Method for electroplating surface of permanent magnet neodymium-iron-boron magnetic steel with copper-nickel alloy plating

A technology of neodymium iron boron and copper electroplating, which is applied in the direction of superimposed layer plating, metal material coating process, coating, etc., can solve the problems of poor aging of neodymium iron boron magnets, achieve optimized appearance, save costs, Does not affect the effect of anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, adopt the method for nickel plating in electroplating tank again after multi-arc ion plating copper plating in the present invention, step is as follows:

[0034] a. After degreasing and degreasing the surface of the permanent magnet NdFeB magnets, wash them in the overflowing pure water washing tank for 40 seconds to ensure that they are clean, then wash them with nitric acid with a mass fraction of 5%, and then wash them with pure water, and then ultrasonically remove the dust. , washed with water, washed with ultrasonic pure water, then dehydrated with alcohol with a mass fraction of more than 98%, and dried;

[0035] b. Dry the permanent NdFeB magnets dehydrated by alcohol in an oven at 60°C for 1 hour, and then put the permanent NdFeB magnets into a multi-arc ion coating machine;

[0036] c Vacuumize the vacuum chamber of the multi-arc ion coating machine to 7×10 -3 pa, close the grating valve, then pass in argon gas at 100L / min, and adjust the vacuu...

Embodiment 2

[0042] Example 2, the same as Example, the difference is that the mass fraction of nitric acid in step a is 4%; the oven temperature in step b is 80°C, and it is dried for 0.5h; the bias power supply in step c is 1200V; step d is more The vacuum in the arc ion coating machine is maintained at 8×10 - 1 pa, the current is maintained at 90A, electroplating for 0.5 hours; step e, the surface temperature of the part is lowered to 80°C, and the furnace door is opened; step f, sandblasting with 60-mesh glass beads for 20 minutes; step g, the nickel sulfate content in the bath is 400g / L, nickel chloride 40g / L, boric acid 40g / L, pH 5.0, current 50A.

Embodiment 3

[0043] Embodiment 3, with embodiment 1, difference is, the mass fraction of the nitric acid of a step is 4.5%; The oven temperature of b step is 50 ℃, dry 3.0h; The bias power supply of c step is 1000V; d step The vacuum in the multi-arc ion coating machine is maintained at 2×10 -1 pa, the current is maintained at 60A, electroplating for 2 hours; step e, the surface temperature of the part is lowered to 20°C and the furnace door is opened; step f, sandblasting with 300 mesh glass beads for 2 minutes; step g, the content of nickel sulfate in the bath is 250g / L, nickel chloride 50g / L, boric acid 50g / L, pH 3.5, current 20A.

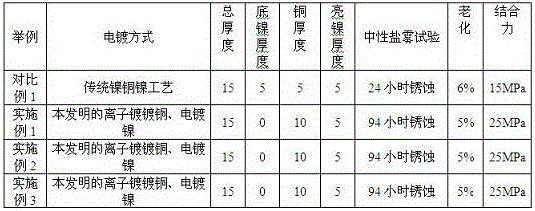

[0044] By controlling the coating time to obtain coatings of different thicknesses, the NdFeB magnets with different thicknesses of coatings were subjected to neutral salt spray test, aging test and binding force test for comparison.

[0045] Table 1 Comparison results Thickness unit: μm

[0046]

[0047] The neutral salt spray test adopts the ISO 9227-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com