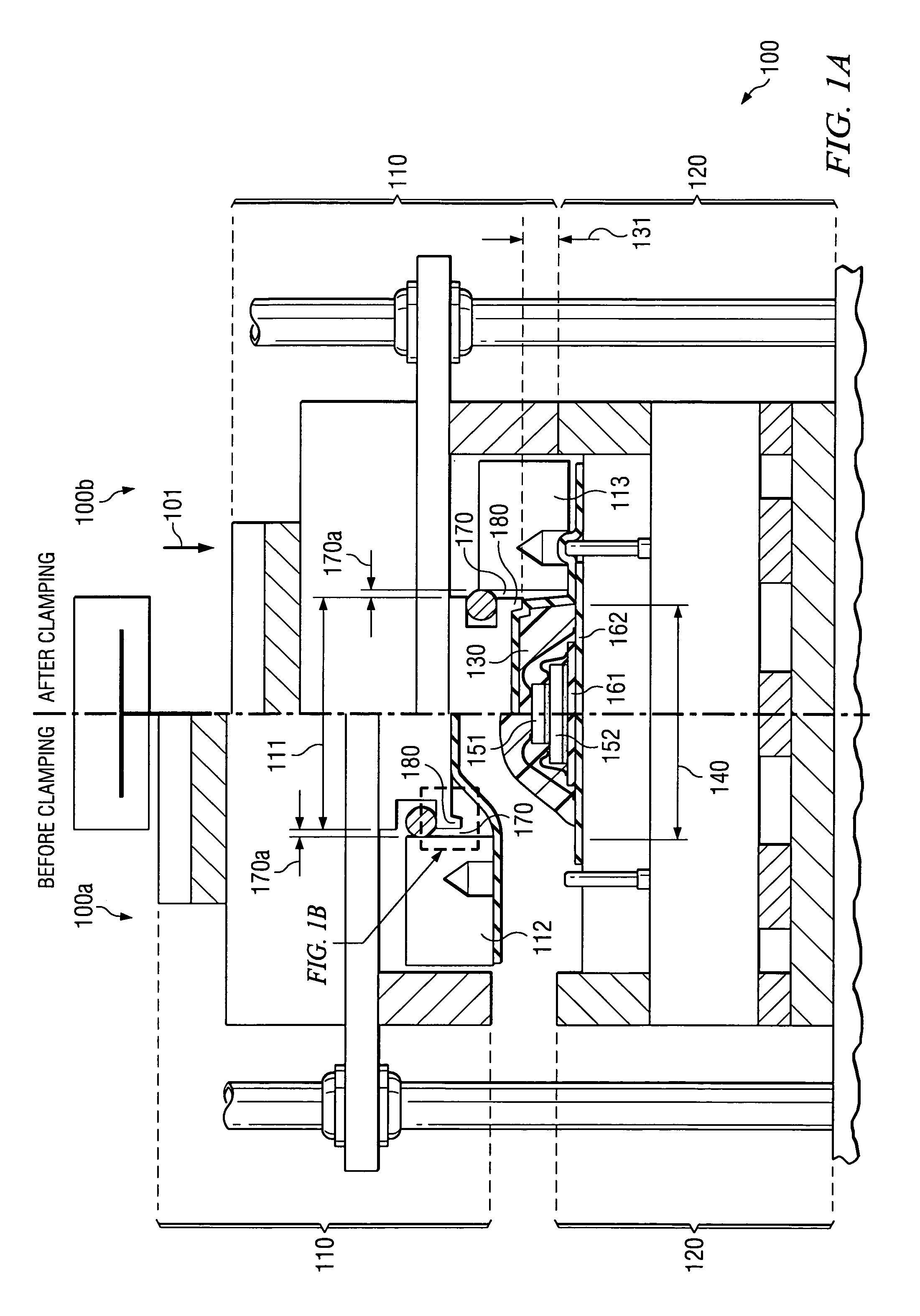

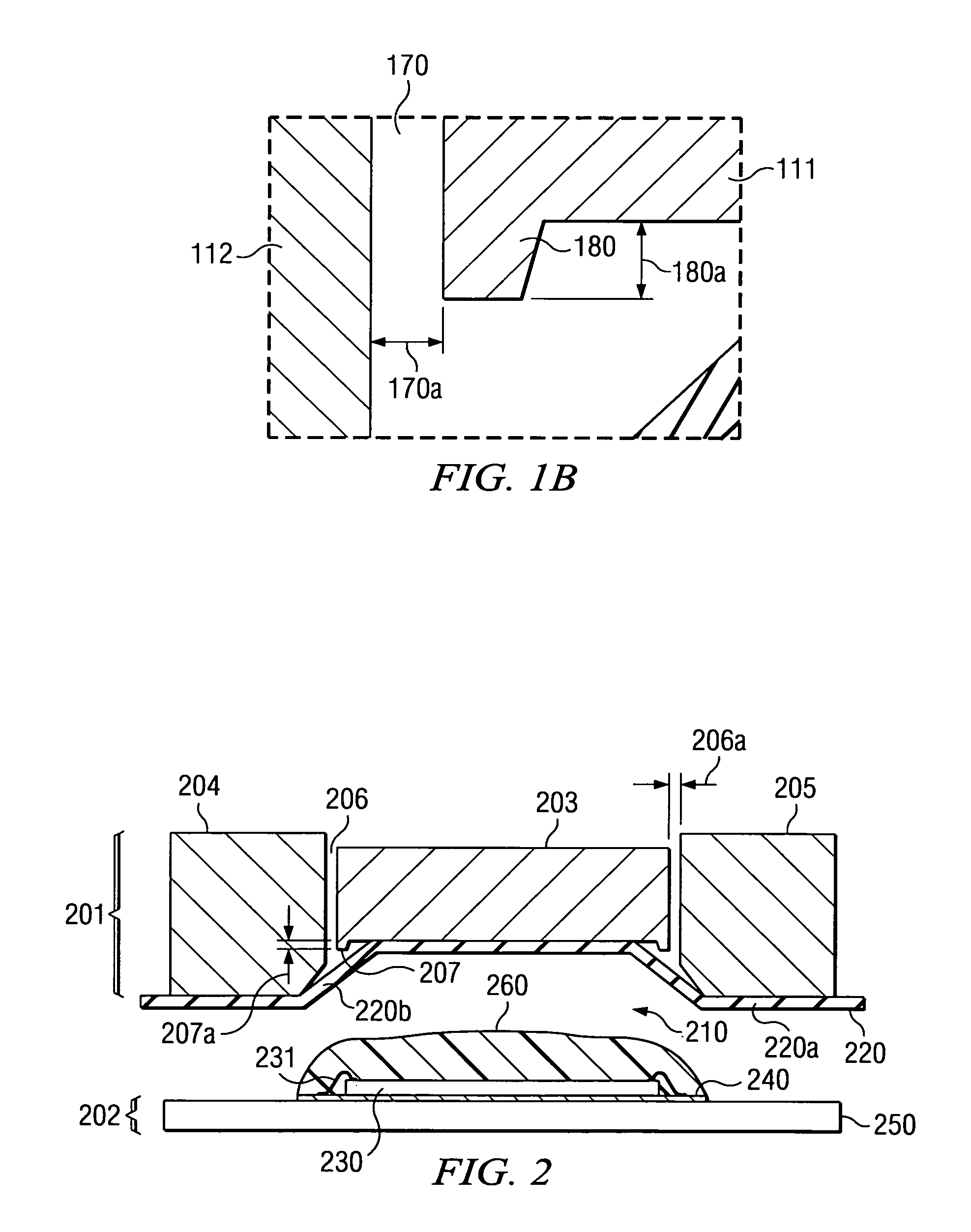

Plastic semiconductor package having improved control of dimensions

ActiveUS7147447B1High lusterThinner deviceTailstocks/centresConfectioneryPlanar substrateSemiconductor chip

A device with a semiconductor chip (801) assembled on a planar substrate (802) and encapsulation compound (810) surrounding the assembled chip and a portion of the substrate near the chip; the compound has a planar top area (811). The encapsulation compound has a plurality of side areas (812) reaching from the substrate to the top area; these side areas form edge lines with the top area, where the top area plane intersects with the respective plane of each side area. The encapsulation compound is recessed (813) along the edge lines so that the material is caved-in along the lines; this feature causes the recess to prevent any compound from the side area planes to reach the top area plane, whereby the planarity of the top area is preserved.

Owner:TEXAS INSTR INC

UV (ultraviolet) duct gloss oil

InactiveCN102925027ABright colorStrong sense of transparencyPolyurea/polyurethane coatingsEpoxy resin coatingsWear resistantPhotochemistry

The invention relates to a UV (ultraviolet) duct gloss oil and a preparation method of the UV duct gloss oil. The UV duct gloss oil is prepared by raw materials consisting of ultraviolet cured resin, an active diluting agent, a photo-initiator, and and the like; weight proportion of each component is as follows: 27-52 parts of ultraviolet cured resin, 35-50 parts of active diluting agent, 5-10 parts of photo-initiator, 8-10 parts of photo sensitive sensitizer, and 1.05-2.1 parts of assistant. After using the UV duct gloss oil prepared according to the proportion of the invention for cigarette-brand printing, the cigarette-brand is bright and beautiful in color, strong in transparence, high in wearing resistant degree, and better in the entire printing effect.

Owner:深圳市深赛尔股份有限公司

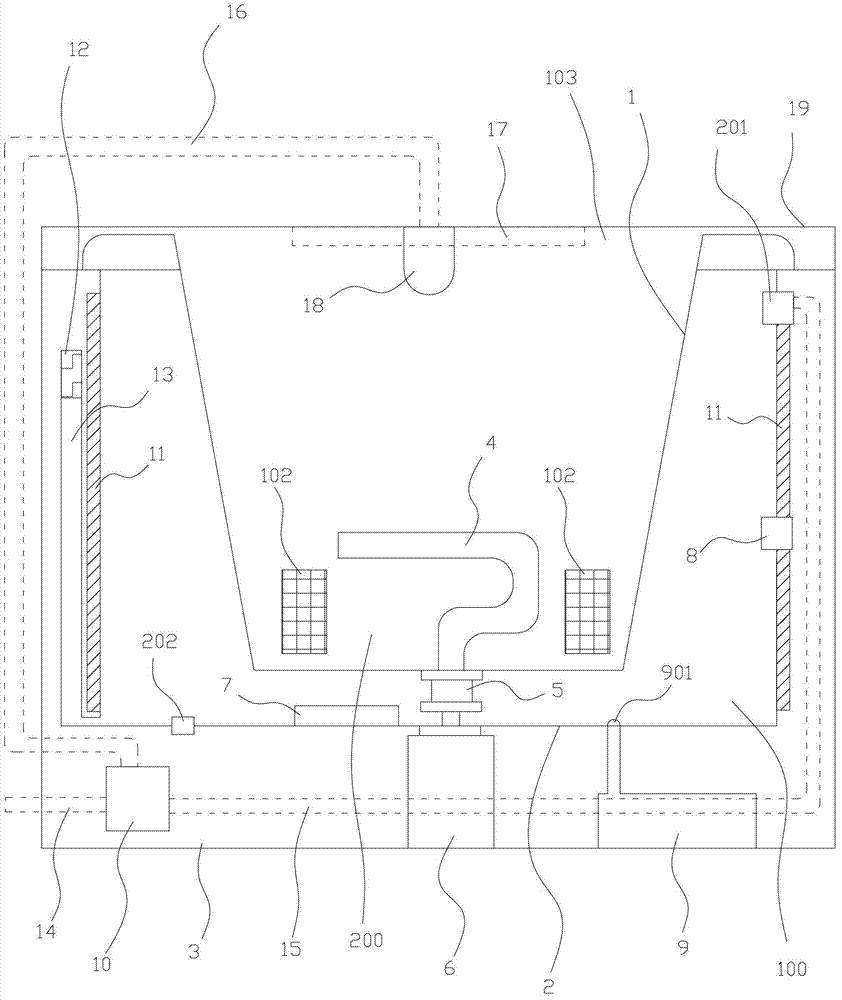

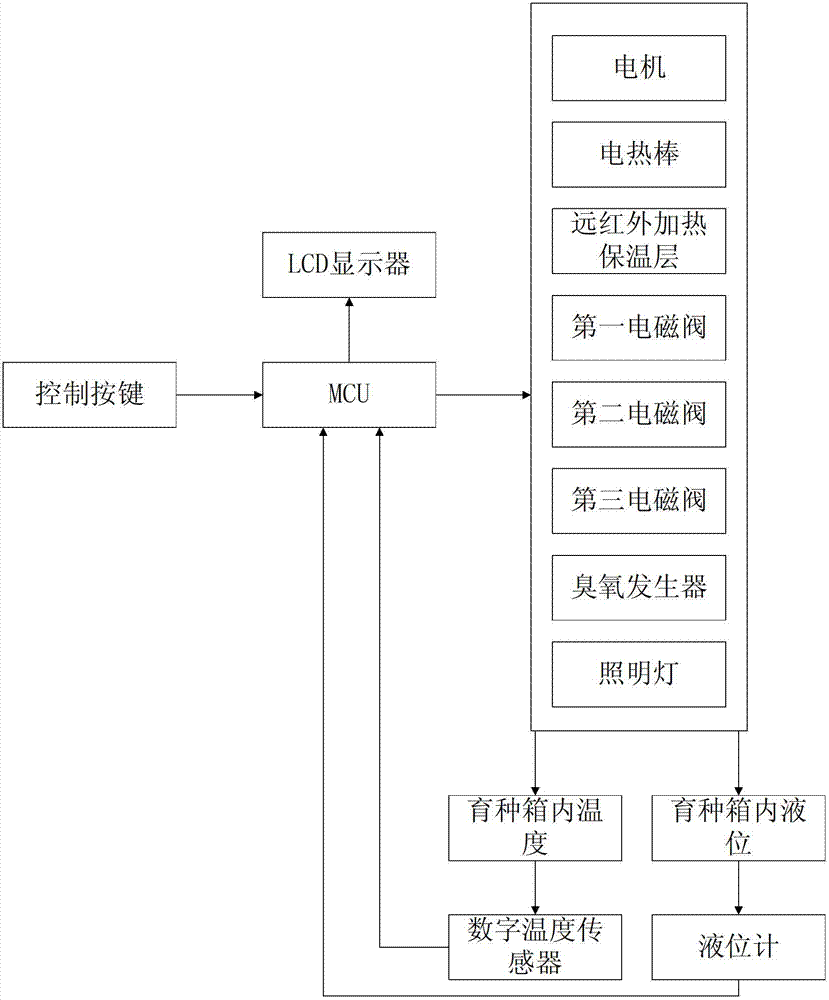

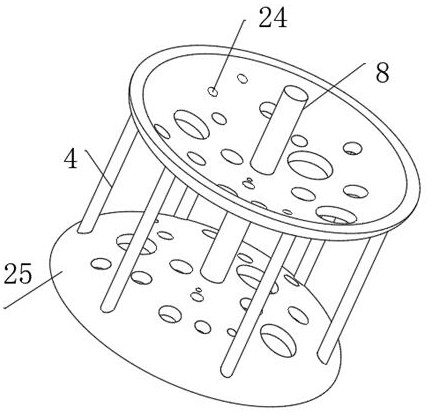

Multifunctional seed breeding box

InactiveCN102812868AEfficient wash offDoes not affect normal germination traitsClimate change adaptationGreenhouse cultivationOzone generatorInsulation layer

The invention relates to a multifunctional seed breeding box, which comprises an inner barrel (1), an outer barrel (2), a box body (3), a box cover (19), an ozone generator (9), a control panel, a stirring rod (4), a motor (6), a far infrared heating heat insulation layer (11), a digital temperature sensor (8), an electric heating rod (7), a sprayer (17), an electric valve module (10), an ozone generator (9) and a MCU (micro control unit), wherein the inner barrel (1), the outer barrel (2) and the box body (3) are sequentially assembly from inside to outside, and the control panel, the digital temperature sensor (8), the motor (6), the ozone generator (9), the electric valve module (10) and the far infrared heating heat insulation layer (11) are respectively and electrically connected with the MCU. The multifunctional seed breeding box has five major functions including 1, seed impurity rinsing; 2, seed surface detoxification and sterilization; 3, high-temperature seed soaking; 4, proper temperature pregermination, wherein the temperature can be automatically regulated, and the seed pregermination is prompted; and 5, seed coating.

Owner:深圳中绿环境集团有限公司

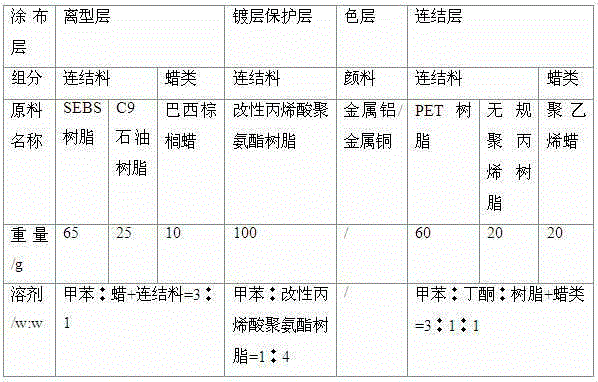

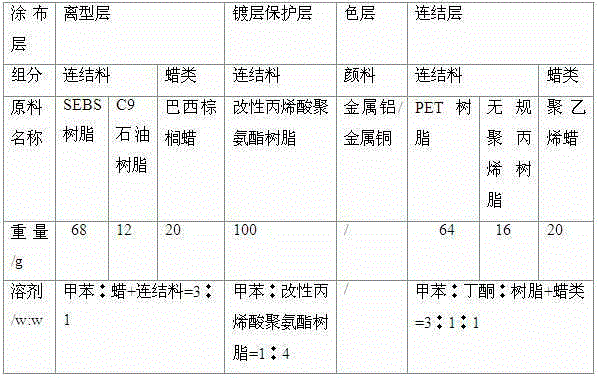

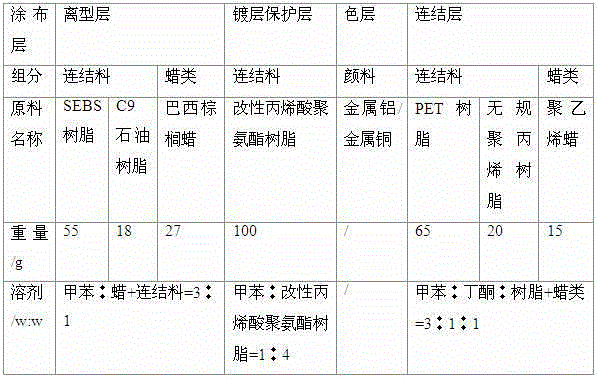

Thermal transfer ribbon for printing golden and silver bar codes and preparation method thereof

ActiveCN105216461AReasonable designEasy to prepareInk ribbonsSynthetic resin layered productsEngineeringPolypropylene

The invention discloses a thermal transfer ribbon for printing golden and silver bar codes and a preparation method thereof, and belongs to the technical field of thermo-printing material. The thermal transfer ribbon for printing the golden and silver bar codes is composed of a ribbon base, a back coating and a thermal transfer printing layer, wherein the back coating and the thermal transfer printing layer are arranged on the two sides of the ribbon base in a coating mode. The thermal transfer printing layer is divided into four parts, namely the release layer, the coating protection layer, the color layer and the connecting layer, wherein the release layer, the coating protection layer, the color layer and the connecting layer are sequentially arranged on the surface of one side of the ribbon base from inside to outside. The release layer is composed of, by weight, connecting material of 73-90% and wax of 10-27%, the connecting material is composed of SEBS resin and petroleum resin, the SEBS resin accounts for 55-80% in total mass of the release layer, the petroleum resin accounts for 0-25% in total mass of the release layer, and the wax can be rice bran wax or polyethylene wax or carnauba wax. The coating protection layer is composed of modified acrylic acid polyurethane resin, wherein the softening point of the modified acrylic acid polyurethane resin ranges from 110 DEG C to 115 DEG C. The color layer is plated to be golden or silver through the vacuum evaporation process. The connecting layer is composed of, by weight, saturated polyester resin of 50-71%, atactic polypropylene resin of 10-30% and polyethylene wax of 10-28%.

Owner:JIAOZUO ZHUOLI STAMPING MATERIAL CO., LTD.

Hollow polymer emulsion and preparation method thereof

InactiveCN102382239AHigh hiding powerHigh elongation at breakPaper coatingCoatingsPolymer scienceWeather resistance

The invention discloses a hollow polymer emulsion and a preparation method thereof. The preparation method adopts the processes of emulsion polymerization, core-shell emulsion polymerization and the like to prepare the hollow polymer emulsion. An emulsion particle is of a structure with a hard shell and a soft shell, and the void fraction of a film formed by the emulsion reaches more than 50 percent. A variety of unsaturated monomers, emulsifier and initiator are adopted to prepare the hollow polymer emulsion, in particular, isobornyl methacrylate and 2,2,3,4,4,4-hexafluorobutyl acrylate are chosen as shell monomers, the contents of isobornyl methacrylate and 2,2,3,4,4,4-hexafluorobutyl acrylate respectively account for 2 to 5 percent and 3 to 6 percent by weight of the total amount of the emulsion, and the mechanical properties, the weather fastness and the dirt resistance of the emulsion film are effectively enhanced. The product has an excellent dry hiding effect, can decrease the density of the film and improve handle, and can be applied in the fields of water-borne coating, paper coating, industrial coating, ink and the like.

Owner:山东聚东新材料有限责任公司

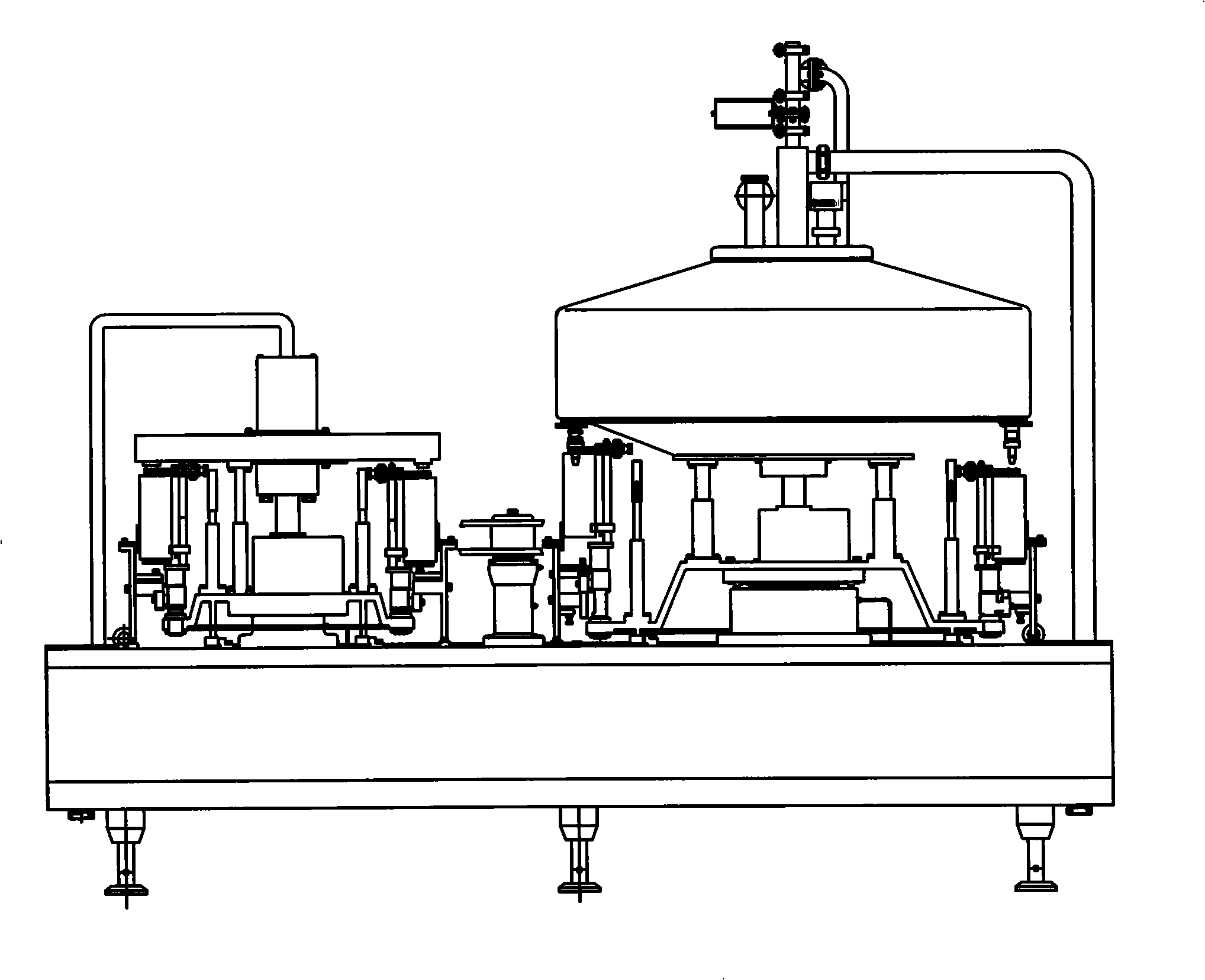

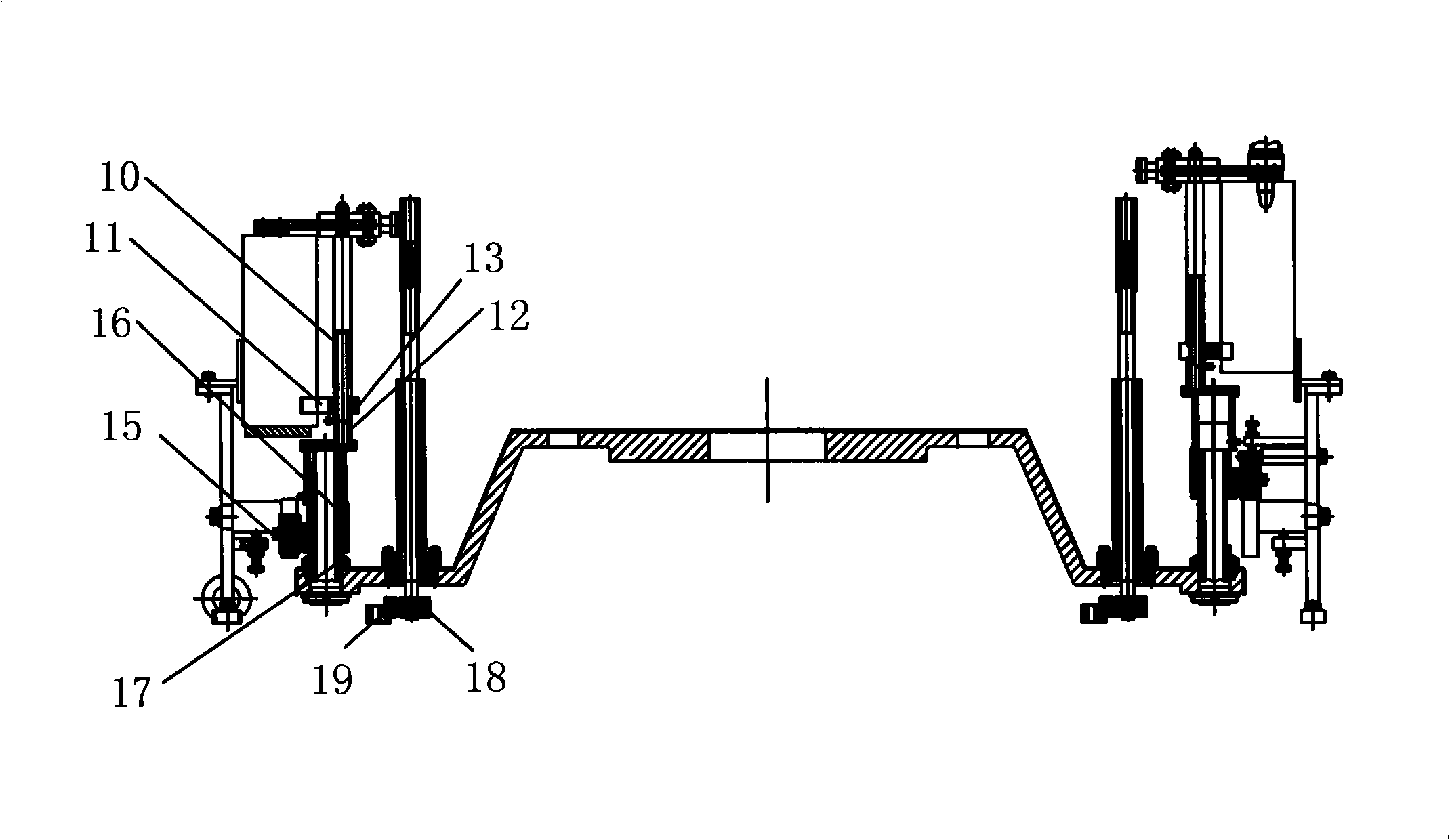

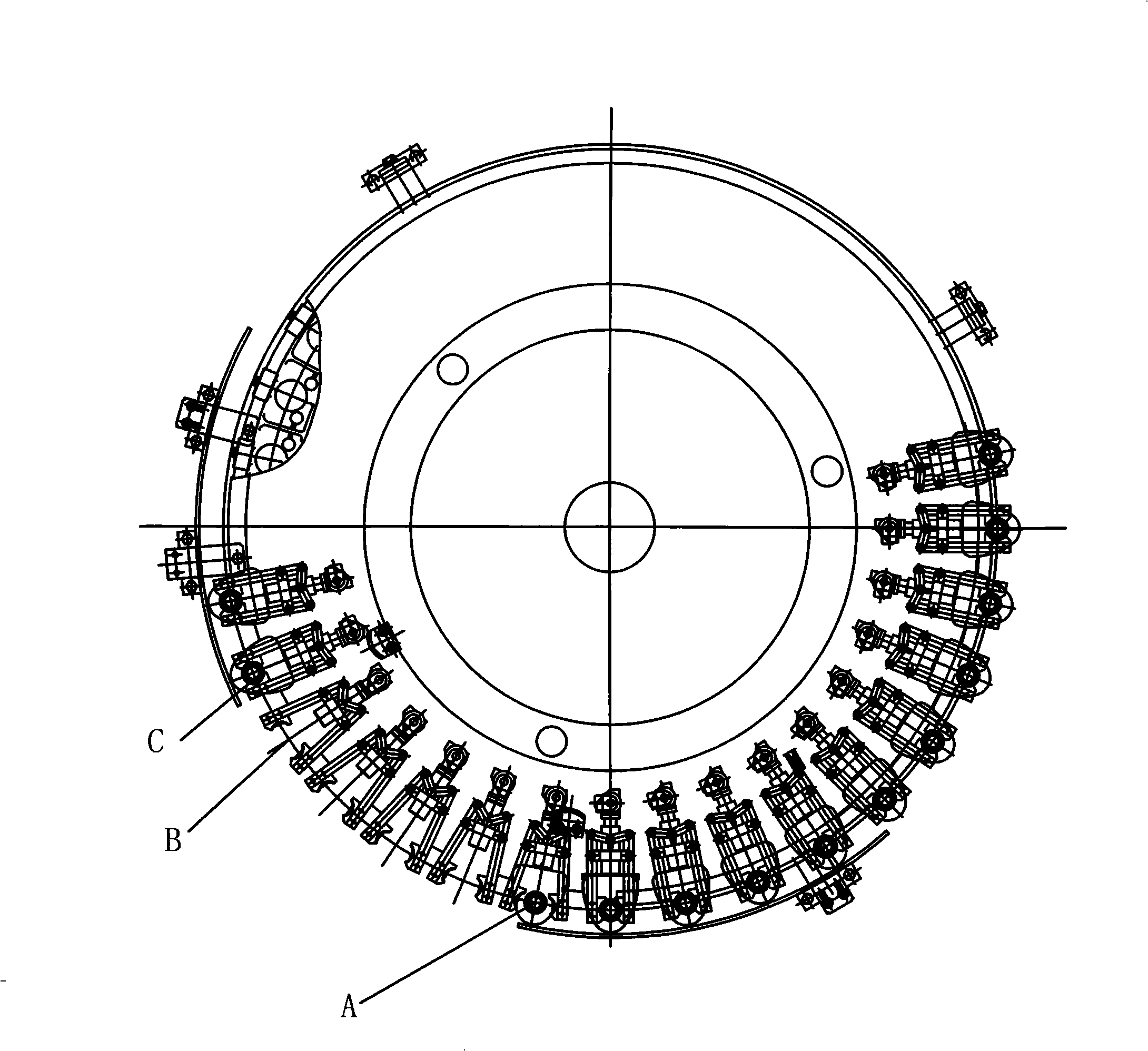

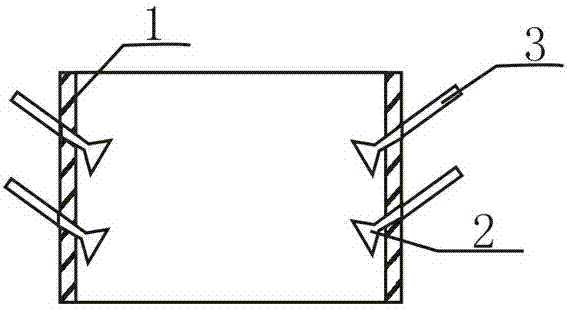

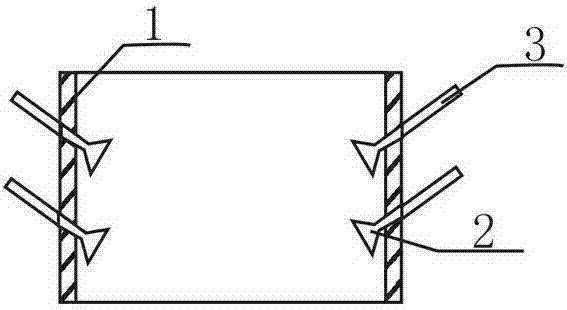

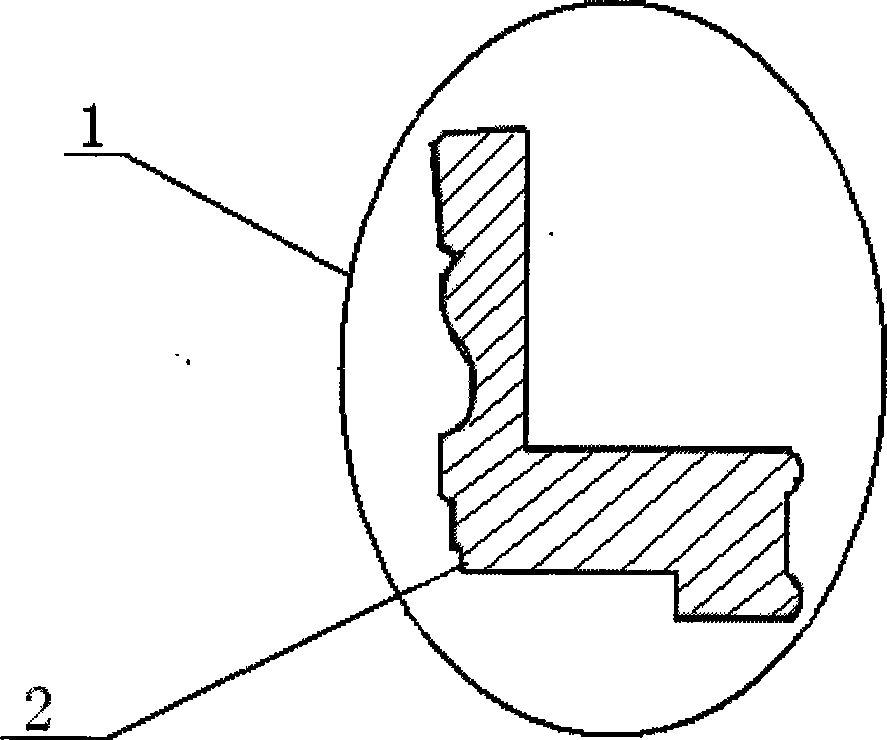

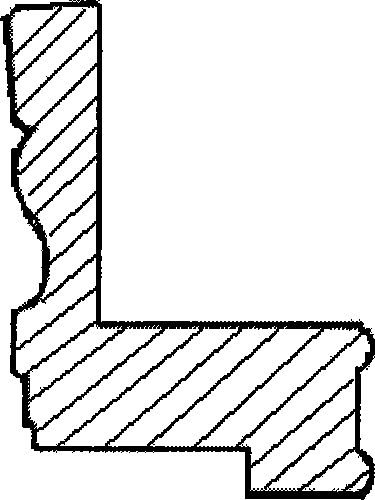

Bottle clamping device of bottle filler

The invention discloses a bottle clamping device for filling machines, having a structure that the bottle clamping device comprises a connecting rod, a support seat and a push rod; one end of the connecting rod is provided with a clamping block; the middle part of the support seat is provided with a bearing; one end inside the bearing is provided with an elastic component, and the other end inside the bearing is provided with the push rod; the other end of the connecting rod is provided with a pull rod; the other end of the pull rod is fixed on a small shaft; and one side of the push rod is provided with a device capable of allowing the push rod and the bearing to move relatively as well. The structure has the main points that the lower end of the support seat is provided with a lifting mechanism; the lifting mechanism consists of a plunger rod, a lifting shaft seat, and so on; the outer side of the upper end of the plunger rod is provided with the lifting shaft seat; the outer side of the lifting shaft seat is provided with a roller; the upper end of the lifting shaft seat is provided with a strut; the outer side of the strut is provided with a bush; and a height adjustment sleeve is arranged above the bush. As the bottle clamping device clamps a bottle mouth for fixation, the whole bottle is little in stress, thereby solving the problem that the pressure needed for filling and sealing causes the deformation of the bottle.

Owner:宁波市永宏机械有限公司

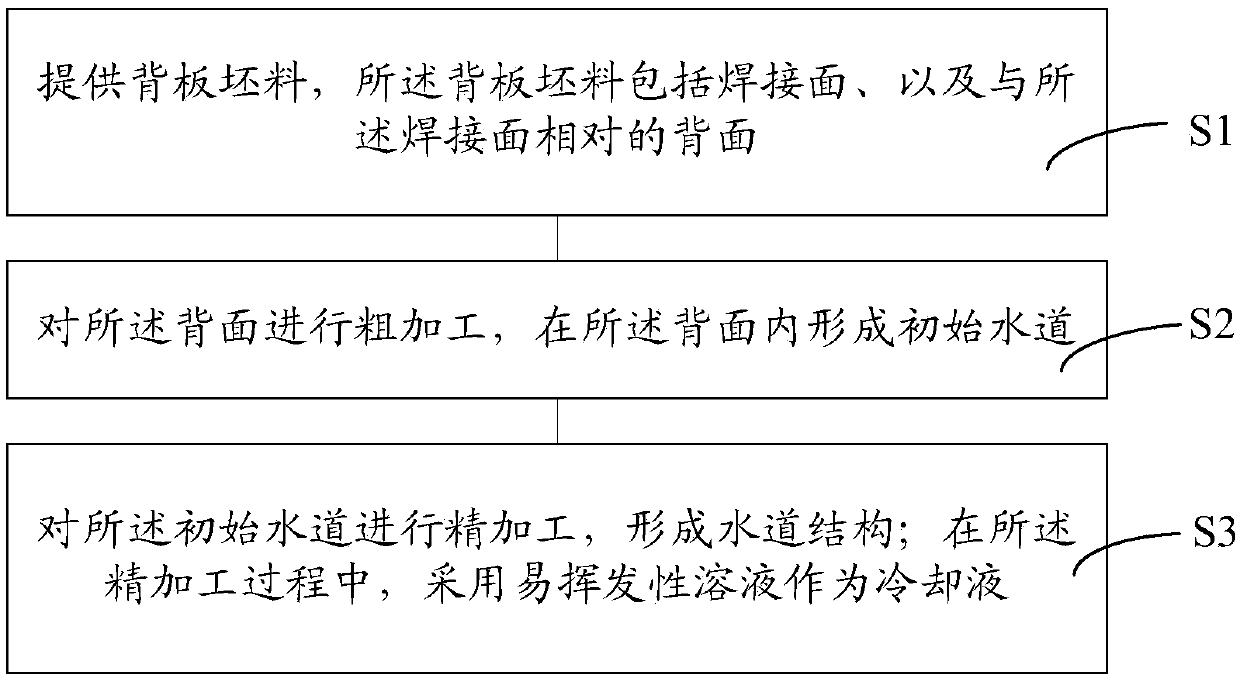

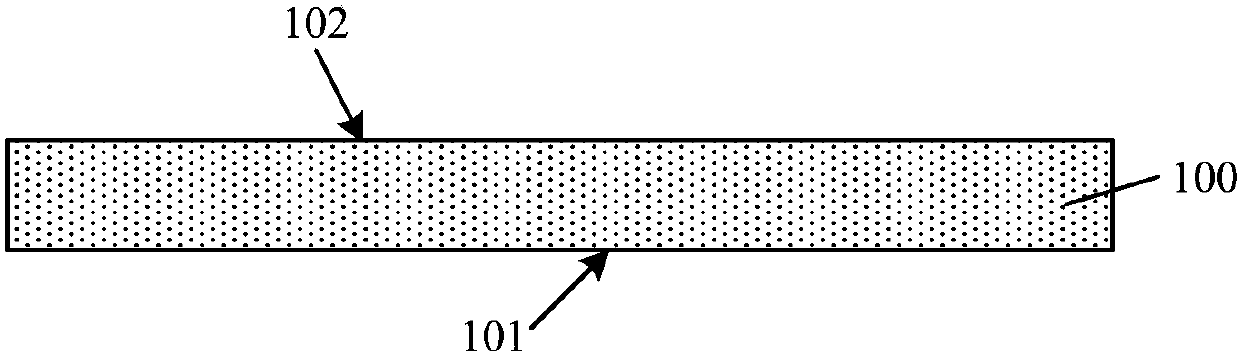

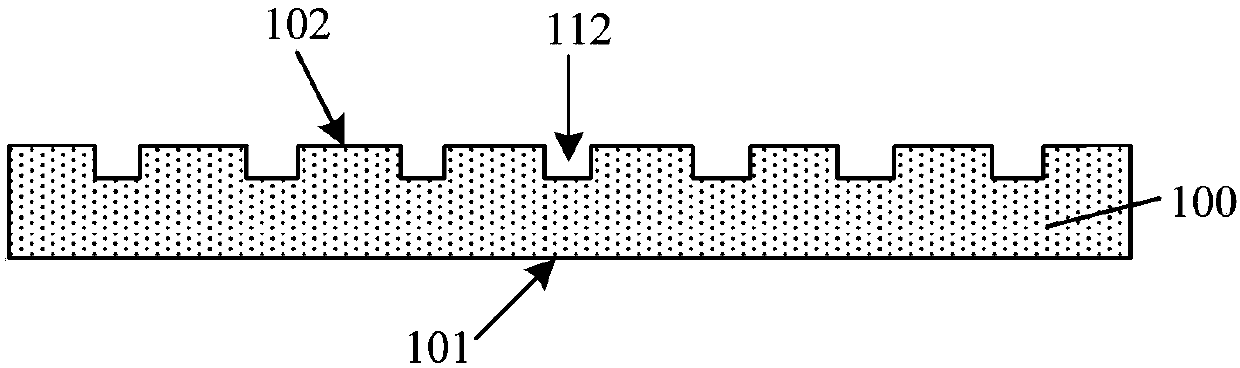

Manufacturing method for backboard and target material assembly

InactiveCN107717024AImprove surface cleanlinessHigh lusterVacuum evaporation coatingSputtering coatingEngineeringMachining process

The invention provides a manufacturing method for a backboard and a target material assembly. The manufacturing method includes the steps that a backboard blank material is provided, and comprises a welding face and a back face opposite to the welding face; the back face is subjected to rough machining, and an initial water channel is formed in the back face; the initial water channel is subjectedto finish machining to form a water channel structure; and in the finish machining process, an easy volatile solution is adopted to serve as cooling liquid. According to the manufacturing method forthe backboard, in the finish machining process on the initial water channel, the easy volatile solution is adopted to serve as the cooling liquid, the cooling liquid is not likely to form residues inthe water channel structure after volatizing of the cooling liquid, and therefore the surface cleanness degree and the luster degree of the water channel structure can be improved, remaining impurities in the water channel structure can be reduced or avoided, and therefore the forming quality of the water channel structure is improved, and therefore the quality of the backboard is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Fullerene reinforced ceramic tile

InactiveCN104150871AVisible and adjustable colorImprove mechanical propertiesClaywaresFiberSodium phosphates

The invention discloses a fullerene reinforced ceramic tile. The fullerene reinforced ceramic tile with good mechanical properties is obtained by applying a glaze on the surface of a green body in a glaze spraying or sprinkling manner, wherein potassium feldspar, albite, clay, attapulgite, alumina, water, fullerene, sodium tripolyphosphate and tempered fiber serve as raw materials of the green body, feldspar, kaoline, quartz, burnt talcum, limestone, iron oxide, diboron pentoxide, alumina, kieselguhr, magnesite, zirconium silicate, titanium oxide, zinc oxide, terbium oxide, samarium oxide, lutecia and metal nano particles serve as raw materials of the glaze, and a glazed surface of the ceramic tile is attractive and elegant.

Owner:朱玉华

Blueberry anthocyanidin extraction method and blueberry fruit pulp preparation method

InactiveCN107793390AImprove extraction efficiencyHigh extraction purityOrganic chemistryFood ingredient as mouthfeel improving agentCyanineExtraction methods

The invention relates to a blueberry anthocyanin extraction process and a blueberry pulp preparation method based on blueberry anthocyanin, which improves the extraction efficiency and product purity of blueberry anthocyanin, maximizes the nutritional and pharmacological value of blueberry, and obtains blueberry flower Green pigments are directly applied to blueberry pulp, and auxiliary probiotics are added to blueberry pulp to improve the drinking taste of blueberry pulp, and to play the role of medicine and health care that blueberries should have in the form of drinks.

Owner:成都老农王农业开发有限公司

Carbon nano tube enhanced ceramic tile

ActiveCN104193292AVisible and adjustable colorImprove mechanical propertiesClaywaresCarbon nanotubeTalc

The invention discloses a carbon nano tube enhanced ceramic tile. The preparation method comprises the following steps: by taking potassium feldspar, albite, Guangxi white clay, attapulgite, mullite, water, carbon nano tubes, sodium tripolyphosphate and steel fibers as blank raw materials and taking feldspar, kaolin, quartz, fired talc, limestone, chromic oxide, pentoxide boron, aluminium oxide, kieselguhr, fused magnesite, zirconium silicate, titanium oxide, zinc oxide, terbium oxide, samarium oxide, lutecia and metal nanoparticles as glaze raw materials, applying the glaze to the surface of a green body by using a glaze spraying or glaze sprinkling mode, thereby obtaining the carbon nano tube enhanced ceramic tile with good mechanical properties. Moreover, the glaze surface of the ceramic tile is attractive and elegant in appearance.

Owner:佛山市金环球陶瓷有限公司

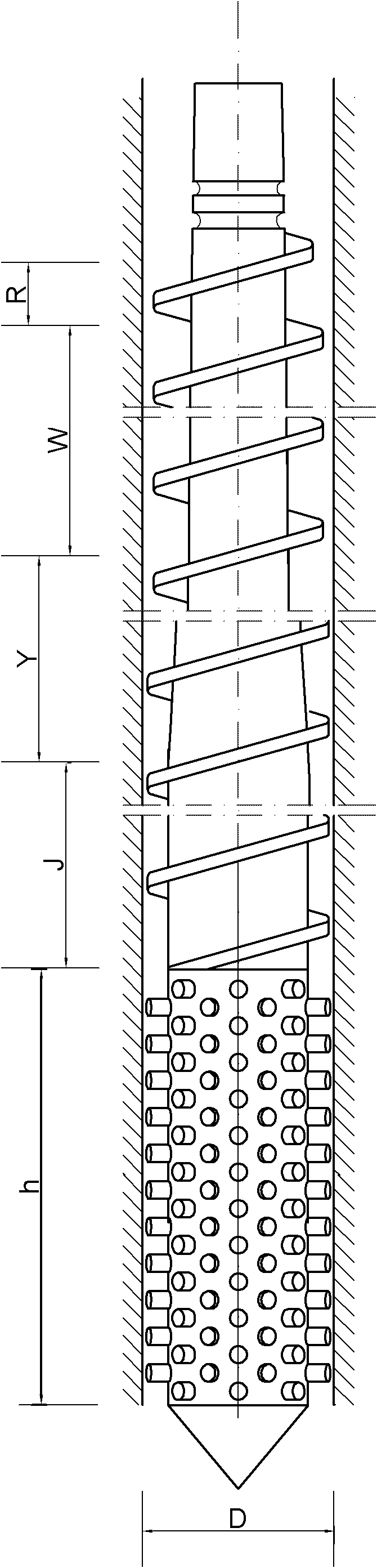

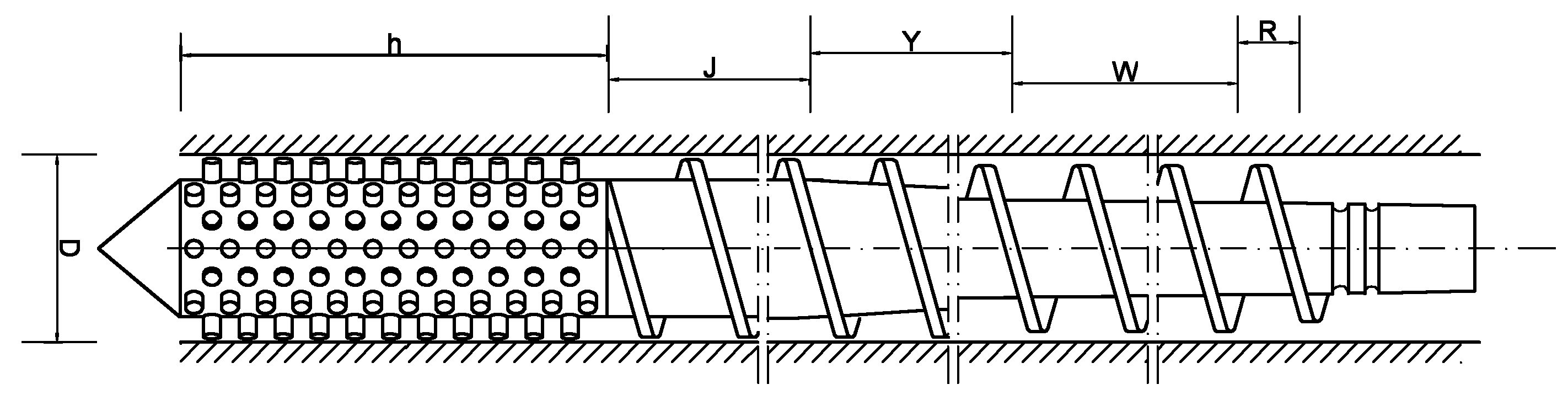

Method for producing high-intensity fine denier fiber from scrap material and returned material of polyester bottles

ActiveCN101845681AHigh fiber strengthGood dispersion performancePlastic recyclingMonocomponent polyesters artificial filamentWater contentScrap

The invention relates to a method for producing high-intensity fine denier fiber from a scrap material and a returned material of polyester bottles. The method is characterized by comprising the following steps of: after the material is dried for the second time and the water content of the material is controlled below 80 ppm, adding the following chemical additives in percentage by mass: 0.02 to 0.04 percent of OB-1 brightening agent, 0.02 to 0.04 percent of barium stearate and 0.04 to 0.06 percent of titanium white into the material, uniformly stirring the mixture, and fusing and stirring the mixture in a screw rod at a high temperature and extruding the mixture; arranging a mixing region at the tail end of a screw extruder, wherein the length of the mixing region H is 3 to 4 times the sleeve diameter D of the screw extruder; and raising the temperature of a heating region of a screw rod sleeve from conventionally 260-310 DEG C to 285-340 DEG C. A product produced by the method belongs to high-intensity fine denier fiber; the linear density of the fiber is less than or equal to 1.55 dtex and the breaking strength of the fiber is CN / dtex is more than or equal to 5.8; and the quality of the product reaches or is close to the quality standard of similar chopped fiber produced by melt direct spinning. The method has the advantages of reliving the situation of material shortage for users, saving the consumption of national resource consumptions, fulfilling the aim of mutual benefits and bringing considerable economic benefit to enterprises.

Owner:广东秋盛资源股份有限公司

Large Zibo kiln ceramic ware sintering technology

InactiveCN104341157AImprove hair colorGood control of firing temperatureSurface layerReducing atmosphere

A large Zibo kiln ceramic ware sintering technology relates to the technical field of ceramic. The technology comprises the following steps: 1, adding water to glaze, mixing, and applying the obtained mixed liquid to a ceramic base substrate; 2, building a die on a surface layer, wherein the die is a cuboid with a bent middle portion; 3, pressing 20-30mass% of carbon, 65-75mass% of silicon and 3-5mass% of clay by a press, putting the obtained substance in a kiln, and carrying out calcining sintering molding at 1650-1750DEG C to form a ware with the thickness of 12-15cm, building a cylinder in the periphery of the large molded ceramic ware, and sealing the top to obtain a saggar; and 4, carrying out radiation heating, sintering the saggar by naked fire without contact with a cylinder from 0DEG C to 300DEG C for 18h, uniformly heating from 300DEG C to 1100DEG C by adopting oxidizing flame for 36h, and heating from 1100DEG C to 1320DEG C by adopting reducing atmosphere for 20h to complete sintering. The technology prevents collapsing, cracking, kiln drawing cracking and other phenomena, and has a high yield.

Owner:牛继伟

Method for pickling radish strips in rice wine

The invention discloses a method for pickling radish strips in rice wine. The method comprises the following steps: mixing rice wine, table salt, chopped chilli, garlic and radish strips with the water content of 10-15%, and pickling in a sealed in state. The radish strips pickled in the rice wine prepared from the special distillery yeast have the advantages of crisp mouthfeel, favorable appearance and color, long storage time and high dietary value, contain rich vitamins, amino acids and other nutrients, and does not need any flavoring agent or preservative. The radish strips have the effects of avoiding suffering from excessive internal heat, eliminating fatigue, promoting digestion, clearing away heat and toxic materials and the like.

Owner:湖南一有味农业开发有限公司

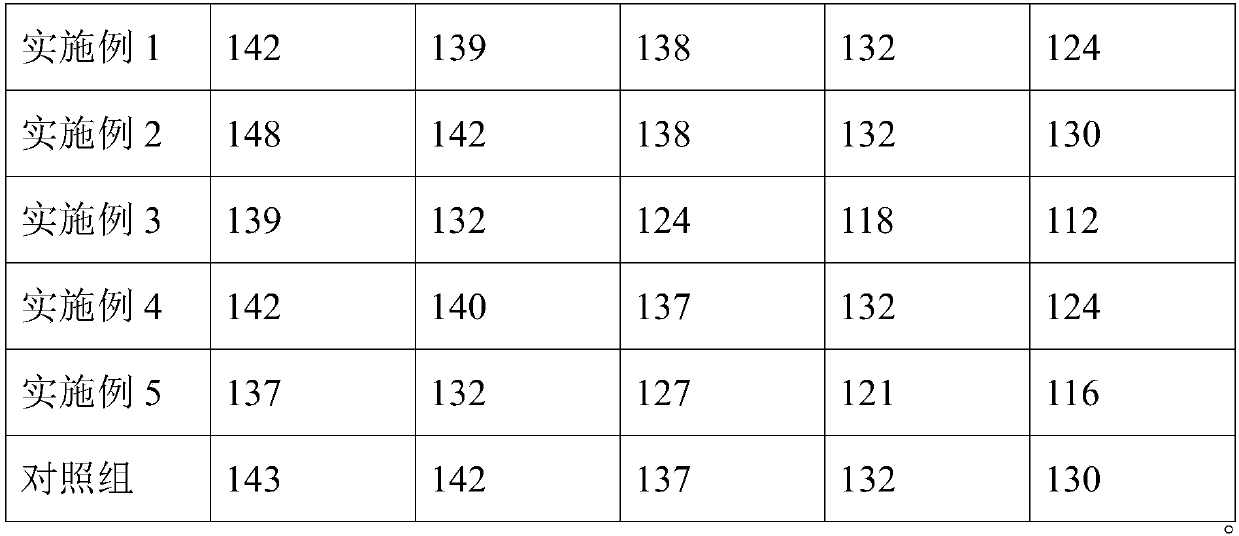

Pure Chinese medicinal composition for improving egg yolk color and preparation method thereof

InactiveCN102579681ANo pollution in the processNo drug residueDrug compositionsPlant ingredientsYolkPharmacy medicine

The invention relates to a pure Chinese medicinal composition for improving egg yolk color, which is prepared by mixing the following components in parts by weight: 15 to 35 parts of red pepper, 20 to 60 parts of pine needle, 15 to 35 parts of kelp, 15 to 35 parts of clover, 10 to 25 parts of calendula officinalis, and 10 to 25 parts of marigold. The pure Chinese medicinal composition has the beneficial effects of reasonable prescription, simpleness in preparation, no pollution, no toxic or side effect and no medicine residues; an advanced superfine grinding technology is adopted in the preparation process, so that effective components of the medicaments can be quickly and sufficiently released, the bioavailability of effective components is greatly improved, and the adding dosage is low with only 0.01 percent which is far lower than that of a common Chinese medicinal product. Clinical application proves that: the pure Chinese medicinal composition has special effect in improving the egg yolk color, and has wide application prospect.

Owner:QINGDAO LVMAN BIOLOGICAL ENG

Method for preparing mercaptopropyltriethoxysilane through constant-pressure low-temperature aqueous phase

ActiveCN104926854AAvoid demandingShort reaction timeGroup 4/14 element organic compoundsPh regulationDistillation

The invention relates to a method for preparing mercaptopropyltriethoxysilane through a constant-pressure low-temperature aqueous phase. The invention discloses a preparation method of a gamma-mercaptopropyltriethoxysilane coupling agent. The method is characterized by comprising the following steps of under constant pressure, gamma-chloropropyltriethoxysilane and crown ether are stirred uniformly, a sodium hydrosulfide solution and a pH regulation agent are matched and are added to a mixed solution drop by drop many times, and after the sodium hydrosulfide solution and the pH regulation agent are added drop by drop and when the content of the gamma-chloropropyltriethoxysilane is lower than 1.5%, the reaction is stopped; reaction liquid is cooled and separated so as to obtain crude products, distillation under reduced pressure is performed on the obtained crude products, and condensate of which the gas-phase temperature is higher than or equal to 78 DEG C is collected to be used as finished products. The method disclosed by the invention has the advantages that the technological production is stable, the cost is low, and synthetic products are high in purity, transparent in color and stable in storability.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Preparation process of white cement

The invention discloses a preparation process of white cement, comprising the following steps of: taking the components in percentage by weight: 70-75% of limestone with calcium content of 50-70%, 20-25% of siliceous stone with silicon content of 9-10% and 5% of pyrophylite with chlorinity of 50-70%; respectively crushing and grinding the limestone, the siliceous stone and the pyrophylite to formgrains of 250-300 meshes in size of 2-4cm; homogenizing for 68-78h, mixing and secondarily homogenizing for 72-80h; then firing at the temperature of 1500-1800 DEG C for 12-48h; bleaching raw materials by using a bleacher; enabling a formed mixture to enter into a deslagging water tank; depositing, filtering, drying and homogenizing for 72-80h to form a homogenized dried material; adding 6% of gypsum and 94% of the homogenized dried material; and grinding to 300-340 meshes to obtain a finished product. The process provided by the invention has the advantages of simplicity, easiness for mastering and reduction of production cost and labor consumption, and the white cement has good color and luster and high strength, reduces resource waste and saves production cost.

Owner:HENAN WANXING SPECIAL CEMENT

Method for covering plastic film on surface of wood or plastic special-shaped substrate

InactiveCN101249740AAchieve full coverageFix damageLaminationLamination apparatusEngineeringPlastic film

The invention discloses a method for coating a plastic film on the surface of woody or plastic deformed basis material, which relates to a method for coating a plastic film. The method solves the problems that the prior method for coating a plastic film influences the exterior quality of a product, the cost of the paint spraying on the surface of the woody basis material is high, and the noxious substance volatilized from the paint is easy to pollute the environment. The inventice method has the following steps that: firstly, plastic heat shrinking material is made into a cylindrical film; secondly, vacuum suction plastic is sprayed on the surface of the woody or the plastic profile basis material; thirdly, the cylindrical film made of the plastic heat shrinking material in the step one is covered on the outer surface of the gummed woody or the gummed plastic profile basis material prepared in the step two; fourthly, the woody or the plastic profile basis material processed through the step three is put into a vacuum sucking and coating machine to perform the contraction and the vacuum sucking and coating, and then the woody or the plastic profile basis material with the plastic film covered on the surface is obtained. The surface of the woody or the plastic profile basis material covered in the invention has no seam, the coating method is simple, and the production cost and the production cycle are reduced.

Owner:施永志

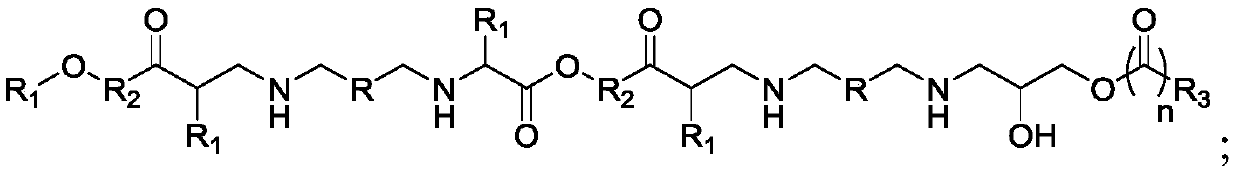

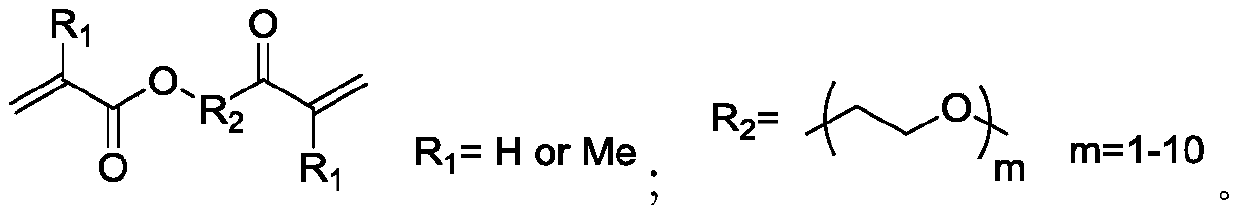

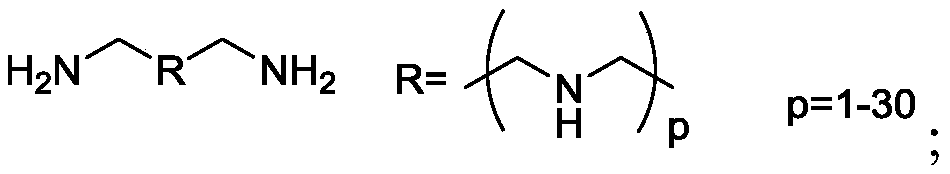

Solvent-free waterborne epoxy curing agent and preparation method thereof

ActiveCN111333818ASimple preparation processReduce energy consumptionEpoxy resin coatingsPolymer scienceSolvent free

The invention discloses a solvent-free waterborne epoxy curing agent and a preparation method thereof, and relates to the technical field of epoxy curing agents. According to the solvent-free waterborne epoxy curing agent disclosed by the invention, a hydrophilic group and an oleophylic group are introduced through a molecular structure design, and the HLB value is well balanced by controlling thelengths of the hydrophilic group and the oleophylic group, so that the solvent-free self-emulsifying epoxy curing agent with high performance and low viscosity is obtained. According to the invention, an acrylate and amine Michael addition method is adopted, the structural arrangement is standard, and a rapid reaction can be carried out at medium and low temperatures, so that a high-solid low-viscosity product is obtained.

Owner:深圳前海飞扬化工有限公司

Blue silk sericin lyophilized ball and preparation method thereof

InactiveCN110433086AImprove permeabilitySuppress generationCosmetic preparationsToilet preparationsSILK SERICINPullulan

The invention relates to a blue silk sericin lyophilized ball, which comprises the following components by mass percentage: 10%-30% of silk sericin, 0.1%-10%of sodium hyaluronate (100-1.4 million Daltons), 25%-35% of mannitol, 10%-20% of pullulan polysaccharide, and 0.2%-1.5% of tripeptide-1 copper, and sterile deionized water is added to 100%. A preparation method comprises the following steps: (1) weighing sodium hyaluronate, mannitol, pullulan polysaccharide and the sterile deionized water, and heating the materials to 70-80 DEG C to prepare a uniform transparent solution; (2) when the temperature of the solution in step 1 is reduced to 25-35 DEG C, adding silk sericin and tripeptide-1 copper, and uniformly stirring the materials; (3) freezing a solution aseptically and shaping the material into balls; and (4) transferring the ice balls to a lyophilizer that is pre-sterilized and frozen to 40-50 DEG C. The blue silk sericin lyophilized ball solves the problems of poor molding effect, easy shrinkage, easy fragmentation, and single color of the existing lyophilized balls.

Owner:广州市玉鑫化妆品有限公司

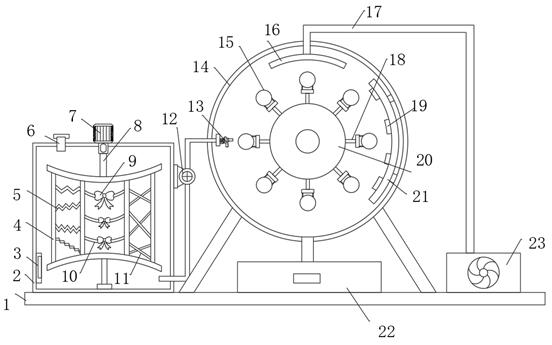

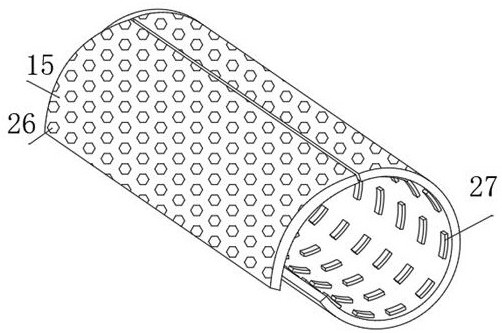

Grape air-drying device for grape wine processing

InactiveCN111808698AHigh lusterQuality improvementWine preparationFood treatmentProcess engineeringGrape wine

The invention belongs to the technical field of wine processing, and particularly relates to a grape air-drying device for grape wine processing. Aiming at the problems of poor processing quality of grape wine, the invention provides the following scheme. The device comprises a bottom plate, a mixing box, an air drying tank and an air heater are arranged on the outer wall of the top of the bottomplate, a hot air disc is arranged on the inner wall of the top of the air drying tank, the inner wall of one side of the hot air disc and the output end of the air heater are provided with a same first guide pipe, a liquid spraying disc is arranged on the inner wall of one side of the air drying tank, and atomization nozzles distributed at equal intervals are arranged on the outer wall of one sideof the liquid spraying disc. The invention discloses the grape wine processing device convenient to fermentation. By arranging a grape placing frame, a water pump, the atomization nozzles, filteringholes and blocking blocks, the grape placing frame is of a cylindrical structure, the cylindrical structure fits the grape structure better, damage to the placing frame and grapes can be reduced, thegrapes can be placed in a separated mode through the arrangement of the blocking blocks, and damage caused by mutual collision when the grapes rotate is avoided.

Owner:姜永全

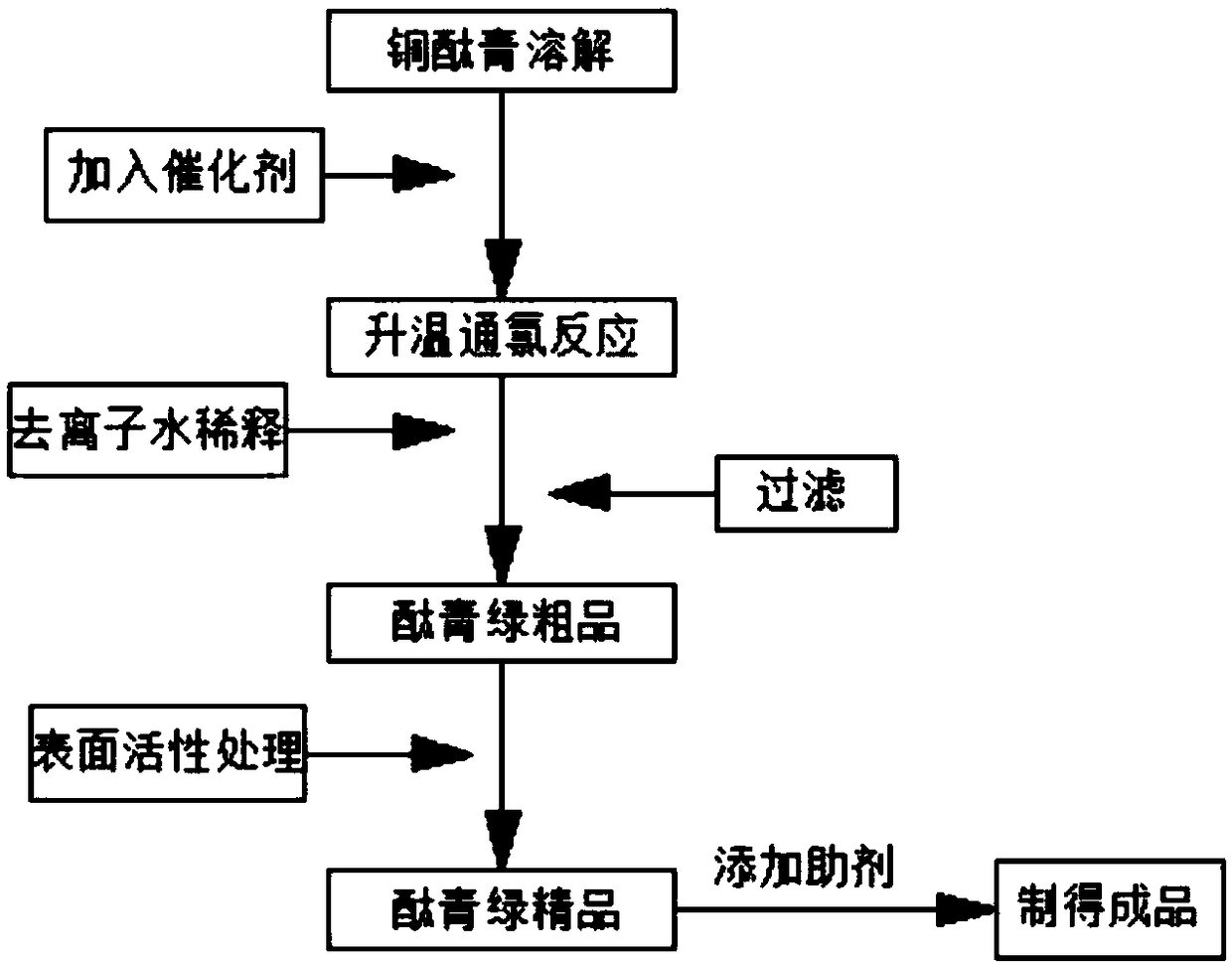

Preparation method of high energy-saving and environment-friendly type phthalocyanine green pigment

InactiveCN108084729ALow viscosityFull color developmentOrganic chemistryPorphines/azaporphinesWater basedHigh energy

The invention discloses a preparation method of high energy-saving and environment-friendly type phthalocyanine green pigment in the field of preparation of organic pigment. The method is characterized by comprising the following specific steps: S1, copper phthalocyanine is pre-dissolved, 6-8 g of a catalyst is added, and the solution is heated to 100-120 DEG C for a chlorine introduction reaction; S2, a crude phthalocyanine green product is obtained after filtering; S3, then 5-7 g of a surfactant is added, stirring is performed sufficiently, an organic medium is removed by steam distillation,and a fine phthalocyanine green product is obtained after filtering and drying; S4, the fine phthalocyanine green product is mixed with 400-600 ml of water-based resin, the mixture is uniformly stirred, and the phthalocyanine green pigment is prepared. Power consumption for temperature increasing is reduced by increasing atmospheric pressure and reducing reaction temperature, meanwhile, system viscosity can be reduced, sufficient color development of the pigment is realized, color and luster are improved, acidic sewage is not discharged in the preparation process, and environmental pollutionis avoided.

Owner:ZHONGSHAN DEGAOXING INTPROP CENT LLP

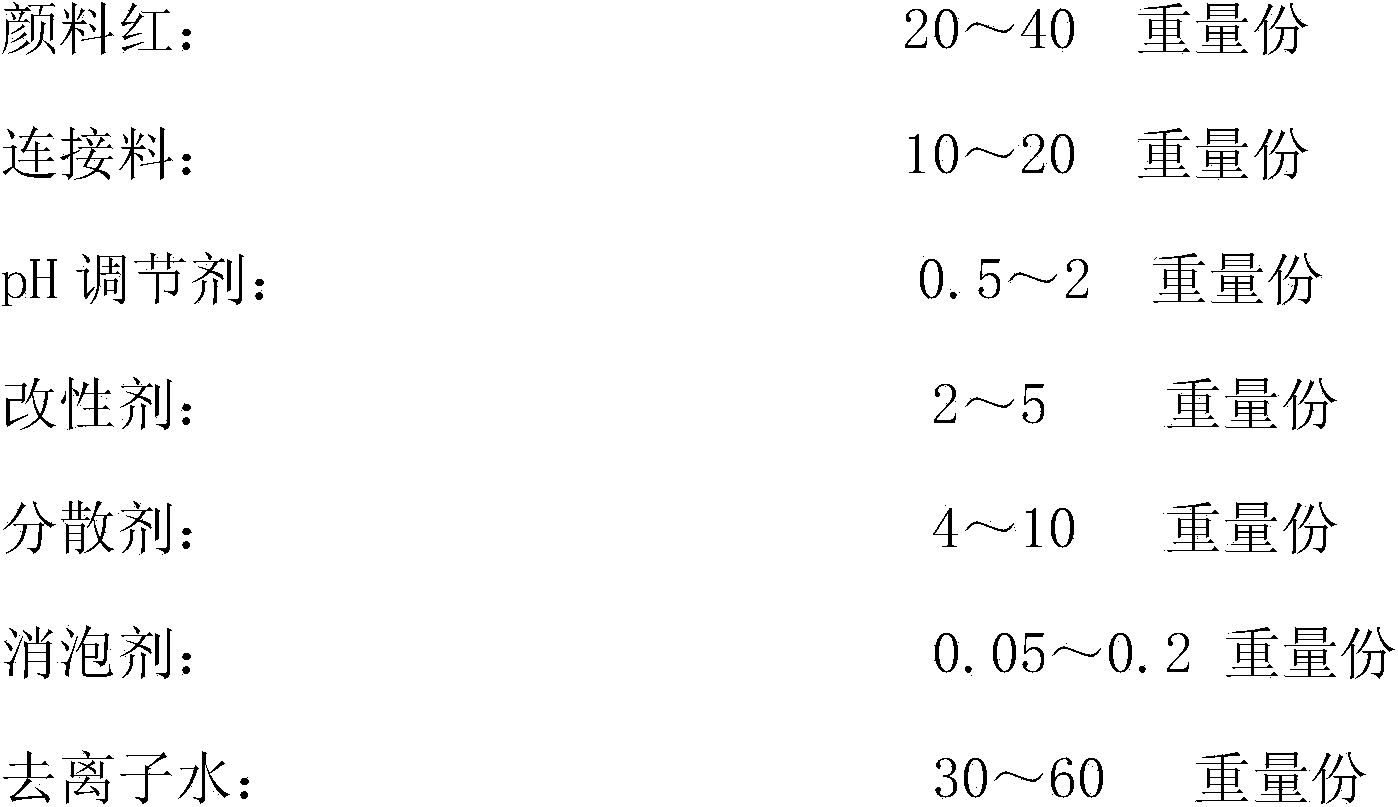

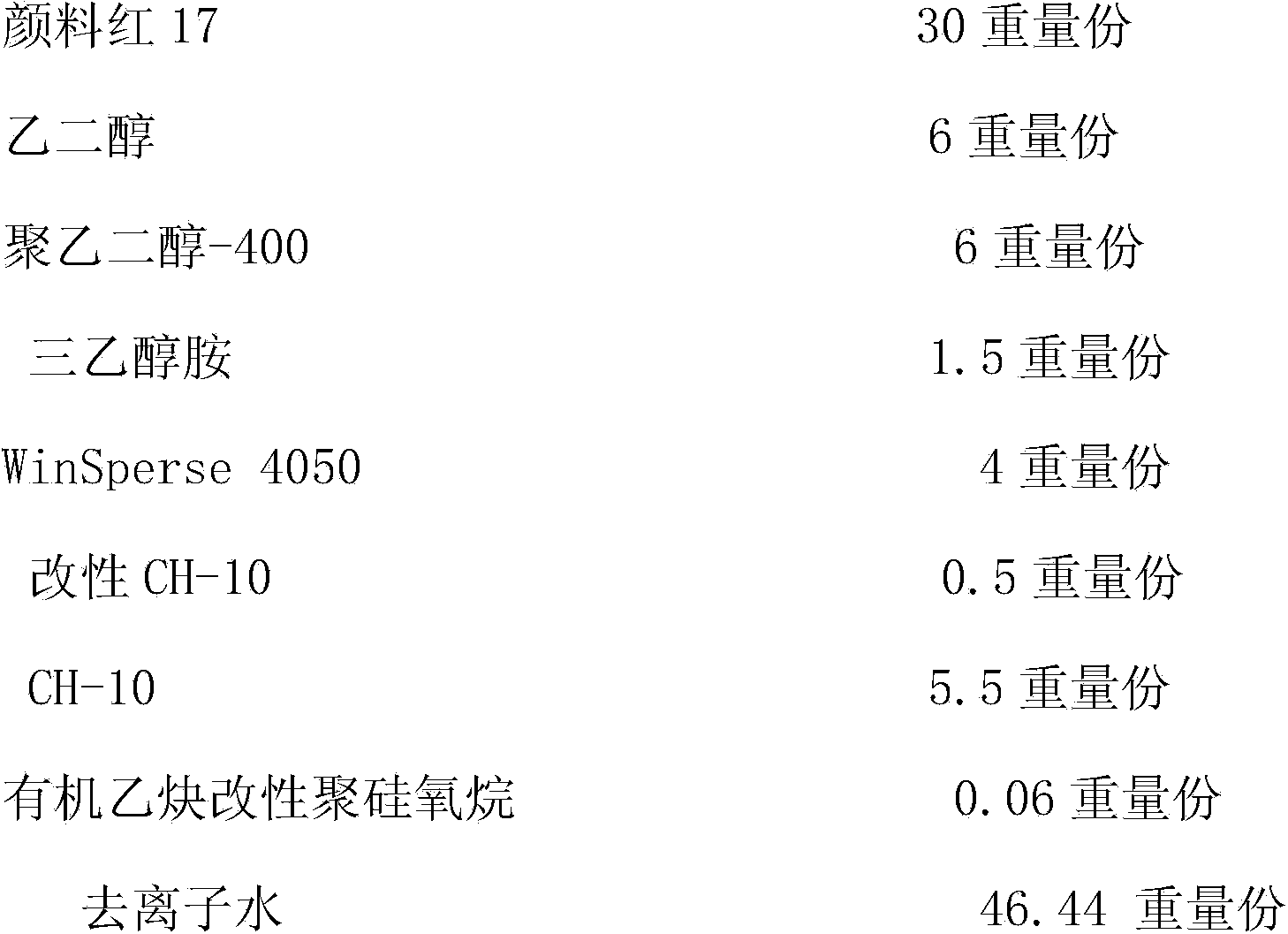

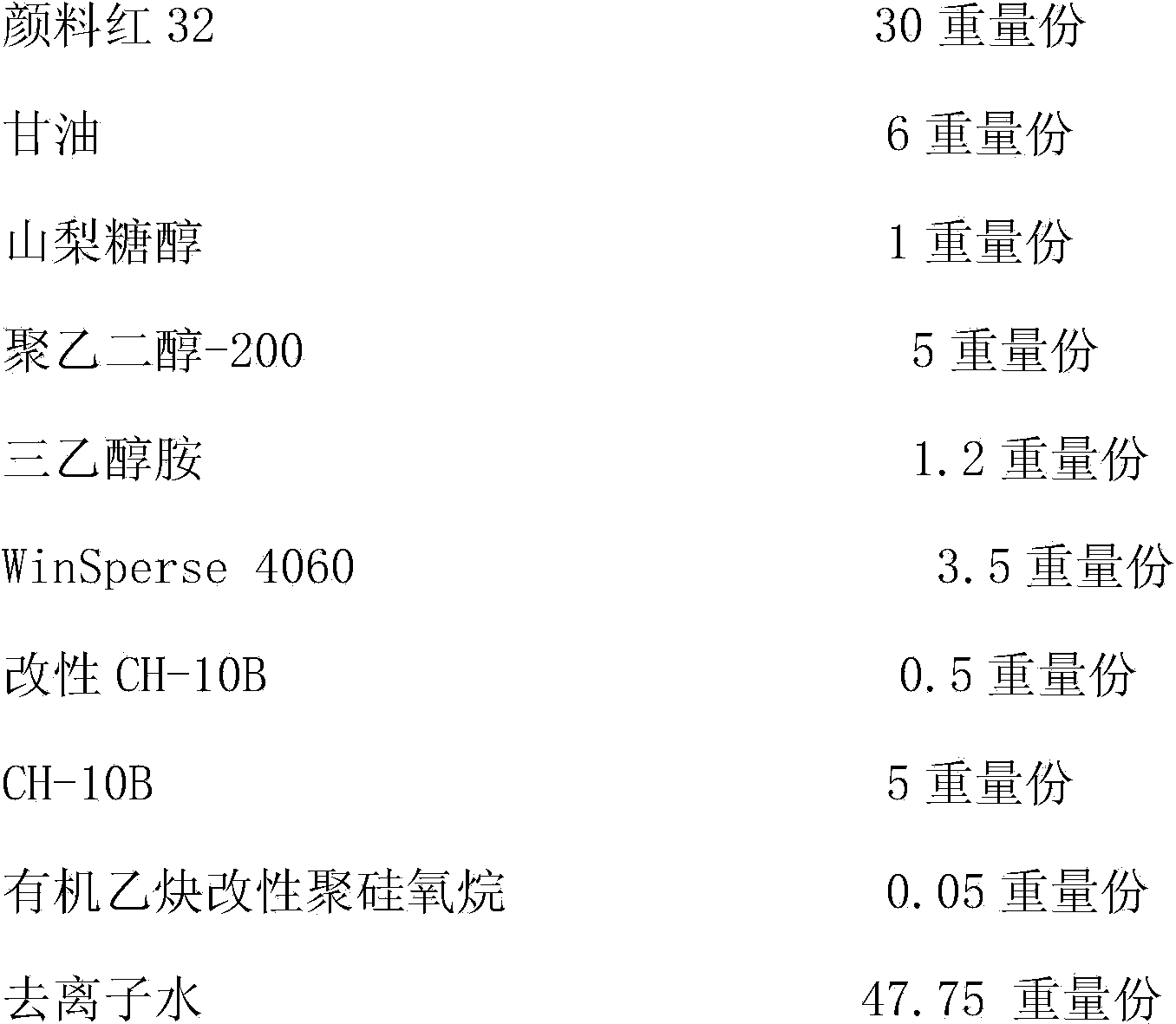

Red pigment paste with ultrahigh dispersity

The invention relates to red pigment paste with ultrahigh dispersity. The red pigment paste comprises the following raw materials in parts by weight: 20 to 40 parts of pigment red, 10 to 20 parts of binder, 0.5 to 2 parts of pH regulator, 2 to 5 parts of modifier, 4 to 10 parts of dispersing agent, 0.05 to 0.2 part of defoaming agent, and 30 to 60 parts of deionized water. The paste is mainly applicable to the preparation of red ink for a gel pen or the preparation of ink-jet printing ink. The paste has the main characteristics of high solid content, low consumption of the dispersing agent, uniformly distributed particle size, high stability, and excellent compatibility with follow-up ink systems.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Method for preparing light reflecting leather

ActiveCN109609707AFully dispersedAdequate responseTanning treatmentLeather/skins/hides/pelt chemical treatment apparatusSecondary colorChemistry

The invention discloses a method for preparing light reflecting leather, and belongs to the technical field of leather. The method for preparing the light reflecting leather comprises the following steps that a leather base is put in a drum, after tempering, retanning velvet improving, neutralizing, pre-adding of ester, dyeing, ester adding, color fixing, product surface treatment and secondary treatment are sequentially treated, then the light reflecting leather is obtained, wherein secondary treatment comprises the following steps of secondary tempering, secondary adding of ester, secondarydyeing, secondary color fixing, drying and milling. The prepared light reflecting leather is high in velvet feeling and high in softness.

Owner:漳州香洲皮革有限公司

Antioxidative brightening agent for leather sofa

InactiveCN104927669AGood anti-oxidation and anti-foulingHigh lusterPolishing compositionsLeather surface finishingAnoxomerSODIUM DODECYL BENZENE SULFONATE

The invention discloses an antioxidative brightening agent for a leather sofa. The antioxidative brightening agent is prepared from the following raw materials in parts by weight: 8 to 14 parts of white mineral oil, 4 to 6 parts of 100-mesh bee wax, 5 to 8 parts of methylparaben, 12 to 22 parts of dibutyl phthalate, 3 to 4 parts of amino silicon oil, 6 to 10 parts of di-tallow ethoxycarbonyl hydroxyethyl methyl ammonium methylsulfate, 5 to 7 parts of sodium dodecyl benzene sulfonate, 2 to 4 parts of magnesium chloride, 3 to 8 parts of carnauba wax, 4 to 7 parts of fatty alcohol-polyoxyethylene ether, 6 to 9 parts of methyl sulfate methyl ammonium and 5 to 7 parts of antioxidant. The antioxidative brightening agent has the beneficial effects that the antioxidative brightening agent the leather sofa has good antioxidative and anti-fouling functions; the antioxidative brightening agent can effectively perform sterilization, improve color and luster of leather, improve appearance, as well as can make leather to be soft and elastic.

Owner:青岛海蓝海洋复合功能材料科技有限公司

Production process of anti-static flame-retardant fabric

InactiveCN106906554AFlame retardantGood anti-static and flame-retardant effectHeating/cooling textile fabricsDyeing processYarnEngineering

The invention discloses a production process of anti-static flame-retardant fabric. The production process comprises the following steps of spinning, weaving and post processing. Flame-retardant acrylic fibers and dacron conductive fibers are combined in a twisting mode to obtain compound yarns A, then the compound yarns A are dyed to obtain dyed yarns A, and the dyed yarns A are added in weaving, so that woven fabric A has flame-retardant and anti-static effects; meanwhile, the interval between two adjacent dyed yarns A is 3 cm, so that the fabric A has the good anti-static and flame-retardant effects; the color and hand feeling of the fabric A can be improved by calendar finish and positioning finish.

Owner:诸暨航丰针纺织有限公司

Nutritional vermicelli easy to be tasty, and production method thereof

The invention discloses a nutritional vermicelli easy to be tasty. The nutritional vermicelli easy to be tasty comprises, by weight, 70-100 parts of sweet potato flour, 10-30 parts of fresh fish flesh, 5-10 parts of mung bean flour, 2-5 parts of cassava flour, 2-5 parts of Radix Puerariae powder, 5-10 parts of corn flour, 2-3 parts of black rice bran, 2-3 parts of lotus root starch, 0.05-0.1 parts of sa-hao seed gum, 1-2 parts of konjac glucomannan, 0.2-0.5 parts of edible salt, and 50-110 parts of water. The invention also discloses a production method of the nutritional vermicelli easy to be tasty. Sweet potato, bean, cereal, plant starch and fish flesh proteins are added, so the nutrition is balanced; and control of the reasonable ratio of raw materials, keeping of the reasonable water content of dough and adjustment of extruding and cooking parameters and the process flow in the making process make the vermicelli have certain rehydration, solve the difficulty tasty problem of the vermicelli, improve the eating mouthfeel, and enhance the market competitiveness of the vermicelli.

Owner:何高俊

Processing method for improving tilia bast fiber knitting property

The invention belongs to the technical field of tilia bast fiber processing and particularly relates to a processing method for improving tilia bast fiber knitting property. The processing method comprises the following specific methodssteps: performing boiling, freezing and steam and treating fluid dipping treatment on tilia bast fiber and performing temperature-change drying, ultrasonic, variable pressure and constant-temperature drying treatment. In the step of performing boiling, freezing and steam and treating fluid dipping treatment on tilia bast fiber, degradation of hemicelluloses in the tilia bast fiber is effectively inhibited; as the hemicelluloses has an adhesion effect in cell walls, the bonding strength among the tilia bast fiber is enhanced, and the toughness and the breaking resistance of the tilia bast fiber are improved; furthermore, a the color and luster degree of the tilia bast fiber is effectively improved, and sun resistance of the tilia bast fiber is enhanced. In the step of performing temperature-change drying, ultrasonic, variable pressure and constant-temperature drying treatment, conduction resistance of moisture in the tilia bast fiber is reduced, permeability of the tilia bast fiber is improved, the combining capacity between components of the treating fluid and tilia bast fiber cellulose molecules is enhanced, hygroscopicity of the tilia bast fiber is reduced, and dimensional stability of the tilia bast fiber is improved; furthermore, breeding of mould and putrefying bacteria is effectively inhibited, service life of the tilia bast fiber is prolonged, and use quality of the tilia bast fiber is improved.

Owner:阜南县宏达工艺品厂

Method for preparing Acer truncatum Bungea seed oil

InactiveCN110106017AFast heatingQuality improvementFatty-oils/fats refiningFatty-oils/fats productionProduction rateMaterials preparation

The invention provides a method for preparing Acer truncatum Bungea seed oil. The method comprises the following steps: material preparation, cleaning, drying, peeling, microwave drying, squeezing, filtration, refining, alkali refining, decolorizing and deodorizing. The microwave heating is used to heat Acer truncatum Bungea seed kernels in order to improve the heating speed and achieve uniform heating and small heat loss, so the process time is shortened, the production rate is increased, and the cost is reduced; the refining step is carried out by centrifuging and extracting the squeezed crude Acer truncatum Bungea seed oil by using a centrifuging extraction machine and filtering out mixed impurities in the crude Acer truncatum Bungea seed oil, so the quality of the finished Acer truncatum Bungea seed oil is improved; the alkali refining step is carried out to remove free fatty acids, unsaponifiable matters and residual phospholipid in the oil, so the purity of the finished Acer truncatum Bungea seed oil is further improved; and the decolorizing step is carried out to remove pigment substances in the oil, so the color of the finished Acer truncatum Bungea seed oil is improved.

Owner:南京康之源农业科技发展有限公司

Optical function modified polyurethane composite paint and preparation method thereof

InactiveCN110564277AHigh glossHigh lusterLuminescent paintsPolyurea/polyurethane coatingsCellulose acetateToxic material

The invention discloses optical function modified polyurethane composite paint. The optical function modified polyurethane composite paint is prepared from, by mass, 25-30% of polyurethane, 12-17% ofurea-formaldehyde resin, 8-11% of cellulose acetate, 4.2-4.8% of polyvinyl butyral, 3.6-4.1% of ethanol, 2.7-3.5% of anhydrous diethyl ether, 1.5-2.5% of fumed silica, 1.2-2.3% of dioctyl phthalate, 6-12% of luminescent powder, 2-5% of dispersing agents and the balance being precipitating agents. The invention further discloses a preparation method of the optical function modified polyurethane composite paint. The method comprises the following steps of performing reacting and filtrating, performing heating and stirring, performing sputtering treatment, performing cleaning, performing high-speed stirring, and performing ultrasonic treatment. According to the optical function modified polyurethane composite paint and the preparation method thereof, the formula is more reasonable, the glossiness and the color degree of the paint are obviously improved, the addition of toxic substances is reduced to a maximum extent, that the physical health of a user is free of being damaged is ensured,the environmental friendliness is high, and the paint has larger market competitiveness; and moreover, the preparation method is simpler and low in equipment requirement, and has a good popularizationeffect.

Owner:HUBEI UNIV OF ARTS & SCI

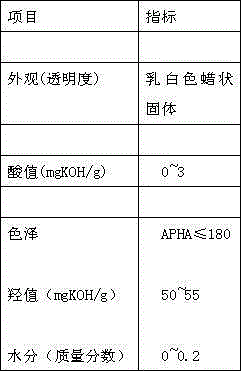

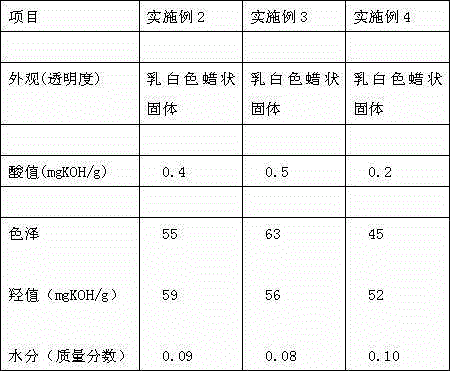

Ultralow-chroma PEHA for TPU and preparation method thereof

The invention discloses ultralow-chroma PEHA for TPU and a preparation method thereof. PEHA is prepared from 50-70% of adipic acid, 10-25% of 1,6-hexanediol, 25-45% of ethylene glycol, 0.3-0.5% of high-temperature antioxidant and 0.01-0.1% of catalyst. Both the raw material formula and the preparation method are improved, the feed quantity and feed time period of the raw materials are regulated, meanwhile, the high-temperature antioxidant-phosphite ester is added to improve the temperature tolerance of original raw materials, and therefore the chroma of produced PEHA resin is obviously increased compared with that of resin commonly used in the market.

Owner:JIAXING ROCK CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com