Patents

Literature

158results about How to "Best friction and wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental ceramic base friction material free of copper or metal and preparation method of material

InactiveCN103881657AGood mechanical skeleton performanceStable coefficient of frictionOther chemical processesFriction liningSulfurMetallic sulfide

The invention discloses an environmental ceramic base friction material free of copper or metal and a preparation method of the material. The environmental ceramic base friction material is characterized by comprising the following components by weight percent: 6-12% of phenolic resin, 2-10% of ceramic fiber, 2-8% of inorganic fiber, 2-10% of rubber, 4-12% of graphite, 10-25% of potassium titanate lamella, 3-15% of mineral fiber, 4-20% of metal sulfur compound, 6-20% of grinding aid and 5-20% of filler. The prepared friction material has excellent friction and wear properties, high heat-conducting property, excellent high-temperature decline property, stable friction coefficient, and excellent noise performance.

Owner:YANTAI SHENGRUI BRAKE SYST

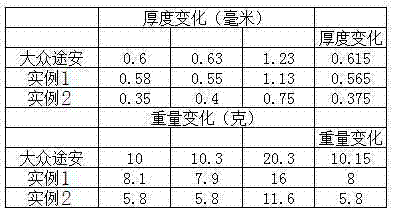

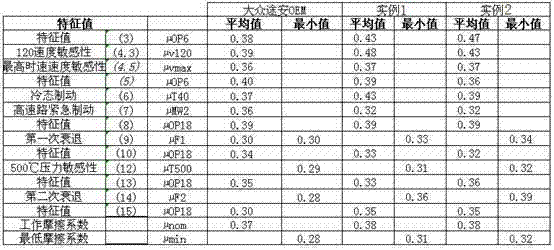

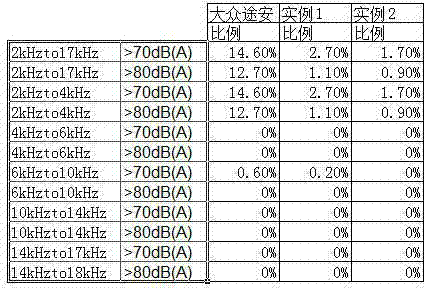

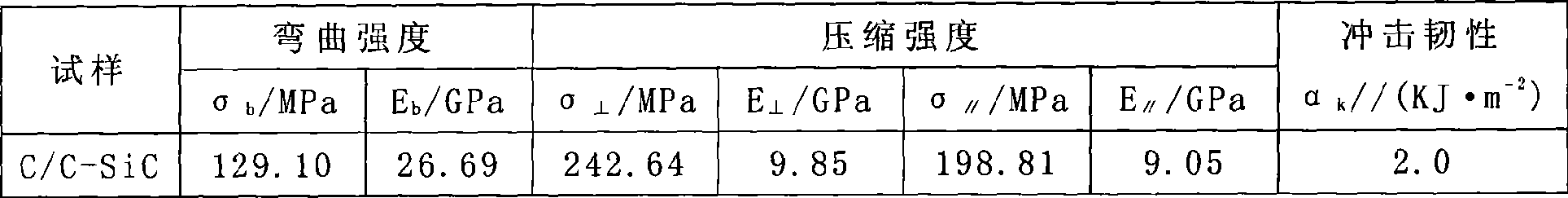

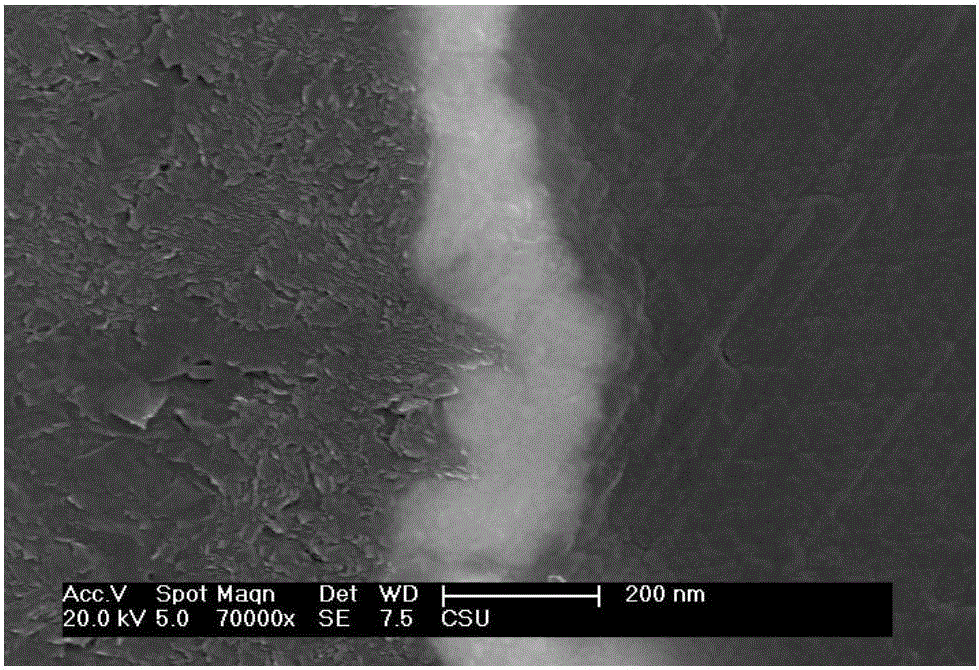

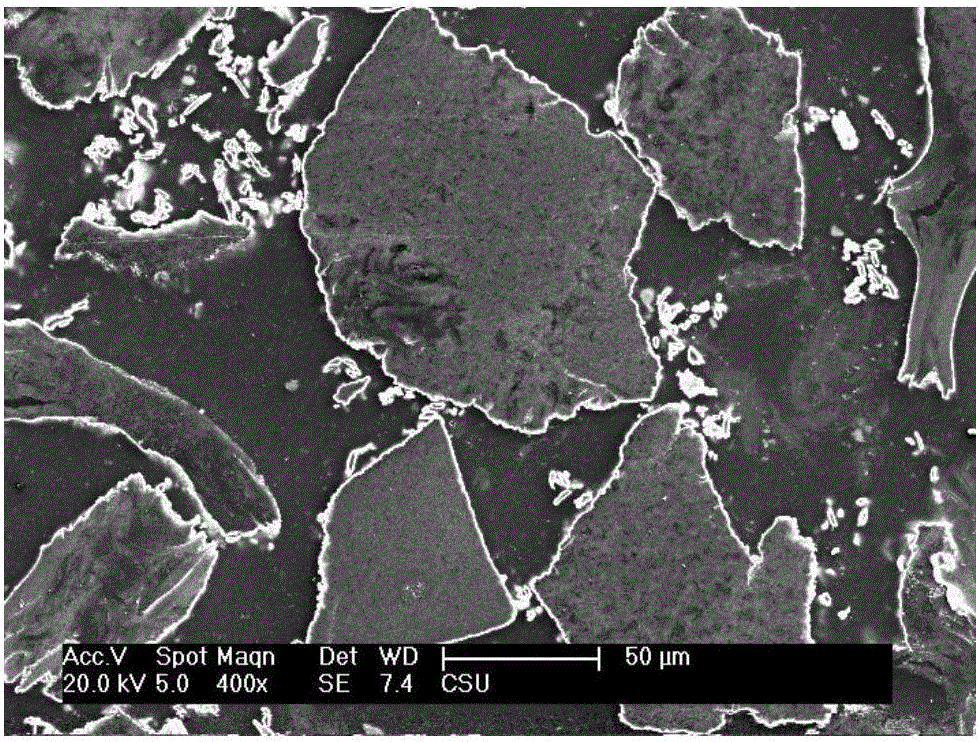

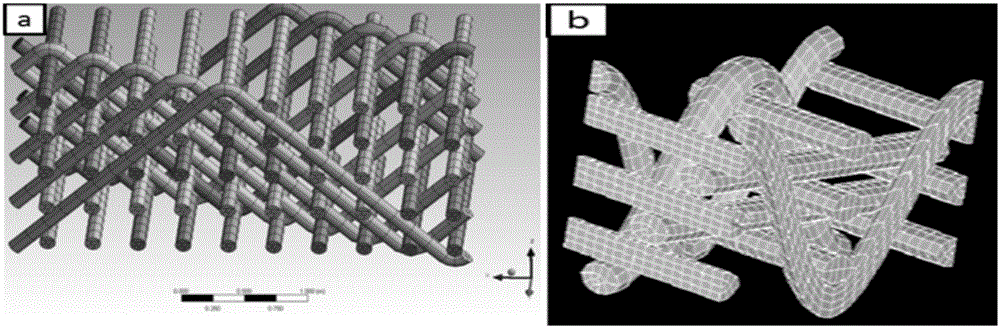

Preparation of carbon fiber reinforced carbon-silicon carbide double matrix friction material

The invention discloses a preparation method for a carbon fiber enhanced carbon-carborundum double-matrix abrasive material. Short chopped carbon fiber, graphite powder, industrial silicon powder and caking agent are employed to be pressed into the block material of carbon fiber enhanced graphite powder and silicon powder (C / C-Si) in a cooling way; then mechanical cracking and pelleting are carried out to the prepared C / C-Si block material; next, the grains are thermally pressed into a C / C-Si biscuit; and then the C / C-Si biscuit is carbonized to prepare a C / C-Si porous body; and finally non-dipping directional fused silica impregnating is carried out to the C / C-Si porous body to prepare the carbon fiber enhanced carbon-carborundum double-matrix (C / C-SiC) abrasive material. The invention relates to a preparation method for a carbon fiber enhanced carbon-carborundum double-matrix abrasive material having higher mechanical property and excellent abrasion resistance and wear performances,with the advantages of short preparation cycle, low cost, and being capable of engineering.

Owner:CENT SOUTH UNIV

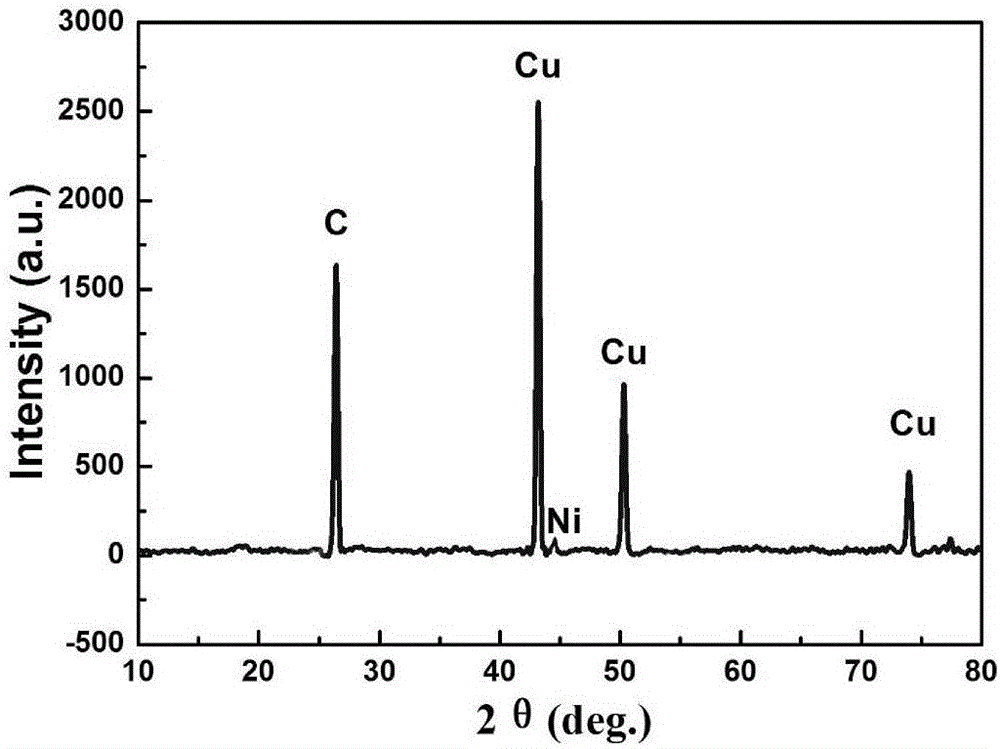

Copper-carbon composite material and preparing method thereof

ActiveCN106424713APromotes even distributionImprove performanceTransportation and packagingMetal-working apparatusFiberCarbon composites

The invention discloses a copper-carbon composite material and a preparing method thereof. Natural flake graphite, colloidal graphite, nano graphite, carbon fiber and the like can be selected as a carbon material in the copper-carbon composite material. The preparing method of the copper-carbon composite material includes the steps that firstly, a chemical nickel plating method is used for preparing a nickel plating carbon material; then a chemical copper plating method is used for plating copper on the nickel plating carbon material; and finally, vacuum semi-solid-state low-pressure sintering is conducted on the copper plating carbon material under the copper melting point temperature, and the copper-carbon composite material is prepared. The copper-carbon composite material and the preparing method thereof have the beneficial effects that a layer of even thin nickel plating layer is formed on the surface of carbon through the nickel plating method so as to reduce the wetting angle of the carbon material, the copper plating layer is formed on the surface of the nickel plating carbon material through the copper plating method so that a three-dimensional copper network can be formed by the material in the sintering process, and the bonding strength of a base body is improved through vacuum semi-solid-state low-pressure sintering. The two phases of the base body and the carbon of the copper-carbon composite material prepared through the method are distributed evenly and are well combined, and the good electricity and mechanical properties and the good frictional wear performance are achieved.

Owner:CENT SOUTH UNIV

High performance and low cost C/C-SiC composite brake disc, preparation method and application thereof

ActiveCN106966751ALow priceLow cost of preparationBraking discsActuatorsMolten siliconThermal conductivity

The invention relates to a high performance and low cost C / C-SiC composite brake disc, a preparation method and application thereof. The preparation method includes: carbonizing a brake disc prefab, and densifying the carbonized brake disc prefab by chemical vapor infiltration method to obtain a C / C composite material; then performing heat treatment in an inert atmosphere to improve the graphitization degree of the composite material; then conducting machining to obtain a C / C composite blank; treating the C / C composite blank by molten silicon infiltration method to obtain a C / C-SiC composite brake disc; then treating the C / C-SiC composite brake disc by means of chemical vapor infiltration or precursor infiltration pyrolysis; and machining the obtained product into a final design size, thus obtaining a composite brake disc finished product. The C / C-SiC composite brake disc and the preparation method thereof provided by the invention can reduce the preparation cost and improve the mechanical performance, thermal conductivity and friction and wear performance of the brake disc.

Owner:BEIHANG UNIV

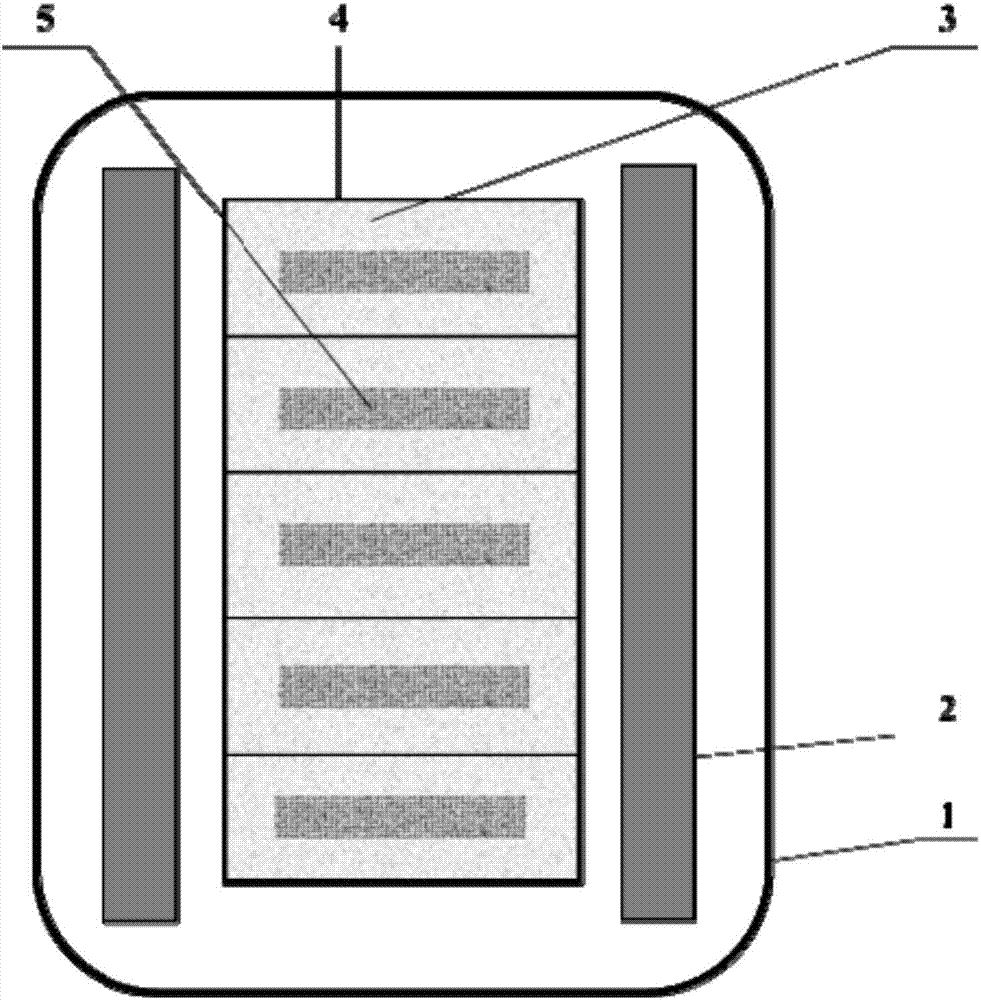

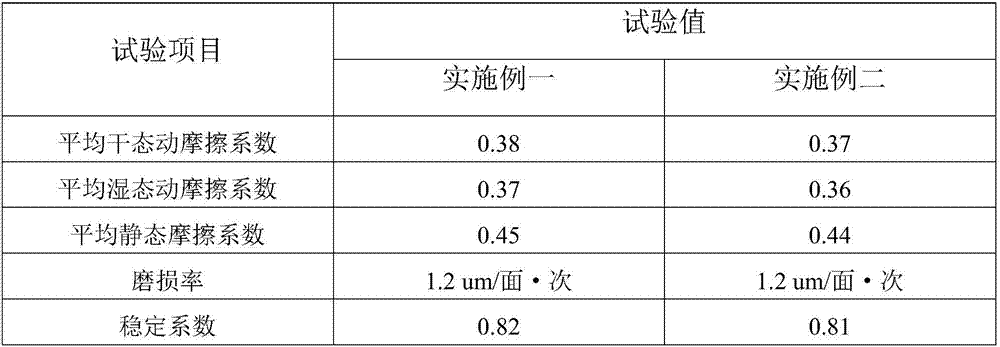

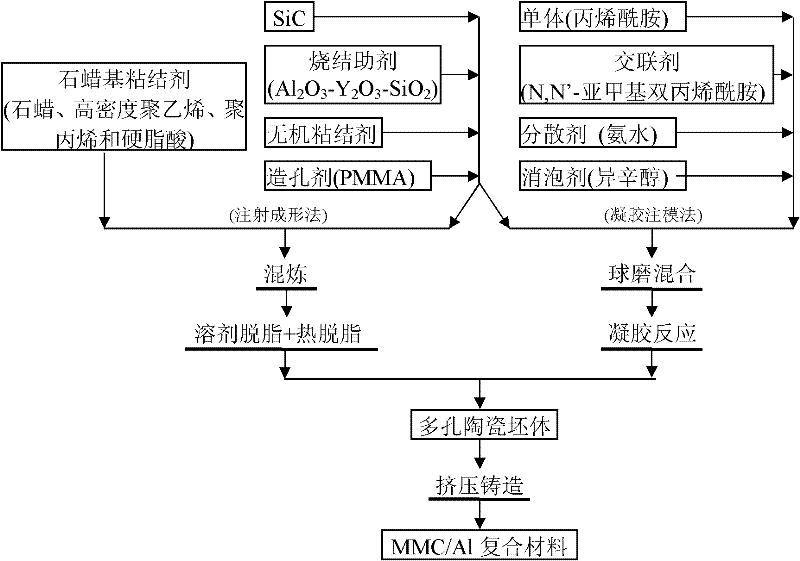

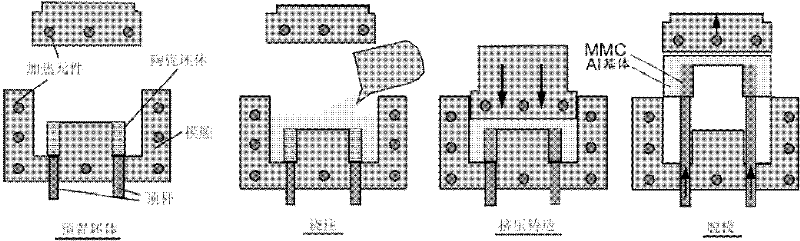

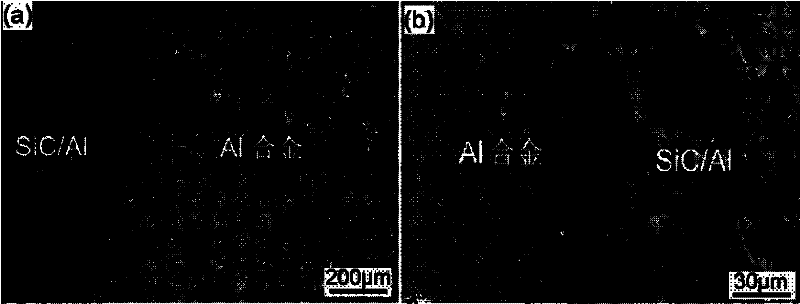

Method for preparing selectively enhanced aluminum-based composite from ceramic particles

The invention relates to a method for preparing selectively enhanced aluminum-based composite from ceramic particles and belongs to the field of metal matrix composites (MMCs). The preparation method comprises the following steps: firstly, preparing porous ceramic blanks; and secondly, putting the porous ceramic blanks at a part needing to be enhanced, injecting molten alloy into a mould at 750-1,100 DEG C, applying pressure of 20-50MPa to forcibly fill the molten alloy into the porous ceramic blanks and a mold cavity, and solidifying, thus obtaining the selectively enhanced aluminum-based composite. The method has the advantages that a foaming technology, an injection molding and a gel casting process are combined, thus leading the porous ceramic blank to have designability; the MMC reinforcement and an aluminum matrix are integrally formed by adopting extrusion casting process, thus fully playing the advantages of high strength and high toughness of the aluminum matrix and wear resistance of the MMC reinforcement. The composite has the advantages of high thermal conductivity, good radiation capability, excellent wear resistance and light weight.

Owner:UNIV OF SCI & TECH BEIJING

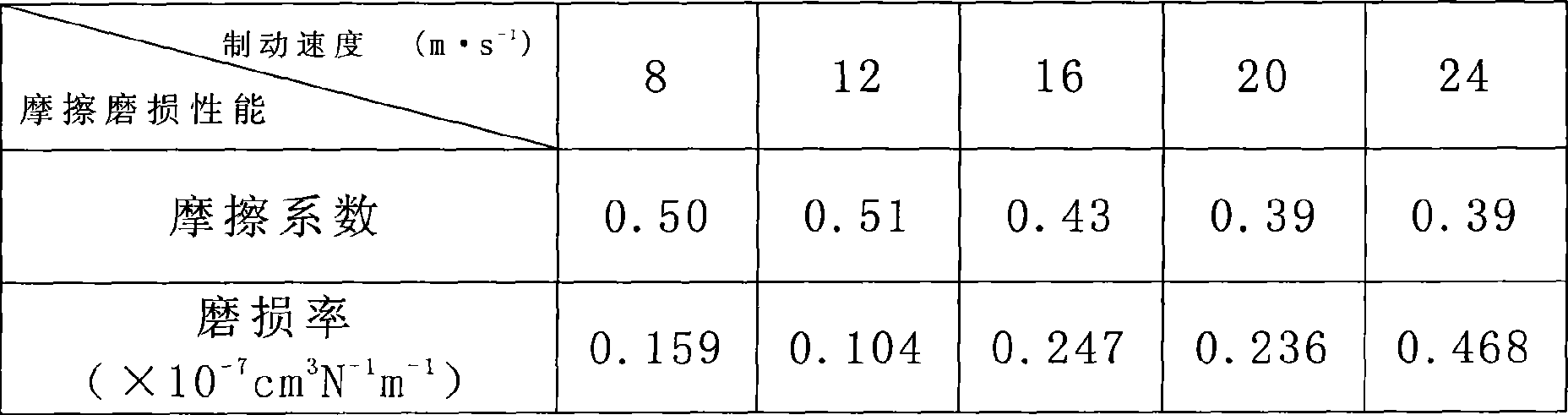

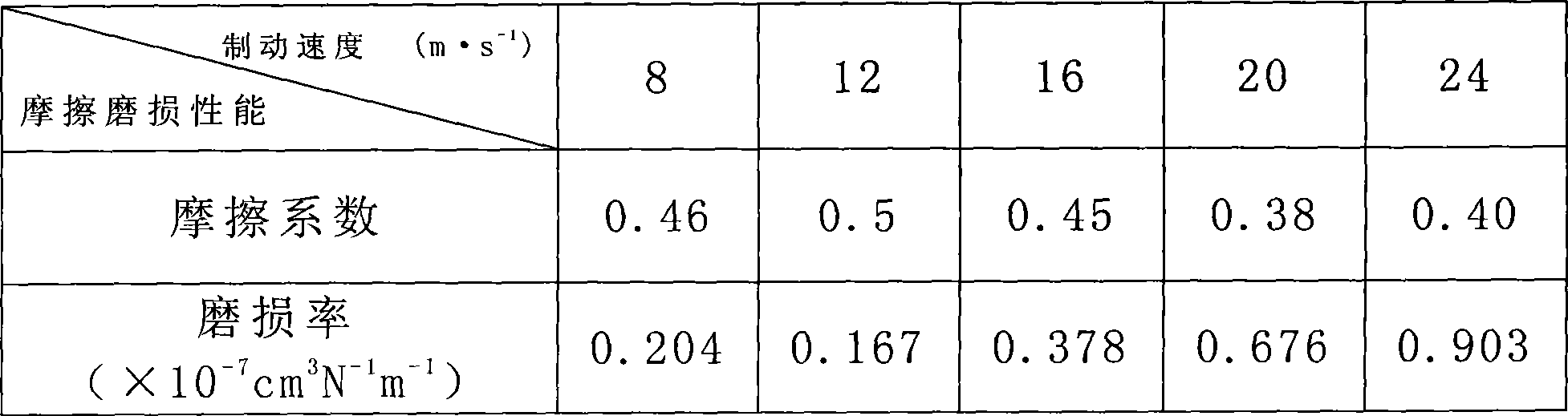

Brake pad material for high-speed railway passenger train and preparing method thereof

ActiveCN107460362ASolve the hardnessPoor ability to solve deformationTransportation and packagingMetal-working apparatusAdhesiveManganese

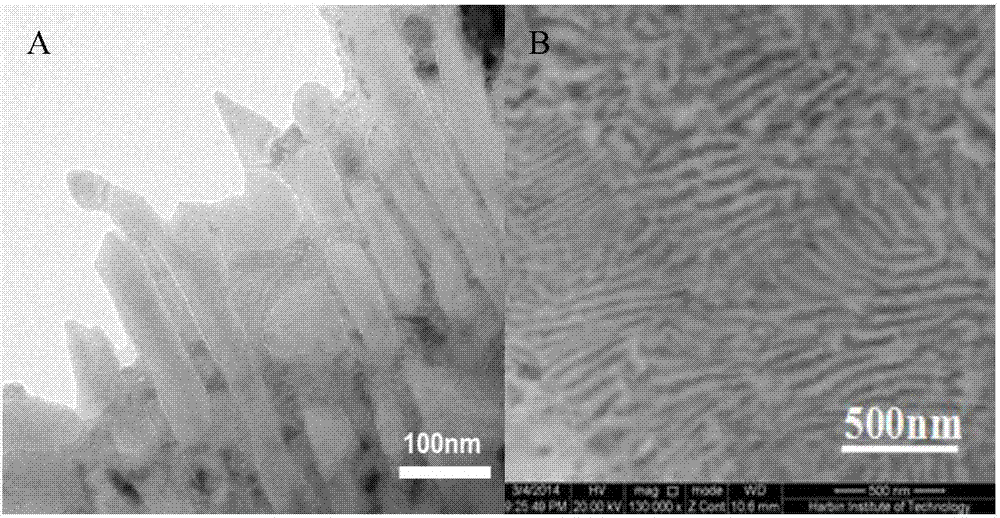

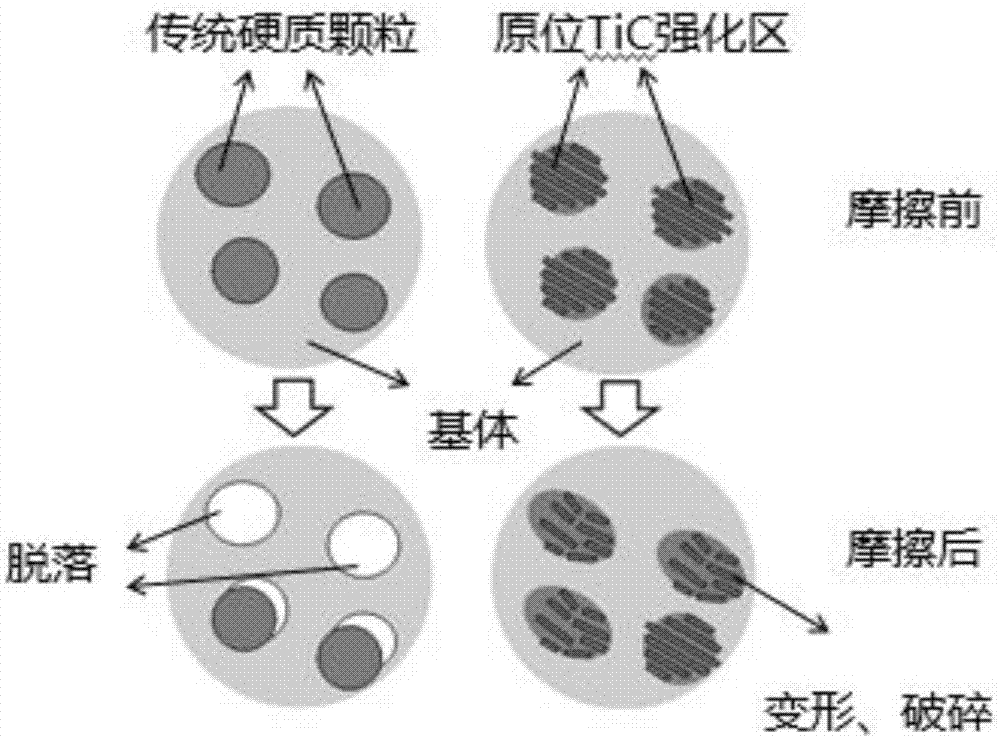

The invention discloses a brake pad material for a high-speed railway passenger train and a preparing method thereof and belongs to the technical field of powder metallurgy friction materials. The brake pad material is prepared by the following steps: after drying and sieving powdery raw materials, feeding the raw materials into a mixer, and spraying an adhesive; after mixing the materials, placing the materials in a steel mould, and carrying out pressing; and then, carrying out sintering at a reduction atmosphere, and then, carrying out heat treatment in a reduction atmosphere, wherein the powdery raw materials comprise copper powder, iron powder, Ti2AlC powder, chromium powder, nickel powder, manganese powder, silicon dioxide, graphite, boron nitride and molybdenum disulfate. The invention further provides the preparing method of the brake pad material. In the invention, in-situ TiC obtained through the Ti2AlC is used as a main friction component, the material of an in-situ nanometer TiC layered framework is prepared, the copper is accordingly used as a matrix, a small quantity of other metals is added, the content of lubricating components, such as the graphite, is regulated, and a novel material with a great brake effect and a low wear rate is finally obtained. The material is suitable for being used as the brake pad material for the high-speed railway passenger train.

Owner:哈尔滨新干线轨道交通科技有限公司

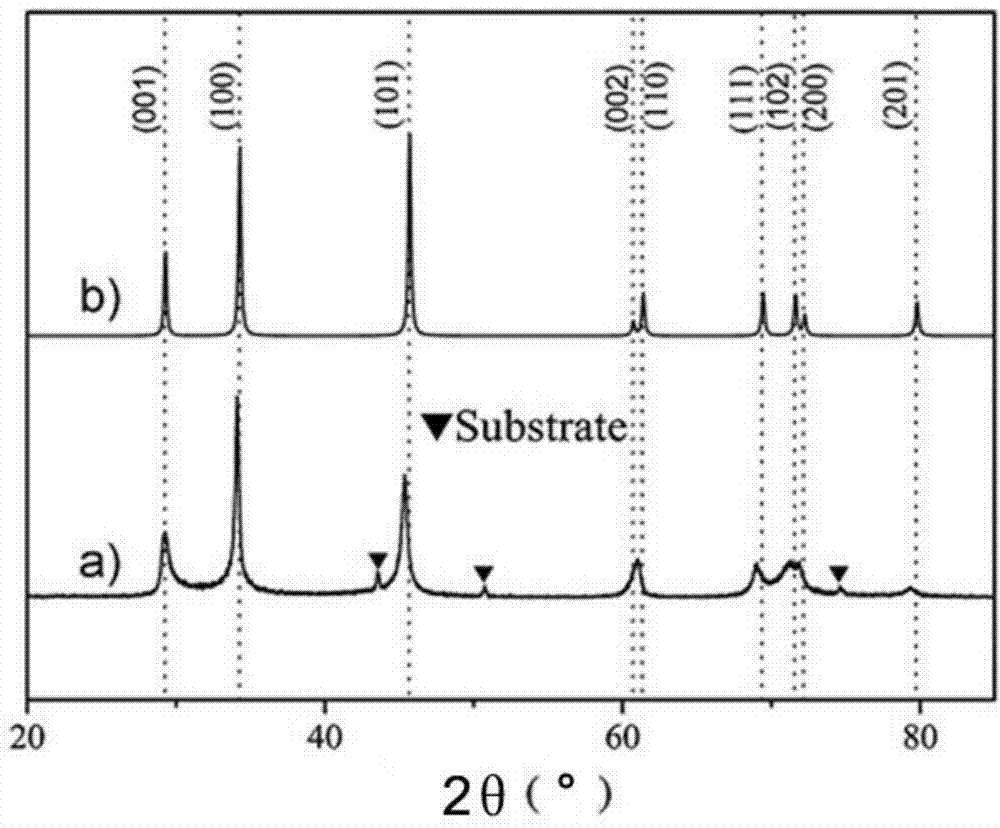

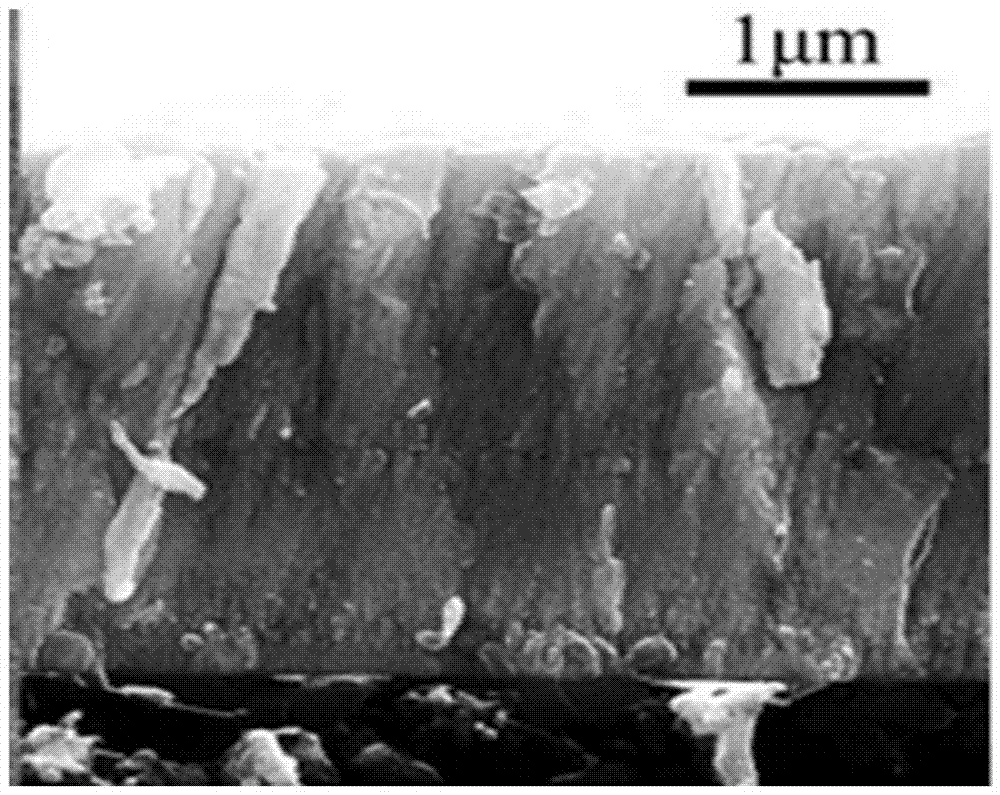

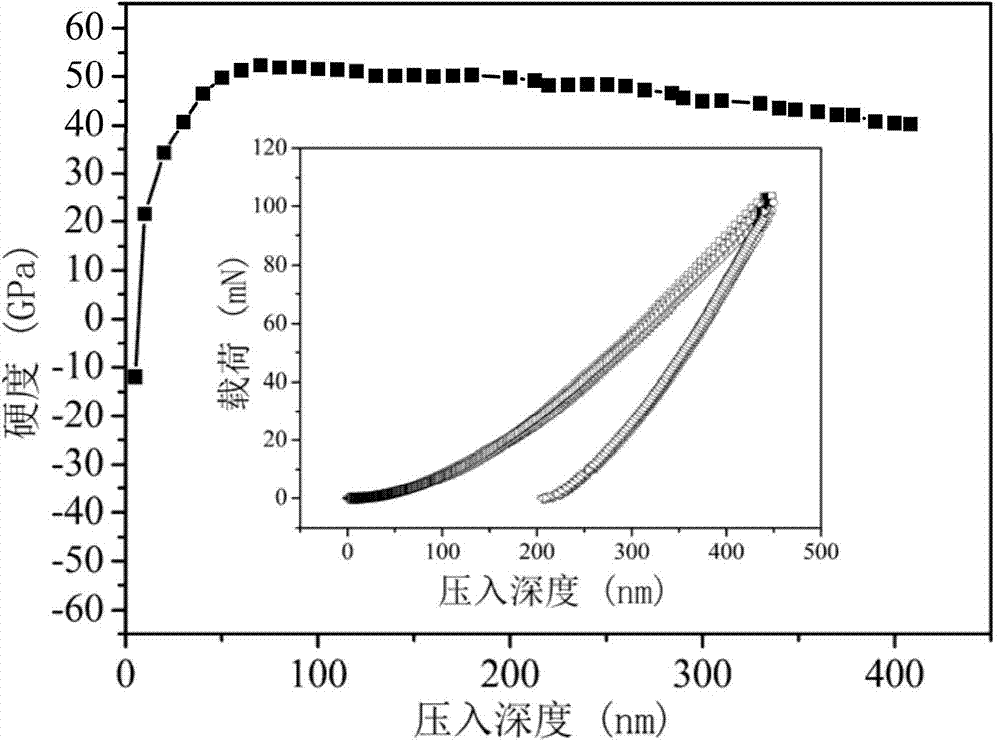

AlB2 type WB2 hard coating and preparation technology thereof

InactiveCN104513954AImprove performanceBest friction and wear resistanceVacuum evaporation coatingSputtering coatingDeposition temperatureWear resistant

The invention discloses an AlB2 type WB2 hard coating and a preparation technology thereof, and belongs to the technical field of depositing a hard and wear-resistant coating on the surface of a metal material. Through regulating and controlling the coating composition, the deposition temperature, and substrate bias voltage, and adopting a direct current (DC) magnetron sputtering method, a WB2 (AlB2 type) hard and wear-resistant coating can be successfully formed on a high-speed steel or hard alloy substrate. The formed coating has the advantages of high microscopic hardness, low average friction coefficient, and low wear rate. The WB2 (AlB2 type) hard coating is successfully synthesized, thus the hardness and wear-resistant performance of the surfaces of cutters or tools are both prominently improved, and the coating also has an important meaning for theory research and practical application of superhard boride coatings.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

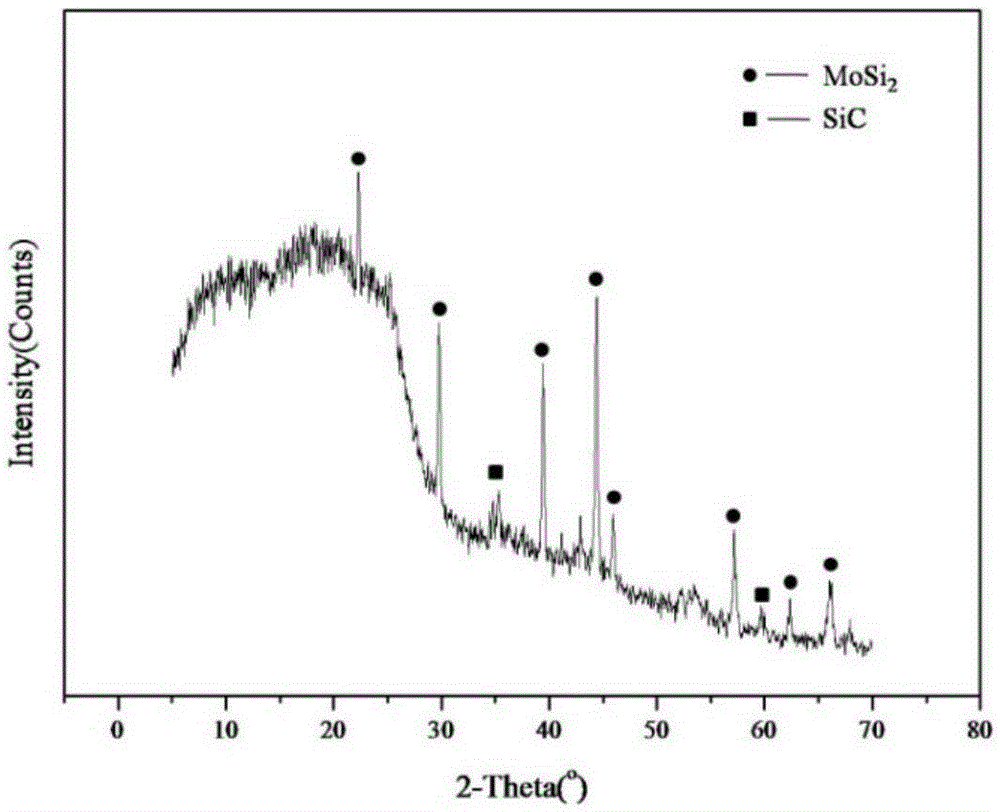

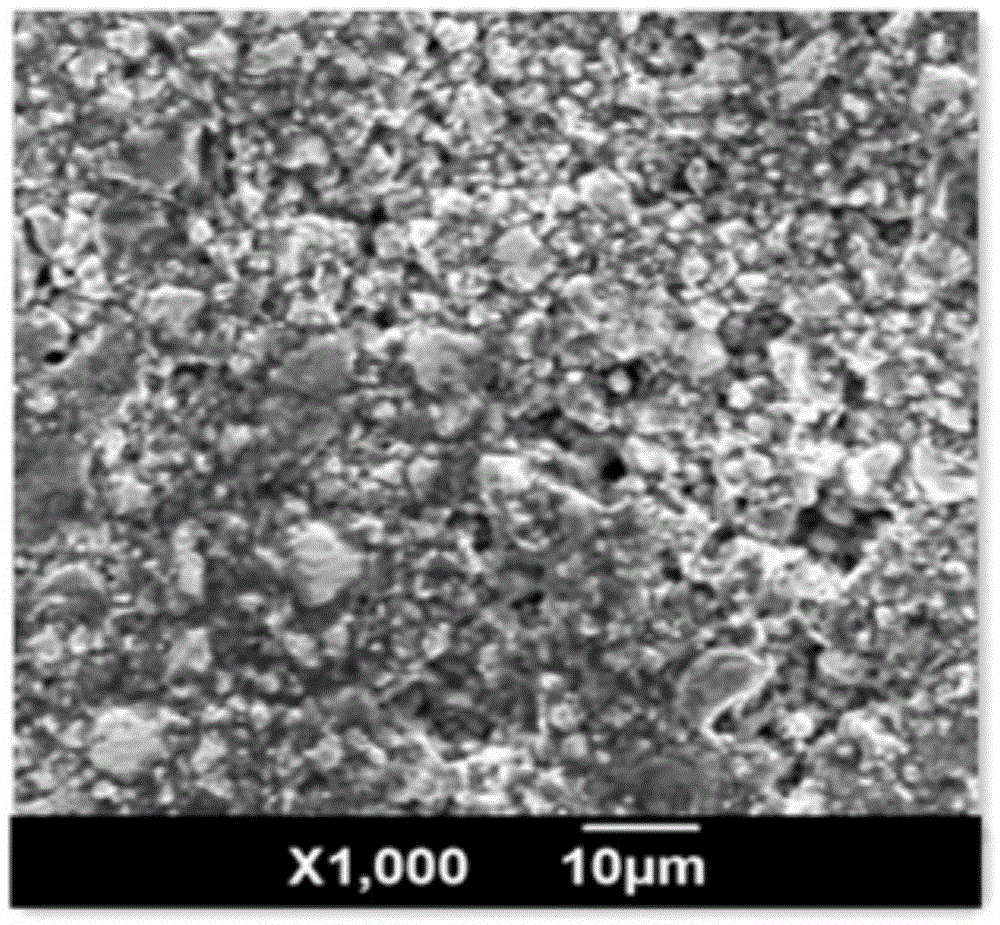

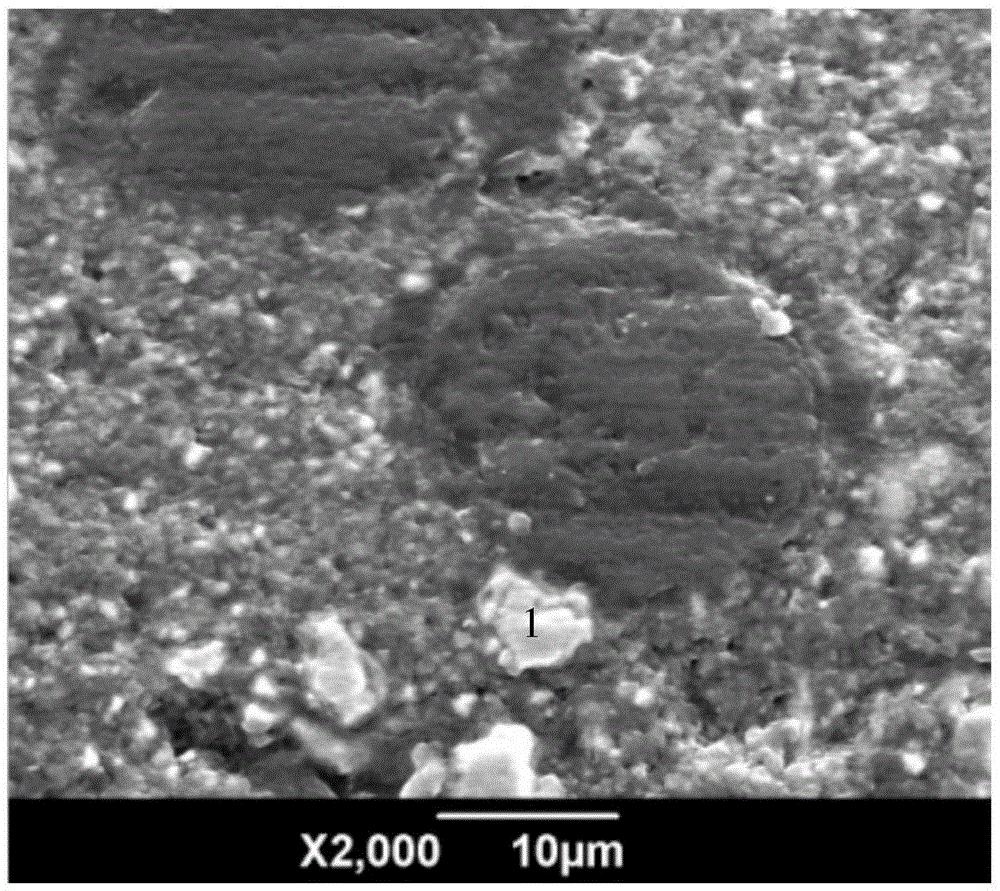

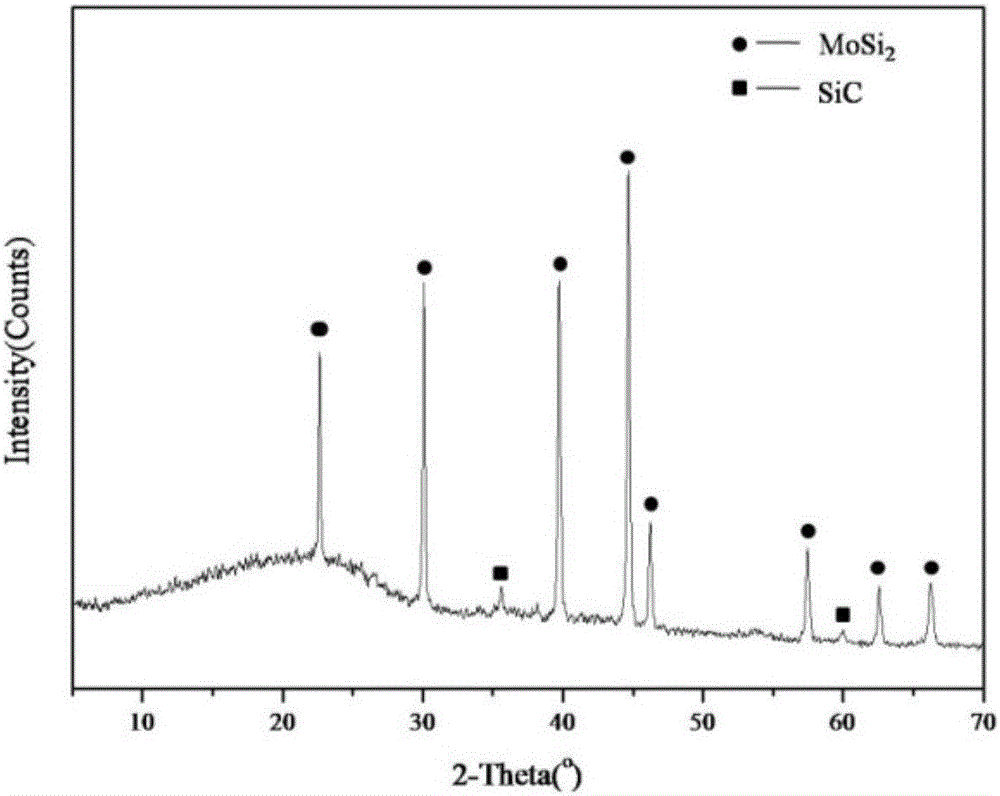

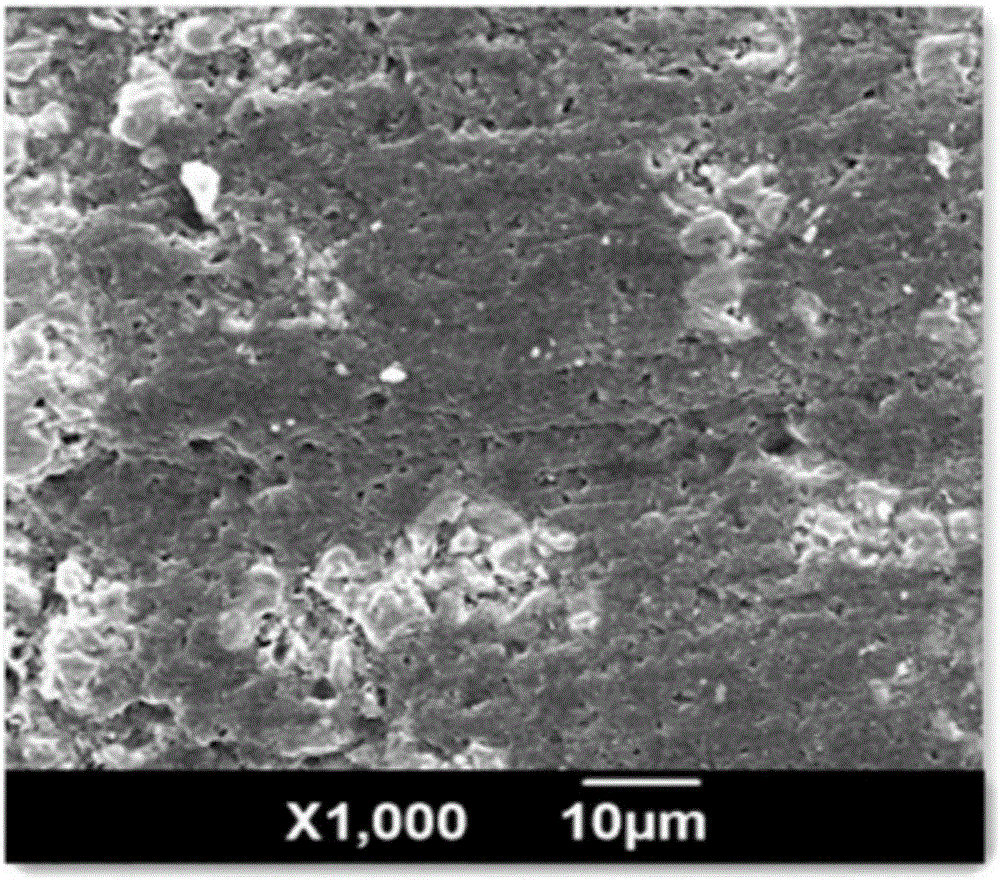

Preparation method of C/C-SiC-MoSi2 ceramic-based composite material

A preparation method of a C / C-SiC-MoSi2 ceramic-based composite material includes the following steps: 1) dispersing silicon carbide powder and molybdenum disilicide powder in isopropyl alcohol, and performing ultrasound vibration and stirring to obtain a suspension liquid A and a suspension liquid B: 2) increasing the density of a low-density carbon fiber stereo fabric in a manner of hydrothermal permeation of glucose, and placing the fabric in a suction filtration device having a glass sand core; 3) pouring the suspension liquid A and the suspension liquid B successively into a suction filtration flat-bottom funnel to enable the suspension liquids to pass the C / C composite material completely; 4) performing a homogeneous phase hydrothermal reaction until the density is 1.2-1.5 g / cm<3>; and 5) performing thermal treatment to obtain the C / C-SiC-MoSi2 ceramic-based composite material. The composite material is moderated in density, is compact in structure, and is excellent in interface binding between a C / C interface and a SiC interface, the SiC interface and a MoSi2 interface and the C / C interface and the MoSi2 interface. The raw materials are easy to obtain. The preparation method is simple in operation, is low in cost, is environment-friendly and is pollution-free.

Owner:浙江领崎科技有限责任公司

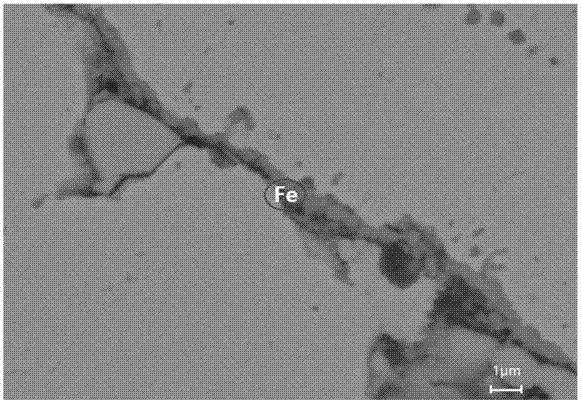

Preparation method of copper-based friction material with uniformly-distributed ferrum phase

ActiveCN107267800ABest friction and wear resistanceImprove wettabilityOther chemical processesTransportation and packagingPowder metallurgyHot pressing

The invention discloses a preparation method of a copper-based friction material with uniformly-distributed ferrum phase, and belongs to the technical field of preparation of powder metallurgy copper-based friction materials. The preparation method comprises the following steps that, by mass percentage, 70-80% of copper-iron alloy powder is taken as a matrix raw material of the copper-based friction material, 5-10% of tin powder, 1-5% of nickel powder, 5-10% of scale-like graphite powder, 1-10% of silica powder, 1-5% of molybdenum disulfide and 5-15% of mullite are added into the copper-iron alloy powder, all the materials are uniformly mixed according to a certain ratio and are subjected to cold-pressing forming and hot-pressing sintering to obtain the copper-based friction material with the ferrum phase uniformly distributed on phase interfaces between the matrix and the additive components, wherein the sintering temperature is 850-950 DEG C, and the heat preservation time is 2-3 hours. The copper-iron alloy powder is prepared by adopting an argon atomization mode, and the mass fraction of the iron element is 2-4%. The copper-iron alloy powder replaces pure copper powder to be taken as the matrix raw material, the ferrum phase can be uniformly distributed on the phase interfaces, so that the interface strength is improved, and meanwhile the wettability between the copper and the graphite is improved; and the prepared copper-based powder metallurgy material for a brake pad is small in porosity, high in matrix strength and has more excellent friction and abrasion performance compared with materials used in a traditional brake pad.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of h-BN added titanium boride-based self-lubricating ceramic cutter material

The invention relates to a preparation method of an h-BN (hexagonal Boron Nitride) added titanium boride-based self-lubricating ceramic cutter material. According to the method, the material is formed in such a way that TiB2 as a base body, added micron WC (Wolfram Carbide) as a reinforced phase, the micron h-BN as a solid lubricant, and micron Mo and micron Ni as sintering additives are sintered. The preparation method comprises the following steps: respectively dispersing the micron TiB2 powder, the micron WC powder and the micron h-BN powder, and carrying out ball milling and drying so as to obtain powders, and finally, sintering the powders through a hot pressing method. The method has the advantages of simplicity, convenience in operation and the like. The self-lubricating ceramic cutter material has an excellent comprehensive mechanical property and an anti-friction wear-resisting property, and can be used for fabricating cutting tools, dies and other friction-resistant corrosion-resistant parts.

Owner:QILU UNIV OF TECH

Environment-friendly lead-free copper-based self-lubricating material and preparation process thereof

InactiveCN102228991AThe production process is simple and easy to controlReduce manufacturing costRoll mill control devicesMetal rolling arrangementsEnvironmental resistanceAl powder

The invention discloses an environment-friendly lead-free copper-based self-lubricating material and a preparation process thereof. The component of copper alloy powder is atomized CuSn8Nil, the granularity of the atomized CuSn8Nil is 200 meshes, and the granularity of Al powder is 200 meshes; and the copper alloy powder comprises the following components in percentage by mass: 90 to 96 percent of atomized CuSn8Nil, and 4 to 10 percent of aluminum. The preparation process comprises the following steps of: (1) mixing, (2) making a supporting steel back, (3) spreading powder, (4) loosening and sintering, (5) blooming, (6) re-sintering, (7) re-rolling, and (8) annealing and finish rolling. The invention discloses the environment-friendly lead-free copper-based self-lubricating material with good bonding performance and good friction and abrasion resistance and the preparation process thereof.

Owner:CENT SOUTH UNIV

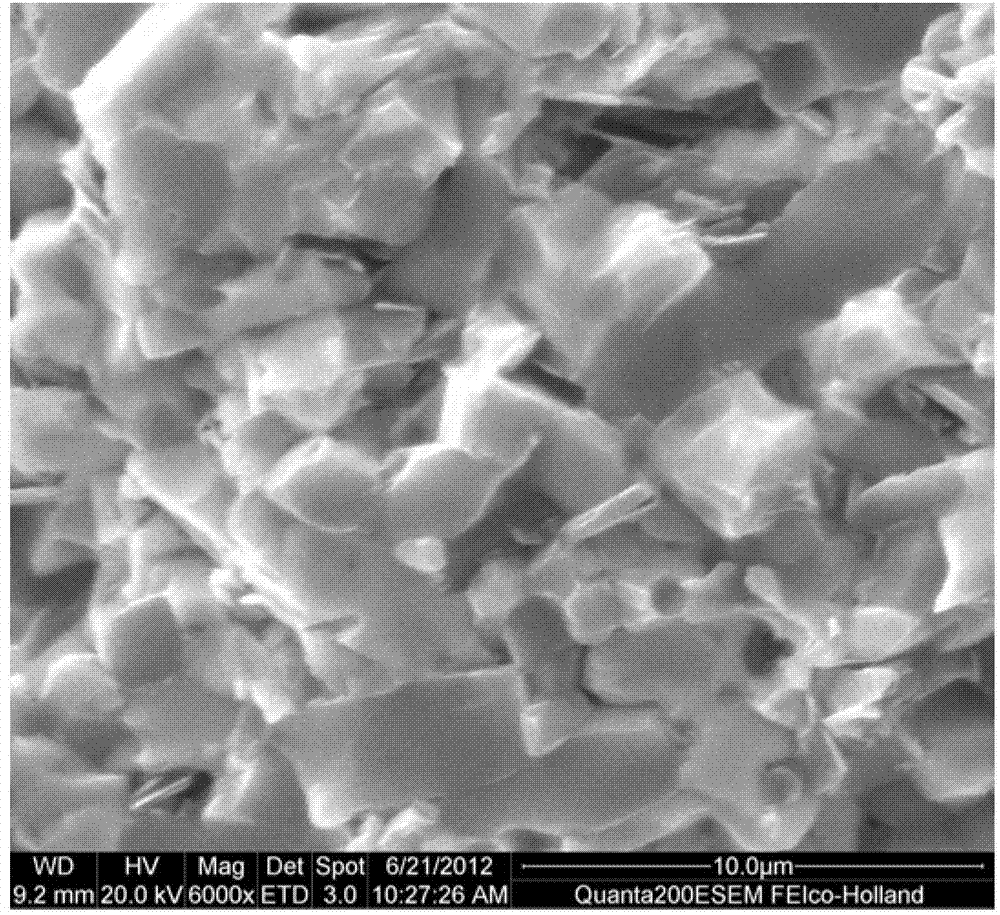

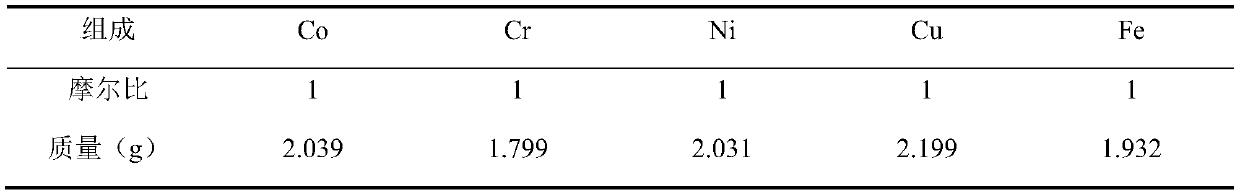

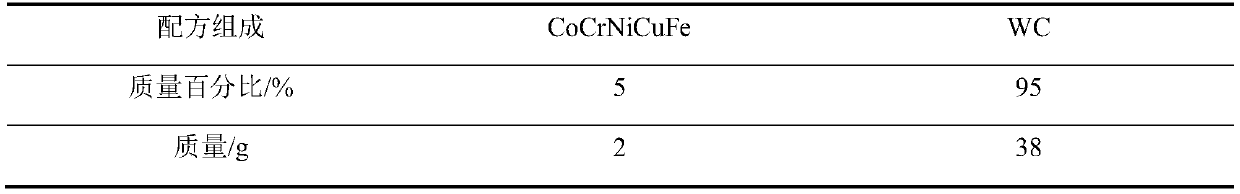

Ultrafine tungsten carbide hard alloy with high-entropy alloy as binding phase and preparation method thereof

InactiveCN111286664AImprove performanceOverall performance exceedsHigh entropy alloysCemented carbide

The invention belongs to the technical field of composite materials, and relates to an ultrafine tungsten carbide hard alloy with a high-entropy alloy as a binding phase and a preparation method thereof. The high-entropy alloy is a Co, Cr, Ni, Cu and Fe five-component high-entropy alloy, the mass percentage of the high-entropy alloy accounts for 5-30wt% of the total system, and the balance is WC.The preparation method comprises the following steps that firstly, nano five-component high-entropy alloy powder is prepared, and WC powder is refined; secondly, the nano five-component high-entropy alloy powder and the nano WC are mixed in a ball mill according to different mass ratios; the uniformly mixed powder is pre-pressed; the pre-pressed part is subjected to annealing treatment; finally, vacuum hot-pressing sintering is carried out, the sintering pressure is 40-50 MPa, and the sintering temperature is 1200-1400 DEG C; then cooling and pressure relief are carried out, and the ultrafinetungsten carbide hard alloy is prepared; and after sintering, the hard alloy sintered body is subjected to annealing treatment. According to the ultrafine tungsten carbide hard alloy with the high-entropy alloy as the binding phase and the preparation method thereof, the production cost is reduced, and the performance of the tungsten carbide hard alloy is improved.

Owner:YANSHAN UNIV

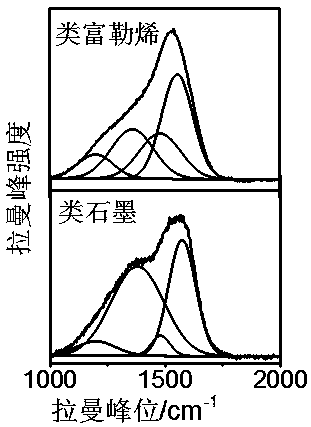

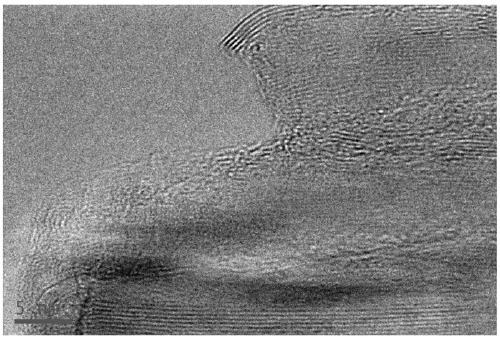

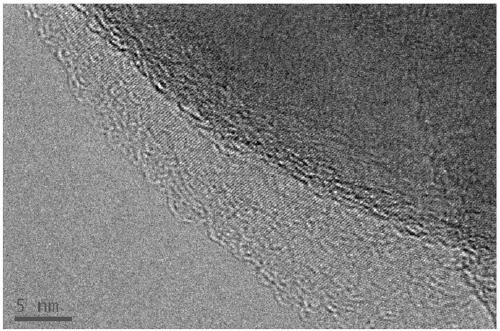

Carbon structure film and graphene additive solid-liquid composite anti-friction and anti-abrasion method

ActiveCN108048160AReduce coefficient of frictionReduce wear rateAdditivesNano structuringOil additive

The invention discloses a carbon structure film and graphene additive solid-liquid composite anti-friction and anti-abrasion method. Nano-structure films made of fullerene-like carbon, graphite-like carbon, onion-like carbon, graphene and the like are prepared and matched in pairs to form friction pairs, and graphene nano-particles serve as lubricating oil additives, so that the friction coefficient and the wear rate are remarkably reduced, the service life is prolonged, and the sensitivity and the reliability are improved. Carbon structure films and graphene additives can efficiently and lastingly form a friction film easy to shear in a friction interface. The film can be used for resisting abrasion on surfaces of metal, ceramic and polymer materials and reducing the friction coefficient,the graphene additive in use can be various sold or self-made products. The method aims to solve the problem that the service life, sensitivity and reliability of existing high-end equipment, aerospace parts and the like can not meet the requirements in 10-15 years.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

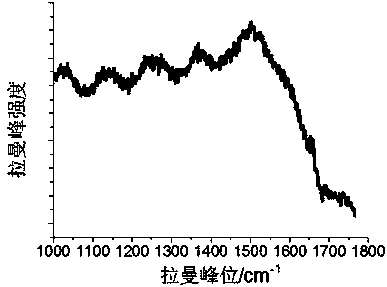

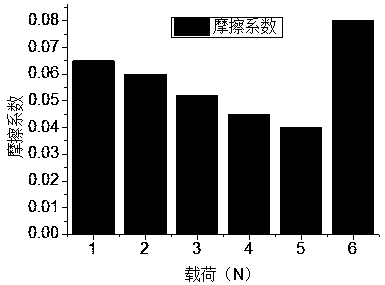

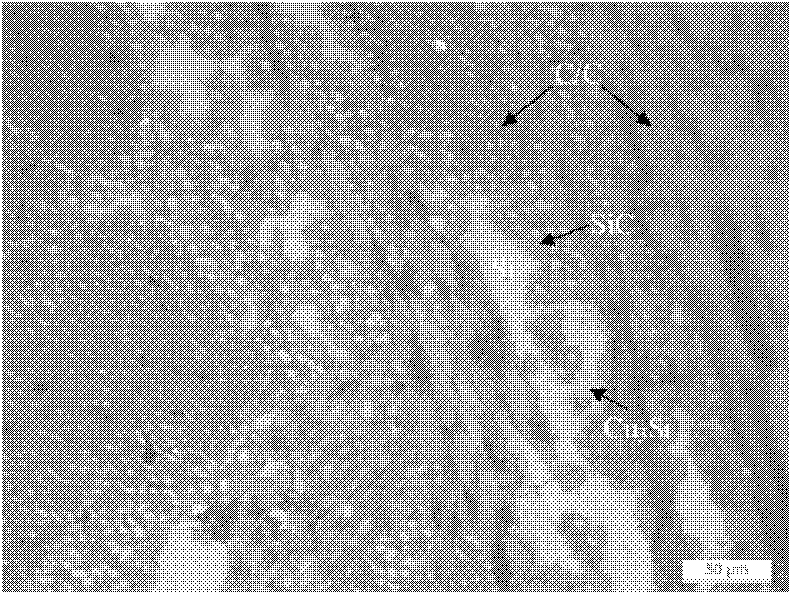

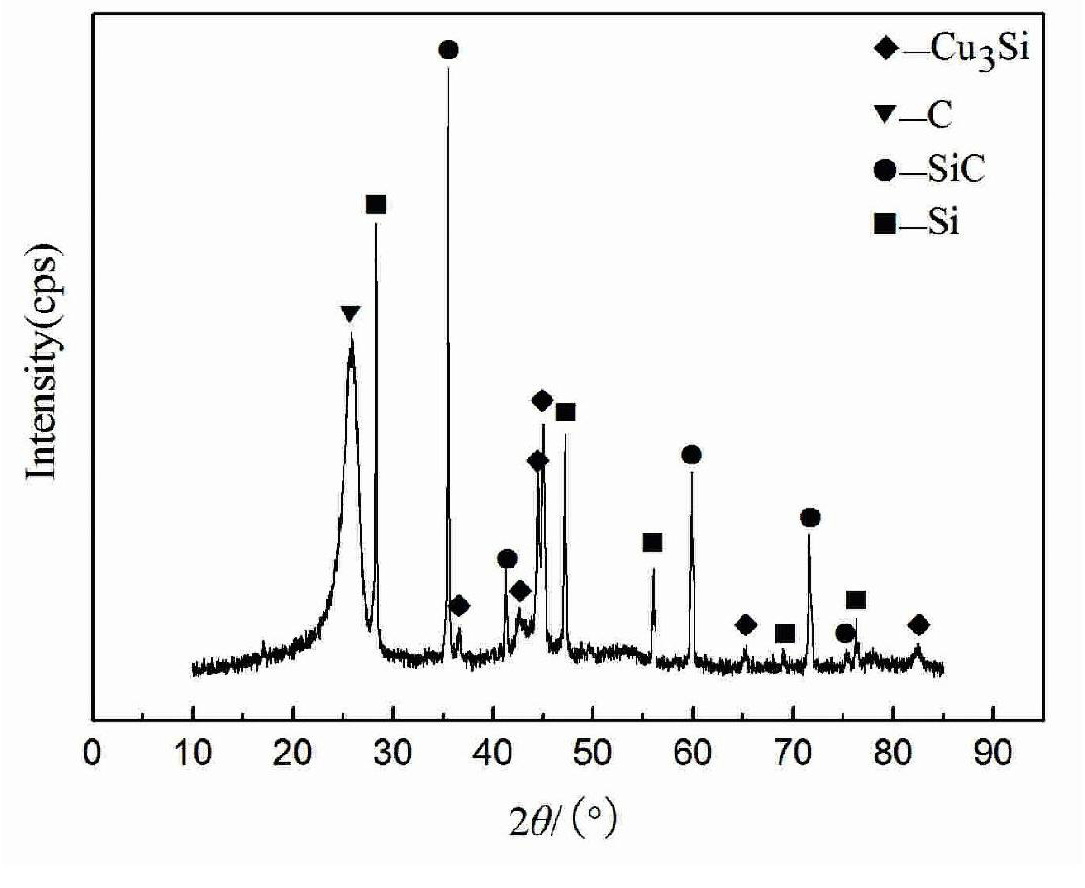

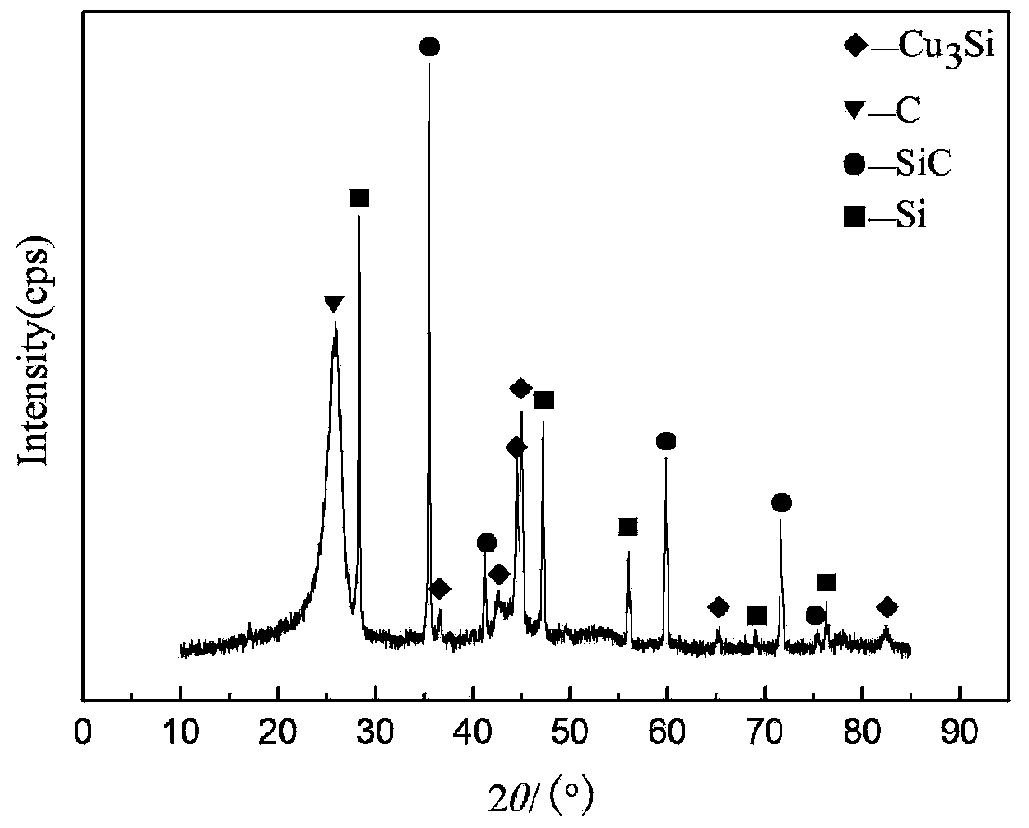

Method for preparing copper silicon alloy modified carbon/ceramic friction material

ActiveCN101818048AStress reliefFacilitate subsequent processingOther chemical processesJet aeroplaneSilicon alloy

The invention discloses a method for preparing a copper silicon alloy modified carbon / ceramic friction material, which comprises the following steps of: 1, thermally treating a carbon fiber prefabricated body at high temperature; 2, performing chemical vapor infiltration and (or) resin impregnation / carbonization densification treatment on the thermally-treated carbon fiber prefabricated body to obtain a low-density carbon fiber reinforced matrix carbon (C / C) porous material; 3, preparing Cu and Si infiltration powder; and 4, placing the Cu and Si infiltration powder into a graphite crucible, spreading the C / C porous material on the powder in the graphite crucible, performing non-immersion smelting infiltration in a high-temperature vacuum furnace, and compounding the C / C porous material and the powder to form the copper silicon alloy modified carbon / ceramic friction material through the reaction of Si and C, Si and Cu. The method has the advantages of simple and easily-controlled production process and low preparation cost; the prepared material has controllable microstructure and performance and excellent heat conducting performance; and the method can realize industrialized production, and has broad application prospect in the civil and military fields of airplanes, rapid trains, automobiles and the like.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

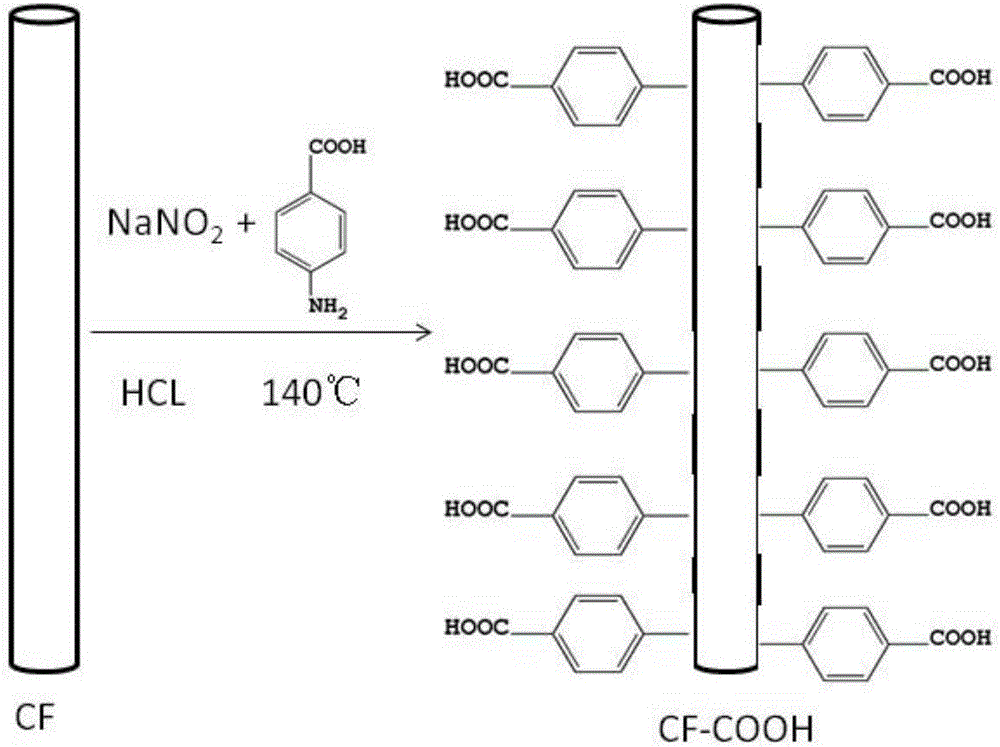

Preparation method for para aminobenzoic acid lossless modified carbon fiber enhanced paper base wet-type friction material

The invention discloses a preparation method for a para aminobenzoic acid lossless modified carbon fiber enhanced paper base wet-type friction material. Carbon fibers, para aminobenzoic acid and excessive hydrochloric acid are added to a three-neck flask, a certain quantity of sodium nitrite is slowly added after a reaction reaches certain temperature, a short-time diazo-reaction is conducted under the condition of a magnetic stirring oil bath, and carbon fibers with the surfaces grafted by benzoic acid are obtained. Then, the modified carbon fibers, aramid fibers, paper fibers, padding and resin are mixed to prepare friction material base paper, the friction material base paper is then hot-pressed and solidified, and the para aminobenzoic acid modified paper base wet-type friction material is obtained. A friction material sample is subjected to a frictional wear performance test, the dynamic friction coefficient of the sample reaches 0.12 to 0.15, the wear rate is 0.9*10<8>cm<3> / J to 1.2*10<8>cm<3> / J, the excellent frictional wear performance is shown, the technological process is simple, cost is low, and the preparation method is an efficient and environment-friendly graft modification treatment method and has the wide application prospect.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method for lamellar C/C-SiC-MoSi2 ceramic matrix composite

The invention provides a preparation method for a lamellar C / C-SiC-MoSi2 ceramic matrix composite. The method comprises the steps that silicon carbide powder and molybdenum disilicide powder are dispersed in isopropyl alcohol and then stirred evenly after iodine is added, and first suspension liquid and second suspension liquid is obtained; the density of a carbon-fiber three-dimensional fabric is increased by adopting the mode of hydrothermal glucose permeation, the carbon-fiber three-dimensional fabric is clamped in a specially-made hydrothermal kettle with a positive electrode and a negative electrode, then the specially-made hydrothermal kettle is placed in a drying oven for heat preservation, and then hydrothermal electrophoretic deposition is performed; homogeneous-phase hydrothermal treatment is repeatedly performed in an aqueous glucose solution until the density reaches 1.3-1.5 g / cm<3>, and then heat treatment is performed after the fabric is dried. According to the preparation method for the lamellar C / C-SiC-MoSi2 ceramic matrix composite, the prepared composite is moderate in density and compact in structure, and binding between a C / C interface and a SiC interface, binding between the SiC interface and a MoSi2 interface and binding between the C / C interface and the MoSi2 interface are good; the composite with the high strength and the good high-temperature oxidation resistance can be obtained at low temperature, and the preparation method has the advantages that the raw materials are easy to obtain, the preparation technology is simple, operation is easy and convenient, and the cost is low.

Owner:广西自贸区见炬科技有限公司 +1

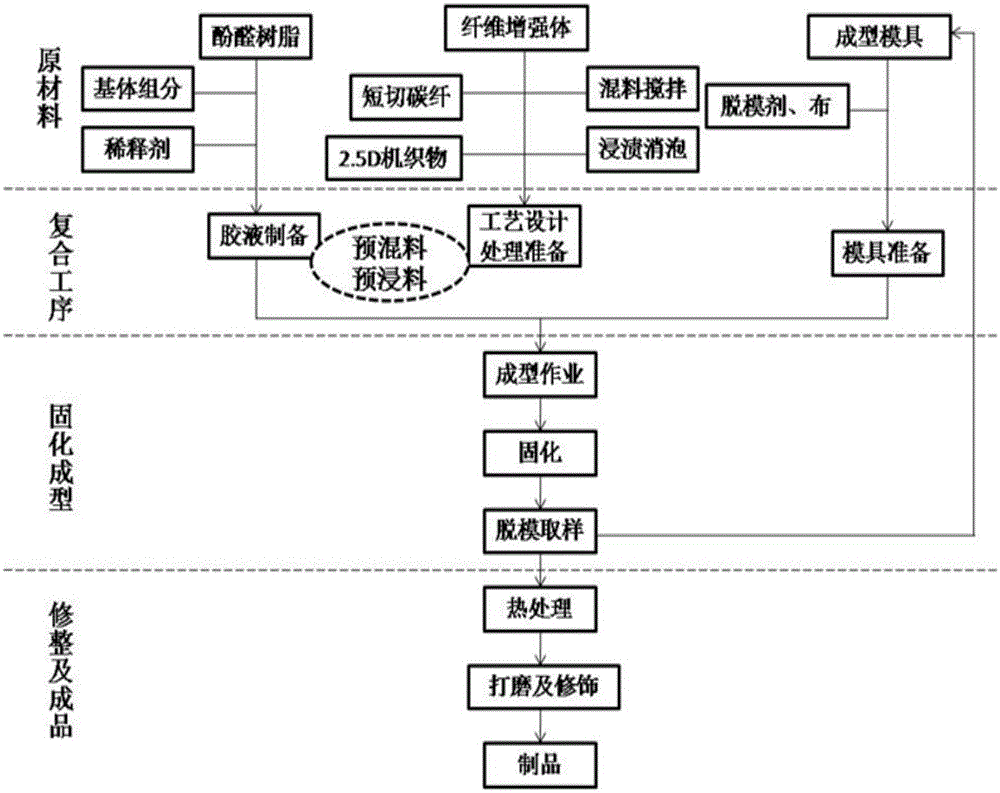

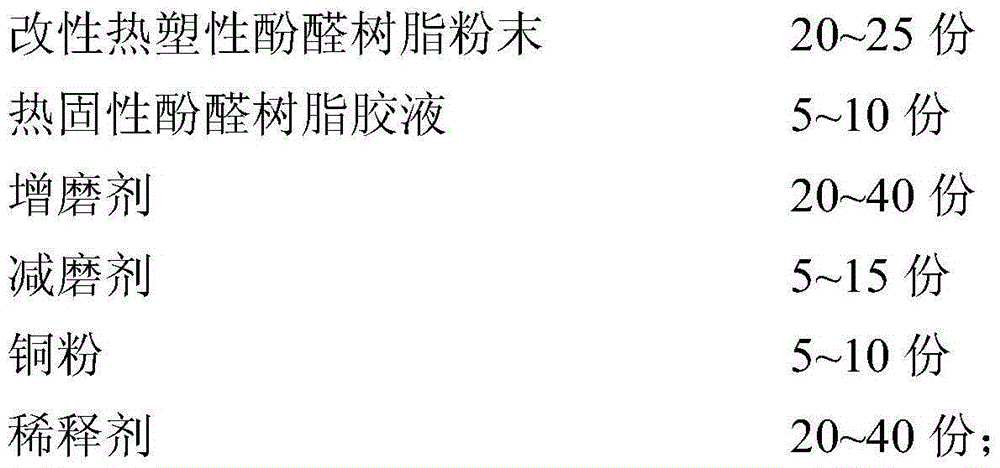

Method for preparing carbon fiber fabrics friction material used for wet clutch and application thereof

InactiveCN102343679ABest friction and wear resistanceAvoid shear damageFriction liningFiberCarbon felt

The invention relates a method for preparing a carbon fiber fabrics friction material used for a wet clutch and an application thereof, which comprises the following steps: 1), 3D braiding carbon felt or carbon fiber and puncturing to carbon fiber fabrics as a preform; 2), dipping the preform into a soaker, wherein the soaker comprises high temperature resistance brake sheet phenol resin containing a rubbing agent with one or more from SiO2, ZrO2, boron iron, manganese iron and chromium iron, controlling the concentration of the dipped perform at 1.68g / cm<3>-2g / cm<3> by controlling the dipping pressure or controlling the addition of high temperature resistance brake sheet phenol resin; 3), pressurizing and thermocuring the dipped preform which is impregnated cloth; 4) punching the processed impregnated cloth into a required shape, coating a binder on one surface of the impregnated cloth and performing a heat bonding with a support steel back. The method for preparing the carbon fiber fabrics friction material used for the wet clutch and the application are capable of raising the friction and wear performance of the wet carbon fiber fabrics and conveying large torsional moment. According to the invention, the obtained friction material still has good friction and wear performance even if the friction material is thinned.

Owner:CENT SOUTH UNIV

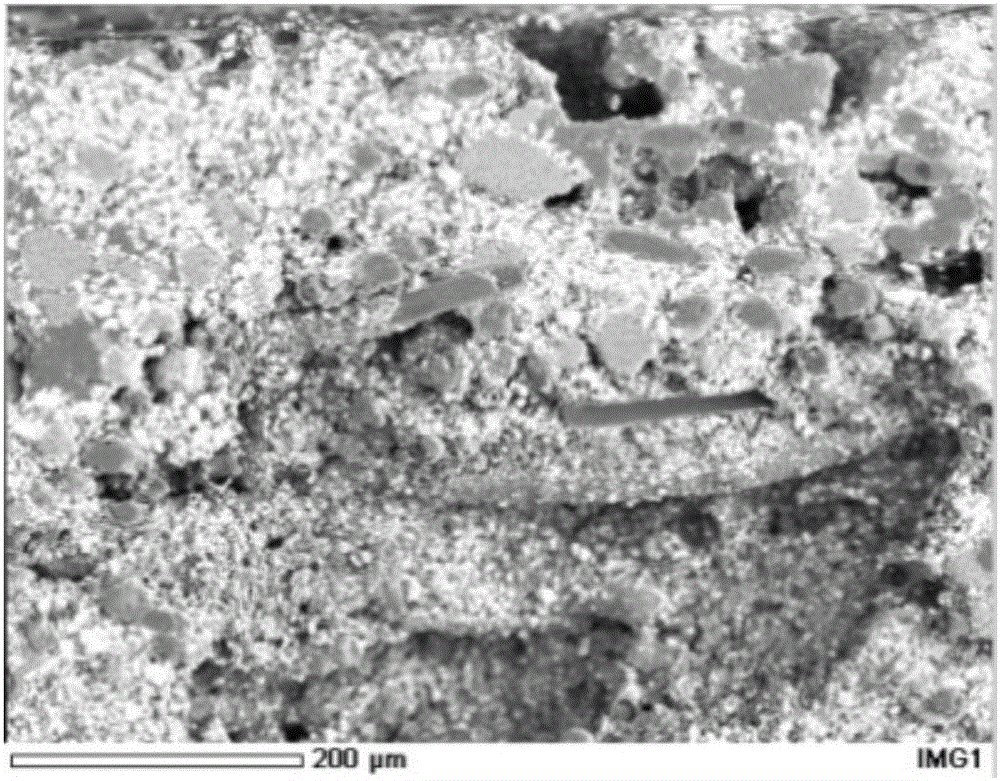

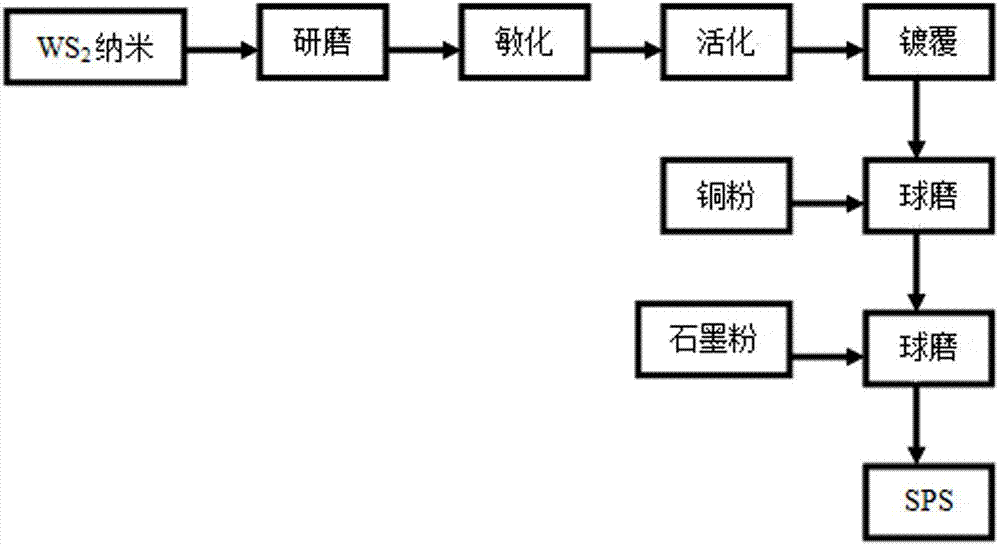

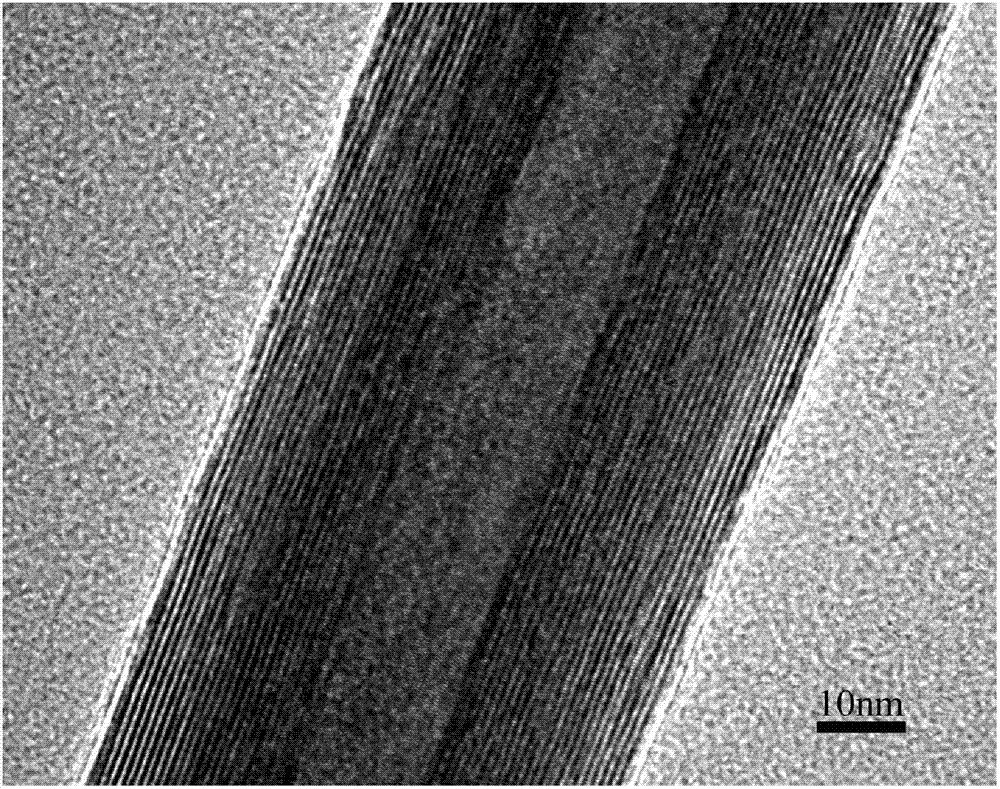

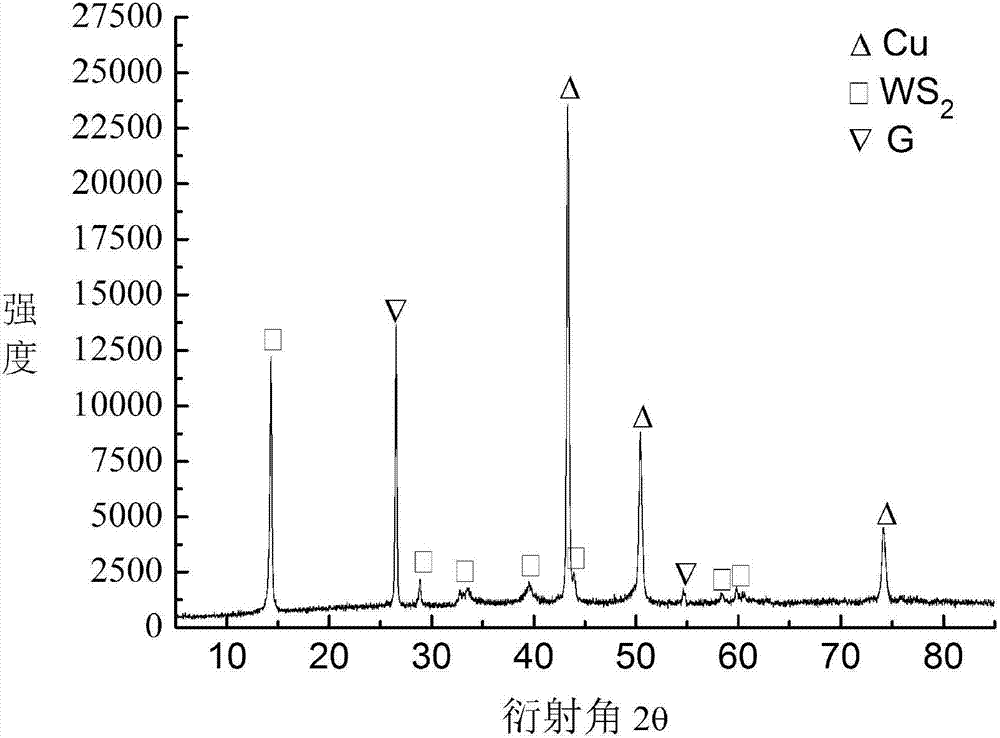

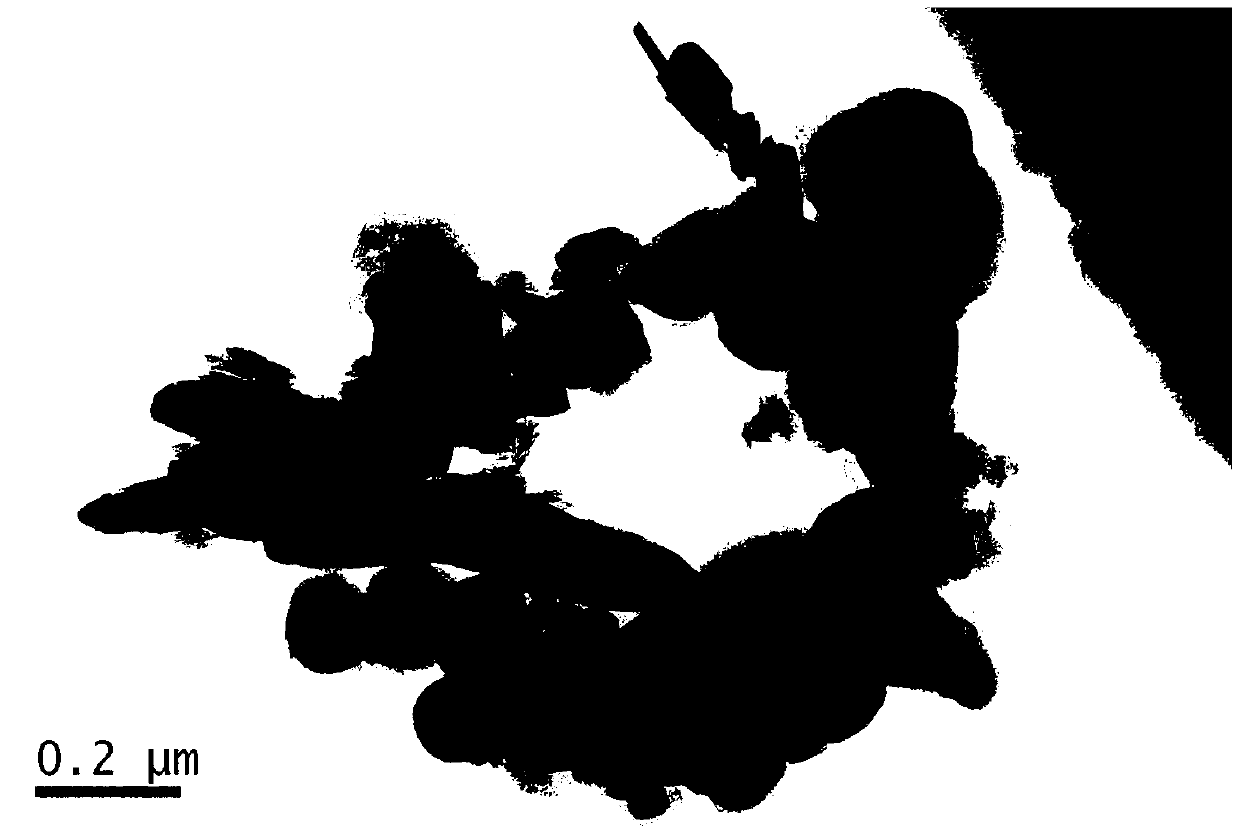

Copper-graphite-tungsten disulfide nanotube self-lubricating composite material and preparation method thereof

ActiveCN103045971AImprove friction and wear propertiesImprove environmental adaptabilityCopper platingElectrolysis

The invention discloses a copper-graphite-tungsten disulfide nanotube self-lubricating composite material and a preparation method thereof, wherein the self-lubricating composite material is prepared by taking copper as a substrate and graphite as well as tungsten disulfide nanotube as solid lubricating additives through a spark plasma sintering process, and consists of the following components in percentage by weight: 80-90% of copper, 7-10% of graphite and 3-10% of tungsten disulfide nanotube. The preparation method comprises the following steps of: grinding, sensitizing, activating and chemically copper-plating the tungsten disulfide nanotube, uniformly mixing with electrolytic copper powder and graphite powder in proportion through a mechanical ball-milling process; and implementing a spark plasma sintering process to the mixing powder, to prepare the tungsten disulfide nanotube and graphite reinforced copper-base self-lubricating composite material. The copper-base self-lubricating composite material prepared by the preparation method disclosed by the invention is high in mechanical intensity, excellent in friction and abrasion resistance and good in environmental suitability.

Owner:HEFEI UNIV OF TECH

Method for preparing sliding bearing by using polyether-ether-ketone composite material

InactiveCN101655127AImprove bindingIncrease coefficient of frictionBearing componentsFiberCarbon fibers

The invention relates to a method for preparing a sliding bearing by using a polyether-ether-ketone composite material, which comprises the following steps: firstly, performing air oxidation treatmentto carbon fibers, wherein the oxidation temperature is 450-500 DEG C and the oxidation time is 1-3min; secondly, laying a layer of bronze powder with thickness of 0.25-0.3mm on a steel plate, sintering the bronze powder and the steel plate substrate together at a temperature 800 DEG C for 2h; rolling a polymer layer of thickness of 0.01-0.03mm on an interlayer of the bronze powder, wherein the pressure is 12MPa, the polymer layer comprises the following raw materials in percentage by weight: 70-95 percent of polyether-ether-ketone, 1-5 percent of molybdenum disulfide and 4-25 percent of carbon fibers; sintering under the condition of nitrogen protection, at 340 DEG C, machining and modifying, rolling, and welding to form a sliding bearing made of the composite material. The invention canimprove the interface bonding performance and the friction coefficient of the composite material to enable the sliding bearing to have excellent friction wear performance.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

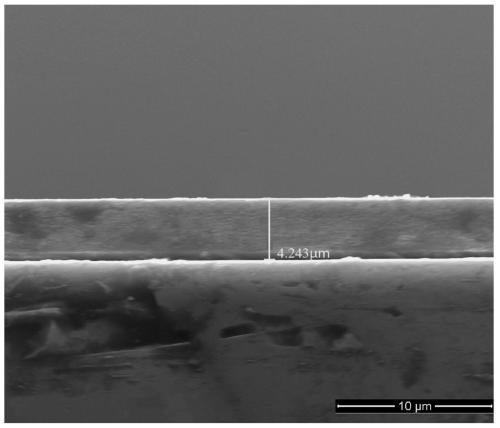

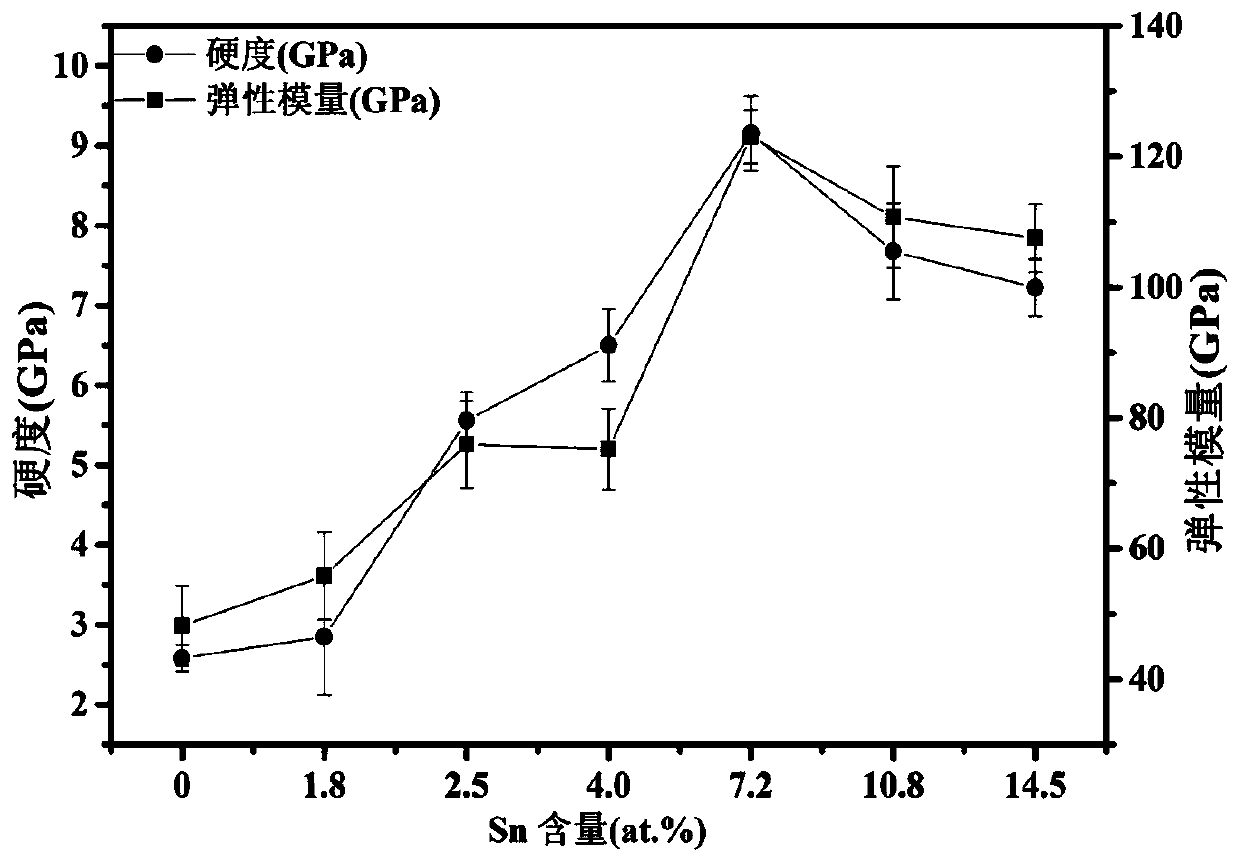

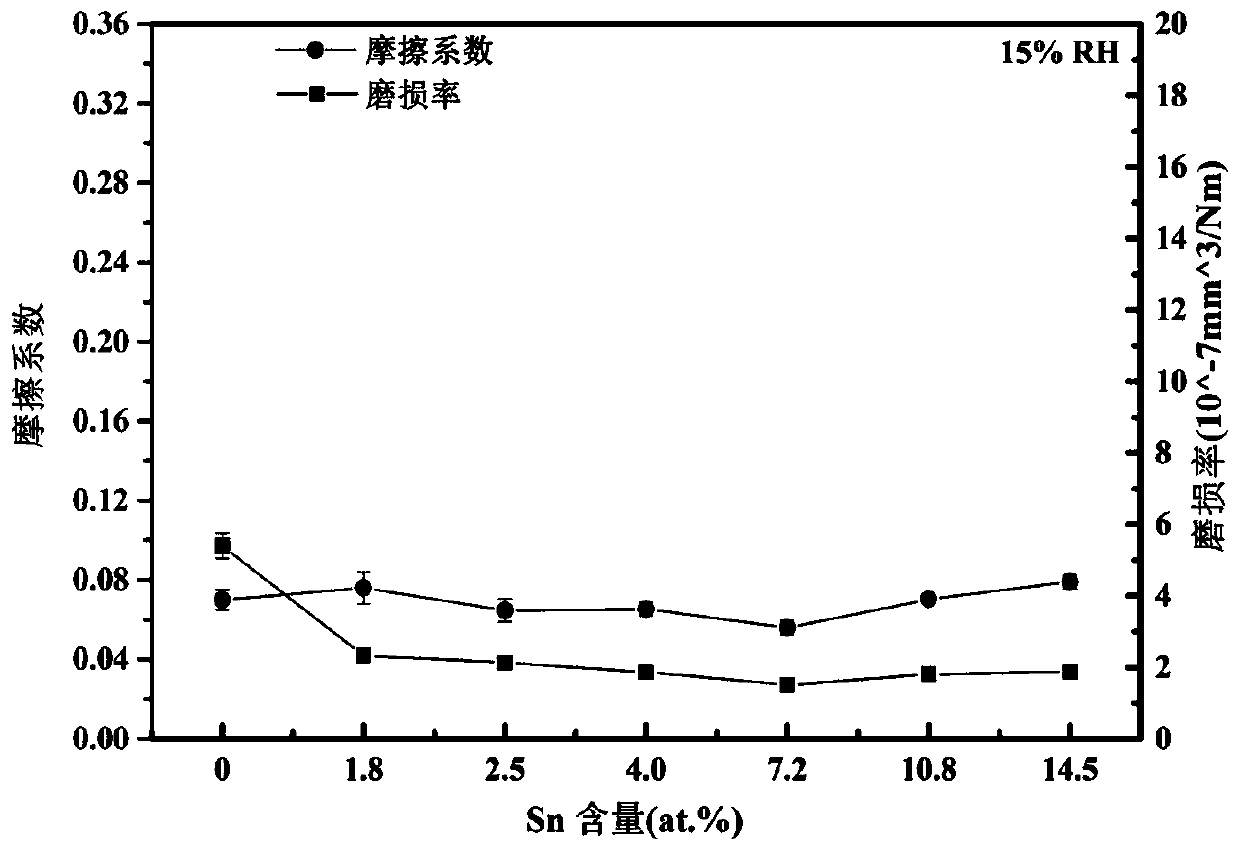

Molybdenum disulfide/Sn co-doping composite film on base body surface and preparing method thereof

InactiveCN110195207AImprove bindingImprove mechanical propertiesVacuum evaporation coatingSputtering coatingHigh humidityComposite film

The invention provides a molybdenum disulfide / Sn co-doping composite film on a base body surface and a preparing method thereof. The composite film sequentially comprises a Ti transition layer, a Ti,MoS2 and Sn gradient transition layer and an MoS2 and Sn co-doping layer from the base body surface in the thickness direction; the composite film has the good mechanical property, the friction wear property, and the damp heat resistance property, particularly, through regulation of Sn content, the hardness and the friction wear properties of the composite film can be regulated, and the compositefilm can be applied to the high humidity atmosphere environment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

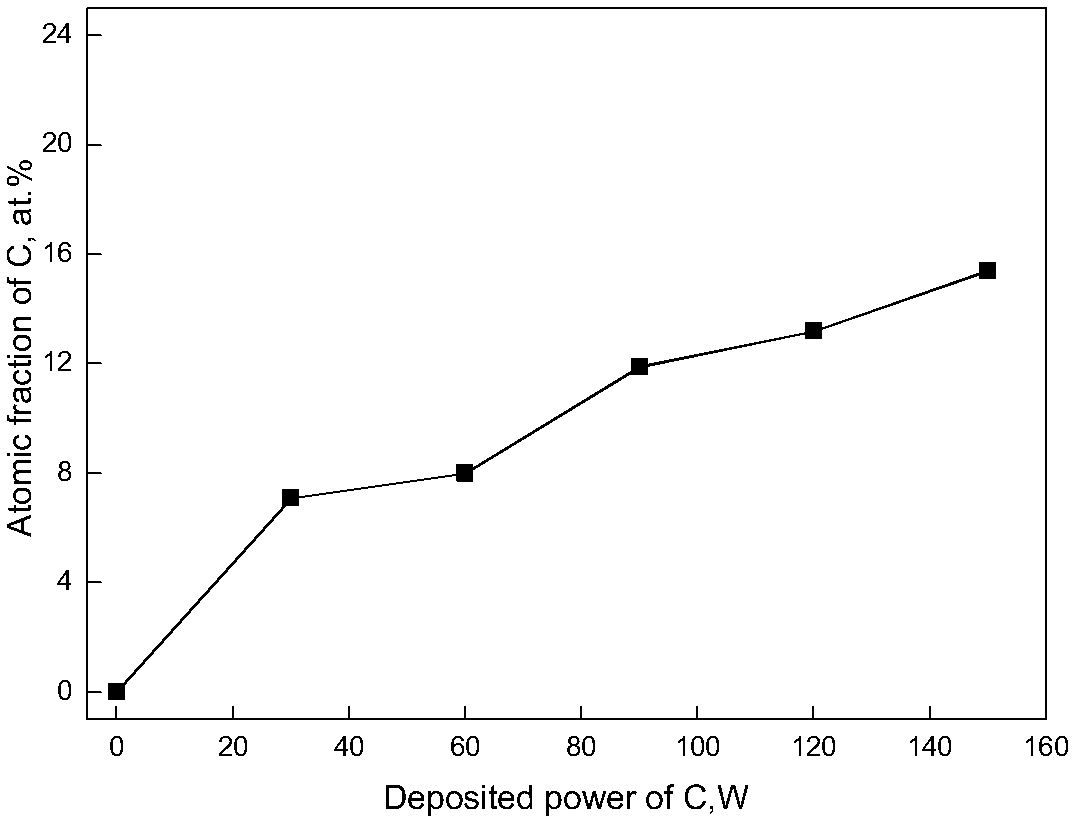

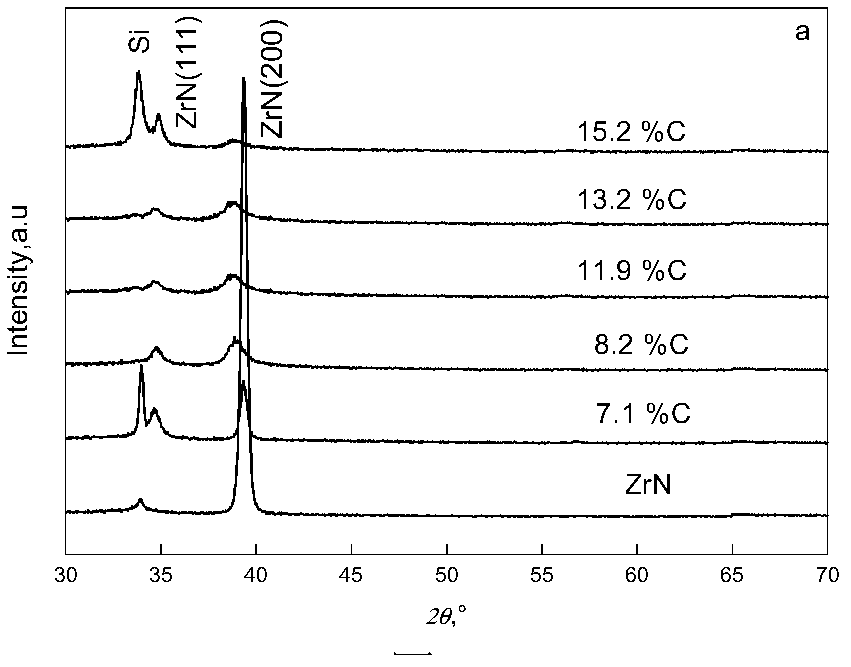

ZrCN nanometer composite membrane and preparation method thereof

InactiveCN102660729AExcellent friction and wear propertiesHigh hardness valueVacuum evaporation coatingSputtering coatingRadio frequencyComposite membrane

The invention discloses a ZrCN nanometer composite membrane which is prepared through a double-target radio-frequency reactive sputtering method and uses stainless steel as a stratum base. The thickness of the ZrCN nanometer composite membrane is 1-3 micrometers, 7.2at.%<=C<=11.9at.%, atomic ratio of (C+N) / Zr is less than 1, C enters ZrN interstitial void to totally form interstitial solid solution, and the hardness of the ZrCN nanometer composite membrane is larger than or equal to 29GPa; or 13.2at.%<=C<=15.4at.%, atomic ratio of (C+N) / Zr is larger than 1, the remaining C (except for the part of C entering the ZrN interstitial void to totally form interstitial solid solution) forms amorphous CN or C elementary substance, and the hardness of the ZrNC nanometer composite membrane is larger than or equal to 18.5GPa.

Owner:JIANGSU UNIV OF SCI & TECH

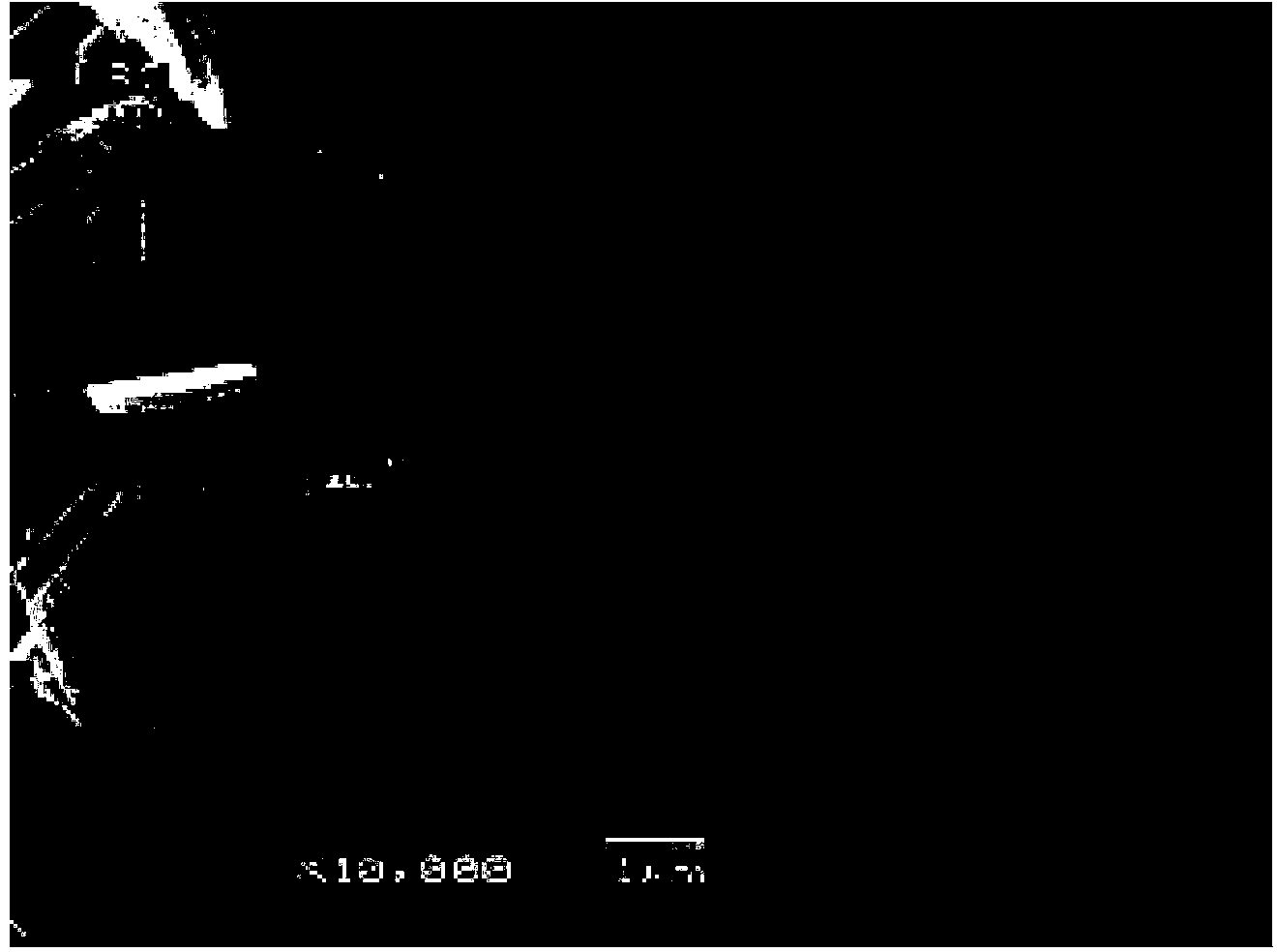

Electric brush-sliding ring system made of silver-tungsten disulfide composite materials

The invention discloses an electric brush-sliding ring system made of silver-tungsten disulfide composite materials. The electric brush-sliding ring system comprises a silver-tungsten disulfide composite electric brush and Ag-Cu10 sliding ring. The electric brush-sliding ring system disclosed by the invention has the advantages that the stability is high in use, the service life is long and the energy consumption is less; and compared with the traditional system made of silver (copper)-molybdenum disulfide or silver (copper)-graphite material, the electric brush-sliding ring system is better in effect and wide in application range.

Owner:CENT SOUTH UNIV

Wear resistant copper-based gradient material for manufacturing pantograph slider and preparation thereof

InactiveCN101407123AHigh mechanical strengthImprove conductivityMetal layered productsPower current collectorsMass ratioGradient material

The invention discloses a wear-resistant copper-matrix gradient material for use in manufacture of pantograph slide plates and a preparation method thereof. The wear-resistant copper-matrix gradient material consists of a copper-zirconium oxide layer, a pure copper layer and a copper-graphite layer. The preparation method comprises the following steps: evenly mixing copper powder and zirconium oxide powder in a ball grinder according to a mass ratio; evenly mixing copper powder and graphite powder in the ball grinder according to a mass ratio; placing the copper-zirconium oxide layer, the pure copper layer and the copper-graphite layer in a mould according to a thickness ratio; placing the mould in a cold isostatic press for press forming; removing the molded material from the mould and sintering the molded mater in a vacuum environment to obtain the copper-matrix gradient wear-resistant material. The wear-resistant copper-matrix gradient material for use in manufacture of pantograph slide plates and the preparation method thereof have advantages of simple preparation process and suitability for industrial large-scale production. The obtained copper-matrix gradient wear-resistant material is used for manufacturing pantograph slide plates for electric locomotives.

Owner:TIANJIN UNIV

Preparation method of carbon/carbon-boron nitride anti-friction composite material

ActiveCN109665855AImprove mechanical propertiesImprove friction and wear propertiesFiberCarbon fibers

The invention discloses a preparation method of a carbon / carbon-boron nitride anti-friction composite material. The preparation method comprises acidizing a graphitized C / C blank, washing the acidizedC / C blank to be neutral to obtain a preprocessed C / C blank, immersing the preprocessed C / C blank into a solution containing modifier for reaction to obtain a functionalized C / C blank, impregnating the functionalized C / C blank with h-BN (hexagonal boron nitride) slurry, then drying the impregnated C / C blank to obtain a C / C-BN precursor, and performing carbonizing densification and graphitization on the C / C-BN precursor with a carbon source to obtain the C / C-BN anti-friction composite material; the modifier is selected from silane coupling agent or polyvinyl alcohol (PVA). According to the preparation method of the carbon / carbon-boron nitride anti-friction composite material, a slurry impregnation method is applied for the first time to produce a BN matrix, and after the C / C blank is functionalized, a slurry impregnation process can effectively introduce BN powder into the C / C blank. The preparation method of the carbon / carbon-boron nitride anti-friction composite material can effectively avoid damage of carbon fiber and ensure excellent structural strength of the C / C-BN composite material; the prepared C / C-BN composite material has excellent friction-wear properties.

Owner:CENT SOUTH UNIV

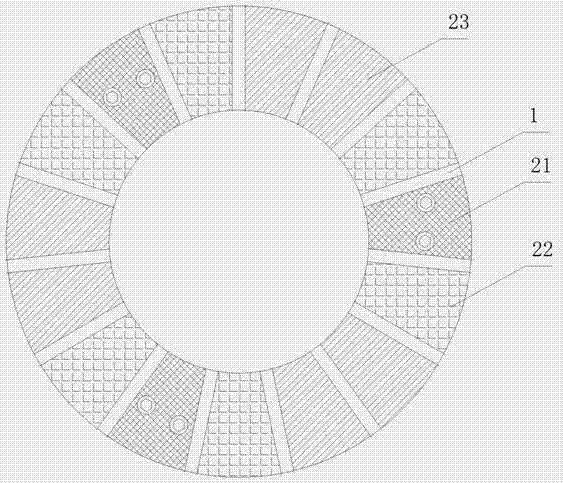

High-performance clutch plate for heavy truck

The invention provides a high-performance clutch plate for a heavy truck. The high-performance clutch plate for the heavy truck achieves the technical purposes of being novel in structure, reasonable in material formula and balanced and excellent in performance index, cost and application effect. The high-performance clutch plate for the heavy truck is divided into a friction working layer and a structural layer. The friction working layer comprises at least three friction linings made of different materials. The three friction linings made of the different materials comprise the rubber-based friction linings, the substitute rubber FA friction linings and the ceramic fiber friction linings, all of which are of the same thickness. The high-performance clutch plate has the following beneficial effects that due to the fact that the rubber-based friction linings, the ceramic fiber friction linings and the substitute rubber FA friction linings are arranged on the surface of the structural layer in a mixed manner, in clutch operation of the clutch plate, the characteristics of the three different materials can be brought into play, when the clutch plate is applied to a clutch mechanism of the heavy truck, friction force resistant to attenuation and stable at high temperature is effectively reduced, and the high-performance clutch plate is particularly suitable for being applied to the heavy truck.

Owner:浙江科马摩擦材料股份有限公司

Environment-friendly composite multisoap base self-repairing bearing grease and preparation method thereof

ActiveCN102604724AImprove performanceOvercoming the lack of extreme pressure wear resistanceLubricant compositionMaximum levelWear resistant

The invention relates to environment-friendly composite multisoap base self-repairing bearing grease and a preparation method of the bearing grease. The bearing grease is prepared from composite base liquid, a composite calcium soap thickening agent, an oxidation and corrosion resistant additive, a tungsten disulfide extreme pressure additive, a metal deactivator, a polarization graphite wear resistant additive, a self-repairing additive and a structure improving agent. According to the bearing grease provided by the invention, an additive containing non-heavy metal elements is used to replace the originally used additive containing heavy metal elements. Because base liquid, a thickening agent and an additive are all optimized, the bearing grease provided by the invention is more excellent in combination property and highlighted in abrasion resistance, maintains an excellent level in extreme pressure property, can fully meet the requirements of the bit bearing extreme pressure, the high temperature, a deep well with high temperature, the high-impact load and the abrasion resistance, meanwhile, can effectively supplement the defect that silver coating is not sufficiently brushed onthe bearing axial diameter plane, and acts a function of repairing an abrasion resistant layer on a metal seal and a rubber seal of a bit bearing, so that the service life of the bearing is prolongedat a maximum level.

Owner:KINGDREAM PLC CO +2

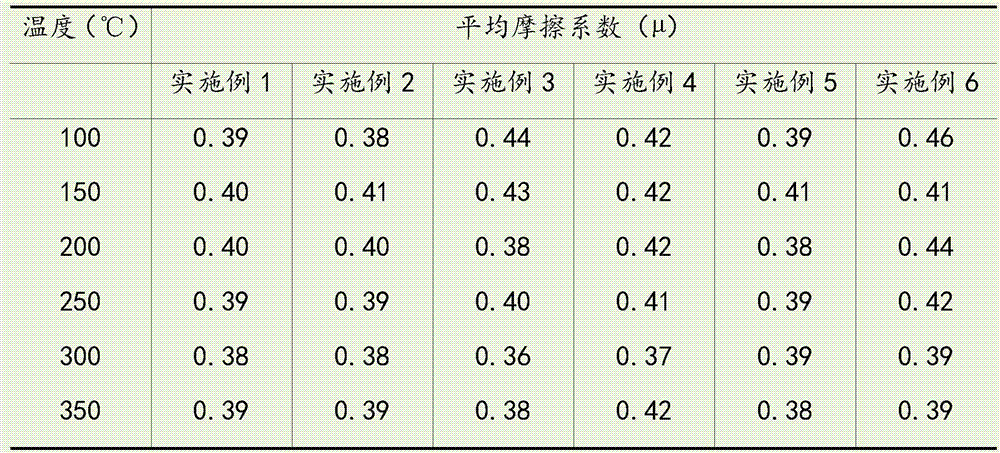

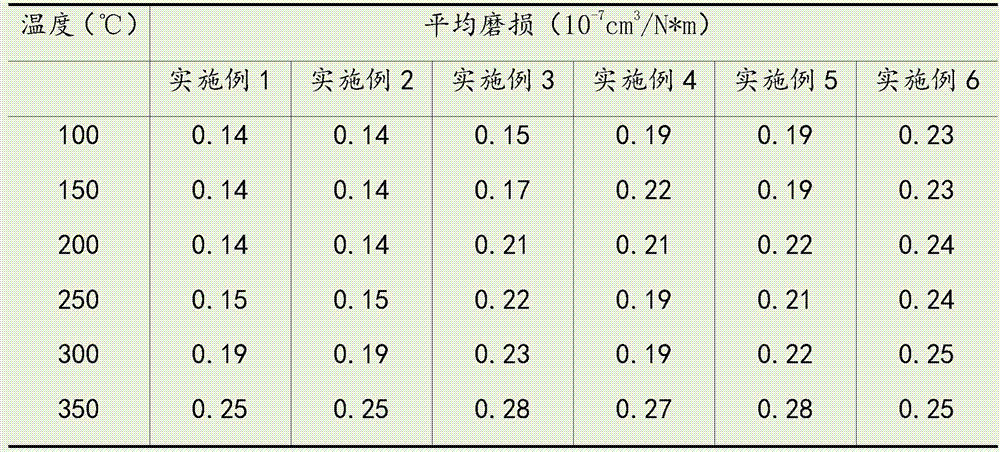

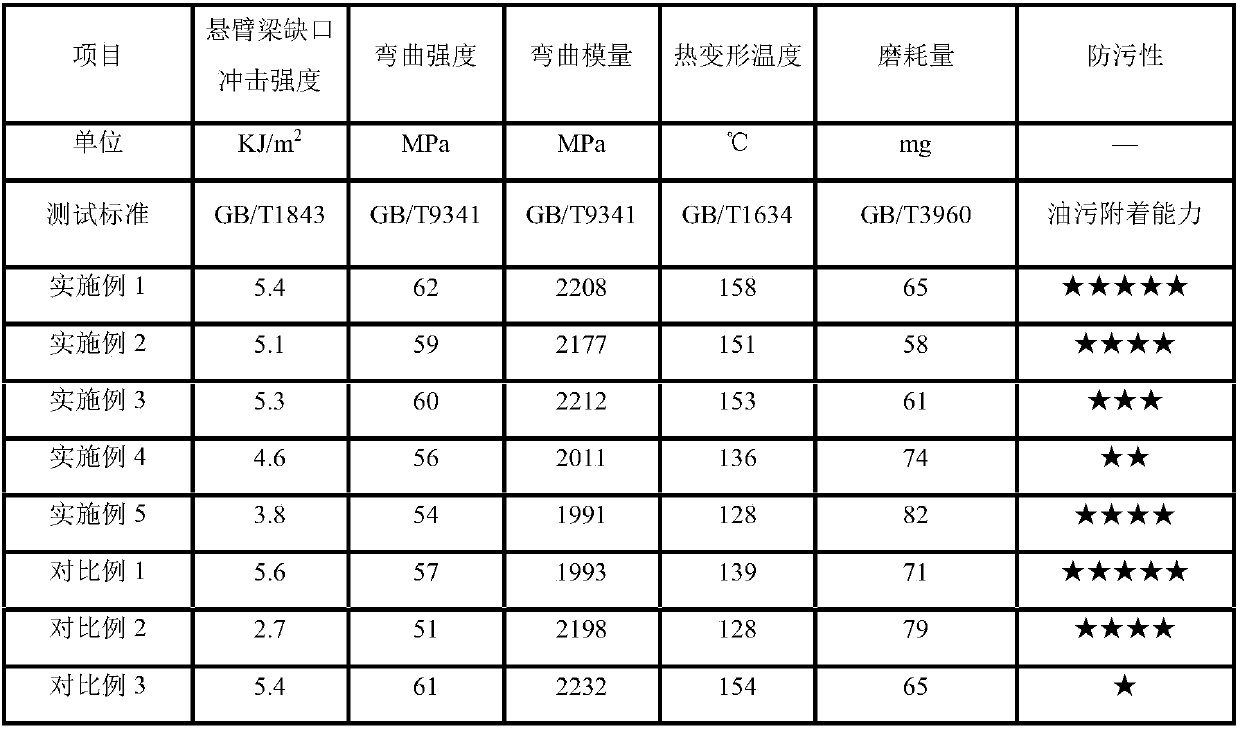

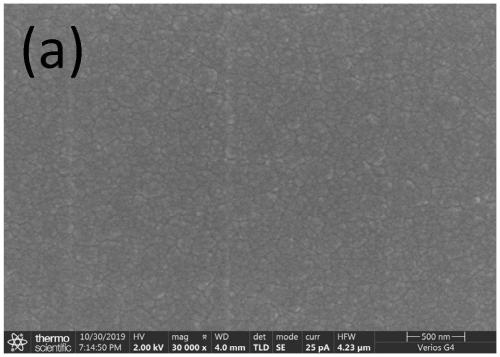

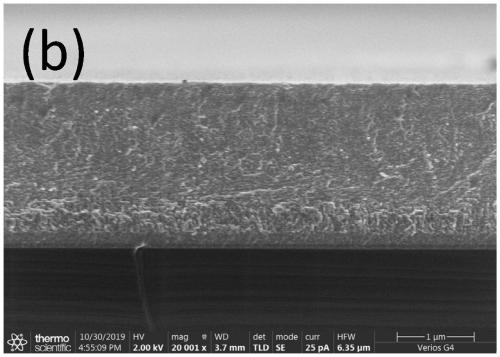

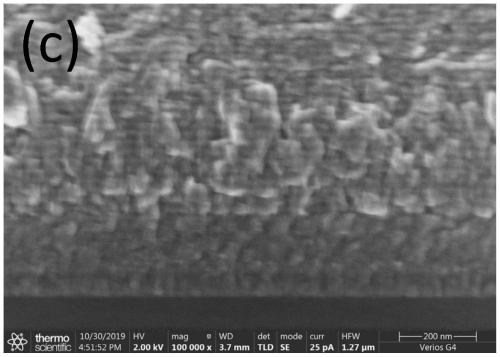

Pollution-resistance high-temperature-resistance polypropylene material and preparation method thereof

The invention belongs to the technical field of polymer composite material modification, and particularly relates to a pollution-resistance high-temperature-resistance polypropylene material and a preparation method thereof. The polypropylene material is characterized in that high-crystallization homopolymer polypropylene is taken as a basic component, polyketone resin is added to improve the wearresistance and mechanical performance of the material, barium sulfate masterbatch is taken as a filling agent to reduce dust pollution, a compatibilizer is added to improve the bonding force betweenraw materials to improve the mechanical performance of the material, organic group modified ultrahigh molecular weight polyorganosiloxane is taken as an antifouling agent to improve the water and oilresistance and the wear resistance of the material, and the anti-ageing performance of the material is improved by adopting an antioxidant. The material has the advantages of easy processing, high glossiness, high wearing resistance, pollution resistance, easy dyeing, excellent physical mechanical performance and the like, the demands by household electrical appliance products and kitchen electrical appliances on housing materials thereof in severe environments can be completely met, and the material can be widely applied to the production of plastic spare parts which need to slide or rotate in the fields of machinery, building materials, sports and the like.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Friction material with good wear-in property

InactiveCN102807843AImprove running-inPlay the role of fixed lubrication componentsOther chemical processesFriction liningSilicon dioxidePhenol

The invention discloses a friction material with a good wear-in property, and the friction material consists of following ingredients in parts by weight: 16 to 18 parts of bucrilate modified phenol resin, 2 to 3 parts of aramid fiber, 3 to 5 parts of copper fiber, 7 to 9 parts of vermiculite fiber, 5 to 7 parts of calcium carbonate whisker, 3 to 5 parts of 60-mesh to 150-mesh silicon dioxide, 3 to 5 parts of 200-mesh to 320-mesh aluminum oxide, 2 to 4 parts of colloid molybdenum disulfide, 6 to 8 parts of -120-mesh crystalline flake graphite, 3 to 5 parts of -200-mesh antimony sulfide powder and 10 to 12 parts of -200-mesh light calcium carbonate.

Owner:湖北久鸣汽车零部件有限公司

Molybdenum disulfide/tungsten disulfide multi-layer tantalum-doped thin film and preparation method and application thereof

InactiveCN111172498AGood substrate bonding strengthExcellent friction and wear propertiesVacuum evaporation coatingSputtering coatingThin membraneTitanium

The invention discloses a molybdenum disulfide / tungsten disulfide multi-layer tantalum-doped thin film and a preparation method and application thereof. The molybdenum disulfide / tungsten disulfide multi-layer tantalum-doped thin film comprises a titanium transition layer, a titanium / tantalum / molybdenum disulfide / tungsten disulfide multi-layer gradient transition layer and a molybdenum disulfide / tungsten disulfide multi-layer tantalum-doped layer which are laminated in the thickness of the film in sequence. The preparation method comprises the step that a magnetron sputtering technology is adopted for depositing the titanium transition layer, the titanium / tantalum / molybdenum disulfide / tungsten disulfide multi-layer gradient transition layer and the molybdenum disulfide / tungsten disulfide multi-layer tantalum-doped layer on the surface of a substrate in sequence to obtain the molybdenum disulfide / tungsten disulfide multi-layer tantalum-doped thin film. The molybdenum disulfide / tungsten disulfide multi-layer tantalum-doped thin film has good bonding strength with the substrate, rigidity and elasticity modulus, has good friction and wear resistance, good temperature self-adaptability,damp heat resistance and high-temperature-oxidation resistance at different temperatures in the atmospheric environment, and can meet the demands of aerospace crafts for stable lubrication and long service life.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Deep-crosslinked-structure carbon-fiber-reinforced phenolic-resin-base friction material and preparation method thereof

ActiveCN105038116AImprove flexural strengthIncreased shear strengthOther chemical processesInterlaminar shearUltimate tensile strength

The invention discloses a deep-crosslinked-structure carbon-fiber-reinforced phenolic-resin-base friction material. The preparation method of the friction material comprises the following steps: preparing a deep-crosslinked-structure carbon fiber prefabricated body, preparing a matrix colloidal liquid, and preparing the friction material, wherein the friction materials is prepared by immersing the deep-crosslinked-structure carbon fiber prefabricated body in the colloidal liquid and carrying out die pressing treatment. The stitching warp penetrates through the friction material in the whole thickness direction to form the three-dimensional structure, thereby overcoming the defect of delamination and increasing the interlaminar shear strength. The friction material has the advantages of excellent structural designability, excellent integral impact resistance and excellent fatigue resistance. The preparation method has the advantages of simple technique and low production cost, and is convenient for popularization.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com