Patents

Literature

37 results about "Nitrate hydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Active carbon used for adsorbing and removing sulfides in gasoline, and preparation method thereof

ActiveCN102188954AHighly selective adsorptionLow ashOther chemical processesHydrocarbon oils refiningHydration reactionAdhesive

The invention relates to active carbon used for absorbing and removing sulfides in gasoline, and a preparation method thereof. The active carbon is composed of the following components in percentage by weight: 40-70% of petroleum coke, 10-50% of coal, 10-30% of adhesive, 0.1-10% of pore forming agent and 0.1-10% of amodifier, wherein the ash content of the petroleum coke is less than 1%; the coalis anthracite or bituminous coal with volatile content less than 35%; the adhesive is one of or the mixture of coal pitch, coal tar, vacuum residue, coked condensed oil, ethylene cracked residue, catalytic slurry, petroleum pitch and petroleum pitch oxide; the pore forming agent is one of or the mixture of carbon black containing active functional groups and active elements, furfural residue, ferrocene, furfuryl alcohol and potassium; and the modifier is a hydrate nitrate of Cr, Fe, Co, Ni, Mo, Ti, Cu or Zn. The active carbon has the characteristics of low ash content, high strength, high selectivity, excellent adsorption performance and the like.

Owner:PETROCHINA CO LTD

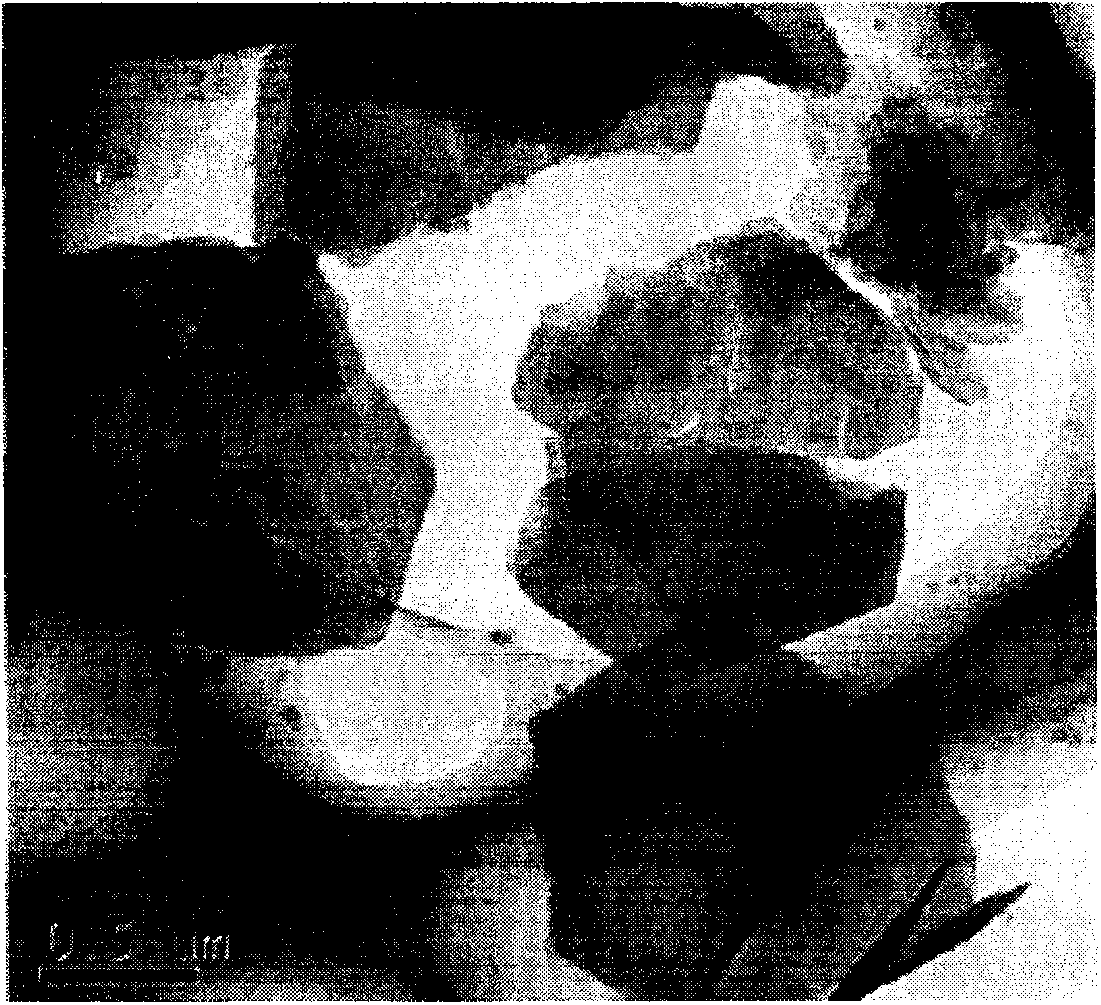

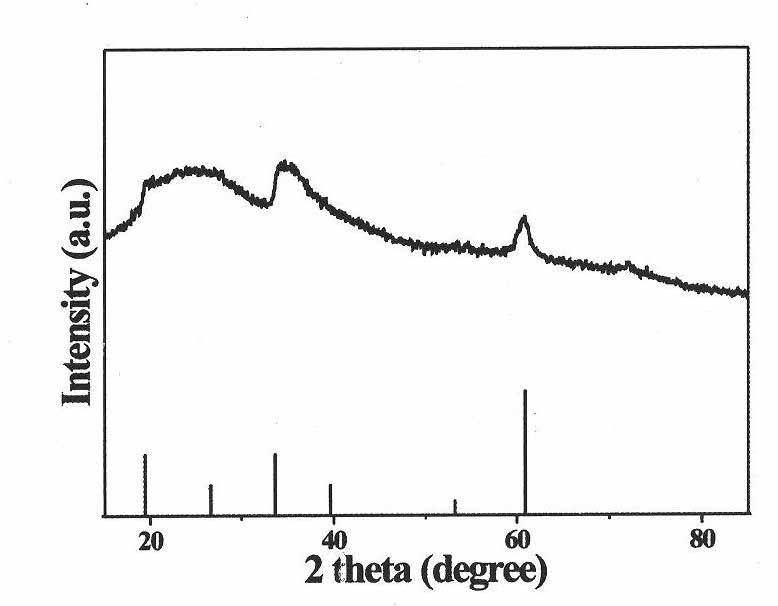

Cathode material for lithium battery

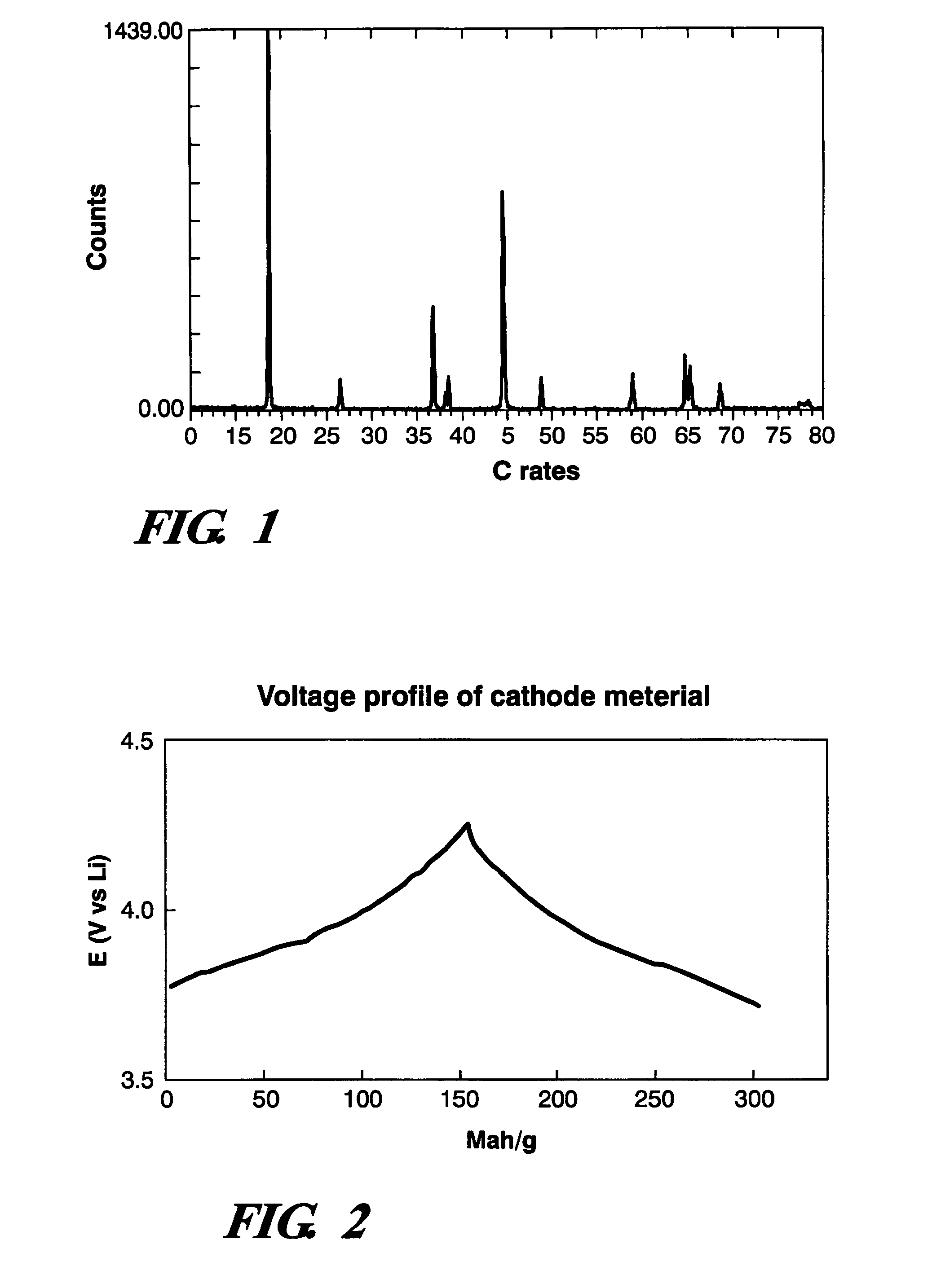

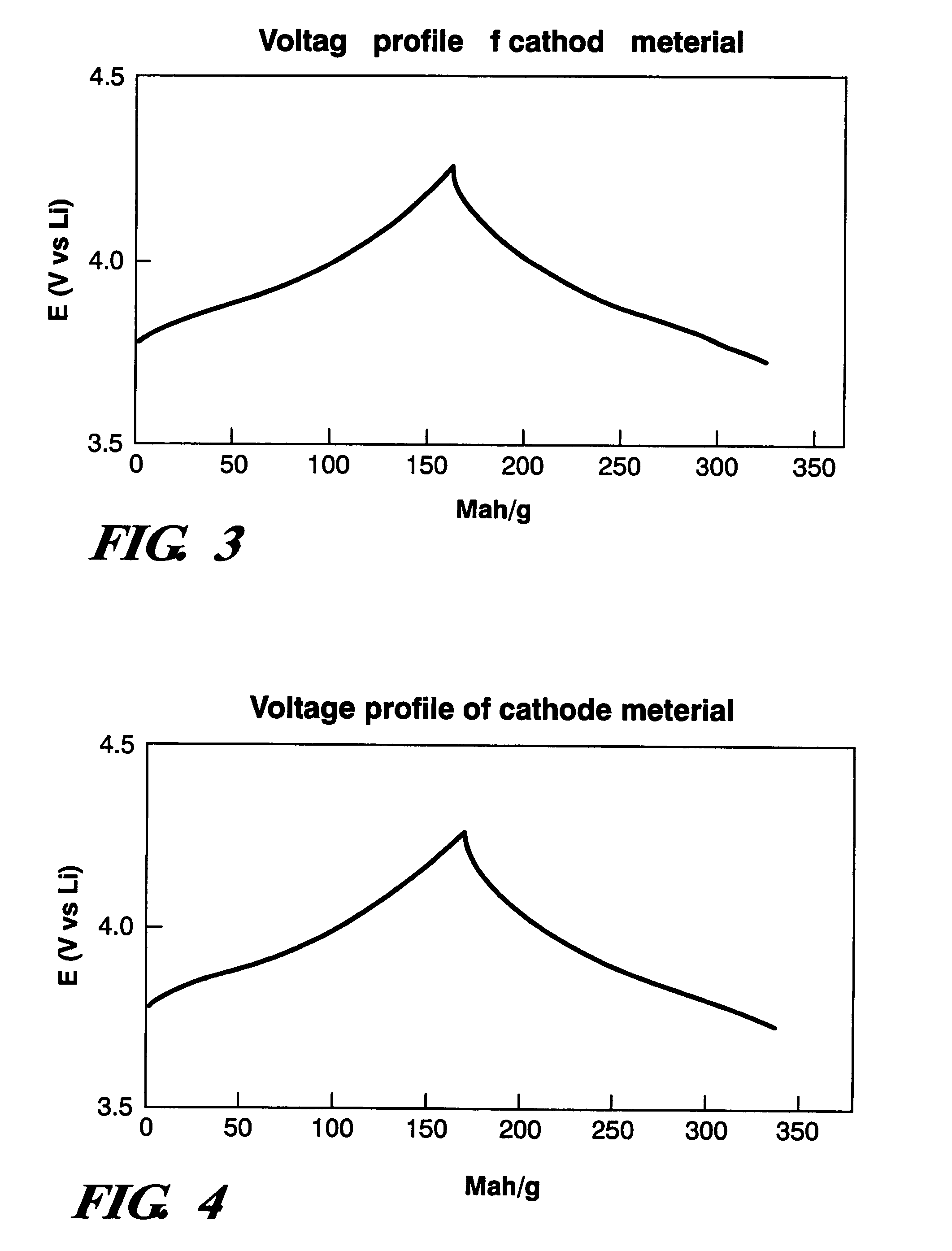

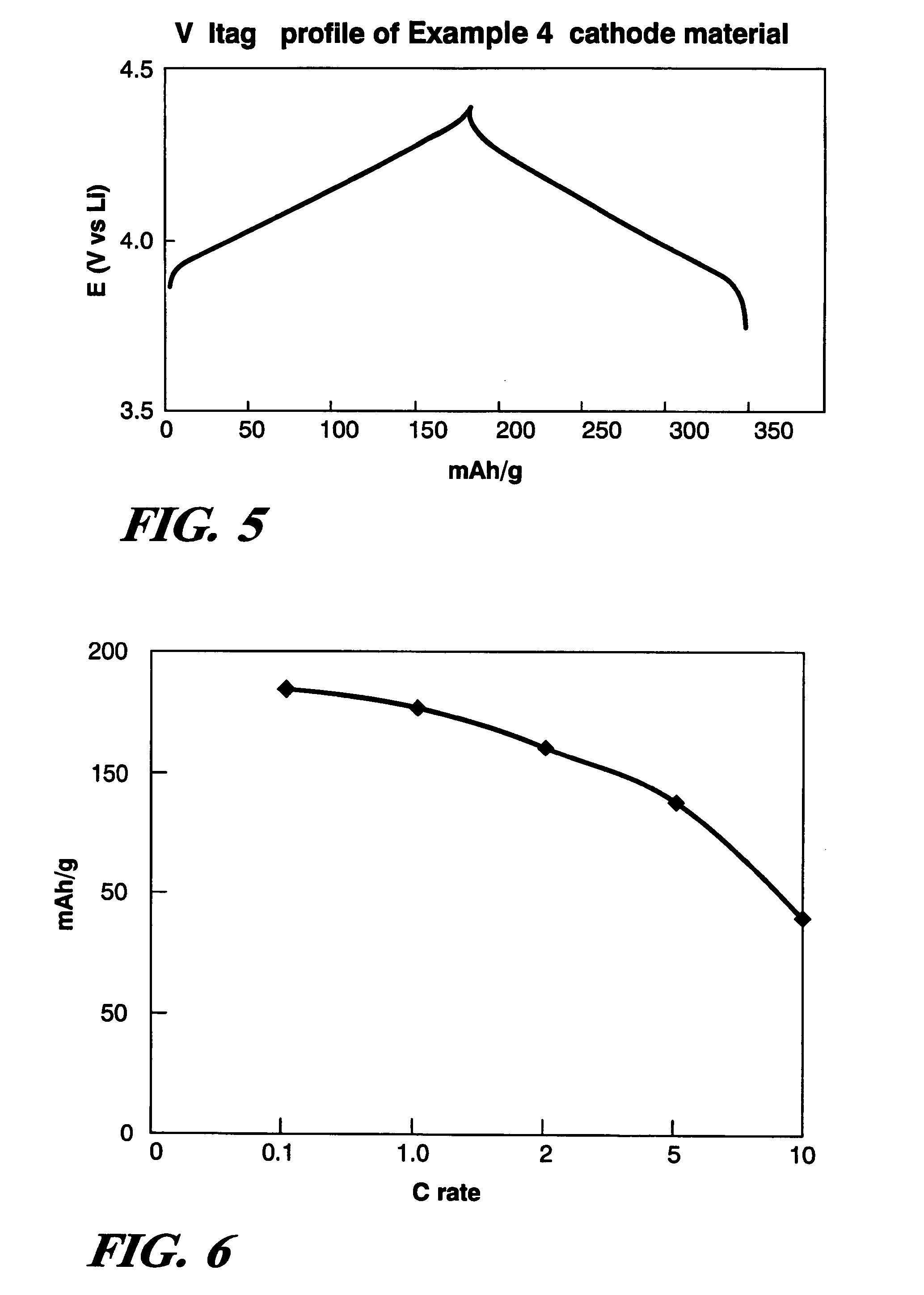

ActiveUS7018607B2Evenly distributedEfficient dryingAluminium compoundsOxygen/ozone/oxide/hydroxideCrystalline oxideOxygen

A method is disclosed for synthesizing a crystalline metal oxide powder material containing two or more uniformly distributed metal elements. Crystalline, water containing, oxygen containing inorganic acid salts of the metals are heated to liquefy the salts. The apparent solution contains a uniform mixture of the metal elements. The water is removed from the liquid and the resulting powder calcined in air to decompose the acid salts to a mixed metal crystalline oxide. The method is particularly useful to make doped LiNiO2 type crystals using hydrated nitrate or nitrite salts of Li, Ni and the dopant elements. Examples of useful salts are LiNO3.H2O, Ni(NO3)2.6H2O, Co(NO3)2.6H2O, Al(NO3)3.9H2O, and Mg(NO3)2.6H2O.

Owner:GM GLOBAL TECH OPERATIONS LLC

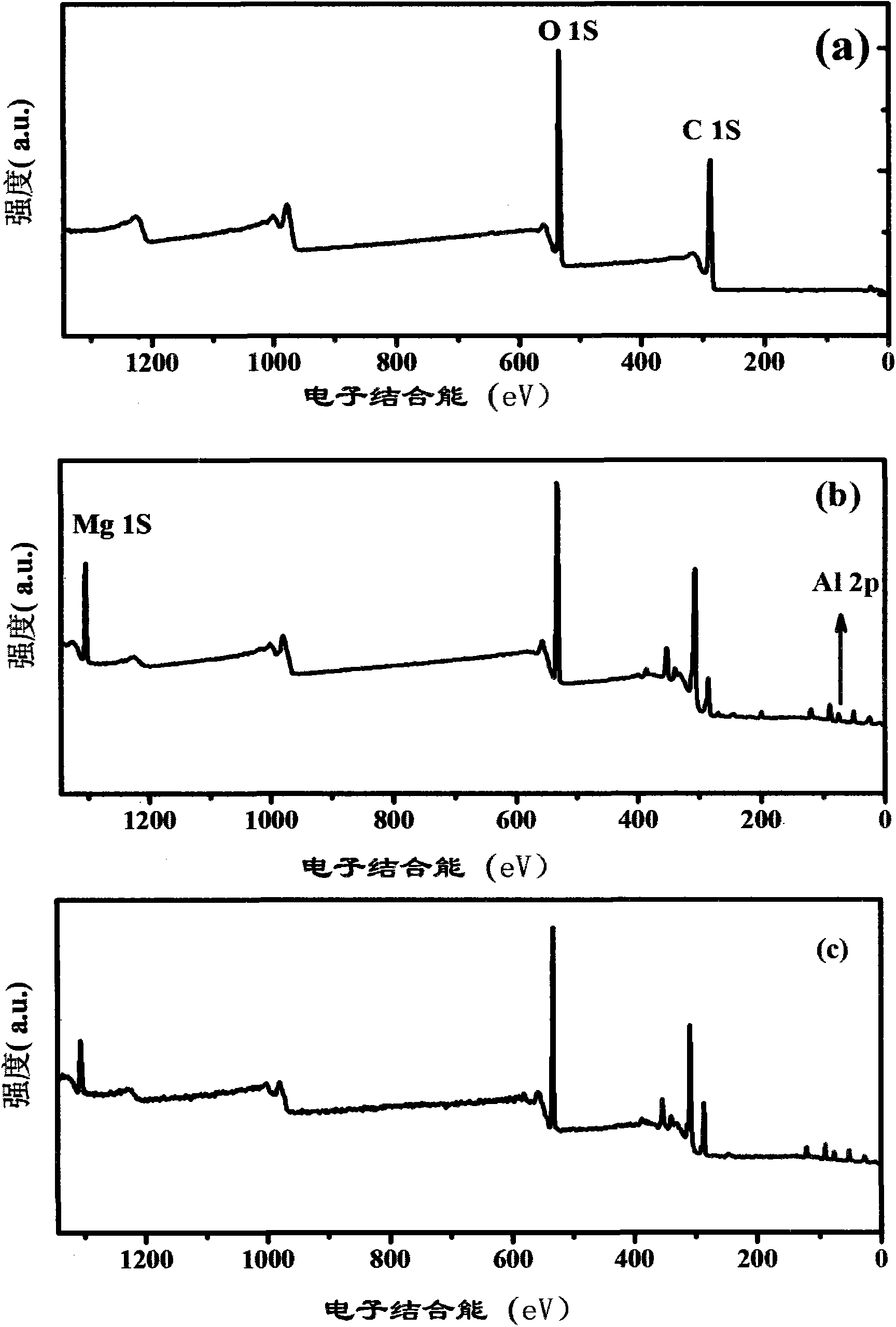

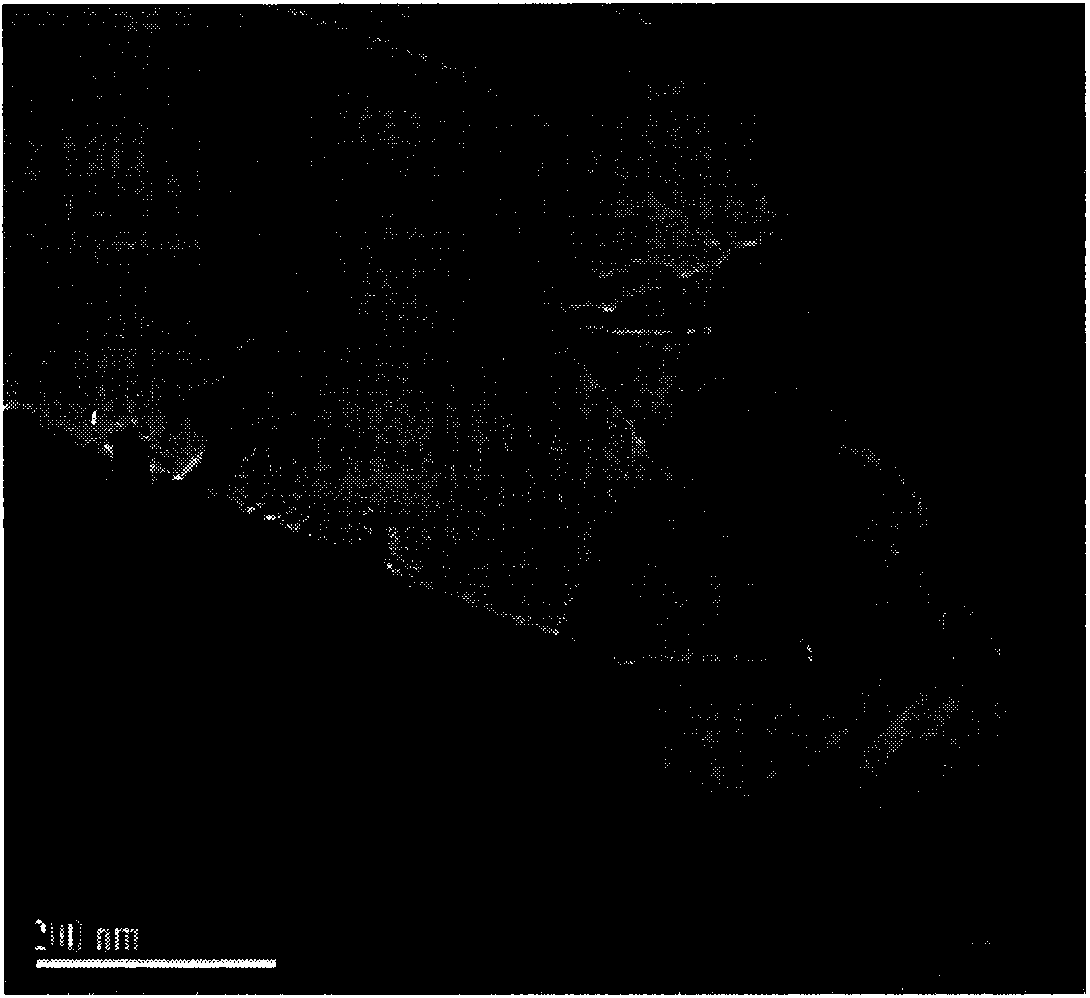

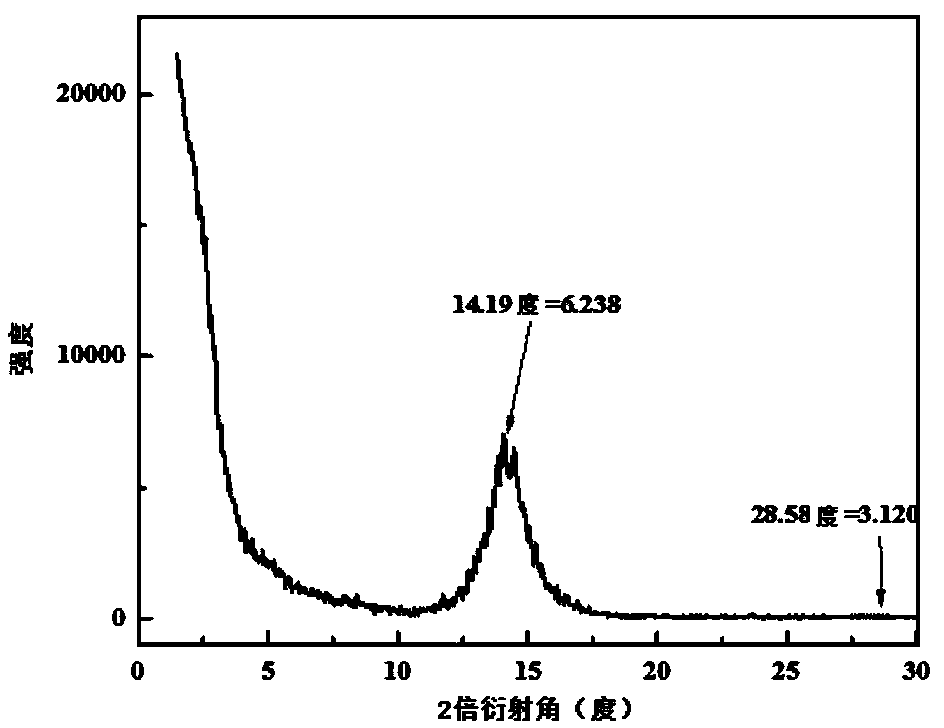

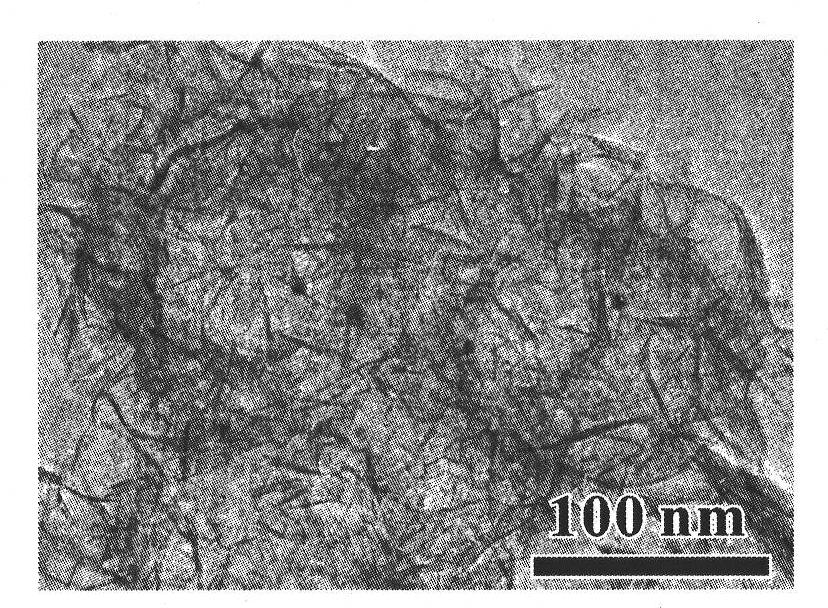

Graphene/double-metal oxide composite material and preparation method and application thereof

InactiveCN103316635ALow priceSimple preparation processOther chemical processesWater contaminantsNitrateOxide composite

The invention discloses a graphene / double-metal oxide composite material, heavy metal ion adsorption of the graphene / double-metal oxide composite material and a preparation method of the graphene / double-metal oxide composite material. The composite material is prepared from a divalent nitrate hydrate, a ferric nitrate hydrate, a basic compound and graphene oxide. According to the composite material disclosed by the invention, the main raw materials are low in cost, and the preparation method is simpler and is easier to control. The composite material has a strong Cr(VI) adsorption function and can be used repeatedly, so that the cost performance is high.

Owner:CHONGQING JIAOTONG UNIVERSITY

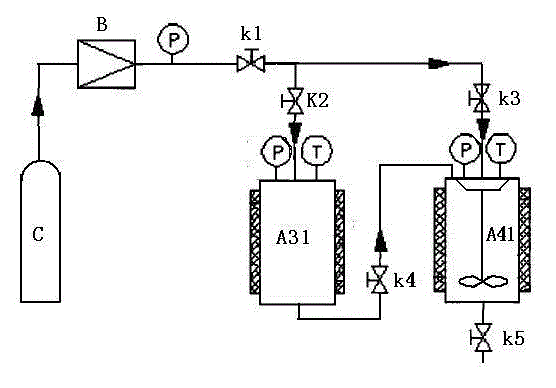

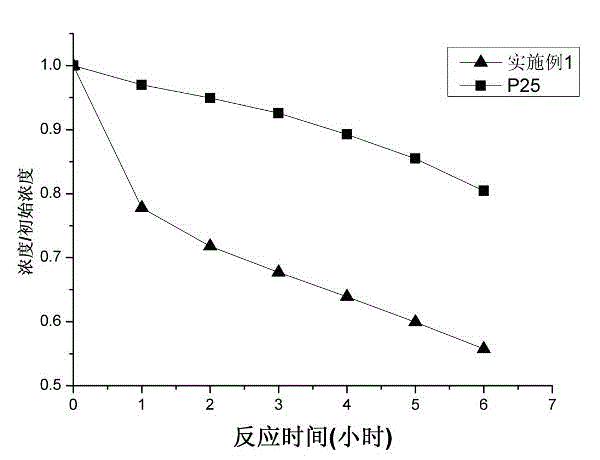

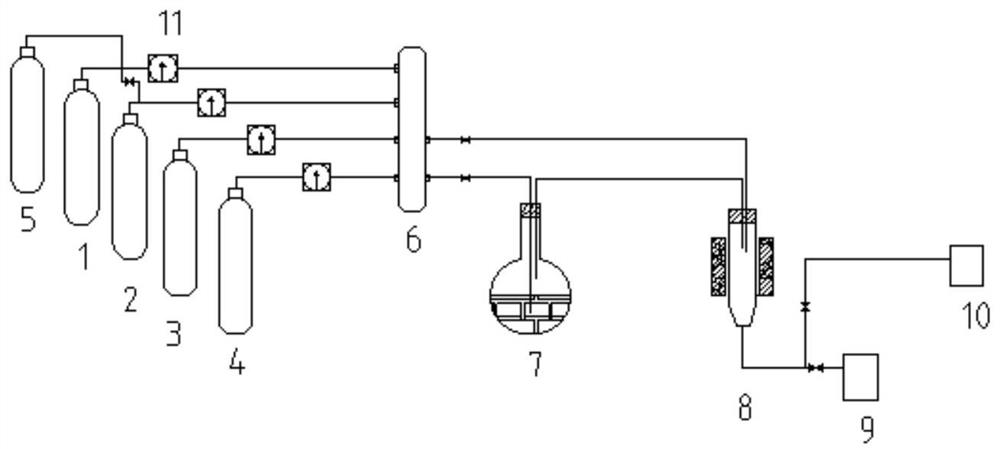

Method and device for preparing rare earth doping nano-titania photocatalyst with supercritical carbon dioxide process

InactiveCN103055840AExcellent degradation rateImprove degradation rateWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementAlcohol

The invention relates to a method and a device for preparing rare earth doping nano-titania photocatalyst with supercritical carbon dioxide process. The method comprises the following specific steps: adding titanium alkoxide, absolute ethyl alcohol and rare earth element nitrate hydrate in a reaction kettle for stirring and dissolving; pumping high purity CO2 in the reaction kettle at the temperature of 110-150 DEG C under the pressure of 80-500 bar; adding deionized water in a deionized water dissolving kettle and raising the temperature till 110-150 DEG C; then pumping high purity CO2 in the deionized water dissolving kettle under the pressure of 80-500 bar, and causing the pressure difference between the deionized water dissolving kettle and the reaction kettle to be kept at 10-30 bar; flowing supercritical CO2 fluid doped with deionized water in the reaction kettle at the temperature of 110-150 DEG C and under the pressure of 80-500 bar, stirring for 4-24h for reaction; and after the reaction is finished, drying obtained products after being washed, and grinding the products so as to obtain the rare earth doping nano-titania photocatalyst.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

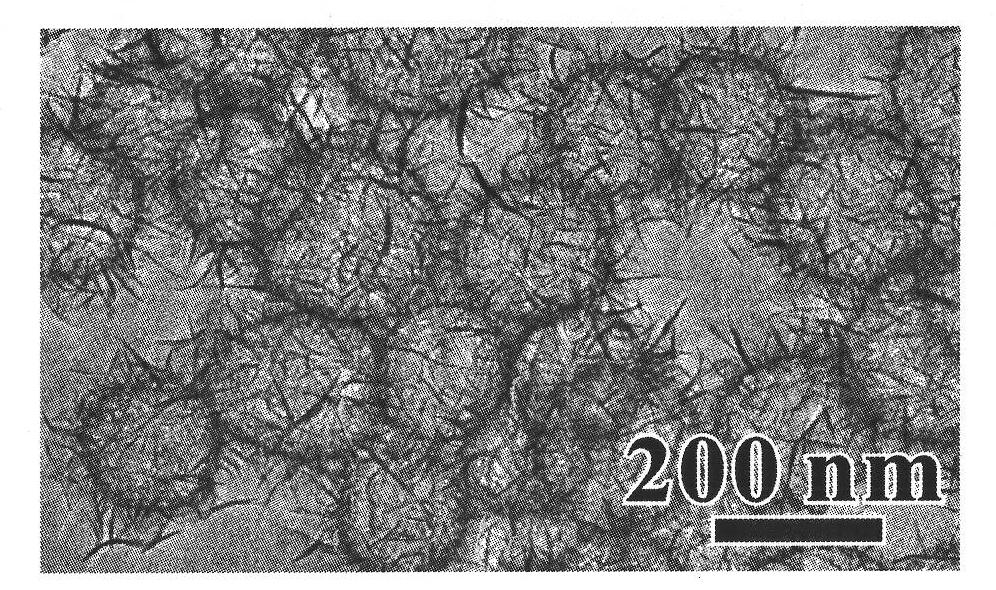

Preparation method of nano-fiber boehmite material

ActiveCN103553097AUniform shapeGood dispersionMaterial nanotechnologyAluminium oxides/hydroxidesDispersityFiber

The invention discloses a preparation method of a nano-fiber boehmite material. The nano-fiber boehmite material is synthesized by a one-step hydrothermal process. The preparation method comprises the following steps of adding a nitrate hydrate mixture of aluminum nitrate nonahydrate and magnesium nitrate hexahydrate into deionized water; adding hexamethylenetetramine and a surfactant; mixing and performing a hydrothermal reaction at 100-145 DEG C; filtering, washing and drying to obtain nano-fiber boehmite with controllable appearance and good dispersity. The preparation method has the characteristics of short time and simplicity and convenience, and the prepared boehmite is applicable to the fields such as water treatment filtering materials, precursors for preparing pure-aluminum and aluminum oxide materials, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method for hollow silicate

InactiveCN101863485ASimple post-processingControl synthesisNanostructure manufactureSilicon compoundsNitrateRoom temperature

The invention relates to silicate and provides a preparation method for hollow silicate, in particular to a simple and effective method for preparing hollow silicate under solvothermal conditions. The method comprises the following steps: synthesizing silicon dioxide nanospheres: mixing tetraethoxysilane, water, ammonia water and ethanol by volume ratio of 1: (0.25-2): (0.25-4): (4.25-68) of tetraethoxysilane to water to ammonia water to ethanol, and washing the obtained products after reaction to obtain the silicon dioxide nanospheres; and adding the silicon dioxide nanospheres, urea, dihydrate-2-hydroxy-5-sulfo-benzoicacid and nitrate hexahydrate in water and ethanol, and cooling the obtained solid product to room temperature after reaction, and washing the obtained solid product to obtain the target product, i.e. the hollow silicate.

Owner:XIAMEN UNIV

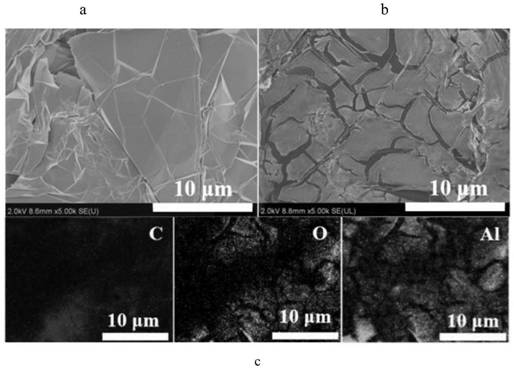

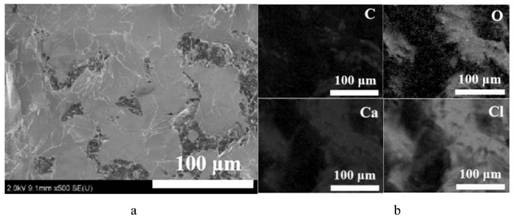

Preparation method of aluminum alloy cobalt salt chemical conversion coating treating fluid

The invention relates to a preparation method of aluminum alloy cobalt salt chemical conversion coating treating fluid, belonging to the field of aluminum alloy surface treatment. A porous chemical conversion coating formed by treating aluminum alloy through treating fluid has the characteristics of no chromium, environment friendliness, and good corrosion resistance property, and the like, the treating fluid is prepared from cobalt salt, oxidant, ligand and water, wherein per liter of cobalt salt chemical conversion treating fluid contains the following compositions by weight: 20-50g of cobalt salt, 1-50g of an oxidant, and 2-7g of ligand, and the PH value of the treating fluid ranges from 3 to 4; the cobalt salt is selected from one or two of cobalt-nitrate hydrate and cobalt-chloride hydrate; the oxidant is selected from one or more of lithium permanganate, sodium permanganate, ammonia permanganate and calcium permanganate; and the ligand is selected from one or two of sodium nitrite or sodium acetate.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

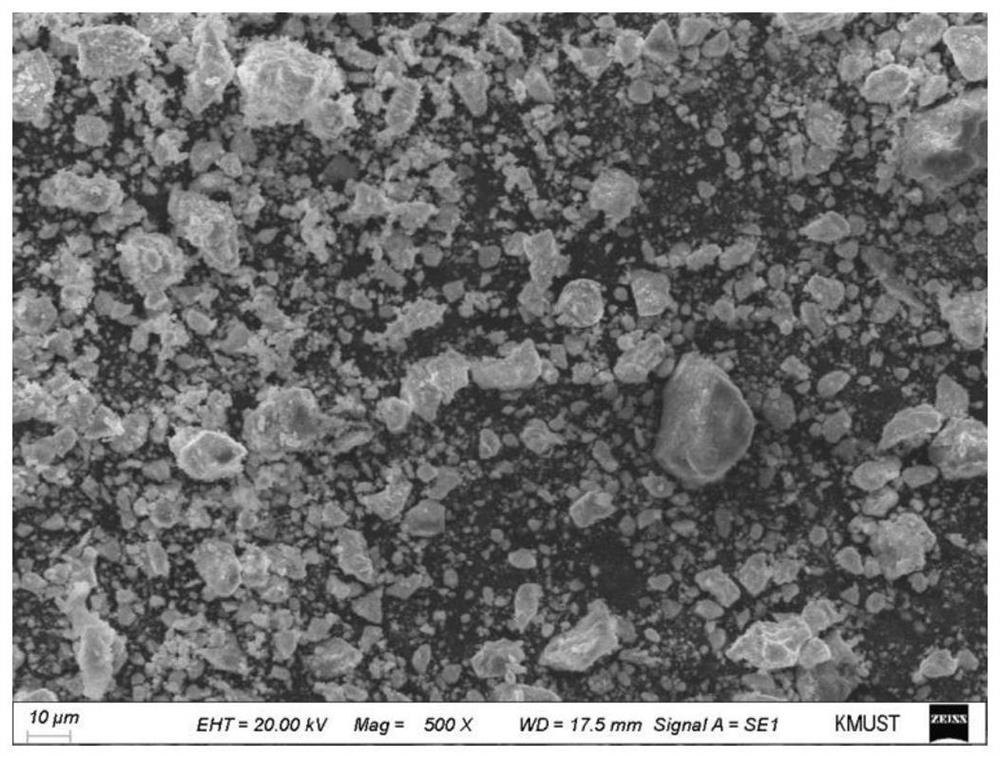

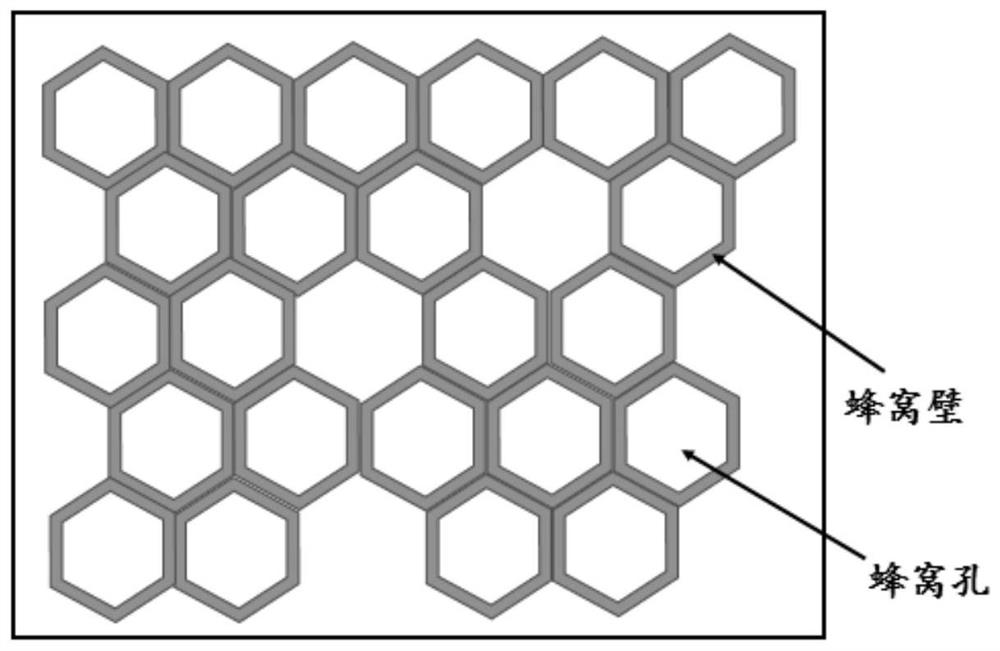

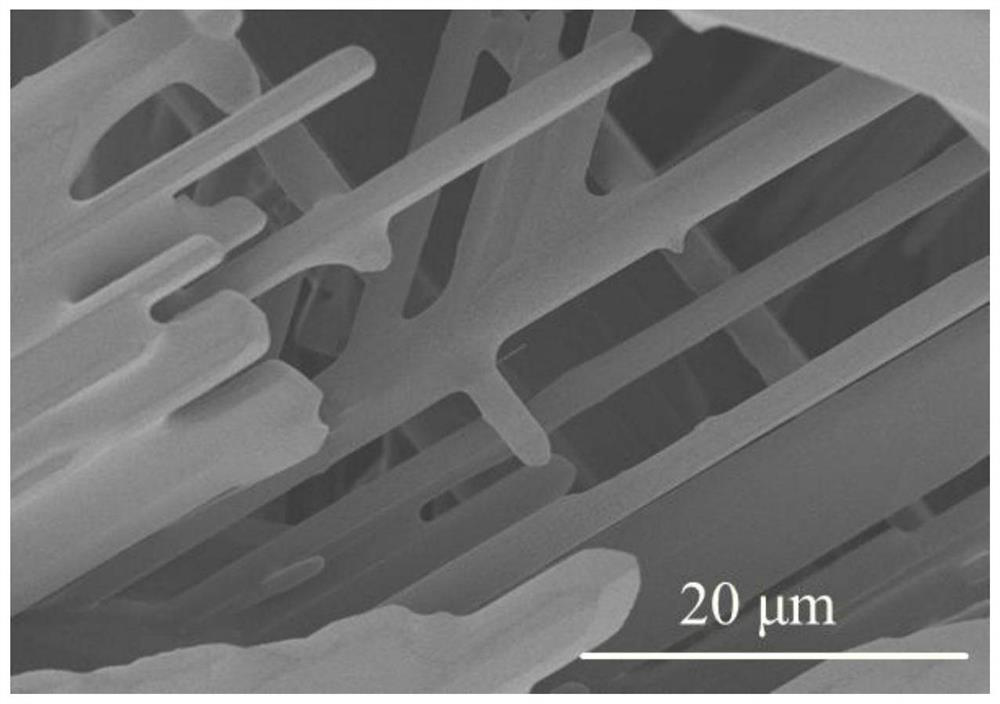

Preparation method of in-situ synthesis ZTA particle reinforced steel-based configuration composite material

ActiveCN113862548ANo pollution in the processGood compatibilityAluminium nitrateMetal matrix composite

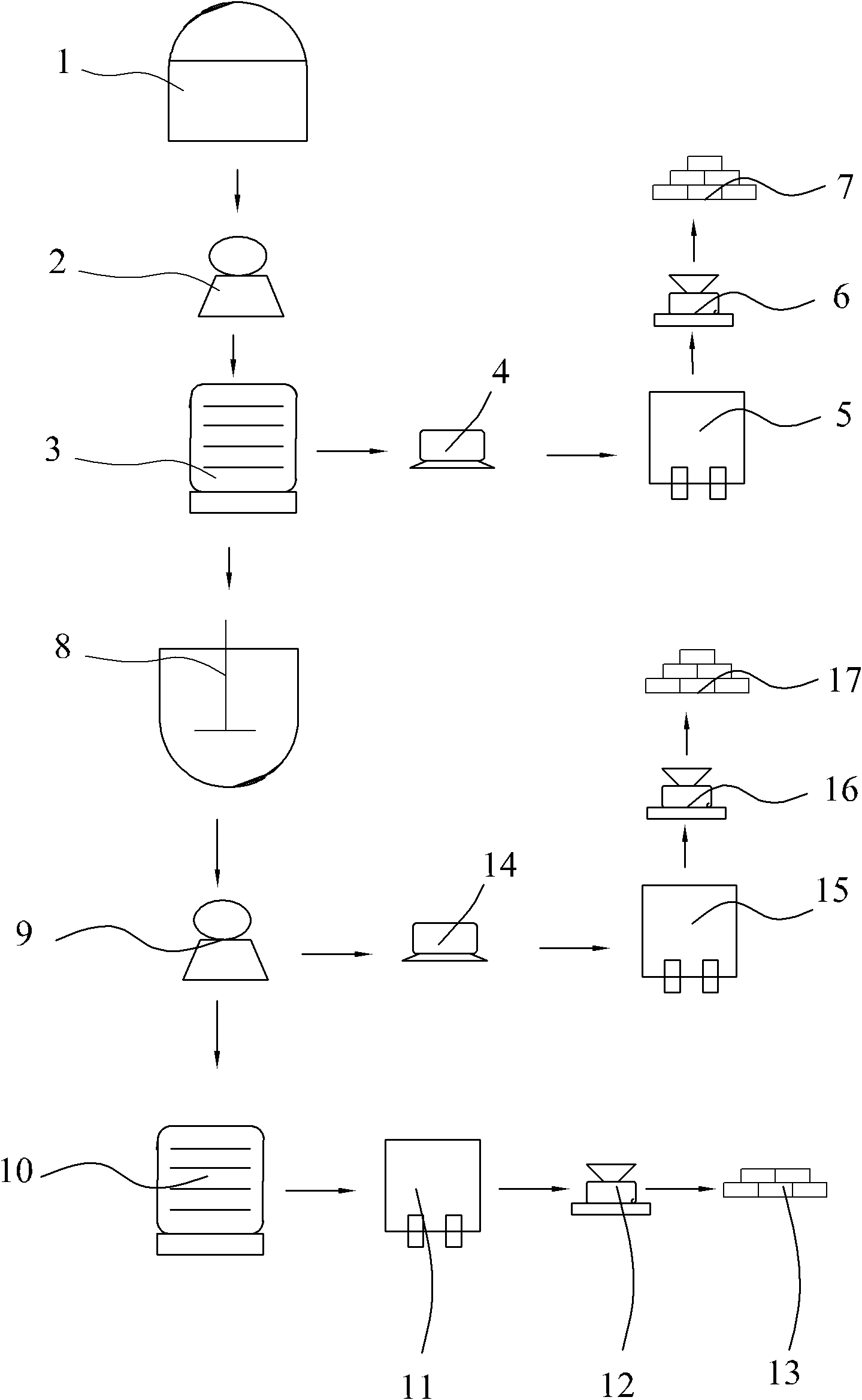

The invention discloses a preparation method of an in-situ synthesis ZTA particle reinforced steel-based configuration composite material, and belongs to the technical field of metal-based composite materials. The preparation method comprises the steps of preparing transparent sol by taking aluminum nitrate nonahydrate, zirconyl nitrate hydrate and the like as raw materials; adding steel-based powder into the sol for liquid-solid doping, stirring until solidification, and sequentially carrying out vacuum drying and reduction on ZTA / steel-iron mixed powder; and filling the honeycomb walls of a honeycomb-shaped mold with the ZTA / steel mixed powder, filling honeycomb holes of the honeycomb-shaped mold with the steel-based powder, and obtaining the in-situ synthesis ZTA ceramic particle reinforced steel-based honeycomb structure composite material after pressing and sintering. ZTA ceramic is generated in situ, the surfaces of ceramic particles are free of pollution, the compatibility with a steel matrix is good, and the interface bonding strength is high; and the honeycomb walls are composed of the composite areas with high hardness, the abrasion effect borne by the honeycomb holes with low hardness can be remarkably reduced, the abrasion resistance is improved by more than three times compared with a traditional steel material, and wide application prospects are achieved.

Owner:KUNMING UNIV OF SCI & TECH

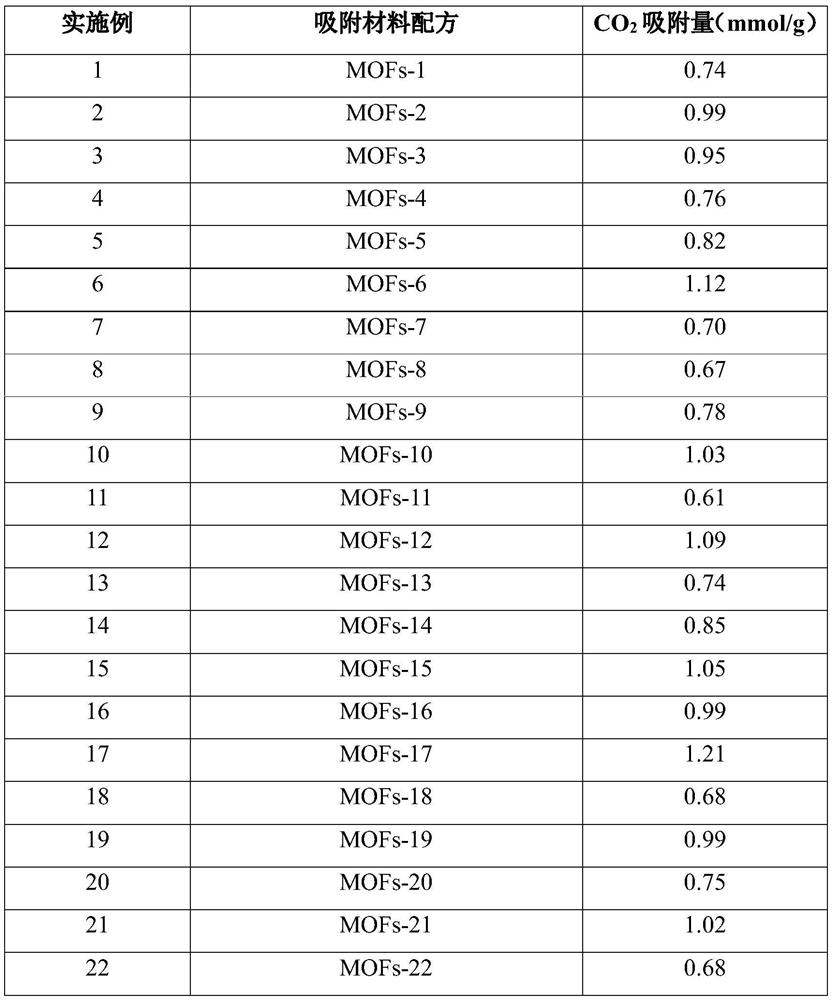

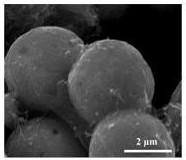

Bimetal MOFs material for CO2 capture and preparation method and application thereof

InactiveCN112979977AEasy to prepareLess corrosiveProductsGas treatmentCopper nitrateMetallic materials

The invention discloses a bimetallic MOFs material for CO2 capture and a preparation method and application thereof, and belongs to the technical field of material science and chemical engineering. The bimetallic MOFs material is prepared by taking copper nitrate hydrate and nitrate hydrate of transition metal as two metal central ion sources and trimesic acid as a ligand material. The specific preparation method comprises the steps that copper nitrate hydrate, nitrate hydrate of transition metal and trimesic acid are dissolved in a solvent to prepare solutions, the solutions are mixed and then subjected to a hydrothermal reaction, and centrifugation, washing and drying are carried out to obtain the bimetallic MOFs material. The bimetallic MOFs material is tableted and sieved, and a 20-40-mesh material is taken; degassing treatment is carried out at normal pressure; and adsorption is carried out in an atmosphere containing CO2 gas at normal pressure. Compared with an original material HKUST-1, the CO2 adsorption capacity of the bimetallic MOFs material can be remarkably improved through the bimetallic synergistic effect of the bimetallic MOFs material.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

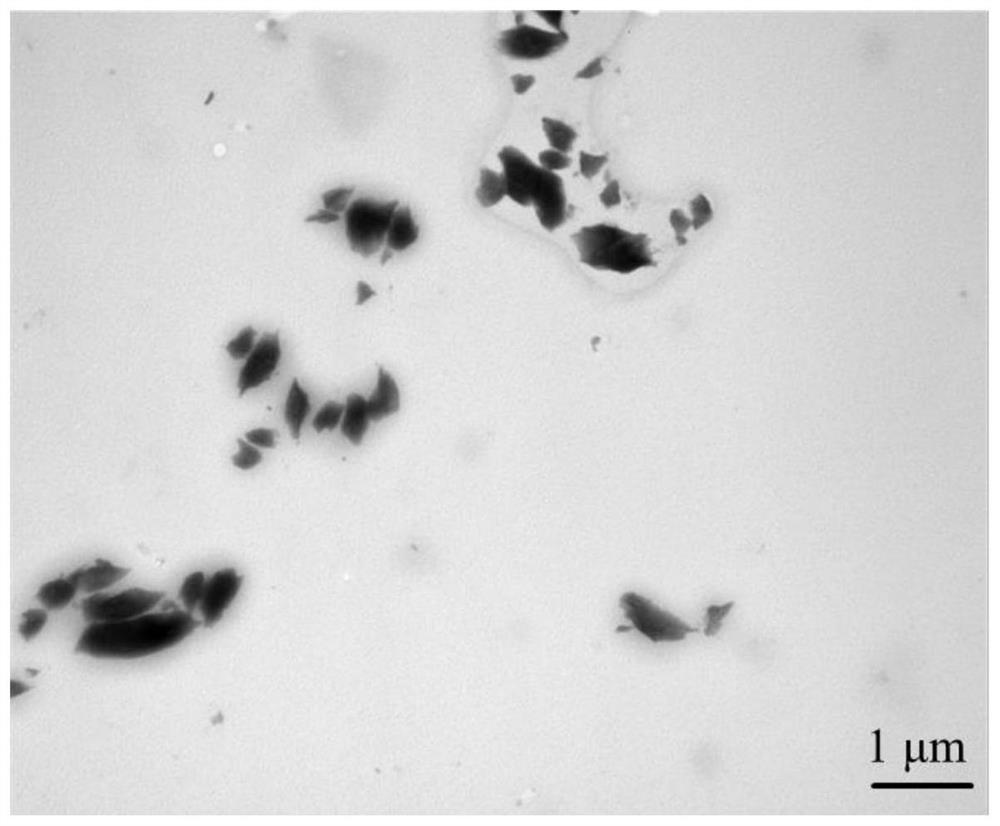

Preparation method of rGO-LaFeO3 nanometer compound material

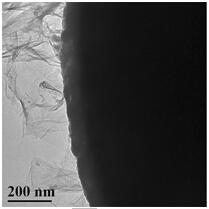

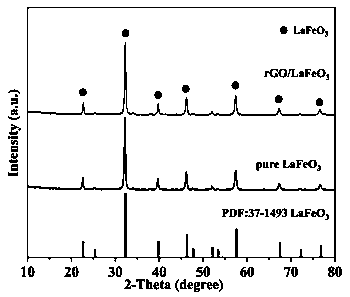

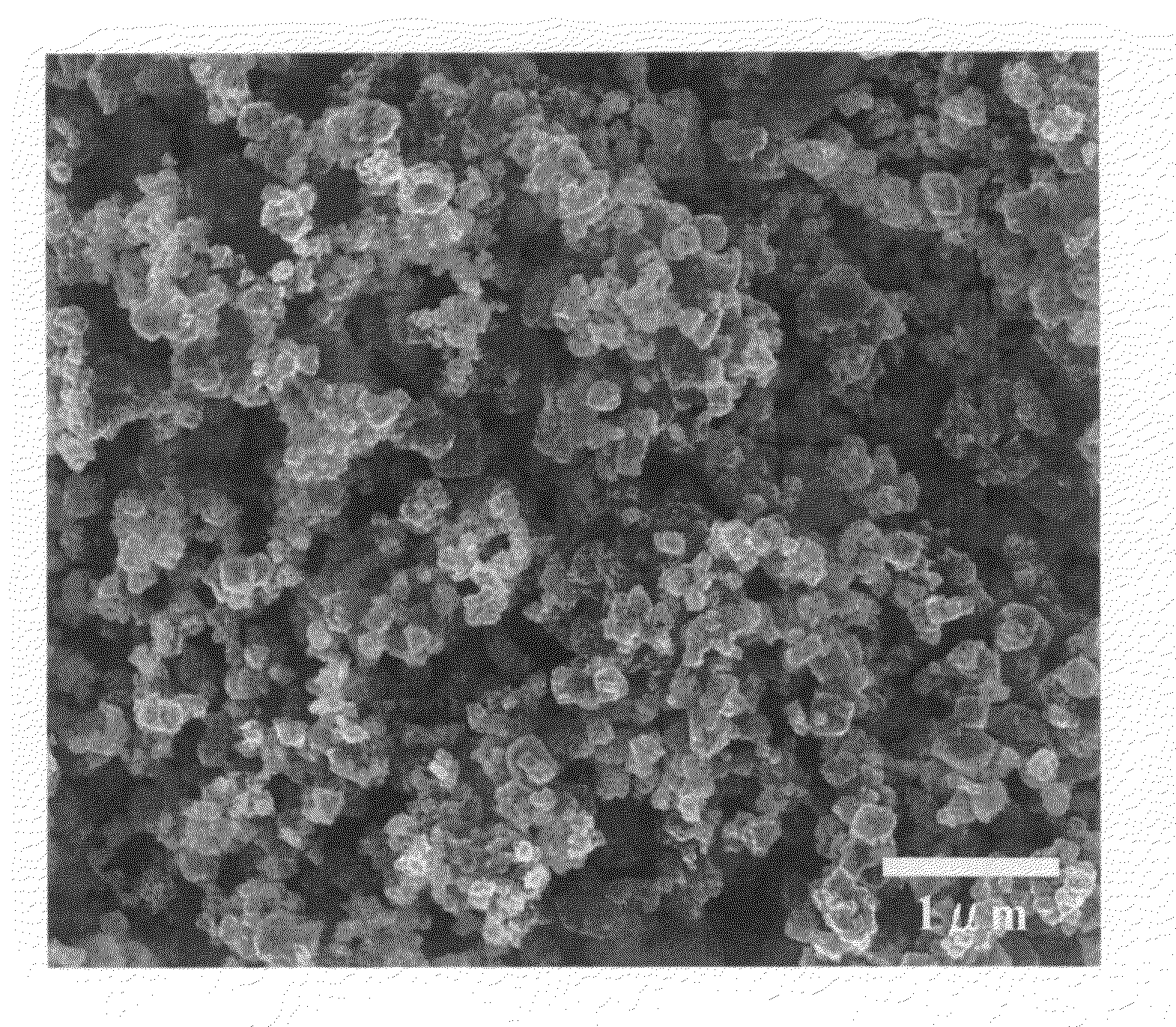

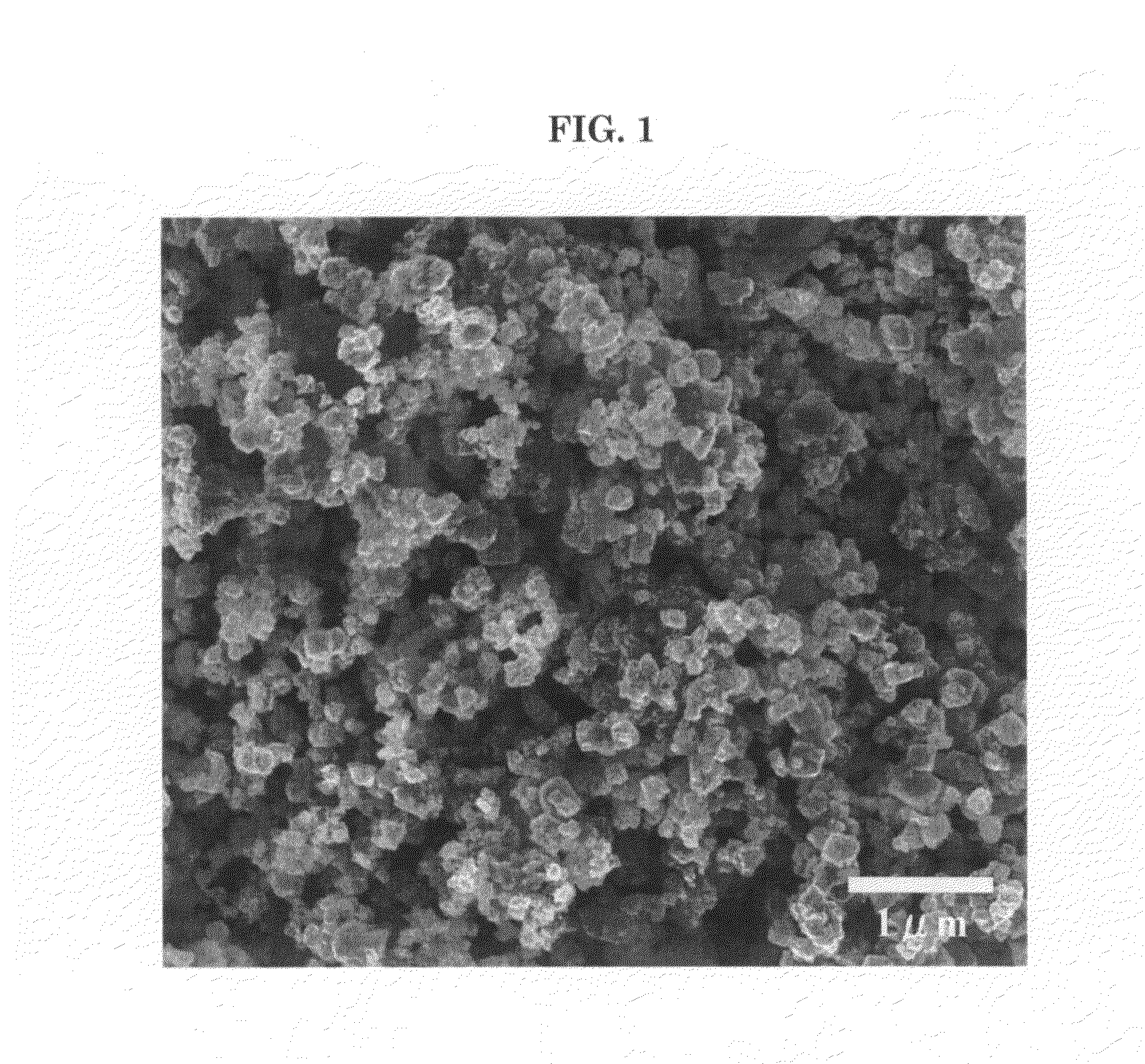

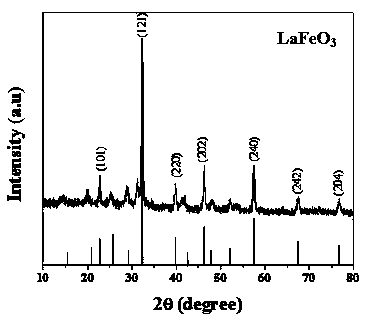

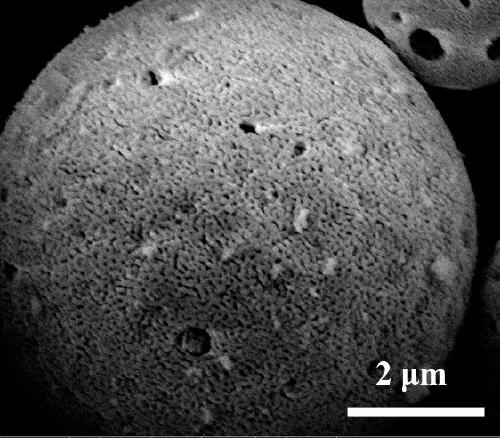

InactiveCN109133181AHigh sensitivityNo pollution in the processCarbon compoundsIron compoundsMicrosphereCalcination

The invention provides a preparation method of an rGO-LaFeO3 nanometer compound material. The preparation method specifically includes the steps of adopting a lanthanum nitrate hydrate, a ferric nitrate hydrate and citric acid as raw materials and making the raw materials subjected to a hydrothermal reaction and calcination treatment to obtain lanthanum ferrite nanometer microspheres; adopting graphene oxide and APTES as raw materials and using the raw materials for compounding sheet-like reduced graphene oxide (rGO) on the surfaces of the lanthanum ferrite nanometer microspheres. The preparation method is simple in process, and the rGO-LaFeO3 nanometer compound material is obtained at last. The rGO-LaFeO3 nanometer compound material has high sensitivity on triethylamine, is fast in response and recovery and can be applied to the field of triethylamine gas sensors, and therefore a novel gas-sensing material with high sensitivity is obtained.

Owner:UNIV OF JINAN

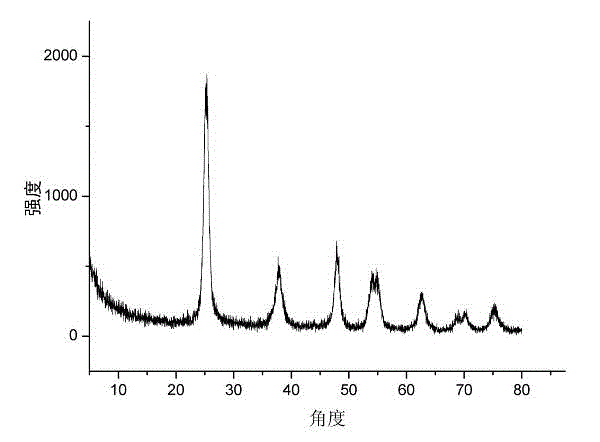

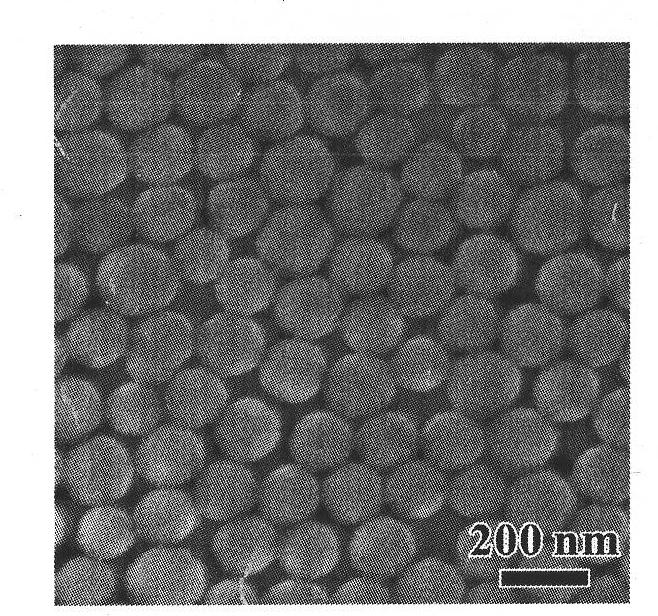

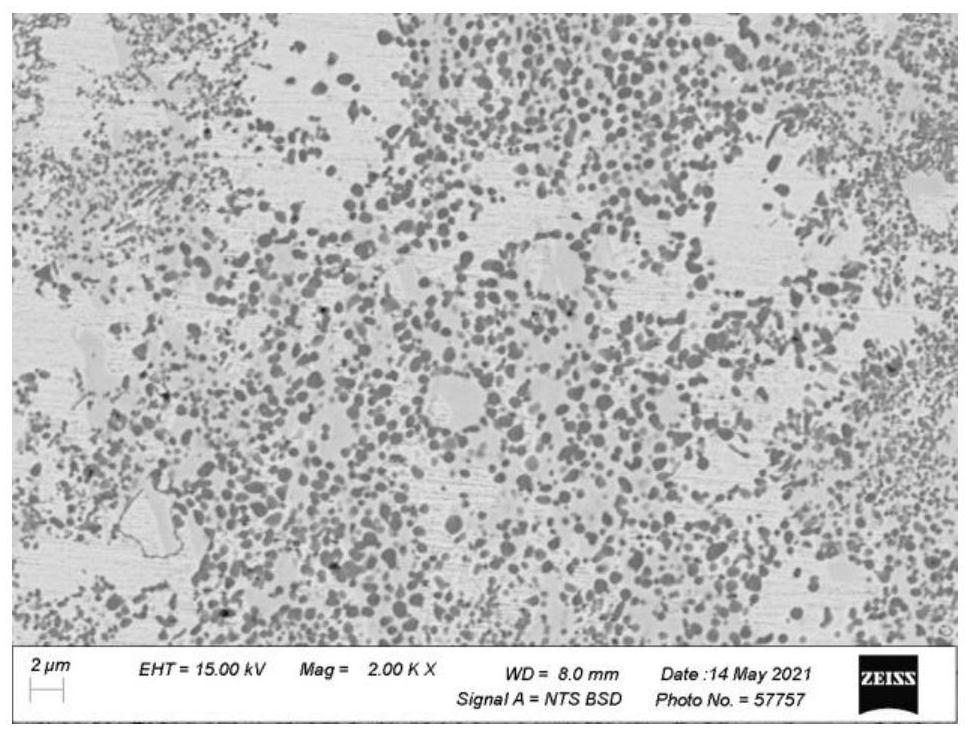

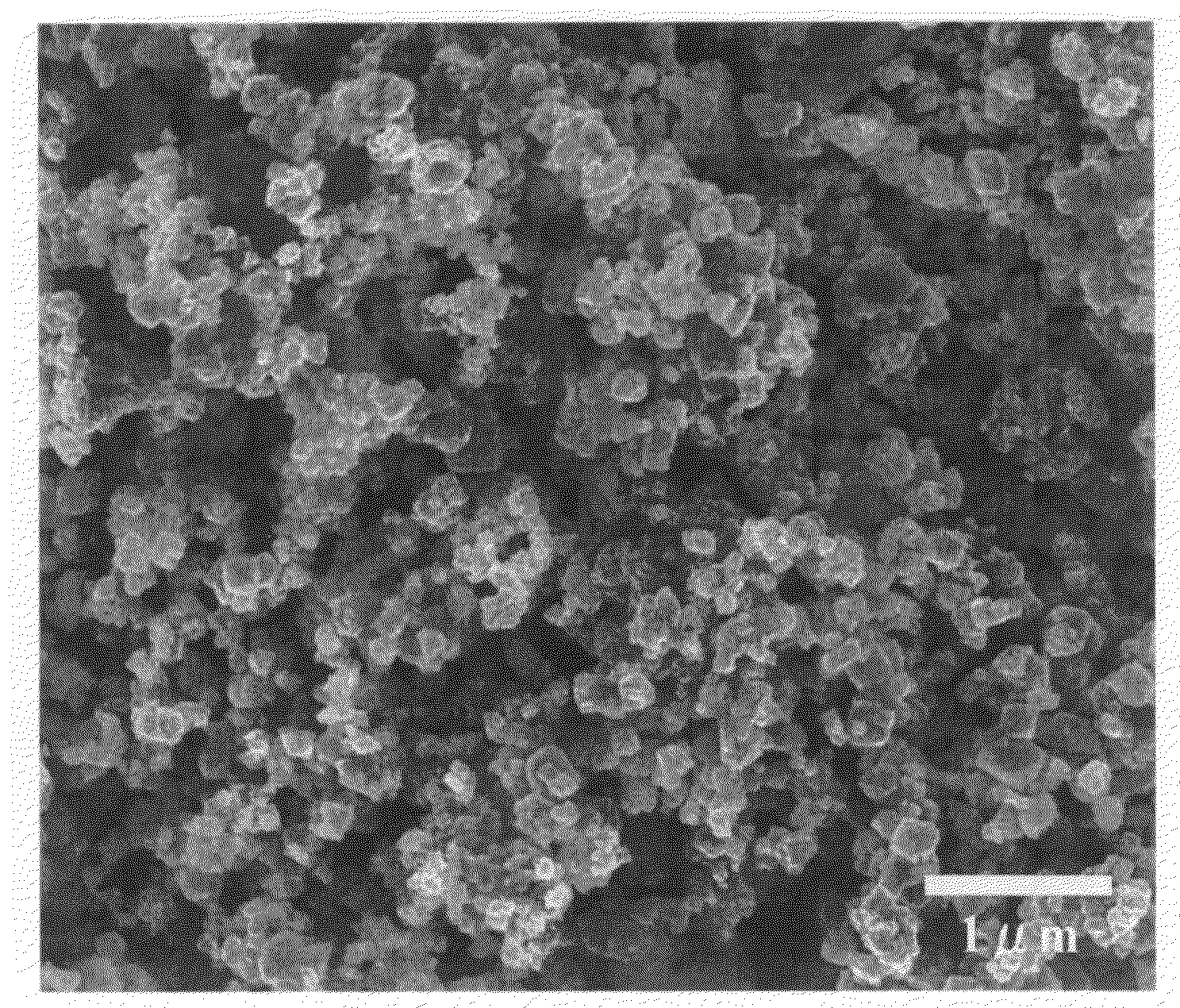

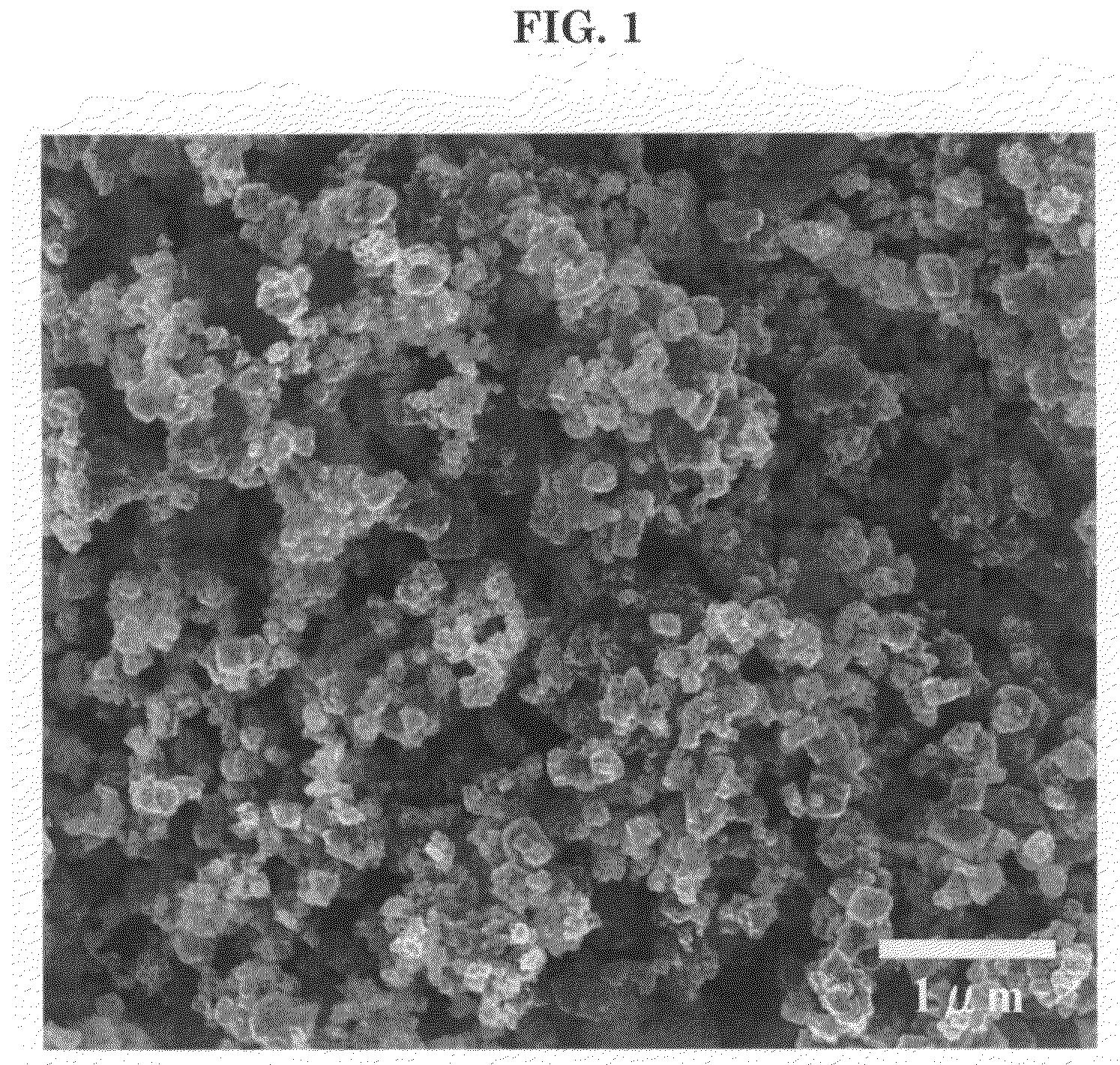

Nickel powder manufacturing method

A melt of nickel nitrate hydrate is introduced as droplets or liquid flow into a heated reaction vessel and thermally decomposed in a gas phase at a temperature of 1200° C. or more and at an oxygen partial pressure equal to or below the equilibrium oxygen pressure of nickel-nickel oxide at that temperature to manufacture a highly crystalline fine nickel powder with an extremely narrow particle size distribution. The oxygen partial pressure during the thermal decomposition is preferably 10−2 Pa or less, and a metal other than nickel, a semimetal and / or a compound of these may be added to the nickel nitrate hydrate melt to manufacture a highly crystalline nickel alloy powder or highly crystalline nickel composite powder. The resultant powder is suited in particular to thick film pastes such as conductor pastes for manufacturing ceramic multilayer electronic components.

Owner:SHOEI CHEM IND CO LTD

Method for preparing Portland cement clinker

InactiveCN102153295AEasy to controlReduce free calcium oxide contentHexamethylenetetramineMaterials science

The invention relates to a method for preparing Portland cement clinker. The method comprises the following steps: proportionally mixing tetraethoxysilane, a calcium nitrate hydrate, an aluminium nitrate hydrate, a ferric nitrate hydrate, ethanol, nitric acid, hexamethylenetetramine, acetylacetone, deionized water and the like uniformly to obtain four kinds of mixed liquid, fully stirring the four kinds of mixed liquid respectively at the temperature of 50-70 DEG C until proper viscosity to obtain monomineral sols of the Portland cement clinker, then mixing the four monomineral sols in a massratio of (36-55):(24-40):(11-19):(20-31), ageing the mixture to form gel, carrying out heat treatment on the gel at the temperature of 1150-1200 DEG C for 4-6 hours and cooling the gel to the room temperature, thus obtaining the Portland cement clinker. Compared with the prior art, the method has the following advantages: the preparation process is simple; the reaction process is easy to control;and the product has high uniformity and purity and can be fired at the temperature lower than the temperature in the traditional methods.

Owner:TONGJI UNIV

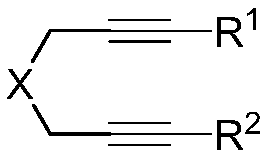

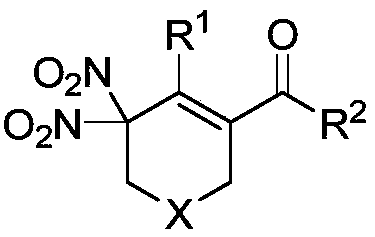

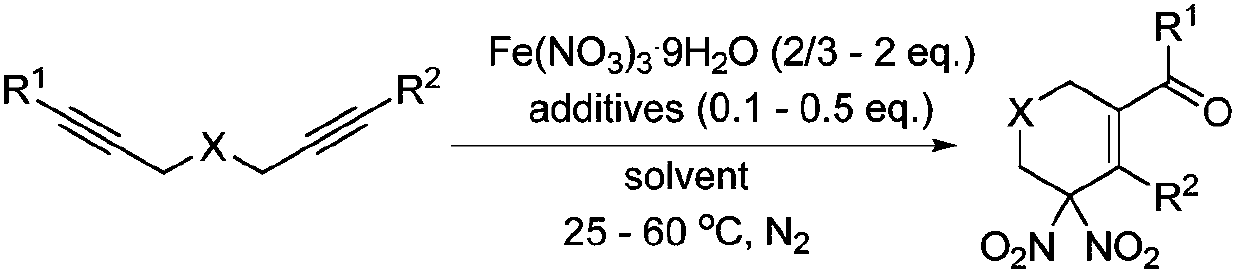

Method of using nitrate hydrate to prepare bisphosphonate nitro compound

InactiveCN109574913AHas Nitric Oxide Release CapabilitiesReduce dosageNitro/nitroso group formation/introductionNitro compound preparationNitro compoundNitrate

The invention discloses a method of using nitrate hydrate to prepare a bisphosphonate nitro compound. The method includes: in an organic solvent, taking nitrate hydrate as a nitro source, an oxygen-containing compound as an additive and 1, 6-diyne as a substrate for nitration-cyclization-oxidation tandem reaction, and performing aftertreatment after reaction is finished to obtain the bisphosphonate nitro compound. The compound is synthesized by direct nitration of 1, 6-diyne; the method is simple, and the nitrate hydrate is used as the nitro source, so that the compound is low in cost, easy toobtain, safe and stable. The method can be used for synthesizing a series of bisphosphonate nitro compounds, and nitric oxide release ability and drug activity of synthesized products can be furtherstudied.

Owner:ZHEJIANG UNIV

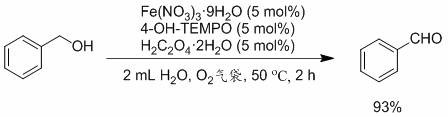

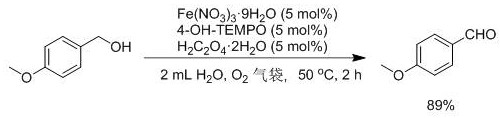

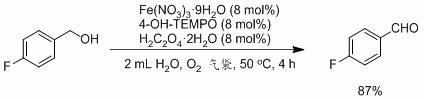

Method for preparing carbonyl compound by oxidizing alcohol

ActiveCN113354525AReduce usageSolve problems that require toxic organic solventsOrganic compound preparationCarboxylic acid esters preparationHydration reactionHalohydrocarbon

The invention provides a method for preparing aldehydes or ketones through alcohol oxidation. According to the method, alcohol is oxidized into aldehyde or ketone by taking water as a solvent, iron nitrate hydrate (Fe (NO3)3.9H2O), 4-hydroxy-2,2,6,6-tetramethylpiperidine oxide (4-OH-TEMPO) and carboxylic acid as catalysts and oxygen or air as an oxidizing agent. Compared with the prior art, the method provided by the invention takes water as a solvent, avoids the use of polluting halogenated hydrocarbon or strong cancerogen sodium nitrite (NaNO2), is more environment-friendly, greatly reduces the cost, and is a method suitable for industrial production.

Owner:SUZHOU UNIV

Nickel powder manufacturing method

A melt of nickel nitrate hydrate is introduced as droplets or liquid flow into a heated reaction vessel and thermally decomposed in a gas phase at a temperature of 1200° C. or more and at an oxygen partial pressure equal to or below the equilibrium oxygen pressure of nickel-nickel oxide at that temperature to manufacture a highly crystalline fine nickel powder with an extremely narrow particle size distribution. The oxygen partial pressure during the thermal decomposition is preferably 10−2 Pa or less, and a metal other than nickel, a semimetal and / or a compound of these may be added to the nickel nitrate hydrate melt to manufacture a highly crystalline nickel alloy powder or highly crystalline nickel composite powder. The resultant powder is suited in particular to thick film pastes such as conductor pastes for manufacturing ceramic multilayer electronic components.

Owner:SHOEI CHEM IND CO LTD

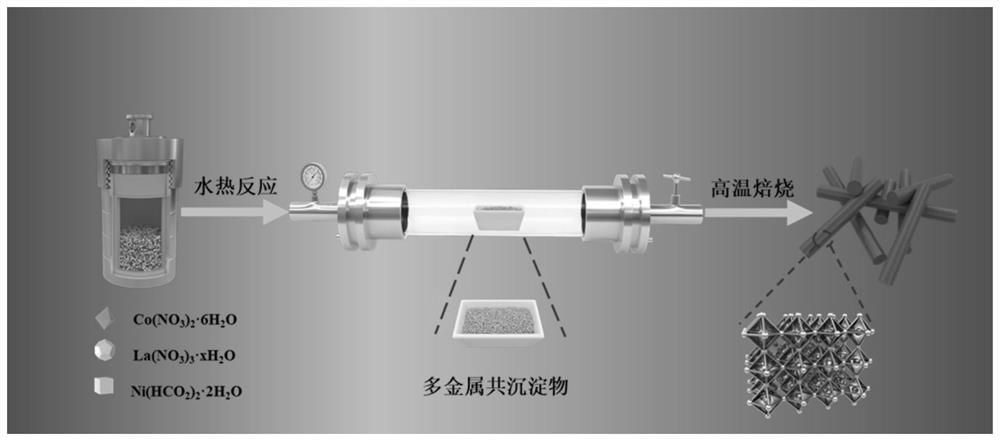

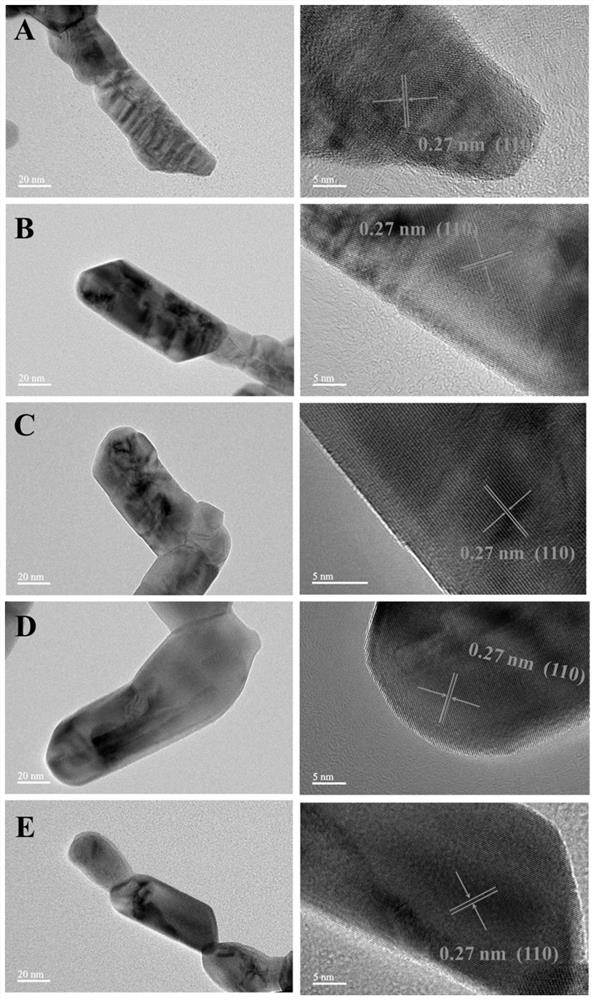

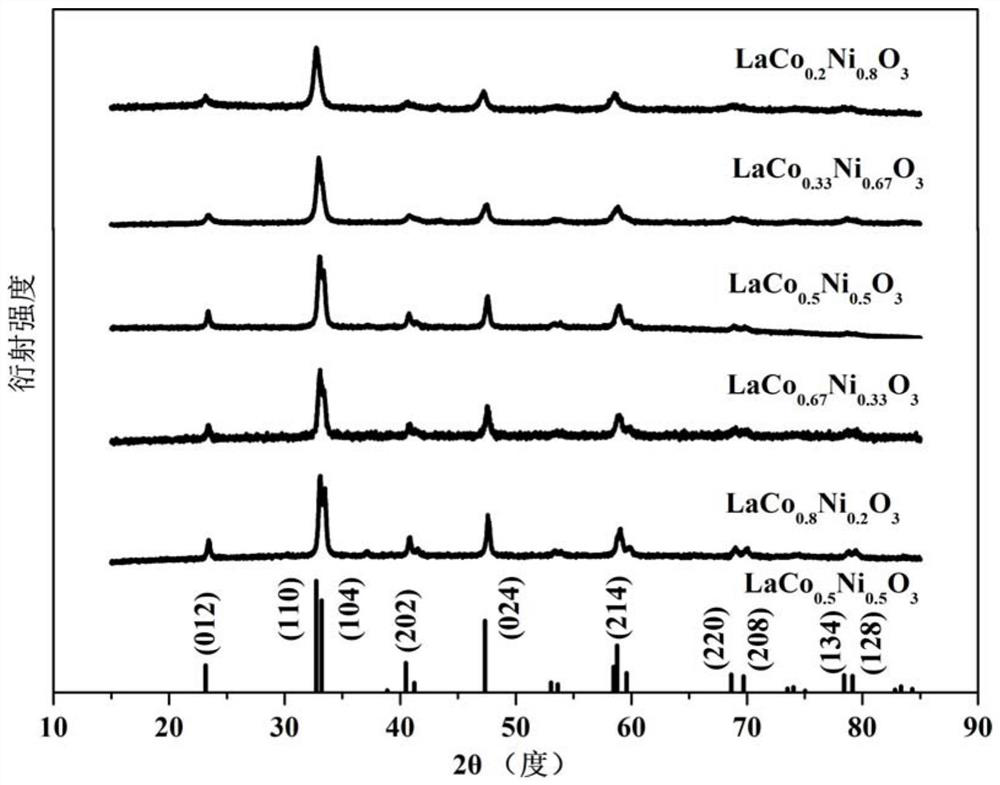

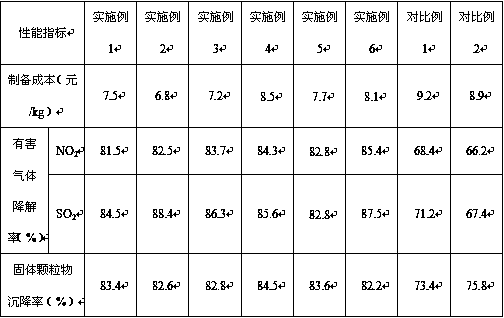

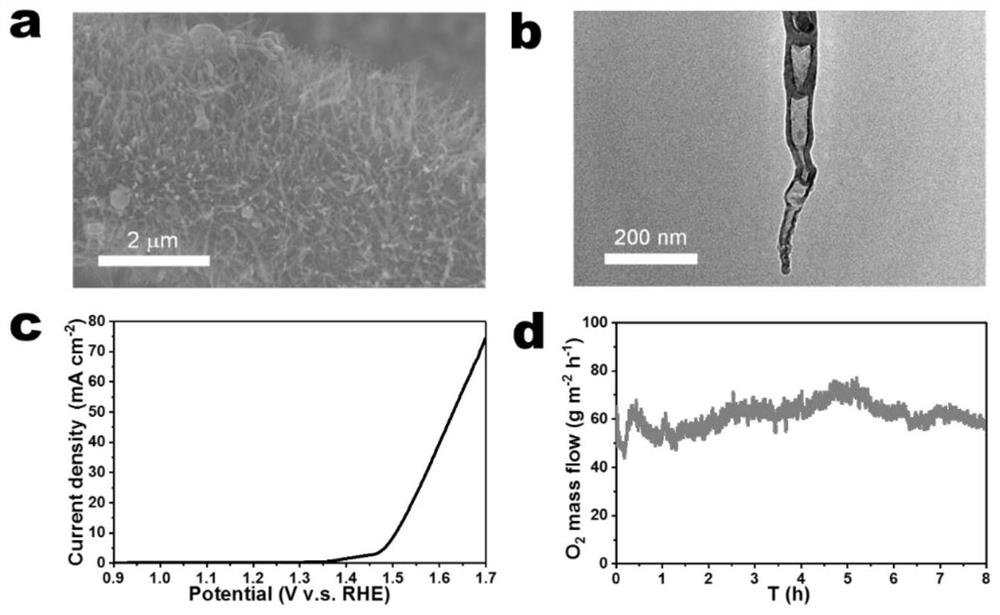

ABO3 type double perovskite LaCoyNi1-yO3 nanorod electro-catalytic material and preparation method thereof

ActiveCN112962116AAchieving electronic structure changesReductive adjustment and optimizationElectrodesHydration reactionAmmonia production

The invention discloses an ABO3 type double perovskite LaCoyNi1-yO3 nanorod electro-catalytic material and a preparation method thereof, and belongs to the technical field of electro-catalytic materials. The electro-catalytic material is prepared from cobalt nitrate hydrate, lanthanum nitrate hydrate, nickel formate hydrate and potassium hydroxide through the processes of coprecipitation, hydrothermal treatment, roasting, acid pickling and the like. The prepared LaCoyNi1-yO3 nanorod has a special nanostructure, so that more electrochemical active sites can be released, and more excellent electrocatalytic activity is shown. Meanwhile, optimization of the catalytic activity of the LaCoyNi1-yO3 nanorod is realized by regulating and controlling the ratio of the catalytic center metal on the B site. The ABO3 type double perovskite LaCoyNi1-yO3 nanorod is moderate in raw material price, simple to prepare and excellent in performance, has a good commercialization prospect, is an excellent electro-catalysis material, and can be used in the field of new energy conversion such as ammonia production through electro-catalysis nitrogen reduction.

Owner:JIANGNAN UNIV

Lanthanum aluminate-doped fuel cell electrolyte and preparation method

InactiveCN108281688AGood effectImprove transmission efficiencyElectrolytesFuel cellsOctahedronApatite

The invention provides lanthanum aluminate-doped fuel cell electrolyte and a preparation method. The preparation method comprises the following steps: mixing hydrated nitrate of lanthanum, hydrated nitrate of aluminum, a doping element A, a doping element B, acetylacetone, isopropyl alcohol and a methylcellulose aqueous solution to prepare a La1-xAxAlyB1-yO3 type compound precursor, coating the surface of a substrate layer with the La1-xAxAlyB1-yO3 type compound precursor to form a thin film precursor, and performing high-temperature sintering to prepare a cubic perovskite type doped lanthanumaluminate thin film, namely obtaining the fuel cell electrolyte. According to the method provided by the invention, an octahedral interstice inside a crystal is enlarged; an interstice conduction channel similar to an apatite structure is formed inside a crystal lattice, and the number of oxygen vacancies is increased by doping, so that the transmission efficiency of electrolyte oxygen ions is effectively improved; the thermodynamic stability is high, and the working temperature is relatively low; meanwhile, the preparation process is simple; the used raw materials are low in cost, so that the anthanum aluminate-doped fuel cell electrolyte is low in energy consumption and low in preparation cost and has a relatively good economical advantage.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

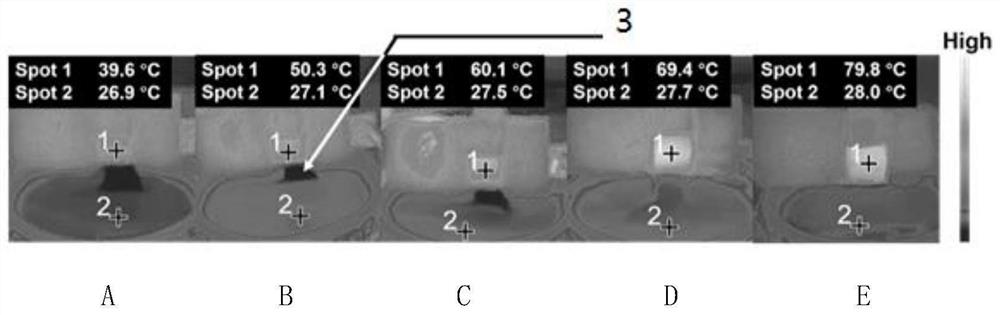

Low-cost haze-removing auxiliary agent capable of rapidly eliminating haze and preparation method

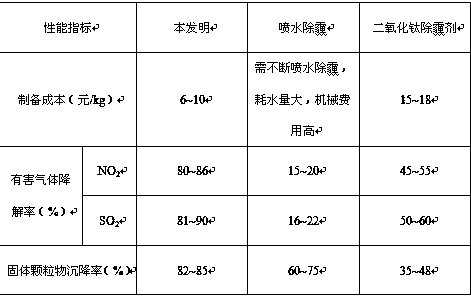

InactiveCN108043223AImprove the efficiency of eliminating smogCost controlGas treatmentDispersed particle separationLithium hydroxideSolid particle

The invention provides a low-cost haze-removing auxiliary agent capable of rapidly eliminating haze and a preparation method. The preparation method comprises the following steps: enabling iron nitrate hydrate, ethylene glycol methyl ether and tetrabutyl titanate to react to prepare ferric oxide nano-crystalline hydrosol; meanwhile, enabling zinc acetate and lithium hydroxide to react in absoluteethyl alcohol, so as to prepare zinc oxide quantum dots; adding the zinc oxide quantum dots, water and glycerin into a homogenization machine together to prepare a dispersion body; adding the prepareddispersion body and liquid carbon dioxide into a dry ice particle manufacturing machine, and granulating to obtain the powdery low-cost haze-removing auxiliary agent capable of rapidly eliminating the haze. According to the method provided by the invention, a photocatalytic material is dispersed into the glycerin and the water, and can be completely dispersed in a utilization process, so that harmful gas sol in the haze can be rapidly and efficiently decomposed; a charge stable system of haze aerosol can be damaged; solid particles are stuck to form large particles, and then the large particles are rapidly deposited to the ground, so that the aim of rapidly eliminating the haze is realized; meanwhile, a preparation process is simple, and the production cost and the utilization cost are low; the low-cost haze-removing auxiliary agent has a good haze elimination effect and has an extremely wide application prospect.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

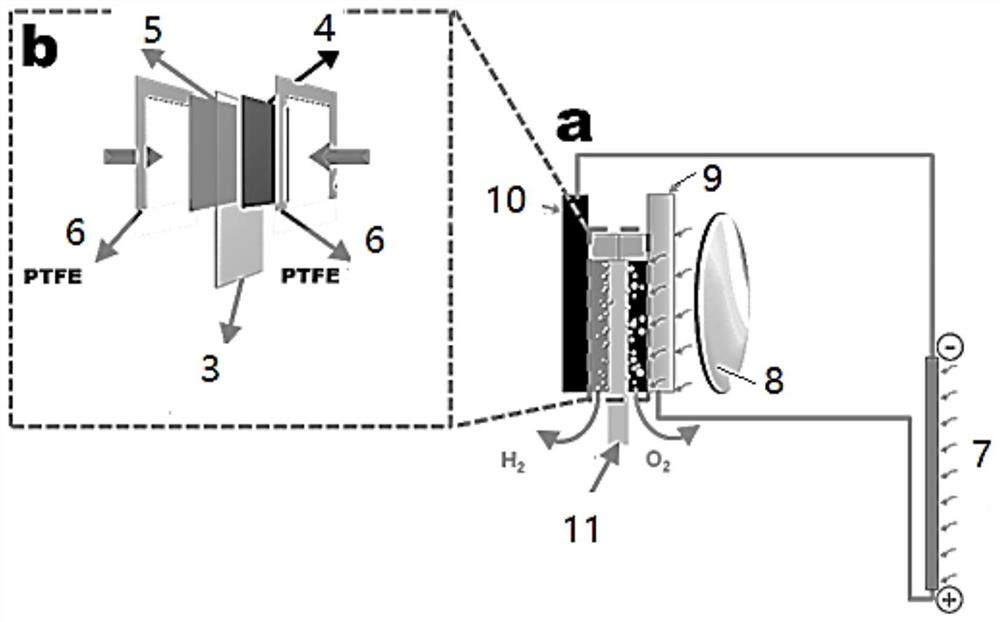

Device preparation method for synchronously generating hydrogen energy and clean water by utilizing light energy

InactiveCN112593246APromote decomposition reactionMaximize utilizationCellsMaterial nanotechnologyPtru catalystLight energy

The invention relates to a device preparation method for synchronously generating hydrogen energy and clean water by using light energy. A bamboo-like carbon nanotube-coated FeNi3 oxygen evolution electrocatalyst raw material is synthesized, and the method comprises the following steps: 1) adding ferric nitrate hydrate, nickel nitrate and urea into distilled water, and conducting stirring for 1 hour or more, wherein the molar ratio of iron to nickel is 1:2.5 to 1:3.5, and the amount of urea and distilled water is excessive; (2) soaking melamine sponge into the solution obtained in the step (1), and conducting aging in the air for 5 hours or more; and (3) conducting drying and carbonizing, grinding the obtained product into powder, and dropwise adding the powder on conductive glass sprayedwith the metal by a dropwise coating method to obtain an oxygen evolution electrode. Pt / C serves as a hydrogen evolution electrode, and maximum utilization from light energy to clean energy is achieved. Under the room temperature condition, the conversion efficiency from light energy to hydrogen energy is 20.1%, the efficiency of generating clean water through photo-thermal reaches 93.5%, and thecomprehensive utilization efficiency of solar energy reaches up to 87.5%.

Owner:NANJING UNIV

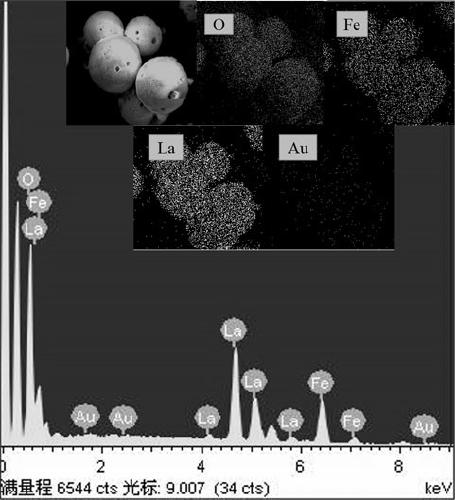

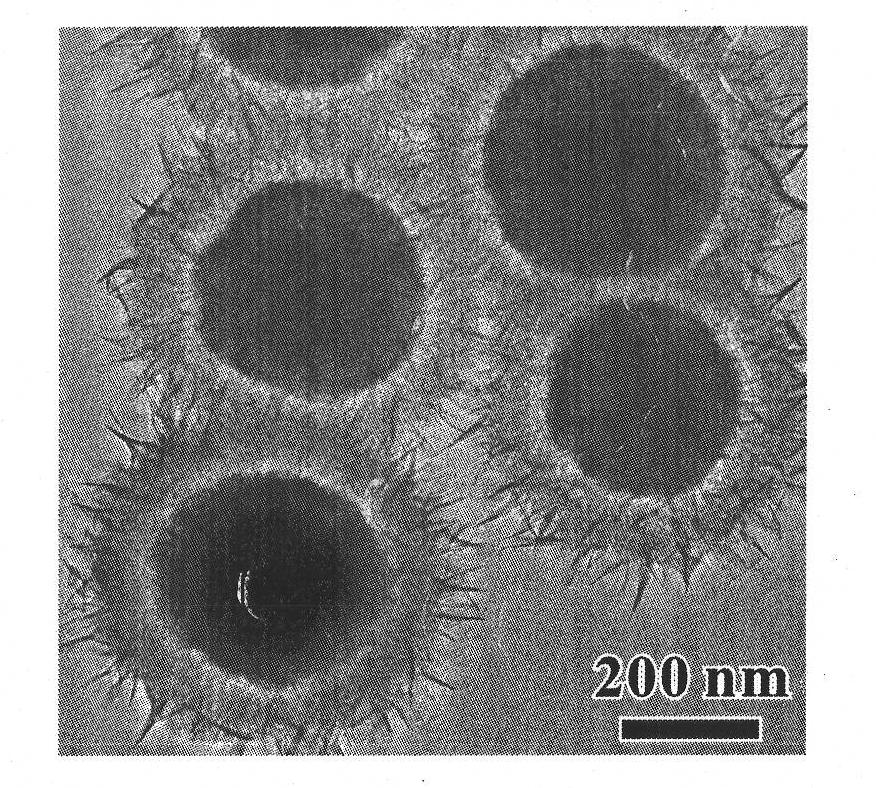

Preparation method of Au-LaFeO3 nanocomposite material

The invention provides a preparation method of an Au-LaFeO3 nanocomposite material. The preparation method specifically comprises the following steps: carrying out a hydrothermal reaction on raw materials including lanthanum nitrate hydrate, ferric nitrate hydrate and citric acid, and calcining to obtain lanthanum ferrite nano-microspheres; and using L-lysine, HAuCl4 and trisodium citrate as raw materials to compound granular gold particles on the surface of the lanthanum ferrite nano-microspheres. The composite material of the invention shows high sensitivity and fast response and recovery toacetone, can be used in the field of acetone gas sensors to obtain novel gas sensitive materials with high sensitivity.

Owner:UNIV OF JINAN

Preparation method of composite hollow silicate

InactiveCN101857239APost-processing is simpleControl synthesisNanostructure manufactureSilicon compoundsSolventNitrate hydrate

The invention provides a preparation method of composite hollow silicate, which relates to silicate. The invention provides the preparation method of the composite hollow silicate which has simpler process and is synthesized under the heat condition of a solvent. The preparation method comprises the following steps of: adding water and ethanol into MaSiO2, urea and nitrate hexahydrate and keeping constant temperature at the temperature of 170 to 190 DEG C for 4 to 36h, wherein the mixture ratio of the MaSiO2 to the urea is 1:(13.5 to 27) according to the mass ratio, the mixture ratio of magnesium nitrate hexahydrate to the urea is 1:(30 to 100) according to the mole ratio, and M is metal, metal oxide or metal oxide / metal; and after cooling a reaction product obtained in the step (1) to room temperature, washing the obtained solid product so as to obtain a target product of the composite hollow silicate.

Owner:XIAMEN UNIV

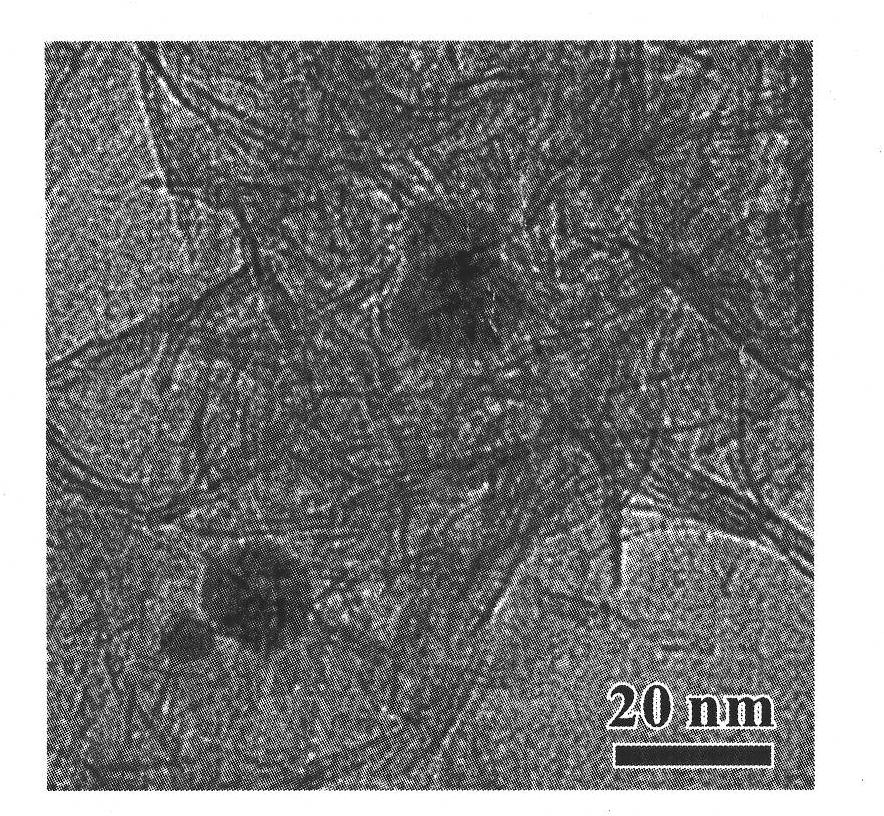

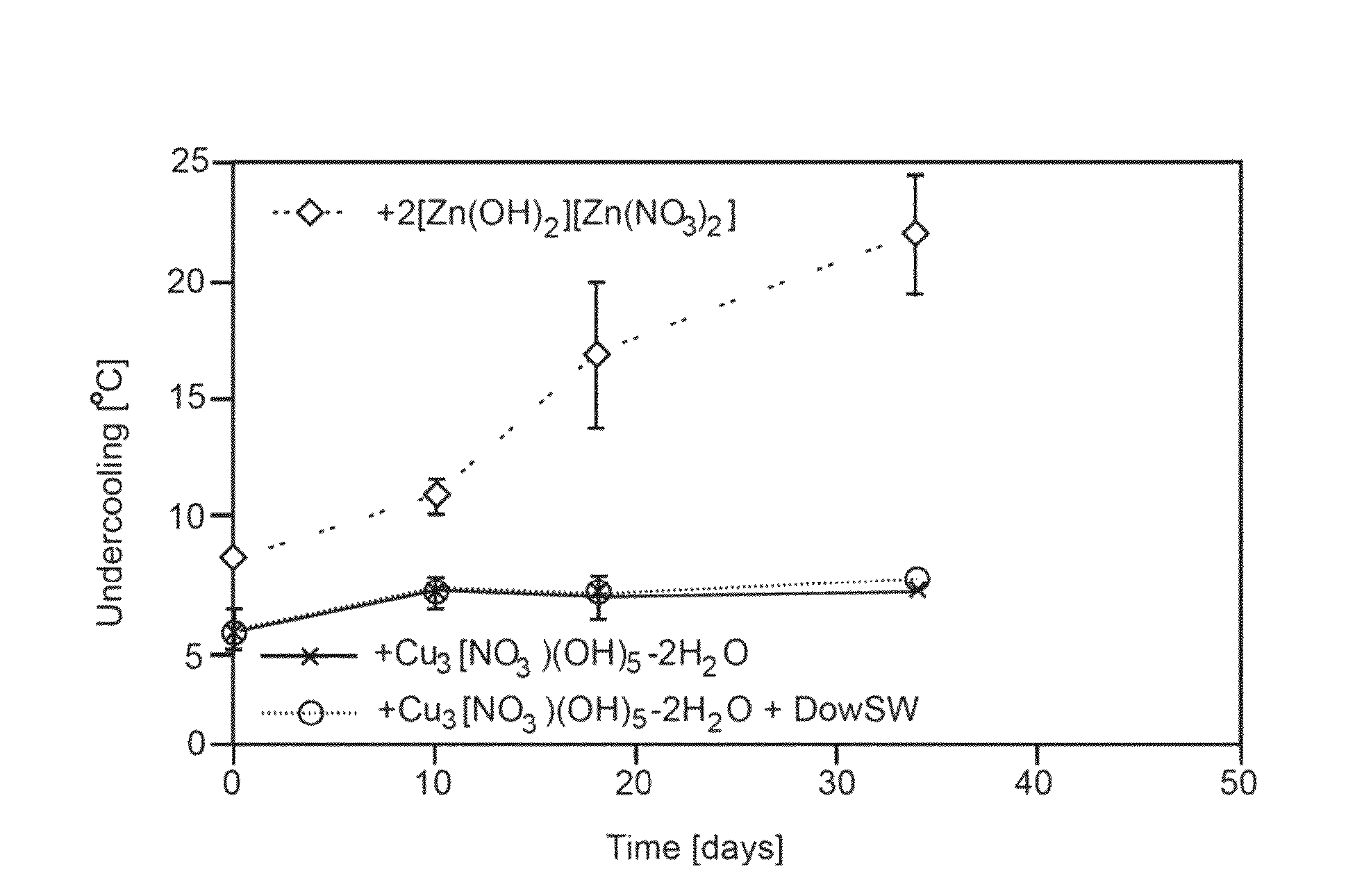

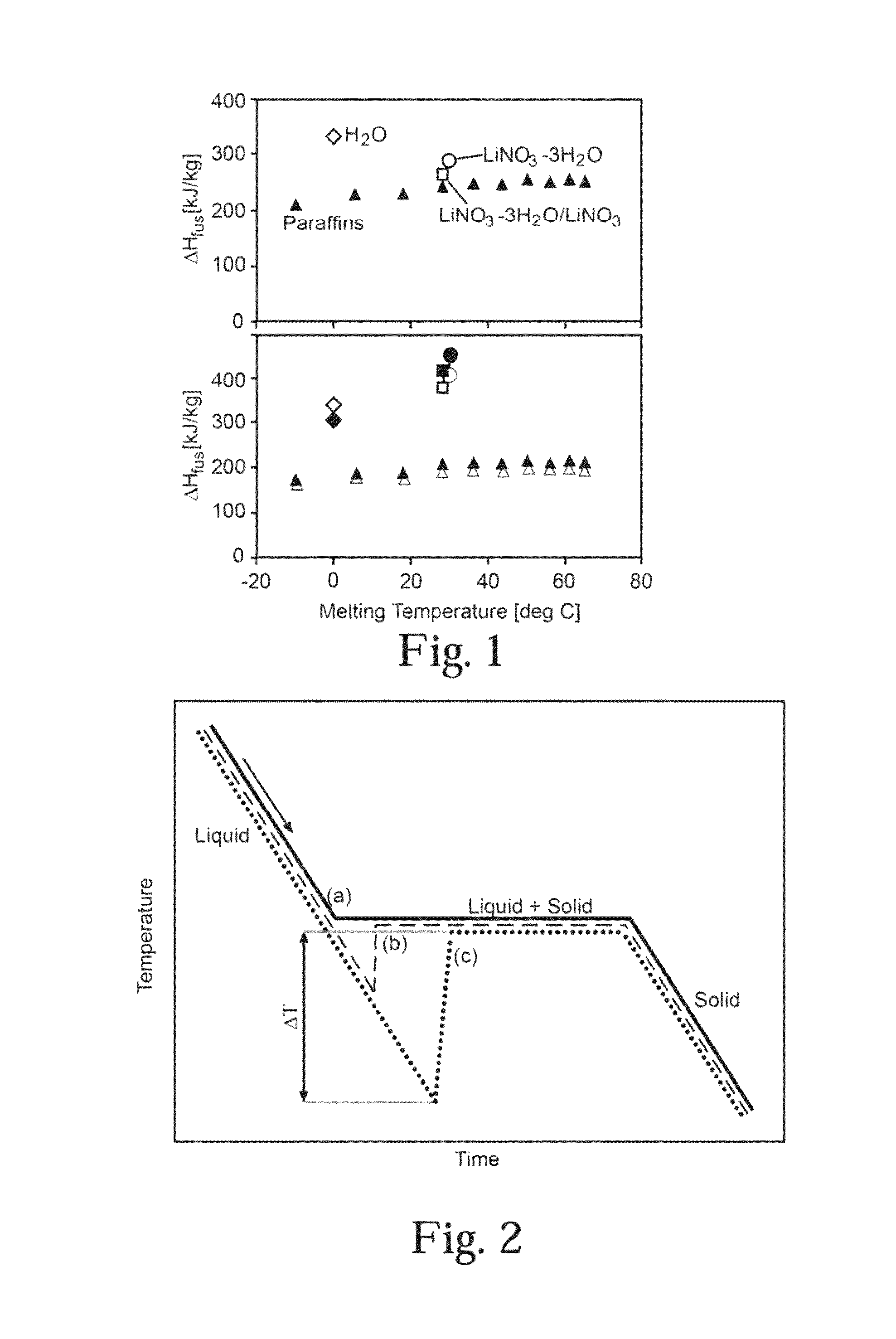

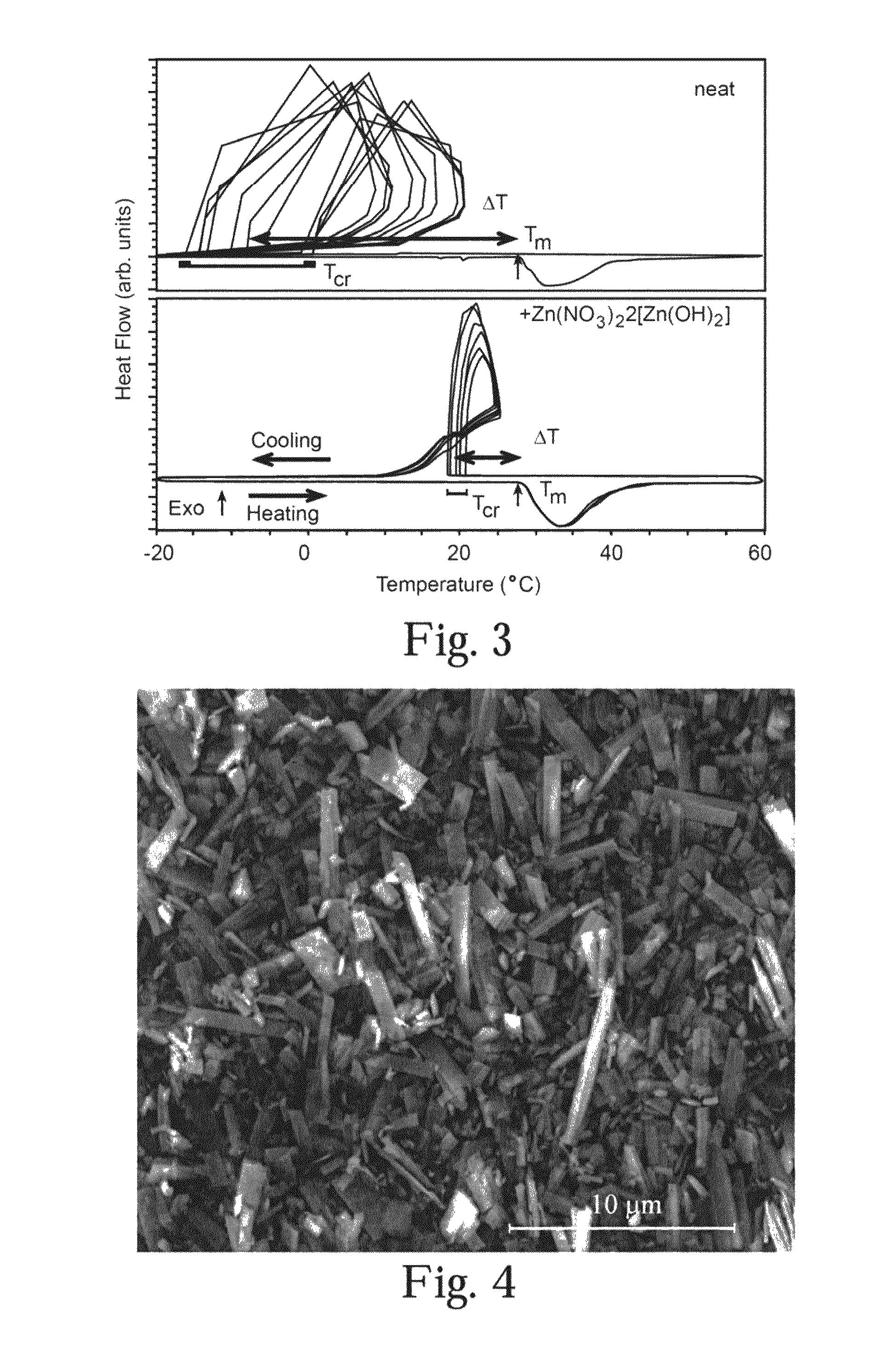

Nucleating agent for lithium nitrate trihydrate thermal energy storage medium

ActiveUS8703258B1Fast heat absorptionLow costEnvelopes/bags making machineryLayered productsThermal energyThermal energy storage

The present invention describes a nucleating agent tailored specifically to the thermal energy storage medium lithium nitrate trihydrate (LiNO3-3H2O), and to the use thereof. Addition of the nucleating agent copper hydroxy nitrate hydrate [Cu3(OH)5(NO3)-2H2O](Likasite) suppresses the undercooling in lithium nitrate trihydrate, forming a superior composite thermal energy storage medium.

Owner:GOVERNMENT OF THE UNITED STATES AS REPRESENTED BY THE SEC OF THE AIR FORCE

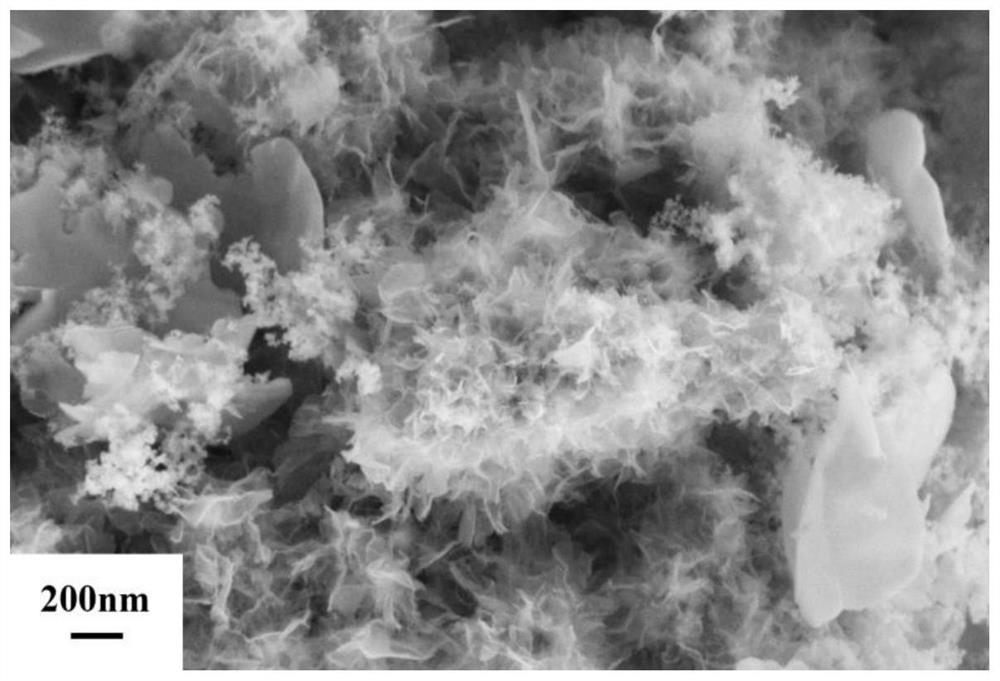

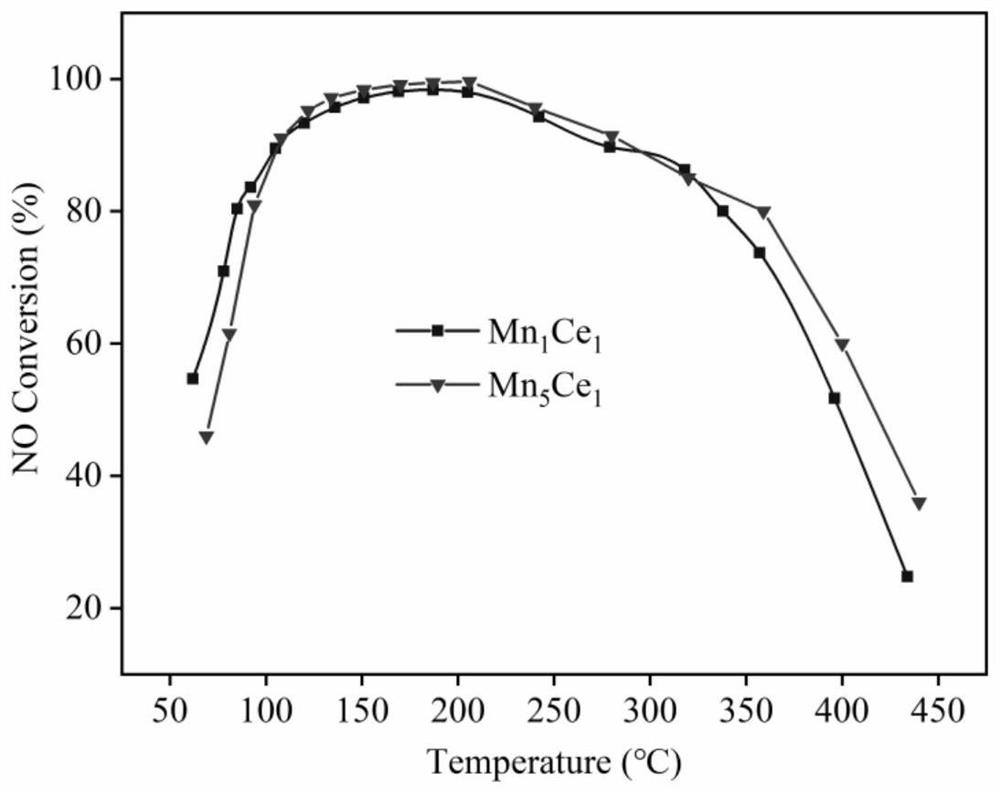

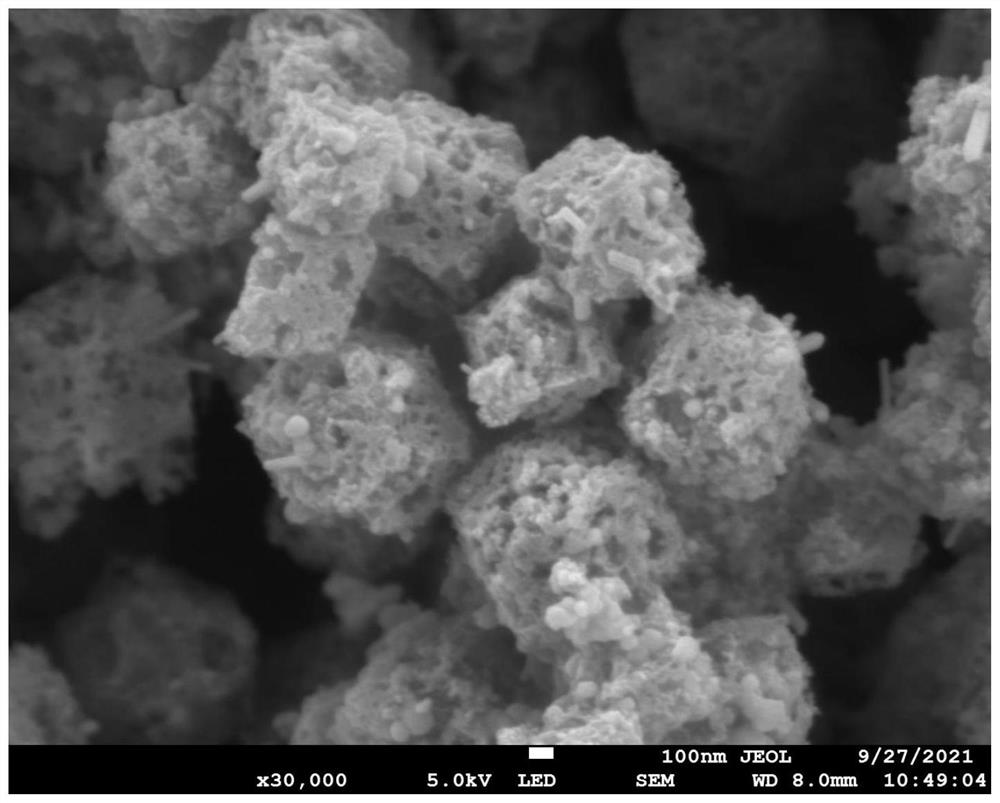

Petal-shaped manganese-cerium composite oxide denitration catalyst and preparation method thereof

ActiveCN114433074ARich activityRich in acidic sitesDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAir atmospherePtru catalyst

The invention relates to a petal-shaped manganese-cerium composite oxide denitration catalyst and a preparation method thereof, and belongs to the field of catalyst technology and environmental protection. The catalyst has a petal-shaped structure and is composed of a manganese-cerium composite oxide. The preparation method of the catalyst comprises the following steps: (1) dissolving potassium permanganate, manganous nitrate hydrate and cerous nitrate hydrate in deionized water, uniformly stirring and mixing, then adding into a hydrothermal reaction kettle, reacting for 10-15 hours at the temperature of 130-160 DEG C, and then cooling; (2) washing and centrifuging the turbid liquid obtained in the step (1), and then drying; and (3) roasting the product obtained in the step (2) in an air atmosphere to obtain the manganese-cerium composite oxide denitration catalyst. The manganese-cerium composite oxide denitration catalyst prepared by a hydrothermal method has abundant active sites and acidic sites, has a petal-shaped structure, and is beneficial to providing more active sites so as to promote gas adsorption.

Owner:DALIAN MARITIME UNIVERSITY

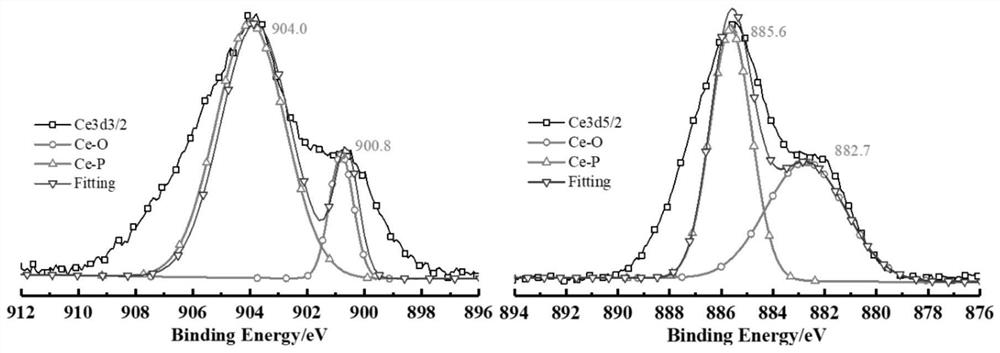

A kind of cerium-phosphorus complex flame retardant, cerium-phosphorus complex flame retardant polycarbonate composite material and their preparation method

ActiveCN110591150BGood dispersionAvoid performance degradationGroup 5/15 element organic compoundsPhysical chemistryPolycarbonate

The invention relates to a cerium-phosphorus complex flame retardant, a cerium-phosphorus complex flame-retardant polycarbonate composite material and a preparation method thereof, belonging to the technical field of polymer materials. The cerium-phosphorus complex flame retardant of the present invention comprises cerium nitrate hydrate and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO); the preparation method comprises: dissolving DOPO in In DMF, solution A is prepared, cerium nitrate hydrate is dissolved in deionized water to prepare solution B; solution B is added to solution A, and then hydrothermal reaction and dehydration treatment are performed. The cerium-phosphorus complex flame-retardant polycarbonate composite material of the present invention comprises 1-20wt% cerium-phosphorus complex and 80-99wt% polycarbonate; the preparation method comprises: separately cerium-phosphorus complex and polycarbonate Dry, premix and then melt blend. The flame retardant of the cerium-phosphorus complex of the invention has good dispersibility, can realize the flame retardant effect by utilizing the condensed phase mechanism and the gas phase mechanism at the same time, has a simple preparation method for the composite material, and has good flame retardant performance.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

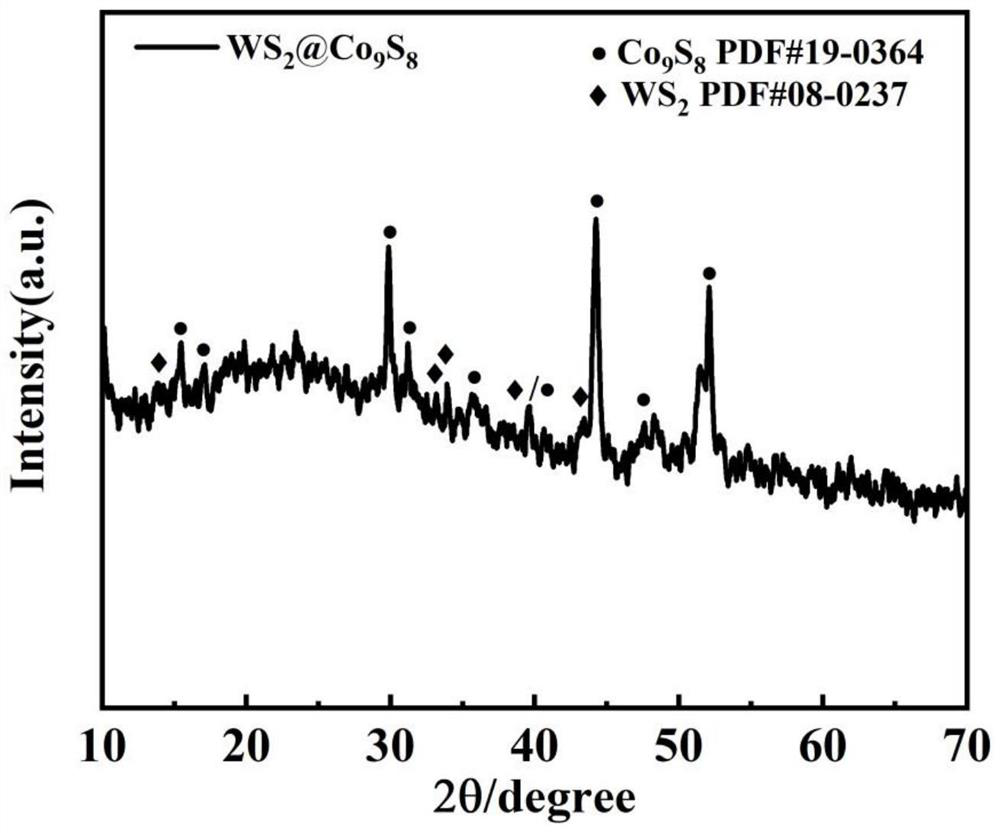

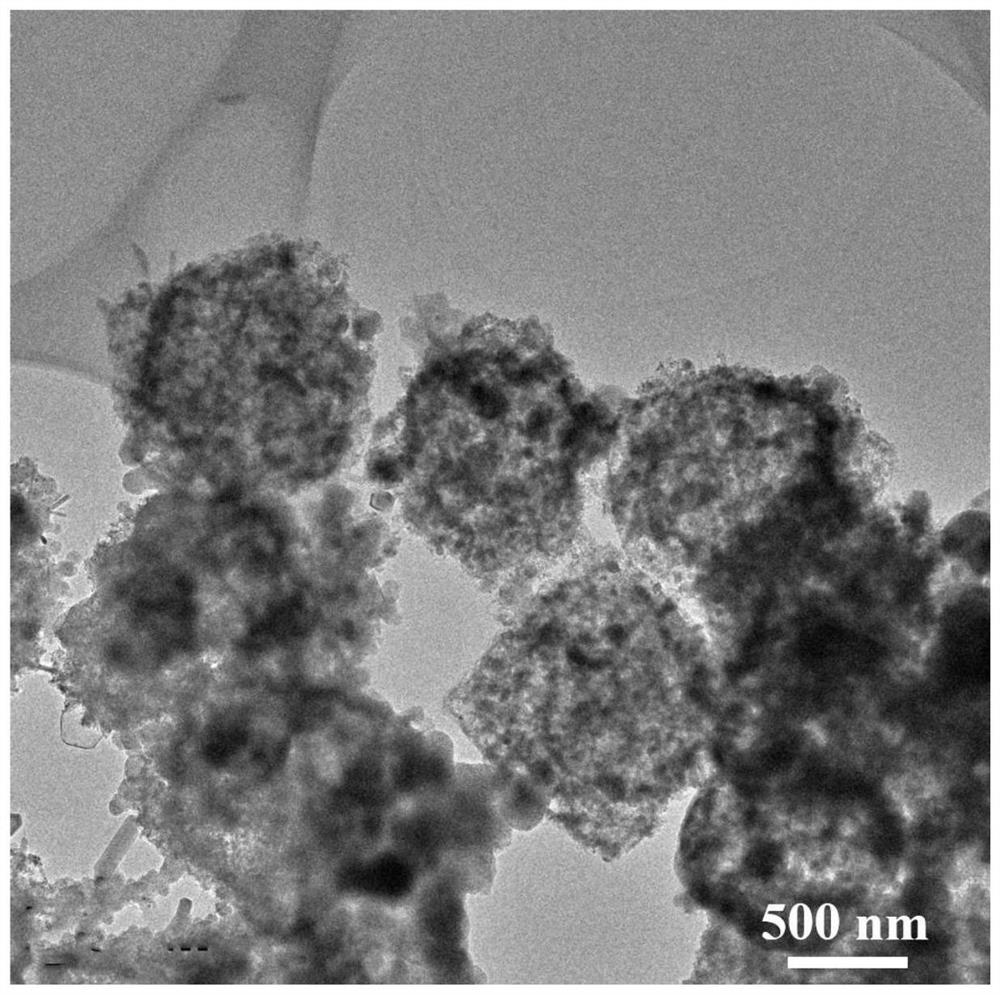

Electrocatalytic bifunctional material with few layers of tungsten disulfide anchored on surface of cobalt-nitrogen-doped carbon-based polyhedron and preparation method of electrocatalytic bifunctional material

The preparation method comprises the following steps: respectively weighing cobalt-containing nitrate hydrate and 2-methylimidazole, adding the cobalt-containing nitrate hydrate and the 2-methylimidazole into methanol to prepare a solution, pouring the latter solution into the former solution, then adding a tungsten source, carrying out a stirring reaction at room temperature, and carrying out suction filtration, washing and drying so as to obtain the electrocatalytic bifunctional material. Centrifuging the obtained product, centrifugally washing the lower precipitate with methanol, drying at 50-70 DEG C, and calcining the obtained WS42-ZIF-67 at two stages of different temperatures in an inert atmosphere; and naturally cooling to obtain the electro-catalysis bifunctional material with few layers of WS2 nanosheets anchored on the surface of the cobalt-nitrogen-doped carbon-based polyhedron. The preparation process is simple and efficient, the requirement for equipment is low, and the prepared electro-catalytic bifunctional material is high in specific surface area, has a specific pore structure and excellent electro-catalytic performance, is used for electro-catalytic oxygen evolution and hydrogen evolution reactions and can replace noble metal catalysts such as Pt and RuO2.

Owner:LUOYANG INST OF SCI & TECH

Method for preparing calcium ferroaluminates

InactiveCN102153144BEasy to controlReduce free calcium oxide contentIron compoundsState of artAluminium nitrate

The invention relates to a method for preparing calcium ferroaluminates. The method comprises the following steps: proportionally mixing an aluminium nitrate hydrate, a calcium nitrate hydrate, a ferric nitrate hydrate, hexamethylenetetramine, acetylacetone, deionized water and the like uniformly by a sol-gel method, then stirring the mixture at the temperature of 50-70 DEG C to obtain sol, ageing the sol to form gel, carrying out heat treatment on the gel at the temperature of 750-800 DEG C for 2-4 hours and slowly cooling the gel to the room temperature, thus obtaining the calcium ferroaluminates. Compared with the prior art, the method has the following advantages: the preparation process is simple; the reaction process is easy to control; and the product has high uniformity and purity and can be fired at the temperature lower than the temperature in the traditional methods.

Owner:TONGJI UNIV

High-thermal-conductivity hydrated nitrate composite phase change material and preparation method thereof

PendingCN114058339AImprove adsorption capacityNo leakage occurredHeat-exchange elementsMolten stateNitrate salts

The invention discloses a high-thermal-conductivity hydrated nitrate composite phase change material, which comprises modified expanded graphite and a phase change material adsorbed around the modified expanded graphite, wherein the phase change material is hydrated nitrate or a hydrated nitrate-hydrated calcium chloride mixture, the mass content of the modified expanded graphite in the composite phase change material is 5-20 wt%, and the modified expanded graphite is hydrophilic modified expanded graphite of which the surface is attached with an aluminum oxide film. The invention also provides a preparation method of the high-thermal-conductivity hydrated nitrate composite phase change material. The method comprises the following steps: 1, modification of expanded graphite: soaking expanded graphite in a soluble aluminum salt solution, adjusting the pH value, filtering, and drying and calcining the solid; and 2, preparation of a composite phase change material: heating a phase change material, uniformly mixing the modified expanded graphite with the phase change material in a molten state, and cooling to obtain the high-thermal-conductivity hydrated nitrate composite phase change material.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

A three-dimensional ordered macroporous transition metal oxide composite material and its preparation method and catalyst application

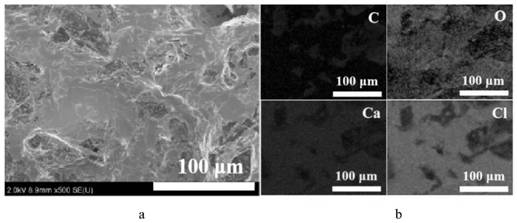

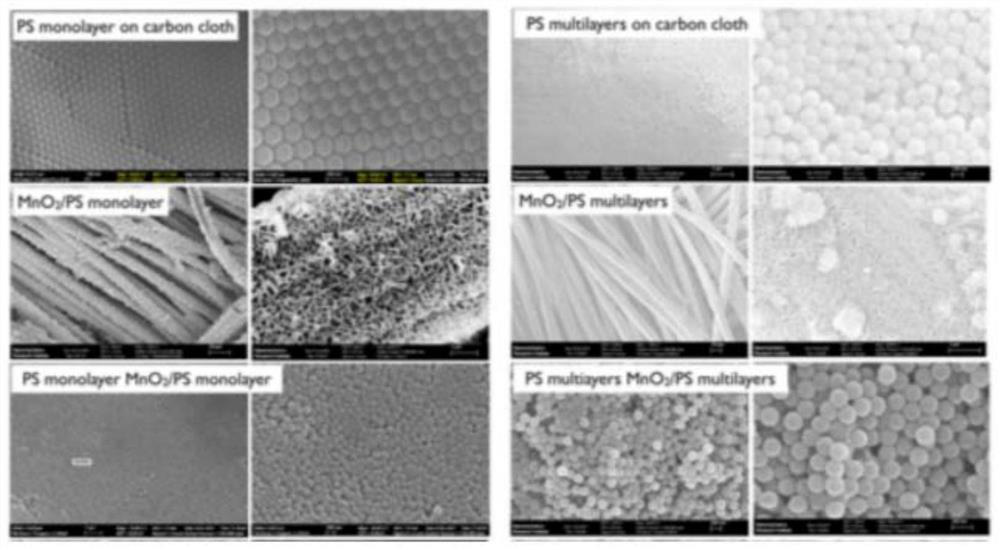

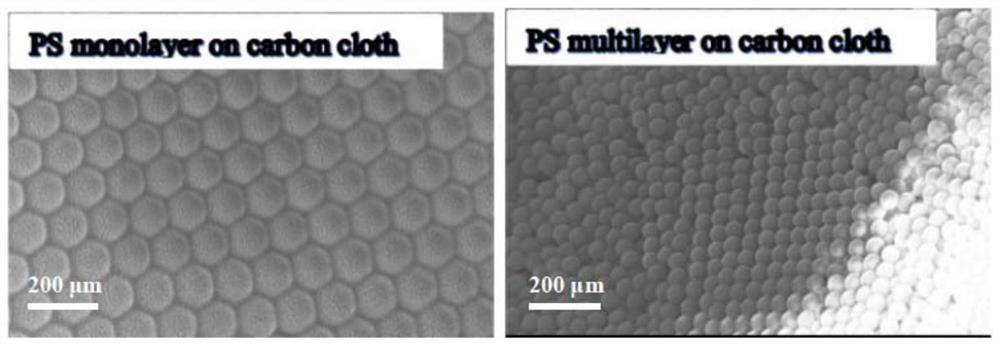

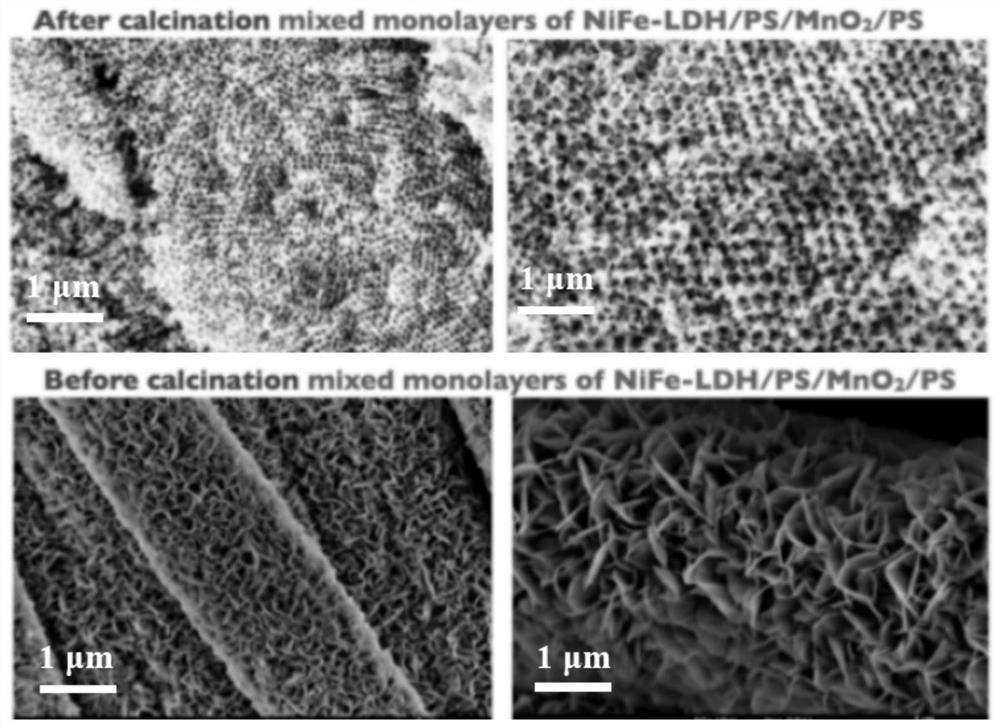

ActiveCN112072121BHigh degree of orderStrong mass transfer abilityFuel and primary cellsCell electrodesPtru catalystMicrosphere

The invention discloses a three-dimensional ordered macroporous transition metal oxide composite material and its preparation method and catalyst application. The method comprises the following steps: S1: soaking carbon cloth in an acidic solution for pretreatment; S2: soaking PS Disperse the microspheres in water, apply them to the carbon cloth after ultrasonic uniformity, and dry; S3: Disperse potassium permanganate and carbon powder evenly in water, immerse the carbon cloth of S2 in it, conduct a closed reaction and dry to obtain the sample; S4 : Disperse PS microspheres in water, apply them dropwise on the sample of S3 after ultrasonication, and dry; Wherein, a sealing reaction is carried out; S6: calcining the dried sample in S5 to obtain a three-dimensional ordered macroporous transition metal oxide composite material. The invention has the advantages of better ORR and OER performance and good electrochemical performance, and has great application potential and industrial value in the electrochemical field.

Owner:WENZHOU UNIV

Method for preparing manganese sulfate, manganous nitrate and calcium sulfate

InactiveCN102249338ANo secondary pollutionEasy to operateCalcium/strontium/barium sulfatesManganese sulfatesDistillationUranium sulfate

The invention provides a method for preparing manganese sulfate, manganous nitrate and calcium sulfate. The method comprises the following steps of: grinding manganosite into coarse powder, soaking titanium dioxide which is produced by a sulfuric acid method at the temperature of between 60 and 80 DEG C for 8 to 10 hours, and suction-filtering to obtain the clarified filtrate, and adding manganic hydroxide to remove impurity to obtain the purified solution of manganese sulfate; performing reduced pressure distillation on the purified solution of manganese sulfate to obtain the saturated solution of manganese sulfate, cooling, separating manganese sulfate crystal containing crystal water out, and drying and crushing to obtain a manganese sulfate crystal product; reacting the purified solution of manganese sulfate and solution of calcium nitrate with stirring, filtering reaction products to obtain a calcium sulfate filter cake and manganous nitrate filtrate; and performing reduced pressure distillation on the manganous nitrate filtrate to obtain the saturated solution of manganous nitrate, cooling and crystallizing to obtain manganous nitrate hydrate, drying and crushing to obtain a manganous nitrate crystal product; and washing, drying and crushing the calcium sulfate filter cake to obtain a dihydrate calcium sulphate product.

Owner:王莉

Preparation method of AuCu-FeMoS electrocatalyst for nitrogen reduction

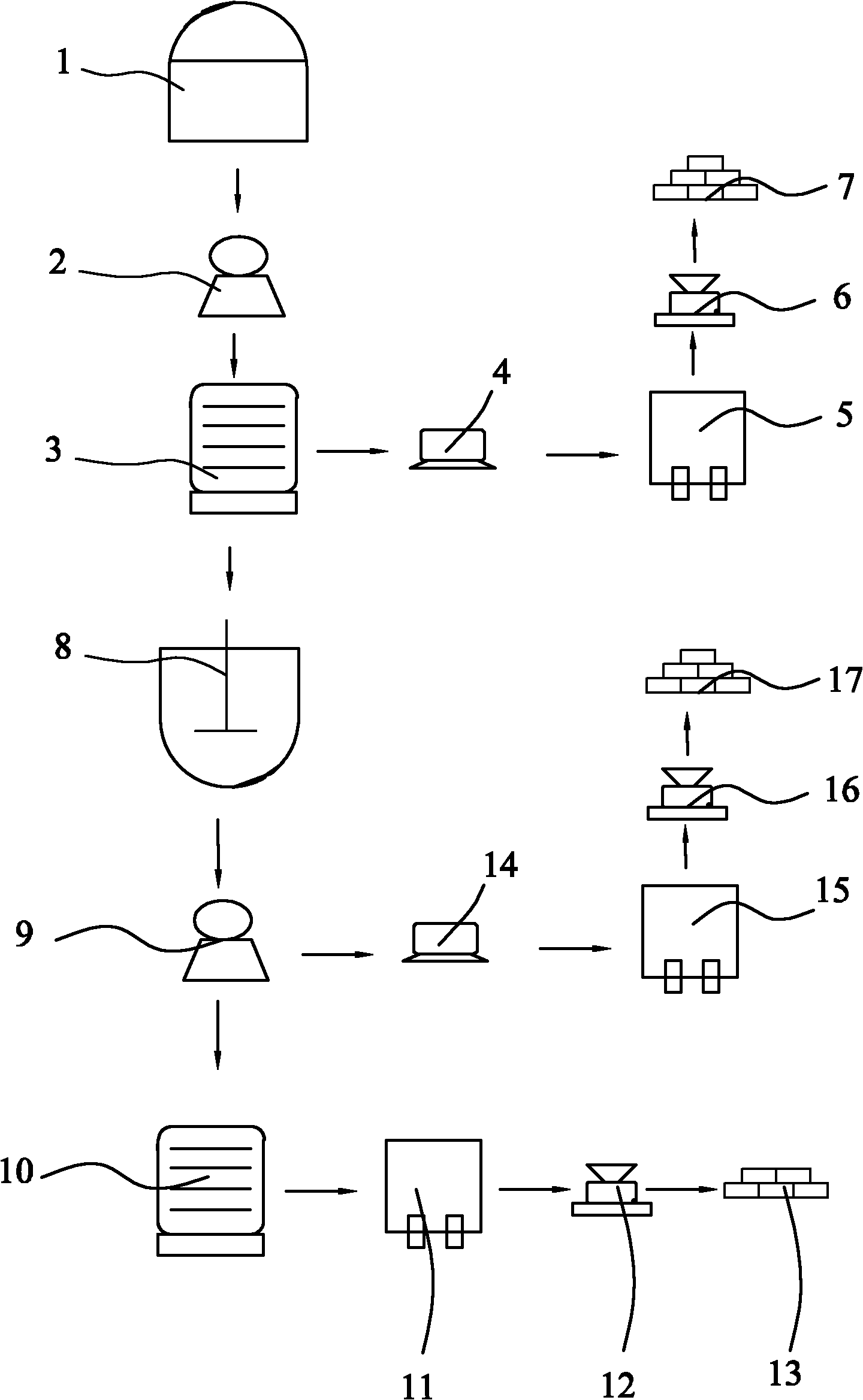

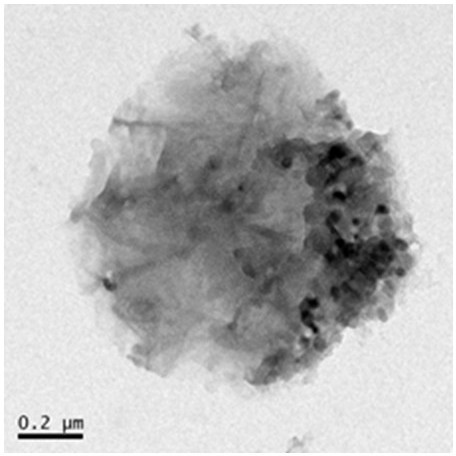

The invention discloses a preparation method of an AuCu-FeMoS electrocatalyst for nitrogen reduction. The preparation method comprises the following steps of: dissolving cuprous chloride and a tetrachloroauric acid hydrate in a hexane and oleylamine mixed solution, quickly stirring to form a uniform solution, adding a triisopropyl silane and hexane mixed solution, placing the final mixed solution under the condition of 60 DEG C until the color becomes black red, thereby obtaining a AuCu alloy nanowire catalyst; dissolving a sodium molybdate hydrate and a ferric nitrate hydrate in water, adding L-cysteine and high-purity water into the solution, stirring, and transferring the solution into a reaction kettle for reaction to obtain a FeMoS catalyst. and adding the AuCu alloy nanowire catalyst into the FeMoS catalyst standby liquid, performing uniformly stirring and dispersing, making an obtained solution stand still at room temperature, sucking out the supernatant after the supernatant is clarified, and drying the bottom precipitate in a vacuum drying box to obtain the electrocatalyst for nitrogen reduction. The synthesis method is simple, reaction conditions are mild, and the prepared product is high in catalytic activity.

Owner:HENAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com