Patents

Literature

186results about How to "Reduce pitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for partial stripping of diffusion aluminide coatings from metal substrates, and related compositions

InactiveUS6758914B2Effective levelingReduced activityMolten spray coatingLighting and heating apparatusSuperalloyAluminide

A method for selectively removing portions of a diffusion aluminide coating from a substrate is described. The coating is treated with an aqueous composition based on an acid having the formula HxZrF6, wherein x is an exemplary 2. The coating being removed is usually a noble metal-aluminide coating, and the substrate is typically a superalloy. Related compositions are also described.

Owner:GENERAL ELECTRIC CO

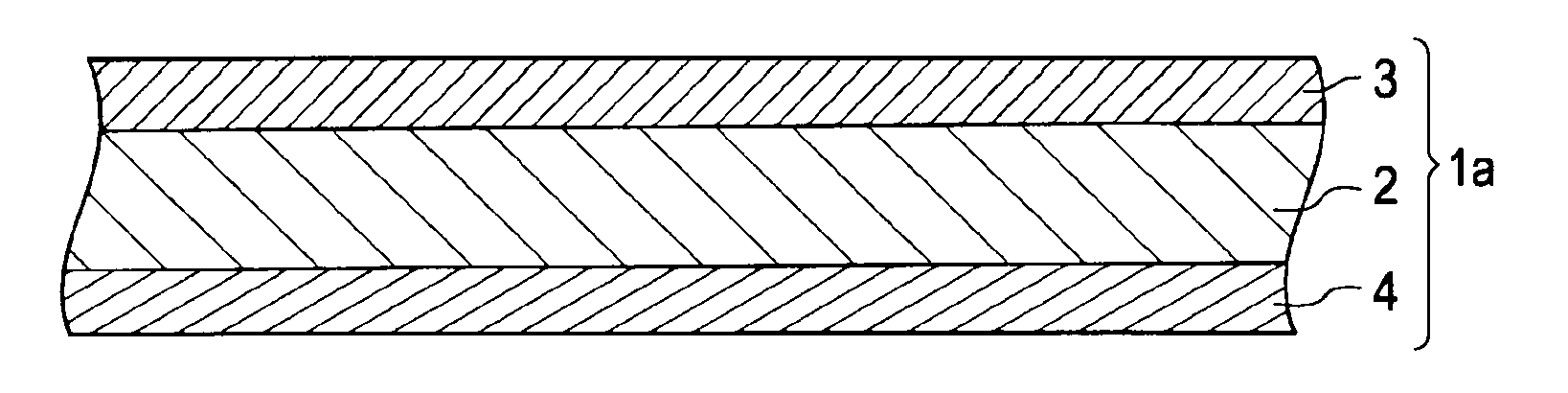

Aluminum alloy clad sheet for heat exchanger

InactiveUS20100183897A1Prevent deterioration in brazeabilityInhibit deteriorationWelding/cutting media/materialsCoatingsImpurityMaterials science

An aluminum alloy clad sheet for heat exchangers includes a core layer, a sacrificial layer disposed on one side of the core layer, and a brazing layer of an Al—Si alloy disposed on the other side of the core layer, wherein the core layer contains Si: 0.15% to 1.6% by mass, Mn: 0.3% to 2.0% by mass, Cu: 0.1% to 1.0% by mass, Ti: 0.02% to 0.30% by mass, and the remainder of Al and incidental impurities, and the sacrificial layer contains Zn: 4.0% to 10.0% by mass, Cr: 0.01% to 0.5% by mass, and the remainder of Al and incidental impurities.

Owner:KOBE STEEL LTD

Degradable magnesium alloy angiocarpy bracket with medicine and preparation method thereof

The present invention relates to technical field of biological material, and is especially suitable for surface modification field of biological medical material. Particularly the invention provides a medicine-taking degradable magnesium alloy cardiovascular bracket and a preparing method thereof. The aim of the invention is to reduce the initial degrading speed of magnesium alloy in biosome and carry therapeutic medicine on the surface of magnesium bracket thereby guaranteeing the mechanical performance of magnesium alloy bracket in vivo and better restraining the hyperplasia of newborn tunica interna. A fluoro-containing transition film is prepared on the surface of magnesium alloy bracket, and a medicine-carrying layer is prepared on the outer layer of magnesium alloy bracket. A protecting layer is the fluoro-containing transition film. The fluoro-containing transition film has self-concrescence capability in the degradation process of magnesium alloy and can effectively reduce the in-vivo degradation velocity of magnesium alloy bracket. The surface of degradable magnesium alloy cardiovascular bracket is smooth and is not easily generated with surface cracking and breaking-off. The medicine-taking layer is composed of medicine carrier polymer or protein and therapeutic medicine. The medicine-taking layer can release therapeutic medicine, reduce the generation rate of stenosis after the implantation of bracket and has a control function to the degradation velocity of magnesium alloy bracket.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

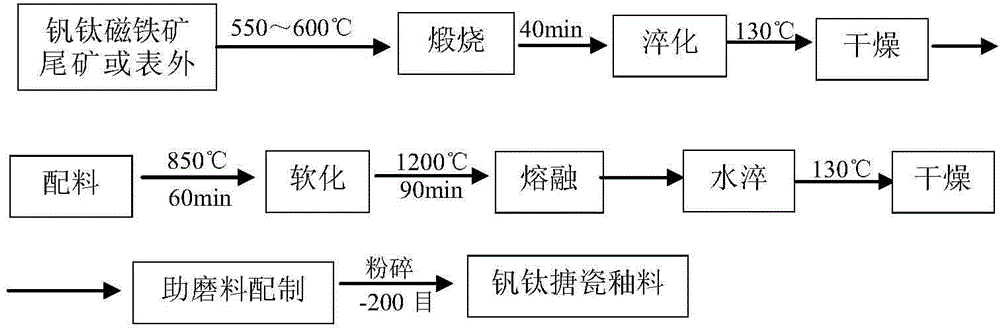

Vanadium-titanium enamel glaze material, and preparation method thereof

The invention belongs to the technical field of enamel material, and specifically relates to a vanadium-titanium enamel glaze material, and a preparation method thereof. The preparation method is used for solving technical problems that cost of a conventional vanadium-titanium enamel glaze material is high, glossiness of enamel glaze obtained via sintering is not high enough, fishscaling is observed, and acid and alkali resistance is not high enough. The vanadium-titanium enamel glaze material is prepared from, by mass, 22 to 28 parts of pretreated vanadium-titanium magnetite titanium separation tailing or vanadium-titanium boundary ore, 20 to 22 parts of feldspar powder, 5 to 8 parts of quartz sand, 24 to 26 parts of borax, 1.5 to 2 parts of sodium nitrate, 3.5 to 5.5 parts of lithium carbonate, 5 to 7 parts of fluorite powder, 0.1 to 0.3 part of sodium fluosilicate, 3 to 5 parts of cryolite, 2 to 4 parts of limestone, 3 to 4 parts of cobalt nitrate, 1 to 2 parts of nickel nitrate, 2 to 3 parts of sodium vanadate, and 1 to 2 parts of antimony oxide. Firm combination of the vanadium-titanium enamel glaze material with carbon steel billet can be realized; acid and alkali resistance is higher than that stipulated by national standard; and the vanadium-titanium enamel glaze material can be used for a plurality of matrixes such as hot-rolled carbon steel and cast iron.

Owner:PANZHIHUA UNIV

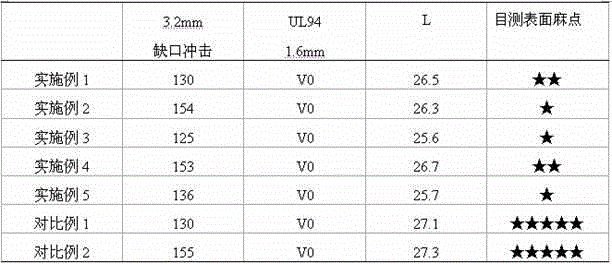

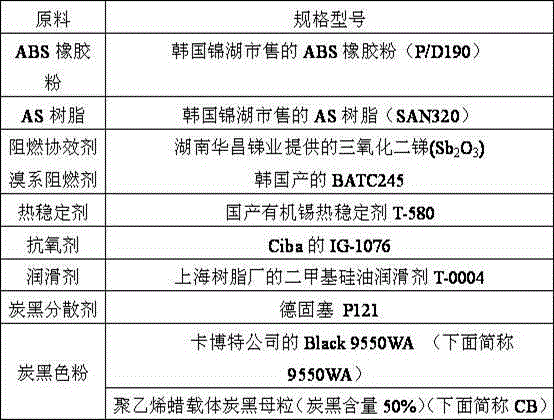

Flame-retardant acrylonitrile butadiene styrene (ABS) resin with excellent surface glossiness and high blackness and preparation method of ABS resin

The invention relates to a flame-retardant acrylonitrile butadiene styrene (ABS) resin with excellent surface glossiness and high blackness. The ABS resin comprises the following components in parts by weight: 20-60 parts of ABS rubber powder, 40-80 parts of AS (Acrylonitrile-Styrene) resin, 2-6 parts of flame-retardant synergist, 5-25 parts of brominated flame retardant, 0.1-1 part of heat stabilizer, 0.1-1 part of antioxidant, 0.1-1 part of lubricating agent, 0.1-2 parts of carbon black dispersing agent and 0.1-5 parts of carbon black powder, wherein the carbon black dispersing agent is a block polymerization amphipathic siloxane compound of which one end is provided with a lipophilic group and of which the other end is provided with a hydrophilic group; the carbon black powder is pure carbon black or carbon black master-batches with polyolefin or ethylene vinyl acetate copolymer as a carrier. The invention also provides a method for preparing the flame-retardant ABS resin. The flame-retardant ABS resin has extremely high surface glossiness and balanced toughness and fluidity and is particularly suitable for household appliance industry with the requirements of high glossiness and flame retardant property.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Mirror polishing method for polishing surface of lens sheet mould main body

The invention discloses a mirror polishing method for polishing a surface of a lens sheet mould main body. The mirror polishing method comprises the following steps: sanding and priming the surface of the lens sheet mould main body; smoothening sand marks on all faces of the lens sheet mould main body; and grinding and cleaning the surface of the mould main body. By polishing in a gradual way of rough polishing first and then fine polishing, the surface of the lens sheet moulding mould main body meets requirements of a mirror surface, thus providing a firm condition for improving the quality of a downstream lens sheet.

Owner:陈林辉

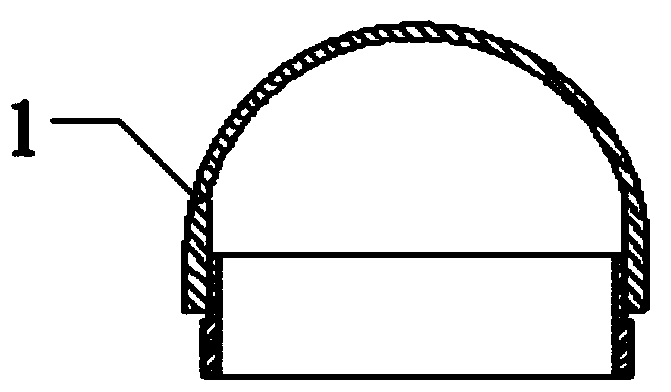

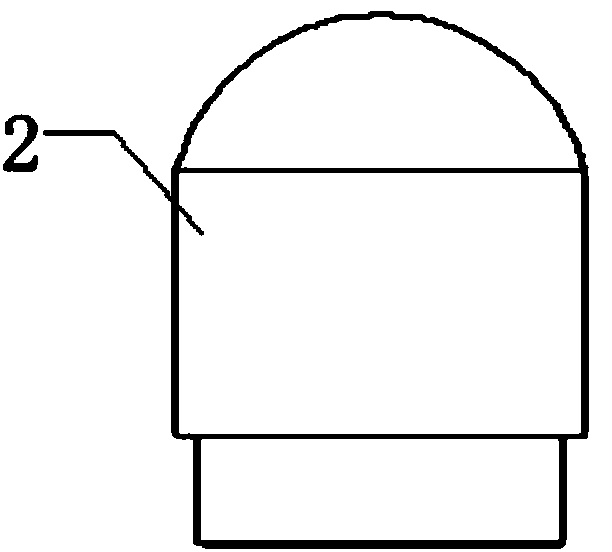

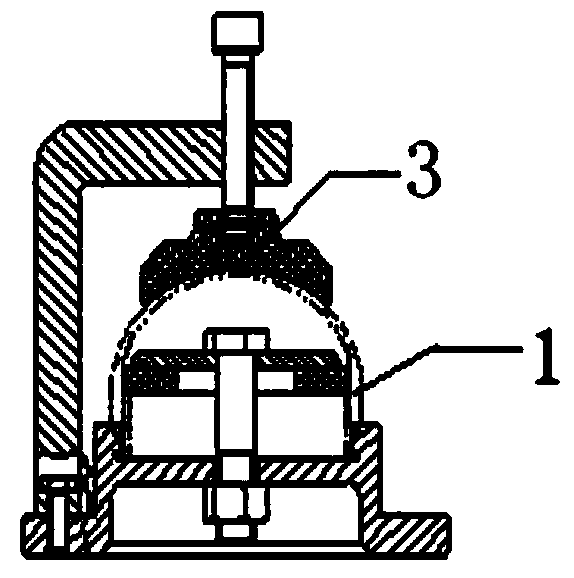

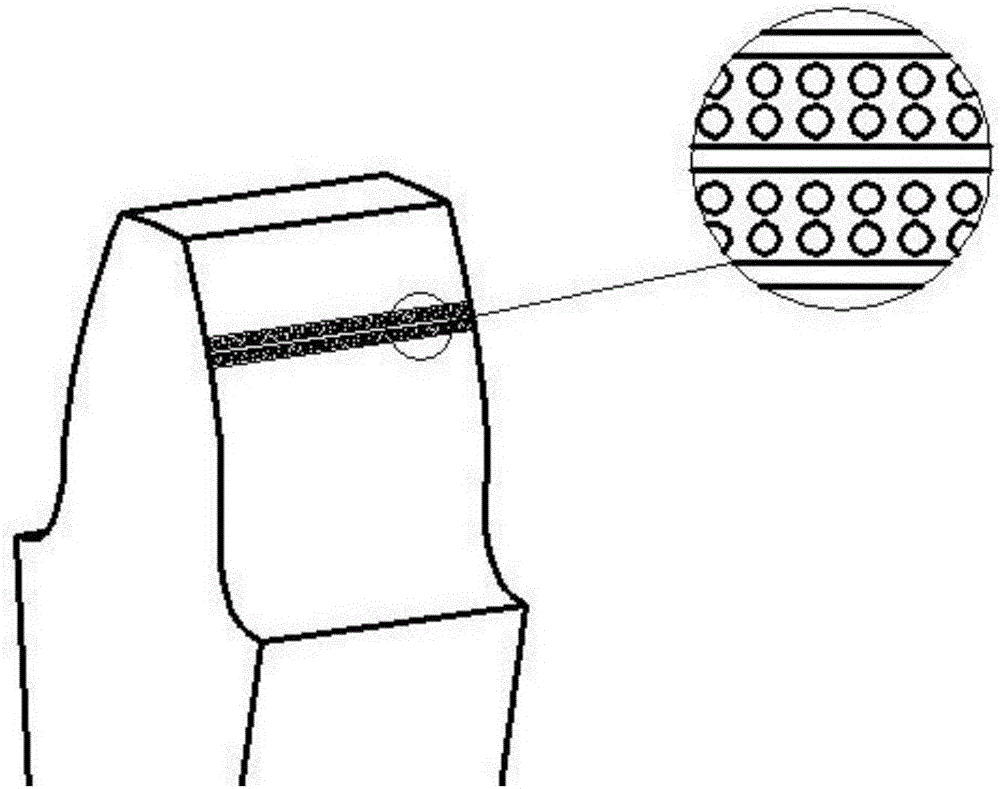

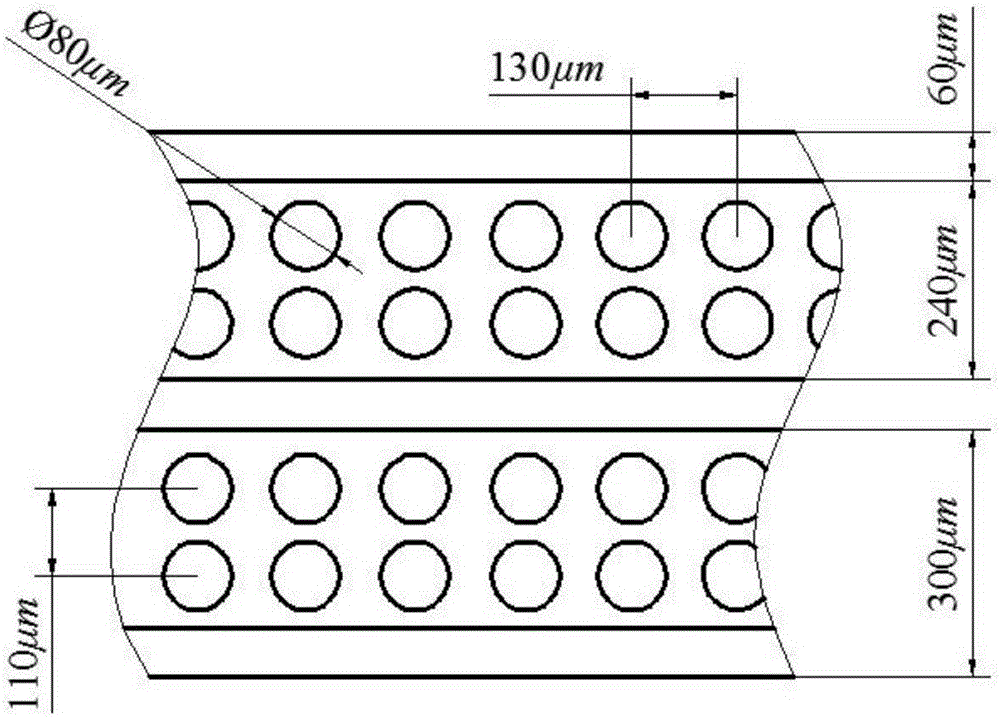

Manufacturing method of miniature and thin-walled composite ceramic wave-transparent antenna housing

ActiveCN104393402AGuarantee processing qualityReduce pittingAntenna adaptation in movable bodiesRadiating element housingsYarnComposite ceramic

The invention discloses a manufacturing method of a miniature and thin-walled composite ceramic wave-transparent antenna housing. The manufacturing method includes the following steps that: a corresponding braiding core model is designed according to size requirements of a housing body; quartz fiber yarns are adopted as raw materials so as to be attached to and braided on the braiding core model, so that required housing body braided fabric can be obtained; the housing body braided fabric is boiled in water, and then is socked in acid liquid, and finally is socked and composited in a container filled with a silica solution, and therefore, a housing body blank can be obtained; and a bonding part of a connecting ring and the housing body is processed, so that the miniature and thin-walled composite ceramic wave-transparent antenna housing can be obtained. According to the manufacturing method of the invention, mechanical processing is divided into coarse processing and fine processing, and therefore, processing quality of the surface of the housing body can be effectively ensured, and pits on the surface of the housing body are decreased significantly, and at the same time, the uniformity of the materials of the housing body can be improved; after mechanical processing every time, high temperature heat treatment is performed on the housing body blank, and therefore, organic impurities such as oil contamination by which the housing body blank is contaminated in a machining process can be effectively removed, and the performance of a product can be effectively ensured.

Owner:湖北三江航天江北机械工程有限公司

Electron beam welding method for dense rectangular ring welding lines of outer ring face

ActiveCN109202254ASuitable for mass productionGuarantee welding quality requirementsElectron beam welding apparatusButt jointLap joint

The invention relates to an electron beam welding method for dense rectangular ring welding lines of an outer ring face. According to the electron beam welding method for the dense rectangular ring welding lines of the outer ring face, a thickness-unequal butt joint form increasing the local thickness of the welding part head portion is designed, and a beam flow guiding welding along long edges and lap-joint and step-attenuating beam flow closing welding method is adopted, so that the amount of molten metal is increased, the welding line molding quality is improved, and the process stability and margin are improved; misplaced and lapped U-shaped protective structures are designed inside an outer ring, and injuries by burning on a shaft rod and an inner ring structure are avoided; and a symmetrical welding method is adopted, the welding sequence is designed, a grouped multiple welding manner is adopted, the accumulation effect of dense welding-line welding heat input and stress deformation is reduced, influence of the dense welding-line stress deformation on welding gaps, order difference and the like is reduced, the welding quantity is improved, control of welding deformation and structural size accuracy is facilitated, and the welding finished product rate is increased.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

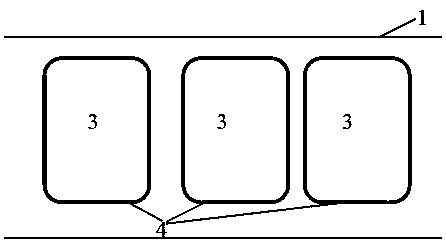

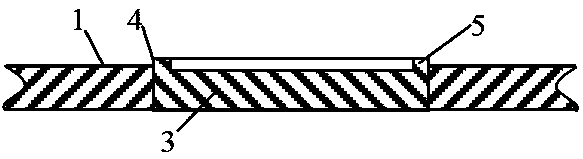

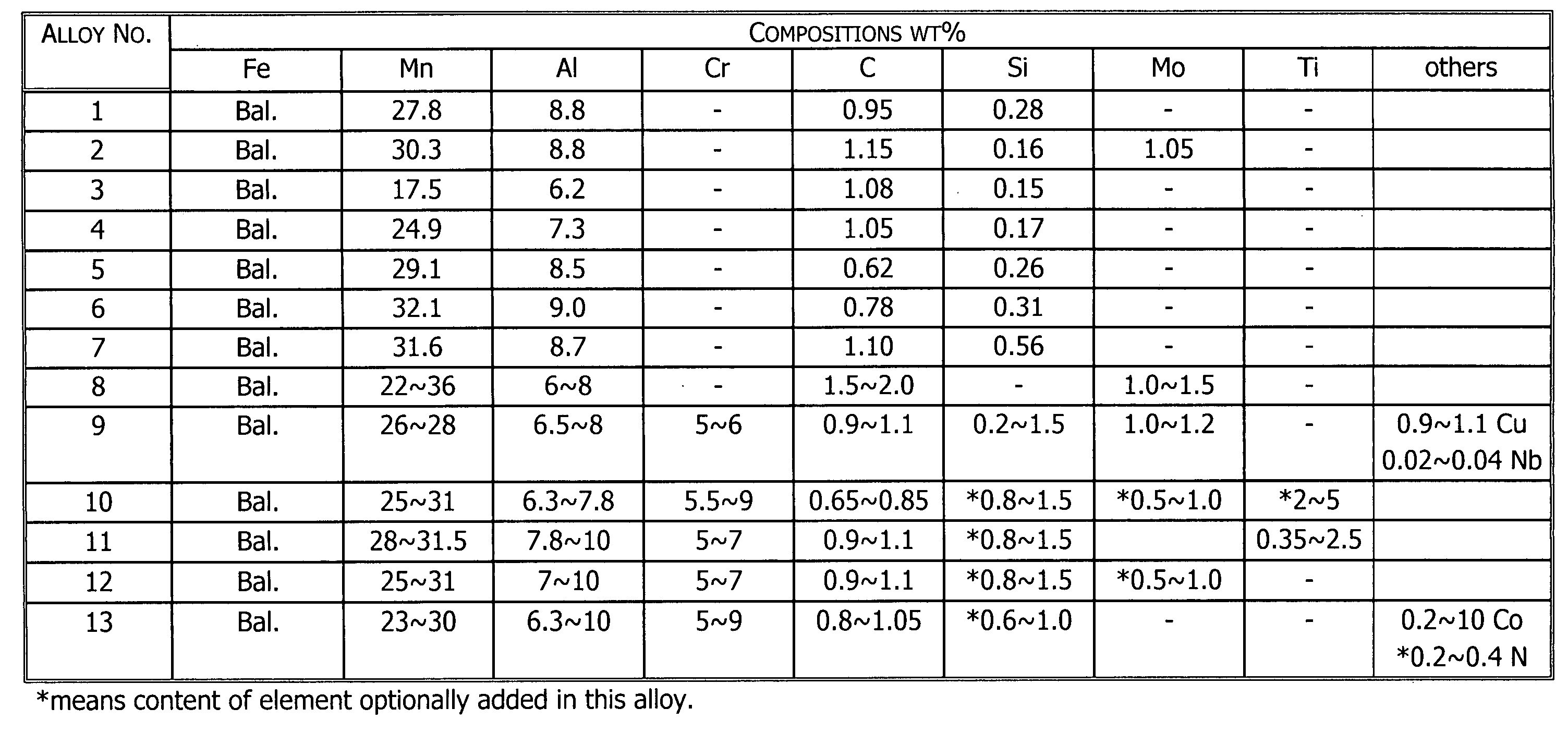

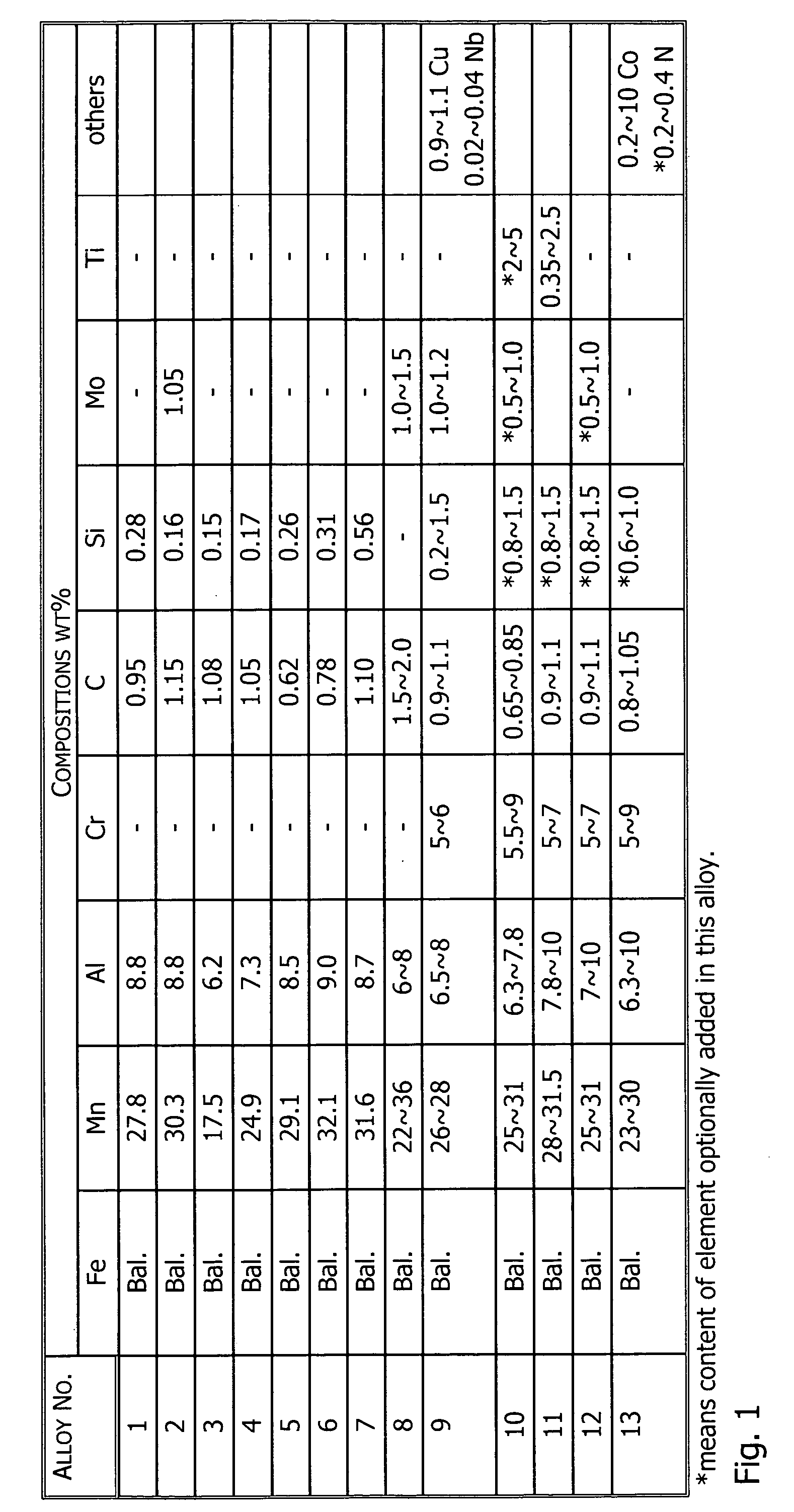

High strength and high toughness alloy with low density and the method of making

InactiveUS20070209738A1Improve ductilityHigh strengthIncreasing energy efficiencyElectric furnaceManganeseVolumetric Mass Density

The present invention relates to a high strength and high toughness alloy with a low density and the method of making thereof. The alloy essentially comprises 15 to 33 wt % of manganese, 6 to 10 wt % of aluminum, 0.6 to 1.2 wt % of carbon, 0.1 to 1.0 wt % of silicon, and the balance of iron. The alloy has excellent properties of a density of 6.6 to 6.9 g / cm3, an elongation of 25 to 70%, and a tensile strength of 100 to 190 ksi. In particularly, and the alloy is useful for golf club heads with excellent properties. Further, the use of the alloy reduces pits and defects generated during the electroplating process of the heads. Therefore, the defect rate of the product is remarkably decreased so that the cost is reduced.

Owner:NAT CHIAO TUNG UNIV

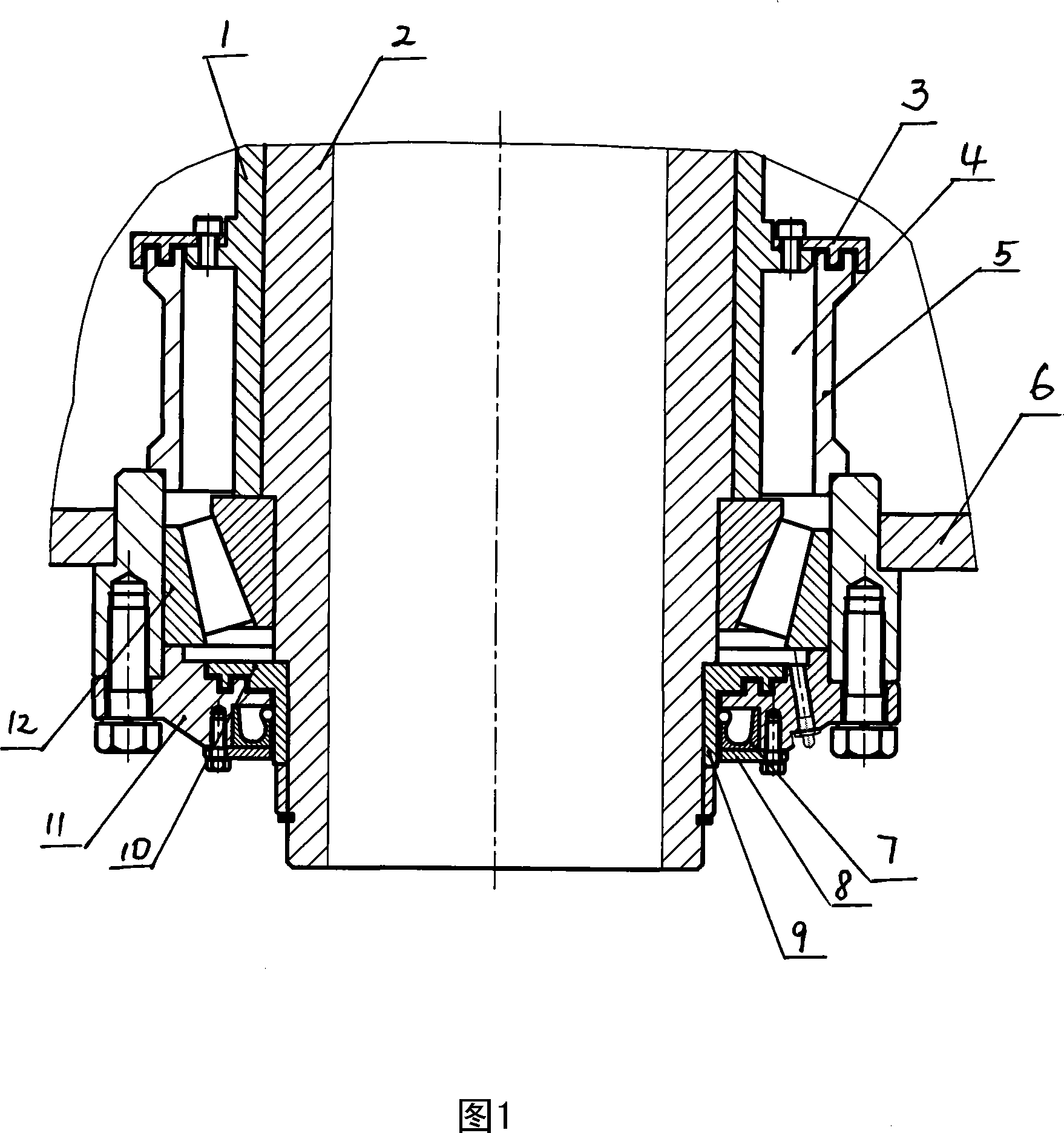

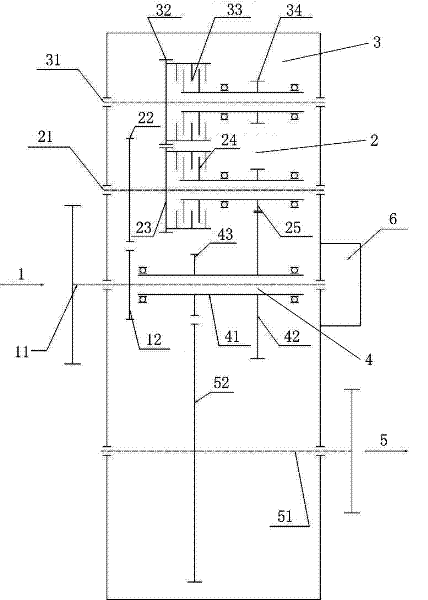

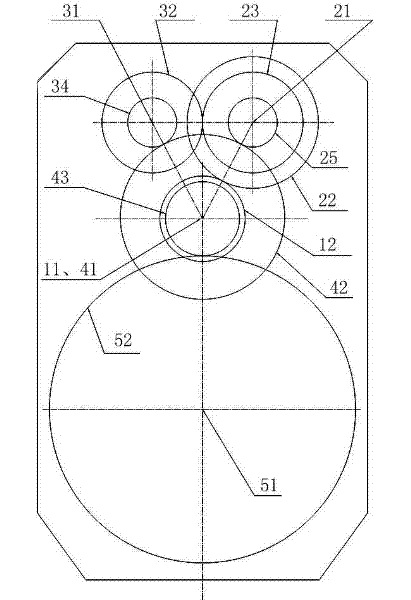

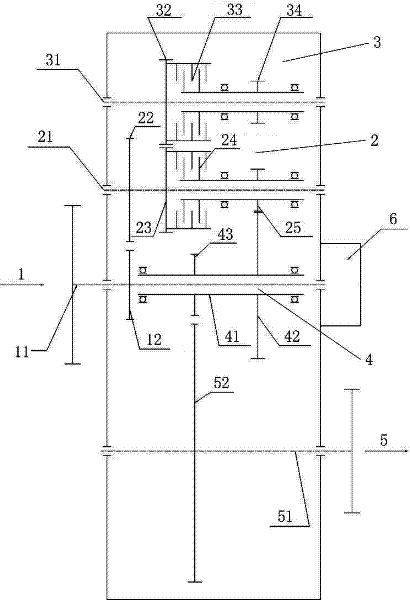

Full hydraulic rock core drilling machine unit head

InactiveCN101105112APrevent flowExtended service lifeConstructionsRotary drillingHydraulic motorGear drive

A power head for all-hydraulic operated drill is driven by double hydraulic motor and adopts the mode of power input, double-geared drive, hydraulic stepless speed regulation, hydraulic chuck clamping and long-travel feeding. A middle and lower labyrinth seals and a skeleton oil seal form a three-layer sealing device of a main shaft of the drill power head. The drill is lubricated by using mixed lubricating grease and thin oil. The middle part realizes labyrinth sealing by matching a supporting sleeve and a rotary plate, so as to provide a lower end bearing sufficient accumulated grease and heat dissipation space, guarantee the reliable lubrication and heat dissipation of the bearing, and increase secondary oil splashing and splash lubrication effect. The lower part realizes labyrinth sealing by matching an oil removal driving disk and an end cover, so as to effectively preserve and retain lubricating grease in the lower bearing box. The main shaft operates at high speed to cause temperature rising, and when the lubricating grease is diluted, its loss can be effectively prevented. The lower skeleton is oil sealed to prevent backflow and splashing of the drilling fluid, and further prevent the outer discharge of the lubricating grease when being diluted to take secondary protection effect.

Owner:H H DRILL TECH DRILLING MACHINERY CO LTD

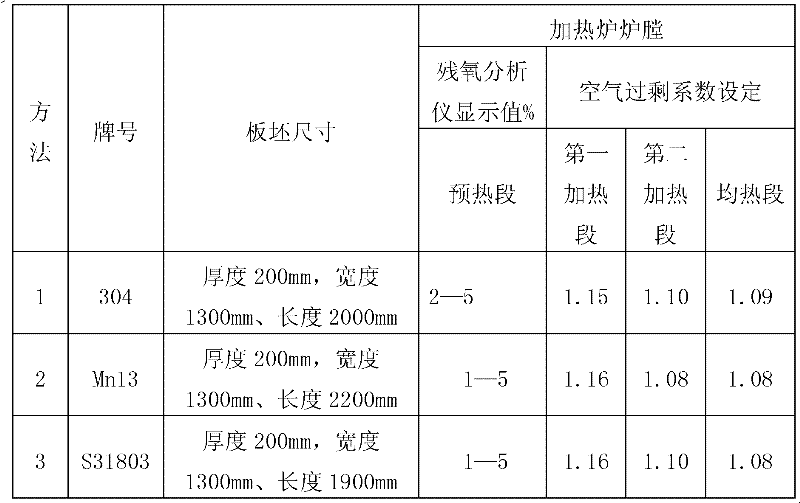

Heating method of weak, micro-oxidation and oxidation combustion for ferrous metal steel slab

InactiveCN102634651ARealize the effect of incomplete combustion + complete combustionTake advantage ofFurnace typesHeat treatment process controlHearthHeating furnace

A heating method of weak, micro-oxidation and oxidation combustion for ferrous metal steel slabs used in industrial furnaces with natural gas as a fuel. Excess air coefficients of a first heating section, a second heating section, and a soaking section of a heating furnace are set; in order to allow a display value of a residual oxygen analyzer to be within 1-4.5%, the excess air coefficients are set to be 1.1-1.2 for the first heating section, 0.96-0.99 for the second heating section, and 0.95-0.98 for the soaking section. The effect is realized that the natural gas combustion in the heating furnace hearth is incomplete combustion and complete combustion. The effect of complete combustion is realized in the first heating section of the heating furnace hearth, and the effect of incomplete combustion is realized in the second heating section and the soaking section. According to the invention, the atmosphere has a characteristic of micro-oxidizability after combustion in the heating furnace; the heating process of ferrous metal steel slabs in the second heating section and the soaking section is reduced; and less oxide scale is generated on the surface; the problem of steel plate surface depression caused by heating factors is reduced; energy saving is realized; the thickness of the oxide scale on the slab surface in the heating furnace hearth is reduced; and the defect of steel plate surface depression caused by heating factors is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Extrusion deformation method of aluminium alloy profile

InactiveCN102059266AImprove toughnessReduce pittingExtrusion control devices5005 aluminium alloyExtrusion

The invention relates to an extrusion deformation method of an aluminium alloy profile, comprising the following steps of: heating an aluminium alloy blank to be 100-200 DEG C, keeping the temperature, preheating an extrusion mold to ensure that the temperature of the extrusion mold is higher than the surface temperature of the aluminium alloy blank by 50-150 DEG C, then placing the aluminium alloy blank into the extrusion mold, and extruding under the conditions that the extrusion ratio is 8-42, and the speed of an extrusion mold punch head is 20-30mm.s<-1>. The extrusion deformation method realizes larger improvement of comprehensive performances of the extruded aluminium alloy such as the tenacity and the like, has the advantages of simple process, low cost, low energy consumption, high production efficiency and great improvement of tenacity of the aluminium alloy, and can be used for producing profiles such as bar materials, wire materials, plate materials and pipe materials and the like made of aluminium alloy.

Owner:张文丛

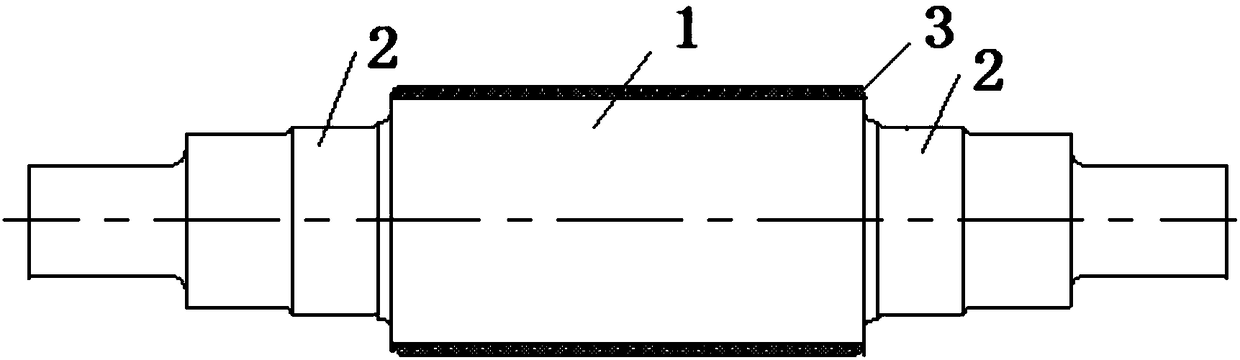

Bearing roller of 4200 mm or above wide and thick plate rolling mill and manufacturing process of bearing roller

ActiveCN108277443AReduced risk of fatigue spallingHigh hardnessRollsMetal rolling arrangementsImpurityChromium

The invention relates to a bearing roller of a 4200 mm or above wide and thick plate rolling mill and a manufacturing process of the bearing roller, and belongs to the technical field of forging. Thebearing roller comprises, by mass percent, 0.50 to 0.65% of C, 0.17 to 0.50% of Si, 0.80 to 2.0% of Mn, 0.30 to 0.70% of Ni, 1.60 to 2.5% of Cr, 0.30 to 1.00% of Mo, 0.10 to 0.35% of V, not larger than 0.020% of P, not larger than 0.010% of S, not larger than 0.15% of Cu, not large than 1.0 ppm of H, and the balance iron and inevitable impurities. The carton content of a new material of the super-huge type forged steel bearing roller is low, alloy elements of chromium, nickel and vanadium are added, the microstructure comprises bainite and pearlite, the strength and toughness of the material are improved, the solidification segregation of a large steel ingot is reduced, the comprehensive performance is good, and the service life is long.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Reverse temperature field extrusion process for producing microcrystal magnesium alloy

ActiveCN1672828AImprove plasticityBig pitExtrusion control devicesTemperature differenceMagnesium alloy

The reverse temperature field extrusion process as improved extrusion process for producing microcrystal magnesium alloy includes the following steps: preheating extrusion mold, setting magnesium alloy blank into the extrusion mold, controlling the mold temperature the same as or 30-50 deg.c higher than that of blank surface and the temperature difference between the core of the blank and the surface of the blank in 20-400 deg.c, and extrusion at extrusion ratio of 2-64 and extrusion ram speed of 20-30 mm / s. Extruding magnesium alloy in the said reverse temperature field and at extrusion ratio of 4-6 can fine the crystal particle to below 10 micron, or below 5 micron optimally. Meanwhile, the extruded magnesium alloy has obvious raised plasticity and unit extension over 20 %. The present invention may be used in producing magnesium alloy rod, plate, section bar and pipe.

Owner:HARBIN INST OF TECH

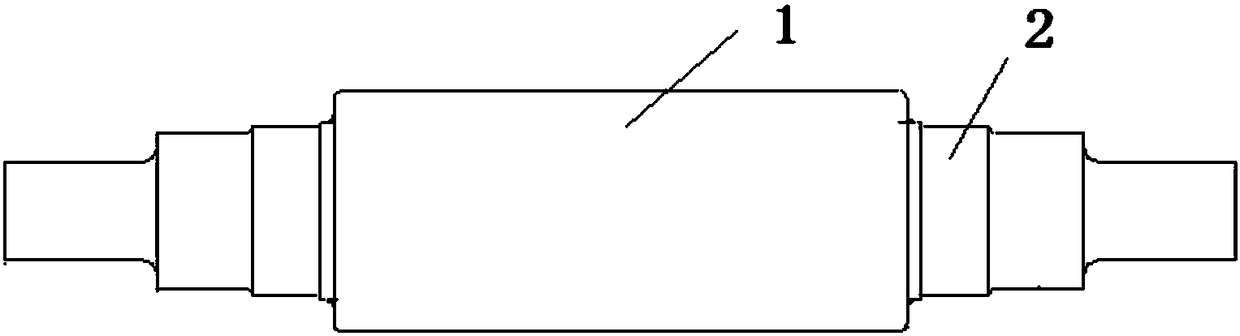

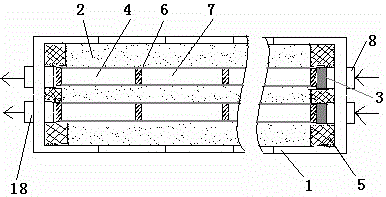

Device for prolonging the lifetime of resistance spot welding electrode

InactiveCN101081456AExtend your lifeReduce alloyingResistance electrode holdersElectrical resistance and conductanceFlywheel

The present invention relates to one kind of life increasing device for resistance spot welding electrode, and belongs to the field of resistance spot welding technology. The device includes one upper movable rack, one upper rack connected movably to the upper movable rack, one lower movable rack, one lower rack connected movably to the lower movable rack, one upper main shaft, one lower main shaft, springs separately between one main shaft and one rack, one arced upper flywheel, one arced lower flywheel, one upper ratchet wheel mechanism, one lower ratchet wheel mechanism, copper tabs on the flywheels, one upper link rod mechanism, one lower link rod mechanism, one upper hook mechanism and one lower hook mechanism. It has the advantages of reduced alloying, less wear, less pitting corrosion, less heat fatigue and long electrode life.

Owner:TIANJIN UNIV

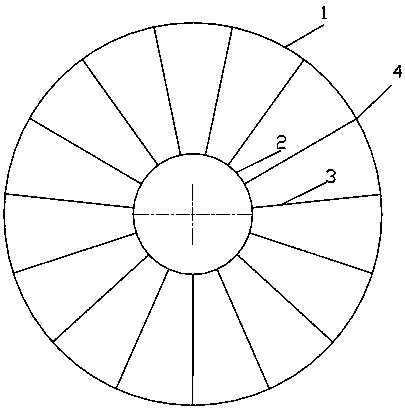

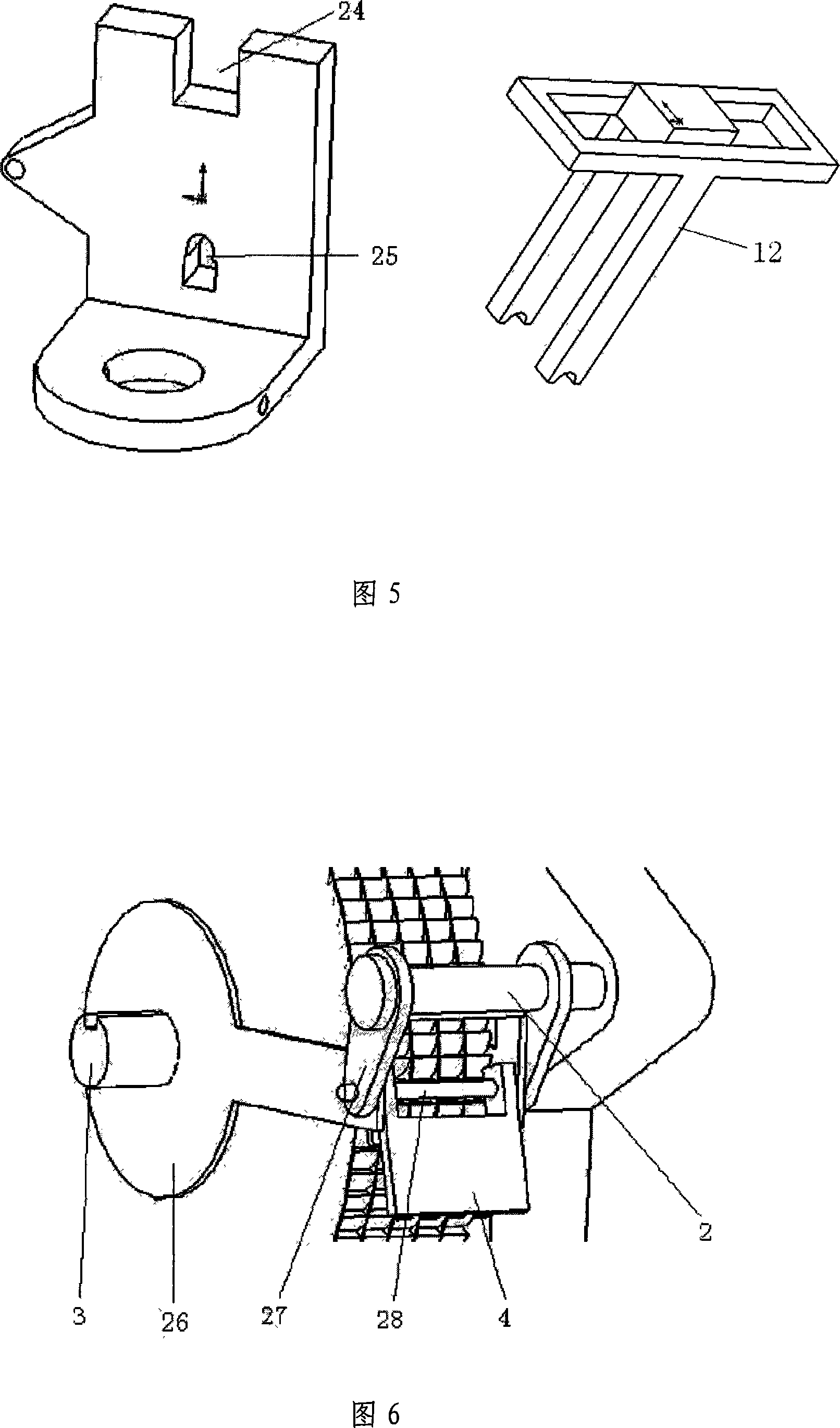

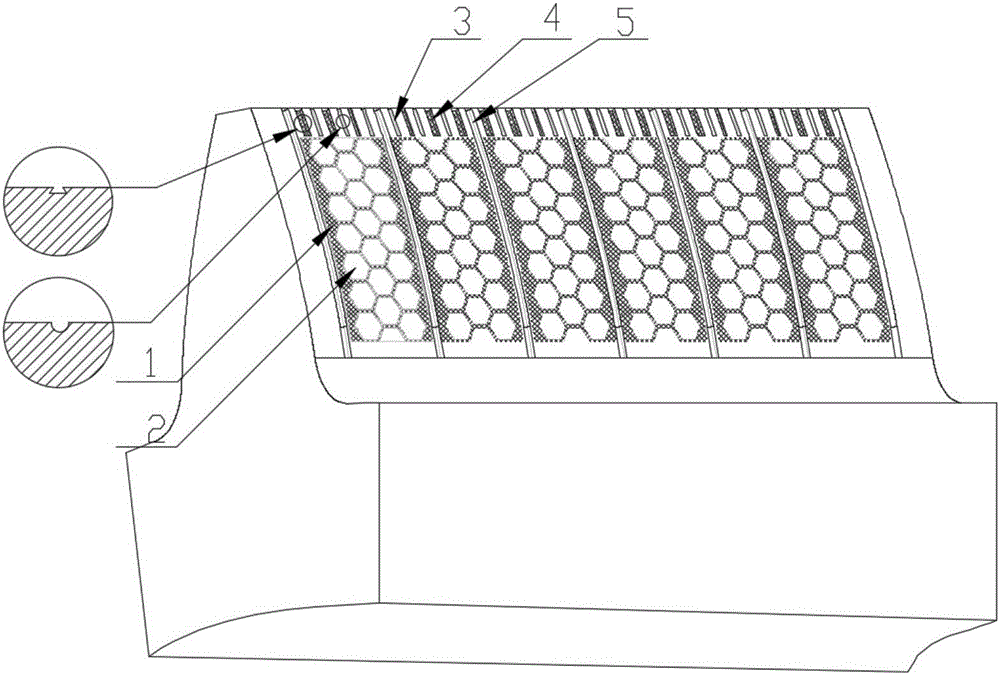

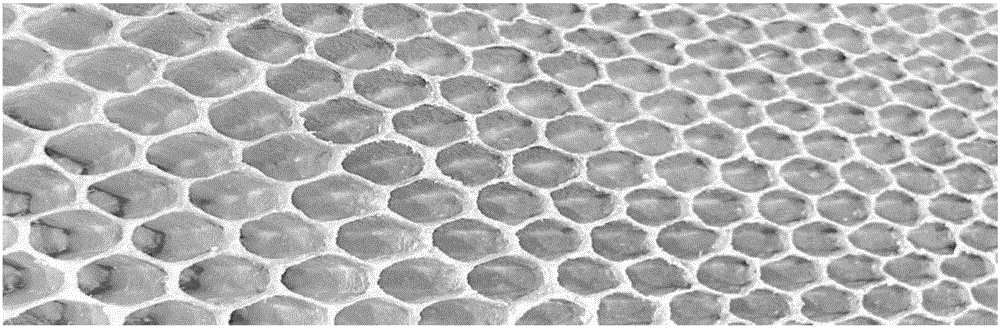

Honeycomb-shaped polygonal self-lubricating gear

InactiveCN106763649AReduce usageGuaranteed StrengthPortable liftingGearing elementsHoneycombEngineering

The invention relates to a honeycomb-shaped polygonal self-lubricating gear. Honeycomb-shaped grooves, strip-shaped grooves, middle strip-shaped chip grooves and top strip-shaped chip grooves are processed in a tooth surface of the honeycomb-shaped polygonal self-lubricating gear; the honeycomb-shaped grooves are positioned in the middle of the tooth surface, and are filled with self-lubricating materials; the strip-shaped grooves are positioned in the top of the tooth surface, and are filled with the self-lubricating materials; and the middle strip-shaped chip grooves and the top strip-shaped chip grooves separately penetrate through the whole tooth surface and are formed in the top of the tooth surface, are distributed in a spaced mode, and are beneficial for chip removal. The invention discloses the honeycomb-shaped polygonal self-lubricating gear which is inspired by a honeycomb shape based on the bionic idea; compared with an existing gear, the honeycomb-shaped polygonal self-lubricating gear has self-lubricating characteristics, does not need to additionally add media such as lubricating oil and lubricating grease, enriches a gear lubricating mode, and can meet normal operation when the gear is under extreme working conditions such as an oil-free working condition and an oil-lack working condition.

Owner:HEFEI UNIV OF TECH

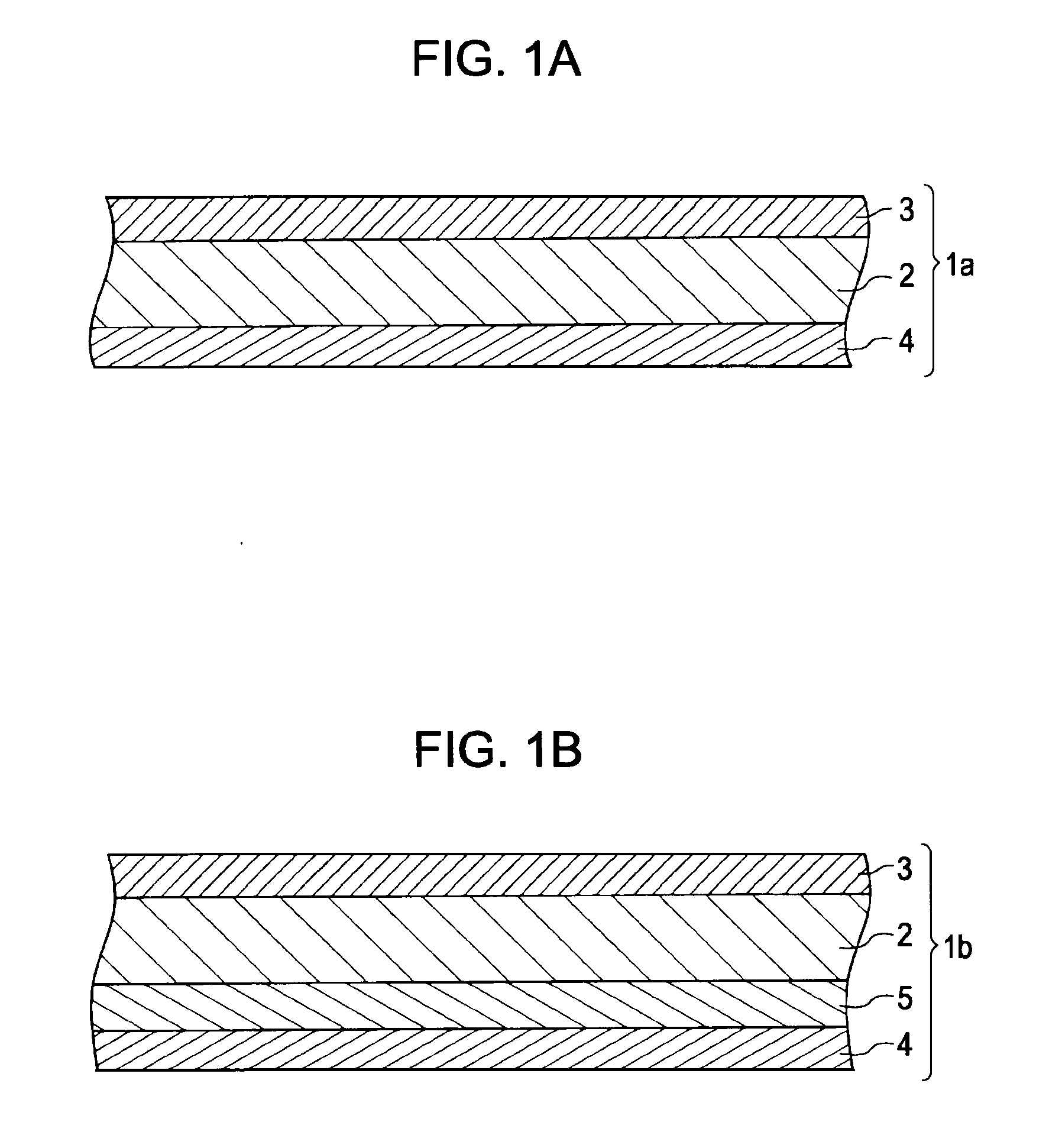

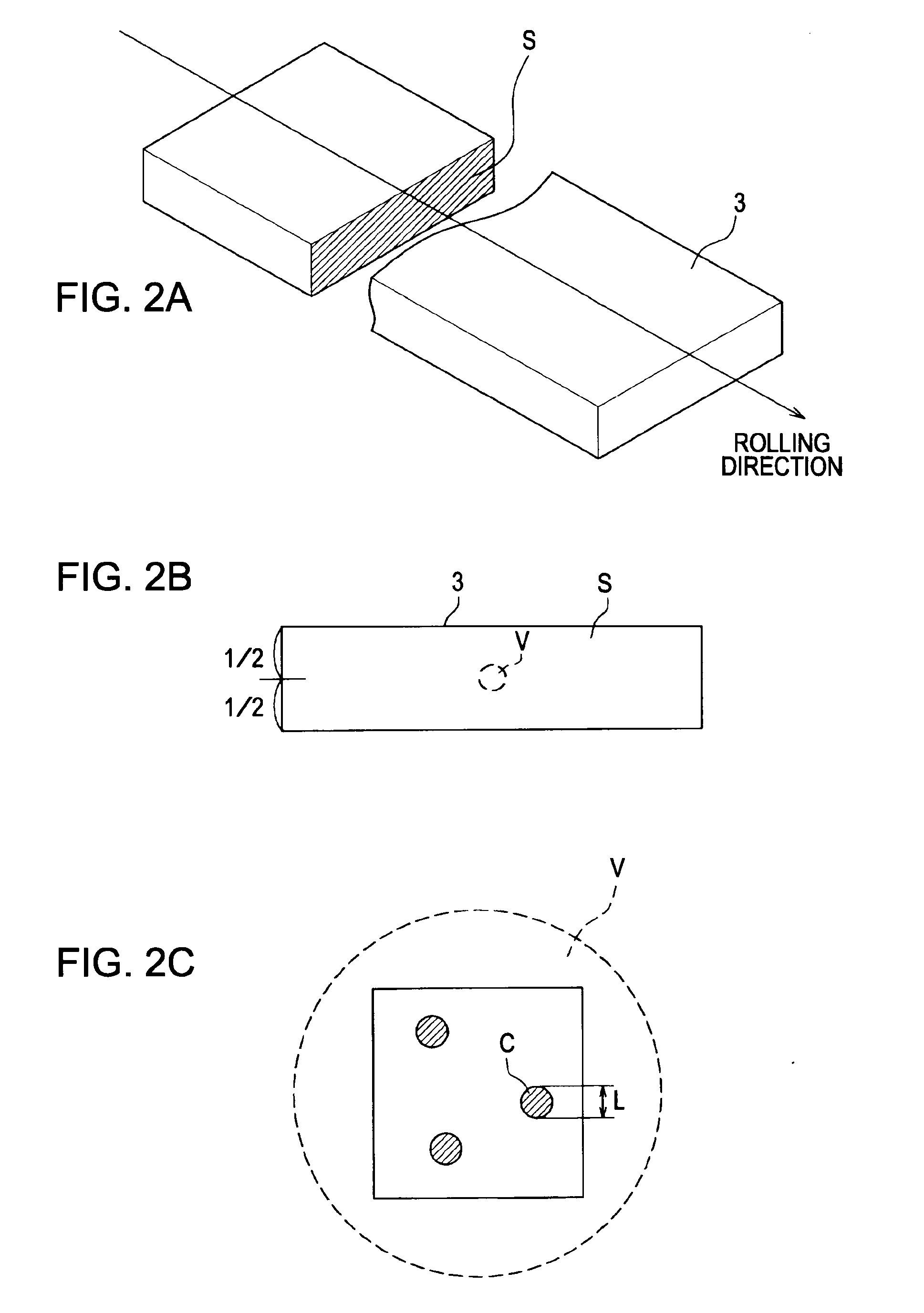

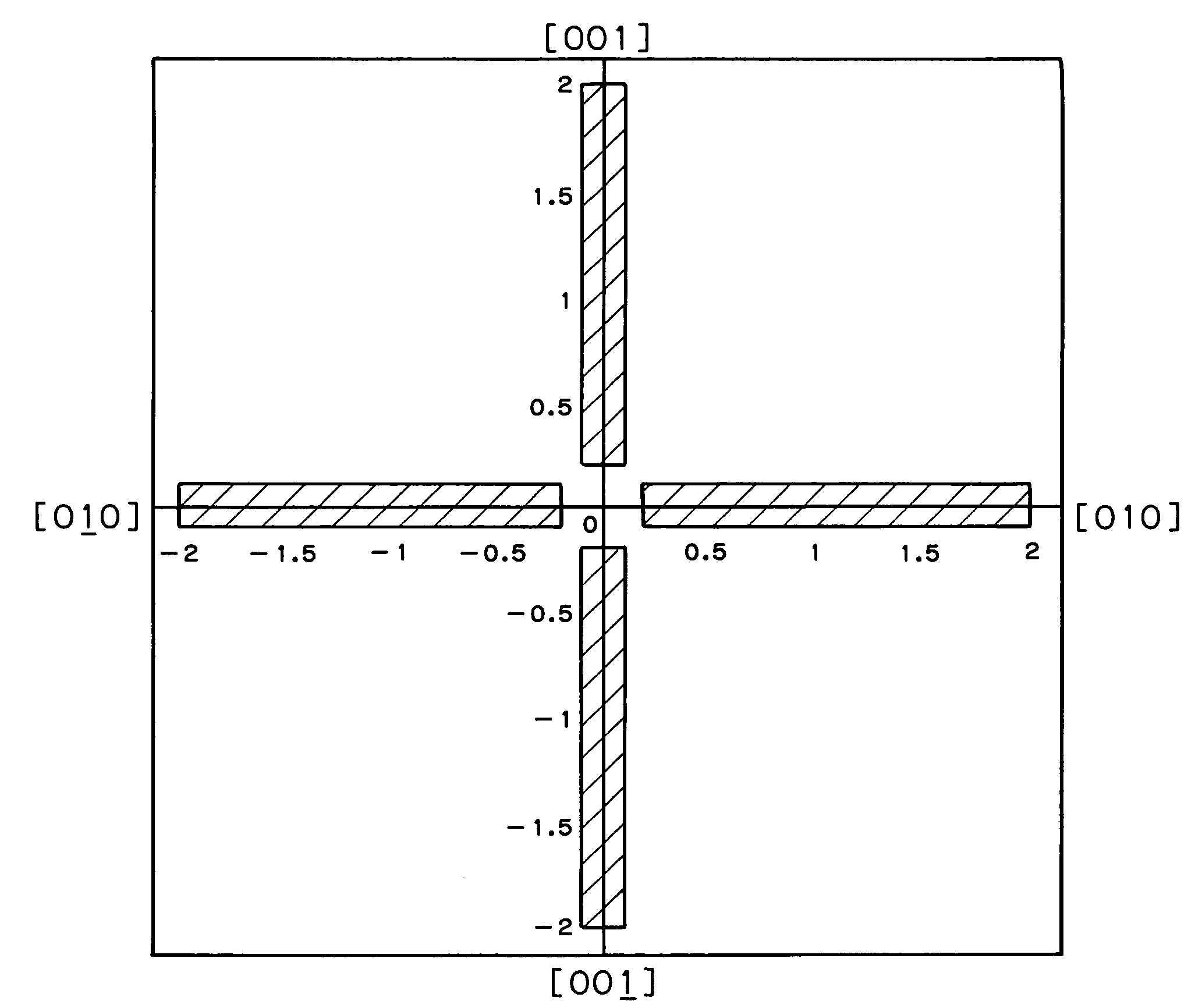

Epitaxial wafer and method for manufacturing method

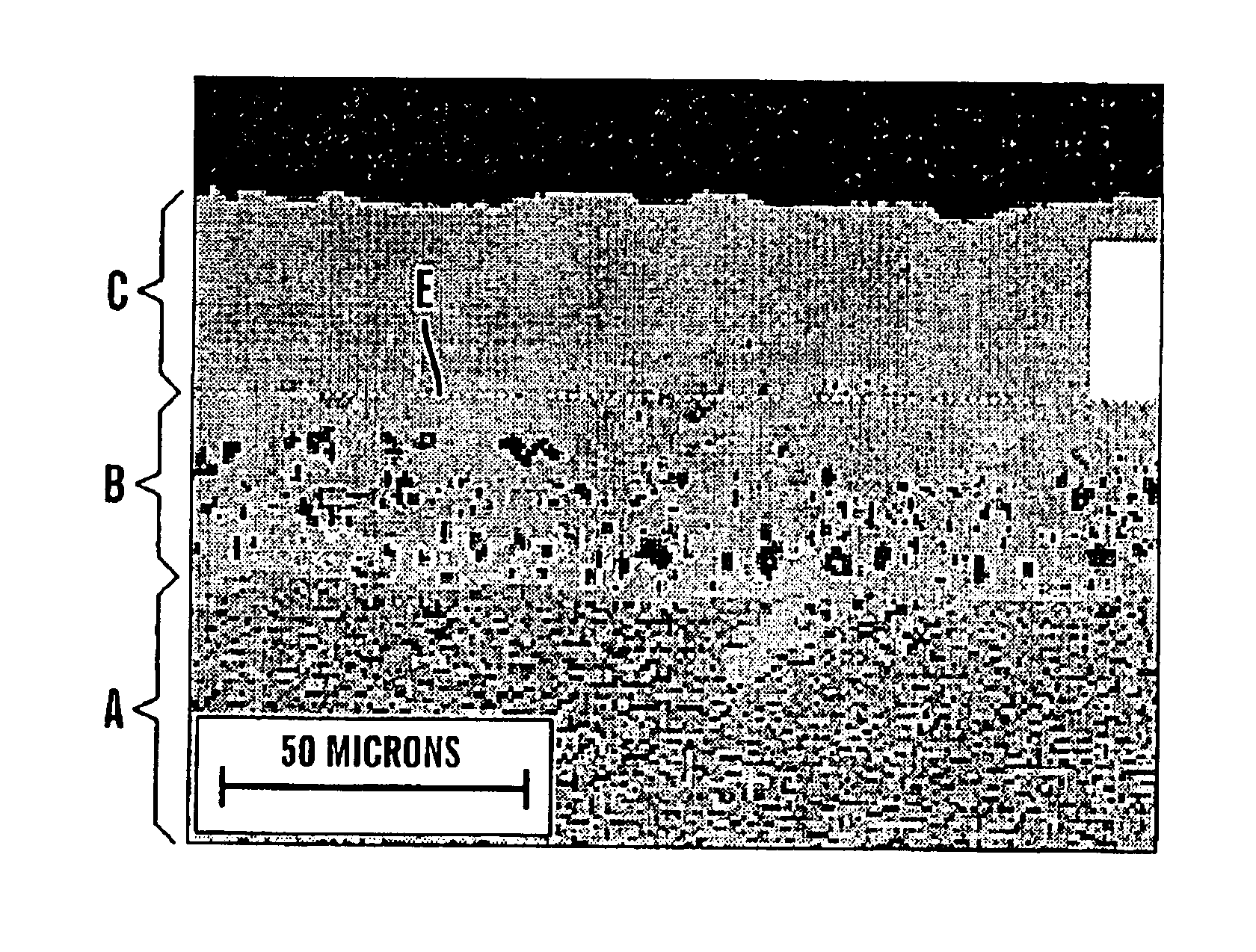

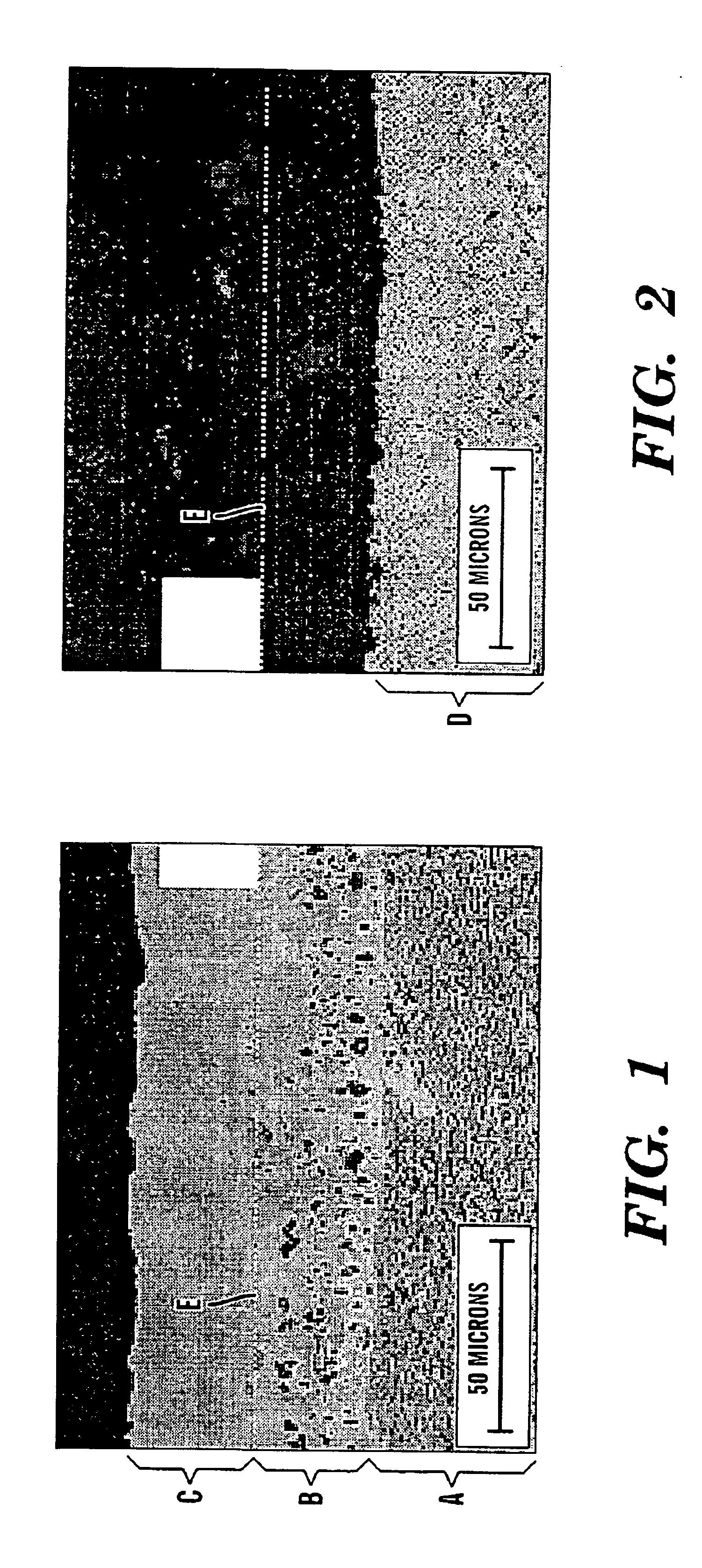

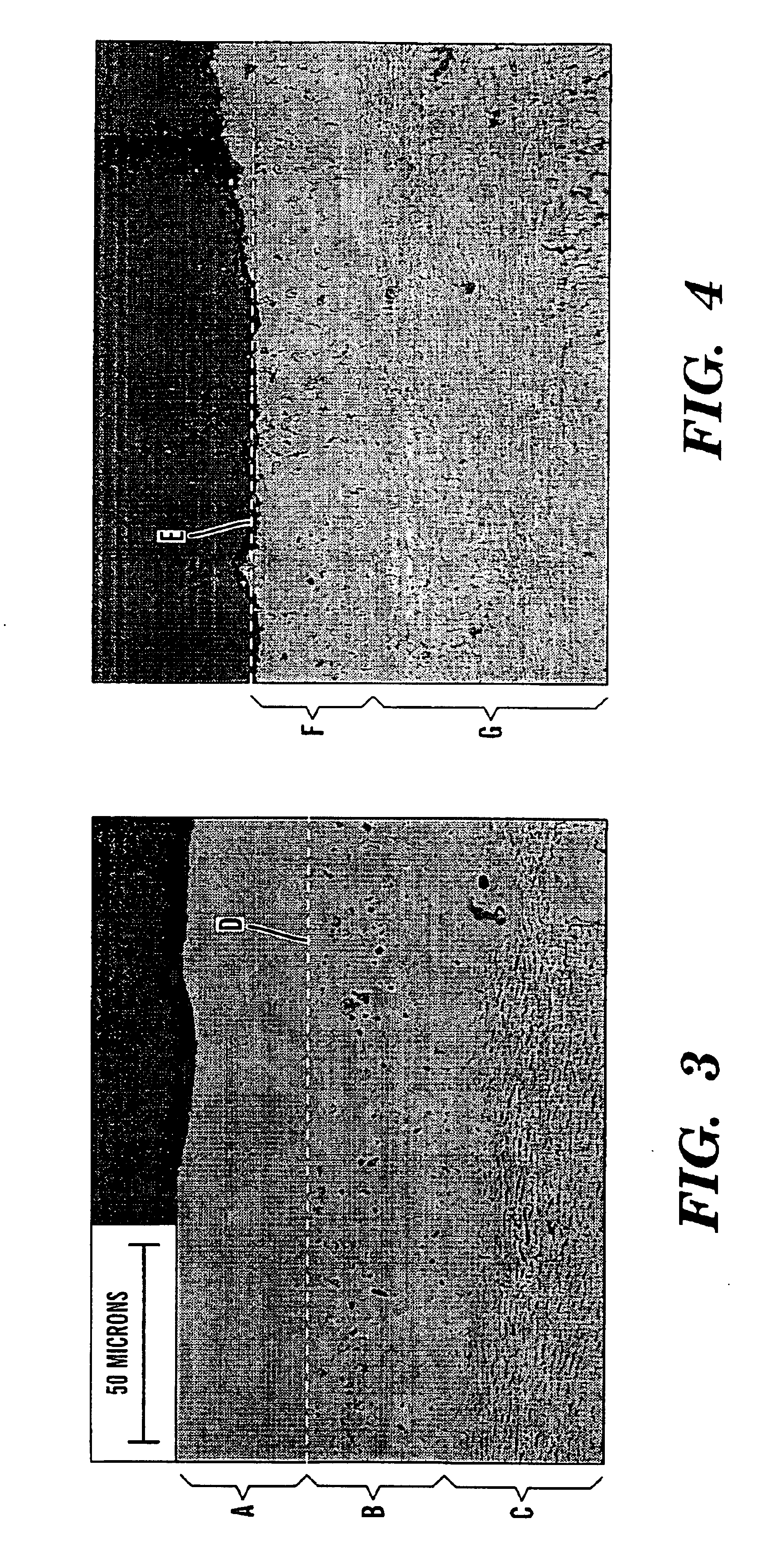

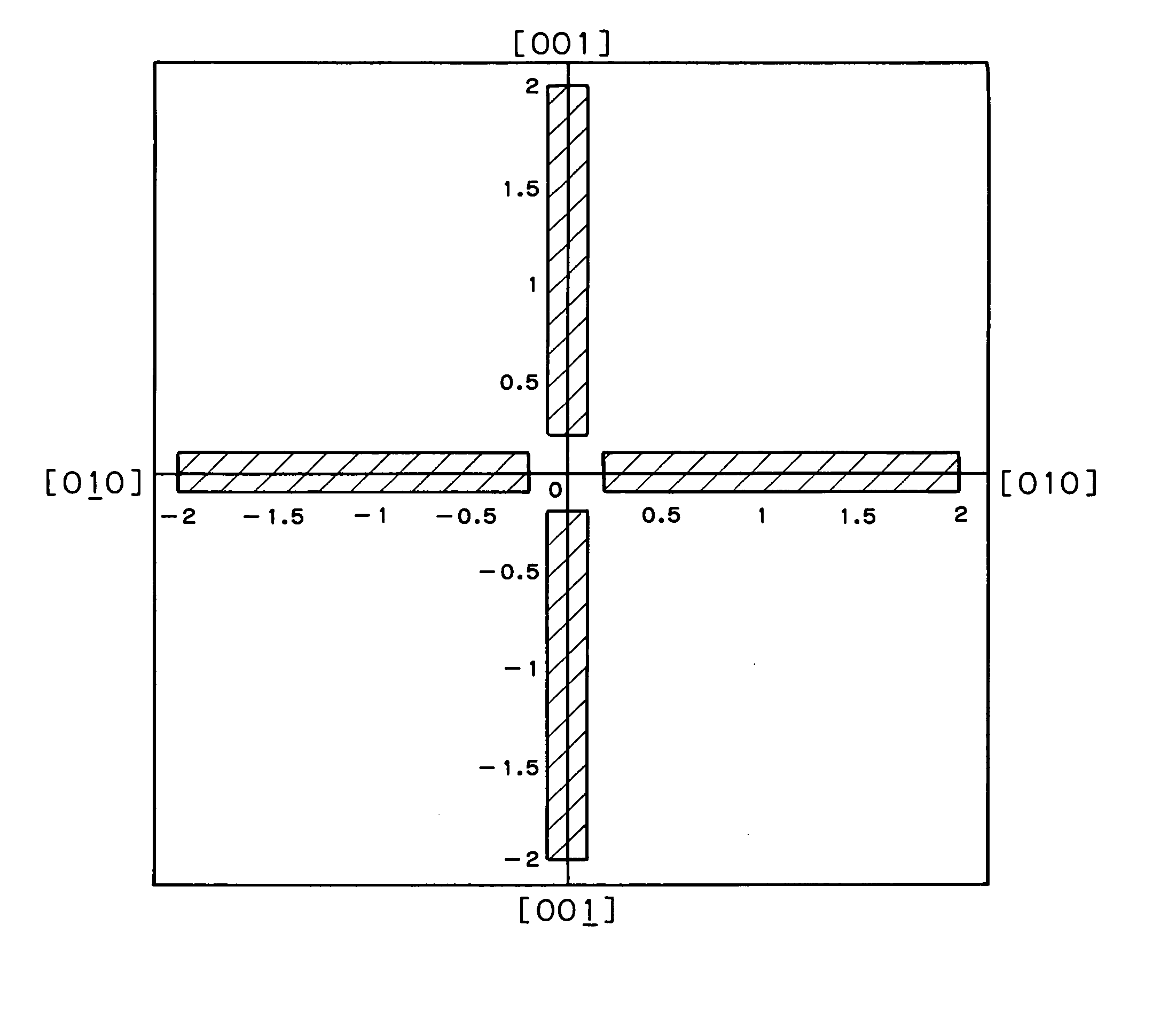

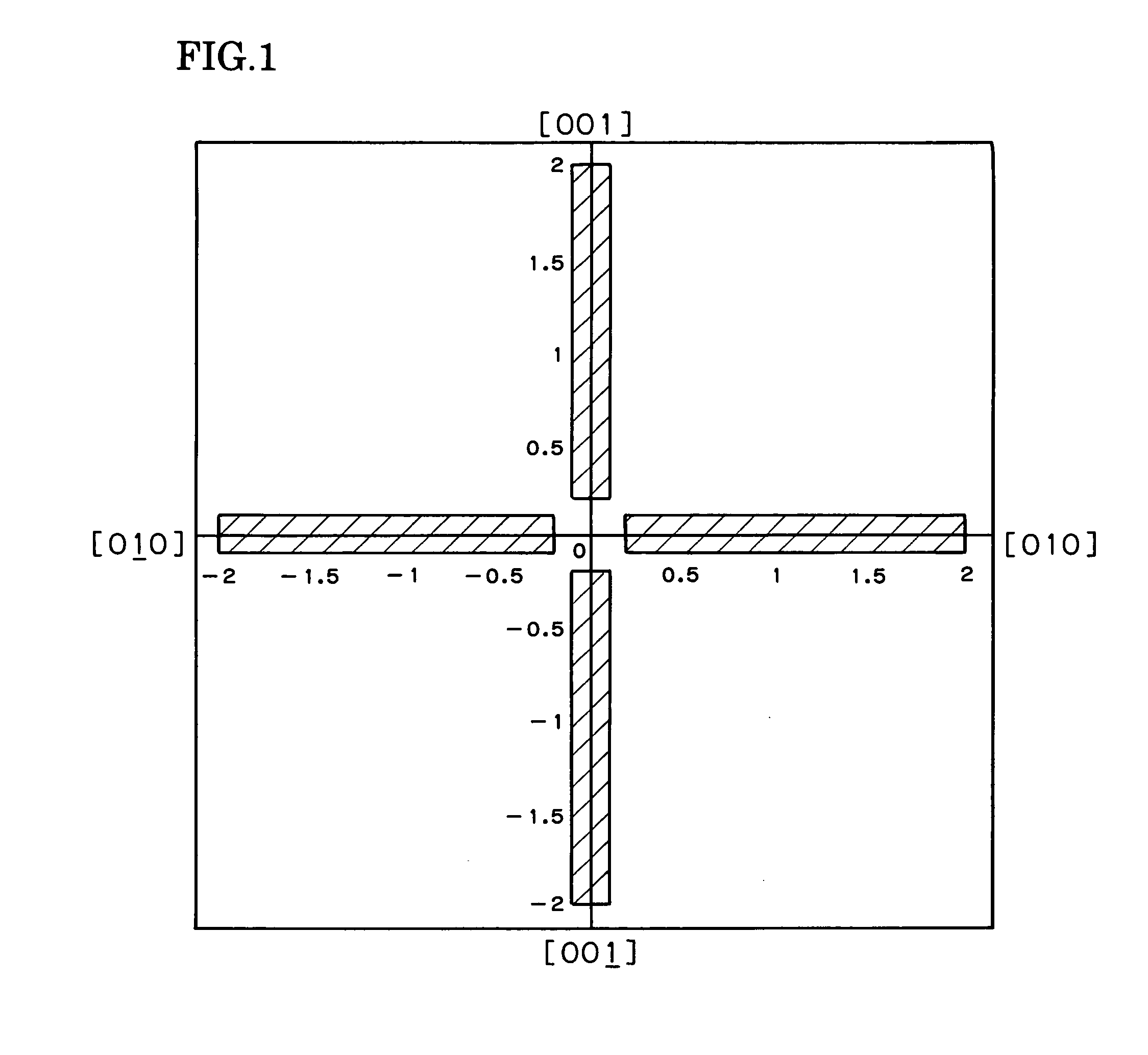

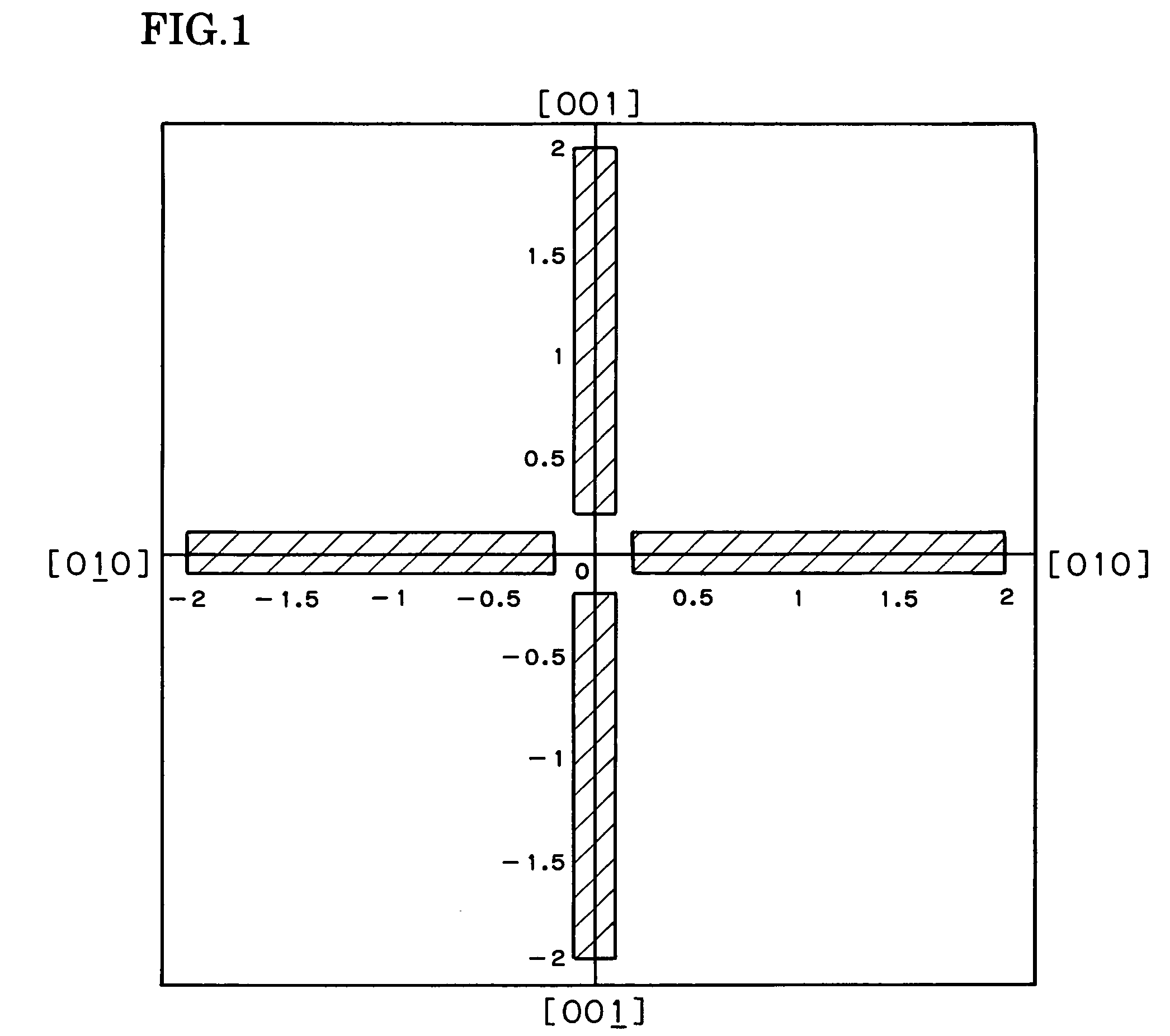

InactiveUS20050035349A1Reduce in quantityFew pit defectPolycrystalline material growthAfter-treatment detailsEtchingCrystal plane

It is an object of the present invention to provide an epitaxial wafer with fewer pit defects in the epitaxial layer of a silicon monocrystalline wafer that has been doped with arsenic. Pit defects tend to occur when gas etching is performed prior to epitaxial film formation, but this tendency is reversed and a sound epitaxial layer is obtained by setting the crystal plane orientation to (100) and specifying the range of the tilt angle for the angle θ in the [001] direction or [001] direction or the angle θ in the [010] direction or [010] direction with respect to the [100] axis.

Owner:SUMITOMO MITSUBISHI SILICON CORP

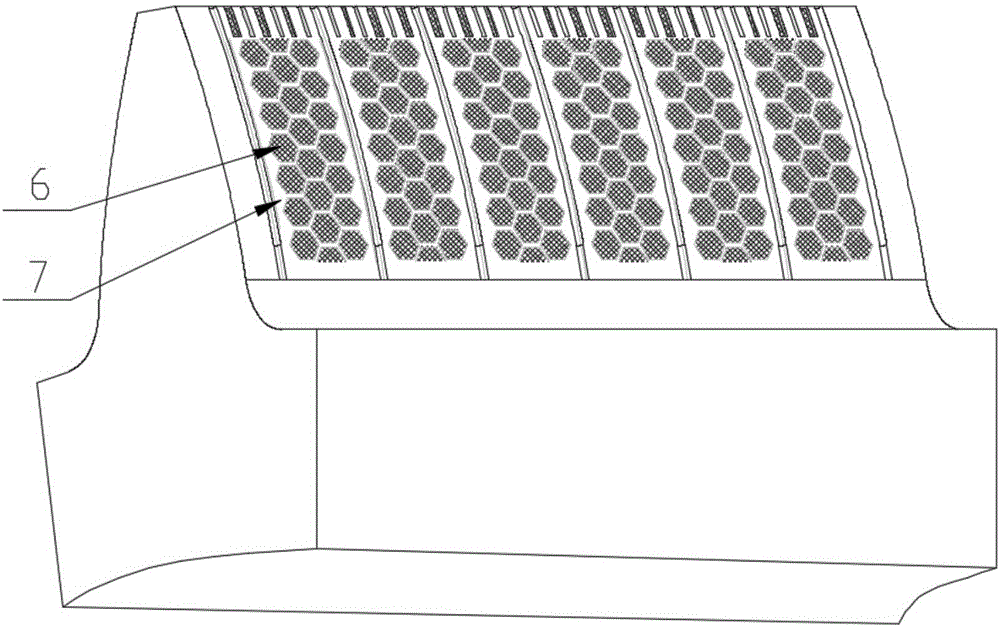

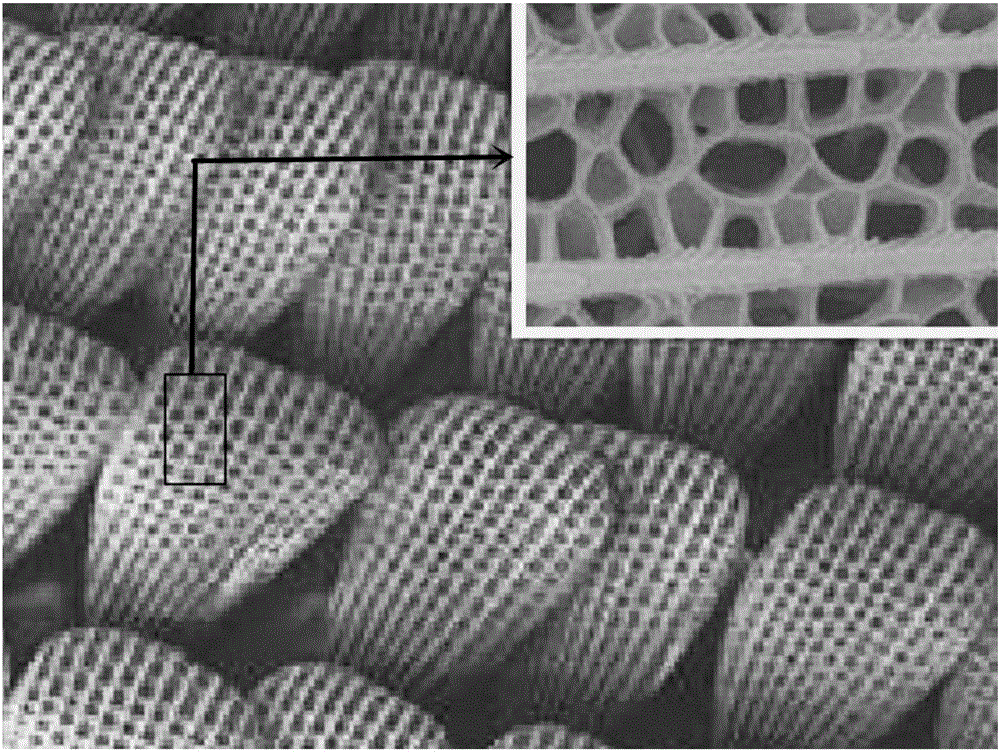

Gear with bionic tooth surfaces based on butterfly scale surface morphology

InactiveCN105736676ATooth surface refinementImprove mechanical propertiesPortable liftingGearing elementsGear driveSemi open

The invention relates to a bionic tooth surface gear based on the surface topography of butterfly scales. Its surface is processed with lines similar to the surface topography of butterfly scales. It consists of regularly arranged grooves and circular pits, and the grooves are arranged in parallel. The circular pits are distributed in the middle of two adjacent grooves. Based on the idea of bionics and inspired by the surface morphology of butterfly scales, the present invention proposes a bionic tooth surface gear based on the surface morphology of butterfly scales. Compared with the existing technology, the self-cleaning performance of gears can be effectively improved, and it can be applied to open, When the semi-open gear is driven, it is beneficial to prolong the life of the gear.

Owner:HEFEI UNIV OF TECH

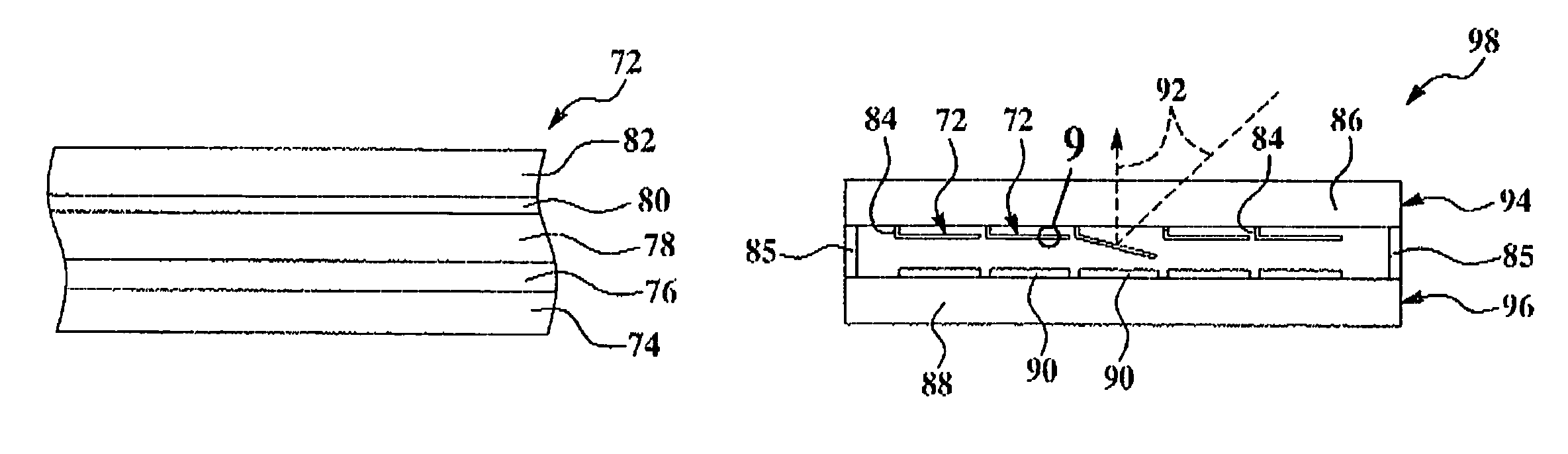

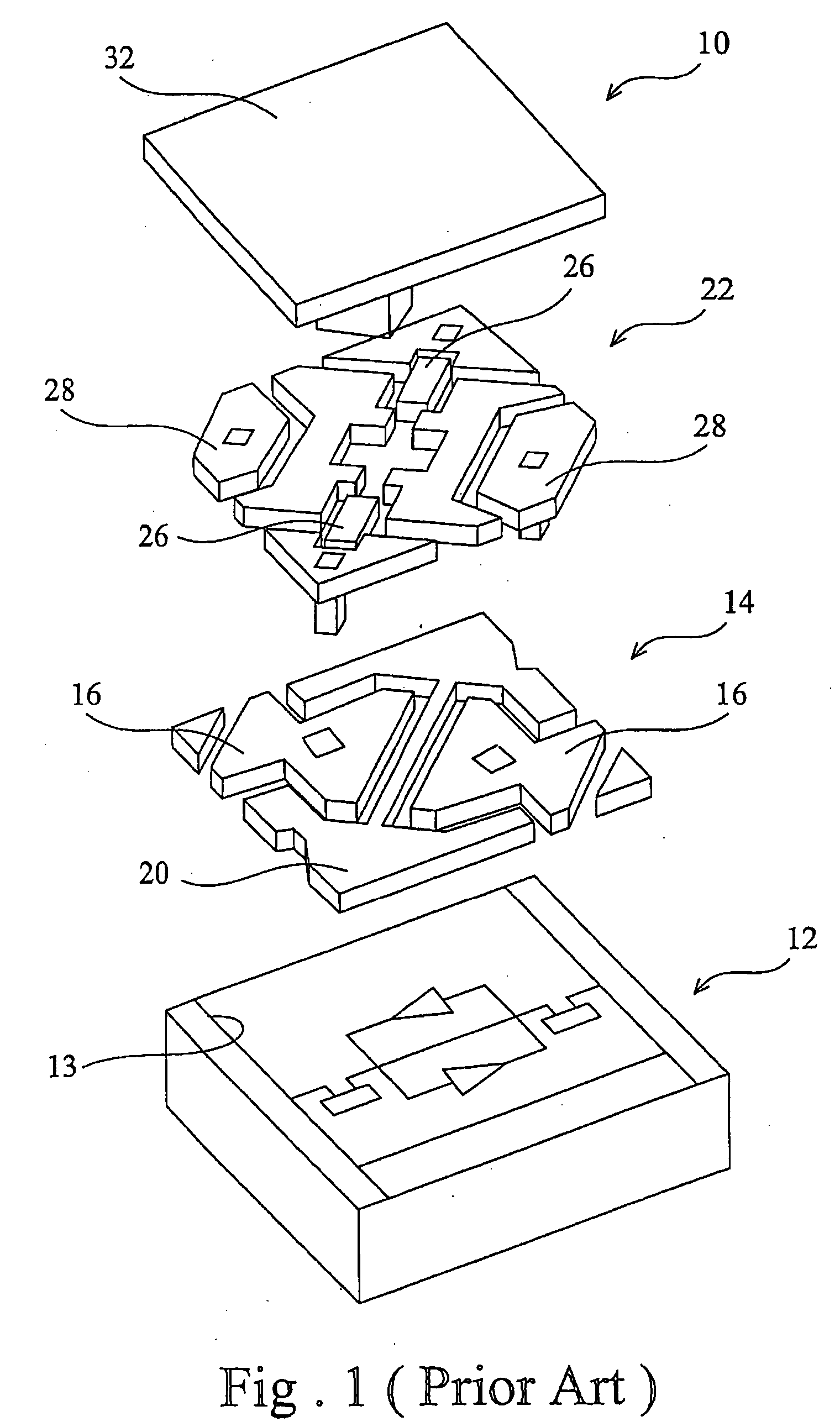

Micromirror for MEMS device

ActiveUS7057794B2Improve featuresReduce pittingCoatingsSpecial surfacesTitanium nitrideOptoelectronics

A micromirror which includes a substrate, a reflective layer comprising pure aluminum overlying the substrate and a protective layer comprising titanium nitride overlying the reflective layer is disclosed.

Owner:TAIWAN SEMICON MFG CO LTD

Polishing liquid with nanometer SiO2 abrasive for SiO2 medium in multilayer wiring of VLSI

InactiveCN1887997AAvoid scratchesAvoid edge saggingSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesIonNano sio2

The present invention is one kind of polishing liquid with nanometer SiO2 abrasive for SiO2 medium in multilayer wiring of VLSI. The polishing liquid consists of SiO2 hydrosol as abrasive 20-45 wt%, composite alkali 0.5-5.5 wt%, penetrant 1.0-10 wt%, surfactant 1.0-10 wt%, chelating agent 0.5-10 wt% and the deionized water for the rest. All the materials are mixed gradually through stirring to form the polishing liquid. The polishing liquid has high polishing efficiency, low cost and less pollution.

Owner:HEBEI UNIV OF TECH

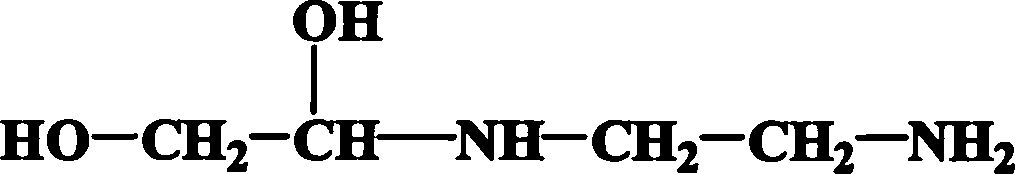

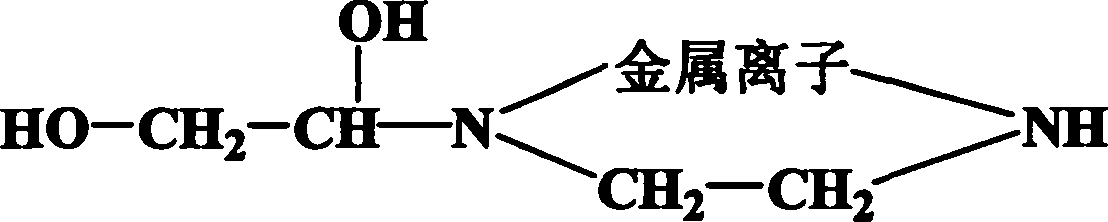

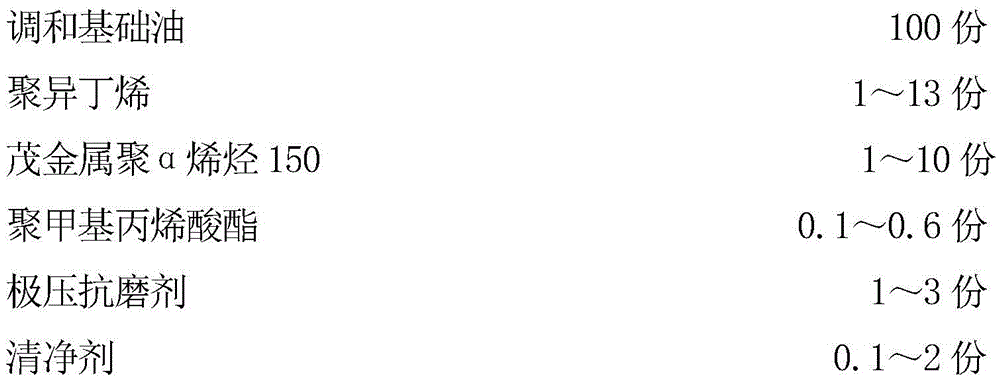

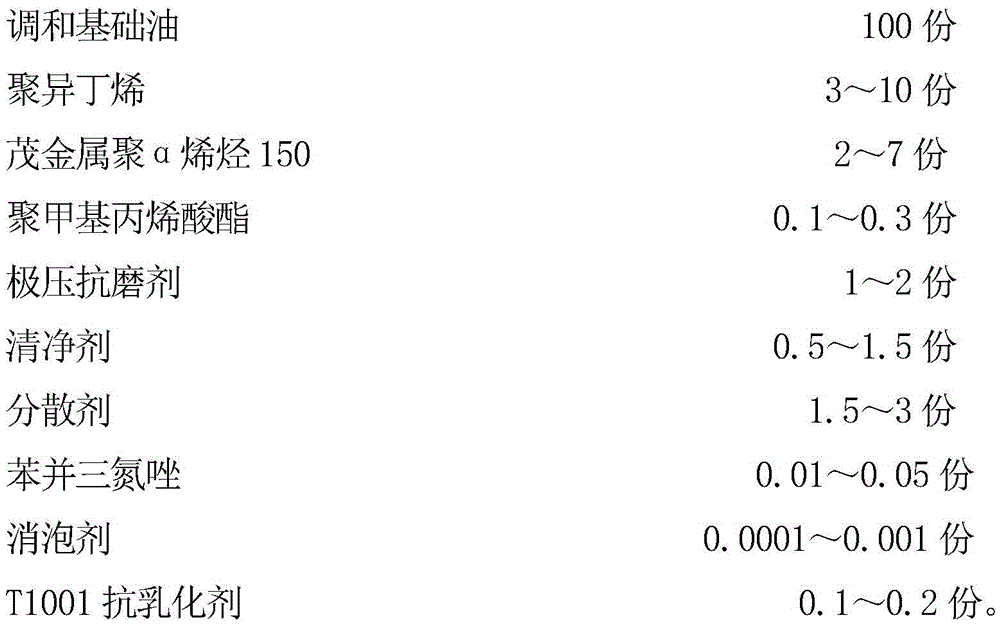

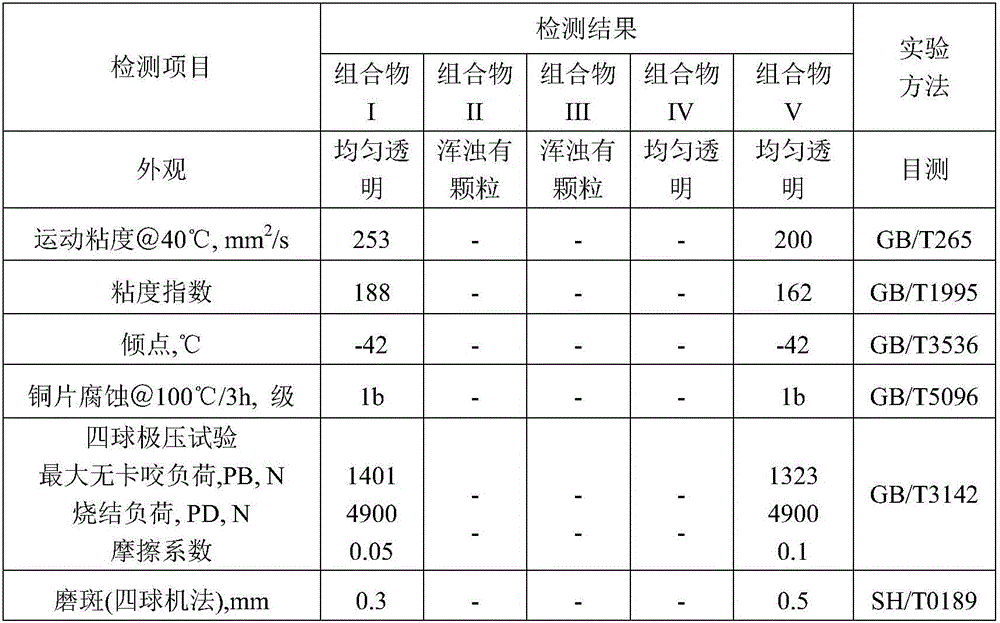

Gear oil special for reduction gearbox of pumping unit

The invention discloses gear oil special for a reduction gearbox of a pumping unit. The gear oil is prepared from, by mass, blend base oil, metallocene polyisobutene, metallocene polymerized alpha olefin 150, polymethacrylate, an extreme pressure anti-wear agent, a cleaning gent, a dispersing agent, benzotriazole, a defoaming agent and a demulsifying agent T1001, wherein the blend base oil is prepared from paraffin-base base oil 600 SN, residual oil 150 BS and hydrofined oil 250 N, and a mixture of thiophosphoric acid amine salt, bisoctyl dithiophosphate zinc and / or oil-soluble molybdenum is adopted as the extreme pressure anti-wear agent. The gear oil for the reduction gearbox is better in physical and chemical index and using performance than industrial closed gear oil, has the good extreme pressure anti-wear performance, thermal oxidation stability, corrosion resistance and anti-emulsification performance and meets the using requirements of oil pumping unit oil of an oil field.

Owner:郑生宏

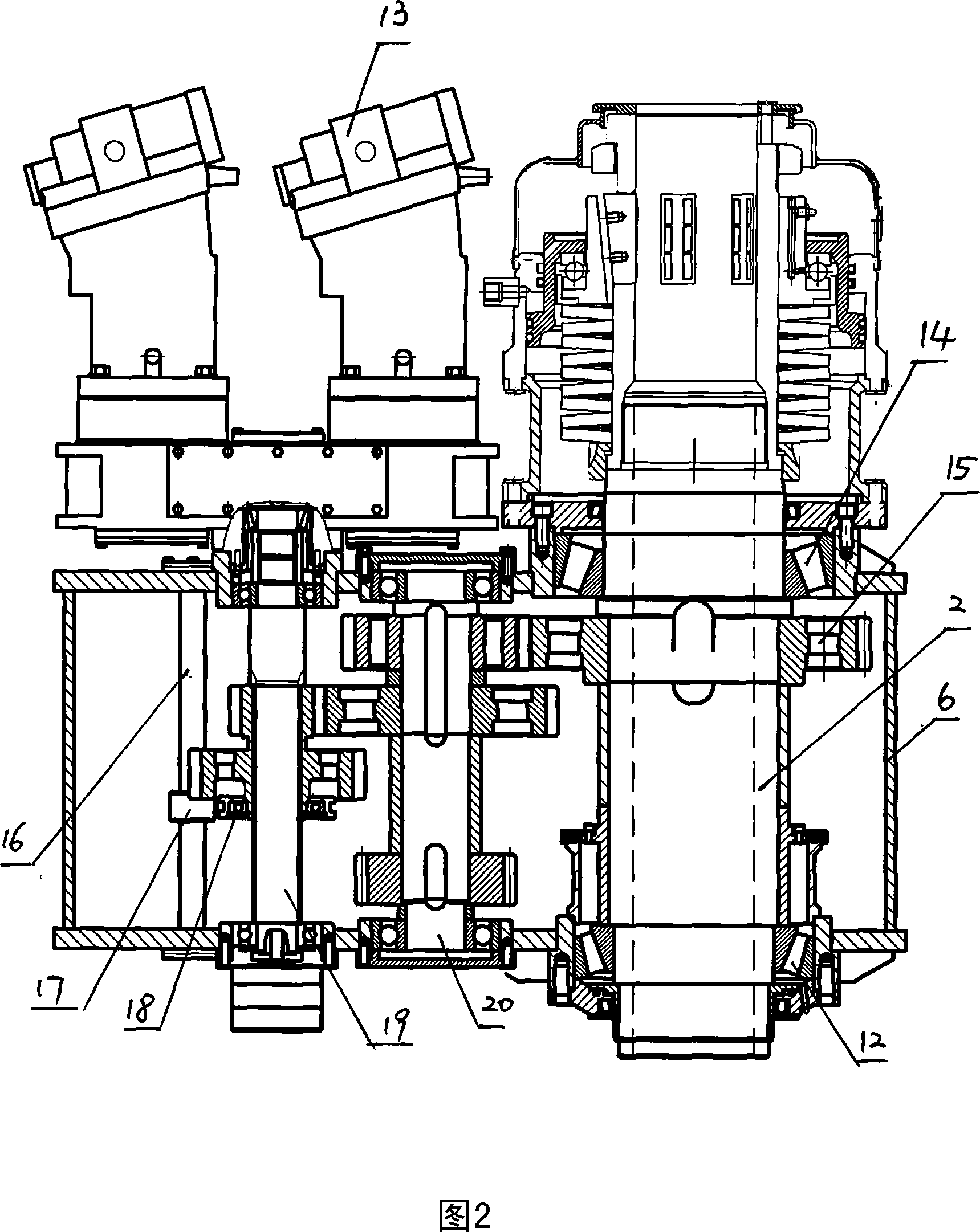

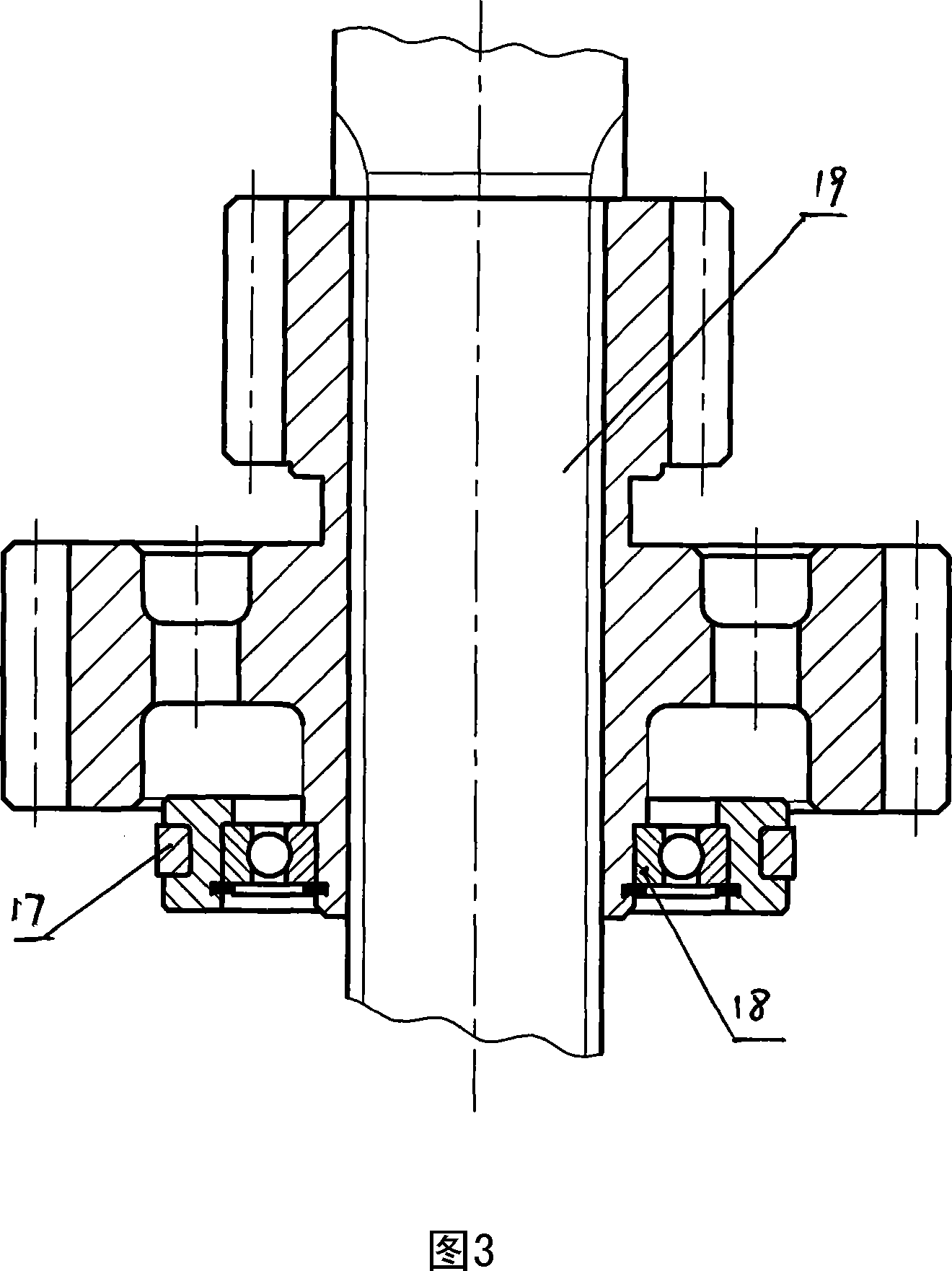

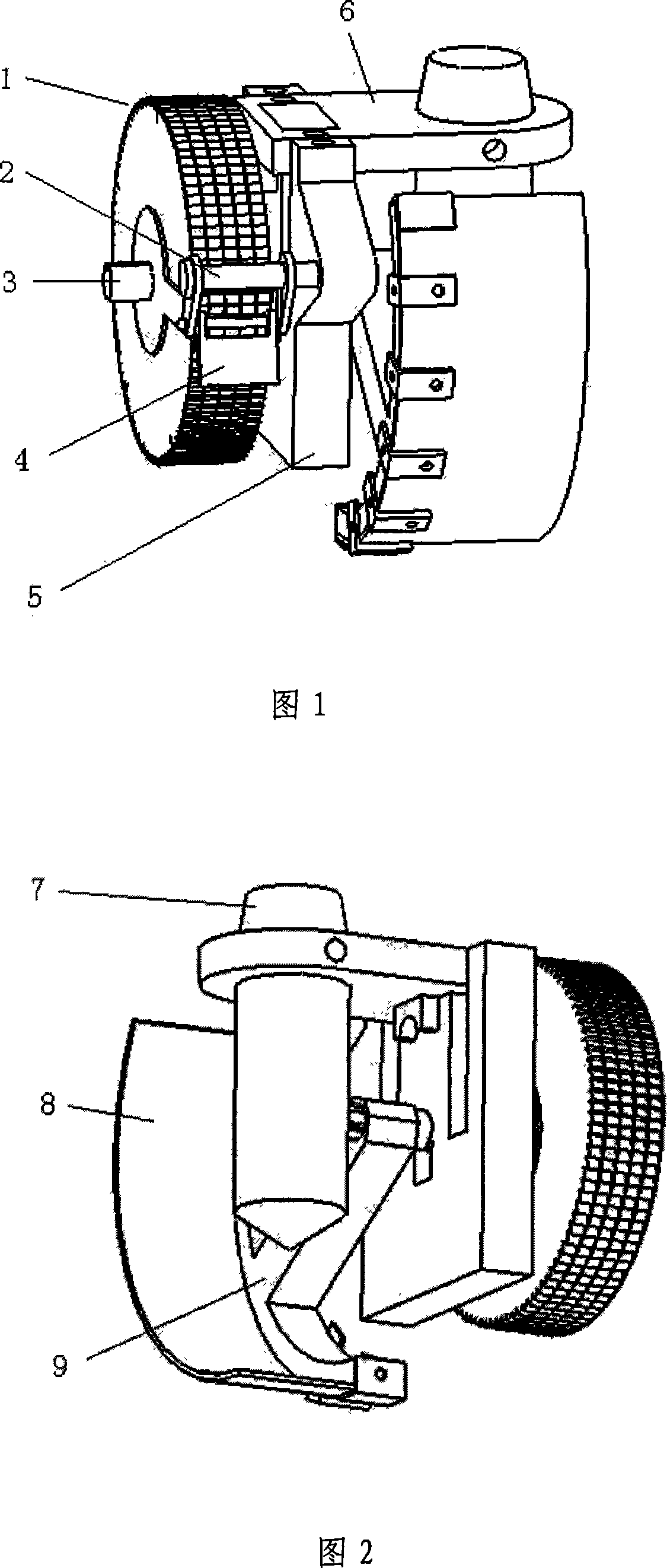

Large velocity ratio marine gearbox

InactiveCN102392879AEasy meshEasy to divideGear lubrication/coolingToothed gearingsControl theoryVelocity ratio

The invention discloses a large velocity ratio marine gearbox, which mainly comprises an input component, an ahead running shaft component, a reversing shaft component, an intermediate shaft component, an output component and a box body component, wherein the input shaft of the input component is provided with an input gear by shrinkage fit, the input gear meshes with an ahead running driving gear which is arranged at the ahead running shaft of the ahead running shaft component by shrinkage fit, the ahead running shaft of the ahead running shaft component is equipped with an ahead running clutch with an ahead running clutch shell gear; the reversing shaft component comprises a reversing shaft and a reversing clutch with a reversing clutch shell gear; the ahead running shaft and the reversing shaft are also respectively sleeved with an ahead running driving gear and a reversing driving gear connected with the ahead running clutch and the reversing clutch, and the above-mentioned ahead running driving gear and reversing driving gear respectively mesh with an intermediate transmission gear fixedly connected with the intermediate shaft of the intermediate shaft component; the intermediate shaft is fixedly connected with an intermediate driving gear meshed with the output gear which is arranged on the output shaft of the output component by shrinkage fit; the intermediate shaft is of a hollow shaft, and the hollow intermediate shaft is sleeved on the input shaft and supported by bearings. The large velocity ratio marine gearbox provided by the invention has the characteristics that gear meshing is improved effectively, assembly and maintenance are convenient, and net weight can be reduced by 20-30% according to different speed reduction ratios.

Owner:HANGZHOU ADVANCE GEARBOX GRP

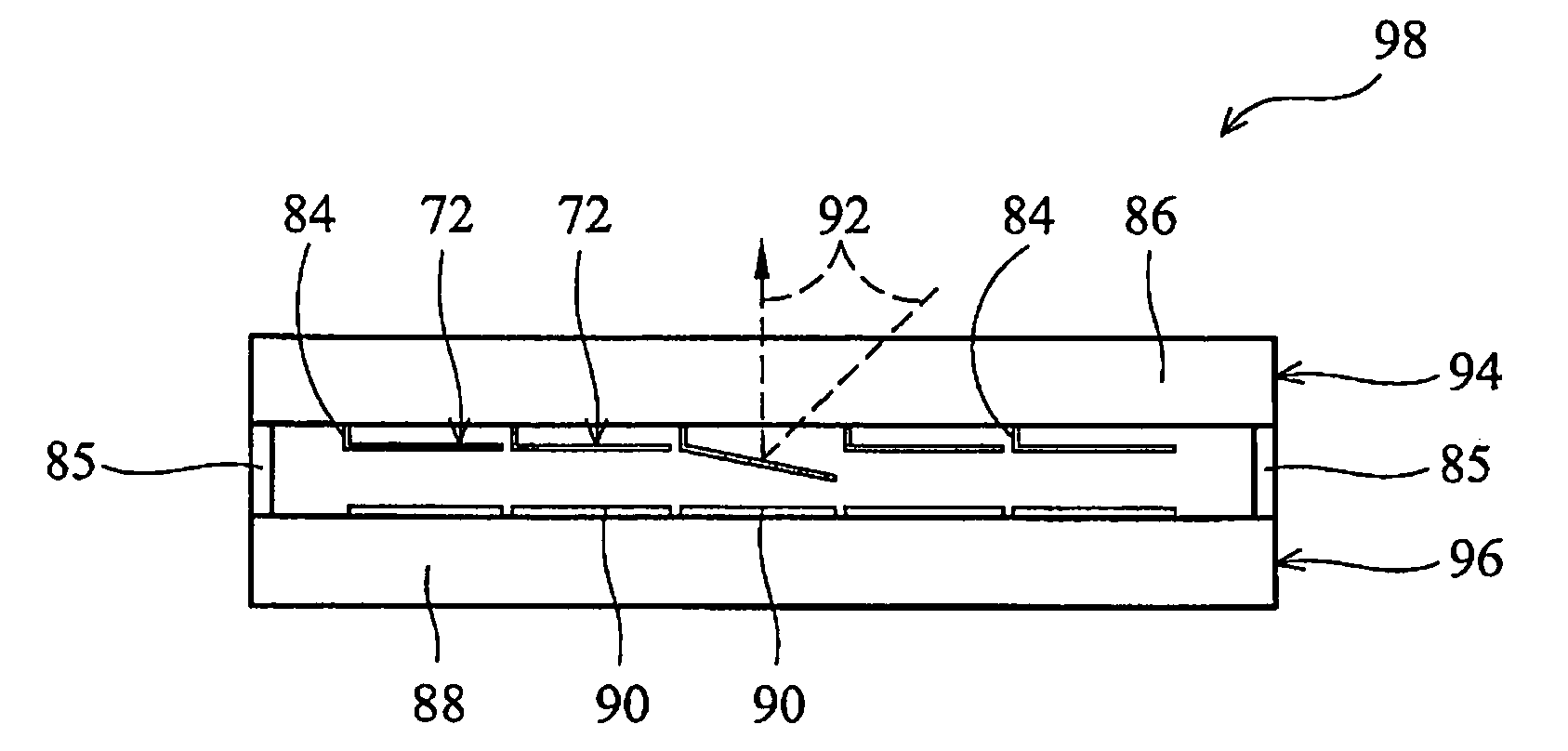

Epitaxial wafer and method for manufacturing method

InactiveUS7288791B2Few pit defectReduce pittingPolycrystalline material growthAfter-treatment detailsEtchingCrystal plane

It is an object of the present invention to provide an epitaxial wafer with fewer pit defects in the epitaxial layer of a silicon monocrystalline wafer that has been doped with arsenic. Pit defects tend to occur when gas etching is performed prior to epitaxial film formation, but this tendency is reversed and a sound epitaxial layer is obtained by setting the crystal plane orientation to (100) and specifying the range of the tilt angle for the angle θ in the [001] direction or [001] direction or the angle φ in the [010] direction or [010] direction with respect to the [100] axis.

Owner:SUMITOMO MITSUBISHI SILICON CORP

Graphite anode for heavy current resistant magnesium electrolysis and preparation process thereof

ActiveCN105967718AHigh bulk densityImprove flexural strengthElectric heating for furnacesElectrodesFiberCarbon fibers

The invention relates to a graphite anode for heavy current resistant magnesium electrolysis. The graphite anode is prepared through the following steps of mixing and kneading delay calcined petroleum coke which accounts for 93-99wt% of a dry material, graphite scraps which account for 1-3wt% of the dry material, an additive Fe2O3 and stearic acid, and medium-temperature modified pitch which accounts for 20-30wt% of the total mass, and performing profiling, roasting, steeping and graphitizing, wherein raw materials also include short cut carbon fibers which account for 0.5-5wt% of the dry material. In a graphitizing process adopted during preparation, an insulated filler is adopted between the side surface of an electrode and a furnace body, and an end part filler is adopted in a clearance between the end surface of the electrode and the furnace body, so that the effects of reducing the resistivity, reducing electric arc and reducing pits in the end surface of the electrode.

Owner:NANTONG YANGZI CARBON +1

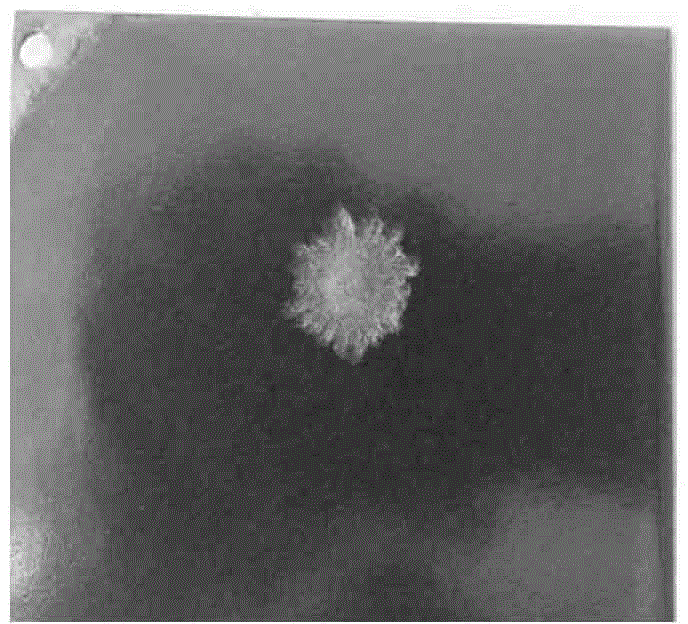

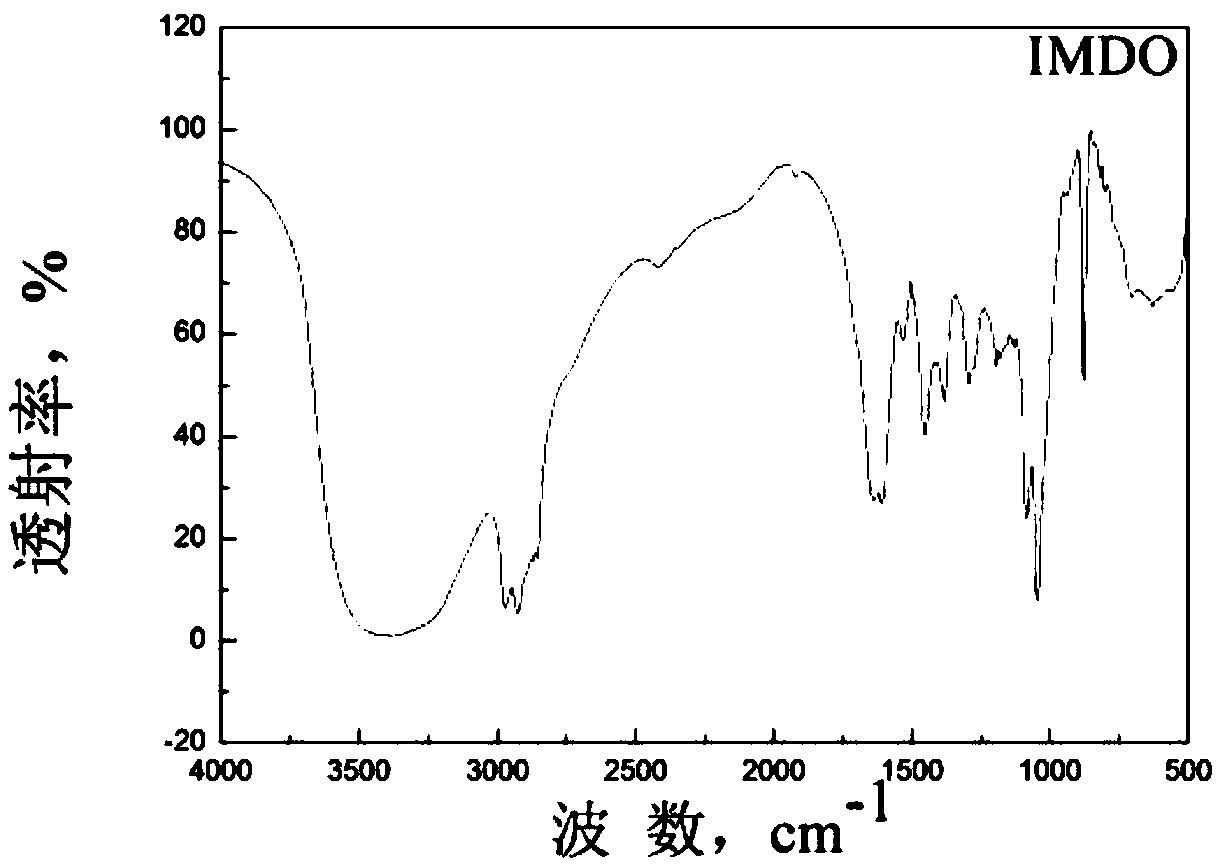

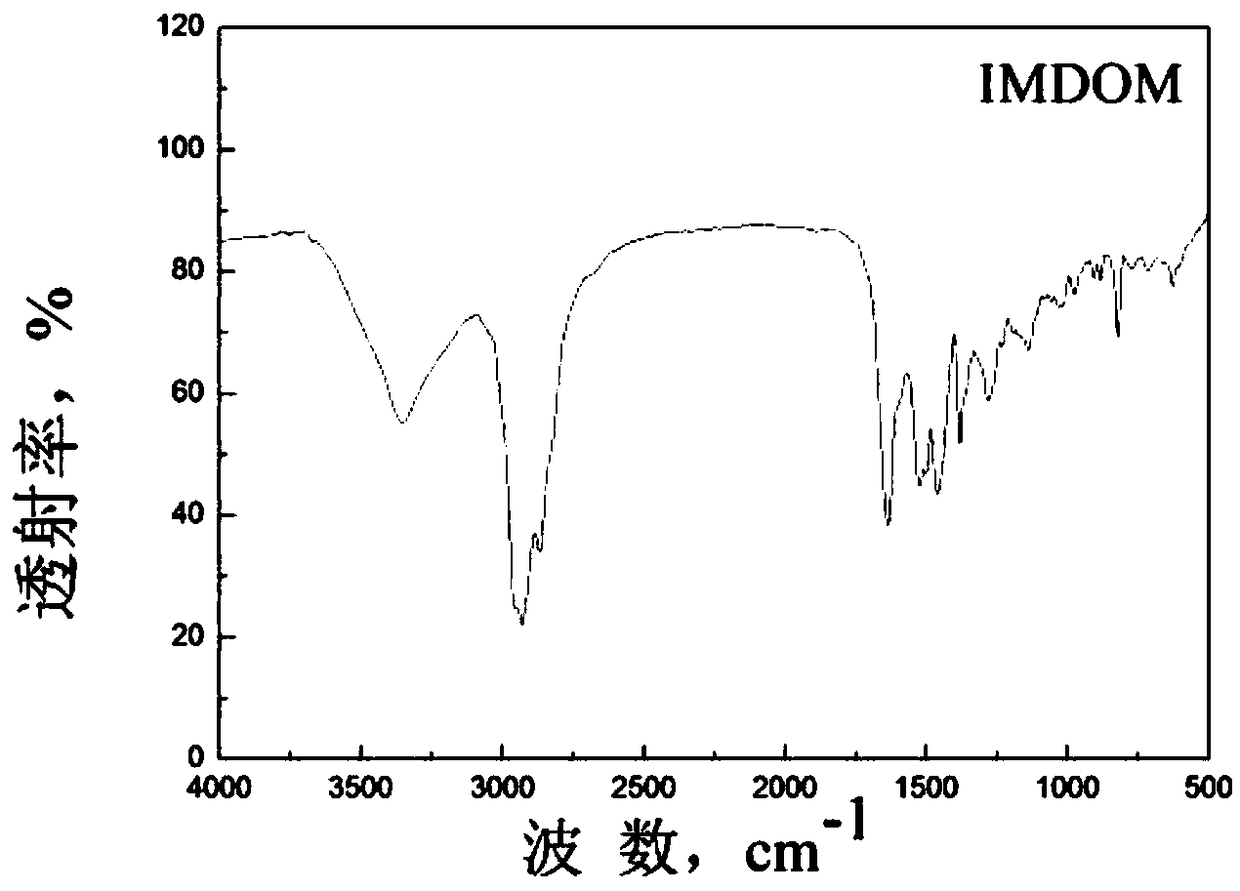

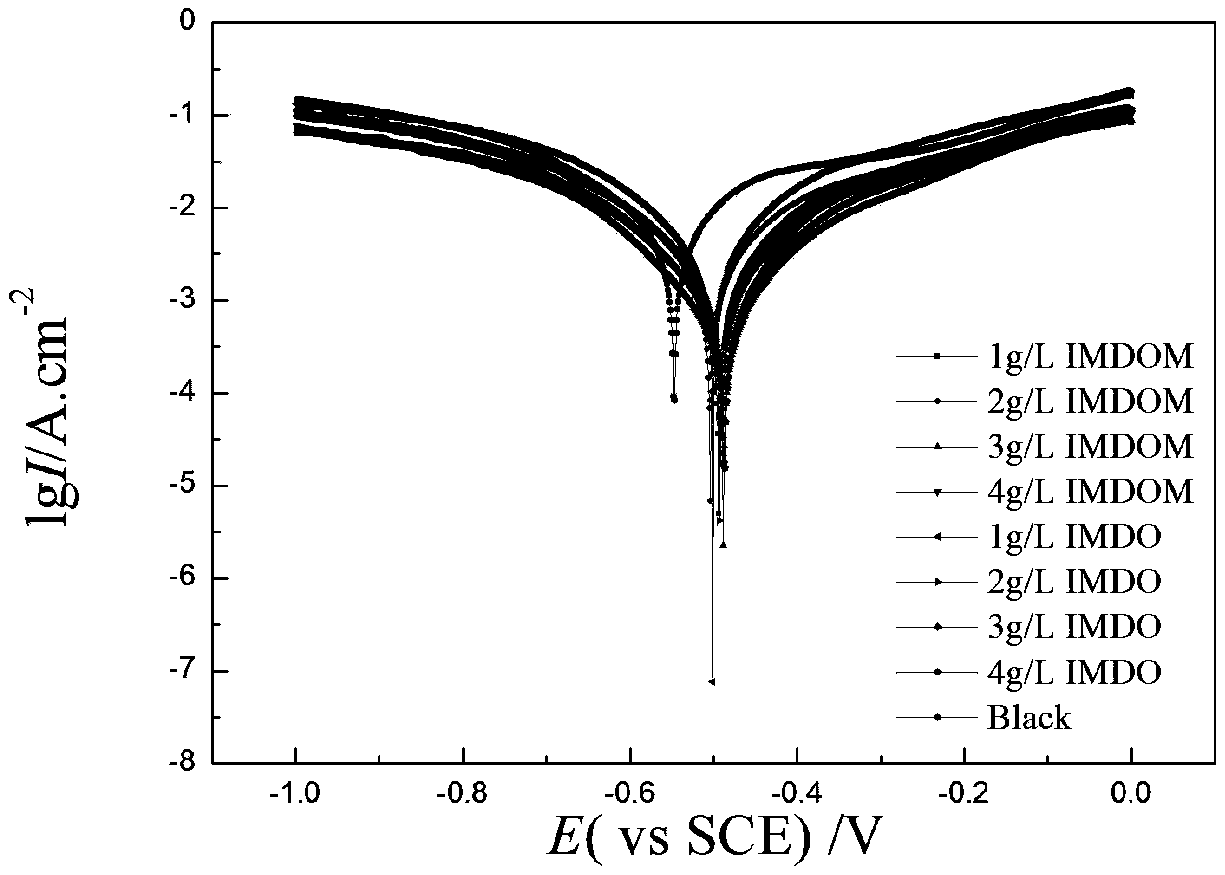

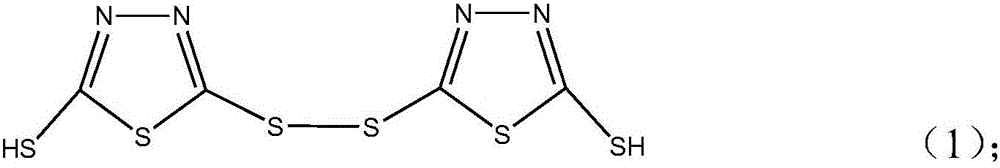

Synthesis method and application of rosin-based imidazoline derivative corrosion inhibitor

ActiveCN108822148ALow corrosion current densityReduce pittingGroup 5/15 element organic compoundsPhosphorous acidMannich reaction

Relating to synthesis and application of metal anticorrosive compounds, the invention specifically discloses a synthesis method and application of a rosin-based imidazoline derivative corrosion inhibitor. In the synthesis process, triethylene tetramine and dehydroabietic acid are adopted as the raw materials to prepare a rosin-based imidazoline derivative corrosion inhibitor intermediate, then phosphorous acid is employed for Mannich reaction modification on the intermediate so as to obtain the rosin-based imidazoline derivative corrosion inhibitor. Structural characterization of the corrosioninhibitor with infrared spectroscopy and analysis by electrochemical process, dynamic weight loss process, energy spectrum analysis, scanning electron microscope and other methods find that the corrosion inhibitor has a good corrosion inhibition effect on metals, and at the same time adding of the corrosion inhibitor can reduce the corrosion current density and decrease the corrosion rate.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Polishing solution for magnesium alloy

The invention provides a polishing solution applied to the magnesium alloy. The polishing solution comprises an abrasive, a strong oxidant, a pH regulator and deionized water; the components are as follows by weight percentage: 10 percent to 40 percent of the abrasive I, 0.1 percent to 3 percent of the strong oxidant, 1 percent to 10 percent of the pH regulator and the balance is deionized water. The polishing solution can be used for polishing treatment of magnesium-alloy surface, effectively improve surface finish of the magnesium alloy, effectively reduce surface scratch after polishing, and reduce surface roughness after polishing; simultaneously, polishing debris is dissolved in the polishing solution, the magnesium-alloy surface is easy to be cleaned, the polishing speed is rapid, the polishing solution has no harm to equipment, and the usage security is high.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Gear oil composition and preparation method thereof

The invention provides a gear oil composition and a preparation method thereof. The gear oil composition comprises the following components in percentage by total weight of100%: 78.5-98.39% of base oil, preferably 85-97%, and more preferably 91-95%, 0.1-4% of a sulfur-containing extreme pressure agent, preferably 0.5-2%, 0.1-4% of a phosphorus-containing anti-wear agent, preferably 0.5-2%, 0.1-3% of fatty acid, preferably 0.3-2%, 0.1-1% of alkylsilane, preferably 0.5-1%, 0.3-6% of hydrophilic fumed silica, preferably 0.5-3%, 0.01-0.5% of a metal deactivator, preferably 0.03-0.1%, 0.3-3% of an antioxidant, preferably 0.5-1.5%. The gear oil composition provided by the invention sufficiently utilizes the wear reduction function of the hydrophilic fumed silica and the extreme pressure anti-wear functions of the sulfur-containing extreme pressure agent and the phosphorus-containing anti-wear agent, and is a gear oil composition with integrated functions of wear reduction, wear resistance, extreme pressure resistance, oxidation resistance and corrosion resistance.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

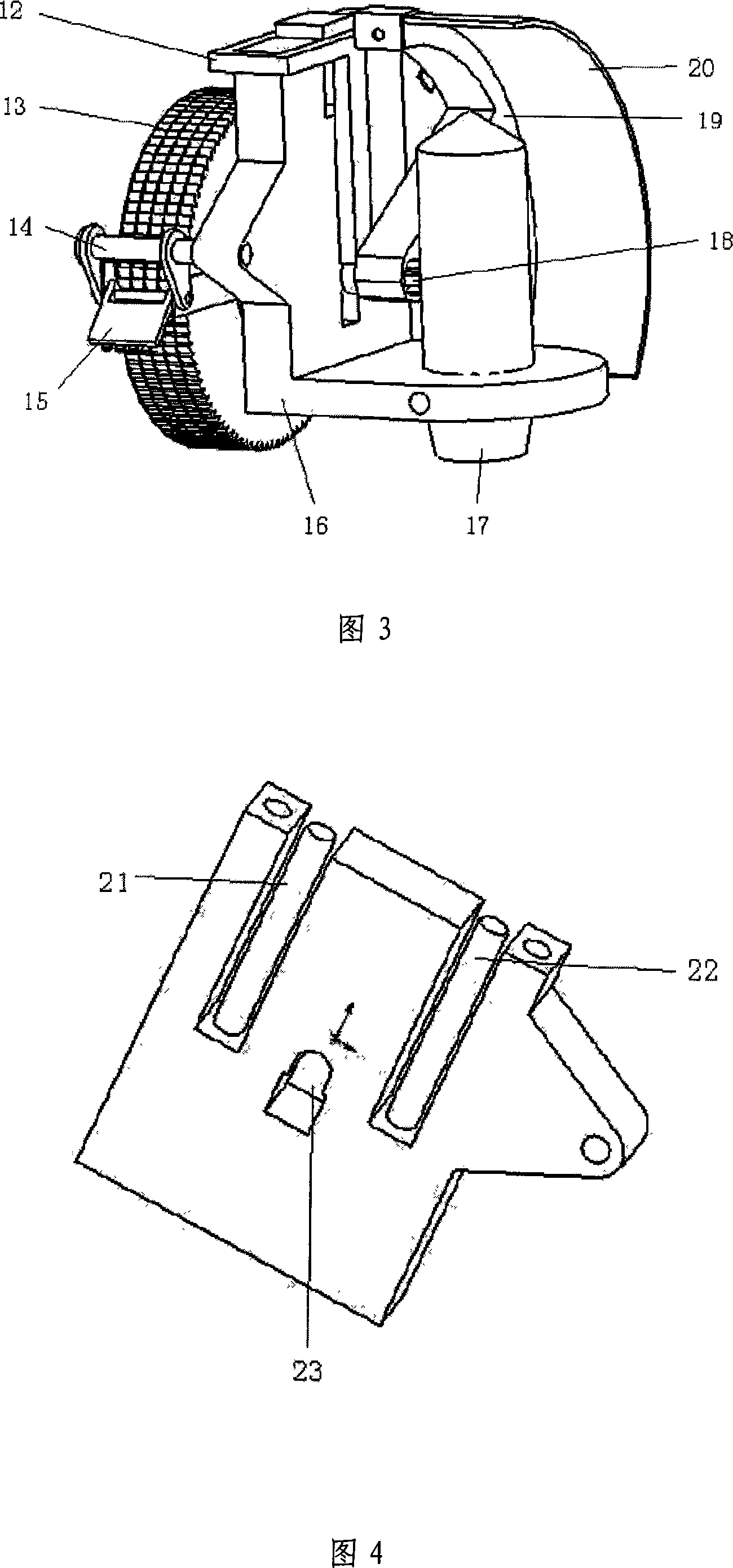

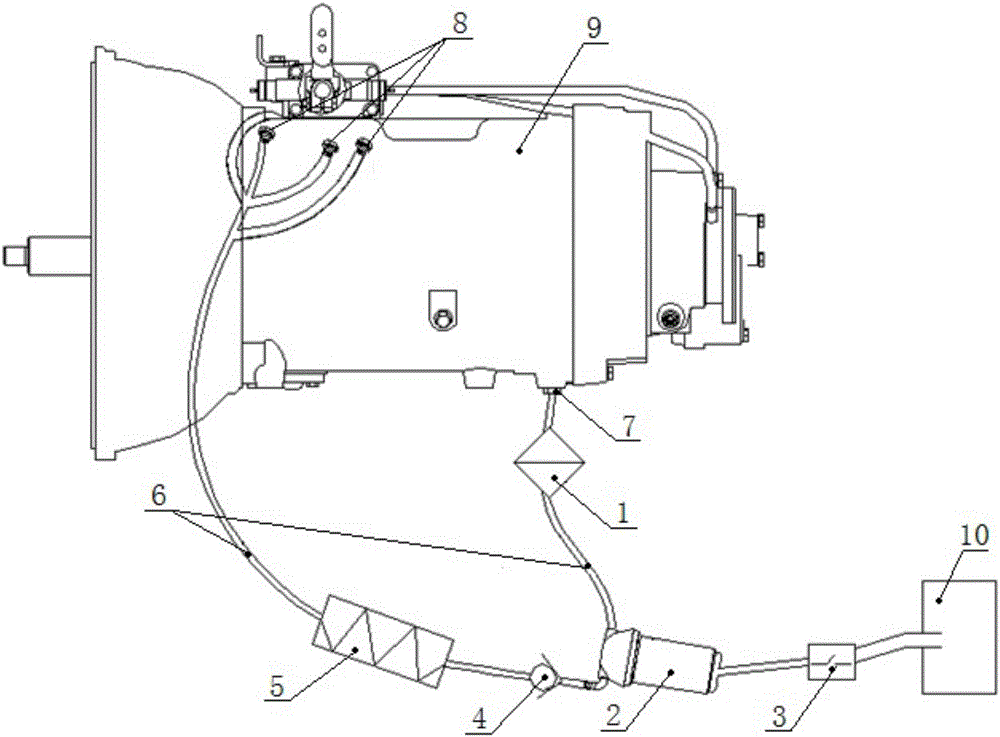

External lubrication device for transmission and method

InactiveCN106641216AMeet lubrication and cooling needsExtended service lifeGear lubrication/coolingLubrication ProblemSpray nozzle

The invention discloses an external lubrication device for a transmission and a method. An external lubrication system is added on the basis of an existing transmission lubrication system. The external lubrication device comprises an external lubrication pump and an angle switch. The external lubrication pump is used as a power source of the external lubrication system. The angle switch is used as a control element. When a vehicle reaches the set slope value in the operation process, the external lubrication pump starts by itself, and normally-engaged gears, the third-gear gear and the fourth-gear gear of the transmission are spattered and lubricated through spray nozzles. When the gradient is smaller than the set value, the angle switch is turned off, and the transmission is lubricated through an internal lubrication system of the transmission. The external lubrication device is simple in structure, convenient to operate, high in reliability, capable of effectively solving the lubrication problem under the condition that a wide-body mining vehicle climbs a slope in a heavy-loaded manner, and capable of prolonging the service life of the transmission.

Owner:SINO TRUK JINAN POWER

Long-service-life multi-protection coolant

InactiveCN105419741AImprove cooling effectSolve the decline of corrosion inhibitionHeat-exchange elementsAdditive ingredientGlycerol

The invention discloses a long-service-life multi-protection coolant. The coolant is prepared from a propylene glycol and ethylene glycol blend, citric acid, simethicone, sodium silicate, starch, glycerol, tribasic polycarboxylic acid, a formic acid and acetic acid mixture, a succinic acid and dodecanedioic acid mixture, montmorillonite nano-particles, a lauric acid and palmitic acid mixture, nano-alumina and guar gum by weight. The coolant is good in cooling performance, the problems that due to gel polymerization of traditional silicate in a coolant, the corrosion inhibition of the coolant is reduced, and a pipeline is blocked are solved, and the problem that an existing engine coolant lacks the protection function for cast aluminum components of a cooling system is also solved; the ingredient composition of the coolant is improved, various comprehensive properties of the coolant are improved, soldering tin of the cooling system is greatly protected, pitting corrosion caused by the engine coolant to the engine cooling system is greatly reduced, and the protection performance of inhibiting cavitation corrosion is improved.

Owner:蚌埠市华科机电有限责任公司

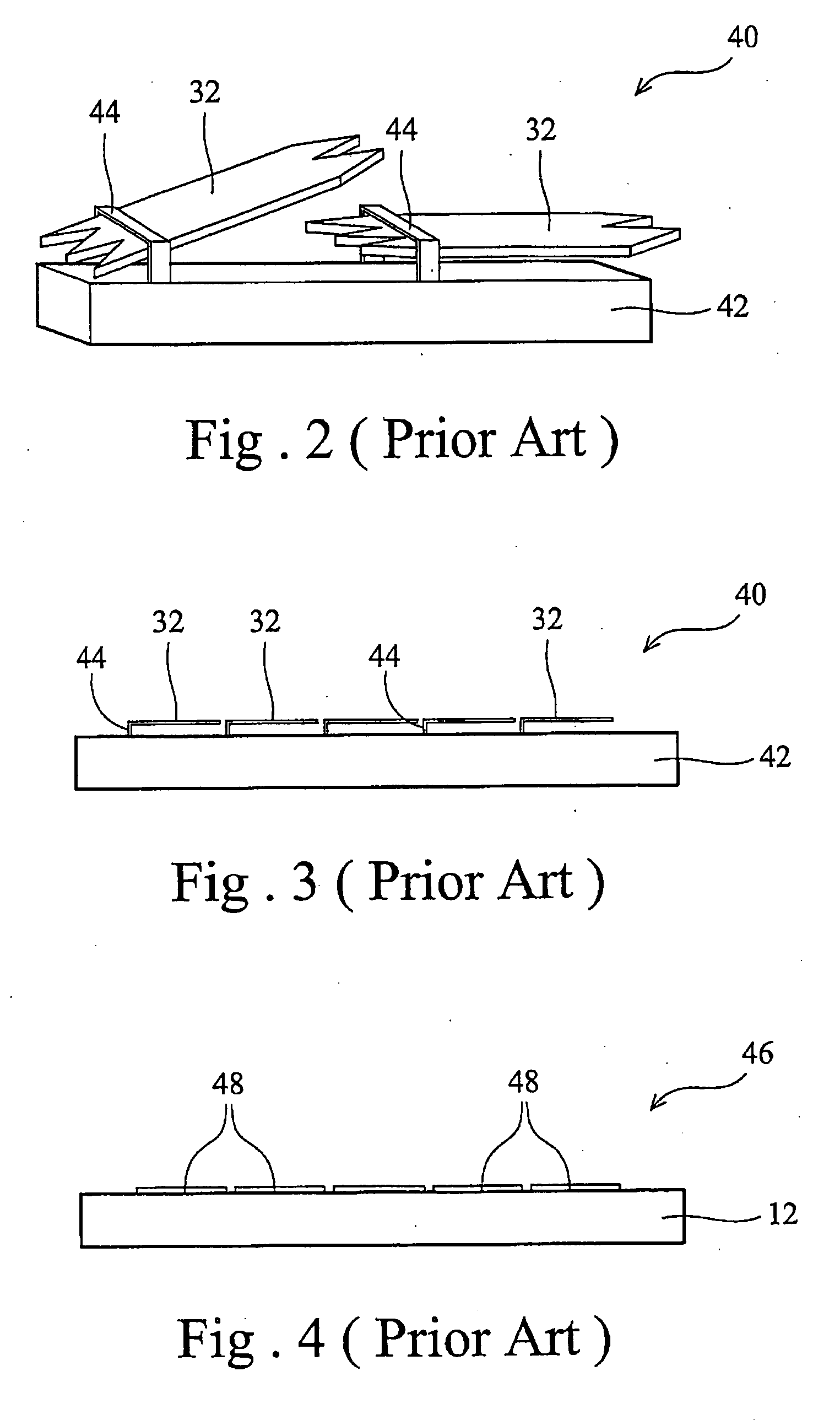

Micromirror for MEMS divice

ActiveUS20050259311A1Good reflective propertiesReduce pittingCoatingsSpecial surfacesTitanium nitrideOptoelectronics

A micromirror which includes a substrate, a reflective layer comprising pure aluminum overlying the substrate and a protective layer comprising titanium nitride overlying the reflective layer is disclosed.

Owner:TAIWAN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com