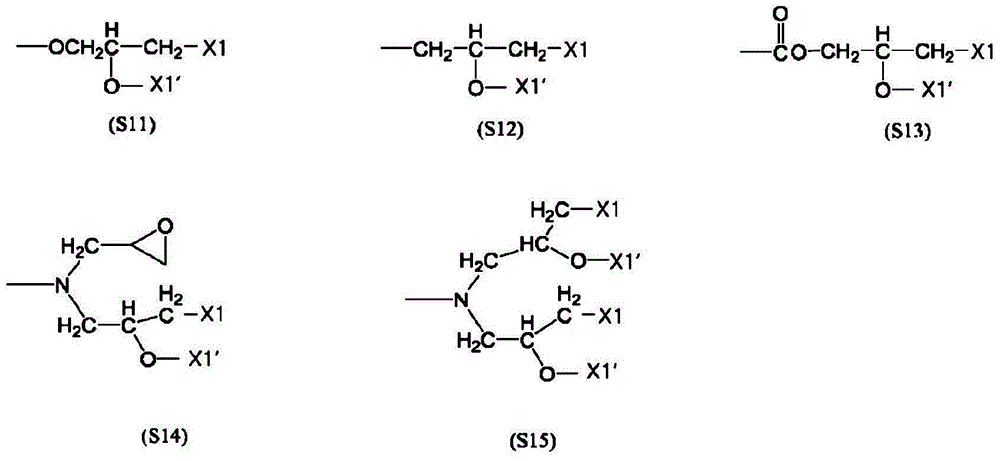

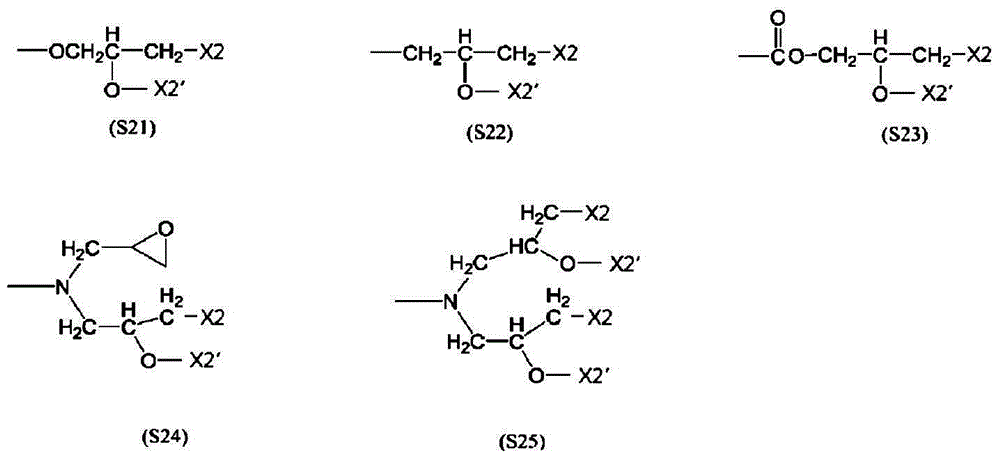

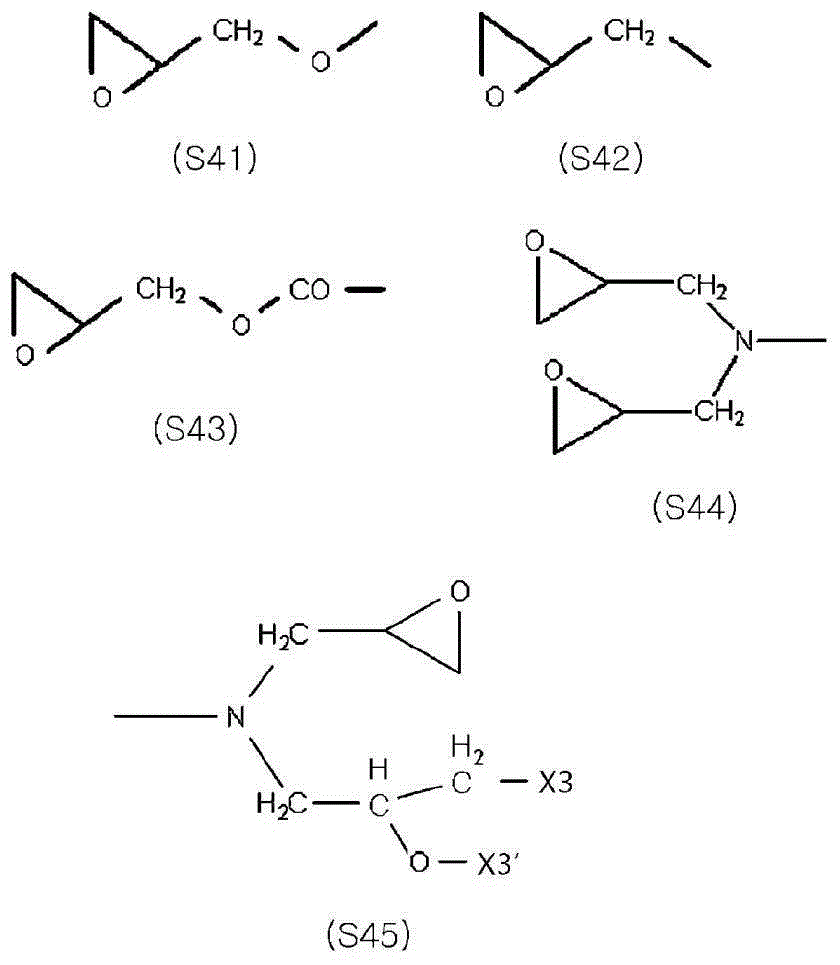

Epoxy compound having alkoxysilyl group, method for manufacturing same, composition and cured product including same, and use thereof

A technology of alkoxysilyl and epoxy compounds, which is applied in the field of epoxy compounds and can solve problems such as differential thermal properties, high CTE, and manufacturing restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0289] Hereinafter, the present invention will be described in detail with reference to examples. The following examples are for illustration, but the present invention is not limited thereto.

[0290] (synthesis example)

[0291] Synthetic Example 1: Synthesis of Naphthalene Epoxy Compound A': with CH 3 CH 2 -OH reaction

[0292]

[0293] (1) Step 1

[0294] 20g of 2,2'-((1,5-bis(oxirane-2-ylmethoxy)naphthalene-2,6-diyl)bis(methylene))bis(oxirane ), 2.92g of NaOH, 3.54g of tetraethylammonium bromide (NEt 4 Br), 70ml of tetrahydrofuran (THF), 70mL of CH 3 CN, and 82 mL of ethanol (EtOH) were added into the two-necked flask at room temperature, followed by stirring at 26° C. for 5 hours and 30 minutes. Then, 5 mL of saturated ammonium chloride (NH4 Cl) solution, followed by stirring for 3 minutes. The solvent was removed using a rotary evaporator and the organic layer was separated by the action of 400 mL of ethyl acetate (EA) and 300 mL of water. Add MgSO to the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com