Graphite anode for heavy current resistant magnesium electrolysis and preparation process thereof

A graphite anode and preparation process technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of uneven temperature distribution, thermal stress, poor thermal conductivity, etc., and achieve high mechanical strength, arc reduction, and resistivity reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

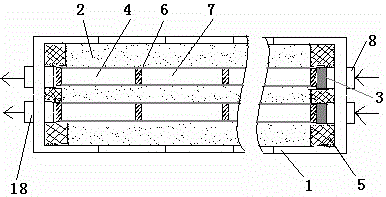

Image

Examples

Embodiment Construction

[0028] A graphite anode for high-current resistant magnesium electrolysis, kneading with the following components by weight ratio as raw materials: delayed calcined petroleum coke with a particle size of 0-2mm accounting for 93-99% of the weight ratio of the dry material, accounting for the weight ratio of the dry material 1-3% graphite scrap, additive Fe 2 o 3 and stearic acid, accounting for 20-30% of the total weight ratio of medium-temperature modified pitch (30%-33% of toluene insoluble matter, 9-12% of quinoline insoluble matter, 55-60% of coking value, and ash A2 o3 The total weight ratio is 0.44-0.6%, and the stearic acid is 0.05-0.09% by total weight ratio.

[0029] in,

[0030] (1) In the kneading step, first put the sieved delayed calcined petroleum coke and graphite scraps into the kneading pot according to the formula requirements and stir evenly. After about 10-15 minutes, add carbon fiber short chips and Fe at the same time. 2 o 3 Continue dry mixing, add asp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com