Catalyst and method for preparing 1, 6-hexanediol by hydrogenation of dialkyl 1, 6-adipate

A technology of dialkyl adipate and hexanediol, which is applied in the field of catalytic chemistry and can solve problems such as high hydrogen/ester molar ratio, limitations of preparation methods, and high reaction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

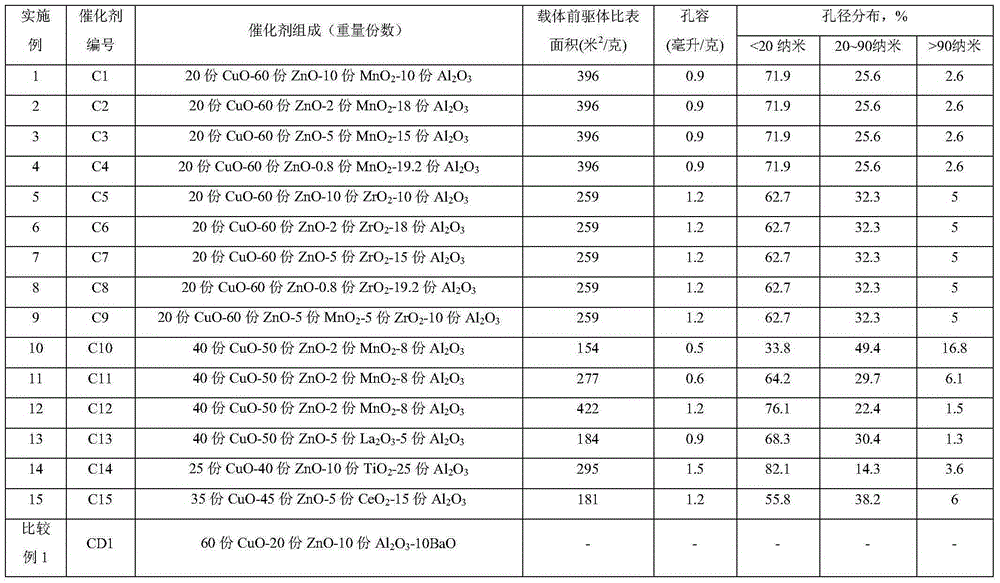

Embodiment 1

[0027] Weigh 73.6 grams of aluminum nitrate nonahydrate, prepare a solution with a concentration of 0.6M, stir evenly, transfer to a three-necked flask, and heat to 65°C. The aluminum nitrate solution was neutralized with 25% ammonia water, the pH value of the end point was controlled to be 8.6, the obtained gel was aged for 4 hours, filtered with suction, washed, dried at 90° C. and then used for later use.

[0028] Weigh 60.4 grams of copper nitrate trihydrate, 220.4 grams of zinc nitrate hexahydrate, and 41.1 grams of 50% manganese nitrate solution, and prepare a solution with a concentration of 0.6M, which is solution I; weigh 129.1 grams of sodium carbonate, and prepare a solution with a concentration of 1.0 The solution of M is solution II. Place the prepared alumina precursor in the bottom liquid, heat it to 75°C, add solution I and solution II dropwise in parallel, control the end point pH value at about 7.0, age the obtained slurry for 3 hours, filter, wash, and heat ...

Embodiment 2

[0030]Weigh 132.4 grams of aluminum nitrate nonahydrate, prepare a solution with a concentration of 0.6M, stir evenly, transfer to a three-necked flask, and heat to 65°C. The aluminum nitrate solution was neutralized with 25% ammonia water, the pH value of the end point was controlled to be 8.6, the obtained gel was aged for 4 hours, filtered with suction, washed, dried at 90° C. and then used for later use.

[0031] Weigh 60.4 grams of copper nitrate trihydrate, 220.4 grams of zinc nitrate hexahydrate, and 8.2 grams of 50% manganese nitrate solution, and prepare a solution with a concentration of 0.6M, which is solution I; weigh 118.4 grams of sodium carbonate, and prepare a solution with a concentration of 1.0 The solution of M is solution II. Put the prepared alumina precursor in the bottom liquid, heat it to 75°C, add solution I and solution II dropwise in parallel, control the end point pH value at about 7.0, and age the obtained slurry for 3 hours, filter, wash, and heat...

Embodiment 3

[0033] Weigh 110.3 grams of aluminum nitrate nonahydrate, prepare a solution with a concentration of 0.6M, stir evenly, transfer to a three-necked flask, and heat to 65°C. The aluminum nitrate solution was neutralized with 25% ammonia water, the pH value of the end point was controlled to be 8.6, the obtained gel was aged for 4 hours, filtered with suction, washed, dried at 90° C. and then used for later use.

[0034] Weigh 60.4 grams of copper nitrate trihydrate, 220.4 grams of zinc nitrate hexahydrate, and 20.6 grams of 50% manganese nitrate solution, and prepare a solution with a concentration of 0.6M, which is solution I; weigh 122.4 grams of sodium carbonate, and prepare a solution with a concentration of 1.0 The solution of M is solution II. Put the prepared alumina precursor in the bottom liquid, heat it to 75°C, add solution I and solution II dropwise in parallel, control the end point pH value at about 7.0, and age the obtained slurry for 3 hours, filter, wash, and he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com