Patents

Literature

40results about How to "Reduce free calcium oxide content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing baking-free slag bricks by using steel slag sludge of rotating furnace

ActiveCN101927524AReduce free calcium oxide contentLow iron contentSolid waste managementMixing operation control apparatusBrickSlag

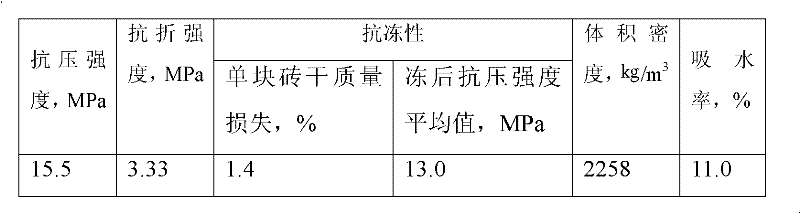

The invention relates to a method for producing baking-free slag bricks by using steel slag sludge of a rotating furnace. The bricks are produced by taking tailings and tailing sludge of the rotating furnace as raw materials, taking slag silicate cement as an auxiliary material, adding a small amount of water into the raw materials and the auxiliary material, stirring the raw materials and the auxiliary material to uniformly mix the raw materials and the auxiliary material, pressing the mixture on a brick press, and naturally curing the pressed mixture. The bricks comprise the following compoennts in part by weight: 20 to 50 parts of tailings of the rotating furnace, 50 to 80 parts of tailing sludge of the rotating furnace and 0 to 5 parts of slag silicate cement. The adding amount of the added water is 0 to 5 percent of the total weight of the raw materials. The baking-free bricks are produced by taking the tailings and the tailing sludge of the rotating furnace as main raw materials, adding a small amount of slag silicate cement and water into the main raw materials, and pressing the mixture. The raw materials do not need to be treated and can be directly used and the mouled product is naturally cured, so that the energy is saved; and no any equipment is added, so that the problem that the tailings of the rotating furnace and the tailing sludge of the rotating furnace occupy space and pollute environment is solved by producing the baking-free slag bricks.

Owner:鞍钢绿色资源科技有限公司

Steel slag composite powder and preparation method thereof

InactiveCN102180613ASolve many problems such as serious pollutionImprove hydraulic hardnessSolid waste managementAluminium sulfateSlag

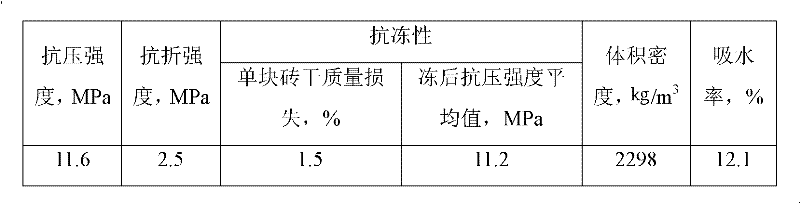

The invention discloses steel slag composite powder and a preparation method thereof. The steel slag composite powder comprises the following raw materials by weight: 30 to 45kg of heat-stewed steel slag micro powder, 5 to 10kg of refining slag micro powder, 30 to 45kg of mineral slag micro powder, 3 to 3.5kg of polycarboxylic acid, 3 to 3.5kg of triethanolamine, 5 to 6kg of calcium sulfate, 4 to 5kg of polyaluminum sulfate and 2 to 3kg of dolomite powder. The preparation method comprises the following steps of: (1) crushing and pulverizing converter steel slag to obtain the heat-stewed steel slag micro powder for later use; (2) crushing refining slag to obtain the refining slag micro powder for later use; (3) putting the raw materials in a weight ratio into a ball mill and performing ball milling to obtain a mixture for later use; (4) pulverizing blast furnace slag to obtain the mineral slag micro powder for later use; and (5) mixing the mineral slag micro powder and the mixture in a weight ratio to obtain the steel slag composite powder. The steel slag composite powder is prepared from steel slag which is not required to be stored and various raw materials, and can be used in the raw materials of products such as cement, concrete and the like so as to fulfill the aims of reducing the manufacturing cost of the cement, the concrete and the like, improving product quality and expanding the use range of the steel slag.

Owner:山东济钢泰航合金有限公司

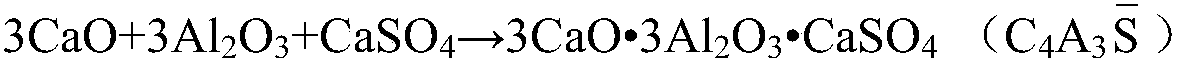

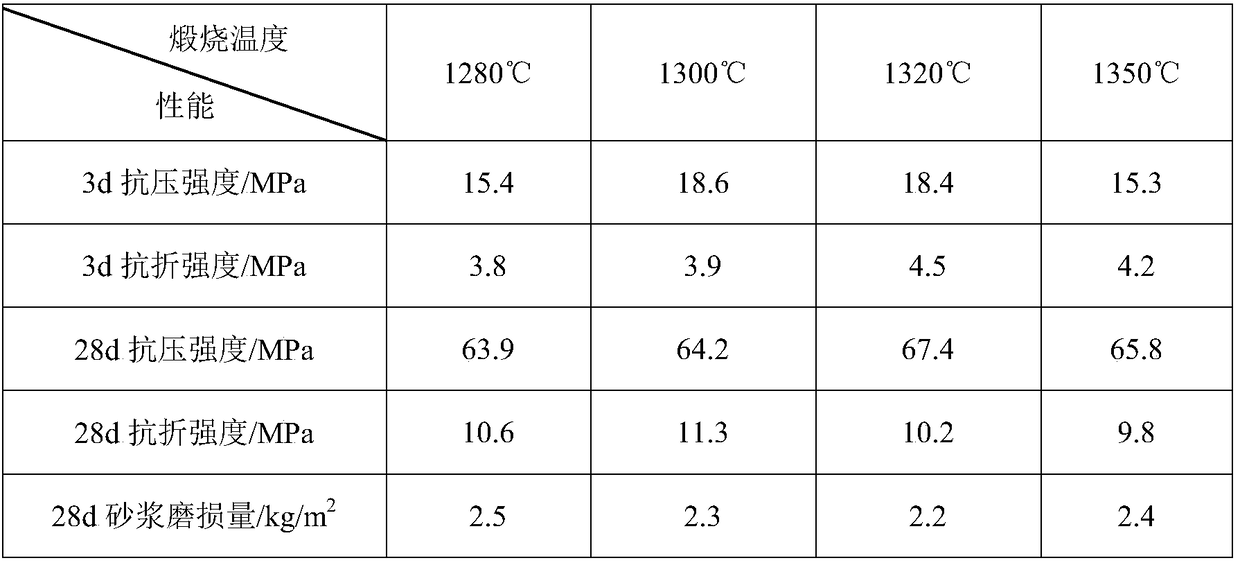

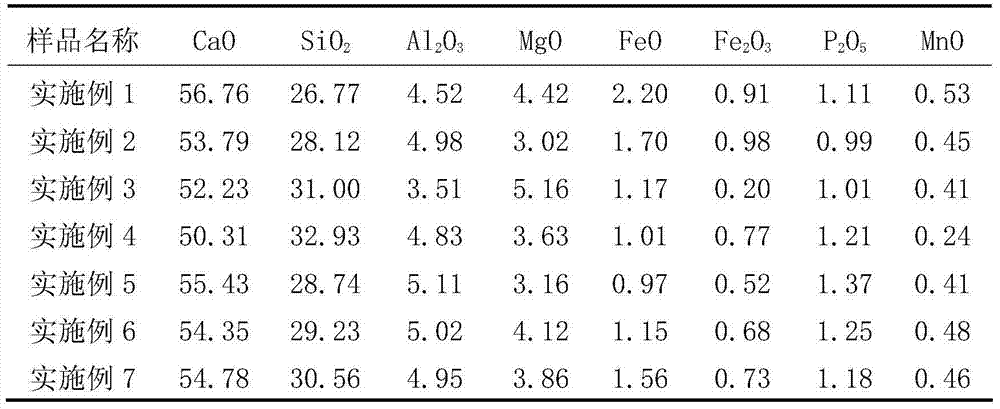

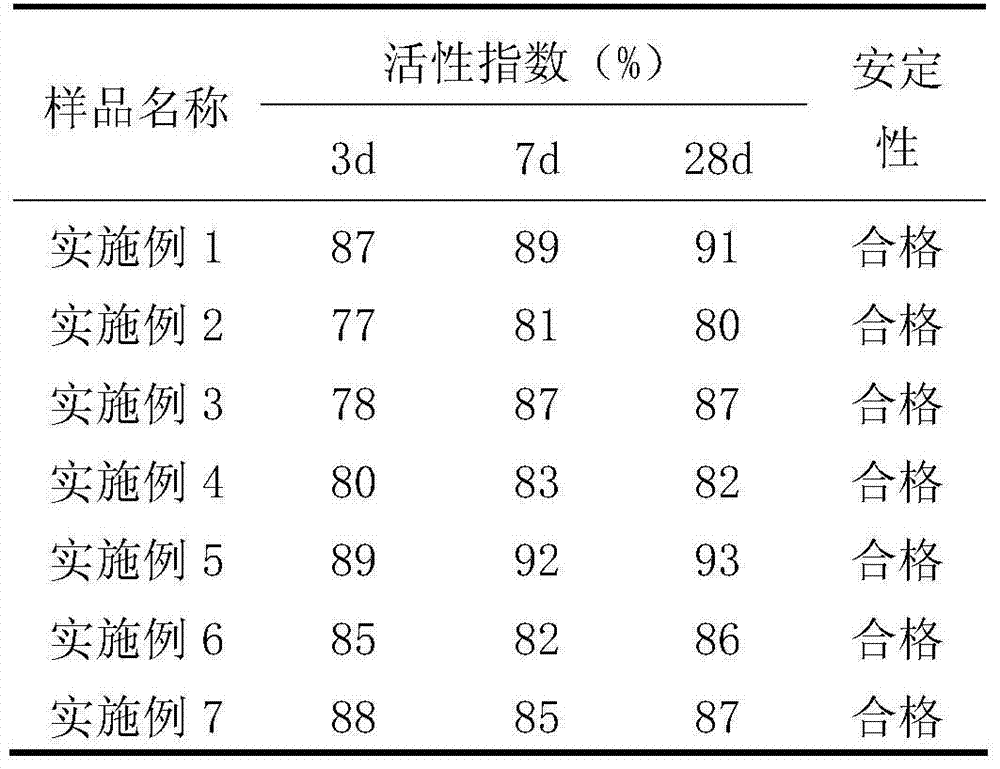

Road silicate cement clinker on basis of industrial waste residues and method for preparing road silicate cement clinker

ActiveCN109081615AStrong mechanical propertiesReduce consumptionCement productionSlagToxic industrial waste

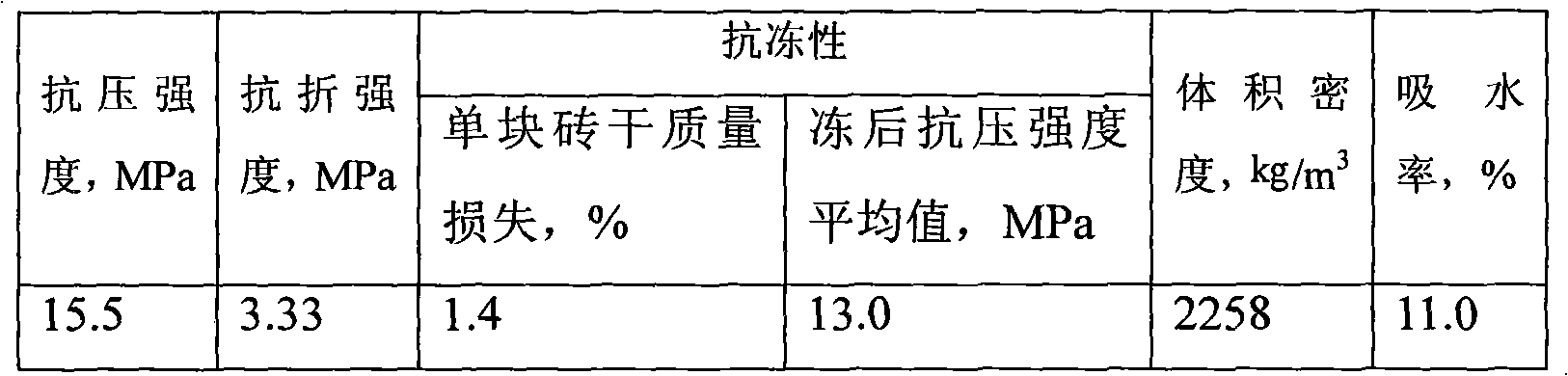

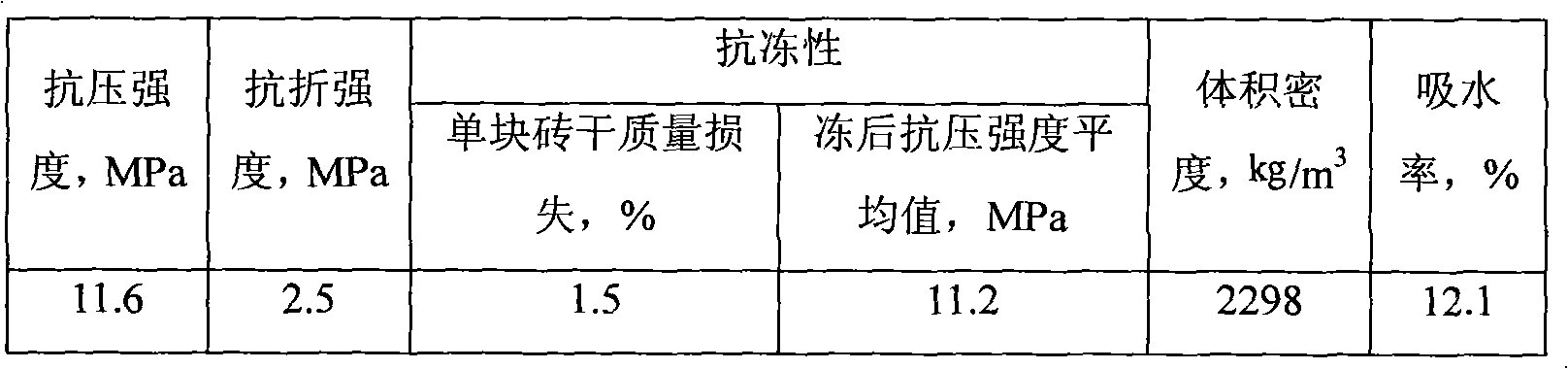

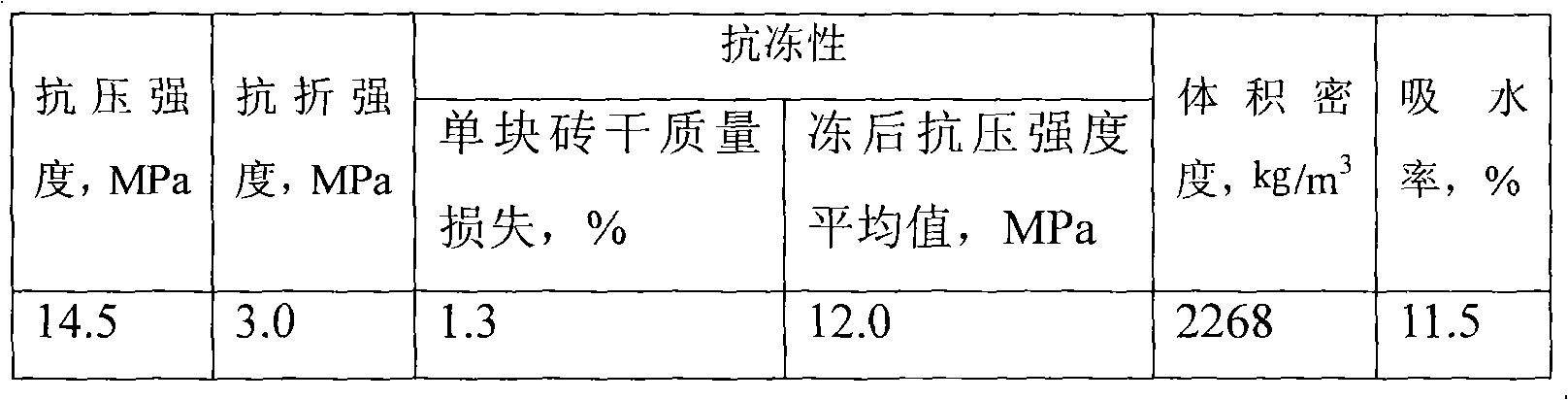

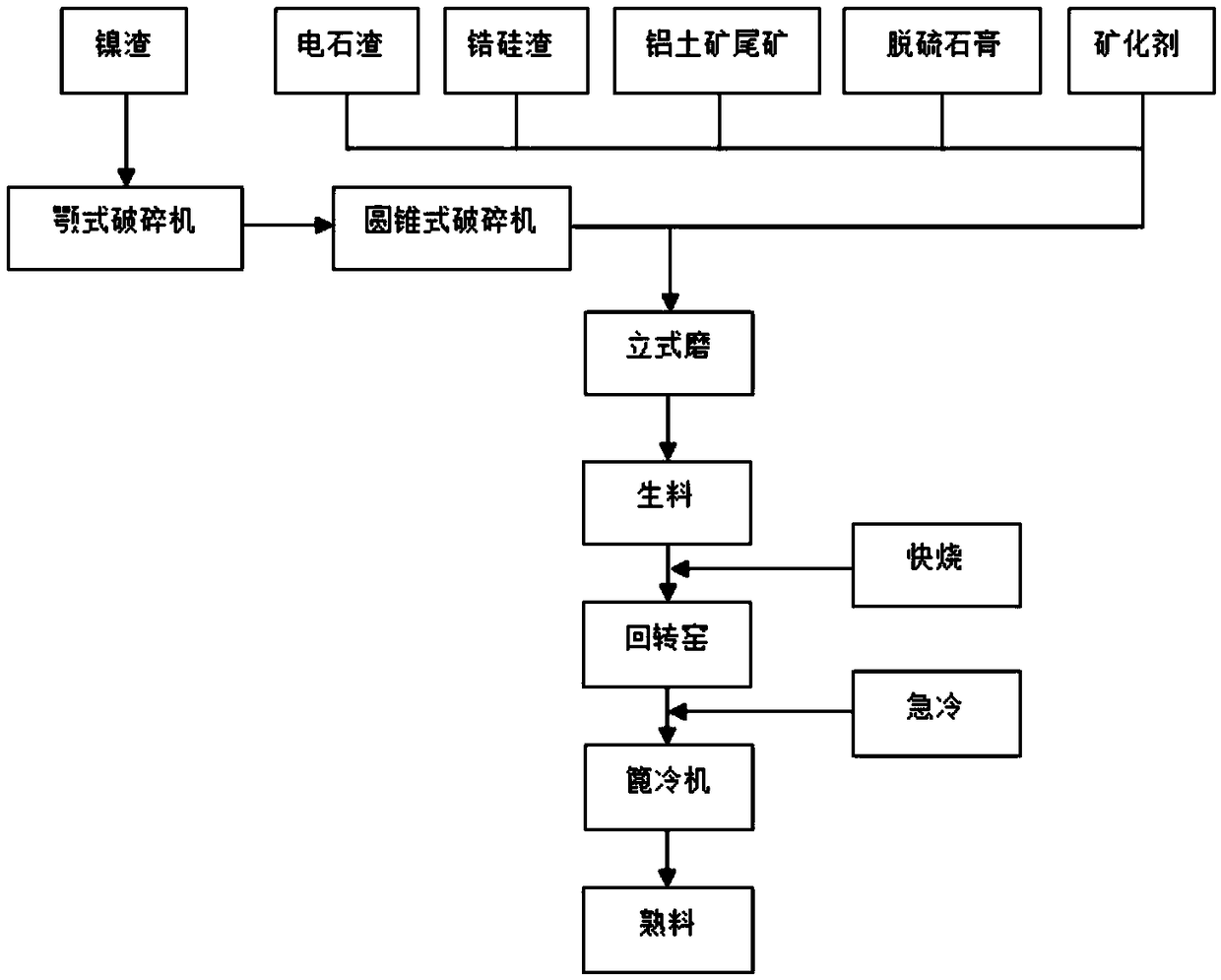

The invention discloses road silicate cement clinker on the basis of industrial waste residues and a method for preparing the road silicate cement clinker. The road silicate cement clinker comprises nickel slag, calcium carbide residues, zirconium-containing silica residues, bauxite tailing, desulfurization gypsum and mineralizers. The method includes mixing, grinding and homogenizing the nickel slag, the calcium carbide residues, the zirconium-containing silica residues, the bauxite tailing, the desulfurization gypsum and the mineralizers to obtain cement raw materials; preheating the cementraw materials, then calcining the cement raw materials under the condition of the temperature of 1280-1350 DEG C for 30-35 min and then carrying out cooling to obtain the road silicate cement clinker.The road silicate cement clinker and the method have the advantages that the 28 d compressive strength of the road silicate cement clinker can reach 63.9-75.2 MPa, the strength grade of the road silicate cement clinker can reach 62.5 grade, the 28 d breaking strength of the road silicate cement clinker can reach 9.8-18.2 MPa, the 28 d mortar abrasion loss of the road silicate cement clinker is lower than 2.5 kg / m<2>, cement is high in stability, and the road silicate cement clinker is high in abrasion resistance and excellent in work performance; the method is simple, complicated working procedures can be omitted, and the road silicate cement clinker and the method are low in cost.

Owner:哈尔滨太行兴隆水泥有限公司

Method for carrying out remelting, reduction and modification treatment on massive steel slag

ActiveCN103789467AUnlimited granularityIngredients unlimitedCement productionRecycling and recovery technologiesGranularityMixed materials

The invention relates to a method for carrying out remelting, reduction and modification treatment on massive steel slag. The method comprises the following steps of (1) mixing materials, uniformly mixing the massive steel slag and a reduced and modified material, and placing into a heating device; (2) increasing the temperature of a mixed material obtained from the step (1) to 1350-1550 DEG C, and stirring at the same time; (3) after the material is completely reacted, naturally separating molten iron from molten slag, discharging the molten iron, and then carrying out cooling treatment on the molten slag. The method disclosed by the invention has the advantages of no steel slag granularity and component limit, short flow, high-efficiency metal element recovery and environmental friendliness; according to the method, the tailings are used as hydraulic cementing materials.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Method for producing cement clinker from stainless steel cold rolling dewatered sludge ingredient

InactiveCN101475325ACalcination temperature is lowBurn completelySludge treatmentWaste water treatment from metallurgical processAdditive ingredientPulverized fuel ash

The invention relates to a method for producing cement clinker through utilization of a stainless steel cold-rolled dehydrated sludge ingredient. The method comprises that: stainless steel cold-rolled dehydrated sludge and other materials of a cement green stock are evenly mixed to prepare the cement green stock; the cement green stock comprises the following compositions in percentage by weight: 70 to 79 percent of limestone, 10 to 14 percent of clay, 1 to 8 percent of the stainless steel cold-rolled dehydrated sludge, 5.3 percent of coal ash, 0 to 3 percent of iron ore powder and 0 to 0.5 percent of gypsum; and the prepared cement green stock is sintered to form silicate cement clinker. The obtained cement clinker and a corresponding cement product have no essential difference with the prior silicate cement clinker and a cement product in composition and performance; the quality of the cement clinker and the corresponding cement product meets the index requirement of national corresponding product standard and can be used as a normal high-quality commodity; and the method effectively utilizes and processes industrial sludge containing harmful metal elements, achieves the effects of resource optimization and utilization and has remarkable environment-friendly benefit.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD +1

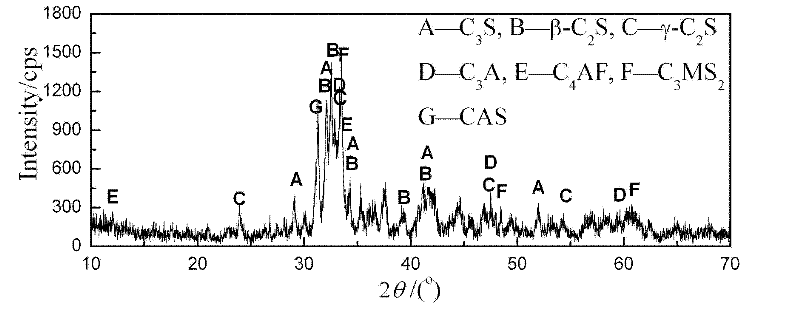

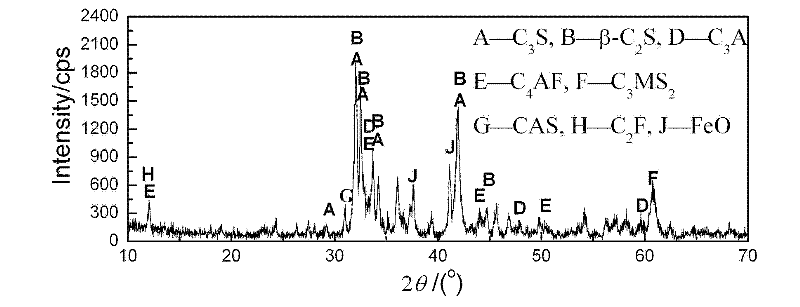

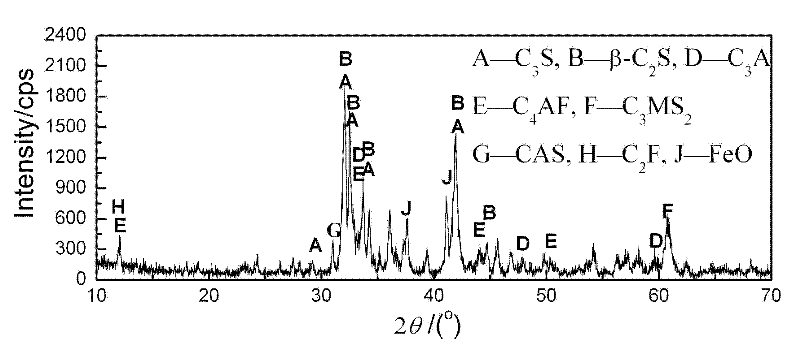

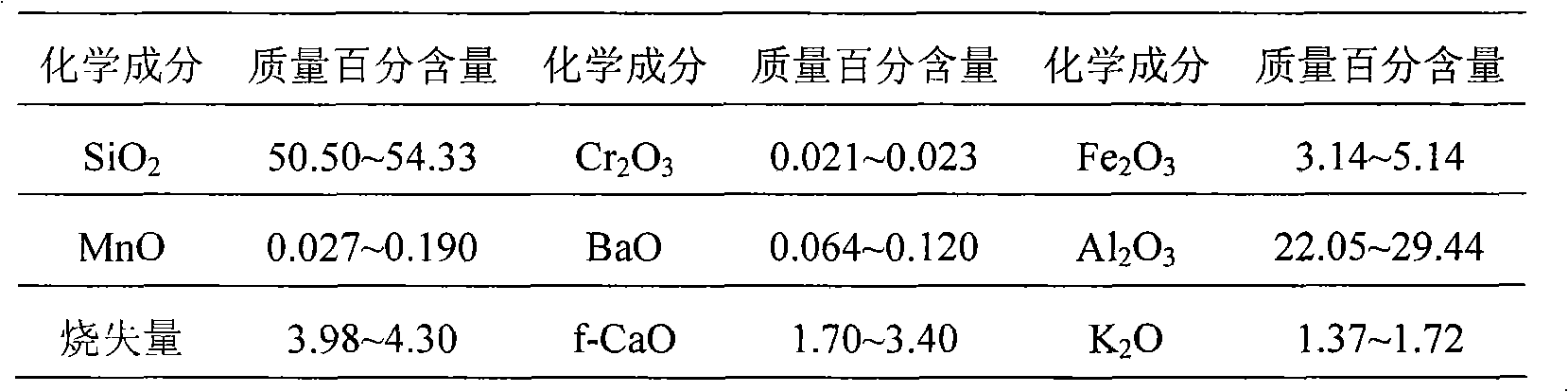

Process method for preparing similar cement clinkers by treating steel slag at thermal state in way of heat preservation

The invention relates to a process method for preparing similar cement clinkers by treating steel slag at a thermal state in a way of heat preservation, which belongs to the application technology of the treatment of steel slag in metallurgical industries. The process method for treating the steel slag preparing class cement clinkers at the thermal state in the way of heat preservation comprises the following steps: (1) mixing a rectifying agent of silicon and aluminum and high-temperature converter steel slag generated in the steel-making process; (2) carrying out heat-preservation treatmenton the mixture of the rectifying agent of the silicon and the aluminum and the converter steel slag in the step (1); and (3) cooling to normal temperature quickly so as to obtain similar cement clinkers. In order to conveniently mix the rectifying agent of the silicon and the aluminum and the converter steel slag, the high-temperature converter steel slag can be poured into slag ladles, the rectifying agent of the silicon and the aluminum is added in a dispersing way in the pouring process, and the quality of the steel slag poured into each slag ladle and the variety and the quality of the added rectifying agent can be concretely regulated according to different slag ladles and process conditions. In order to better mix the rectifying agent and the converter steel slag for reacting, nitrogen gas can be blown into the bottoms of the slag ladles for stirring and homogenizing in the heat-preservation process. According to the method, the problem of low stability and activity of the steelslag can be simultaneously solved; and moreover, the process is simple, and the cost is low.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Machining method of ground steel slag

The invention provides a machining method of ground steel slag. The method includes the following steps of directly smashing raw material steel slag into a particle material with a certain particle size, selectively removing part of iron from the particle material, sending the material into a vapor stream smashing machine to be smashed, and conducting classified collecting to obtain the ground steel slag, wherein the particle size of the ground steel slag d50 is 3-15 micrometers. In smashing, the pressure of vapor used by the vapor stream smashing machine is 0.32-0.45 MPa, the temperature is 270-400 DEG C, and meanwhile CO2 gas is introduced into the vapor stream smashing machine. Bottom material tailings with total iron amount smaller than or equal to 30% are separated from a steel slag iron-rich bottom material depositing at the bottom of the vapor stream smashing machine through magnetic separation and then mixed into the steel slag particle material and then enter the vapor stream smashing machine again to be smashed. By means of the method, after-tapping fused steel slag is directly machined into the ground steel slag after being rapidly chilled without being dried; the obtained ground steel slag product is high in activity and low in free calcium oxide content; the steel slag is directly machined into a product in situ, transport cost is saved, and the machining process is simplified.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for recovering phosphorus from urban mud anaerobic digestion solution

ActiveCN101585522ALow costReduce free calcium oxide contentPhosphorus compoundsChemistryPre treatment

The invention discloses a method for recovering phosphorus from the urban mud anaerobic digestion solution, comprising: mixing and stirring the fly ash and water with the mass ratio of 1:5-40, standby, producing the leaching liquid; anaerobic digestion of the urban mud, taking the supernatant for acidification to regulate the pH value of the solution for preprocessing; mixing the leaching liquid and the preprocessed digestion liquid according to initial reaction calcium phosphorus molar ratio of 0.5-3.3:1; regulating the reaction pH value to 7.5-11.0, stirring and reacting for 5-120 min; obtaining the calcium phosphate precipitates. The invention subtly utilizes the fly ash leaching solution to provide calcium source and recovers phosphorus in the mode of calcium phosphate, can recover the valuable products from the mud and the fly ash and relieve the phosphorus load in the subsequent sewage treatment. Because the leaching solution is enriched with hydroxyl ions, the alkali feed quantity is reduced and the recovered products has high purity.

Owner:NANJING FORESTRY UNIV

Method for preparing calcium ferroaluminates

The invention relates to a method for preparing calcium ferroaluminates. The method comprises the following steps: proportionally mixing an aluminium nitrate hydrate, a calcium nitrate hydrate, a ferric nitrate hydrate, hexamethylenetetramine, acetylacetone, deionized water and the like uniformly by a sol-gel method, then stirring the mixture at the temperature of 50-70 DEG C to obtain sol, ageing the sol to form gel, carrying out heat treatment on the gel at the temperature of 750-800 DEG C for 2-4 hours and slowly cooling the gel to the room temperature, thus obtaining the calcium ferroaluminates. Compared with the prior art, the method has the following advantages: the preparation process is simple; the reaction process is easy to control; and the product has high uniformity and purityand can be fired at the temperature lower than the temperature in the traditional methods.

Owner:TONGJI UNIV

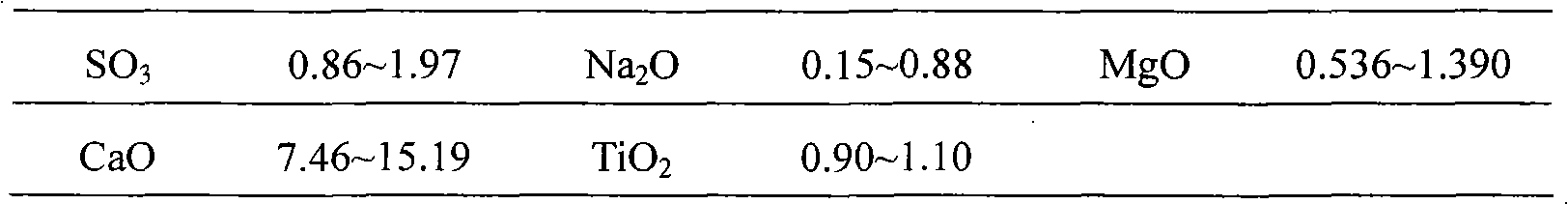

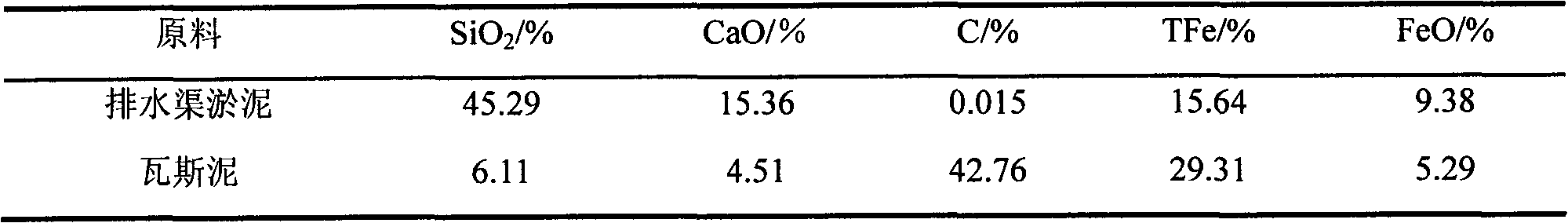

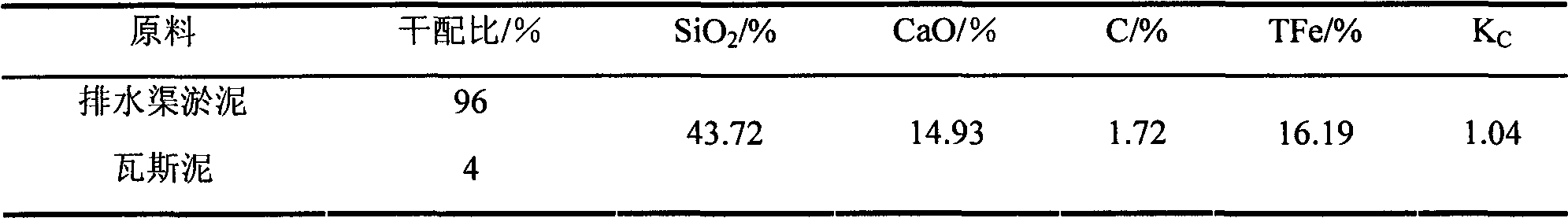

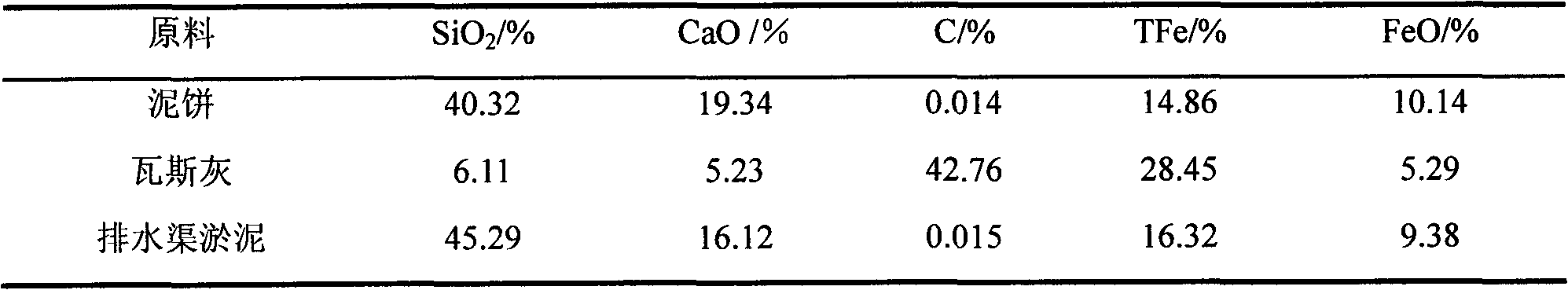

Converter slag modifier and manufacture and using method thereof

ActiveCN102719575AReduce free calcium oxide contentIncrease the scope of applicationManufacturing convertersRecycling and recovery technologiesSludge cakeChemical composition

The invention provides a converter slag modifier using low-iron wastes as raw materials, a manufacture method and a using method thereof. The modifier is a mixture composed of one or several of the following materials: press-filtered sludge cakes through metallurgy waste water treatment, drainage ditch sludge, gas mud and gas ash, and main chemical compositions simultaneously meet the following conditions by weight percentage: 27% to 99.9% of SiO2, 0.01% to 25% of CaO and 0.01% to 50% of TFe. A carbon excess coefficient Kc is 1 to 8. The manufacture method of the converter slag modifier comprises drying, proportioning, mixing, and screening to obtain a finished product. The using method of the converter slag modifier comprises feeding, slagging, slag granulating, etc., thereby making a f-CaO of the converter slag less than or equal to 1.5%, and fulfilling a stable treatment of the converter slag.

Owner:ANGANG STEEL CO LTD

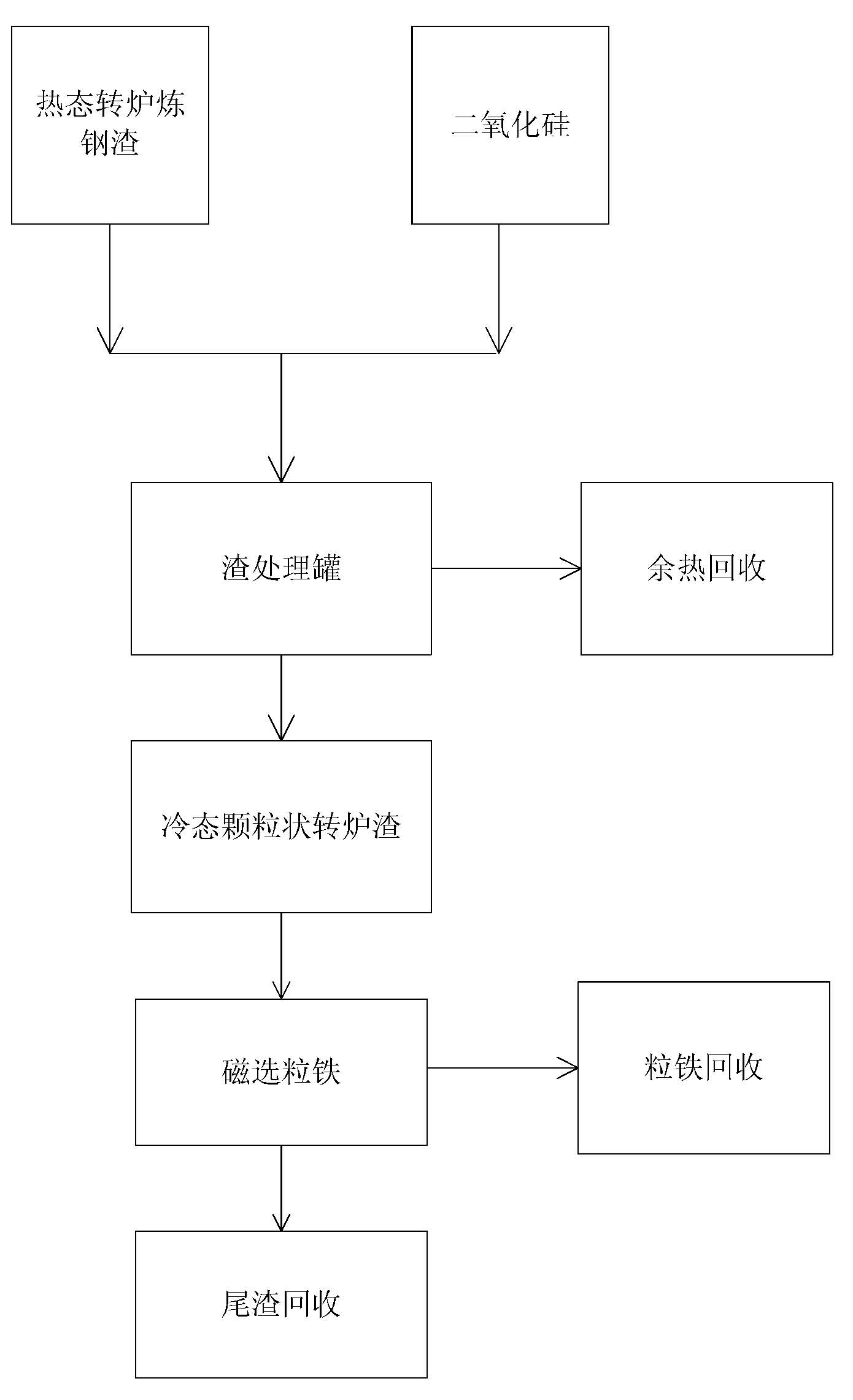

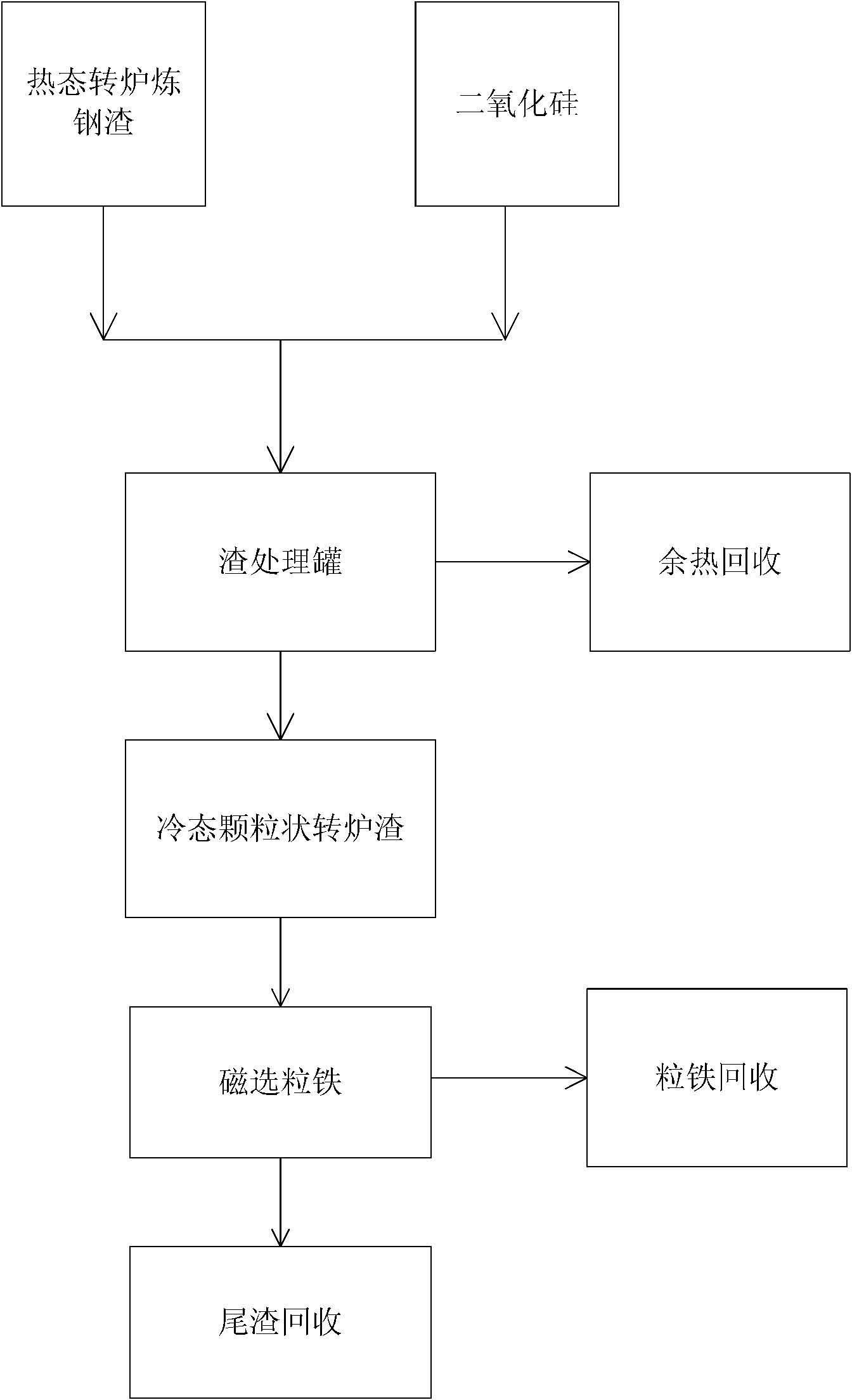

Method for processing convertor steelmaking slag

InactiveCN102534070AAchieve natural pulverizationUniform particle sizeRecycling and recovery technologiesSteelmakingVolume expansion

The invention relates to a method for processing convertor steelmaking slag. A raw material containing SiO2 is added into thermal convertor steelmaking slag, so that CaO in the convertor steelmaking slag generates 2CaO.SiO2 through a solid-phase reaction in a high temperature. The 2CaO.SiO2 generating crystal transformation and volume expansion in a cooling process of the convertor steelmaking slag is utilized to realize the natural pulverization of the convertor steelmaking slag, convertor slag with even grain sizes is obtained, and grained iron is magnetically separated. According to the technical scheme, the raw material containing the SiO2 is added into the convertor steelmaking slag in the high temperature, the crystal transformation and the volume expansion of the 2CaO.SiO2 in the cooling process of the convertor steelmaking slag are utilized to realize the natural pulverization of the convertor steelmaking slag, the convertor slag with even grain sizes is obtained, the grained iron is magnetically separated, tailings are recovered, and large amounts of heat energy of high-temperature convertor steelmaking slag in the cooling process are recovered.

Owner:WISDRI ENG & RES INC LTD

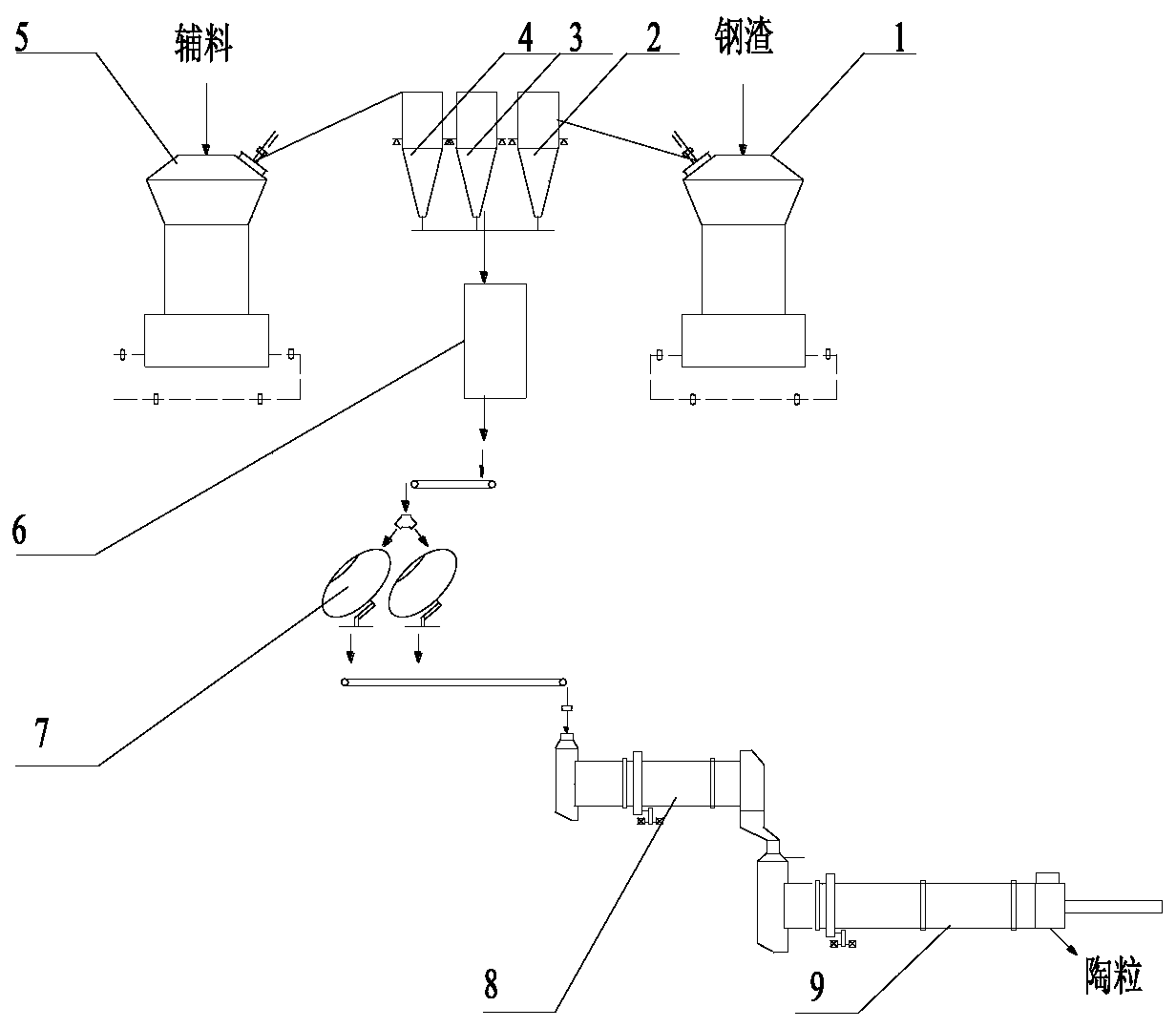

Method and system for preparing steel slag ceramsite

PendingCN110981536AReduce free calcium oxide contentHigh cylinder compressive strengthCeramic materials productionCeramicwareSlagWaste material

The invention discloses a method and a system for preparing steel slag ceramsite. Steel slag is used as the main raw material, and one or more industrial solid waste materials such as blast furnace slag, clay, and waste porcelain are used as auxiliary materials, and a fired brick is manufactured by firing at high temperature. The method includes grinding the steel slag to 100-500 microns to obtainsteel slag powder, and grinding the auxiliary materials to 50-200 microns to prepare auxiliary material powder; mixing a binder and water to prepare binder slurry; mixing the steel slag powder, the auxiliary material powder and the binder slurry according to a certain ratio in a granulator to prepare spherical masterbatch; pelleting the spherical masterbatch in a pelleting machine to prepare rawmaterial pellets, drying, and firing at 900-1250 DEG C to prepare the steel slag ceramsite. The bulk density of the steel slag ceramsite prepared by the invention reaches 500 kg / m<3> to 1100 kg / m<3>,the cylinder compressive strength reaches up to 35 MPa, the content of free calcium oxide in the ceramsite is less than 0.5 wt%, stability is good, a problem that steel slag volume stability is poor is solved, facilitating large-scale resource utilization of the steel slag.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for preparing Portland cement clinker

InactiveCN102153295AEasy to controlReduce free calcium oxide contentHexamethylenetetramineMaterials science

The invention relates to a method for preparing Portland cement clinker. The method comprises the following steps: proportionally mixing tetraethoxysilane, a calcium nitrate hydrate, an aluminium nitrate hydrate, a ferric nitrate hydrate, ethanol, nitric acid, hexamethylenetetramine, acetylacetone, deionized water and the like uniformly to obtain four kinds of mixed liquid, fully stirring the four kinds of mixed liquid respectively at the temperature of 50-70 DEG C until proper viscosity to obtain monomineral sols of the Portland cement clinker, then mixing the four monomineral sols in a massratio of (36-55):(24-40):(11-19):(20-31), ageing the mixture to form gel, carrying out heat treatment on the gel at the temperature of 1150-1200 DEG C for 4-6 hours and cooling the gel to the room temperature, thus obtaining the Portland cement clinker. Compared with the prior art, the method has the following advantages: the preparation process is simple; the reaction process is easy to control;and the product has high uniformity and purity and can be fired at the temperature lower than the temperature in the traditional methods.

Owner:TONGJI UNIV

Road steel slag pretreatment method

InactiveCN109622571AFast free calcium oxide contentReduce free calcium oxide contentSolid waste disposalSteelmakingPretreatment method

The invention discloses a road steel slag pretreatment method. Waste steel slag generated in a steelmaking process in a steel mill is intensively stacked after being treated through processes such ascrushing and iron separation, and a solution obtained by mixing a plurality of materials at a normal temperature is used for carrying out continuous spraying treatment on the intensively stacked steelslag. The solution comprises materials including, by weight part, 100 parts of water, 6-10 parts of industrial acetic acid, 0.5-2 parts of monocalcium phosphate, 10-30 parts of calcium chloride and 3-6 parts of sodium pyrophosphate, after the materials are mixed to be uniform, 30-90 days of spraying treatment is carried out on the stacked steel slag at the normal temperature, and the content of free calcium oxide in the steel slag can be obviously reduced. The content of the free calcium oxide of the treated steel slag is lower than 3%, and the steel slag can be used for building and maintaining of high-grade roads.

Owner:葛洲坝武汉道路材料有限公司

Safety process for preventing desilicication slag and dephosphorization slag contained in converter slag pot from splashing

ActiveCN109321706AAddressing the Safety Concerns of SplashingRealize resource utilizationManufacturing convertersProcess efficiency improvementSlagSilicon

The invention discloses a safety process for preventing desilicication slag and dephosphorization slag contained in a converter slag pot from splashing. The safety process comprises the steps that firstly, dry aluminum ash in an aluminum electrolysis plant is pulled and transported to a steel slag pot stockpiling area of a steel works; secondly, after converter desilicication slag is poured, a slag pot car is driven out, according to the proportion that 100 to 300 kg of aluminum ash is added in each ton of converter steel slag, operation is carried out, the aluminum ash is added, according tothe converter tapping amount, and the 100 kg slag amount of a ton of steel, the converter dephosphorization steel slag amount is calculated, the slag pot is used for continuously containing converterdephosphorization slag, and after converter deslagging is finished, according to the normal slag treatment process, steel slag is treated; thirdly, under the condition that the above operation condition is not allowable, the slag pot is used for containing the desilicication slag firstly, after the dephosphorization slag is contained, the slag pot car is driven out of the slag pot stockpiling area, and the aluminum ash is added from the upper portion of the slag pot; and fourthly, according to the manner of adding the aluminum ash into the slag pot, a loading machine loads the aluminum ash todirectly add the aluminum ash into the slag pot or ton bags are adopted for packaging the aluminum ash, a traveling crane is used for lifting the ton bags, the ton bags are added into the slag pot, orthe injection manner is used.

Owner:新疆互力佳源环保科技有限公司

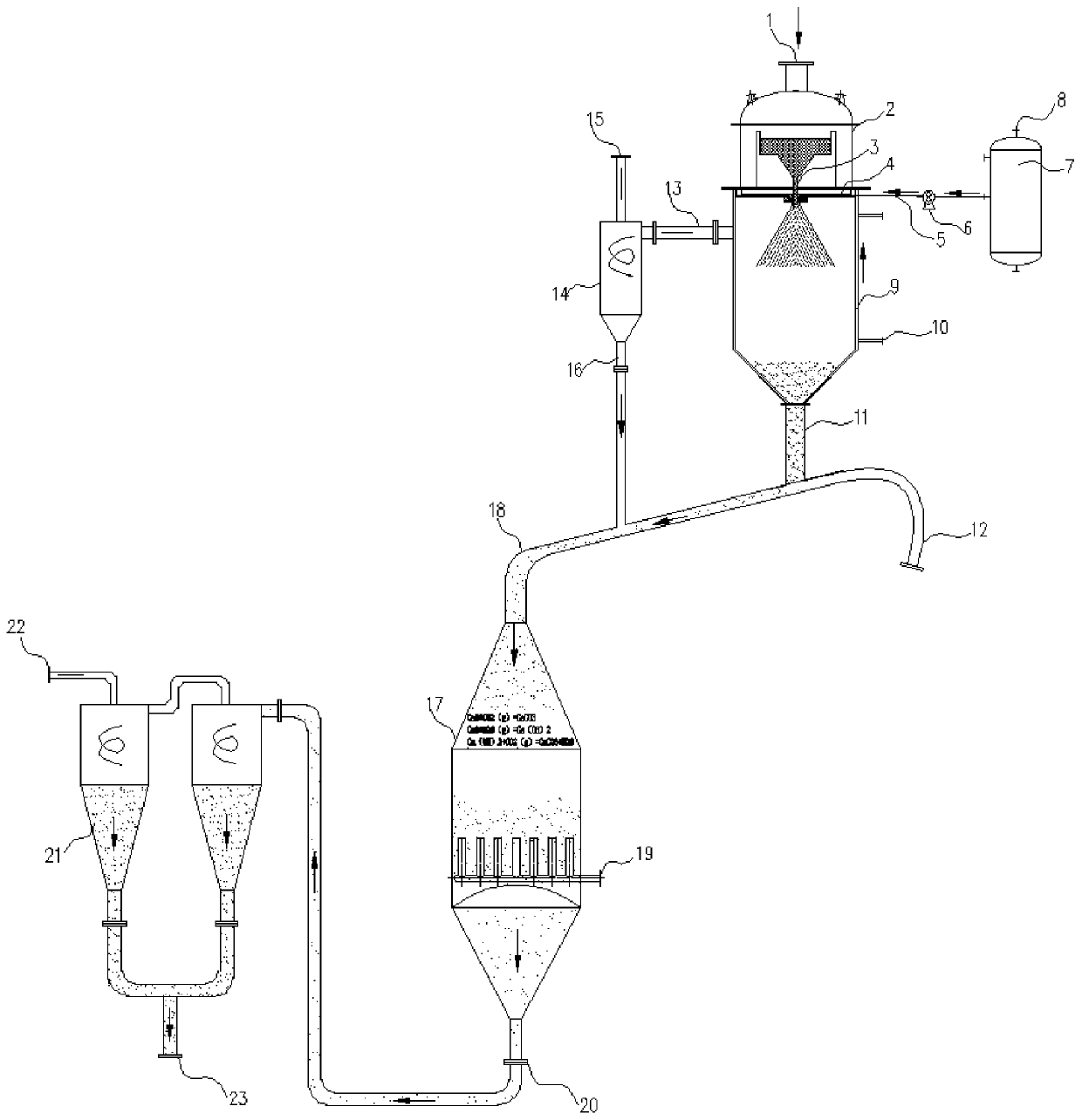

Steel slag pulverization and carbon fixation treatment system and application thereof

ActiveCN110665614AImprove energy savingGood molding effectGas treatmentWaste processingSlagWater vapor

The invention relates to the technical field of steel slag pulverization, in particular to a steel slag pulverization and carbon fixation treatment system and application thereof. The steel slag pulverization and carbon fixation treatment system uses high-pressure gas as a cold source and power for molten steel slag pulverization, and realizes the low energy consumption and deep pulverization of steel slag. The particle diameter of the obtained steel slag is less than 2mm. Steel slag powder reacts with carbon dioxide and superheated steam in a fluidized reactor to form stable calcium carbonate. Excess steam and carbon dioxide gas can be recycled as industrial waste heat; the steam becomes water to be separated from the carbon dioxide; and the carbon dioxide is used as make-up gas. The steel slag pulverization and carbon fixation treatment system can realize the rapid cooling, pulverization, and carbon fixation of the molten steel slag, and can fix greenhouse gases while saving energy.

Owner:SHANDONG XIANGHUAN ENVIRONMENTAL TECH CO LTD

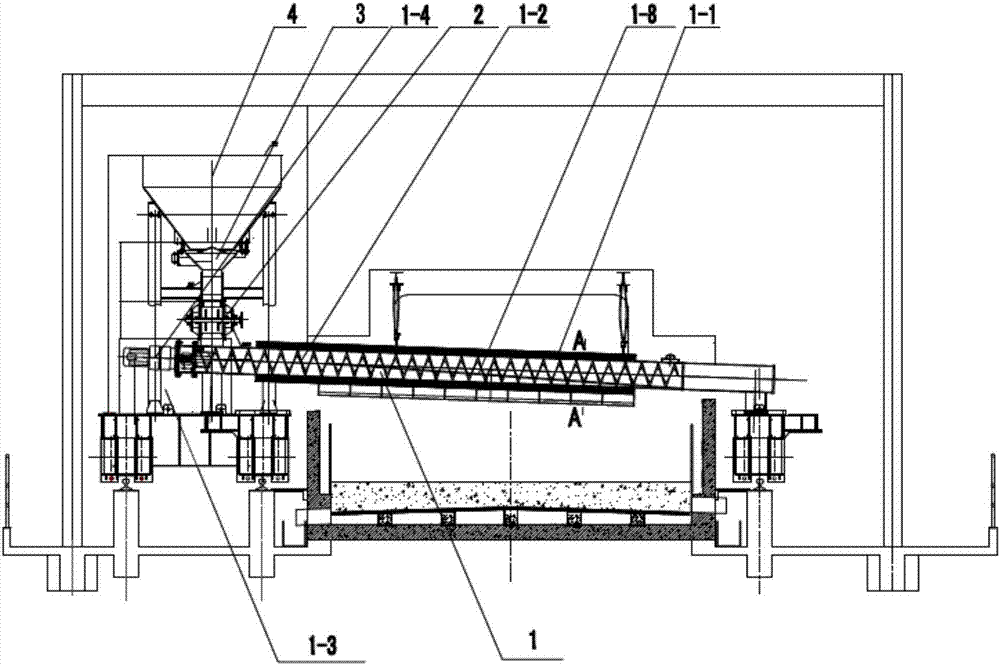

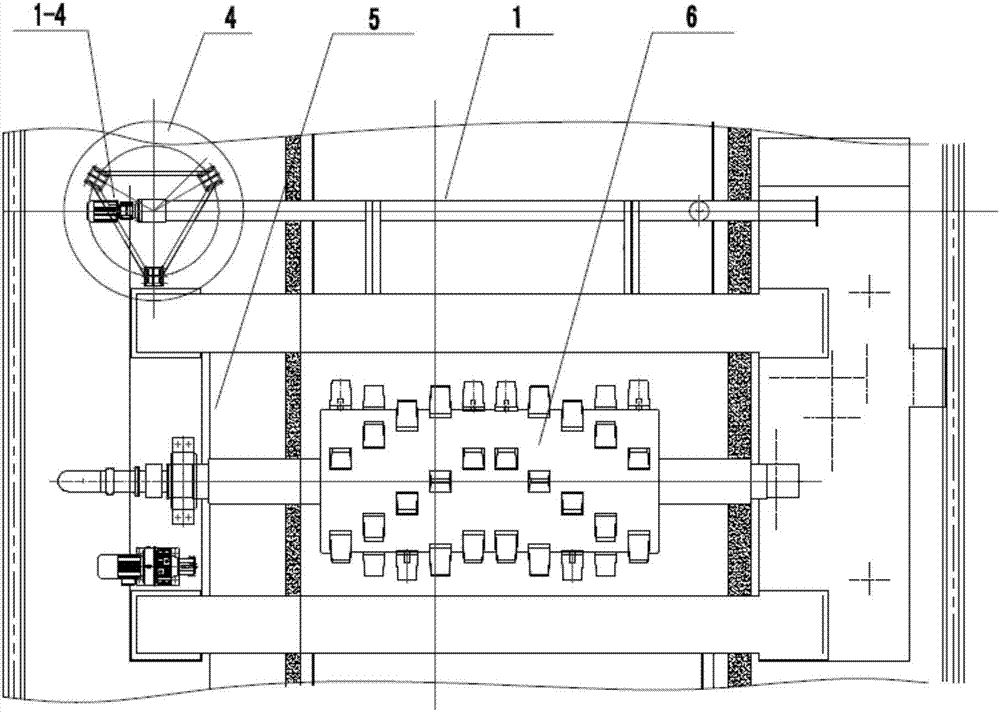

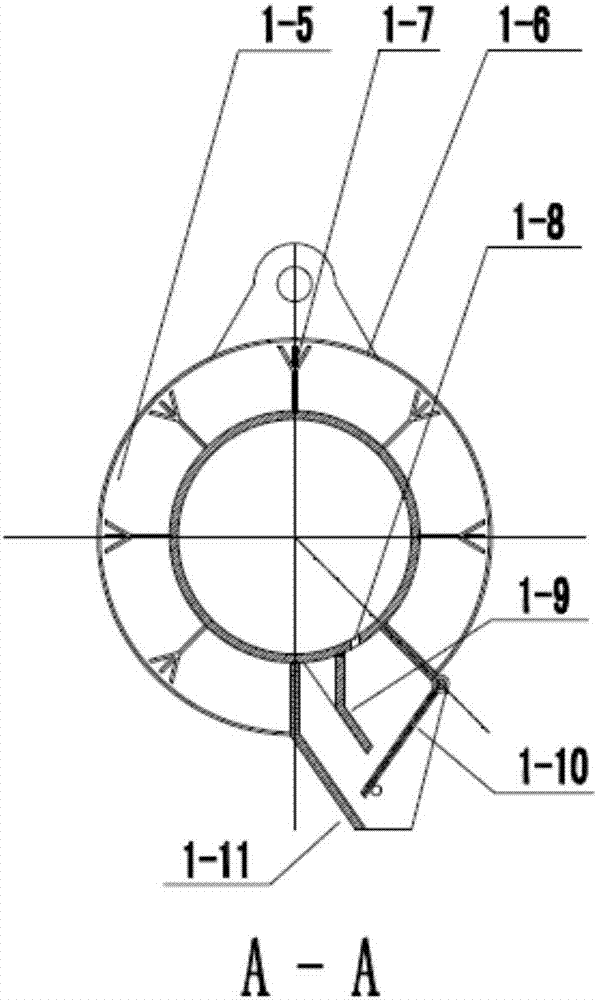

Molten steel slag rolling modification treatment device and method

ActiveCN107119155AReduce free calcium oxide contentImprove volume stabilityRecycling and recovery technologiesSlagMolten steel

The invention relates to a molten steel slag rolling modification treatment device and method. The device comprises a screw feeding device, a rotary feed valve, a pulse feeding device and a material bin. The molten steel slag rolling modification treatment device is located on a thermal state steel slag rolling breaking trolley. The molten steel slag rolling modification treatment device and the rolling breaking trolley move jointly to scatter modifying materials to a slag bed. The treatment method is simple and convenient to operate, and high-temperature thermodynamic conditions of molten steel slag and dynamic conditions that a steel slag rolling breaker walks in a reciprocating manner to stir the steel slag are fully utilized.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +2

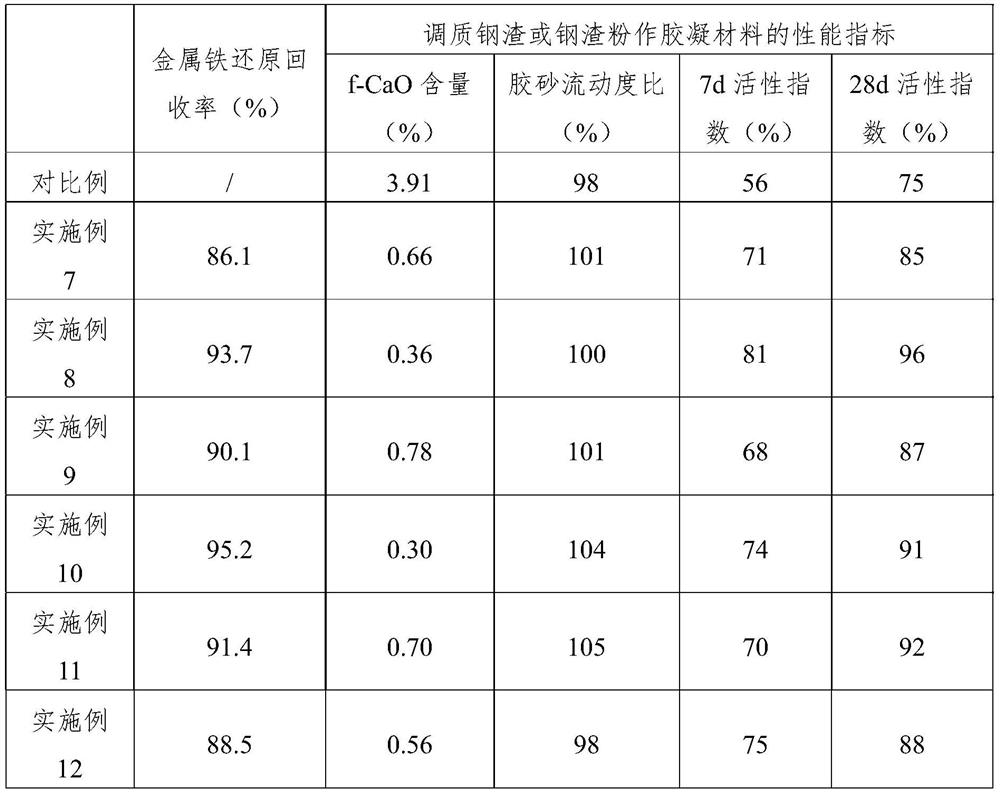

Reduction tempering agent and application thereof in treating steel slag

ActiveCN114292040ARealize full quantification and waste-free utilizationImprove the level of scale utilizationCement productionRecycling and recovery technologiesTemperingChemical reaction

The invention relates to the field of building materials, in particular to a reduction tempering agent and application thereof in treating steel slag. The reduction conditioning agent comprises 35 to 90 weight percent of a carbon-containing component; in the carbon-containing component, fixed carbon is greater than or equal to 40.0 wt%, volatile components are less than or equal to 50.0 wt%, and ash content is less than or equal to 10.0 wt%; the reduction tempering agent further comprises fluorite; the mass ratio of the carbon-containing component to the fluorite is (35-90): (2-40). According to the reduction tempering agent provided by the invention, the steel slag can be subjected to a chemical reaction at a relatively low temperature, a valuable metal iron resource is reduced and recovered, and the tempered steel slag with high gelling activity and no stability problem can be obtained and used as a building material resource, so that the whole full-quantization waste-free utilization of the steel slag can be realized, and the production cost is reduced. The large-scale comprehensive utilization of the steel slag is favorably improved.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

Device and method for pretreating steel slag through air quenching of CO2-containing tail gas

InactiveCN113149495AReduce free calcium oxide contentEfficient preprocessingSolid waste managementSlagFlue gas

The invention discloses a device and method for pretreating steel slag through air quenching of CO2-containing tail gas. The device comprises a steel slag tank and an air quenching device, wherein the steel slag tank is a square tank, a grating plate is obliquely arranged in the middle of the interior of the steel slag tank, and a waste slag chamber is fixedly connected to the middle of the side wall, away from the air quenching device, of the steel slag tank, and the bottom discharging port of thesteel slag tank is fixedly connected with a conveying pipe. The method has the beneficial effects that the content of free calcium oxide in the steel slag at about 100 DEG C obtained by the production method is low, the steel slag has good stability, efficient pretreatment of the steel slag can be well realized, and the subsequent resource utilization rate of the steel slag is greatly improved; after high-temperature flue gas at an air pipe outlet of the cyclone separator is discharged from a flue gas port, waste heat is removed for power generation for waste heat recovery, the heat energy utilization rate is improved, the heater is installed at the bottom of the steel slag tank, the heating temperature of the heater is higher than the steel slag melting temperature, the steel slag tank can be heated when necessary, and the steel slag is ensured to be in a liquid state.

Owner:南京腾达环保科技有限公司

Method for eliminating f-CaO in steel slag through water soaking hot closing

InactiveCN108913826AImprove product qualityAvoid situations that are difficult to penetrateRecycling and recovery technologiesWater bathsRoad engineering

The invention discloses a method for eliminating f-CaO in steel slag through water soaking hot closing. The method is characterized in that water is sprayed from the top of a hot closing container; the lower part is gradually soaked in water to generate saturated steam; saturated steam is simultaneously generated at the upper and lower parts in the container to realize the sufficient contact withf-CaO; along with the water filling, the water level in the container gradually rises; the contact with high-temperature water bath with the f-CaO in the refined steel slag is utilized, so that the elimination reaction of the f-CaO is sufficiently performed; after the steel slag is treated by the method, the f-CaO content in the steel tailing is stably lowered to a value below 3.0 percent; the inherent process defects of the conventional steel slag pressure-free hot closing treatment process are overcome; the instability of the steel slag is eliminated; the performance index meets the standardrequirements of industries of cement, building materials and the like; the method can be used for the fields of steel slag powder production, building material product production, road engineering and the like. The beneficial conditions are created for the resource utilization of the steel slag.

Owner:WUKUN STEEL

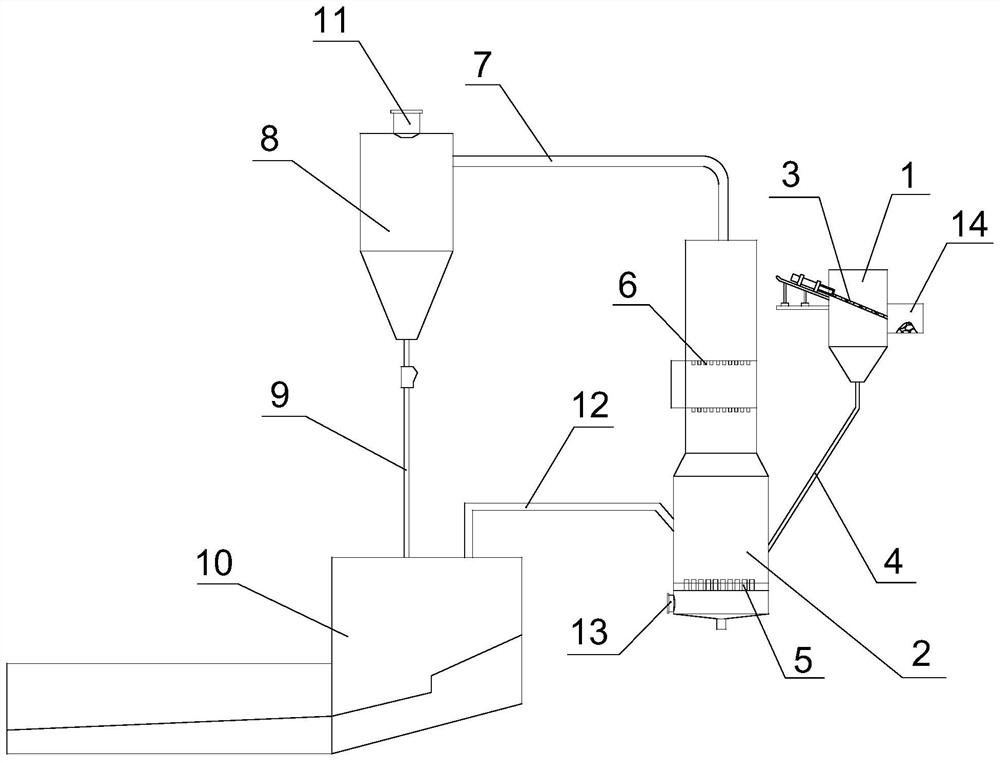

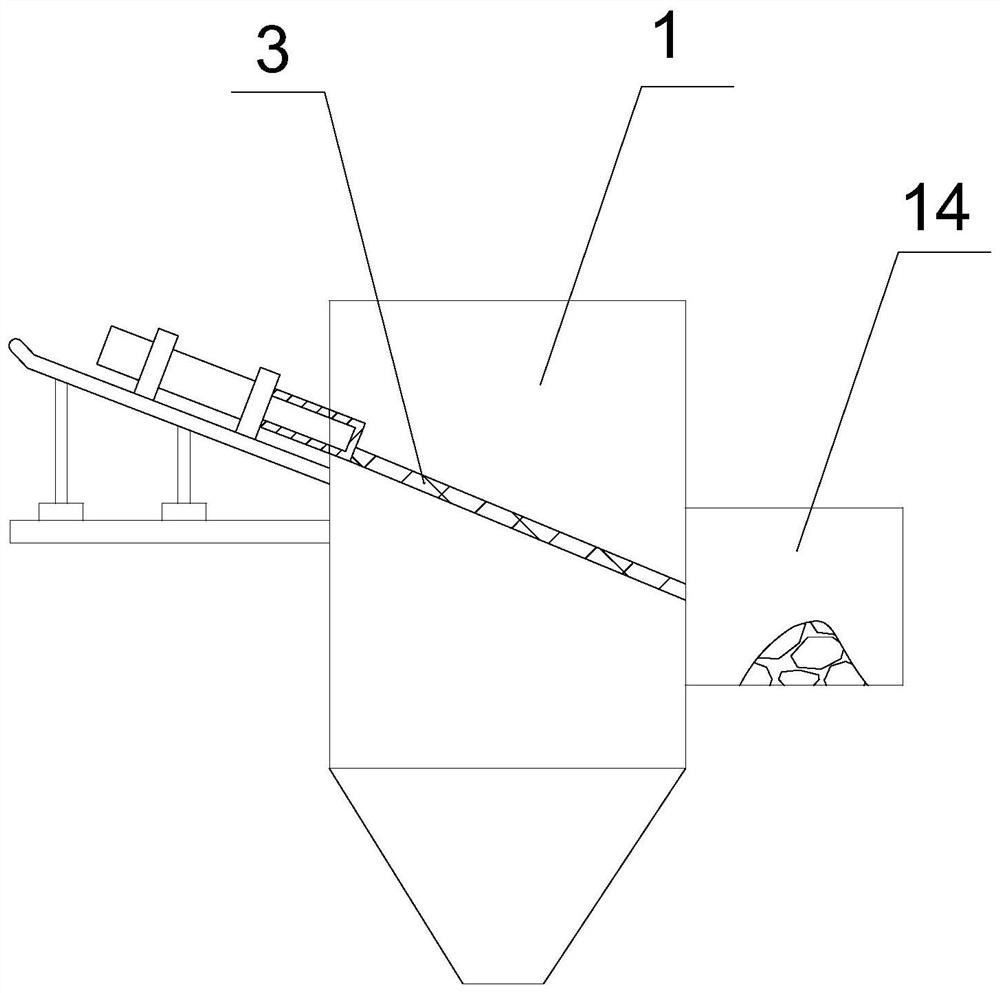

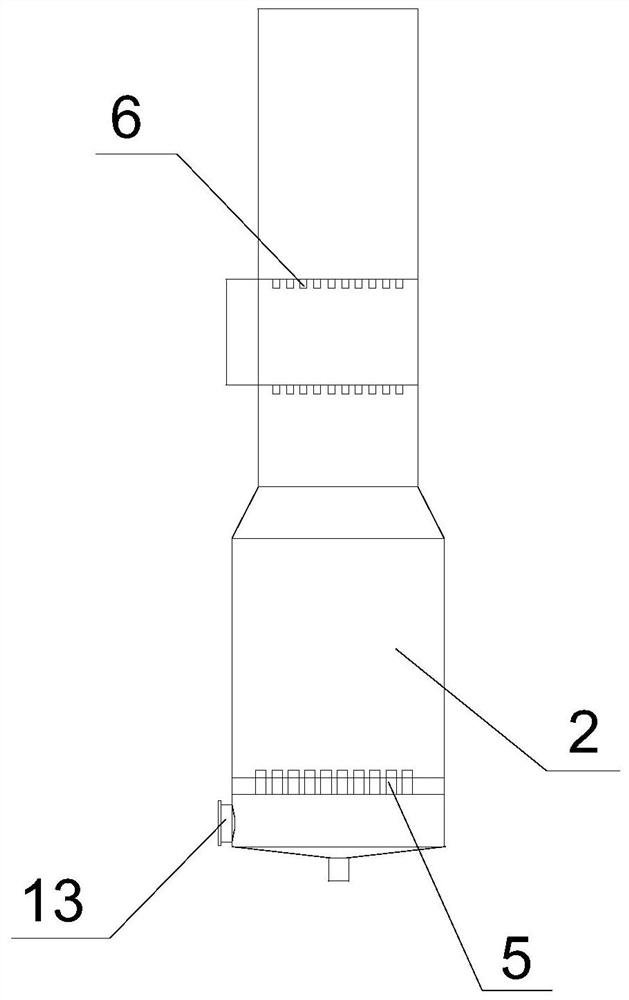

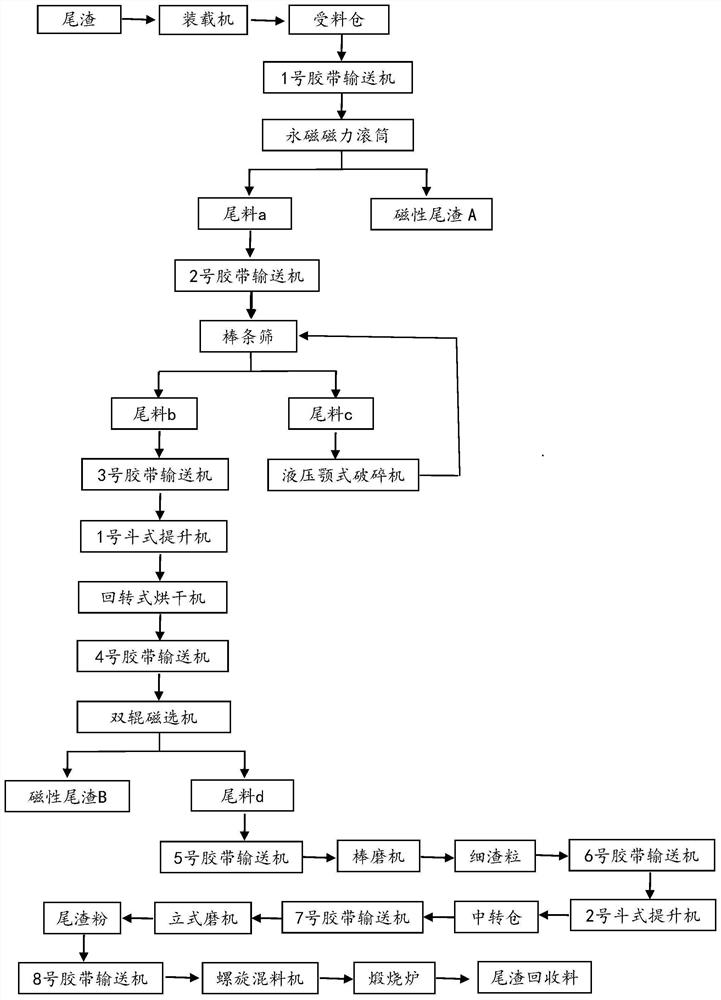

Steel smelting tailing treatment process

The invention relates to the technical field of steelmaking tailing treatment, and provides a steel smelting tailing treatment process. The process comprises the following steps: feeding tailings into a permanent magnetic roller for primary magnetic separation to separate out magnetic tailings A and tailings a, and screening through a bar screen to obtain tailings b with the particle size smaller than screen holes and tailings c with the particle size larger than the screen holes; performing drying and secondary magnetic separation on the tailings b to obtain magnetic tailings B and tailings d, sequentially performing coarse grinding through a rod mill and fine grinding through a vertical mill on the tailings d to obtain tailings powder with the specific surface area being 420 m < 2 > / kg or above, uniformly stirring and mixing the tailings powder and carbonized sludge, and then putting the mixture into a calcining furnace to be calcined to obtain the tailings recycled material. The problems that an effective treatment method for tailings generated in the existing steel smelting process is lacked and the resource utilization rate is low are solved, the tailings recycled material serving as a mineral admixture is applied to concrete to replace part of cement, and the use amount of the cement is reduced.

Owner:王庆乐

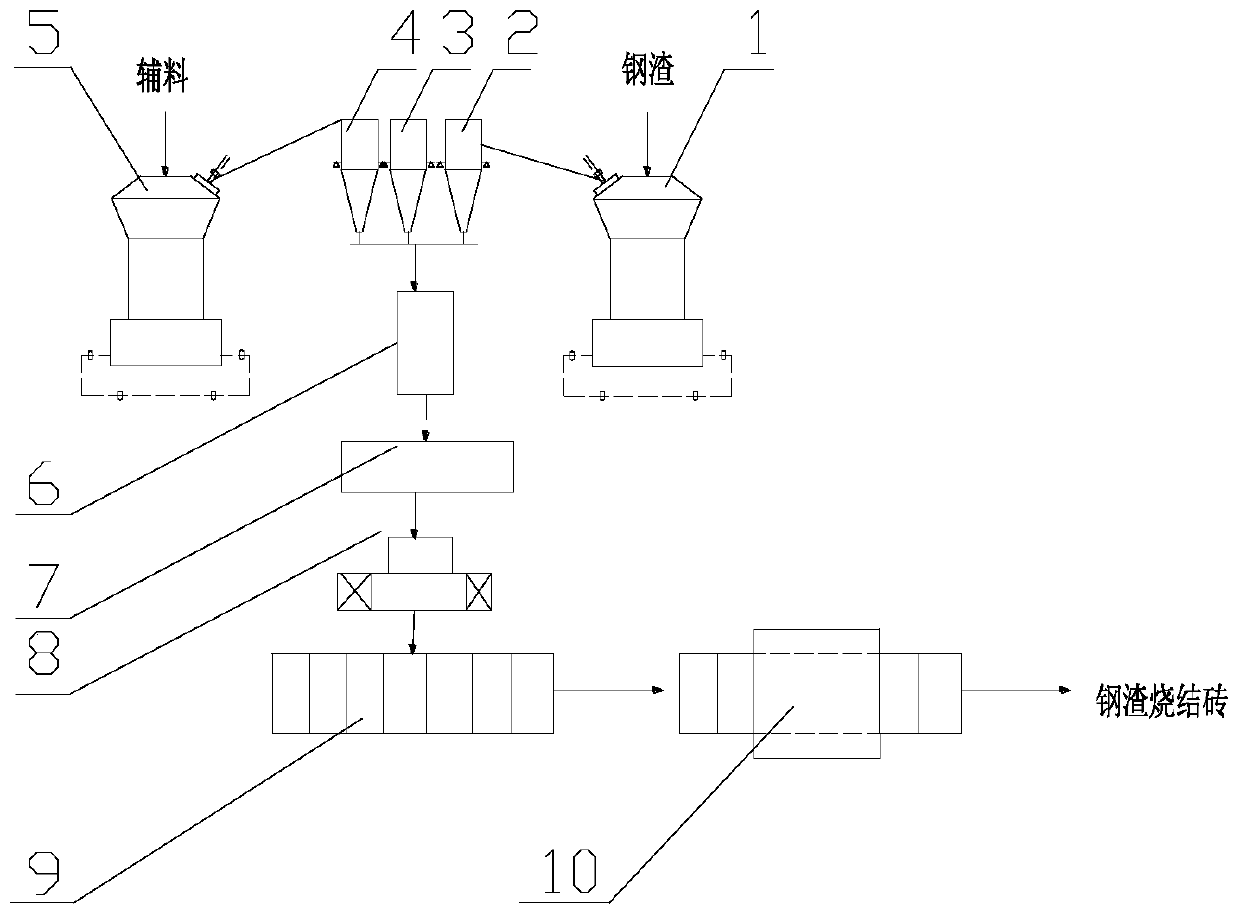

Method and system for producing steel slag sintered brick

ActiveCN110903073AImprove stabilityReduce free calcium oxide contentCeramic materials productionClaywaresBrickSlag

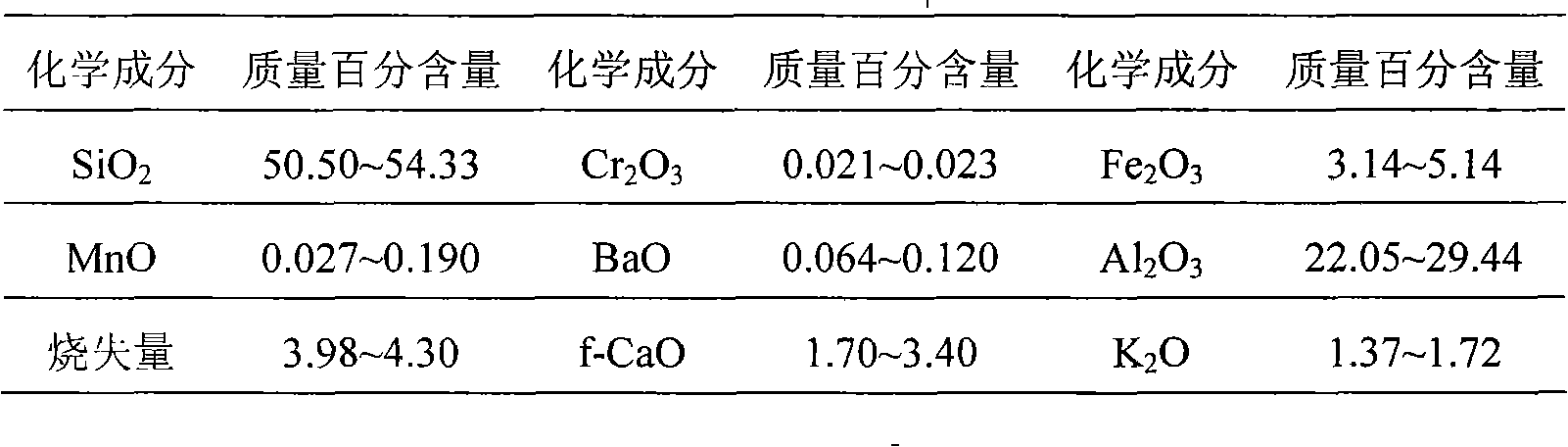

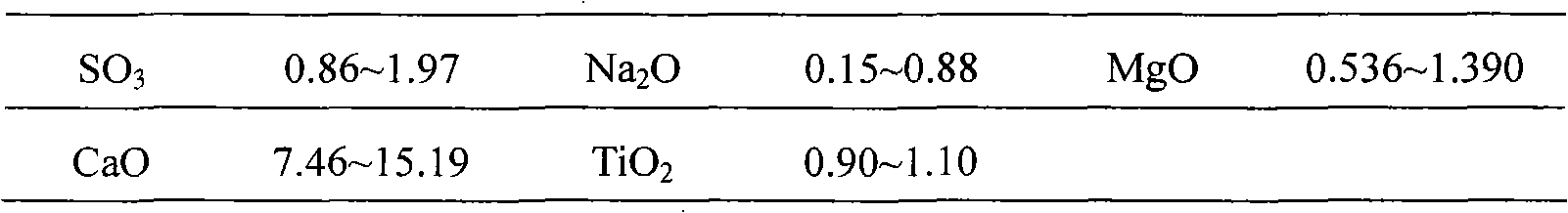

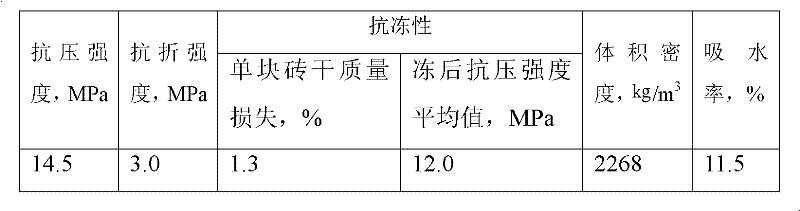

The invention discloses a method and a system for producing a steel slag sintered brick. Steel slag used as a main raw material and one or more industrial solid wastes such as blast furnace slag, clayand waste porcelain, which are used as auxiliary materials, are sintered at a high temperature to produce the sintered brick. The method specifically comprises the following steps: grinding steel slag to 300-500 [mu]m to prepare steel slag powder, and grinding the auxiliary materials to 50-200 [mu]m to prepare auxiliary material powder; mixing the binder and water to prepare a binding slurry; uniformly mixing the steel slag powder, the auxiliary material powder and the binding slurry in a balling chamber according to a certain ratio to prepare raw material balls; and aging the raw material balls in an aging chamber for 0.5-7 days to form a steel slag brick blank, drying the steel slag brick blank, and sintering the steel slag brick blank at 1000-1300 DEG C to obtain the steel slag sintered brick. The content of free calcium oxide in the produced steel slag sintered brick is lower than 0.5 wt%, the stability is good, the problem that the volume stability of steel slag is poor is solved, and large-scale recycling of the steel slag is facilitated.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for recovering phosphorus from urban mud anaerobic digestion solution

ActiveCN101585522BReduce free calcium oxide contentEasy accessPhosphorus compoundsPregnant leach solutionCalcium biphosphate

The invention discloses a method for recovering phosphorus from the urban mud anaerobic digestion solution, comprising: mixing and stirring the fly ash and water with the mass ratio of 1:5-40, standby, producing the leaching liquid; anaerobic digestion of the urban mud, taking the supernatant for acidification to regulate the pH value of the solution for preprocessing; mixing the leaching liquid and the preprocessed digestion liquid according to initial reaction calcium phosphorus molar ratio of 0.5-3.3:1; regulating the reaction pH value to 7.5-11.0, stirring and reacting for 5-120 min; obtaining the calcium phosphate precipitates. The invention subtly utilizes the fly ash leaching solution to provide calcium source and recovers phosphorus in the mode of calcium phosphate, can recover thevaluable products from the mud and the fly ash and relieve the phosphorus load in the subsequent sewage treatment. Because the leaching solution is enriched with hydroxyl ions, the alkali feed quantity is reduced and the recovered products has high purity.

Owner:NANJING FORESTRY UNIV

A method for remelting and reducing modification of massive steel slag

ActiveCN103789467BUnlimited granularityIngredients unlimitedMetal recyclingCement productionGranularityMixed materials

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

White slag recovery treatment method

ActiveCN114380522AReduce alkalinityReduce free calcium oxide contentRecycling and recovery technologiesProcess efficiency improvementSlagFree calcium

The invention provides a white slag recovery treatment method which comprises the following steps: mixing liquid converter slag and liquid white slag, controlling the alkalinity of mixed slag obtained after mixing to be 2.5-4.5, controlling the content of calcium oxide in the mixed slag to be 40-55 wt%, and then solidifying and cooling the liquid mixed slag; the components of the white slag are adjusted through the slag mixing process, so that the alkalinity of the mixed slag is small, the content of free calcium oxide in the mixed slag is small, the content of iron oxide in the mixed slag is increased, and the problems of automatic pulverization and over-serious pulverization of the white slag in the cooling process are solved; the method has the advantages that the defect that fine powder formed after the white slag is pulverized is easy to pollute the environment is overcome, the cooled mixed slag has high adhesiveness, the cooled mixed slag can be used as a building material, wide application of the white slag is obviously promoted, and treatment and recycling application of the white slag are achieved.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

Method for preparing calcium ferroaluminates

InactiveCN102153144BEasy to controlReduce free calcium oxide contentIron compoundsState of artAluminium nitrate

The invention relates to a method for preparing calcium ferroaluminates. The method comprises the following steps: proportionally mixing an aluminium nitrate hydrate, a calcium nitrate hydrate, a ferric nitrate hydrate, hexamethylenetetramine, acetylacetone, deionized water and the like uniformly by a sol-gel method, then stirring the mixture at the temperature of 50-70 DEG C to obtain sol, ageing the sol to form gel, carrying out heat treatment on the gel at the temperature of 750-800 DEG C for 2-4 hours and slowly cooling the gel to the room temperature, thus obtaining the calcium ferroaluminates. Compared with the prior art, the method has the following advantages: the preparation process is simple; the reaction process is easy to control; and the product has high uniformity and purity and can be fired at the temperature lower than the temperature in the traditional methods.

Owner:TONGJI UNIV

Preparation method of cement raw material regulator

PendingCN114685072AReduce coarse particle contentUniform compositionDicarboxylic acidHydrogen peroxide

The invention relates to the field of cement modifier production, in particular to a preparation method of a cement raw material modifier, the cement raw material modifier comprises the following ingredients: main materials and auxiliary materials, the main materials comprise 20-30 parts of unsaturated dicarboxylic acid or anhydride thereof, 40-50 parts of allyl polyoxyethylene ether, and 30-50 parts of unsaturated polyoxyethylene macromonomer; the auxiliary materials comprise the following components in parts by weight: 20-50 parts of dihydrogenated tallow dimethyl ammonium chloride and 10-30 parts of soluble active nano aluminum salt, and the auxiliary materials comprise the following components in parts by weight: 5-10 parts of hydrogen peroxide, 1-5 parts of a reducing agent, 1-5 parts of potassium persulfate, 5-10 parts of metal oxide and 1-5 parts of trace elements. Calcium oxide absorption is accelerated; the liquid phase is promoted to appear in advance, the liquid phase amount is increased, and the liquid phase viscosity during clinker formation is reduced; the raw material burnability is improved, the solid-phase reaction speed is high, and sintering is easy.

Owner:广东誉益新材料有限公司

Method for producing baking-free slag bricks by using steel slag sludge of rotating furnace

ActiveCN101927524BReduce free calcium oxide contentLow iron contentSolid waste managementMixing operation control apparatusBrickSludge

The invention relates to a method for producing baking-free slag bricks by using steel slag sludge of a rotating furnace. The bricks are produced by taking tailings and tailing sludge of the rotating furnace as raw materials, taking slag silicate cement as an auxiliary material, adding a small amount of water into the raw materials and the auxiliary material, stirring the raw materials and the auxiliary material to uniformly mix the raw materials and the auxiliary material, pressing the mixture on a brick press, and naturally curing the pressed mixture. The bricks comprise the following compoennts in part by weight: 20 to 50 parts of tailings of the rotating furnace, 50 to 80 parts of tailing sludge of the rotating furnace and 0 to 5 parts of slag silicate cement. The adding amount of theadded water is 0 to 5 percent of the total weight of the raw materials. The baking-free bricks are produced by taking the tailings and the tailing sludge of the rotating furnace as main raw materials, adding a small amount of slag silicate cement and water into the main raw materials, and pressing the mixture. The raw materials do not need to be treated and can be directly used and the mouled product is naturally cured, so that the energy is saved; and no any equipment is added, so that the problem that the tailings of the rotating furnace and the tailing sludge of the rotating furnace occupyspace and pollute environment is solved by producing the baking-free slag bricks.

Owner:鞍钢绿色资源科技有限公司

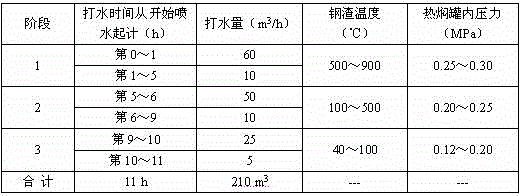

A method for thermally braising steel slag with low content of free calcium oxide

ActiveCN105420429BReduce free calcium oxide contentReduce instabilityRecycling and recovery technologiesProcess efficiency improvementSlagResource utilization

The invention discloses a steel slag heat stewing method capable of reducing the content of free calcium oxide in steel slag. The steel slag heat stewing method comprises the steps that after smelting with a converter is finished, liquid steel slag is poured into a heat stewing tank; in a steel slag pouring process, nitrogen at the pressure range of 0.3-0.7MPa is used to carry out blowing on the steel slag, and large steel slag blocks are broken to be crushed by a mixing method; during steel slag pouring, the steel slag put in the heat stewing tank is subjected to initial water drilling slag wakening with the water drilling quantity of 3-5m<3> / h and the water drilling time of 1-5min / furnace slag, and after the heat stewing tank is loaded with the steel slag to 60-70% of the capacity of the heat stewing tank, the water drilling slag wakening is carried out with the water drilling quantity of 3-5m<3> / h and the water drilling time of 5-20min, so to allow the mean temperature of the steel slag in the heat stewing tank to be 850-1100 degrees; after the slag wakening is finished, a heat stewing tank cover is covered, and heat stewing water drilling is carried out with the water drilling quantity and the water drilling time controlled according to a control table, and after the heat stewing water drilling is finished, the steel slag are taken out of the heat stewing tank. With the adoption of the steel slag heat stewing method, the content of free calcium oxide in the steel slag can be reduced to below 3.0%, and the instability of the steel slag is eliminated, so that the performance indexes of the steel slag can meet the industry standards of cement, building materials and the like, the steel slag can be applied to the fields of steel slag powder production, building material products, project backfill materials, etc., and conditions are created for resource utilization of the steel slag.

Owner:WUKUN STEEL

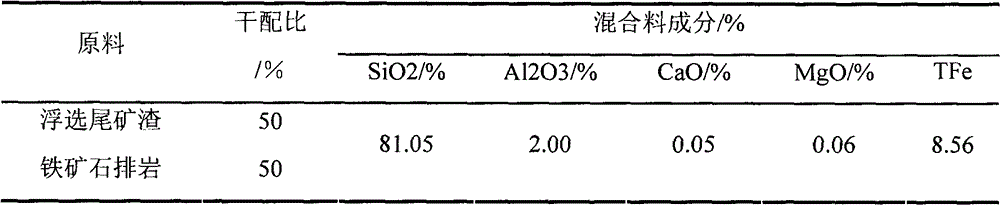

Converter slag stability modifier and application method thereof

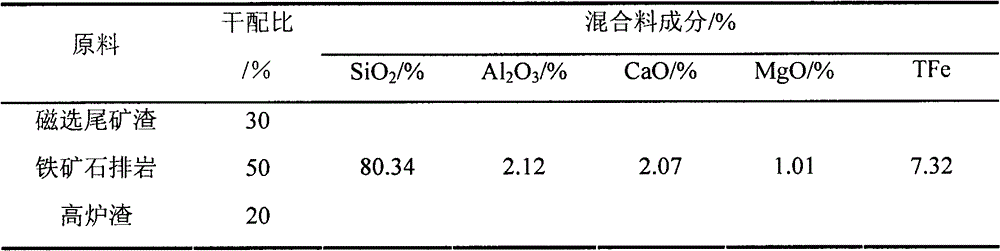

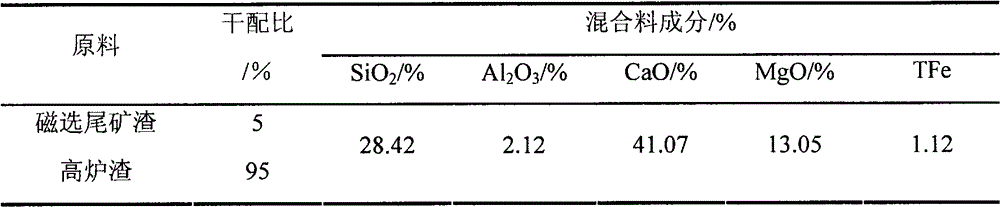

ActiveCN102719574BSimple processing methodStabilizationRecycling and recovery technologiesSlagBlast furnace

The invention provides a converter slag stability modifier and an application method thereof, wherein the modifier is a mixture composed of one or more from the group of iron ore tail slag, an iron ore rock dump and blast furnace slag, characterized in that the ingredients, by weight, are 28%-99% of SiO2, 0.01%-20% of Al2O3, 0.01%-20% of CaO, 0.01%-10% of MgO, and 0.01%-22% of TFe. The application method of the converter slag stability modifier comprises material preparing, material feeding, gas blowing stirring, slag tapping, steel slag graining, etc., making f-CaO <=1.5% and realizing stabilizing treatment for the converter slag.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com