Reduction tempering agent and application thereof in treating steel slag

A conditioner and steel slag technology, applied in the field of building materials, can solve the problems of limited improvement of gelling activity, low comprehensive utilization rate of steel slag, waste of metal iron resources, etc., to promote the formation of gelling active minerals and increase the scale Utilization level, to achieve the effect of non-waste utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

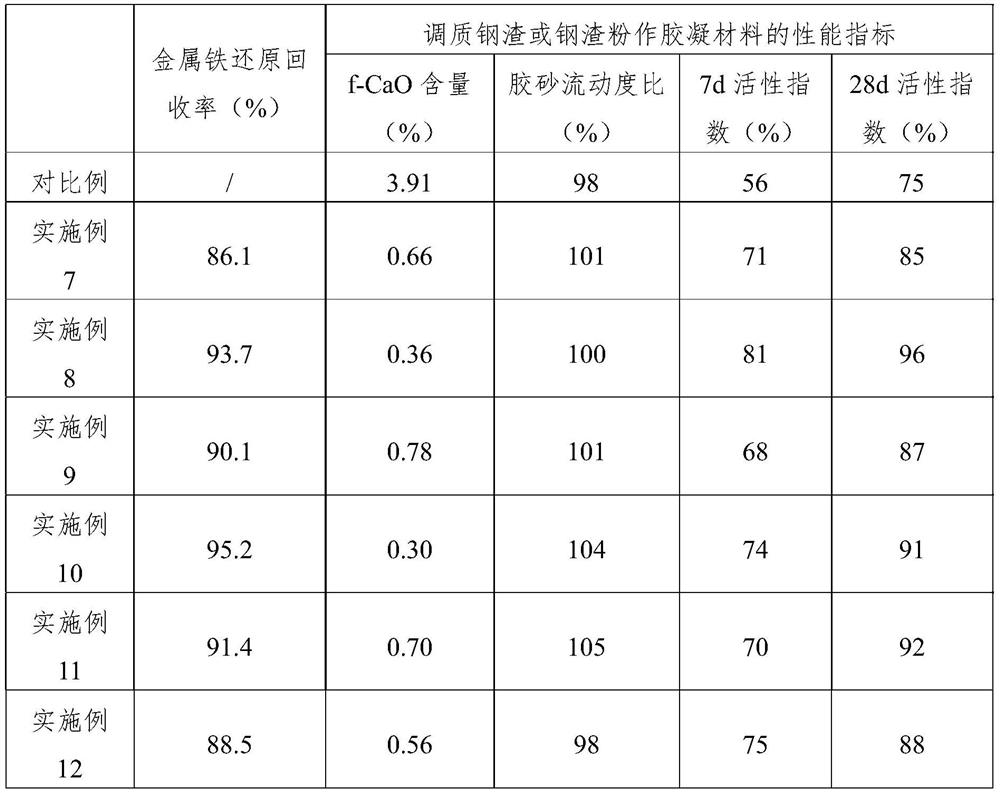

Examples

Embodiment 1

[0049] This embodiment provides a reducing conditioner, which includes the following components by weight: 40 parts of coal powder, 40 parts of fluorite, and 20 parts of desulfurized gypsum;

[0050] The specific surface area of the reducing conditioner is 300±10m 2 / kg.

Embodiment 2

[0052] This embodiment provides a reducing conditioner, which includes the following components in parts by weight: 80 parts of carbon powder, 10 parts of fluorite, 5 parts of desulfurized gypsum, and 5 parts of barite;

[0053] The specific surface area of the reducing conditioner is 300±10m 2 / kg.

Embodiment 3

[0055] This embodiment provides a reducing conditioner, which includes the following components in parts by weight: 65 parts of carbon powder, 5 parts of fluorite, and 30 parts of desulfurized gypsum;

[0056] The specific surface area of the reducing conditioner is 300±10m 2 / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com