Preparation method of h-BN added titanium boride-based self-lubricating ceramic cutter material

A technology of hexagonal boron nitride and ceramic cutting tools, which is applied in the field of preparation of ceramic cutting tool materials, can solve problems such as the full play of performance advantages, and achieve the effects of inhibiting grain growth, reducing friction coefficient, and good self-lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

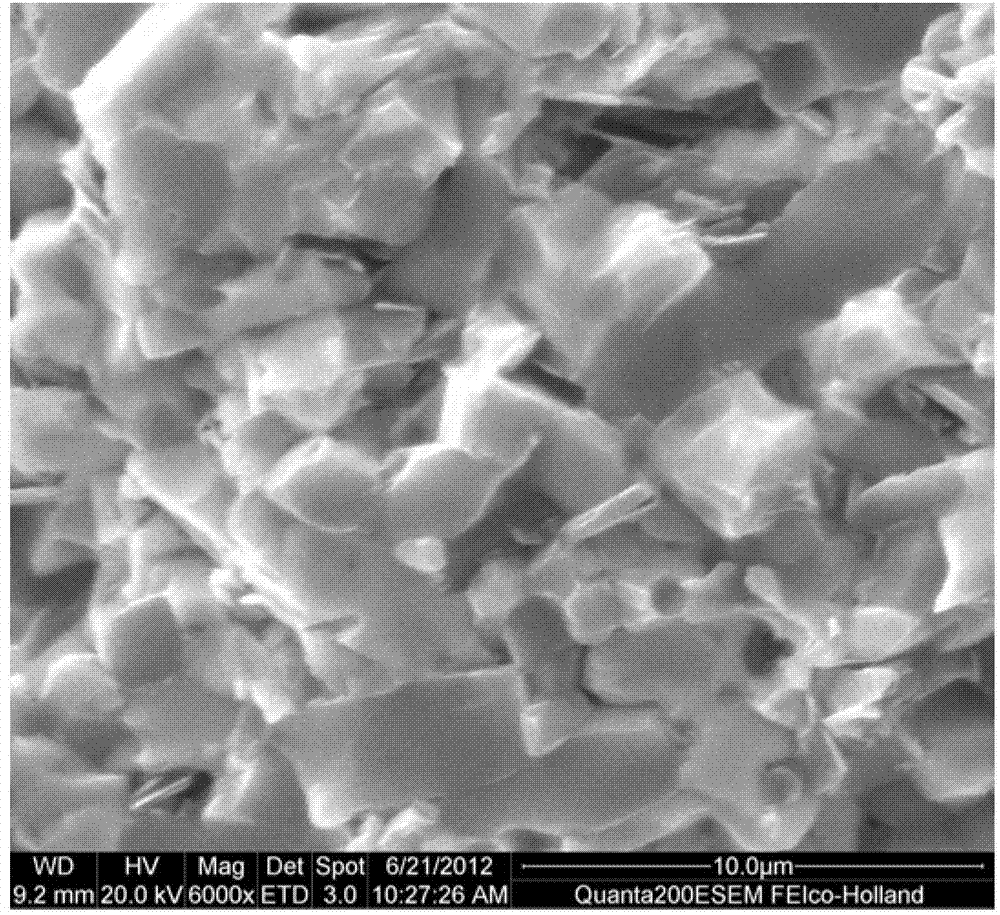

Image

Examples

Embodiment 1

[0036] Add hexagonal boron nitride titanium boride-based self-lubricating ceramic tool material, the volume percentage of raw material components is:

[0037] micron titanium diboride (TiB 2 ) 65%, micron tungsten carbide (WC) 25%, micron hexagonal boron nitride (h-BN) 5%, micron molybdenum (Mo) 2%, micron nickel (Ni) 3%.

[0038] The preparation method is as follows:

[0039] Weigh TiB in proportion 2 Powder, with an appropriate amount of absolute ethanol as the dispersion medium, made into TiB 2 Suspension, fully stirred with a stirrer, ultrasonically dispersed for 20 minutes; WC powder and h-BN powder were weighed in proportion, added with absolute ethanol to make a mixed suspension, fully stirred, ultrasonically dispersed for 20 minutes; the obtained TiB 2 , WC and h-BN suspensions were mixed to obtain a multi-phase suspension, and then sintering aids Mo and Ni were added in proportion, after ultrasonic dispersion for 20 minutes, and mixed evenly; the mixture was poured...

Embodiment 2

[0043] Titanium boride-based self-lubricating ceramic tool material with hexagonal boron nitride added, the volume percentage of raw material components is: 70%TiB 2 , 18%WC, 8%h-BN, 2%Mo, 2%Ni. The preparation method is as follows:

[0044] Weigh TiB in proportion 2 Powder, with an appropriate amount of absolute ethanol as the dispersion medium, made into TiB 2 Suspension, fully stirred with a stirrer, and ultrasonically dispersed for 25 minutes; the obtained WC powder and h-BN powder were weighed in proportion, and anhydrous ethanol was added to make a mixed suspension, fully stirred, and ultrasonically dispersed for 25 minutes; the obtained TiB 2 , WC and h-BN suspensions were mixed to obtain a multi-phase suspension, and then sintering aids Mo and Ni were added in proportion, after ultrasonic dispersion for 30 minutes, and mixed uniformly; the mixture was poured into a ball mill jar, and nitrogen was used as a protective atmosphere to Anhydrous ethanol is used as the me...

Embodiment 3

[0047] The preparation method of titanium boride-based self-lubricating ceramic tool material with hexagonal boron nitride added, the volume percentage of raw material components is: micron titanium diboride 60%, micron tungsten carbide 30%, micron hexagonal boron nitride 5%, micron Molybdenum 2%, micron nickel 3%. Operation steps and process condition are with embodiment 1.

[0048] The obtained ceramic tool material was processed by wire cutting, rough grinding, fine grinding, grinding, and polishing to prepare test samples, and its mechanical performance parameters were measured: bending strength 627MPa, fracture toughness 5.1MPa m 1 / 2 , Vickers hardness 14.7GPa. The coefficient of friction is 0.34.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com