Polyurethane for sports shoe sole and preparation method thereof

A technology for polyurethane and shoe soles, applied in the field of polyurethane materials, can solve problems such as loss of cushioning, human injury, and gradual thinning, and achieve high rebound performance, reduced physical energy consumption, and high comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

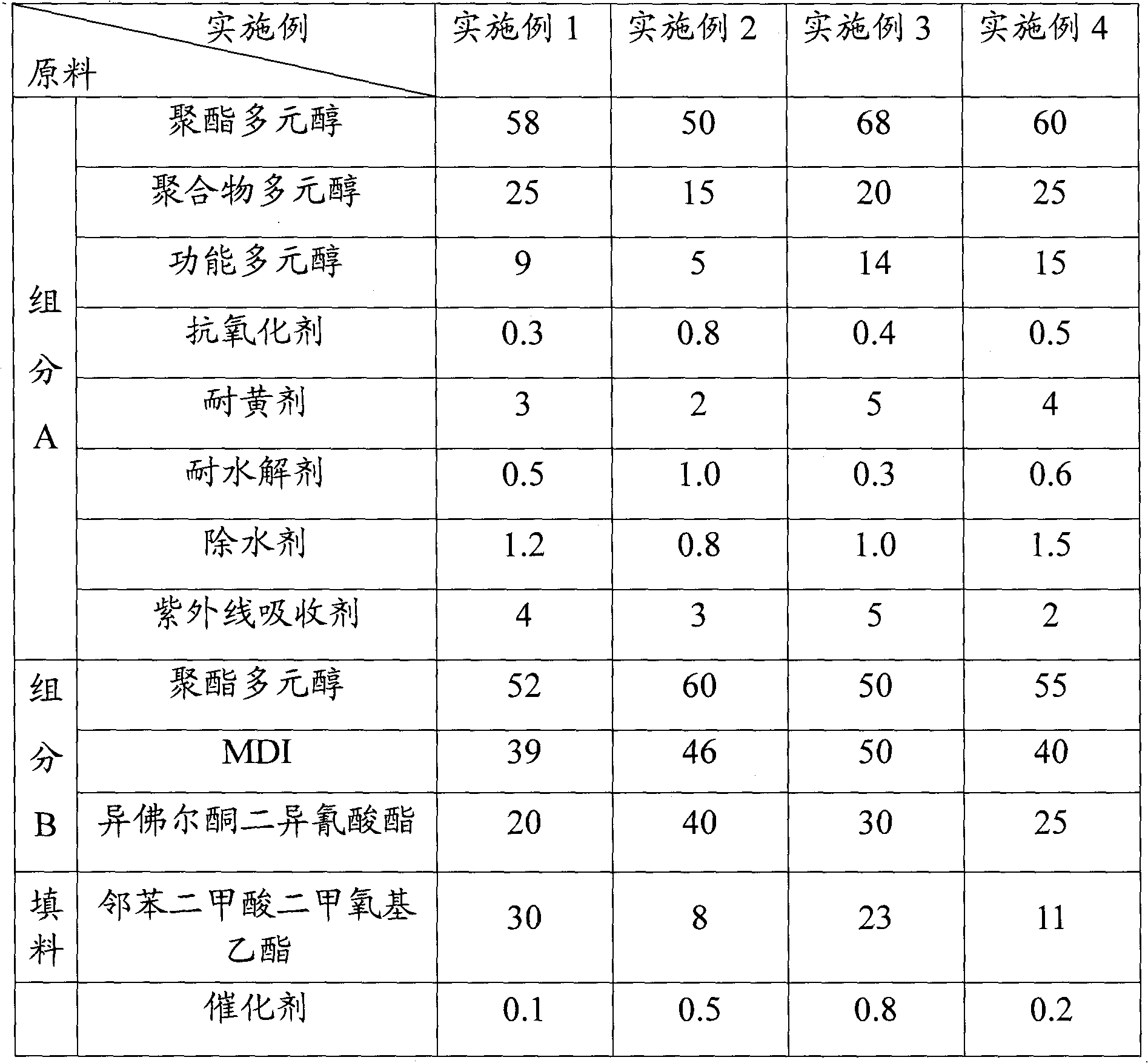

[0022] A polyurethane for sports shoe soles, comprising two components: component A, component B and filler, the weight ratio of the three being 1:1.7~1.86:0.1~0.3;

[0023] The component A mainly includes the following components by weight: 50-70 polyester polyols, 20-50 polymer polyols, 10-30 functional polyols; wherein the functional polyols are selected from 1-4 butanediol , 1-2 propylene glycol, 1-6 hexanediol or trimethylolpropane;

[0024] The component B mainly includes the following ingredients in parts by weight: 30-60 parts of diphenylmethane diisocyanate, 21-50 parts of polyester polyol, and 20-40 parts of isophorone diisocyanate;

[0025] The filler is dimethoxyethyl phthalate.

[0026] The above-mentioned polyurethane used for sports shoe soles is mainly composed of two mixture components: component A and component B, which are formed by mixing in a reasonable proportion, which can make the hardness of the material reach an excellent state and provide extremely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com