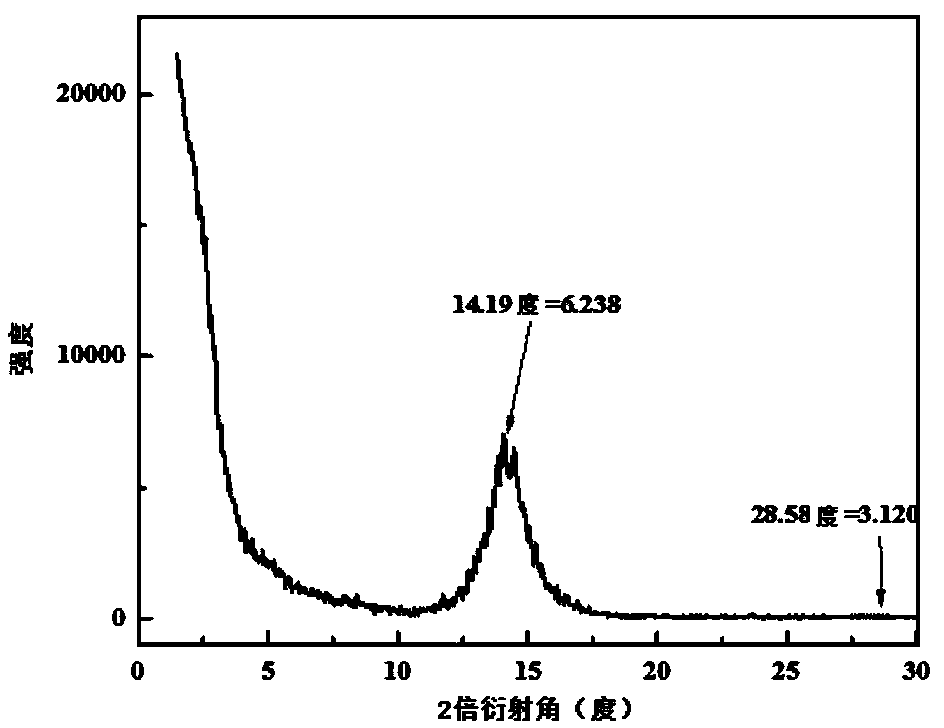

Preparation method of nano-fiber boehmite material

A technology of nanofibers and boehmite, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex multi-step reaction process, time-consuming, low crystallinity, etc., and achieve dispersion Good stability, short time consumption, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

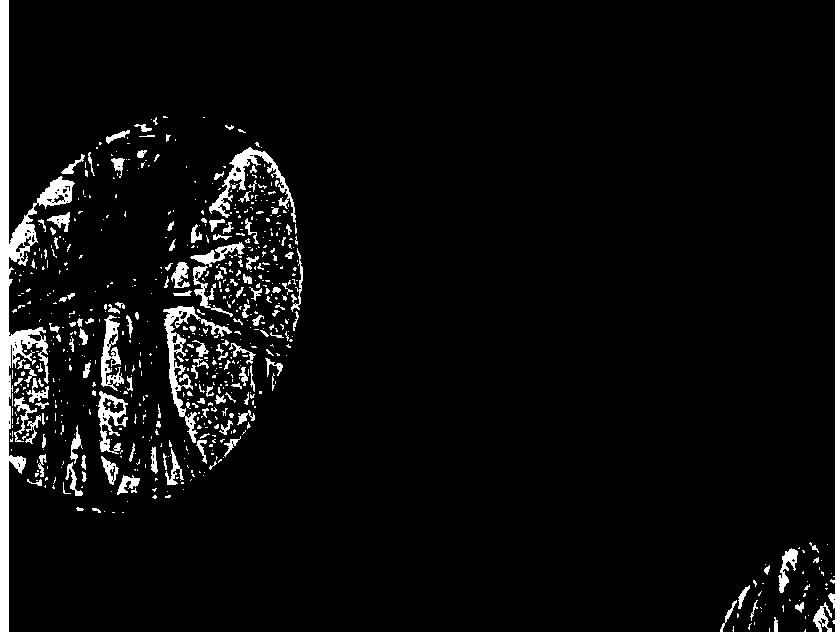

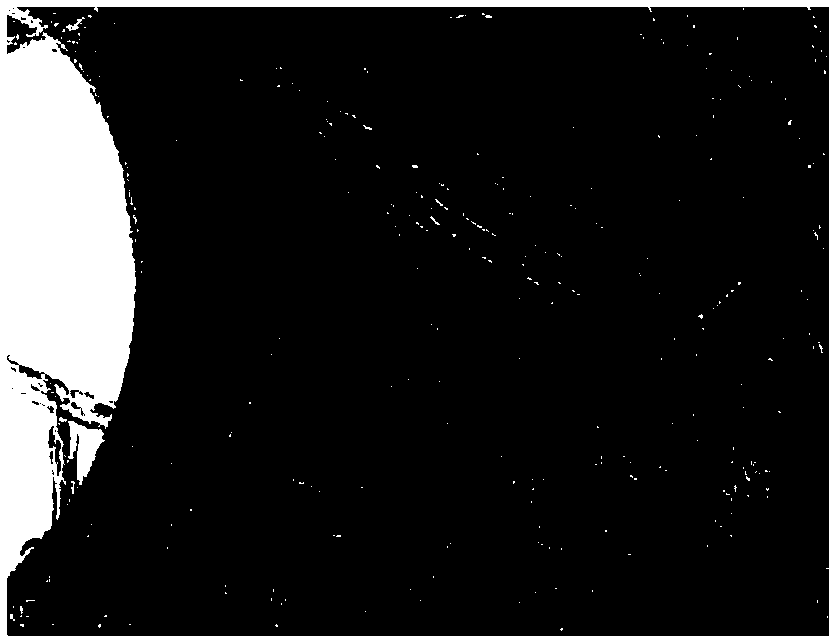

Embodiment 1

[0022] (1) Add 1.795g of magnesium nitrate hexahydrate and 1.313g of aluminum nitrate nonahydrate into 50ml of deionized water, stir, and mix well.

[0023] (2) Add 1.717g of hexamethylenetetramine to the mixture and mix evenly, then measure 20ml of 99% formamide and slowly pour it into the mixture and stir for 5 minutes.

[0024] (3) Transfer the mixed solution to a 100ml reactor and seal it, add it to 140°C in an oven, and react for 24 hours. The reactant was suction-filtered and washed three times with deionized water, and the resultant was dried in an oven at 80° C. and ground to obtain a boehmite powder material.

Embodiment 2

[0026] Add 1.795g (0.007mol) of magnesium nitrate hexahydrate and 1.313g (0.0035mol) of aluminum nitrate nonahydrate into 50mL of deionized water, stir and mix well. Add 0.981g of hexamethylenetetramine to the mixed solution at a molar ratio of hexamethylenetetramine to aluminum nitrate of 2:1, and stir to mix evenly. Measure 30 mL of 99% formamide with a graduated cylinder, slowly add it to the mixed solution, and stir for 5 minutes with a magnetic stirring bar. After stirring evenly, transfer the mixed solution to a 100mL hydrothermal reaction kettle, and seal the reaction kettle. The reaction kettle was placed in an oven and heated to 145° C. for 20 hours. After the reaction, the product was suction filtered and washed three times with deionized water (approximately 250 mL of deionized water). After suction filtration, the resultant was placed in an oven and dried at 80°C. After drying, the resultant is ground to obtain a boehmite powder material.

Embodiment 3

[0028] Add 1.795g (0.007mol) of magnesium nitrate hexahydrate and 1.313g (0.0035mol) of aluminum nitrate nonahydrate into 50mL of deionized water, stir and mix well. Add 1.717g of hexamethylenetetramine to the mixed solution at a molar ratio of hexamethylenetetramine to aluminum nitrate of 3.5:1, and stir to mix evenly. Measure 20mL of N,N-dimethylformamide with a graduated cylinder, slowly add it into the mixed solution, and stir for 5 minutes with a magnetic stirring bar. After stirring evenly, transfer the mixed solution to a 100mL hydrothermal reaction kettle, and seal the reaction kettle. The reaction kettle was placed in an oven and heated to 125° C. for 24 hours. After the reaction, the product was suction filtered and washed three times with deionized water (approximately 250 mL of deionized water). After suction filtration, the resultant was placed in an oven and dried at 80°C. After drying, the resultant is ground into powder to obtain boehmite powder material.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com