Patents

Literature

71results about How to "Reduce large particles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cathode material of lithium ion battery, preparation method of cathode, and lithium ion battery

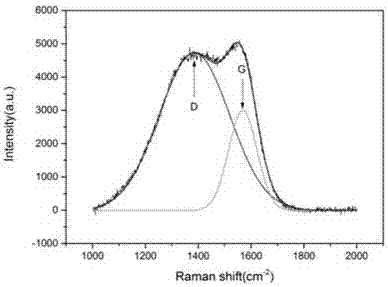

ActiveCN103199258APromote accumulationEvenly dispersedCell electrodesSecondary cellsSodium-ion batteryNano carbon

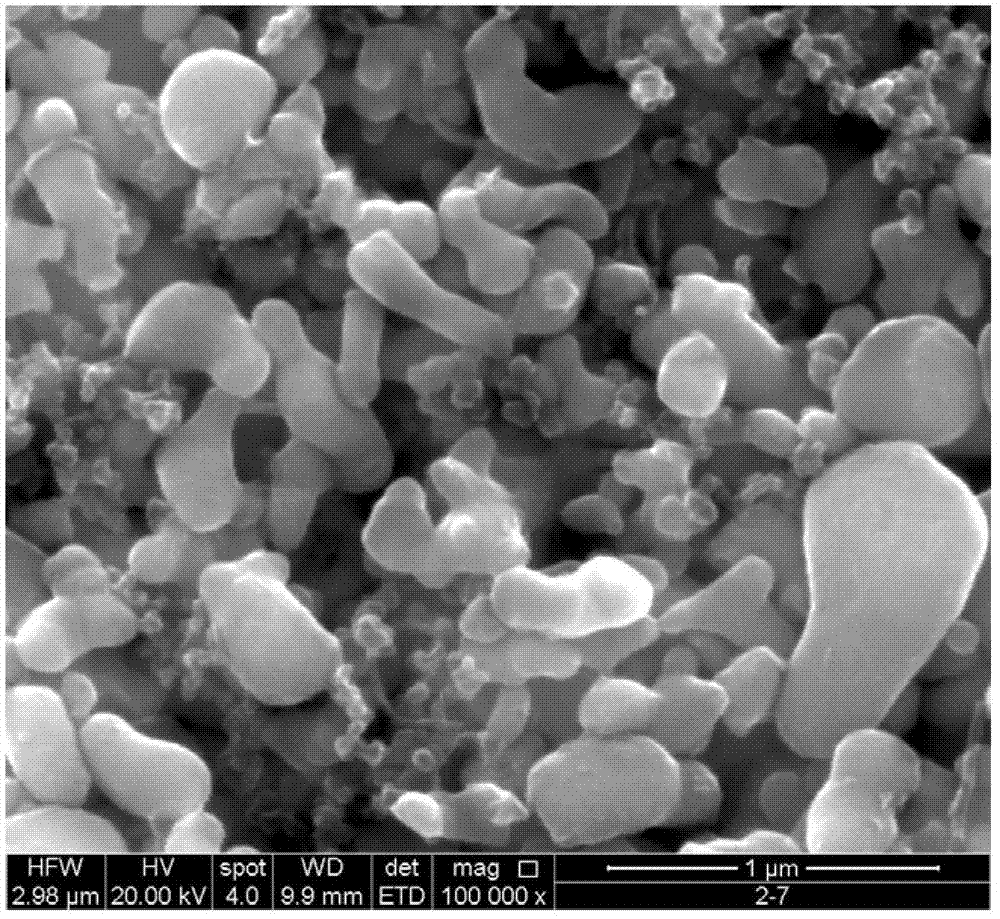

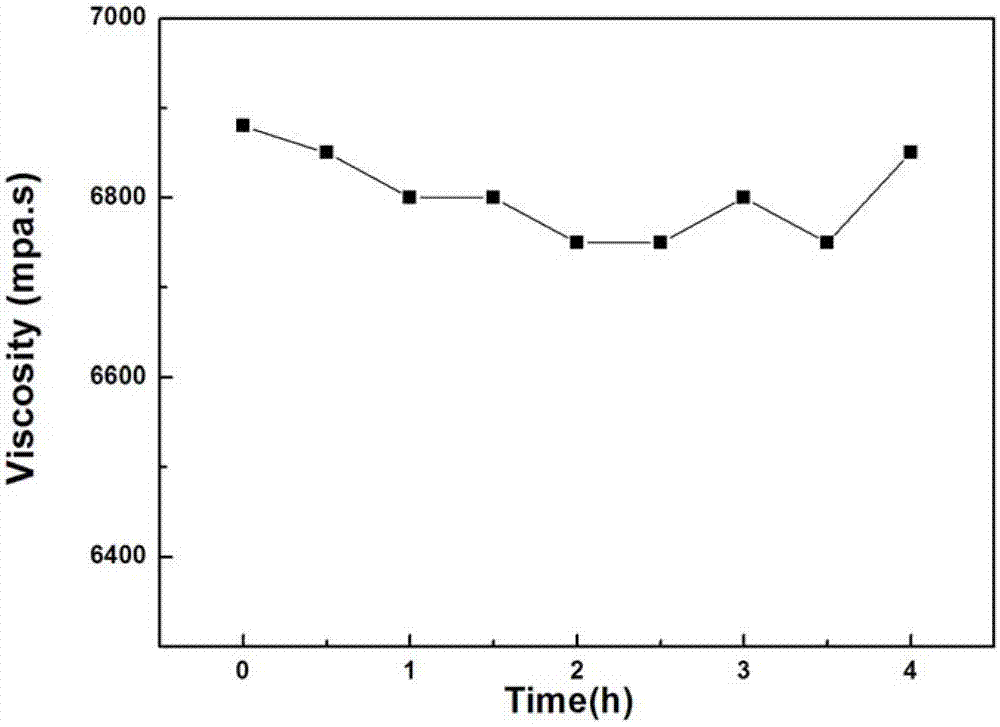

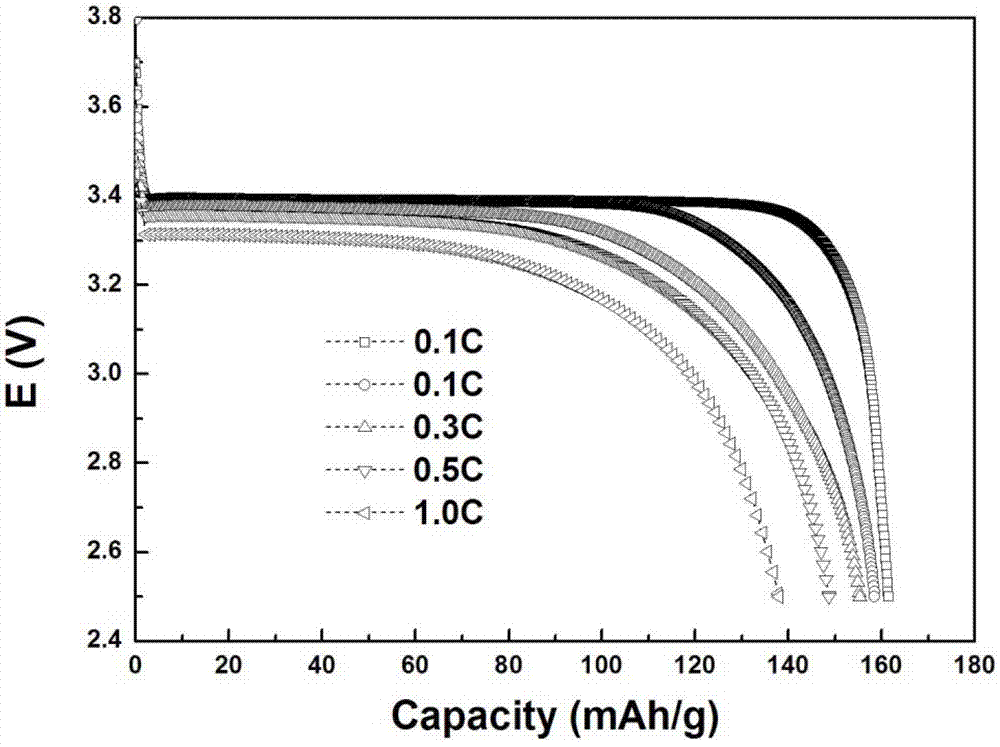

The invention discloses a cathode material of a lithium ion battery, a preparation method of the cathode, and the lithium ion battery using the cathode material, belonging to the technical field of energy material. According to the invention, a chemical dispersant is added into the cathode of an aqueous lithium-ion battery, thereby solving problems of uniform dispersion for active materials of positive electrode and a nano-carbon mixed conductive agent; and a mechanical dispersion method is combined, preferably with a revolution speed of the mechanical dispersion being 15-35 HZ and a rotation speed being 10-30 HZ, thereby realizing uniform dispersion of the nano-active substances in a relatively short time. The cathode material of a lithium ion battery and the preparation method provide technical approach for solving uniform dispersion of the aqueous nano-active substances, and are high in production efficiency and low in cost; the prepared battery is high in discharge capacity, and is significantly improved in low temperature, multiplying power and cycling performances; and a new approach is provided for a large scale application of the nanometer lithium batteries which are limited to a high cost and a high-polluting oil system in the field.

Owner:中创新航科技(江苏)有限公司

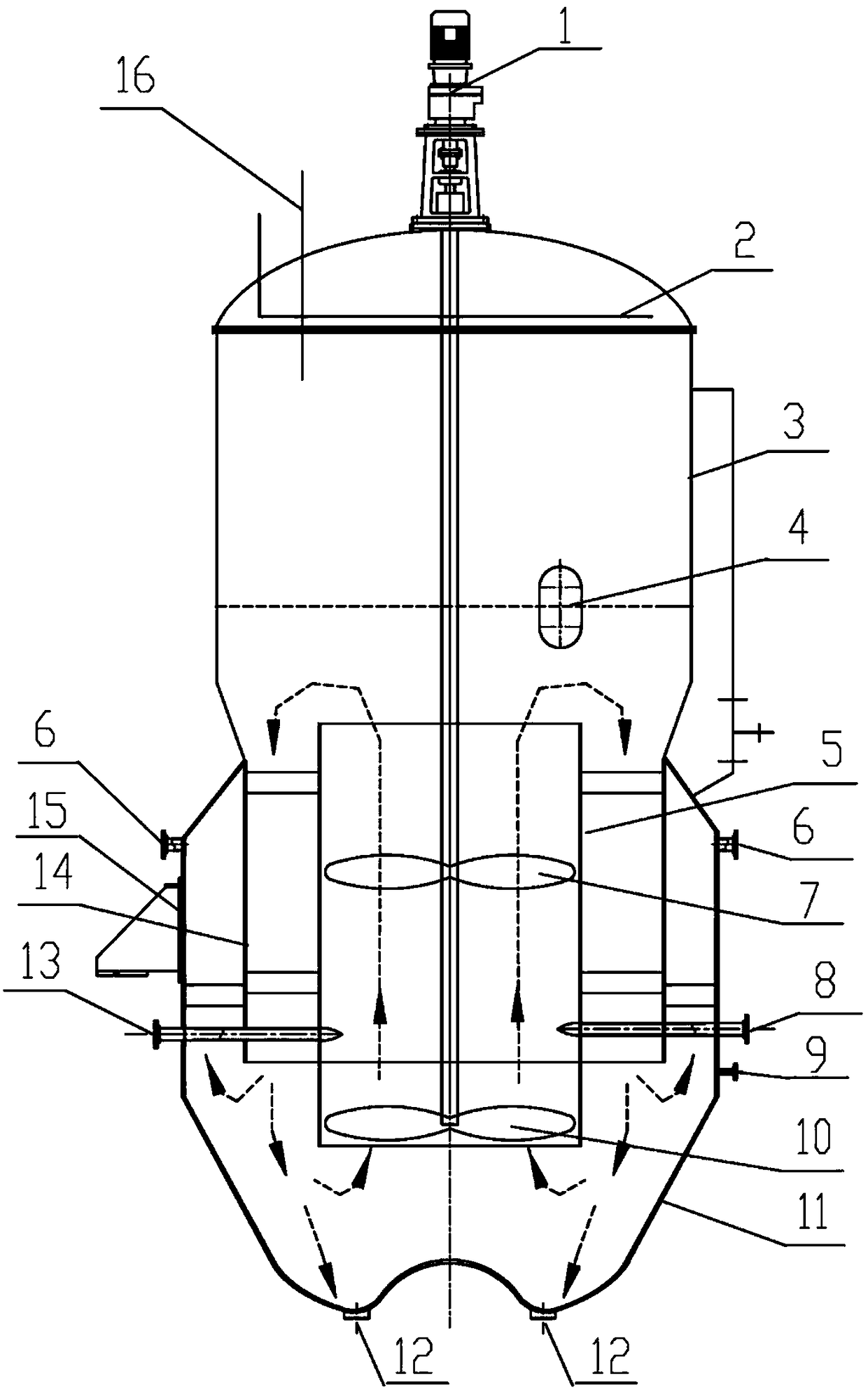

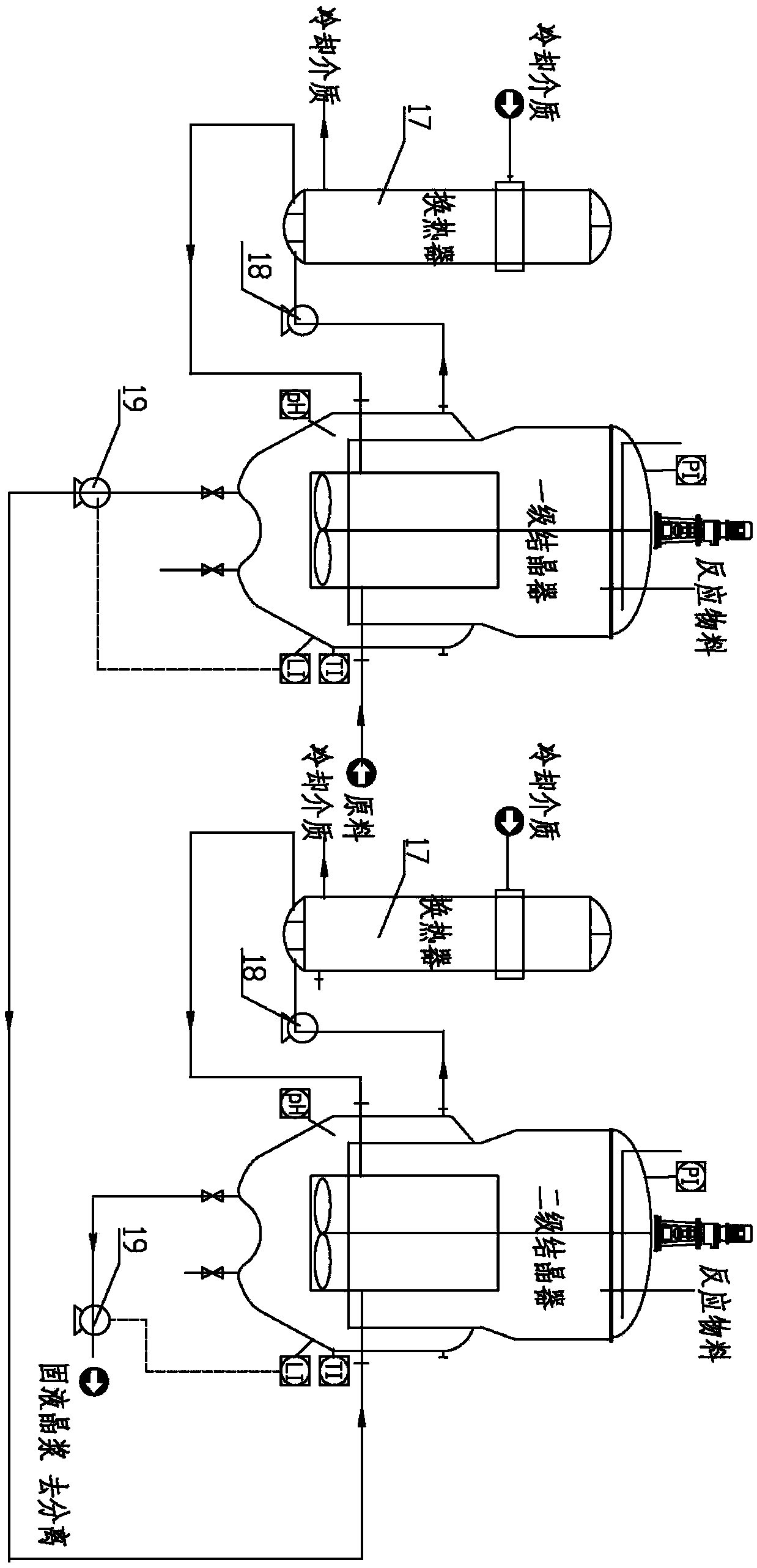

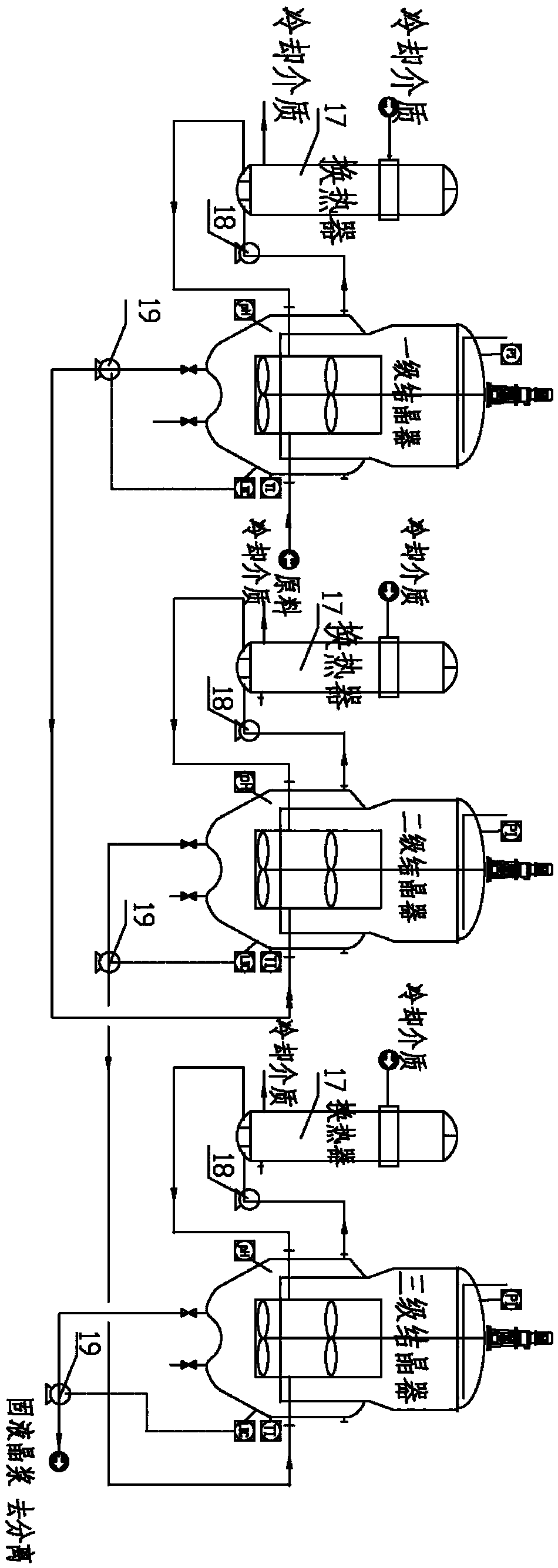

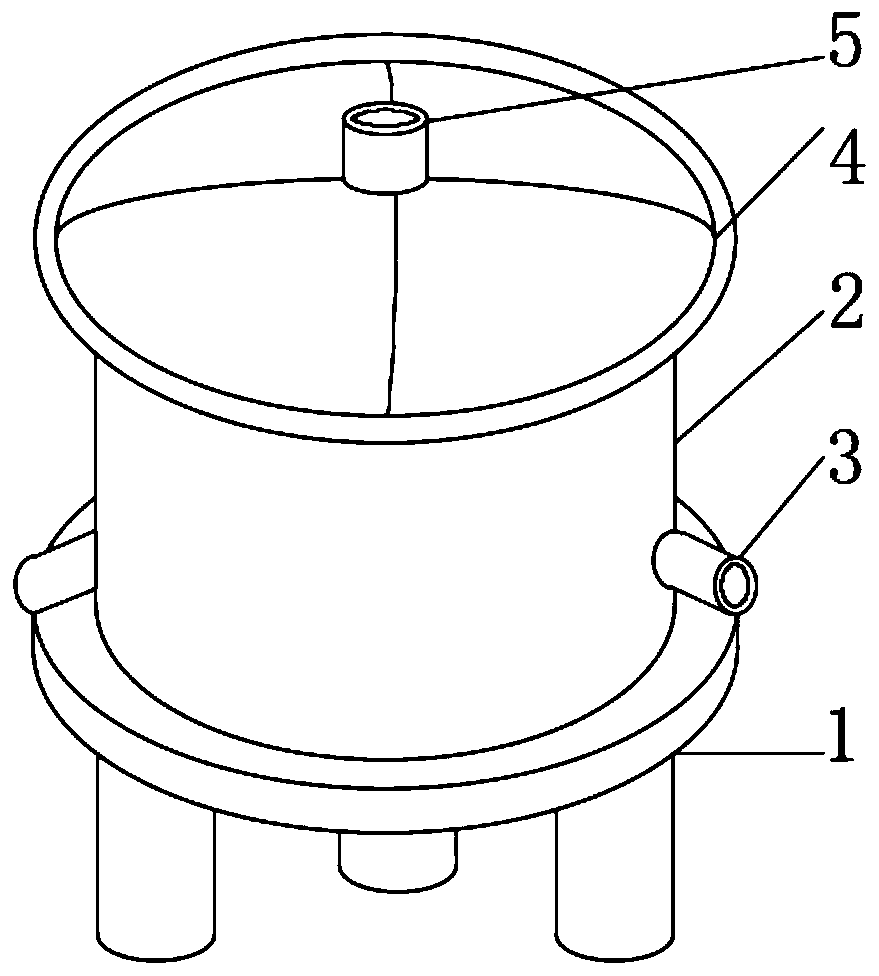

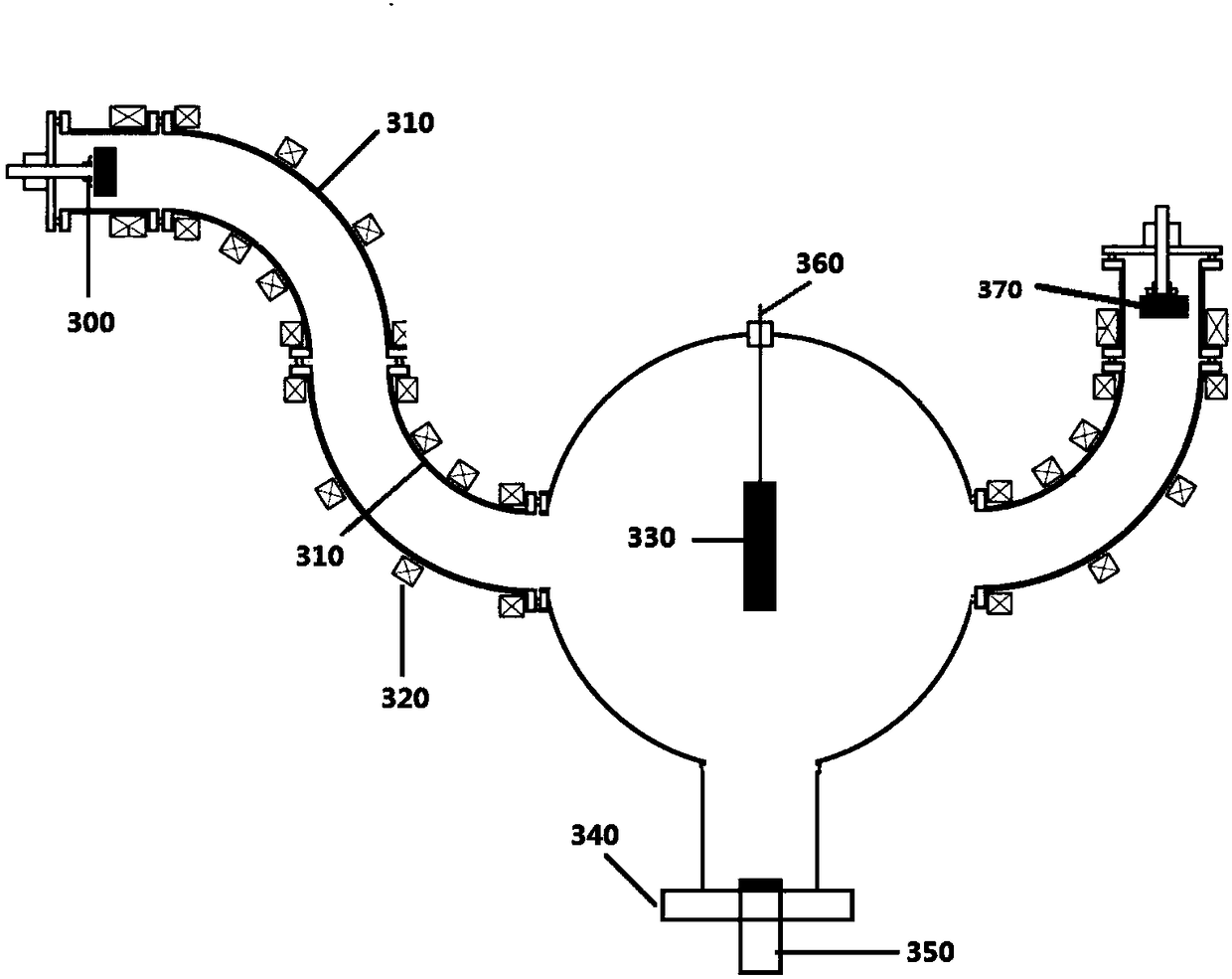

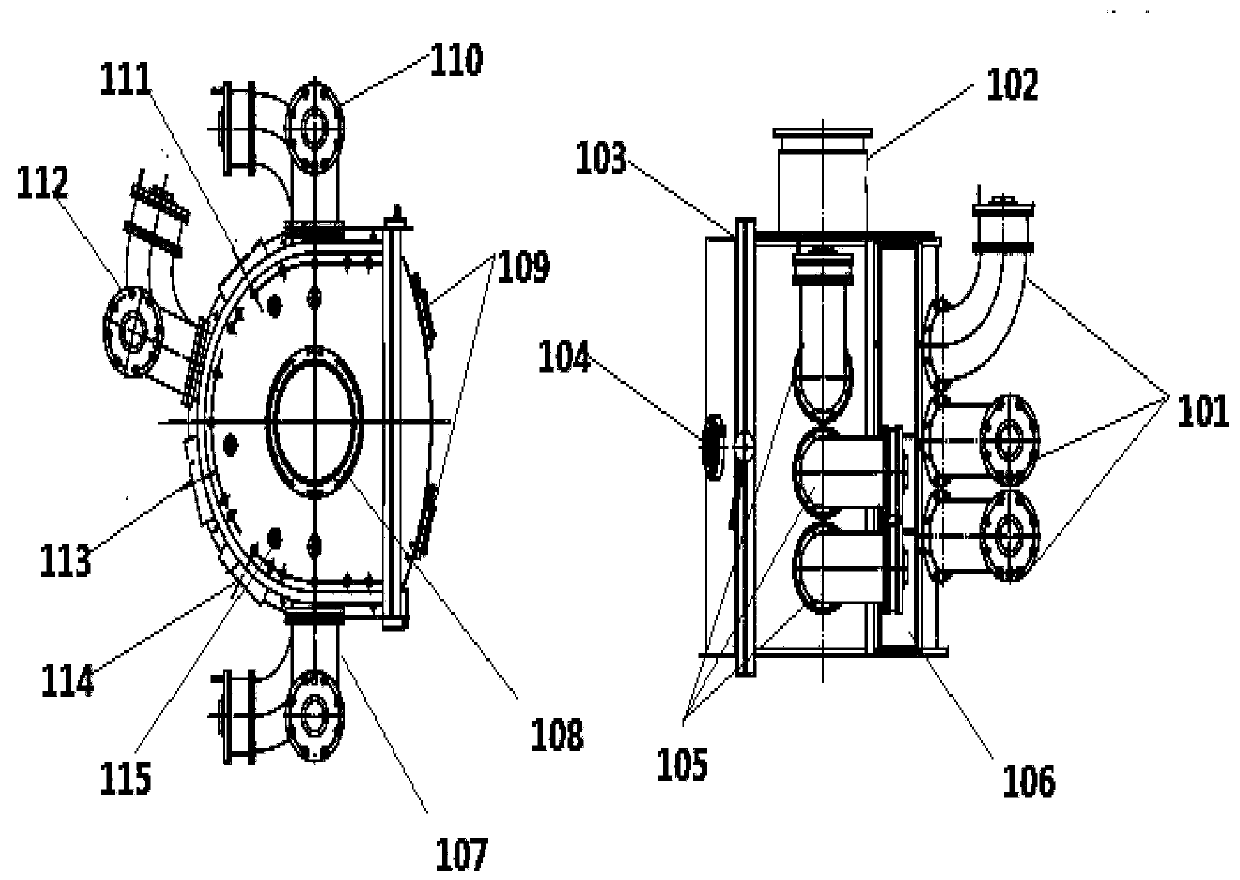

Self-circulating crystallizer and multistage continuous crystallization method

ActiveCN108939599AReduce the chance of collision nucleationStable particle sizeEvaporator accessoriesSolution crystallizationGranularityEvaporation

The invention relates to a self-circulating crystallizer and a multistage continuous crystallization method. The crystallizer sequentially comprises a kettle head, an upper cylinder body, a middle cylinder body and a bottom hole-shrinkage cylinder body with a W-shaped bottom from top to bottom, wherein a steam outlet and / or a feeding hole are / is arranged on the kettle head, an annular spraying pipe is arranged at the lower part of the kettle head; a middle straight cylinder section is arranged in the middle cylinder body, a flow guiding cylinder is arranged in the middle straight cylinder section, and a stirrer is arranged in the flow guiding cylinder; the diameter of the middle cylinder body is larger than that of the upper cylinder body, and the diameter of the upper cylinder body is larger than that of the middle cylinder body; and the lower part of the upper cylinder body and the upper part of the middle cylinder body are respectively connected with the circumference of the top ofthe middle straight cylinder section via a hole-shrinkage transition section, and a discharging hole is formed in the W-shaped bottom. The invention provides the method for realizing multistage continuous evaporation, cooling or reaction crystallization through the series connection of the crystallizer, the prepared crystals are large in granularity and uniform in particle size, the problems thatthe product granularity is small, equipment is seriously scaled, a pipeline is blocked, and the like in the continuous crystallization process are improved, and the operation period of the continuouscrystallization process is prolonged.

Owner:TIANJIN UNIV

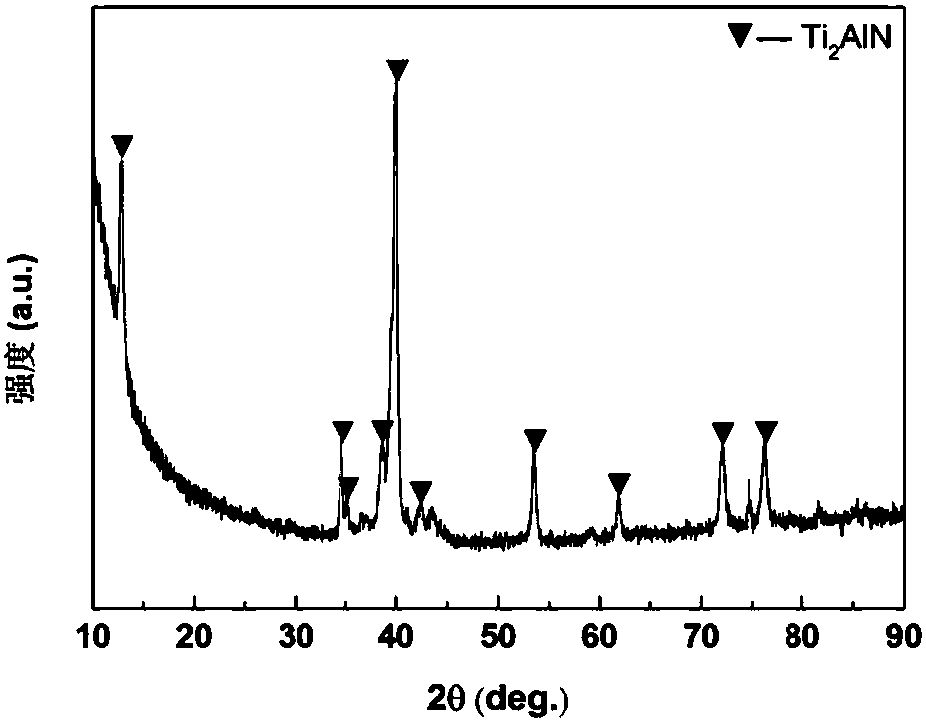

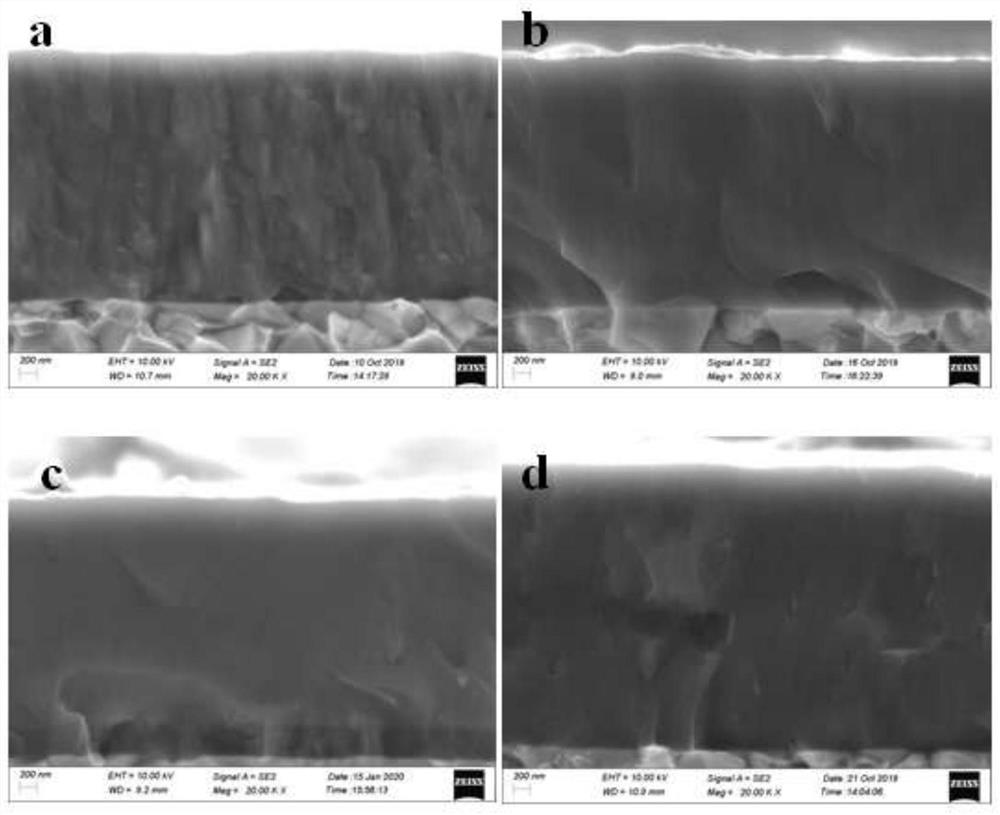

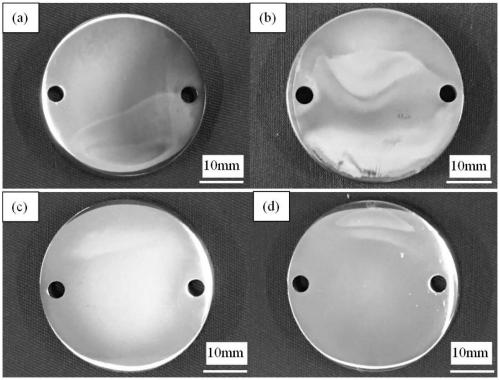

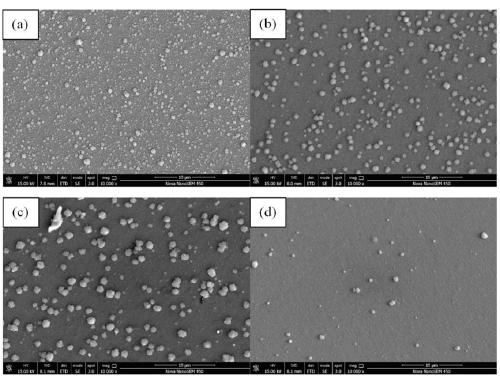

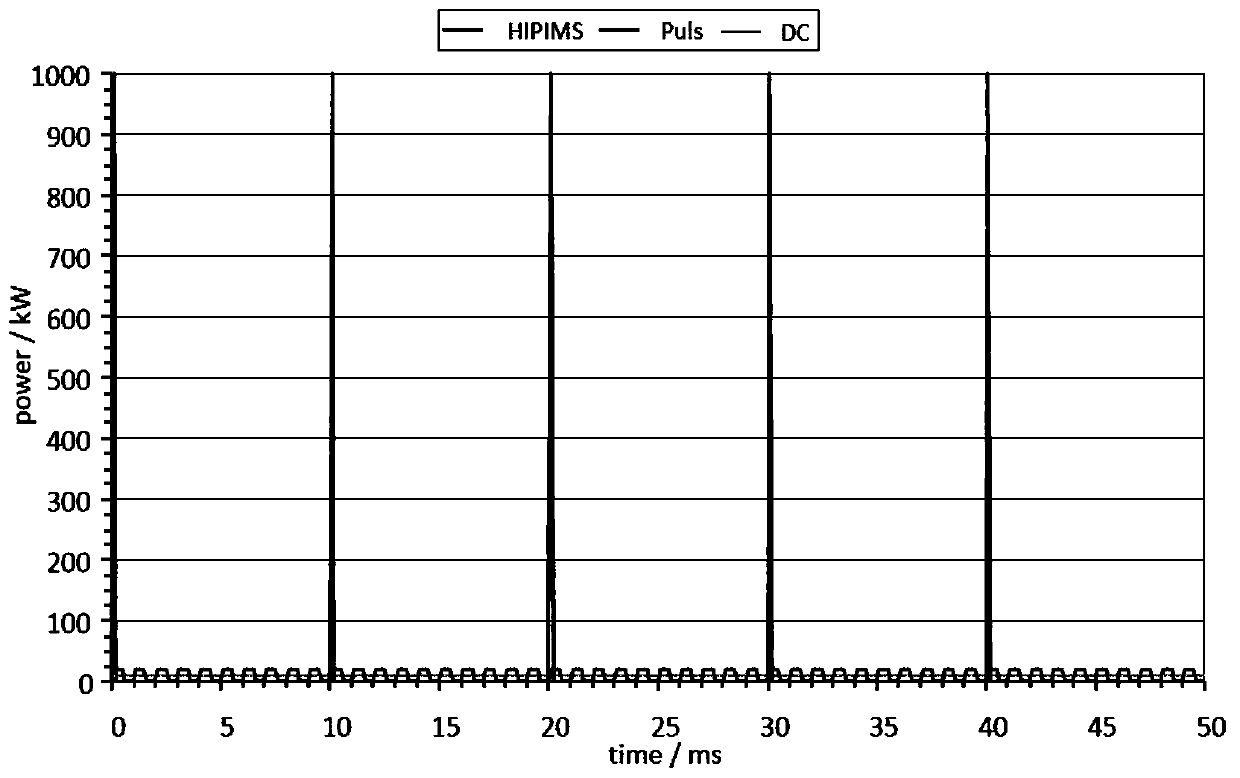

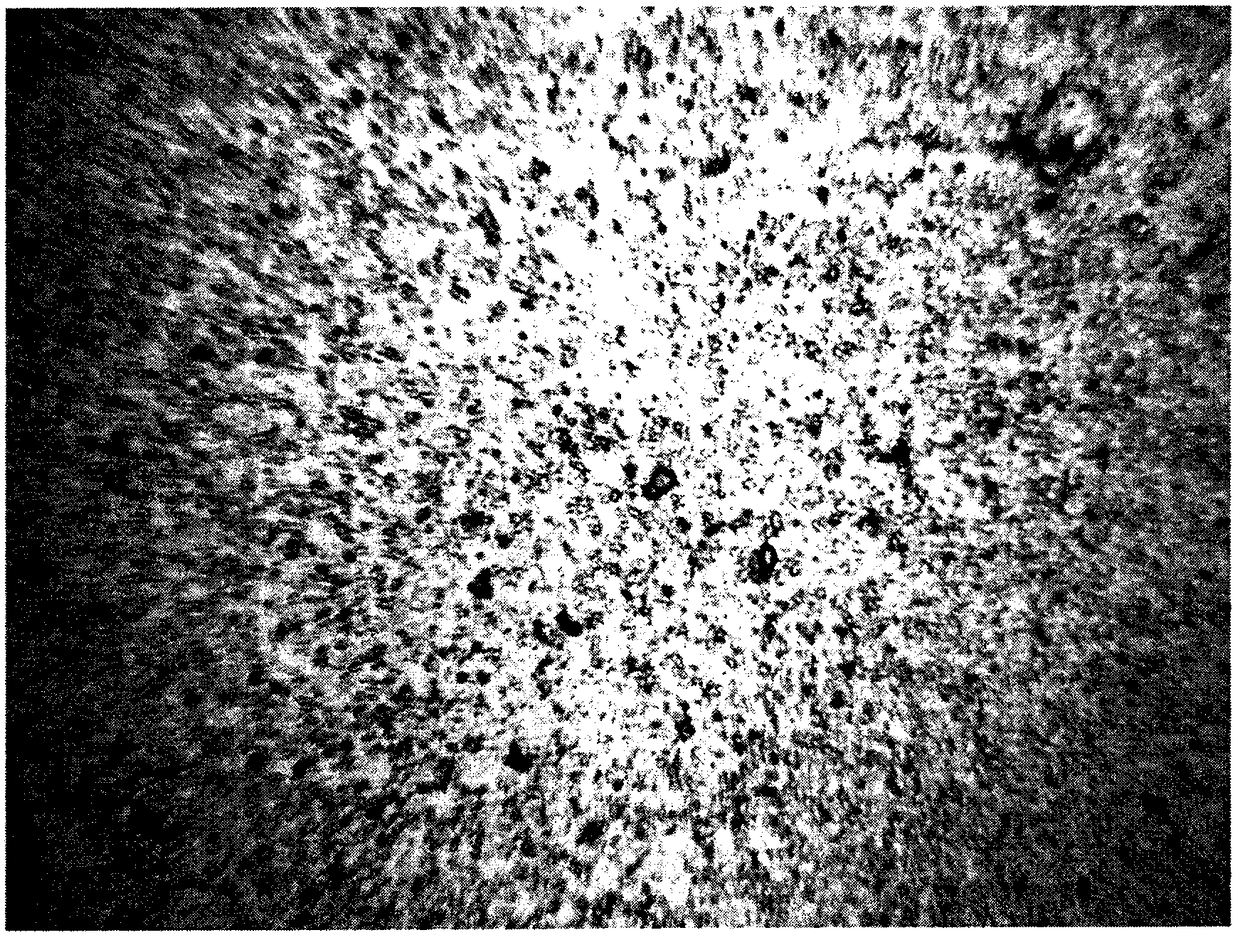

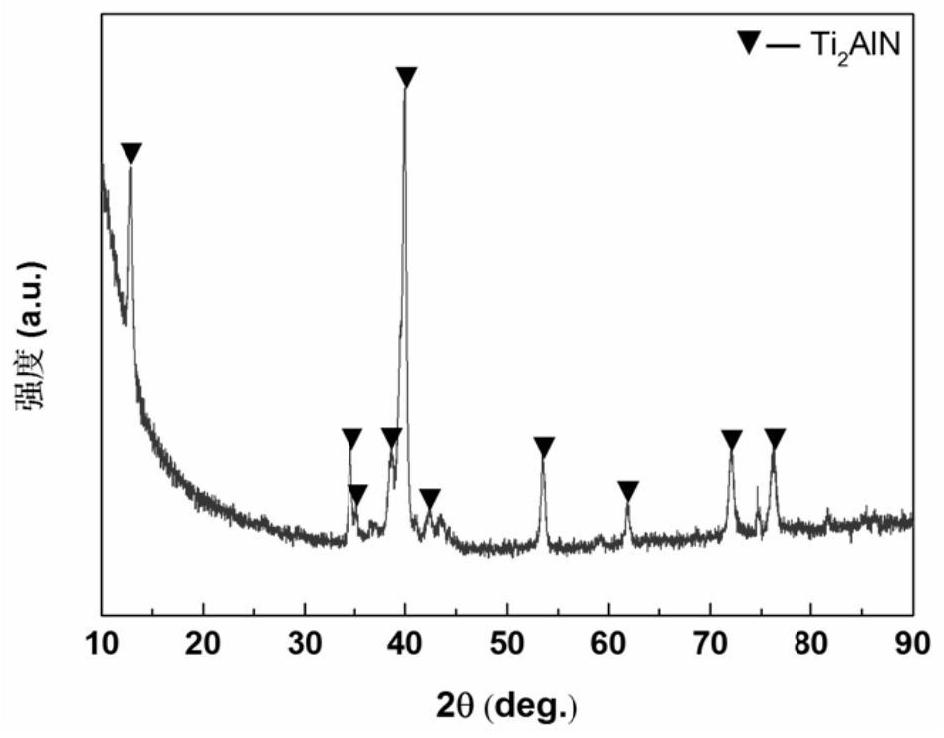

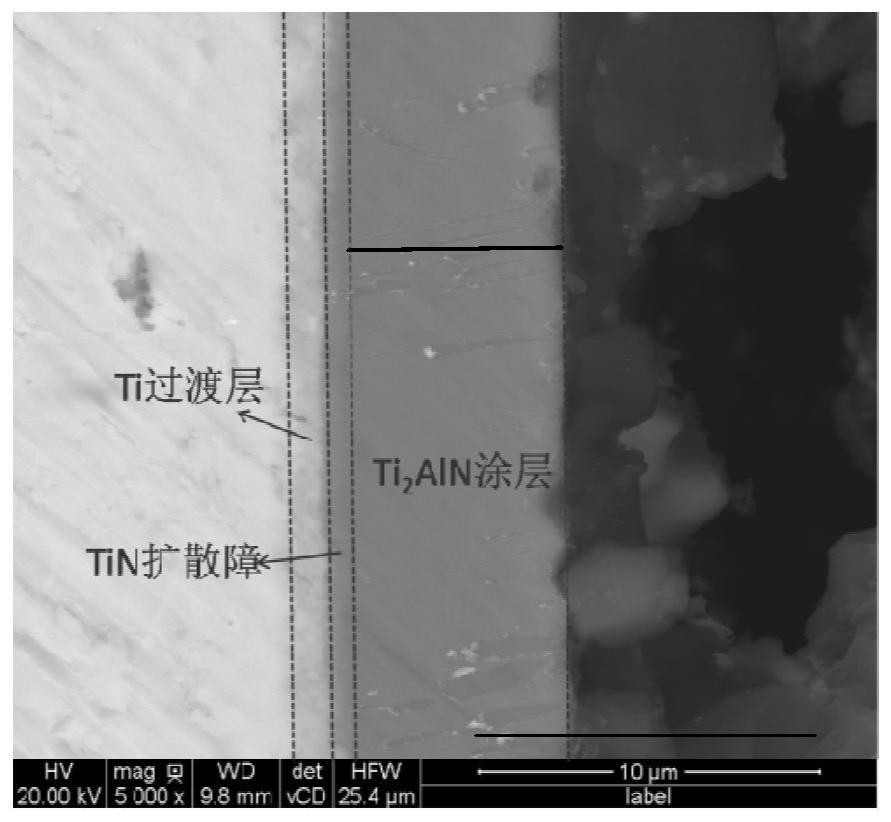

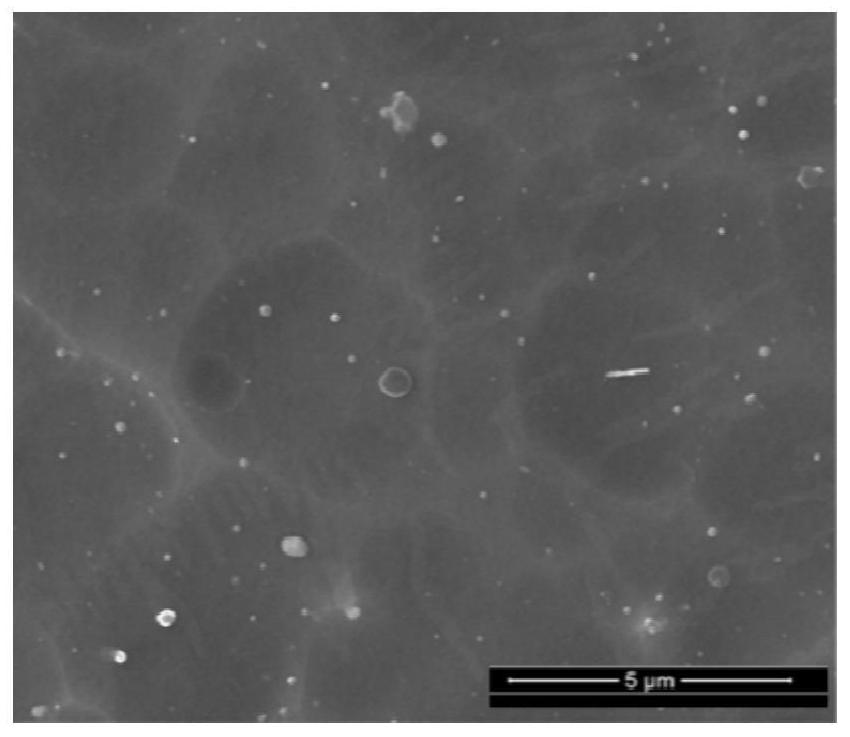

Preparation method for high-purity high-density MAX phase coating

ActiveCN107620033AEasy to controlEasy to homogenize large area depositionVacuum evaporation coatingSputtering coatingHigh densityNitrogen

The invention provides a preparation method for a high-purity high-density MAX phase coating. According to the method, an arc ion plating technology is combined with a magnetron sputtering technology,an M-position element is provided for the arc, an A-position Al element is provided for magnetron, nitrogen or hydrocarbon as reaction gas is introduced for deposition, then thermal treatment is adopted, and the high-purity high-density MAX phase coating is prepared. The prepared MAX phase coating is high in purity, good in compactness, free of a microdefect, high in preparation efficiency, low in cost and capable of overcoming the defects that large particles on the surface of a MAX phase coating prepared through a single arc method are excessive, the density is low, the efficiency is low bymeans of a magnetron sputtering method, and the defects are obvious and has the wide application prospects on the aspects of high-temperature protection, corrosion-resistant application and the like,and the industrial production of the MAX phase coating can be achieved easily.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

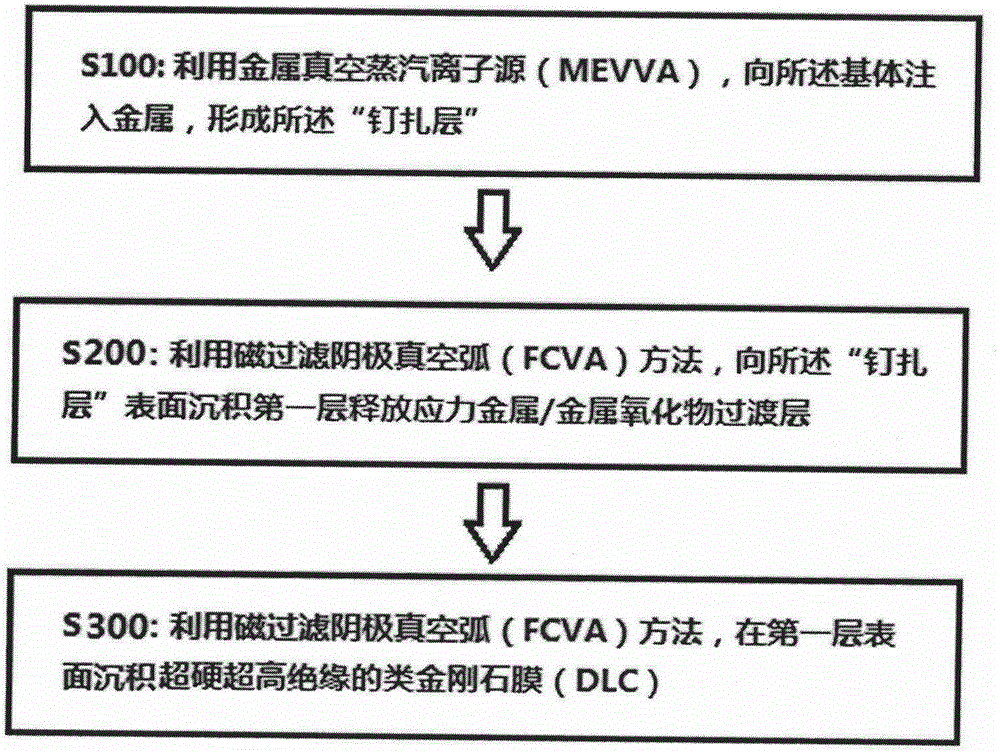

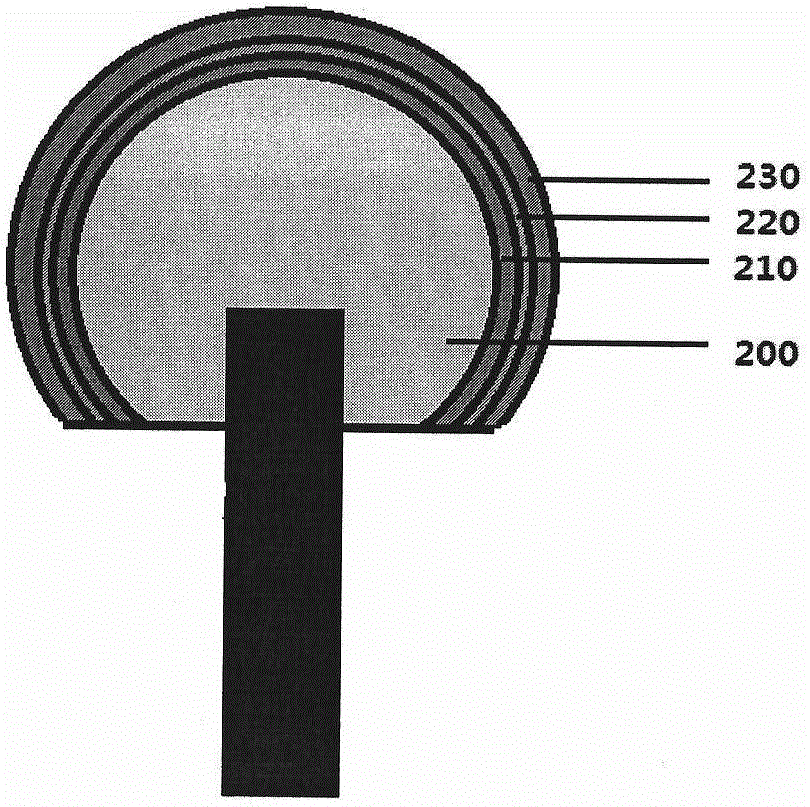

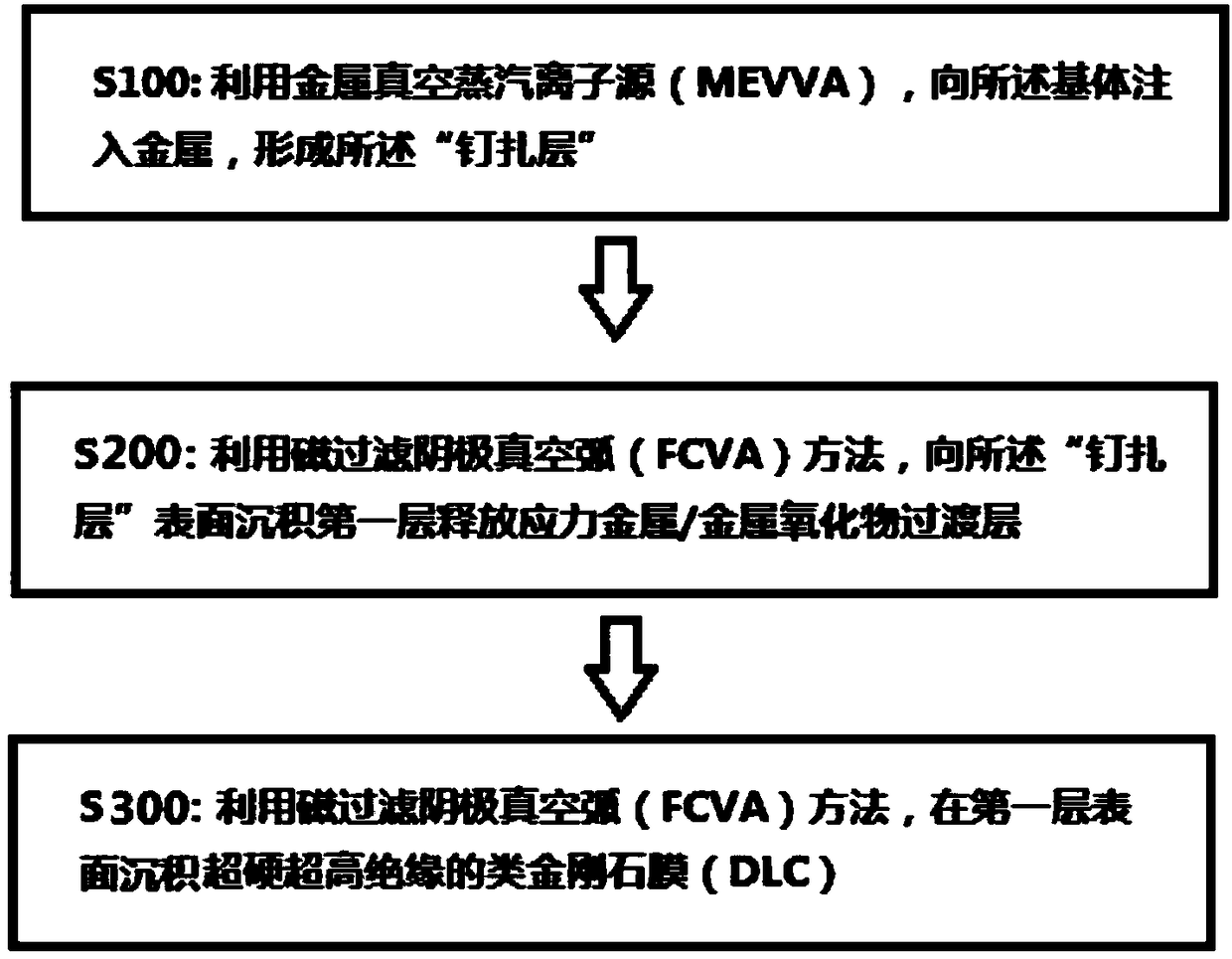

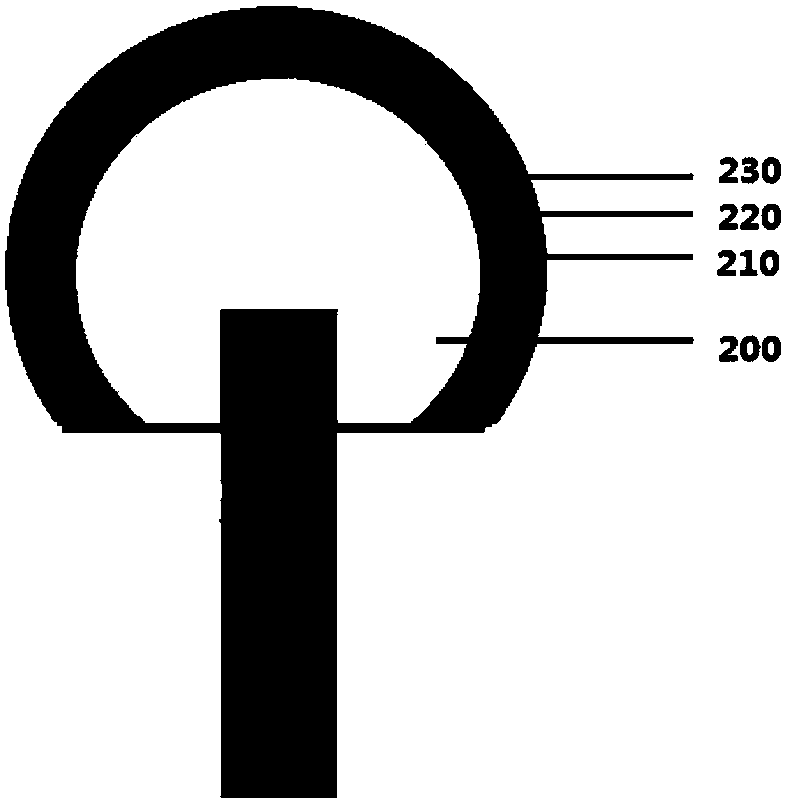

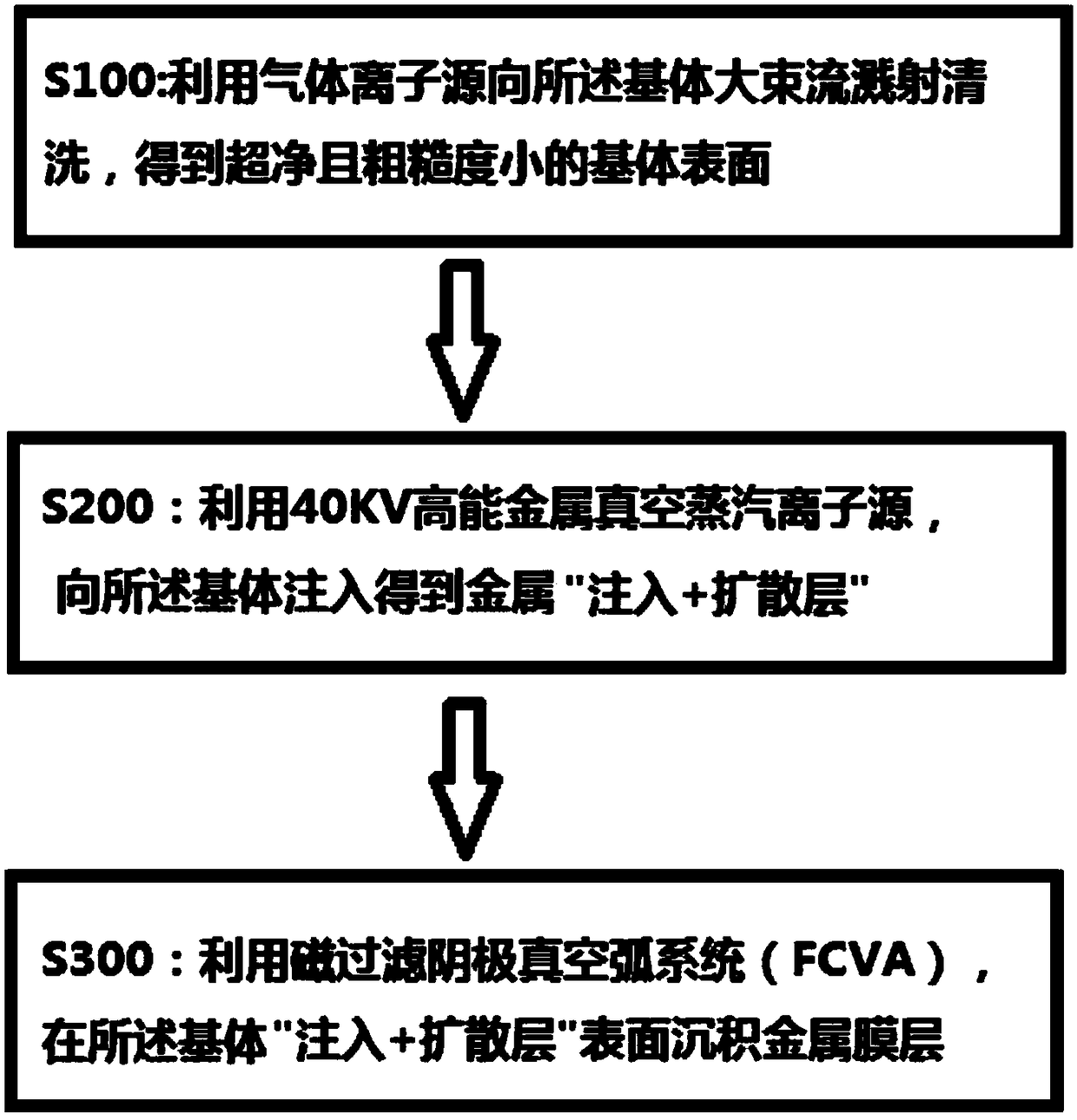

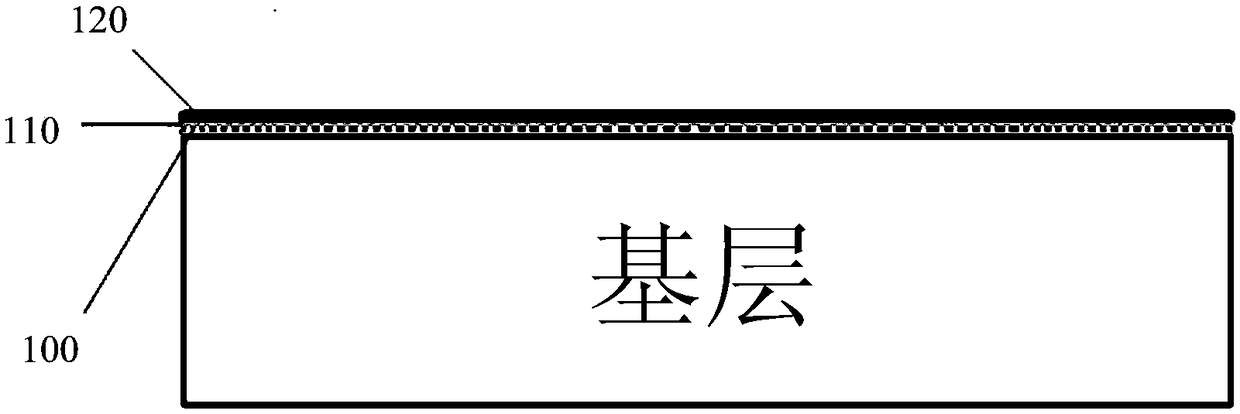

Method and equipment for prolonging life of push rod component in aerospace relay

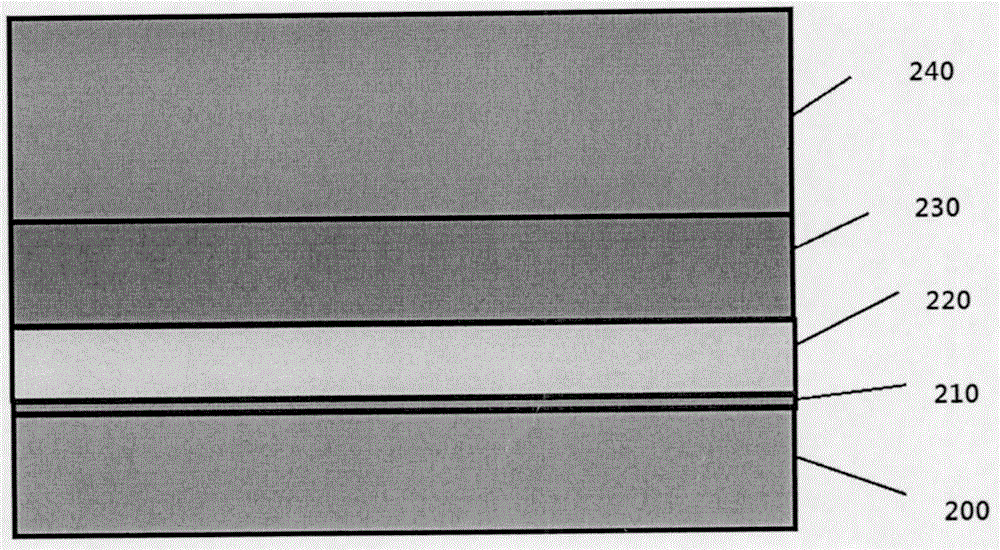

ActiveCN105755443AImprove bindingHigh peel strengthVacuum evaporation coatingSputtering coatingWear resistantBinding force

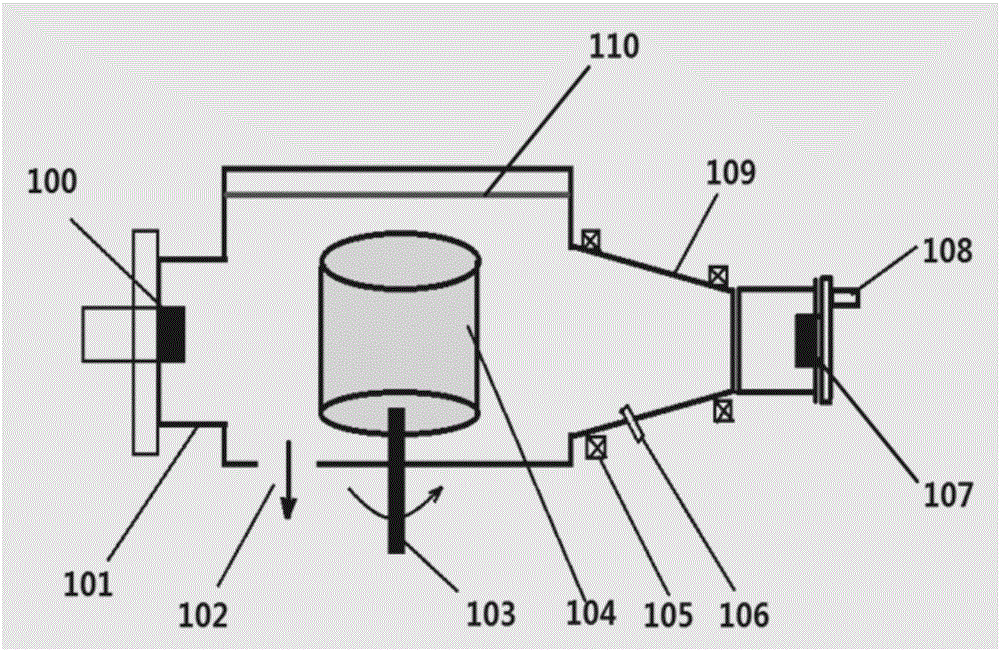

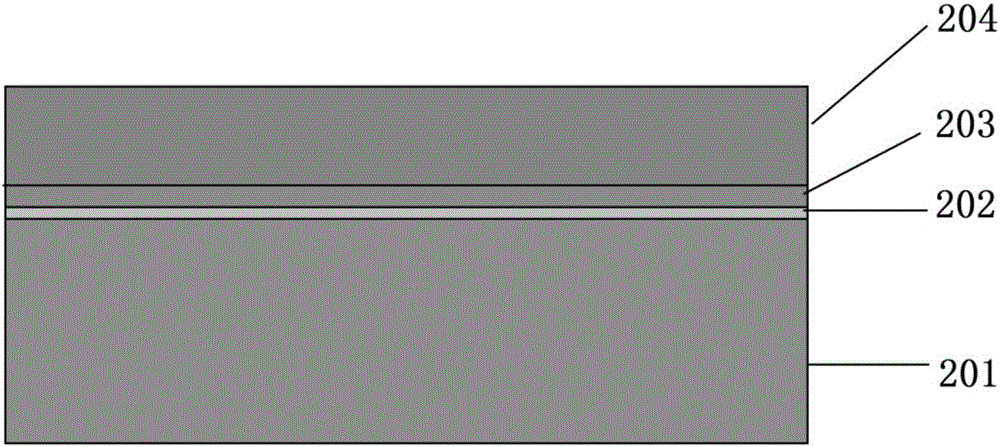

The invention discloses method and equipment for prolonging the life of a push rod component in a sealed relay. In the method, a superhard wear-resistant film layer with good insulating property is deposited on the surface of a push ball in the push rod component by a low-energy ion beam technology; and the film is prepared by the following steps: injecting a layer of metal 'pinning layer' capable of improving binding force of the film into glass surface by a metal vapor vacuum arc (MEVVA) ion source method; depositing a first metal film transition layer for releasing internal stress on the metal 'pinning layer' by a magnetic filtered cathodic vacuum arc (FVCA) deposition method; and depositing a superhard wear-resistant DLC layer on the first transition layer by the magnetic FVCA deposition method, wherein the total thickness of the film is 0.1-5 microns. Through the invention, the life of the push ball in the push rod component of the sealed relay can be obviously prolonged by depositing the superhard DLC film on the push rod component of the sealed relay.

Owner:BEIJING NORMAL UNIVERSITY

TiAlN/W2N multi-layer coating with high hardness and high corrosion resistance and preparation method thereof

ActiveCN108517487AHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingSputteringHardness

The invention discloses a TiAlN / W2N multi-layer coating with high hardness and high corrosion resistance and a preparation method thereof. The TiAlN / W2N multi-layer coating is characterized in that amode of successive sputtering of multiple targets is utilized to deposit a TiN transition layer and alternatively sputtering and depositing TiAlN layers and W2N layers on a matrix, the two layers close to the matrix are the TiN transition layer and the TiAlN layer in sequence, and the uppermost layer is the W2N layer. The total thickness of the TiAlN / W2N multi-layer coating is 2.5-3.5mu m, the thickness of each TiAlN layer is 50-210nm, the thickness of each W2N coating is 40-160nm, and the total number of periodic layers is 10-50. The preparation method comprises the steps of: cleaning the matrix, depositing the TiN transition layer and alternatively sputtering and depositing the TiAlN layer and the W2N layer. The TiAlN / W2N multi-layer coating is high in hardness and good in wear resistance, the thickness of single layer is easy in control and large in controllable range, and the process is simple.

Owner:SOUTH CHINA UNIV OF TECH

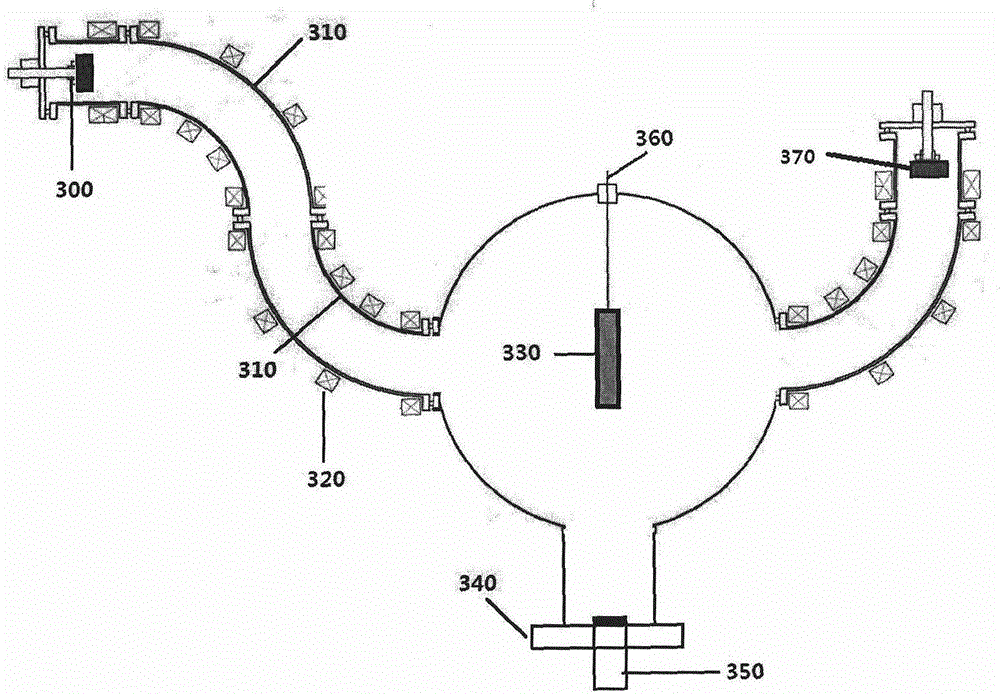

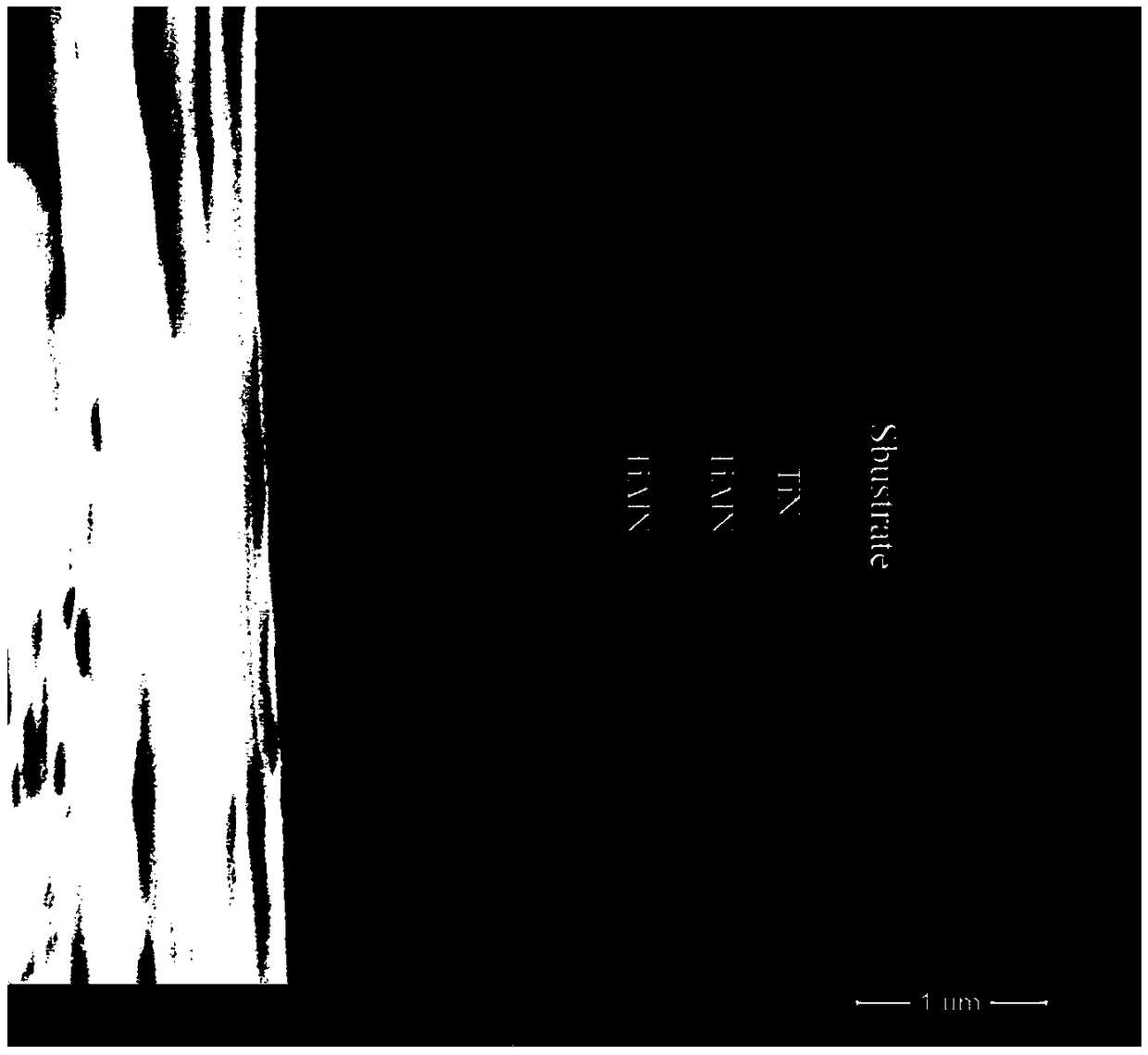

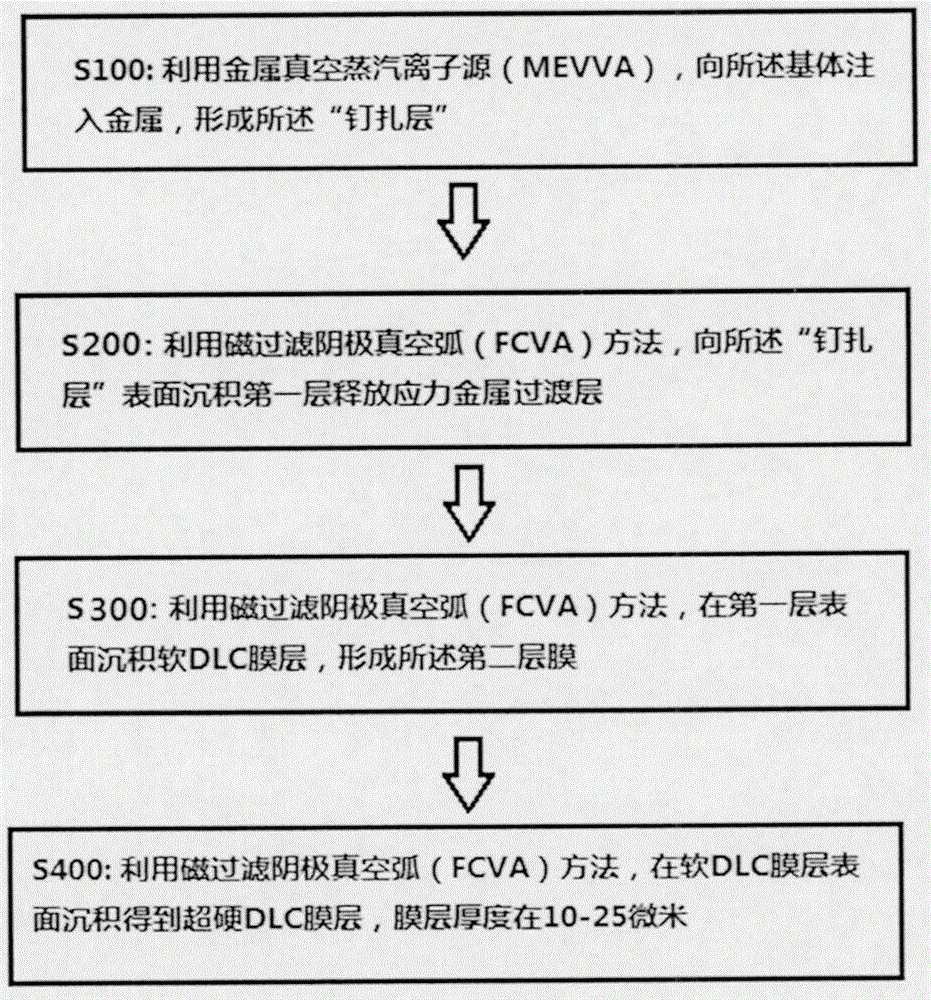

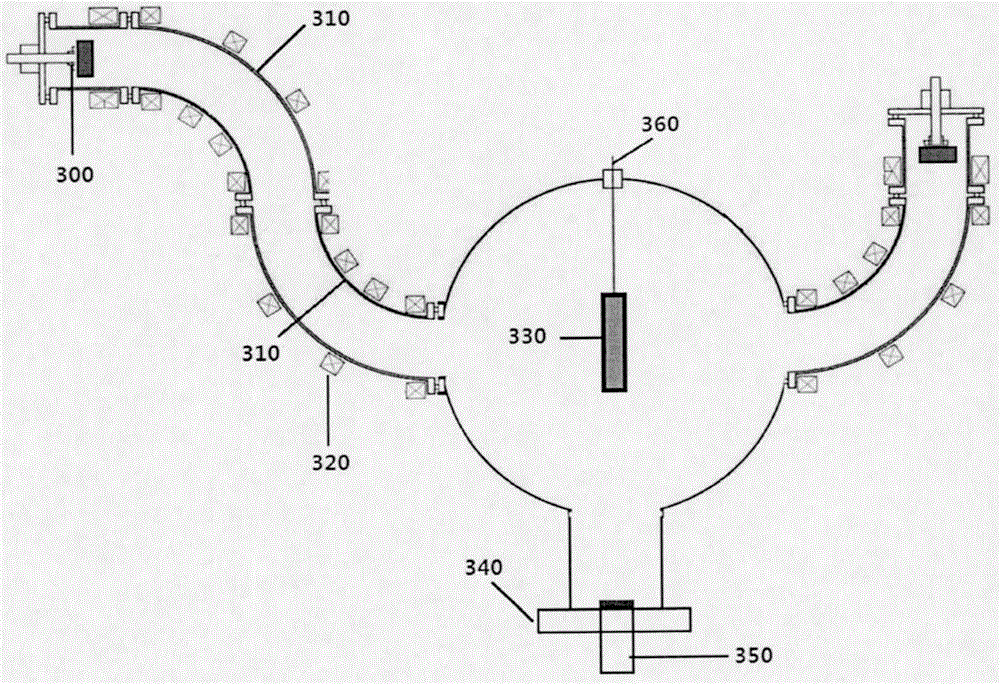

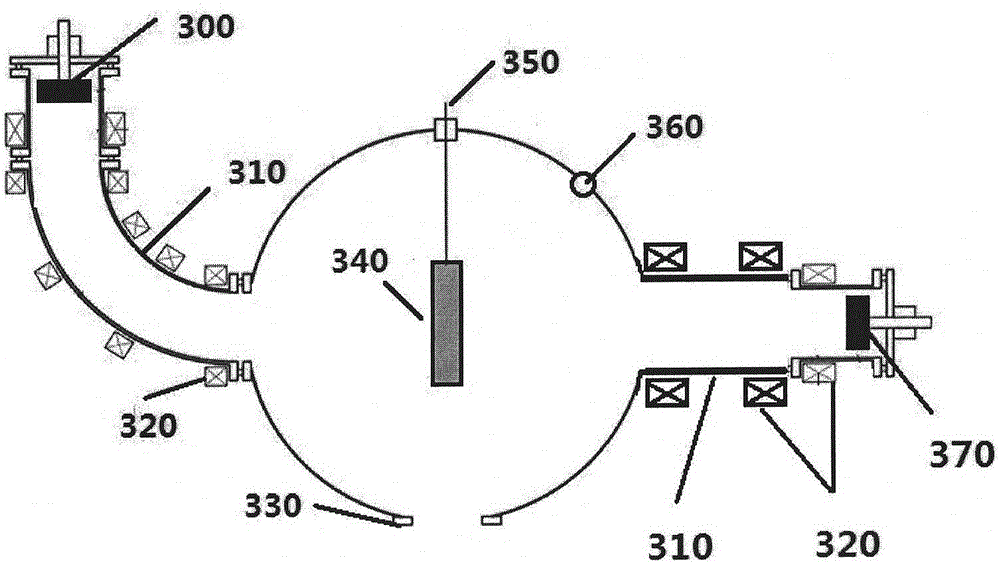

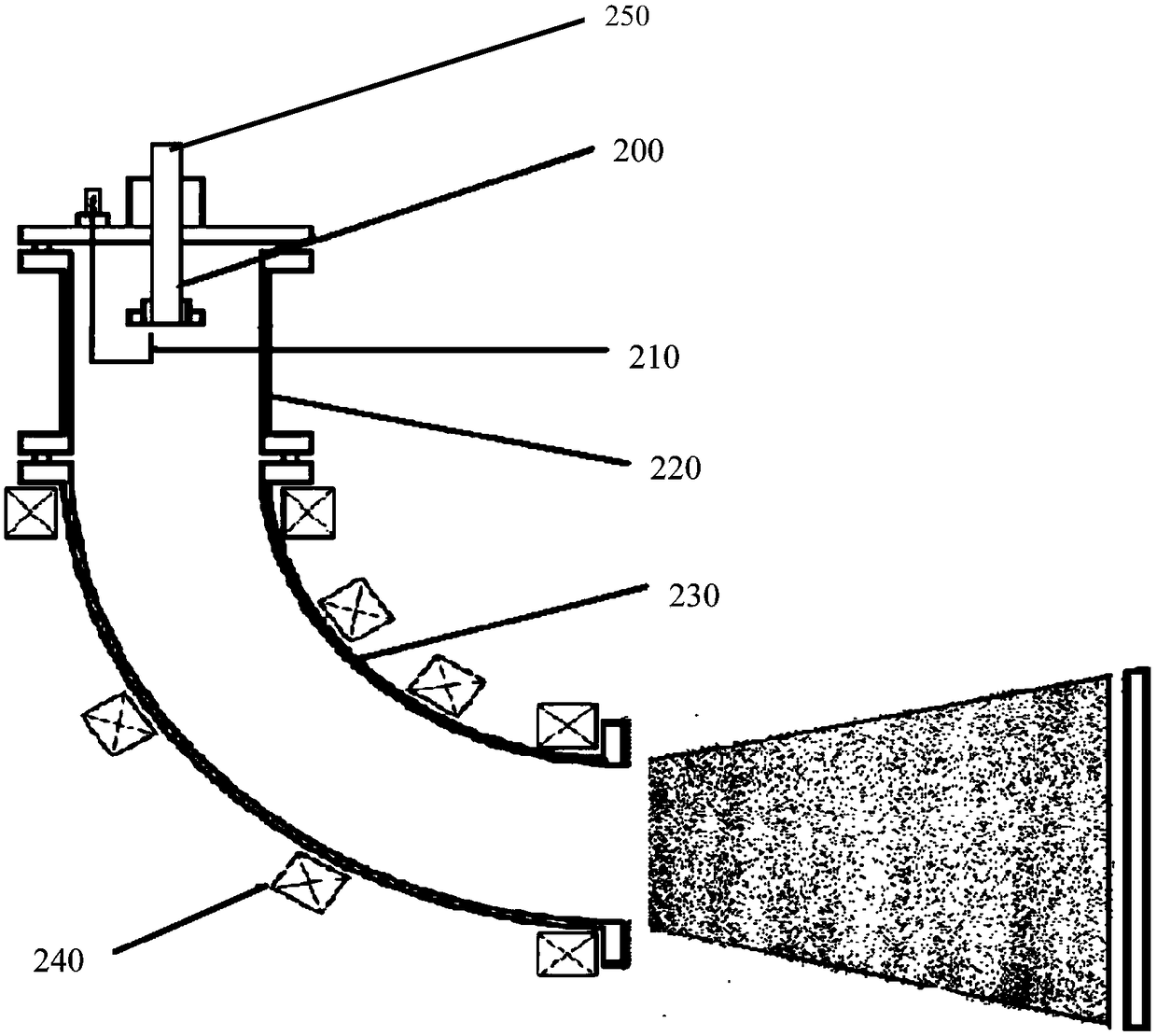

Method and equipment for depositing ultrahard and ultrathick DLC film layers on aircraft blade based on ion beam technology

ActiveCN105779941AImprove bindingHigh peel strengthVacuum evaporation coatingSputtering coatingDiamond-like carbonMetal binding

The invention discloses a method and equipment for depositing ultrahard and ultrathick diamond-like carbon (DLC) film layers with excellent bonding force and high sand dust erosion resistance on the surface of an engine blade based on an ion beam technology, and the method for preparing DLC films comprises the following steps: a metal vapor vacuum arc ion source method (MEVVA) is adopted to inject a metal binding layer capable of improving the film base bonding force on the surface of the blade; a 90-degree magnetic filtered cathodic vacuum arc deposition method (FCVA) is adopted to deposit on the metal binding layer to obtain a first metal film transition layer for releasing internal stress; a 180-degree magnetic filtered cathodic vacuum arc (FCVA) deposition method is adopted to deposit on the first transition layer to obtain a second soft DLC layer; and negative-pressure 180-degree magnetic filtered deposition is changed on the second soft layer to obtain an ultrahard DLC film layer until the total film thickness is 10-25 microns. The engine blade can be preferably protected through depositing the DLC films on the engine blade, and is prevented from being damaged by erosion of sand dust.

Owner:BEIJING NORMAL UNIVERSITY

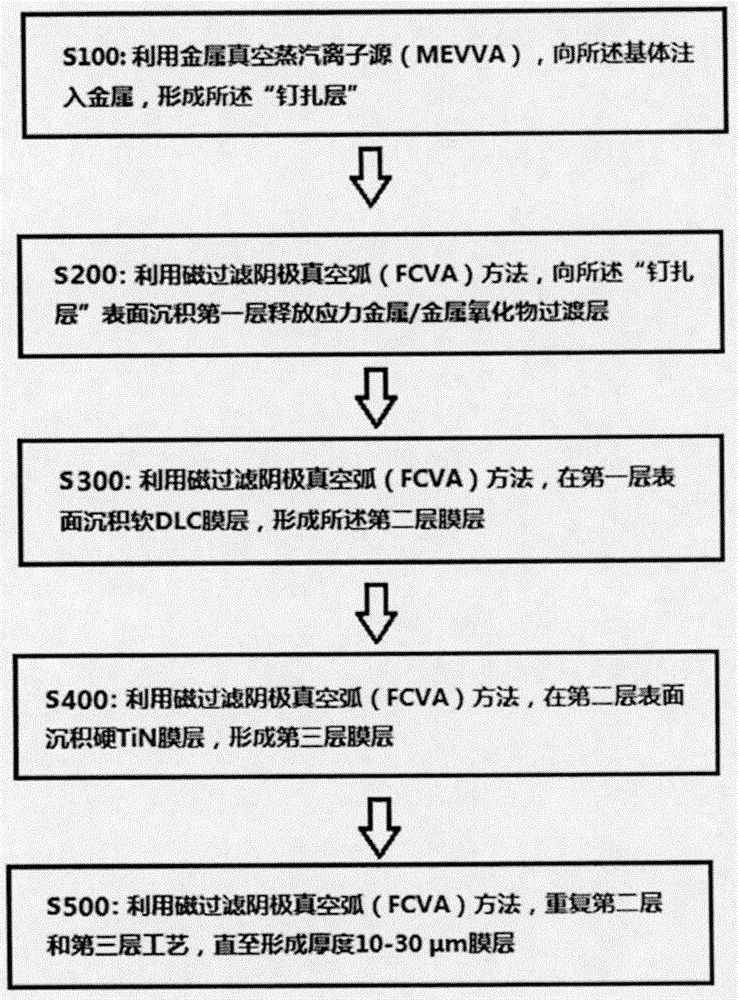

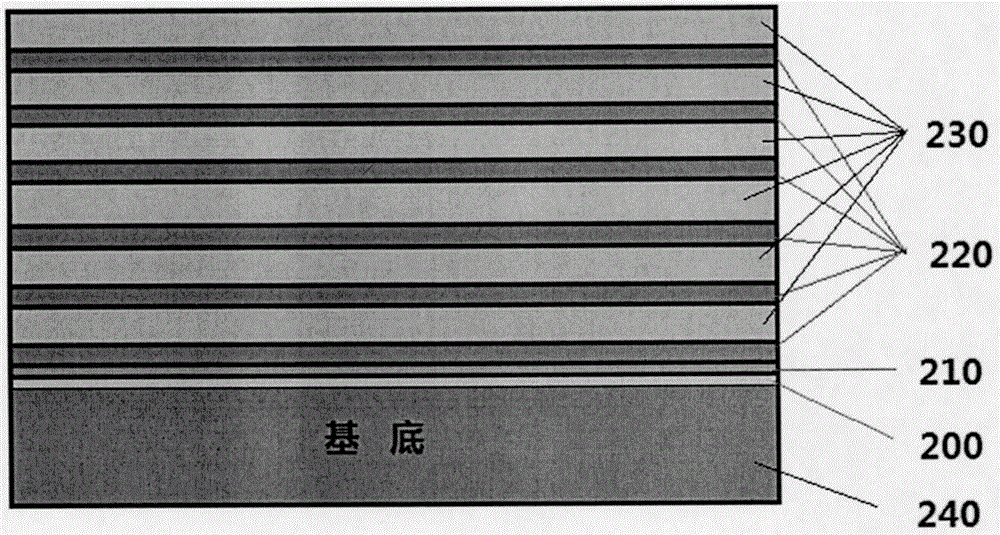

Method and device for depositing sand erosion-resisting nano composite film on blade of helicopter

ActiveCN105779958AImprove bindingHigh peel strengthVacuum evaporation coatingSputtering coatingComposite filmVacuum arc

The invention discloses a method and device for repairing a TiN / DLC / TiN nano composite film which is excellent in bonding force and high in sand erosion resistance on the surface of a blade of an engine. The method for preparing the TiN / DLC / TiN nano composite film comprises the steps that a metal 'pinning layer' which can improve the bonding force of a film base is injected into the surface of the blade through a metal vapor vacuum arc (MEVVA) ion source method; deposition is conducted on the metal 'pinning layer' through a magnetic filtered cathodic vacuum arc (FCVA) deposition method, so that a first metal / metal oxide film transition layer used for releasing the internal stress is obtained; deposition is conducted on the first transition layer through the magnetic FCVA deposition method, so that a second soft DLC layer is obtained; deposition is conducted on the second soft layer, so that a third superhard TiN film is obtained; and the second layer and the third layer are prepared by repeatedly conducting the process till the overall thickness of the TiN / DLC / TiN nano composite film is 10-30 micrometers. By the adoption of the method and device, the TiN / DLC / TiN nano composite film is deposited on the blade of the engine, so that the blade of the engine is well protected, and the situation that the blade of the engine is damaged due to sand erosion is prevented.

Owner:BEIJING NORMAL UNIVERSITY

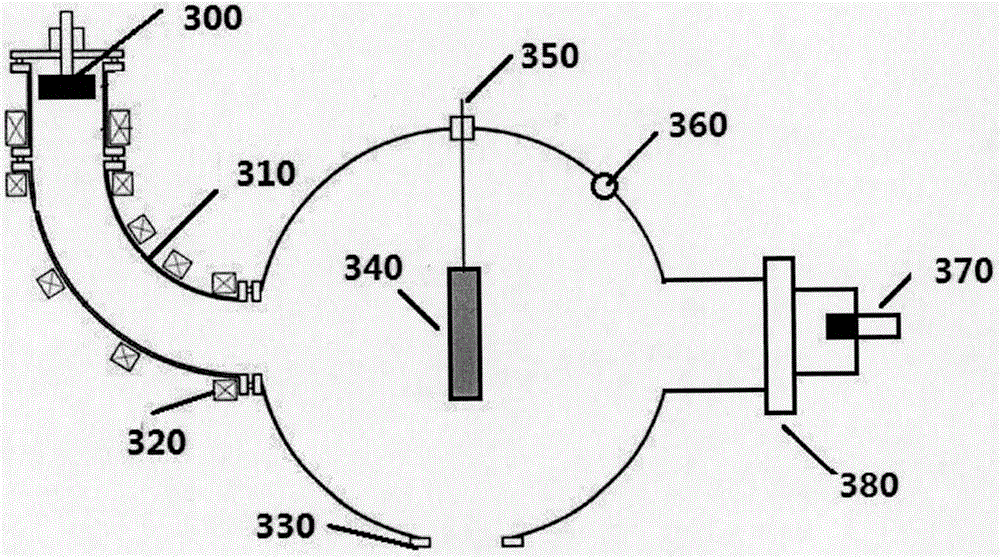

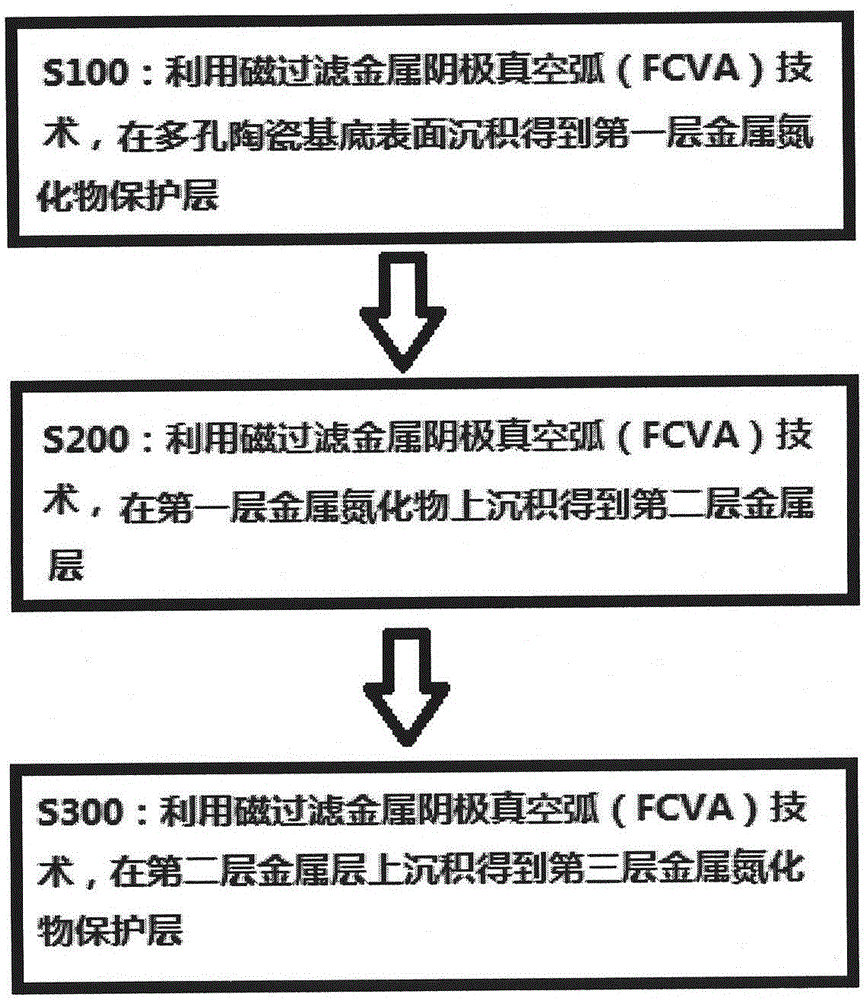

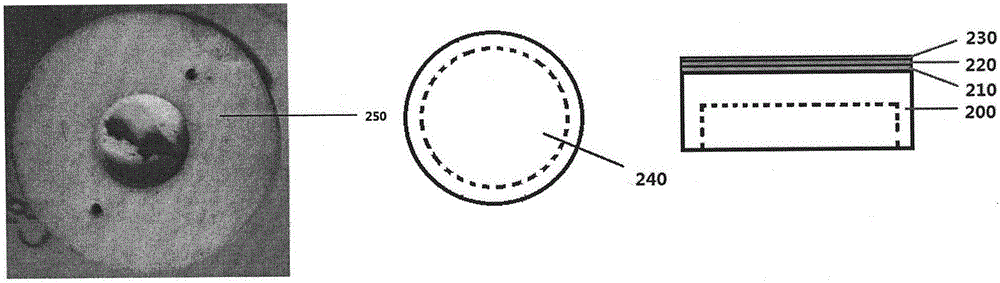

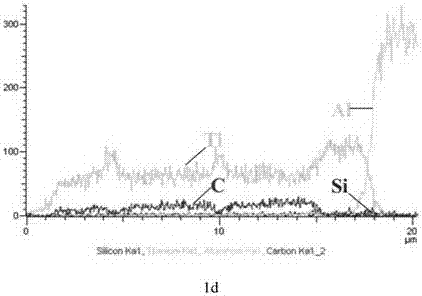

Manufacturing method and equipment for conductive layer in novel electronic cigarette atomizer device based on ion beam technology

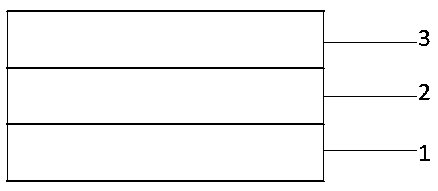

ActiveCN105755434AExtended service lifeHigh atomic ionization rateVacuum evaporation coatingSputtering coatingSecondary layerTotal thickness

The invention discloses a manufacturing method and equipment for a conductive layer in a novel electronic cigarette atomizer device based on the ion beam technology. The preparation method for preparing the conductive layer in the electronic cigarette atomizing device comprises the following steps of: taking porous aluminum nitride ceramic as a basal body, adopting a magnetic filter metal cathode vacuum arc (FCVA) technology, depositing a first metal nitride conductive layer on the surface of the basal body, and depositing on the first layer by adopting the FCVA process to obtain a second metal layer; and depositing on the second metal layer by adopting the FCVA depositing method to obtain a third conductive metal nitride layer, wherein the total thickness of the three layers of composite films is 1-10 microns, and the resistance is 1-10 ohms. According to the manufacturing method and the equipment, the novel electronic cigarette atomizer device with a long service life can be manufactured.

Owner:BEIJING NORMAL UNIVERSITY

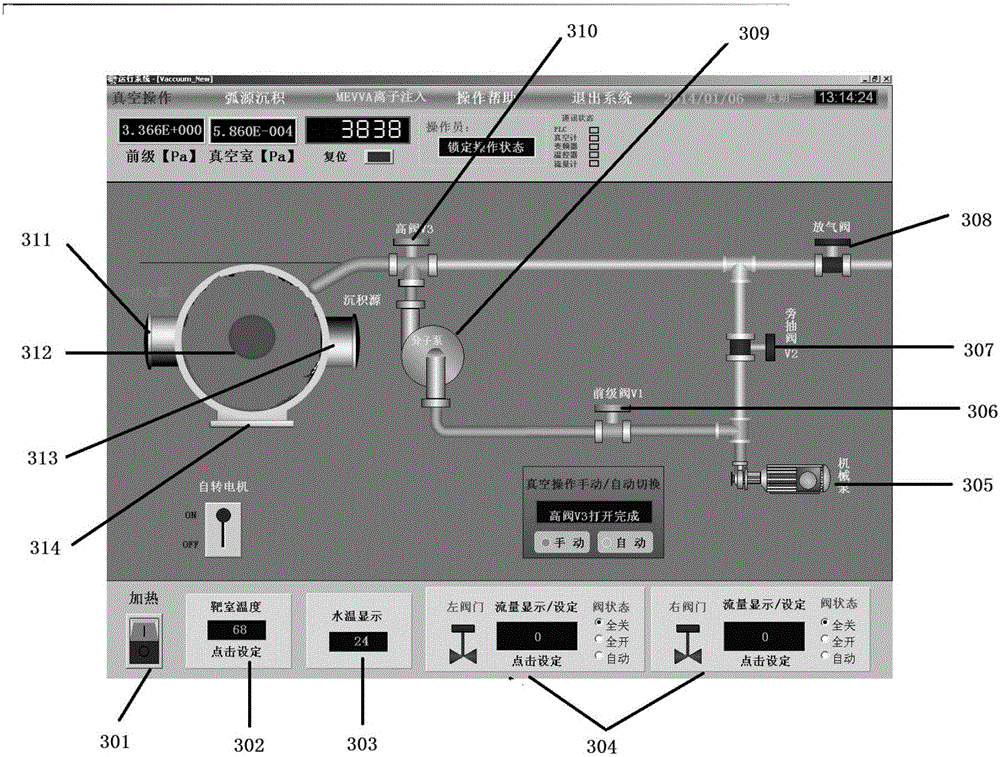

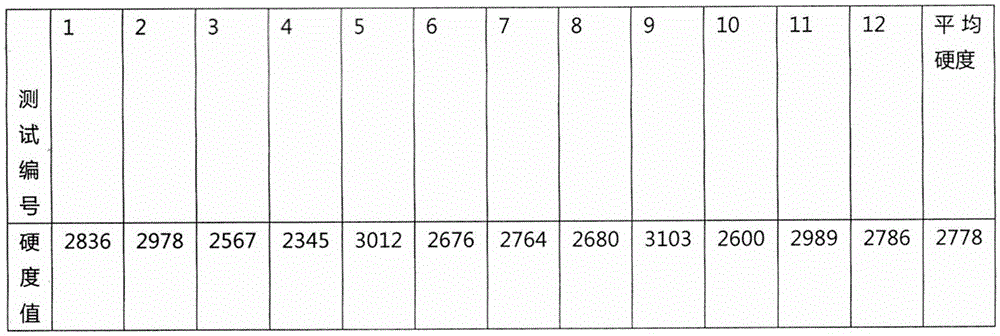

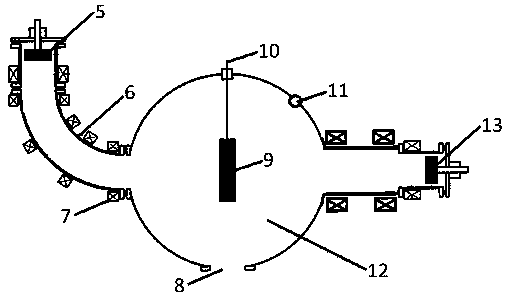

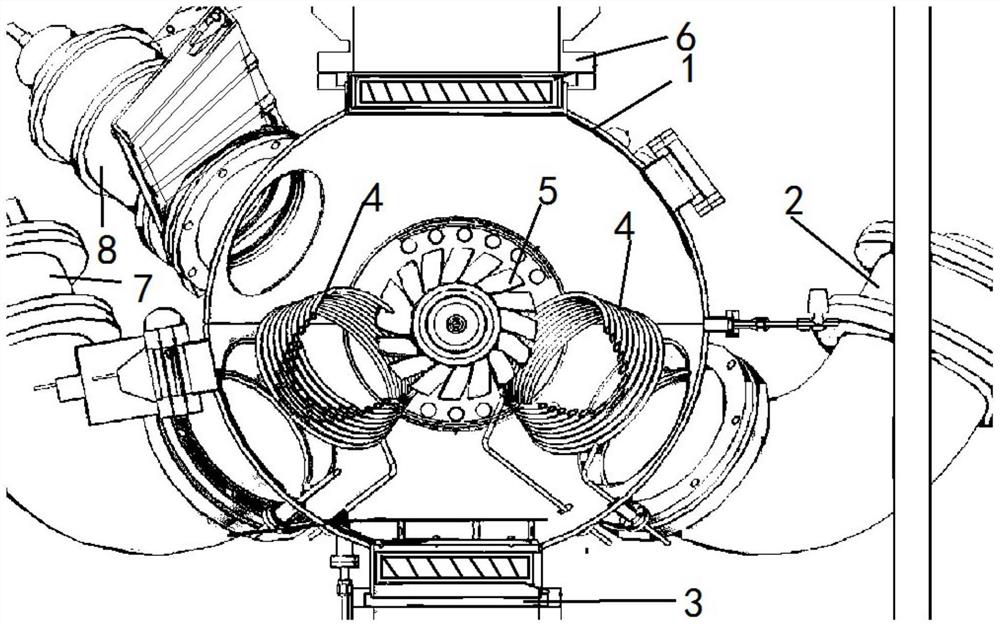

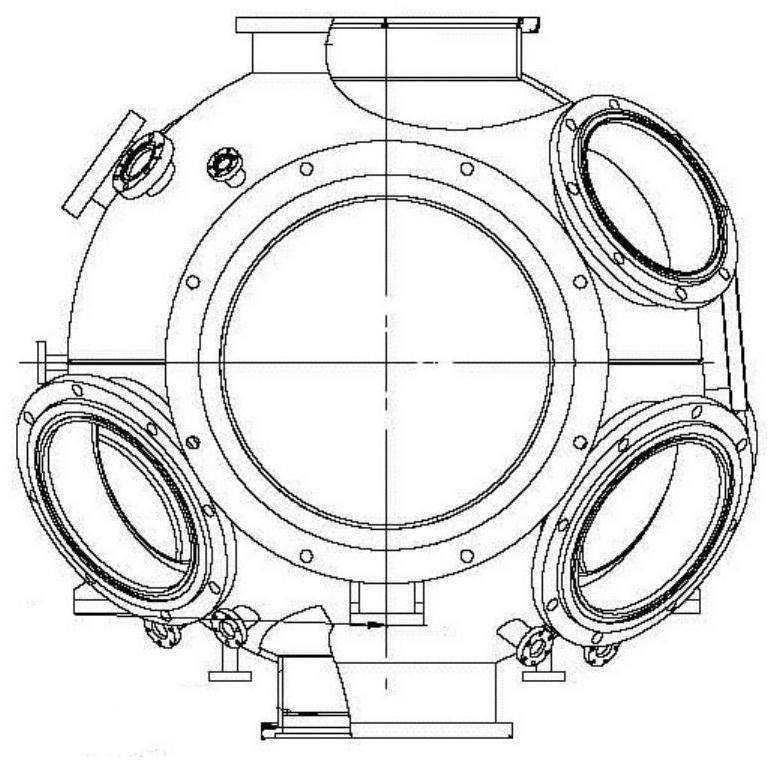

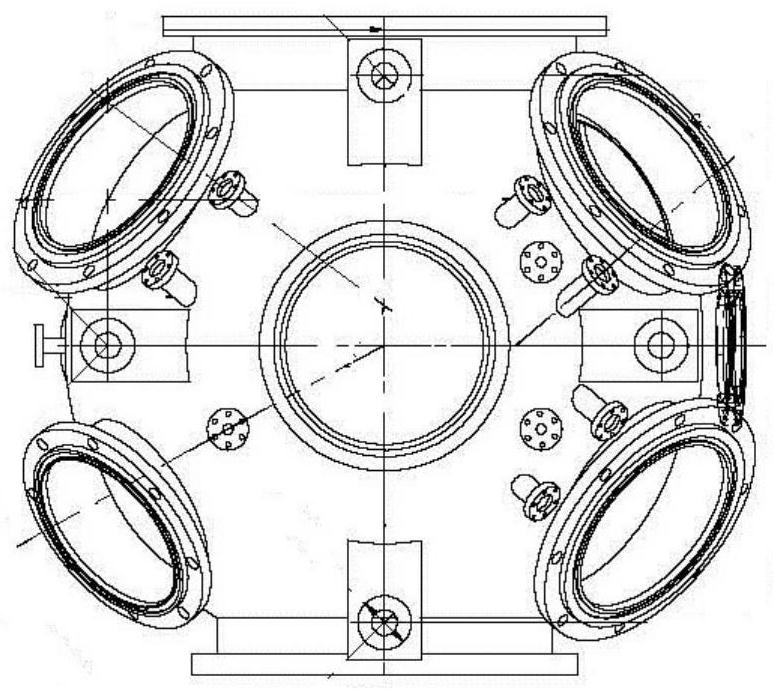

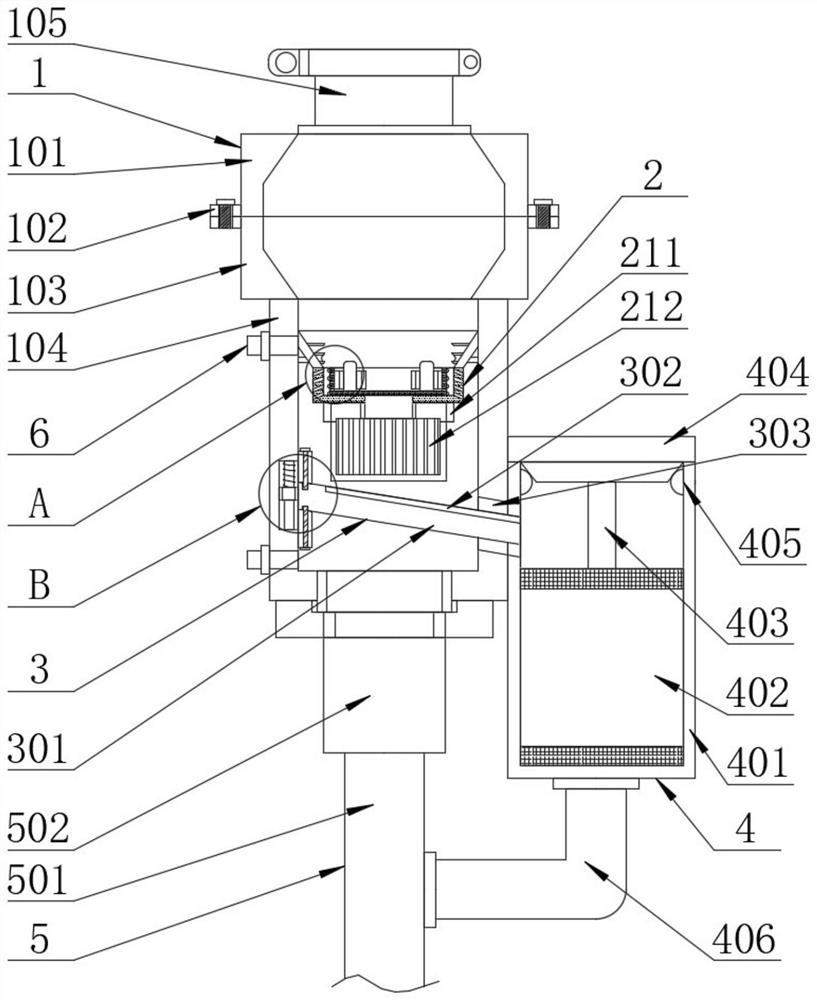

Apparatus for rapidly depositing DLC film on surface of piston ring, and method thereof

ActiveCN106011771AImprove bindingHigh peel strengthVacuum evaporation coatingSputtering coatingPiston ringHardness

The invention discloses an apparatus for rapidly depositing a DLC film on the surface of a piston ring, and a method thereof. The apparatus comprises: an ion injection system used for vertically uniformly injecting ion flow; a vacuum chamber, wherein one end of the vacuum chamber is in sealing connection with the ion injection system, the other end of the vacuum chamber is in sealing connection with one end of a broad-beam magnetic filtering deposition system, and the other end of the broad-beam magnetic filtering deposition system is provided with an FCVA deposition cathode; a tool system used for realizing autorotation of a piston ring tool cylinder; and an intelligent control device used for controlling the ion injection and film deposition process, displaying a measurement result and preliminarily processing data. The apparatus and the method can realize large-batch uniform plating of the surface of the piston ring with the DLC film with high hardness and low friction coefficient.

Owner:BEIJING NORMAL UNIVERSITY

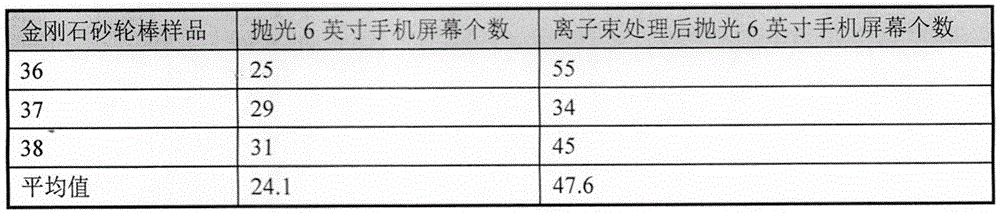

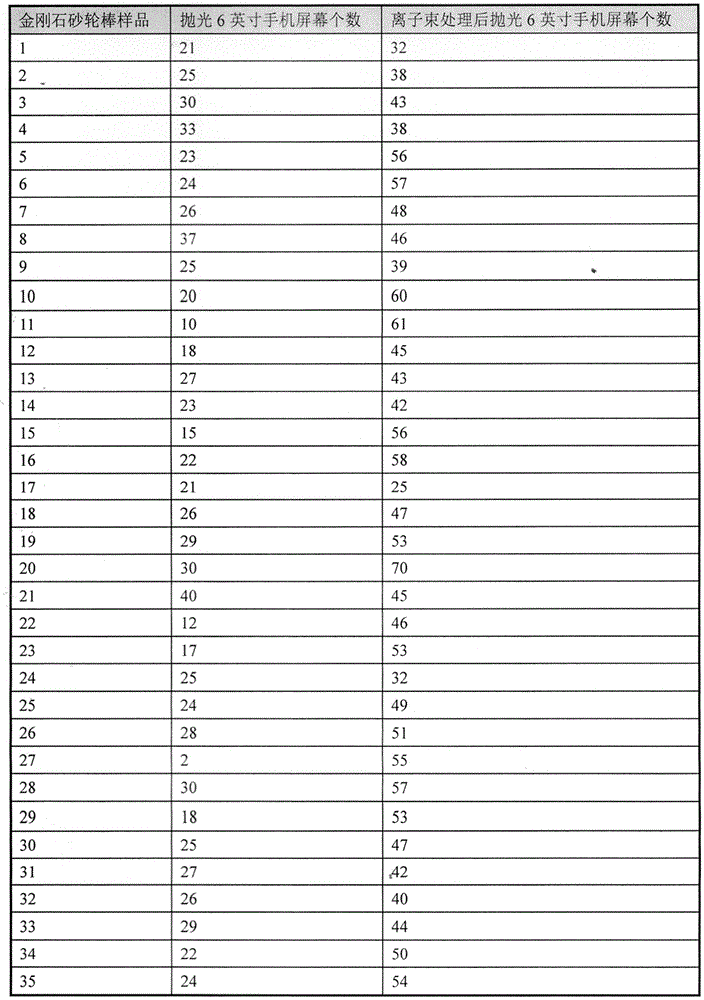

Method and device for prolonging service life of diamond grinding wheel rod of polished optical glass based on ion beam technology

InactiveCN105773462AImprove bindingHigh peel strengthVacuum evaporation coatingAbrasion apparatusComposite filmHigh energy

The invention discloses a method for prolonging the service life of a diamond grinding wheel rod of polished optical glass based on the ion beam technology. According to the method, an ultra-thick and ultra-hard (AlTi)1-xNx / AlTiCN / TiAl / (ZrAl)1-xNx composite film which is high in friction coefficient and good in toughness is deposited on the surface of silicon carbide through an ion implantation technique and a magnetic filtration deposition technique. A method for preparing the (AlTi)1-xNx / AlTiCN / TiAl / (ZrAl)1-xNx composite film comprises the steps that a metal cathode filtered cathodic vacuum arc (FCVA) system is adopted, and a workpiece is cleaned on the surface of the grinding wheel rod through high-energy large-beam metal ion beams; then a metal vacuum vapor ion source (MEVVA) method is adopted, and a metal "pinning layer" capable of improving the film-base combination force is injected into the surface of the workpiece; sine or cosine modulated deposition is conducted on the gas inlet amount on the metal"pinning layer" through a magnetic filtration filtered cathodic vacuum arc (FCVA) method, and the ultra-hard thick (AlTi)1-xNx / AlTiCN / TiAl / (ZrAl)1-xNx composite film which is good in toughness is obtained; and the modulation period is repeated till the total thickness of the (AlTi)1-xNx / AlTiCN / TiAl / (ZrAl)1-xNx composite film reaches 10-30 microns. By the adoption of the method, the (AlTi)1-xNx / AlTiCN / TiAl / (ZrAl)1-xNx composite film deposited on the workpiece is good in toughness and quite high in microhardness, and the service life of the grinding wheel rod can be prolonged by 2-5 times.

Owner:BEIJING NORMAL UNIVERSITY

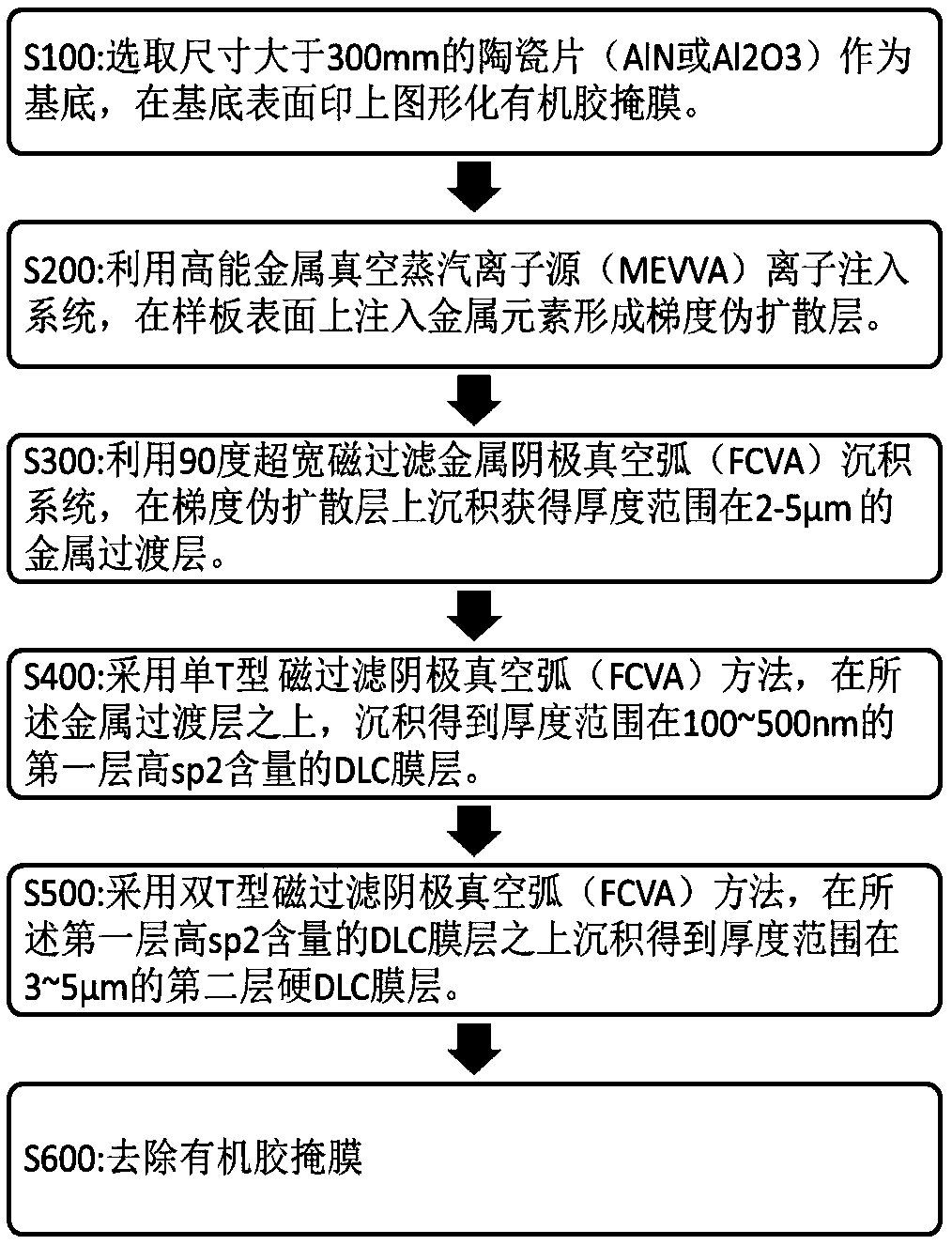

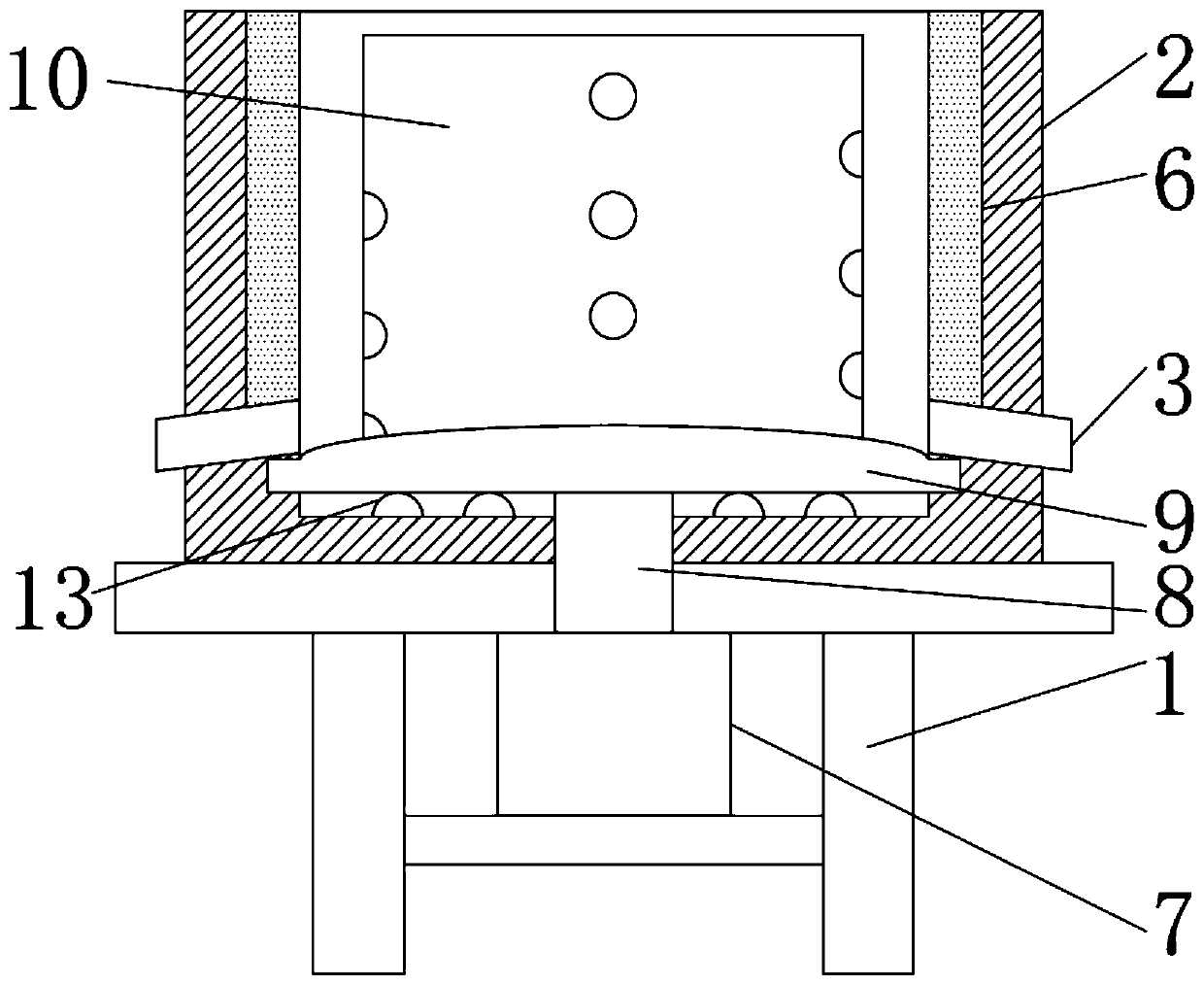

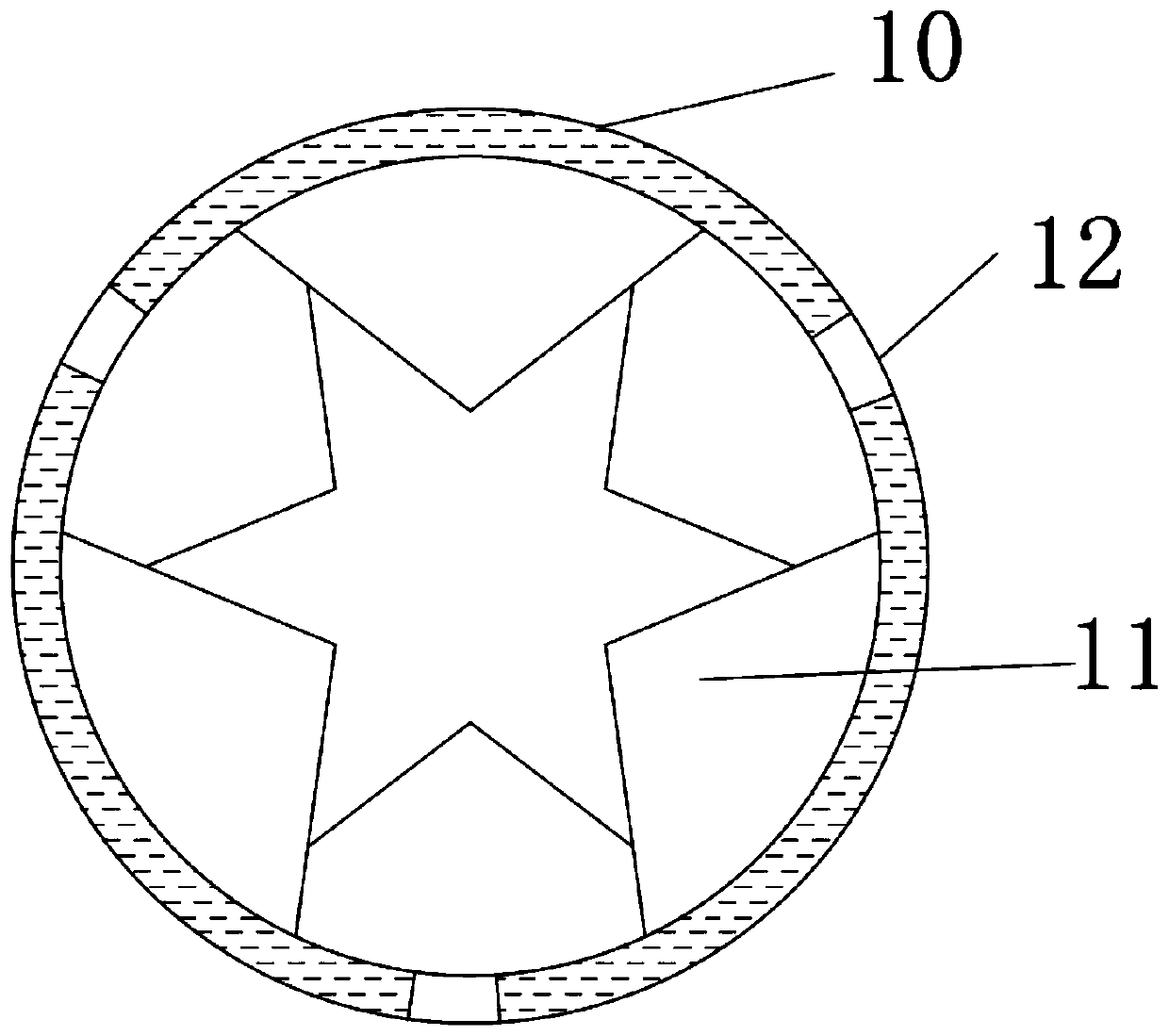

Preparation method and equipment of patterned electrostatic chuck

ActiveCN108842133AImprove bindingHigh peel strengthVacuum evaporation coatingSputtering coatingAdhesiveHigh energy

The invention discloses a preparation method and equipment of a patterned electrostatic chuck. The preparation method comprises the following steps that an ultra-large size (greater than 300 mm) ceramic sheet (AlN or Al2O3) is selected as a substrate, a patterned organic adhesive mask is printed on the substrate, and a high resistivity, high hardness, wear resistance and ion erosion resistance DLCfilm layer is deposited by utilizing an ion beam technology; a deposition method comprises the following steps that a high-energy metal vacuum vapor ion source (MEVVA ) is adopted, a metal element isinjected into the substrate to form a graded pseudo diffusion layer, and then a 90-degree ultra-wide magnetic filtration metal cathode vacuum arc (FCVA) technology is adopted, and a metal transitionlayer is deposited; a single T-shaped magnetic filtration cathode vacuum arc (FCVA) is adopted on the metal transition layer, and a DLC film layer with high sp2 content is obtained through the deposition; and a double-T-shaped magnetic filtration cathode vacuum arc (FCVA) is utilized on the DLC film layer with the high-sp2-content, and a super-hard DLC film layer is obtained through the deposition; and the resistance of the film layer can reach 10-50 megohm, and the hardness can reach 80 Gpa or above. According to the method and the equipment, the electrostatic chuck is enabled to have excellent wear resistance, and the service life is prolonged.

Owner:BEIJING NORMAL UNIVERSITY

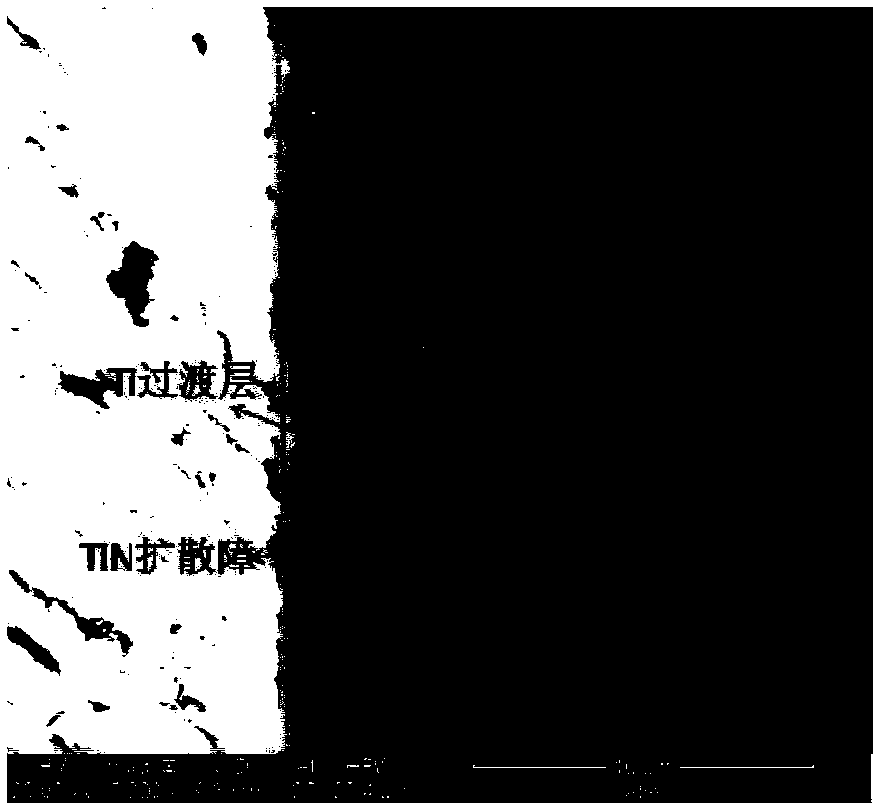

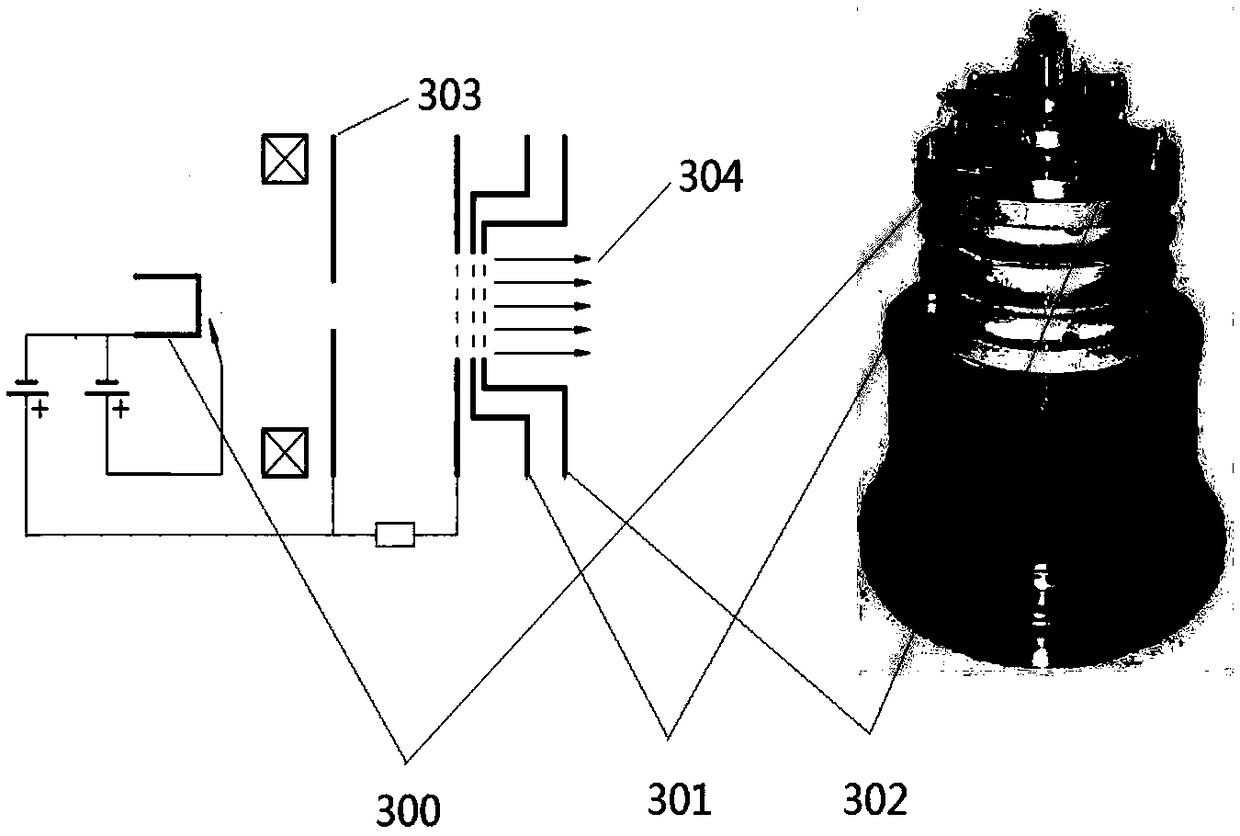

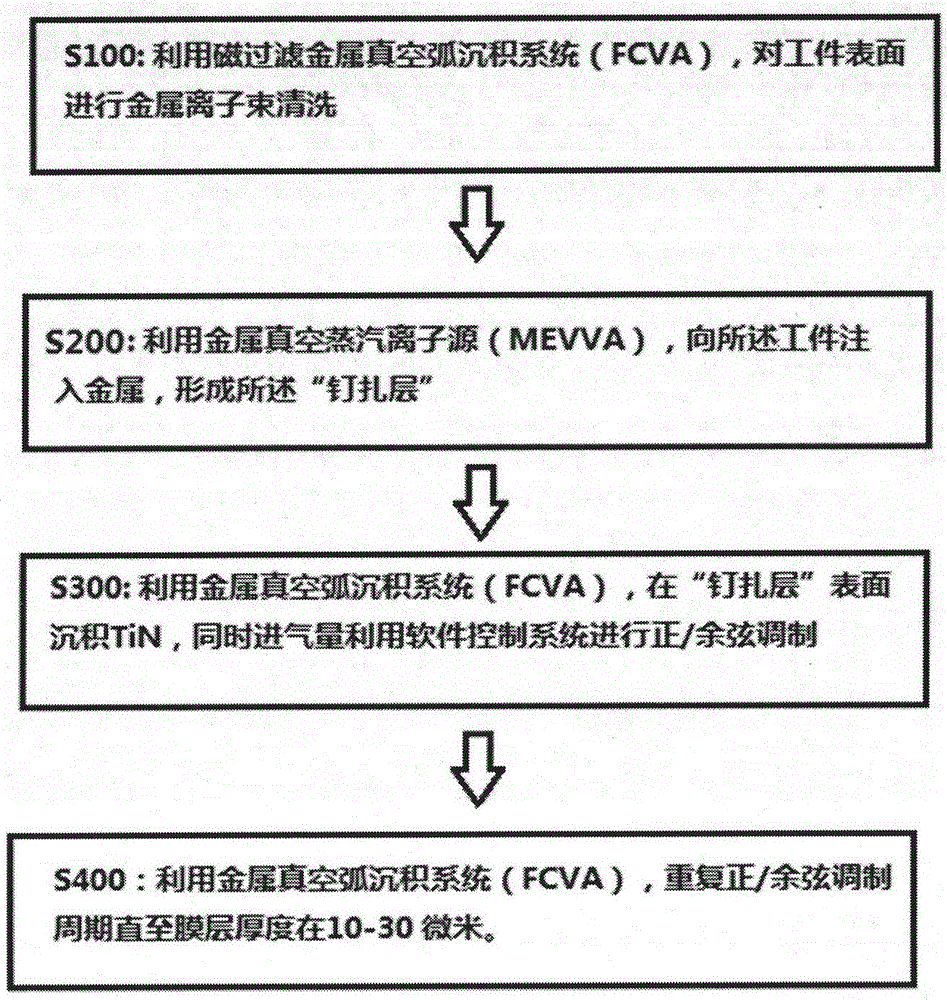

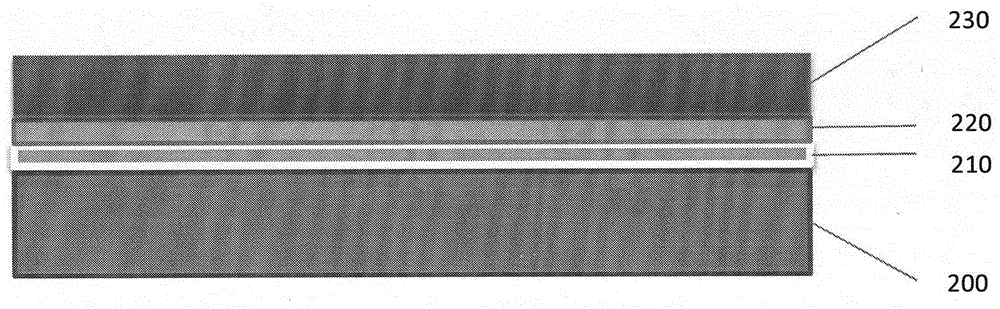

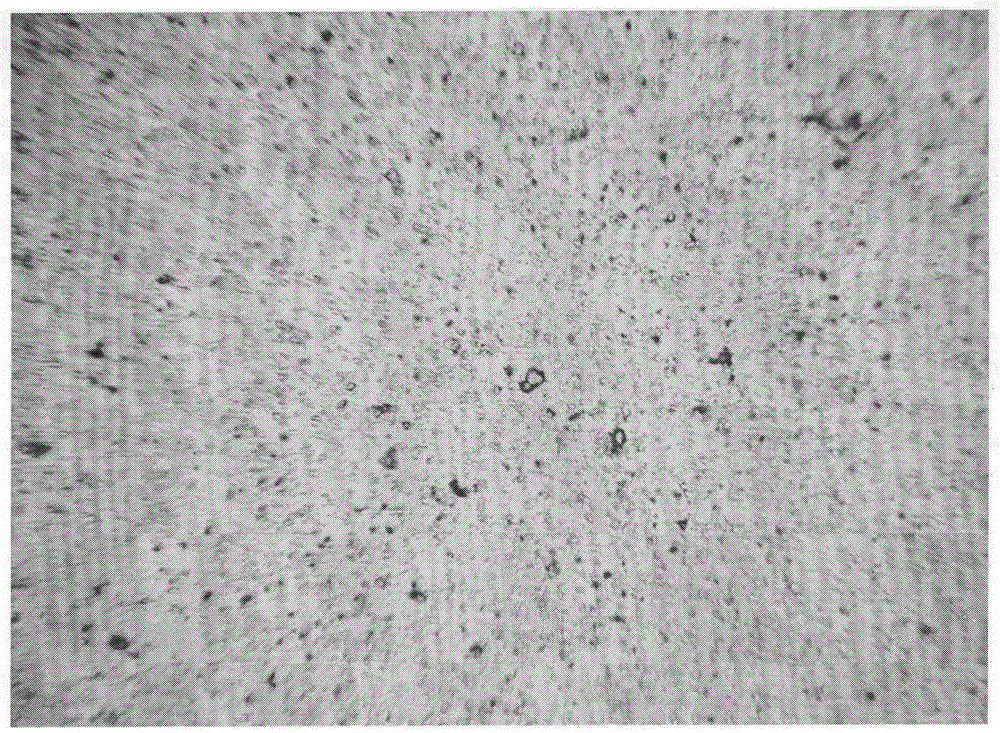

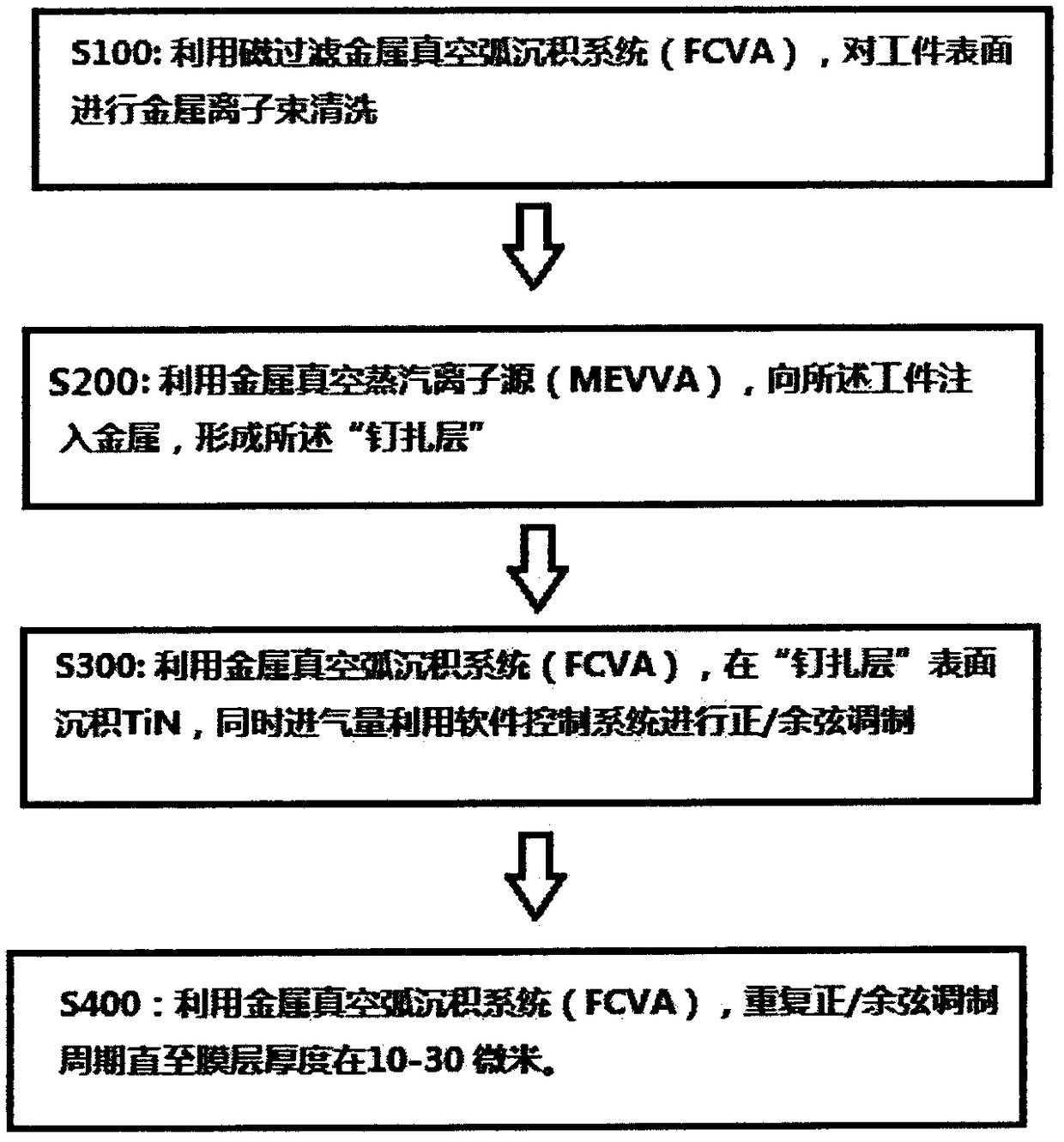

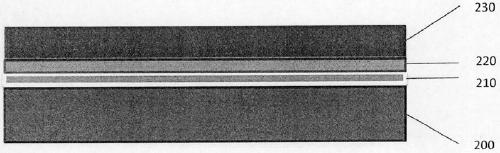

Super-thick TiN film layer preparation method capable of maintaining super-hard characteristic and improving toughness at the same time

ActiveCN105779936AImprove bindingImprove toughnessVacuum evaporation coatingSputtering coatingHigh energyIon beam

The invention discloses a method for preparing a super-thick and high-toughness TiN film. The method for preparing the TiN film comprises the steps that 1, a metal filtered cathodic vacuum arc (FCVA) deposition system is adopted, and the surface of a workpiece is cleaned through high-energy large-beam metal ion beams; 2, a layer of metal 'pinning layer' capable of improving the film base binding force is injected into the surface of the workpiece through a metal vapor vacuum arc (MEVVA) ion source method; 3, on the metal 'pinning layer', the gas inlet quantity is subjected to sine or cosine modulation and deposition through a filtered cathodic vacuum arc (FCVA) deposition method, and thus the super-hard good-toughness thick TiN film layer is obtained; and 4, the modulation period is repeated till the total thickness of the TiN film is 10-30 microns. By means of the method for preparing the super-thick and high-toughness TiN film, the TiN film deposited on the workpiece has very good toughness and very high microhardness.

Owner:广东省广新创新研究院有限公司

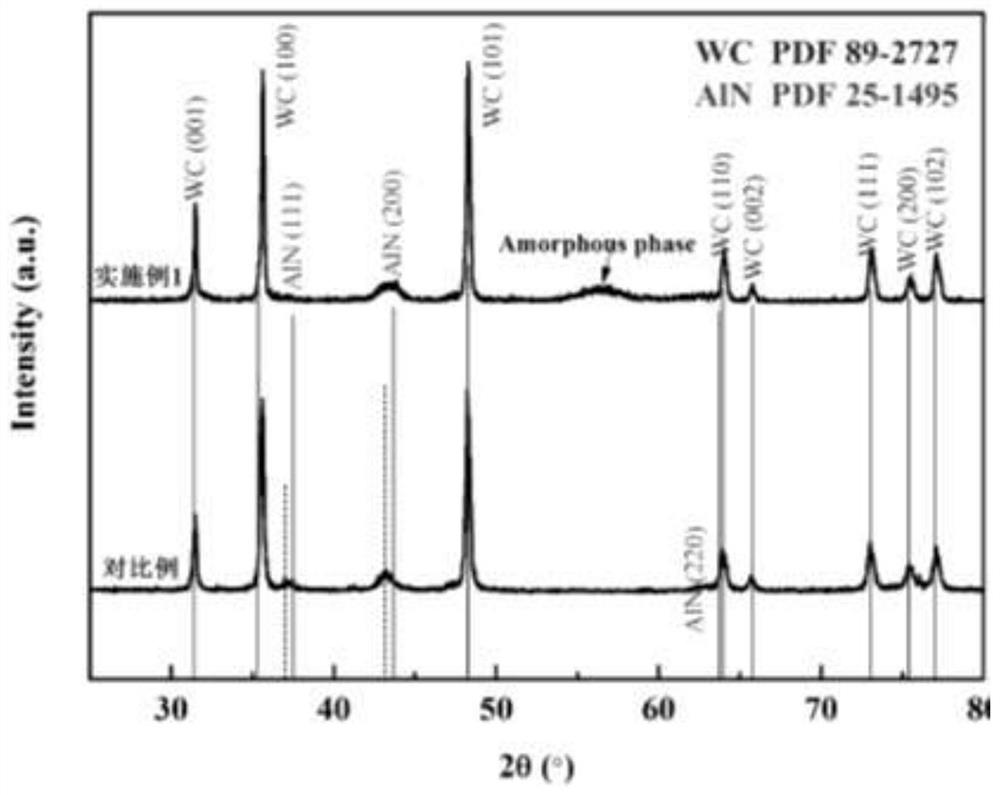

Nanocrystalline amorphous composite coating, preparation method thereof and cutter

ActiveCN111910159ASmall elastic modulus changesLittle changeVacuum evaporation coatingSputtering coatingWear resistanceSi element

The invention provides a TiAl (Nb, Si, C) N-containing nanocrystalline amorphous composite coating, a preparation method thereof and a cutter. The composite coating is a nanocrystalline amorphous TiAl(Nb, Si, C) N coating formed by physical vapor deposition. The TiAlN composite coating with a hardening and wear-resistant Si element, a toughening Nb element and an antifriction C element co-doped in an optimal proportion maintains the characteristics of excellent comprehensive performance and no short plate and good 'wooden barrel effect' of a TiAlN-based coating, meanwhile, the adhesive force,wear resistance and high-temperature stability of the coating can be greatly improved, and the integration of toughness and wear resistance of the coating is realized. The preparation method is simple in process, easy to operate in actual production, low in production cost and suitable for large-scale popularization.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

Piston with Ti-doping diamond multi-layer thick heat-insulating film on top face and preparation method and application of piston

ActiveCN106978593AEffective stress reliefImprove bindingVacuum evaporation coatingSputtering coatingTi dopingThermal impact

The invention relates to a piston with a Ti-doping diamond multi-layer thick heat-insulating film on the top face and a preparation method and application of the piston. The piston comprises a piston substrate, a transitional layer, n layers of TiC / DLC film layers and m buffer layers, wherein the outermost layer of the top face of the piston is the last TiC / DLC film layer. According to the preparation method of the piston, the transitional layer is prepared on the top face of the piston substrate; then the first TiC / DLC film layer is prepared; one buffer layer is formed on the first TiC / DLC film layer; the TiC / DLC film layers and the buffer layers are formed alternately, so that a middle layer is obtained, and then the last TiC / DLC film layer is prepared. According to the piston with the Ti-doping diamond multi-layer thick heat-insulating film on the top face has excellent abrasion resistance and thermal impact resistance and can meet the requirement of modern engines for high efficiency and low emission.

Owner:XIANGTAN UNIV

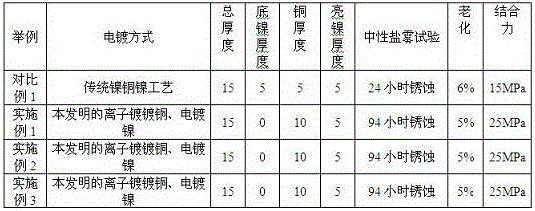

Method for electroplating surface of permanent magnet neodymium-iron-boron magnetic steel with copper-nickel alloy plating

InactiveCN106119844ALow costImprove anti-corrosion performanceVacuum evaporation coatingSputtering coatingAbrasive blastingCopper plating

The invention discloses a method for electroplating the surface of permanent magnet neodymium-iron-boron magnetic steel with copper-nickel alloy plating. The method is characterized in that the surface of the permanent magnet neodymium-iron-boron magnetic steel is plated with copper through a multi-arc ion plating device, wherein the purity of copper is 99.9% or above, and in the copper plating process, the current range is controlled to be 40 A to 90 A and the copper plating with the thickness being 1 micrometer to 20 micrometers is obtained; then, the abrasive blasting operation is conducted on the surface, and particles of the surface are reduced; copper-based electronickelling is conducted on the part subjected to abrasive blasting in a bright nickel tank, and therefore the copper-nickel alloy plating of the permanent magnet neodymium-iron-boron magnetic steel is obtained; and copper plating is conducted through multi-arc ion plating, the bottom nickel procedure is omitted, the anti-corrosion effect is not influenced while cost is saved, the ageing property is improved, and meanwhile the wear resistance of the part is improved and the appearance of the neodymium-iron-boron magnetic steel is optimized.

Owner:YANTAI DONGXING MAGNETIC MATERIALS INC

Self-supporting germanium film with mass thickness ranging from 700 to 1400 mu g/cm<2> and its preparation method thereof

ActiveCN109136831ASimple methodEase of industrial applicationVacuum evaporation coatingSputtering coatingIndiumFishing

The invention discloses a self-supporting germanium film with mass thickness ranging from 600 to 1200 mu g / cm<2> and its preparation method thereof. The preparation method includes the steps of (1), depositing a sodium chloride release agent on the surface of a substrate; (2), depositing a zinc oxide buffer film on the surface of the substrate through a 90-degree magnetron filtered cathode vacuumarc (FCVA) system; (3), turning a sample 180 DEG, depositing the indium film again through a straight magnetron FCVA system; (4), subjecting the treated substrate to stripping in a container containing ethanol solution; (5), picking the germanium film through a fishing plate to obtain the self-supporting germanium film with mass thickness ranging from 700 to 1400 mu g / cm<2>. The self-supporting germanium film with mass thickness ranging from 700 to 1400 mu g / cm<2> has low stress, is uniform and compact, and the preparation method is simple.

Owner:泰安泰山科技有限公司

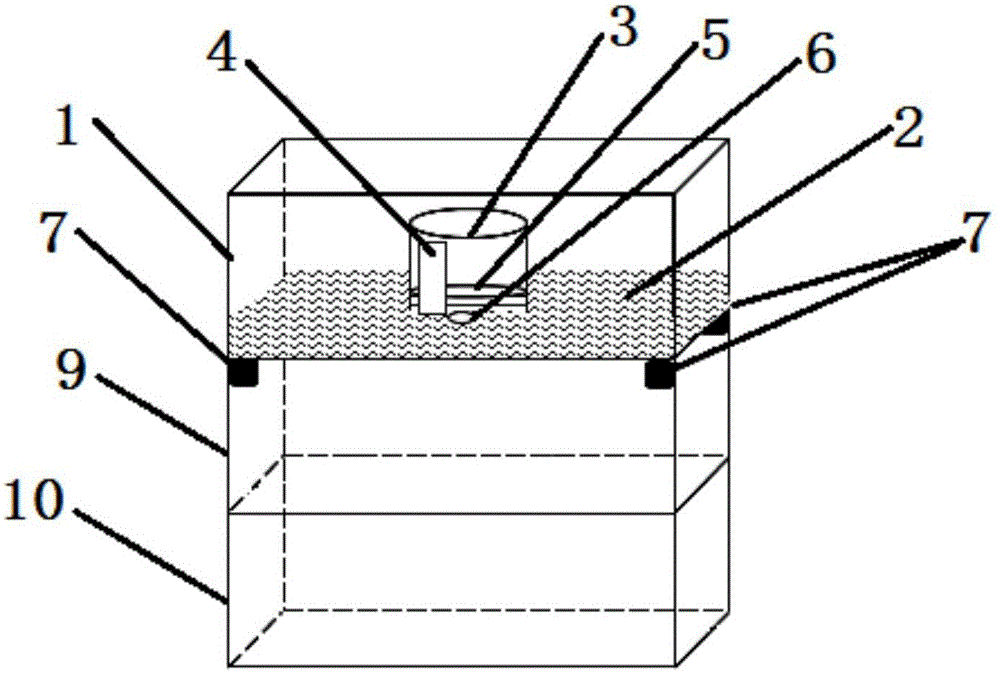

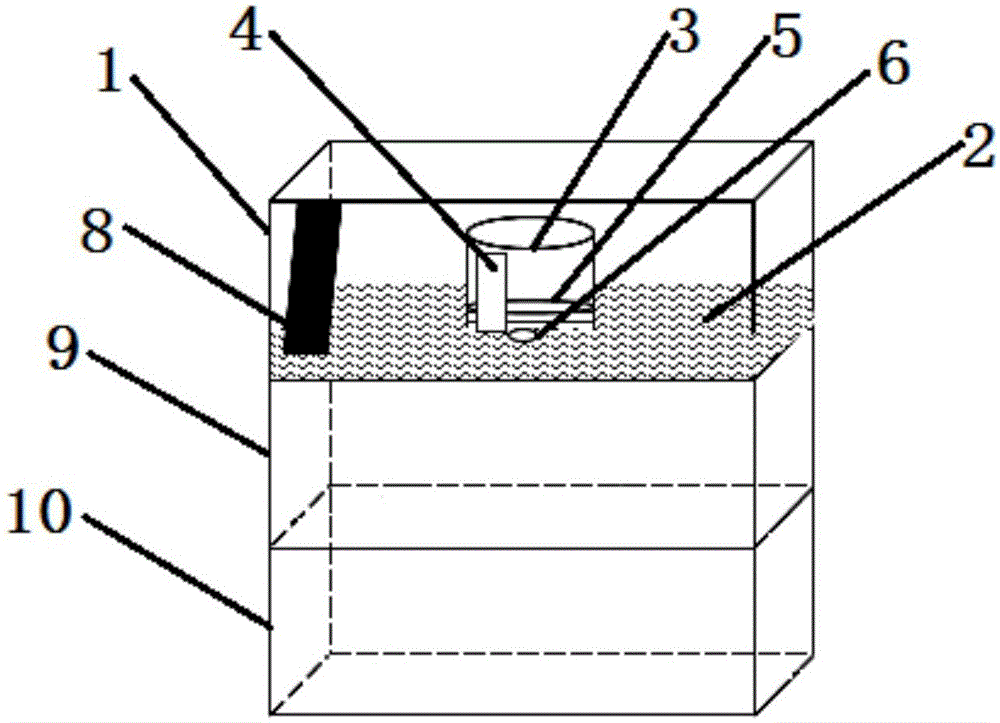

Compact cadmium sulfide thin film preparation device and method

InactiveCN105132893AStir fully and evenlySimple and fast operationLiquid/solution decomposition chemical coatingWater bathsPhysical chemistry

The invention discloses a compact cadmium sulfide thin film preparation device. The compact cadmium sulfide thin film preparation device comprises a water tank, a magnetic stirrer and an ultrasonic generator which are sequentially arranged from top to bottom, wherein the water tank contains water and is internally provided with a reaction vessel, the reaction vessel is internally provided with at least one substrate and a magnon and contains a reaction solution, and meanwhile, at least one ultrasonic vibrator is arranged at the bottom of the water tank, or an ultrasonic vibrating plate is arranged in the water tank; the magnetic stirrer is arranged at the bottom of the water tank and is used for controlling the temperature of the reaction solution and the rotating speed of the magnon; and the ultrasonic generator is arranged below the magnetic stirrer. The compact cadmium sulfide thin film preparation device has the advantages that the compact cadmium sulfide thin film preparation device is simple in operation, high in finished product quality, low in cost and high in stability, can realize uniform and sufficient stirring of the reaction solution in chemical bath deposition, can also reduce the adhesion of large particles and clusters and is conductive to the growth of uniform compact large-sized cadmium sulfide thin films.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

Preparation process of high-concentration paraffin emulsion

PendingCN111019155AQuality improvementImprove processing efficiencyRotary stirring mixersTransportation and packagingParaffin waxPhysical chemistry

The invention discloses a preparation process of a high-concentration paraffin emulsion, and relates to the related technical field of paraffin emulsion processing. The preparation process comprises the following steps: 1, material preparing; 2, heating and stirring; 3, emulsifying; 4, cooling; and 5, filtering. According to the invention, through a series of steps, the quality of the paraffin solution can be improved, and the processing efficiency of the paraffin solution can be improved; through the homogenizer, the mixing uniformity degree can be improved, and large particles in the paraffin solution can be reduced, so that the quality of the paraffin solution can be improved; the emulsifying efficiency of the paraffin solution can be improved through the reaction kettle so as to improve the production efficiency of the paraffin solution; the reaction barrel can be sealed through the sealing cover, so that the heat loss in the reaction barrel can be prevented so as to improve the emulsifying efficiency of the paraffin solution; the interior of the reaction barrel can be kept at a constant temperature through the heating plate; and the rapid stirring can be achieved through the motor, the transmission rod, the rotating plate and the stirring roller.

Owner:HUZHOU MELON CHEM

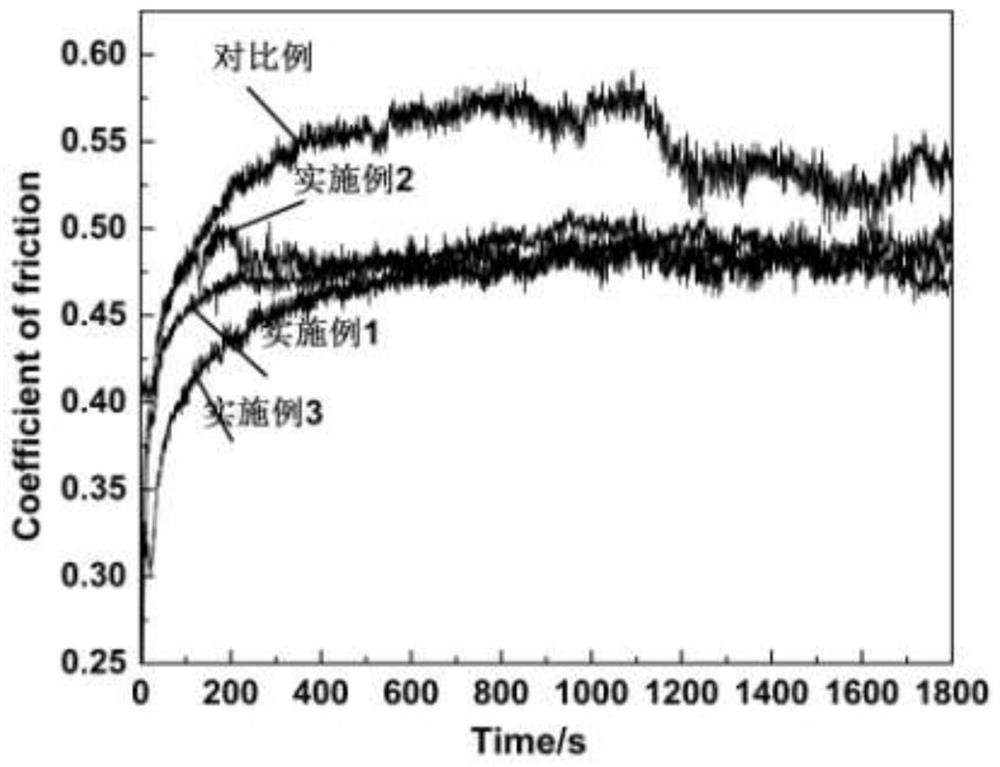

Method for improving anti-friction and anti-wear performance of impactor piston

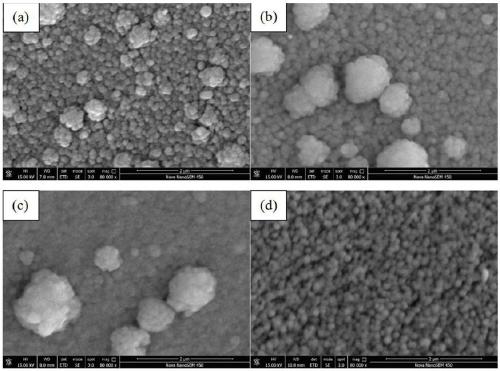

PendingCN109234668AGood anti-frictionIncreased coefficient of frictionSolid state diffusion coatingFurnace typesPistonSulfide

The invention relates to a method for improving the anti-friction and anti-wear performance of an impactor piston. The method specifically comprises the steps that carburization treatment is conductedfirstly, and sulphurizing treatment is conducted after that. 20CR2Ni steel is accurately ground and polished, and then the surface of the steel is subjected to carburization treatment and low temperature ionic sulphurizing treatment in sequence. The obtained composite sulphurized layer surface is composed of tiny and compact spherical sulfide, and conglobated large particles of the sulfide are fewer. The composite sulphruized layer has good anti-friction performance under the mediate load, and when the load is too low or too high, the friction coefficient of the composite sulphurized layer issomewhat increased on the contrary. The carburized-sulphurized composite layer with a solid lubricating effect is prepared on the surface of a 20Cr2Ni4 steel impactor piston carburized layer, the service life of a piston is effectively prolonged, the working time of an impactor is prolonged, and the quality of an impactor product is improved greatly.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

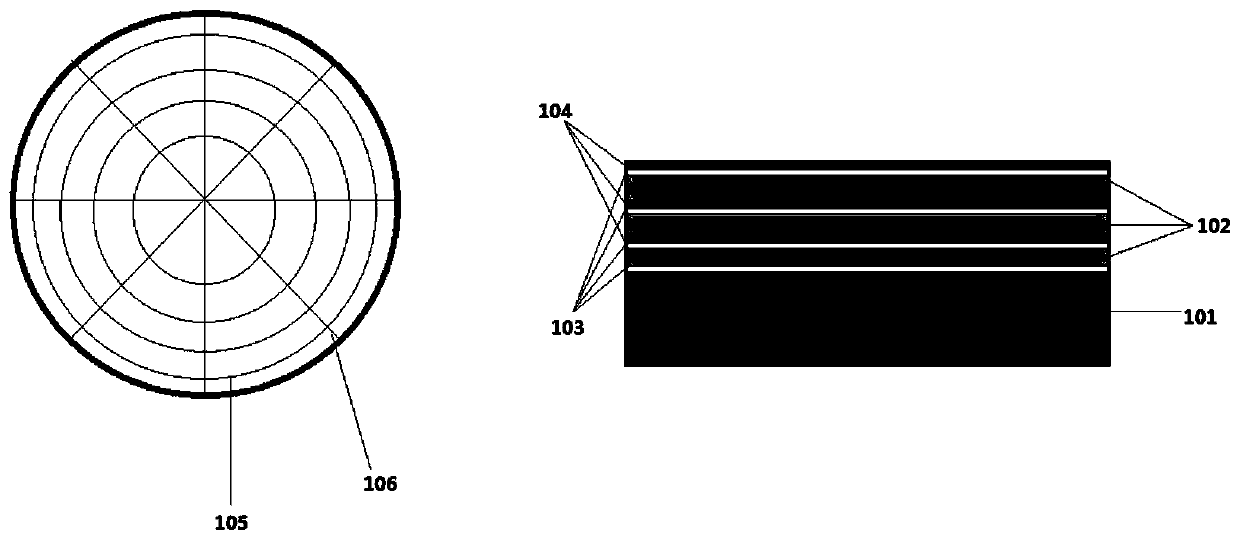

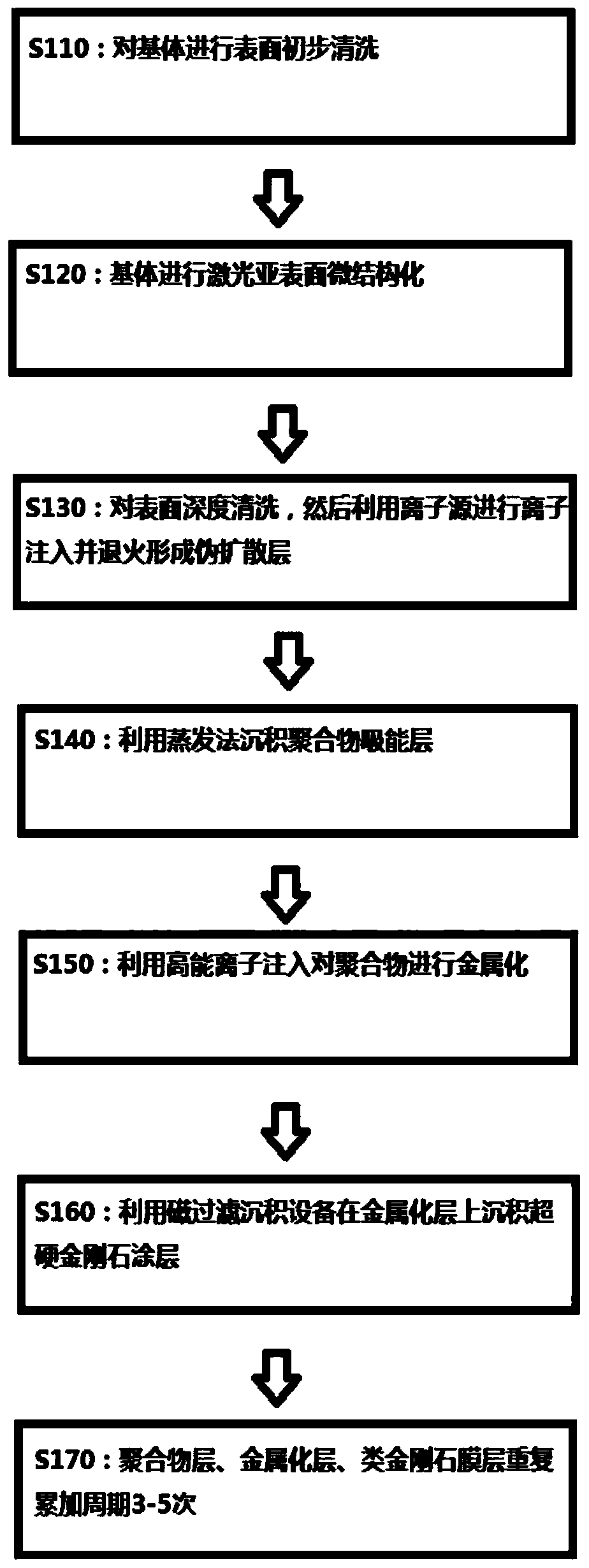

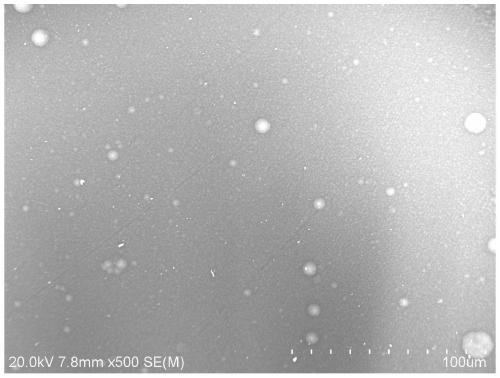

Coating method for preventing high-speed impact

ActiveCN111575669AImprove bindingHigh densityVacuum evaporation coatingSputtering coatingCarbon layerEvaporation (deposition)

The invention relate to a coating method for preventing high-speed impact. The coating method comprise the following steps that preliminary ion cleaning is carried out on the surface of a substrate; the substrate after surface cleaning is subjected to laser subsurface microstructure; after deep cleaning on a structured surface, ion implantation is carried out and annealing is carried out to form apseudo diffusion layer; a polymer energy-absorbing film layer is deposited on the pseudo diffusion layer by an evaporation method; a polymer layer is metallized by polymer layer by high energy ion implantation; a superhard diamond coating is deposited on a metallized layer by using magnetic filtration deposition equipment; and the polymer layer, the metallized layer and a superhard diamond-like carbon layer are circularly prepared for 3-5 times. According to the coating method provided by the invention, the impact resistance of the matrix against high-speed moving objects is obviously improved by combining a matrix microstructure, ion implantation and deposition coating. The coating method is simple and easy to operate, low in cost and high in efficiency, and thus is very suitable for batch production.

Owner:BEIJING NORMAL UNIVERSITY

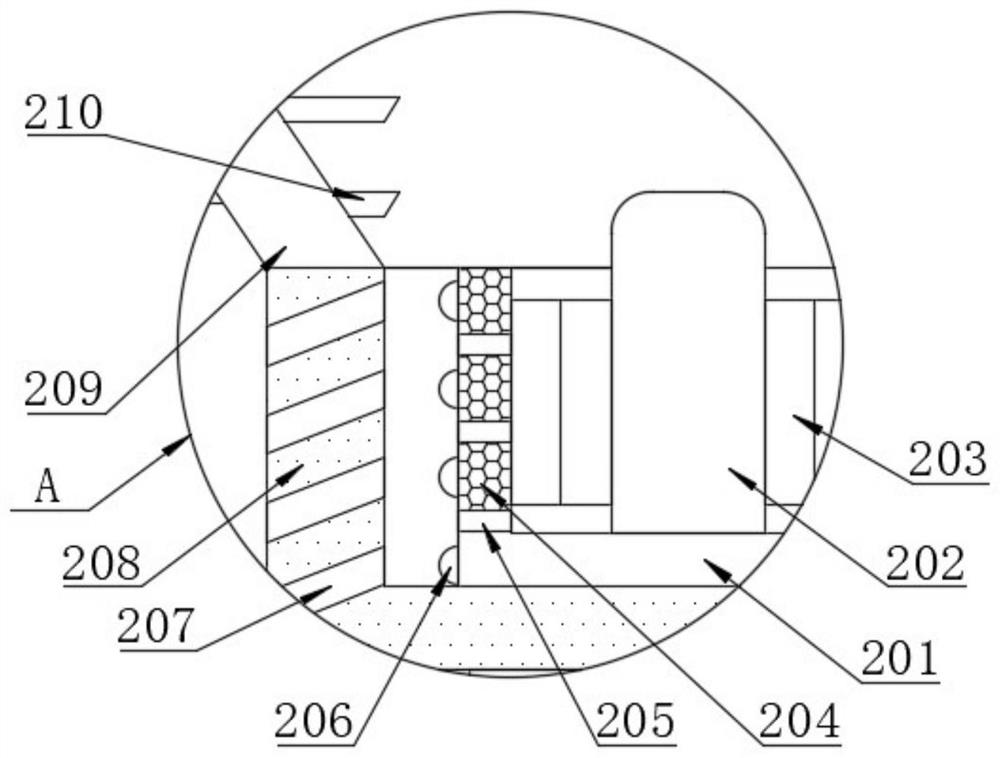

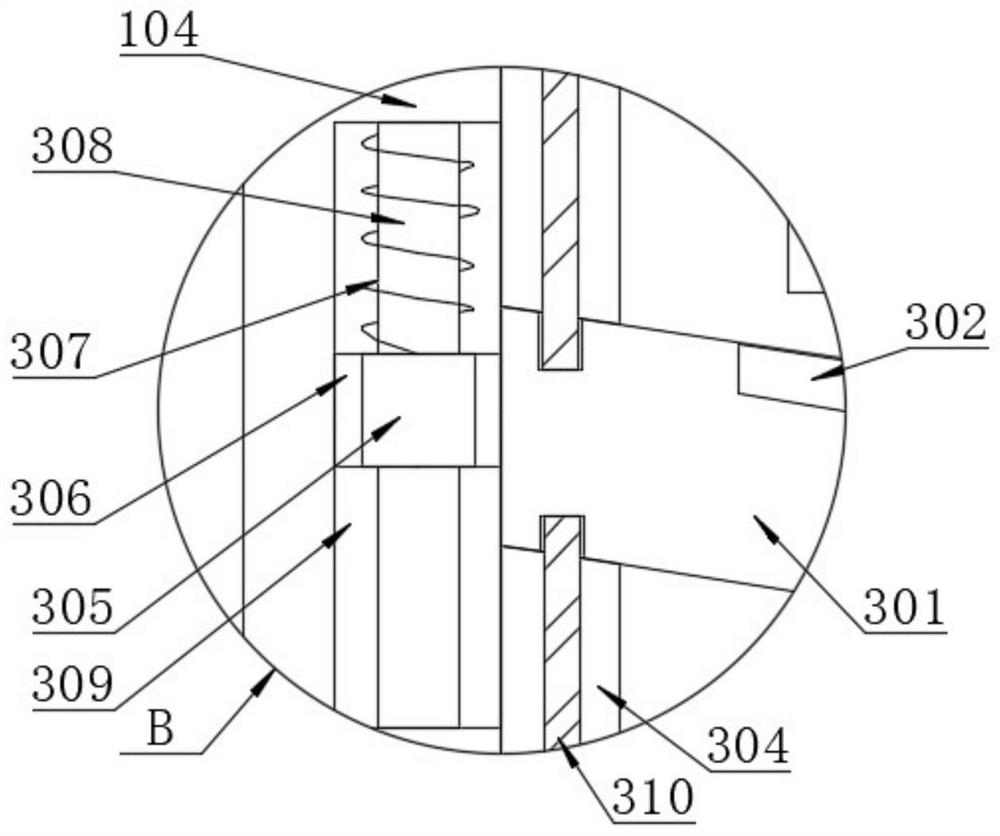

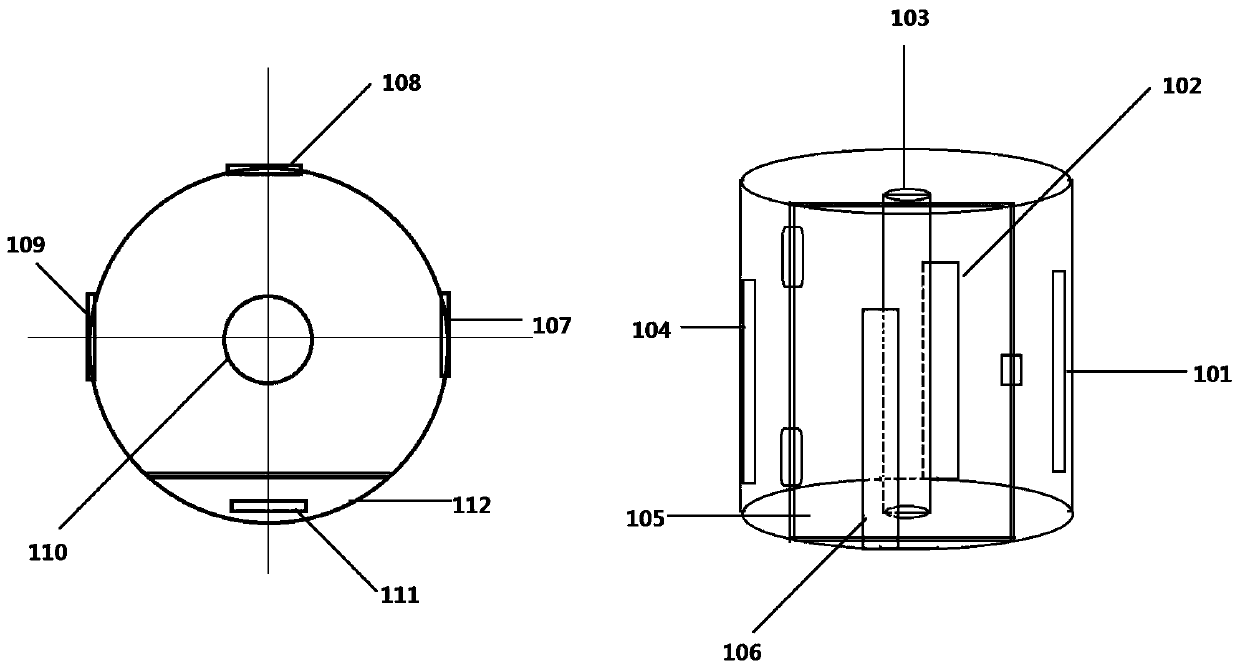

Device for preparing high-shielding substrate coating

InactiveCN111663106AReduced effects of fatigue propertiesHigh atomic ionization rateVacuum evaporation coatingSputtering coatingNanocrystalNitrogen gas

The invention discloses a device for preparing a high-shielding substrate coating, and relates to the technical field of coating devices. The device for preparing the high-shielding substrate coatingmainly comprises a vacuum chamber, a first flange hole is formed in the rear side of the middle of the vacuum chamber in the horizontal direction, and a to-be-machined workpiece enters the vacuum chamber through the first flange hole; the vacuum chamber also communicates with a gas ion source system, a deposition system and a molecular pump; the vacuum chamber is provided with an air inlet; surface gas ion source cleaning is performed on the to-be-machined workpiece through the gas ion source system; nitrogen is introduced to carry out surface nitridation, the fatigue resistance of a substrateis improved, and preparation of a circulating multilayer coating is performed; and the workpiece is rotated in the vacuum chamber. Each layer in the unit coating is a mixture of nitride and oxide nanocrystals, so that the internal stress generated during deposition can be released, and oxides of Al and Cr in the coating have good high-temperature resistance at the same time.

Owner:BEIJING NORMAL UNIVERSITY

Cr/CrNx heat insulating film for top surface of aluminium alloy piston and preparation method of Cr/CrNx heat insulating film

ActiveCN107587110AImprove adaptabilityReduce stressVacuum evaporation coatingSputtering coatingPistonTitanium

The invention relates to a Cr / CrNx heat insulating film for the top surface of an aluminium alloy piston and a preparation method of the Cr / CrNx heat insulating film. The Cr / CrNx heat insulating filmis formed by a pure metal Cr layer attached to the top surface of the aluminium alloy piston and a CrNx layer coating the pure metal Cr layer uniformly. The preparation method of the Cr / CrNx heat insulating film comprises the following steps: firstly, the cleaned and dried aluminium alloy piston is placed in an FCVA (filtered cathodic vacuum arc) deposition system, a magnetic filtered Ti power arcis switched on, and the pure metal Cr layer is deposited with a pure metal Cr target as a cathode; the aluminium alloy piston with the pure metal Cr layer on the top surface is obtained; then the pure metal Cr target is taken as the cathode, nitrogen is taken as working gas, the nitrogen introducing amount is regulated, and the CrNx layer is generated on the pure metal Cr layer of the aluminium alloy piston with the pure metal Cr layer on the top surface. The strength, the wear resistance and the heat insulation performance of the obtained product are all better than those of the existing products, requirements of modern engines for high power and low emission can be met, and large-scale industrial application is facilitated.

Owner:XIANGTAN UNIV

A method and device for improving the service life of push rod components in aerospace relays

ActiveCN105755443BImprove bindingHigh peel strengthVacuum evaporation coatingSputtering coatingWear resistantBinding force

The invention discloses method and equipment for prolonging the life of a push rod component in a sealed relay. In the method, a superhard wear-resistant film layer with good insulating property is deposited on the surface of a push ball in the push rod component by a low-energy ion beam technology; and the film is prepared by the following steps: injecting a layer of metal 'pinning layer' capable of improving binding force of the film into glass surface by a metal vapor vacuum arc (MEVVA) ion source method; depositing a first metal film transition layer for releasing internal stress on the metal 'pinning layer' by a magnetic filtered cathodic vacuum arc (FVCA) deposition method; and depositing a superhard wear-resistant DLC layer on the first transition layer by the magnetic FVCA deposition method, wherein the total thickness of the film is 0.1-5 microns. Through the invention, the life of the push ball in the push rod component of the sealed relay can be obviously prolonged by depositing the superhard DLC film on the push rod component of the sealed relay.

Owner:BEIJING NORMAL UNIVERSITY

Coating of light-water reactor

InactiveCN109913823AQuality improvementReduce human defectsVacuum evaporation coatingSputtering coatingOxidation resistantHigh pressure

The invention provides a method for preparing zirconium pipe coating of a light-water reactor. The method mainly comprises the following steps that a CrAbSi circulating nano coating and a MoNbZr circulating nano coating are alternately deposited by utilizing a high-power pulse technology and a magnetic filtration deposition technology, the thickness of the CrAbSi circulating nano coating and the MoNbZr circulating nano coating in a unit period is 0-15 nanometers, and the total thickness of the coating is 0-15 micrometres. After the nano coatings are deposited alternately, the oxidation resistance of the zirconium pipe at high temperature and high pressure in a high-pressure kettle is obviously enhanced, by implementing the method, a nano-circulation composite structure (especially the elements of Al, Cr and Si are added) is deposited alternately on the zirconium pipe, so that the inward diffusion of an oxygen element at the high temperature can be very well prevented, due to the mutualsynergistic effect of various elements, falling off, cracking and diffusion behaviors of oxygen atoms of a film layer can be effectively prevented in the high temperature and high pressure, and the safety and reliability of a fault-tolerant fuel are improved.

Owner:BEIJING NORMAL UNIVERSITY

Kitchen sewage treatment device capable of avoiding sewer blockage

InactiveCN112459180AMeet the needs of crushingAvoid crushing efficiency impactDomestic plumbingCleaning using liquidsFiberKitchen utensils

The invention discloses a kitchen sewage treatment device capable of avoiding sewer blockage, and belongs to the technical field of kitchen utensils. The kitchen sewage treatment device comprises an accommodating mechanism, a smashing mechanism is arranged in an inner cavity of the accommodating mechanism, a material-out mechanism is arranged on one side of the accommodating mechanism in a communicating mode, discharging mechanisms are arranged at the bottom of the accommodating mechanism and the bottom of the material-out mechanism in a communicating mode, a screening mechanism is further arranged in an inner cavity of the accommodating mechanism, and one side of the screening mechanism communicates with the material-out mechanism. According to the kitchen sewage treatment device capableof avoiding sewer blockage, by arranging an outer crushing disc and an inner smashing disc, the carrying capacity of kitchen garbage is improved, repeated filling is not needed, the crushing efficiency and precision can be improved through relative rotation crushing of the inner smashing disc and the outer crushing disc, and large particles which are not completely crushed in the kitchen garbage are remarkably reduced; and crushing blades and the outer blades can effectively crush high-fiber fruit peels, the situation that the crushing blades are wound around the outer wall of the grinding roller, and the crushing efficiency is affected is avoided, and the kitchen garbage crushing use requirement is met.

Owner:杭州墙镪科技有限公司

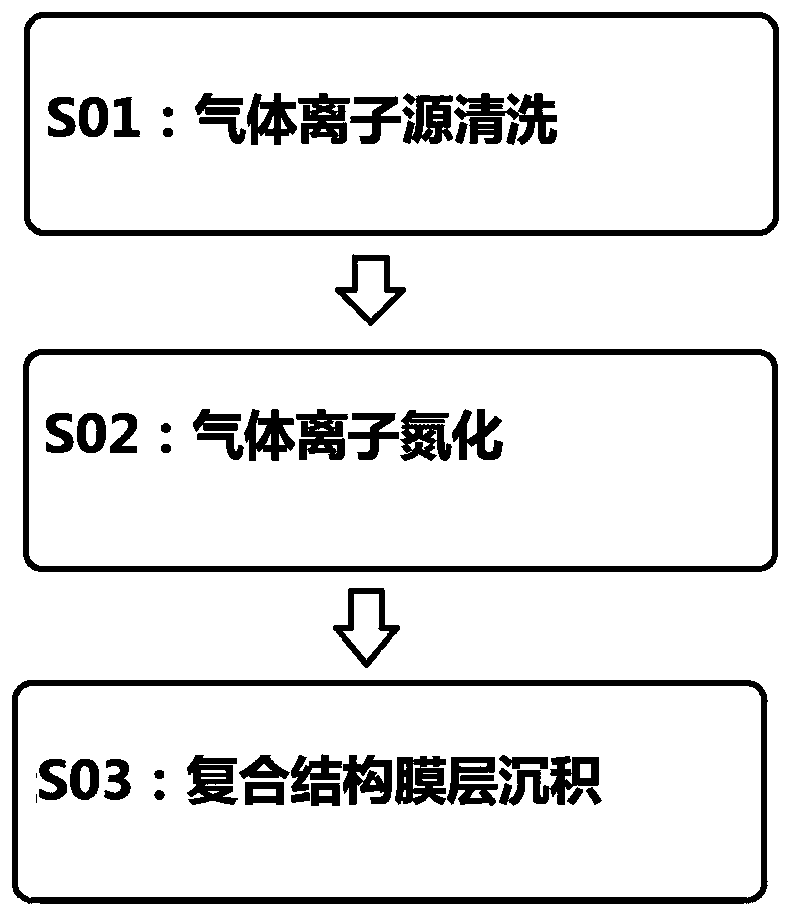

Surface treatment method of saw web

ActiveCN109722623AReduce coefficient of frictionImprove cutting lifeVacuum evaporation coatingSputtering coatingComposite filmComposite laminates

The invention discloses a surface treatment method of a saw web. According to the method, a composite film which is low in friction coefficient and good in toughness is deposited on the surface of thesaw web by the aid of a gas ion source with the high-power pulse technology and the electric arc technology. The method includes the following steps that gas ion source cleaning is performed on the saw web; the saw web is subjected to ionic nitriding by the aid of the gas ion source; and a coating adopting a composite laminated structure is deposited with the high-power pulse technology and the electric arc technology. The prepared sandwich composite film layer has the high toughness, the high micro-hardness and the low friction coefficient, the service life of the saw web can be obviously prolonged by 2-5 times, and the method has the very good application prospect in the field of saw webs.

Owner:BEIJING NORMAL UNIVERSITY

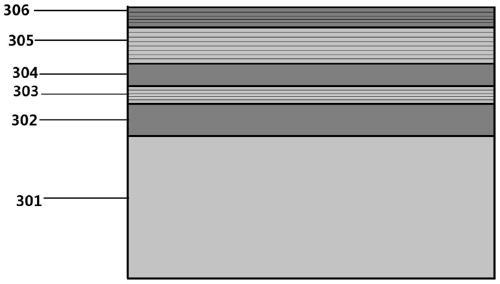

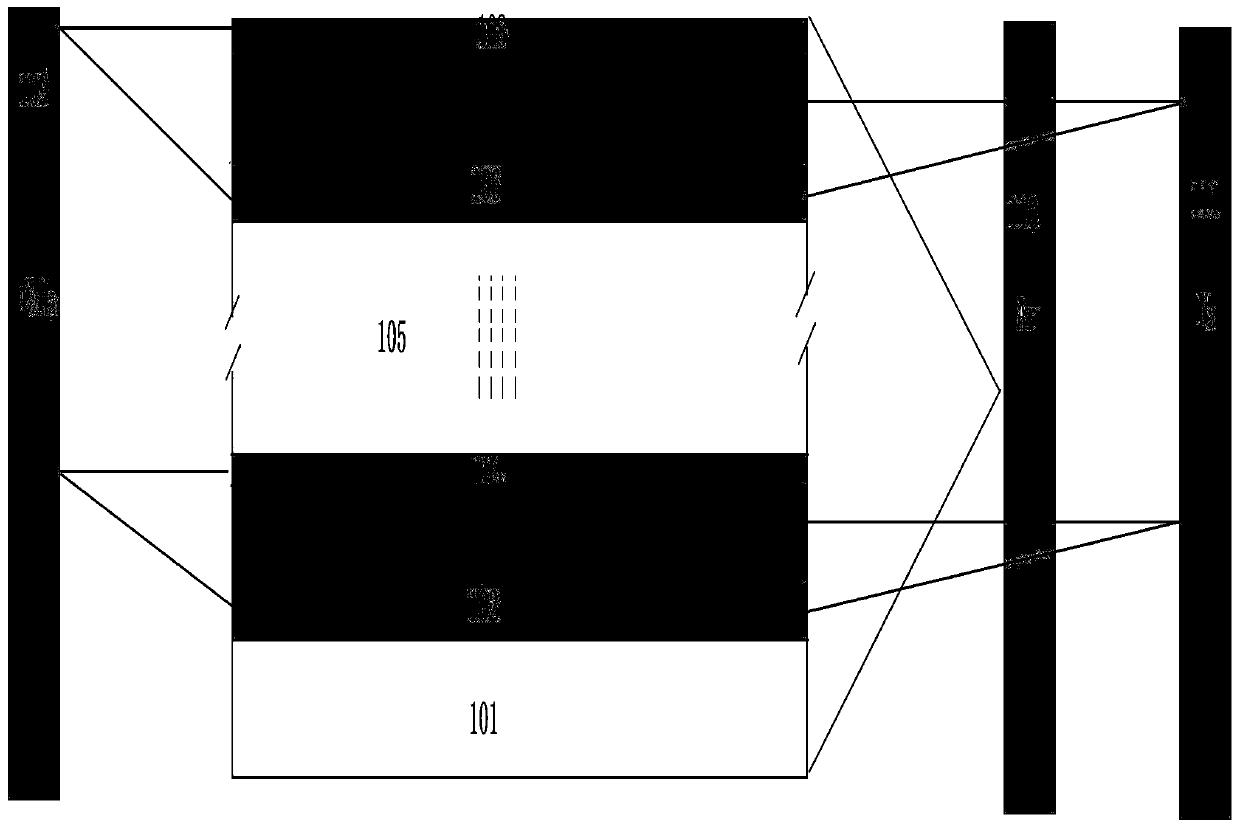

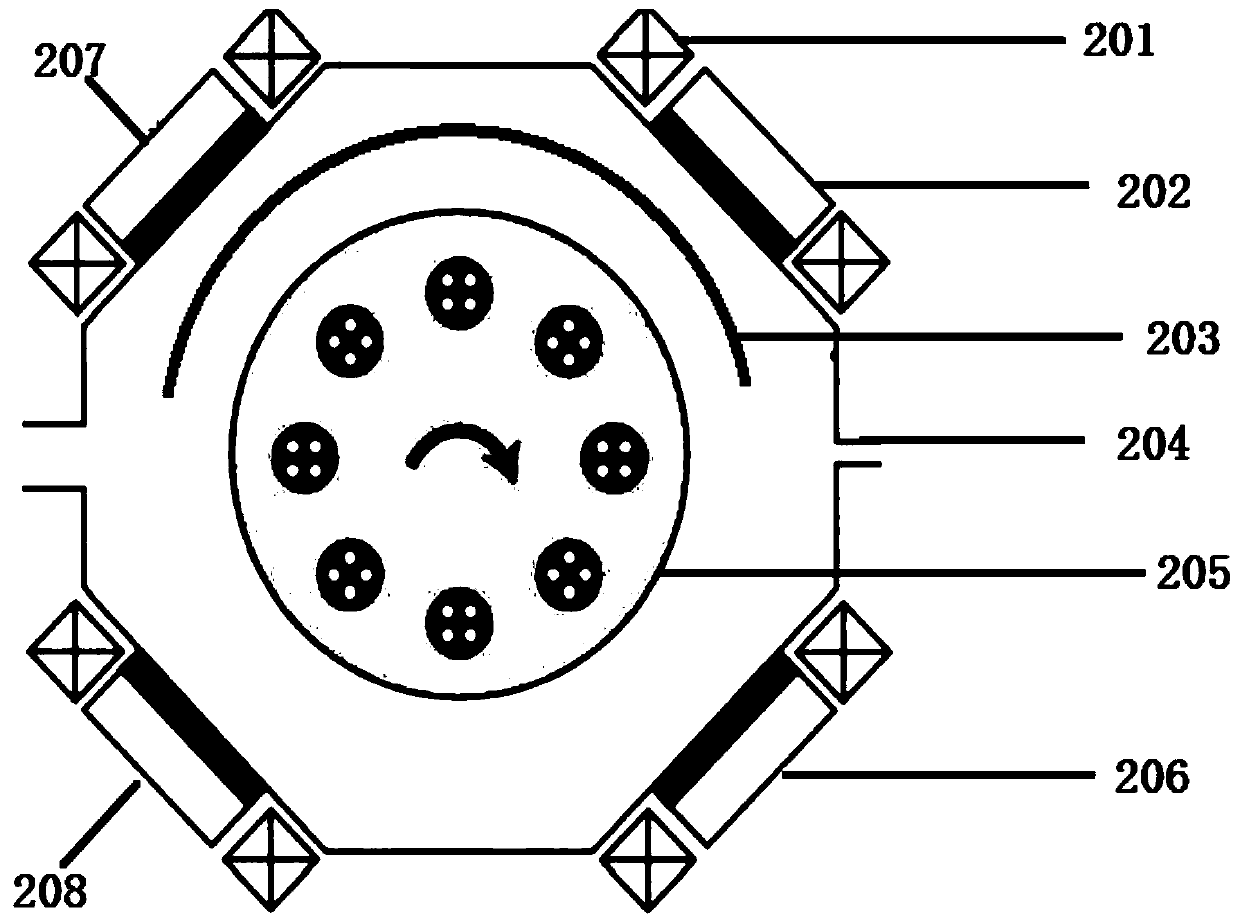

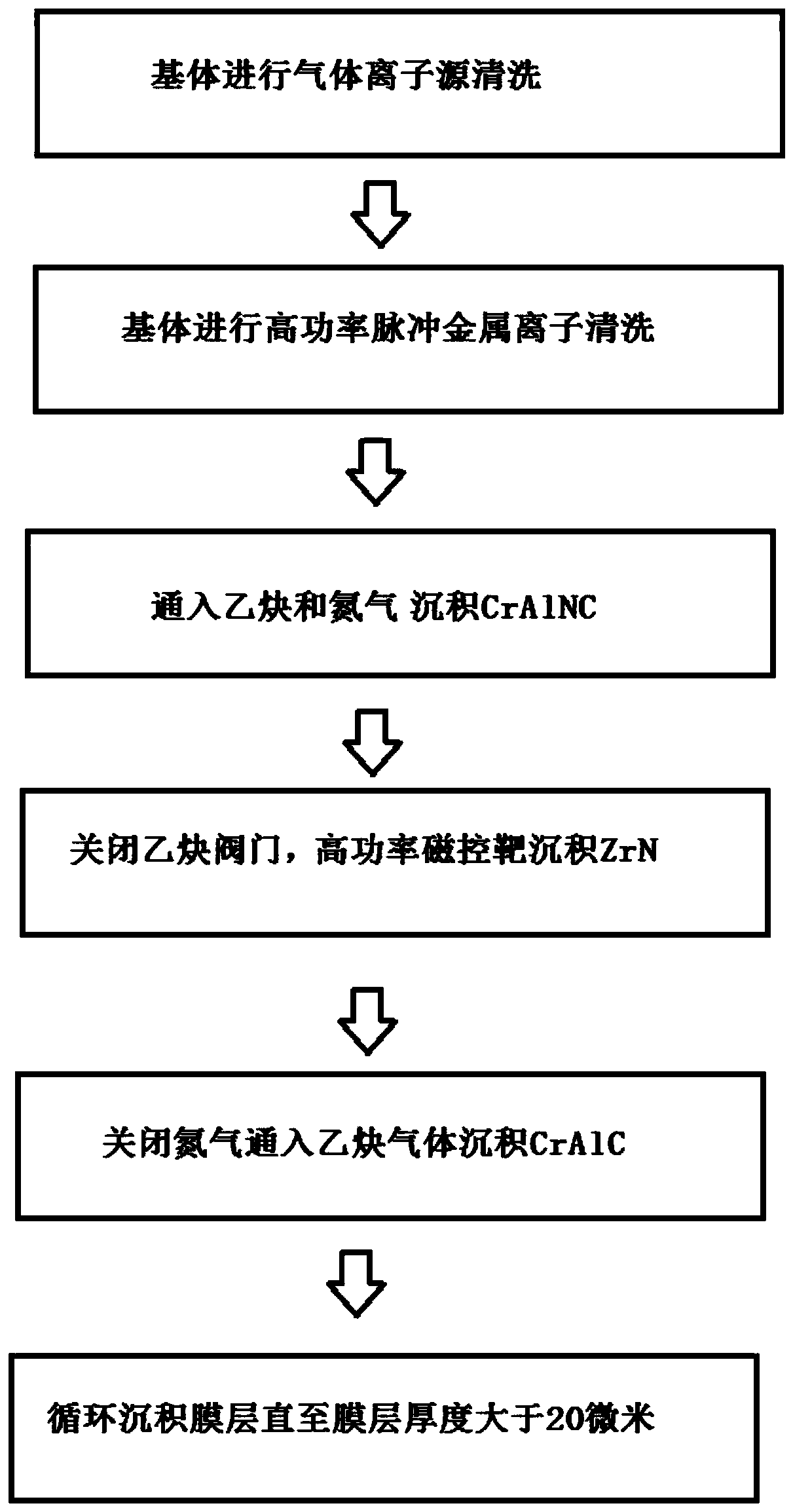

Preparation method for super-thick energy absorption coating layer

ActiveCN110144562AQuick removalHigh specific surface areaVacuum evaporation coatingSputtering coatingEnergy absorptionChemistry

The invention relates to a preparation method for a super-thick energy absorption coating layer. The preparation method comprises the steps that S01, a substrate is subjected to gas ion source cleaning; S02, the substrate is subjected to high-power pulse metal ion cleaning; S03, acetylene and nitrogen are injected for CrAlNC deposition; S04, an acetylene valve is closed, and ZrN is deposited through high-power pulse magnetic control; S05, the nitrogen is stopped, and the acetylene is injected for CrAlC deposition; and S06, a film layer is circularly deposited till the thickness of the film layer is larger than 20 [mu]m. According to the preparation method provided by the embodiment of the invention, through the mode of combining a gas ion source technology and a high-power pulse magnetic control technology with a multi-arc ion plating technology, the deposited super-thick coating layer is small in internal stress and good in toughness, impact resistance and energy absorption performance. The preparation method is simple, easy to implement, low in cost and high in efficiency, and then is quite suitable for batch production.

Owner:BEIJING NORMAL UNIVERSITY

A preparation method for maintaining superhard properties and improving toughness for ultra-thick tin film layers

ActiveCN105779936BImprove bindingImprove toughnessVacuum evaporation coatingSputtering coatingFilm baseHigh energy

The invention discloses a method for preparing a super-thick and high-toughness TiN film. The method for preparing the TiN film comprises the steps that 1, a metal filtered cathodic vacuum arc (FCVA) deposition system is adopted, and the surface of a workpiece is cleaned through high-energy large-beam metal ion beams; 2, a layer of metal 'pinning layer' capable of improving the film base binding force is injected into the surface of the workpiece through a metal vapor vacuum arc (MEVVA) ion source method; 3, on the metal 'pinning layer', the gas inlet quantity is subjected to sine or cosine modulation and deposition through a filtered cathodic vacuum arc (FCVA) deposition method, and thus the super-hard good-toughness thick TiN film layer is obtained; and 4, the modulation period is repeated till the total thickness of the TiN film is 10-30 microns. By means of the method for preparing the super-thick and high-toughness TiN film, the TiN film deposited on the workpiece has very good toughness and very high microhardness.

Owner:广东省广新创新研究院有限公司

A kind of preparation method of high-purity strong dense max phase coating

ActiveCN107620033BEasy to controlEasy to homogenize large area depositionVacuum evaporation coatingSputtering coatingCoated surfacePhysical chemistry

The invention provides a preparation method for a high-purity high-density MAX phase coating. According to the method, an arc ion plating technology is combined with a magnetron sputtering technology,an M-position element is provided for the arc, an A-position Al element is provided for magnetron, nitrogen or hydrocarbon as reaction gas is introduced for deposition, then thermal treatment is adopted, and the high-purity high-density MAX phase coating is prepared. The prepared MAX phase coating is high in purity, good in compactness, free of a microdefect, high in preparation efficiency, low in cost and capable of overcoming the defects that large particles on the surface of a MAX phase coating prepared through a single arc method are excessive, the density is low, the efficiency is low bymeans of a magnetron sputtering method, and the defects are obvious and has the wide application prospects on the aspects of high-temperature protection, corrosion-resistant application and the like,and the industrial production of the MAX phase coating can be achieved easily.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com