Patents

Literature

109results about How to "Low CTE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

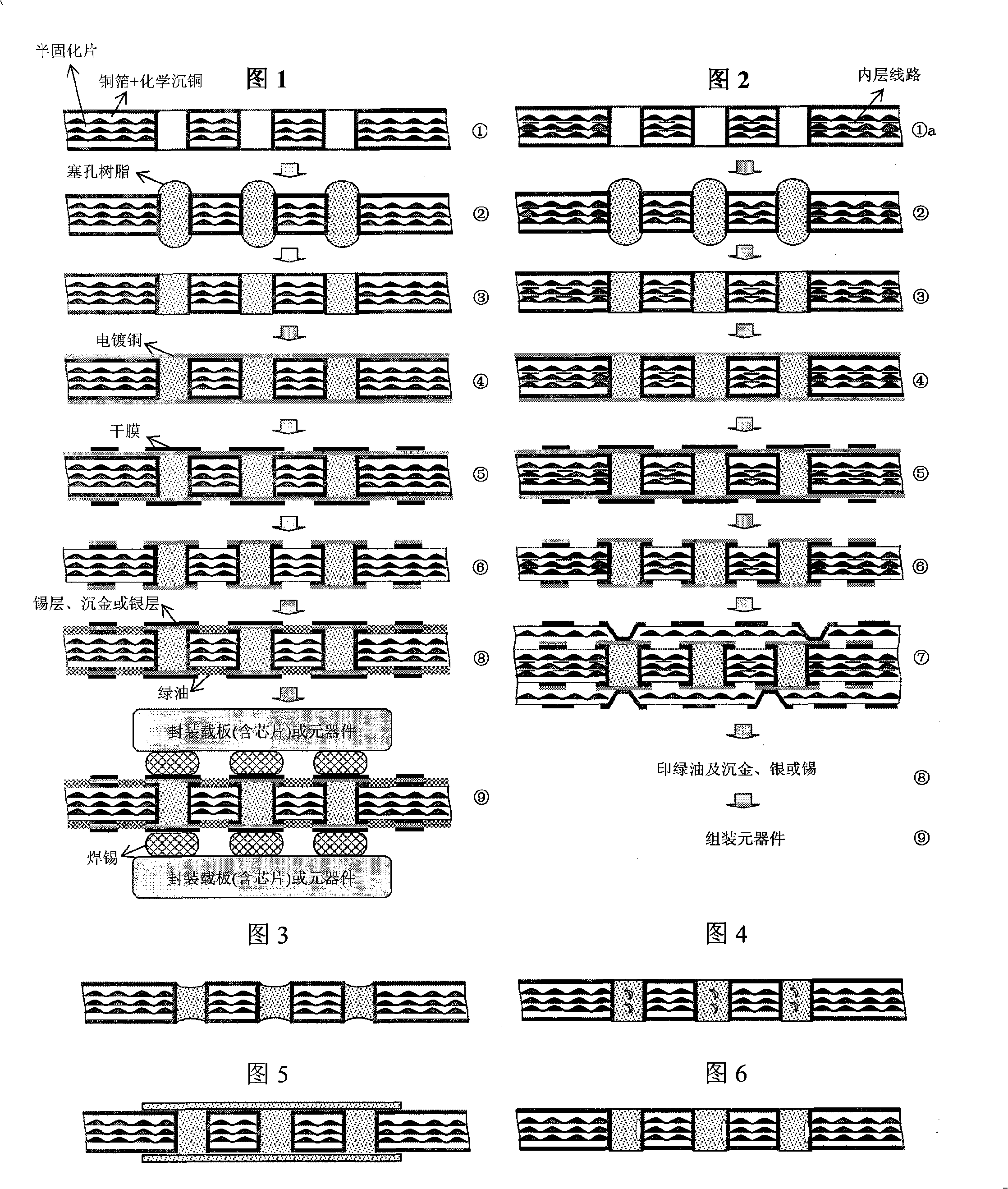

Liquid thermosetting resin composition and method for manufacturing printed circuit board using the same

InactiveCN101328301AImprove thixotropyStrong defoaming performancePrinted circuit detailsPolymer sciencePtru catalyst

The invention provides a liquid thermosetting resin composition. The composition comprises the components in weight percentage: 30 to 80 percent of epoxide resin, 2 to 25 percent of firming agent, 20 to 80 percent of filling material, 0.001 to 5 percent of thixotropic agent, 0.001 to 5 percent of visbreaking dispersant, 0 to 5 percent of foam suppressor and a catalyst the weight of which is no more than 0.5 percent of the total weight of the epoxide resin and the firming agent; the components are mixed and evenly stirred; the liquid thermosetting resin composition has the advantages of good fluidity and metallic wettability, higher Tg, lower CTE and good self deaeration performance, and can overcome the defects of shrinkage in a hole, cracking in the hole, bubble in the hole and the connection of resins between holes. The invention also provides a method for manufacturing a printed circuit board by using the liquid thermosetting resin composition, which aims to improve the defects of the insufficient rubber filling after plate pressing and the cracking or the layering of resins after thermal shock and improve the credibility such as the heat reliability, etc. of the thick copper printed circuit board.

Owner:曾灿旺

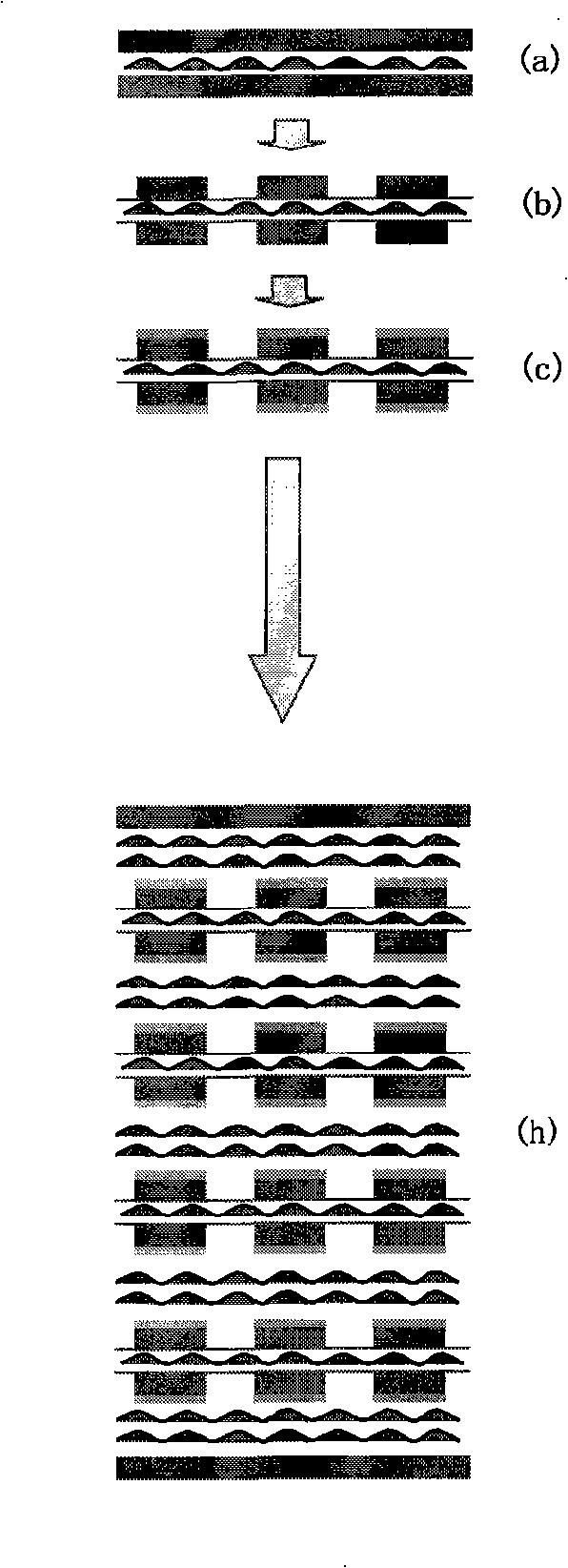

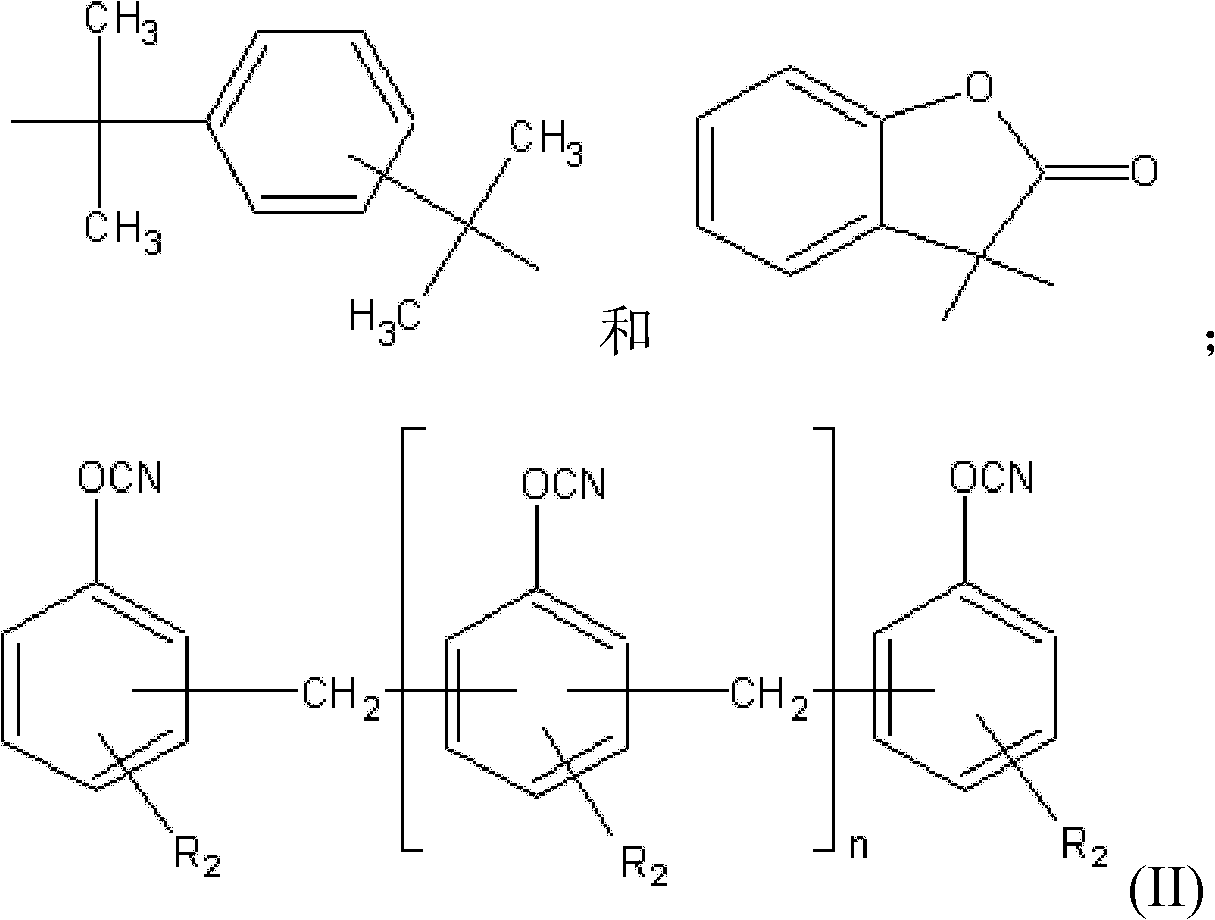

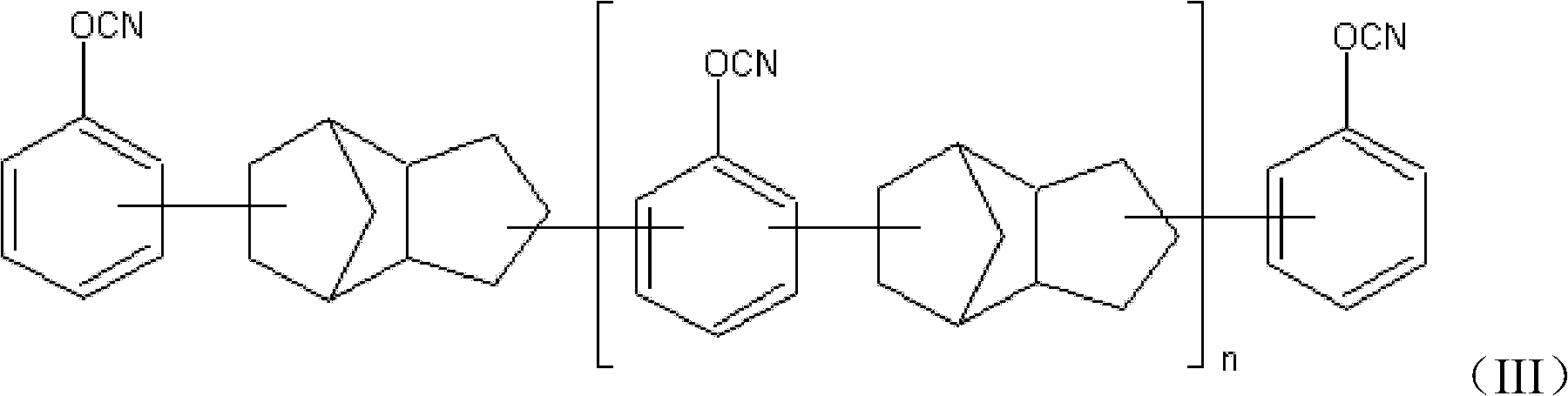

Halogen-free Tg resin composite and presoaked material and laminated board made by adopting same

ActiveCN102134375AExcellent dielectric propertiesLow dielectric propertiesPrinted circuit aspectsSynthetic resin layered productsVitrificationPhosphonium

The invention relates to a halogen-free Tg resin composite and a presoaked material and a laminated board made by adopting the composite. Counted by part by weight of organic solid matters, the halogen-free high-Tg resin composite contains the following components according to part by weight: (A) 10 to 50 parts by weight of cyanate resin; (B) 10 to 50 parts by weight of at least one compound withdihydro-benzoxazine ring; (C) 10 to 50 parts by weight of at least one kind of bismaleimides resin; (D) 10 to 50 parts by weight of at least one kind of poly-epoxy compound; and (E) 5 to 30 parts by weight of at least one kind phosphonium flame retardant. The halogen-free high-Tg resin composite has the performances of low water absorption, low CTE (coefficient of thermal expansion), high Tg, good dielectric property and the like, and the presoaked material and laminated board made by adopting the composite has the characteristics of high vitrification transition temperature, low CTE, low dielectric constant, low water absorption, high thermal resistance and the like, thus being application to multi-layer circuit boards.

Owner:GUANGDONG SHENGYI SCI TECH

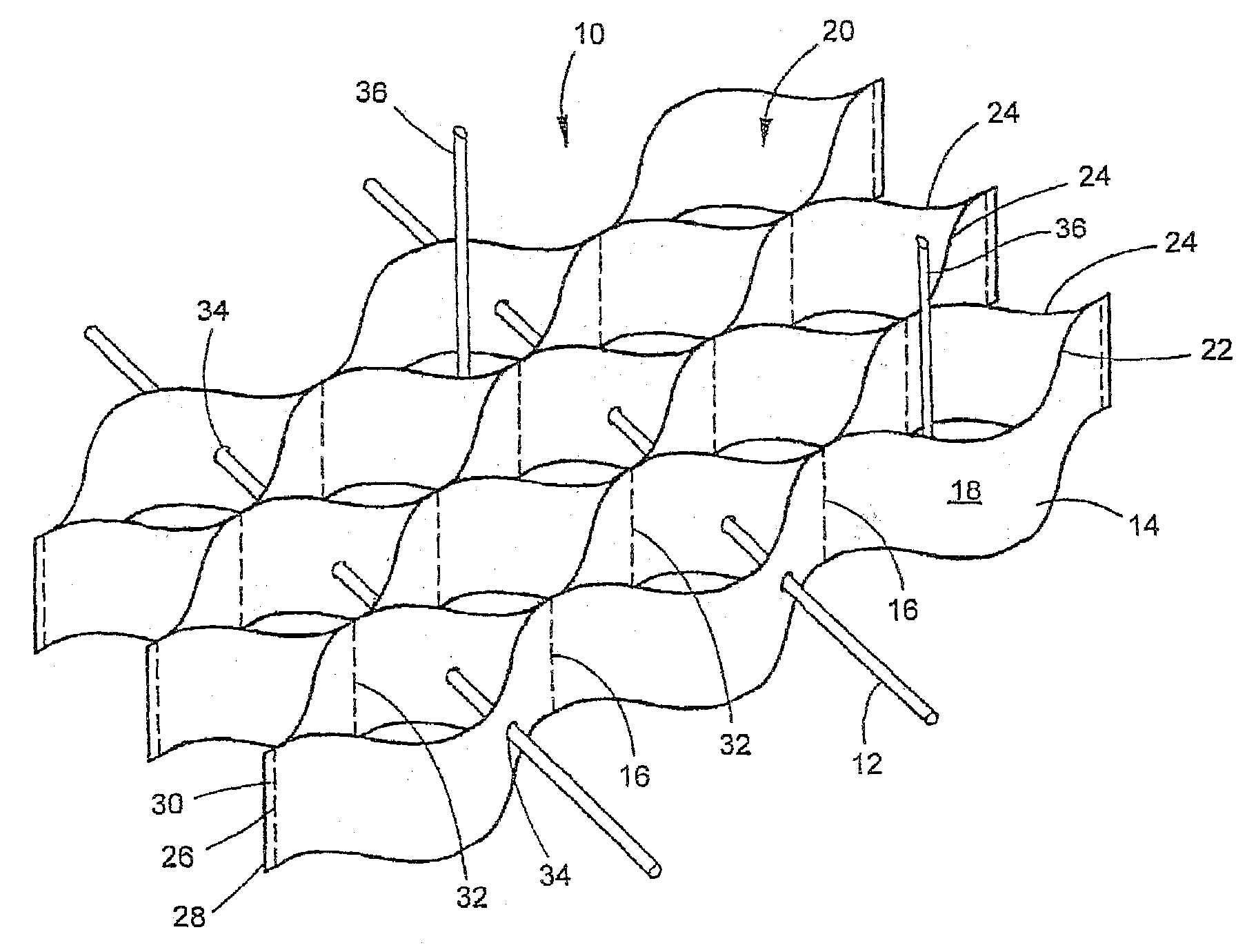

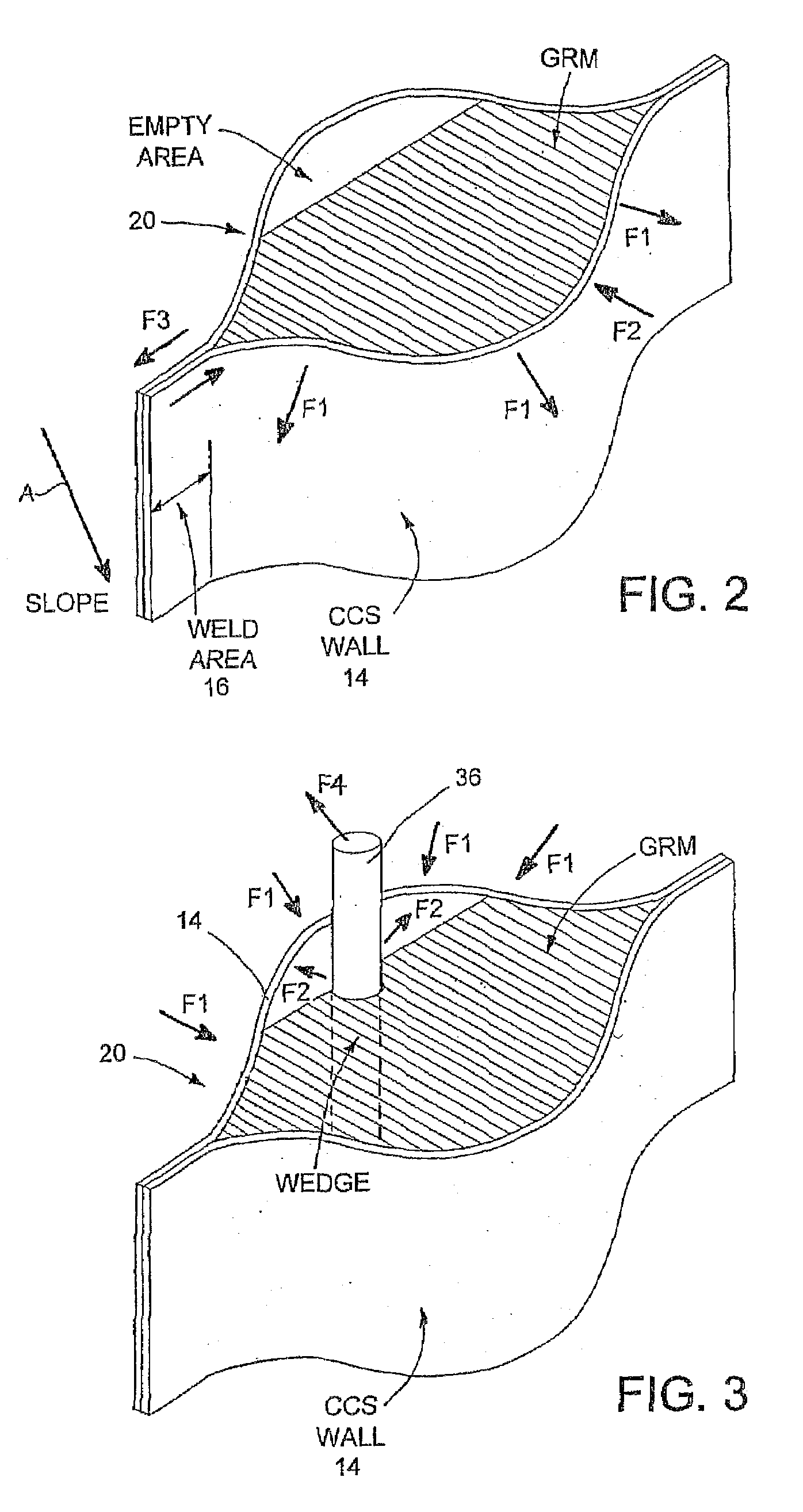

Geotechnical articles

InactiveUS20080213521A1Improve creep resistanceImprove tear resistanceDomestic netsThin material handlingCold areaCellular confinement

A multiphase polymeric material comprises a first rigid continuous phase and a second elastic phase dispersed in the first phase. The multiphase polymeric material may be formed into polymeric strips and used to make a cellular confinement system which is suitable for use in cold areas.

Owner:PRS MEDITERRANEAN

Thermally conductive polymer compositions having low thermal expansion characteristics

ActiveUS20050272845A1Low CTE propertyImparts thermal conductivitySynthetic resin layered productsSpecial tyresConductive polymerThermal expansion

An injection moldable, thermally conductive polymer composition that has ultra low CTE properties is provided. The composition is suitable both for substrate applications in high precision electronics assemblies as well as over molding applications in conjunction with ceramic substrates. The composition includes a base polymer matrix material loaded with thermally conductive filler, which imparts thermal conductivity to the polymer matrix while also maintaining or enhancing the dielectric properties of the base polymer. The resultant composition exhibits CTE properties in the range of between 9 ppm / ° C. and 2 ppm / ° C., exhibits an optical anisotropy of below 1.5, and a thermal conductivity of greater than 2 W / m° K. The composition is suitable for use in over molding applications in conjunction with virtually any suitable electronics substrate material without the introduction of mechanical stresses produced by large CTE differentials.

Owner:TICONA POLYMERS INC

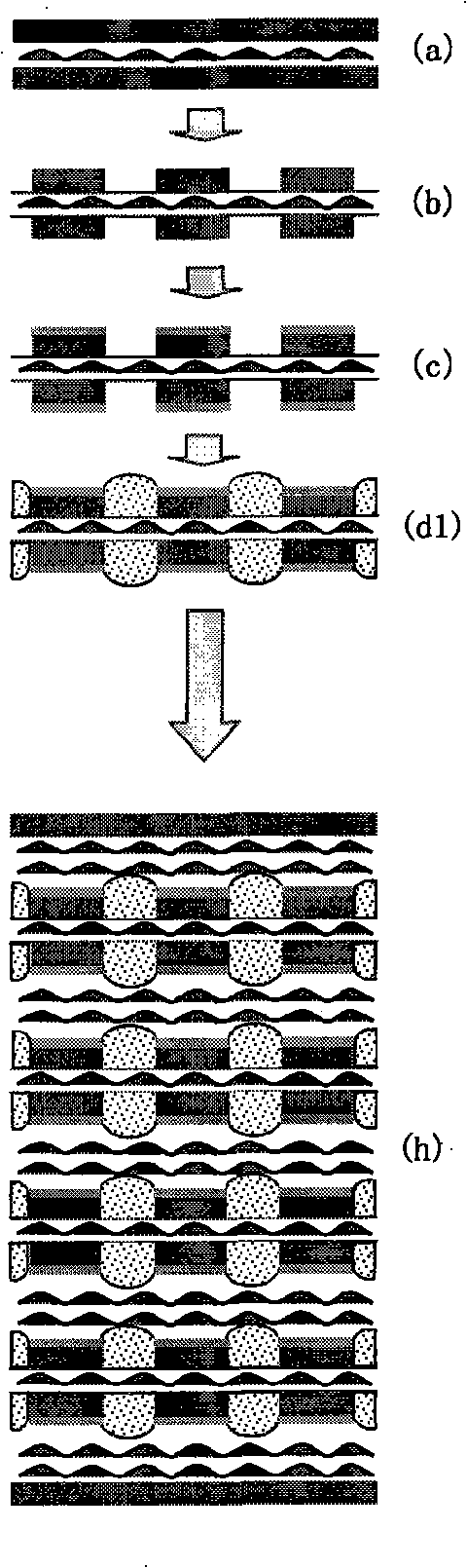

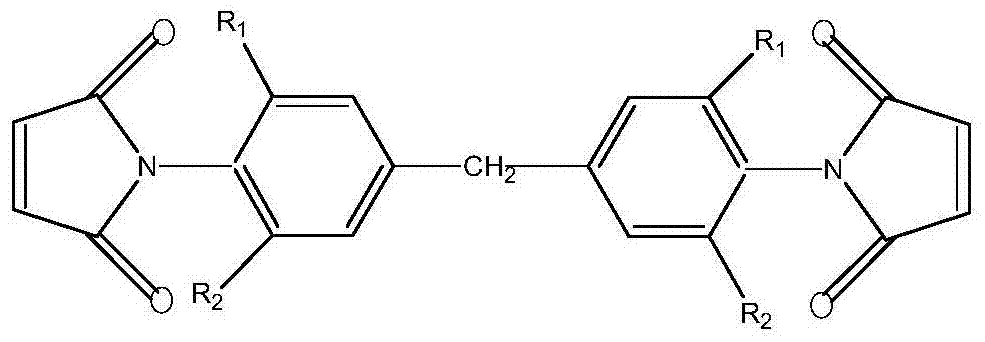

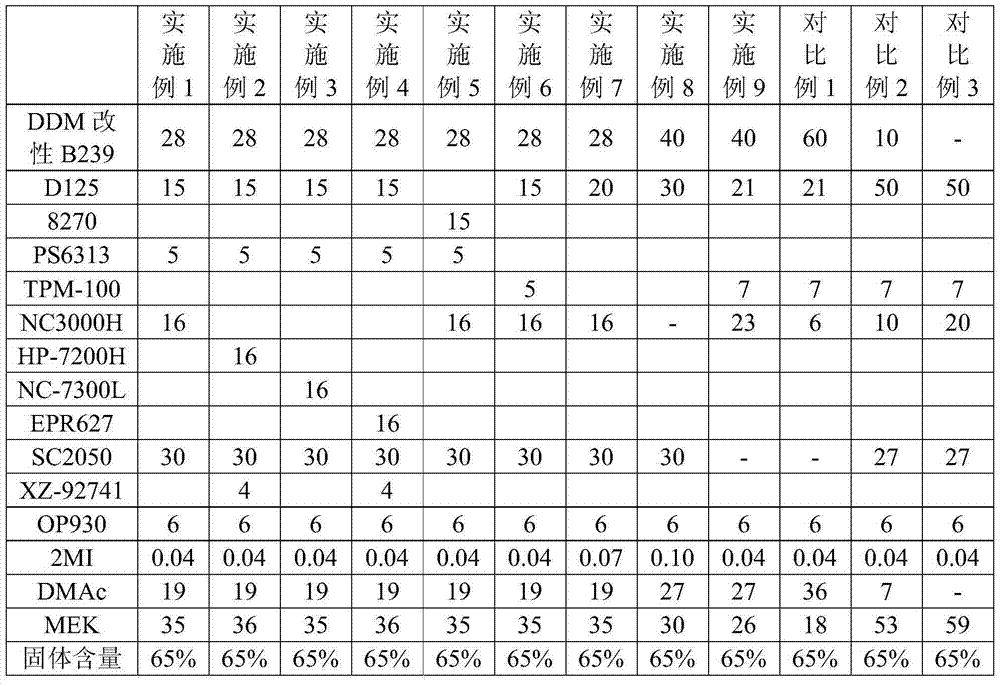

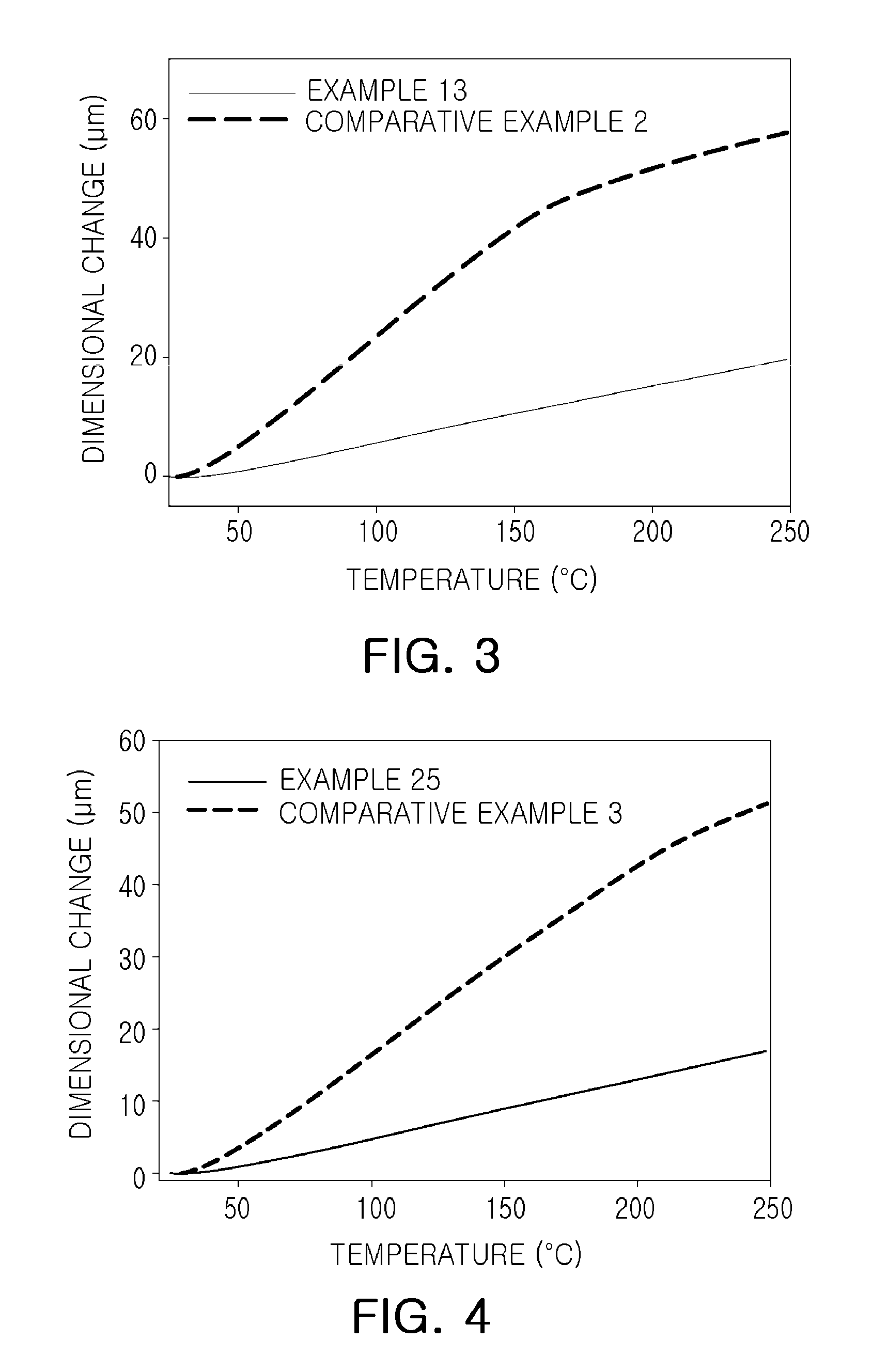

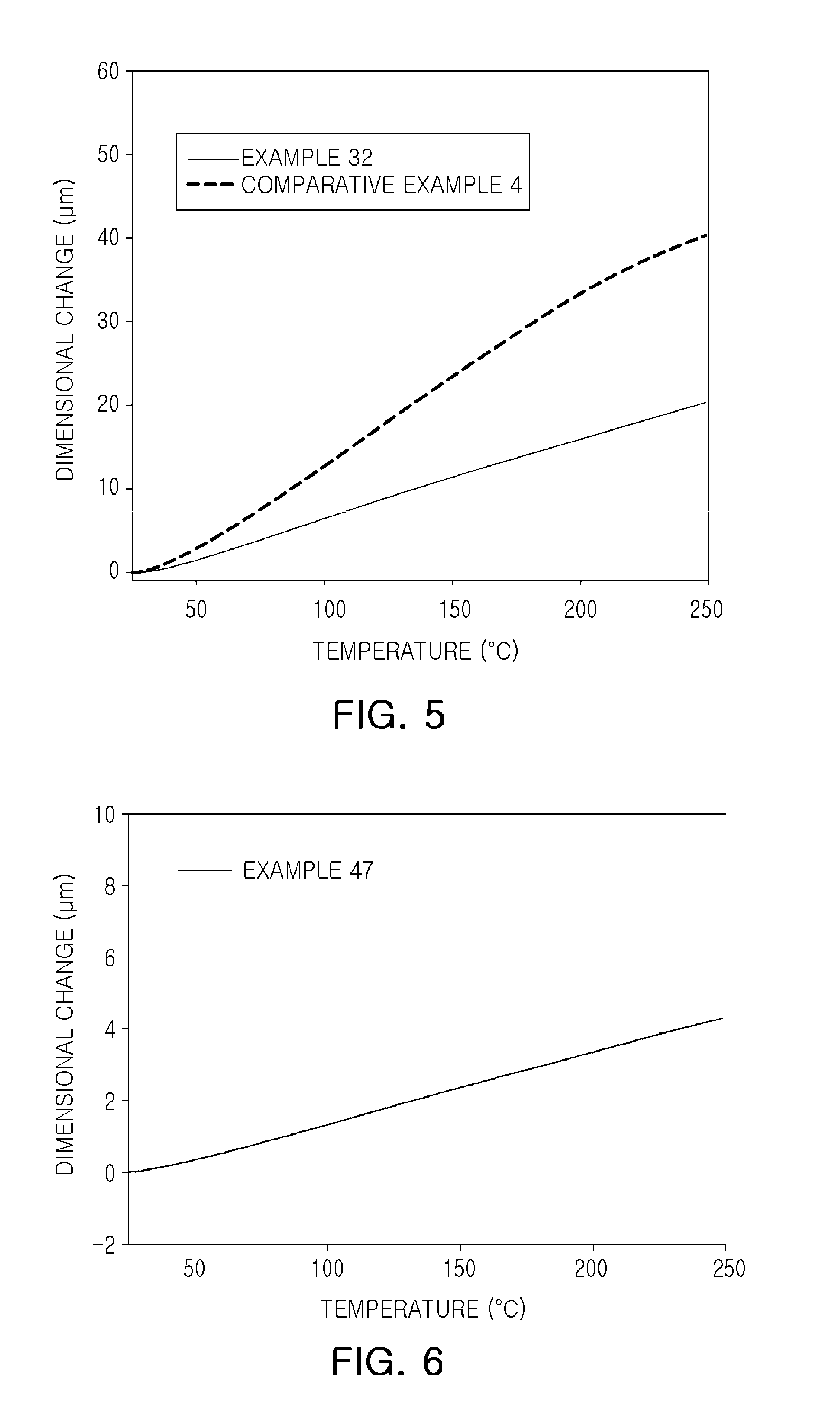

Resin composition, prepreg using resin composition and laminate

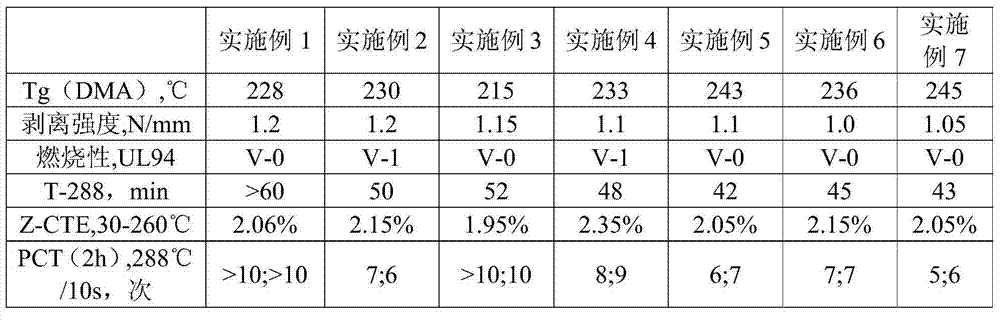

ActiveCN104725781AHigh TgLow CTESynthetic resin layered productsCircuit susbtrate materialsDielectric lossElastic modulus

The invention belongs to the technical field of copper clad laminates and particularly relates to a resin composition, prepreg using the resin composition and a laminate. The resin composition contains the ingredients in percentage by weight: 15-55% of amine modified bismaleimide (BMI), 10-45% of benzoxazine resin and 0-75% of epoxy resin. According to the resin composition, through further reaction of benzoxazine (BOZ) and amine modified bismaleimide (BMI), performance advantages of two kinds of high-performance resin, namely BMI and BOZ, are excellently exerted, so that the prepreg and the copper clad laminates, manufactured from the resin composition, have the properties of high Tg, relatively high peeling strength, relatively low CTE, relatively low water absorbing capacity, relatively low dielectric loss, relatively high elastic modulus high-temperature retention rate, relatively good resistance to hot and damp and the like, and reach a flame-retardant level UL94-V0.

Owner:GUANGDONG SHENGYI SCI TECH

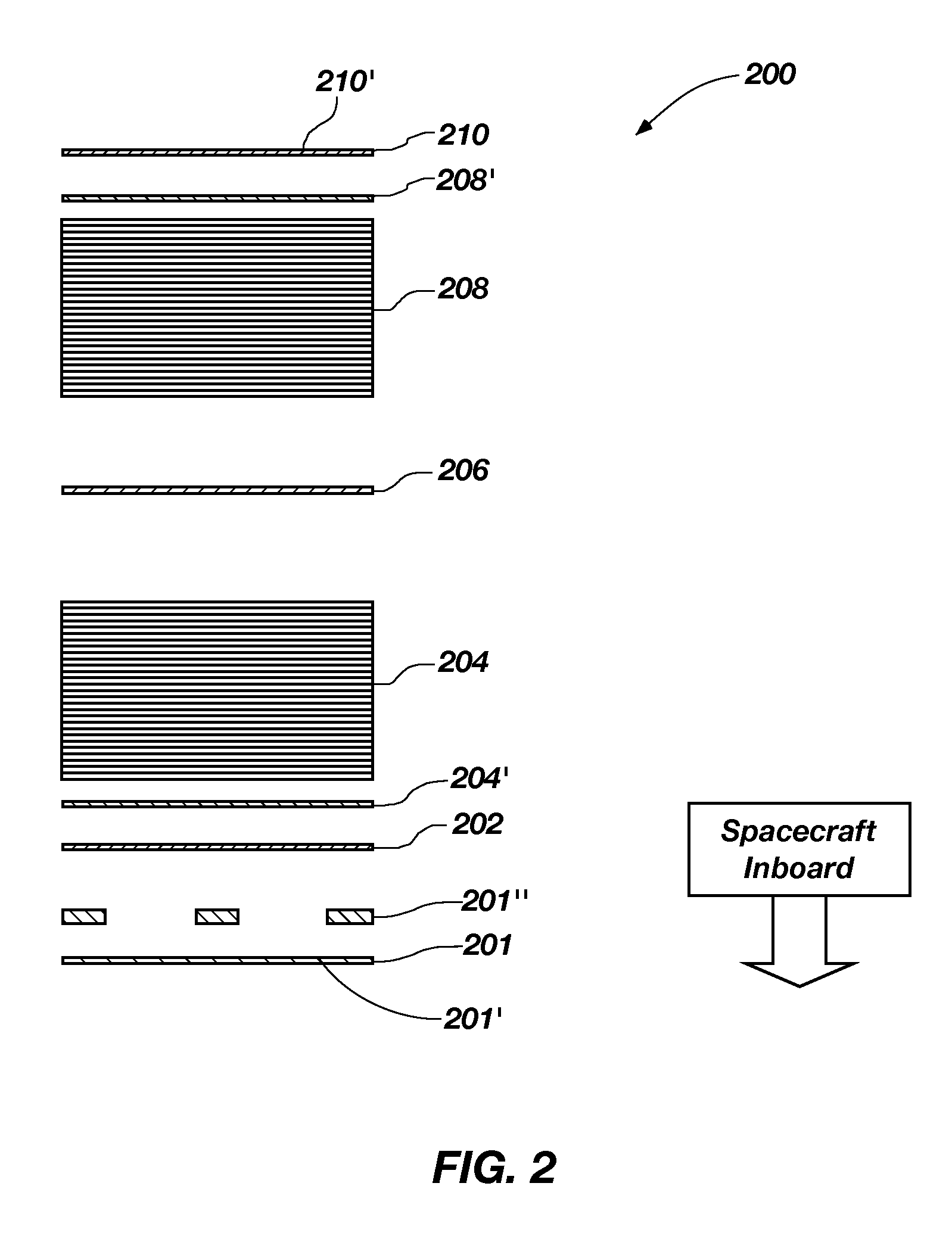

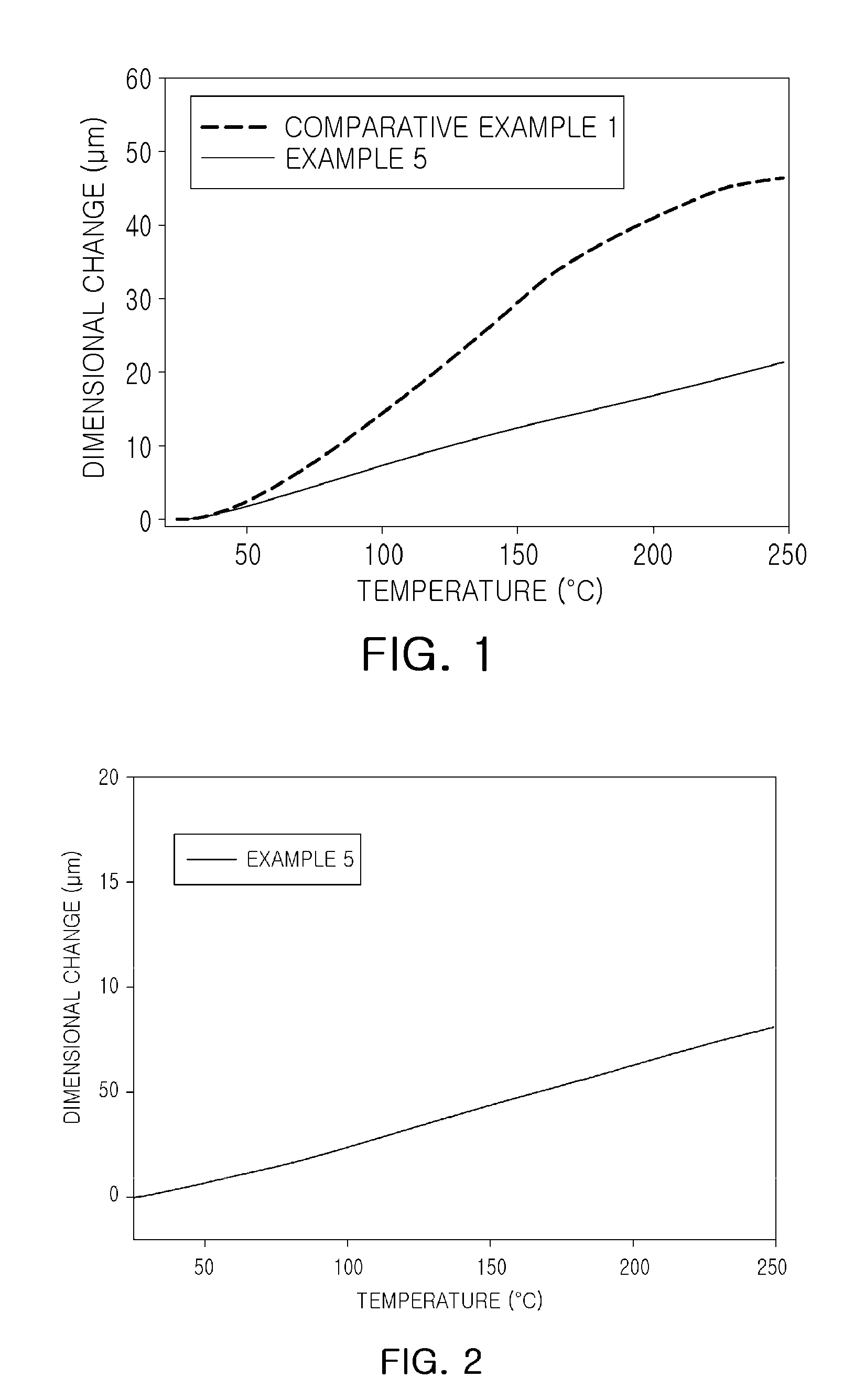

Preparation of low thermal expansion coefficient thermoplastic polyimide film

The invention relates to a preparation method of a thermoplastic polyimide film with low coefficient of thermal expansion, which obtains an objective product by copolymerization, sol-gel process and condensation. Two different diamine and dianhydride are added into copolyreaction to generate polyreaction. A sol-gel in situ method is adopted, the reaction process is easy to control, the purity of the product is good and the uniformity is good; and the obtained solution is heated step by step in a vacuum oven and carries out condensation. The preparation technique is simple and is easy to control; the obtained product has better heat resistance; and the invention is suitable for being used by flexible copper clad laminate and has higher application value in the industry.

Owner:NANJING UNIV OF TECH

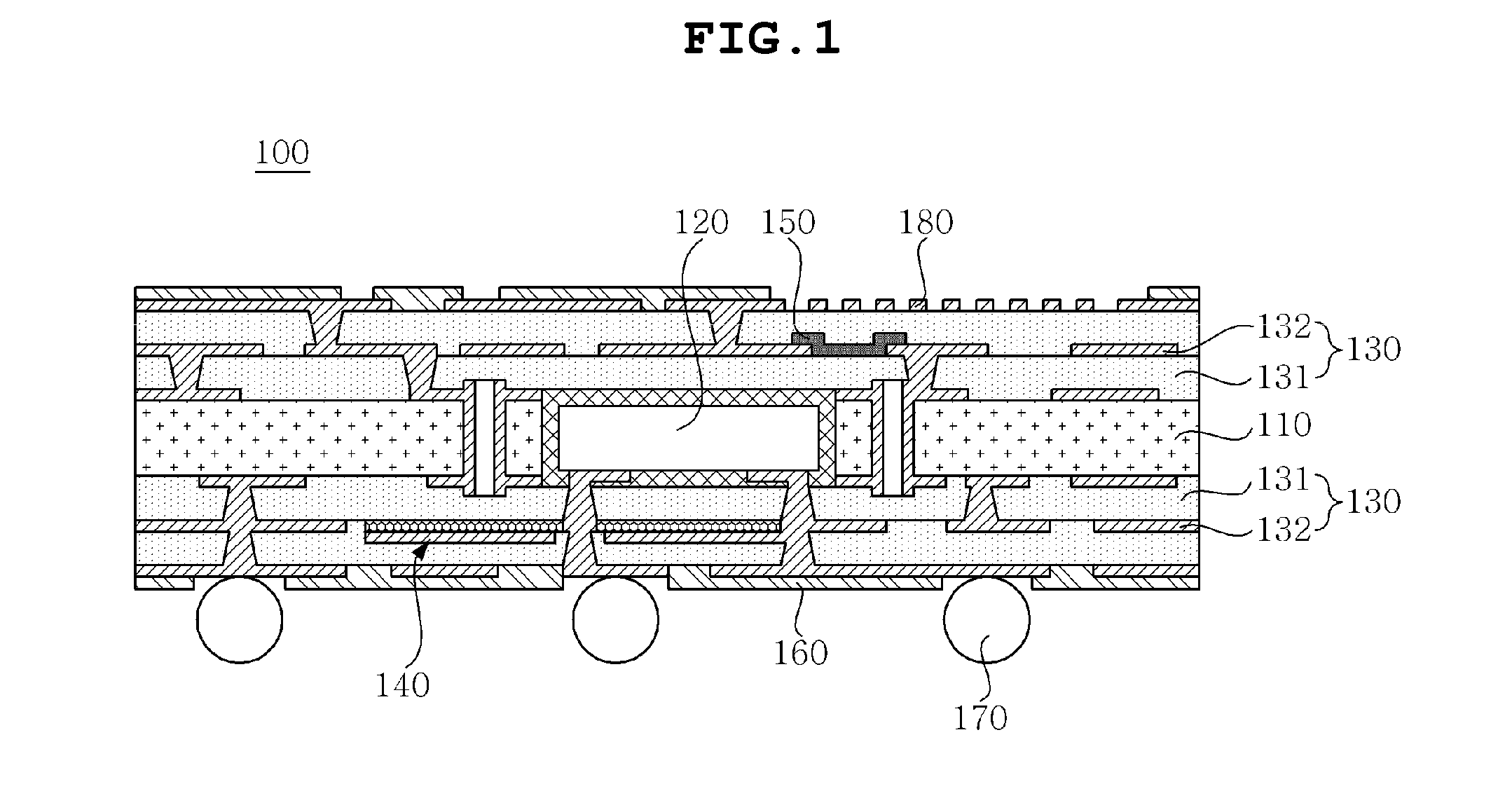

Resin composition with enhanced heat-releasing properties, heat-releasing film, insulating film, and prepreg

InactiveUS20140187674A1Heat releasing property is improvedDecreasing mechanical propertySemiconductor/solid-state device detailsSolid-state devicesOligomerLiquid crystal

This invention relates to a resin composition with enhanced heat-releasing properties, including a liquid crystal oligomer, an epoxy resin, or a resin mixture thereof, and graphene oxide as a filler, and to a heat-releasing film for an electronic device, an insulating film for a printed circuit board, and a prepreg, which are manufactured using the resin composition.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Polyimide film

ActiveUS20100255221A1Superior mechanical propertyHigh thermal stabilityLiquid crystal compositionsSynthetic resin layered productsChemistryPolyimide

Disclosed is a polyimide film, which is colorless and transparent, with superior mechanical properties and high thermal stability.

Owner:KOLON IND INC

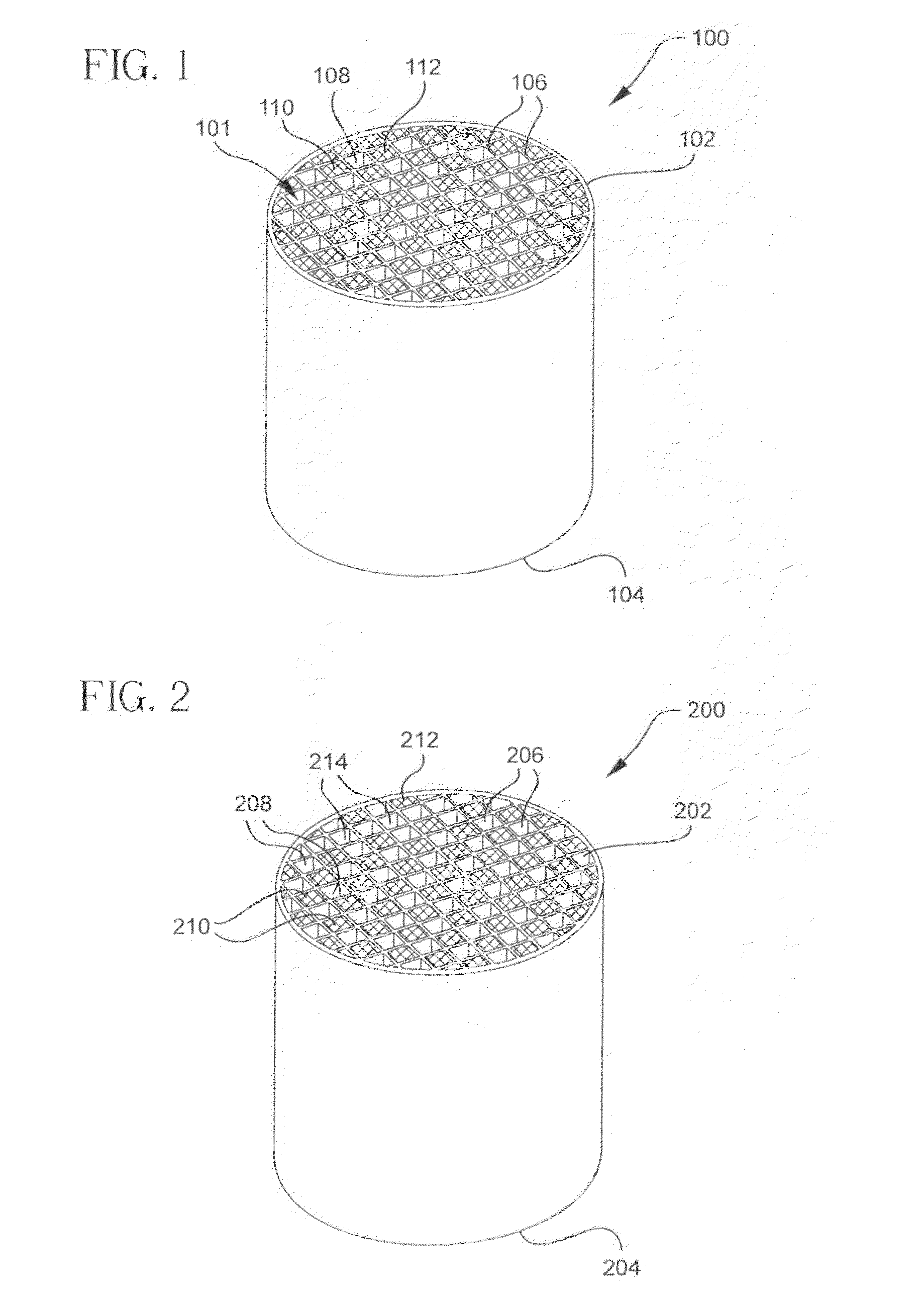

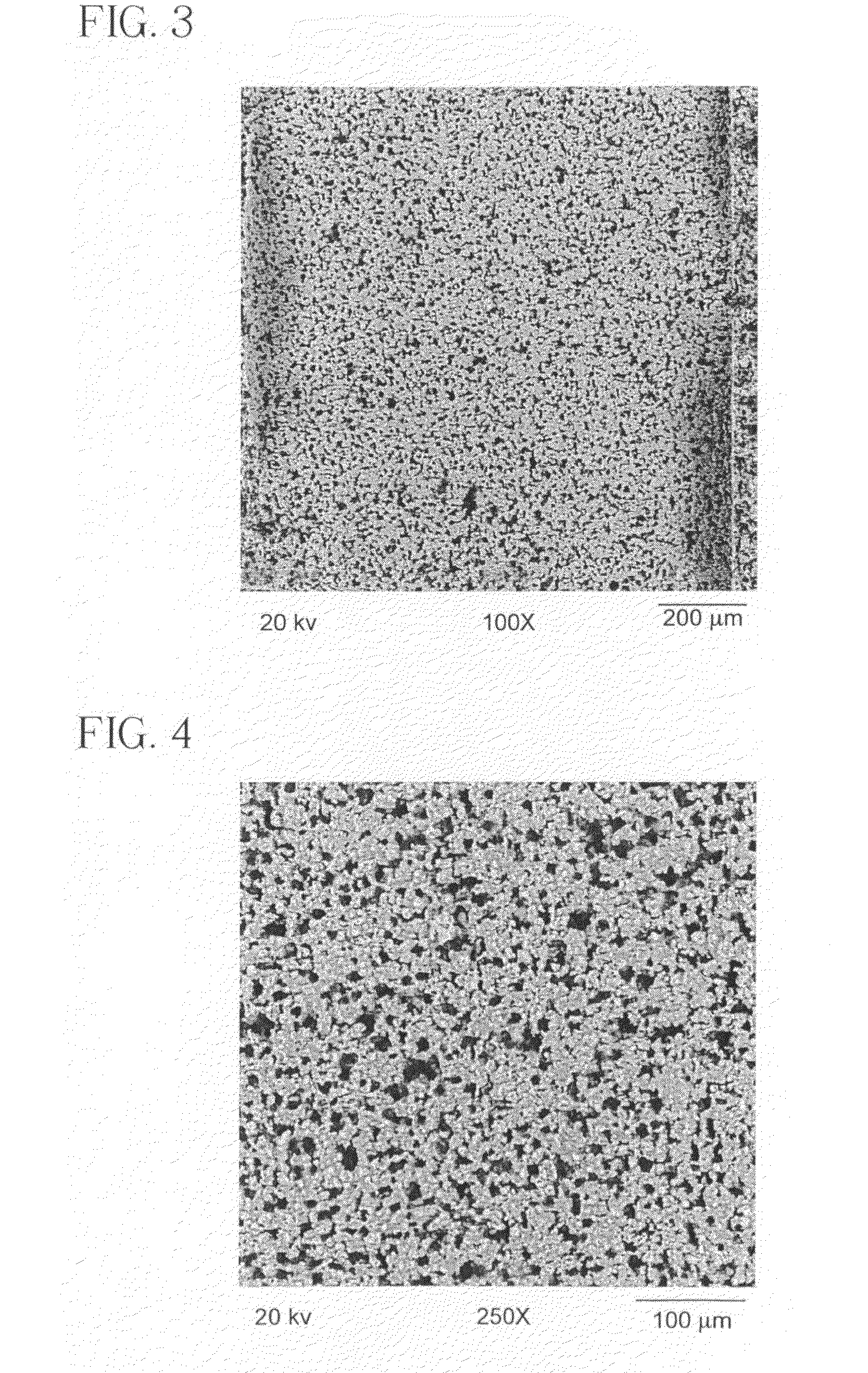

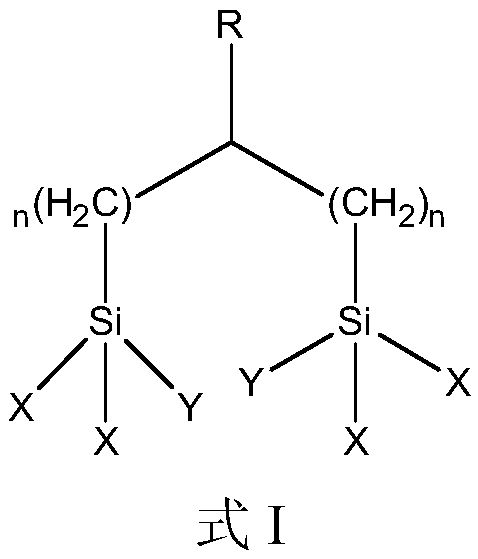

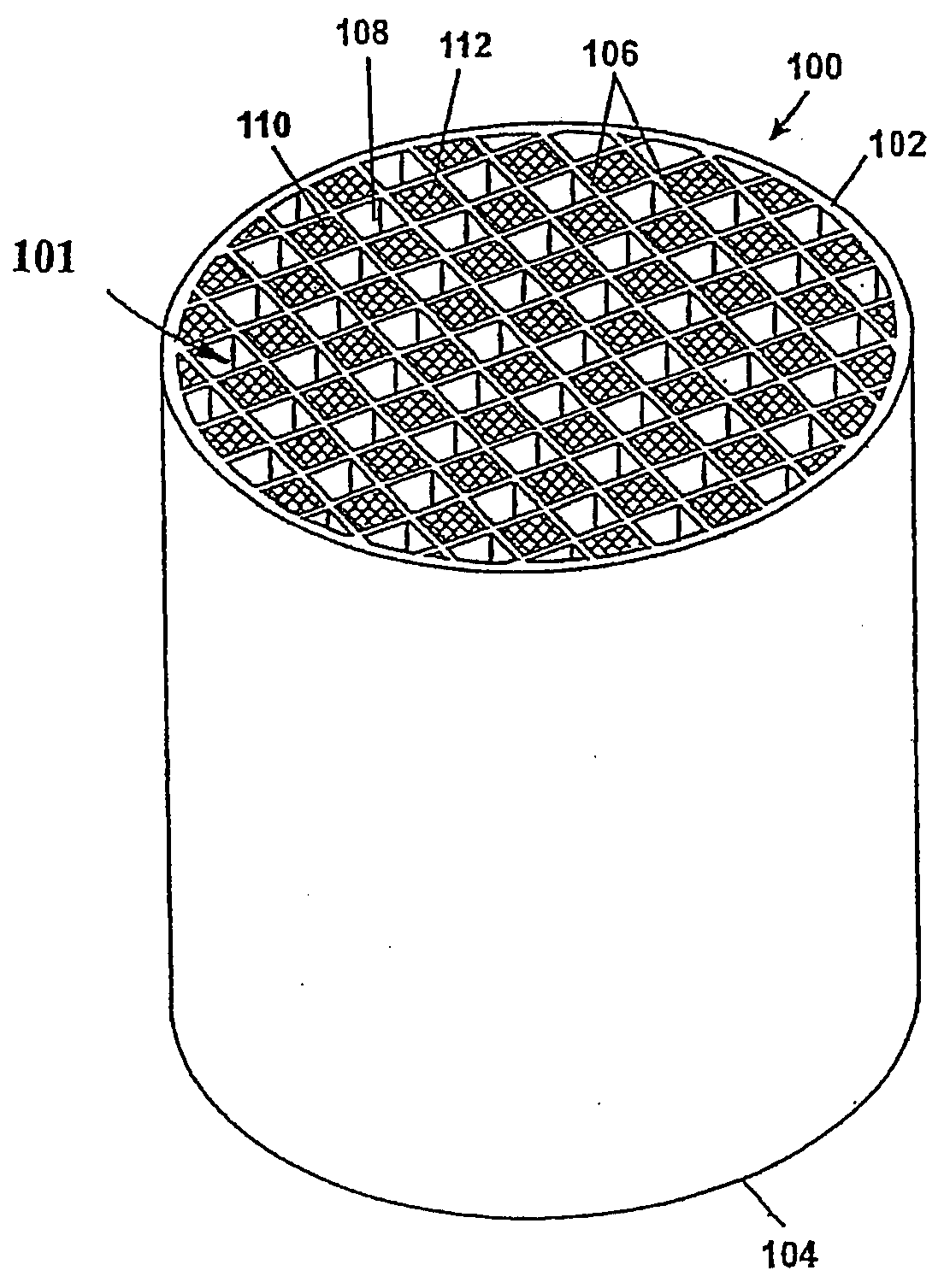

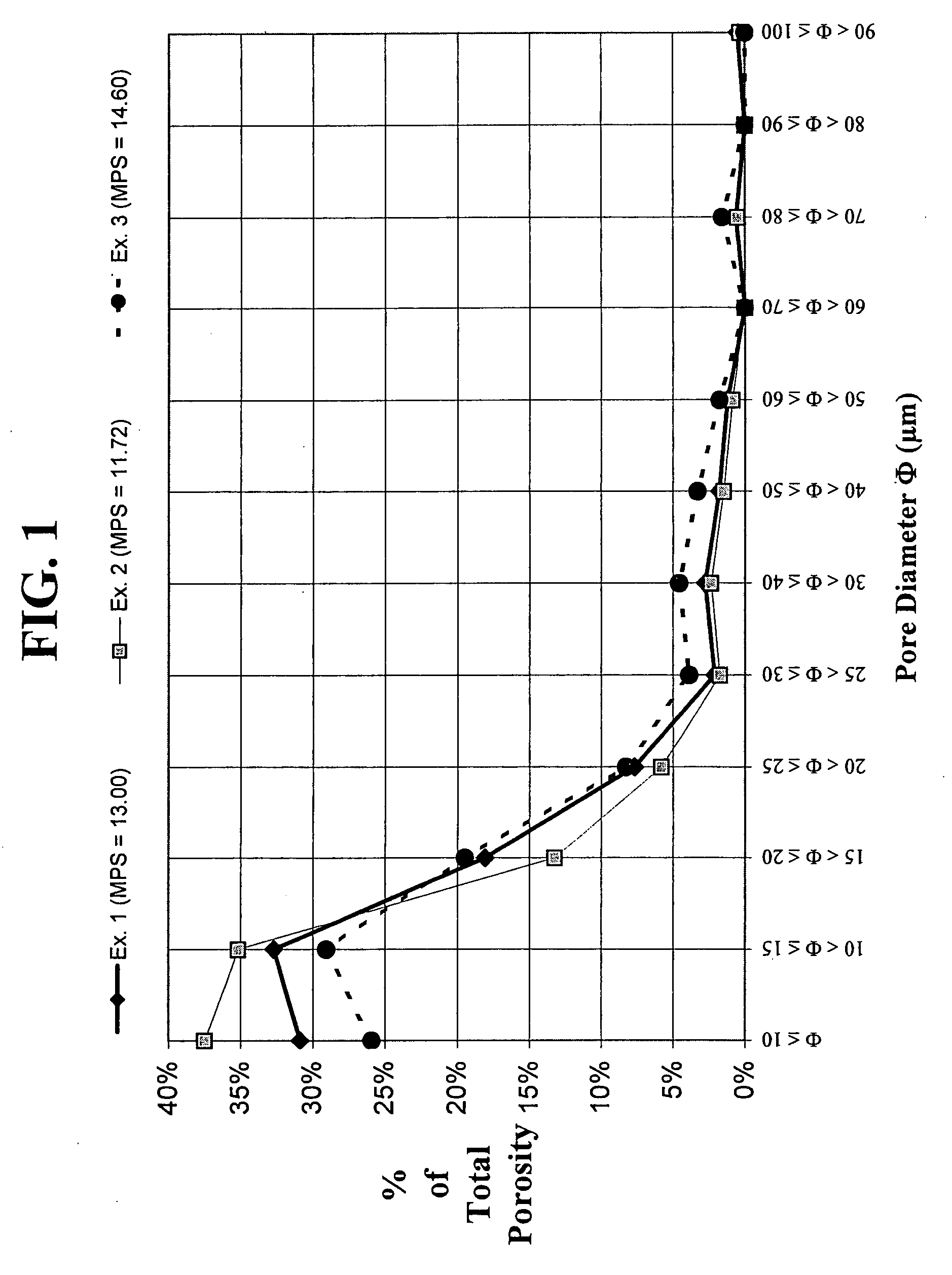

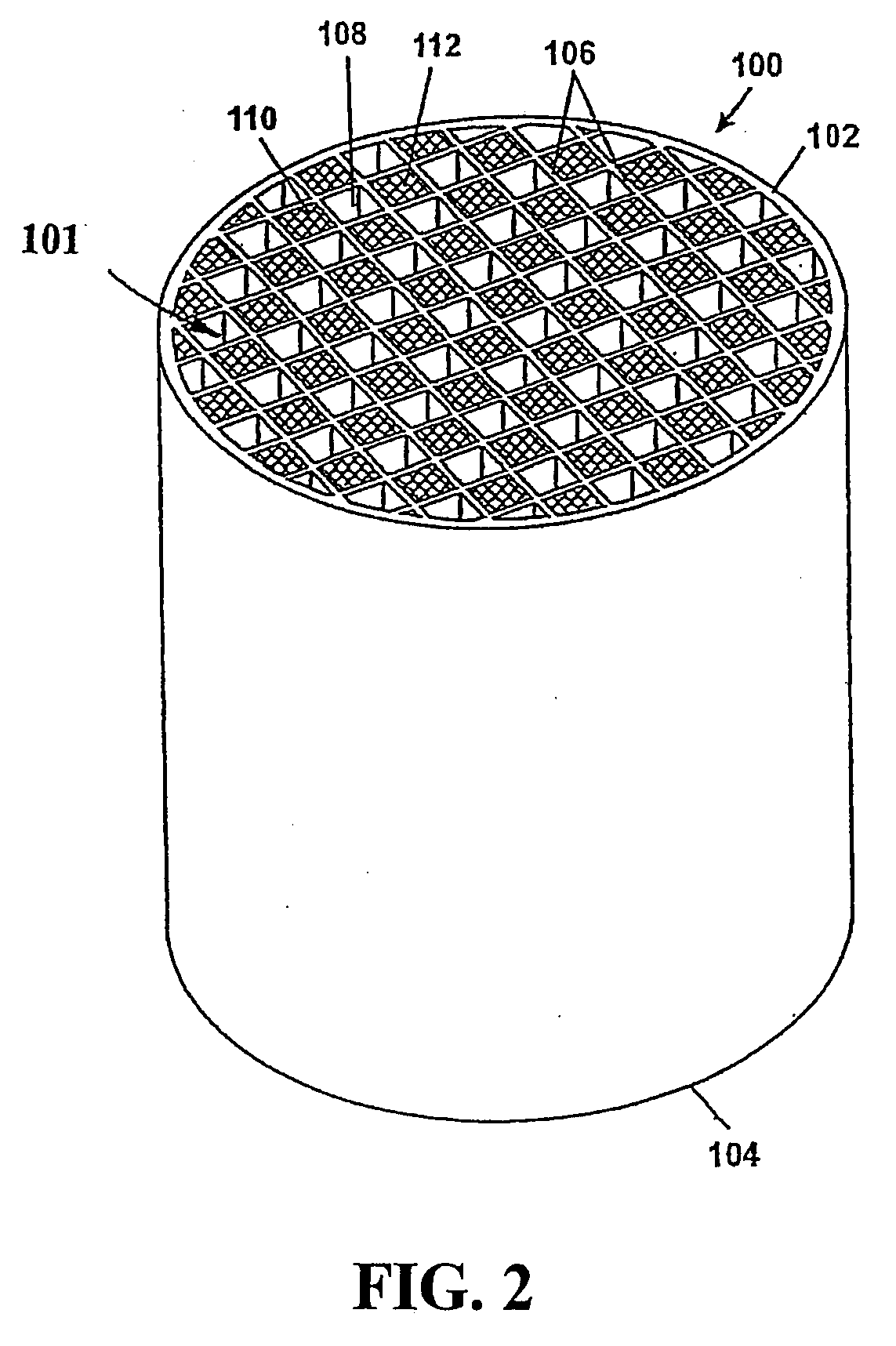

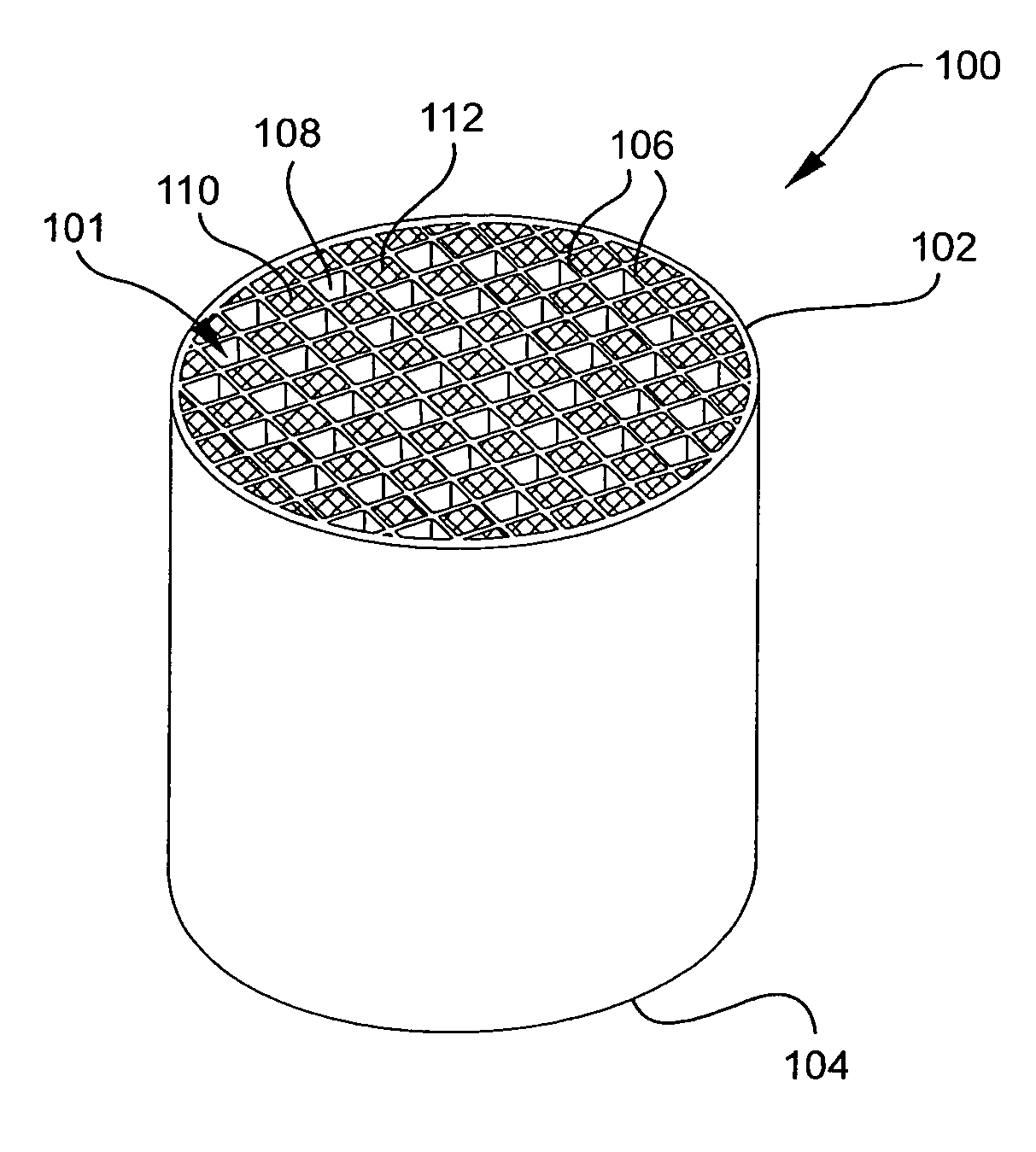

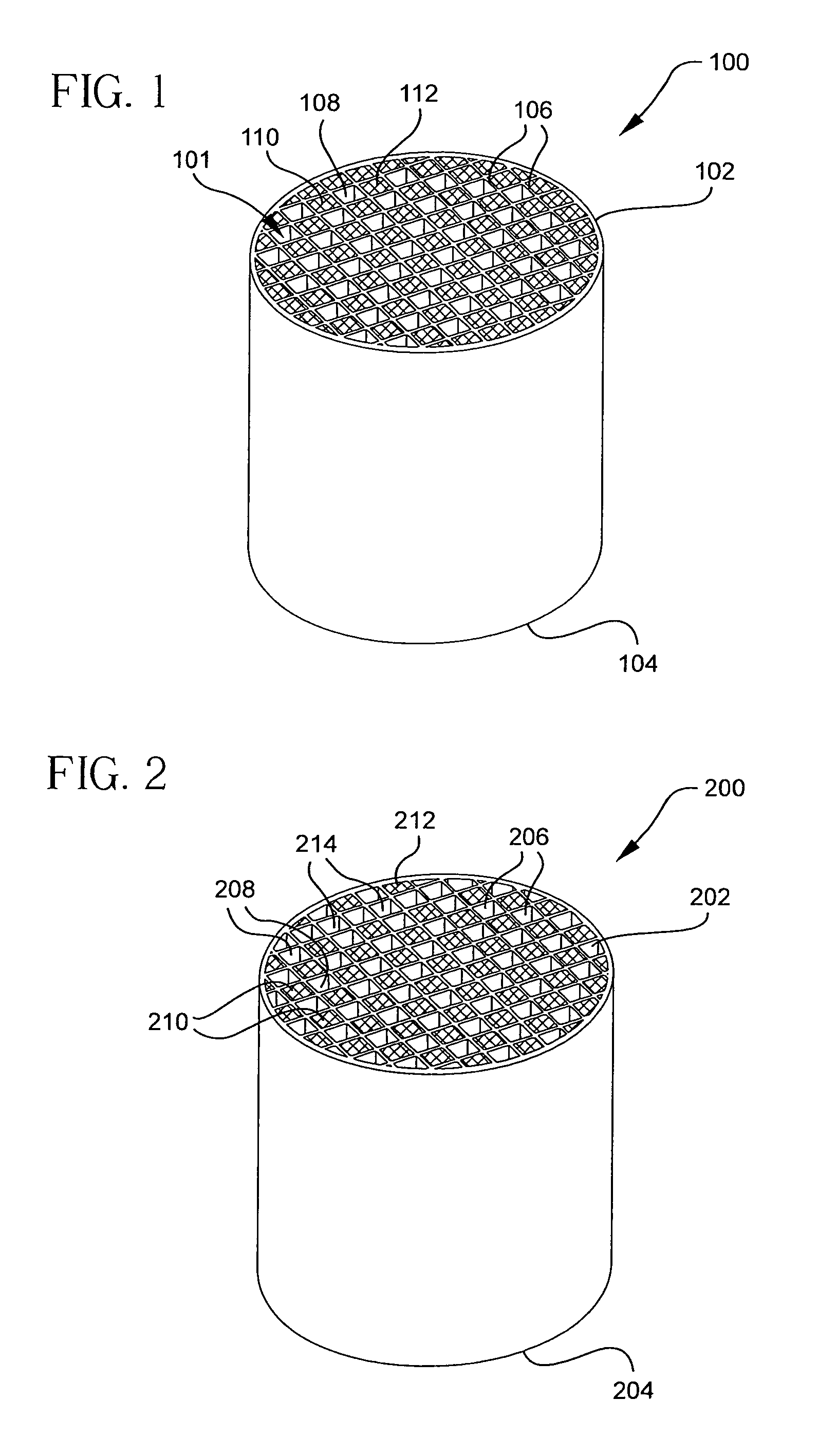

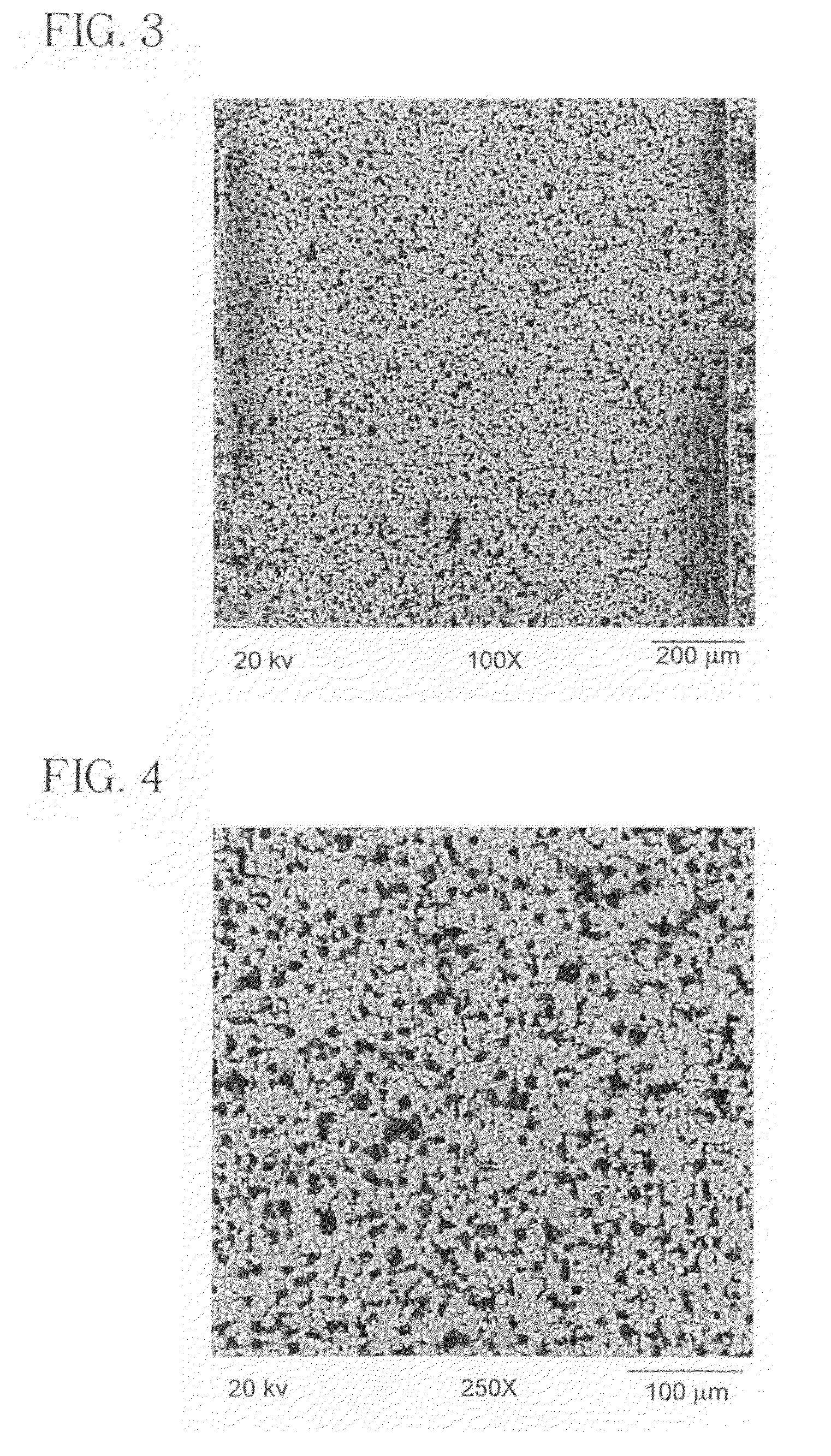

Cordierite honeycomb article and method of manufacture

ActiveUS20090087613A1Improve toleranceReduction factorLayered productsCeramic shaping apparatusFiltrationSurface roughness

Disclosed are ceramic honeycomb articles which are composed predominately of a crystalline phase cordierite composition. The porous cordierite ceramic honeycomb articles has a plurality of cell channels and intersecting porous walls and possess a microstructure characterized by a pore size distribution wherein greater than or equal to 75% of the pore size distribution of the porosity of the porous walls, by volume, have a pore diameter (dv) wherein dv<10.0 mum and less than or equal to 35% of the pore size distribution have dv<=4.0 mum. Additionally, the pore diameter dv90<=14.0 mum, and CTE<=12.0x10-7 / ° C. from 25° C. to 800° C. The articles exhibits high filtration efficiency coupled with low pressure drop across the filter. Additionally, high porosity articles having porosity greater than or equal to 40% and low surface roughness of Ra<4.0 mum are described. Additionally, a method for manufacturing the ceramic honeycomb articles wherein fine talc, fine silica-forming source and a fine pore former are disclose.

Owner:CORNING INC

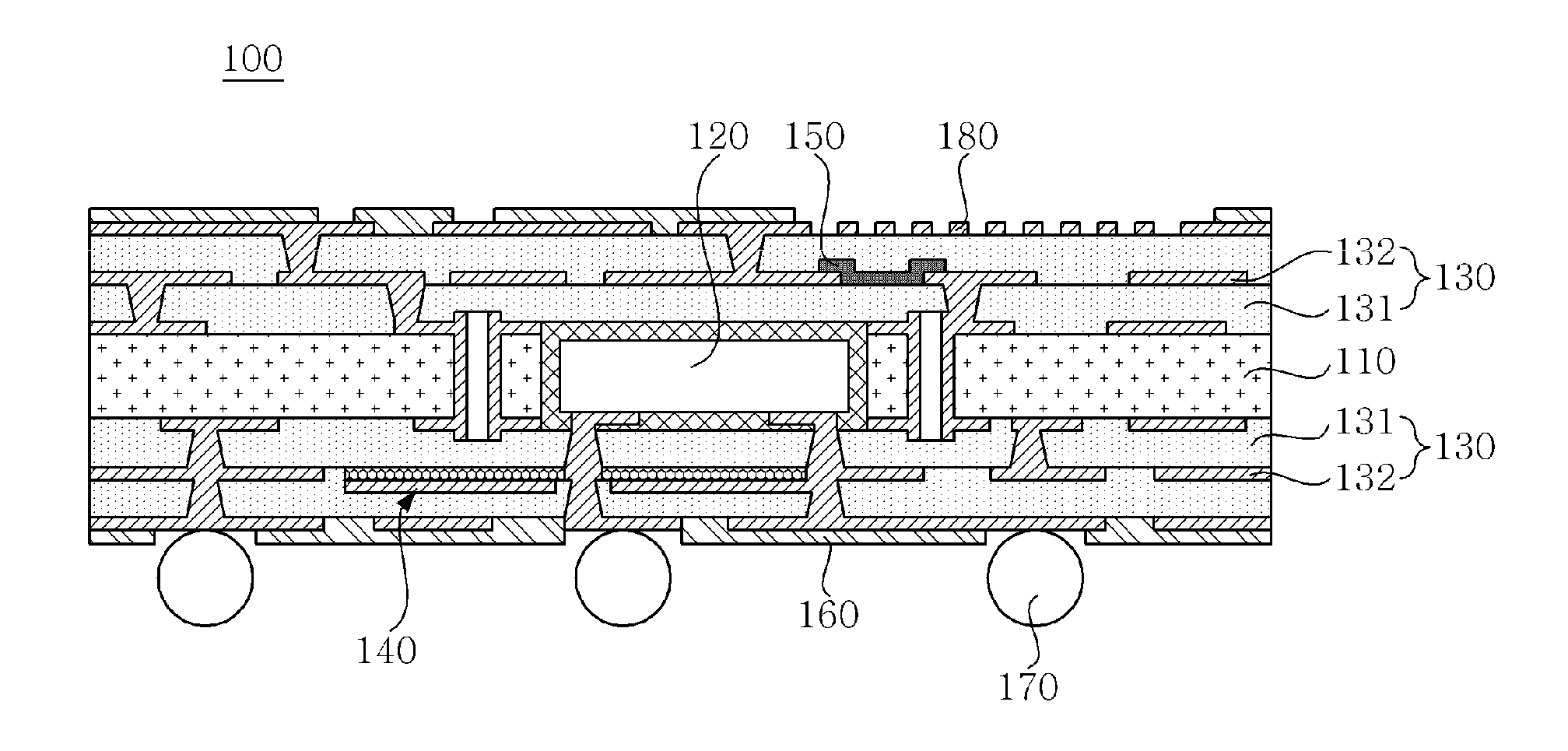

Thermosetting resin composition as well as prepreg, laminated board and circuit carrier containing same

ActiveCN105504686ASmall expansion coefficientPromote absorptionSynthetic resin layered productsGlass/slag layered productsThermal expansionCopper

The invention provides a thermosetting resin composition as well as a prepreg, a laminated board and a circuit carrier containing the same. The thermosetting resin composition comprises thermosetting resin, a laser direct forming additive, an inorganic filler, and a silane coupling agent with 2-3 groups capable of being hydrolyzed at each of two ends of a molecular chain. The laser direct forming additive is added in the thermosetting resin composition provided by the present invention to ensure that a circuit can be formed on thermosetting resin after laser irradiation and metallization, the CTE of the composition can be reduced and the absorption of laser energy by a matrix can be enhanced by adding the inorganic filler and the silane coupling agent with 2-3 groups capable of being hydrolyzed at each of the two ends of the molecular chain, the activation rate of an LDS auxiliary agent is effectively improved, the attachment and the sedimentary thickness of the matrix to copper are obviously enhanced at the same time, and three types of components mutually cooperate with the thermosetting resin to ensure that the thermosetting resin composition has a low coefficient of thermal expansion, thereby making the prepared circuit carrier have relatively good quality of signal transmission.

Owner:江苏生益特种材料有限公司

Epoxy resin pouring sealant and preparation method thereof

InactiveCN107163888AImprove crack resistanceImprove stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAging resistance

The present invention relates to an epoxy resin pouring sealant and a preparation method thereof, the epoxy resin pouring sealant includes A and B components, the A component includes, by weight, 40-70 parts of bisphenol F epoxy resin, 20-50 parts of an active polyurethane toughening agent, 10-20 parts of an active diluent, 30-50 parts of an inorganic filler and 1-10 parts of an additive; the B component includes, by weight, 40-70 parts of modified alicyclic amine; 30-60 parts of polyetheramine and 3-10 parts of a promoter. The weight ratio of A to B is 2-4:1. The epoxy resin pouring sealant has better aging resistance and strong resistance to cold and hot impact, and meets the high temperature and cold impact requirement of electronic sealing.

Owner:COLLTECH DONGGUAN BONDING TECH CO LTD

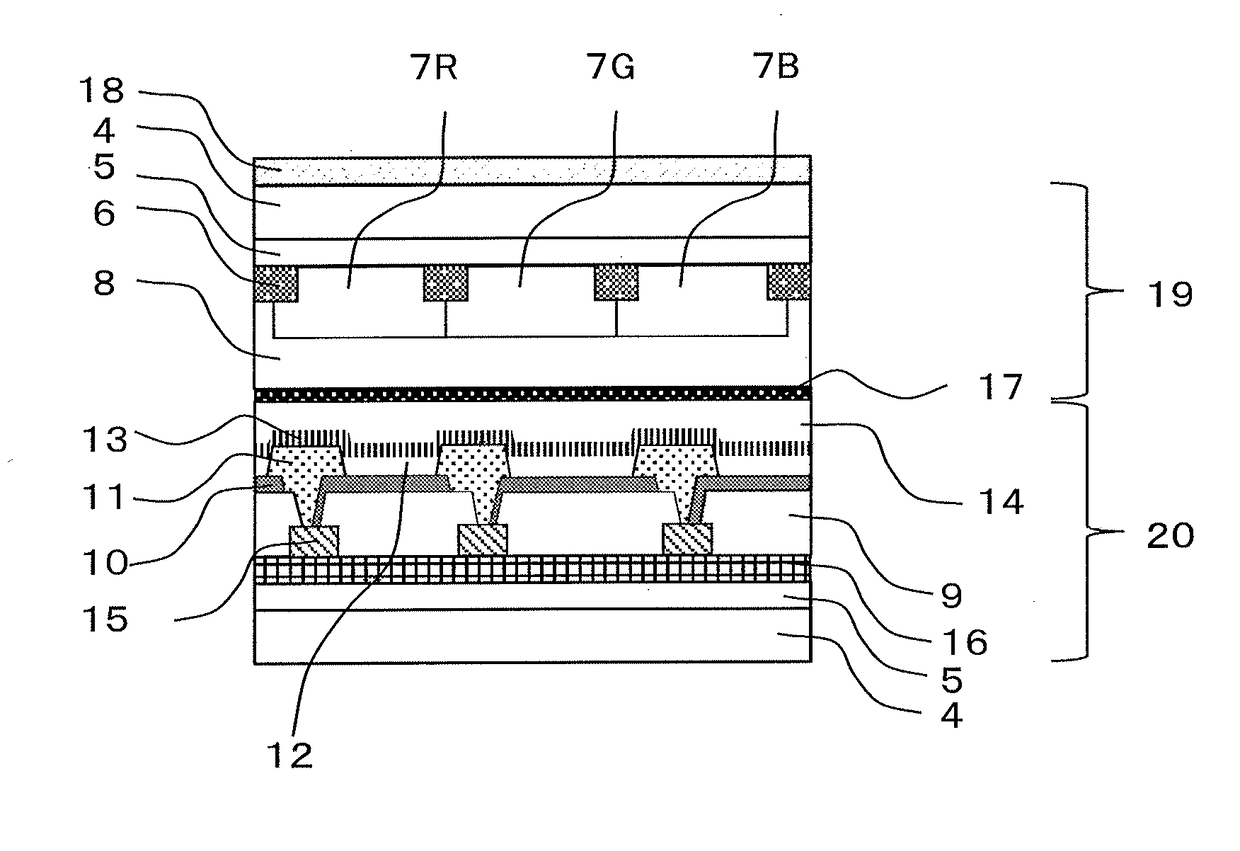

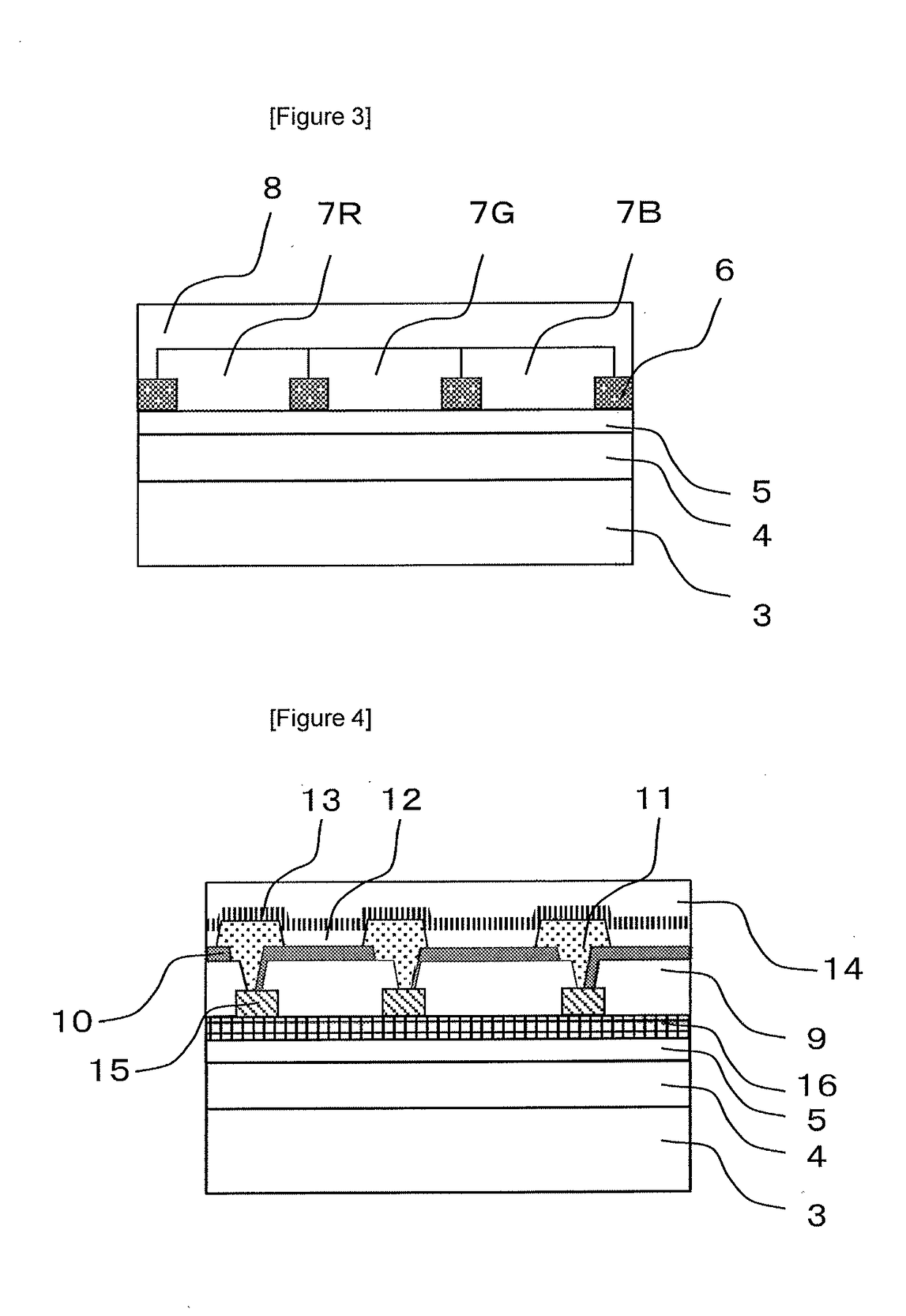

Substrate for display, color filter using the same and method for the production thereof, organic el element and method for the production thereof, and flexible organic el display (as amended)

ActiveUS20170309844A1Low CTELow birefringenceFinal product manufactureOptical filtersChemistryColor gel

The present invention is a substrate for a display, the substrate having a film B including a polysiloxane resin on at least one surface of a film A including a polyimide resin, wherein the film B contains inorganic oxide particles therein, and the present invention has an object to provide a substrate for a display: being able to be applied to a color filter, an organic EL element, or the like without the need to carry out any complex operations; allowing high-definition displays to be manufactured; and being provided with a low CTE, a low birefringence, and flexibility.

Owner:TORAY IND INC

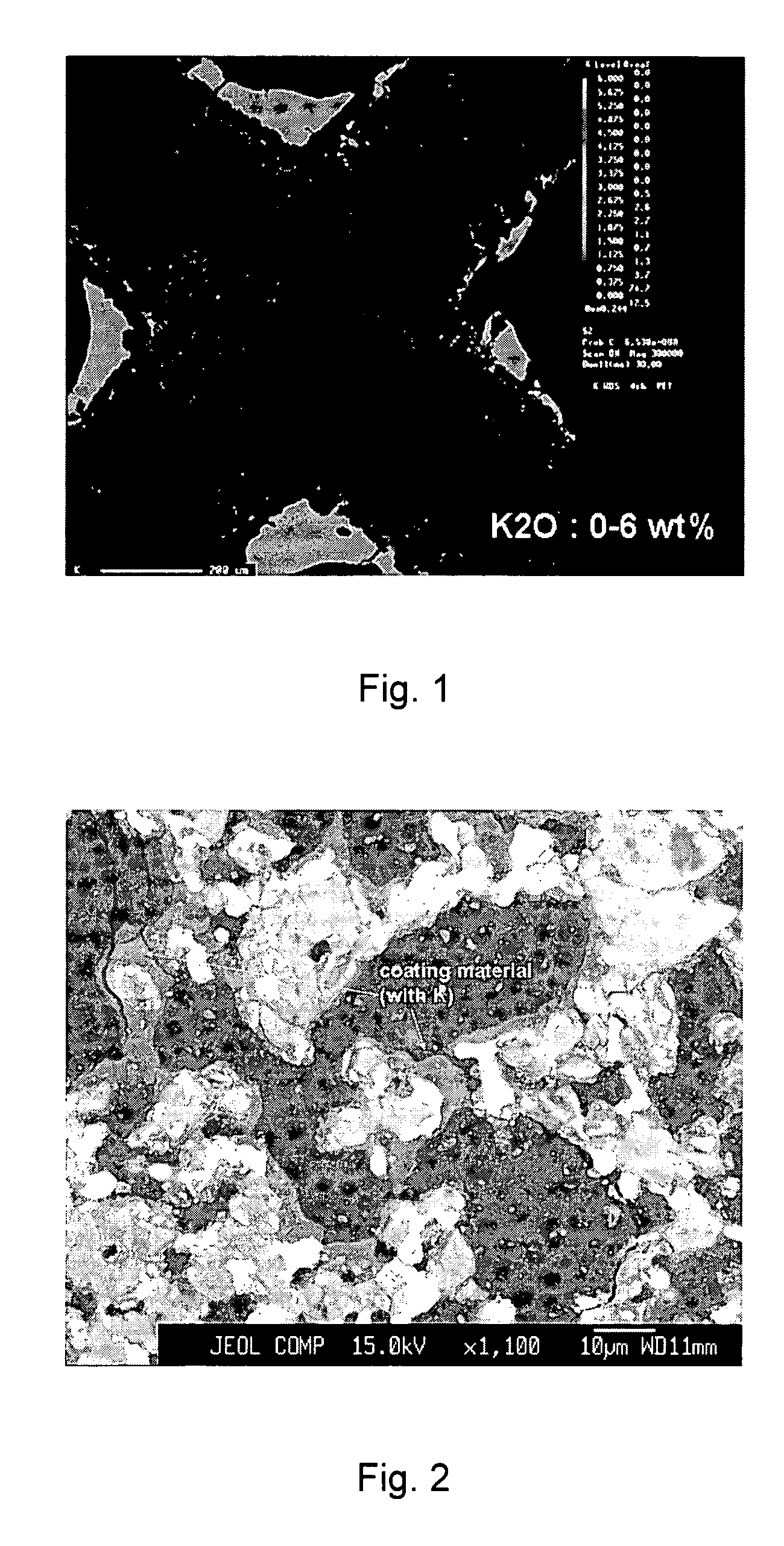

Ceramic materials for 4-way and NOx adsorber and method for making same

ActiveUS7713897B2Increase heating capacityReduction factorCeramic shaping apparatusLoose filtering material filtersNOx adsorberOxide

Owner:CORNING INC

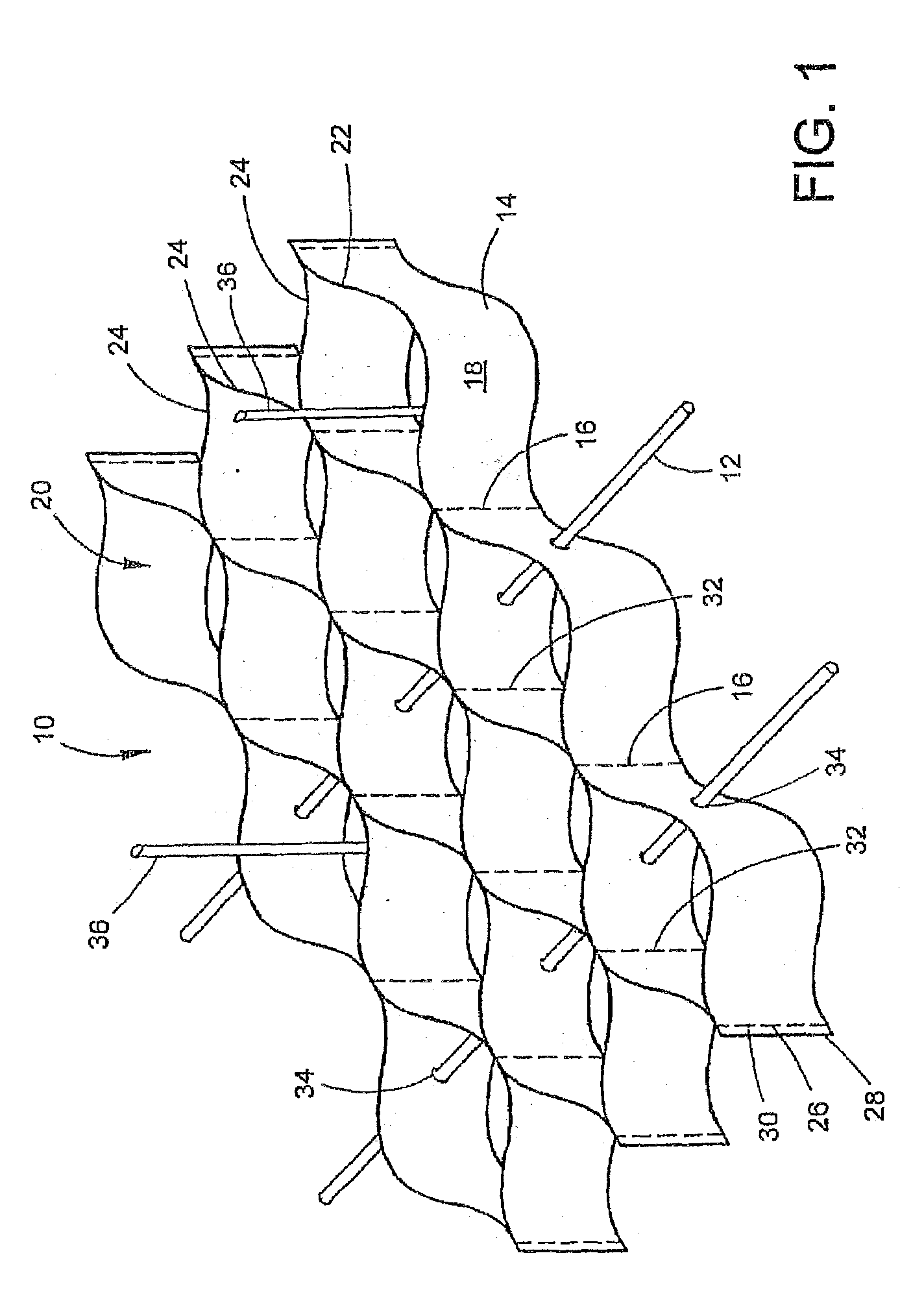

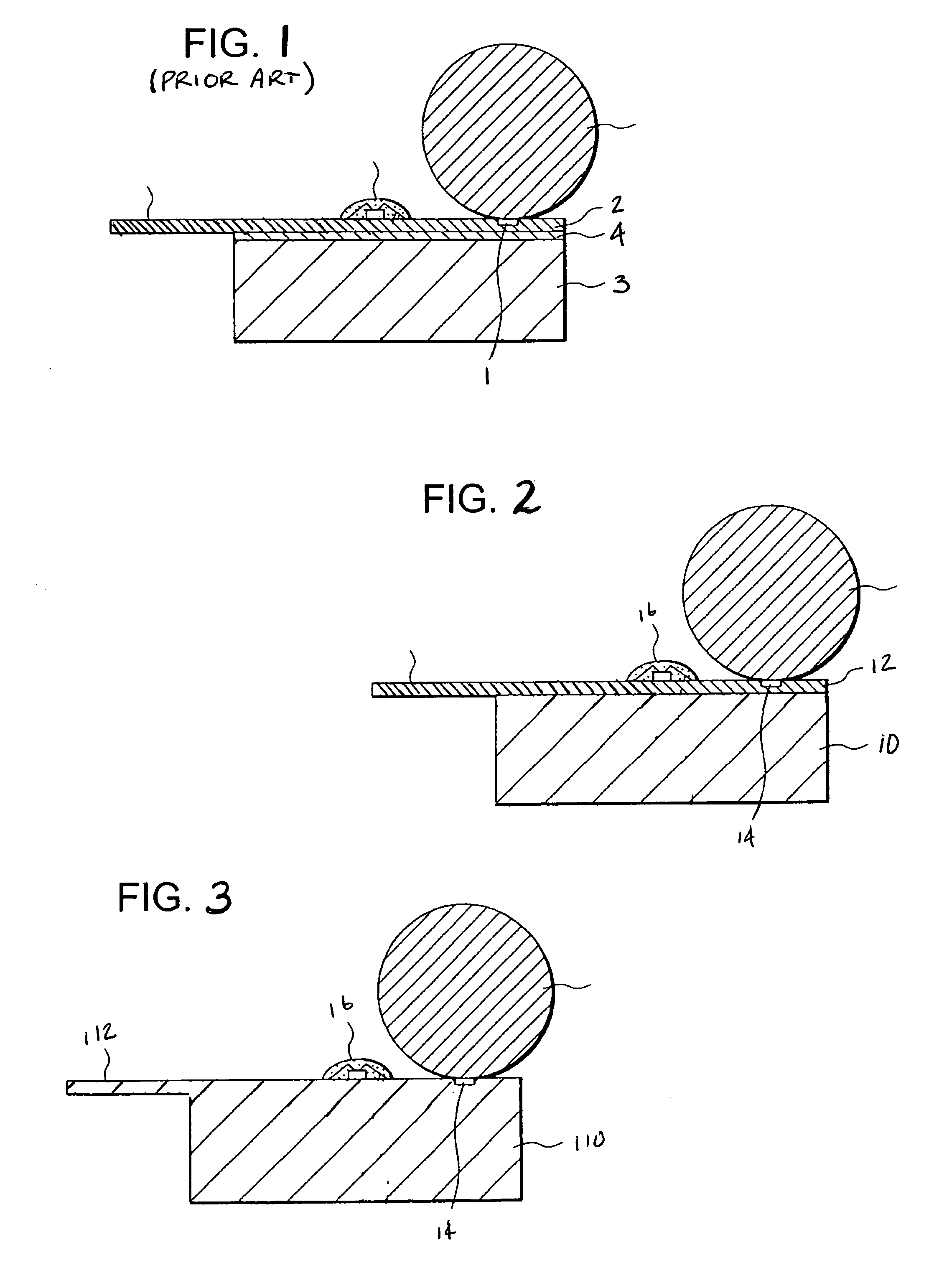

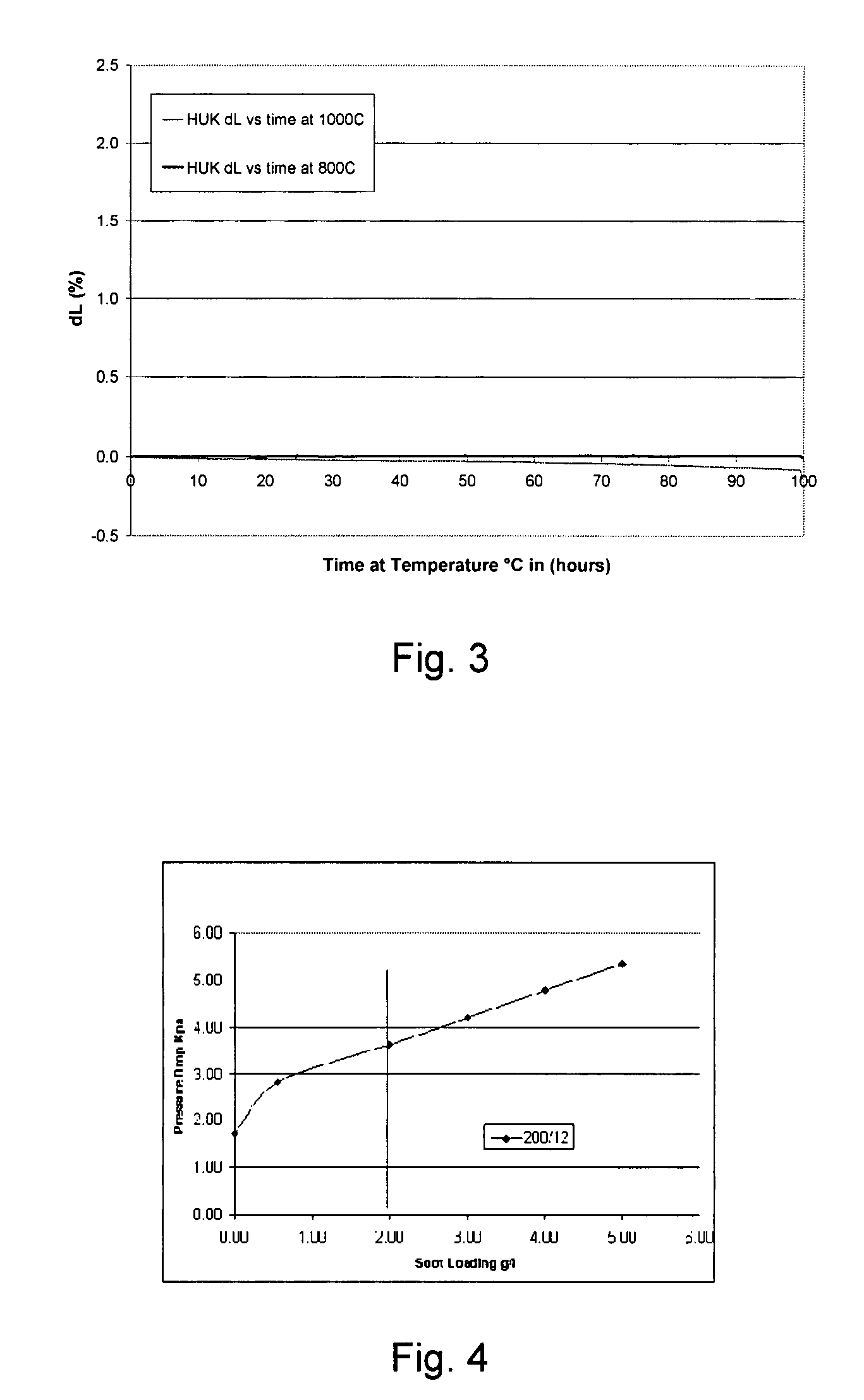

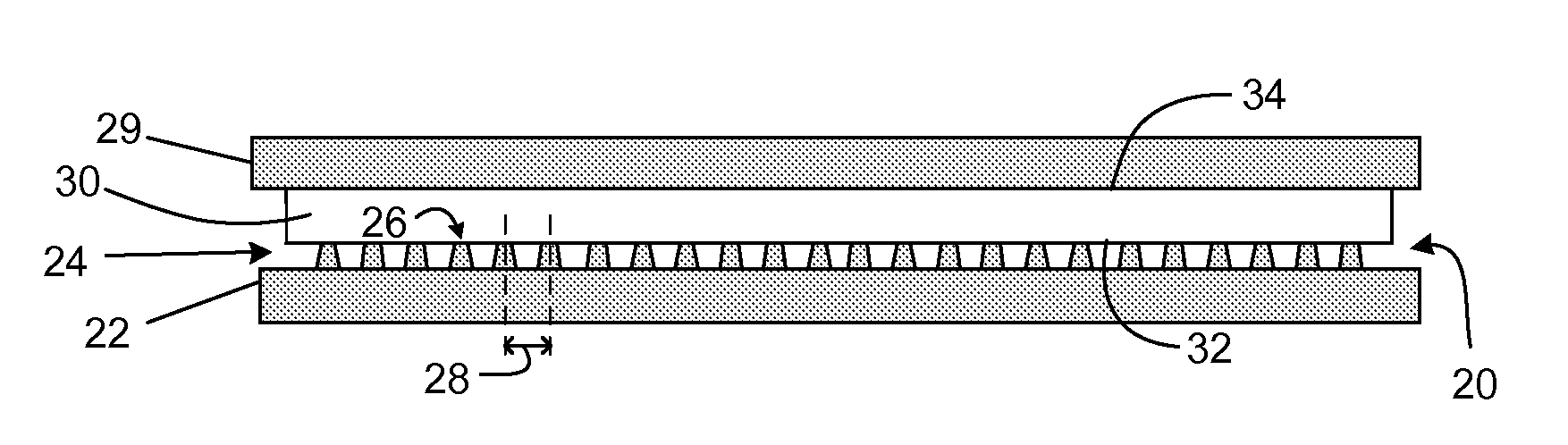

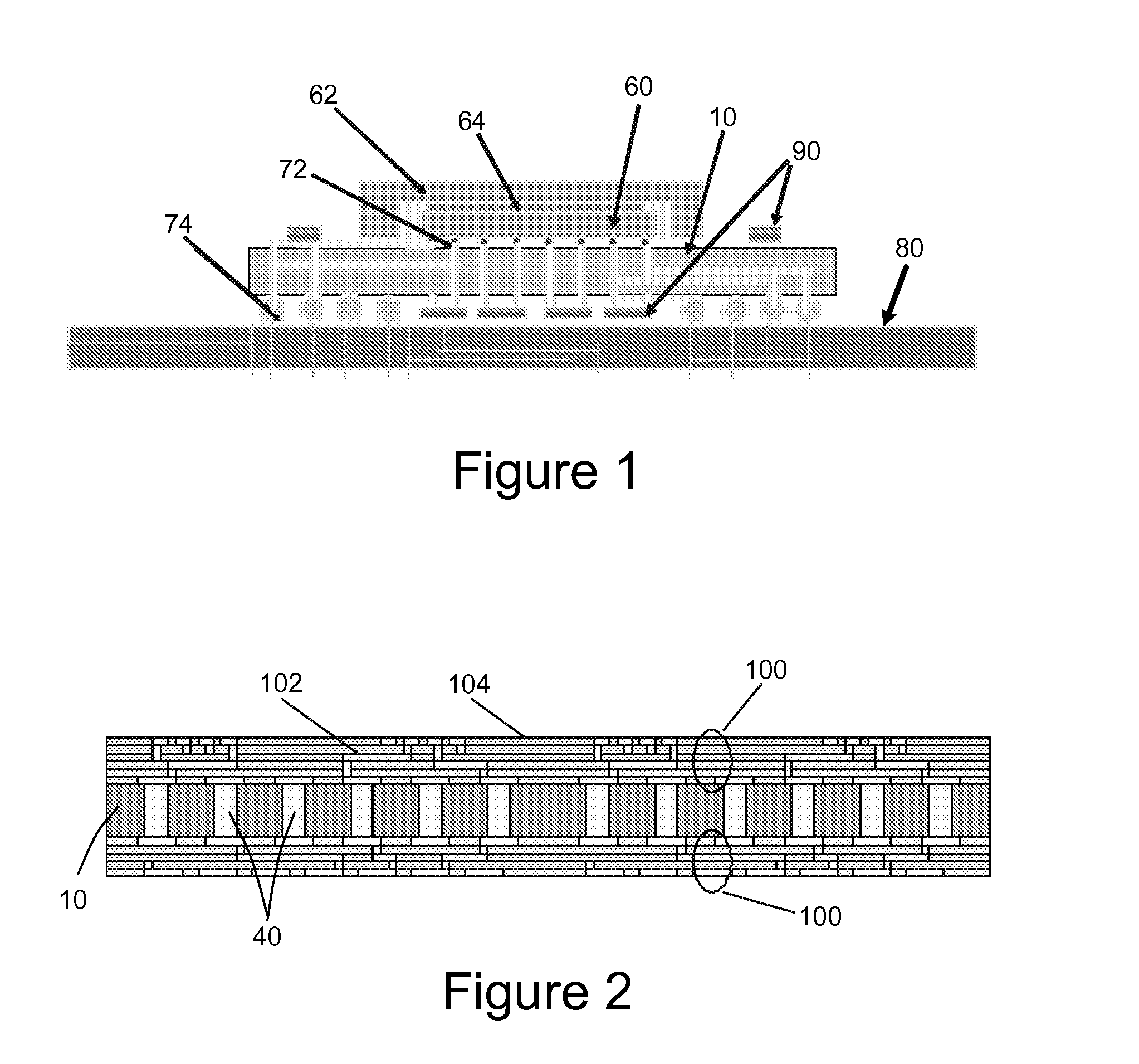

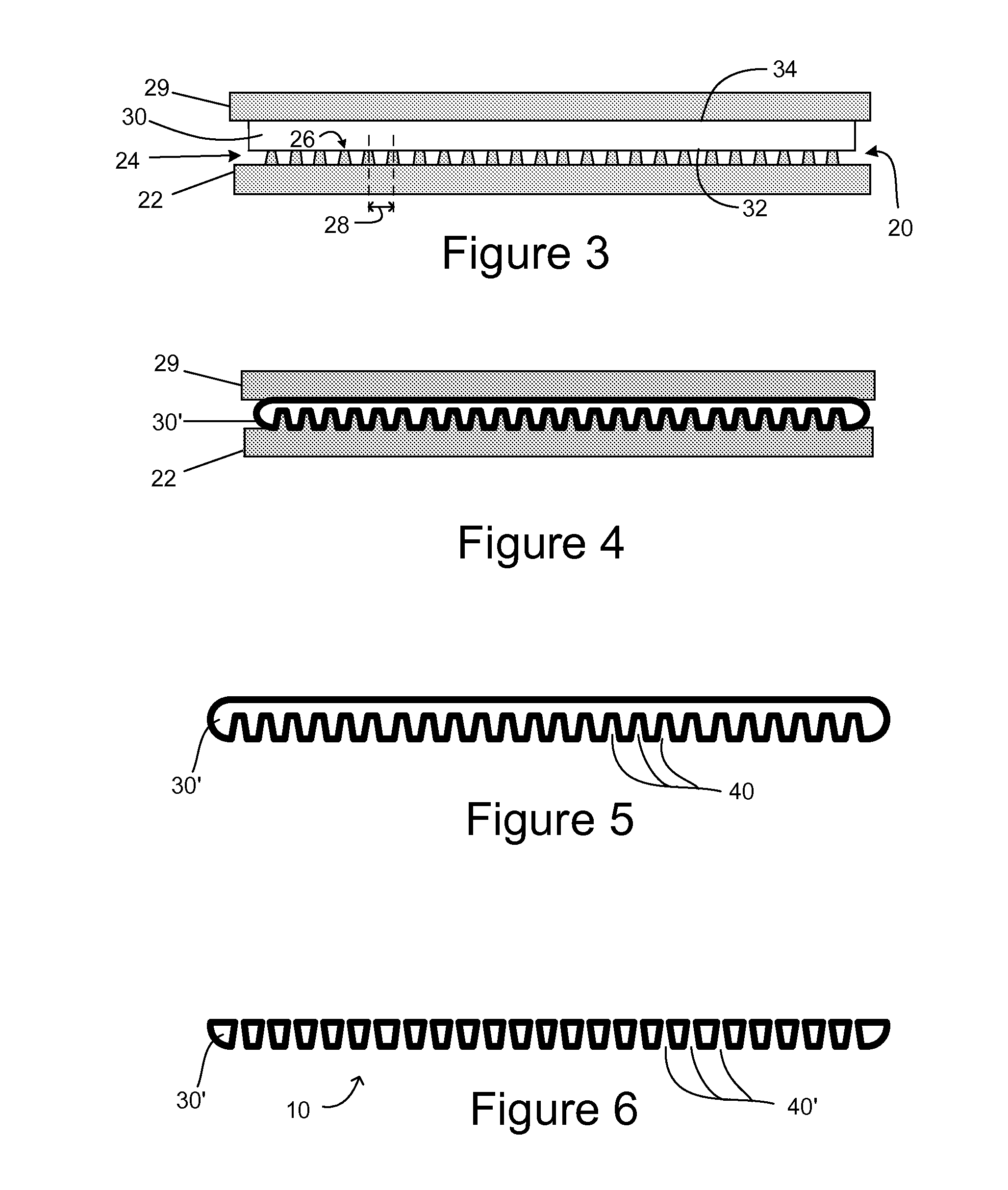

Methods of forming a glass wiring board substrate

InactiveUS20130239617A1Low CTEWell-matchedSolid-state devicesGlass reforming apparatusMicrometerIntegrated circuit

Disclosed is a method or process for forming a glass wiring board substrate for integrated circuit wiring boards, including providing a first molding surface (20) positioned on a first mold (22) having truncated conical pins (24) protruding therefrom, the pins (24) having a diameter at the top end (26) thereof of 150 micrometers or less, and a minimum pitch (28) of 400 micrometers or less, providing a glass sheet (30) having first and second surfaces (32,34) on opposite major sides thereof, pressing the first surface (32) of the glass sheet against the molding surface (20), heating the glass sheet (30) and the first molding surface (20) together to a temperature sufficient to soften a glass of which the glass sheet (30) is comprised, such that the pattern of the first molding (20) surface is replicated in the first surface (32) of the glass sheet (30), thereby producing a formed glass sheet (30′) having an array of holes (40) therein, cooling the formed glass sheet (30′) and the molding surface (20) together to a temperature below the softening point of said glass, and separating the formed glass sheet (30) from the molding surface (20). The forming may press the glass sheet using one mold surface or two mold surfaces simultaneously. For embodiments using a single mold, the holes may be blind holes after pressing, and may then be opened to form through-holes by back side lapping. Alternatively, the glass is pressed up to through-hole formation, avoiding the need of back side lapping.

Owner:CORNING INC

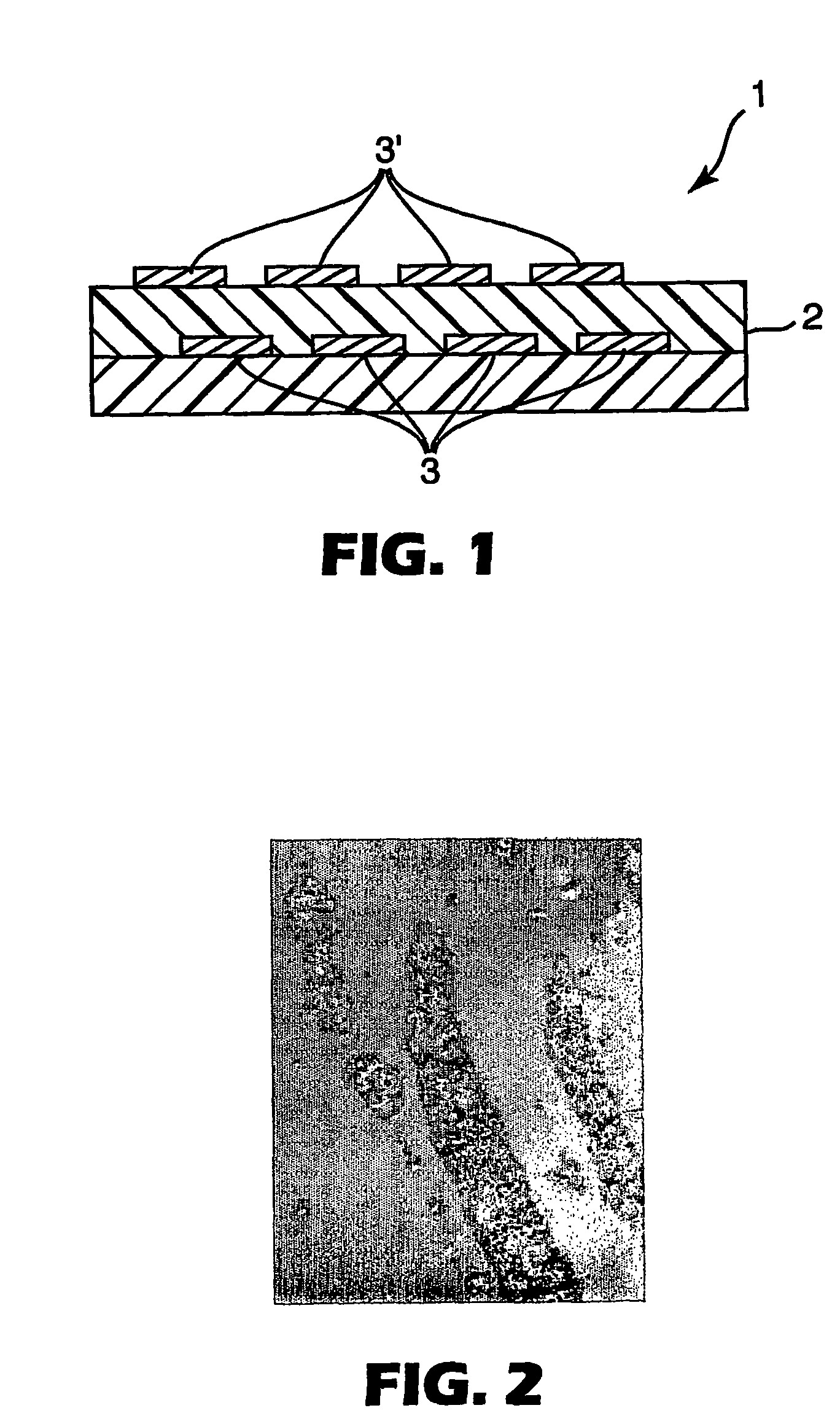

Thermosetting adhesive film, and an adhesive structure based on the use thereof

InactiveUS20040068061A1High elastic modulusLow CTENon-macromolecular adhesive additivesMacromolecular adhesive additivesFilling materialsThermal expansion

A thermosetting adhesive film comprising a uniform adhesive matrix containing a thermosetting resin and a curing agent therefor, and a thermoplastic resin; and a filler material dispersed in the adhesive matrix, wherein the filler material comprises an inorganic material and a domain to incorporate the inorganic material, the domain consisting of an elastic polymer which is elongated and oriented in one direction substantially perpendicular to the thickness direction of the adhesive film. This adhesive film provides good properties of coefficient of thermal expansion and elastic modulus, without exhibiting reduced adhesive force which would be otherwise observed in association with the addition of large amounts of filler material.

Owner:3M INNOVATIVE PROPERTIES CO

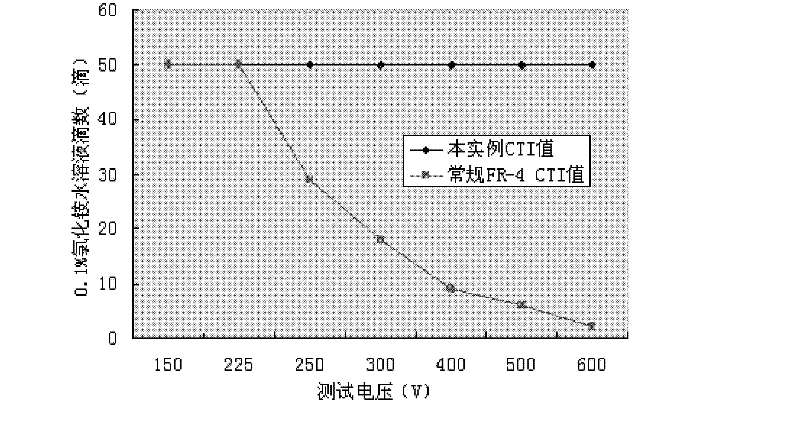

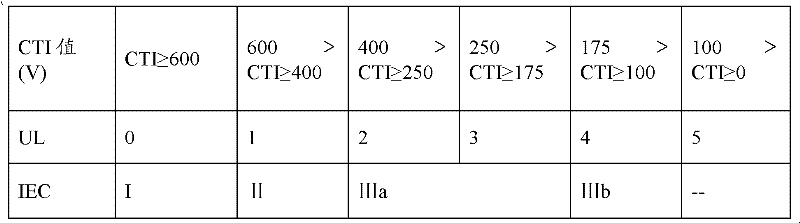

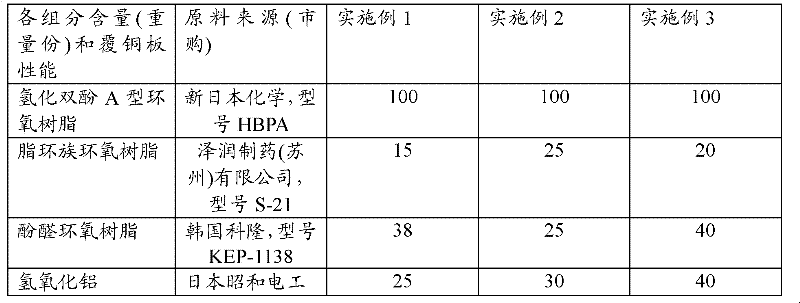

Halogen-free resin composition and copper clad plate prepared from composition

ActiveCN102286190AHigh CTI valueReduce dosageCircuit susbtrate materialsMetal layered productsOrganic solventComparative Tracking Index

The invention discloses a halogen-free resin composition. The composition is prepared by fully mixing hydrogenated bisphenol A type epoxy resin, alicyclic epoxy resin, novolac epoxy resin curing agent, aluminum hydroxide serving as an inorganic filler and organic solvent uniformly. The invention also discloses a copper clad plate prepared from the halogen-free resin composition. The copper clad plate has good thermal stability and creepage tracing property. The halogen-free resin with high comparative tracking index (CTI) resin is adopted, and the consumption of the aluminum hydroxide servingas the inorganic filler is reduced, so that the composition has high CTI value, avoids series problems caused by using excessive aluminum hydroxide and simultaneously realizes halogen-free and environment-friendly properties.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

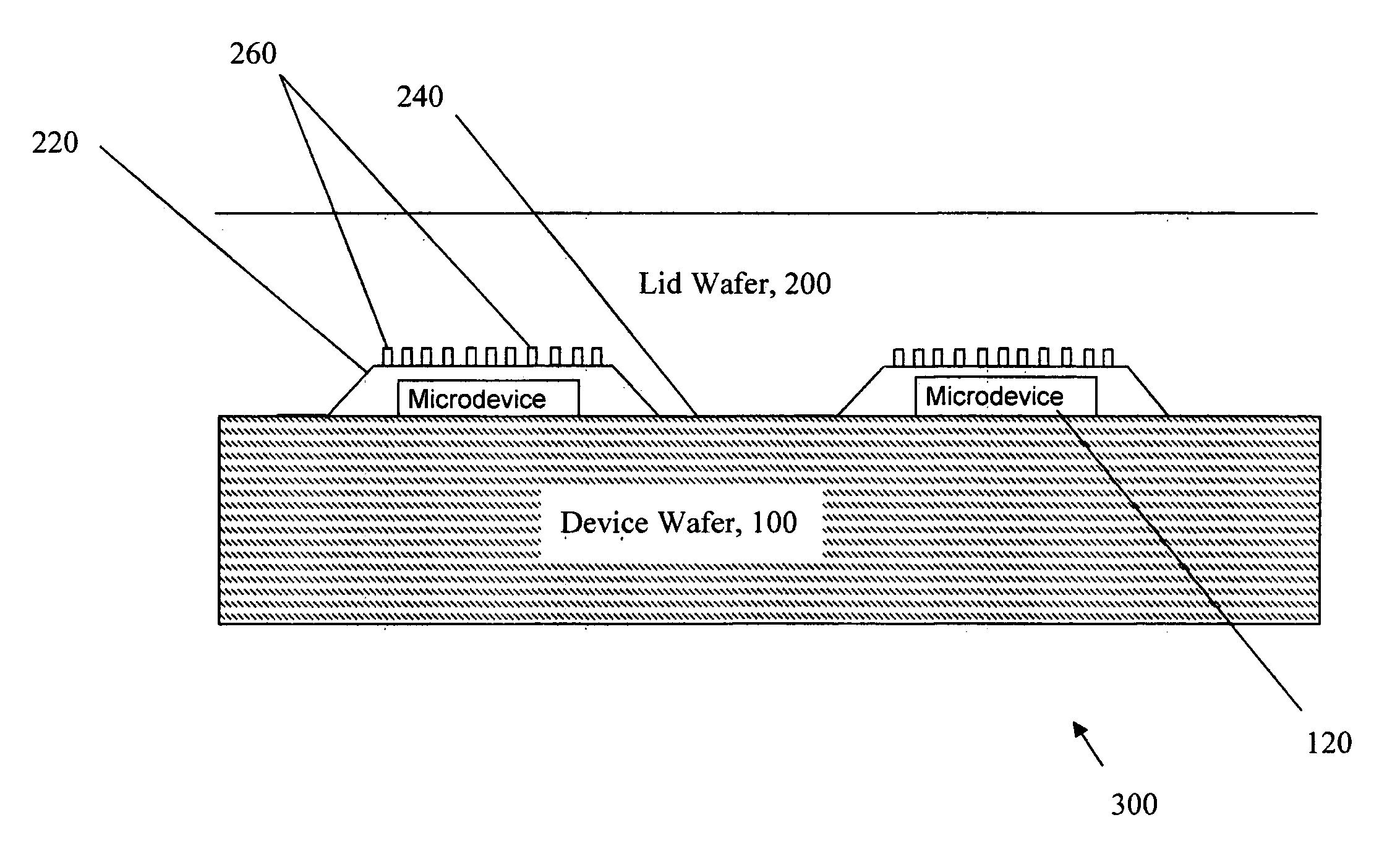

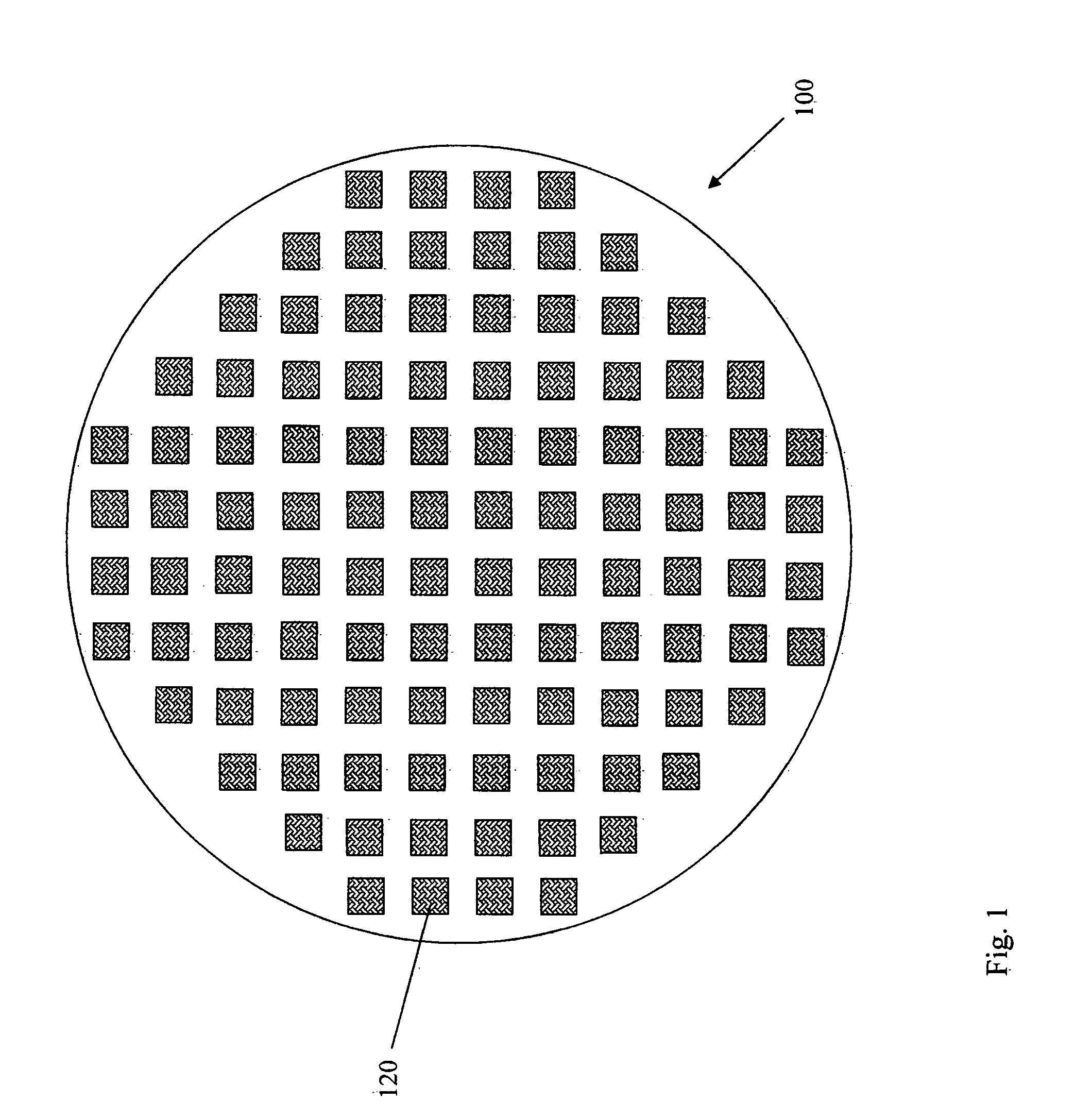

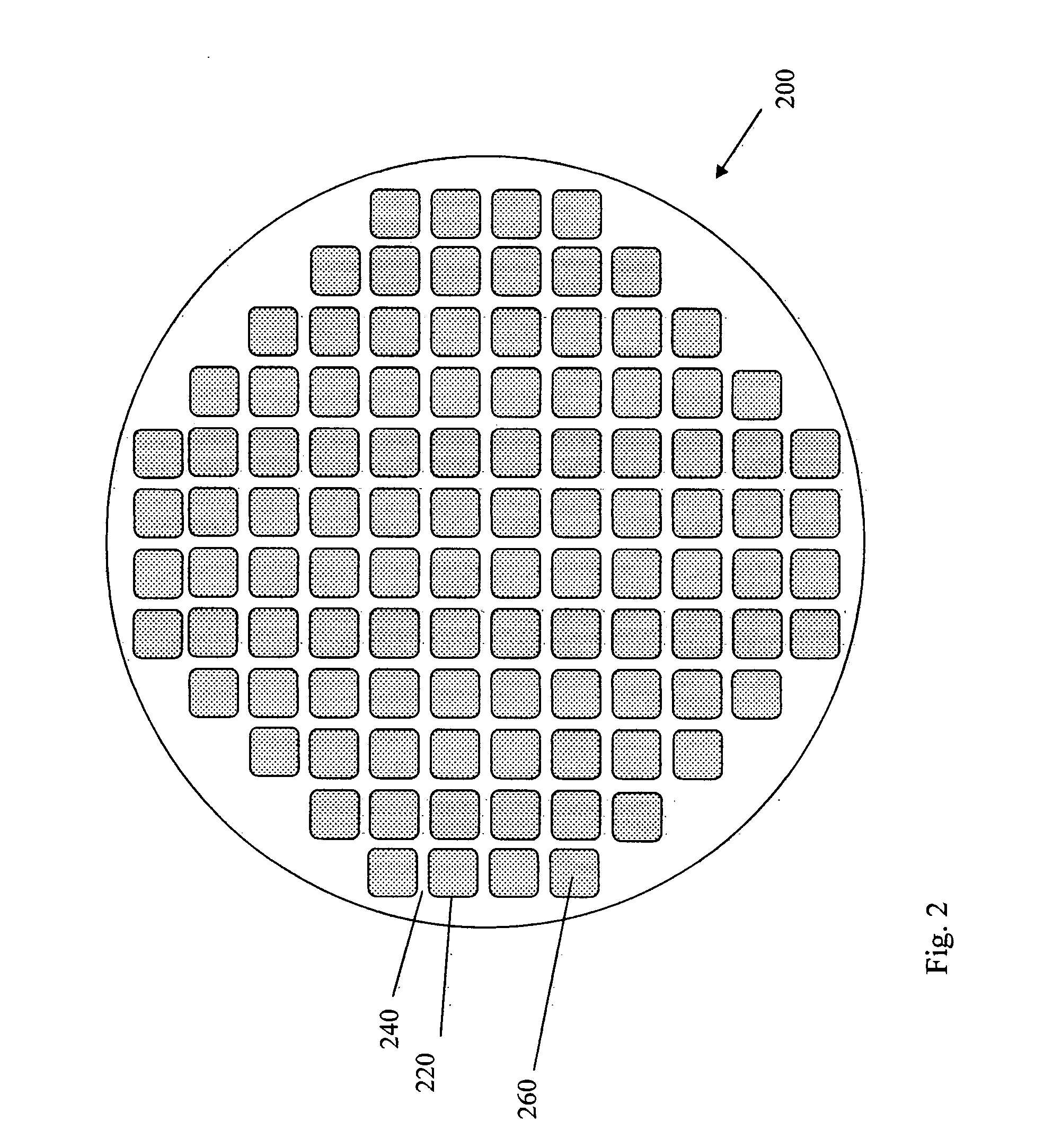

Gettering material for encapsulated microdevices and method of manufacture

InactiveUS20090001537A1Increase Zr compositionReduce Fe compositionSemiconductor/solid-state device detailsSolid-state devicesAlloy depositionThermal expansion

A method for providing improved gettering in a vacuum encapsulated microdevice is described. The method includes designing a getter alloy to more closely approximate the coefficient of thermal expansion of a substrate upon which the getter alloy is deposited. Such a getter alloy may have a weight percentage of less than about 8% iron (Fe) and greater than about 50% zirconium, with the balance being vanadium and titanium, which may better match the coefficient of thermal expansion of a silicon substrate. In one exemplary embodiment, the improved getter alloy is deposited on a silicon substrate prepared with a plurality of indentation features, which increase the surface area of the substrate exposed to the vacuum. Such a getter alloy is less likely to delaminate from the indented surface of the substrate material during heat-activated steps, such as activating the getter material and bonding a lid wafer to the device wafer supporting the microdevice.

Owner:INNOVATIVE MICRO TECH

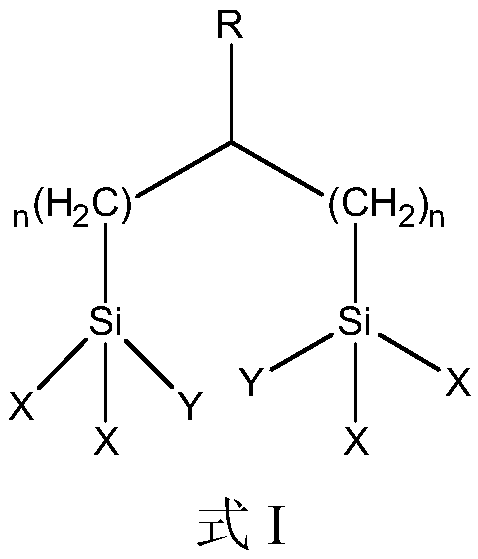

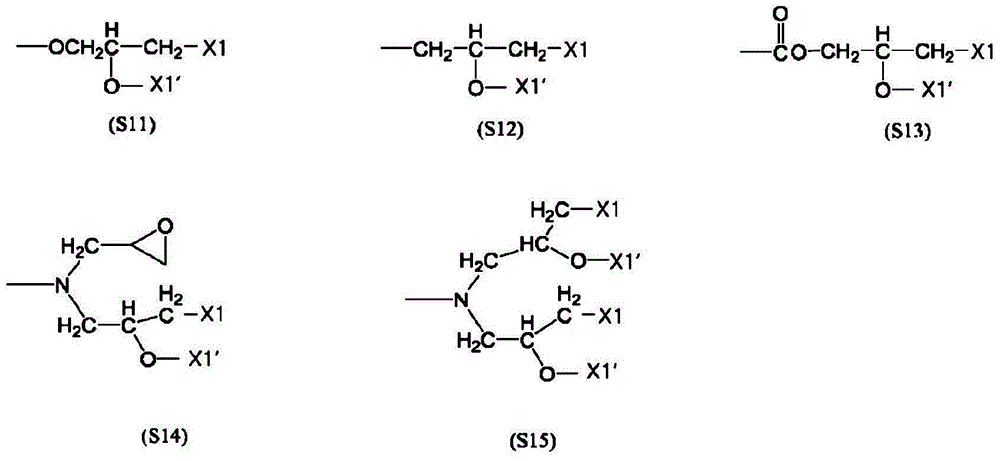

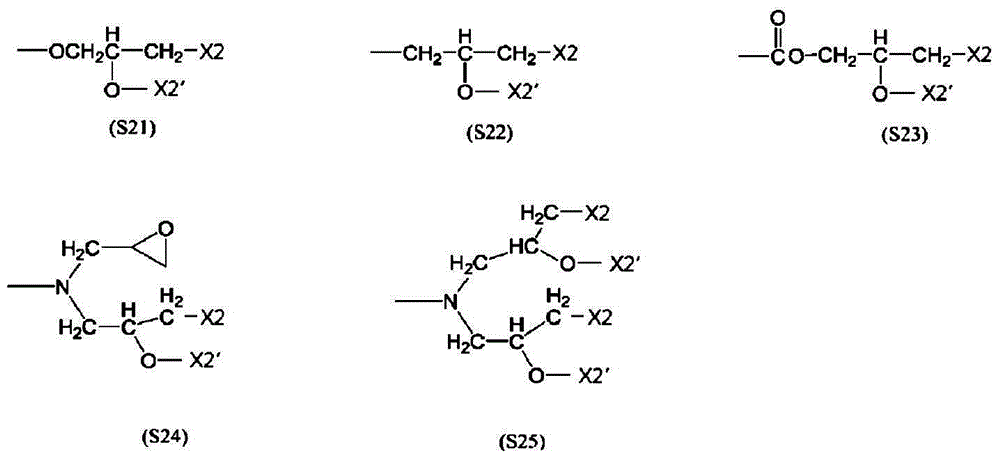

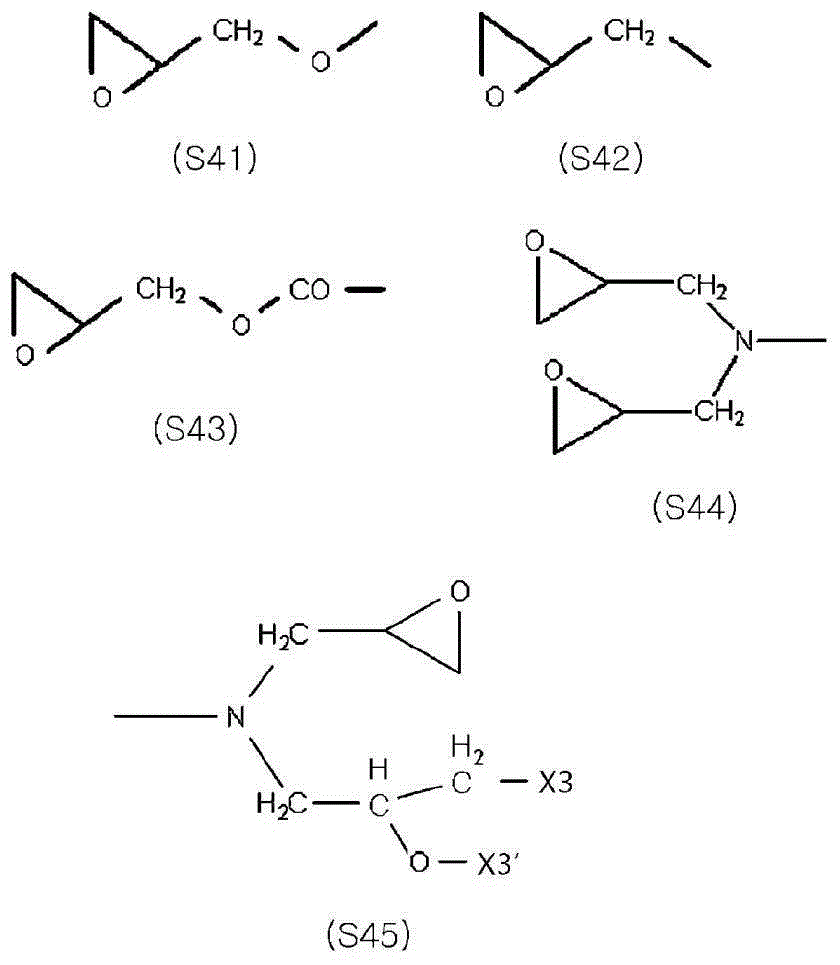

Epoxy compound having alkoxysilyl group, method for manufacturing same, composition and cured product including same, and use thereof

ActiveCN105073760ALow CTEImprove flame retardant performanceGroup 4/14 element organic compoundsCopper organic compoundsEpoxyHeat resistance

The present invention relates to an alkoxysilyl group epoxy compound, a method for producing the same, a composition including the same, and a hardening material, wherein the compound has excellent heat resistance, particularly exhibits a low coefficient of thermal expansion (CTE) and a high glass transition ascending effect in the composition and / or exhibits excellent flame retardance in the hardened material, and a separate silane coupling agent is not needed. By means of the present invention, provided are: an epoxy compound having a core including an epoxy group and at least one alkoxysilyl group which is an S1 substituent independently selected from the group consisting of Chemical Formula S11 to S15 or an S2 substituent independently selected from the group consisting of Chemical Formula S21 to S25; a method for producing the alkoxysilyl-based epoxy compound produced through the epoxy ring-opening reaction and alkoxysilylation of a start material; an epoxy composition including the epoxy compound; a hardened material of the same; and a use of the same. The hardened material which is a composite of the composition including the novel alkoxysilyl group epoxy compound by means of the present invention has the improved chemical bond of the alkoxysilyl group from the epoxy compound and a filling agent. Coupling and bonding efficiency is also improved when a composite is produced by means of the coupling and bonding of alkoxysilyl groups of the epoxy compound having the alkoxysilyl group. Accordingly, excellent heat resistance properties such as a low CTE and a high glass transition temperature are exhibited in the composite, and / or excellent flame retardance is exhibited in the hardened material.

Owner:KOREA INST OF IND TECH

Thermally conductive polymer compositions having low thermal expansion characteristics

ActiveUS8221885B2Low CTE propertyImparts thermal conductivitySynthetic resin layered productsSpecial tyresConductive polymerThermal expansion

An injection moldable, thermally conductive polymer composition that has ultra low CTE properties is provided. The composition is suitable both for substrate applications in high precision electronics assemblies as well as over molding applications in conjunction with ceramic substrates. The composition includes a base polymer matrix material loaded with thermally conductive filler, which imparts thermal conductivity to the polymer matrix while also maintaining or enhancing the dielectric properties of the base polymer. The resultant composition exhibits CTE properties in the range of between 9 ppm / ° C. and 2 ppm / ° C., exhibits an optical anisotropy of below 1.5, and a thermal conductivity of greater than 2 W / m° K. The composition is suitable for use in over molding applications in conjunction with virtually any suitable electronics substrate material without the introduction of mechanical stresses produced by large CTE differentials.

Owner:TICONA POLYMERS INC

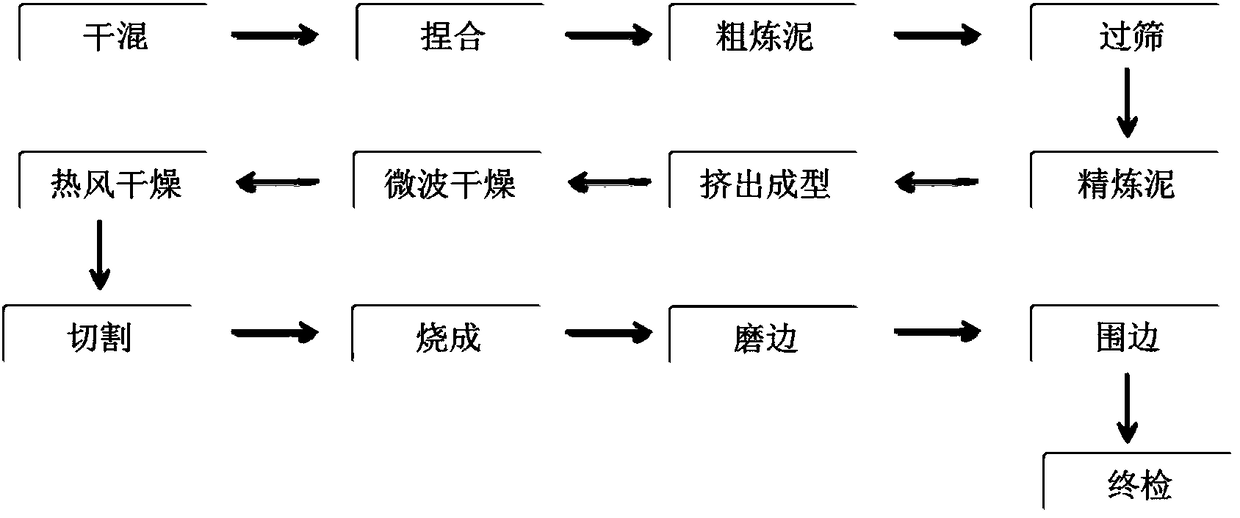

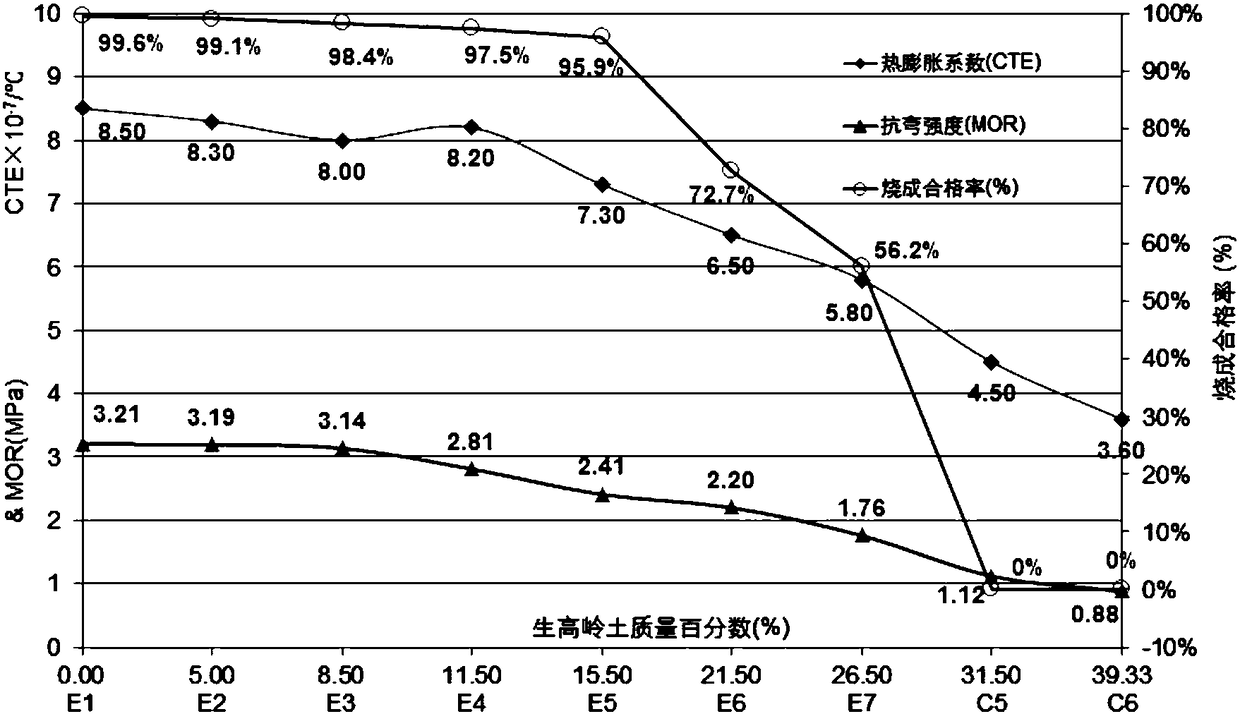

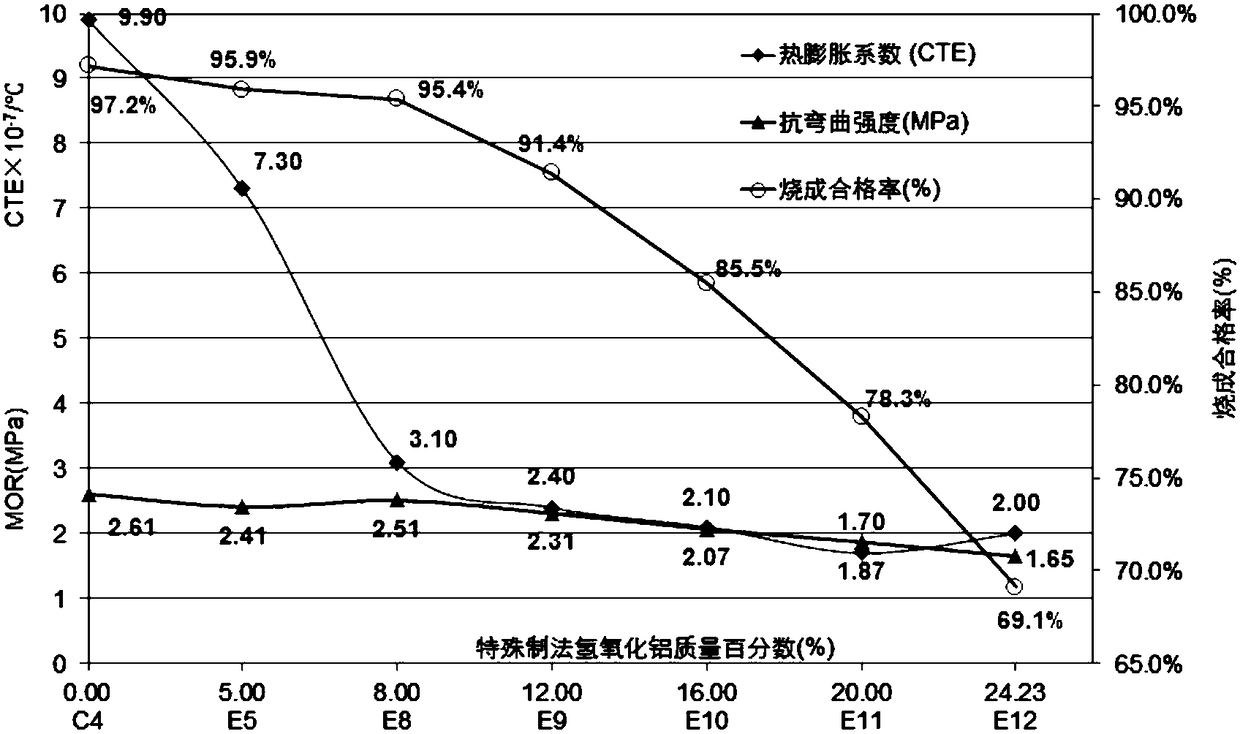

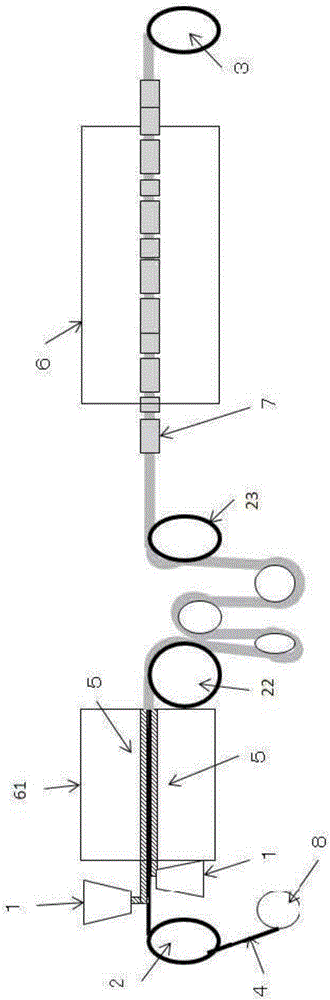

Low-expansion high-strength thin-wall cordierite honeycomb ceramic and preparation method thereof

The invention discloses low-expansion high-strength thin-wall cordierite honeycomb ceramic and a preparation method thereof. Content of cordierite in ceramic is greater than 95%, and the ceramic is prepared from the following chemical components in percentage by mass: 47.5-52.5% of SiO2, 32.7-37.7% of Al2O3 and 11.5-15.5% of MgO; porosity of honeycomb ceramic is greater than or equal to 16%, and awater absorption rate is 14%-30%; bending strength of the honeycomb ceramic is greater than or equal to 1.6 MPa; and a thermal expansion coefficient at the room temperature of 800 DEG C is smaller than or equal to 5*10<-7> / DEG C. According to the preparation method, aluminum hydroxide prepared by a special preparation method is led, so that the product has low CTE (Coefficient of Thermal Expansion), high strength and low cost.

Owner:SHANDONG AOFU ENVIRONMENTAL PROTECTION SCI & TECH

Method for manufacturing multilayer body having polyimide layers and method for manufacturing polyimide film

InactiveCN106553352ALow CTEPrevent peelingLamination ancillary operationsSynthetic resin layered productsOptoelectronicsPolyimide membrane

The invention provides a method for manufacturing a curl reduced multilayer body having polyimide layers and a method for manufacturing polyimide film. The method for manufacturing the multilayer body having the polyimide layer comprises the steps: the multilayer body comprises more than one layer of polyimide layer on a support substrate, wherein a flexible film serves as the support substrate, the support substrate is coated by a polyamide acid solution or a polyimide solution, so that more than one coating layers are formed; the support substrate having coating layers is moved while one side of the support substrate is heated; in the last step, a mechanism on the end in the width direction of the support substrate is holden, the end in the width direction of the support substrate having the coating layer is fixed or stretched in the width direction, the support substrate is moved in the convey direction, then polyimide layers are formed.

Owner:NIPPON STEEL CHEM &MATERIAL CO LTD

Low back pressure porous cordierite ceramic honeycomb article and methods for manufacturing same

InactiveUS20080050557A1Improve thermal shock resistanceLower overall pressure dropLayered productsThin material handlingMetallurgyHeat resistance

Disclosed are porous ceramic honeycomb articles, such as filters, which are composed predominately of a cordierite composition. The ceramic honeycomb articles possess a porous microstructure characterized by a unique combination of relatively high porosity (>45%), and moderately narrow pore size distribution wherein greater than 15% and less than 38% of the total porosity exhibits a pore diameter less than 10 μm, and low CTE wherein CTE≦6.0×10−7 / ° C. (from 23° C. to 800° C.). The articles exhibit high thermal durability and high filtration efficiency coupled with low pressure drop. Such ceramic articles are particularly well suited for use in filtration applications, such as in diesel exhaust filters. Also disclosed are methods for manufacturing the porous ceramic honeycomb article.

Owner:CORNING INC

Cordierite honeycomb article and method of manufacture

ActiveUS7887897B2Improve toleranceReduction factorLayered productsCeramic shaping apparatusFiltrationSurface roughness

Disclosed are ceramic honeycomb articles which are composed predominately of a crystalline phase cordierite composition. The porous cordierite ceramic honeycomb articles has a plurality of cell channels and intersecting porous walls and possess a microstructure characterized by a pore size distribution wherein greater than or equal to 75% of the pore size distribution of the porosity of the porous walls, by volume, have a pore diameter (dv) wherein dv<10.0 μm and less than or equal to 35% of the pore size distribution have dv≦̸4.0 μm. Additionally, the pore diameter dv90≦̸14.0 μm, and CTE≦̸12.0×10−7 / ° C. from 25° C. to 800° C. The articles exhibits high filtration efficiency coupled with low pressure drop across the filter. Additionally, high porosity articles having porosity greater than or equal to 40% and low surface roughness of Ra<4.0 μm are described. Additionally, a method for manufacturing the ceramic honeycomb articles wherein fine talc, fine silica-forming source and a fine pore former are disclose.

Owner:CORNING INC

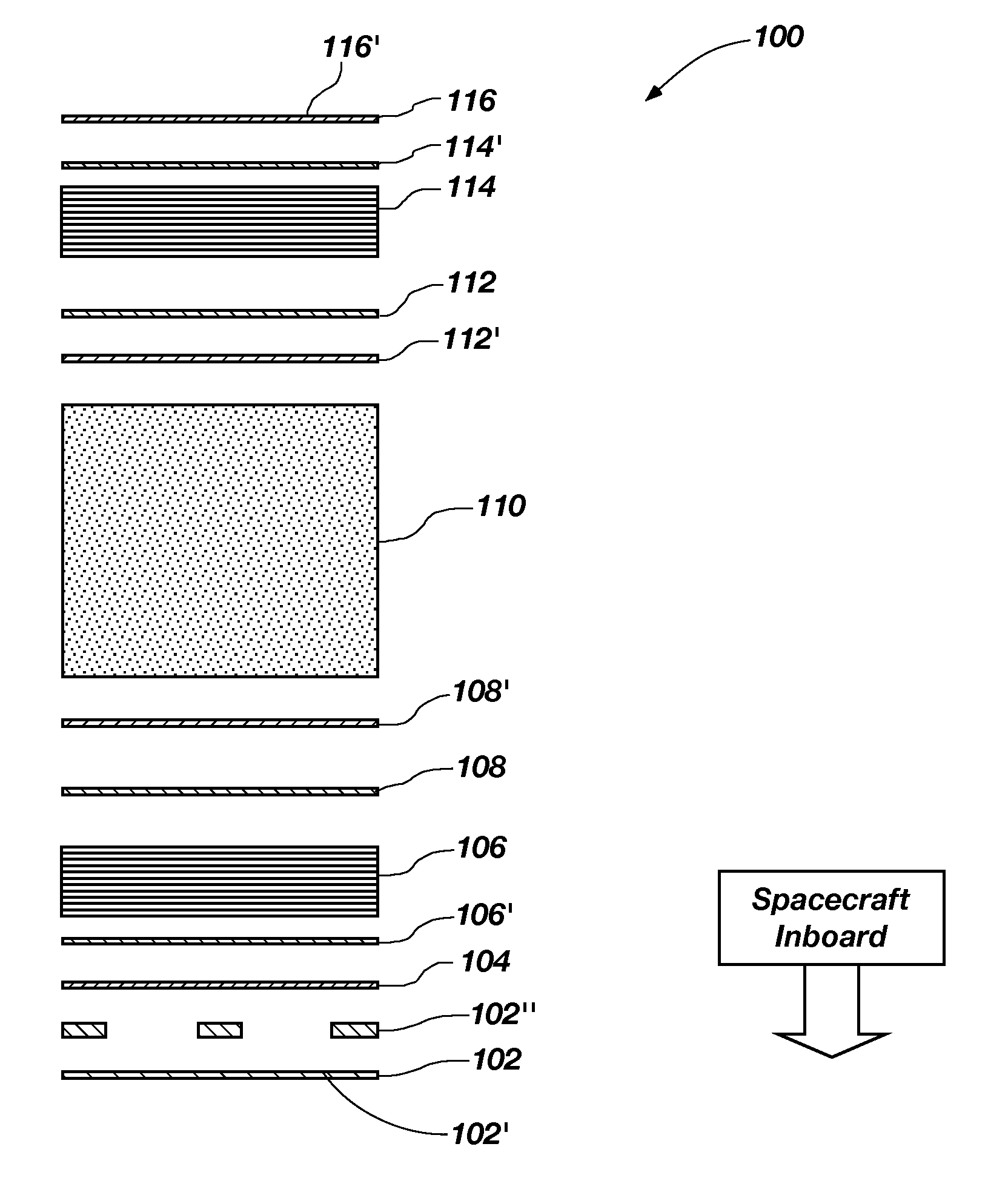

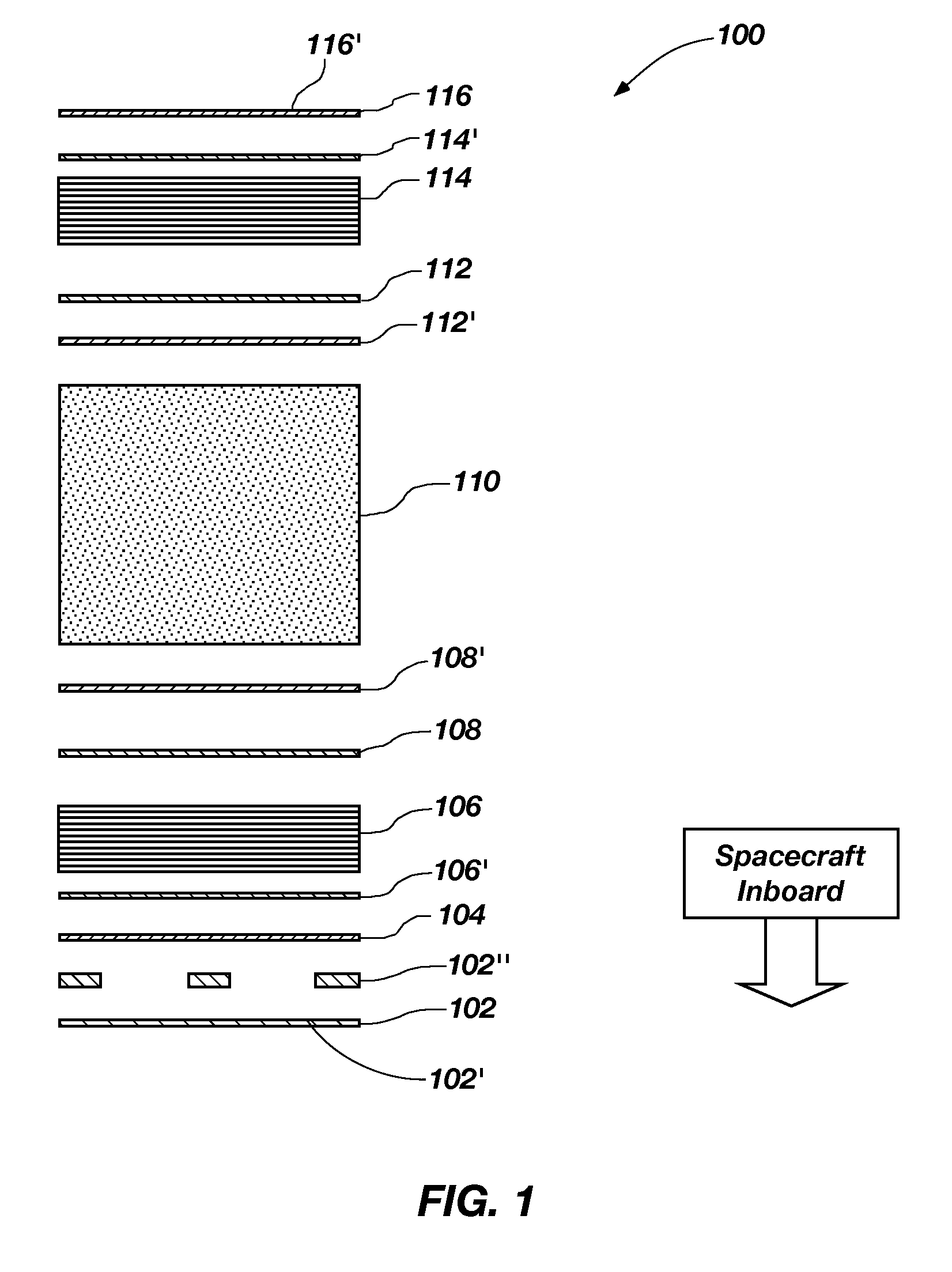

Multifunctional radiation-hardened laminate

ActiveUS8460777B2High strengthReduce weightSynthetic resin layered productsLaminationLow distortionHigh intensity

A multifunctional composite having high strength, low weight, low distortion, low CTE, impact resistance, and multi-faceted radiation protection.

Owner:NORTHROP GRUMMAN SYST CORP

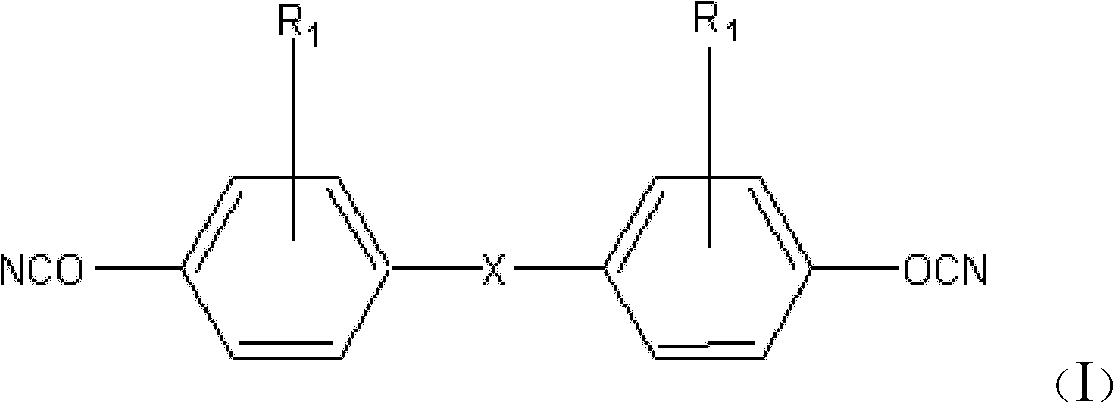

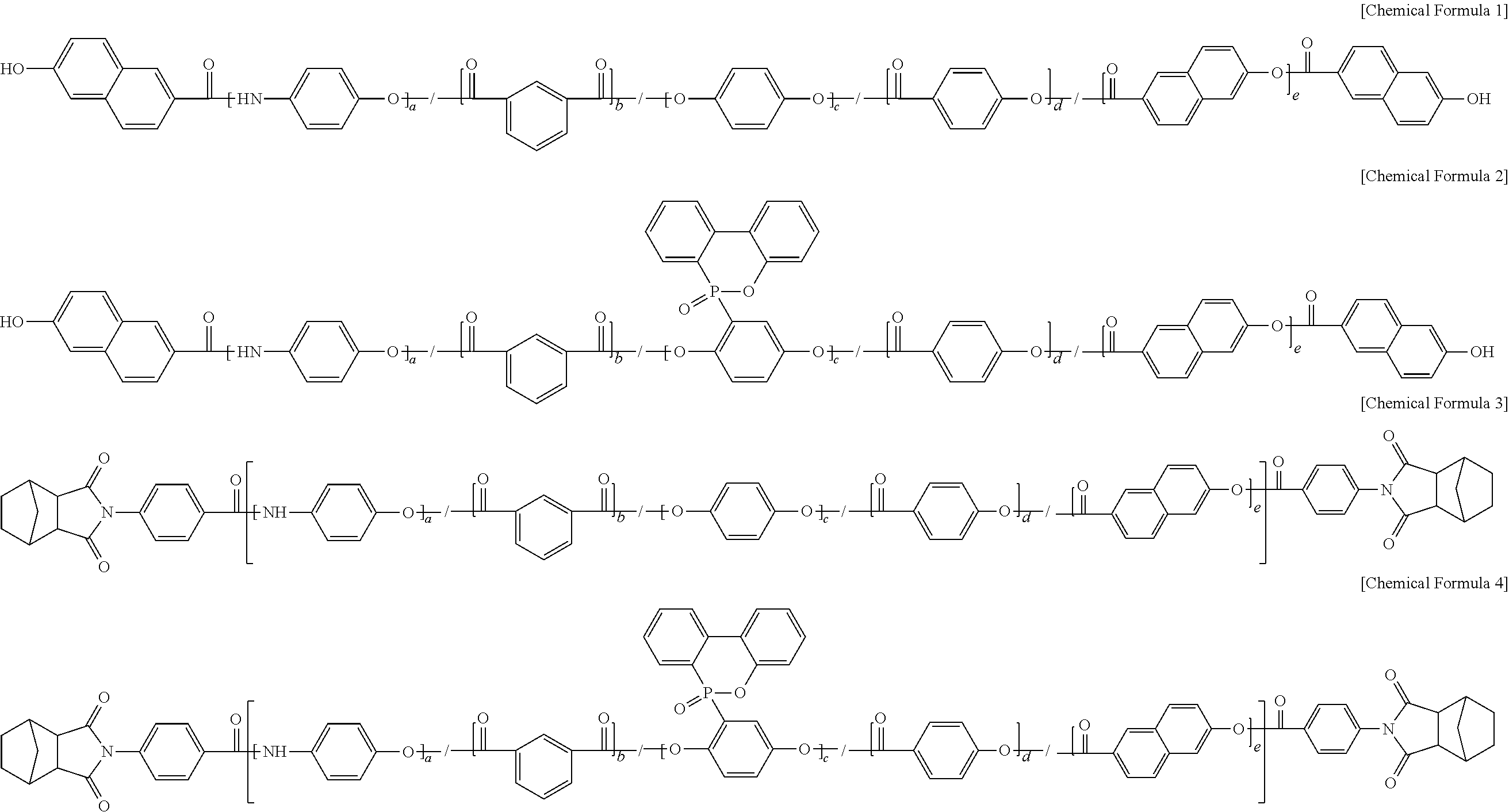

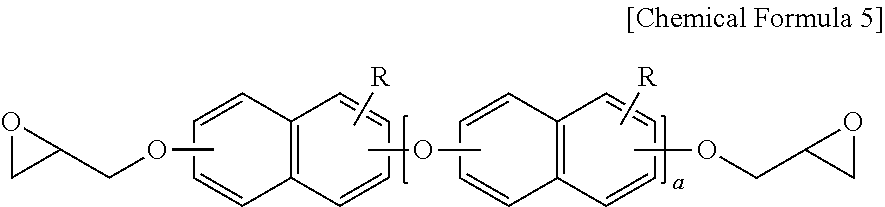

Epoxy compound having alkoxy silyl group, composition comprising same, cured product, use thereof and method for preparing epoxy compound having alkoxy silyl group

ActiveUS20150105493A1Improve flame retardant performanceImprove heat resistanceSilicon organic compoundsSemiconductor/solid-state device detailsPolymer sciencePtru catalyst

The present invention relates to an alkoxysilylated epoxy compound, a composite of which exhibits good heat resistance properties, low CTE and high glass transition temperature and not requiring a coupling agent, a composition including the same, a cured product formed of the composition, a use of the cured product, and a method of preparing the epoxy compound having alkoxysilyl group. An epoxy compound having an epoxy group and an alkoxysilyl group, a composition including the epoxy compound, a curing agent, a filler and / or a reaction catalyst, a cured product of the composition, and a use of the composition including an electronic part are provided. In a composite and / or cured product, the epoxy composition forms chemical bonds and exhibits improved heat resistance properties, decreased CTE, and increased glass transition temperature or Tg less. The cured product exhibits good flame retardant property by the introduction of the alkoxysilyl group.

Owner:KOREA INST OF IND TECH

Graphite anode for heavy current resistant magnesium electrolysis and preparation process thereof

ActiveCN105967718AHigh bulk densityImprove flexural strengthElectric heating for furnacesElectrodesFiberCarbon fibers

The invention relates to a graphite anode for heavy current resistant magnesium electrolysis. The graphite anode is prepared through the following steps of mixing and kneading delay calcined petroleum coke which accounts for 93-99wt% of a dry material, graphite scraps which account for 1-3wt% of the dry material, an additive Fe2O3 and stearic acid, and medium-temperature modified pitch which accounts for 20-30wt% of the total mass, and performing profiling, roasting, steeping and graphitizing, wherein raw materials also include short cut carbon fibers which account for 0.5-5wt% of the dry material. In a graphitizing process adopted during preparation, an insulated filler is adopted between the side surface of an electrode and a furnace body, and an end part filler is adopted in a clearance between the end surface of the electrode and the furnace body, so that the effects of reducing the resistivity, reducing electric arc and reducing pits in the end surface of the electrode.

Owner:NANTONG YANGZI CARBON +1

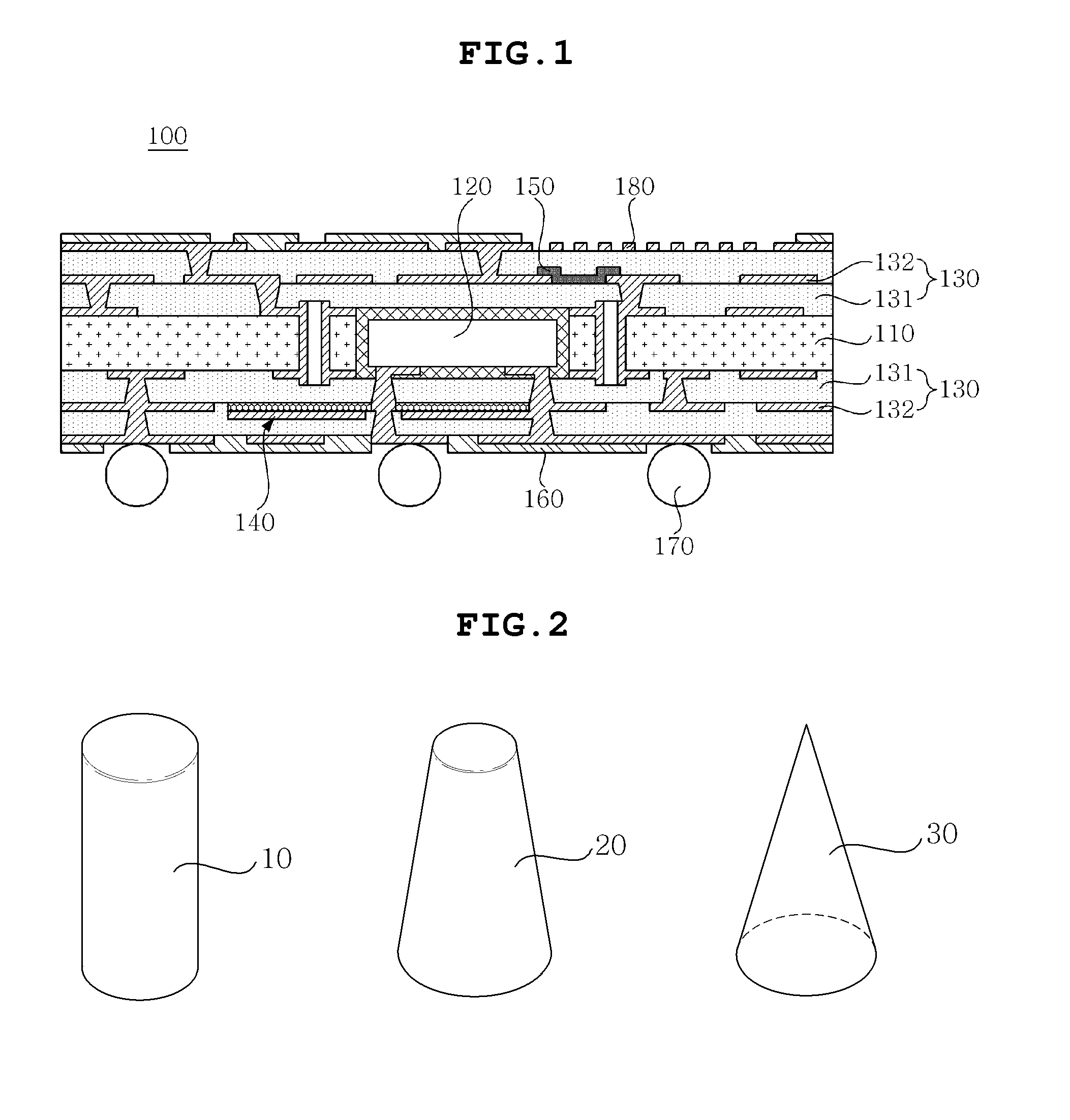

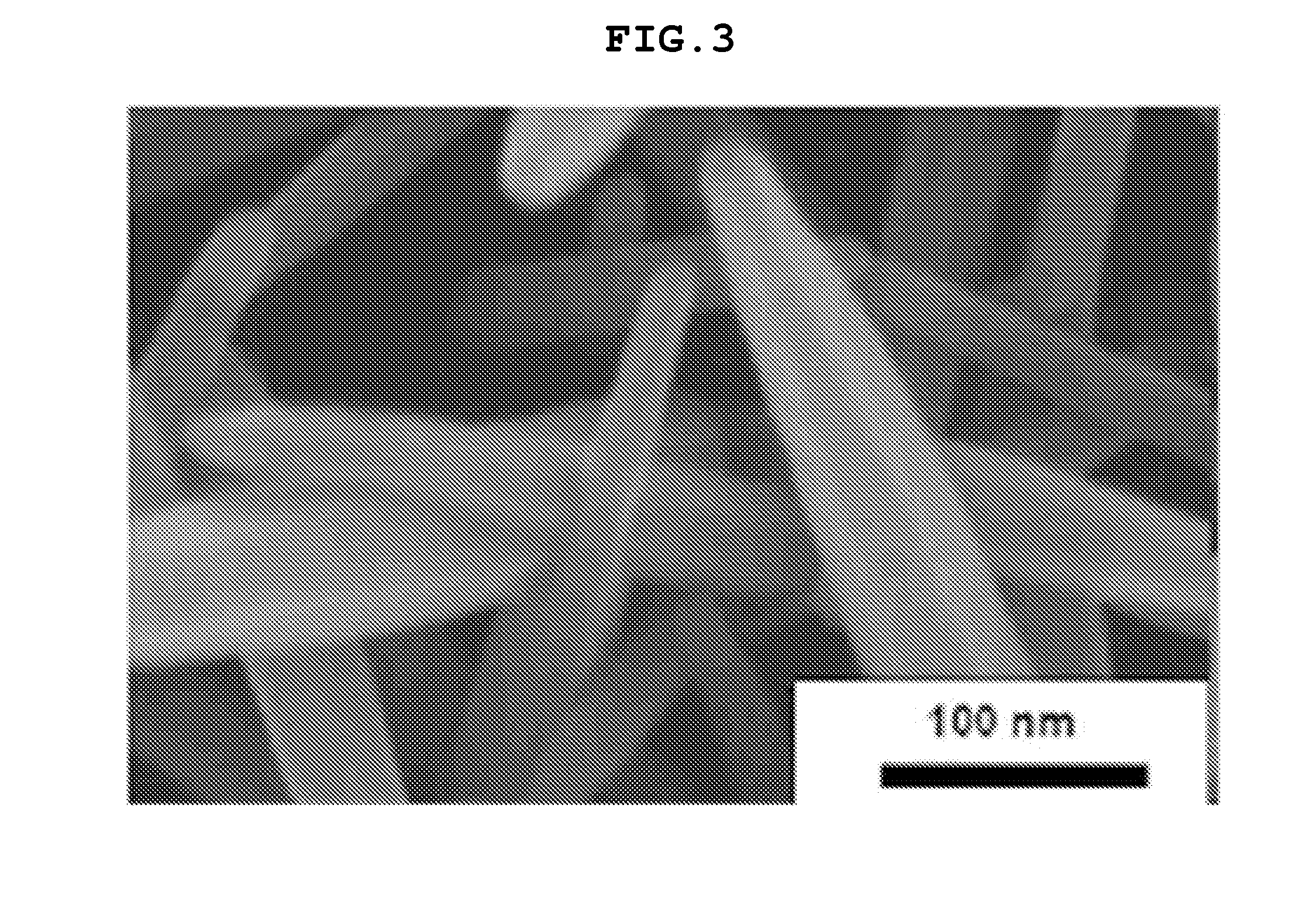

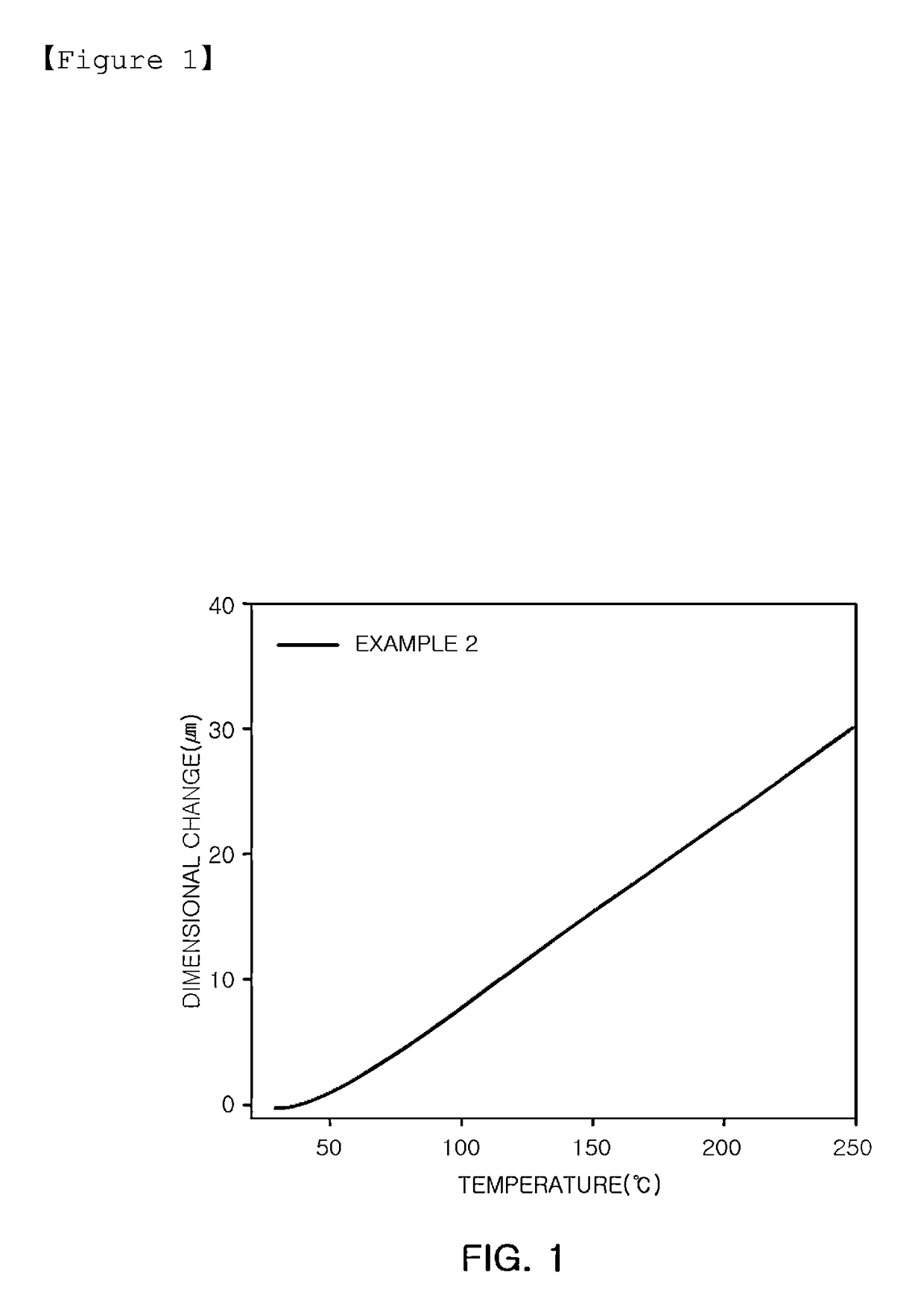

Resin composition with good workability, insulating film, and prepreg

InactiveUS20140187679A1Improve mechanical propertiesImprove thermal propertiesPrinted circuit aspectsPrinted circuit manufactureEpoxyPrinted circuit board

This invention relates to a resin composition with good workability, including a liquid crystal oligomer, an epoxy resin, or a resin mixture thereof, and an inorganic filler having a nanocone shape, and to an insulating film for a printed circuit board, and a prepreg, which are manufactured using the resin composition.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Epoxy compound having alkoxysilyl group, method for preparing the same, composition including the same, cured product made from the composition, and use of the composition

ActiveUS9725590B2Improve flame retardant performanceImprove heat resistanceSilicon organic compoundsEpoxy resin adhesivesEpoxyPolymer science

Provided are an alkoxysilylated epoxy compound, a composite of which exhibits good heat resistance properties, particularly low CTE and increased glass transition temperature, and a cured product thereof exhibits good flame retardancy and composition of which does not require additional silane coupling agent, a method for preparing the same and a composition and a cured product including the same. An alkoxysilylated epoxy compound including at least one alkoxysilyl group and at least two epoxy groups, a method for preparing the same by epoxide ring-opening reaction of starting material and alkoxysilylation, an epoxy composition including the epoxy compound, and a cured product and a use of the composition are provided. Since chemical bonds may be formed between alkoxysilyl group and filler and between alkoxysilyl groups, chemical bonding efficiency of the composite may be improved. Thus, the composite exhibits good heat resistance properties and the cured product exhibits good flame retardancy.

Owner:KOREA INST OF IND TECH

Polyamide acid slurry, preparation method thereof and polyimide film

The invention discloses polyamide acid slurry, a preparation method thereof and a polyimide film, excessive dianhydride reacts with diamine containing an imidazole structure, and then alcohol is added to obtain an ester-terminated polyamide acid composition; by adding a second part of dianhydride monomer and diamine monomer into the solution, a polyamide acid solution in which the molar weight of the dianhydride monomer is basically close to the molar weight of the diamine monomer is obtained; when the first part of dianhydride or diamine monomer and the second part of dianhydride or diamine monomer are different in type, polyamic acid of a block structure can be obtained, the polyamic acid is further cured to obtain the polyimide film of the block structure, the viscosity is small and controllable in the reaction process, the ratio of the dianhydride to the diamine monomer can be increased, batch solution feeding is achieved, a high-molecular-weight low-viscosity imidazole structure-containing block type polyamide acid solution is prepared, and due to the action of an imidazole structure, a substrate hydrogen bond and the like, a film cured at a high temperature is excellent in comprehensive performance, and the adhesive force of the film and a coated substrate is greatly improved.

Owner:武汉柔显科技股份有限公司

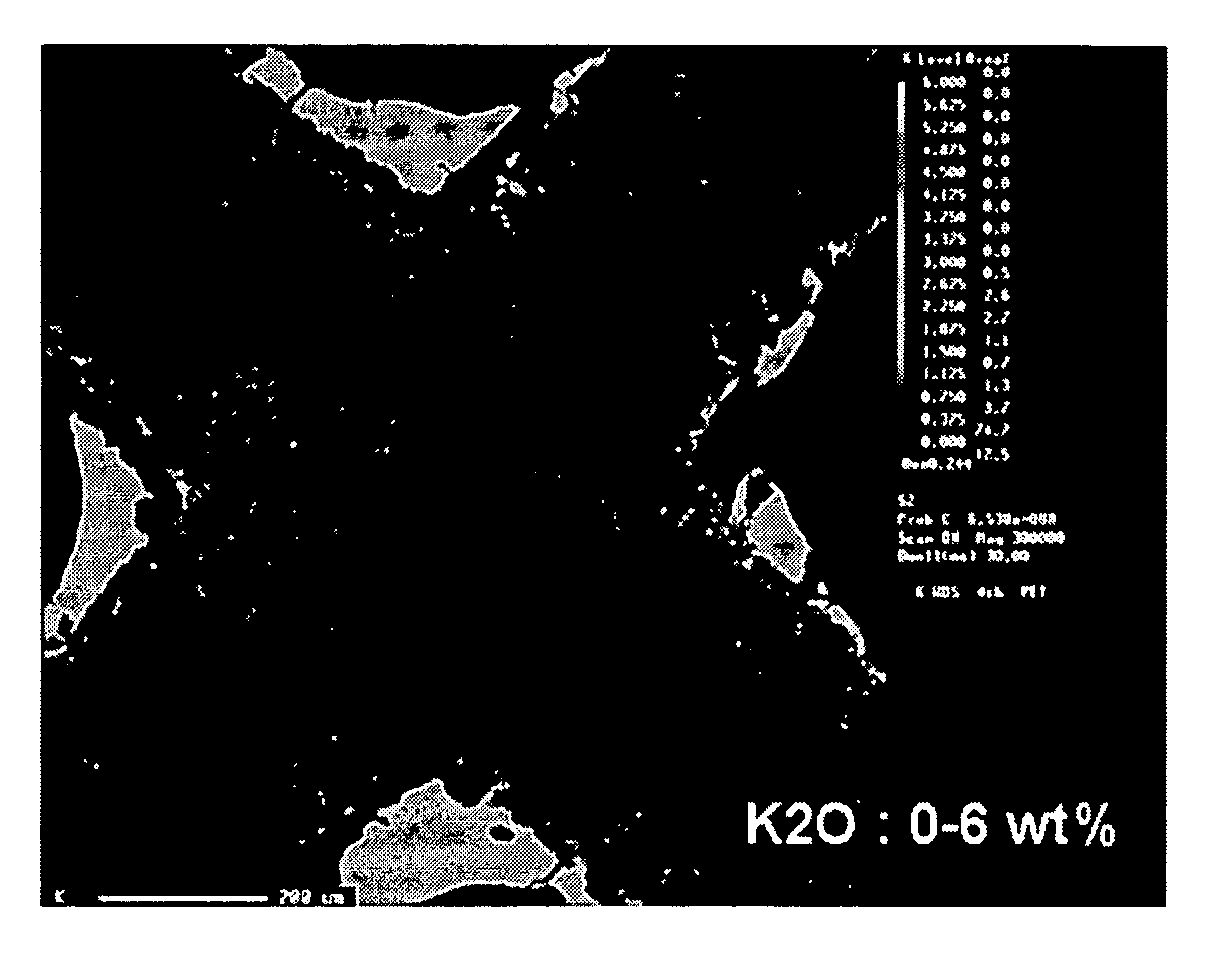

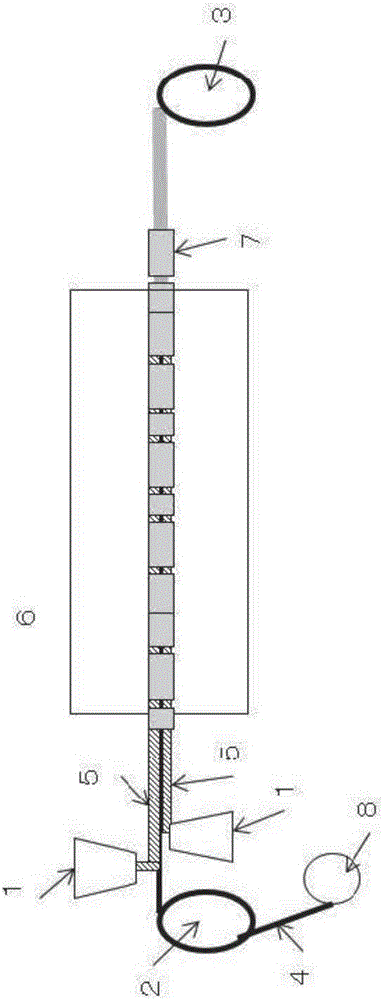

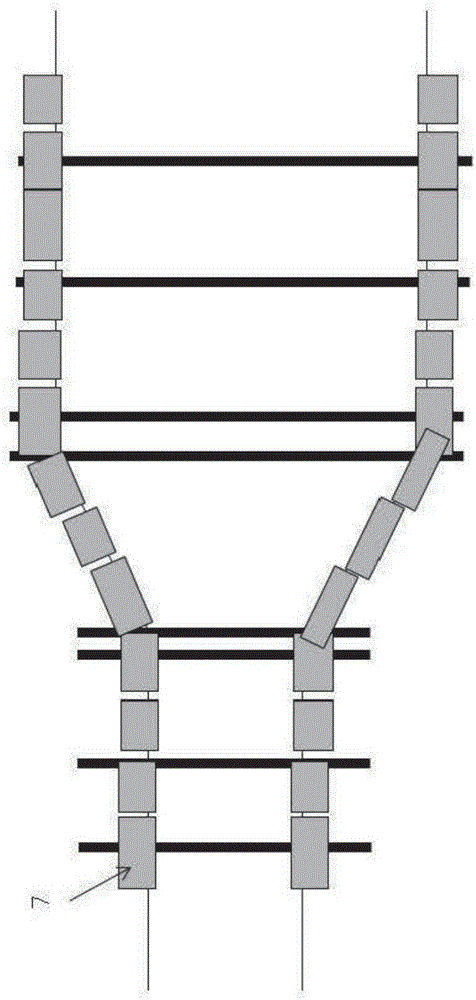

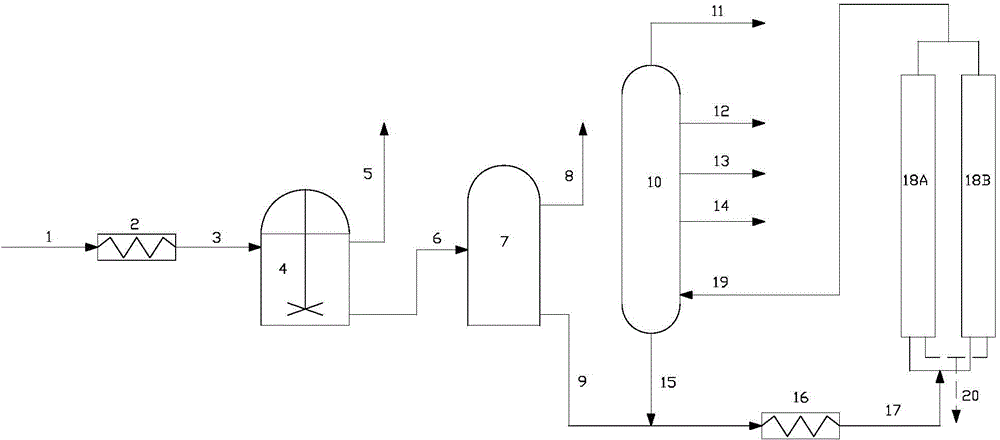

Needle coke preparation method and device

ActiveCN105733631ALow CTEEvenly dispersedCoking carbonaceous materialsProcess engineeringReaction zone

The invention provides a needle coke preparation method and device. The preparation method comprises mixing raw oil and a part of coker gas oil, preheating the mixture, feeding the mixture into a pretreatment reactor with a stirring function, wherein the upper part of the reactor is provided with gas vents and the rear part of the reactor is provided with a buffer tank, buffering the reactor distillate through the buffer tank, feeding the reactor distillate into a coking heating furnace, carrying out heating, feeding the material into a delayed coking device and preparing needle coke. A relaxative reaction zone is built in front of the coking device, a stirring process always keeps a uniform state of a system and a high activity component polymerization rate is effectively controlled. Through control of raw material pretreatment conditions, in the reaction system, a lot of an intermediate phase precursor is produced. The number of the intermediate phase precursor is large, volume is small and dispersion is uniform so that the high-quality needle coke product can be prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com