Surface treatment method of saw web

A technology for surface treatment and saw blades, applied in the field of deposition methods and related equipment to improve the life of saw blades, to achieve the effects of reducing heat radiation, reducing impact, and reducing diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

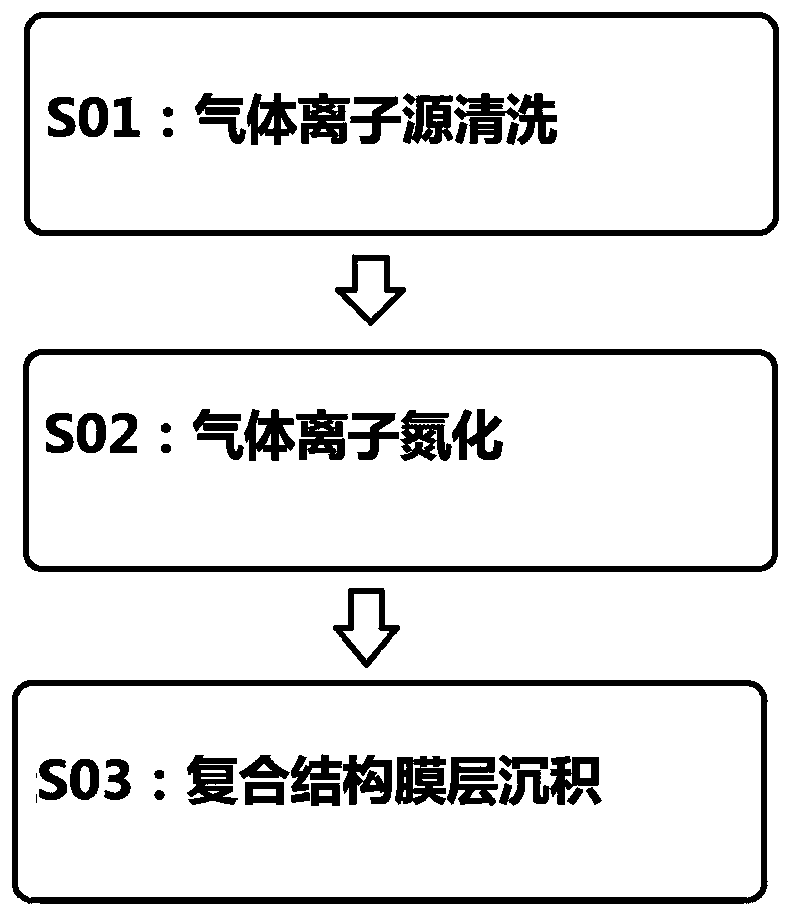

[0069] S01: Use a gas ion source to clean the surface of the saw blade with a large beam to form a metal interface layer with high surface energy.

[0070] The saw blade is cleaned by the method of gas ion source, the gas is a mixed gas of inert gas and hydrogen, the partial pressure ratio of inert gas and hydrogen is 5, the air pressure is 15pa, the cleaning voltage is 800V, and the beam intensity is 0.1- 5A, cleaning time is 60min;

[0071] S02: Nitriding the saw blade with a gas ion source

[0072] In the embodiment, a gas ion source is used to nitride the saw blade, the gas fed is a mixture of nitrogen and inert gas, the partial pressure ratio of nitrogen and inert gas is 10, the air pressure is 15 Pa, and the voltage is 1000V. The flow intensity is 5A, the nitriding time is 120min, the temperature is 500°C, and the nitriding depth is 20 microns.

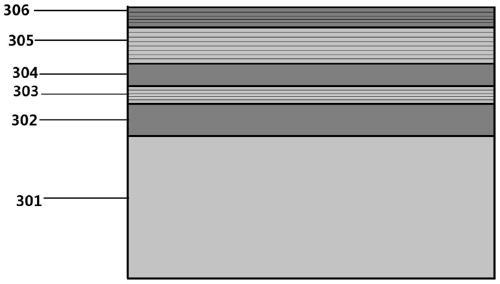

[0073] S03: Preparation of composite laminate structure coating

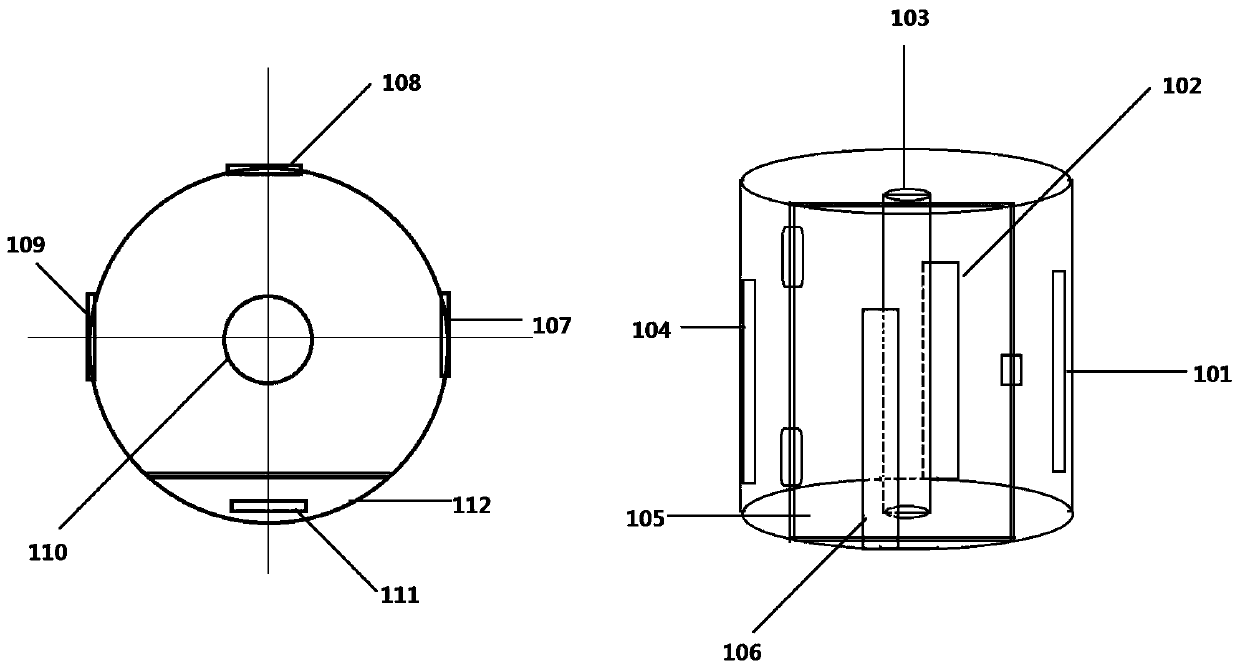

[0074] Magnetic filtration metal vacuum arc deposition sy...

Embodiment 2

[0079] S01: Use a gas ion source to clean the surface of the saw blade with a large beam to form a metal interface layer with high surface energy.

[0080] The saw blade is cleaned by the method of gas ion source, the gas is a mixed gas of inert gas and hydrogen, the partial pressure ratio of inert gas and hydrogen is 5, the air pressure is 15pa, the cleaning voltage is 800V, and the beam intensity is 0.1- 5A, cleaning time is 60min;

[0081] S02: Nitriding the saw blade with a gas ion source

[0082] In the embodiment, a gas ion source is used to nitride the saw blade, the gas fed is a mixture of nitrogen and inert gas, the partial pressure ratio of nitrogen and inert gas is 10, the air pressure is 15 Pa, and the voltage is 1000V. The flow intensity is 5A, the nitriding time is 120min, the temperature is 500°C, and the nitriding depth is 20 microns.

[0083] S03: Preparation of composite laminate structure coating

[0084] Magnetic filtration metal vacuum arc deposition sy...

Embodiment 3

[0089] S01: Use a gas ion source to clean the surface of the saw blade with a large beam to form a metal interface layer with high surface energy.

[0090] The saw blade is cleaned by the method of gas ion source, the gas is a mixed gas of inert gas and hydrogen, the partial pressure ratio of inert gas and hydrogen is 5, the air pressure is 15pa, the cleaning voltage is 800V, and the beam intensity is 0.1- 5A, cleaning time is 60min;

[0091] S02: Nitriding the saw blade with a gas ion source

[0092] In the embodiment, a gas ion source is used to nitride the saw blade, the gas fed is a mixture of nitrogen and inert gas, the partial pressure ratio of nitrogen and inert gas is 10, the air pressure is 15 Pa, and the voltage is 1000V. The flow intensity is 5A, the nitriding time is 120min, the temperature is 500°C, and the nitriding depth is 20 microns.

[0093] S03: Preparation of composite laminate structure coating

[0094]Magnetic filtration metal vacuum arc deposition sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com