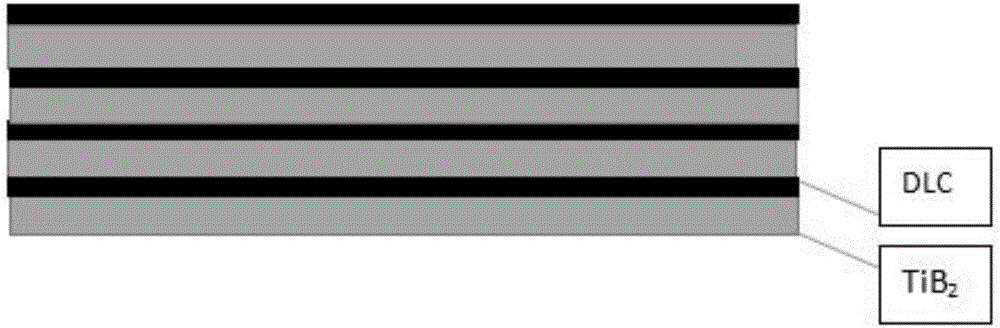

Self-lubricating titanium diboride/diamond-like carbon coating and preparing method and application thereof

A titanium diboride and self-lubricating technology, which is applied in the field of titanium diboride/diamond-like coating and its preparation, can solve the problem of protective coating use efficiency and application field limitations, poor toughness of titanium diboride, and coating performance Instability and other problems, to achieve the effects of large-scale industrial production, low cost, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation:

[0034] S1. Cleaning the substrate: send the polished WC-Co cemented carbide substrate into an ultrasonic cleaning machine, and use acetone and absolute ethanol to perform ultrasonic cleaning at 30kHz for 10 minutes, then clean it with deionized water, and then clean it with purity ≥ 99.5% nitrogen blow dry.

[0035] S2. Vacuuming and ion beam etching to clean the cavity and substrate: install TiB on the ion coating machine 2 For planar targets and graphite cylindrical targets, clean the coating chamber with a high-powered vacuum cleaner. Place the substrate after ultrasonic cleaning on the workpiece support in the vacuum chamber, and pump it to a vacuum degree of 5.0×10 -3Below Pa, then turn on the ion source, pass 80sccm argon gas into the ion source, set the ion source power to 0.9kW, set the workpiece support bias to -300V, and the etching cleaning process lasts for 20min.

[0036] S3. Ion beam etching substrate: rotate the turret, place the subs...

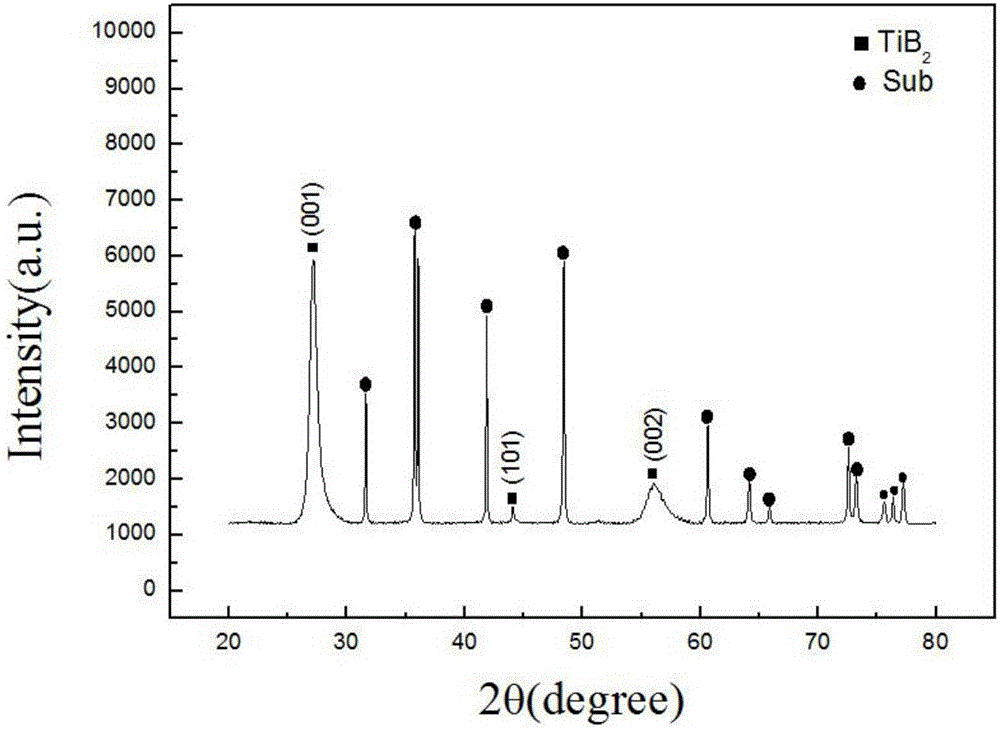

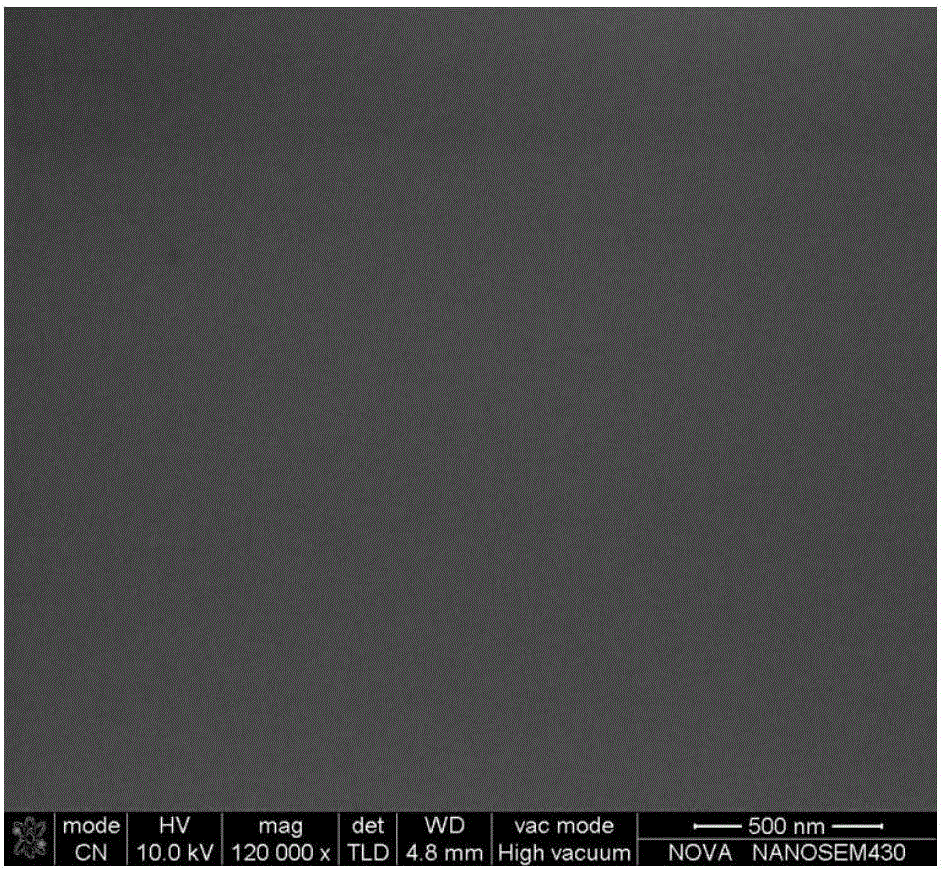

Embodiment 2

[0043] S1. Cleaning the substrate: send the polished (100) oriented single crystal silicon substrate into an ultrasonic cleaning machine, perform ultrasonic cleaning with acetone and absolute ethanol at 30kHz for 10min respectively, then rinse with deionized water, and then use Nitrogen with a purity ≥ 99.5% is blown dry.

[0044] S2. Vacuuming and ion beam etching to clean the cavity and substrate: install TiB on the ion coating machine 2 For planar targets and graphite cylindrical targets, clean the coating chamber with a high-powered vacuum cleaner. Place the substrate after ultrasonic cleaning on the workpiece support in the vacuum chamber, and evacuate the vacuum chamber to a vacuum of 5.0×10 -3 Below Pa, then turn on the ion source, feed 80sccm argon gas into the ion source, set the ion source power to 0.9kW, set the workpiece support bias to 300V, and the etching and cleaning process lasts for 20min.

[0045] S3. Ion beam etching substrate: rotate the turret, place th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com