Method for improving anti-friction and anti-wear performance of impactor piston

A technology of wear resistance and impactor, applied in the direction of coating, furnace type, furnace, etc., can solve problems such as weakening effect, and achieve the effect of improving service life, improving quality and prolonging working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

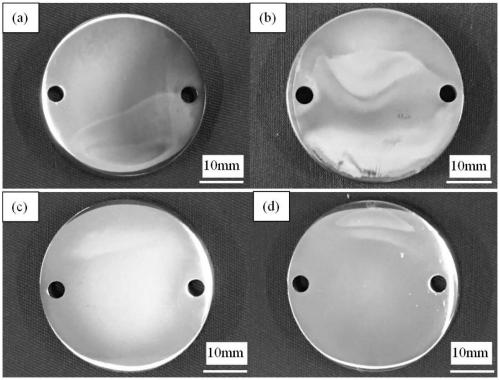

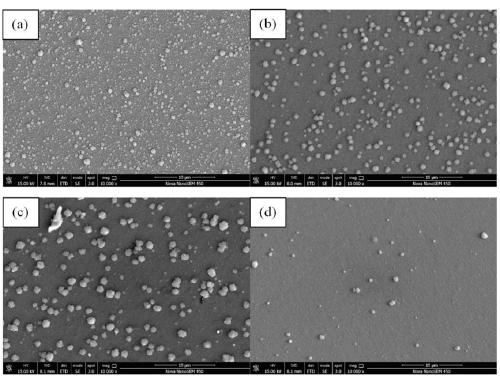

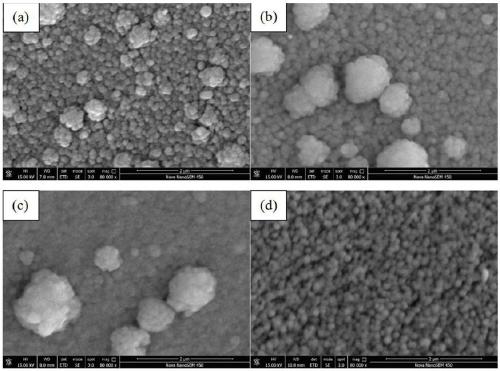

Image

Examples

Embodiment 1

[0057] A method for improving the antifriction and wear resistance of 20Cr2Ni4 steel, specifically:

[0058] (1) Finely grind and polish the surface of 20Cr2Ni4 steel; heat the 20Cr2Ni4 steel to 930°C and keep it warm for 1h;

[0059] (2) Gas carburizing of 20Cr2Ni4 steel with endothermic atmosphere and methane, that is, strong carburizing for 6 hours at a carbon potential of 1.2% and a temperature of 930°C;

[0060] (3) Diffusion for 4 hours at a carbon potential of 0.8% and a temperature of 930°C;

[0061] (4) Pre-cool the 20Cr2Ni4 steel to 850°C, heat it for 1 hour and then oil quench it;

[0062] (5) Heat the 20Cr2Ni4 steel to 180°C for low-temperature tempering, and the heating time for tempering is 2h.

[0063] (6) the 20Cr2Ni4 steel after step (6) is cooled to room temperature, and its surface is finely ground and polished;

[0064] (7) Place 20Cr2Ni4 steel on the cathode tower of the ion sulfurization furnace body, connect the sample to the cathode of the ion sulfur...

Embodiment 2

[0066] A method for improving the antifriction and wear resistance of 20Cr2Ni4 steel, specifically:

[0067] (1) Finely grind and polish the surface of 20Cr2Ni4 steel; heat the 20Cr2Ni4 steel to 930°C and keep it warm for 1h;

[0068] (2) Gas carburizing of 20Cr2Ni4 steel with endothermic atmosphere and methane, that is, strong carburizing for 6 hours at a carbon potential of 1.2% and a temperature of 930°C;

[0069] (3) Diffusion for 4 hours at a carbon potential of 0.8% and a temperature of 930°C;

[0070] (4) Pre-cool the 20Cr2Ni4 steel to 850°C, heat it for 1 hour and then oil quench it;

[0071] (5) Heat the 20Cr2Ni4 steel to 180°C for low-temperature tempering, and the heating time for tempering is 2h.

[0072] (6) the 20Cr2Ni4 steel after step (6) is cooled to room temperature, and its surface is finely ground and polished;

[0073] (7) Place 20Cr2Ni4 steel on the cathode tower of the ion sulfurization furnace body, connect the sample to the cathode of the ion sulfur...

Embodiment 3

[0075] A method for improving the antifriction and wear resistance of 20Cr2Ni4 steel, specifically:

[0076] (1) Finely grind and polish the surface of 20Cr2Ni4 steel; heat the 20Cr2Ni4 steel to 930°C and keep it warm for 1h;

[0077] (2) Gas carburizing of 20Cr2Ni4 steel with endothermic atmosphere and methane, that is, strong carburizing for 6 hours at a carbon potential of 1.2% and a temperature of 930°C;

[0078] (3) Diffusion for 4 hours at a carbon potential of 0.8% and a temperature of 930°C;

[0079] (4) Pre-cool the 20Cr2Ni4 steel to 850°C, heat it for 1 hour and then oil quench it;

[0080] (5) Heat the 20Cr2Ni4 steel to 180°C for low-temperature tempering, and the heating time for tempering is 2h.

[0081] (6) the 20Cr2Ni4 steel after step (6) is cooled to room temperature, and its surface is finely ground and polished;

[0082] (7) Place 20Cr2Ni4 steel on the cathode tower of the ion sulfurization furnace body, connect the sample to the cathode of the ion sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com