Patents

Literature

153 results about "1,6-Hexanediol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1,6-Hexanediol is an organic compound with the formula (CH₂CH₂CH₂OH)₂. It is a colorless water-soluble solid.

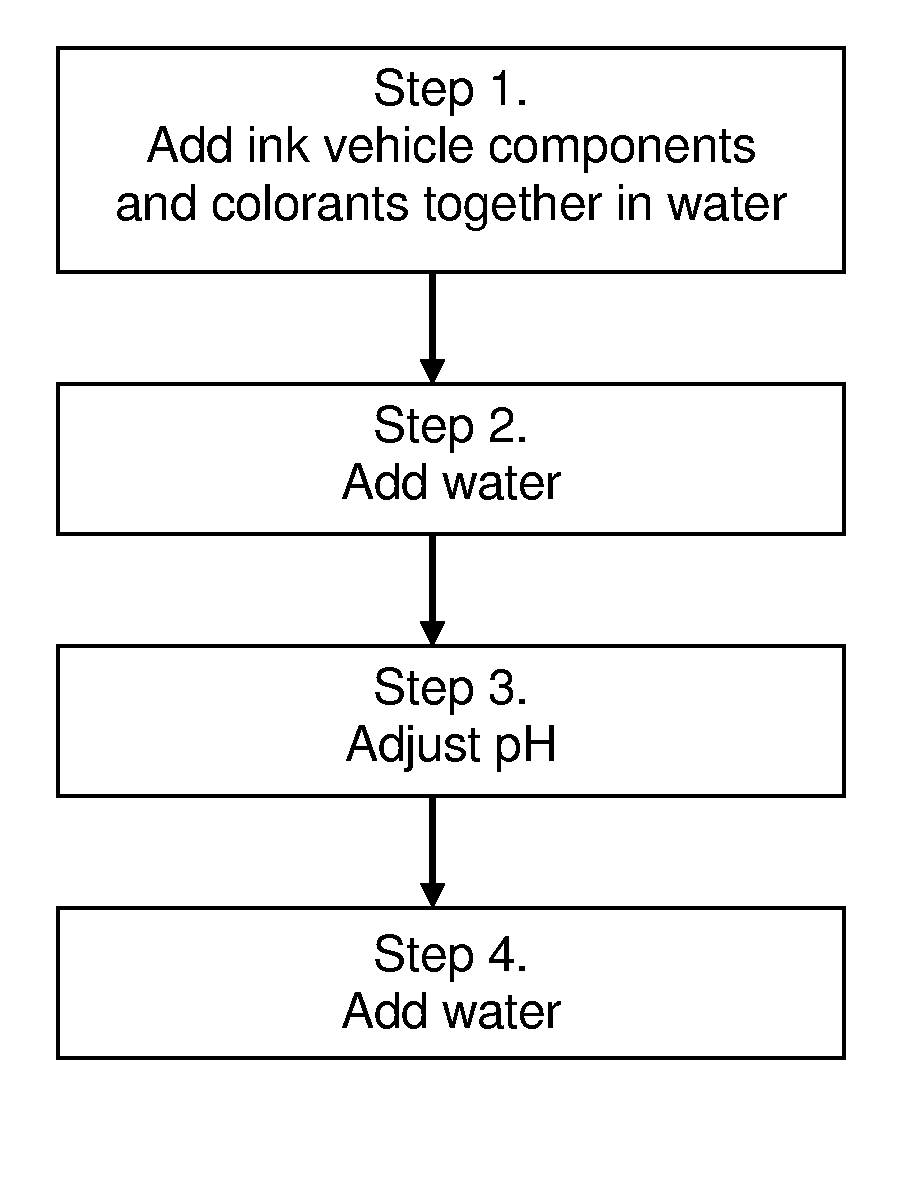

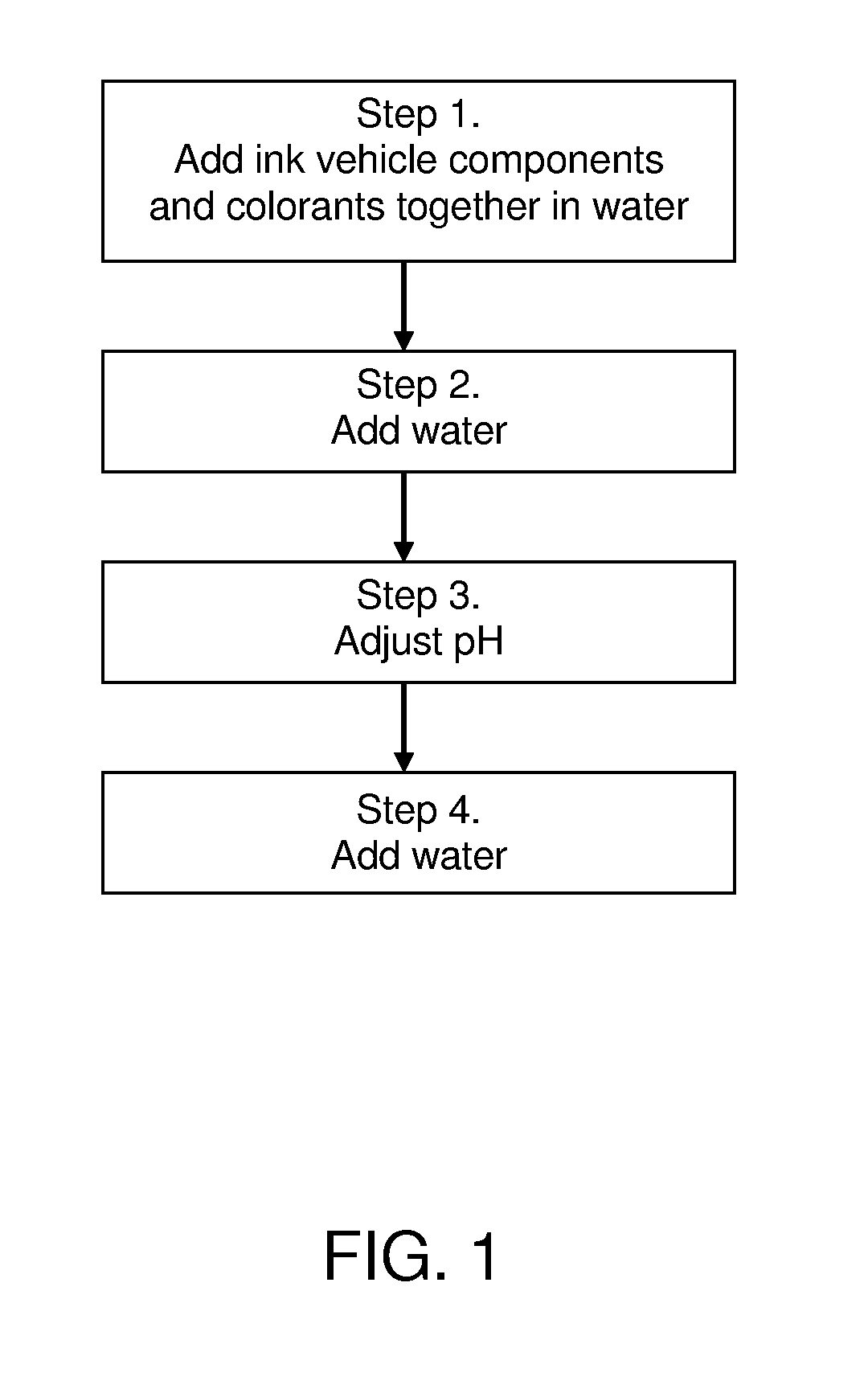

Ink for ink jet recording, ink set for ink jet recording, method for ink jet recording, ink cartridge for ink jet recording, ink jet recording apparatus and recorded article

InactiveUS20030107632A1Excellent ejection stabilityGood storage stabilityMeasurement apparatus componentsInksImaging qualityEngineering

An ink for ink jet recording and an ink jet recording method which realize an image quality of laser printer on a plain paper in a one-pass printing mode under conditions of a volume of an ink droplet ejected being 5 to 43 Pico liter, a velocity of an ink droplet being 6 to 20 m / sec, frequency of 1 kHz and resolution of 300 dpi or more. The ink for ink jet recording is a penetrating type ink which comprises (1) at least one humectant selected from glycerin, 1,3-butandiol, triethyleneglycol, 1,6-hexanediol, propyleneglycol, 1,5-pentanediol, diethyleneglycol, dipropyleneglycol, trimethylolpropane and trimethylolethane, (2) colorant contained in the amount of 6 % by weight or more, (3) a polyol having 8 to 11 carbon atoms and glycolether, and an anionic surfactants or non-ionic surfactants, the ink has viscosity of 5 mPa.s or more at 25° C. and a surface tension of 40 mN / m or less.

Owner:RICOH KK

High-quality strawberry planting dedicated slow-release compound fertilizer

InactiveCN104030800AImprove the phenomenon of single fixationGood release effectFertilizer mixturesMicrobial agentGluconates

The invention relates to the compound fertilizer field, and particularly relates to a high-quality strawberry planting dedicated slow-release compound fertilizer. The fertilizer is prepared from the following raw materials in parts by weight: 10-15 parts of a 1250-2000 mesh diatomite, 4-5 parts of borax, 2-3 parts of ammonium molybdate heptahydrate, 10-12 parts of sodium humate, 20-25 parts of urea, 18-22 parts of potassium nitrate, 25-28 parts of organic compost, 2-4 parts of fish meal, 1-3 parts of sesame leaves, 8-10 parts of alfalfa meal, 15-18 parts of corn distiller grains, 2-4 parts of brine, 8-10 parts of an erythromycin fungi residue, 1-2 parts of an EM microbial agent, 4-6 parts of a fern root residue, 1-3 parts of nano silver, 1-2 parts of a semen ginkgo powder, 4-6 parts of 1,6-hexanediol diacrylate, 10-12 parts of an acrylic resin dispersion liquid, 1-2 parts of isocyanate, 1-2 parts of calcium stearoyl lactate, 2-4 parts of zinc gluconate, 6-8 parts of table vinegar, and 4-5 parts of an auxiliary agent. The compound fertilizer has multiple nutrients, is low in production cost and good in slow-release effect, allows double coating to be formed on the nutrients by utilizing diatomite and a coating agent in the process, also contains various trace elements, has no toxicity and no pollution, and is excellent in quality of planted strawberry and obvious in yield and income increasing effects.

Owner:ANHUI SUNSON CHEM

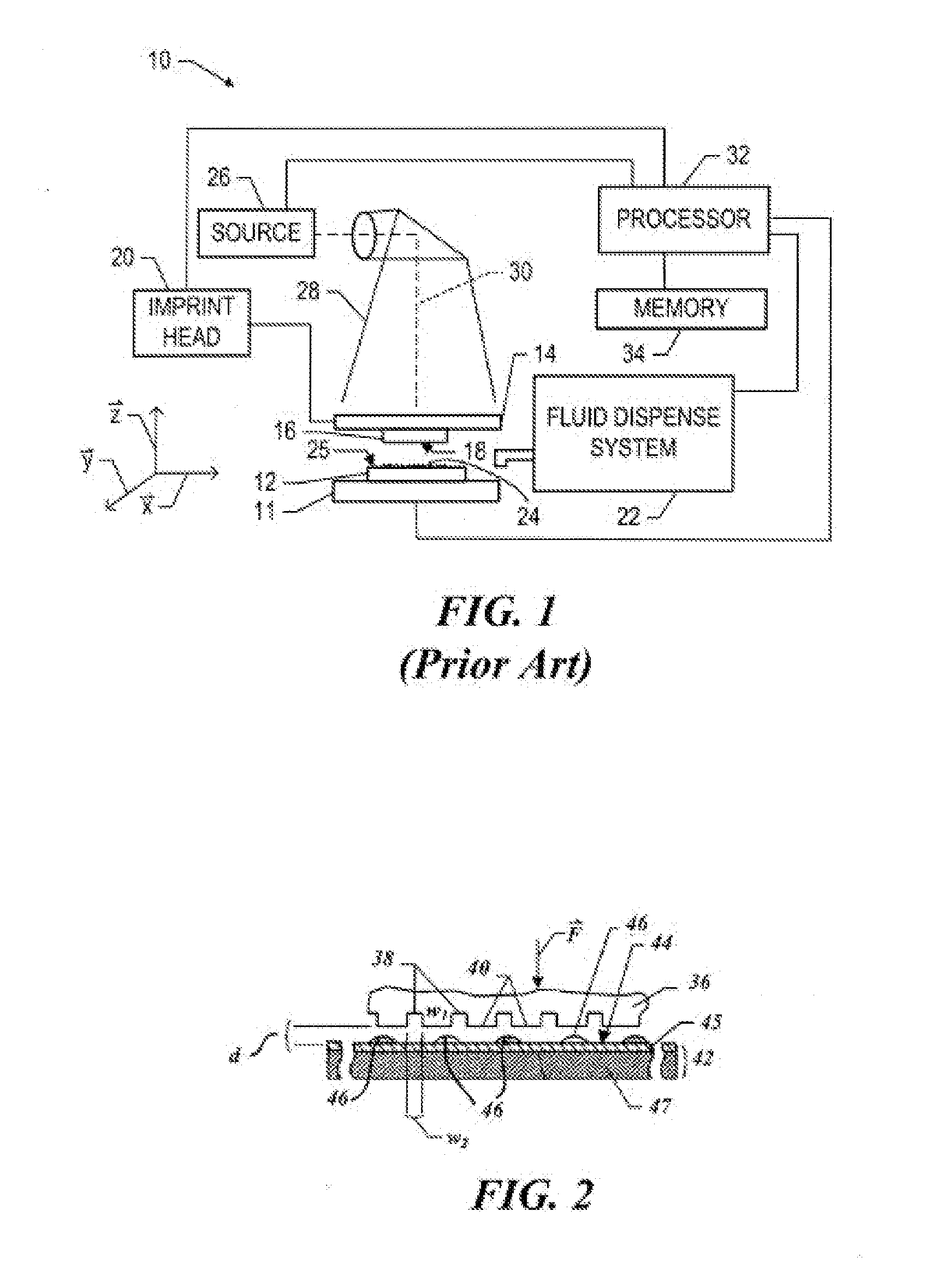

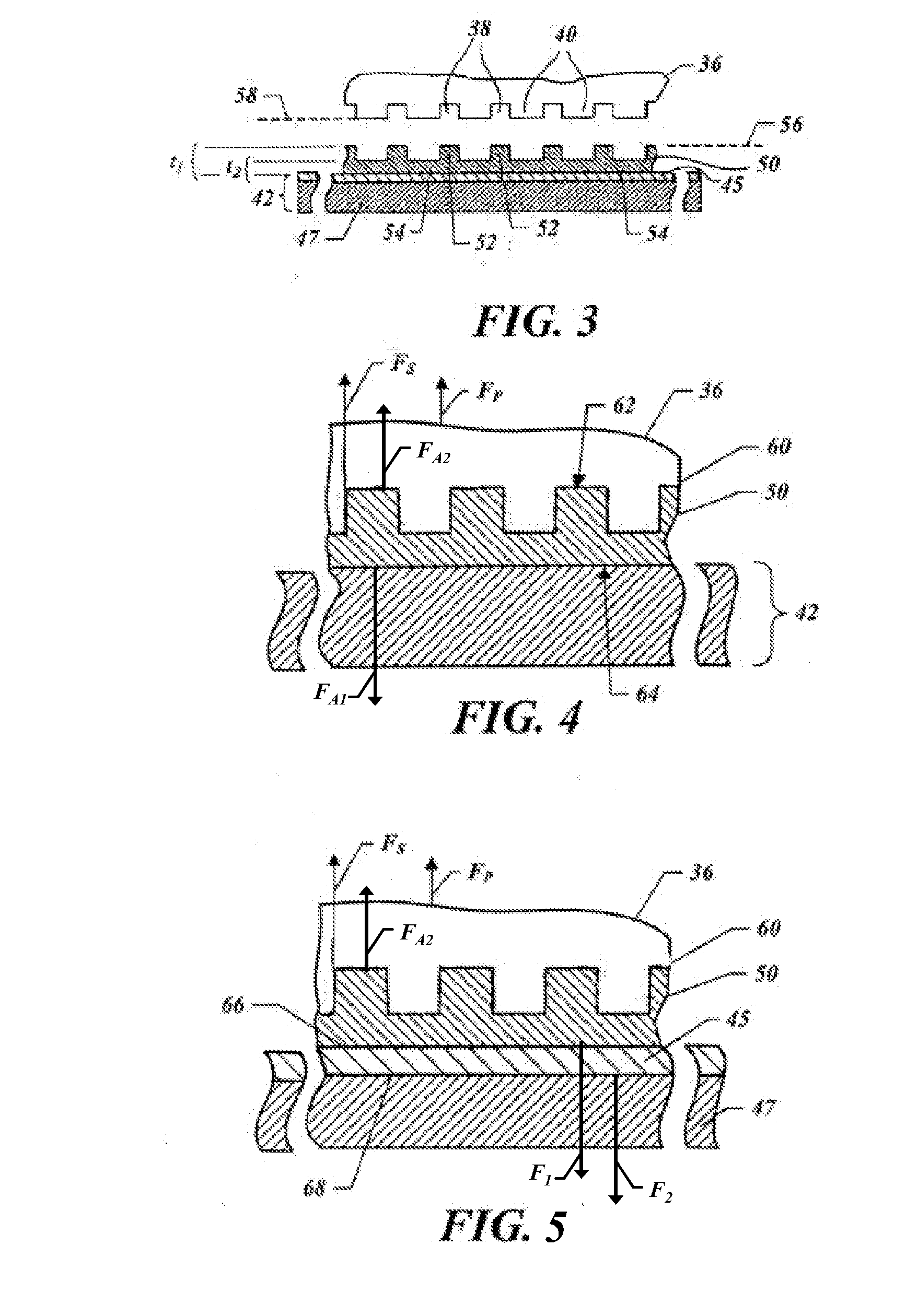

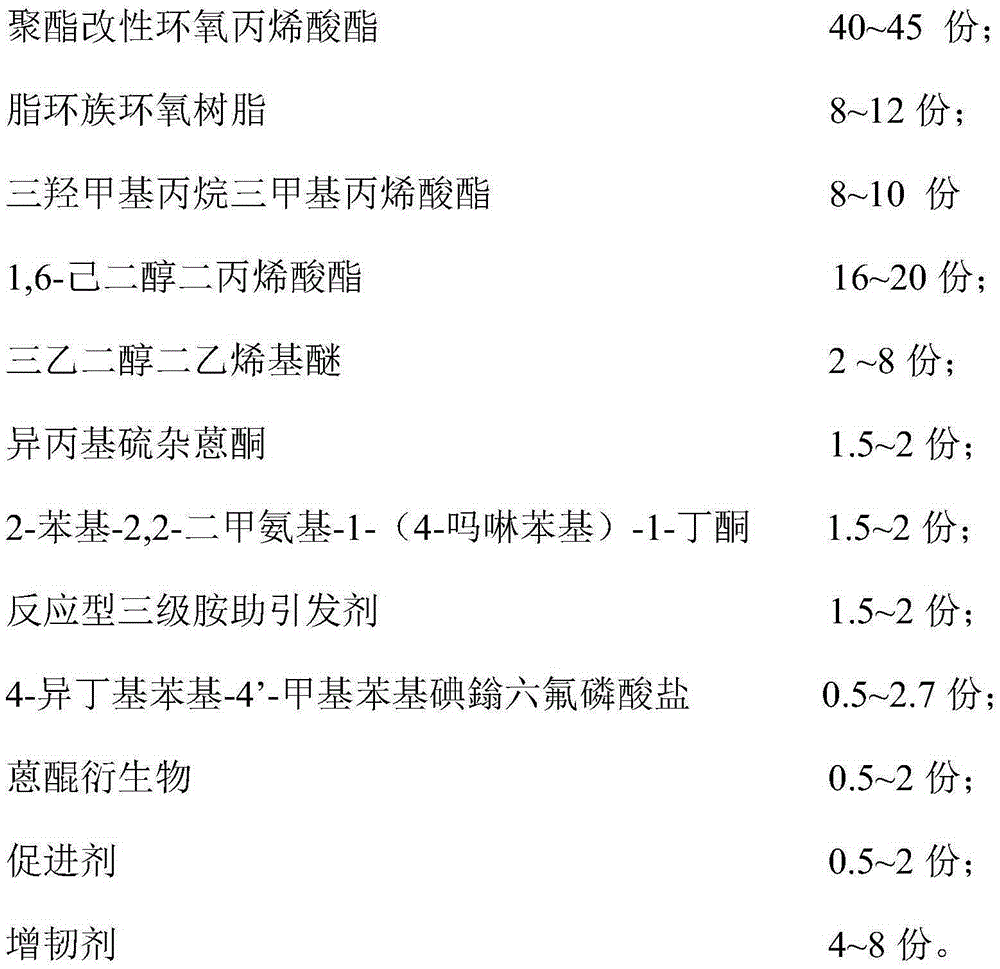

Methods and Compositions for Providing Preferential Adhesion and Release of Adjacent Surfaces

The present invention provides a method and composition for providing preferential adhesion and release of adjacent surfaces, that features solidifying a composition to form a solidified layer having first and second opposed sides, with the first side facing a first surface and being adhered thereto with a first adhesive forces and the second side facing the second surface and being adhered thereto with a second adhesive force, with the first and second adhesive forces establishing a predetermined preferential adhesion ratio. Generally, the first surface is covalently bonded to the first side and adhesion between the second side and the second surface occurs through Van der Waal forces. It has been found that the use of a fluorine group for enhancing the release properties (as a priori fluorinated release layer or a fluorinated release agent) is no longer needed for such method and composition. In one embodiment, the composition can be formed from an isobornyl acrylate component; an aliphatic urethane acrylate component; a 1,6-hexanediol diacrylate component; and a 2-hydroxy-2-methyl-1-phenyl-propan-1-one component. The first surface can be formed by polymerizing a compound formed from a multi-functional component that contains functional groups facilitating the formation of covalent bonds with the above mentioned polymerizable composition during an imprinting process, a cross-linking agent component, a catalyst component, and a solvent component. The second surface is usually a patterned or smoothed portion of a quartz mold.

Owner:MOLECULAR IMPRINTS

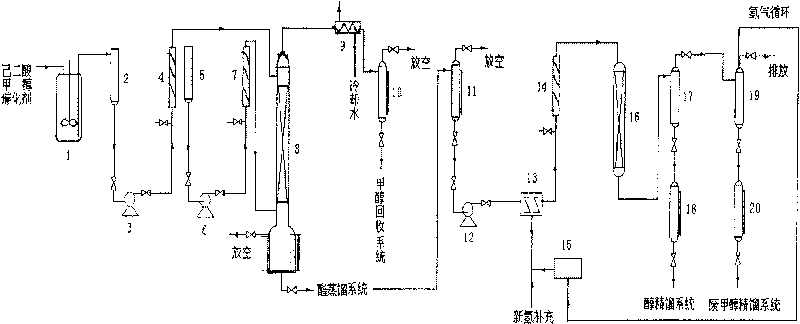

Method for preparing 1, 6-hexanediol by hydrogenating 1, 6-dimethyl adipate

InactiveCN102372604AHigh activityMild reaction conditionsOrganic compound preparationHydroxy compound preparationPolymer scienceHydrogen

The invention discloses a method for preparing 1, 6-hexanediol by hydrogenating 1, 6-dimethyl adipate, which is characterized by comprising the following steps and metering in parts by weight: 1000 to 10000 parts of oxide is as a carrier, 100 to 200 parts of heavy metal and 40 to 400 parts of co-catalyst metal salt are immersed for 12h at a room temperature to be pumped, filtered, vacuum dried and calcined to obtain a loaded heavy metal catalyst; 1 to 30 parts of the catalyst and 20 to 400 parts of solvent are filled into a reaction kettle, high-pure hydrogen is used for replacing oxygen in the reaction kettle for 3 to 5 times, the catalyst is activated for 2 to 8h under the temperature of 100 to 200 DEG C, pressure of 1.0 to 3.0 MPa and the blending speed of 200 to 1000 rpm, 50 to 200 parts of 1, 6-dimethyl adipate is filled into the reaction kettle after the reaction kettle is opened, the high-pure hydrogen is again used for replacing the oxygen inside the reaction kettle for 3 to 5 times to be reacted for 5 to 12h under the temperature of 150 to 220 DEG C, the pressure of 3.0 to 5.0 MPa and the blending speed of 500 to 1000rpm, and reaction solution is taken out to analyze; and the conversion rate is 60.0 to 99.9 percent, and the selectivity is 70.0 to 99.9 percent.

Owner:SICHUAN UNIV

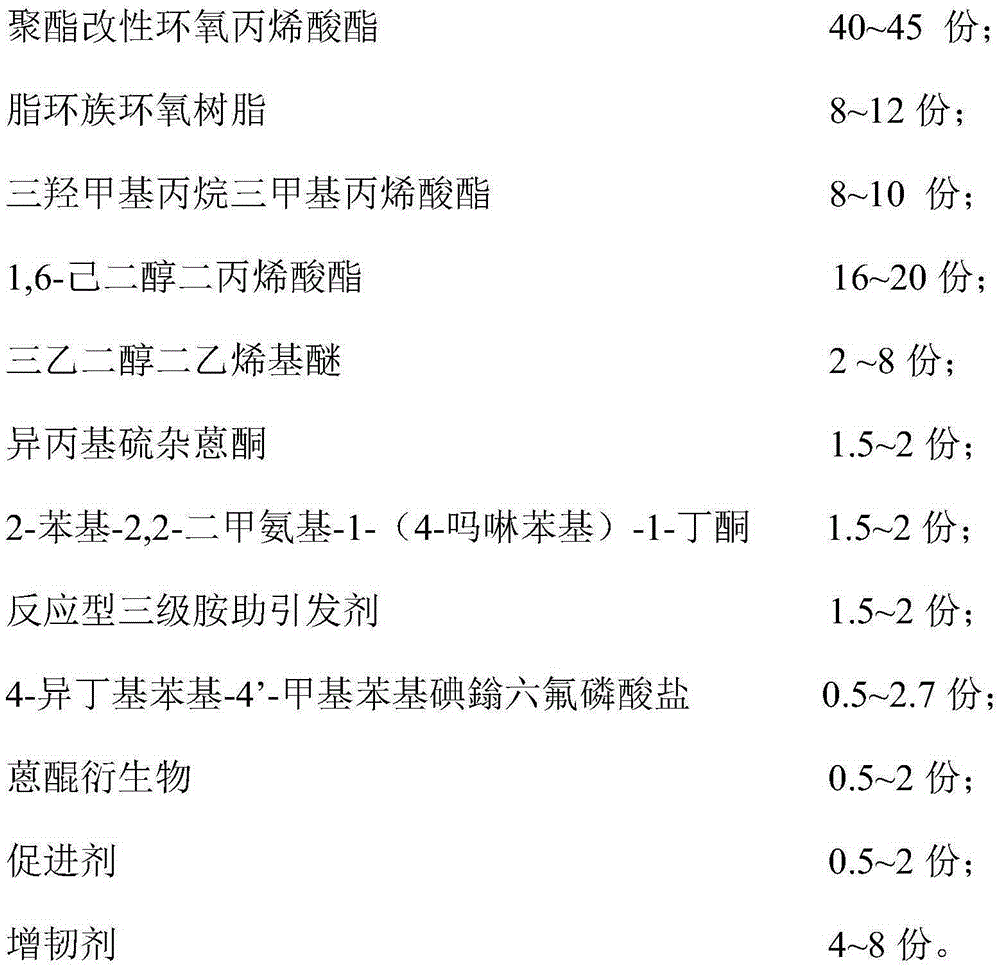

Light-cured three dimensional printing material and preparation method thereof

The invention discloses a light-cured three dimensional printing material and a preparation method thereof. The light-cured three dimensional printing material comprises, by mass, 40-45 parts of polyester modified epoxy acrylate, 8-12 parts of cycloaliphatic epoxy resin, 8-10 parts of trihydroxymethylpropyl trimethylacrylate, 16-20 parts of 1,6-hexanediol diacrylate, 2-8 parts of triethyleneglycol divinyl ether, 1.5-2 parts of isopropylthioxanthone, 1.5-2 parts of 2-phenyl-2,2-dimethylamino-1-(4-morpholinylphenyl)-1-butanone, 1.5-2 parts of a reactive tertiary amine co-initiator, 0.5-2.7 parts of 4-isobutylphenyl-4'-methylphenyliodonium hexafluorophosphate, 0.5-2 parts of an anthraquinone derivative, 0.5-2 parts of a promoter and 4-8 parts of a flexibilizer. Shaped parts made by using the light-cured three dimensional printing material have the advantages of low shrinkage, high toughness and high shaping precision.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +2

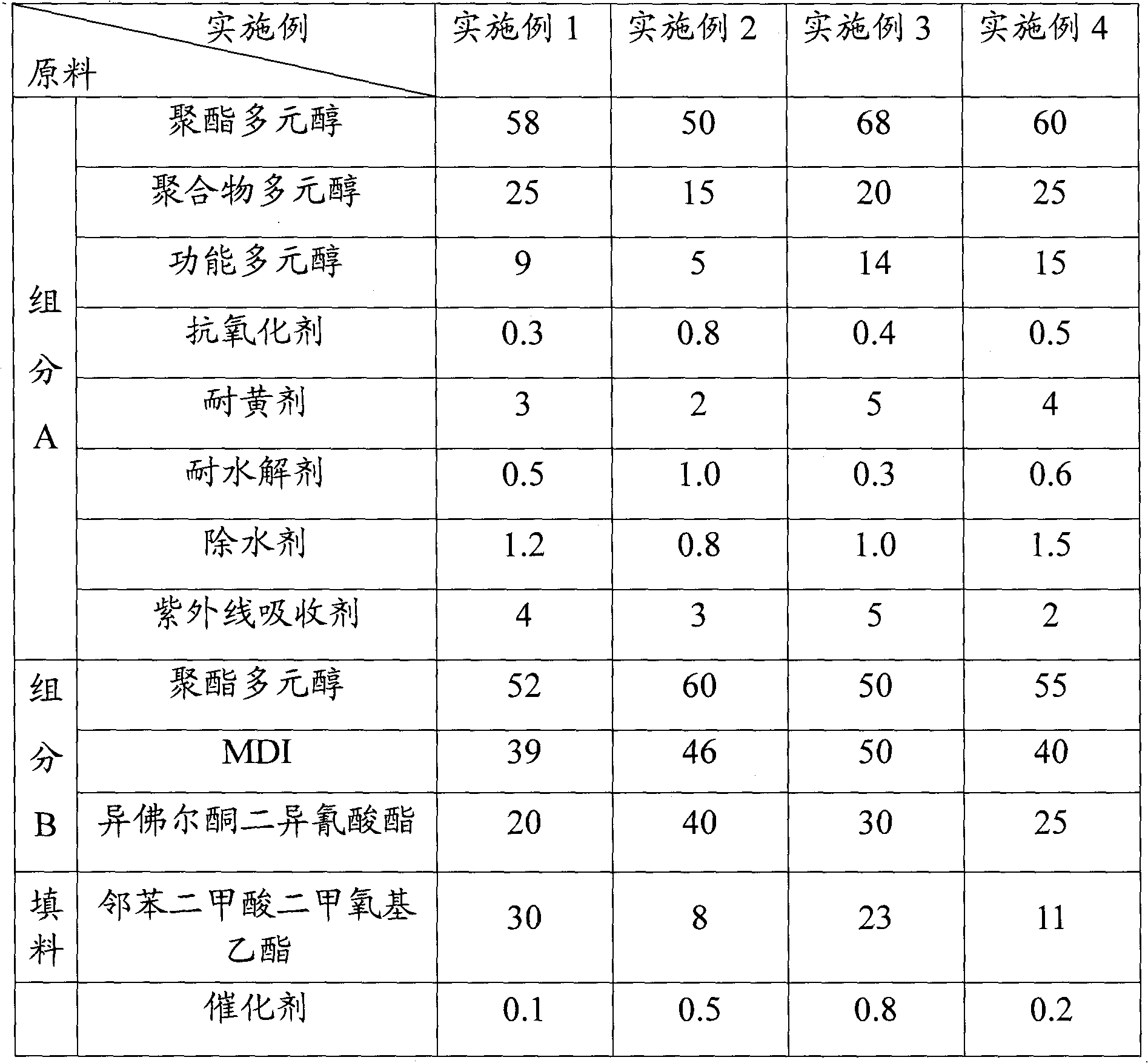

Polyurethane for sports shoe sole and preparation method thereof

The invention discloses polyurethane for a sports shoe sole, which comprises a component A, a component B and filler in the ratio of 1:(1.7-1.86):(0.1-0.3), wherein the component A mainly comprises the following components in part by weight: 50-70 parts of polyester polyol, 20-50 parts of polymer polybasic alcohol and 10-30 parts of functional polyol, wherein the functional polyol is selected from 1-4 butanediol, 1-2 propylene glycol, 1-6 hexanediol or trimethylolpropane; the component B mainly comprises the following components in part by weight: 30-60 parts of diphenyl-methane-diisocyanate,21-50 parts of polyester polyol and 20-40 parts of isophorone diisocyanate; and the filler is dimethoxyethyl phthalate. The invention discloses a preparation method of polyurethane. The invention hasthe transparency, high resilience and comfort which are superior to those of common polyurethane in the formula, greatly reduces the physical consumption of athletes and has a plurality of performances such as energy return, durable comfort, durable buffer resistant performance and the like.

Owner:ANTA CHINA

Ultraviolet-curable coating material with antibacterial and antioxidant effects and preparation method thereof

InactiveCN103834272AImprove antioxidant capacityGood mold resistanceAntifouling/underwater paintsPaints with biocidesOxidation resistantTrimethylolpropane

The invention discloses an ultraviolet-curable coating material with antibacterial and antioxidant effects. The ultraviolet-curable coating material is characterized by being prepared from the following raw materials in parts by weight: 40-45 parts of epoxy acrylate, 10-14 parts of polyurethane acrylate resin, 9-12 parts of 1,6-bis(acryloyloxy)hexane, 7-9 parts of methacryloyl chloride, 3-4 parts of 1-hydroxyl cyclohexyl phenyl ketone, 13-16 parts of ethoxylated triacrylate trimethylolpropane, 9-12 parts of o-methylphenyl phenyl glycidyl ether, 1-2 parts of polydimethylsiloxane, 1-2 parts of IPBC (Iodopropynylbutylcarbamate), 5-7 parts of clay and 4-5 parts of assistant. According to the coating material disclosed by the invention, IPBC is added as an antibacterial component, so that the coating material has a good antioxidant effect and an antifungal effect; the assistant is added, so that the coating material is good in leveling property, a uniform coating can be formed, and the coating material is high in curing speed and tough and has a strong adhesive force, and can be used for treating various sterile surfaces in public places.

Owner:WUHU EDISON AUTOMATION EQUIP

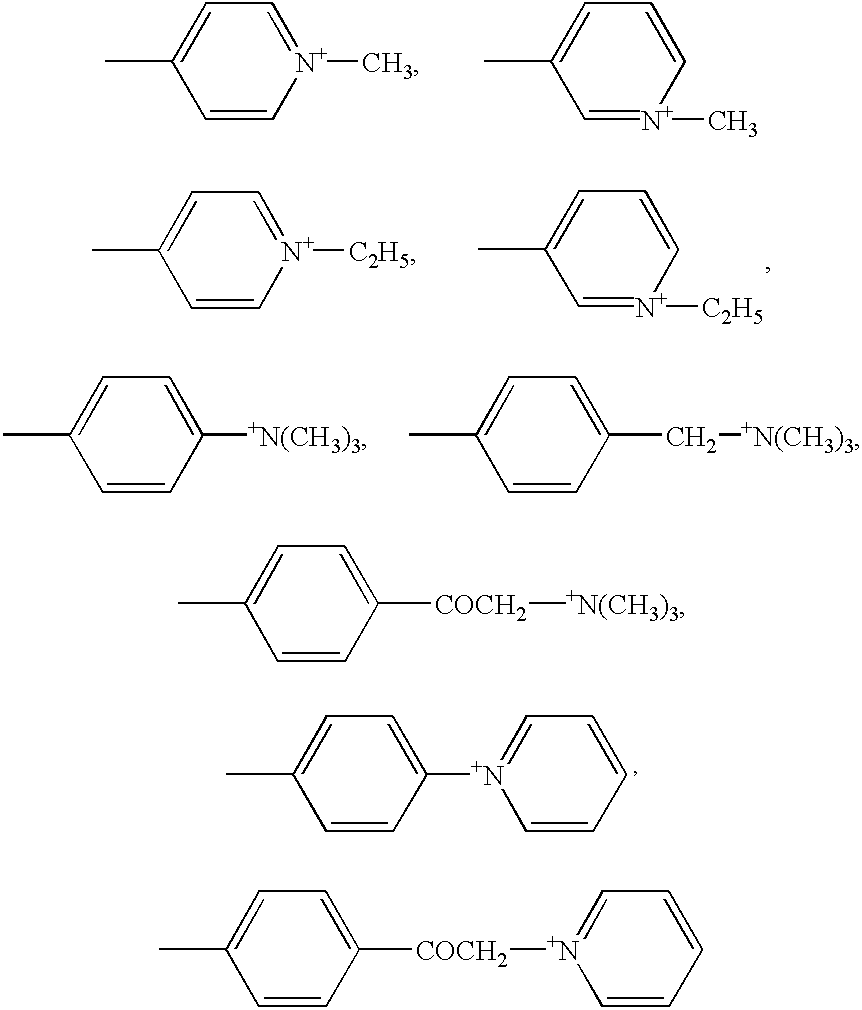

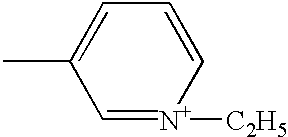

Ink-jet ink formulations containing imidazole

InactiveUS7632344B2Improve printing qualityExtending decap timeDuplicating/marking methodsInksPrinting inkColoring agents

An ink for use in combination with an ink-jet printer comprises a mixture including a colorant, a liquid vehicle comprising 1,6-hexanediol and 1,5-pentanediol in a ratio in the range of 1:4 (wt / wt) to 4:1 (wt / wt), and / or an amount of imidazole in the range of 0.1 wt % to 6 wt %, and potentially provides at least one of the following enhancements to the ink improved print quality, increased decap time, pen reliability, environmental robustness of ink in pen, environmental robustness of printed ink on media, and aid in maintaining the pH of the ink in a desired range.

Owner:HEWLETT PACKARD DEV CO LP

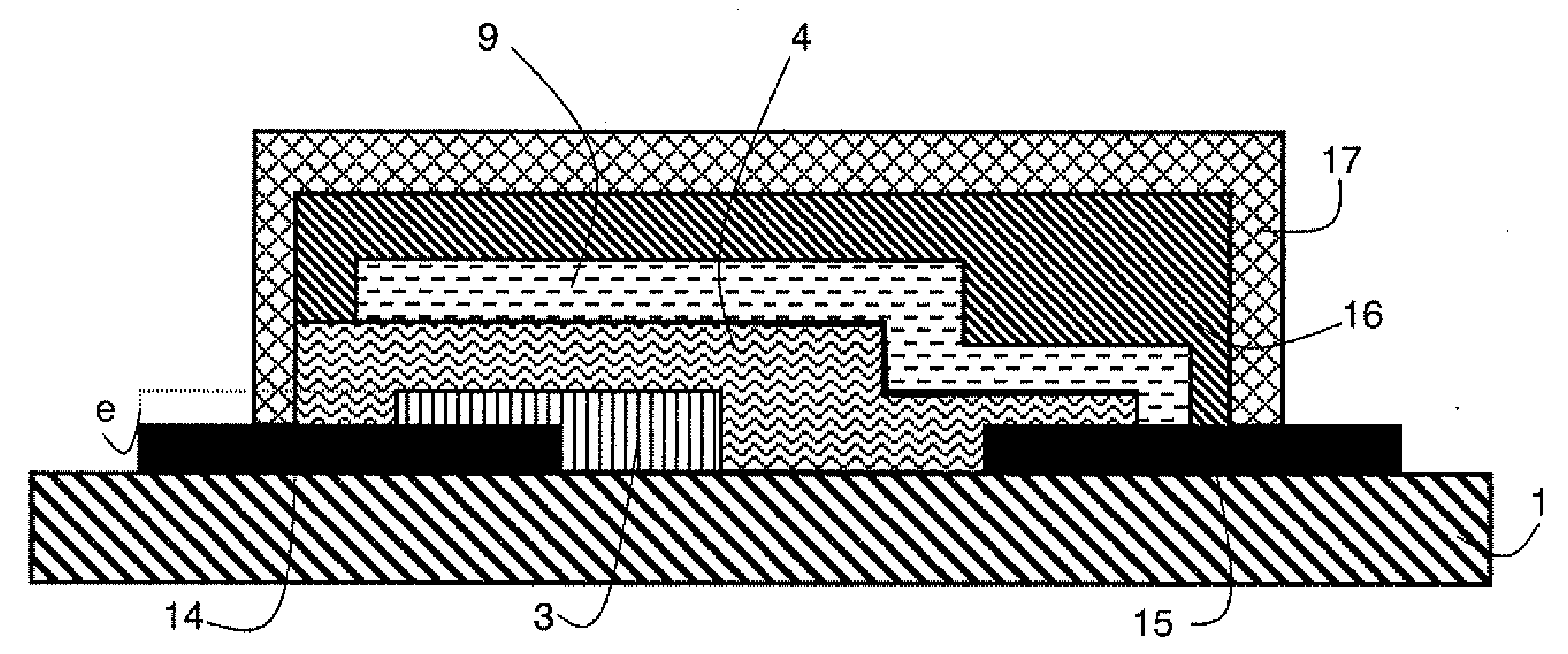

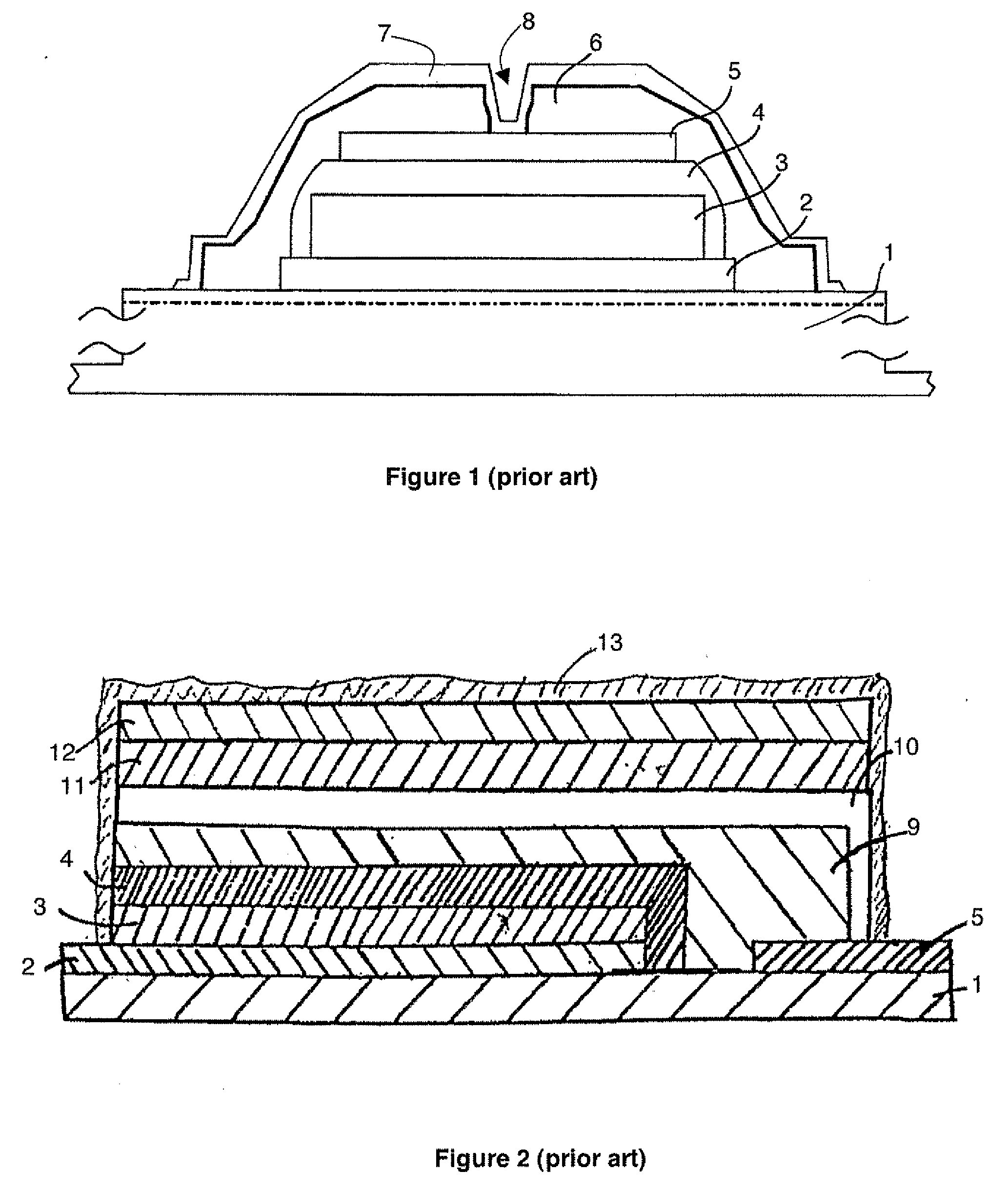

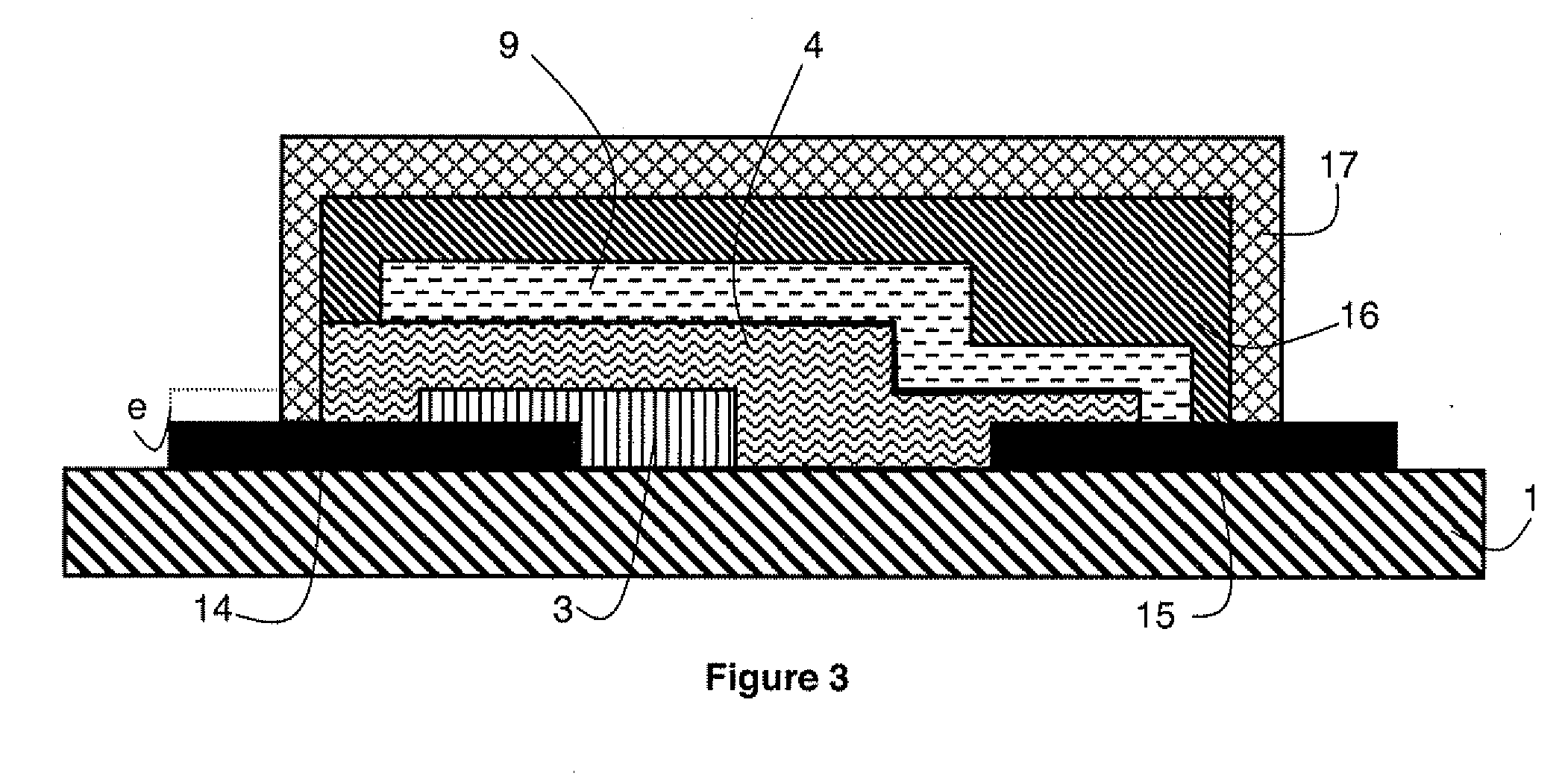

Lithium microbattery provided with an electronically conductive packaging layer

ActiveUS20110097625A1Reduce manufacturing costEasy to manufactureCell electrodesFinal product manufactureMethacrylateCarboxylic salt

A lithium microbattery comprises a packaging thin layer formed by a matrix of polymer material in which metallic particles are dispersed. The packaging thin layer constitutes at least a part of the anodic current collector of the lithium microbattery. The polymer material is advantageously obtained from at least a photopolymerizable precursor material chosen from bisphenol A diglycidylether, bisphenol F butanediol diglycidil ether, 7-oxabicylco[4.1.0]heptane-3-carboxylate of 7-oxabicylco[4.1.0]hept-3-ylmethyl and a mixture of bisphenol A and epichloridine. It can also be a copolymer obtained from a homogenous mixture of at least two photopolymerizable precursor materials, respectively acrylate-base, such as diacrylate 1,6-hexanediol and methacrylate, and epoxide-base, for example chosen from bisphenol A diglycidylether, 7-oxabicylco[4.1.0]heptane-3-carboxylate of 7-oxabicylco[4.1.0]hept-3-ylmethyl and a mixture of bisphenol A and epichloridine.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Thermoplastically processable polyurethane molding material

Owner:INTIER AUTOMOTIVE EYBL INTERIORS +1

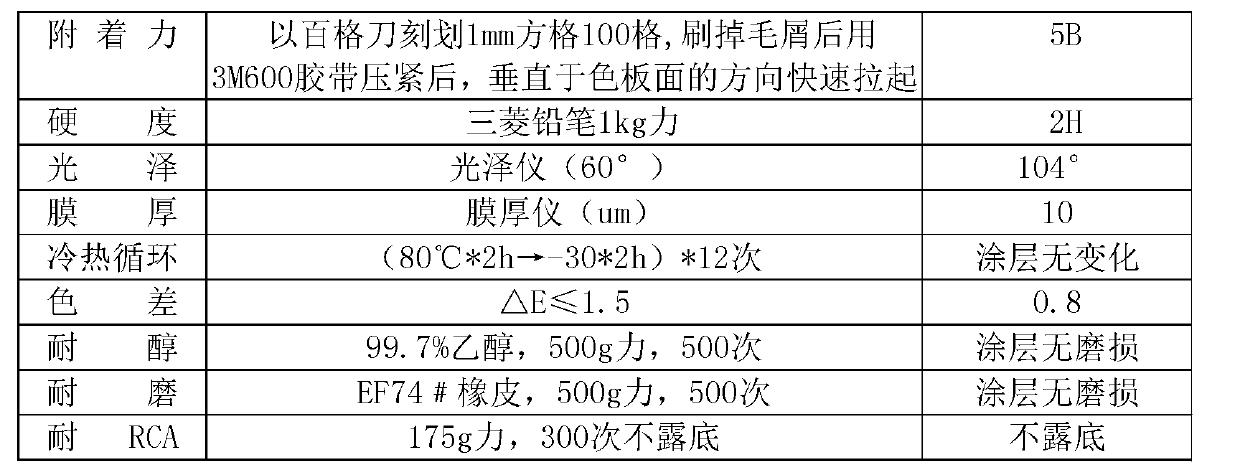

UV (Ultraviolet) varnish and preparation method thereof

ActiveCN103087626AStrong adhesionHigh hardnessPolyurea/polyurethane coatingsEpoxy resin coatingsSilanesEthyl acetate

The invention discloses a UV (ultraviolet) varnish and a preparation method thereof. The UV varnish is composed of the following raw materials in parts by weight: 50-60 parts of polyurethane acrylate, 10-20 parts of epoxy acrylate, 10-15 parts of ethyl acetate, 8-10 parts of toluene, 2-4 parts of 1,6-hexandiol diacrylate, 2-3 parts of tripropylene glycol diacrylate, 2-4 parts of 1-hydroxy-cyclohexy-phenyl ketone, 1-2 parts of 2,4,6-trimethyl benzoyl ethyl phenyl phosphoinate, 1-2 parts of zinc dialkyl dithiophosphate, 0.8-1 part of poly(butyl acrylate), 0.8-1 part of ehtanediamine, 0.8-1 part of N-2-(aimno ethyl)-3-aminopropyl trimethoxy silane, 0.8-1 part of ehtanediamine tetramethylene phosphornic acid sodium salt, 0.3-0.5 part of plant ash, 3-5 parts of modified complexing agent, and 2-4 parts of light calcium carbonate. The paint produced by the method disclosed by the invention is strong in adhesive force, good in paint film hardness and gloss, and strong in cold-heat circulating resistance, alcohol resistance and wear resistance; and the physical property of the paint film is further enhanced by the added modified complexing agent and light calcium carbonate.

Owner:惠州市汇流实业有限公司

Ultraviolet curable water-based paint used for wooden products

InactiveCN104877552AFast curingNo pollutionAntifouling/underwater paintsPaints with biocidesWater basedAcrylic resin

The invention belongs to the field of paint and in particular relates to ultraviolet curable water-based paint used for wooden products. The water-based paint comprises the following raw materials in parts by weight: 40-65 parts of water-based polyurethane acrylate, 10-15 parts of rosin-based hyperbranched polyester acrylic resin, 5-10 parts of 1,6-hexanediol diacrylate, 5-10 parts of acrylic resin, 5-10 parts of nano aluminium oxide dispersion, 2-4 parts of photoinitiators, 0.2-0.5 part of levelling agent, 10-20 parts of water-based organic assistants, 0.2-0.5 part of anti-settling agent, 0.5-1 part of defoaming agent and 10-15 parts of graphene. The water-based paint can meet the requirements of high performance and environmental protection, has high gloss and longer valid time, and has good compatibility with ultraviolet curable resin.

Owner:CHENGDU NASHUO TECH

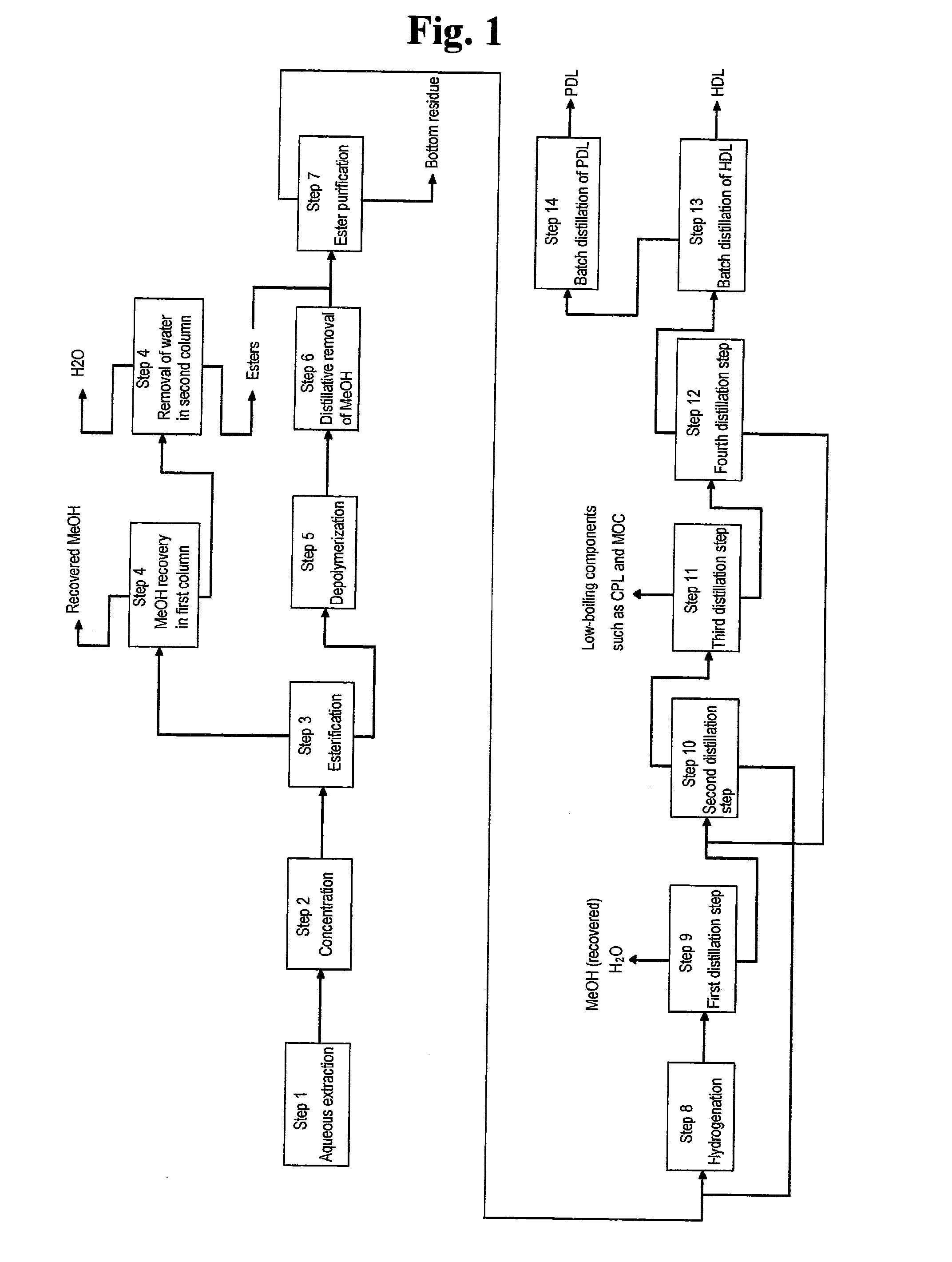

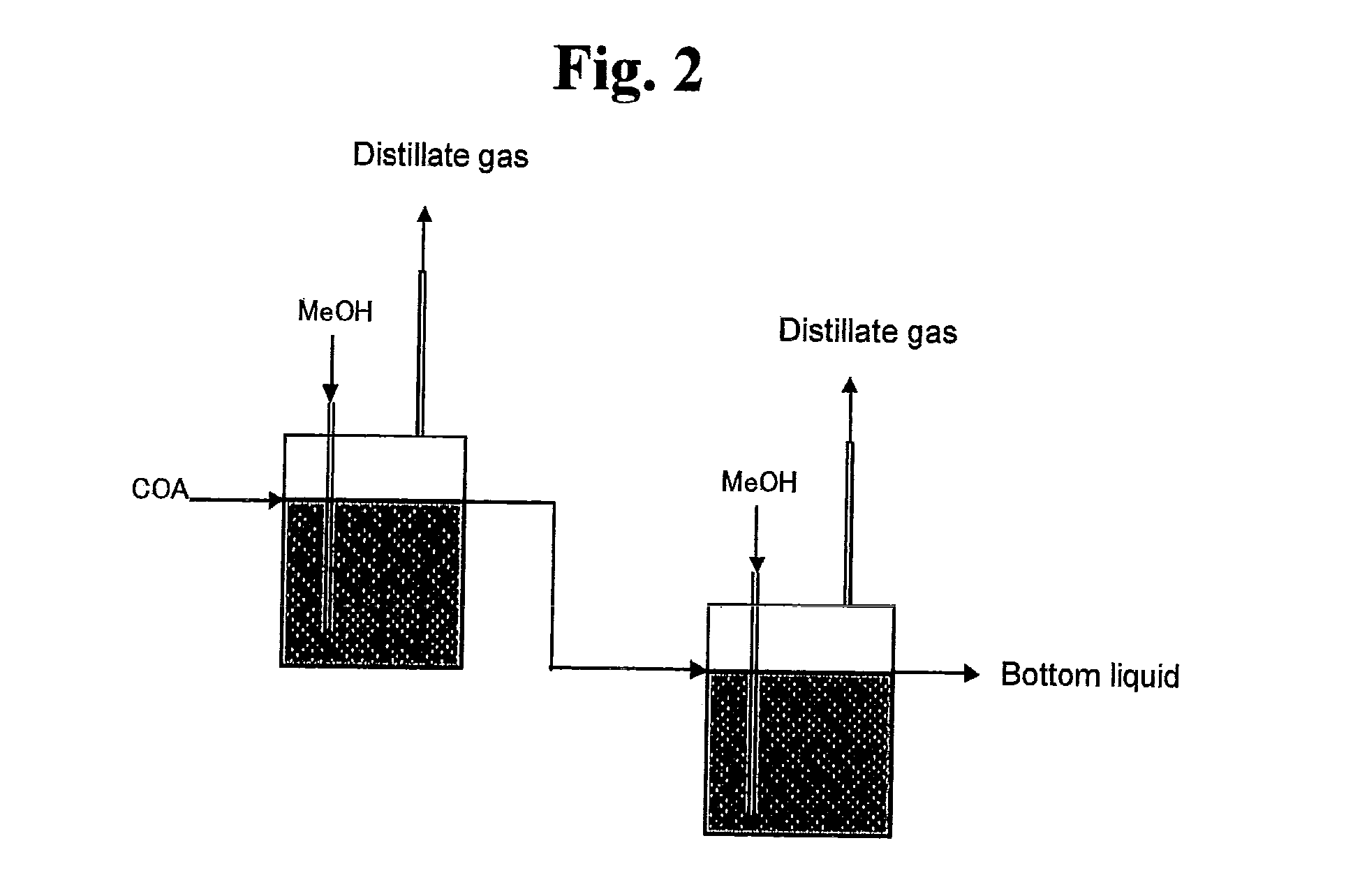

Production Process of 1,6-Hexanediol

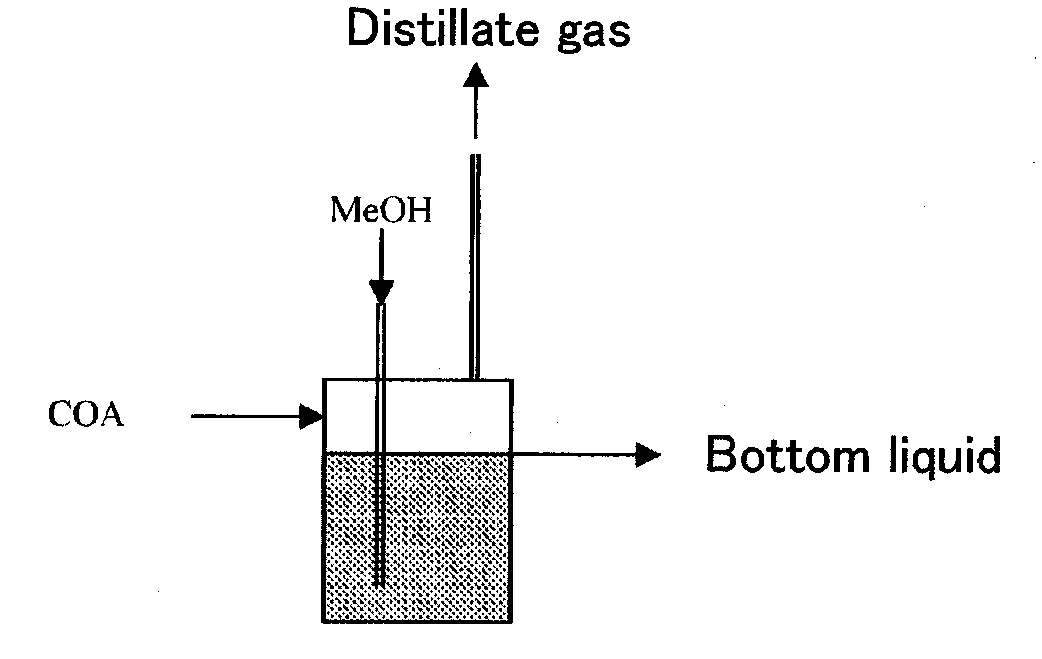

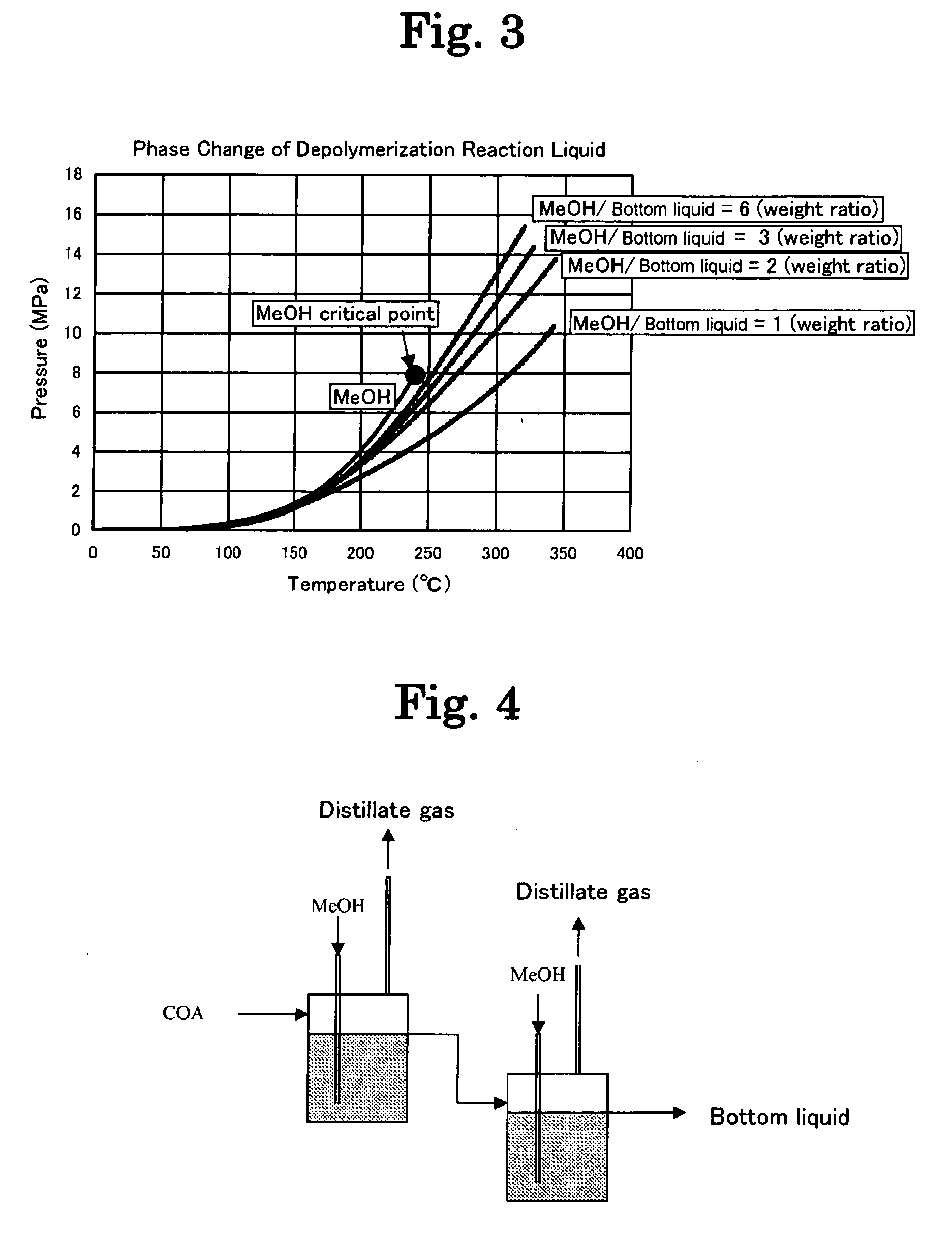

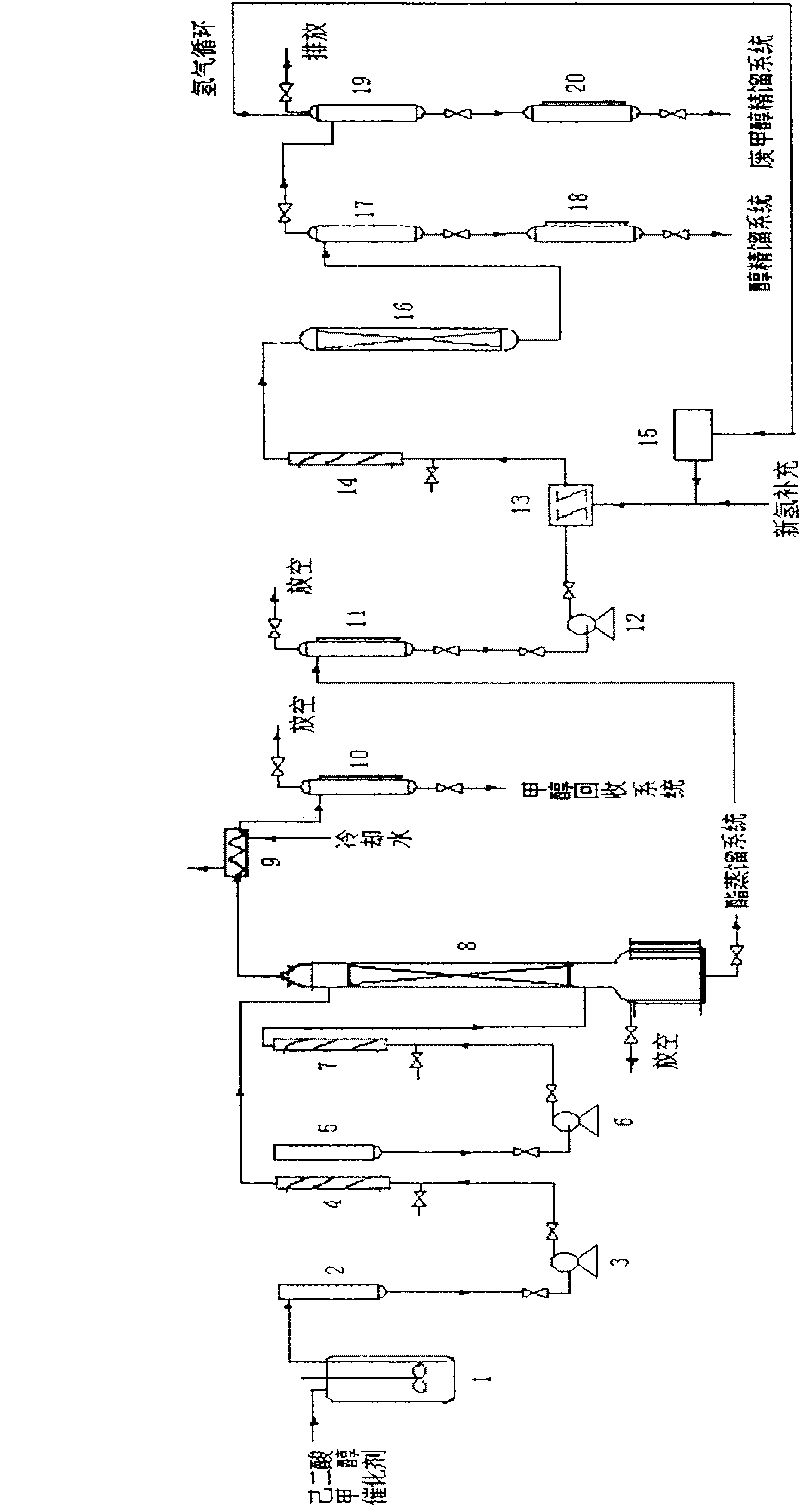

ActiveUS20090048471A1Avoid corrosionEfficient executionPreparation by oxidation reactionsPreparation by ester-hydroxy reactionDistillationHigh pressure

A method is provided for obtaining highly pure 1,6-hexanediol in which the contents of impurities such as 1,4-cyclohexanediol, 1,5-hexanediol, 1,2-cyclohexanediol, 1,7-pentanediol, 1,5-pentanediol and high boiling point components are significantly reduced.This process for producing 1,6-hexanediol from cyclohexane comprises the steps of:(1) treating an aqueous extraction concentrate of a reaction mixture obtained by oxidation of cyclohexane with a lower alcohol to esterify monocarboxylic acids and dicarboxylic acids contained in the extract, and simultaneously remove and separate by distillation water, excess lower alcohols and carboxylic acid esters; (2) converting oligomer esters contained in the bottom liquid to carboxylic acid esters by depolymerizing the oligomer esters at a high temperature and high pressure in the presence of a lower alcohol and a catalyst; and (3) hydrogenating the carboxylic acid esters distilled off in the step (1) and the carboxylic acid esters obtained in the step (2) either respectively or collectively to convert to 1,6-hexanediol.

Owner:UBE CORP

Method for producing 1,6-hexandiol

The invention relates to a method of producing 1, 6-hexanediol, which is that solid acid catalysts that are adipate and methanol are pre-esterified at atmospheric pressure; the supernatant fluid of reaction products after pre-esterifying is delivered to a continuous esterifying tower to act the continuous esterifying reaction with methanol vapor under the action of a catalyst, and the temperaturefor the continuous esterifying reaction ranges from 70 DEG C to 15 DEG C; based on the quality of the adipate, the addition amount of a solid catalyst ranges from 1 to 10 percent; the molar ratio of the methanol and the adipate is 1 to 10:1, and a solid acid catalyst is strong acidic ion exchange resin; reactants act the hydrogenation reaction after purification by rectification, wherein, the molar ratio of the hydrogen and ester is 50 to 350:1, the temperature ranges from 150 to 250 DEG C, the pressure ranges from 2.5 to 10.0MPa, and the catalysts are copper oxide ranging from 25 to 60 percent, zinc oxide ranging from 25 to 60 percent and alumina ranging from 10 to 30 percent; the obtained crude methanol is performed through the purification by rectification to gain the 1, 6-hexanediol the purity quotient of which is 99.0 percent, and the waste methanol can be recycled after the rectification.

Owner:PETROCHINA CO LTD

Adhesive Compositon for Optical Disk, Cured Product and Article

InactiveUS20080152857A1Increased durabilityHigh bonding strengthLayered productsPolyureas/polyurethane adhesivesMeth-Adhesive

Disclosed is an adhesive which enables to obtain a bonded optical disk, wherein optical disks having a total reflection film or a translucent reflection film made of silver or a silver alloy are bonded together, which exhibits high adhesion strength between the reflection film and a cured product of the adhesive as well as between a polycarbonate substrate and the cured product of the adhesive, while having high durability equivalent to those of the conventional optical disks using translucent reflective film made of gold. Specifically disclosed is an ultraviolet-curable adhesive resin composition containing a bisphenol-type epoxy (meth)acrylate (A), a di(meth)acrylate (B) and a photopolymerization initiator (C) which is characterized in that the di(meth)acrylate (B) is composed of one or more selected from a di(meth)acrylate (B-1) having an adipate structure, a di(meth)acrylate (B-2) having a caprolactone-modified structure, an alkylene oxide-modified neopentyl glycol di(meth)acrylate compound (B-3) and an alkylene oxide-modified 1,6-hexanediol di(meth)acrylate compound (B-4).

Owner:NIPPON KAYAKU CO LTD

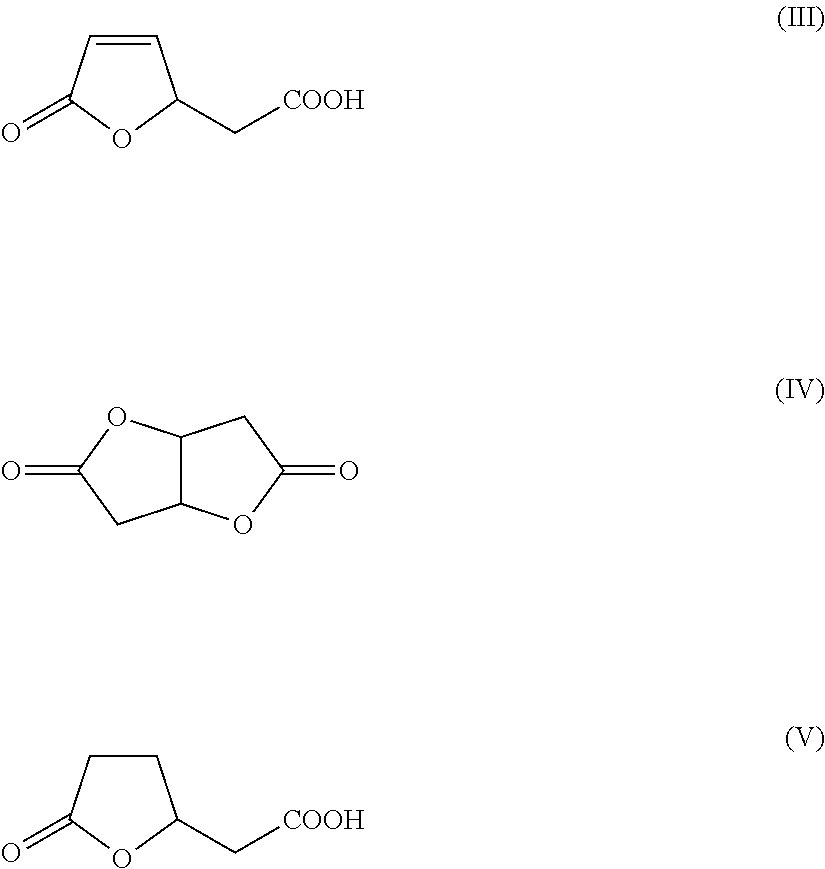

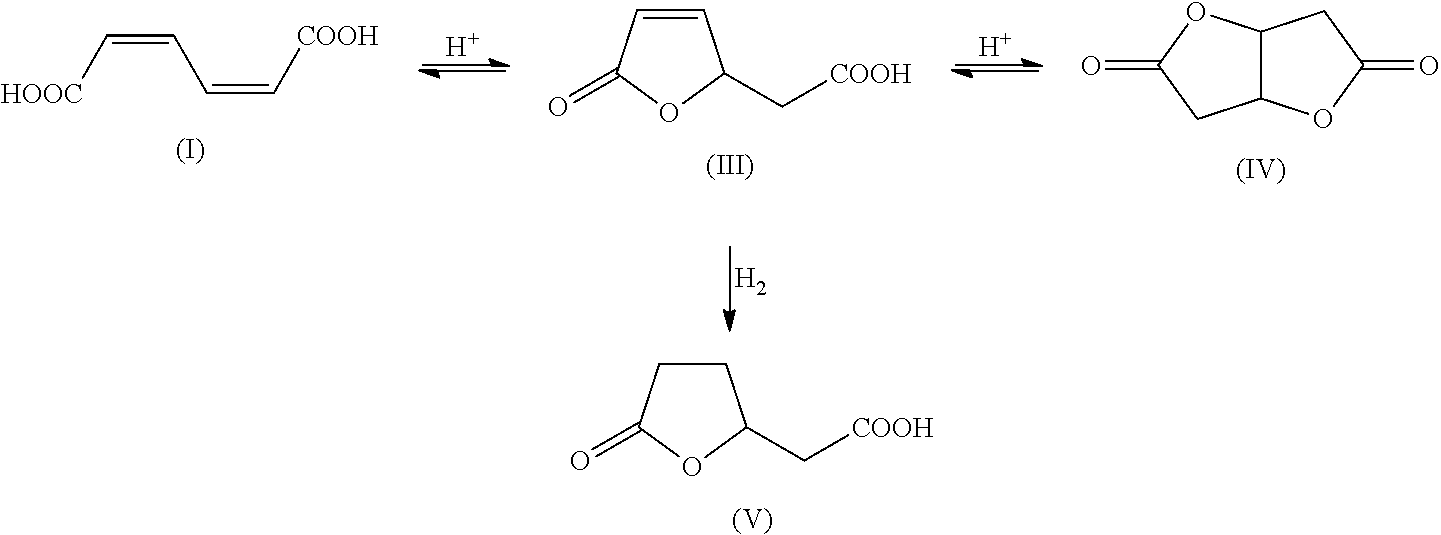

Method for producing hexamethylenediamine

InactiveUS20160326092A1Adipic acid yieldHigh melting pointAmino compound purification/separationOrganic compound preparationMuconic acidHexamethyldiamine

The invention relates to a method for producing hexamethylenediamine, wherein a) a muconic acid starting material is provided, which is selected from among muconic acid, esters of muconic acid, lactones of muconic acid, and mixtures thereof, b) the muconic acid starting material is subjected to a reaction with hydrogen in the presence of at least one hydrogenation catalyst in order to form 1,6-hexanediol, and c) the 1,6-hexanediol obtained in step b) is subjected to amination in the presence of an amination catalyst in order to obtain hexamethylenediamine. The invention further relates to hexamethylenediamine which can be produced by means of said method.

Owner:BASF AG

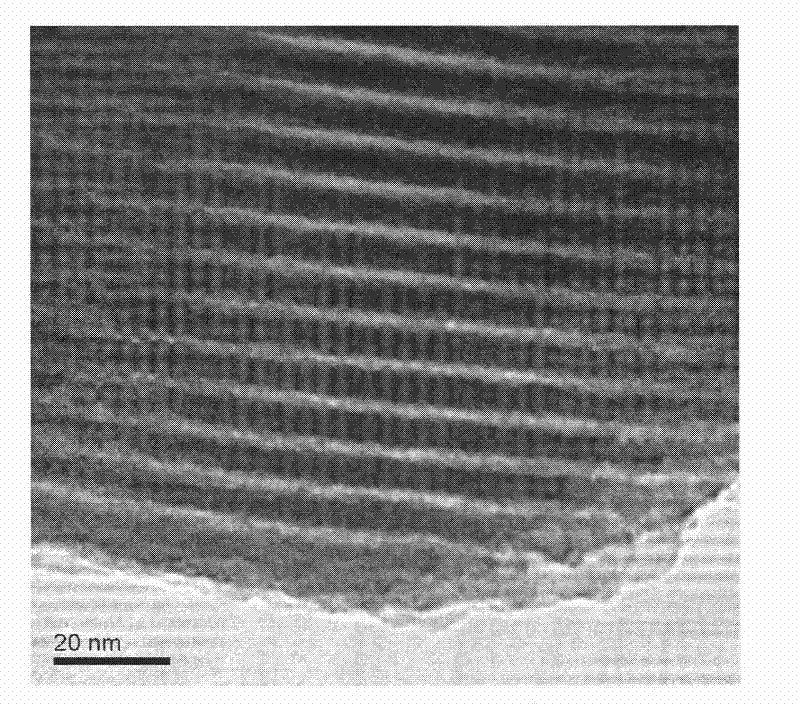

A kind of method for synthesizing 1,6-hexanediol by gas-phase hydrogenation of dimethyl adipate

ActiveCN101531568BOrganic compound preparationHydroxy compound preparationAlkaline earth metalPotassium

The invention discloses a method for synthesizing 1,6-hexanediol by gas-phase hydrogenation of dimethyl adipate. The preparation of the hydrogenation catalyst used in the method comprises the following steps: adding a mesoporous silicon oxide carrier and a copper-containing Aqueous salt solution, stirred, evaporated to dryness by microwave, dried by microwave and calcined to obtain hydrogenation catalyst. In addition, the preparation of the protective bed used to remove the impurity gas in hydrogen in the method of the present invention comprises the following steps: active carbon carrier, and alkali metal salt or / and alkaline earth metal calcium salt are formulated into an aqueous solution in proportion, stirred, microwave evaporated to dryness, microwave dried Roasting under the protection of an inert gas; a high-performance guard bed is obtained, which contains: 5-90wt% activated carbon, 10-95wt% potassium oxide and calcium oxide, and the method of the invention greatly improves the physical properties and catalytic performance of the catalyst.

Owner:WANHUA CHEM GRP CO LTD +1

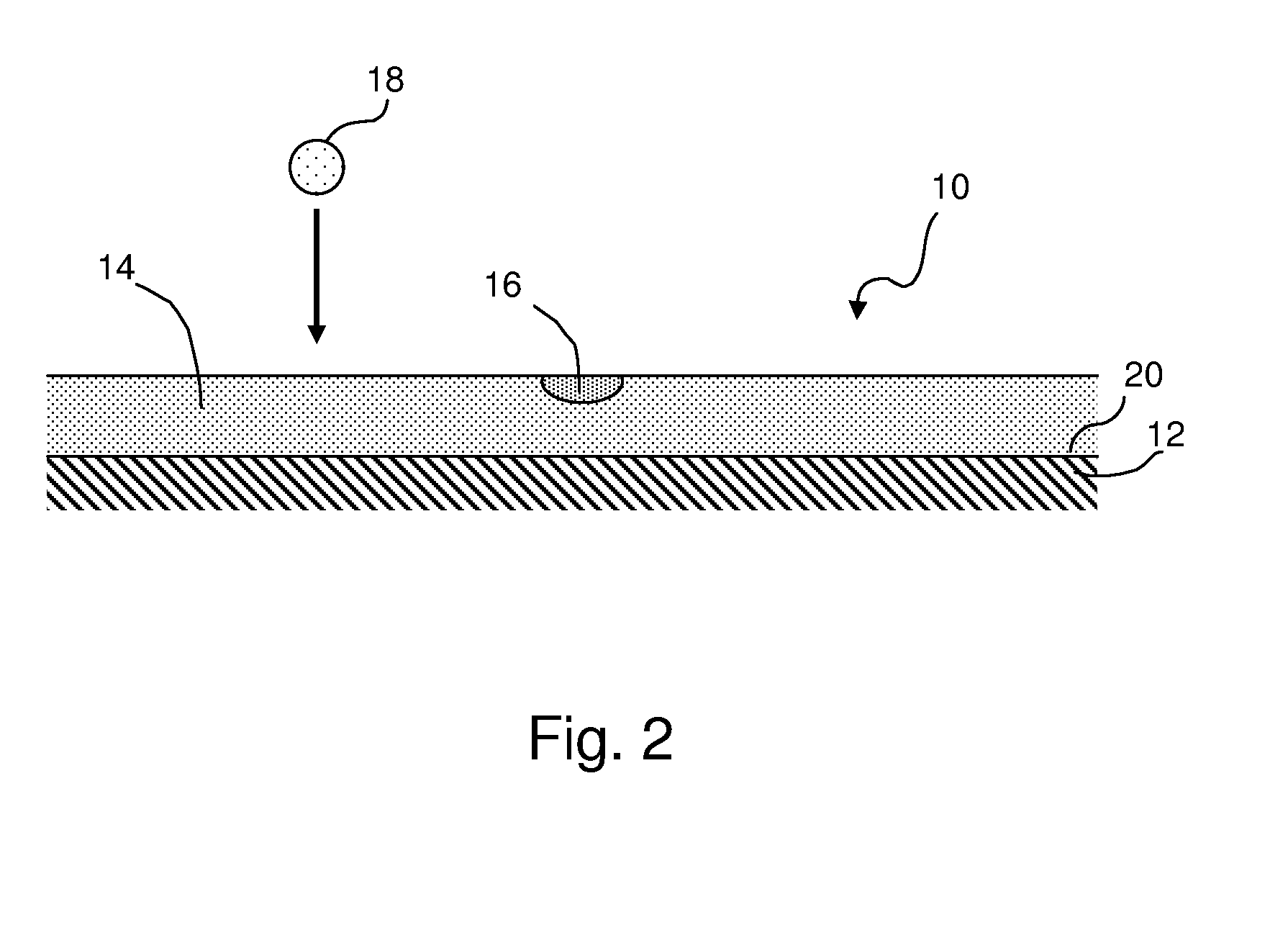

Inkjet recording method and inkjet recording apparatus

ActiveUS20080079796A1Achieve effectDuplicating/marking methodsCoatingsCritical micelle concentrationActinic Rays

The present invention provides: an inkjet recording method comprising: applying an undercoating liquid on a recording medium, the undercoating liquid containing at least one surfactant in an amount of from 0.001% to the critical micelle concentration, the surfactant achieving a surface tension of 25 mN / m or smaller when dissolved in 1,6-hexanediol diacrylate at a critical micelle concentration; semi-curing the applied undercoating liquid; and recording an image by ejecting an ink onto the semi-cured undercoating liquid, the ink being curable by irradiation with an actinic ray; and an inkjet recording apparatus.

Owner:FUJIFILM CORP

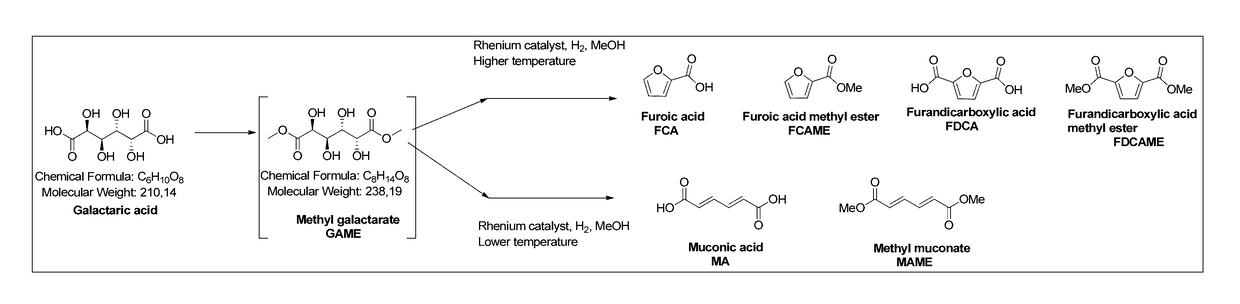

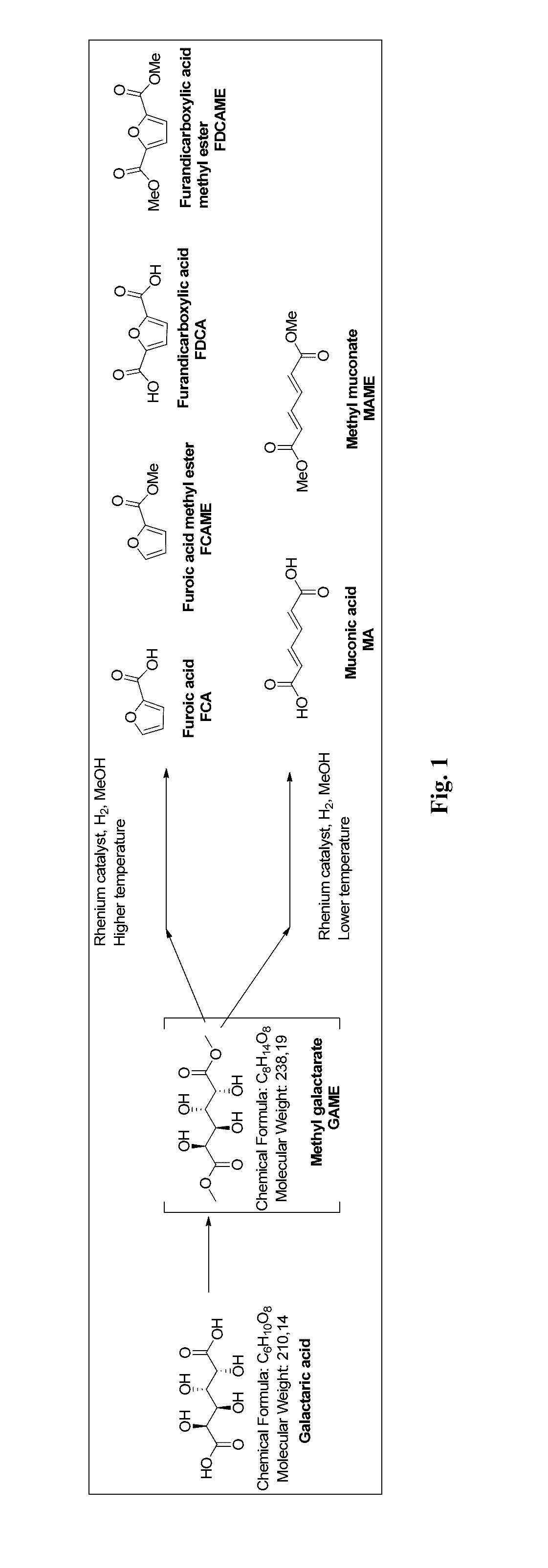

Method for producing muconic acids and furans from aldaric acids

InactiveUS20170137363A1Improve scalabilityEasy to purifyOrganic compound preparationCarboxylic acid esters preparationFuranMuconic acid

The present invention relates to selective catalytic dehydroxylation method of aldaric acids for producing muconic acid and furan chemicals, which can be used directly in fine chemical and polymer applications (FCA / FDCA) and as intermediates in the preparation of industrially significant chemicals, such as terephthalic acid, adipic acid, caprolactone, caprolactam, nylon 6.6, 1,6-hexanediol and multiple pharmaceutical building blocks (MA / MAME).

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

High purity 1,6-hexanediol and process for preparing the same

InactiveUS20110201848A1Easy to disassembleDifficult to separateOrganic compound preparationOrganic chemistry methodsCyclohexanoneAlcohol

There is provided a process for preparing 1,6-hexanediol by esterifying a carboxylic acid mixture resulted from oxidation of cyclohexane with oxygen, and then hydrogenating the esters, which substantially does not contain a compound leading to a high ester value.A process for preparing 1,6-hexanediol from a carboxylic acid mixture containing adipic acid and 6-hydroxycaproic acid, the carboxylic acid mixture is obtained as a by-product in oxidization of cyclohexane to cyclohexanone / cyclohexanol using oxygen or an oxygen-containing gas, the process comprises esterifying the acids with an alcohol, followed by hydrogenation, and the process is characterized by comprising the following steps of:a) separating a component having a boiling point lower than that of water and the alcohol used in the esterification from a mixture obtained by the hydrogenation in a first distillation step;b) separating an EV component having a boiling point higher than that of 1,6-hexanediol further in a second distillation step;c) separating an EV component having a boiling point lower than that of 1,6-hexanediol further in a third distillation step; and thend) obtaining 1,6-hexanediol in a fourth distillation step, in this order.

Owner:UBE IND LTD

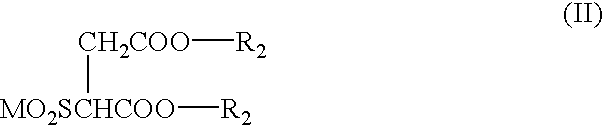

Biodegradable oil absorbing composite material and preparation method therefor

InactiveCN105001515AImprove adsorption capacityImprove adsorption speedSodium bicarbonatePotassium persulfate

The present invention discloses a biodegradable oil absorbing composite material and a preparation method therefor. The biodegradable oil absorbing composite material is characterized by being prepared by using the following raw materials in parts by weight: 3-5 parts of sodium bentonite, 0.3-0.5 parts of cetyl trimethyl ammonium bromide (CTAB), 4-6 parts of methacrylate, 3-5 parts of styrene, 0.1-0.5 parts of 1,6-hexanediol diacrylate, 3-4 parts of ethyl acetate, 1-3 parts of polyvinyl alcohol, 0.8-1.2 parts of organophosphorus ester, 0.01-0.05 parts of potassium persulfate, 0.5-1 parts of sodium bicarbonate, 2-5 parts of polyethylene wax, 2-3 parts of stearic acid, 1-2 parts of calcium sulfate, 80-95 parts of polypropylene, 0.1-0.3 parts of antioxidant 1010, 10-15 pats of azodicarbonamide, 0.5-1 parts of silane coupling agent KH550, 3-4 parts of chitosan, 2-4 parts of bamboo fiber, 0.5-1 parts of sodium alginate, and an appropriate amount of water. The biodegradable oil absorbing composite material provided by the present invention is environmentally friendly, simple in preparation method, wide in material sources, and worth popularizing.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

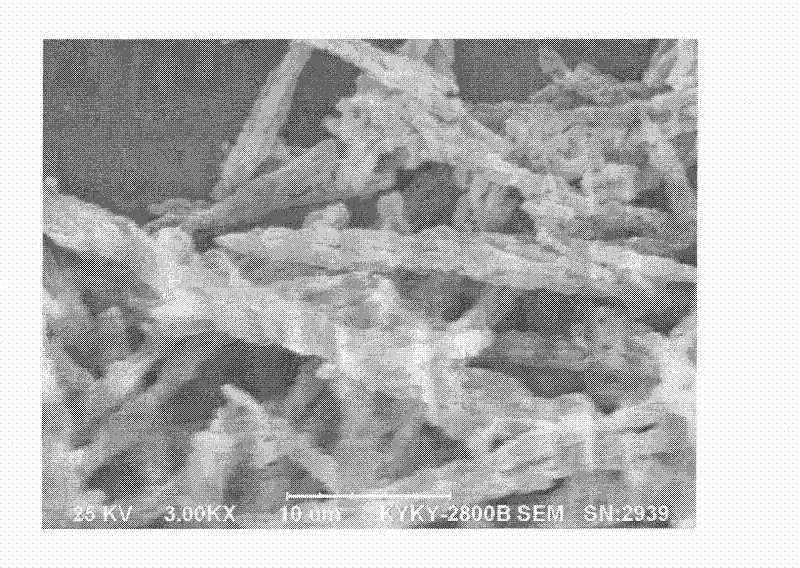

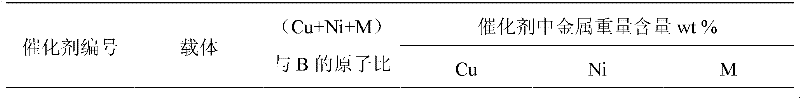

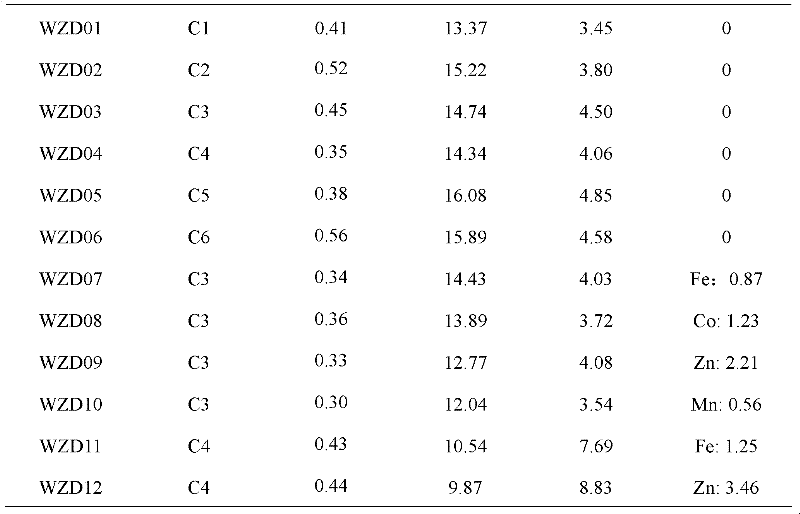

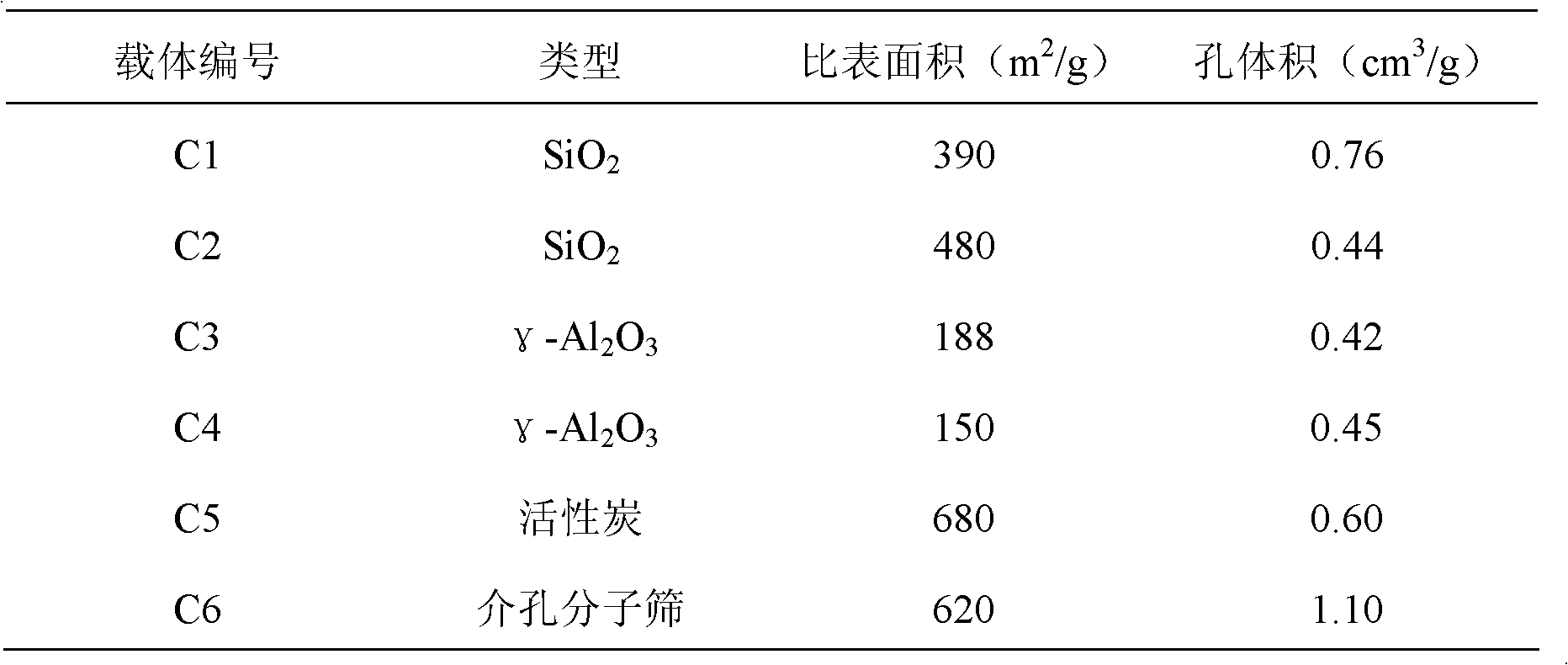

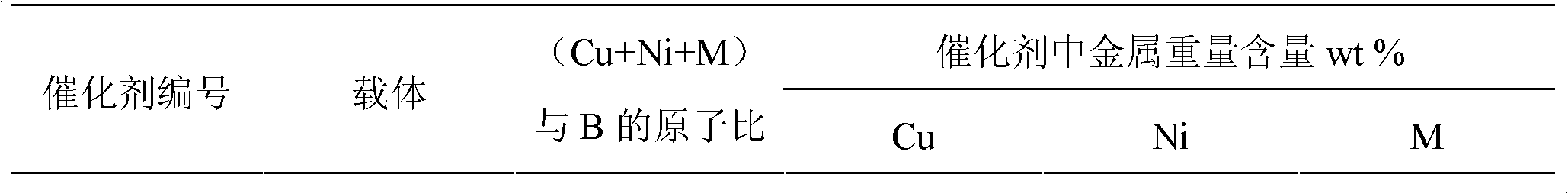

Catalyst for preparation of 1,6-hexanediol by hydrogenating 1,6-hexanedioic acid dialkyl ester and preparation method and application thereof

ActiveCN102380389ASimple preparation processRelieve pressureMolecular sieve catalystsOrganic compound preparationMetalloleSpace velocity

The invention provides a catalyst for preparation of 1,6-hexanediol by hydrogenating 1,6-hexanedioic acid dialkyl ester and a preparation method and application thereof. The catalyst comprises, by weight, 5%-30% of Cu, 2-10% of Ni, 5%-20% of B, 0%-5% of metallic addition and the balance being a porous carrier. Since the catalyst is applied to reaction for preparation of hexanediol by hydrogenating 1,6-hexanedioic acid dialkyl ester, pressure during reaction can be reduced effectively, the liquid hourly space velocity is increased and H2-to-ester ratio is lowered.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

Food-additive-resistant flexible packaging compound binder and preparation method thereof

InactiveCN104559905AHigh bonding strengthImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesFood additiveAdipic acid

The invention discloses a food-additive-resistant flexible packaging compound binder and a preparation method thereof. The binder comprises a main agent and a curing agent, wherein the main agent is an ethyl acetate solution comprising polyamide-polyester polyol, bisphenol A type epoxy resin and a silane coupling agent, and the polyamide-polyester polyol is synthesized by isophthalic acid, terephthalic acid, adipic acid, dimer acid, 4-aminomethyl-1,8-diamine, neopentyl glycol, 1,6-hexanediol and ethylene glycol; and the curing agent is an ethyl acetate solution which contains an isocyanate prepolymer and is synthesized by isocyanate, low-molecular-weight polyol and ethyl acetate. The binder, which is prepared by mixing the main agent and a curing agent at a ratio, can be directly used for compounding high-permeability food additive packaging materials. A PET / AL / RCPP composite material prepared from an aged product has the advantages of excellent peeling strength, heat resistance, food additive resistance and the like.

Owner:BEIJING COMENS NEW MATERIALS

Catalyst for preparation of 1,6-hexanediol by hydrogenating 1,6-hexanedioic acid dialkyl ester and preparation method and application thereof

ActiveCN102380389BSimple preparation processRelieve pressureMolecular sieve catalystsOrganic compound preparationMetalloleSpace velocity

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

High-water-resistance ultraviolet-curing wood paint

InactiveCN104629614AFast curingImprove water resistanceAntifouling/underwater paintsPaints with biocidesPhosphinePeroxide

The invention discloses a high-water-resistance ultraviolet-curing wood paint which is prepared from polyurethane acrylate, epoxy resin modified acrylate, epoxy soybean oil acrylate, fluorinated acrylate, modified nano titanium dioxide, water, 1,6-hexanediol diacrylate, trimethylolpropane triacrylate, 2-hydroxyethyl acrylate, methylethyl ketone peroxide, phosphine 2,4,6-trimethylphenylformacyldiphenyl oxide, ethylene glycol, ethyl acetate, glycol ether, triethanolamine, thickener, a defoaming agent, a wax emulsion, a leveling agent, an epoxy curing agent and a dispersing agent. The high-water-resistance ultraviolet-curing wood paint has the advantages of high curing speed, favorable water resistance, favorable weather resistance and long service life.

Owner:安徽嘉年华漆业有限公司

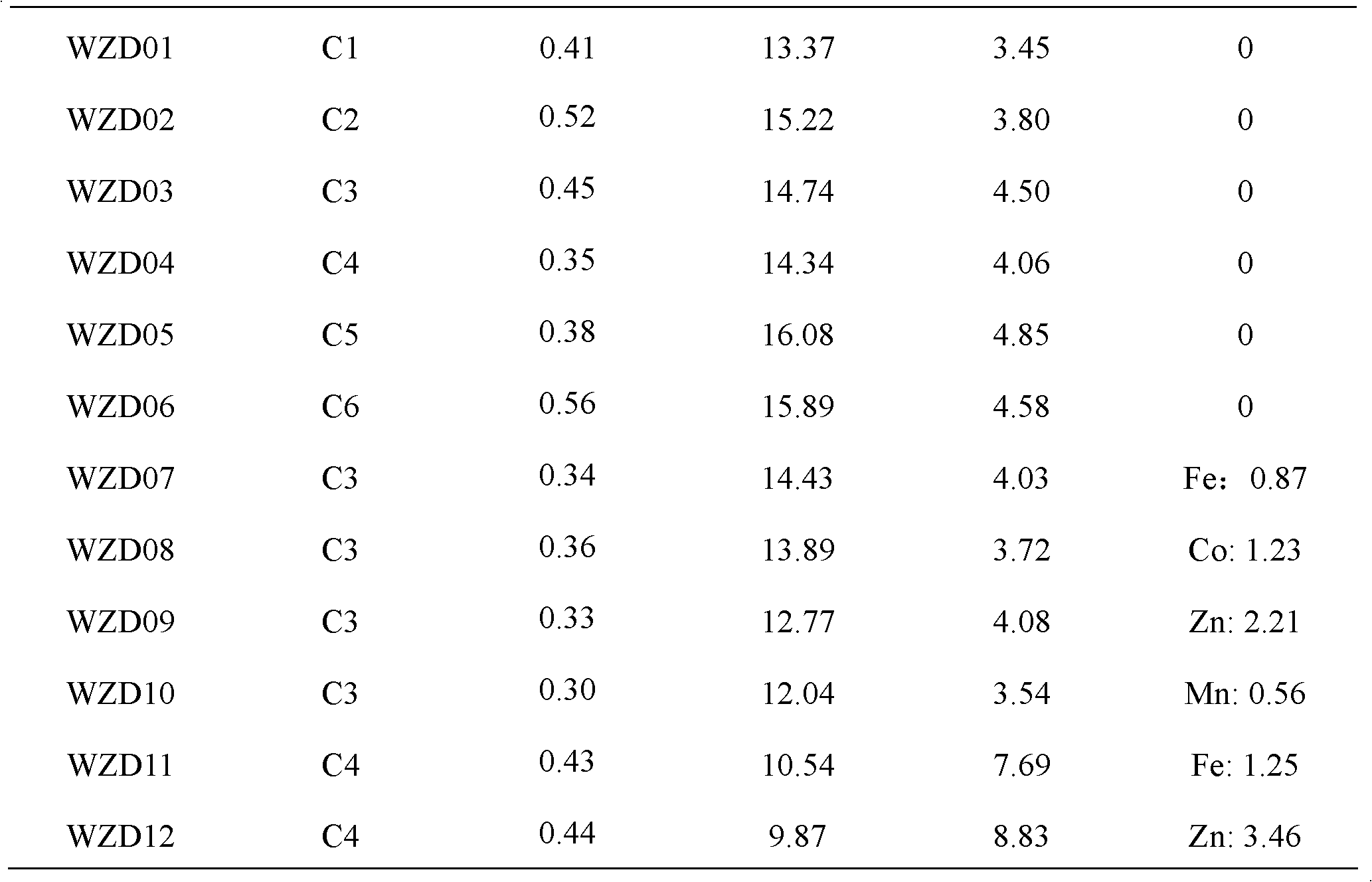

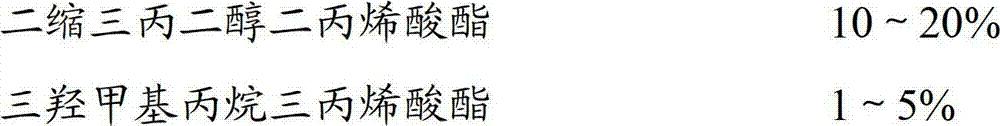

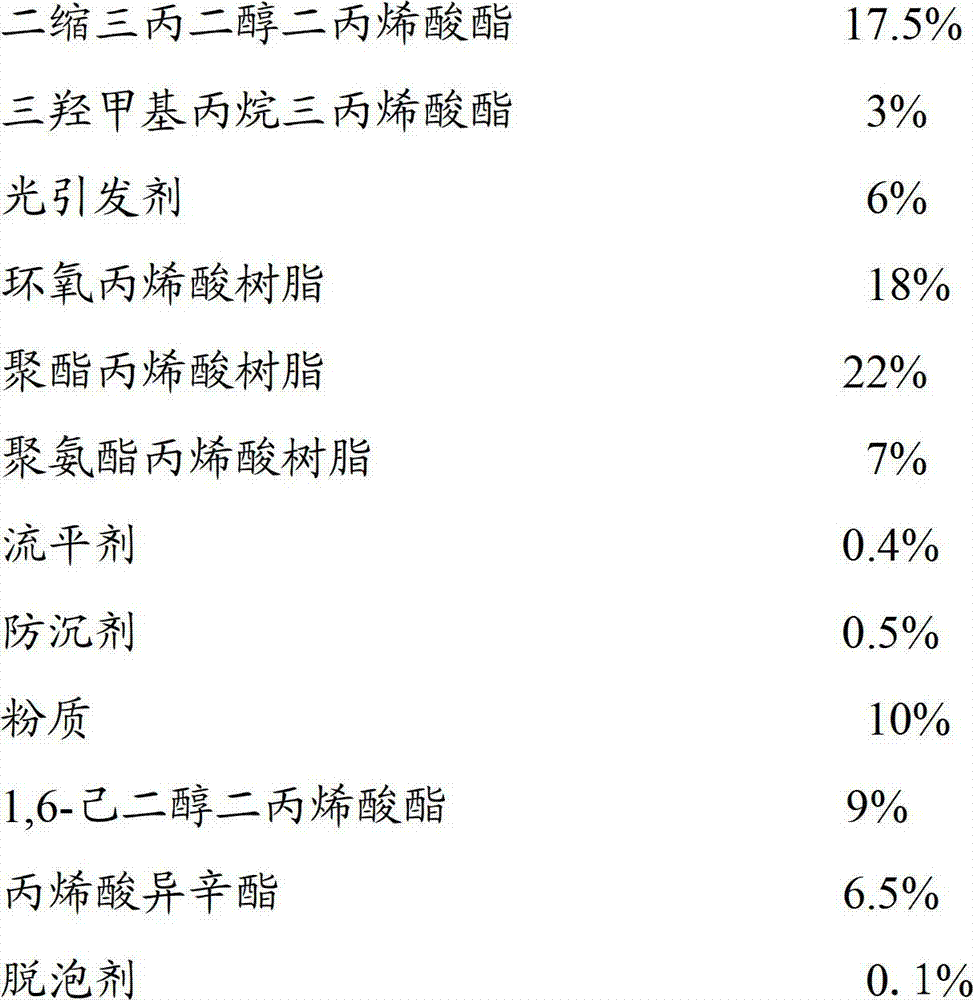

Environment-friendly light-curing electrostatic spraying primer

InactiveCN102732137ALow viscosityIncrease moisturePolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterAcrylic resin

The invention provides an environment-friendly light-curing electrostatic spraying primer, comprising the following components in percentage by weight: 10-20% of 2-Propenoic acid,1,1'-[(1-methyl-1,2-ethanediyl)bis[oxy(methyl-2,1-ethanediyl)]] ester, 1-5% of trimethylolpropane triacrylate, 5-8% of a photo-initiator, 15-20% of epoxy acrylate, 20-25% of polyester acrylic resin, 5-8% of polyurethane acrylic resin, 0.2-0.5% of a flatting agent, 0.2-0.5% of an anti-settling agent, 5-12% of flour, 5-10% of 1,6-hexanediol diacrylate, 5-8% of 2-ethylhexyl acrylate and 0-0.2% of a defoaming agent. The light-curing electrostatic spraying primer adopts a UV monomer with low viscosity and strong dilution capacity to replace an original solvent, contains no VOC (Volatile Organic Compounds), can be recycled and belongs to green and environment-friendly paints; UV resin with low viscosity and good wettability is used as main resin so that the content of solid paint is high; and the light-curing electrostatic spraying primer can be directly applied to electrostatic spraying without being diluted by the organic solvent and has the advantages of good atomization effect, good package to devices, excellent adherence and good rubbing property.

Owner:东莞大宝化工制品有限公司 +1

Silk-screen UV glaze printing ink and preparation method thereof

The invention discloses silk-screen UV glaze printing ink and a preparation method thereof, and belongs to the technical field of printing ink and preparation thereof. The printing ink is prepared from 28-32% of epoxy modified acrylate, 18-22% of urethane acrylate, 8-12% of tri(propylene glycol)diacrylate, 18-22% of 1,6-hexamethylene diacrylate, 6-10% of a 184 macroinitiator, 3-7% of an active-amine auxiliary photoinitiator, 0.8-3% of an organosilicone flatting agent, 0.8-3% of an organosilicone antifoaming agent and 3-7% of fumed silica, and is prepared by processes of mixing, stirring at a high speed, grinding, and the like. The preparation method is simple. The printing ink prepared by the method has a transparency effect and a matte effect, thus satisfying a conceive of applying the technical quality of blue and white porcelain and other famous porcelain in history to packaging and printing, and simulating the glaze quality, of the porcelain, that is mild and humid like jade. The printing ink provided by the invention has high environmental protection property. The VOCs smell residue totally reaches requirements of the national standards.

Owner:ZHEJIANG MINONG CENTURY GRP +1

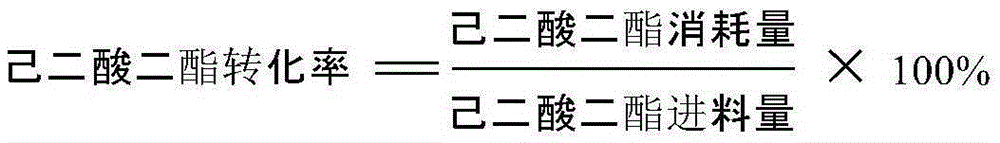

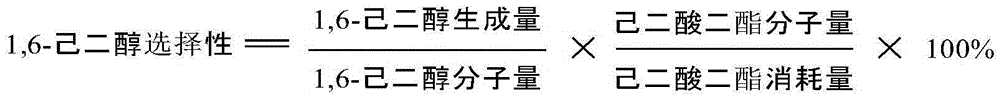

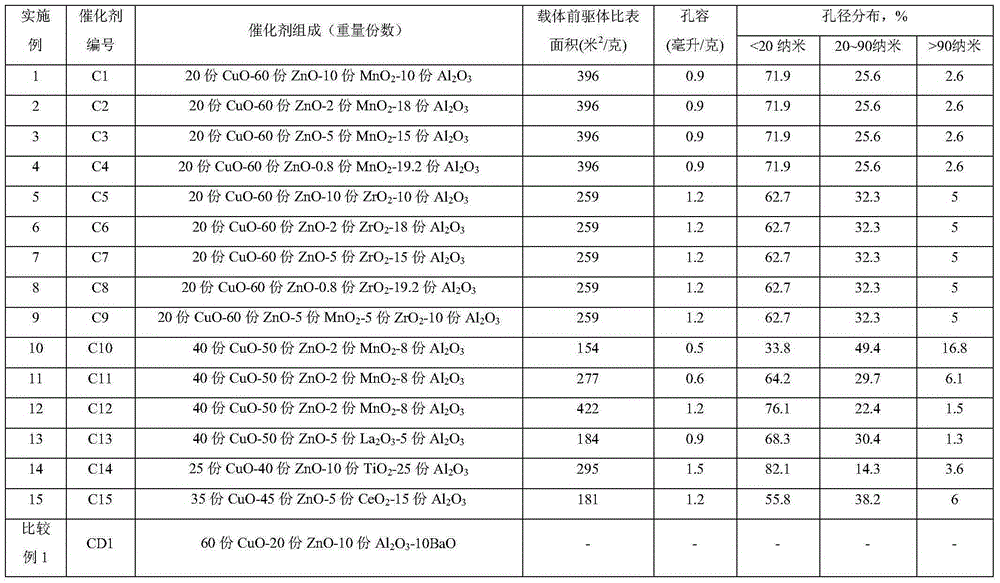

Catalyst and method for preparing 1, 6-hexanediol by hydrogenation of dialkyl 1, 6-adipate

InactiveCN106607044AImprove stabilityImprove conversion rateOrganic compound preparationHydroxy compound preparationCopperAdipate

The invention relates to a catalyst and method for preparing 1, 6-hexanediol by hydrogenation of dialkyl 1, 6-adipate. The catalyst comprises, by weight, a) 20 to 50 parts of metallic copper or an oxide thereof, b) 30 to 60 parts of metal zinc or an oxide thereof, c) 1 to 20 parts of at least one transition metal or its oxide, and d) 1 to 20 parts of alumina. The desired alumina precursor has a specific surface area of 50 to 500m<2> / g and a total pore volume of 0.3 to 2.0ml / g. The volume of pores having diameters less than 20nm is 40-80% total pore volume. The volume of pores having diameters of 20-90nm is 10-40% total pore volume. The volume of pores having diameters greater than 90nm is 0-16% total pore volume. The catalyst can be used in the industrial production of 1, 6-hexanediol by hydrogenation of dialkyl 1, 6-adipate.

Owner:CHINA PETROLEUM & CHEM CORP +1

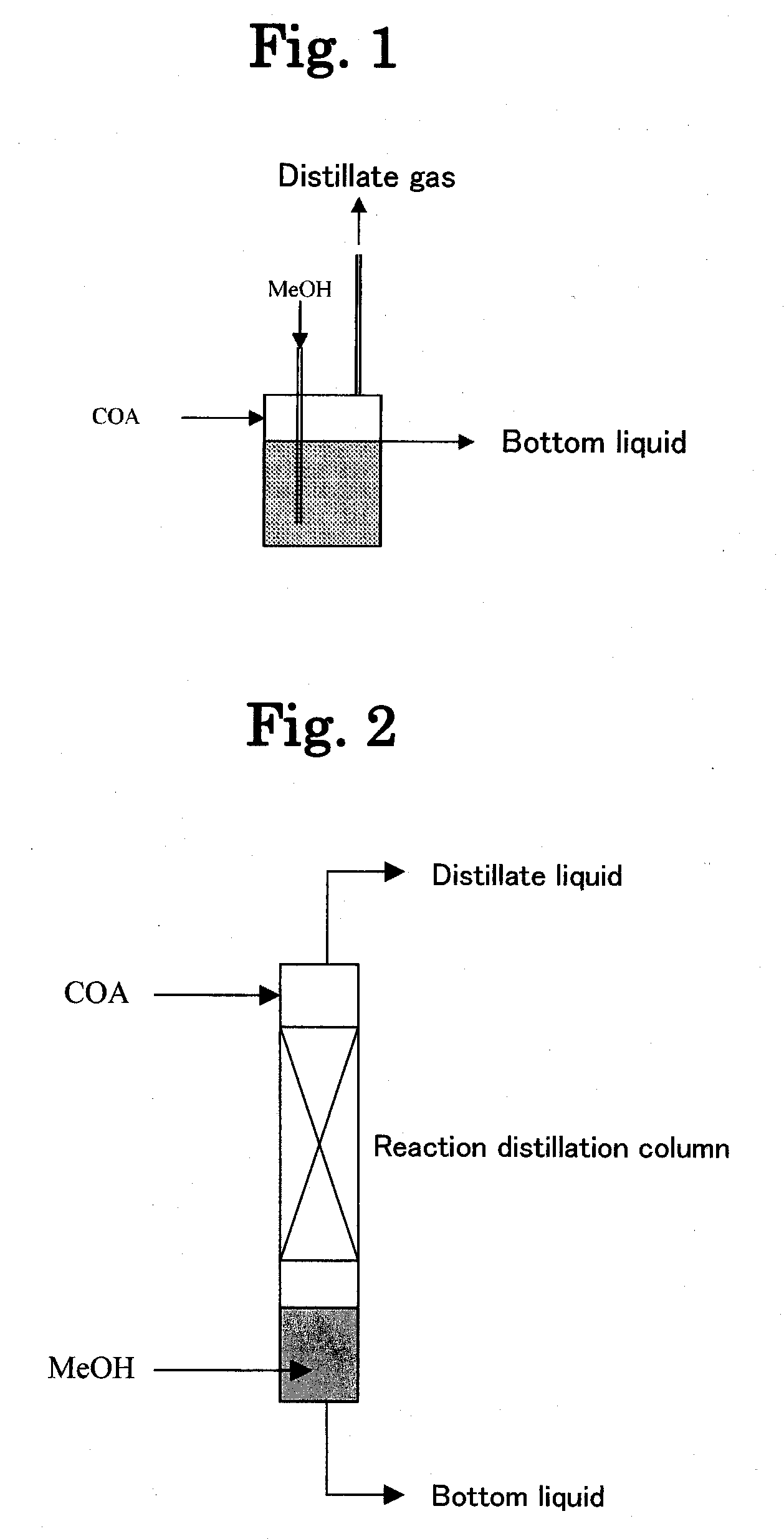

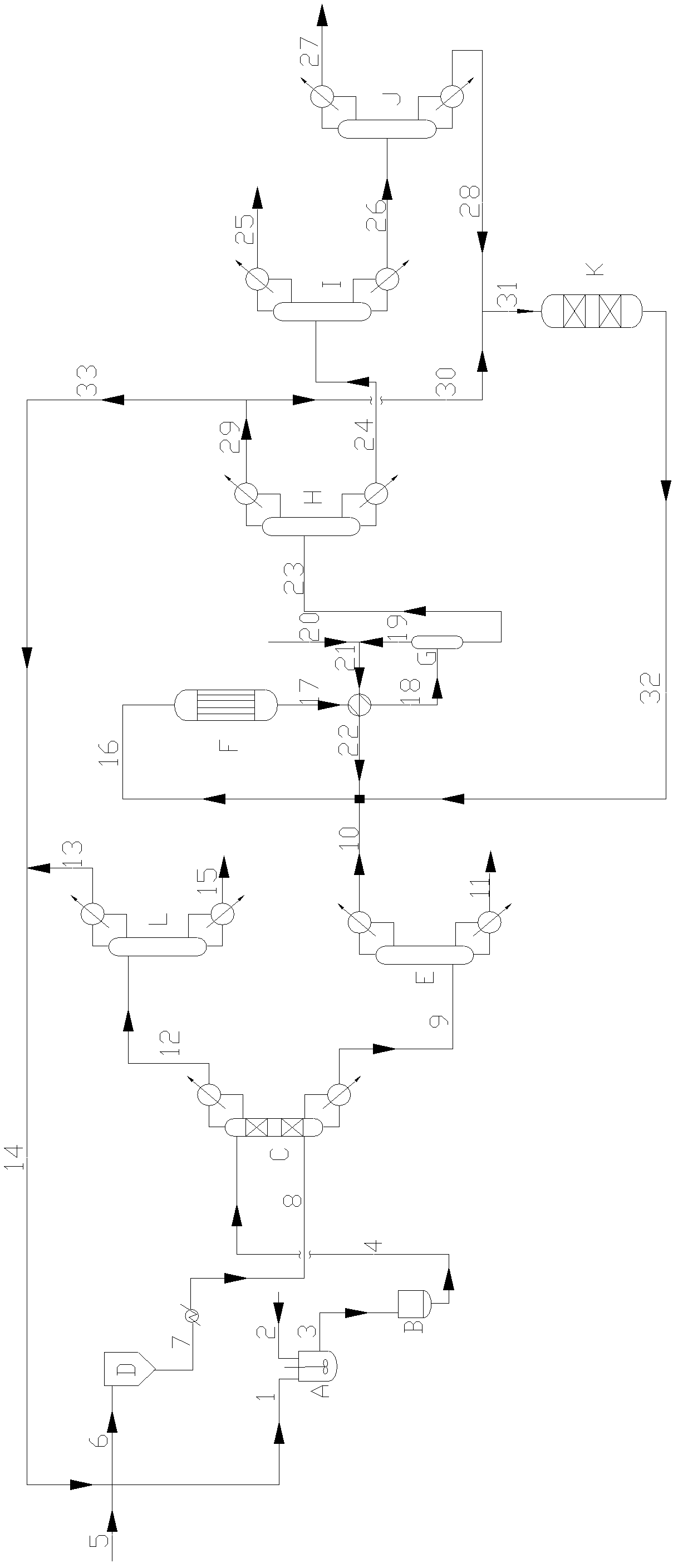

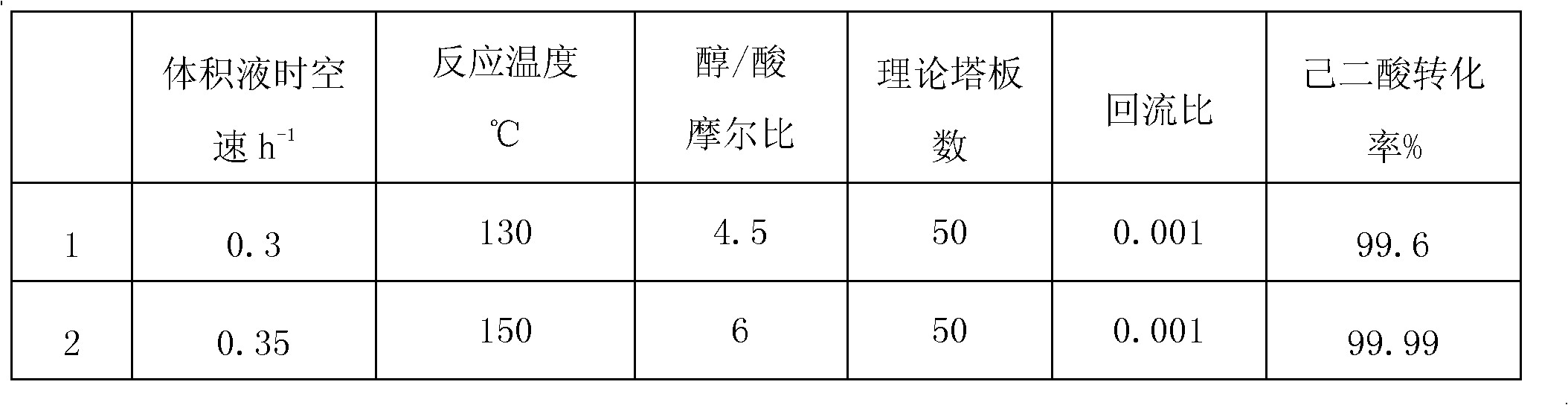

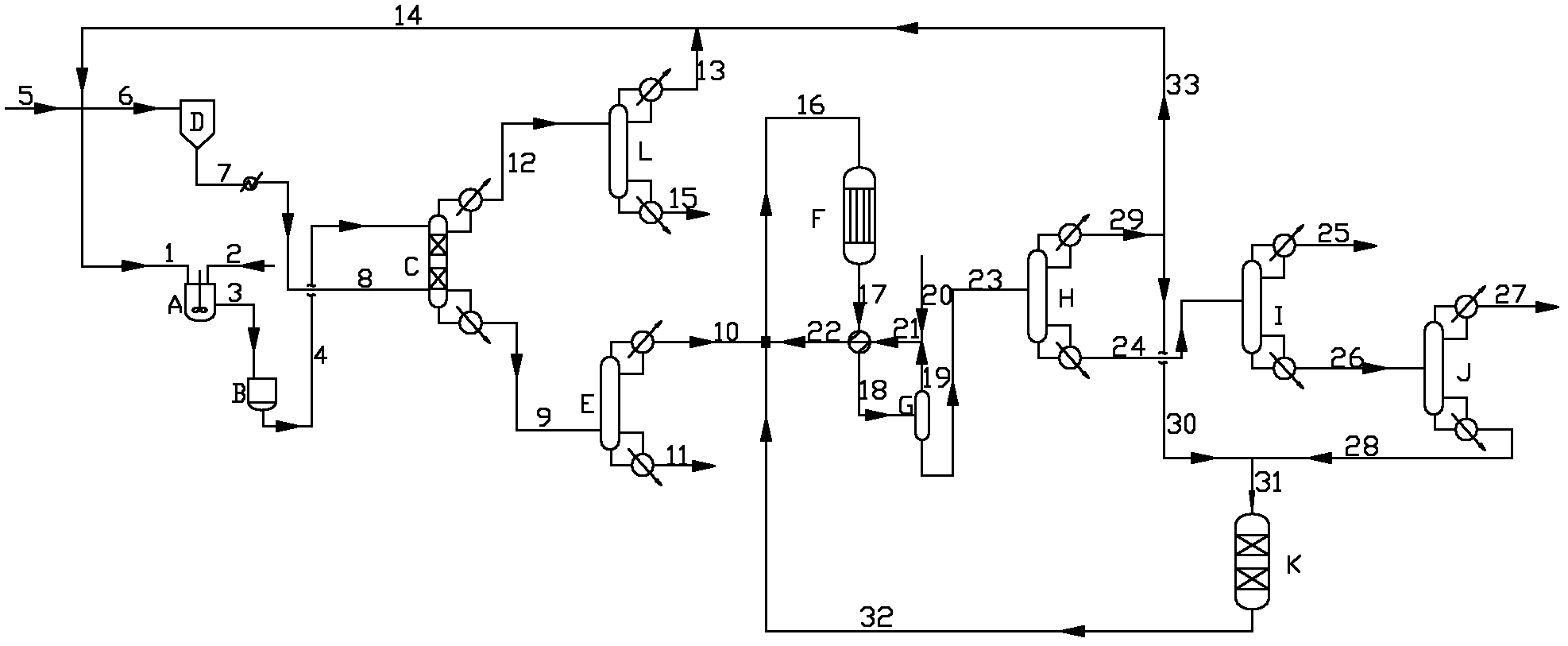

Process for producing 1,6-hexanediol and coproducing epsilon-caprolactone

ActiveCN102351648AEfficient use ofEasy to separateOrganic compound preparationHydroxy compound preparationCatalytic distillationAdipic acid

The invention provides a process for preparing 1,6-hexanediol and coproducing epsilon-caprolactone through esterification and hydrogenation of adipic acid. The process comprises the following steps of: performing countercurrent contact of pure adipic acid and methanol steam on a catalyst active ingredient-loaded filler in a reaction catalytic distillation tower, and performing esterification reaction; and purifying dimethyl adipate, and performing hydrogenation purification to obtain the 1,6-hexanediol and coproduce epsilon-caprolactone, wherein polymer generated after product separation is subjected to ester exchange reaction to be recycled. The catalyst has high activity and selectivity, the products are high in yield, energy consumption is low, the equipment investment is small, the catalyst is environment-friendly, and the preparation process is simple, economic and practical.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

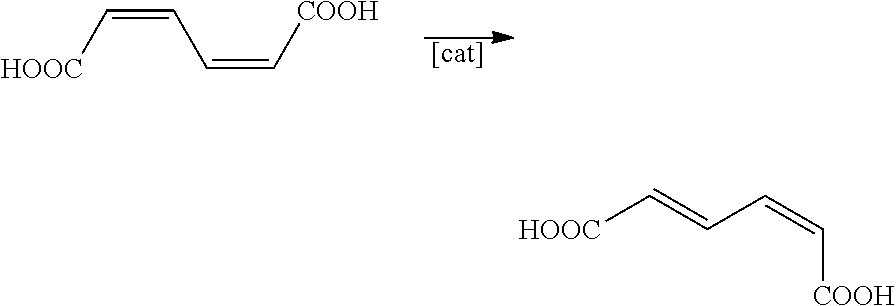

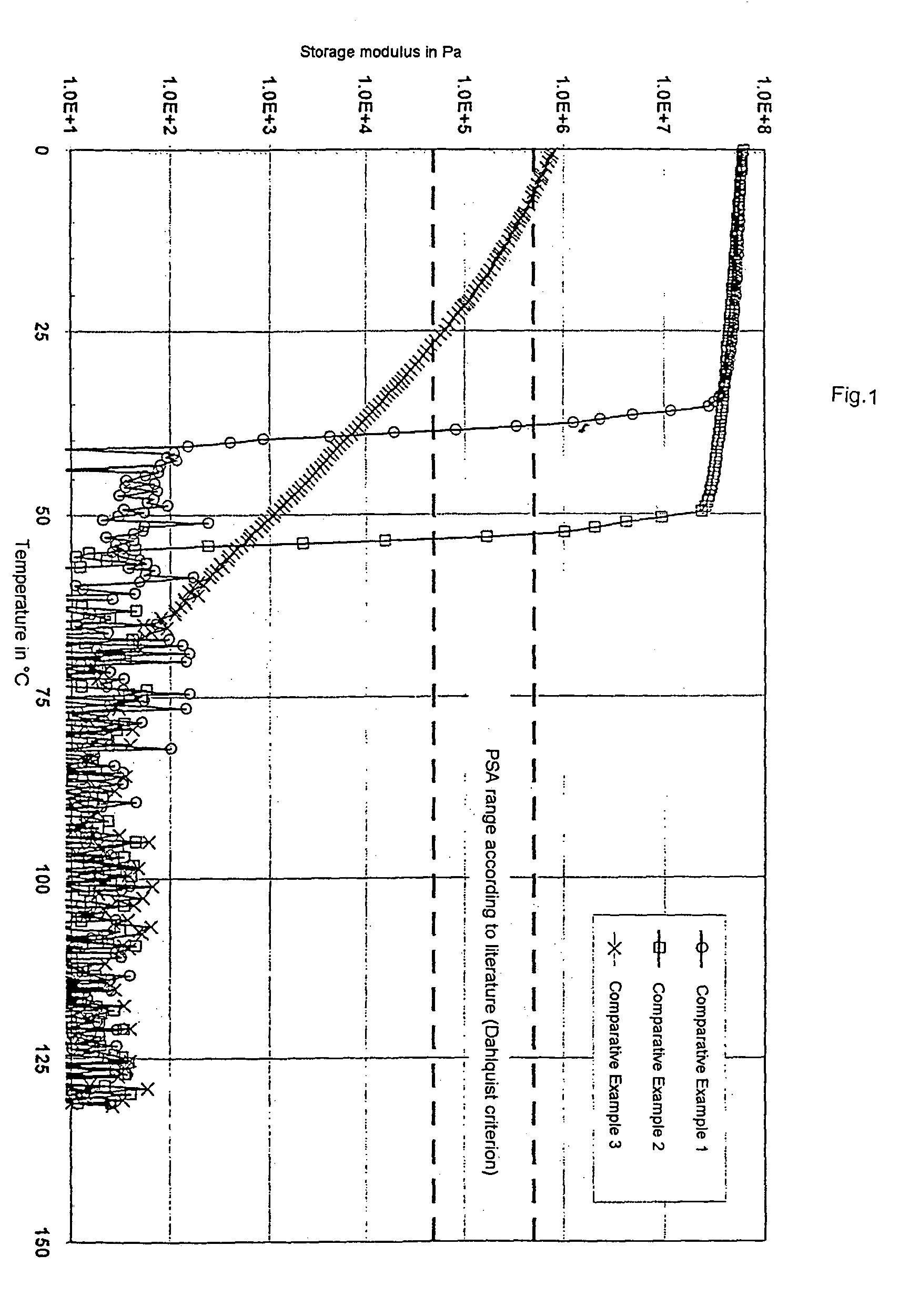

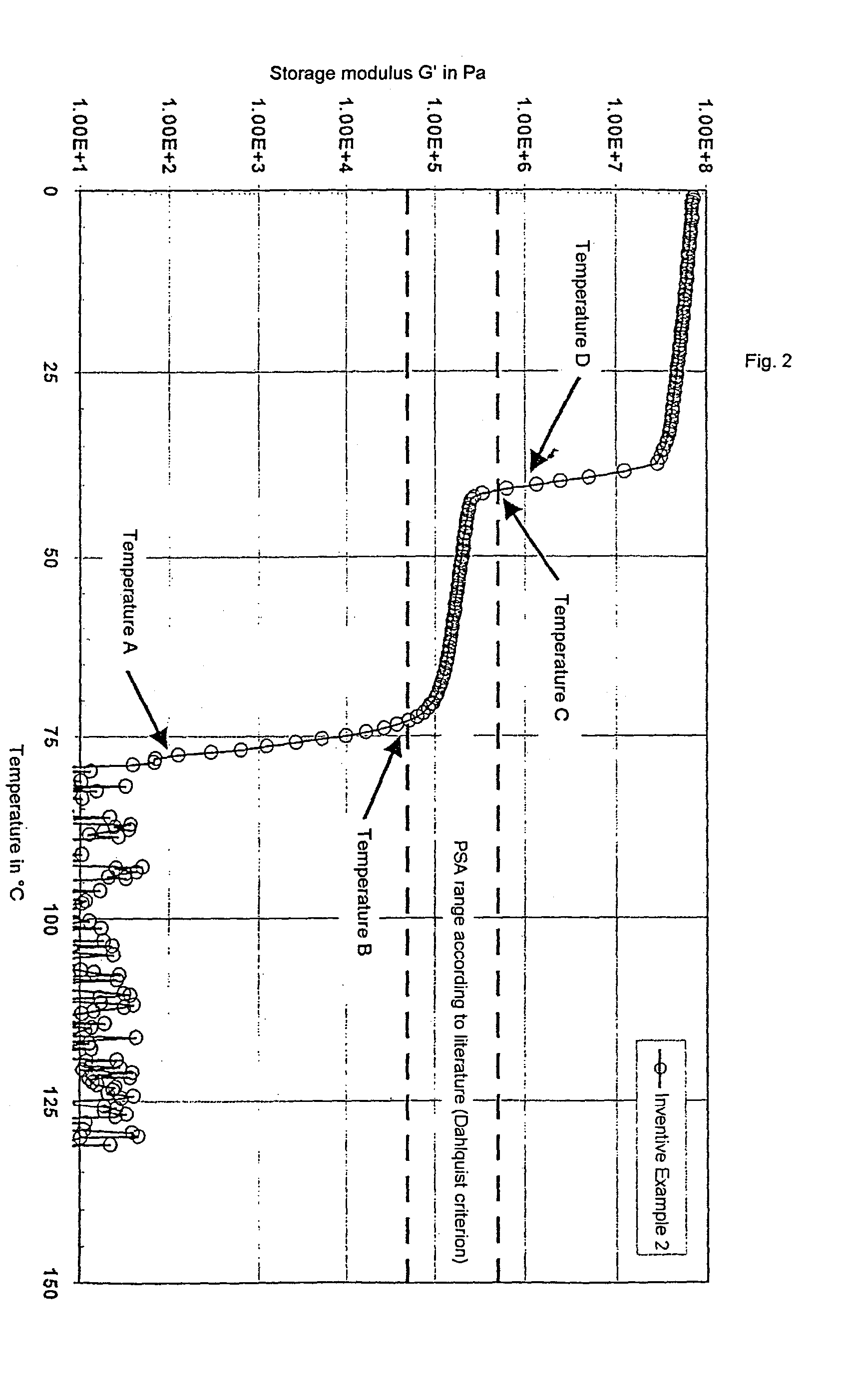

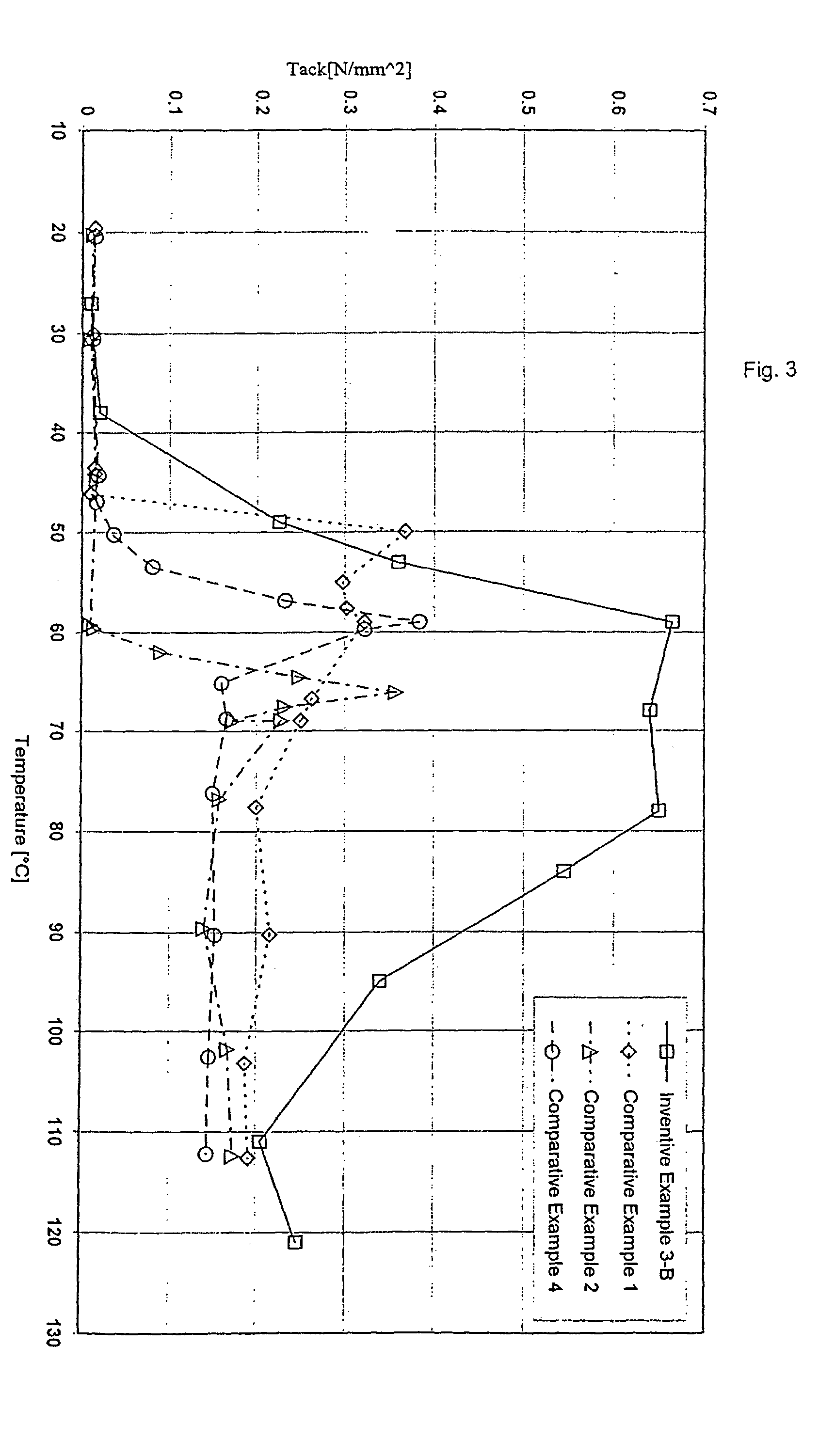

Reactive polyurethane hotmelts with large PSA range

Reactive polyurethane hotmelts comprising crystallizing polyesterpolyols based on fumaric acid and 1,6-hexanediol. These hotmelts exhibit good pressure-sensitive adhesive (PSA) properties over a very broad temperature range. The reactive polyurethane hotmelts are prepared by mixing a polyol mixture containing at least on crystallizing polyesterpolyol with an excess of polyisocyanates.

Owner:COVESTRO DEUTSCHLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com