Polyurethane composite material tire and producing method thereof

A composite material and polyurethane technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of low tear strength, low wear resistance, poor safety performance, etc., to achieve high mechanical properties and reduce rolling Resistance, life-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

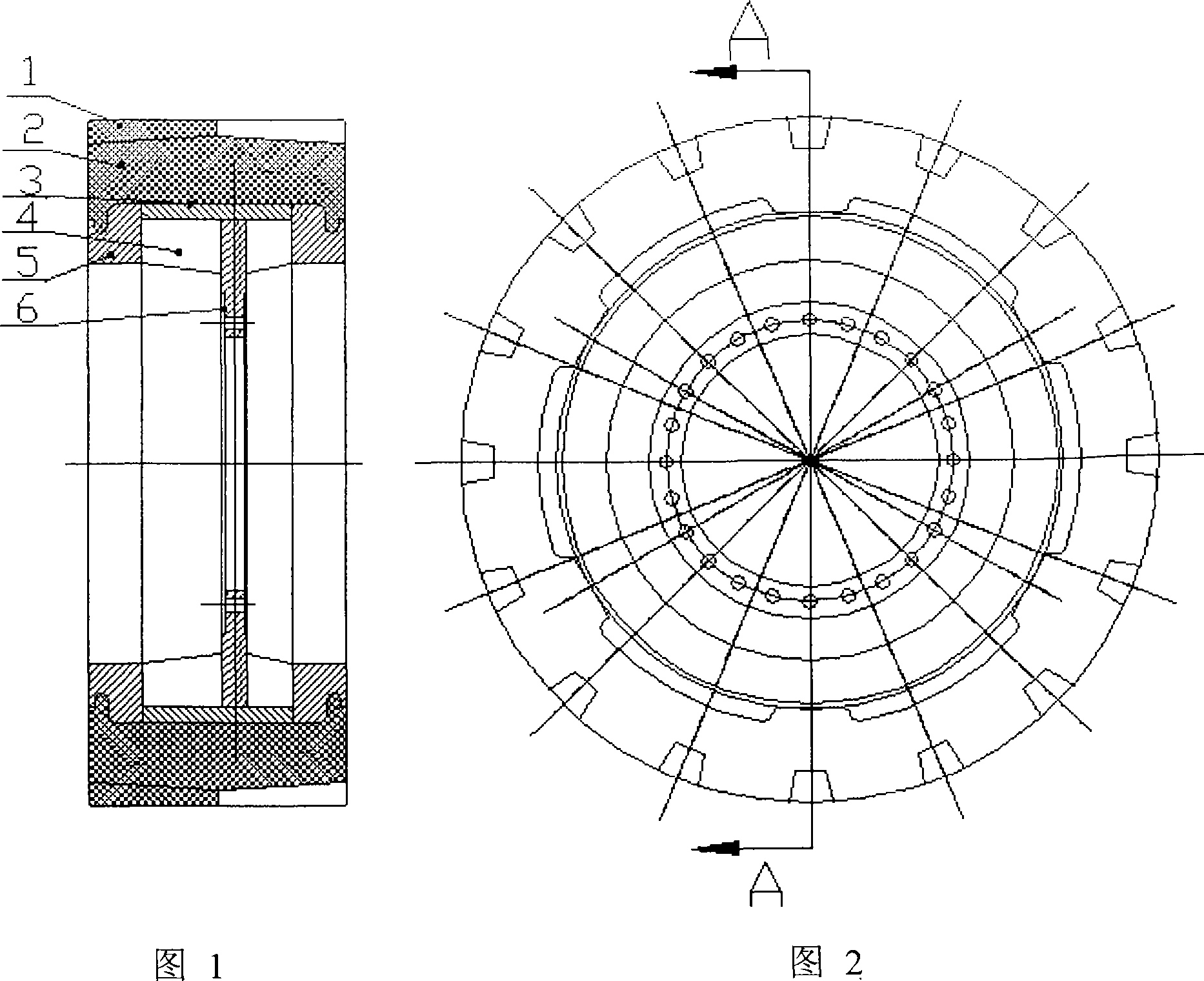

[0028] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises wheel hub 5, hub plate 6, reinforcing rib 4, tread 1, inner tube 3 and filler 2 between tread 1, inner tube 3, tread 1, inner tube 3 adopt casting type polyurethane elastomer, belt The beam layer is four layers, which is composed of three layers of steel cords and a layer of aramid fibers compounded by adhesives. The carcass ply is composed of steel cords and aramid fibers. The inner lining layer is composed of chlorinated butyl rubber and steel cords. Layer composite; the filler is composited with the following two polyurethanes: one is a polyurethane elastomer with a hardness of Shore A45, and the other is a self-skinned polyurethane foam elastomer.

[0029] The manufacturing process of this product is as follows:

[0030] 1. Clean the surface of the rim:

[0031] 1) Surface treatment of metal rims, sandblasting; not only the surface of the rim but also the 10mm...

Embodiment 2

[0043] The tread 1 and the inner tube 3 are made of cast polyurethane elastomer, and the belt layer is four layers, which are compounded by three layers of steel cords and a layer of aramid fibers through an adhesive; the carcass ply has steel cords and aramid fibers Composite, the inner lining is composed of chlorinated butyl rubber and steel cord, and the filler is polyurethane elastomer with a hardness of Shore A45. Others are the same as in Example 1.

Embodiment 3

[0045] The tread 1 and the inner tube 3 are made of cast polyurethane elastomer, and the belt layer is four layers, which are compounded by three layers of steel cords and a layer of aramid fibers through an adhesive; the carcass ply has steel cords and aramid fibers Composite, the inner lining is composed of chlorinated butyl rubber and steel cord; the filling is made of self-skinned polyurethane foam elastomer. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com