Patents

Literature

254 results about "Green manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Green manufacturing is the renewal of production processes and the establishment of environmentally-friendly operations within the manufacturing field. Essentially, it is the “greening” of manufacturing, in which workers use fewer natural resources,...

Process for preparing regenerated cellulose films and wires

The invention discloses a method for manufacturing cellulose film and silk. The cellulose is dissolved in mixed liquid 5-12wt% natrium oxyhydrogen and 8-20wt% ureophil, gets the cellulose liquid, then carries on film scratching and silk spraying to the cellulose, they are solidified in the solidifying bath, then the regenerated cellulose film and silk will be got after being cleaned. The cellulose thick liquid has excellent fiber textile performance and compactibiity of film, the regenerated cellulose has excellent light transmission and mechanical performance, the silk also has good mechanical performance. The method can obtain cellulose thick liquid by dissolving cellulose in room temperature. It has no contamination and its price is low, it is a kind of green manufacturing process.

Owner:WUHAN UNIV

Preparation method for super white ceramic vitrified tile produced by using magnesium aluminum silicate as raw material

The invention provides a preparation method for a super white ceramic vitrified tile produced by using magnesium aluminum silicate as a raw material. The super white ceramic vitrified tile comprises components of potassium feldspar, albite, calcined talc, black clay, a water reducing agent, a lithium feldspar, diopside, an intensifier, washed mud and quartz. The ultralow temperature fast firing vitrified tile belongs to a special ultralow temperature, high-strength, high-hardness, high abrasion-resistance, strong antifouling, low-radiation, environment-friendly, healthy and novel vitrified tile material and product. The technology can reduce firing temperature and shorten a firing period greatly and is favorable for energy conservation and emission reduction of ceramic industry, green manufacturing and low carbon production.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD +2

Autothermal catalytic marsh gas reforming process of preparing synthetic gas

InactiveCN1468800ASelf-heating reactionHigh activityHydrogenWaste based fuelSyngasCatalytic reforming

The present invention relates to the efficient clean utilization of marsh gas and is especially one new kind of catalyst for reforming methane-CO2 to produce synthetic gas. The present invention is one green process to utilize marsh gas with methane and CO2 as main components to produce synthetic gas via reformation. The present invention is significant for sustained supply of power source and environment protection.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

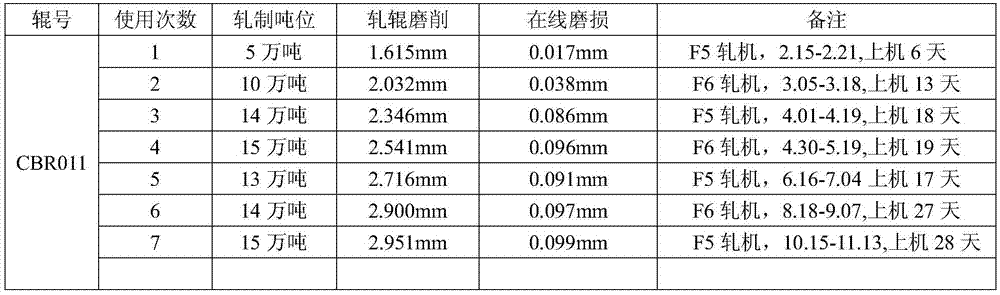

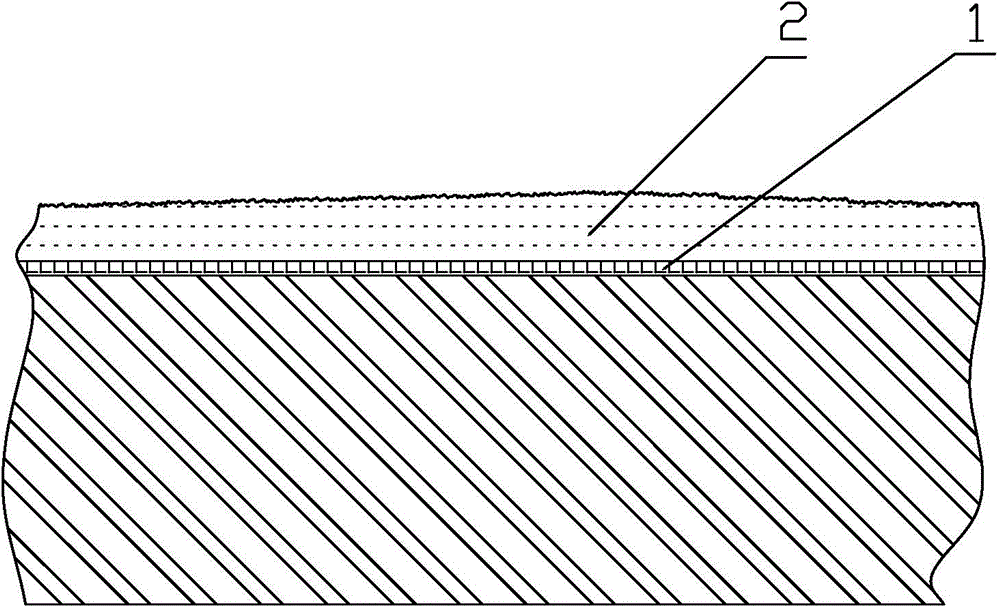

Surfacing reconstructed layer of large hot-rolled supporting roll Cr4 and method for repairing roll

InactiveCN105436665AExtended service lifeMeet the rolling use requirementsArc welding apparatusRollsGreen manufacturingHeat treated

The invention relates to a surfacing reconstructed layer of a large hot-rolled supporting roll Cr4 and a method for repairing a roll. The surfacing reconstructed layer is prepared by surfacing prepared flux-cored wires of a bottoming layer, a transitional layer and a working layer on the surface of a base body of the roll layer by layer, and the bottoming layer, the transitional layer and the working layer are sequentially arranged in a surfacing manner from the surface of the base body to the outside. The method comprises the following specific steps: roll preparation, preparation of the flux-cored wires, roll preheating, preparation before welding, sequential surfacing of the bottoming layer, the transitional layer and the working layer, intermediate heat treatment, final heat treatment, machining, examining and shipment. The method is suitable for repairing large and ultra-large hot-rolled supporting rolls, and the service lives of the repaired rolls are close to and even equal to the service lives of new rolls. The cost-performance ratio of the reconstructed layer is high, base body bonding strength, high-temperature resistance, wear resistance and corrosion resistance are excellent, and the using performance of the roll can be improved. The surfacing reconstructed layer of the large hot-rolled supporting roll Cr4 and the method for repairing the roll conform to a green manufacturing technology of national circular economy and a stainable development strategy, and have a wide application prospect and an economic benefit.

Owner:QINHUANGDAO HONGXIANG WELDING IND CO LTD

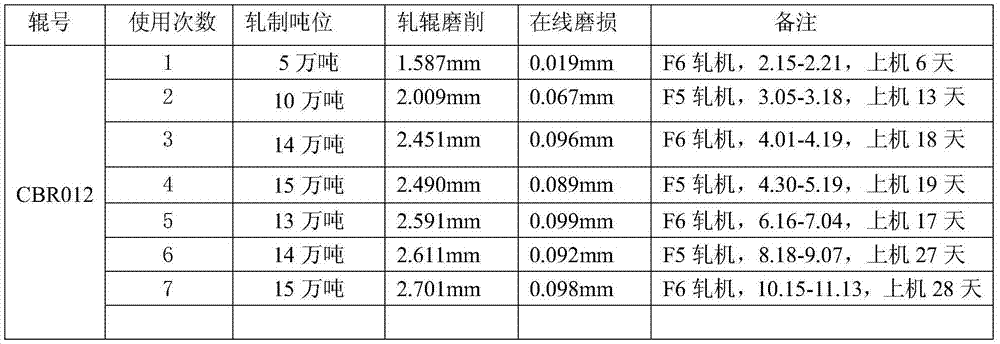

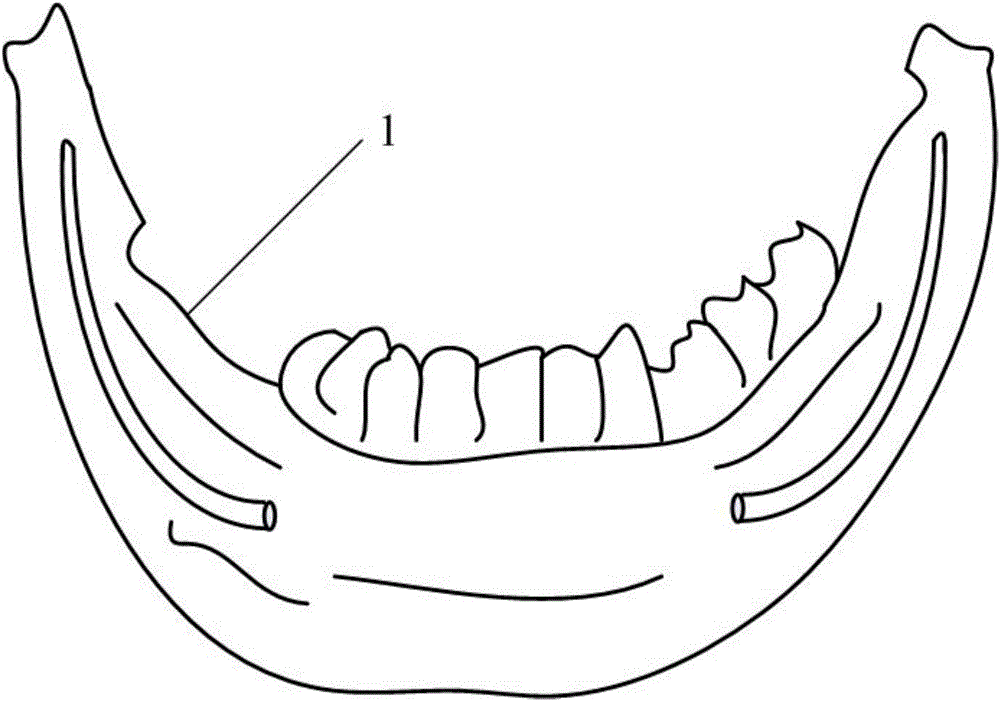

Oral cavity dental implant reconstructable guide plate and manufacturing method thereof

ActiveCN106361452AMeet the needs of individualized treatmentReduce wasteDental implantsAdditive manufacturing apparatusDentistryGreen manufacturing

The invention discloses an oral cavity dental implant reconstructable guide plate and a manufacturing method thereof. The oral cavity dental implant reconstructable guide plate consists of a movable drilling template and a personalized base plate; a designing and manufacturing method of the oral cavity dental implant reconstructable guide plate comprises the following steps: acquiring oral cavity CBCT of a patient; comprehensively evaluating the oral cavity situations of the patient; manufacturing and scanning a plaster model of an oral cavity part of the patient, matching plaster scanning data and CBCT data, and reconstructing three-dimensional models of teeth and bones; making a planting plan; analyzing the strength of an implant; designing a standard drilling template corresponding to a drilling bit of the drilling template; designing a personalized guide plate substrate; importing an implant body model into a computer to perform virtual planting; designing an implant denture; manufacturing the reconstructable guide plate. According to the oral cavity dental implant reconstructable guide plate and the manufacturing method thereof, the treatment time can be shortened by performing virtual planting by utilizing planting software; moreover, the survival rate of the dental implant is favourably improved; quick manufacturing and field reconstruction of a dental implant drilling and cutting guide plate are realized; a medical material is saved and the cost is also reduced through the use of the drilling template; the requirement of green manufacturing is met.

Owner:SHANDONG UNIV

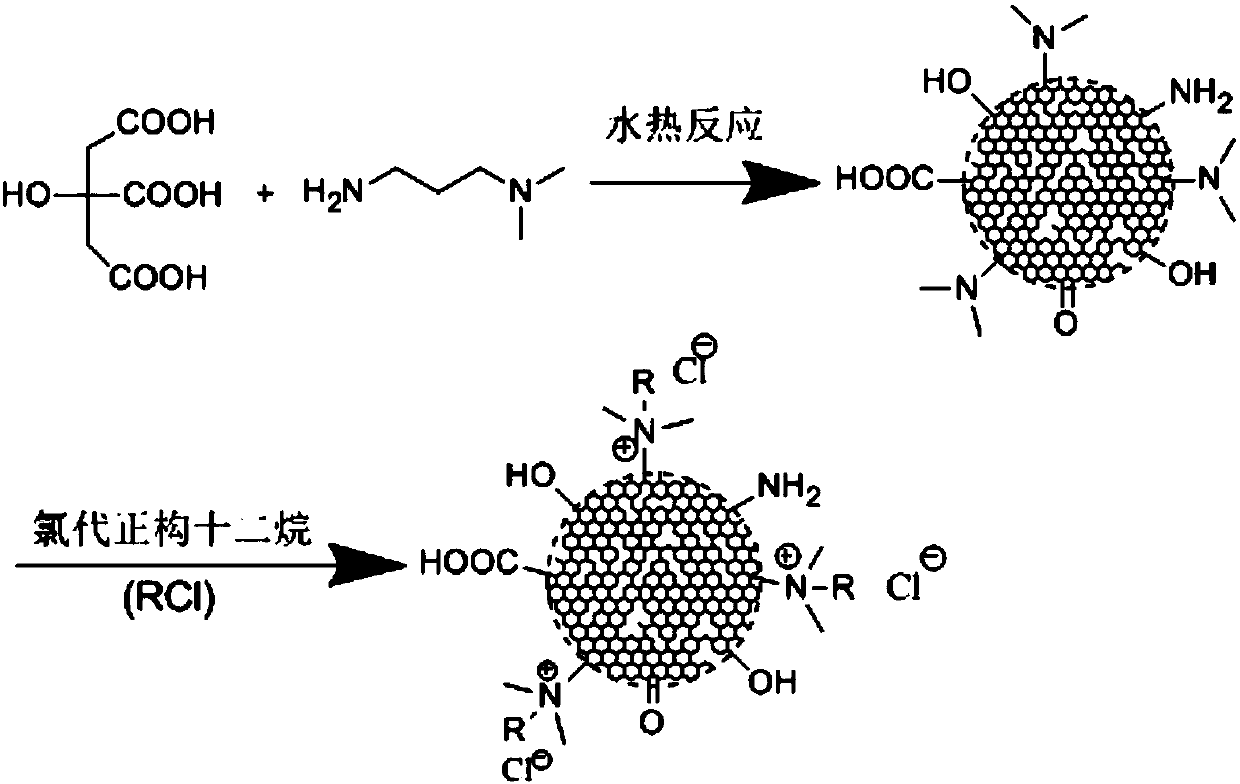

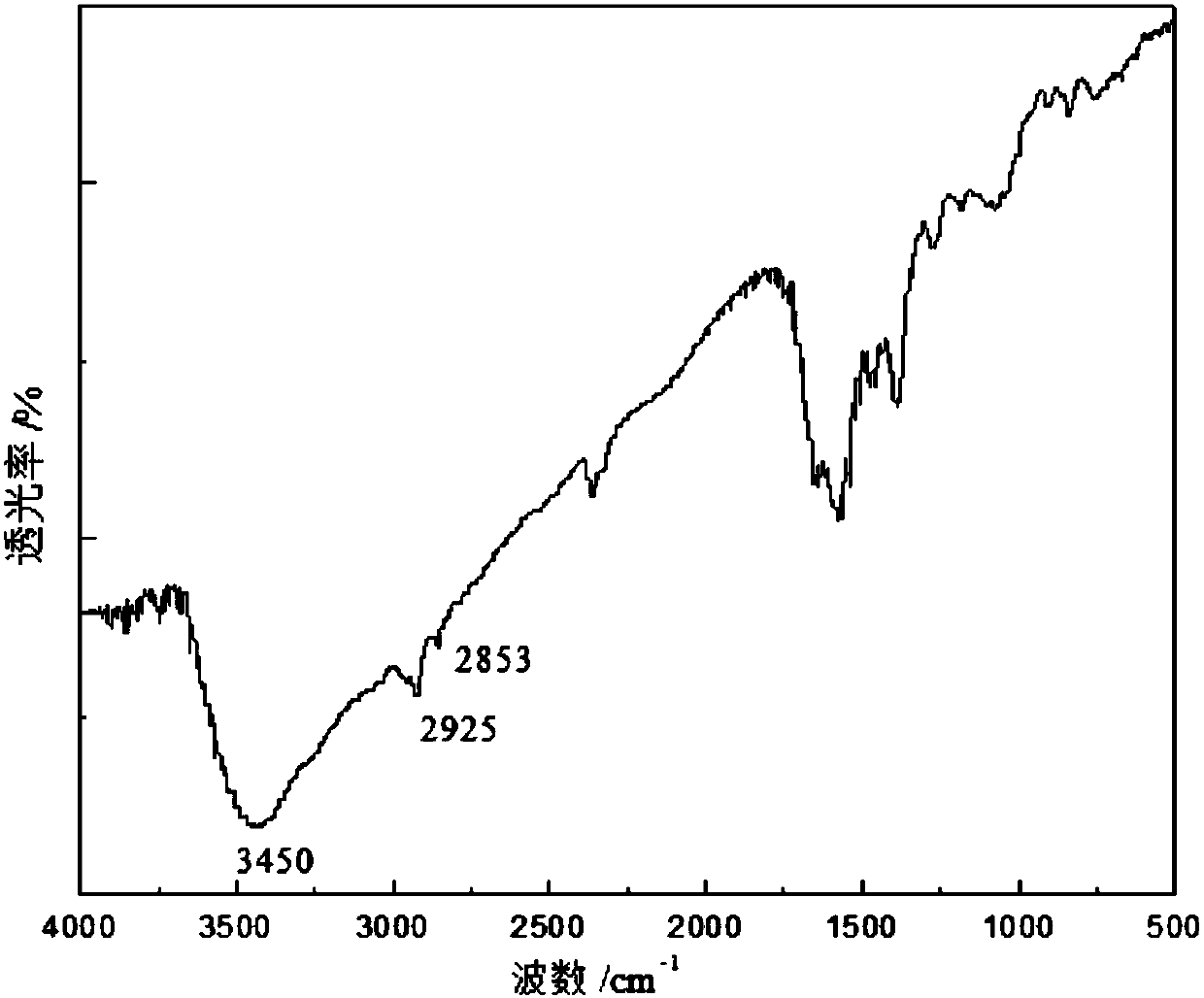

Synthesis method of CQD (carbon quantum dot) quaternary ammonium salt cationic surfactant

ActiveCN107626258AGreenSimple processBiocideCationic surface-active compoundsSynthesis methodsAntibacterial activity

The invention discloses a synthesis method of a CQD (carbon quantum dot) quaternary ammonium salt cationic surfactant and belongs to the field of green manufacturing of fine chemicals. The synthesis method comprises steps as follows: citric acid is taken as a carbon source, a diamino compound with primary amino at one end and tertiary amino at the other end is taken as an N source, an N-doped CQDis synthesized with a hydrothermal method, the CQD is taken as a raw material and subjected to quaternarization with normal halogenated hydrocarbon in ethanol water, and the CQD quaternary ammonium salt cationic surfactant is prepared. The technological method is simple, a product separation method is simple, the preparation process is green, pollution-free and low in synthesis cost, and the prepared CQD quaternary ammonium salt cationic surfactant integrates surface activity, antibacterial activity and fluorescent brightening property and can be widely applied to fields of detergent preparation, bactericide preparation, fluorescent brightener compounding and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Production method for ultra low temperature rapid firing vitrification ceramic brick

The present invention provides a production method for an ultra low temperature rapid firing vitrification ceramic brick. In a blank entering ball mill step, low temperature ceramic mineral raw materials are mixed and poured into a ball mill to carry out wet grinding, wherein the low temperature ceramic mineral raw materials comprise a calcination material, lithium sand, black mud, a water reducing agent, a reinforcing agent and an auxiliary agent. The present invention relates to a production method for producing the ultra low temperature rapid firing vitrification brick by using the calcium magnesium silicate material and the tantalum-niobium tailings. The ultra low temperature rapid firing vitrification ceramic brick belongs to a special and novel vitrification brick material and a product, wherein the special and novel vitrification brick material has characteristics of ultra low temperature, high strength, high hardness, high wear resistance, strong pollution prevention, no radiation, environmental protection, and health. With the technology of the present invention, the firing temperature can be substantially reduced, the firing period can be substantially shortened, and the method provides good benefits for energy-saving emission reduction, green manufacturing and low carbon production of the ceramic industry.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

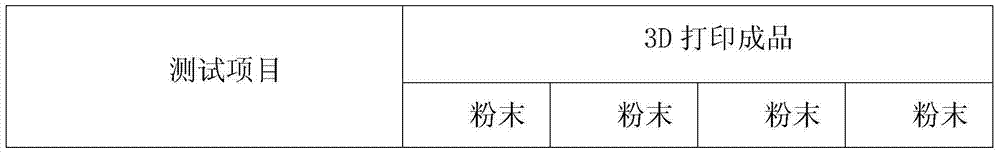

Polymer powder for 3D printing and preparation method of polymer powder

The invention discloses a polymer powder for 3D printing and a preparation method of the polymer powder. The polymer powder comprises the following substances in parts by weight: 30-90 parts of main body molding resin, 10-60 parts of bonding resin, 0-10 parts of composite resin and 0-10 parts of powder leveling agent. The preparation method for preparing the powder comprises: blending the substances at room temperature and then sufficiently stirring till the substances are evenly mixed. The powder can be used for printing human body medical implant materials with good flexibility and medical appliances; when the powder is used for 3D printing, only deionized water is used as bonding solution, so that the process is simple and the cost is low; therefore, the 3D printing environment is environmental friendly and can meet a modern green manufacturing direction.

Owner:ZHONGSHAN POLYTECHNIC

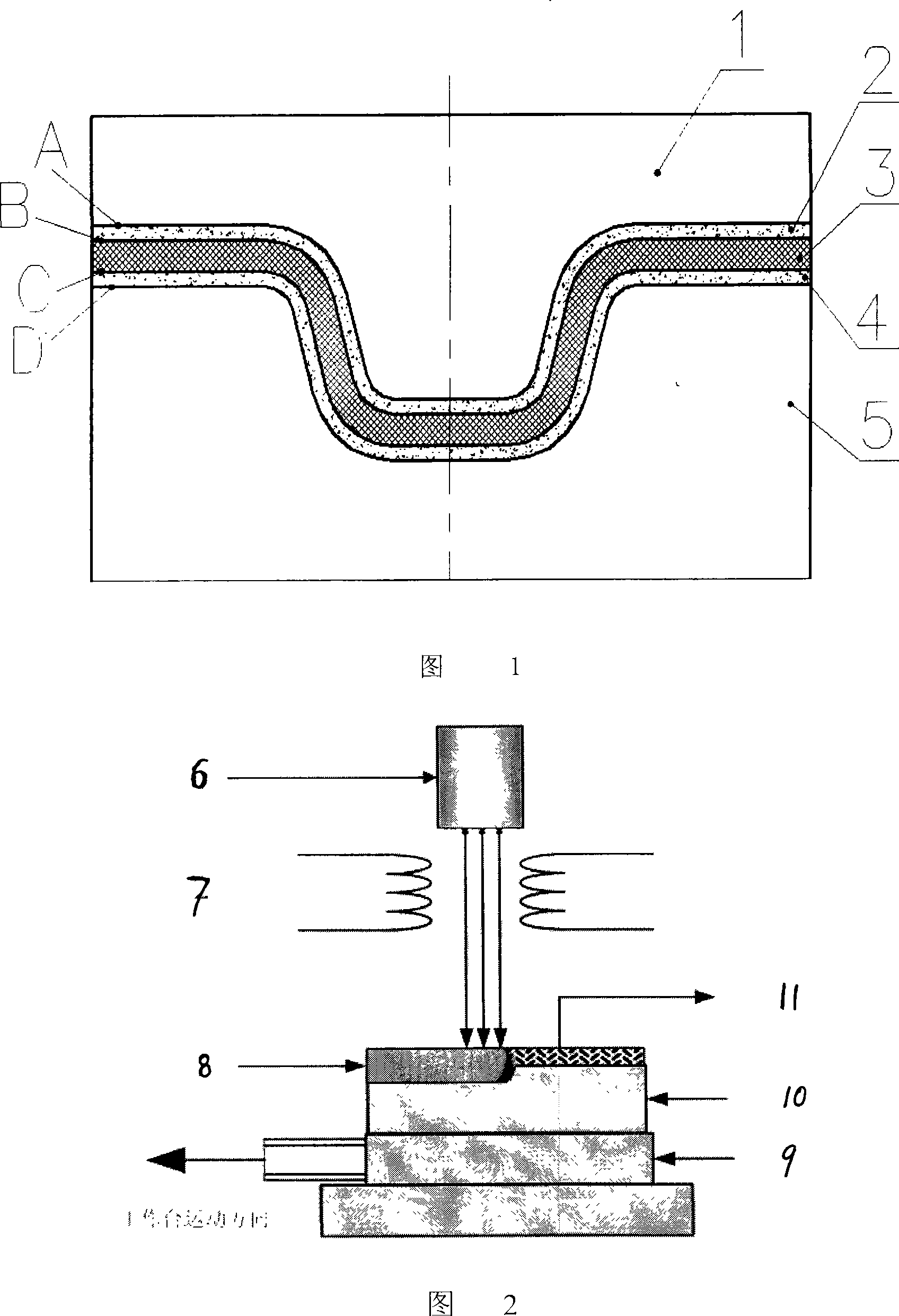

Polyurethane composite material tire and producing method thereof

InactiveCN101219631AExtended service lifeGuaranteed not to disbondSpecial tyresManufacturing technologyAdhesive

The invention discloses a large truck tire, in particular a large truck tire of polyurethane composite and a production method thereof. The tire of polyurethane composite comprises a wheel hub, a wheel hub board, a tire tread, an inner tube, and a filler between the tire tread and the inner tube. The invention is characterized in that the tire tread and a tire sidewall adopt casting polyurethane elastomers; a tread bracing layer is provided with four layers which are compounded from three layers of steel wire cords and a layer of aramid fibers through adhesive; a tire body cord layer is compounded from steel wire cords and aramid fibers; an inner liner layer is compounded from a chlorinated butyl rubber and a steel wire cord layer; the filler adopts at least one of the following two elastomers: a polyurethane elastomer with Shore hardness of A 45 and a polyurethane foaming elastomer with self crust. The invention has the advantages of wear resistance, low temperature performance, better elastic performance under high hardness, better uniformity of colloid due to fully automatic casting technology, more stable performance, tear resistance, strong performance of pealing resistance, and non pollution from three wastes during manufacturing; the invention belongs to a green manufacture technology.

Owner:晋城蓝焰煤业股份有限公司 +1

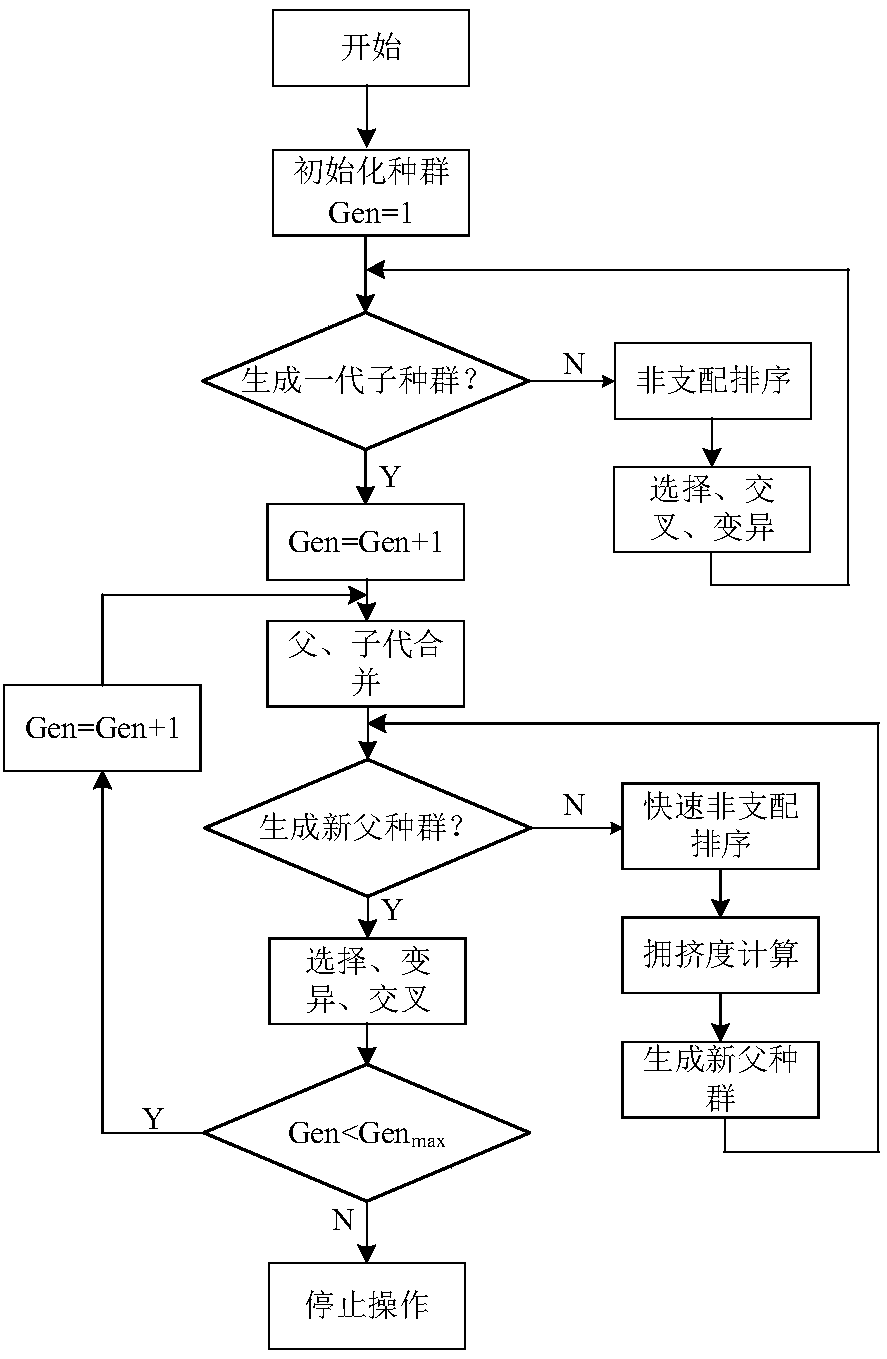

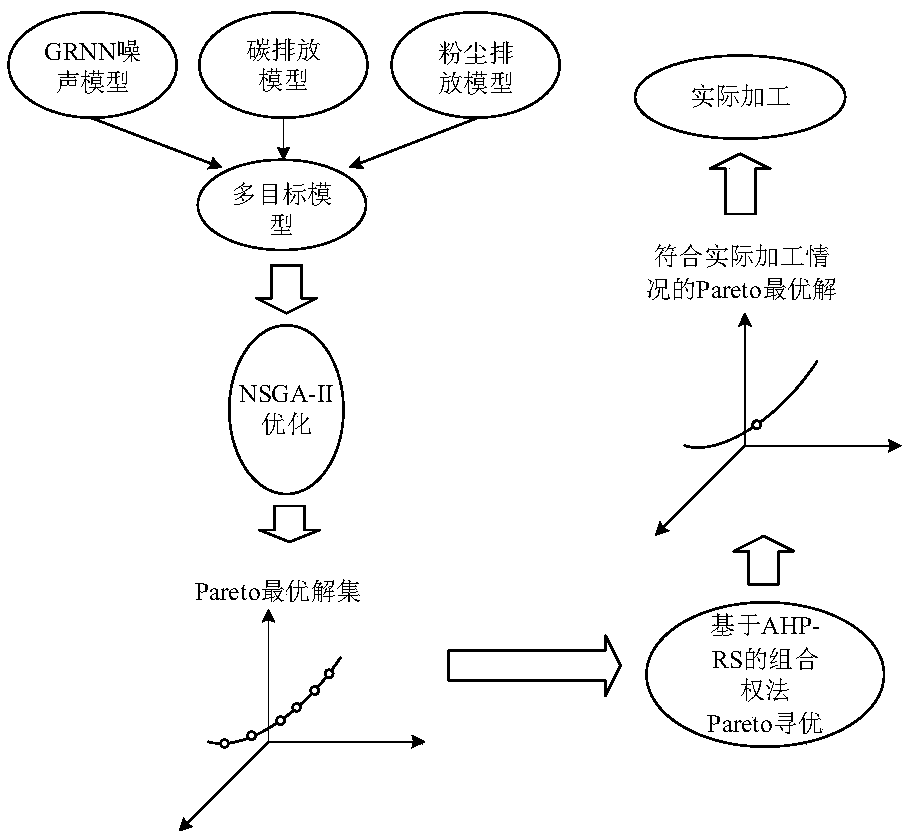

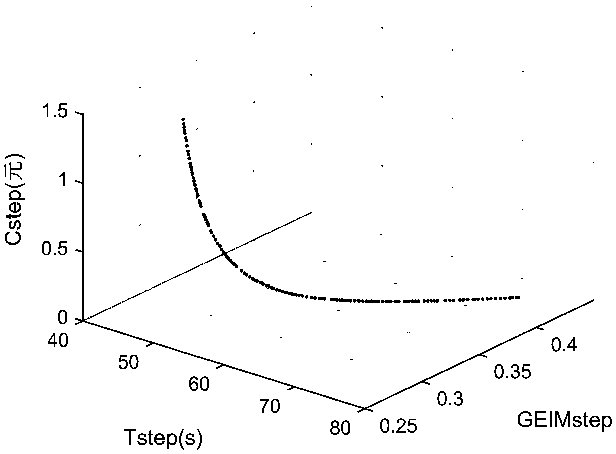

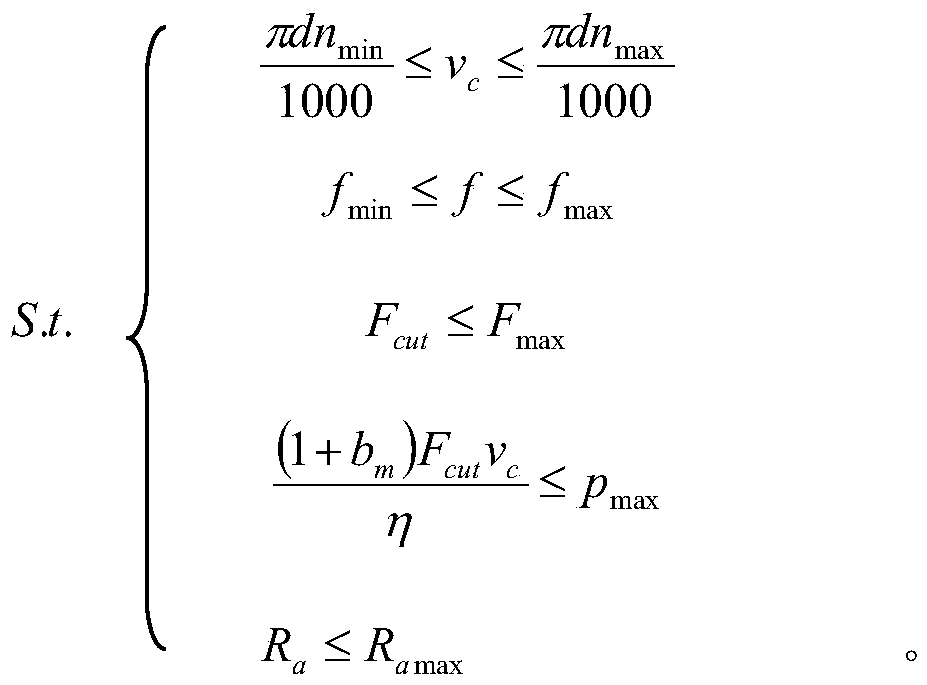

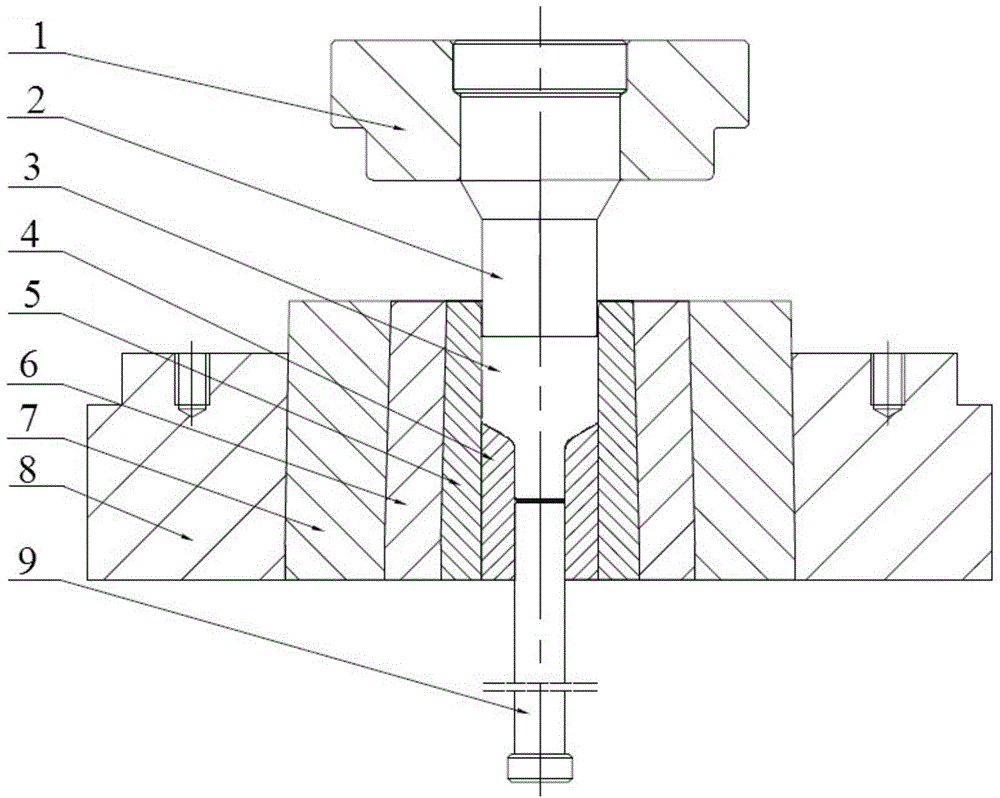

Thread turning process parameter optimization method for green manufacturing

InactiveCN108319223AEmission reductionReduce noiseProgramme controlComputer controlMechanical equipmentGreen manufacturing

The invention discloses a thread turning process parameter optimization method for green manufacturing, which comprises the steps of 1) determining optimization variables such as the cutting speed Vcand the feeding amount f; 2) establishing a multi-objective optimization function; 3) determining constraint conditions; 4) optimizing the objective function to obtain a Pareto optimal solution set thereof; 5) determining the weight of each target attribute according to an AHP (Analytic Hierarchy Process) and RS (Rough Set) based combined weight determination method, and obtaining an optimal solution meeting actual processing requirements from the optimal solution set in the step 4. In the application process of the method disclosed by the invention, parameters in the model can be determined firstly according to the actual condition, then the model is solved by adopting the method so as to obtain the cutting speed Vc and the feeding amount f when the carbon emission, noise emission and dust emission are synthetically optimized, and finally a purpose of reducing the carbon emission, noise remission and dust emission is achieved through controlling mechanical equipment.

Owner:HEFEI UNIV OF TECH

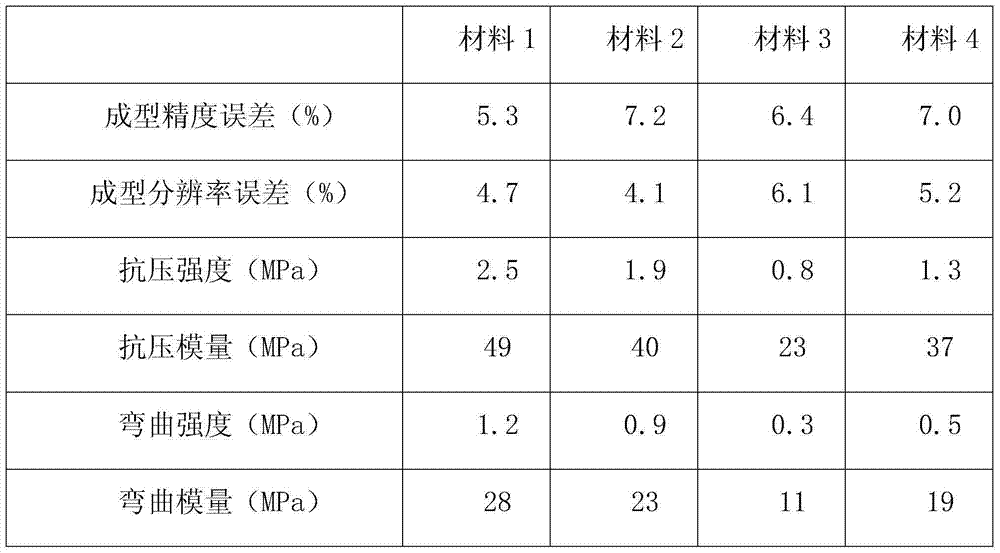

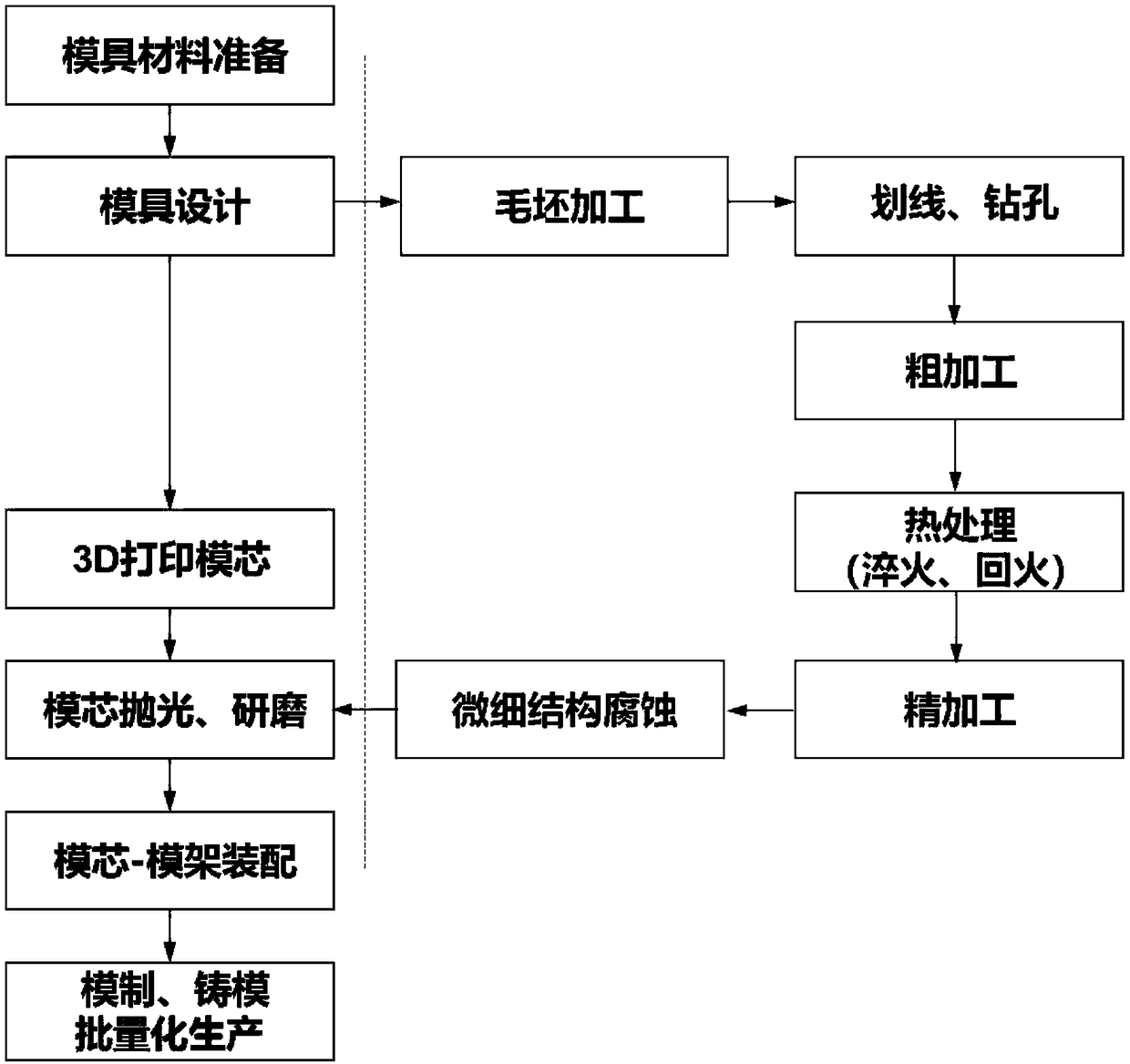

Mold rapid machining method based on 3D printing mold core

InactiveCN109128165AShorten the processing cycleRealize green and intelligent transformation and upgradingAdditive manufacturing apparatusCeramic shaping apparatusCasting moldRapid tooling

The invention discloses a mold rapid machining method based on a 3D printing mold core. The mold rapid machining method based on the 3D printing mold core is characterized by comprising the followingsteps of S1, preparing needed raw materials; S2, designing a geometric structure of the mold core, and converting the geometric structure of the mold core into a format matched with a format in a control equipment system; S3, using a 3D printing technology to print the mold core after S2 is finished; S4, polishing and grinding the mold core in S3 to a desired size and surface accuracy; S5, assembling the mold core in a mold base after S4 is finished; and S6, carrying out follow-up molding or casting mold batch production. By directly and rapidly performing 3D printing on the mold core, polishing the surface of the mold core and fastening the mold core on the mold base, the follow-up molding or casting mold batch production of the mold core is carried out and realized. According to the moldrapid machining method based on the 3D printing mold core, an optimal design is realized, the efficiency or function of a terminal product is enhanced, a difficult problem of traditional machining technologies such as CNC during machining the complicated geometric structures is solved, the design is free, the manufacturing is rapid and green, and green and intelligent transformation and upgradingof the traditional mold industry are really realized.

Owner:HUAZHONG UNIV OF SCI & TECH

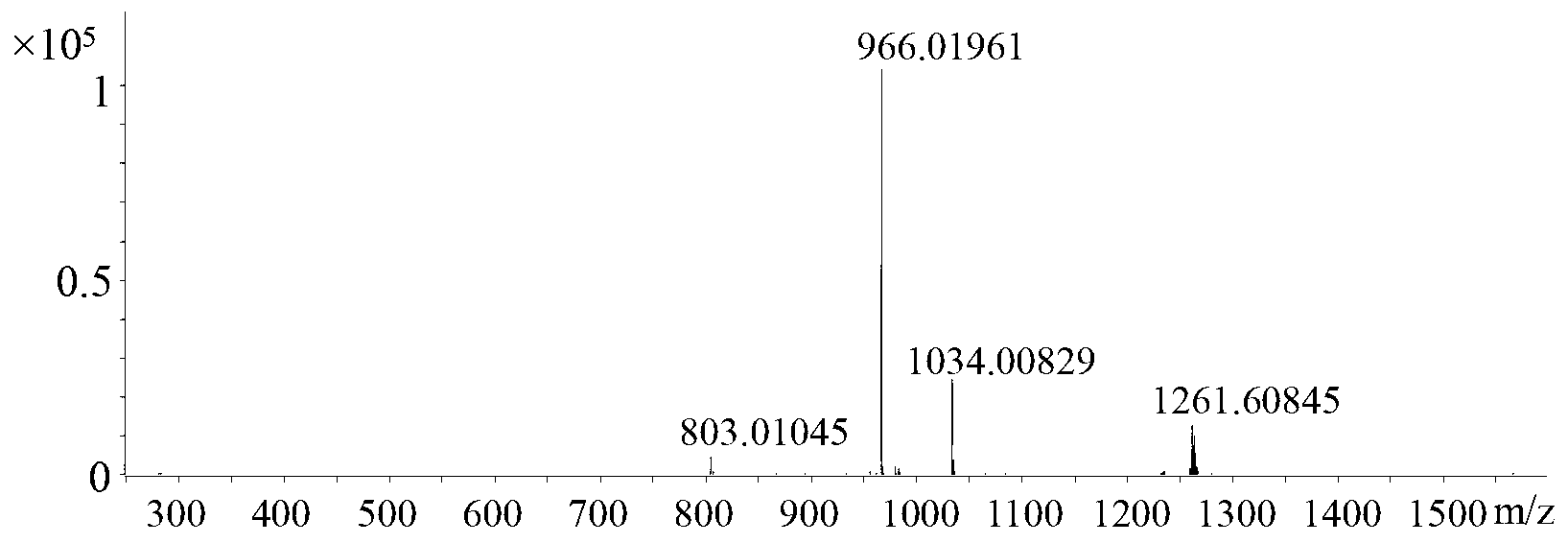

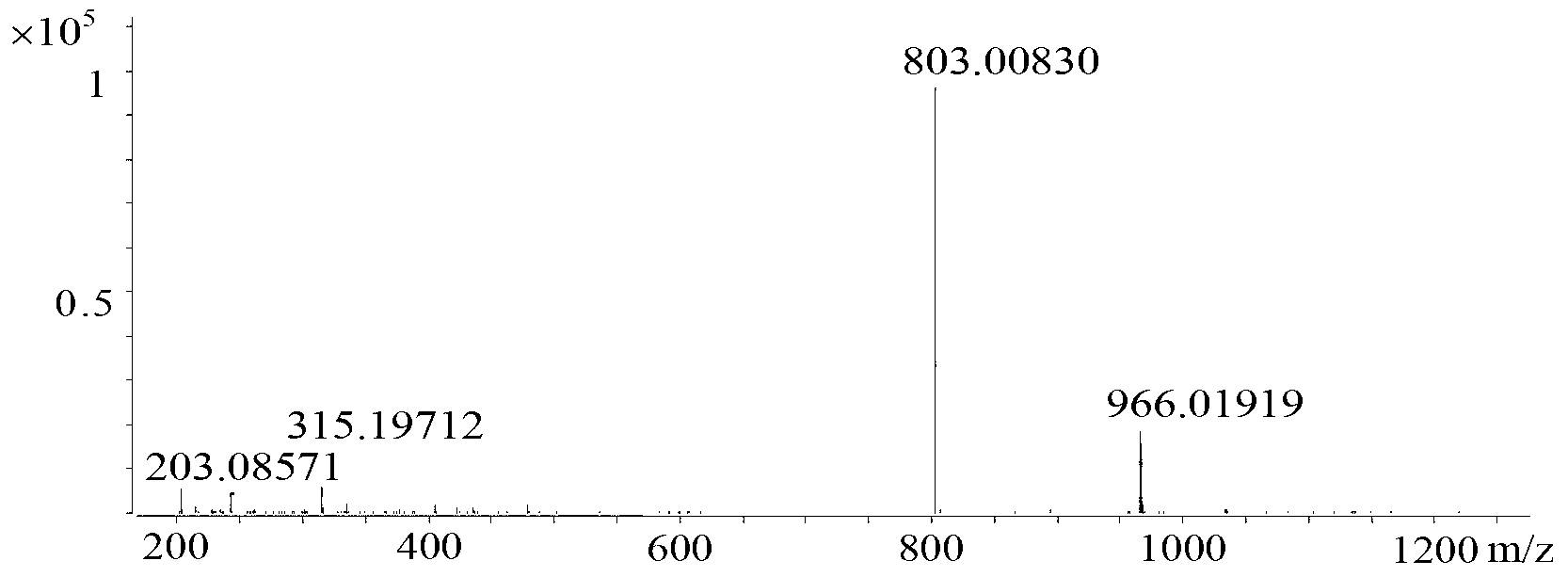

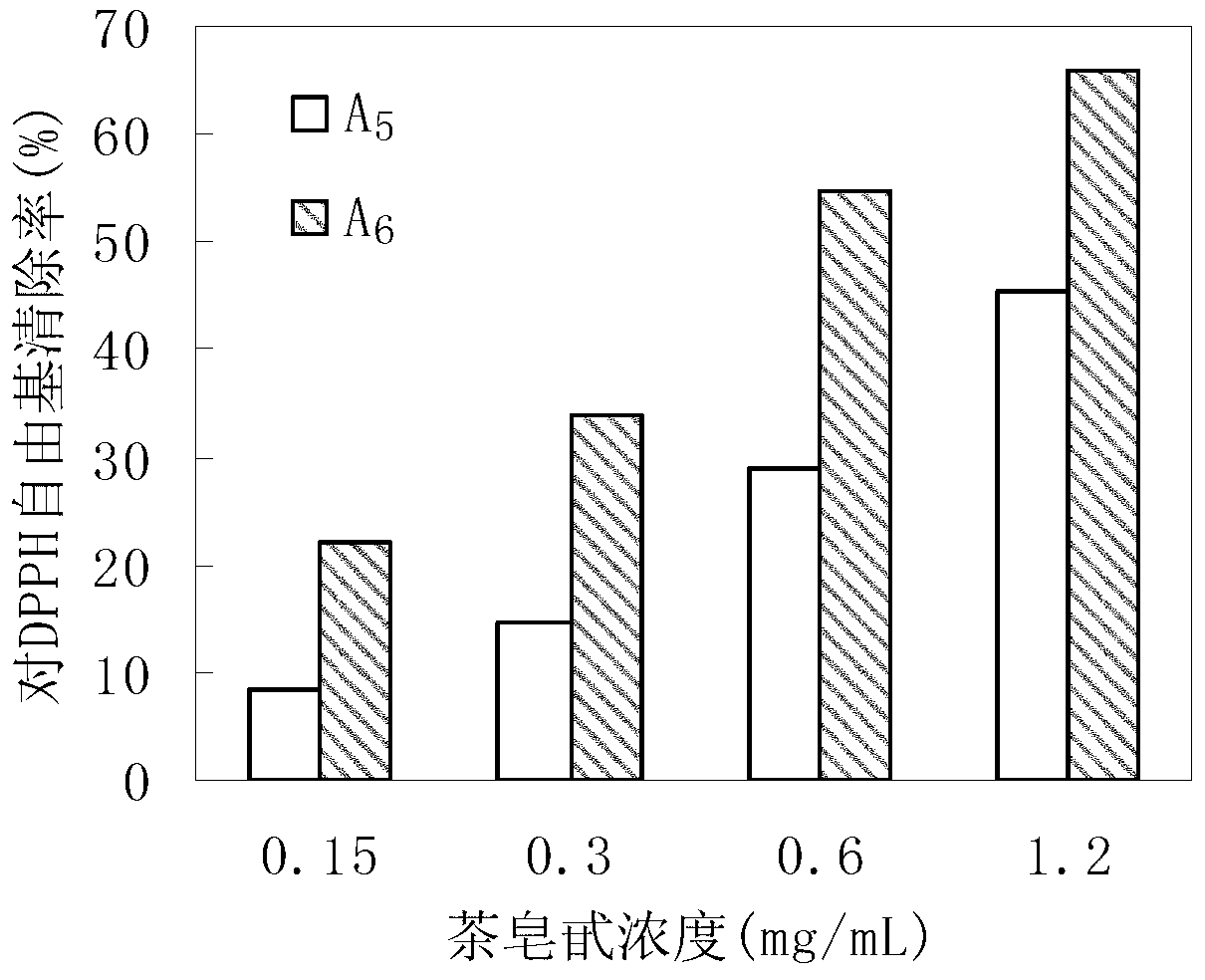

Biological transformation method for preparing high-activity theasaponin

InactiveCN103266154AImprove use valueImproves antioxidant activityMicroorganism based processesFermentationSocial benefitsAspergillus oryzae

The invention provides a biological transformation method for preparing high-activity theasaponin and belongs to the technical field of biochemical engineering. The biological transformation method comprises the following technological processes of: purifying crude theasaponin by AB-8 macroporous resin, preparing a theasaponin enzymolysis substrate, extracting enzyme liquid, carrying out enzymolysis on the theasaponin and separating enzymolysis components. According to the biological transformation method, firstly sasanguasaponin hydrolytic enzymes are extracted from aspergillus oryzae and aspergillus niger strains, and then sasanguasaponin is hydrolyzed by an enzymic method, experimental conditions are mild, products are easy to control, the pollutant discharge is reduced, and therefore, the biological transformation method is a new green manufacturing technology. Compared with the antioxidant activity of the original sasanguasaponin, the antioxidant activity of the obtained theasaponin is greatly increased. Oil-tea cakes mainly contain crude protein, saccharides, oil, the theasaponin and the like and have very high comprehensive utilization value. Therefore, the oil-tea cakes are used for extracting the theasaponin which is subjected to the enzymolysis, so that the theasaponin with low sugar chain and high activity is obtained. The biological transformation method has prominent economic benefits and social benefits in the research, development and application of the comprehensive utilization of the oil-tea cakes.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Wear-resistant hydrophobic nano composite film and preparation method thereof

InactiveCN104694877AImprove mechanical propertiesImprove hydrophobicityVacuum evaporation coatingSputtering coatingComposite filmWear resistant

The invention relates to a wear-resistant hydrophobic nano composite film and a preparation method thereof, belonging to the technical field of metal surface treatment and modification. The composite film is based on high-speed steel, or titanium alloy, or hard alloy, or pure metal, and a pure metal film and a microstructure nano composite film are sequentially prepared on the base surface. The preparation method comprises the following steps: depositing a nano composite hard film with excellent mechanical properties on the base material surface by arc ion plating, and generating a micro / nano dual structure on the film surface by an ultra-fast laser processing technique to obtain the surface film with favorable mechanical properties and certain hydrophobicity. The film maintains excellent mechanical properties of the nano composite hard film: high surface hardness, high toughness, high wearability and high scratch resistance; and the microstructure on the film surface is constructed, so that the film has certain hydrophobicity. The preparation method has the advantages of simpler equipment, low cost, low energy consumption and no pollution, and can implement efficient green manufacturing.

Owner:常州翊迈新材料科技有限公司

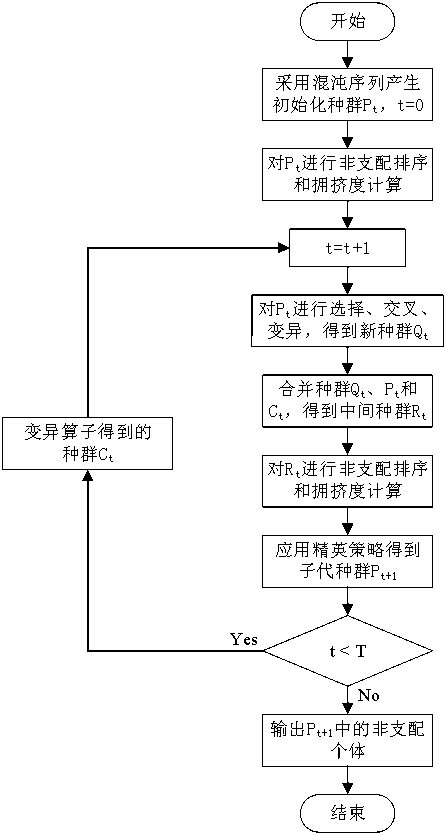

Multi-target cutting parameter optimization method for green manufacturing

ActiveCN110579971AImprove the distribution effectFast convergenceAdaptive controlNumerical controlMachine parts

The invention relates to a multi-target cutting parameter optimization method for green manufacturing. The method comprises the following steps that S1, according to the machining condition of a single working step in cutting, the cutting speed and the feeding amount serve as optimization variables, and a machining time optimization objective function, a machining greenization evaluation exponential function comprehensively considering machine tool energy consumption and cutting fluid consumption and a machining cost optimization objective function are established; S2, constraint conditions ofa multi-target cutting parameter optimization model are determined according to the performance of a numerical control machine tool and the surface machining quality requirement for a machined part;S3, the multi-target cutting parameter optimization model is constructed according to the optimization objective function in the S1 and the constraint conditions in the S2; and S4; optimization solution is carried out on the multi-target cutting parameter optimization model by utilizing an improved NSGA-II algorithm, and a Pareto optimal solution set of the multi-target cutting parameter optimization model is obtained. On the premise that smooth cutting machining is guaranteed, the resource utilization rate is increased, and negative influence on the environment is reduced.

Owner:FUZHOU UNIV

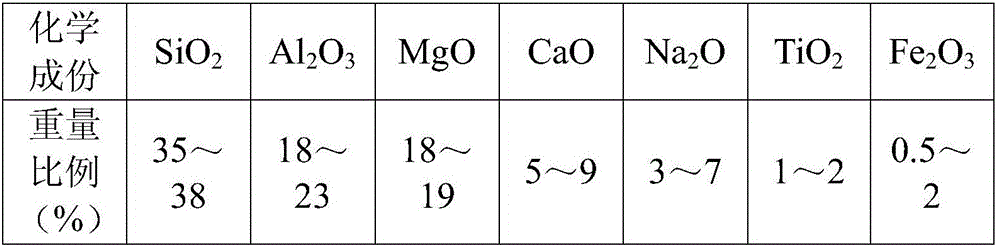

Microcrystalline glass produced from fly ash through all-electric melting calendaring process and production method thereof

ActiveCN105924014AMaintain healthTurn waste into treasureGlass rolling apparatusSlagGreen manufacturing

The invention discloses a microcrystalline glass produced from fly ash through an all-electric melting calendaring process, and a production method thereof. The microcrystalline glass is prepared from 320 to 350 parts by weight of fly ash used as a main raw material and accessory materials consisting of 98 to 115 parts by weight of light-burnt magnesia, 55 to 66 parts by weight of ground calcium carbonate, 42 to 44 parts of sodium carbonate and 2 to 3.5 parts by weight of titanium dioxide by using the all-electric melting calendaring process. The production method mainly comprises the following steps: mixing and melting of the raw materials; calendaring and molding; annealing; nucleation and crystallization; and surface treatment. The production method provided by the invention can consume a great amount of slag waste, turn the waste into the valuable, improve the environment and promote economic development; the production method also realizes green manufacturing, broadens the application space of the calendared microcrystalline glass as a base material and guides consumers to carry out green consumption; and the production method increases the varieties of microcrystalline glass products, improves market competitiveness of microcrystalline glass products and maximally meets consumption demands of different industries and different populations.

Owner:四川一名微晶科技股份有限公司

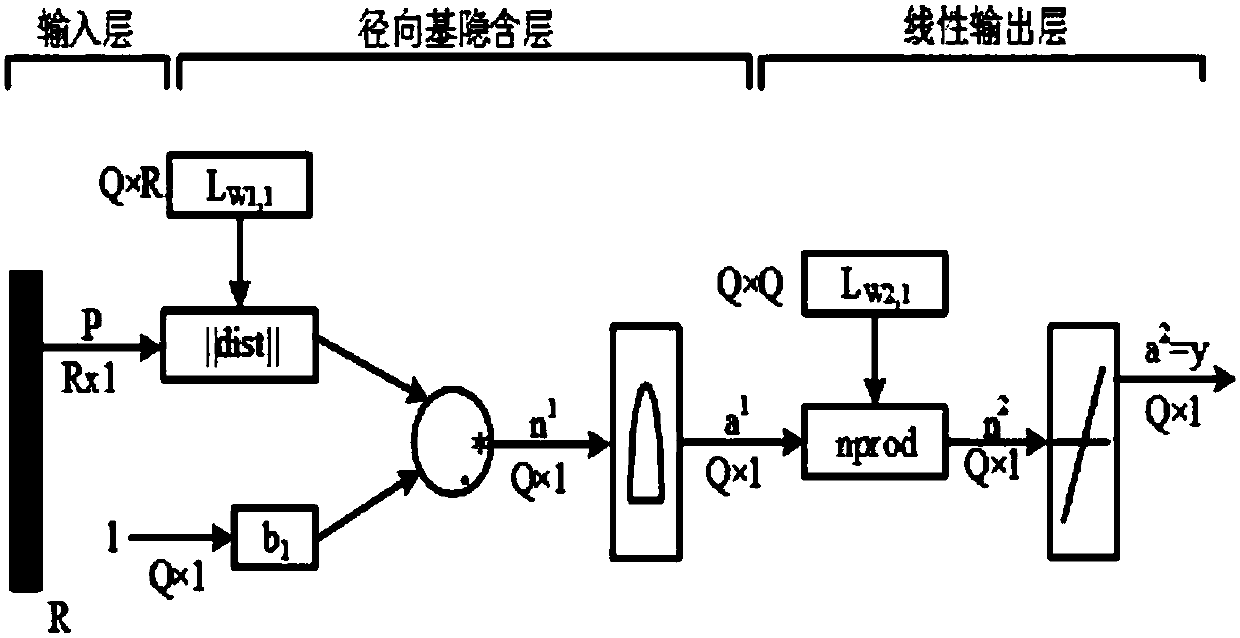

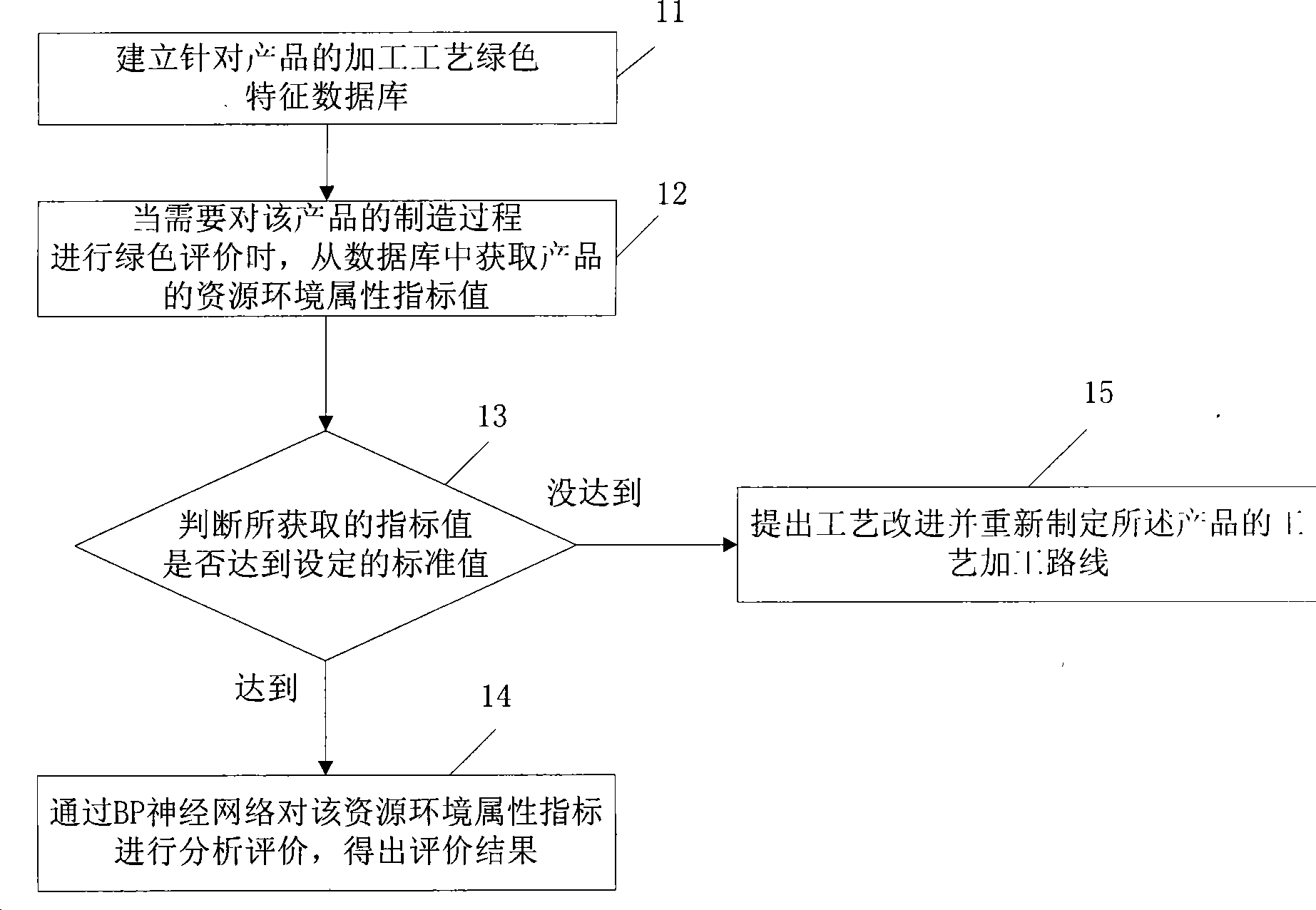

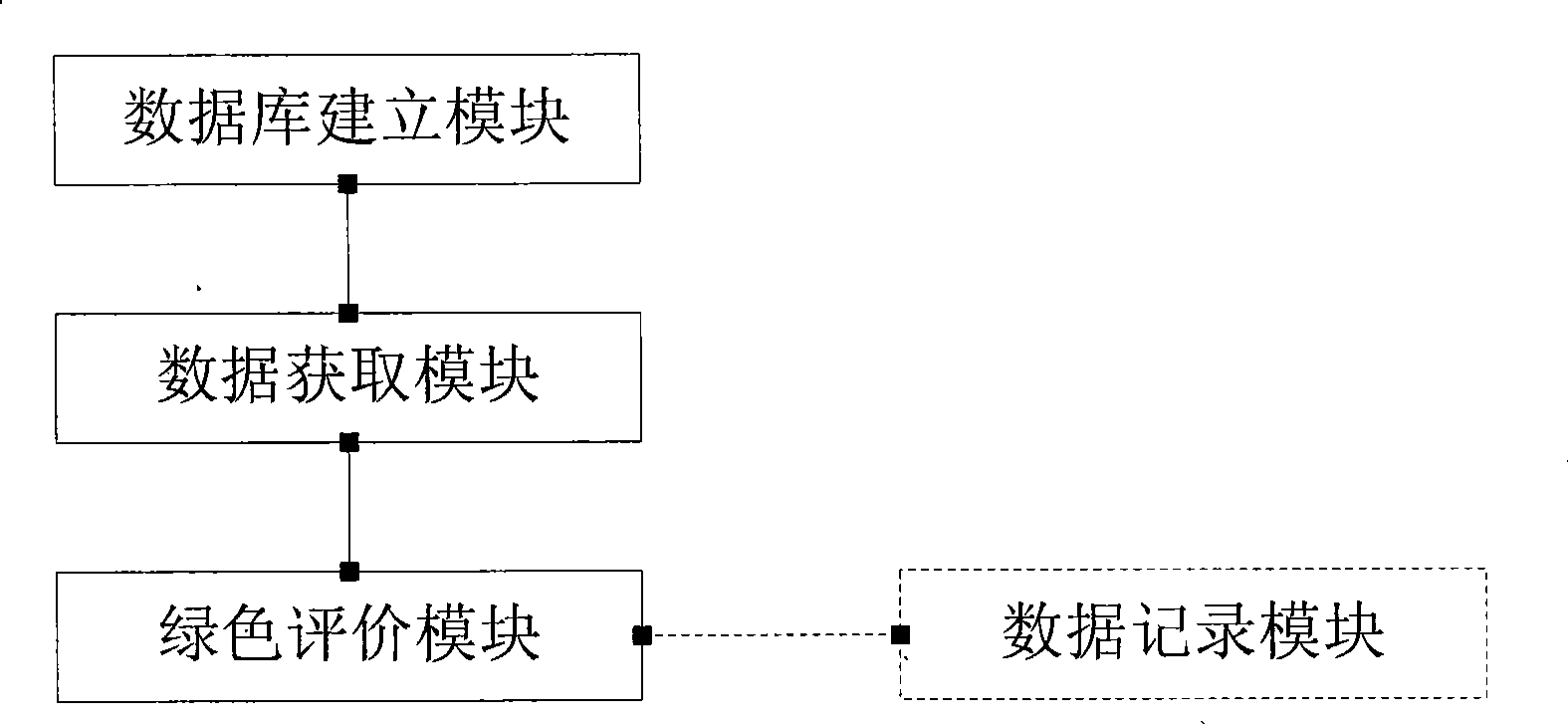

Green appraising method and device in manufacture course of products

InactiveCN101419690AIncrease profitSmall negative impact on the environmentBiological neural network modelsEnvironment effectResource utilization

The embodiment of the invention provides a pollution-free evaluation method in product manufacturing process and a device thereof. The method specifically comprises the following steps: establishing a pollution-free characteristic database for a processing technique of the product; acquiring resource environment attribute index values generated in the product manufacturing process from the database when the product manufacturing process needs pollution-free evaluation; and then judging whether the resource environment attribute index values reach preset standard values; if reaches, calling index values quantizing rule from the database, and analyzing and evaluating the resource environment attribute by a BP neural network. In such way, resource consumption and environmental impact condition in the product manufacturing process can be analyzed and evaluated, thus being capable of taking corresponding measures to reduce the negative environmental impact produced in the product manufacturing process, improving the resource utilization rate, and realizing pollution-free product manufacturing.

Owner:WUHAN UNIV OF SCI & TECH

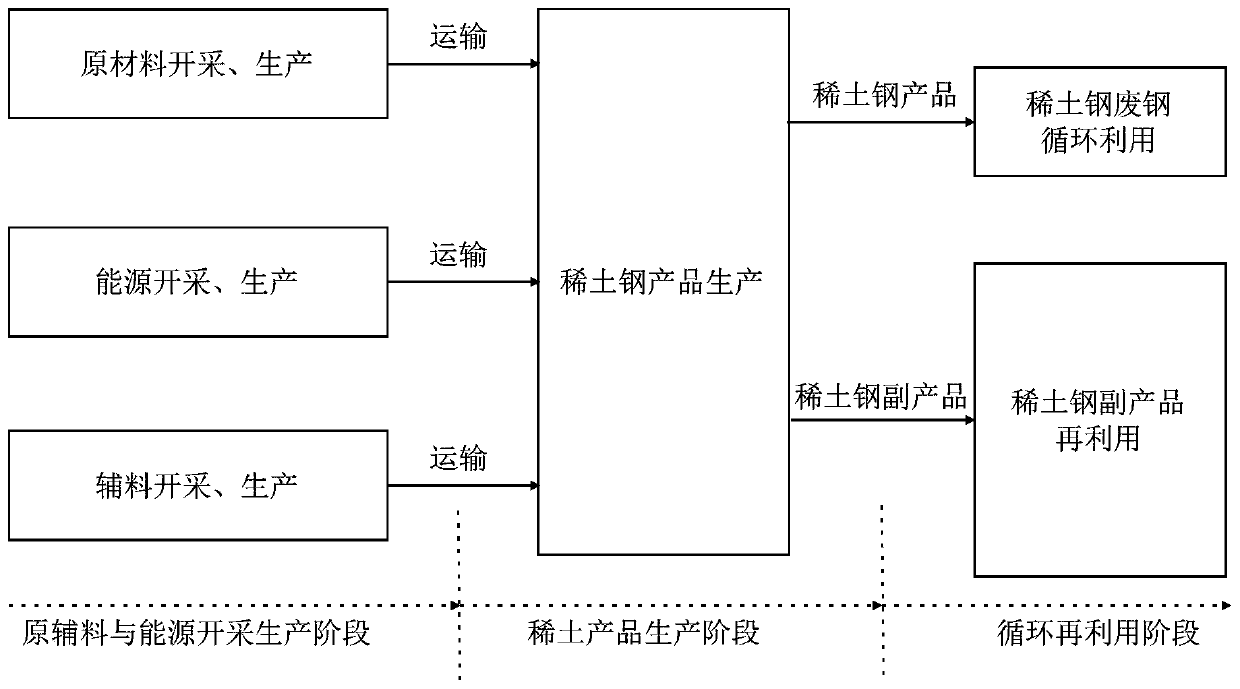

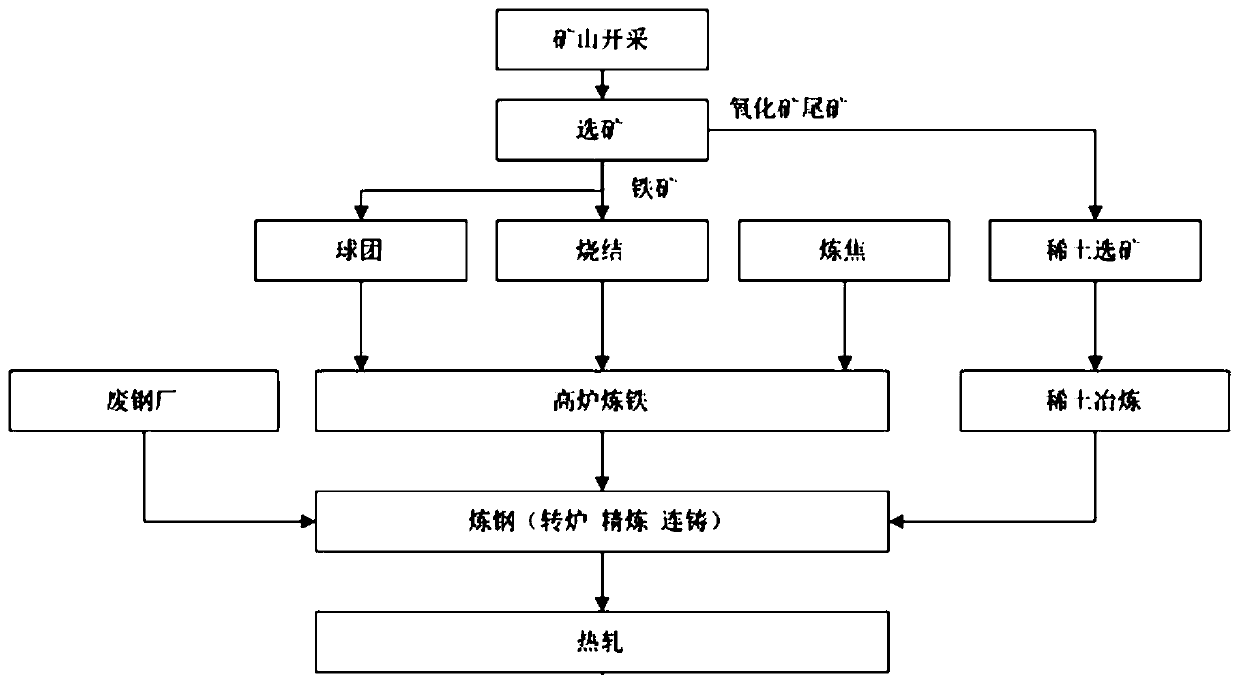

Rare earth steel life cycle environment influence evaluation method

InactiveCN109740833AScientific and Effective Guidance MethodResourcesManufacturing computing systemsRare earthEnvironmental impact assessment

The invention discloses a rare earth steel life cycle environment influence evaluation method. The method includes assembling and quantifying the rare earth steel life cycle environment influence factors by adopting a process list analysis method; and quantitatively describing the damage degree of the environmental influence factors of the life cycle of the rare earth steel to the end point environmental influence type, calculating the weight value of the end point environmental influence type in the environmental influence caused by the life cycle of the rare earth steel through an analytic hierarchy process, and finally obtaining the total environmental influence latent value of the life cycle of the rare earth steel through weighted summation. According to the rare earth steel life cycle environment influence evaluation method, the environmental load in the whole rare earth steel production process can be scientifically, objectively and comprehensively evaluated, the list index environmental load of rare earth steel products and the distribution condition of environmental influence potential values in all stages of the life cycle are obtained through analysis, and a scientific and effective guiding method is provided for green manufacturing of rare earth steel.

Owner:BAOTOU IRON & STEEL GRP

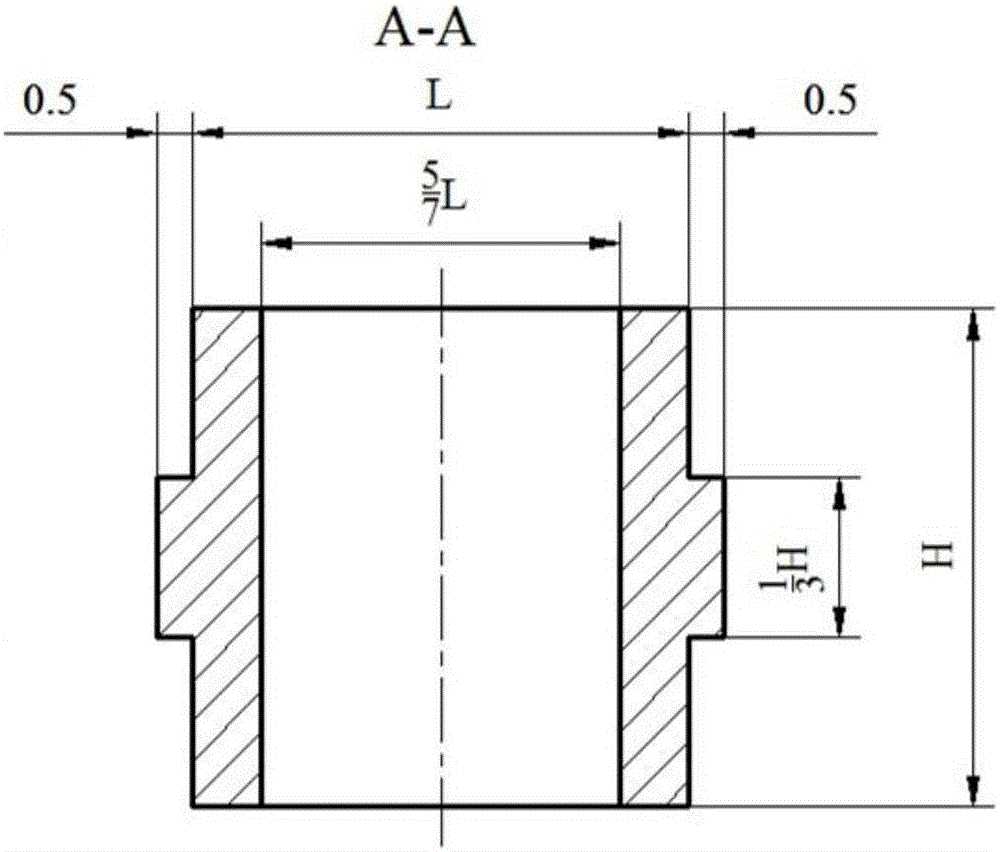

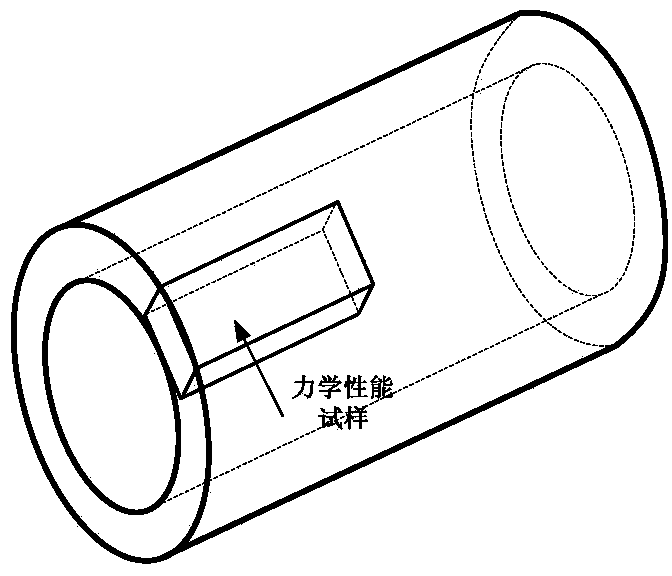

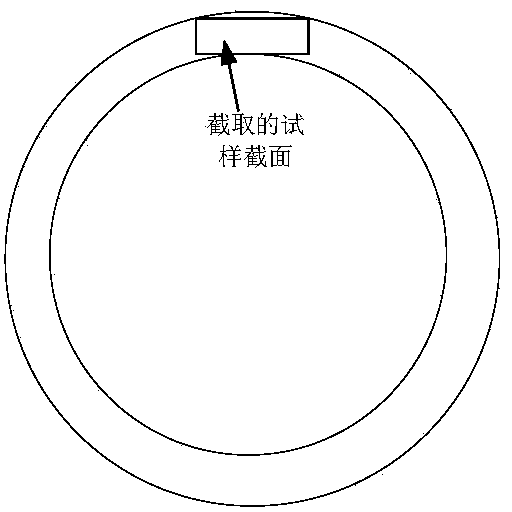

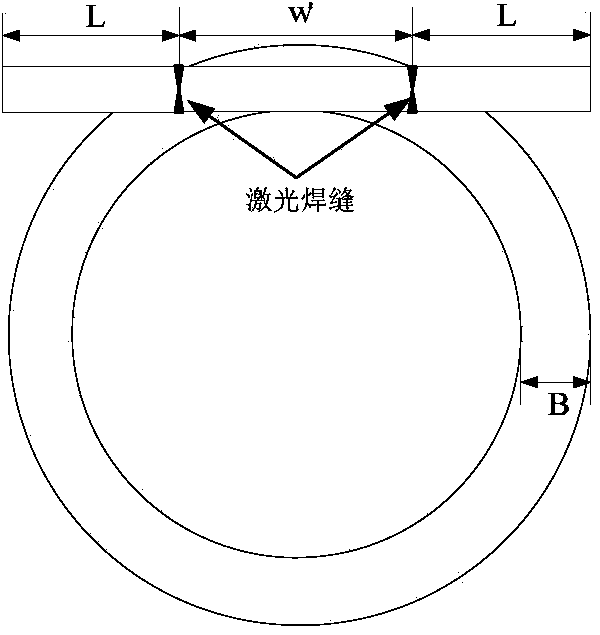

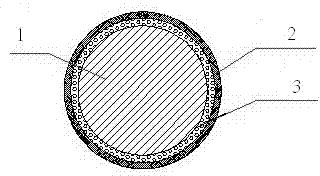

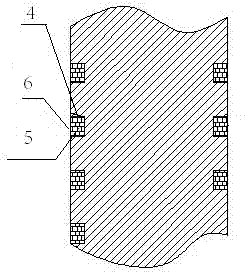

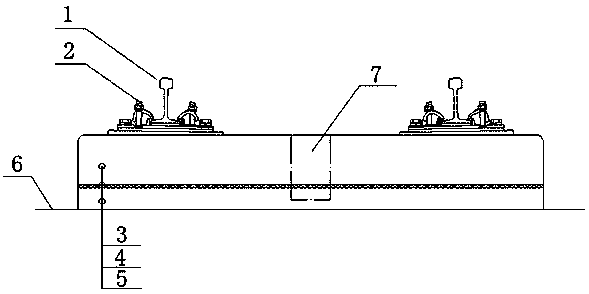

Method for preparing specimens used in testing of mechanical properties of thin-walled and small-diameter petroleum and natural gas pipelines

ActiveCN103884557AIncrease profitSave materialPreparing sample for investigationGreen manufacturingPetroleum

The present invention discloses a method for preparing specimens used in testing mechanical properties of thin-walled and small-diameter petroleum and natural gas pipelines, which comprises the following steps: (1) cutting specimens having width of W mm and thickness of B mm from the circumferential direction of thin-walled and small-diameter petroleum and natural gas pipelines to be tested; and (2) carrying out laser welding on two lengthening blocks on both sides of specimens to obtain test specimens, wherein the width of the lengthening block is L, the thickness of the lengthening block is larger than or equal to B, the sum of L, W and L is greater than or equal to the minimum length of the test specimens required for testing the tensile, impact, CTOD (crack tip opening displacement) fracture toughness or crack propagation rate. Mechanical properties data, which are uneasily acquired by conventional methods, can be measured by virtue of the method disclosed by the invention and have an important practical significance on improvement of the safety evaluation of petroleum and natural gas pipelines. The laser penetration fusion welding technology is applied in preparation of small specimens to effectively increase the utilization rate of specimens, thereby saving materials, saving energy and reducing consumption. The method disclosed by the invention has a nature of green manufacture.

Owner:湖州双林建设发展有限公司

Three-dimensional (3D) printing and manufacturing method of porous niobium parts

ActiveCN104476653AAvoid smeltingAvoid millingCeramic shaping apparatusSelective laser sinteringMolten salt

The invention discloses a three-dimensional (3D) printing and manufacturing method of porous niobium oxide parts. The method comprises the steps of carrying out selective laser sintering (SLS) on niobium oxide powder to form niobium oxide parts of complicate shapes; carrying out molten salt electrolysis and deoxidization by taking the oxide parts as cathodes, restoring the niobium oxide parts to niobium parts, and keeping the primary shapes, so as to obtain the porous niobium parts of complicate shapes and realize the integrated manufacturing 'metallurgy-material-device'. According to the 3D printing and manufacturing method provided by the invention, the porous niobium parts of complicate shapes can be manufactured by providing the cheap niobium oxide parts without any mould; furthermore, the 3D printing and manufacturing method has the advantages of being simple and feasible in technological process, complicate in shape, low in cost, and green to manufacture.

Owner:CENT SOUTH UNIV

Preparation method for super wear-resistant composite roll

ActiveCN103692221AHas super wear resistanceIncrease usageRollsOther manufacturing equipments/toolsAl powderManufacturing technology

The invention relates to a preparation method for a composite roll, in particular to the preparation method for a super wear-resistant composite roll. The super wear-resistant composite roll is manufactured by adopting the composite technology of a surfacing technology of self-fluxing alloy powder with super wear-resistant performance and an explosion hardening process or a laser surface hardening engineering technology. The roll consists of a roll core part and a roll working layer, wherein the roll working layer is prepared on the roll core part by a surfacing process; the roll core part is made of QT400-QT800-2 ductile iron and 235-450 cast steel; the composite material of the surface working layer comprises the following components of 42CrMo powder, 65 nickel alloy powder, nano-tungsten carbide powder, aluminum powder and graphite powder. The surface of the roll manufactured by the composite technology has super wear-resistant performance. Over 80 percent of the materials used by the roll can enter a cyclic remanufacturing process; the manufacturing process has the characteristic of green manufacturing. The forms of rolls comprise sheet rolls and profile rolls.

Owner:西安奥奈特固体润滑工程学研究有限公司

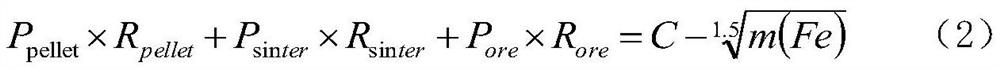

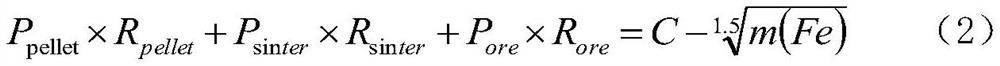

Methods for preparing and using pre-reduced fluxed pellets by taking steel slag as part of raw materials

InactiveCN111910072ARealize green manufacturingAchieve recyclingBlast furnace detailsProcess efficiency improvementBlast furnace smeltingFly ash

The invention relates to a method for preparing pre-reduced fluxed pellets by taking steel slag as part of raw materials. The method comprises the following steps of (1) screening the steel slag, screening out steel slag particles with the particle size of 2-4 mm, and grinding the rest steel slag into steel slag powder; (2) drying fly ash, and grinding the fly ash into fly ash powder; (3) mixing the steel slag powder, the fly ash powder, iron oxide red, iron ore concentrate powder and a composite binder in a mixer; (4) taking the steel slag particles with the particle size of 2-4mm as a pelletizing core, and continuously putting the steel slag particles into a pelletizer for pelletizing to obtain green pellets; and (5) carrying out drying, preheating and roasting to obtain finished pelletsof the pre-reduced fluxed pellets. After the technical scheme is adopted in blast furnace production, the cost of blast furnace production is reduced, so that the market competitiveness of an iron-making process is enhanced, meanwhile, cyclic utilization of secondary resources of an iron and steel plant can be realized, then application of high-added-value products is realized, and further, greenmanufacturing of blast furnace smelting is realized.

Owner:ANGANG STEEL CO LTD

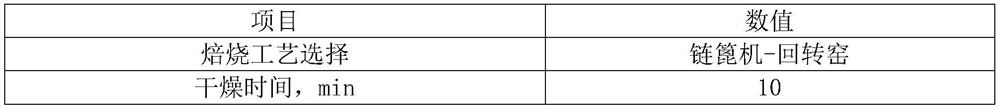

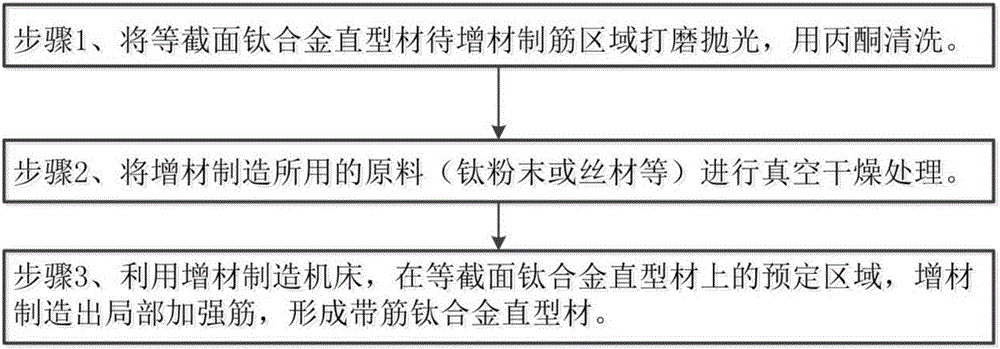

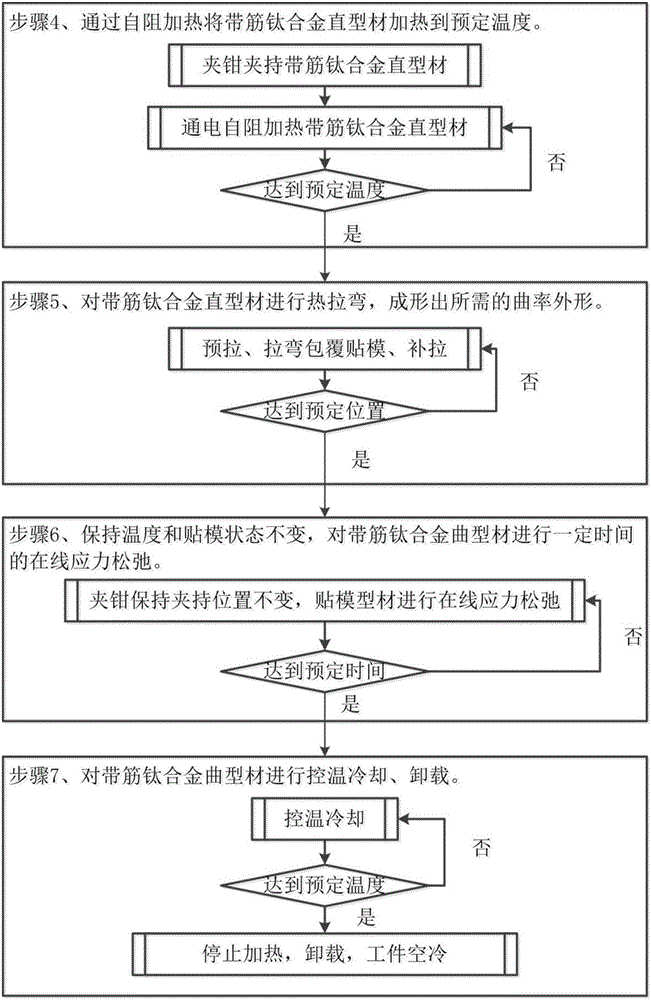

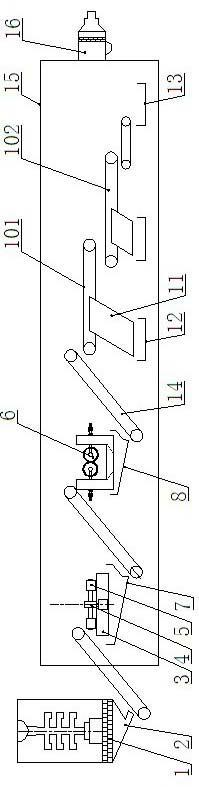

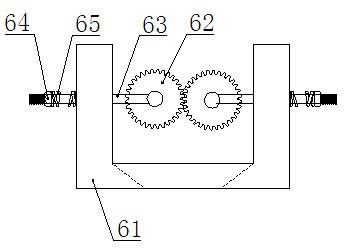

Combined manufacturing method of titanium alloy curvature component with ribs

InactiveCN106425314AIncrease profitReduce residual stress levelsNumerical controlManufacturing technology

Owner:BEIHANG UNIV

Investment cast shell crushing, grading and screening system

The invention relates to an investment cast shell crushing, grading and screening system comprising a vibration cleaning and shakeout mechanism, a grinding and crushing mechanism, a gear pair rolling mechanism and a grading and screening mechanism which are connected through a conveyer belt. When mould sand is cleared, an investment cast is arranged on the vibration cleaning and shakeout mechanism; the mould sand outside the cast is vibrated to a shakeout collection hopper, conveyed into the grinding and crushing mechanism and the gear pair rolling mechanism, so that large caked mould sand can be crushed; and the mould sand is conveyed to the grading and screening mechanism to be graded and collected according to the sizes of the mould sand particles after being crushed. According to the mould sand grading and screening system in the structure, an assembly line which carries out sand cleaning, shakeout, crushing and screening processes on the investment cast automatically, no manual operation is needed, so that the mechanical automation degree is high, the working efficiency and the reuse rate are greatly improved, the labor intensity of a worker is reduced, dust is not scattered, and green manufacturing, environmental protection and sustainable development are realized.

Owner:RUGAO DASHENG LINE EQUIP

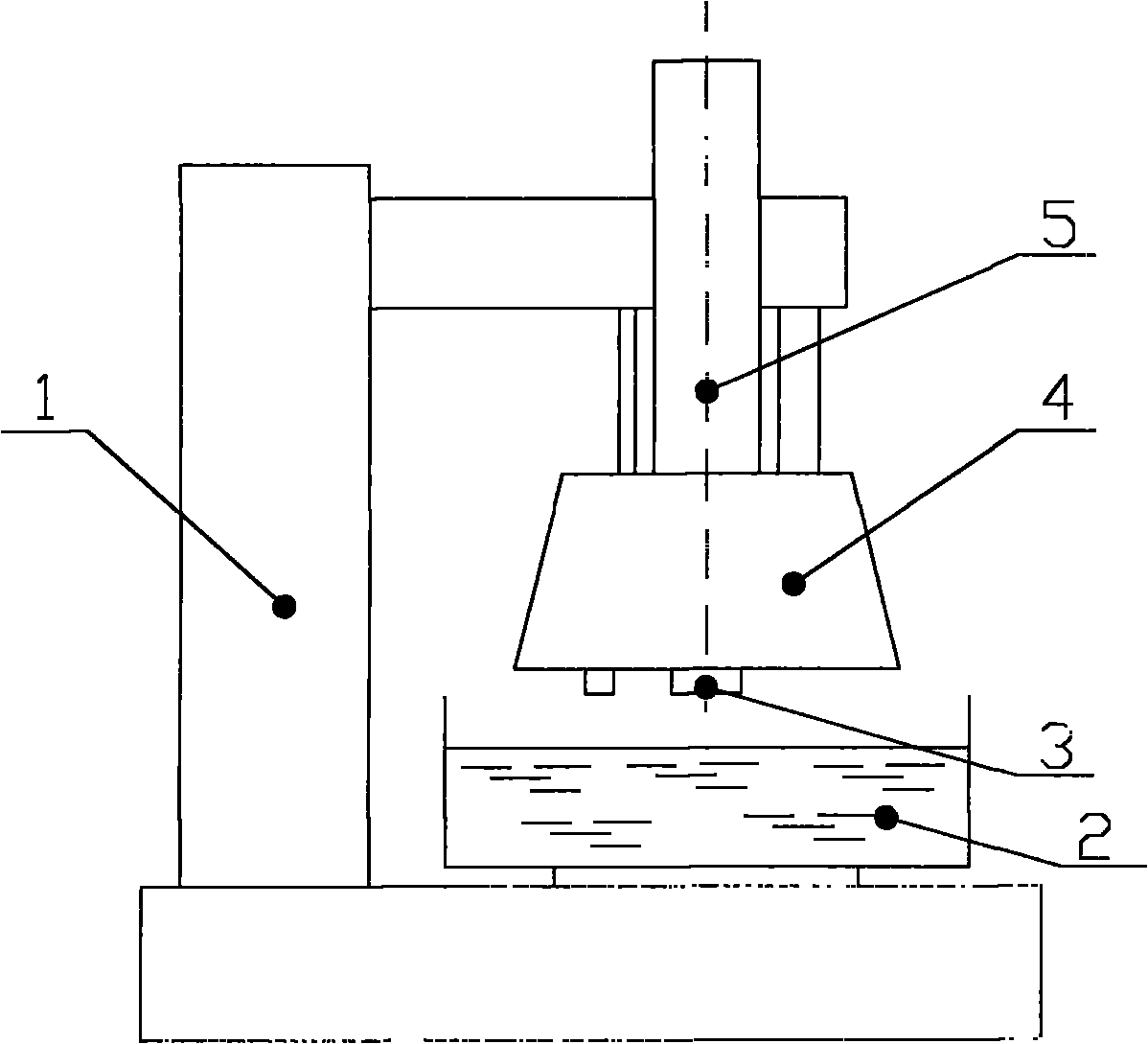

Electric spark milling process method with mist

The invention relates to an electric spark milling method by mist, which pertains to special process technology domain. The invention takes mist as dielectric medium between work piece and instrument to make electrodischarge machining. Compared with gas and liquid medium, mist medium has a lower breakdown voltage and can reduce the cost of liquid, and with rotatable instrument pole it can accelerate decorporation of elaboration product. The invention has a fast process velocity and can produce product with good surface quality.

Owner:SHANGHAI JIAO TONG UNIV

Thin-gauge high-performance ultrahigh-strength semi-hard steel belt and production method thereof

The invention discloses a thin-gauge high-performance ultrahigh-strength semi-hard steel belt and a production method thereof. The steel belt is prepared from the chemical components in percentage bymass: 0.15 to 0.20 percent of C, 0.90 to 1.20 percent of Mn, less than or equal to 0.015 percent of S, less than or equal to 0.020 percent of P, 0.05 to 0.10 percent of Si, 0.025 to 0.050 percent of Als, less than or equal to 0.0050 percent of N, 0.32 to 0.40 percent of Ceq, and the balance iron and inevitable impurities. The production method comprises the processes of smelting through a converter, ladle furnace (LF) refining, continuous casting, heating, rough rolling, finish rolling, cooling, reeling and cold rolling. According to the thin-gauge high-performance ultrahigh-strength semi-hardsteel belt and the production method thereof provided by the invention, by adopting the composition design of low carbon and conventional manganese, and through a cooling path and medium-temperaturereeling control, the obtained thin-gauge high-performance ultrahigh-strength semi-hard steel belt is suitable for producing cold roll forming thin-wall steel sections such as bus frameworks, truck edge beams and penetrating beams, so that the weight of a car body is reduced, the fuel oil consumption is reduced, and the product can be manufactured in a green way.

Owner:TANGSHAN STAINLESS STEEL +1

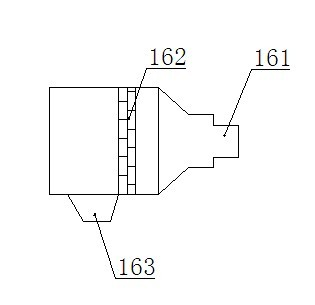

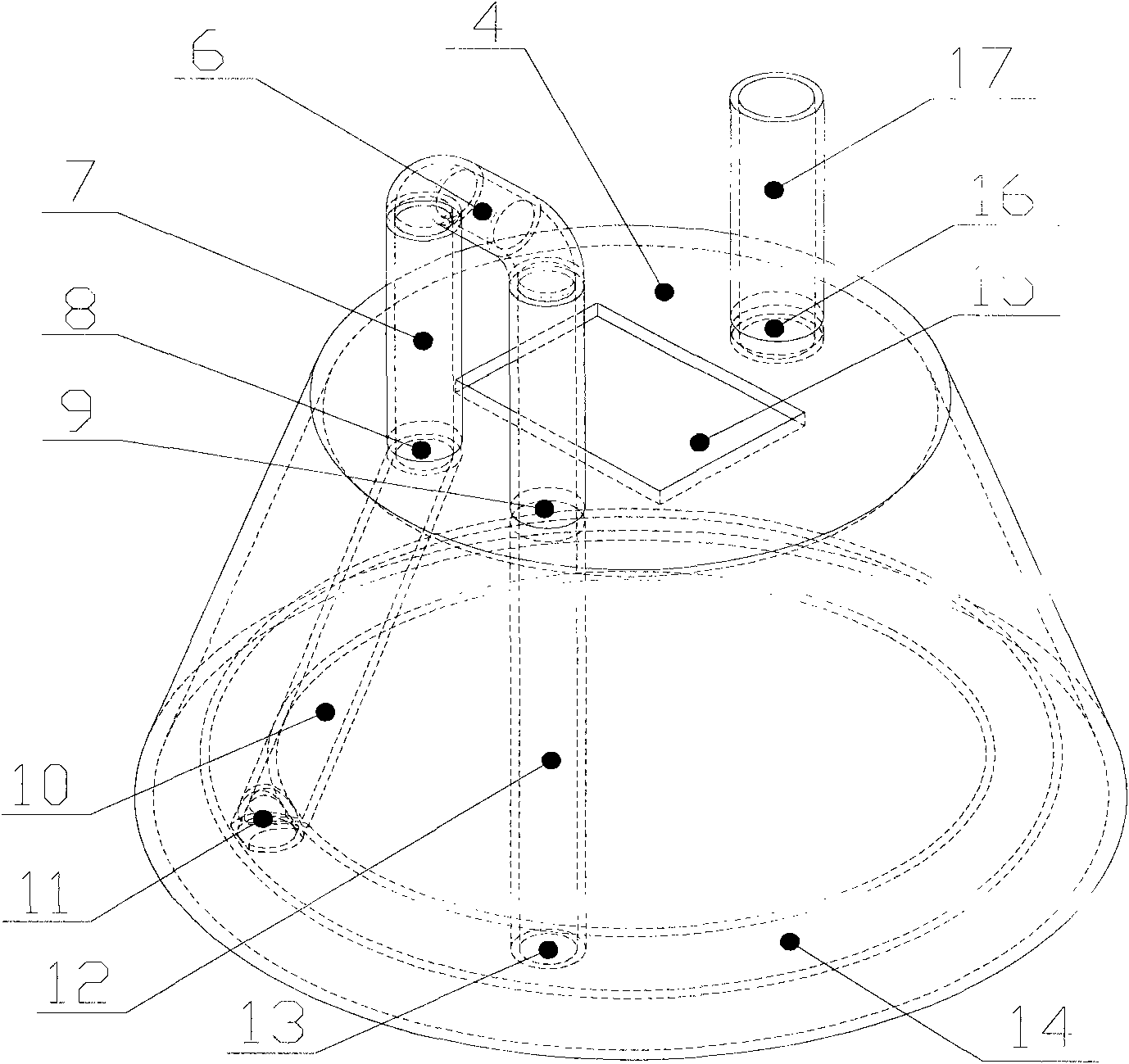

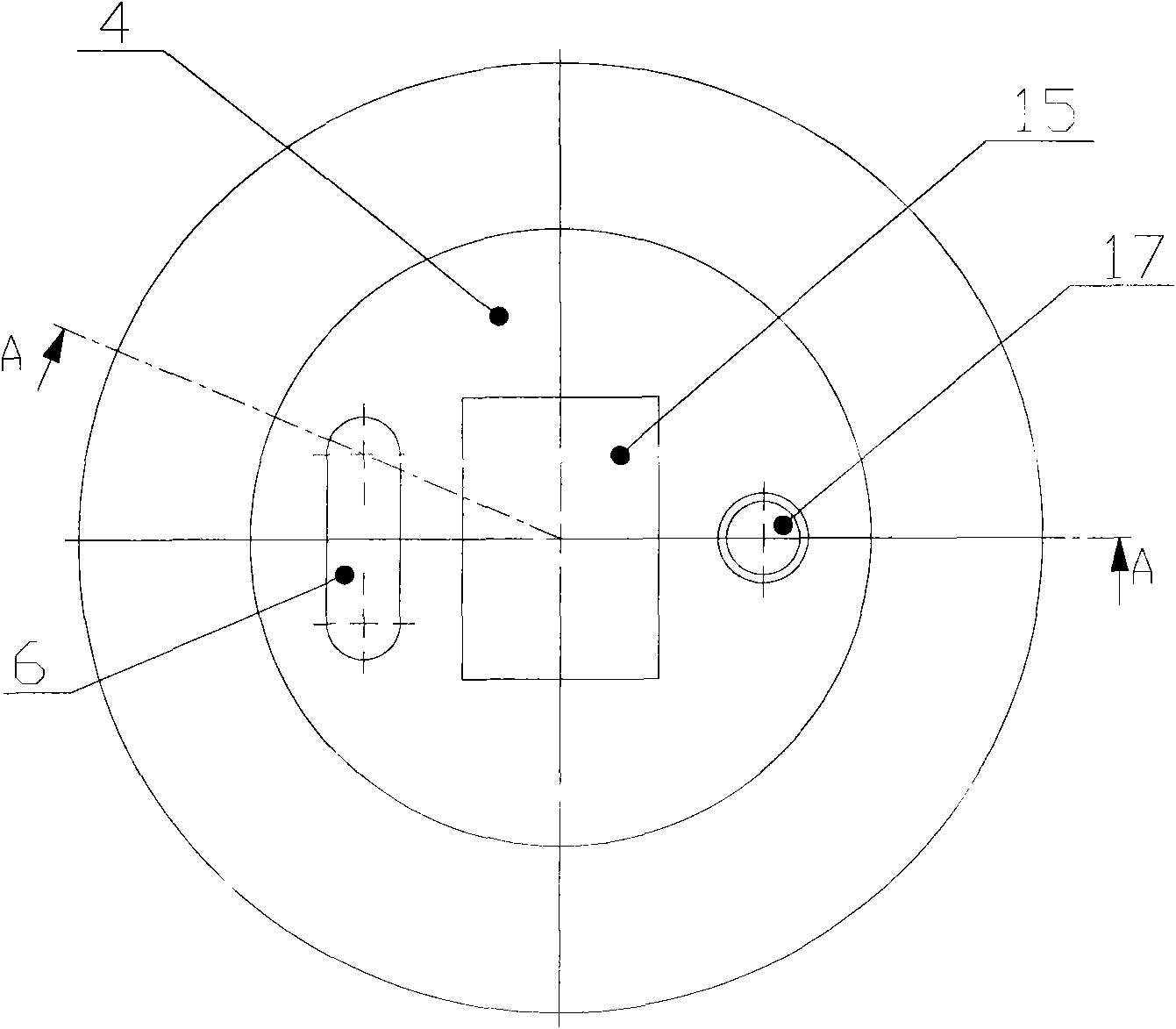

Main spindle hood of electric spark moulding machine

InactiveCN102009236AGuarantee processing qualityRemove harmful ingredientsAdditive ingredientGreen manufacturing

The invention discloses a main spindle hood of an electric spark moulding machine, comprising a main spindle hood body, a connecting pipeline, a medium purifying channel, a medium downlink channel upper port, a medium uplink channel upper port, a medium downlink channel, a medium downlink channel lower port, a medium uplink channel, a medium uplink channel lower port, an annular oil screen spraying channel, a main spindle connecting hole, a smoke purifying channel port and a smoke purifying channel. The main spindle hood of the electric spark moulding machine can circularly purify the electric spark processing media so as to guarantee the processing and moulding quality; and simultaneously an enclosed oil screen is formed in the moulding and processing region of the electric spark, and the harmful smoke generated by processing can be collected and purified through a smoke purifying port so as to eliminate the harmful ingredients in the discharged air, thus realizing green manufacturing.

Owner:ZHEJIANG UNIV +2

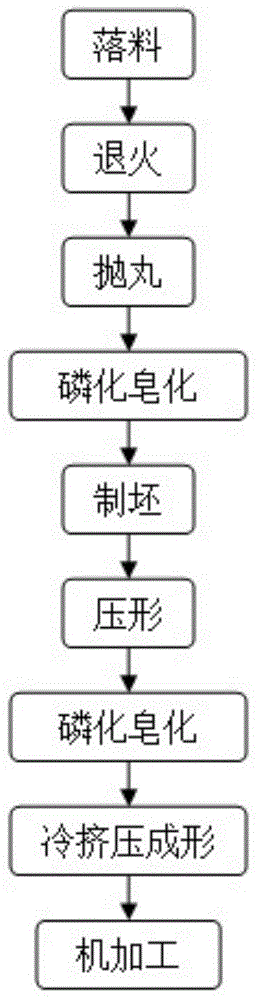

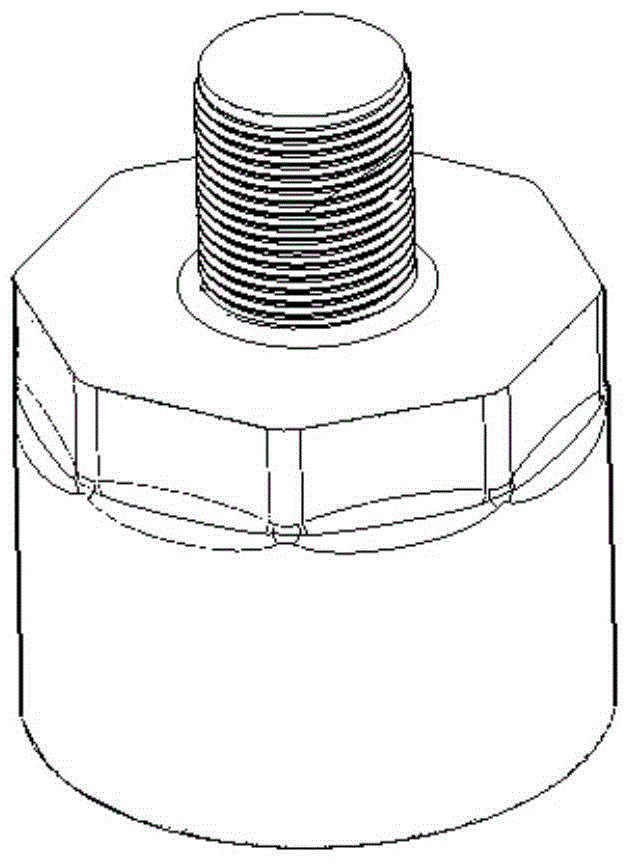

Cold extrusion forming method of axisymmetric pull rod joint part

ActiveCN104148428AImprove mechanical propertiesLow costExtrusion cleaning devicesSocial benefitsMethods of production

The invention relates to a cold extrusion forming method of an axisymmetric pull rod joint part. The cold extrusion forming method comprises the following steps: (1) preparing a pull rod joint workblank; (2) annealing the workblank, so as to soften the workblank; (3) performing shot blasting on the annealed workblank, so as to eliminate burrs and oxide skins; (4) phosphatizing and saponifying the workblank after shot blasting; (5) putting the workblank into a blank preparation die, so as to prepare blanks and obtain the blanks; (6) pressing the blanks; (7) phosphatizing and saponifying the blanks; (8) putting the blanks into a forming die and performing cold extrusion forming; and (9) machining a formed part, so as to prepare the axisymmetric pull rod joint part. Compared with the prior art, the extrusion production method for producing the pull rod joint part has the advantages that the production process is perfect, the material utilization ratio is high, the mechanical property of the part is good, the production cost is low, the required equipment tonnage is low, and the method conforms to the requirement of modern green manufacturing and has great social benefits.

Owner:SHANGHAI UNIV OF ENG SCI +1

Treatment method for increasing die self-demouding performance

InactiveCN101168844AImprove self-release performanceEliminate different levels of pollutionFoundry mouldsForging/hammering/pressing machinesBeam energyAlloy

The invention discloses a processing method for improving the mold unloading performance of a die, and the method comprises the following processes that: pretreatment is operated to the surface; proper alloy powder is chosen; the chosen alloy powder is pre-coated on a die forming surface; the die forming surface is irradiated by strong current pulsed electron beams to lead the alloy powder of the die forming surface to be melted under the radiation of electron-beam energy to obtain a surface mold unloading layer on the upper and the lower die forming surfaces; after being alloyed, the die is thermally treated. The processing method of improving the mold unloading performance of the die of the invention realizes the improvement of die self-mold unloading performance through the processing method, and replaces the original method of spraying and coating mold releasing agent on the die forming surface, thereby being in favor of eliminating the different degree pollution of the mold releasing agent to the product, the die and the environment, thereby the green manufacture can be realized. An alloying protective film, namely, a surface mold unloading layer on the die forming surface can decrease the attrition and the abrasion of the product to the die surface, and reduce the binding property of the product and the die material, thereby attaining the purpose for improving the die self-mold unloading performance.

Owner:重庆工学院

3D (three-dimensional) printing stack forming ballast bed elevation adjusting method

InactiveCN107938440AReduce on-site workloadReduce on-site laborBallastwayRailway track constructionNumerical controlMathematical model

The invention discloses a 3D printing stack forming ballast bed elevation adjusting method. The 3D printing stack forming ballast bed elevation adjusting method comprises, according to a base poured according to a gradient and line adjusting drawing and a track construction drawing, which are designed according to line through measurement and tunnel section output, and a prefabricated part arrangement plan, sectionally performing base surface elevation measurement to establish a base surface elevation three-dimensional map mathematical model; measuring the flatness of the lower surface of every prefabricated part, and establishing a lower surface flatness three-dimensional mathematical model of every prefabricated part; based on design and practical mathematical models, producing 3D printing input files, and layer-by-layer printing materials onto the surface of the base or the prefabricated parts through numerical control 3D printing equipment. Between a base assembling layer and the prefabricated parts, elastic buffer layers different in thickness are arranged to adjust the elevation of a ballast bed to meet the requirements of tracks on directional, horizontal and height smoothness and meanwhile a prefabricated part adjusting surface can meet the requirement that the prefabricated parts can be directly assembled on the base. The 3D printing stack forming ballast bed elevationadjusting method is rapid in construction speed and high in precision and is a key technical breakthrough of green track manufacturing.

Owner:GUANGXI SANWEI RAIL MANUFACTURING CO LTD

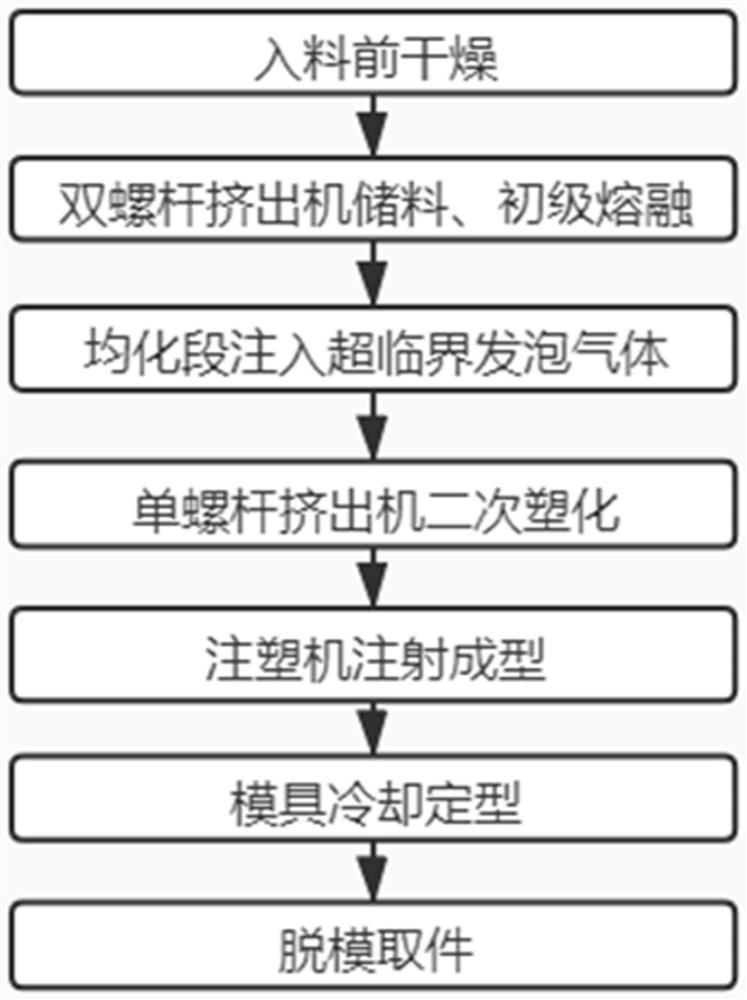

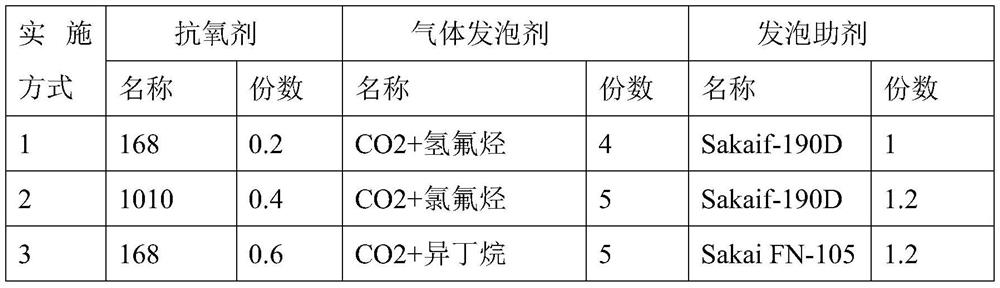

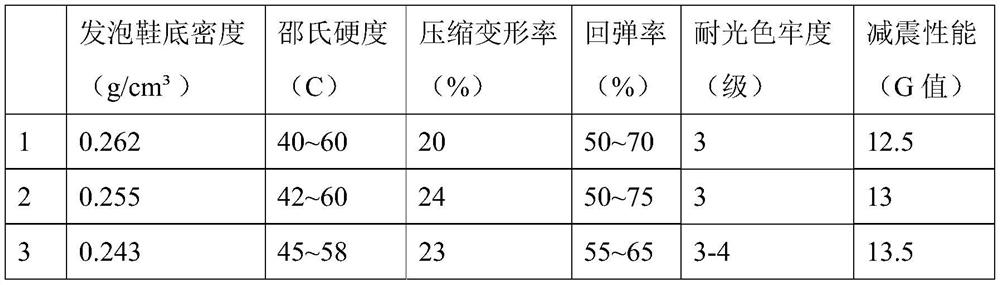

Foaming shoe midsole material made of TPEE material and preparation process thereof

The invention relates to the technical field of shoe material foaming midsoles, and in particular relates to a foaming shoe midsole material made of a TPEE material and a preparation process thereof. The foaming midsole material made of the TPEE material comprises the following raw materials: a thermoplastic polyester elastomer, a foaming agent, a nucleating agent, an antioxidant, a lubricating agent, a cross-linking agent and a cell stabilizer. The foaming shoe midsole material has the advantages that compared with the most common EVA foaming midsole, the thermoplastic polyester elastomer foaming material is excellent in fatigue resistance, and the midsole made of the thermoplastic polyester elastomer foaming material can still keep soft, cushioning performance and resilience for a long time after being repeatedly treaded; the TPEE foaming material adopted by the invention has excellent temperature resistance, and compared with a TPU foaming midsole, the thermoplastic polyester elastomer foaming material has the advantages that the density of the foamed material is smaller than that of TPU, the weight is light, the rebound rate is high, and the weather resistance is strong; the foaming shoe midsole material is non-toxic and odorless, and has favorable recyclability; no harmful carcinogenic substance is generated in the production process; and low-carbon, environment-friendly and green manufacturing is met, and cyclic recycling and sustainable development can be achieved.

Owner:GUANGDONG ANGSI NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com