Patents

Literature

188 results about "Aluminum nitrate nonahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparation of antioxidant composite coating on carbon fiber surface

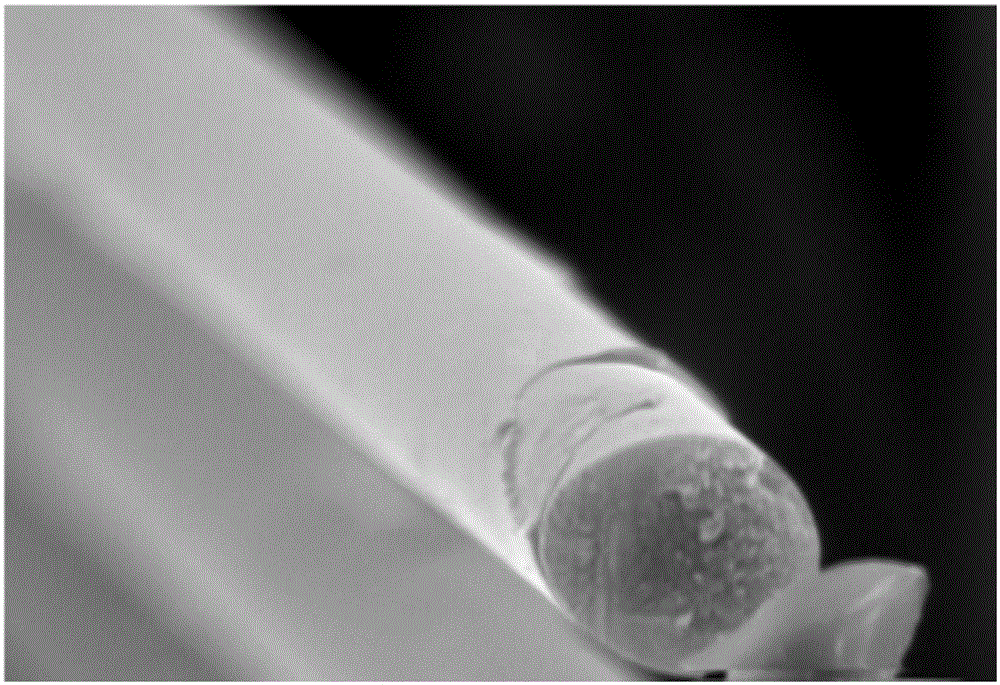

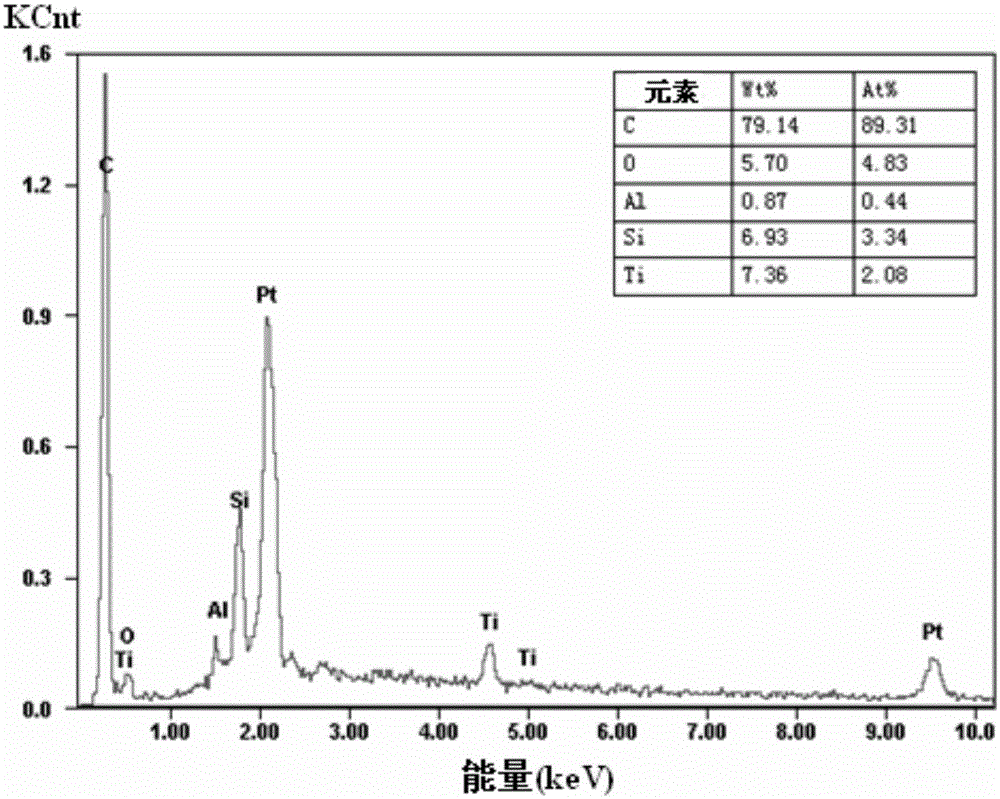

ActiveCN105113213ASimple preparation processReduced total preparation timeCarbon fibresFiberCarbon fibers

The invention relates to a method for preparation of an antioxidant composite coating on a carbon fiber surface. The antioxidant composite coating is an Al2O3-SiO2-TiO2 composite coating. The method is sol-gel method, which includes: composite sol preparation, carbon fiber surface activation treatment, coating, drying and heat treatment. The composite sol is prepared under room temperature, and the preparation process includes: firstly preparing a water-alcohol solution of tetraethyl orthosilicate and acetic acid into a mixed solution A, then pouring the mixed solution A into an alcohol solution of butyl titanate to prepare a mixed solution B, then under stirring, pouring an alcohol solution of aluminum nitrate nonahydrate into the mixed solution B to prepare a mixed solution C, finally adding an alcohol-water mixed solvent into the mixed solution C, and performing stirring to obtain the composite sol. With the ternary composite sol prepared by the method provided by the invention, a uniform and complete antioxidant coating with good adhesion and thickness within 3 micrometers can be prepared on the carbon fiber surface.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

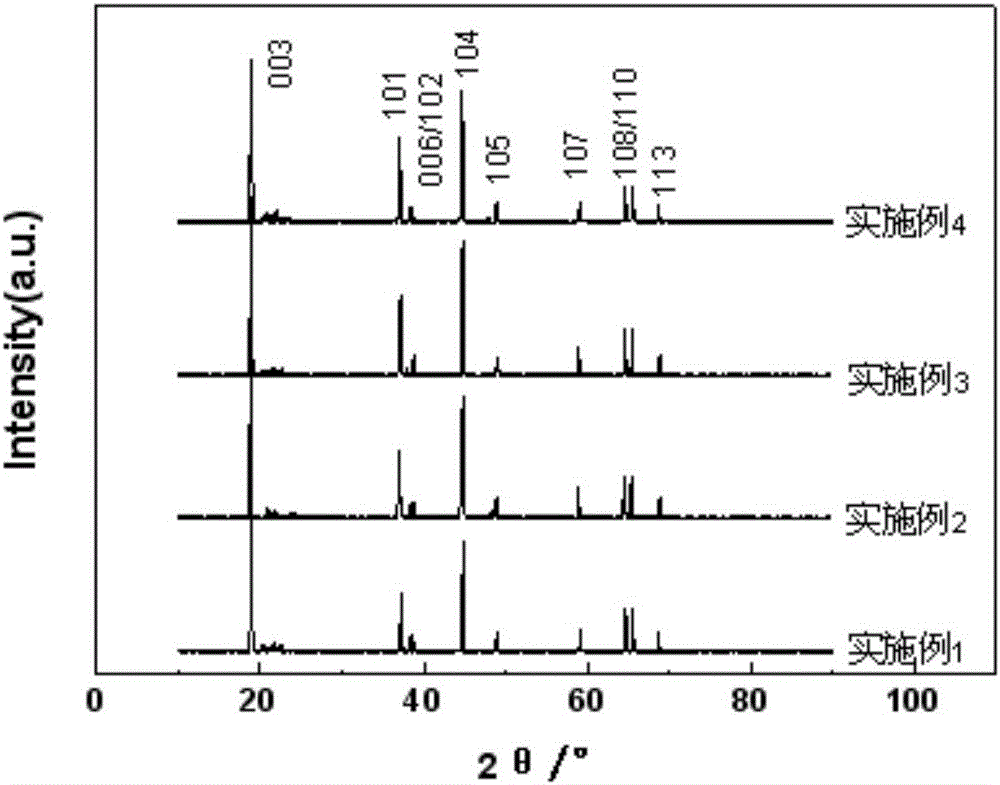

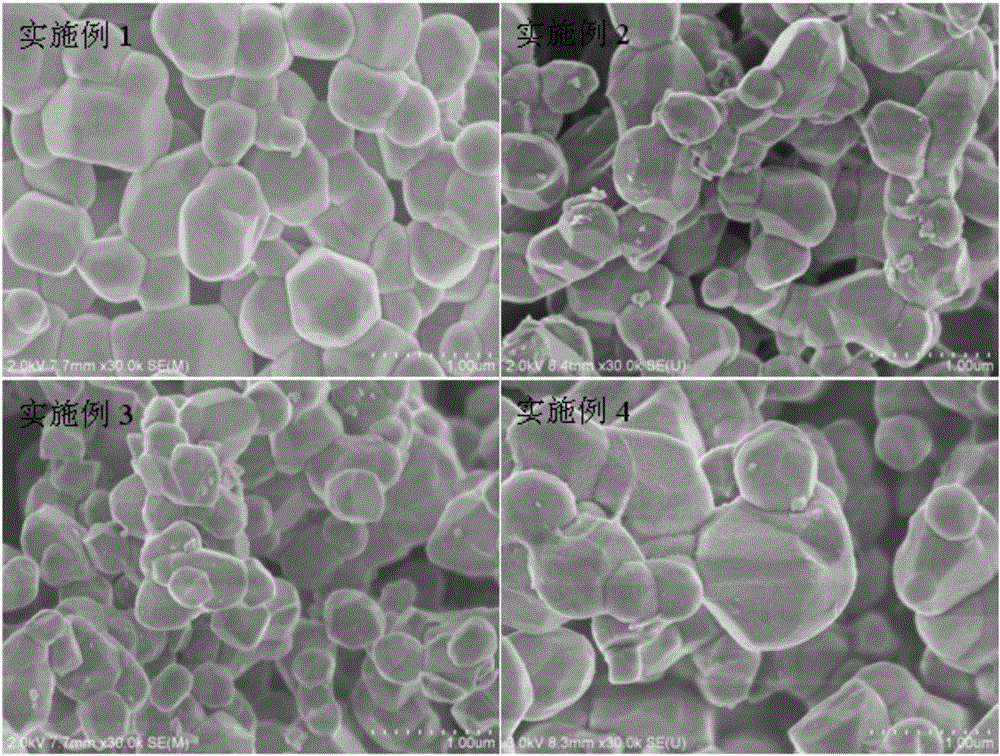

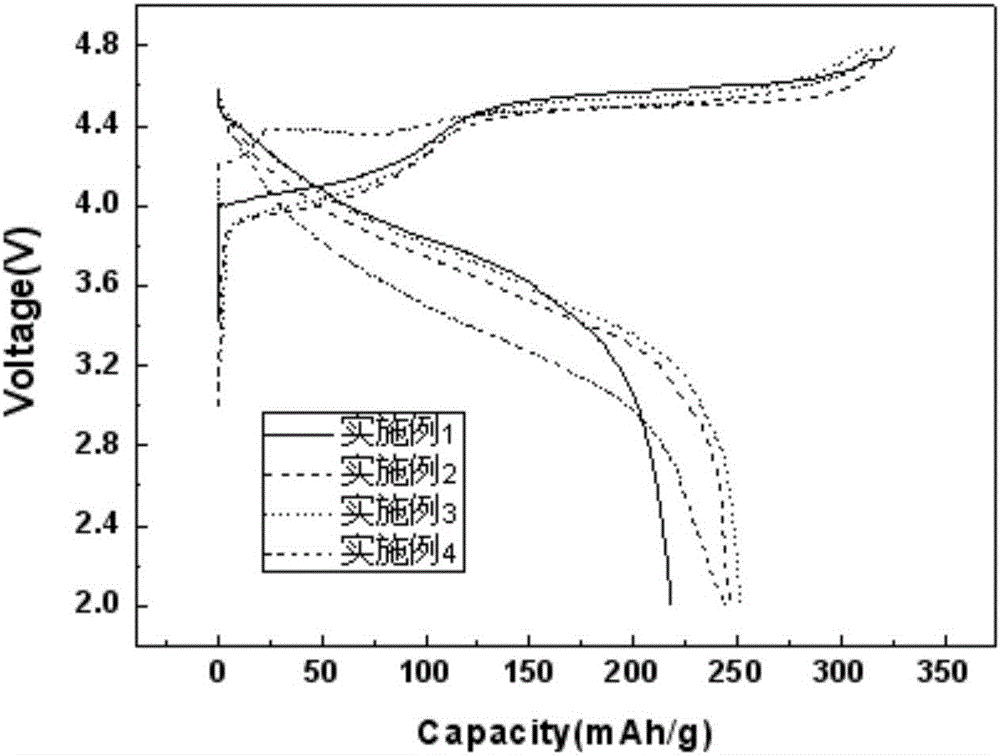

Lithium-rich positive electrode modified material of lithium ion battery and preparation method of lithium-rich positive electrode modified material

InactiveCN106602009AHigh puritySmall particle sizeCell electrodesSecondary cellsWater bathsSodium-ion battery

The invention relates to a lithium-rich positive electrode modified material of a lithium ion battery and a preparation method of the lithium-rich positive electrode modified material, and belongs to the technical field of a positive electrode material of the lithium ion battery. The lithium-rich positive electrode modified material comprises a positive electrode material and a three-class metal oxide cladding material, wherein the cladding material is TiO2, MnO2 or Al2O3. The preparation method comprises the steps of performing water bath stirring and heating to obtain gel by a sol-gel method, performing drying to obtain dried gel, respectively performing low-temperature pre-sintering and high-temperature calcination, obtaining the positive electrode material after cooling and grinding, dispersing the prepared positive electrode material and TiO2 and MnO2 cladding materials in deionized water, performing constant-temperature stirring, and performing standing, filtering, washing, drying and calcination to obtain the lithium-rich positive electrode modified material of the lithium ion battery. While for Al2O3, a liquid phase cladding method is adopted, the positive electrode material is dispersed in an aluminum nitrate nonahydrate solution, and the required modified material is obtained after constant-temperature stirring, standing, filtering, washing, drying and calcination. The preparation method is simple and easy to operate, the lithium-rich positive electrode modified material obtained through preparation is uniform in particle grain distribution and high in crystallinity, and the rate performance and the cycle performance of the material after cladding both are obviously improved.

Owner:JIANGNAN UNIV

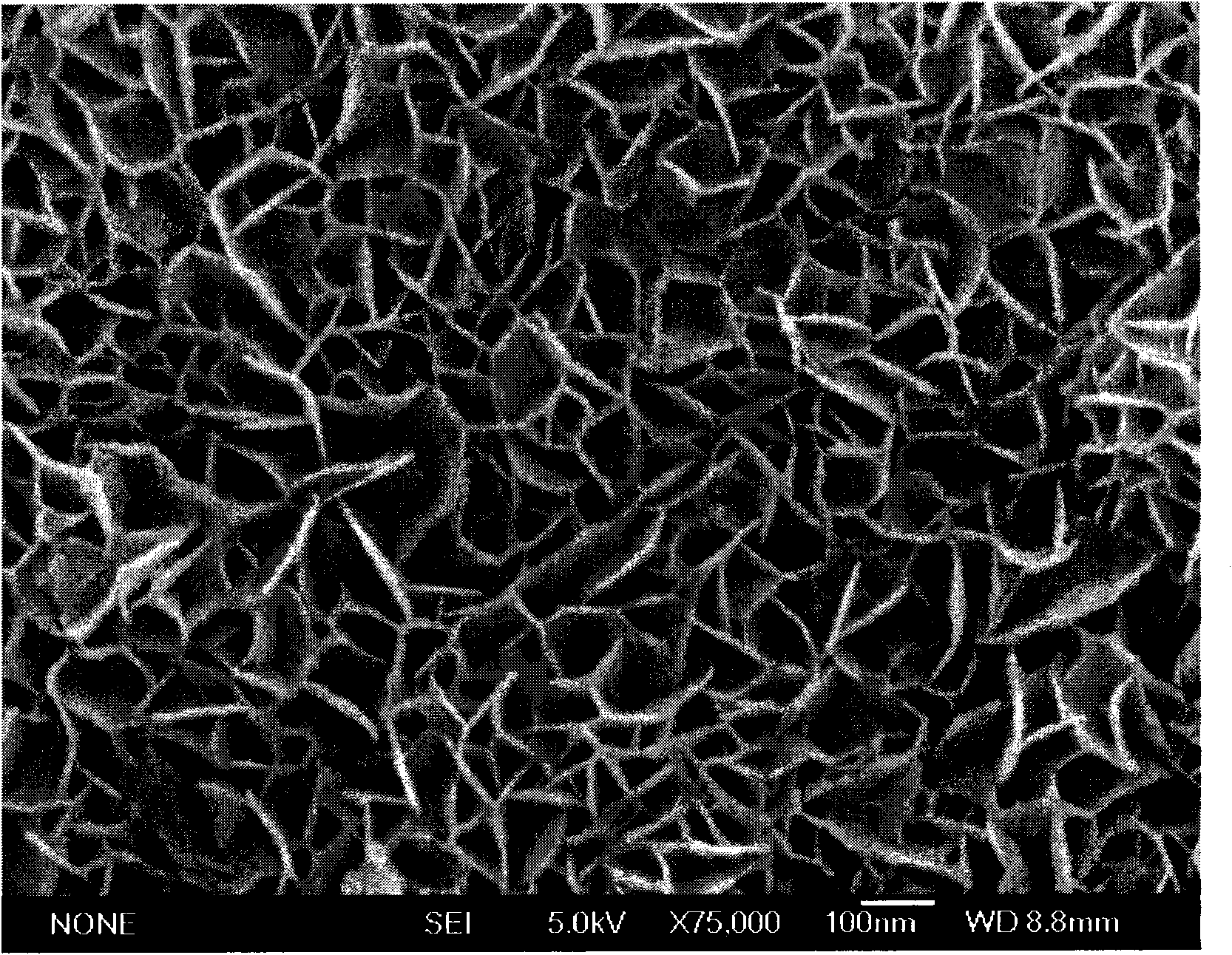

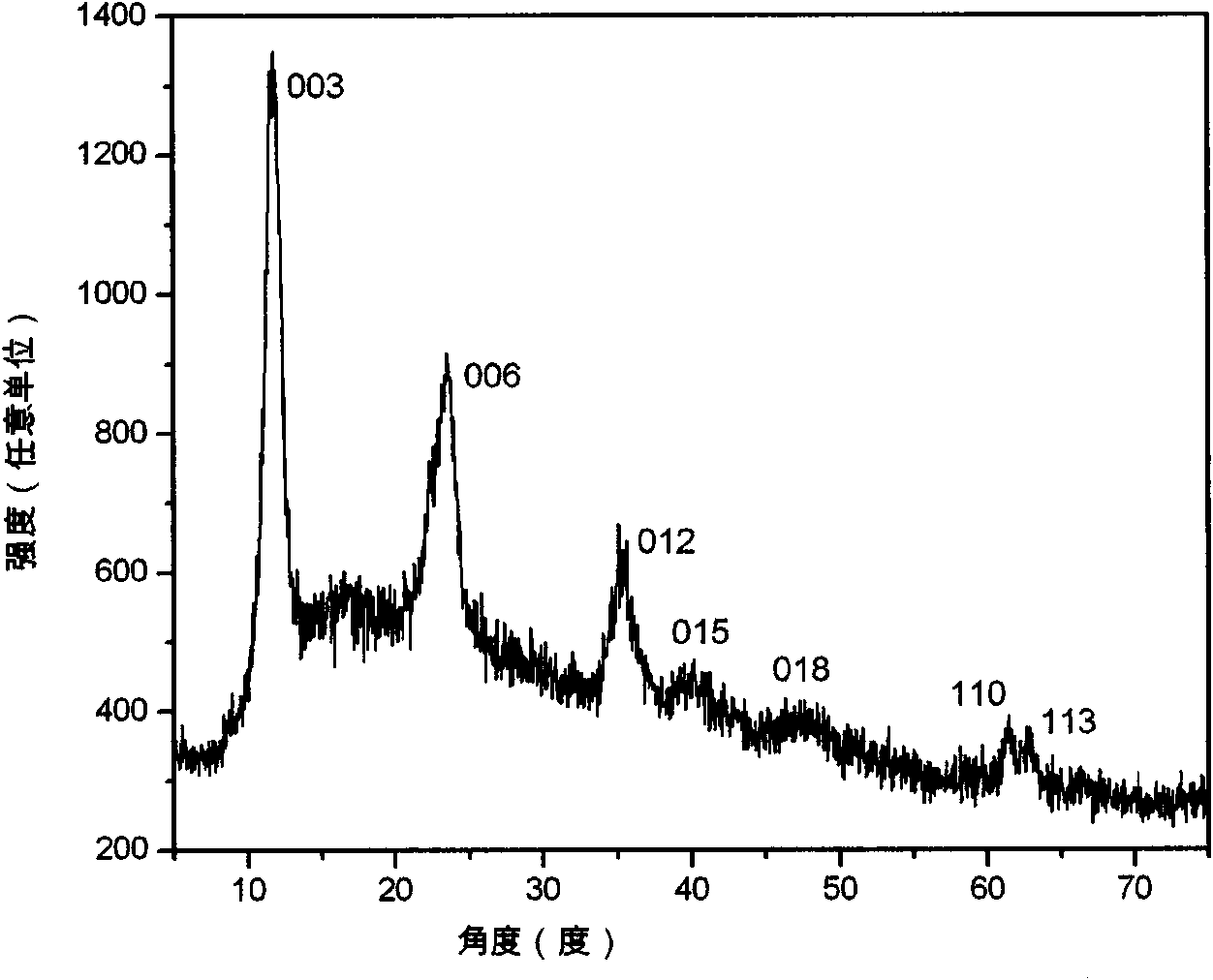

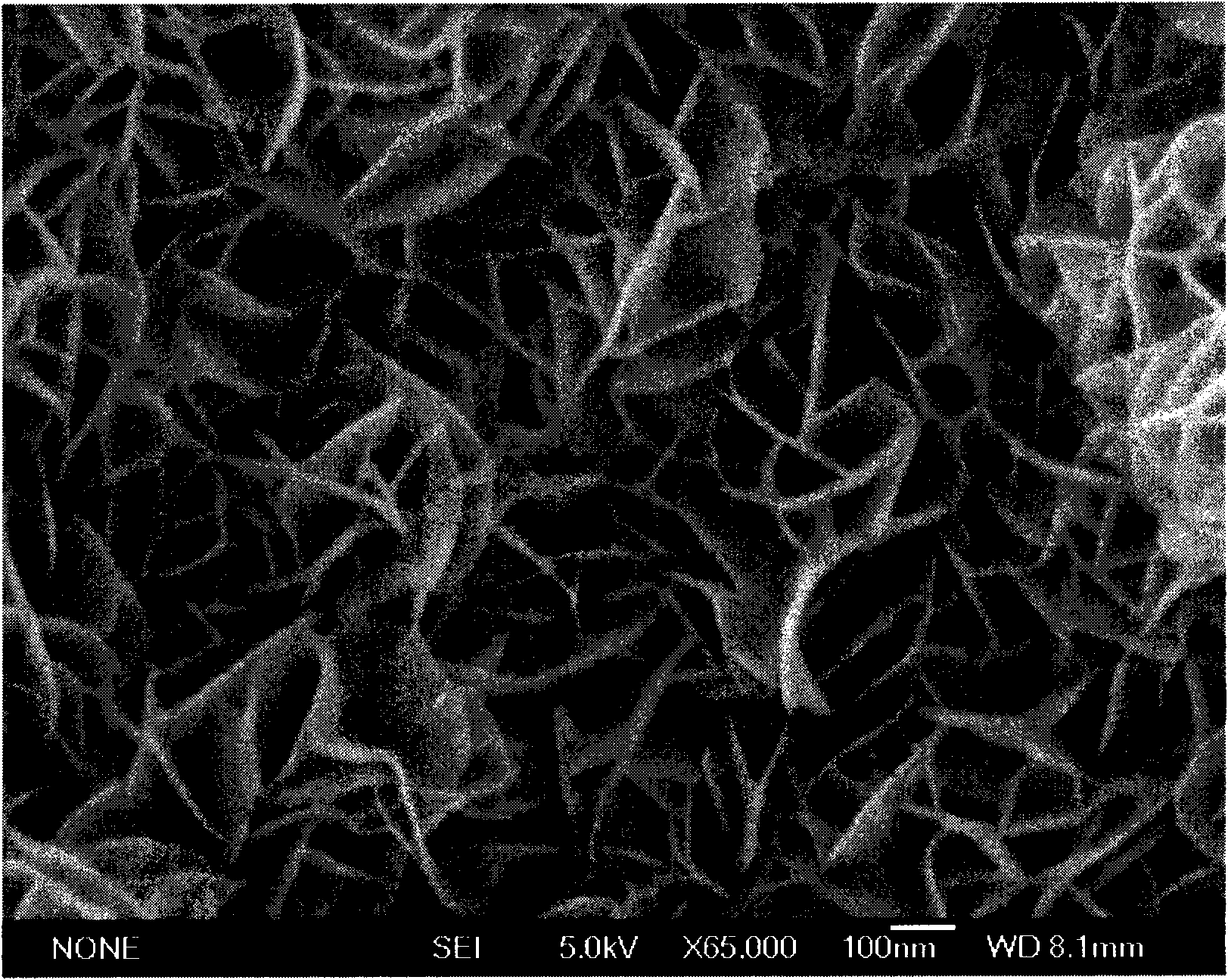

Glucose sensor electrode without enzyme with nickel-aluminium-hydrotalcite nano-chip arrays on substrate of titanium

InactiveCN101598697AGuaranteed stabilityEasy to storeMaterial electrochemical variablesGlucose sensorsTitanium metal

A glucose sensor electrode without enzyme with nickel-aluminium-hydrotalcite nano-chip arrays on a substrate of titanium is composed of the nickel-aluminium-hydrotalcite nano-chip arrays on the substrate of the titanium, the thickness of the single nickel- aluminium-hydrotalcite nano-chip is 20-40nm, and the diameter thereof is 200-400nm; the nickel-aluminium-hydrotalcite nano-chip arrays are distributed on the surface of the titanium metal vertically, evenly and densely in an arrayed manner. The preparation method is as follows: the titanium metal is soaked in hydrofluoric acid solution, and is placed into aqueous solution prepared by nickel nitrate hexahydrate, aluminum nitrate nonahydrate and carbamide after being washed by clean water; and then the titanium metal is sealed in a polytetrafluoroethylene liner in an autoclave and heated to over 70 DEG C for more than 36 hours; the titanium metal is taken out after being cooled naturally to obtain an electrode sample, wherein, the concentration of the nickel nitrate hexahydrate is 2.036g / 70-140ml of water, the concentration of the aluminum nitrate nonahydrate is 1.313g / 70-140ml of water and the concentration of the carbamide is 4.200g / 70-140ml of water. The electrode is applicable to the products in the fields such as biology, medicine, electronic instruments and the like. The glucose sensor electrode has high sensitivity to glucose detection, low detection limit, fast response, large linear range, stable work performance.

Owner:HUAZHONG NORMAL UNIV

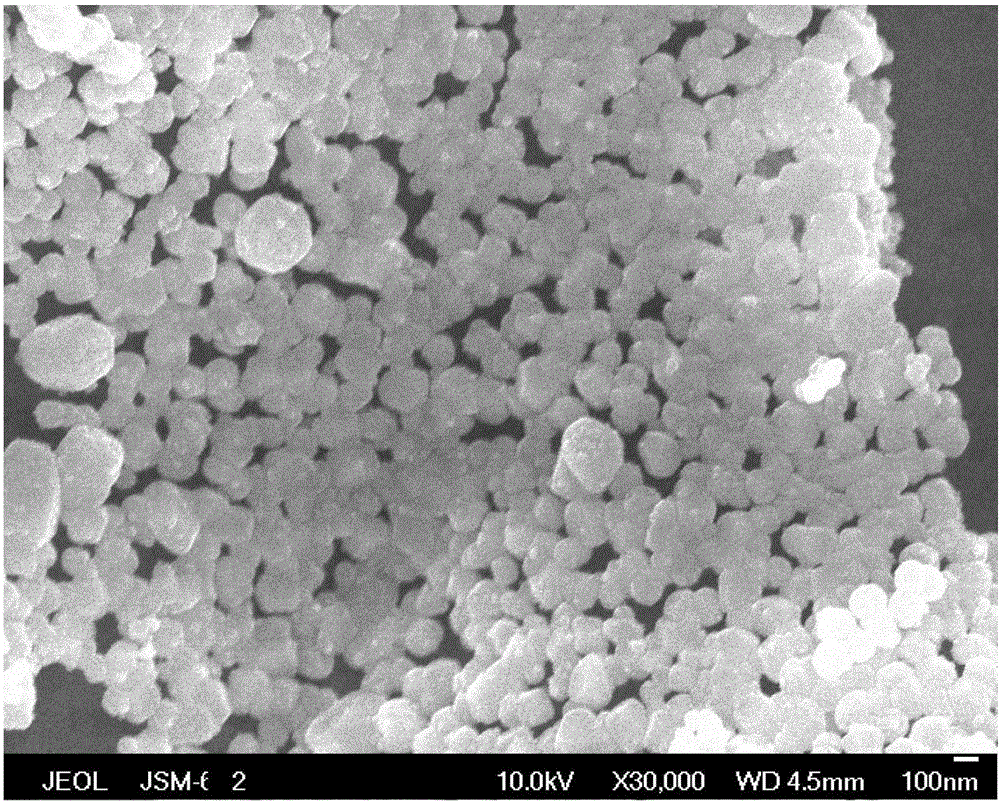

Preparation method of nickel oxide/alumina and nickel/alumina nanometer compound microparticle

InactiveCN103212417AGood uniformity of particle distributionImprove bindingMetal/metal-oxides/metal-hydroxide catalystsMicroparticleSolvent

A preparation method of nickel oxide / alumina and nickel / alumina nanometer compound microparticle specifically comprises the following steps of: (1) orderly dissolving aluminum nitrate nonahydrate, cetyl trimethyl ammonium bromide and sodium hydroxide to solvent and adding ethyl acetate, carrying out microwave hydrothermal reaction after magnetic stirring, centrifugally separating and washing for multiple times by using deionized water and absolute ethyl alcohol, and finally carrying out vacuum drying to obtain Boehmite self-assembly microparticle powder; and (2) adding the Boehmite self-assembly microparticle powder obtained in the step (1) to nickel nitrate hexahydrate for ultrasonic vibration, then centrifugally separating and washing for multiple times by using deionized water for vacuum drying, naturally cooling the product after calcining to obtain nickel oxide / alumina nanometer compound microparticle; preparing nicel / alumina nanometer compound microparticle after heating reduction of the nickel oxide / alumina nanometer compound microparticle. The particles of the nickel oxide / alumina and nickel / alumina nanometer compound microparticle prepared by the method are good in distribution uniformity and firmly combined with carriers.

Owner:SHAANXI UNIV OF SCI & TECH

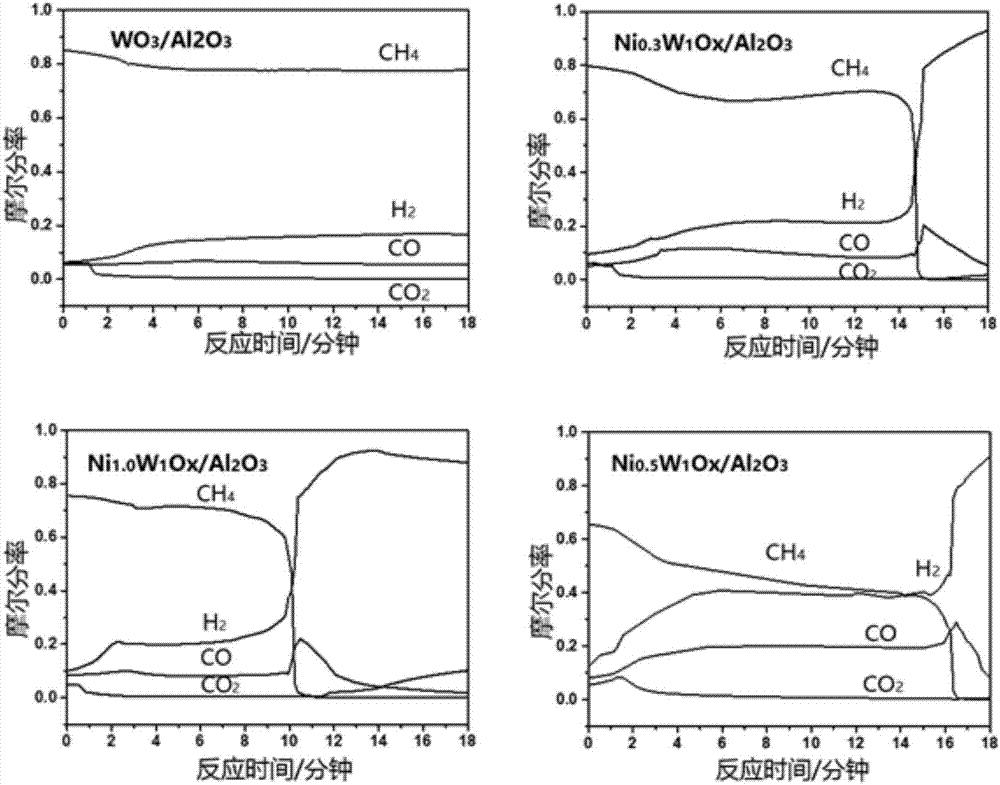

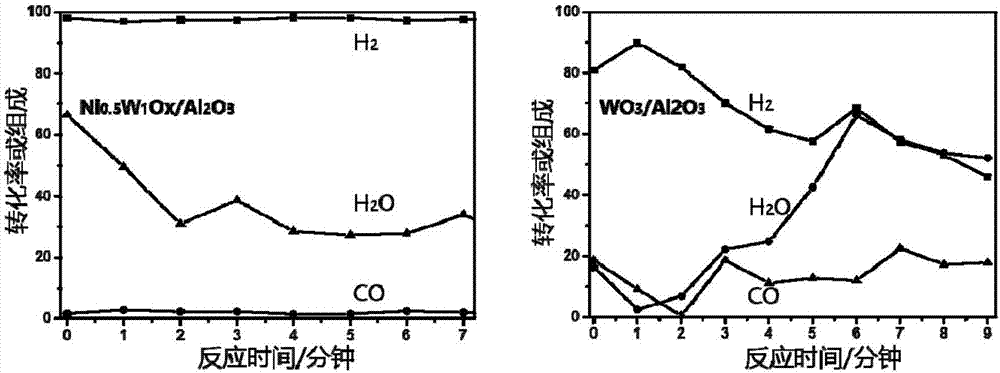

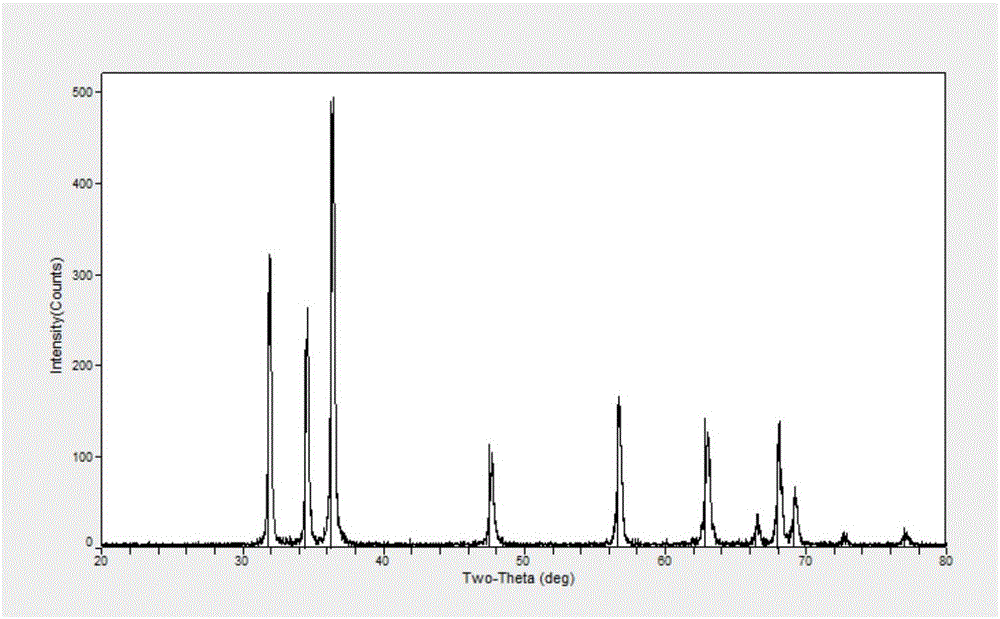

Supported nickel tungsten bimetallic composite oxide and preparation method and application thereof

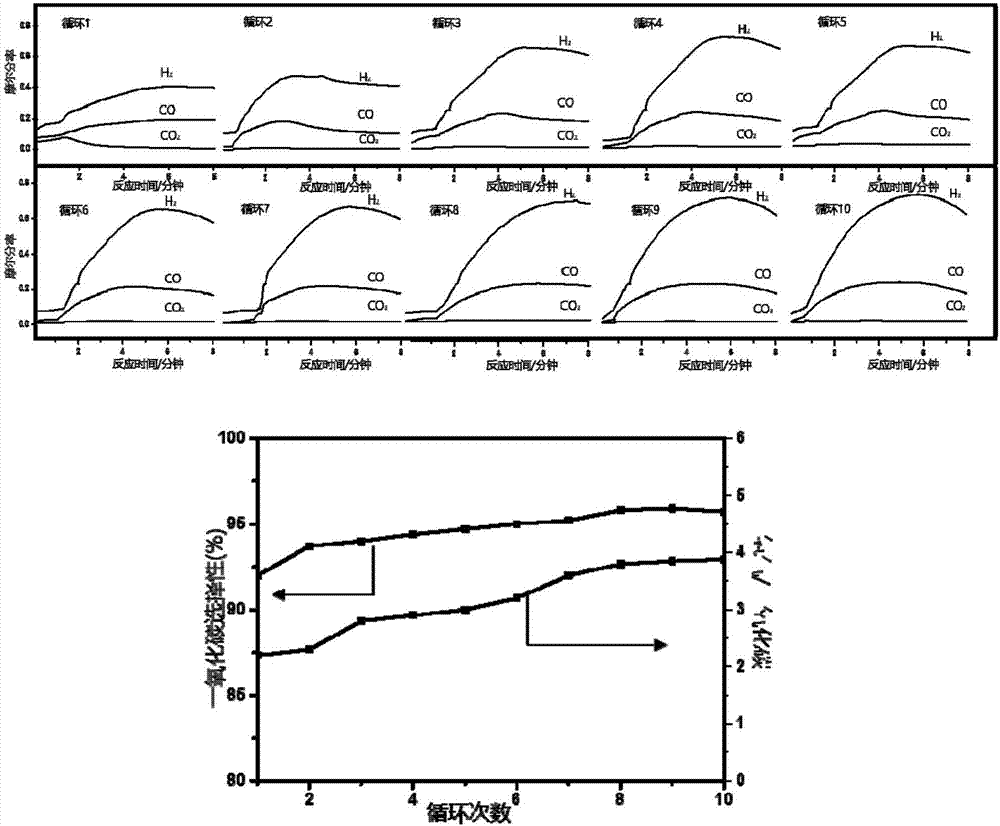

The invention belongs to the technical field of chemical looping hydrogen, and discloses supported nickel tungsten bimetallic composite oxide and a preparation method and an application thereof. A molecular formula is NiyW1O3+y / Al2O3, y is 0.3-1; the preparation method comprises the following steps: completely mixing nickel nitrate hexahydrate, tungsten hexachloride and aluminum nitrate nonahydrate in ethanol according to proportion and then dissolving the materials; then dropping a NaOH aqueous solution and mixing with a mixture, after standing, performing centrifugal filtration on a flocculent precipitate and washing the material; and drying and roasting the material to obtain the product. The supported nickel tungsten bimetallic composite oxide can be used for tribed self-heating gasification with light alkane, and reforming and direct production of hydrogen and carbon dioxide. The advantages of chemical looping combustion, catalytic reforming and high purity hydrogen production by pyrolysis water, and self-heating reforming of a gas-solid counter current operation-type tribed reactor are combined, the coprecipitation preparation method having the advantages of simple operation and low cost is used, so that fuel can be directly converted to carbon dioxide and high purity hydrogen, and near-zero energy consumption in-situ separation of the product is realized.

Owner:TIANJIN UNIV

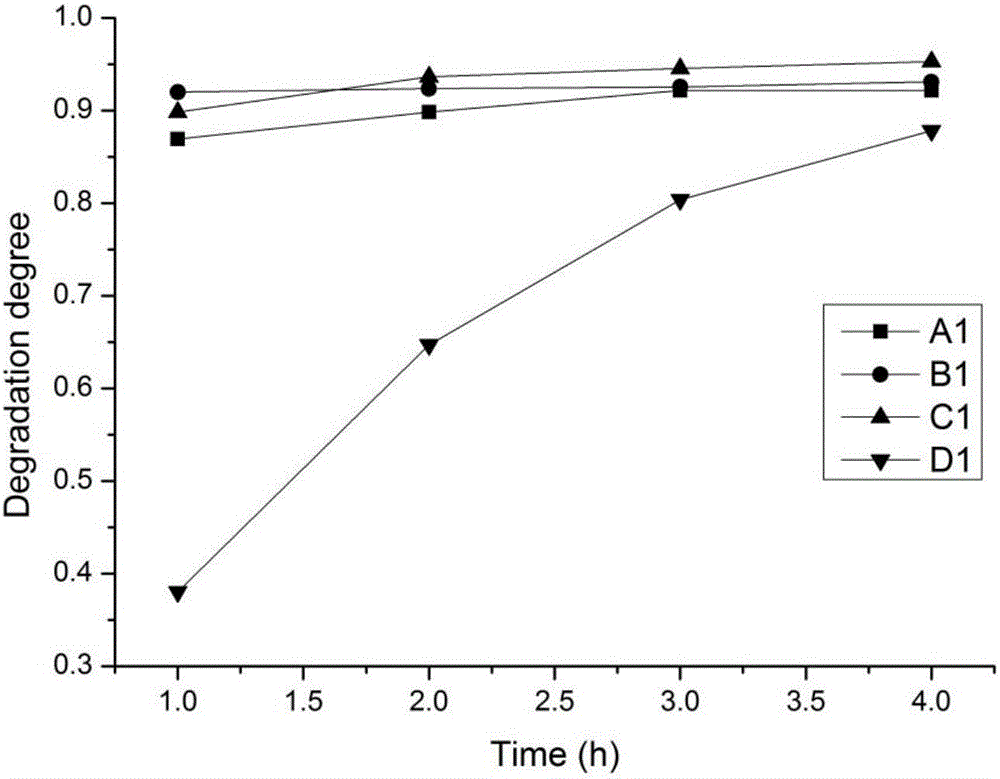

Preparation method of doped nanometer zinc oxide and application of doped nanometer zinc oxide in photocatalysis

ActiveCN106111108ASimple operating conditionsReduce manufacturing costWater/sewage treatment by irradiationWater treatment compoundsFreeze-dryingPolyvinyl alcohol

The invention discloses a preparation method of doped nanometer zinc oxide and an application of doped nanometer zinc oxide in photocatalysis. The preparation method comprises the following steps: polyvinyl alcohol, zinc nitrate hexahydrate and aluminum nitrate nonahydrate or cerium nitrate hexahydrate or lanthanum nitrate hexahydrate are taken as raw materials, a homogeneous aqueous solution is prepared from the raw materials and subjected to vacuum freeze drying and calcination, and aluminum, cerium or lanthanum doped nanometer zinc oxide powder is obtained. The flow of the preparation process is simple, one-step uniform mixing is performed in a doping process, the raw materials are easily available, and the preparation process is clean and pollution-free; the prepared aluminum doped nanometer zinc oxide powder is agglomeration-free, has photocatalytic activity better than that of pure nanometer zinc oxide when used for degrading reactive brilliant blue KN-R under ultraviolet light, while rare-earth metal cerium doped nanometer zinc oxide can degrade organic dyes by using visible light and has good application prospect in organic dye wastewater treatment.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

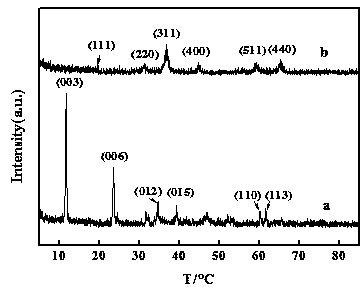

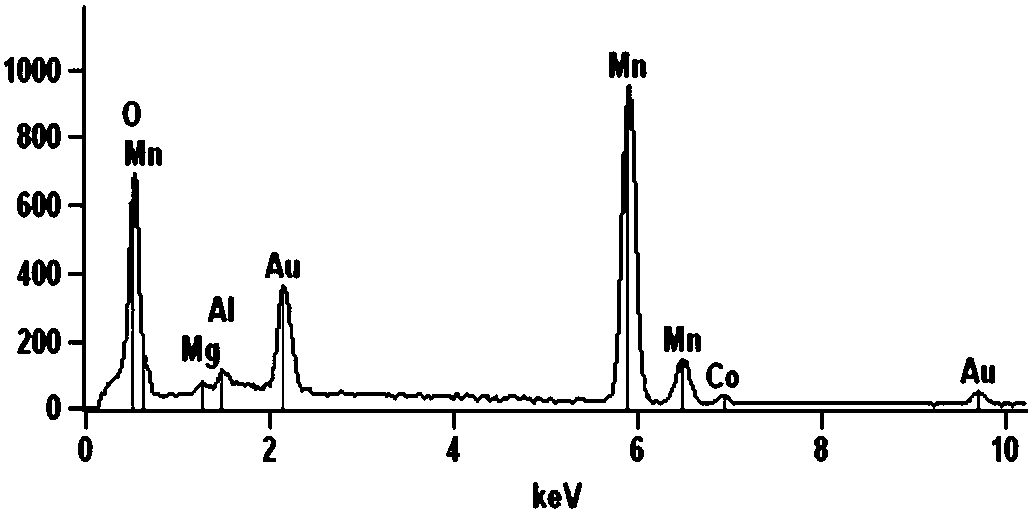

Preparation method and application of low-temperature flue gas denitration catalyst based on CoMnAl layered double hydroxide

ActiveCN108927170ALarge specific surface areaImprove thermal stabilityGas treatmentDispersed particle separationHexamethylenetetramineFiltration

The invention discloses a preparation method and application of a low-temperature flue gas denitration catalyst based on CoMnAl layered double hydroxide. The preparation of the catalyst is divided into two steps. The first step comprise: by taking cobalt nitrate nonahydrate, aluminum nitrate nonahydrate and a manganese nitrate solution with a mass fraction of 50% as raw materials, taking hexamethylenetetramine (HMT) as a precipitant and taking deionized water as a solvent and a detergent, performing solution preparation, hydrothermal treatment, suction filtration, washing and drying to obtaina CoMnAl layered double hydroxide precursor (CoMnAl-LDH); and the second step comprises roasting the obtained CoMnAl layered double hydroxide precursor to obtain a CoMnAl composite oxide catalyst (CoMnAl-LDO). After subjected to tableting and sieving, the prepared catalyst has good catalytic activity, high N2 selectivity and good water resistance and sulfur resistance when applied to low-temperature (90-300 DEG C) ammonia selective catalytic reduction (NH3-SCR) denitration reactions.

Owner:TAIYUAN UNIV OF TECH

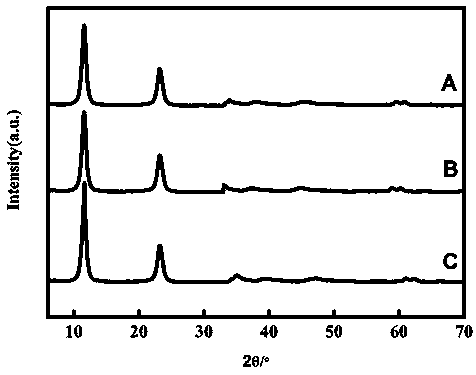

Method for preparing nitrate intercalation cobalt and aluminum type hydrotalcite in one step through coprecipitation

The invention discloses a method for preparing nitrate intercalation cobalt and aluminum type hydrotalcite in one step through coprecipitation. An acetic acid-sodium acetate buffer solution is used; the pH value of a preparation system is stably controlled at 4.00 to 5.00; cobalt-nitrate hexahydrate and aluminum nitrate nonahydrate are used as raw materials; sodium hydroxide is used as a precipitator; deionized water is used as a solvent and a washing agent; the nitrate intercalation cobalt and aluminum type hydrotalcite is prepared through the steps of solution preparation, titration co-precipitation, hydro-thermal treatment, washing, suction filtration and drying. The preparation method has the advantages that the influence of CO3<2-> ion formation due to dissolution of CO2 in the environment can be effectively avoided; the method belongs to a fast preparation method of the pure phase nitrate intercalation cobalt and aluminum type hydrotalcite.

Owner:TAIYUAN UNIV OF TECH

Microgel stabilizer with slow release performance and preparation method of microgel stabilizer

InactiveCN104073232AInhibition of thermo-oxidative chain scission reactionRelease rate control and reductionDrilling compositionIon exchangePolyethylene glycol

The invention relates to a microgel stabilizer with slow release performance and a preparation method of the microgel stabilizer. According to the microgel stabilizer, sodium thiosulfate, formaldehyde, urea, polyethylene glycol, aluminum nitrate nonahydrate and magnesium nitrate hexahydrate are adopted as reaction raw materials to be reacted to generate host-guest complex structure compound of thiosulphate-magnesium aluminum hydrotalcite, the thiosulphate in the host-guest complex structure compound can be released from hydrotalcite layer boards through ion exchange reaction, and the speed of the thiosulphate released from the hydrotalcite layer boards is slow. In addition, the polyethylene glycol is polyhydric linear polymer, and hydroxide radical of the polyethylene glycol is interacted with the hydroxide radical of the surface of the hydrotalcite layer boards to package the outer surface of the hydrotalcite of thiosulphate embedded layer to form a new blocked layer to further control and reduce the release speed of the thiosulphate.

Owner:LIAONING LIAOHE OILFIELD KANGDA IND GRP

Method for preparing ultrathin g-C3N4/Al2O3 nano-grade composite photocatalyst

ActiveCN106040275AImprove separation efficiencyEasy to makePhysical/chemical process catalystsWater/sewage treatment by irradiationHydrogenMelamine

The invention discloses a method for preparing an ultrathin g-C3N4 / Al2O3 nano-grade composite photocatalyst. The method comprises the following steps: (1) melamine is added into methanol; heating, condensation, reflux and stirring are carried out, such that a suspension liquid A is obtained; (2) a certain amount of aluminum nitrate nonahydrate is dissolved in methanol; the solution is mixed and stirred with the suspension liquid obtained in the step (1), such that a suspension liquid B is obtained; (3) the suspension liquid B obtained in the step (2) is filtered, washed and dried; and a solid obtained after drying is calcined in a Muffle furnace, such that a finished product is obtained. According to the synthesized ultrathin g-C3N4 / Al2O3 nano-grade composite photocatalyst provided by the invention, the specific surface area of g-C3N4 can be improved; with the compounding of aluminum oxide, photocatalytic activity of g-C3N4 can be effectively improved. Under visible light, the rates of the ultrathin g-C3N4 / Al2O3 nano-grade composite photocatalyst for producing hydrogen by decomposing water and for photo-degrading Rhodamine B are substantially higher than those of single-phase g-C3N4 prepared through melamine pyrolysis. The method is simple, and has the advantages of low cost and low pollution. The method meets the requirements of production reality.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

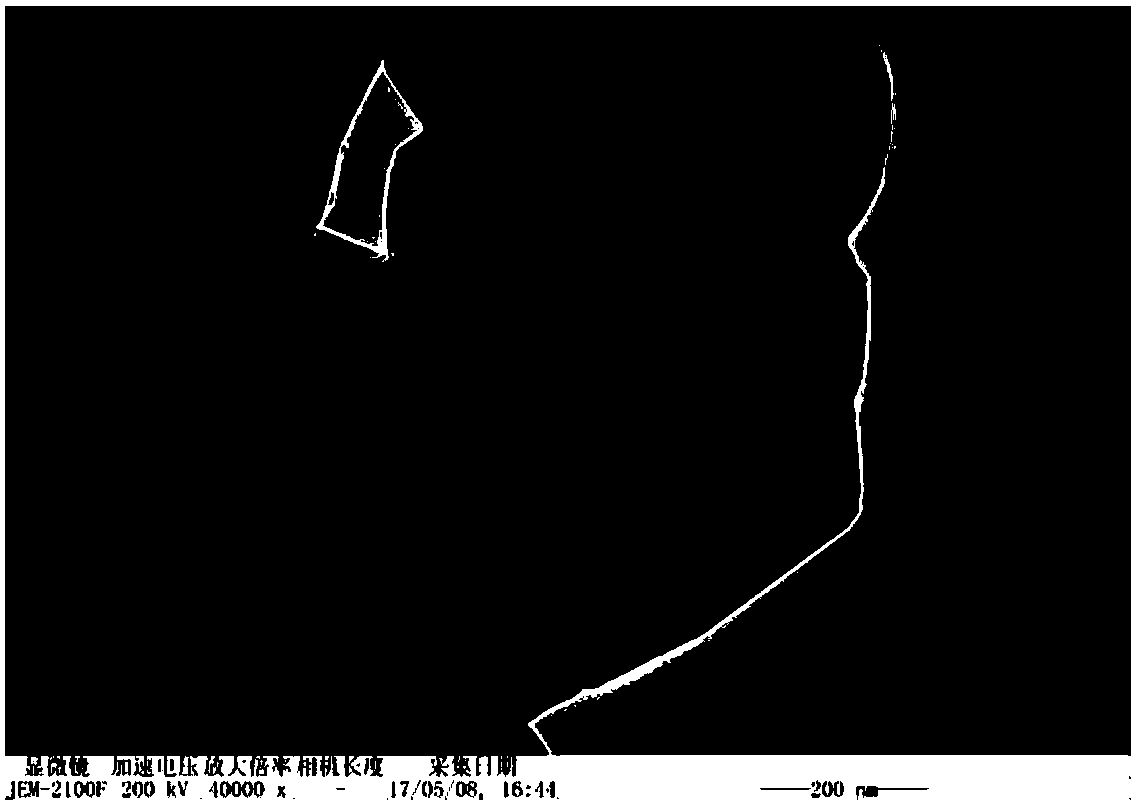

Preparation method of nano-fiber boehmite material

ActiveCN103553097AUniform shapeGood dispersionMaterial nanotechnologyAluminium oxides/hydroxidesDispersityFiber

The invention discloses a preparation method of a nano-fiber boehmite material. The nano-fiber boehmite material is synthesized by a one-step hydrothermal process. The preparation method comprises the following steps of adding a nitrate hydrate mixture of aluminum nitrate nonahydrate and magnesium nitrate hexahydrate into deionized water; adding hexamethylenetetramine and a surfactant; mixing and performing a hydrothermal reaction at 100-145 DEG C; filtering, washing and drying to obtain nano-fiber boehmite with controllable appearance and good dispersity. The preparation method has the characteristics of short time and simplicity and convenience, and the prepared boehmite is applicable to the fields such as water treatment filtering materials, precursors for preparing pure-aluminum and aluminum oxide materials, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of nano-alumina fibers

InactiveCN104451954AHigh purityHigh aspect ratioMaterial nanotechnologyInorganic material artificial filamentsFiberAluminum Carbonate

The invention discloses a preparation method of nano-alumina fibers, and particularly relates to a preparation method of nano-alumina fibers. The preparation method comprises the following steps: by adopting a hydrothermal-pyrolysis method, preparing AACH (ammonium aluminum carbonate hydroxide) nanofiber by taking aluminum nitrate nonahydrate as a raw material through adopting a hydrothermal synthesis method, and preparing the nano-alumina fibers by adopting a high-temperature pyrolysis method. The prepared nano-alumina fiber has the advantages of being high in purity, high in length-diameter ratio, uniform in particle size and the like, and the preparation method has the advantages that I. the preparation processes are simple and controllable, and II. the prepared particles are uniform in dimension, and the fibrous alumina is high in length-diameter ratio.

Owner:广东华科新材料研究院有限公司 +1

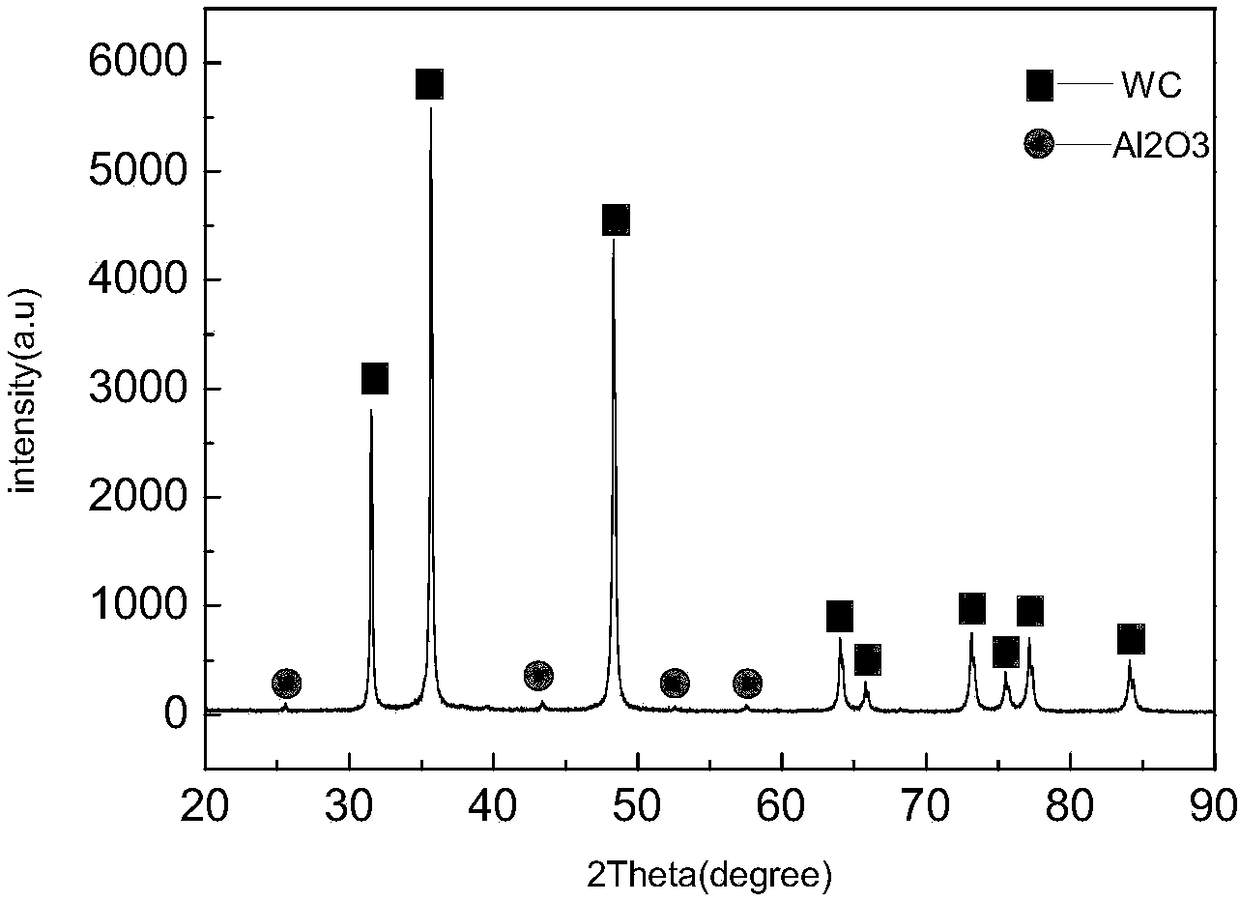

La2O3-Al2O3-(W, Mo2)C binding phase-free hard alloy material and preparation method thereof

InactiveCN108585870AExcellent corrosion resistanceExcellent deformation resistanceAmmonium metatungstateAlloy

The invention discloses a method for preparing a La2O3-Al2O3-(W, Mo2)C binding phase-free hard alloy. The method comprises the following steps: adding ammonium metatungstate, ammonium molybdate, lanthanum nitrate hexahydrate, aluminum nitrate nonahydrate and glucose into deionized water and stirring, continuously heating to be boiling and evaporating so as to obtain a precursor composite powder; adding the precursor composite powder into a closed tube furnace, vacuumizing, introducing mixed gas of H2 and N2, and carbonizing to obtain a composite powder; adding the composite powder into a SPS (Spark Plasma Sintering) furnace, and preparing the binding phase-free hard alloy under reaction conditions. According to the method disclosed by the invention, strategic metal cobalt is replaced withalumina toughened particles, a nano-scale composite powder is prepared by using a chemical liquid mixing method, and finally the binding phase-free hard alloy with excellent overall performance is prepared by using the SPS furnace, and has excellent corrosion and deformation resistance, excellent polishability and high red hardness.

Owner:HUNAN UNIV OF SCI & TECH

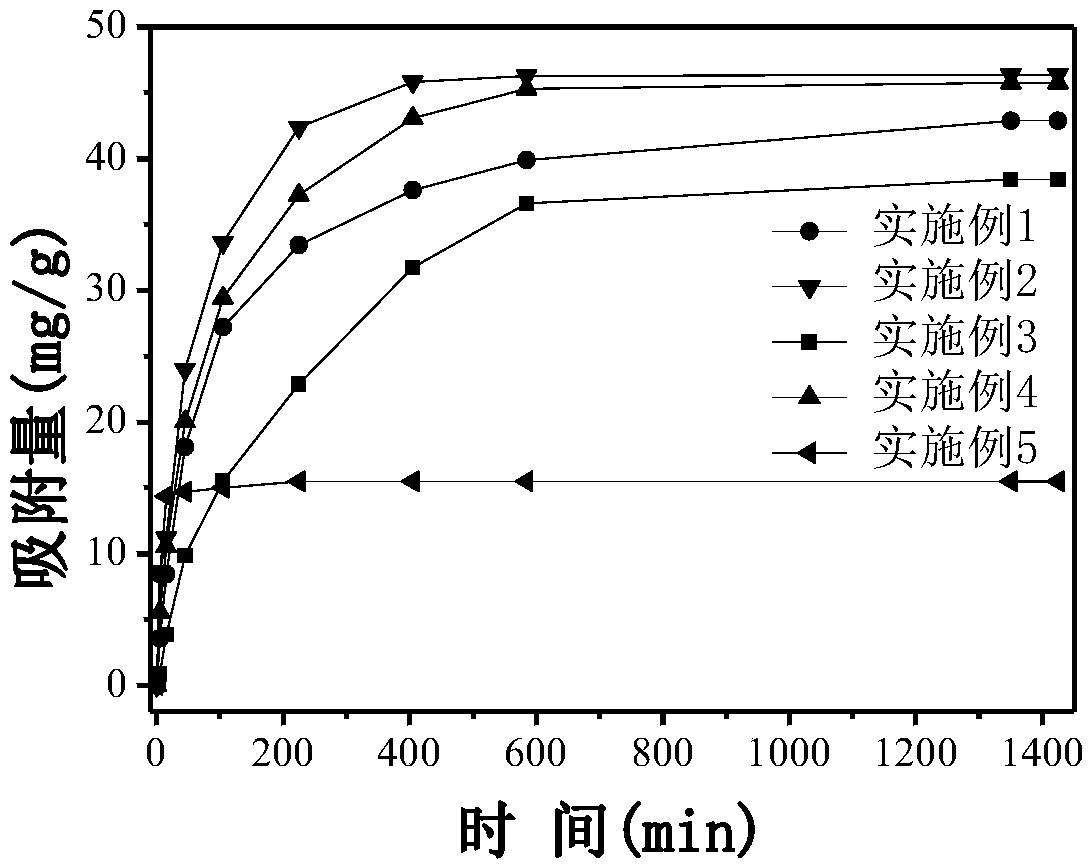

Preparation method of calcined magnesium-aluminum hydrotalcite film

InactiveCN109012573AHigh removal rateThe preparation process is simple and controllableOther chemical processesWater contaminantsHydrotalciteRoom temperature

The invention relates to a preparation method of a calcined magnesium-aluminum hydrotalcite film. The method concretely comprises the following steps: sequentially dissolving aluminum nitrate nonahydrate and magnesium nitrate hexahydrate in a certain amount of deionized water at room temperature; adding a certain amount of ammonia water after above two substances are completely dissolved in orderto obtain a precipitate, and carrying out centrifugal washing on the obtained precipitate with deionized water until the pH value is about 7.5; uniformly dispersing the precipitate in deionized waterunder a magnetic stirring condition; sequentially adding citric acid and a film-forming aid PVA solution, continuously performing stirring at room temperature to obtain a magnesium-aluminum mixed sol,uniformly applying the sol to a polytetrafluoroethylene sheet, carrying out tape casting, and drying the sheet coated with the sol to form a film in order to obtain a magnesium-aluminum hydrotalcitefilm; and calcining the film in a muffle furnace for 4 h to obtain the calcined magnesium-aluminum hydrotalcite film for adsorbing a Cr (VI) solution having a pH value of 3-5 and a concentration of 50mg / L. The method has the advantages of simple preparation process, mild conditions and good adsorption performance on heavy metal ions Cr (VI).

Method for preparing hydroxyapatite-based composite bioceramic material through in-situ reaction

ActiveCN104987058AGood biocompatibilityImprove mechanical propertiesImpression capsDentistry preparationsCalcium nitrate tetrahydrateApatite

The invention belongs to the technical field of biomedical biomaterial preparation, and relates to a method for preparing a hydroxyapatite-based composite bioceramic material through an in-situ reaction. According to the method, calcium nitrate tetrahydrate (Ca(NO3)2.4H2O), diammonium hydrogen phosphate ((NH4)2HPO4), aluminum nitrate nonahydrate (Al(NO3)3.9H2O) and ammonium fluoride (NH4F) serve as raw materials, a chemical precipitation method is adopted to prepare fluorine-doped hydroxyapatite and aluminium oxide nanometer composite powder, and then hydroxyapatite-based composite bioceramic is prepared through hot-pressed sintering. The in-situ method is adopted to synthesize the hydroxyapatite and aluminium oxide nanometer composite powder, and uniform distribution of aluminum oxide in a hydroxyapatite matrix is improved; the prepared hydroxyapatite-based composite bioceramic has high biocompatibility and mechanical properties and can be used in the field of repairing or replacing bone tissue of a human body.

Owner:SHANDONG UNIV

Preparation method for desulfurizing agent for boiler coal combustion

ActiveCN104479792AImprove desulfurization effectIncrease temperatureSolid fuelsZinc hydroxideEngineering

The invention discloses a preparation method for a desulfurizing agent for boiler coal combustion, and belongs to the technical field of desulfurizing agents. The preparation method comprises the following steps: adding aluminum nitrate nonahydrate in water, heating, dropping a sodium hydroxide solution, holding the temperature after completing dropping, and adding calcium oxide to obtain a sol mixture; drying the sol mixture, and sintering the dried mixture in a muffle furnace to obtain calcium-oxide-doped aluminum oxide; uniformly mixing and crushing the calcium-oxide-doped aluminum oxide, silicon dioxide, ferric oxide, sodium nitrate, zinc hydroxide, calcium fluoride, ferric trichloride, magnesium oxide, iron powder and aluminum powder to obtain the desulfurizing agent for the boiler coal combustion. According to the preparation method for the desulfurizing agent for the boiler coal combustion, the desulfurizing agent is prepared by utilizing the aluminium oxide as a carrier, so that the coal combustion procedure can be greatly desulfurized, and the temperature of a furnace box can be remarkably improved.

Owner:龙基能源集团有限公司

Method using co-precipitation to prepare nitrate intercalation nickel-aluminum layered double hydroxides in one step

The invention discloses a method using co-precipitation to prepare nitrate intercalation nickel-aluminum layered double hydroxides in one step. The method is characterized in that an acetic acid-sodium acetate buffer solution is used to stably control the pH of a preparation system to be at 4.00-5.00, nickel nitrate hexahydrate and aluminum nitrate nonahydrate are used as the raw materials, sodiumhydroxide is used as the precipitator, deionized water is used as the solvent and the washing agent, and solution preparation, titration co-precipitation, hydrothermal processing, washing, suction filtration and drying are performed to prepare the nitrate intercalation nickel-aluminum layered double hydroxides. The method has the advantages that influence caused by the fact that CO2 in an environment is dissolved to form CO3<2-> ions can be avoided effectively, and the method is a fast preparation method of the pure-phase nitrate intercalation nickel-aluminum layered double hydroxides.

Owner:TAIYUAN UNIV OF TECH

Preparation method of Al-doped graded structure tin disulfide gas sensitive material

ActiveCN107686125AImplement responseHigh sensitivityTin compoundsMaterial resistanceMicrowaveGas detector

The invention provides a preparation method of an Al-doped graded structure tin disulfide gas sensitive material, belongs to the field of a gas sensitive material, particularly relates to a preparation method of an Al-doped flower-shaped graded structure SnS2 gas sensitive material, and aims to solve the problem that the existing NO2 sensor based on an in organic two-dimensional layered SnS2 nanometer material cannot work at room temperature. The method is as follows: the Al-doped flower-shaped graded structure SnS2 is synthesized by taking tin chloride pentahydrate as a tin source, thiourea as a sulfur source, aluminum nitrate nonahydrate as an aluminum source and glycol as a solvent and by a one-step microwave heating method. The gas sensitive sensor is prepared by the Al-doped flower-shaped graded structure SnS2. The gas sensitive sensor can detect the NO2 with the ppb concentration grade at room temperature, is high in sensitivity, safe and portable, and has wide application prospect.

Owner:黑龙江省工研院资产经营管理有限公司

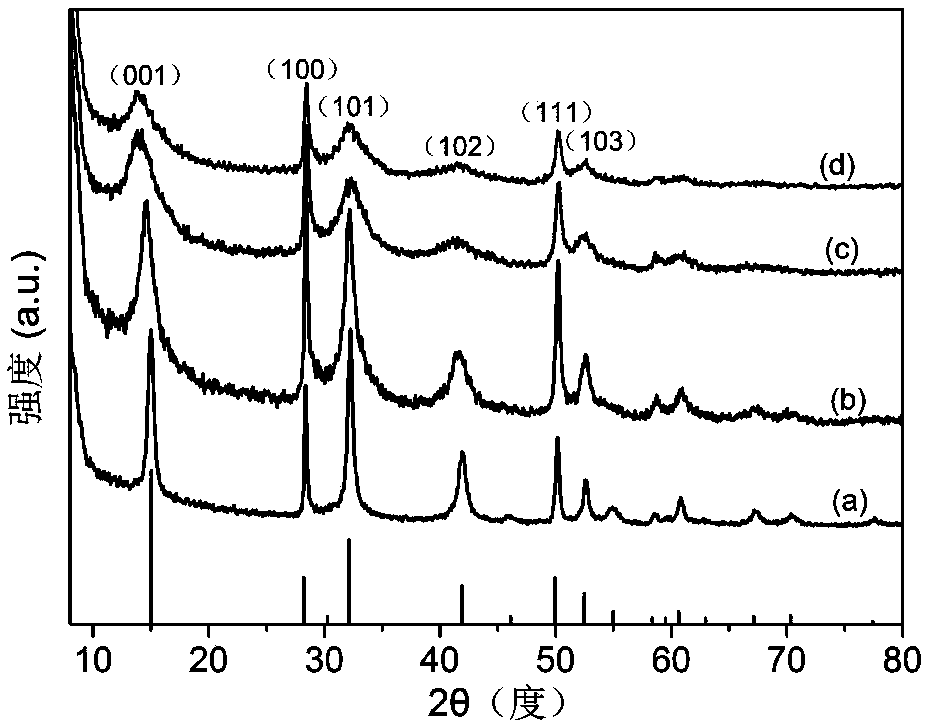

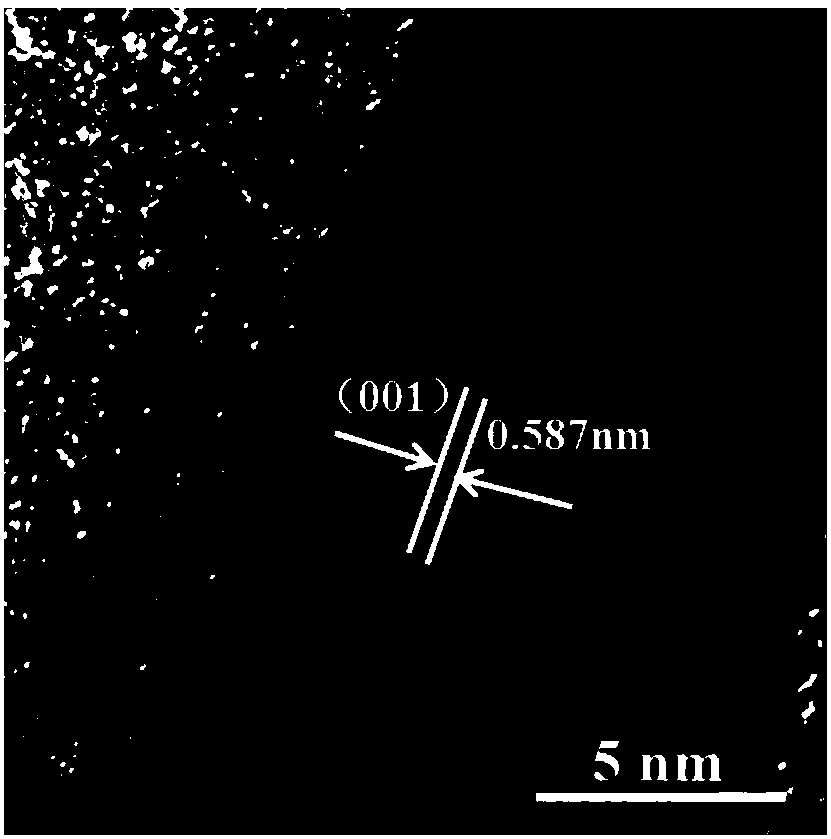

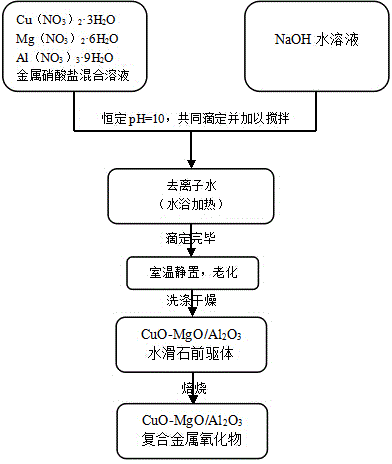

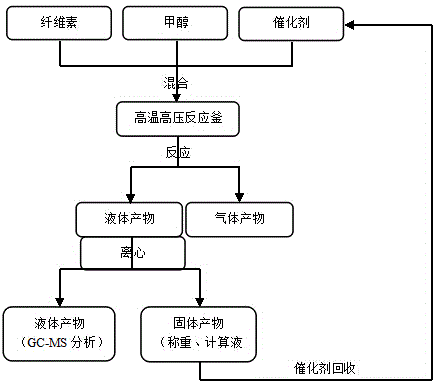

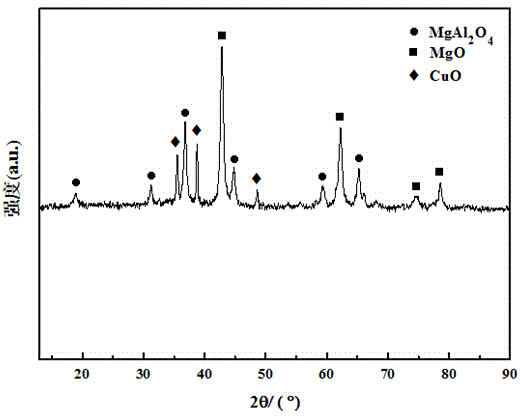

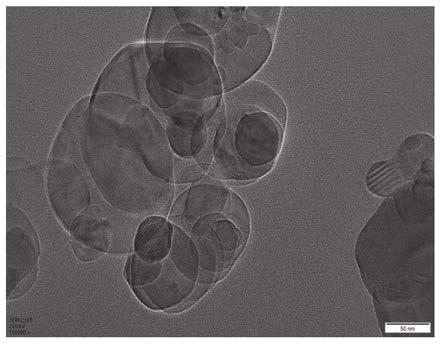

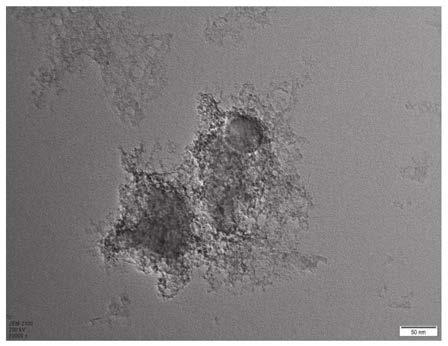

Catalyst preparation method and application

InactiveCN104128181ALow reaction pressureHigh activityOrganic compound preparationHydroxy compound preparationCellulosePtru catalyst

The invention discloses a catalyst preparation method and an application, which belongs to the catalytic chemistry field. The method employs three metal salts of copper nitrate hydrate, magnesium nitrate hexahydrate, aluminum nitrate nonahydrate as main part, uses sodium hydroxide as a precipitating agent, the raw materials are subjected to titration, stirring, aging, pumping filtration, washing and drying to CuO-MgO-Al2O3 hydrotalcite (a precursor) through a constant pH value coprecipitation method, the corresponding CuO-MgO-Al2O3 composite metal oxide catalyst can be obtained through high temperature roasting, and is used in supercritical methanol for catalyzing and liquefying cellulose. The composite metal oxide catalyst can be taken as the catalyst, and can perform liquefaction reaction of cellulose in supercritical methanol, and the result proves that the catalyst has high activity and good stability, and has high liquefaction rate to cellulose in a liquefaction experiment.

Owner:KUNMING UNIV OF SCI & TECH

Aluminum oxide coated nano flaky hexagonal boron nitride composite powder as well as preparation method and application thereof

ActiveCN111547752ASimple processLow equipment requirementsNitrogen compoundsNanotechnologySodium acetateHexagonal boron nitride

The invention relates to aluminum oxide coated nano flaky hexagonal boron nitride composite powder as well as a preparation method and application thereof, and belongs to the field of nano solid lubricant surface-modified coated composite materials. The preparation method comprises the steps: dispersing nano h-BN powder subjected to acid pickling into absolute ethyl alcohol, and adding a proper amount of dispersing agent PVP and distilled water; after carrying out ultrasonic stirring for a period of time, pouring an aluminum nitrate nonahydrate solution into the solution, and then adding a sodium acetate buffer solution to control the pH value to be 4.5; heating and stirring a suspension in a magnetic stirrer, keeping the temperature at 75 DEG C, slowly dropwise adding dilute ammonia water, and keeping the temperature for 30 min; centrifuging the suspension after the reaction, and cleaning with absolute ethyl alcohol; and carrying out vacuum drying at the temperature of 60-110 DEG C toobtain h-BN@Al(OH)3 composite powder taking nano h-BN as a core and Al(OH)3 as a shell; and calcining the powder at the temperature of 850 DEG C to obtain the CaF2@Al2O3. According to the aluminum oxide coated nano hexagonal boron nitride composite powder prepared by the method, a coating layer is compact and uniform. When the composite powder is added into a metal or ceramic matrix, the mechanical property of the material can be improved, and the lubricating property of the material is not reduced.

Owner:QILU UNIV OF TECH

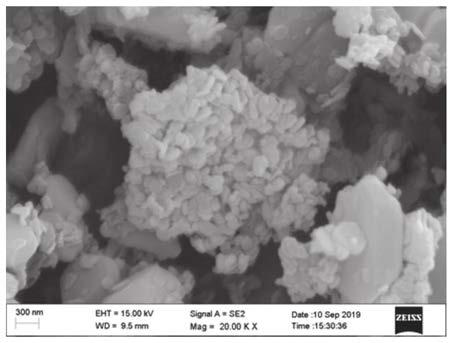

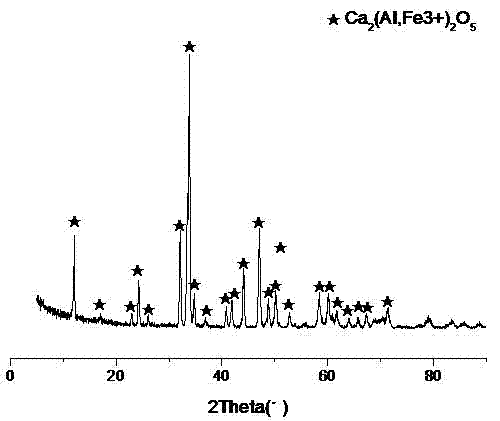

Method for synthesis of tetracalcium aluminoferrite by sol-gel technology

InactiveCN102897843AWell mixedOvercome temperatureIron compoundsCalcium nitrate tetrahydrateCitrinin hydrate

Belonging to the technical field of building materials, the invention specifically relates to a method for synthesis of tetracalcium aluminoferrite by a sol-gel technology. The raw materials used by the synthesis method include: calcium nitrate tetrahydrate, aluminum nitrate nonahydrate, iron nitrate nonahydrate, citric acid monohydrate, ethylene glycol and water. The specific synthesis steps consist of: dissolving three inorganic salts of certain stoichiometric ratio in deionized water and mixing them uniformly, adding citric acid to prepare a light yellow metal-citric acid chelate solution, then adding ethylene glycol to undergo an esterification reaction, subjecting the obtained sol to aging under complete stirring at 80DEG C so as to obtain sticky wet gel, then further drying it for 24h at 150DEG C to obtain dry gel, and grinding and calcining the dry gel so as to obtain a tetracalcium aluminoferrite monomineral. The tetracalcium aluminoferrite powder prepared by the sol-gel technology has the characteristics of high purity, superfineness, and easy sintering, etc.

Owner:TONGJI UNIV

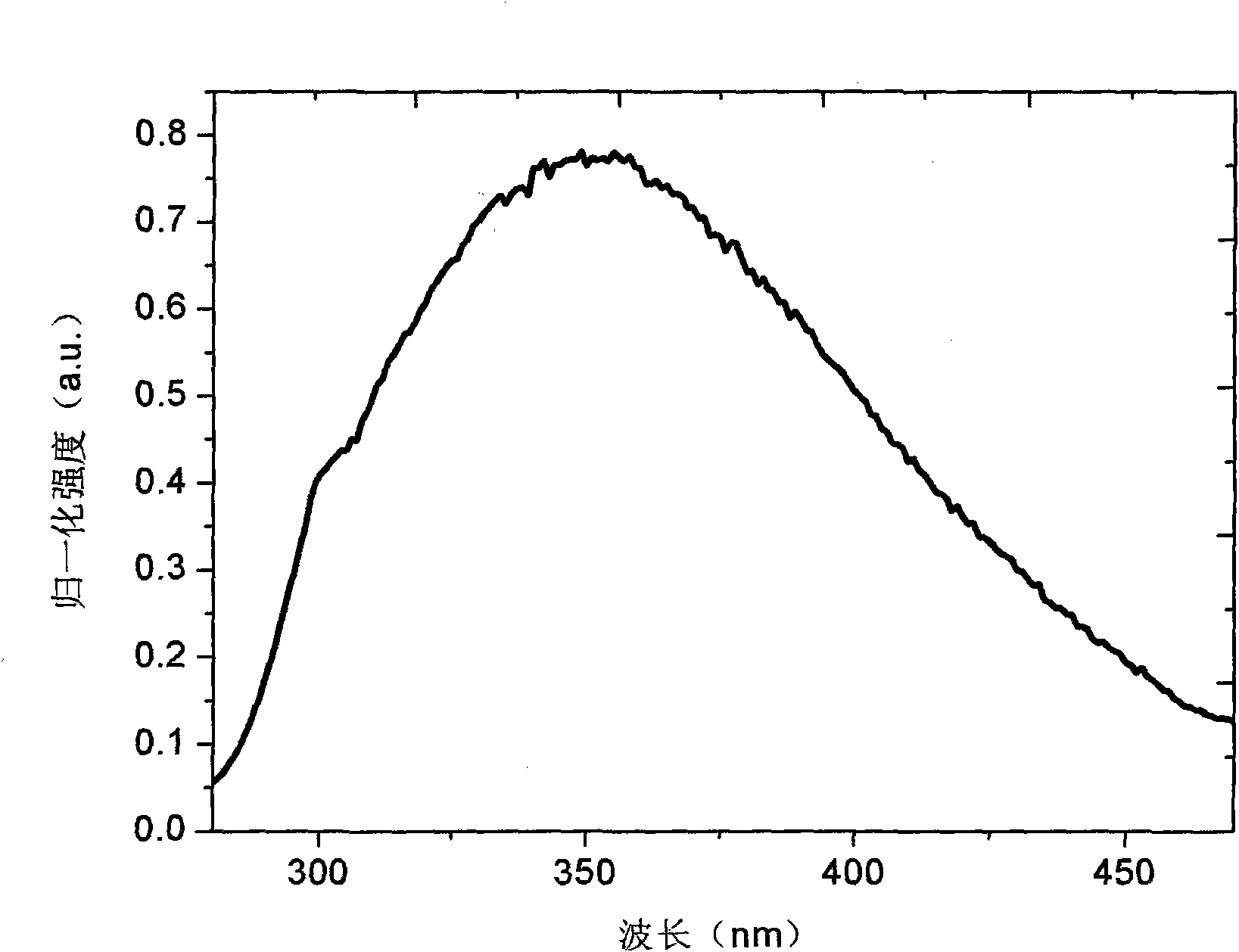

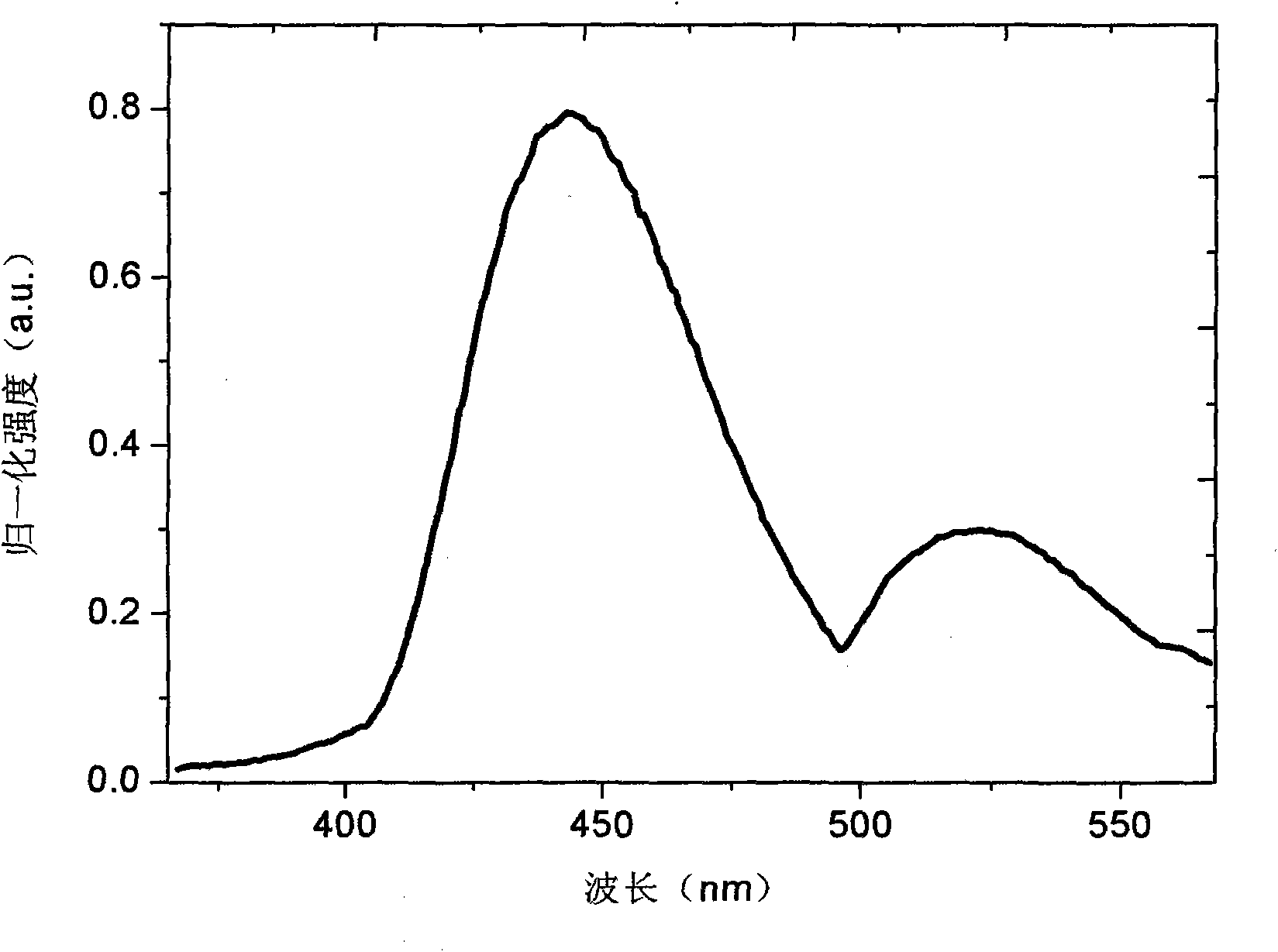

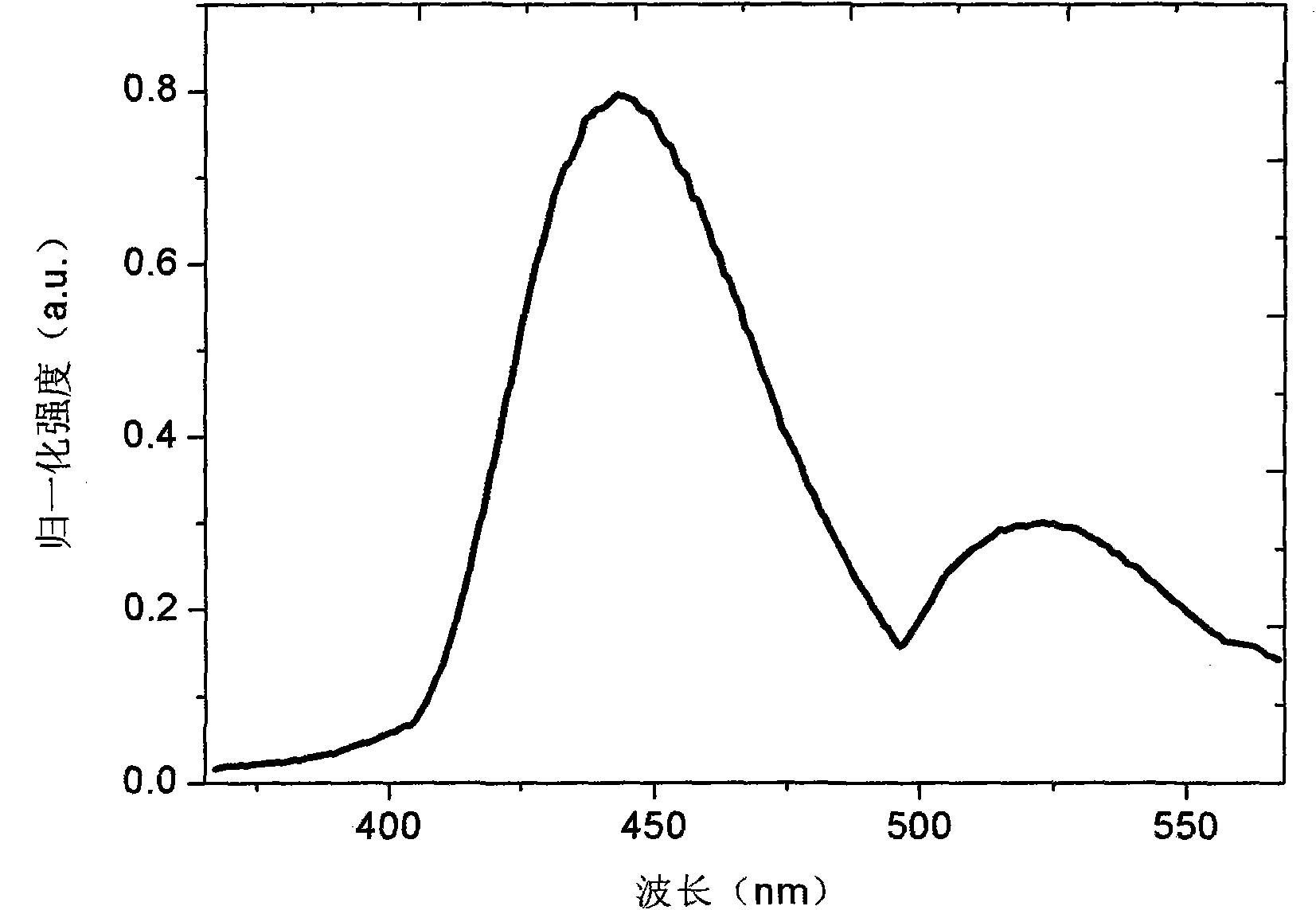

Europium and manganese codoped and activated blue-green fluorescent powder and preparation method thereof

InactiveCN102127429ASimple production processReduce manufacturing costGas discharge lamp usageLuminescent compositionsManganeseUltraviolet

The invention discloses europium and manganese codoped and activated blue-green fluorescent powder and a preparation method thereof, which belong to the technical field of rare-earth luminescent materials. The blue-green fluorescent powder is characterized in that: the chemical general formula is Ba1-xSr1-yAl10O17:xEu<2+>, yMn<2+>, wherein x is between 0.01 and 0.2 and y is between 0.01 and 0.1. The preparation method comprises the following steps of: weighing reagents such as barium carbonate BaCO3 (A.R.) (A.R. refers to analytically pure), strontium oxide SrO (A.R.), aluminum nitrate nonahydrate Al(NO3)3.9H2O (99.99 percent), manganese carbonate MnCO3 (A.R.) and europium oxide Eu2O3 (with the purity of 99.99 percent); uniformly grinding; sintering at high temperature; smashing; grinding; screening; washing with water; and drying to obtain the fluorescent powder. The fluorescent powder can be combined with an ultraviolet or near-ultraviolet LED wafer to prepare a high-color-renderingwhite-light LED (Light-Emitting Diode), and has good application prospect.

Owner:CHINA JILIANG UNIV

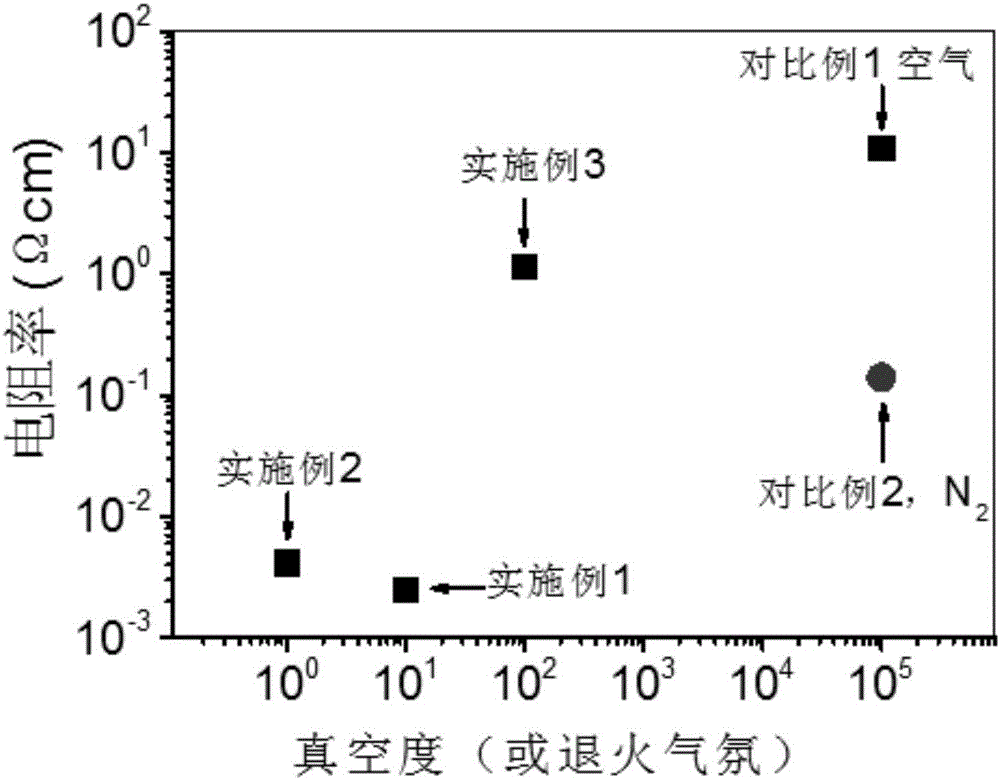

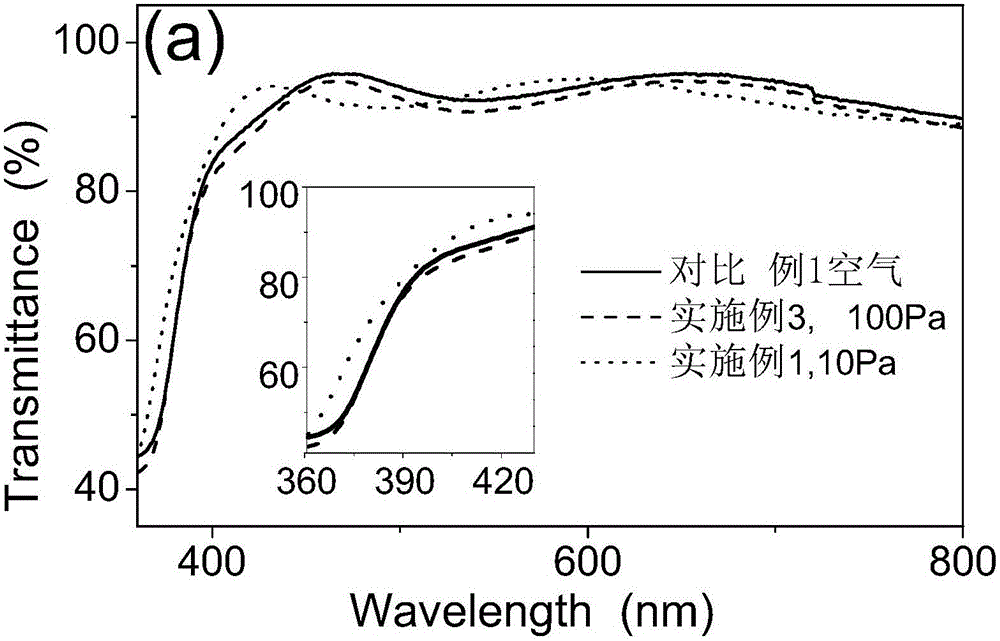

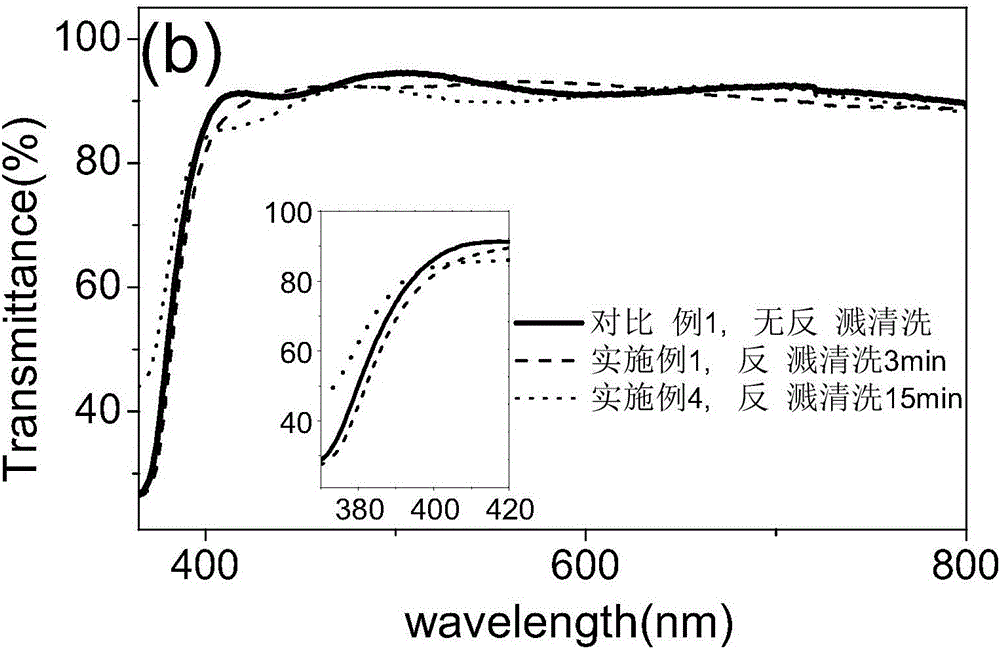

Method for preparing high-performance AZO transparent conductive thin film

InactiveCN106435533ALow costImprove uniformityLiquid/solution decomposition chemical coatingWater bathsUltraviolet lights

The invention discloses a method for preparing a high-performance AZO transparent conductive thin film. The method comprises three main steps which are respectively a precursor sol preparation step, a thin film preparation step adopting a spin-coating method, and a vacuum annealing and anti-sputtering washing step. The method specifically comprises the following steps: step (1) dissolving a certain amount of octan zinecnaty in an ethylene glycol monomethyl ether solvent or a glycol ether solvent, subsequently adding a stabilizing agent monoethanolamine and doping ions aluminum nitrate nonahydrate into the solution, performing water-bath stirring, and ageing at room temperature to obtain uniform and stable precursor sol; step (2) spin-coating and depositing the precursor wet soil on substrates such as a glass substrate, a quartz substrate and a silicon substrate by adopting a sol-gel spin-coating method, drying and performing low-temperature thermal treatment to obtain an AZO thin film with certain thickness; step (3) firstly annealing the AZO thin film under a medium-vacuum-degree condition and subsequently performing anti-sputtering washing on the surface of the thin film by using Ar<+>. By the three steps, the method disclosed by the invention is capable of obtaining an AZO transparent conductive thin film which is extremely low in resistance rate and quite high in visual light and ultraviolet light penetration rate.

Owner:LIAONING UNIVERSITY

Plasma corrosion-resistant aluminum oxide coating hole sealing method

The invention discloses a plasma corrosion-resistant aluminum oxide coating hole sealing method. After aluminum nitrate nonahydrate, pseudoboehmite and water are uniformly ground at a weight ratio of(0.5-3): (10-30): 100, standing is performed, and supernatant is taken, and is sprayed onto an aluminum oxide coating; and standing is performed again after spraying, heating and heat preserving are performed, and then hole sealing is completed. According to the hole sealing method, due to changing of the composition of a hole sealing material and improvement of a hole sealing treatment method, the aluminum oxide coating porosity is smaller than 2% after hole sealing; and compared with traditional phosphate hole sealing, the plasma corrosion rate is also lowered by 113% or so, and the performance is improved remarkably.

Owner:CHONGQING GENORI IND CO LTD

Preparation method of sol solution containing two-dimensional nano container supported corrosion inhibitor

InactiveCN109399629AGood dispersionInhibition of agglomerationCarbon compoundsZinc compoundsEpoxySilanes

The invention discloses a preparation method of a sol solution containing a two-dimensional nano container supported corrosion inhibitor. The method is based on oxidized graphene, uses zinc nitrate hexahydrate and aluminum nitrate nonahydrate as raw materials, the inhibitor nano container oxidized graphene / layered double hydroxide (GO / LDHs) with a two-dimensional structure is synthesized through acoprecipitation method, a modified GO / LDHs nano container is subjected to anion exchange after silanization modification, and corrosion inhibitor vanadate is supported to the GO / LDHs nano container;then, the corrosion inhibitor is added into a sol solution using 3-epoxy silane and zirconium salt as a precursor and using an anhydrous ethanol as solvent by adopting a wet transfer method, and the solution containing the two-dimensional nano container corrosion inhibitor is prepared.

Owner:BEIHANG UNIV

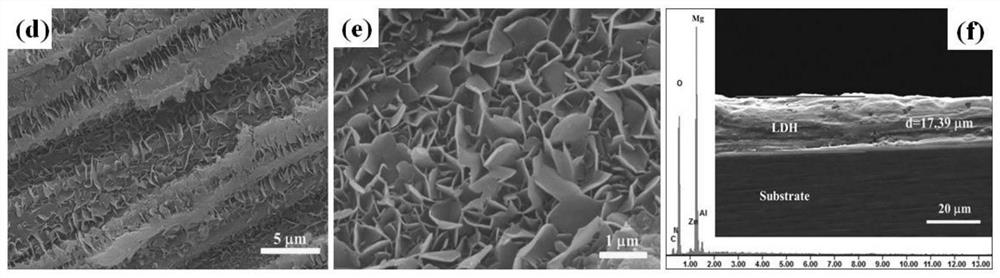

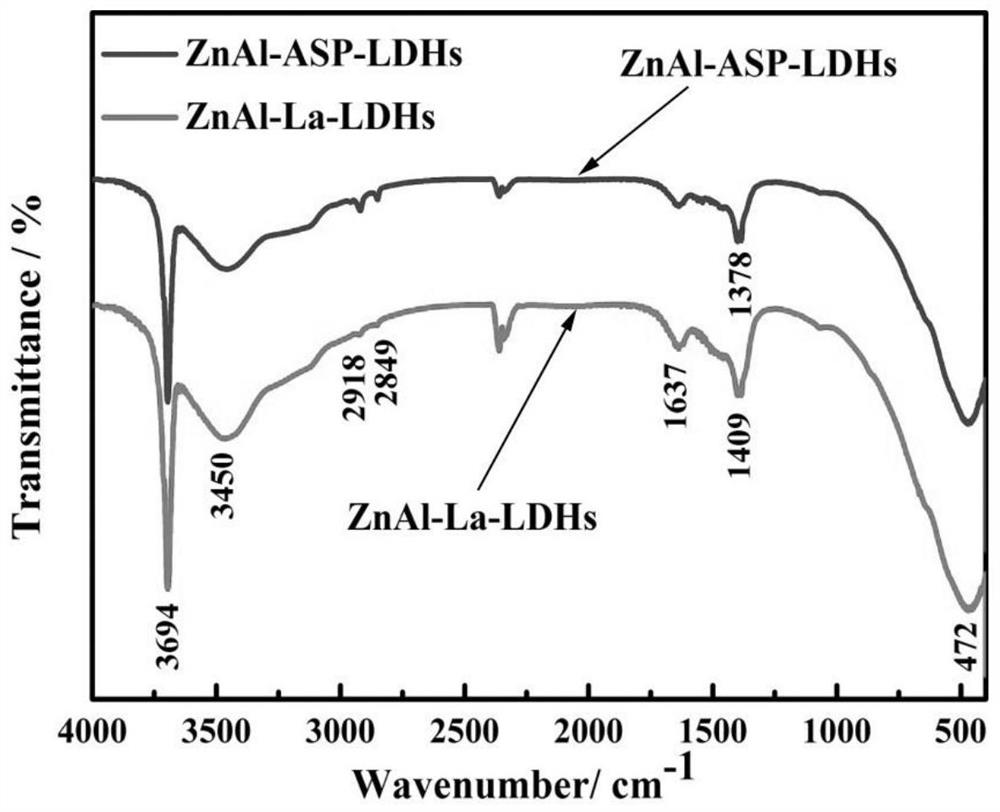

Preparation method of amino acid ion intercalated ZnAl-LDHs film

PendingCN112176338AImprove corrosion resistanceImprove performanceMetallic material coating processesMg alloysZinc nitrate

The invention discloses a preparation method of an amino acid ion intercalated ZnAl-LDHs film. The preparation method comprises the following steps: step S001, pretreating the surface of a magnesium alloy; S002, under the protection of nitrogen, dissolving a zinc nitrate hexahydrate solution and an aluminum nitrate nonahydrate solution in deionized water to form a mixed solution; Step S003, dropwise adding an organic acid solvent into the mixed solution; S004, adding a sodium hydroxide solution into the solution, and adjusting the pH value of the solution to 10; Step S005, putting the solutioninto a polytetrafluoroethylene autoclave for heating treatment; and step S006, cleaning and drying to obtain the amino acid ion intercalated ZnAl-LDHs film. The preparation method is simple; the ASPand La intercalated ZnAlLDHs film is prepared on the magnesium alloy substrate in situ through a hydrothermal method, corrosive liquid can be effectively prevented from permeating the magnesium alloysubstrate, and the corrosion resistance of the magnesium alloy can be remarkably improved.

Owner:CHONGQING UNIV +1

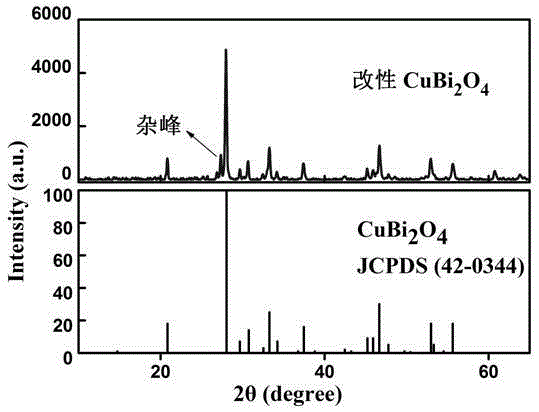

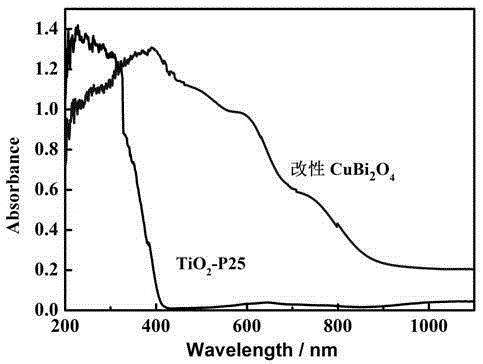

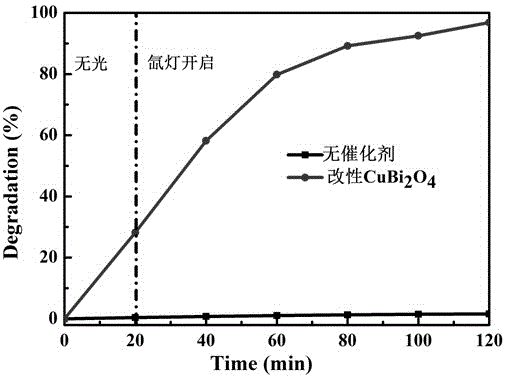

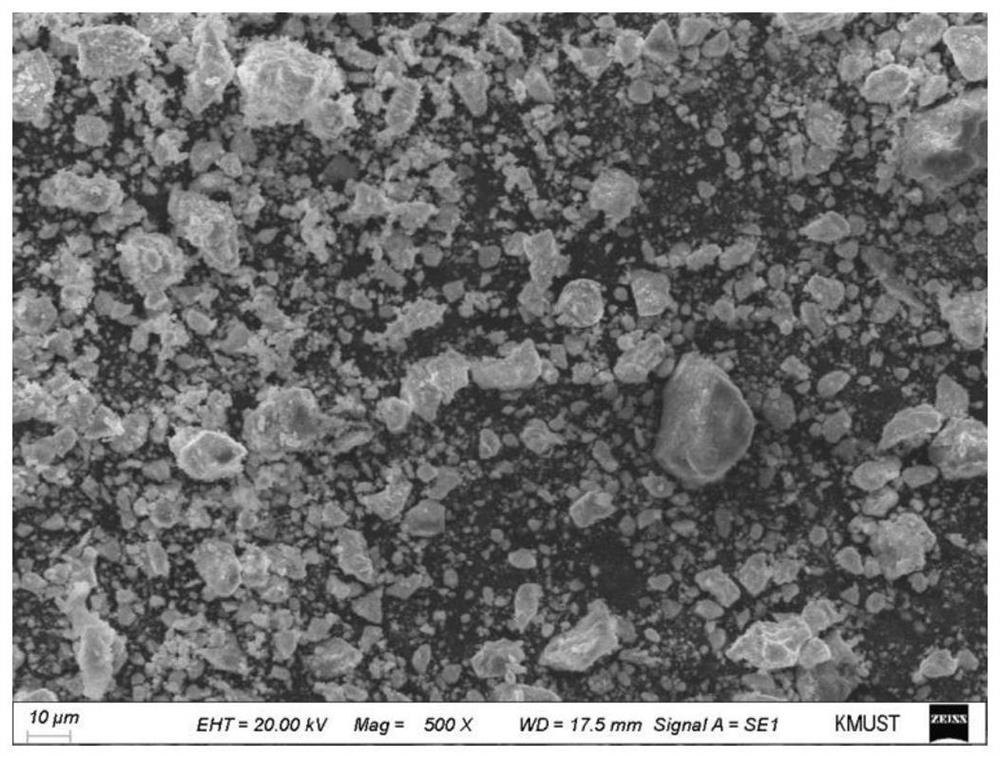

Modified copper bismuthate photocatalyst and preparation method thereof

ActiveCN105233837ASolve the problem that can not be prepared by sol-gel methodGood visible light response performanceWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsGlycerolCopper nitrate

The invention discloses a modified copper bismuthate photocatalyst and a preparation method thereof. The modified copper bismuthate photocatalyst is doped with metal aluminum. The preparation process comprises the following steps: adding copper nitrate trihydrate, bismuth nitrate pentahydrate and aluminum nitrate nonahydrate into a mixed solution of acetone, glycerol, nitric acid and ethanoic anhydride, carrying out stirring so as to obtain yellow gel, drying the yellow gel so as to obtain dried gel, and calcining the dried gel so as to obtain the modified copper bismuthate photocatalyst. According to the invention, through the above-mentioned manner, the preparation method is simple; cost is low; the problem of incapability of preparation of bismuth photocatalytic materials by using a sol-gel method is solved; and the prepared honeycomb ceramic loaded modified copper bismuthate photocatalyst has good visible-light response performance and is capable of decomposing various pollutants under irradiation of visible light.

Owner:泳锌高新技术有限公司

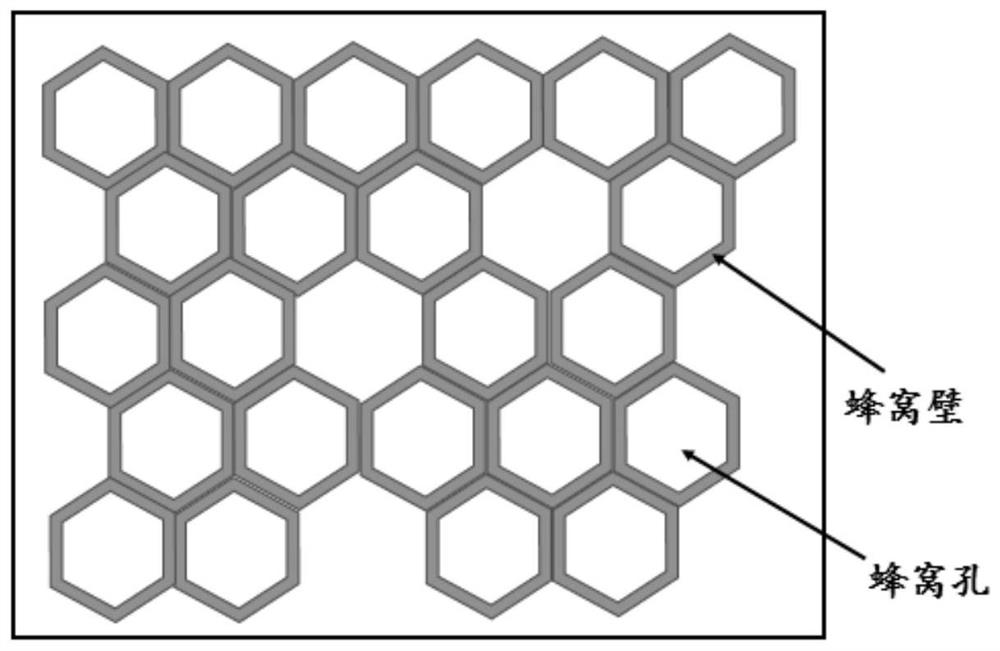

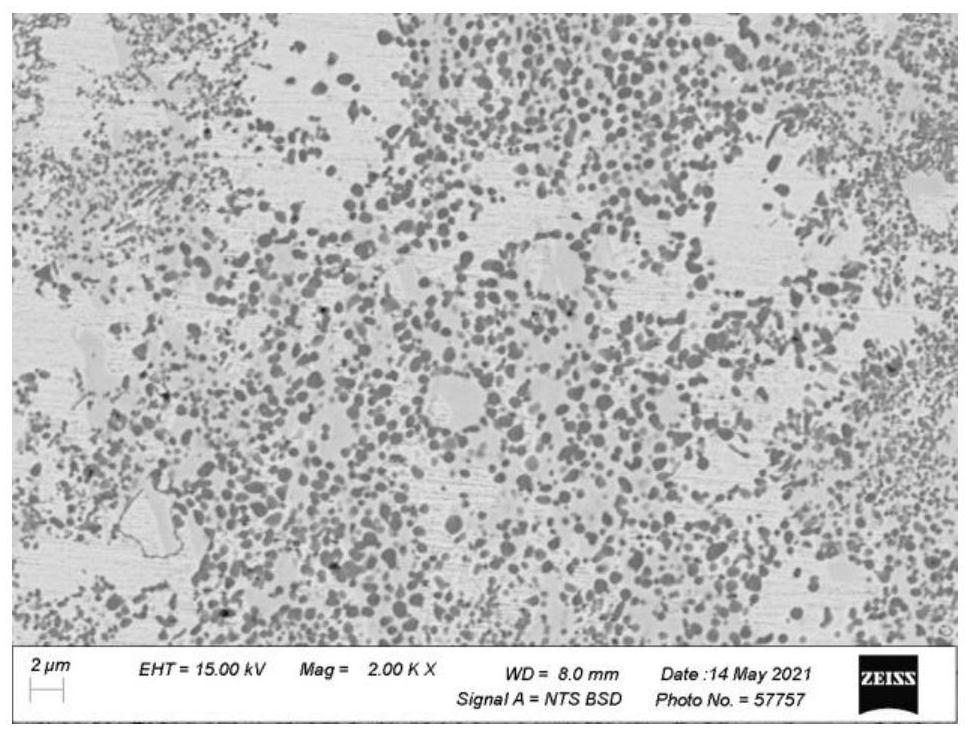

Preparation method of in-situ synthesis ZTA particle reinforced steel-based configuration composite material

ActiveCN113862548ANo pollution in the processGood compatibilityAluminium nitrateMetal matrix composite

The invention discloses a preparation method of an in-situ synthesis ZTA particle reinforced steel-based configuration composite material, and belongs to the technical field of metal-based composite materials. The preparation method comprises the steps of preparing transparent sol by taking aluminum nitrate nonahydrate, zirconyl nitrate hydrate and the like as raw materials; adding steel-based powder into the sol for liquid-solid doping, stirring until solidification, and sequentially carrying out vacuum drying and reduction on ZTA / steel-iron mixed powder; and filling the honeycomb walls of a honeycomb-shaped mold with the ZTA / steel mixed powder, filling honeycomb holes of the honeycomb-shaped mold with the steel-based powder, and obtaining the in-situ synthesis ZTA ceramic particle reinforced steel-based honeycomb structure composite material after pressing and sintering. ZTA ceramic is generated in situ, the surfaces of ceramic particles are free of pollution, the compatibility with a steel matrix is good, and the interface bonding strength is high; and the honeycomb walls are composed of the composite areas with high hardness, the abrasion effect borne by the honeycomb holes with low hardness can be remarkably reduced, the abrasion resistance is improved by more than three times compared with a traditional steel material, and wide application prospects are achieved.

Owner:KUNMING UNIV OF SCI & TECH

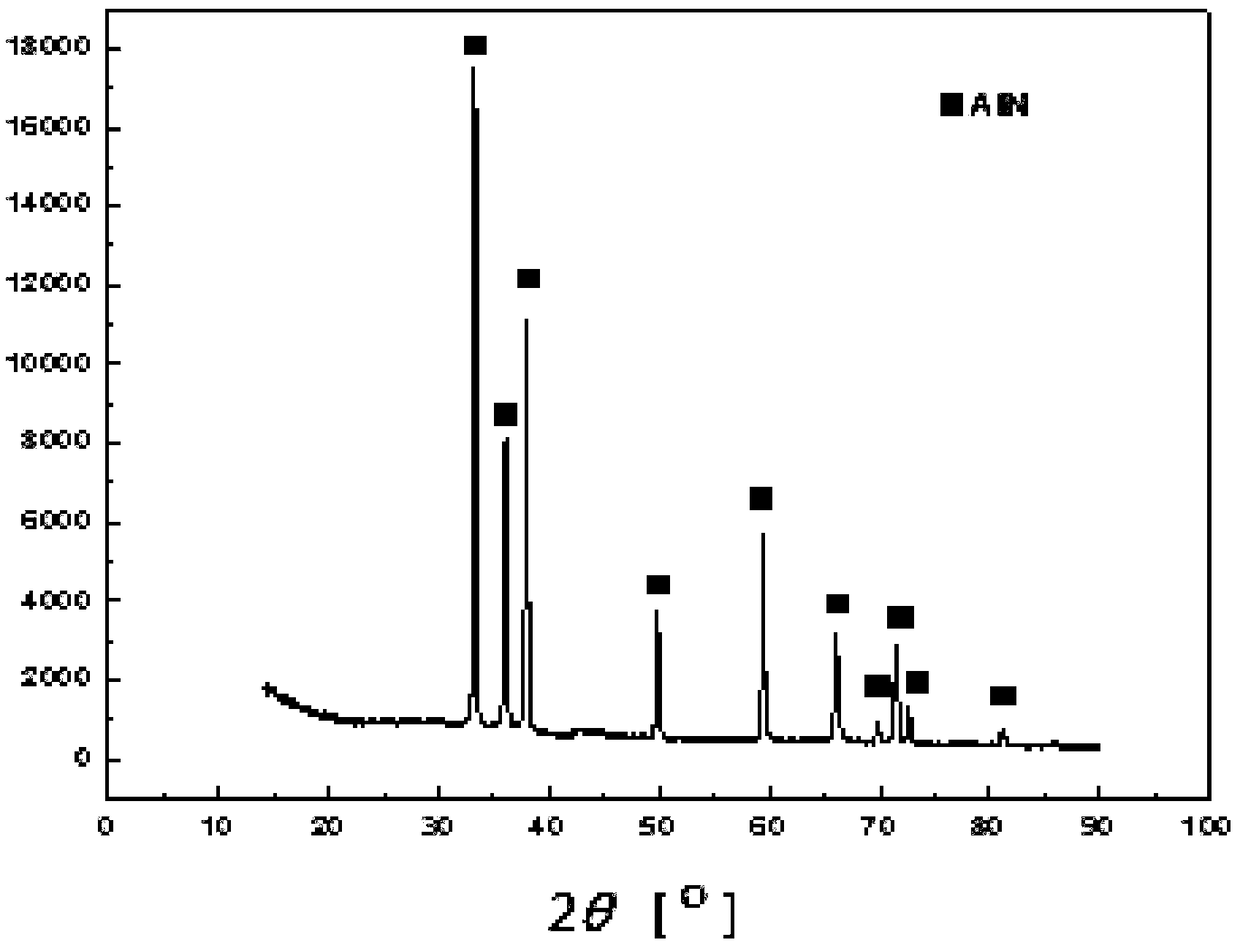

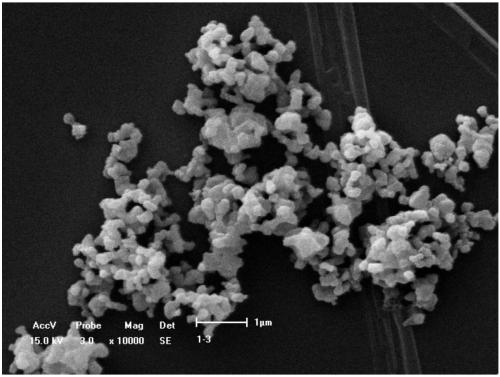

Method for preparing aluminum nitride ceramic powder based on urea/melamine nitrogen source

The invention relates to a method for preparing aluminum nitride ceramic powder based on a urea / melamine nitrogen source. The method comprises the following steps: (1) preparing raw materials; (2) dissolving aluminum nitrate nonahydrate into water, adding a coupling agent and polyethylene glycol and uniformly stirring; (3) adding a precipitant, stirring to form a precursor gel, and filtering afteralcohol washing to obtain a gel; (4) putting the gel into absoluteethyl alcohol, adding phenolic resin under a stirring condition, stirring to form a paste body, baking, calcining and grinding to obtain a precursor powder; (5) grinding and mixing with a nitrogen source, placing into a heating furnace, increasing temperature to 950-1500 DEG C for performing nitridation synthesis when the air pressure in the heating furnace is higher than barometric pressure, performing furnace cooling, and grinding to obtain rough powder; and (6) and heating to 550-650 DEG C for removing carbon. According to the method provided by the invention, high-activity urea / melamine instead of nitrogen is taken as a nitrogen source, and a surface modification dispersion technology is adopted, so that atom- or molecule-level uniform mixing between an aluminum source and a carbon source is realized, and the temperature of carbon thermal reduction reaction is lowered.

Owner:SHENYANG UNIV

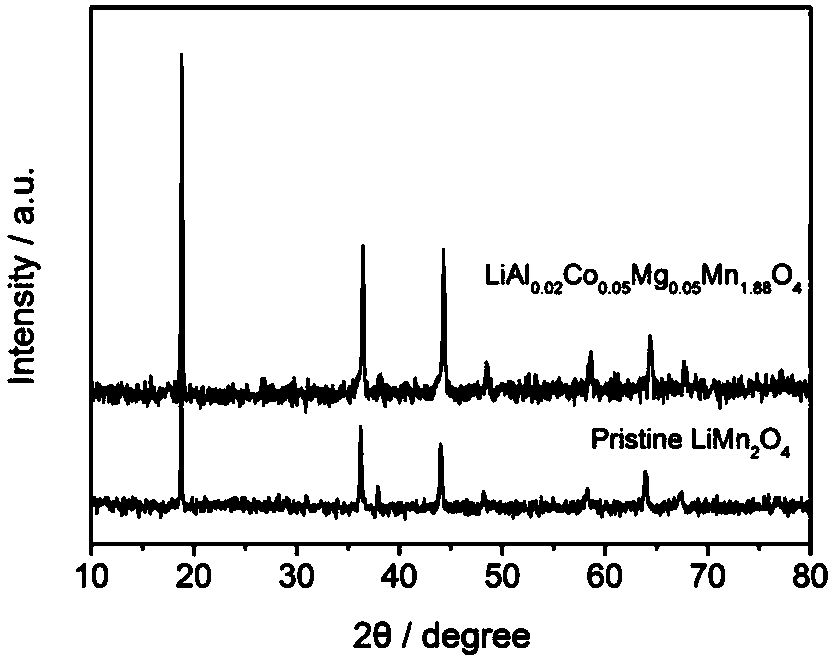

Method for preparing multi-element co-doped lithium manganate composite material

InactiveCN108539159AStable structureInhibition of Ginger-Taylor EffectCell electrodesSecondary cellsMagnesium Acetate TetrahydrateMANGANESE ACETATE TETRAHYDRATE

The invention discloses a method for preparing a multi-element co-doped lithium manganate composite material. The method adopts a sol-gel method, firstly, a mixed solution of manganese acetate tetrahydrate, aluminum nitrate nonahydrate, magnesium acetate tetrahydrate, and cobalt acetate tetrahydrate is slowly added dropwise to a lithium hydroxide monohydrate and citric acid mixed solution under stirring, an ammonia solution is added to adjust the pH of the solution, and the mixture is heated and stirred until a sol is formed, the sol is dried to obtain a dry gel, and the dry gel is calcined and ground into powder, and finally calcined to obtain the aluminum-cobalt-magnesium three-element co-doped lithium manganate composite material. The method has the advantages of simple process, wide source of raw materials, large output, low cost and easy control, and is favorable for large-scale industrial production, and the prepared lithium ion battery positive electrode material has excellent rate charge and discharge performance and excellent cycle service life.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com