Patents

Literature

96results about How to "Good abrasiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

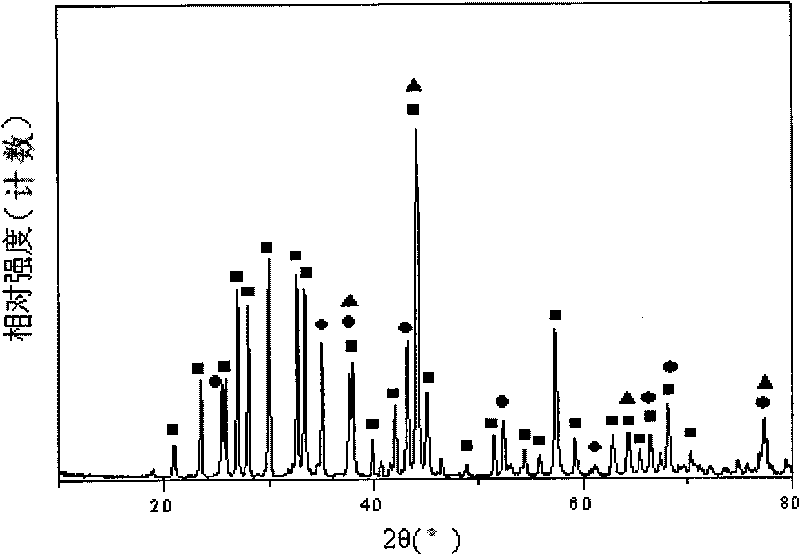

Copper alloy materials with high-strength and conducting performances and production thereof

InactiveCN1818109AHigh temperature strengthImprove plasticityHigh intensityUltimate tensile strength

The invention opened a high strength and conductance aldary material which includes: Cr 0.05%-0.10wt%; Zr 0.05%-0.50%; Mg 0.05-0.20wt%; (Ce+Y)<=0.20%; The residue is Cu. The process is : water quench for 1h in 900-960DEG C->30%-45% of cold-drawing deformation->aging treatment for 0.5-4h in 440-520 ->formed by cold-drawing. The strength can reach above 550-600MPa and the specific conductivity can keep above 80% IACS, and the life is improved to 3-5 times, the sintering can reach 550DEG C; the slip is less than 10% in the 300DEG C, the elongation percentage is above 5%, also the alloy has the performance of resistance to elevated temperatures and stand wear and tear.

Owner:HENAN UNIV OF SCI & TECH

High-strength high conduction copper alloy and its preparation method

InactiveCN1733953AHigh temperature strengthImprove plasticityHigh intensityUltimate tensile strength

The invention discloses a high-strength high-conductive copper alloy, which comprises 0.04~0.16 Ag, 0.02~0.4% Zr and copper. The opposite method comprises: melting alloy; solidifying alloy; deformation treating and failure treating. This invention overcomes the conflicting problem for high-strength and high-conductive. The product prolongs service life 3~5 times, has strength 500~600MPa, conductivity more than 80%IACS, softening temperature more than 400Deg, strength reduction rate less than 10% and extension rate more than 5% at 300Deg, and fit to all request for copper alloy.

Owner:HENAN UNIV OF SCI & TECH

Rare earth copper alloy and its preparation method

The invention discloses a rare earth copper alloy and its preparation method, which comprises charging electrolytic copper by weight percentage, smelting 20-30 minutes, then charging 0.03-0.1% of zirconium, 0.02-0.16% of silver, 0.02-0.155 of rare-earth elements, smelting 1-3 minutes and casting, subjecting the cast alloy to heat preservation 1-4 hours at 800-850 deg C, forming bar stock through processing, the forging deformation amount is 50-80%, loading the bar stock into heat treatment furnace, thermally insulating 30-60 minutes at 800-950 deg C, then carrying out quenching treatment, subjecting the quenched alloy to 30-80% deformation treatment, cold drawing the alloy, thermally insulating 1-8 hours at 440-520 deg C, carrying out 50-70% deformation treatment to the alloy undergone ageing treatment. The invention can achieve high-strength and high conductivity.

Owner:HENAN UNIV OF SCI & TECH

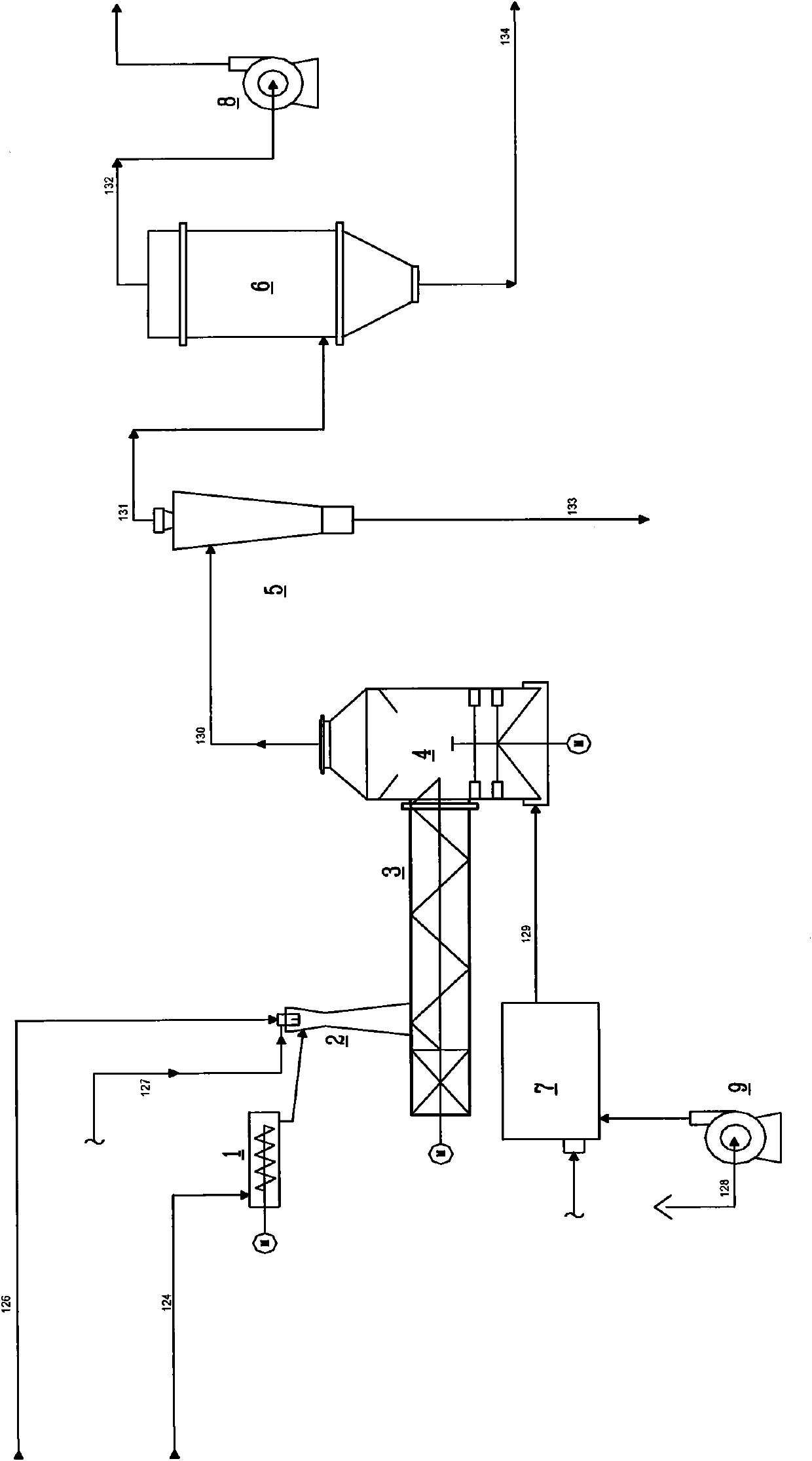

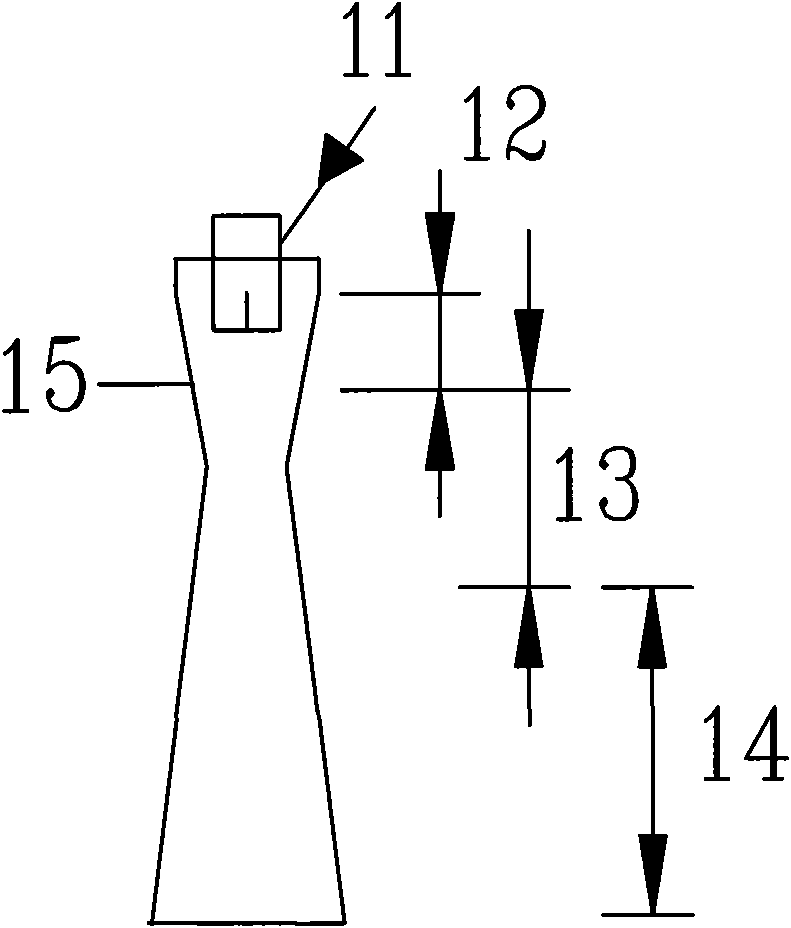

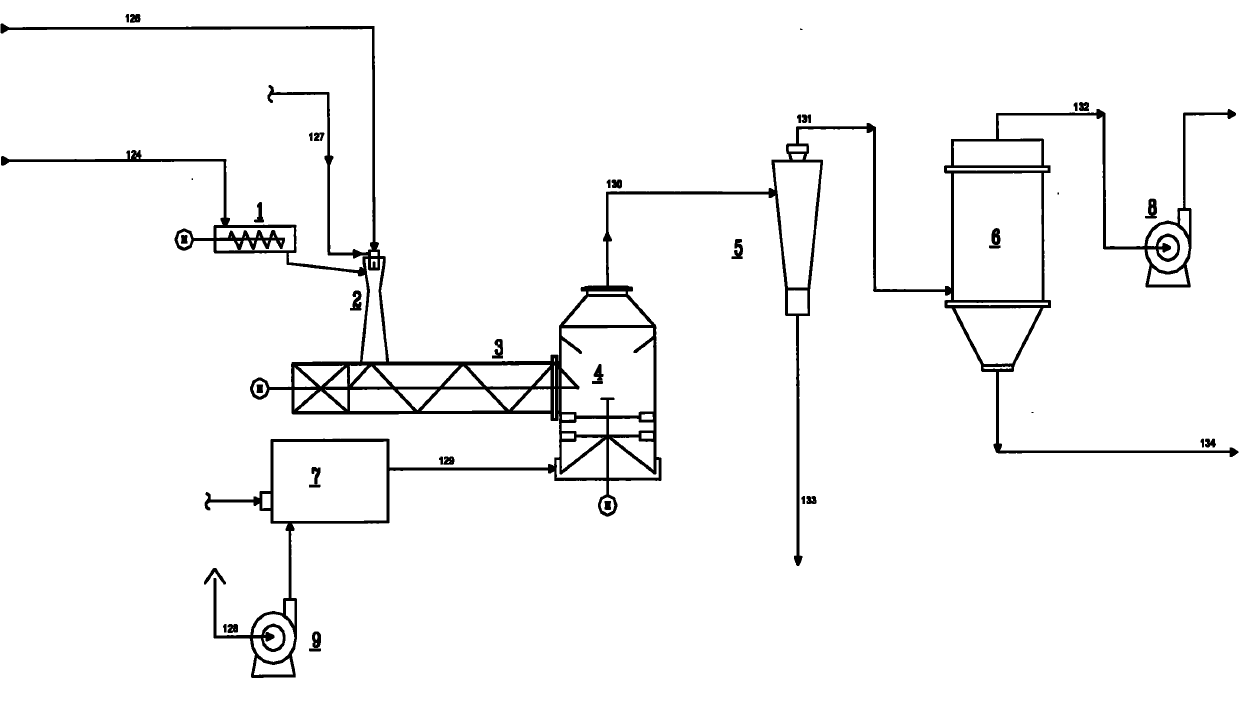

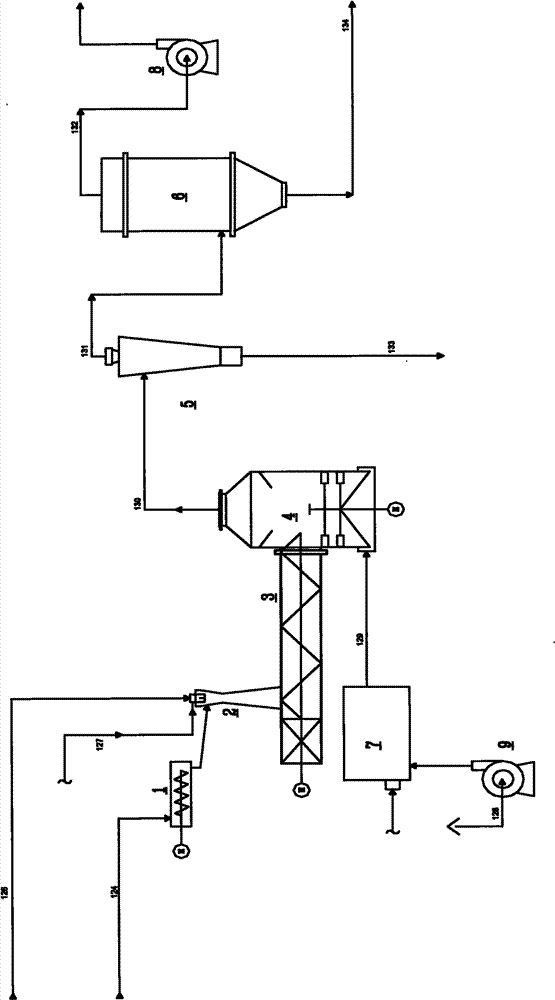

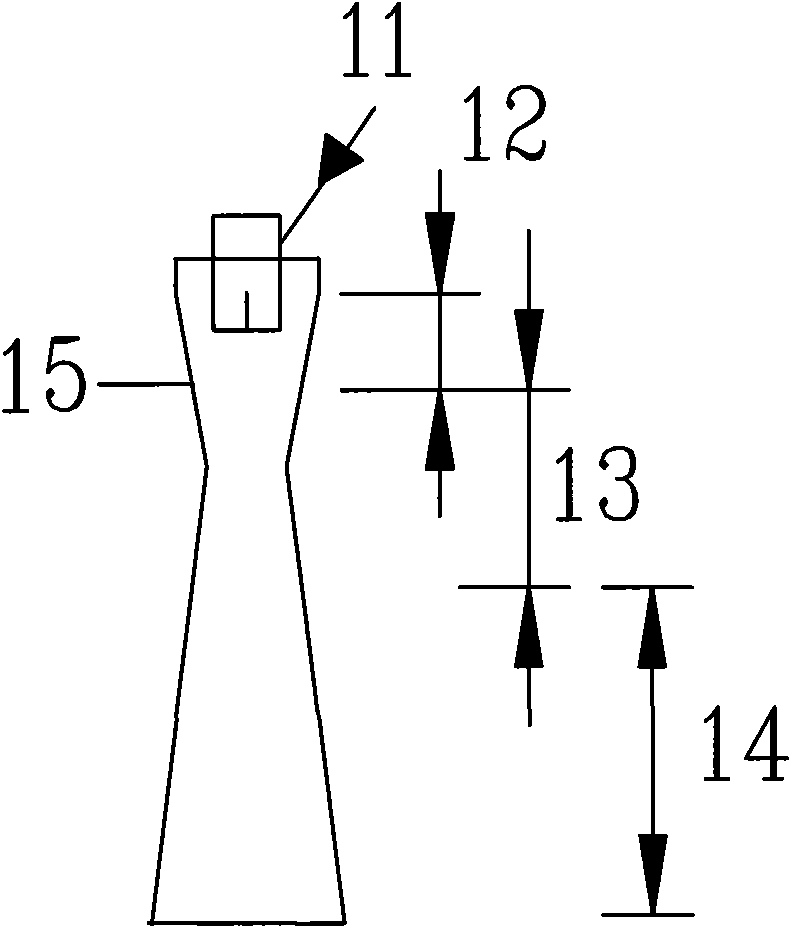

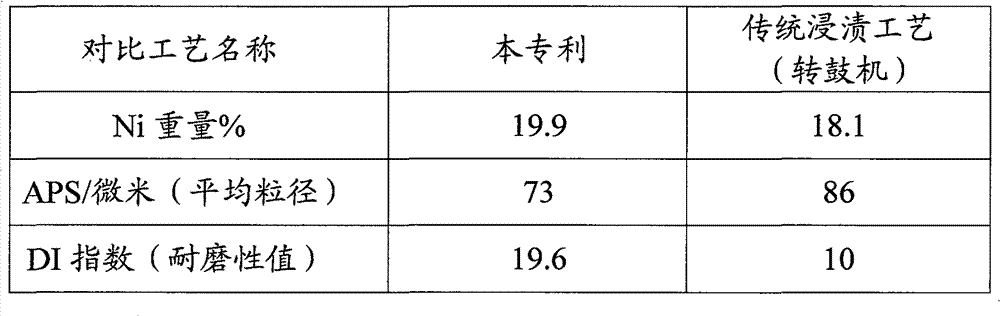

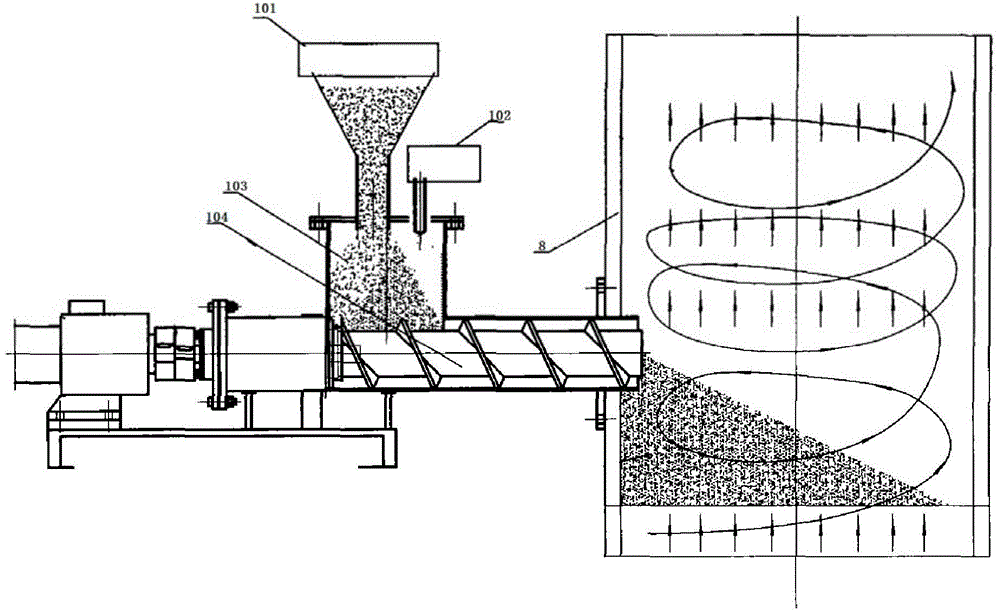

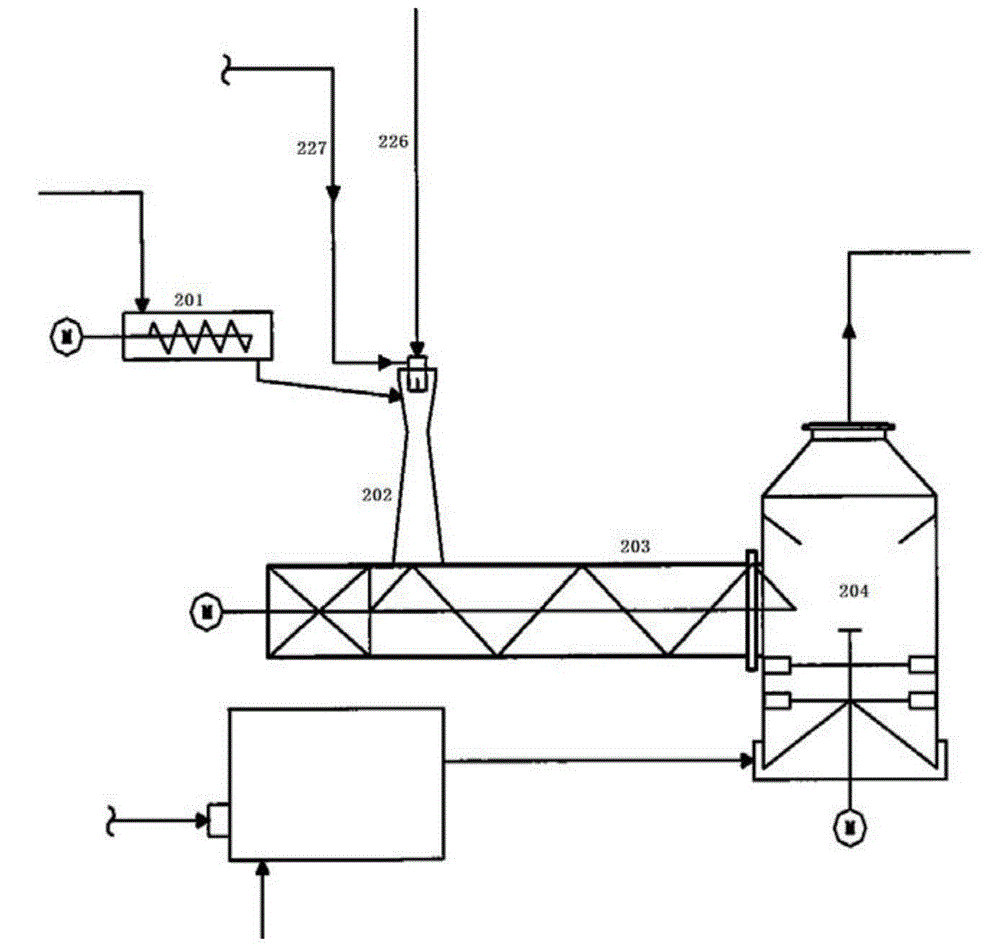

Continuous steeping method for grain carrier and equipment thereof

ActiveCN102019208AImprove impregnation efficiencyGuaranteed uptimeOther chemical processesCatalyst activation/preparationActive componentSorbent

The invention relates to a continuous steeping method for a grain carrier and equipment thereof. The continuous steeping method comprises the following steps that steeping liquor is atomized into drops through a nozzle and is jetted into an atomizer; carrier grains are led into the atomizer; the steeping liquor drops and the carrier grains are mixed in the atomizer to form a mixture; the mixture enters into a steeping mixer to carry out sufficient contact; the average grain diameters of the carrier grains are 40-90 microns; the average grain diameters of the steeping liquor drops are 0.5-1.0 time the average grain diameters of the carrier grains; and the ratio of the volume flow of the steeping liquor to the mass flow of the carrier is 0.30-0.60L / kg. The continuous steeping equipment comprises the atomizer and the steeping mixer which is connected with the outlet of the atomizer. The method can implement the continuous steeping process of the grain carrier and can make active component evenly distributed in the carrier, thereby ensuring the strength of an adsorbent finished product.

Owner:CHINA PETROLEUM & CHEM CORP +1

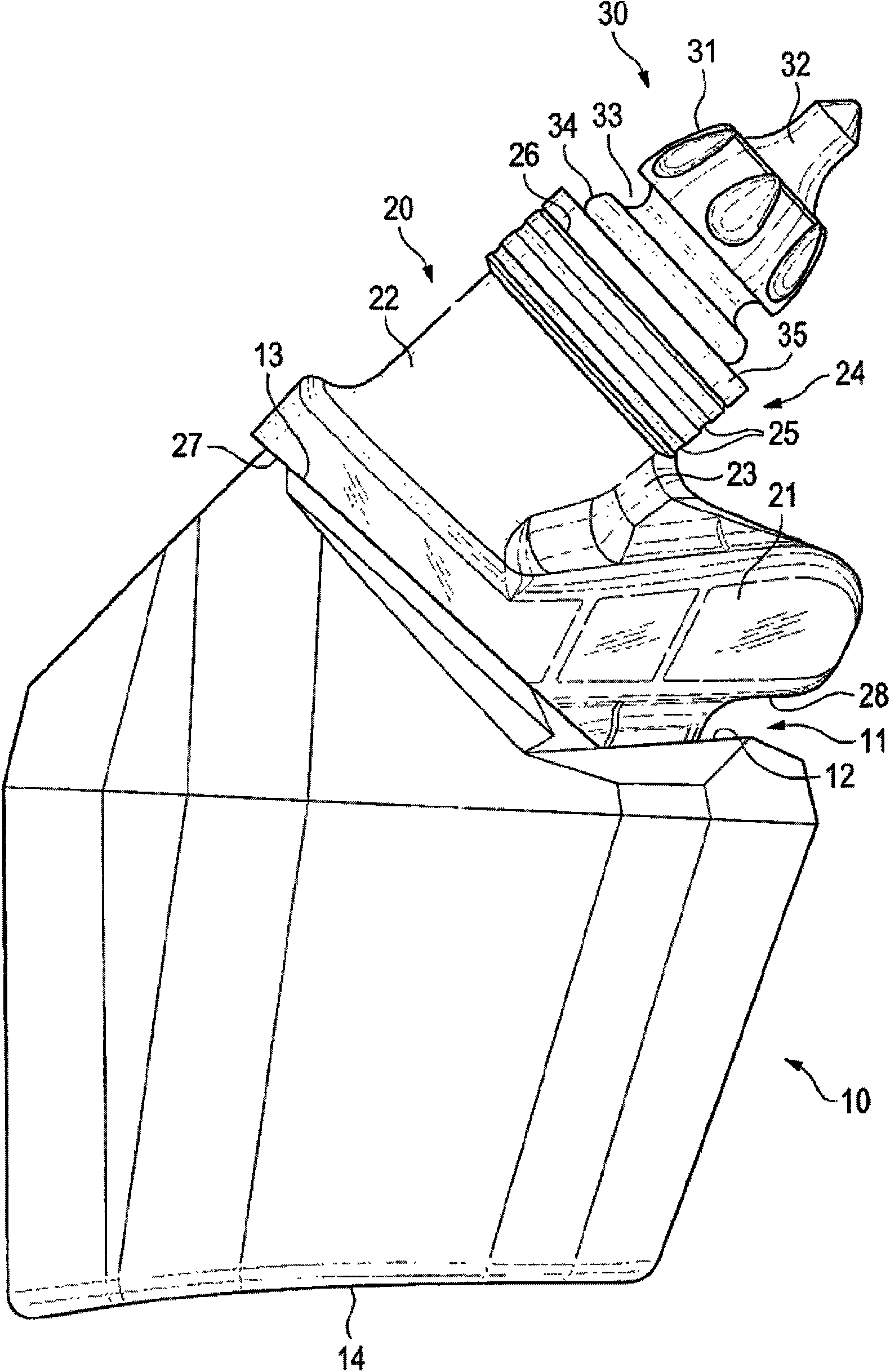

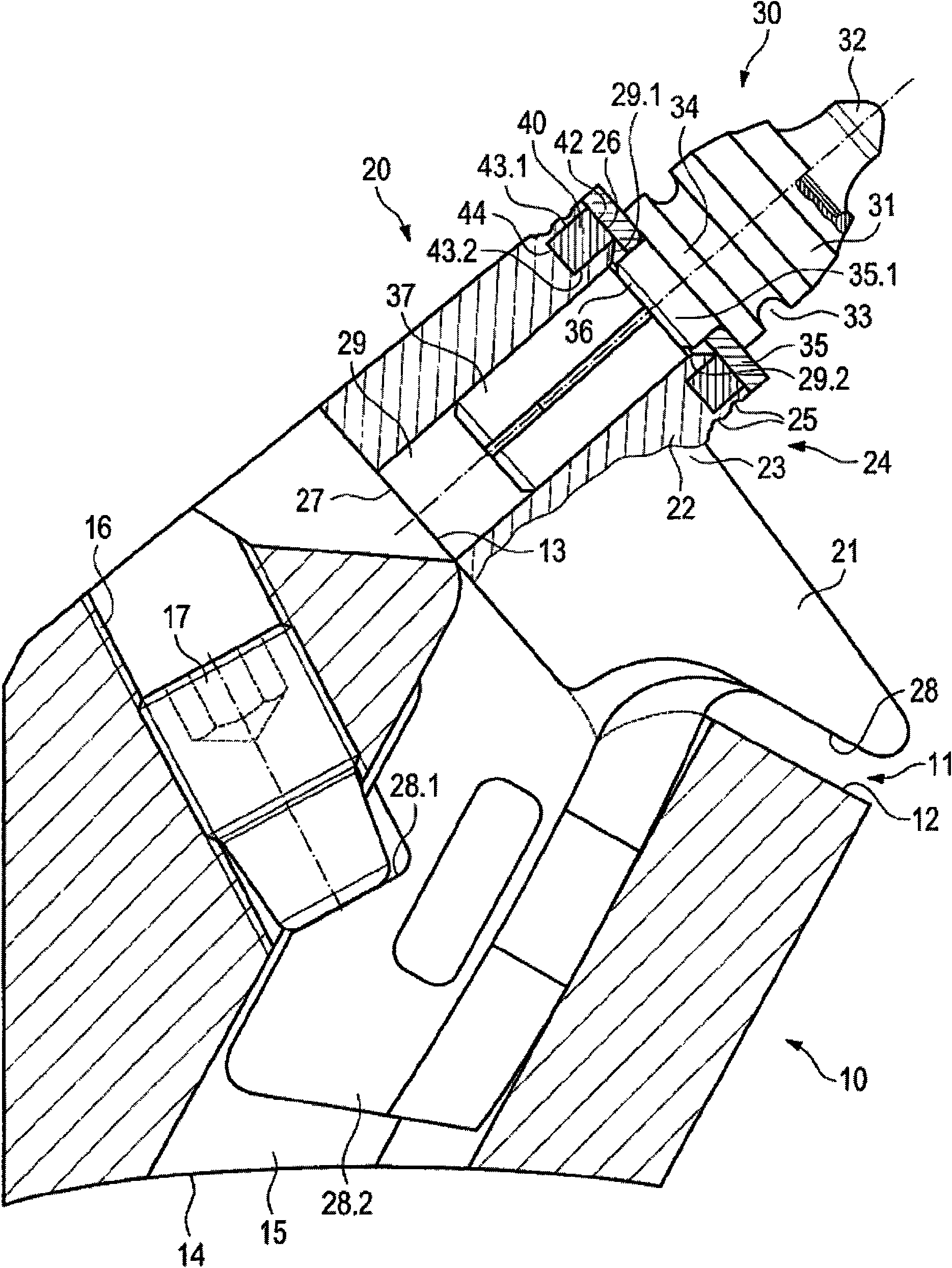

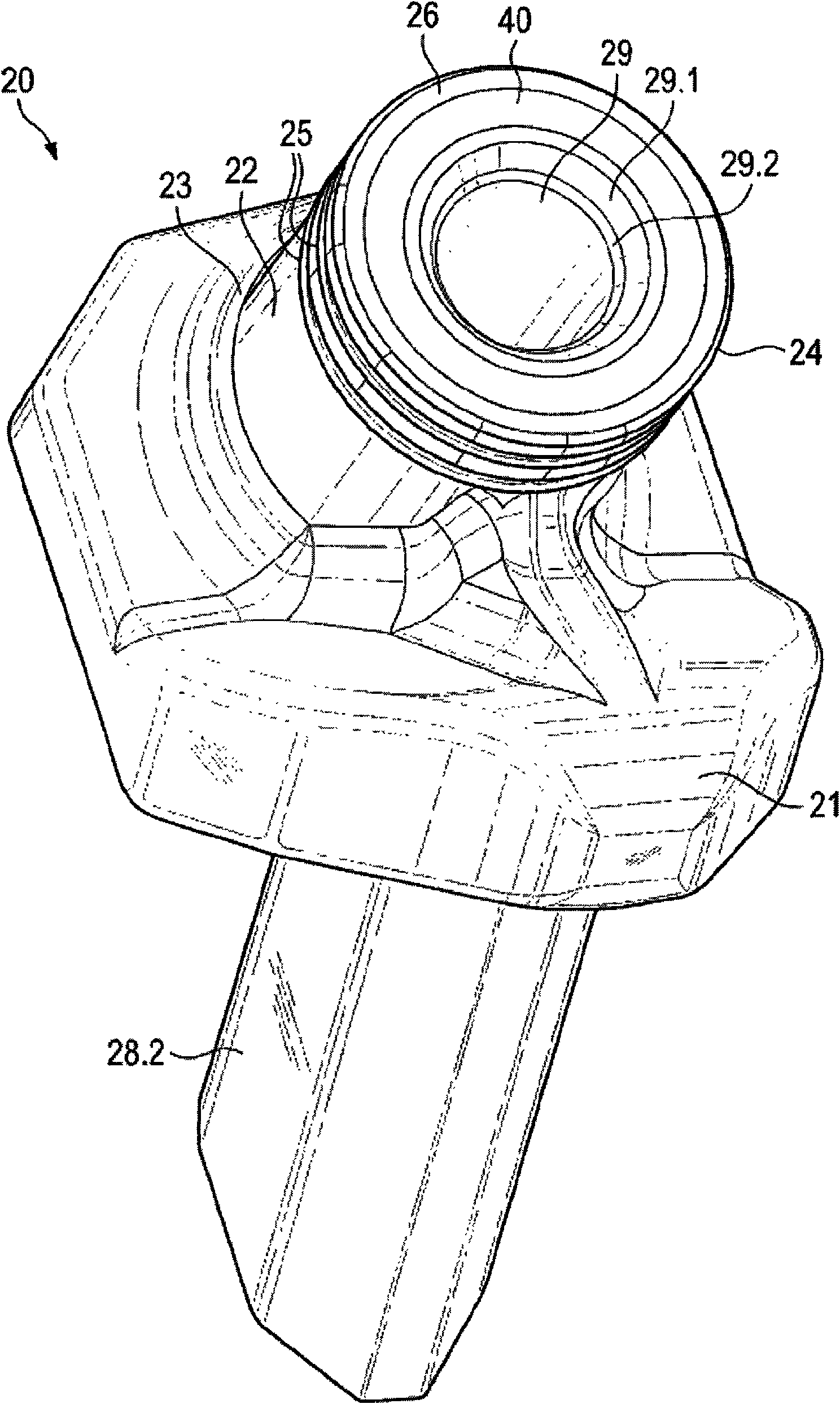

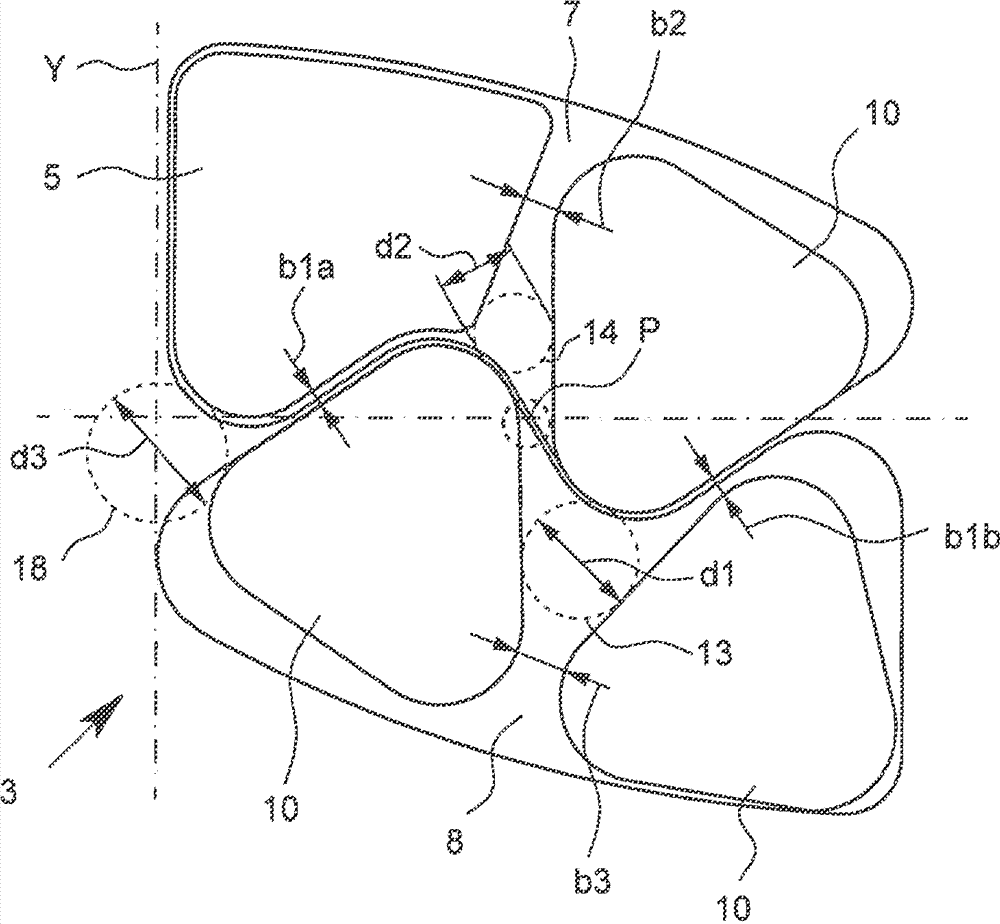

Chisel holder

ActiveCN101666229AConstant wear resistanceReliable arrangementSlitting machinesCutting machinesChiselSupport surface

The invention relates to a chisel holder for a cutting machine, road milling machine, surface miner, or the like, having a chisel receptacle, which comprises an insertion opening, and having a chiselsupporting surface, wherein at least one wear protection element is arranged in an area associated with the chisel supporting surface. In order to bring about effective wear protection in such a chisel holder at low cost, it is provided that the at least one wear protection element is designed as a weld and is arranged at least in areas in at least one opening.

Owner:WIRTGEN GMBH

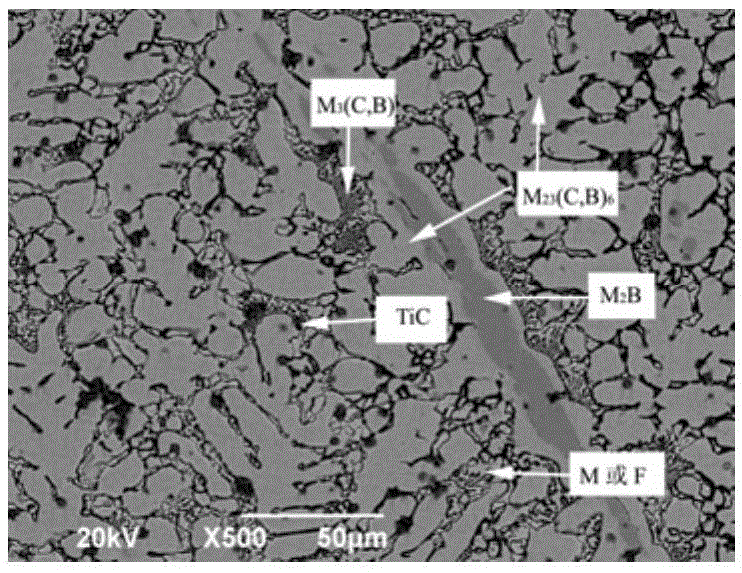

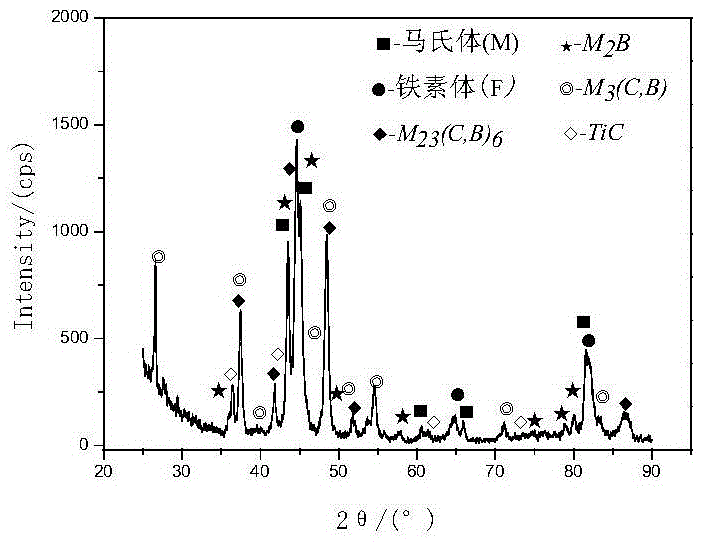

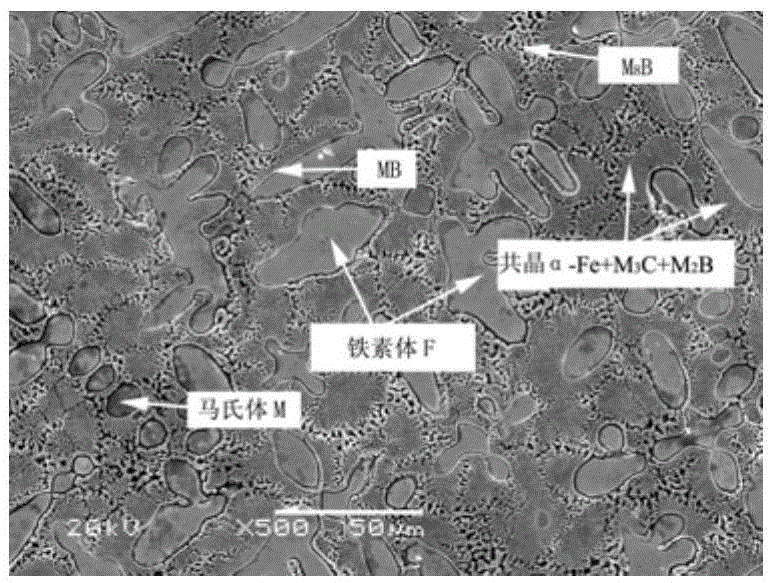

Carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire

InactiveCN105537797ARealize carbon control and tougheningReduce carbon contentWelding/cutting media/materialsSoldering mediaHigh carbonFerrosilicon

The invention discloses a carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire. According to the technical scheme, a low-carbon-steel H08A cold-rolled thin steel strip is adopted as an outer sheath, and an alloy, graphite and other metal powder are mixed in the sheath to form a powder core, wherein the surfacing alloy is alloy powder obtained by adding high-content ferro-boron, high-carbon ferrochrome and ferrotitanium with different melting properties into the flux-cored wire; by virtue of open-arc surfacing current control, a high-boron surfacing melt with the alloy component in an incompletely-molten and unevenly-mixed state is formed, so that an alloy element phase structure is selectively optimized and configured; the powder core mainly consists of the following components: ferro-boron, high-carbon ferrochrome, ferrotitanium, graphite, medium-carbon ferromanganese, ferrosilicon and reduced iron powder. The carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire overcomes the defect that a current high-boron surfacing alloy is great in brittleness due to microstructure characteristics of the high-boron surfacing alloy, can be widely applied to surfacing manufacturing or repairing of parts with abrasive wear resistance, for example, a concrete cement conveying tube, and is especially suitable for surfacing manufacturing or paring of the parts with low-stress abrasive wear resistance.

Owner:XIANGTAN UNIV

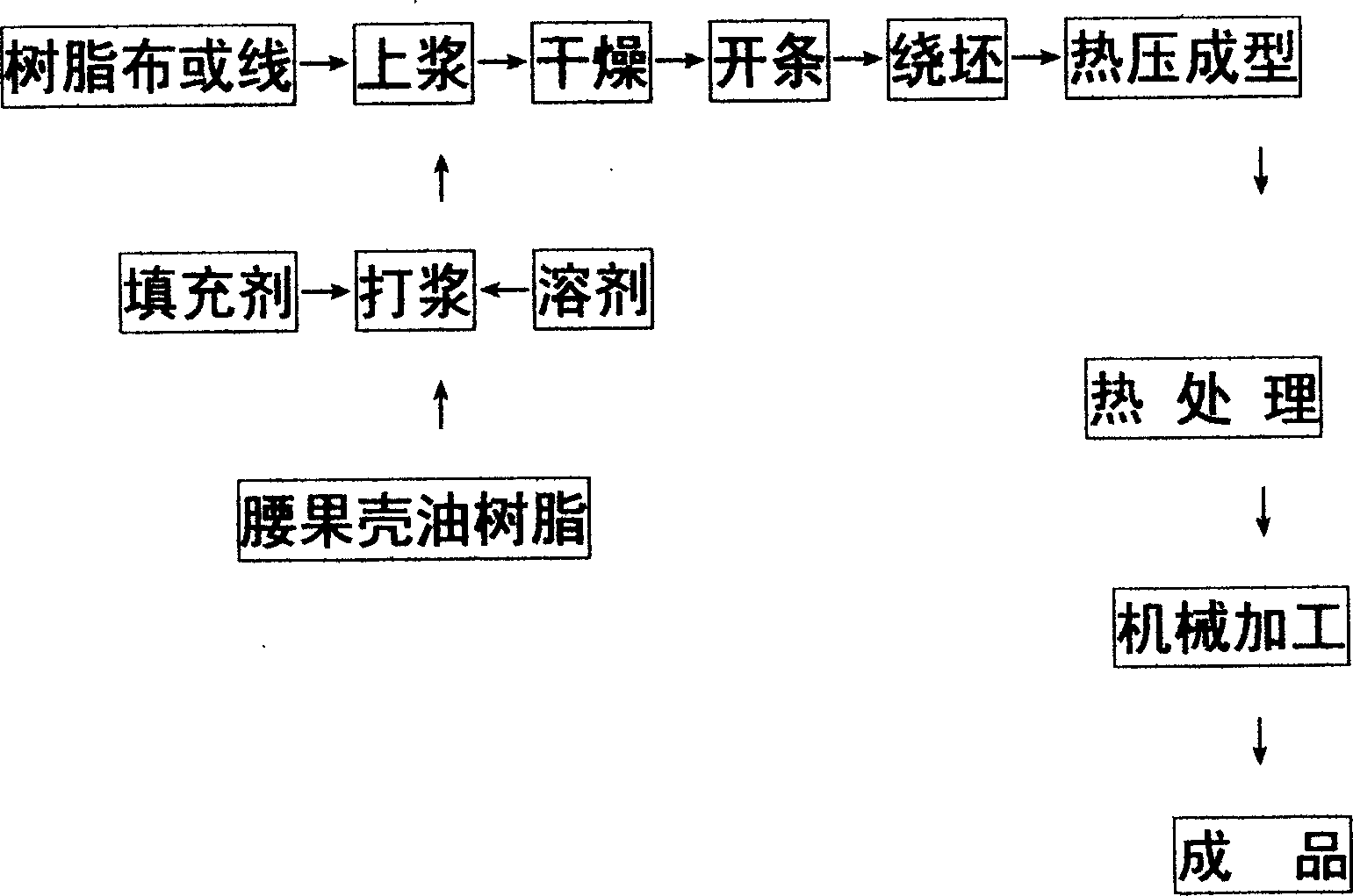

Formula of rubber-free type winding form clutch plate and technique thereof

The invention discloses a formula and its technique of non-rubber wound formed clutch piece as the structure of composite material of cashew oil resin slurry and winding fiber textile, which is characterized by the following: reducing the consumption of petroleum because not synthesizing rubber and solvent petroleum; saving the manufacturing cost of the product greatly; releasing the pressure of petroleum inlet to certain extent; adopting pure cashew oil as raw material without phenol; improving the elasticity, flexibility and mechanic strength; making each property reach the technical demand of GB5764-1998 'automobile clutch piece' national standard regulation and industrial mechanic amianthine friction disk GB11834-2000.

Owner:李刚

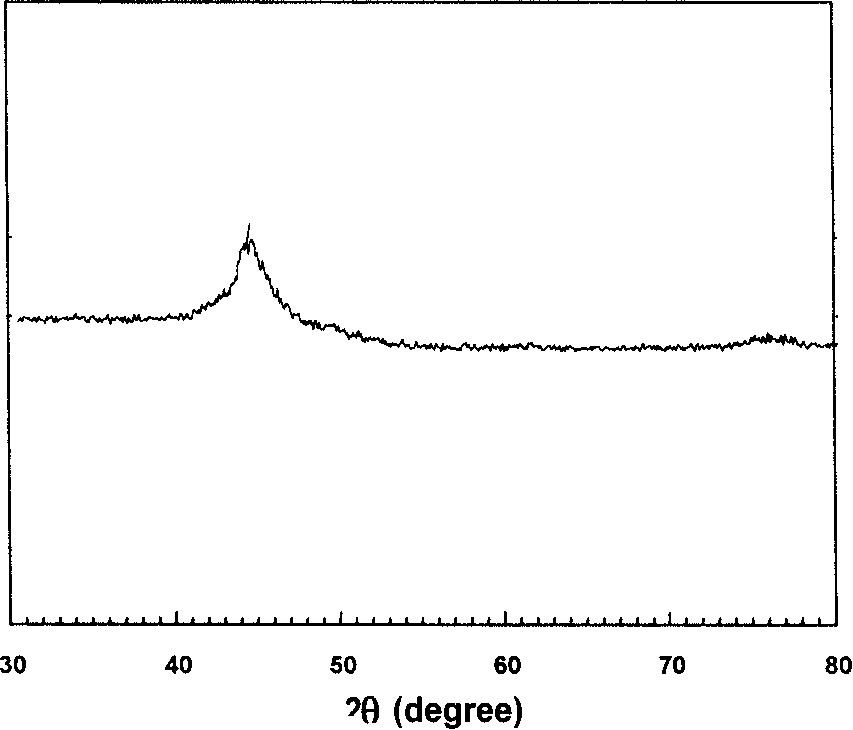

High-hardness material of high-entropy alloy nitride coating and preparation method of the high-hard material

ActiveCN109338300AHigh hardnessGood abrasivenessVacuum evaporation coatingSputtering coatingHigh entropy alloysNitrogen

The invention discloses a high-hardness material of a high-entropy alloy nitride coating and a preparation method of the high-hardness material. The high-hardness material is composed of a Cr transition layer located on the surface of a substrate, a CrN transition layer located on the surface of the Cr transition layer and a nitride coating located on the surface of the CrN transition layer; the nitride coating is obtained by using a radio frequency sputtering method through deposition of nitrogen and a high-entropy alloy, and the thickness of the Cr transition layer is 80-150 nm, the thickness of the CrN transition layer is 50-100 nm, and the thickness of the nitride coating is 1.5-2.5 [mu]m. The obtained high-hardness material of the high-entropy alloy nitride coating not only has a highhardness of more than 50 GPa, but also has good abrasion performance; and the coating has the characteristics of simple production technology, high deposition speed, low costs and the like, has the advantages of high efficiency, low energy consumption and low requirements for a device, and is suitable for being used a hard cutter coating.

Owner:XIAN TECH UNIV

Cobalt catalyst, preparation method and application thereof

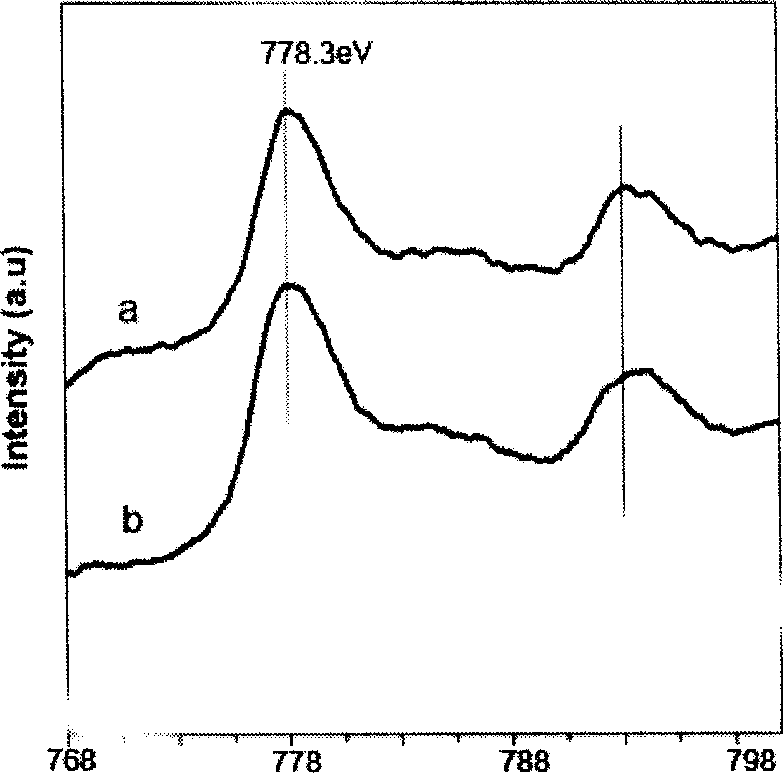

ActiveCN101164692AEasy to separateGood abrasivenessHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsChemical elementNanocrystal

The present invention relates to a cobalt catalyst. It is characterized by that said catalyst is formed from 30-95wt% of cobalt, 0.5-30wt% of aluminium and 0-40wt% of at least one transition metal M selected from subgroups of IB, IIB, IIIB, IVB, VIB, VIIB and VIIIB of periodic table of chemical elements. The cobalt is existed by mainly adopting metal state form of amorphous or nano crystal grains. When said catalyst is used for making Fischer-Tropsch synthesis reaction, as compared with skeleton cobalt it passes higher acitivity and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

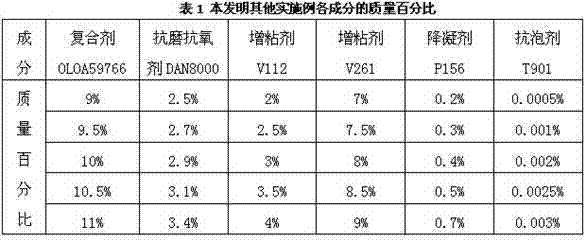

Formula and production process of engine oil

ActiveCN102391905AGood high and low temperature performanceHigh viscosity indexLubricant compositionFoaming agentBase oil

The invention relates to a formula and a production process of engine oil. The engine oil comprises base oil and additives, wherein the base oil comprises mineral base oil and synthetic base oil; the additives comprise complexing agent OLOA59766, anti-wear and anti-oxidation agent DAN8000, viscosity increaser V112, viscosity increaser V261, pour point reducer P156 and anti-foaming agent T901; and the base oil and the additives are mixed in a certain ratio. The engine oil is a product with ultra-long oil change period and low oil consumption, has good abrasion performance and high bearing capacity, has repair function on the abraded surface, has no pollution to the environment, improves energy conservation and prolongs the service life.

Owner:浙江丹弗中绿科技股份有限公司

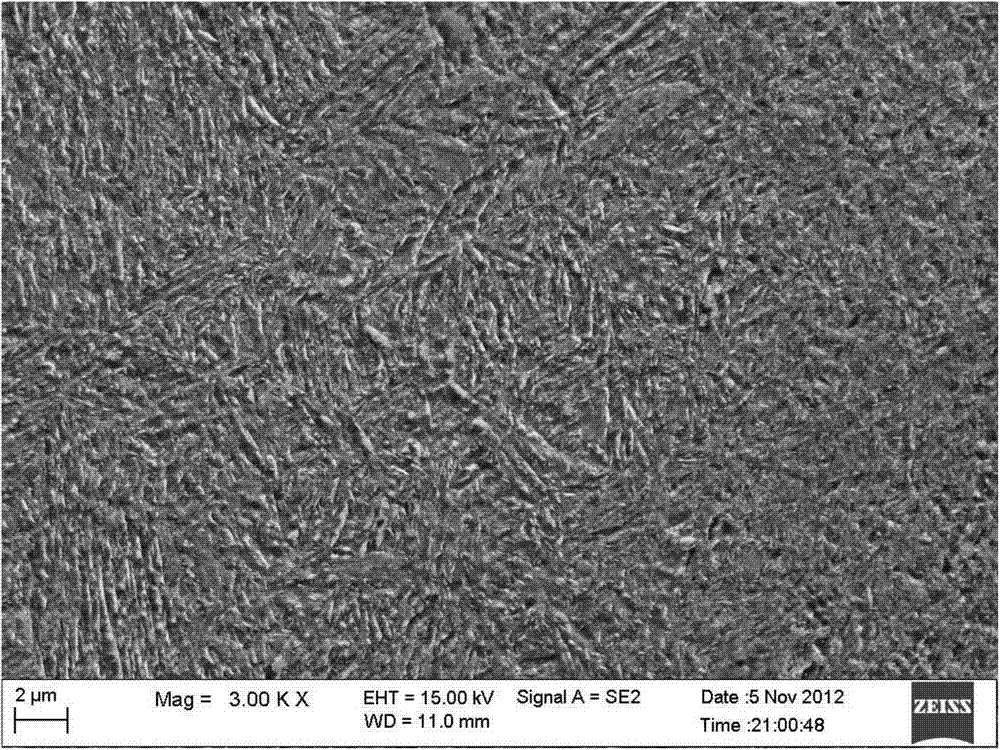

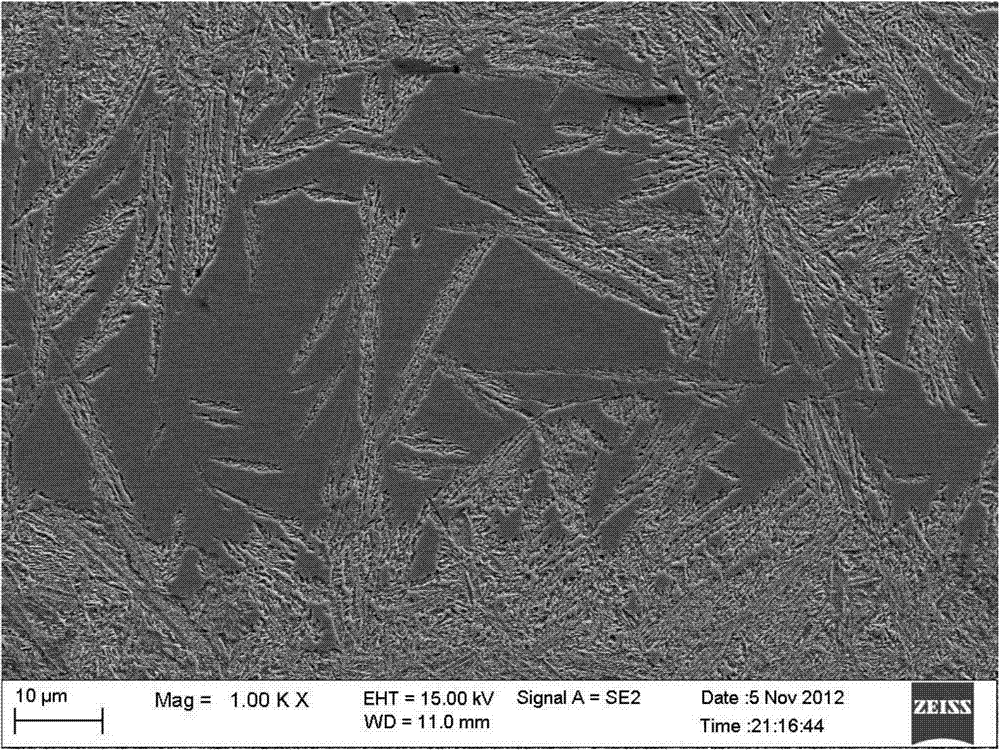

High-hardenability big-diameter 65MnCr grinding ball and preparation method thereof

The invention provides a high-hardenability big-diameter 65MnCr grinding ball and a preparation method thereof, which belong to the field of wear-resistant materials. The grinding ball consists of the following components in percentage by weight: 0.55-0.75% of C, 0.1-0.5% of Si, 1.0-3.0% of Mn, 0.5-1.5% of Cr, 0.01-0.1% of Al, less than or equal to 0.1% of P, less than or equal to 0.01% of S, less than or equal to 0.01% of N and the balance of unavoidable impurities. The preparation technology comprises the following steps: heating a steel billet at temperature of 1050-1100 DEG C, preserving heat for 1 hour, soaking, milling the steel billet on a two-roll mill, placing the steel billet in water with temperature of 900-950 DEG C, quenching for 2.5-3 minutes in water, at grinding ball re-reddening temperature of 120-150 DEG C, then preserving heat for 6 hours in a furnace at temperature of 320-400 DEG C, and taking the steel billet out and cooling in heap. After tempering, internal stress is eliminated, impact toughness is enhanced and non-notched impact energy at normal temperature is over 25 J. The production technology is simple and feasible to operate, the produced 65MnCr grinding ball has very good hardenability as well as excellent matching of hardness and toughness, and the production can achieve practical industrial application.

Owner:UNIV OF SCI & TECH BEIJING

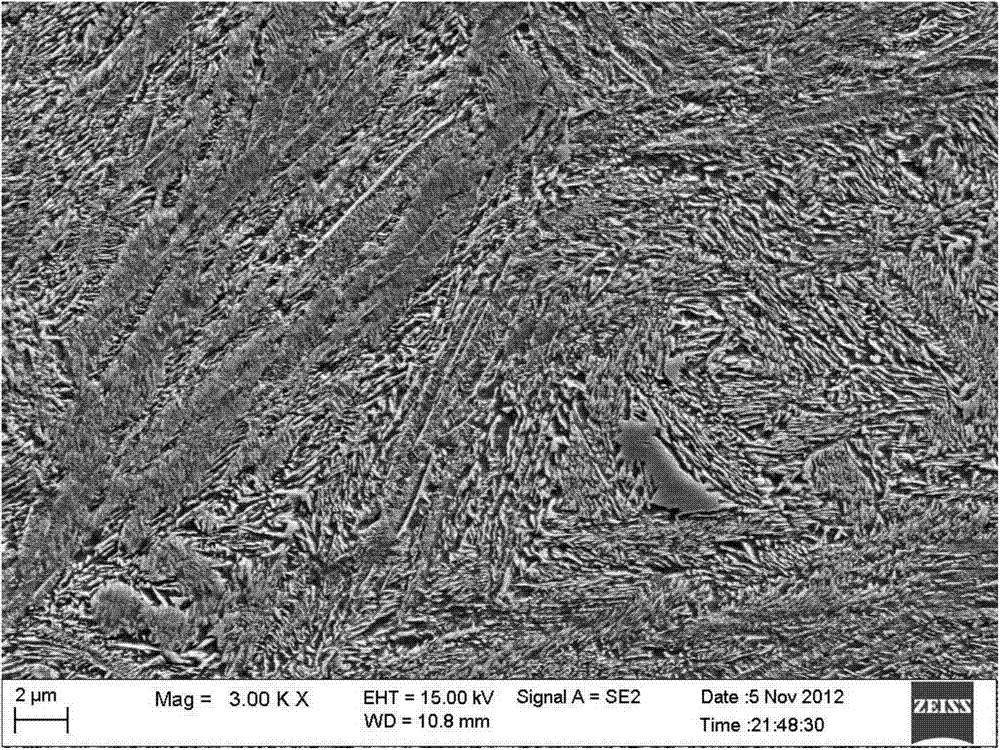

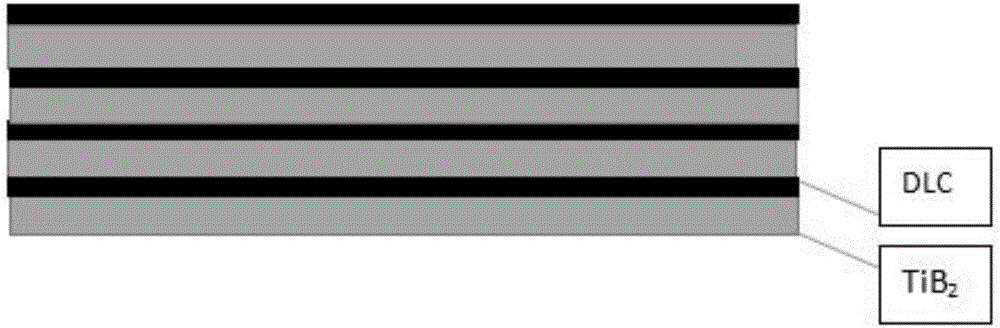

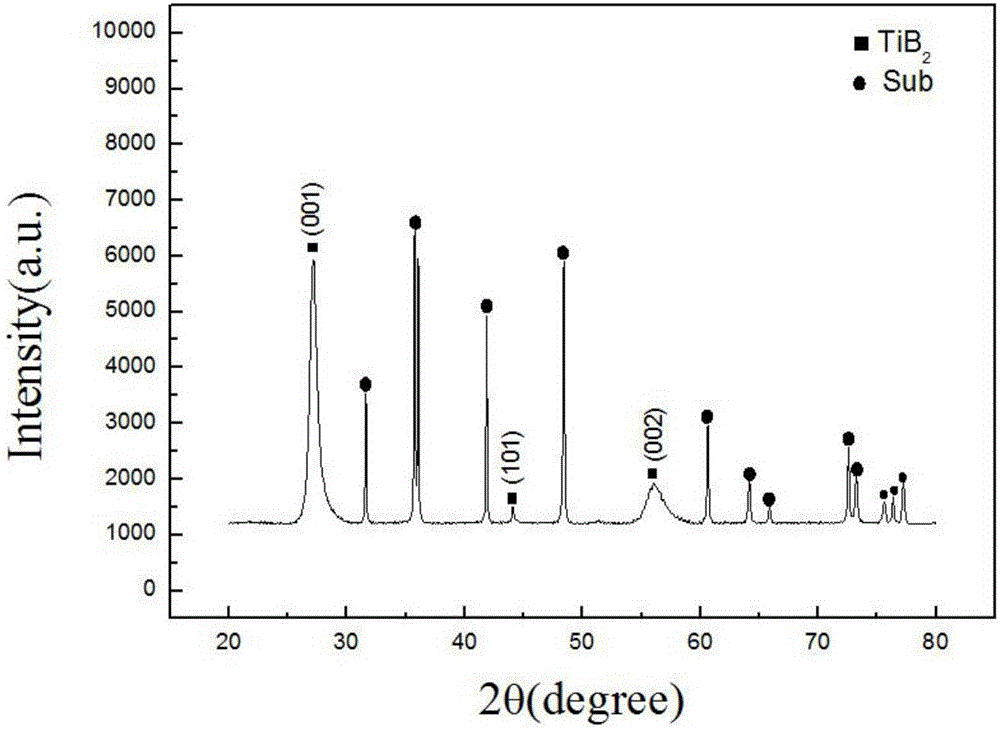

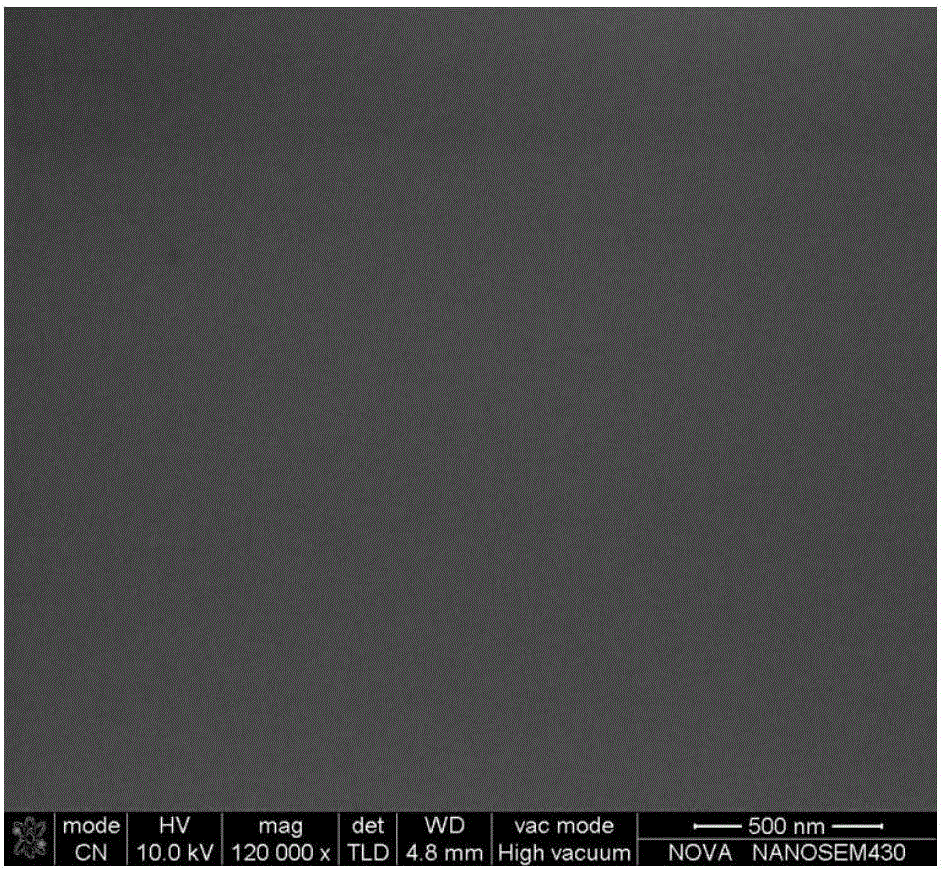

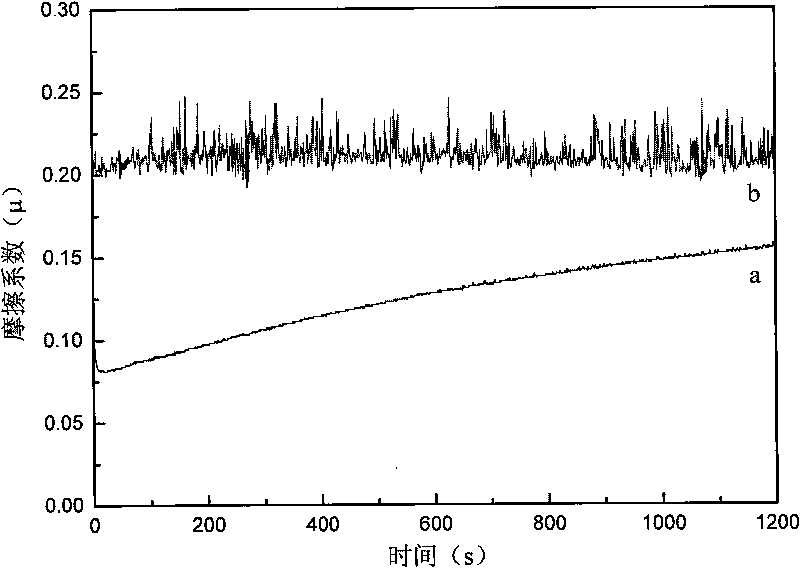

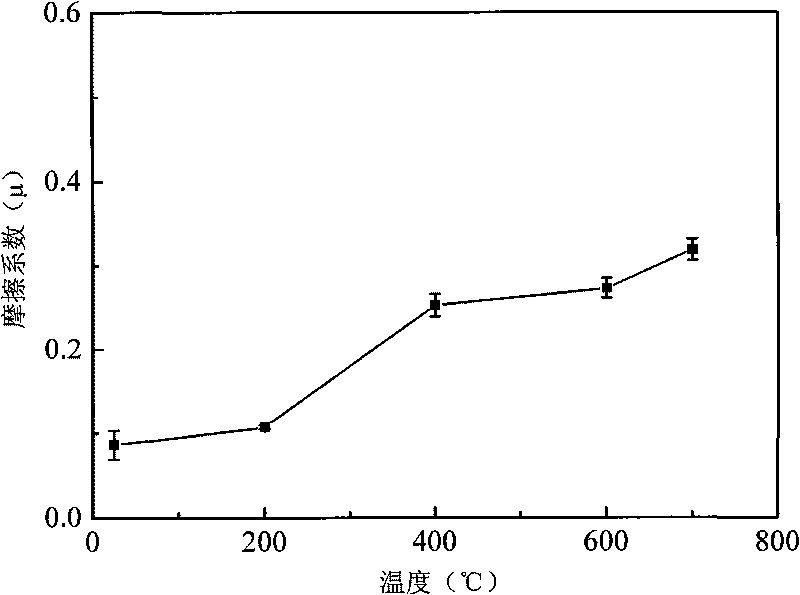

Self-lubricating titanium diboride/diamond-like carbon coating and preparing method and application thereof

ActiveCN106086886AHigh hardnessImprove toughnessSuperimposed coating processDiamond-like carbonMicrometer

The invention discloses a self-lubricating titanium diboride (TiB2) / diamond-like carbon (DLC) hard coating and a preparing method of the coating. According to the TiB2 / DLC hard coating, a bipolar pulse magneto-sputtering deposition technology is adopted to enable a TiB2 ceramic layer and a DLC layer to be periodically overlaid on a base to form the coating; the modulation period of the TiB2 / DLC hard coating ranges from 15 nm to 60 nm, and the total thickness of the coating ranges from 1.2 micrometers to 1.4 micrometers; according to the TiB2 / DLC hard coating, advantages of TiB2 and advantages of DLC are integrated, the coating has the excellent hardness and lubricating characteristics, the good conducting property is achieved, meanwhile, the pulse magneto-sputtering deposition technology is convenient to operate, the process is simple, the preparing period is short, the cost is low, large-scale industrial production is facilitated, and the coating can be widely applied to fields of cutters, molds, microelectronics, protection and the like.

Owner:GUANGDONG UNIV OF TECH

Two-stage grinding-classifying process for preparing alumina pulp

InactiveCN1569339AGood abrasivenessImprove classification efficiencyGrain treatmentsAluminium oxides/hydroxidesEngineeringSolid content

The invention discloses a two-segment mineral grinding-classification process, it grinds the bauxite and lime in the rod mill, the grinded raw mine pulp is poured into a pump pool. The classified bottom flow after classified by water swirler is grinded in ball grinder, adjusts the best liquid and solid rate with proper alkali liquid, the discharged mine pulp is poured into the same pump pool, and adds in alkali liquid to maintain the solid content at 470-520g / L, and carries on classification to the compound mine pulp in the water swirler, the bottom flow enters the ball grinder to be grinded.

Owner:GUIYANG AL-MG DESIGN & RES INST

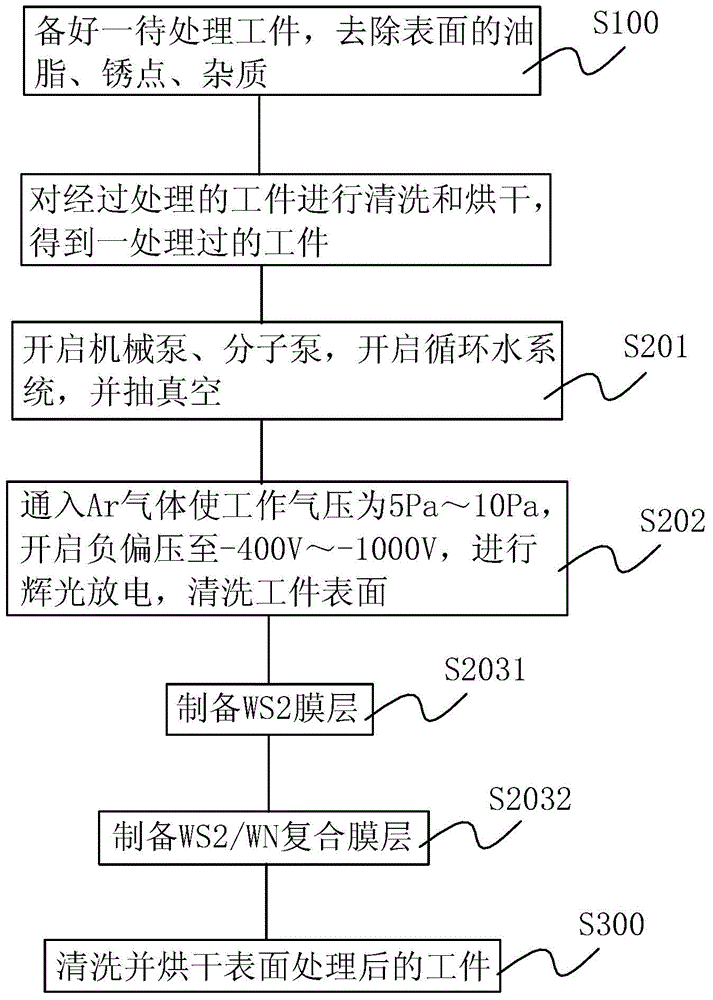

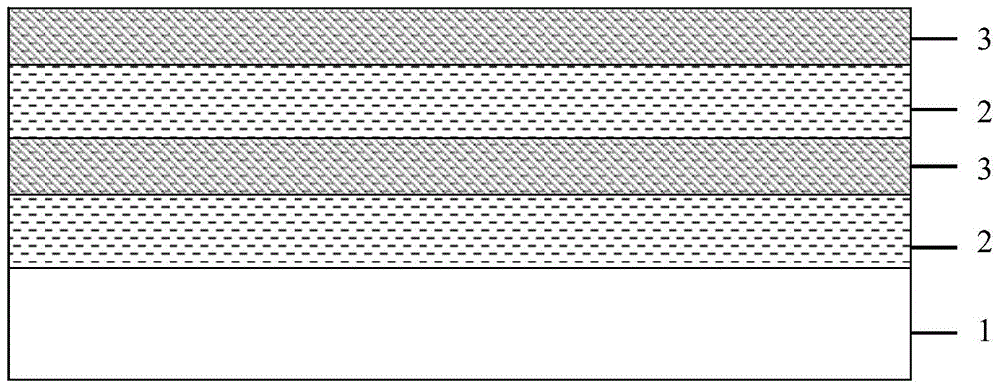

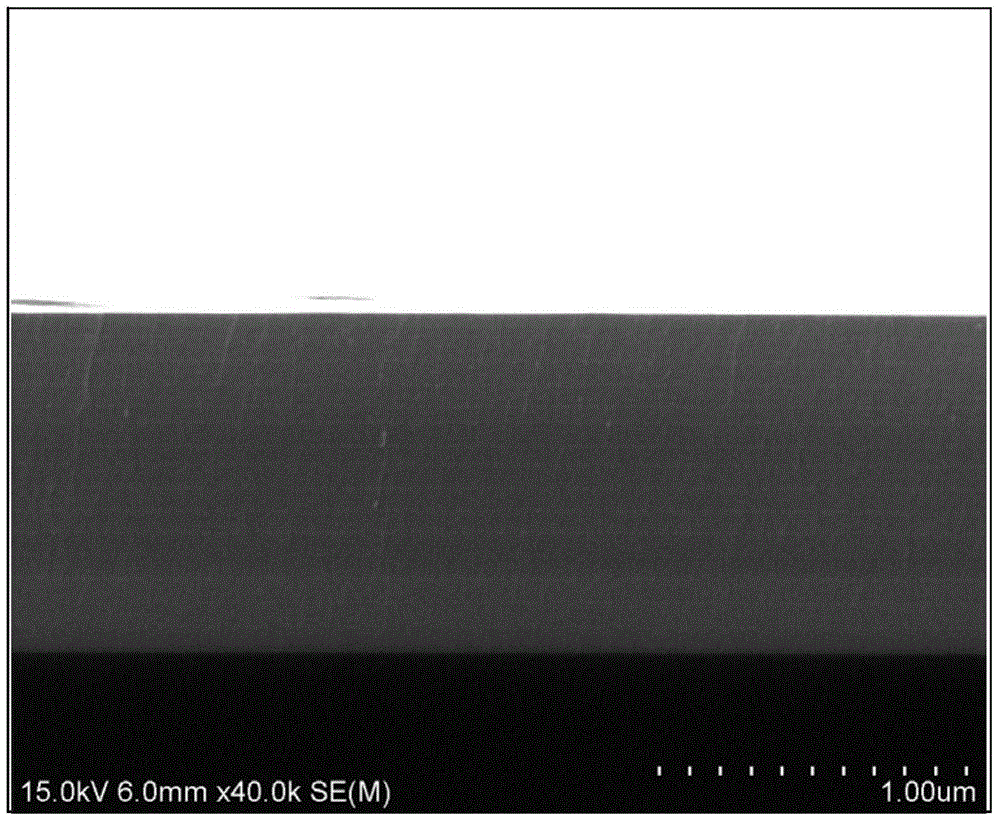

Method for preparing multiphase coupled WS2/WN solid lubrication film

ActiveCN104962860ASimple structureImprove friction and wear performanceVacuum evaporation coatingSputtering coatingVacuum pumpingComposite film

The invention discloses a method for preparing a multiphase coupled WS2 / WN solid lubrication film. The multiphase coupled WS2 / WN solid lubrication film is formed on the surface of a metal material base body in a magnetron sputtering method. The method for preparing the multiphase coupled WS2 / WN solid lubrication film includes the steps that the metal material base body to be processed is preprocessed; the metal material base body is put into a vacuum room, and vacuum pumping is conducted; a low-energy ion source is used for conducting ion bombardment cleaning on the metal material base body; a magnetron sputtering device is used for conducting surface modification on the metal material base body, Ar gas and N2 gas are used as magnetron sputtering and reacting gases, WS2 serves as the target material, a WS2 film layer is deposited on the surface of the metal material base body firstly, then a WS2 / WN film composite film layer is deposited, the operation of depositing a WS2 film layer and the operation of depositing a WS2 / WN composite film layer are cycled in turns, and 1-10 WS2 film layers are deposited and 1-10 WS2 / WN composite film layers are deposited; the metal material base body is put into an acetone solution to be cleaned and then dried, and the dried metal material base body is sealed and stored in a vacuum mode.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

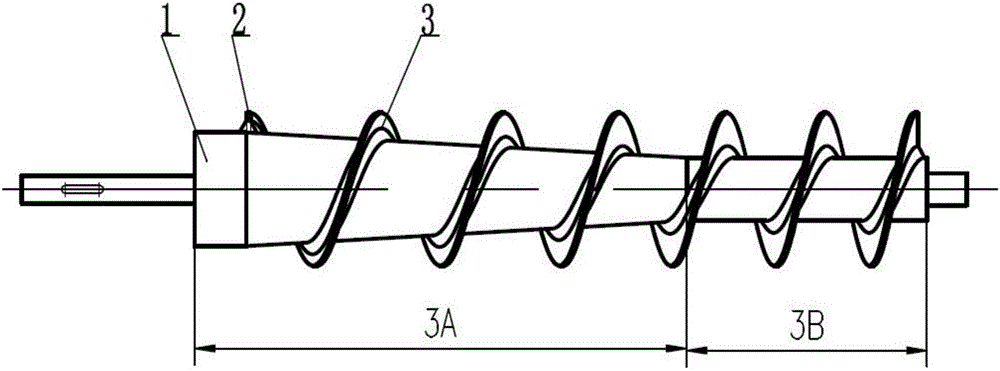

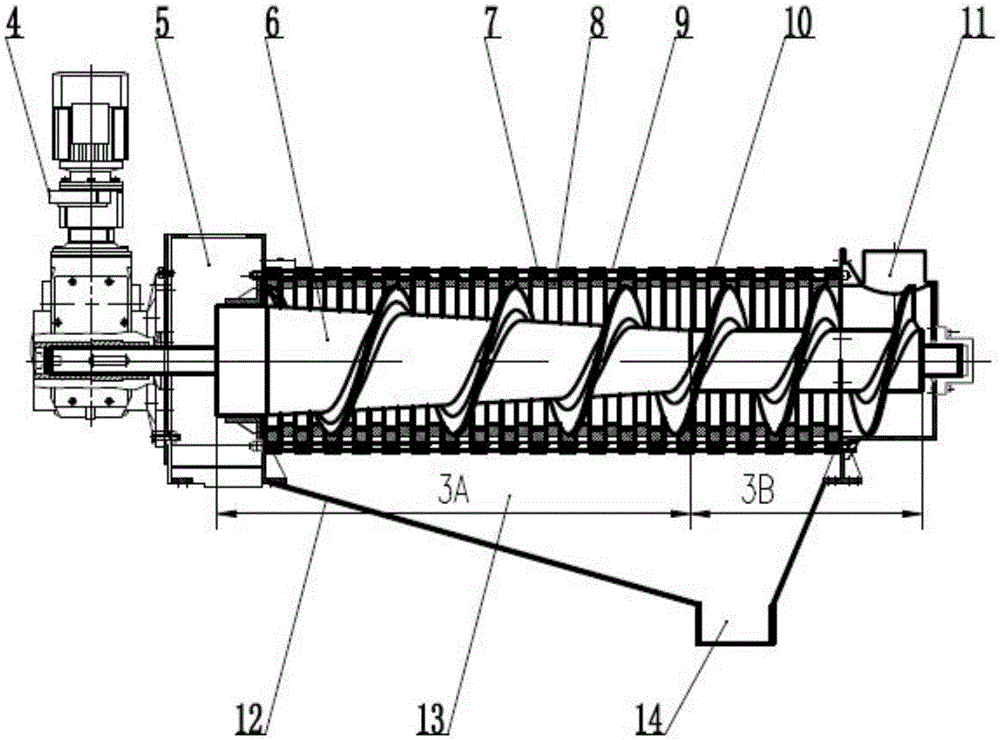

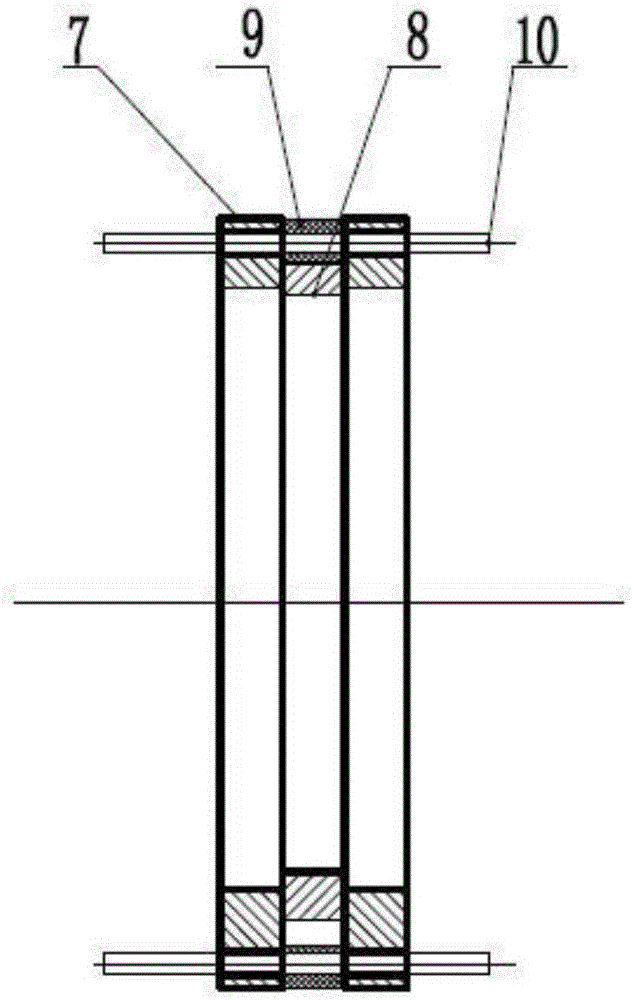

Novel stacked screw sludge dewatering machine and spiral shaft thereof

ActiveCN105712605AHigh strengthGood high temperature fatigue resistanceSludge treatment by de-watering/drying/thickeningSpiral bladeWear resistant

The invention discloses a novel stacked screw sludge dewatering machine and a spiral shaft thereof. The lead angle arrangement order of spiral blades of the novel spiral shaft is that the lead angle gradually becomes smaller from a sludge discharge box to a sludge feed box, and the lead angle is gradually reduced from 16-22 degrees to 6-14 degrees; the screw pitch of a shaft body of the spiral shaft is gradually increased along the direction of the sludge discharge box, and from a 1 / 3 position of the shaft length of the shaft body of the spiral shaft, the diameter of the spiral shaft is gradually increased in a direction from the sludge feed box to the sludge discharge box; and an anti-blocking plate, an included angle between which and the centerline of the shaft body is 20-45 degrees, is arranged on each of two sides of the bottom of the spiral blades, and the height of each anti-blocking plate is not less than 2 / 3 of the height of the spiral blades. The novel spiral sludge dewatering machine disclosed by the invention can be used for treating slurry which is large in proportion, poor in fluidity, high in viscosity and easy in agglomeration, expands the treating capacity and application range of a stacked screw machine, is more reasonable in screw pitch, has a smoother spiral shaft surface, can effectively reduce the frictional resistance when sludge passes through the spiral shaft, and can prevent sludge shaft blockage; and a hard alloy wear-resistant layer is sprayed on the surface of the spiral shaft, so that the service life of the spiral shaft is prolonged.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

Polymer-ceramic composite material

The invention discloses a polymer composite material for manufacturing a roller, which is prepared from the following materials in percentage by weight: 35-45% of nylon 6 (PA6), 20-35% of ceramic powder, 15-25% of glass fiber and 3-8% of composite solid lubricant, wherein the composite solid lubricant is prepared by mixing supramoly, graphite and other solid lubricant according to a weight ratio of 1:1-2. After being mixed according to the ratio, all the materials are mixed and extruded by a screw extruder, are subject to water-cooling pelleting, and are processed by an injection molding machine to be molded into a belt roller. The belt conveyor roller made of the composite material combines performance characteristics of polymer materials and ceramic materials, has the advantages of high strength, abrasion resistance, antistatic performance, flame retardance, corrosion prevention, light weight, low noise for high-speed operation, long service life, low price and the like, and can be widely used in industries or fields of smelting, mining, thermal power generation and the like.

Owner:HUNAN YINGHONG SCI & TECH

Ceramic sliding vane used for rotary vane type compressor and preparation method thereof

The invention provides a ceramic sliding vane used for a rotary vane type compressor and a preparation method thereof. The ceramic sliding vane comprises following components by weight: 90-99.9% of Al2O3 powder, 0.1-10% of Y2O3 powder, 0-1% of SiO2 powder, 0-1% of CeO2 powder, 0-1% of LiO2 powder and 0-1% of MOS2 powder, with the average particle size of the components being not more than 100 nm. The ceramic sliding vane is used for a sealed rotary compressor, and can obtain good wear resistance and reduce wear and friction loss between the ceramic sliding vane and a cooperated air cylinder or a rolling piston of the sealed rotary compressor. The ceramic sliding vane has good heat insulation, and increases the heat exchange efficiency of an air conditioner.

Owner:佛山市高明区生产力促进中心

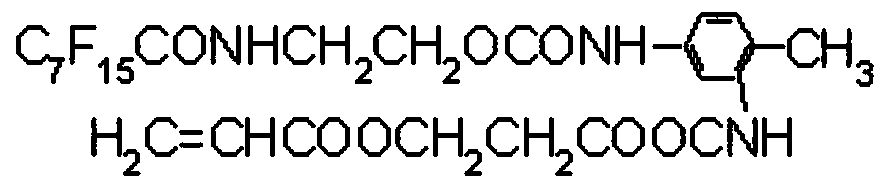

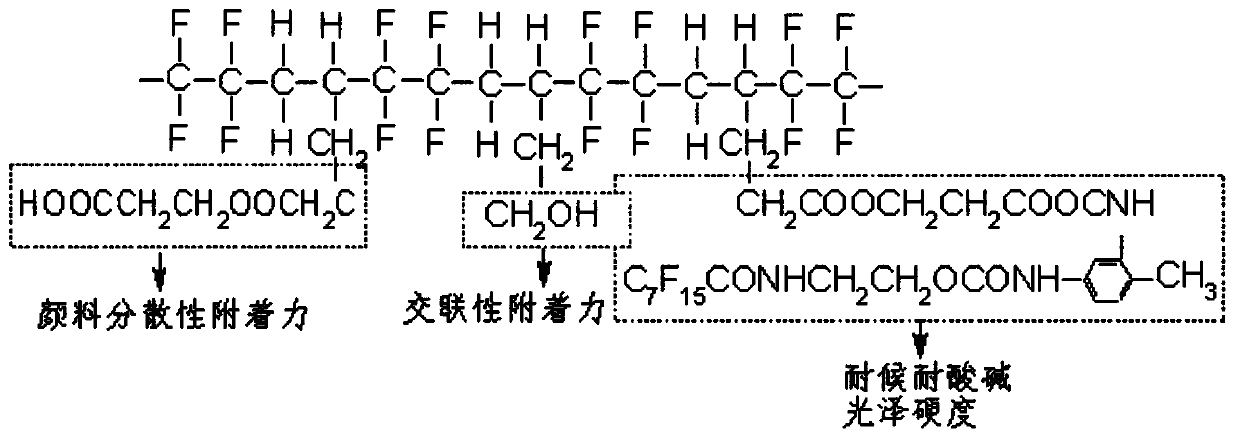

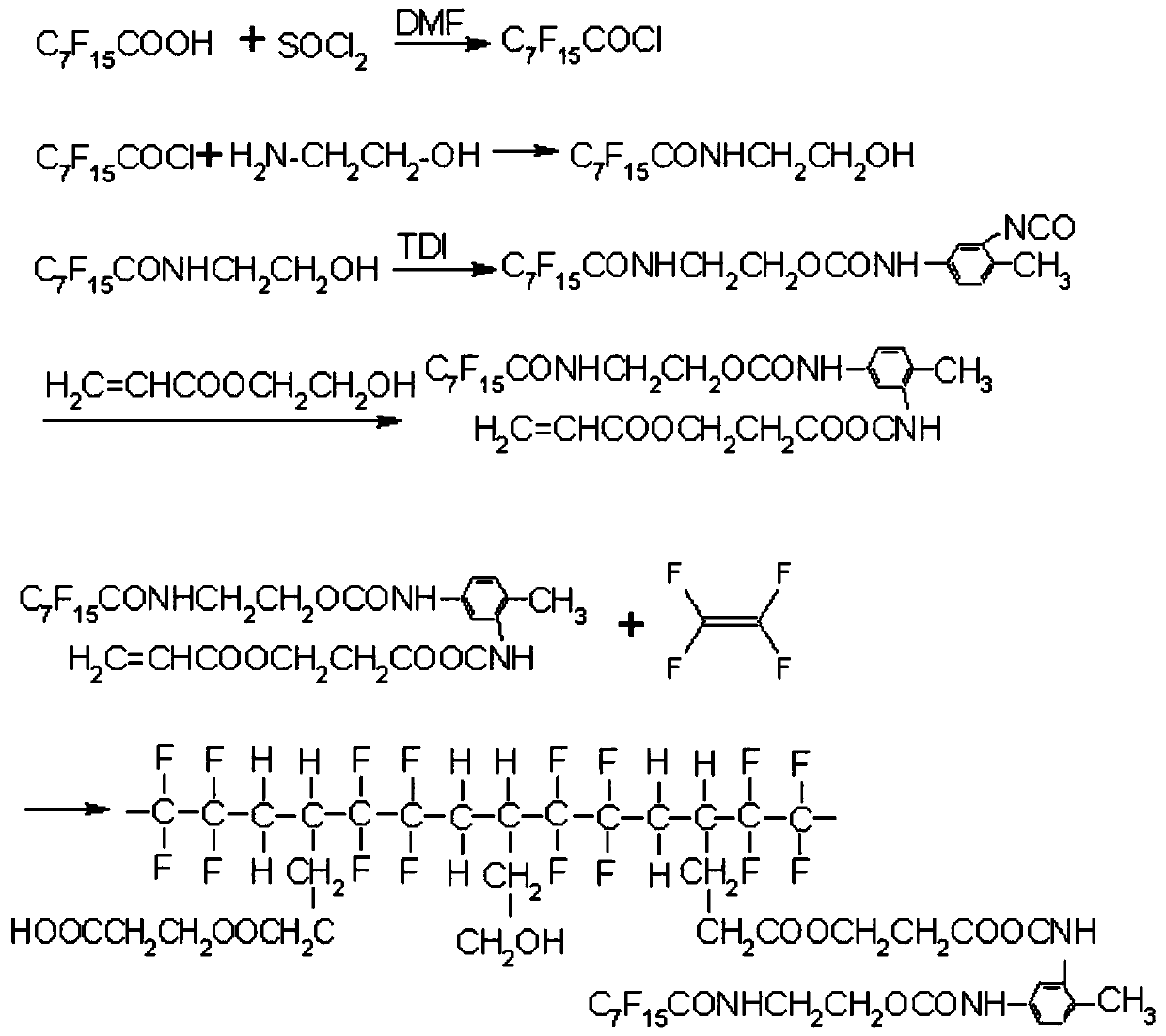

Vinyl modified fluorocarbon resin, preparation method thereof, and corrosion-resistant coating and preparation method and application thereof

InactiveCN111592614AResistant to strong acidDry fastLiquid surface applicatorsAnti-corrosive paintsFluorocarbon ResinsWeather resistance

The invention relates to the technical field of protective coating, in particular to vinyl modified fluorocarbon resin, a preparation method thereof, corrosion-resistant coating, a preparation methodof the corrosion-resistant coating and application of the corrosion-resistant coating. The preparation method of the vinyl modified fluorocarbon resin provided by the invention comprises the followingsteps: mixing a vinyl monomer containing a fluorine group, an initiator and a tetrafluoroethylene gas-phase monomer, and carrying out an addition reaction to obtain the vinyl modified fluorocarbon resin. Vinyl monomer resin containing fluorine groups is grafted with tetrafluoroethylene, so that the prepared vinyl modified fluorocarbon resin has excellent strong acid resistance, strong alkali resistance and excellent weather resistance; and the corrosion-resistant coating prepared by taking the vinyl modified fluorocarbon resin as matrix resin has excellent strong acid resistance, strong alkali resistance and weather resistance.

Owner:CHENGDU HONRE PAINT MAKING CO LTD

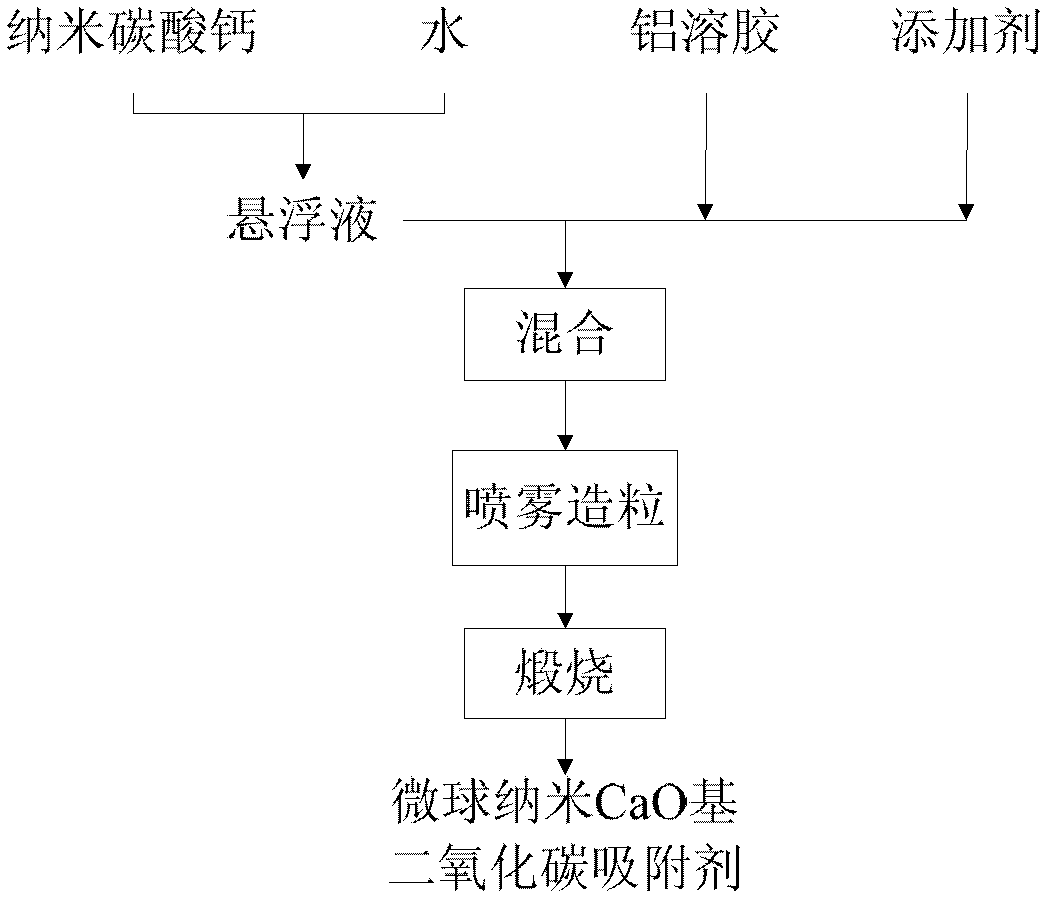

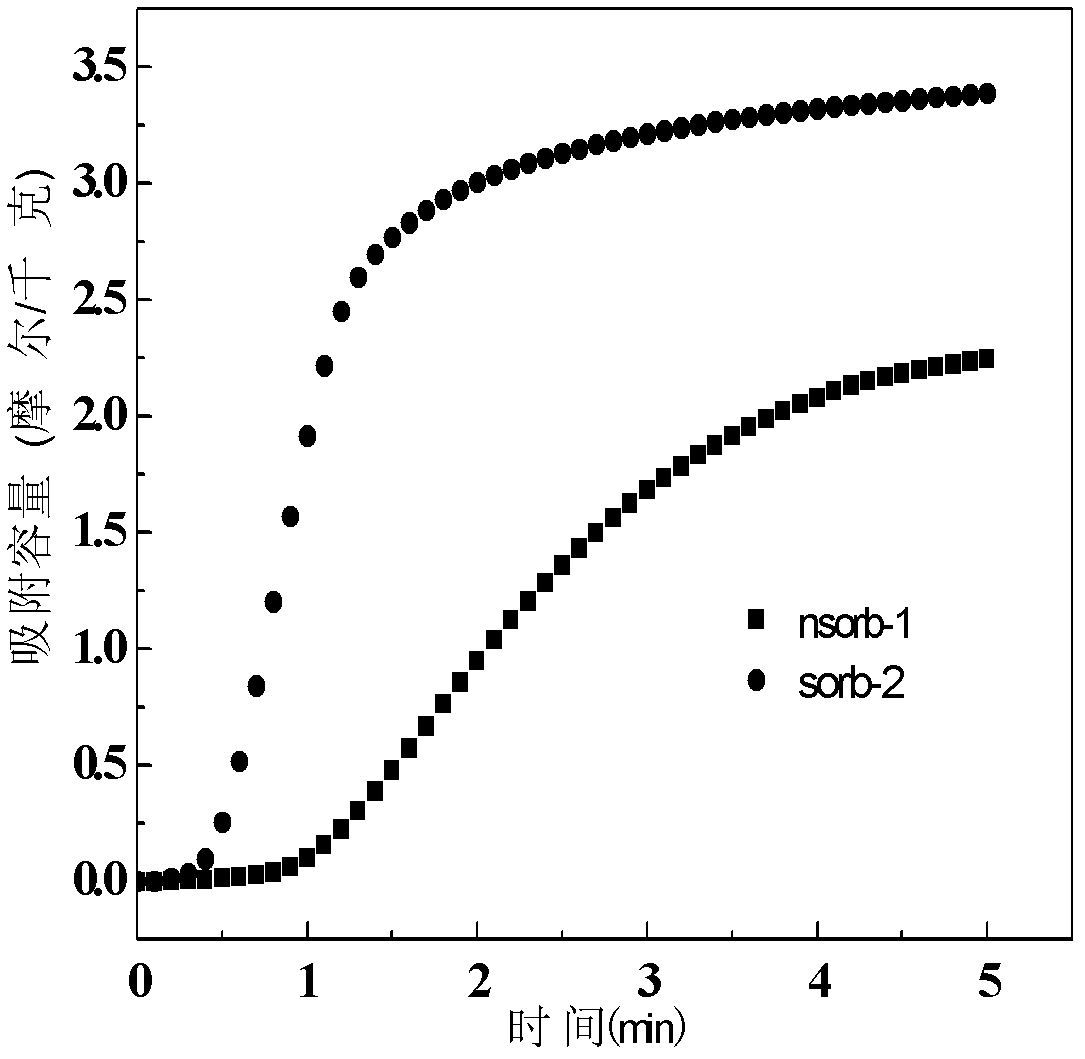

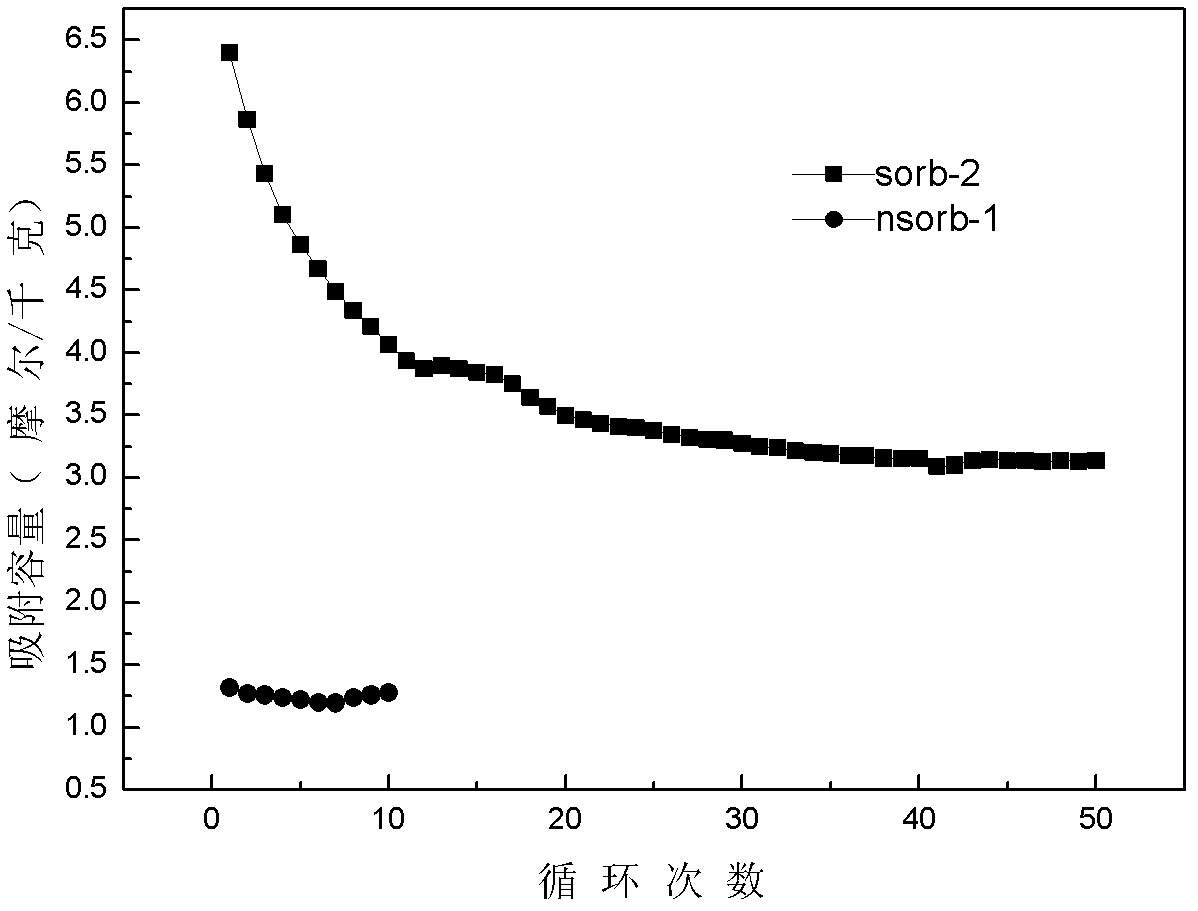

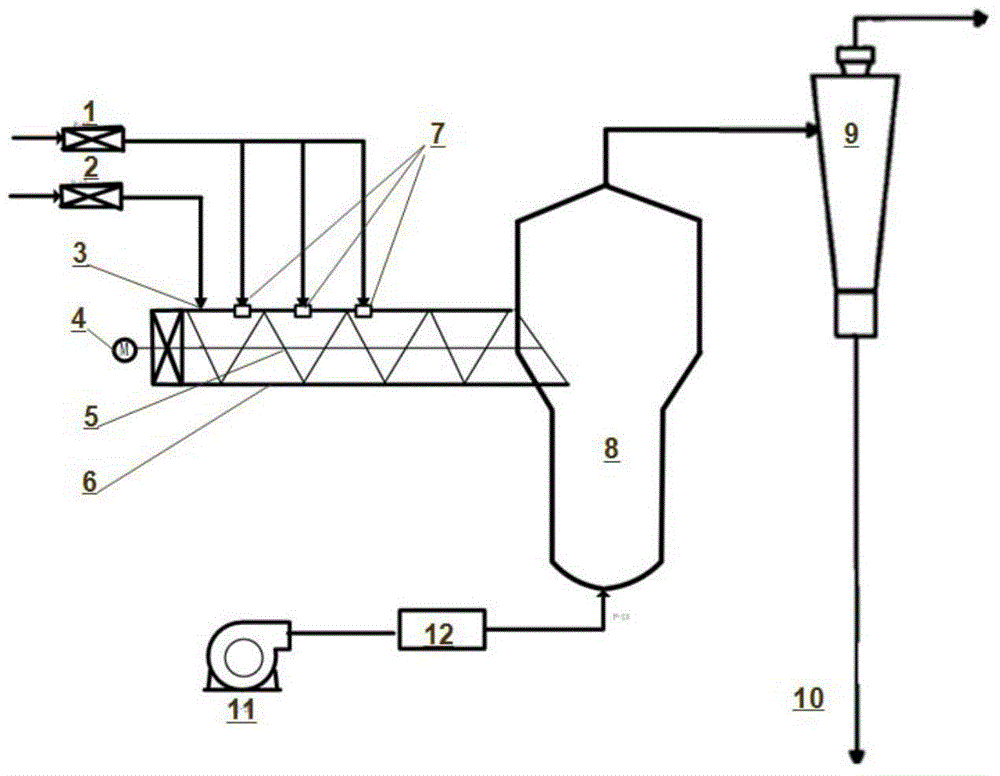

Preparation method for microspherical nano CaO-based CO2 adsorber for circulating fluidized bed, product and application

ActiveCN102671618AGood adsorption performanceEfficient mass transferOther chemical processesDispersed particle separationMicrometerCarbon dioxide

The invention discloses a preparation method for a microspherical nano CaO-based CO2 adsorber for a circulating fluidized bed. The preparation method comprises the following steps: dispersing nano CaCO3 in water to obtain suspension; stirring and mixing the suspension, additives and aluminum sol uniformly; performing spray granulation to obtain microspherical granules with the grain size of 20-200 micrometers; and calcining to obtain the microspherical nano CaO-based CO2 adsorber. The invention also discloses the microspherical nano CaO-based CO2 adsorber prepared by the method, and a method for capturing CO2 by using the microspherical nano CaO-based CO2 adsorber. The method is simple and feasible; the prepared adsorber has high adsorption speed, high adsorption capacity, high adsorption property and high wear resistance, the continuous decarbonization-regeneration circulating process can be realized in a circulating fluidized bed system, the capacity and efficiency of treating CO2 are greatly improved and the cost of removing the CO2 is reduced.

Owner:ZHEJIANG UNIV

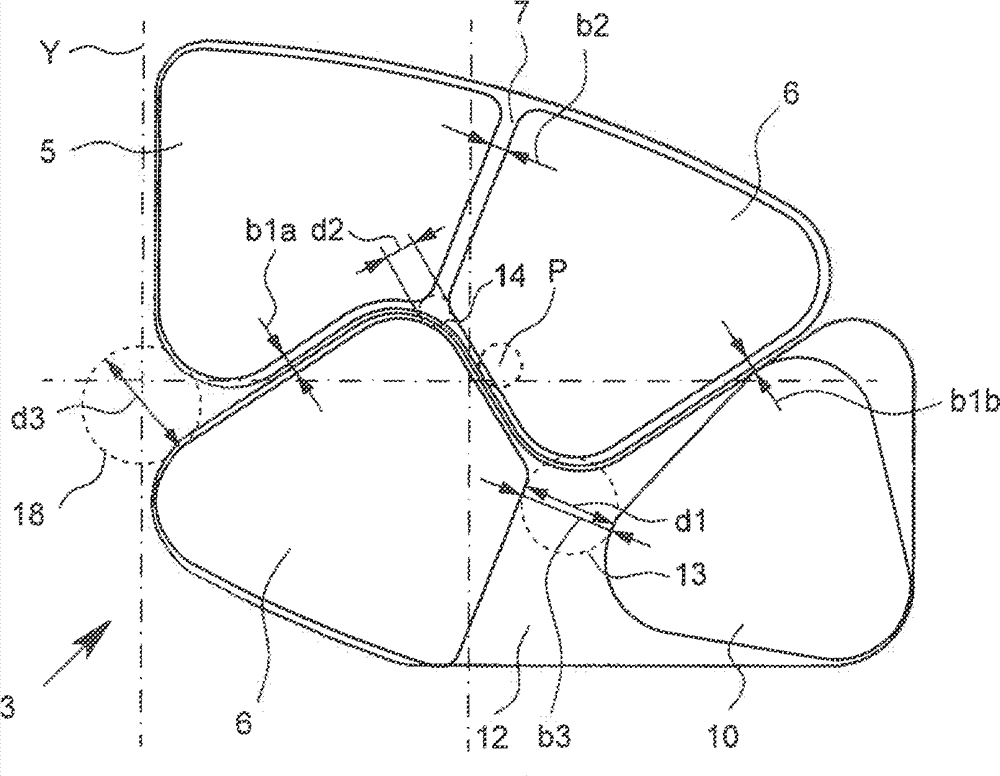

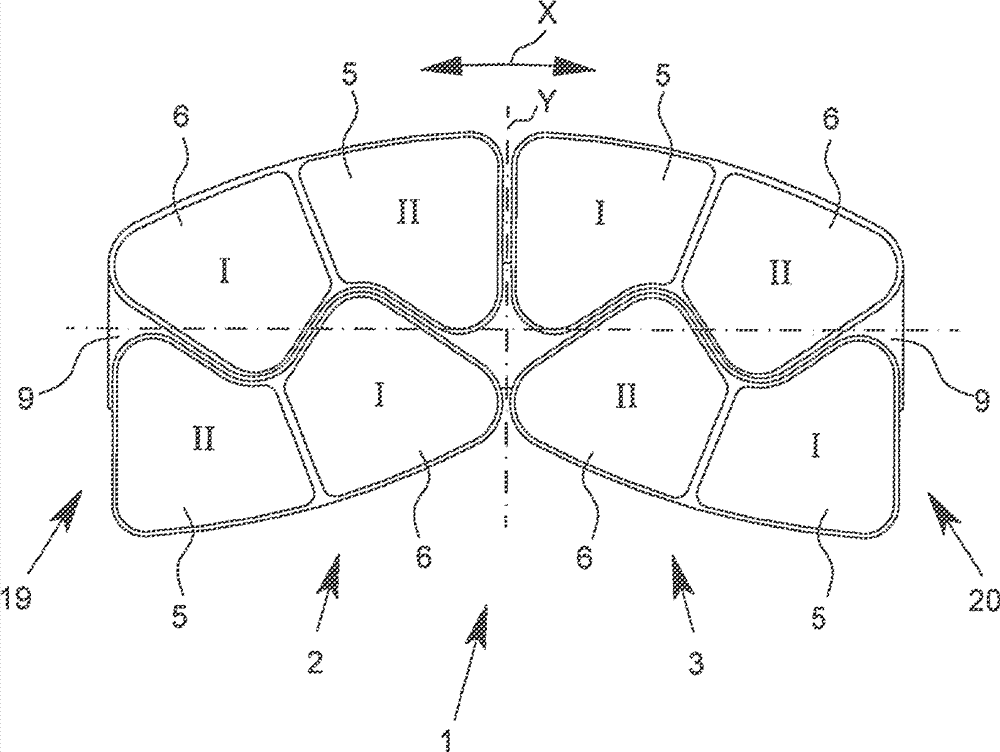

Modular brake lining system and brake lining

InactiveCN104813061AChange braking characteristicsGood abrasivenessBraking elementsFriction liningTransverse axisBrake lining

The invention relates to a modular brake lining system, in particular for a brake disc (4) of a disc brake, moreover in particular for rail vehicles, having mounting plates (7, 8, 12) held on at least one rear part (9) and having a plurality of different friction segments (5, 6, 10, 11), wherein different friction segments (5, 6, 10, 11) have friction surfaces having different geometries and / or different sizes and / or different coefficients of friction and / or of different friction materials and wherein, as required, different friction segments (5, 6, 10, 11) of the brake lining system can be fastened to the mounting plates (7, 8, 10, 11). According to the invention, by changing the arrangement of the friction segments (5, 6, 10, 11) on the brake lining (1) and / or by changing the number of identical or different friction segments (5, 6, 10, 11), the maximum clearance diameter (d1, d2) of a clearance circle (13, 14) positioned beyond the central transverse axis (Y) of the brake lining (1) tangentially to at least two, preferably at least three, adjacent friction segments (5, 6, 10, 11) is adjustable to a value between 5 and 40 mm.

Owner:BECORIT

Oxide ceramic/alkali-earth metal sulphate/silver composite material and preparation method thereof

InactiveCN101701310AImprove the lubrication effectBest friction and wear resistanceWide areaOxide ceramic

An oxide ceramic / alkali-earth metal sulphate / silver composite material and a preparation method thereof relate to the preparation method of an oxide ceramic base composite material. The invention solves the problem that the existing oxide ceramic material has bad frictional wear performance in the wide area temperature of the room temperature to 760 DEG C and the existing preparation technology has the high sintering temperature. The oxide ceramic / alkali-earth metal sulphate / silver composite material comprises an oxide ceramic phase, an alkali-earth metal sulphate and a silver phase. The method is as follows: boll milling, wet mixing, drying and sieving; after being sieved, fine powder body is placed into a graphite die and processed in cold pressing way; and then electro-discharge is carried out on plasma sintering, thus obtaining the oxide ceramic / alkali-earth metal sulphate / silver composite material. The friction coefficients of the oxide ceramic / alkali-earth metal sulphate / silver composite material in the room temperature and 760 DEG C high temperature are respectively 0.05-0.2 and 0.18-0.25; the wear rate is lower than 10-6mm3 / N.m order of magnitude; and the method has simple technique and low sintering temperature.

Owner:HARBIN INST OF TECH

Porcelainized aluminum wear-resistant brick and preparation method thereof

InactiveCN107840638AHigh mechanical strengthImprove wear resistanceCeramic materials productionClaywaresBrickPhosphate

The invention belongs to the technical field of refractory matters, and particularly relates to a porcelainized aluminum wear-resistant brick and a preparation method thereof, which mainly solve the technical problem that an existing refractory matter is poor in wear-resisting property. The invention has the technical scheme that the porcelainized aluminum wear-resistant brick is prepared from a mixed batch and a binding agent, wherein the mixed batch is prepared from the following raw materials in percentage by weight: 50 to 70 percent of aluminum oxide porcelainized aluminum particle, 10 to20 percent of silicon carbide particle, 10 to 30 percent of bauxite clinker, and 3 to 11 percent of Suzhou clay; the binding agent is a mixture of solid aluminum dihydrogen phosphate and lignosulfite;the additive amount of the binding agent is 3 to 8 percent of the total weight of the mixed batch. The preparation method of the porcelainized aluminum wear-resistant brick comprises the following steps of (1) preparing an aluminum oxide porcelainized aluminum raw material; (2) preparing the binding agent; (3) mixing and milling the raw material; (4) forming to make a blank; (5) drying; (6) firing; (7) cooling to obtain a finished product. The porcelainized aluminum wear-resistant brick provided by the invention has the advantages of high wear resistance, long service life, capability of low-temperature firing, and the like.

Owner:吕梁耀金道冶金材料工程技术有限公司

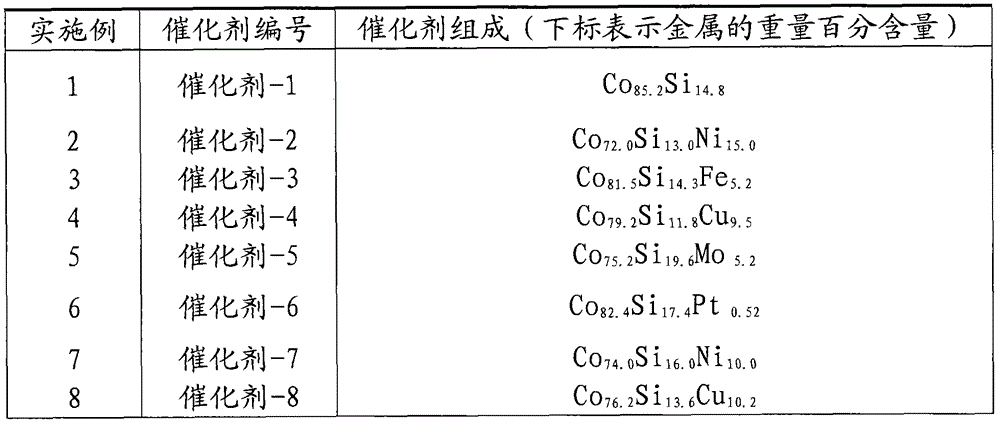

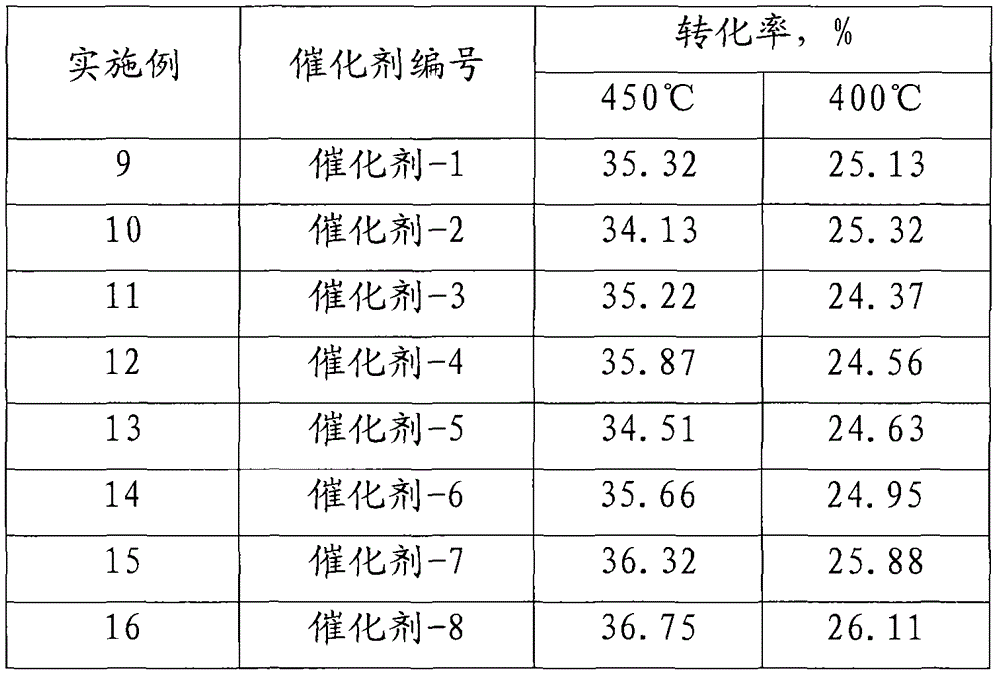

Cobalt catalyst and preparation method and application thereof

ActiveCN103055866AGood abrasivenessMetal/metal-oxides/metal-hydroxide catalystsHalogenated silanesHydrogenation reactionAlloy

The invention provides a cobalt catalyst. The cobalt catalyst contains 20-95wt% of cobalt and 0.5-70wt% of silicon. A preparation method of the catalyst is characterized by heating cobalt, silicon and a transition metal M until the metals are molten, quickly curing the melt at a cooling rate more than 1000 DEG C / S and carrying out extraction treatment on the alloy obtained after curing with an alkali-acid solution to extract part of silicon, thus obtaining the catalyst. The catalyst has higher activity and selectivity than conventional catalysts and has good stability when used in the silicon tetrachloride hydrogenation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Continuous steeping method for grain carrier and equipment thereof

ActiveCN102019208BImprove impregnation efficiencyGuaranteed uptimeOther chemical processesCatalyst activation/preparationMetallurgySorbent

The invention relates to a continuous steeping method for a grain carrier and equipment thereof. The continuous steeping method comprises the following steps that steeping liquor is atomized into drops through a nozzle and is jetted into an atomizer; carrier grains are led into the atomizer; the steeping liquor drops and the carrier grains are mixed in the atomizer to form a mixture; the mixture enters into a steeping mixer to carry out sufficient contact; the average grain diameters of the carrier grains are 40-90 microns; the average grain diameters of the steeping liquor drops are 0.5-1.0 time the average grain diameters of the carrier grains; and the ratio of the volume flow of the steeping liquor to the mass flow of the carrier is 0.30-0.60L / kg. The continuous steeping equipment comprises the atomizer and the steeping mixer which is connected with the outlet of the atomizer. The method can implement the continuous steeping process of the grain carrier and can make active component evenly distributed in the carrier, thereby ensuring the strength of an adsorbent finished product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Particle carrier impregnation method

ActiveCN104549557AGuaranteed carrier particle size distribution and strengthGood wear performanceOther chemical processesCatalyst activation/preparationContact timeActive component

The invention discloses a particle carrier impregnation method. The method comprises steps as follows: (1) contacting impregnation liquid droplets with a particle carrier, wherein the contact time is shorter than 5 s; (2) drying the impregnated particle carrier. According to the method, an impregnation liquid is fully contacted with the particle carrier for a short time (shorter than 5 s) before drying, so that uniform distribution of active components during impregnation can be guaranteed, the particle size distribution and the strength of the impregnated carrier are also guaranteed, and a prepared adsorbent product has the good wear resistance in the reaction process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aqueous thick slurry type aliphatic polyurethane floor coating material and preparation method thereof

The invention relates to an aqueous thick slurry type aliphatic polyurethane floor coating material and a preparation method thereof, wherein the aqueous thick slurry type aliphatic polyurethane floorcoating material comprises, by weight, 40-48% of a first aqueous polyurethane emulsion, 20-28% of a second aqueous polyurethane emulsion, 3-5% of a pigment, 2-8% of titanium dioxide, 2-15% of precipitated barium sulfate, 1-2% of a hardening wear-resistant aid, 0.3-0.5% of an aqueous dispersant, 0.1-0.2% of an aqueous defoamer, 0.2-0.5% of an aqueous leveling agent, 0.2-0.4% of a surfactant, 0.5-1% of an aqueous polyamide wax slurry, 3.5-6.7% of deionized water, 2-3% of a film forming aid, 2-5 of a cosolvent, and 0.3-0.8% of an amine neutralizing agent. The aqueous thick slurry type aliphaticpolyurethane floor coating material of the present invention has characteristics of fast drying, no foaming during thick coating, good leveling property, high hardness, good wear resistance, good water resistance, good chemical resistance, good weather resistance, low VOCs and the like.

Owner:CHENGDU HONRE PAINT MAKING CO LTD

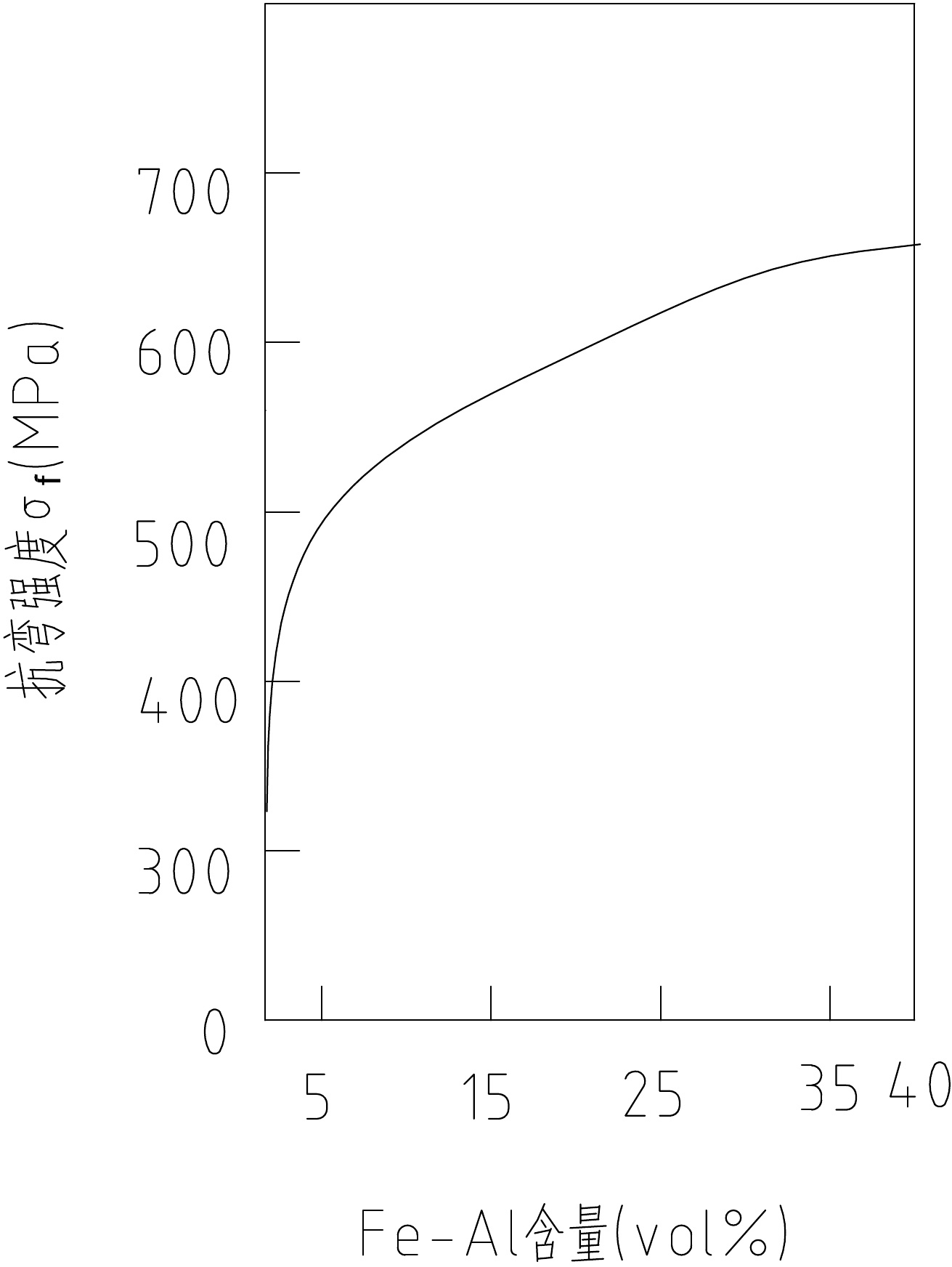

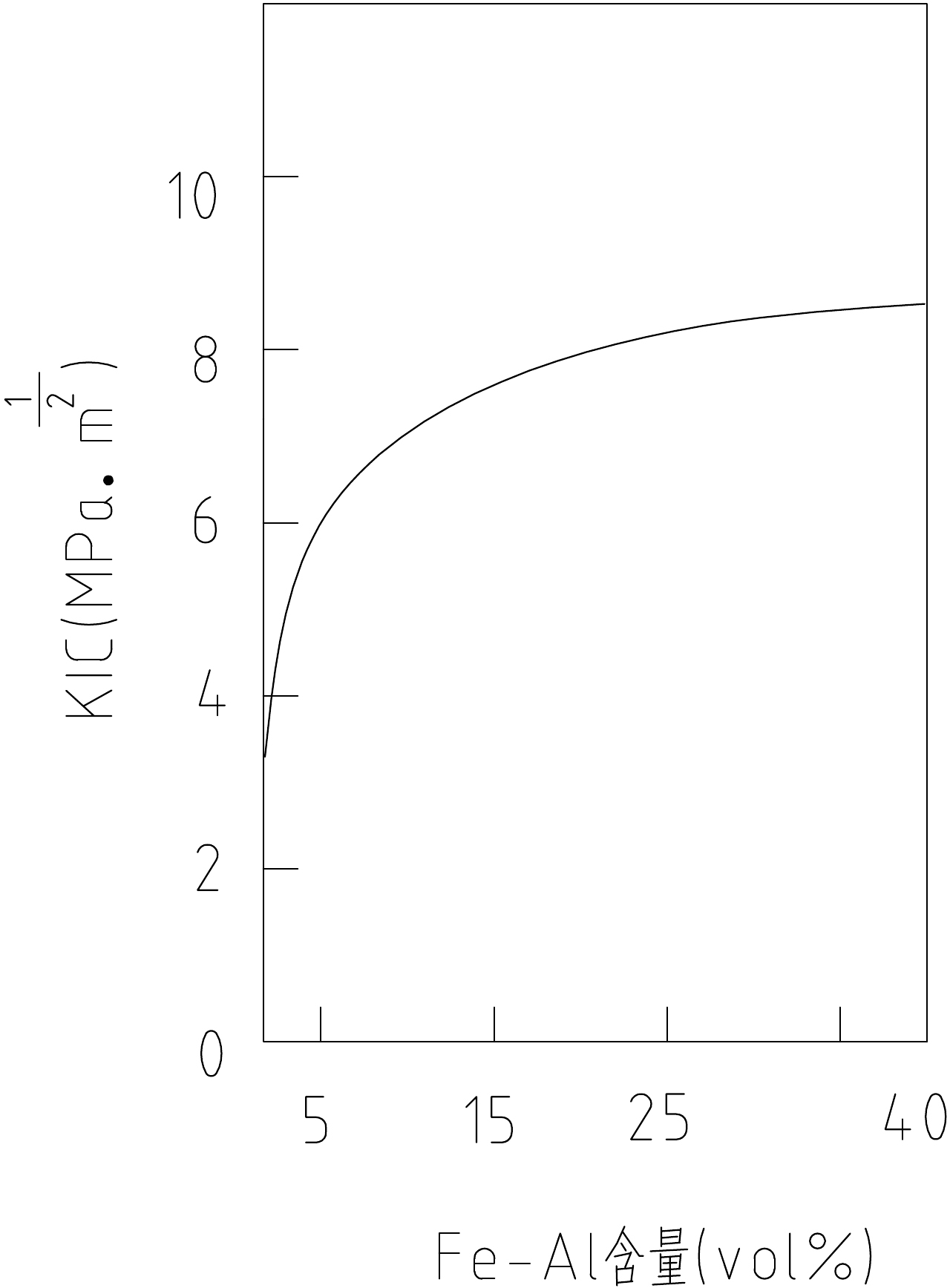

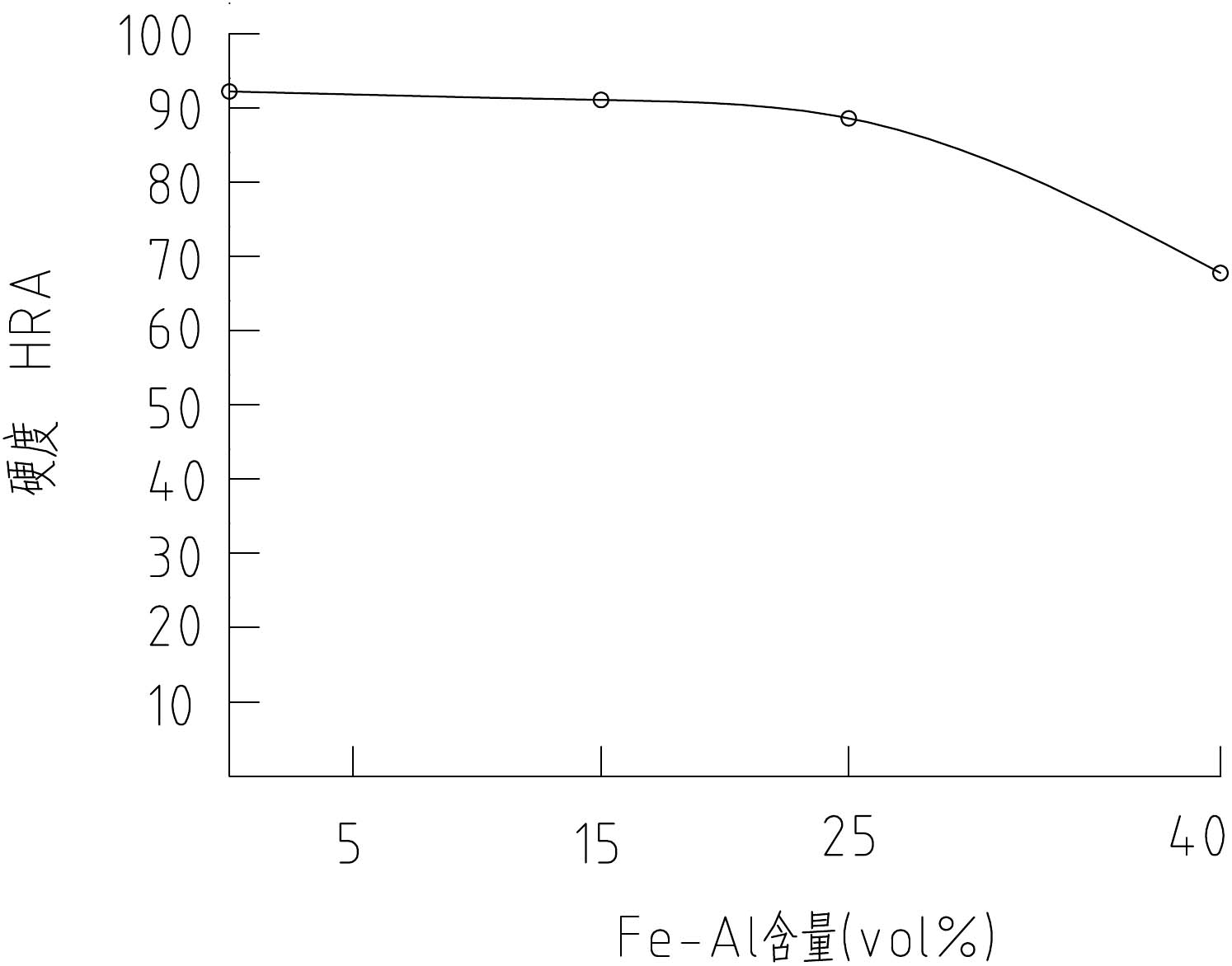

Ceramic sliding vane

The invention provides a ceramic sliding vane for a rotary compressor. The ceramic sliding vane comprises a sintered body and a stabilizer, wherein the sintered body comprises 50-94.5% of aluminum oxide and 5.0-40% of Fe-Al intermetallic compound by weight; and the stabilizer accounts for 0.5-10% by weight of the ceramic sliding vane. The ceramic sliding vane provided by the invention has not only high hardness and good corrosion resistance but also very low friction coefficient, so that the ceramic sliding vane used in a sealed rotary compressor can obtain good abrasion performance and reduce the abrasion and friction losses between the sealed rotary compressor and a sealed rotary compressor cylinder or a rolling piston matched with the sealed rotary compressor.

Owner:GUILIN AIPU HI TECH MATERIAL

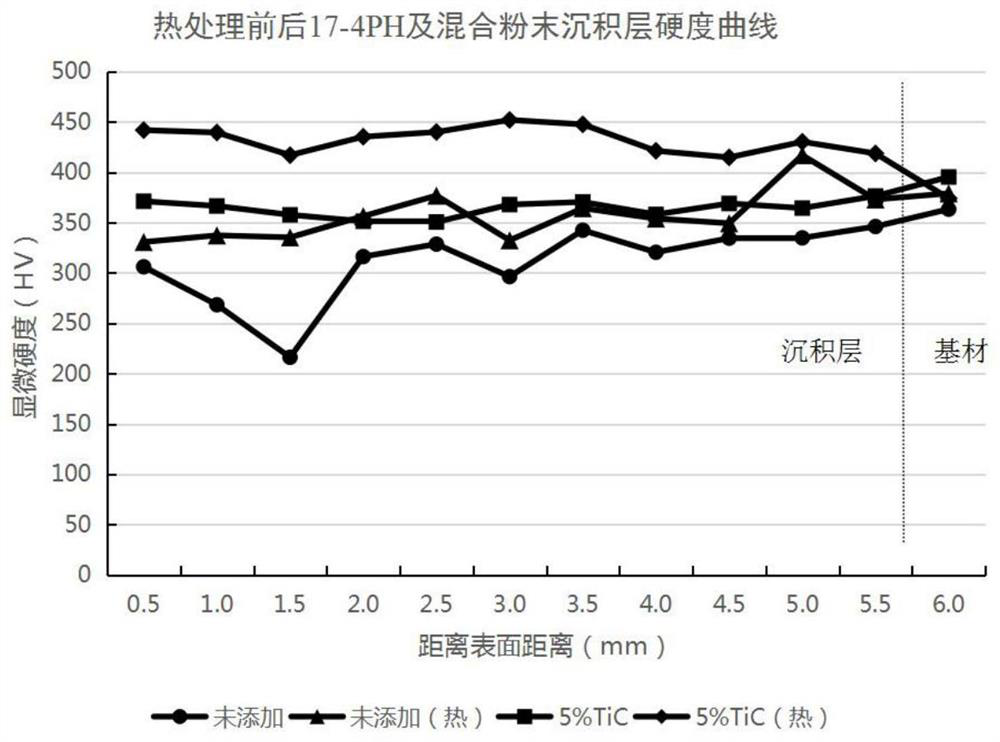

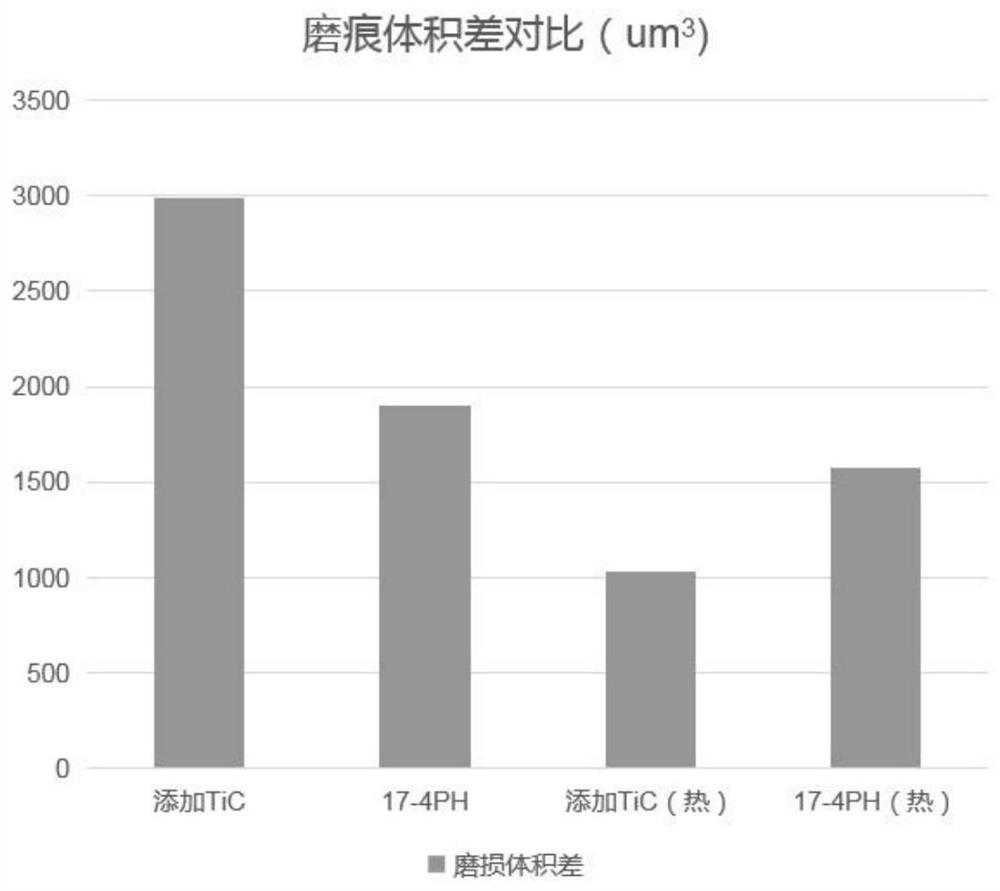

Process method for repairing and strengthening 17-4PH part by laser

InactiveCN112692292AControl performanceConvenient process sequenceMetallic material coating processesHardnessMachining

The invention discloses a process method for repairing and strengthening a 17-4PH part by laser. The process method comprises the following steps that (1) defects and oil stains on the surface of the 17-4PH part (base material) are removed; (2) (adjusted and optimized) composite laser melting deposition powder is adopted for repairing and strengthening, and a repaired part is obtained; (3) aging heat treatment is performed on the repaired part to further reinforce the performance of a coating; and (4) finish machining is performed. The laser repaired and strengthened 17-4PH part obtained through the process method for repairing and strengthening the 17-4PH part by lasers is high in hardness and excellent in abrasion resistance, the use performance is improved, and the service life is prolonged. Compared with the average hardness 380HV of a 17-4PH homogeneous repair layer, the average hardness of a deposited repair layer using the powder can reach 435HV, and the abrasion resistance is improved by about 20%.

Owner:浙江翰德圣智能再制造技术有限公司

Build up welding layer of continuous casting roller

InactiveCN105479038AReduce coefficient of frictionImprove impact resistanceWelding/cutting media/materialsSoldering mediaAlloySS - Stainless steel

The invention discloses a build up welding layer of a continuous casting roller. The build up welding layer is characterized in that the build up welding layer comprises a stacking bottom layer and a surface wire layer which are stacked on the continuous casting roller; the stacking bottom layer comprises 0.04-0.08 part of C, 1.0-1.5 parts of Mn, 0.4-0.8 part of Si, 16-22 parts of Cr and the balance Fe; and the surface wire layer comprises 0.04-0.08 part of C, 1.3-1.8 parts of Mn, 0.4-0.8 part of Si, 10-15 parts of Cr, 3.5-5 parts of Ni4, 0.5-1 part of Mo and the balance Fe. The build up welding layer of the bottom face of the continuous casting roller is made of ferritic stainless steel alloy, the friction coefficient of the build up welding layer is small, good impact resistance is achieved, multi-layer build up welding can be achieved, no crack is generated, machining is easy, and the build up welding layer is mainly used for repairing of carbon steel pieces or transition layers of other build up materials. The surface wire layer has excellent fatigue resisting performance and good corrosion resisting performance and wear resisting performance, and the build up welding layer simulates 1,000 times of quick heating and cooling circulating tests of the continuous casting roller, can find fatigue cracks and is mainly used for various kinds of steel rollers, hot-rolled work rollers, continuous casting rollers, crane rollers and blast-furnace top bell sealing faces.

Owner:JIANGSU XINGYUAN POWER PLANT & METALLURGICAL EQUIP MFG

High-temp alloy for temp-measuring thermocouple protection tube of cement rovolving kilin

ActiveCN1775985AGood high temperature oxidation resistanceGood abrasivenessThermometer detailsChemical compositionSuperalloy

The invention discloses a concrete rotary kiln temperature detecting thermocouple protection use high temperature alloy that contains Si less than 1.0%, Mn less than 2.0%, Ni 5-15%, Cr 22-35%, Al 4-9%, Mo 2-6%, Re less than 1.0, and the rest is Fe. The invention is low cost and has long useful life.

Owner:CHONGQING MATERIALS RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com